Page 1

Lab-NB

User Manual

Low-Cost Multifunction I/O Board for Macintosh NuBus

September 1995 Edition

Part Number 320174B-01

© Copyright 1989, 1995 National Instruments Corporation.

All Rights Reserved.

Page 2

National Instruments Corporate Headquarters

6504 Bridge Point Parkway

Austin, TX 78730-5039

(512) 794-0100

Technical support fax: (800) 328-2203

(512) 794-5678

Branch Offices:

Australia 03 9 879 9422, Austria 0662 45 79 90 0, Belgium 02 757 00 20, Canada (Ontario) 519 622 9310,

Canada (Québec) 514 694 8521, Denmark 45 76 26 00, Finland 90 527 2321, France 1 48 14 24 24,

Germany 089 741 31 30, Hong Kong 2645 3186, Italy 02 48301892, Japan 03 5472 2970, Korea 02 596 7456,

Mexico 5 202 2544, Netherlands 03480 33466, Norway 32 84 84 00, Singapore 2265886, Spain 91 640 0085,

Sweden 08 730 49 70, Switzerland 056 20 51 51, Taiwan 02 377 1200, U.K. 01635 523545

Page 3

Limited Warranty

The Lab-NB is warranted against defects in materials and workmanship for a period of one year from the date of

shipment, as evidenced by receipts or other documentation. National Instruments will, at its option, repair or replace

equipment that proves to be defective during the warranty period. This warranty includes parts and labor.

The media on which you receive National Instruments software are warranted not to fail to execute programming

instructions, due to defects in materials and workmanship, for a period of 90 days from date of shipment, as

evidenced by receipts or other documentation. National Instruments will, at its option, repair or replace software

media that do not execute programming instructions if National Instruments receives notice of such defects during

the warranty period. National Instruments does not warrant that the operation of the software shall be uninterrupted

or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the

outside of the package before any equipment will be accepted for warranty work. National Instruments will pay the

shipping costs of returning to the owner parts which are covered by warranty.

National Instruments believes that the information in this manual is accurate. The document has been carefully

reviewed for technical accuracy. In the event that technical or typographical errors exist, National Instruments

reserves the right to make changes to subsequent editions of this document without prior notice to holders of this

edition. The reader should consult National Instruments if errors are suspected. In no event shall National

Instruments be liable for any damages arising out of or related to this document or the information contained in it.

EXCEPT AS SPECIFIED HEREIN, NATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED,

AND SPECIFICALLY DISCLAIMS ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE

OF

NATIONAL INSTRUMENTS WILL NOT BE LIABLE FOR DAMAGES RESULTING FROM LOSS OF DATA, PROFITS,

USE OF PRODUCTS, OR INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF ADVISED OF THE POSSIBILITY

THEREOF

whether in contract or tort, including negligence. Any action against National Instruments must be brought within

one year after the cause of action accrues. National Instruments shall not be liable for any delay in performance due

to causes beyond its reasonable control. The warranty provided herein does not cover damages, defects,

malfunctions, or service failures caused by owner's failure to follow the National Instruments installation, operation,

or maintenance instructions; owner's modification of the product; owner's abuse, misuse, or negligent acts; and

power failure or surges, fire, flood, accident, actions of third parties, or other events outside reasonable control.

. CUSTOMER'S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE PART

NATIONAL INSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTOMER.

. This limitation of the liability of National Instruments will apply regardless of the form of action,

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or

mechanical, including photocopying, recording, storing in an information retrieval system, or translating, in whole

or in part, without the prior written consent of National Instruments Corporation.

Trademarks

LabVIEW®, NI-DAQ®, and RTSI® are trademarks of National Instruments Corporation.

Product names and company names listed are trademarks or trade names of their respective companies.

Page 4

WARNING REGARDING MEDICAL AND CLINICAL USE

OF NATIONAL INSTRUMENTS PRODUCTS

National Instruments products are not designed with components and testing intended to ensure a level of reliability

suitable for use in treatment and diagnosis of humans. Applications of National Instruments products involving

medical or clinical treatment can create a potential for accidental injury caused by product failure, or by errors on

the part of the user or application designer. Any use or application of National Instruments products for or involving

medical or clinical treatment must be performed by properly trained and qualified medical personnel, and all

traditional medical safeguards, equipment, and procedures that are appropriate in the particular situation to prevent

serious injury or death should always continue to be used when National Instruments products are being used.

National Instruments products are NOT intended to be a substitute for any form of established process, procedure, or

equipment used to monitor or safeguard human health and safety in medical or clinical treatment.

Page 5

Contents

About This Manual............................................................................................................xi

Organization of This Manual.........................................................................................xi

Conventions Used in This Manual.................................................................................xii

National Instruments Documentation............................................................................xii

Related Documentation..................................................................................................xiii

Customer Communication.............................................................................................xiii

Chapter 1

Introduction

About the Lab-NB..........................................................................................................1-1

What You Need to Get Started......................................................................................1-2

Software Programming Choices....................................................................................1-2

Optional Equipment.......................................................................................................1-4

Unpacking......................................................................................................................1-5

..........................................................................................................................1-1

LabVIEW and LabWindows/CVI Application Software..................................1-2

NI-DAQ Driver Software...................................................................................1-3

Register-Level Programming.............................................................................1-4

Cabling...............................................................................................................1-4

Chapter 2

Configuration and Installation

Board Configuration......................................................................................................2-1

Factory Default Jumper Settings........................................................................2-3

Analog Output Configuration............................................................................2-3

Bipolar

Unipolar Output Selection.....................................................................2-4

Analog Input Configuration...............................................................................2-4

Bipolar Input Selection..........................................................................2-4

Unipolar

Installation......................................................................................................................2-5

Signal

Connections........................................................................................................2-5

I/O Connector Pin Description...........................................................................2-5

Signal Connection Descriptions.........................................................................2-7

Analog Input Signal Connections..........................................................2-7

Analog

Digital

Timing

Output Selection........................................................................2-3

Input Selection........................................................................2-5

Connections for Signal Sources.................................................2-8

Output Signal Connections........................................................2-9

I/O Signal Connections..............................................................2-10

Port

C Pin Connections..............................................................2-11

Timing Specifications................................................................2-12

Mode

1 Input Timing.................................................................2-14

Mode

1 Output Timing...............................................................2-15

Mode

2 Bidirectional Timing.....................................................2-16

Connections...............................................................................2-17

DAQ Timing Connections.........................................................2-17

General-Purpose

.......................................................................................2-1

Timing Signal Connections............................2-21

© National Instruments Corporation v Lab-NB User Manual

Page 6

Contents

Chapter 3

Theory

of Operation...........................................................................................................3-1

Functional Overview......................................................................................................3-1

NuBus Interface Circuitry..............................................................................................3-2

Analog

Input and DAQ Circuitry...................................................................................3-3

Analog Input Circuitry.......................................................................................3-4

DAQ

Timing Circuitry.......................................................................................3-4

Single-Channel Data Acquisition...........................................................3-5

Multichannel (Scanned) Data Acquisition.............................................3-5

DAQ Rates.............................................................................................3-6

Analog Output Circuitry................................................................................................3-7

Digital I/O Circuitry.......................................................................................................3-9

Timing I/O Circuitry......................................................................................................3-10

Chapter 4

Register-Level Programming

Register Access..............................................................................................................4-1

Slot Address Space.............................................................................................4-1

Register Map......................................................................................................4-2

Register Sizes.....................................................................................................4-4

Register

Configuration EPROM..................................................................................................4-35

Descriptions.....................................................................................................4-4

Register Description Format..............................................................................4-4

Analog Input Register Group.............................................................................4-5

A/D Configuration Register...................................................................4-6

Status Register........................................................................................4-9

A/D FIFO Register.................................................................................4-10

A/D Clear Register.................................................................................4-12

Analog Output Register Group..........................................................................4-13

DAC Configuration Register.................................................................4-14

DAC0 and DAC1 Data Registers...........................................................4-15

8253 Counter/Timer Register Groups................................................................4-16

Counter A0 Data Register......................................................................4-17

Counter A1 Data Register......................................................................4-18

Counter A2 Data Register......................................................................4-19

Counter A Mode Register......................................................................4-20

Counter B0 Data Register......................................................................4-21

Counter B1 Data Register......................................................................4-22

Counter B2 Data Register......................................................................4-23

Counter B Mode Register......................................................................4-24

82C55A Digital I/O Register Group..................................................................4-25

Port A Register.......................................................................................4-26

Port B Register.......................................................................................4-27

Port C Register.......................................................................................4-28

Digital

Interrupt

Control Register.........................................................................4-29

Control Register Group.......................................................................4-30

Interrupt Control Register......................................................................4-31

Interrupt Status Register.........................................................................4-33

Timer Interrupt Clear Register...............................................................4-34

.........................................................................................4-1

Lab-NB User Manual vi © National Instruments Corporation

Page 7

Contents

Programming Considerations.........................................................................................4-35

Register Programming Considerations..............................................................4-35

Initializing the Lab-NB Board...........................................................................4-35

Programming

the Analog Input Circuitry..........................................................4-36

Analog Input Circuitry Programming Sequence....................................4-36

A/D FIFO Output Binary Modes...........................................................4-38

Clearing the Analog Input Circuitry......................................................4-39

Programming Multiple A/D Conversions on a Single Input Channel...............4-39

Programming in Controlled Acquisition Mode.....................................4-40

Programming

in Freerun Acquisition Mode..........................................4-43

External Timing Considerations for Multiple A/D Conversions.......................4-45

Using the EXTTRIG Signal to Initiate a Multiple A/D Conversion

DAQ

Operation (Posttrigger Mode)......................................................4-45

Using the EXTTRIG Signal to Terminate a Multiple A/D

Conversion DAQ Operation (Pretrigger Mode).....................................4-46

Using the EXTCONV* Signal to Initiate A/D Conversions..................4-46

Programming Multiple A/D Conversions Using External Timing....................4-46

Programming in Controlled Acquisition Mode.....................................4-46

Posttrigger Mode........................................................................4-46

Pretrigger Mode.........................................................................4-49

Programming

in Freerun Acquisition Mode..........................................4-51

Posttrigger Mode........................................................................4-51

Pretrigger Mode.........................................................................4-51

Programming Multiple A/D Conversions with Channel Scanning....................4-51

Interrupt Programming for the Analog Input Circuitry.....................................4-52

Programming the Analog Output Circuitry.......................................................4-52

Interrupt Programming for the Analog Output Circuitry...................................4-54

Programming the Digital I/O Circuitry..............................................................4-55

82C55A Modes of Operation.................................................................4-55

Mode 0–Basic I/O......................................................................4-56

Mode 1–Strobed I/O...................................................................4-56

Mode 2–Bidirectional Bus.........................................................4-56

Single Bit Set/Reset Feature......................................................4-56

Register Descriptions and Programming Examples...............................4-57

Mode 0 Control Words..............................................................4-58

Mode 0 Programming Examples................................................4-58

Mode 1 Strobed Input Control Words........................................4-59

Mode 1 Input Programming Example........................................4-61

Mode 1 Strobed Output Control Words.....................................4-61

Mode 1 Output Programming Example.....................................4-63

Mode 2 Control Words..............................................................4-63

Mode 2 Programming Example.................................................4-65

Single Bit Set/Reset Control Words...........................................4-65

Interrupt

Programming for the Digital I/O Circuitry.........................................4-65

© National Instruments Corporation vii Lab-NB User Manual

Page 8

Contents

Chapter 5

Calibration

Calibration Equipment Requirements............................................................................5-1

Calibration Trimpots......................................................................................................5-2

Analog Input Calibration...............................................................................................5-3

Analog

.............................................................................................................................5-1

Board Configuration..........................................................................................5-4

Bipolar Input Calibration Procedure..................................................................5-4

Unipolar

Output Calibration.............................................................................................5-5

Board Configuration..........................................................................................5-6

Bipolar

Unipolar Output Calibration Procedure.............................................................5-7

Appendix A

Specifications

Appendix B

I/O Connector

Input Calibration Procedure................................................................5-5

Output Calibration Procedure...............................................................5-6

........................................................................................................................A-1

.......................................................................................................................B-1

Appendix C

AMD 8253 Data Sheet

.......................................................................................................C-1

Appendix D

OKI 82C55A Data Sheet

..................................................................................................D-1

Appendix E

Customer Communication

...............................................................................................E-1

Glossary........................................................................................................................Glossary-1

Index..................................................................................................................................Index-1

Lab-NB User Manual viii © National Instruments Corporation

Page 9

Contents

Figures

Figure 1-1. The Relationship between the Programming Environment, NI-DAQ, and Your

Hardware............................................................................................................1-3

Figure 2-1. Parts Locator Diagram.......................................................................................2-2

Figure 2-2. Bipolar Output Jumper Configuration...............................................................2-4

Figure 2-3. Unipolar

Figure 2-4. Bipolar Input Jumper Configuration..................................................................2-5

Figure 2-5. Unipolar Input Jumper Configuration................................................................2-5

Figure 2-6. Lab-NB I/O Connector Pin Assignments...........................................................2-6

Figure 2-7. Analog

Figure 2-8. Analog Output Signal Connections....................................................................2-9

Figure 2-9. Digital I/O Connections.....................................................................................2-11

Figure 2-10. EXTCONV*

Figure 2-11. Posttrigger DAQ Timing (EXTCONV* High When Trigger Sensed)..............2-18

Figure 2-12. Posttrigger DAQ Timing (EXTCONV* Low When Trigger Sensed)...............2-18

Figure 2-13. Pretrigger DAQ Timing.....................................................................................2-19

Figure 2-14. Waveform Generation Timing with the EXTUPDATE*

Figure 2-15. NuBus Interrupt Generation with the EXTUPDATE*

Figure 2-16. Event-Counting Application with External Switch Gating................................2-22

Figure 2-17. Frequency Measurement Application................................................................2-23

Figure 2-18. General-Purpose Timing Signals.......................................................................2-24

Output Jumper Configuration.............................................................2-4

Input Signal Connections......................................................................2-8

Signal Timing...............................................................................2-17

Signal.......................2-20

Signal...........................2-20

Figure 3-1. Lab-NB Block Diagram.....................................................................................3-1

Figure 3-2. NuBus Interface Circuitry Block Diagram........................................................3-2

Figure 3-3. Analog Input and DAQ Circuitry Block Diagram.............................................3-3

Figure 3-4. Analog

Figure 3-5. Digital

Figure 3-6. Timing

Figure 3-7. Counter

Output Circuitry Block Diagram...........................................................3-8

I/O Circuitry Block Diagram.................................................................3-9

I/O Circuitry Block Diagram.................................................................3-10

Block Diagram.....................................................................................3-11

Figure 4-1. Control-Word Format with Control-Word Flag Set to 1...................................4-57

Figure 4-2. Control-Word Format with Control-Word Flag Set to 0...................................4-57

Figure 5-1. Calibration

Trimpot Location Diagram.............................................................5-2

Figure B-1. Lab-NB I/O Connector.......................................................................................B-1

Tables

Table 2-1. Lab-NB Jumper Settings....................................................................................2-3

Table 2-2. Port

Table 3-1. Analog Input Settling Time Versus Gain...........................................................3-6

Table 3-2. Lab-NB Maximum Recommended DAQ Rates................................................3-6

Table 3-3. Bipolar Analog Input Signal Range Versus Gain..............................................3-7

Table 3-4. Unipolar Analog Input Signal Range Versus Gain............................................3-7

C Signal Assignments................................................................................2-12

Table 4-1. Macintosh Slot Addresses..................................................................................4-2

Table 4-2. Lab-NB Register Map........................................................................................4-3

Table 4-3. Unipolar Input Mode A/D Conversion Values (Straight Binary Coding).........4-38

© National Instruments Corporation ix Lab-NB User Manual

Page 10

Contents

Table 4-4. Bipolar Input Mode A/D Conversion Values (Two’s Complement Coding)....4-38

Table 4-5. Analog Output Voltage Versus Digital Code....................................................4-53

Table 4-6. Analog Output Voltage Versus Digital Code

(Bipolar Mode, Two's Complement Coding).....................................................4-54

Table 4-7. Mode

Table 4-8. Port

0 I/O Configurations................................................................................4-58

C Set/Reset Control Words........................................................................4-65

Lab-NB User Manual x © National Instruments Corporation

Page 11

About This Manual

This manual describes the mechanical and electrical aspects of the Lab-NB and contains

information concerning its installation and operation. The Lab-NB is a low-cost multifunction

analog, digital, and timing I/O board for Macintosh NuBus computers. It contains a 12-bit

successive-approximation A/D converter (ADC) with eight analog inputs, two 12-bit D/A

converters (DACs) with voltage outputs, 24 lines of transistor-transistor logic (TTL) compatible

digital I/O, and three 16-bit counter/timer channels for timing I/O.

Organization of This Manual

The Lab-NB User Manual is organized as follows.

• Chapter 1, Introduction, describes the Lab-NB, lists what you need to get started, software

programming choices, optional equipment, and explains how to unpack the Lab-NB.

• Chapter 2, Configuration and Installation, describes how to configure and install the Lab-NB

into your Macintosh computer, and also includes signal connections to the Lab-NB and cable

wiring.

• Chapter 3, Theory of Operation, contains a functional overview of the Lab-NB and explains

the operation of each functional unit making up the Lab-NB.

• Chapter 4, Register-Level Programming, describes in detail the address and function of each

of the Lab-NB control and status registers. This chapter also includes important information

about register-level programming the Lab-NB.

• Chapter 5, Calibration, discusses the calibration procedures for the Lab-NB analog input and

analog output circuitry.

• Appendix A, Specifications, lists the specifications of the Lab-NB.

• Appendix B, I/O Connector, contains the pinout and signal names for the I/O connector on

the Lab-NB.

• Appendix C, AMD 8253 Data Sheet, contains the manufacturer data sheet for the AMD 8253

System Timing Controller integrated circuit (Advanced Micro Devices, Inc.). This circuit is

used on the Lab-NB.

• Appendix D, OKI 82C55A Data Sheet, contains the manufacturer data sheet for the

OKI 82C55A (OKI Semiconductor) CMOS programmable peripheral interface. This

interface is used on the Lab-NB.

• Appendix E, Customer Communication, contains forms you can use to request help from

National Instruments or to comment on our products and manuals.

© National Instruments Corporation xi Lab-NB User Manual

Page 12

About This Manual

• The Glossary contains an alphabetical list and description of terms used in this manual,

including abbreviations, acronyms, metric prefixes, mnemonics, symbols, and terms.

• The Index alphabetically lists topics covered in this manual, including the page where you

can find each one.

Conventions Used in This Manual

The following conventions are used in this manual.

bold Bold text denotes menus, menu items, or dialog box buttons or options.

bold italic Bold italic text denotes a note, caution, or warning.

italic Italic text denotes emphasis, a cross reference, or an introduction to a key

concept.

Macintosh Macintosh refers to all Macintosh II, Macintosh Quadra, and Macintosh

Centris computers, except the Centris 610, unless otherwise noted.

NI-DAQ NI-DAQ is used throughout this manual to refer to the NI-DAQ software

for Macintosh unless otherwise noted.

SCXI SCXI stands for Signal Conditioning eXtensions for Instrumentation and

is a National Instruments product line designed to perform front-end signal

conditioning for National Instruments plug-in DAQ boards.

< > Angle brackets containing numbers separated by an ellipsis represent a

range of values associated with a bit or signal name (for example,

ACH <0..7> stands for ACH0 through ACH7).

Abbreviations, acronyms, metric prefixes, mnemonics, symbols, and terms are listed in the

Glossary.

National Instruments Documentation

The Lab-NB User Manual is one piece of the documentation set for your data acquisition (DAQ)

system. You could have any of several types of manuals, depending on the hardware and

software in your system. Use the different types of manuals you have as follows:

• Getting Started with SCXI—If you are using SCXI, this is the first manual you should read.

It gives an overview of the SCXI system and contains the most commonly needed

information for the modules, chassis, and software.

• Your SCXI hardware user manuals—If you are using SCXI, read these manuals next for

detailed information about signal connections and module configuration. They also explain

in greater detail how the module works and contain application hints.

Lab-NB User Manual xii © National Instruments Corporations

Page 13

About This Manual

• Your DAQ hardware user manuals—These manuals have detailed information about the

DAQ hardware that plugs into or is connected to your computer. Use these manuals for

hardware installation and configuration instructions, specification information about your

DAQ hardware, and application hints.

• Software manuals—Examples of software manuals you may have are the LabVIEW and

LabWindows

NI-DAQ supports LabWindows for DOS). After you set up your hardware system, use either

the application software (LabVIEW or LabWindows/CVI) manuals or the NI-DAQ manuals

to help you write your application. If you have a large and complicated system, it is

worthwhile to look through the software manuals before you configure your hardware.

• Accessory installation guides or manuals—If you are using accessory products, read the

terminal block and cable assembly installation guides or accessory board user manuals. They

explain how to physically connect the relevant pieces of the system. Consult these guides

when you are making your connections.

• SCXI chassis manuals—If you are using SCXI, read these manuals for maintenance

information on the chassis and installation instructions.

®

/CVI manual sets and the NI-DAQ manuals (a 4.6.1 or earlier version of

Related Documentation

The following documents contain information that you may find helpful as you read this manual.

• Macintosh II or Quadra Owner’s Manual, Getting Started manual, or Setting Up manual

• Inside Macintosh–Volume 5

Customer Communication

National Instruments wants to receive your comments on our products and manuals. We are

interested in the applications you develop with our products, and we want to help if you have

problems with them. To make it easy for you to contact us, this manual contains comment and

configuration forms for you to complete. These forms are in Appendix E, Customer

Communication, at the end of this manual.

© National Instruments Corporation xiii Lab-NB User Manual

Page 14

Chapter 1 Introduction

This chapter describes the Lab-NB, lists what you need to get started, software programming

choices, optional equipment, and explains how to unpack the Lab-NB.

About the Lab-NB

Thank you for buying the National Instruments Lab-NB. The Lab-NB is a low-cost multifunction analog, digital, and timing I/O board for Macintosh NuBus computers. It contains a

12-bit successive-approximation ADC with eight analog inputs, two 12-bit DACs with voltage

outputs, 24 lines of TTL-compatible digital I/O, and six 16-bit counter/timer channels for timing

I/O.

The low cost of a Lab-NB-based system makes it ideal for laboratory work in industrial and

academic environments. The multichannel analog input is useful in signal analysis and data

logging. The 12-bit ADC is useful in high-resolution applications such as chromatography,

temperature measurement, and DC voltage measurement. The analog output channels can be

used to generate experiment stimuli and are also useful for machine and process control and

analog function generation. The 24 TTL-compatible digital I/O lines can be used for switching

external devices such as transistors and solid-state relays, for reading the status of external digital

logic, and for generating interrupts. The counter/timers can be used to synchronize events,

generate pulses, and measure frequency and time. The Lab-NB, used in conjunction with the

Macintosh, is a versatile, cost-effective platform for laboratory test, measurement, and control.

Note: The Lab-NB cannot sink sufficient current to drive the SSR-OAC-5 and

SSR-OAC-5A output modules. However, it can drive the SSR-ODC-5 output module

and all SSR input modules available from National Instruments.

If you need to drive a SSR-OAC-5 or SSR-OAC-5A, you can use a non-inverting digital

buffer chip between the Lab-NB and the SSR backplane.

Detailed Lab-NB specifications are in Appendix A, Specifications.

© National Instruments Corporation 1-1 Lab-NB User Manual

Page 15

Introduction Chapter 1

What You Need to Get Started

To set up and use your Lab-NB board, you will need the following:

Lab-NB board

Lab-NB User Manual

One of the following software packages and documentation:

NI-DAQ software for Macintosh

LabVIEW for Macintosh

Your computer

Software Programming Choices

There are several options to choose from when programming your National Instruments DAQ

and SCXI hardware. You can use LabVIEW, LabWindows/CVI, or NI-DAQ. A 4.6.1 or earlier

version of NI-DAQ supports LabWindows for DOS.

LabVIEW and LabWindows/CVI Application Software

LabVIEW and LabWindows/CVI are innovative program development software packages for

data acquisition and control applications. LabVIEW uses graphical programming, whereas

LabWindows/CVI enhances traditional programming languages. Both packages include

extensive libraries for data acquisition, instrument control, data analysis, and graphical data

presentation.

LabVIEW features interactive graphics, a state-of-the-art user interface, and a powerful graphical

programming language. The LabVIEW Data Acquisition VI Library, a series of VIs for using

LabVIEW with National Instruments DAQ hardware, is included with LabVIEW. The

LabVIEW Data Acquisition VI Libraries are functionally equivalent to the NI-DAQ software.

LabWindows/CVI features interactive graphics, a state-of-the-art user interface, and uses the

ANSI standard C programming language. The LabWindows/CVI Data Acquisition Library, a

series of functions for using LabWindows/CVI with National Instruments DAQ hardware, is

included with the NI-DAQ software kit. The LabWindows/CVI Data Acquisition libraries are

functionally equivalent to the NI-DAQ software.

Using LabVIEW or LabWindows/CVI software will greatly reduce the development time for

your data acquisition and control application.

Lab-NB User Manual 1-2 © National Instruments Corporation

Page 16

Chapter 1 Introduction

NI-DAQ Driver Software

The NI-DAQ driver software is included at no charge with all National Instruments DAQ

hardware. NI-DAQ is not packaged with SCXI or accessory products, except for the SCXI-1200.

NI-DAQ has an extensive library of functions that you can call from your application

programming environment. These functions include routines for analog input (A/D conversion),

buffered data acquisition (high-speed A/D conversion), analog output (D/A conversion),

waveform generation, digital I/O, counter/timer operations, SCXI, RTSI, self-calibration,

messaging, and acquiring data to extended memory.

NI-DAQ has both high-level DAQ I/O functions for maximum ease of use and low-level DAQ

I/O functions for maximum flexibility and performance. Examples of high-level functions are

streaming data to disk or acquiring a certain number of data points. An example of a low-level

function is writing directly to registers on the DAQ device. NI-DAQ does not sacrifice the

performance of National Instruments DAQ devices because it lets multiple devices operate at

their peak performance.

NI-DAQ also internally addresses many of the complex issues between the computer and the

DAQ hardware such as programming interrupts and DMA controllers. NI-DAQ maintains a

consistent software interface among its different versions so that you can change platforms with

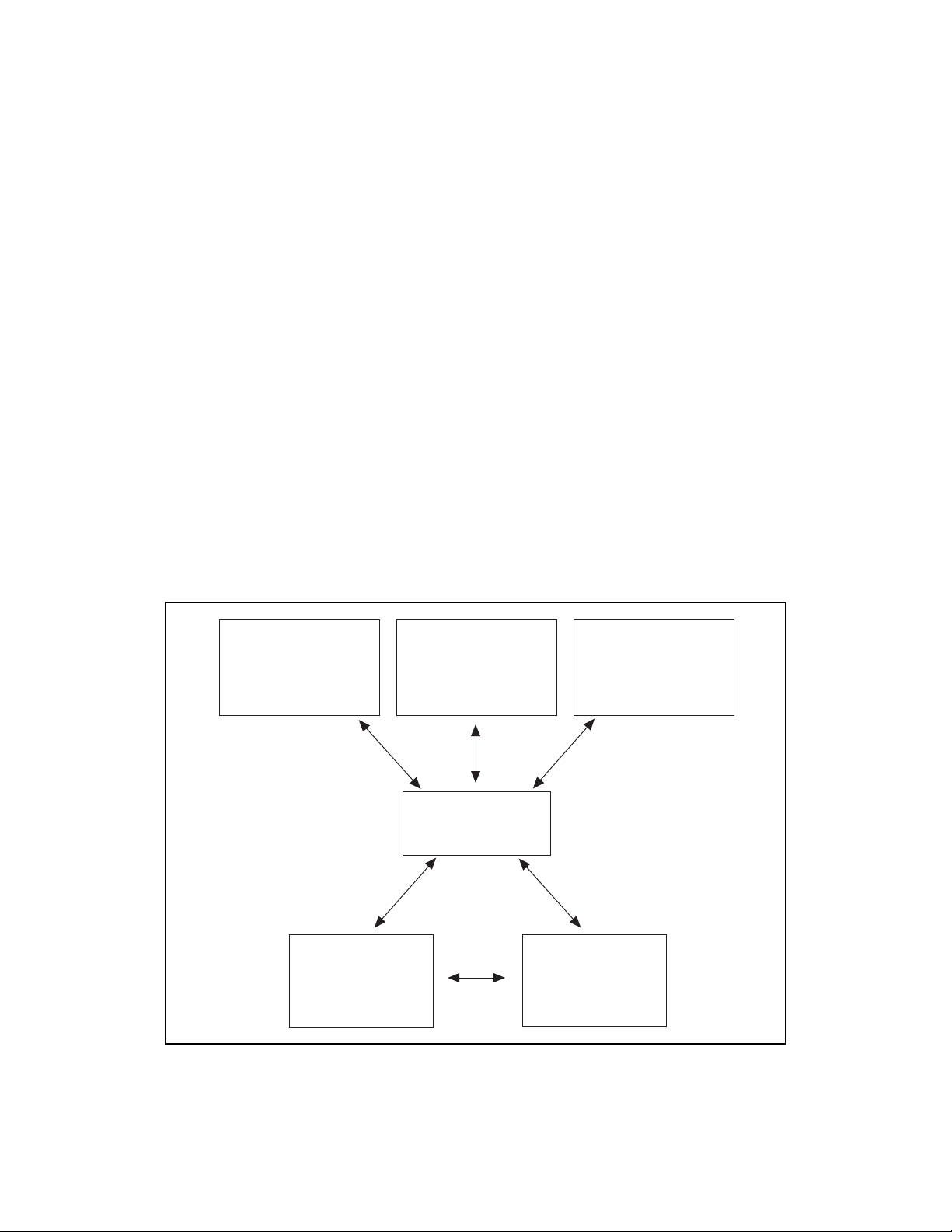

minimal modifications to your code. Figure 1-1 illustrates the relationship between NI-DAQ and

LabVIEW and LabWindows/CVI.

Conventional

Programming

Environment

(PC, Macintosh, or

Sun SPARCstation)

DAQ or

SCXI Hardware

LabVIEW

(PC, Macintosh, or

Sun SPARCstation)

NI-DAQ

Driver Software

LabWindows/CVI

(PC or Sun

SPARCstation)

Personal

Computer or

Workstation

Figure 1-1. The Relationship between the Programming Environment,

NI-DAQ, and Your Hardware

© National Instruments Corporation 1-3 Lab-NB User Manual

Page 17

Introduction Chapter 1

Register-Level Programming

The final option for programming any National Instruments DAQ hardware is to write registerlevel software. Writing register-level programming software can be very time-consuming and

inefficient, and is not recommended for most users.

Even if you are an experienced register-level programmer, consider using NI-DAQ, LabVIEW,

or LabWindows/CVI to program your National Instruments DAQ hardware. Using the NI-DAQ,

LabVIEW, or LabWindows/CVI software is easier than, and as flexible as, register-level

programming, and can save weeks of development time.

Optional Equipment

National Instruments offers a variety of products to use with your Lab-NB board, including

cables, connector blocks, and other accessories, as follows:

• Cables and cable assemblies, shielded and ribbon

• Connector blocks, shielded and unshielded 50-pin screw terminals

• Real Time System Integration (RTSI) bus cables

• Signal conditioning eXtensions for Instrumentation (SCXI) modules and accessories for

isolating, amplifying, exciting, and multiplexing signals for relays and analog output. With

SCXI you can condition and acquire up to 3,072 channels.

• Low channel count signal conditioning modules, boards, and accessories, including

conditioning for strain gauges and RTDs, simultaneous sample and hold, and relays.

For more specific information about these products, refer to your National Instruments catalog or

call the office nearest you.

Cabling

National Instruments offers cables and accessories for you to prototype your application or to use

if you frequently change board interconnections.

If you want to develop your own cable, however, the following guidelines may be useful:

National Instruments currently offers a cable termination accessory, the CB-50, for use with the

Lab-NB board. This kit includes a terminated, 50-conductor, flat ribbon cable and a connector

block. Signal input and output wires can be attached to screw terminals on the connector block

and thereby connected to the Lab-NB I/O connector.

The CB-50 is useful for initially prototyping an application or in situations where Lab-NB

interconnections are frequently changed. When you develop a final field wiring scheme,

however, you may wish to develop your own cable.

Lab-NB User Manual 1-4 © National Instruments Corporation

Page 18

Chapter 1 Introduction

The Lab-NB I/O connector is a 50-pin male ribbon cable header. The manufacturer part

numbers used by National Instruments for this header are as follows:

• Electronic Products Division/3M (part number 3596-5002)

• T&B/Ansley Corporation (part number 609-500)

The mating connector for the Lab-NB is a 50-position, polarized, ribbon socket connector with

strain relief. National Instruments uses a polarized (keyed) connector to prevent inadvertent

upside-down connection to the Lab-NB. Recommended manufacturer part numbers for this

mating connector are as follows:

• Electronic Products Division/3M (part number 3425-7650)

• T&B/Ansley Corporation (part number 609-5041CE)

The following are the standard ribbon cables (50-conductor, 28 AWG, stranded) that can be used

with these connectors:

• Electronic Products Division/3M (part number 3365/50)

• T&B/Ansley Corporation (part number 171-50)

Unpacking

Your Lab-NB board is shipped in an antistatic package to prevent electrostatic damage to the

board. Electrostatic discharge can damage several components of the board. To avoid such

damage in handling the board, take the following precautions:

• Ground yourself via a grounding strap or by holding a grounded object.

• Touch the antistatic package to a metal part of your computer chassis before removing the

board from the package.

• Remove the board from the package and inspect the board for loose components or any other

sign of damage. Notify National Instruments if the board appears damaged in any way. Do

not install a damaged board into your computer.

• Never touch the exposed pins of connectors.

© National Instruments Corporation 1-5 Lab-NB User Manual

Page 19

Chapter 2 Configuration and Installation

This chapter describes how to configure and install the Lab-NB into your Macintosh computer,

and also includes signal connections to the Lab-NB and cable wiring.

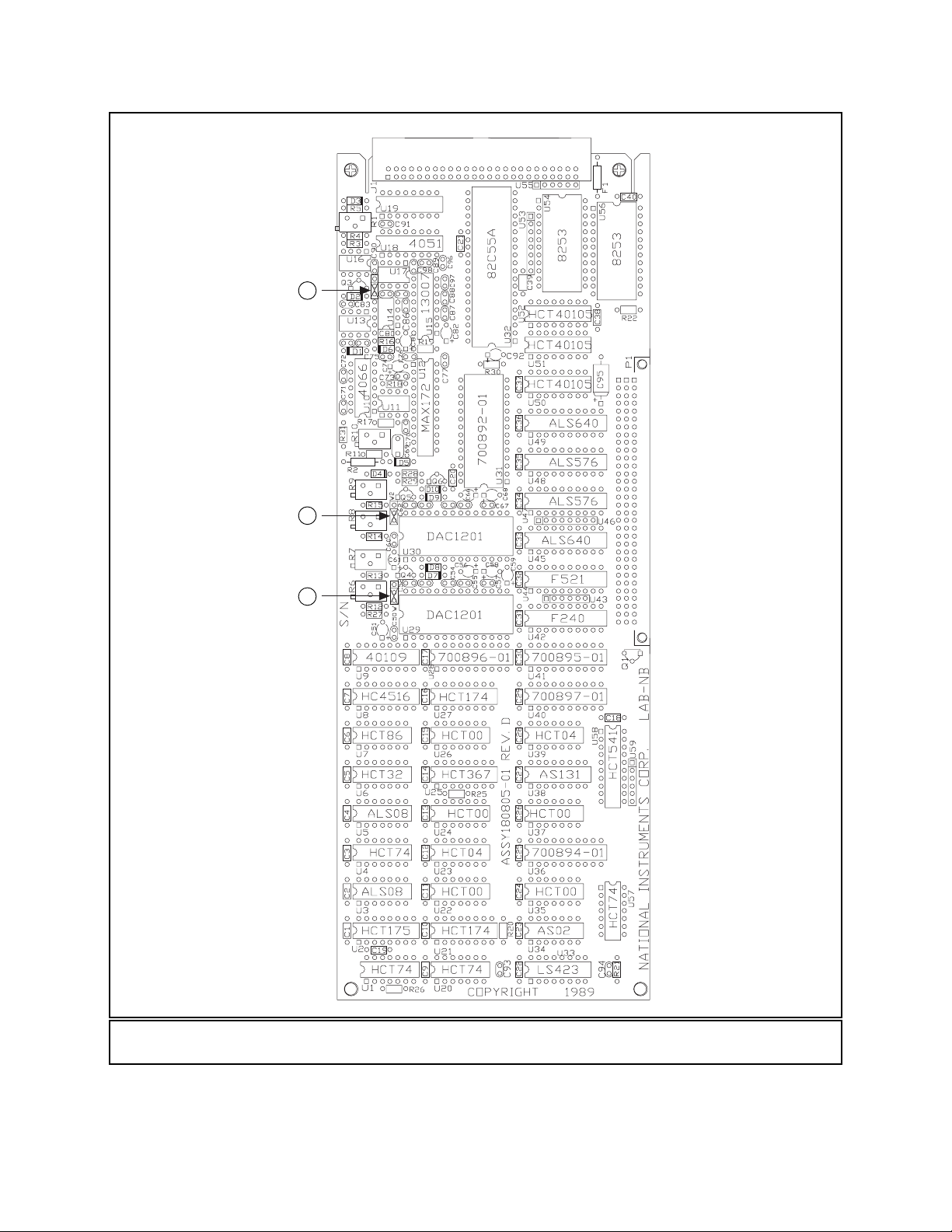

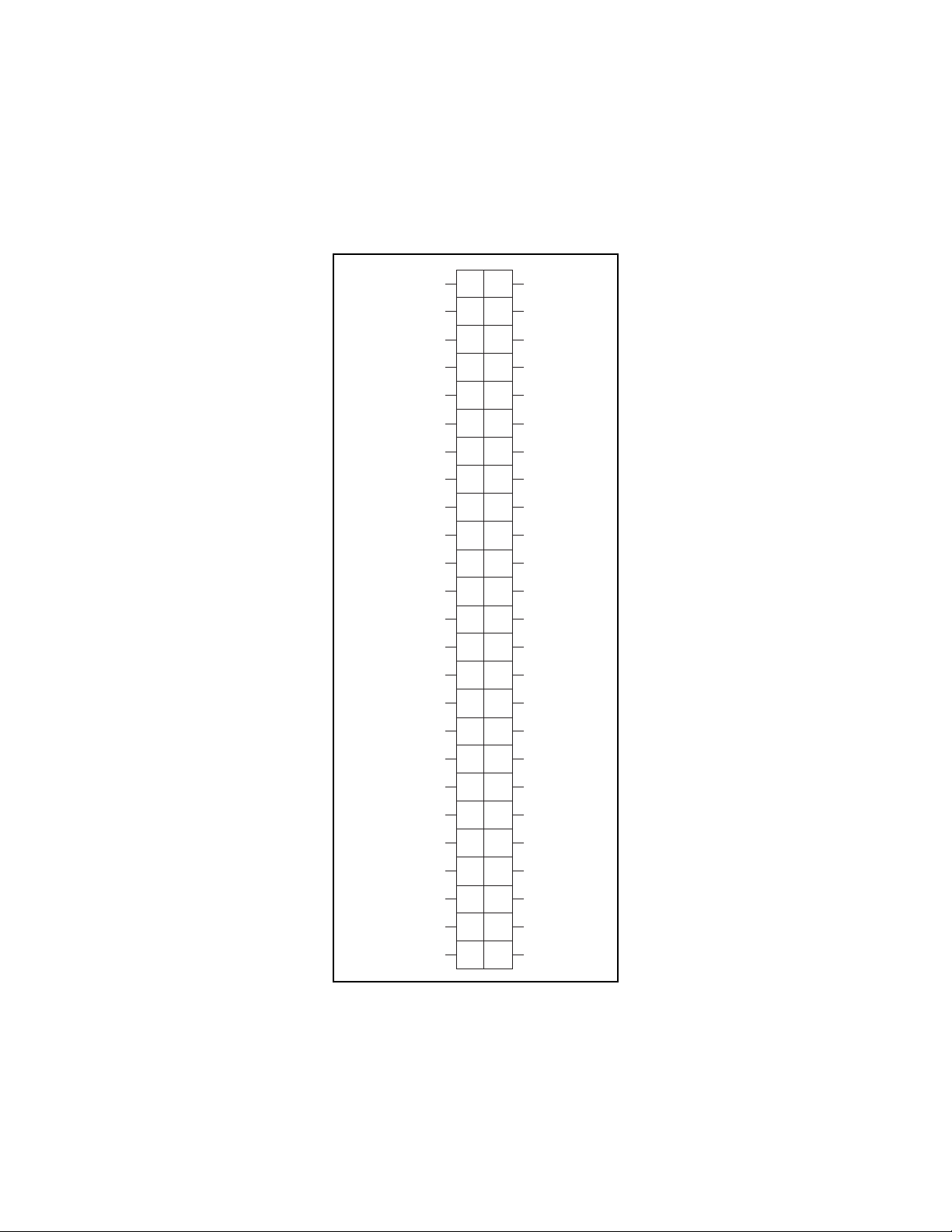

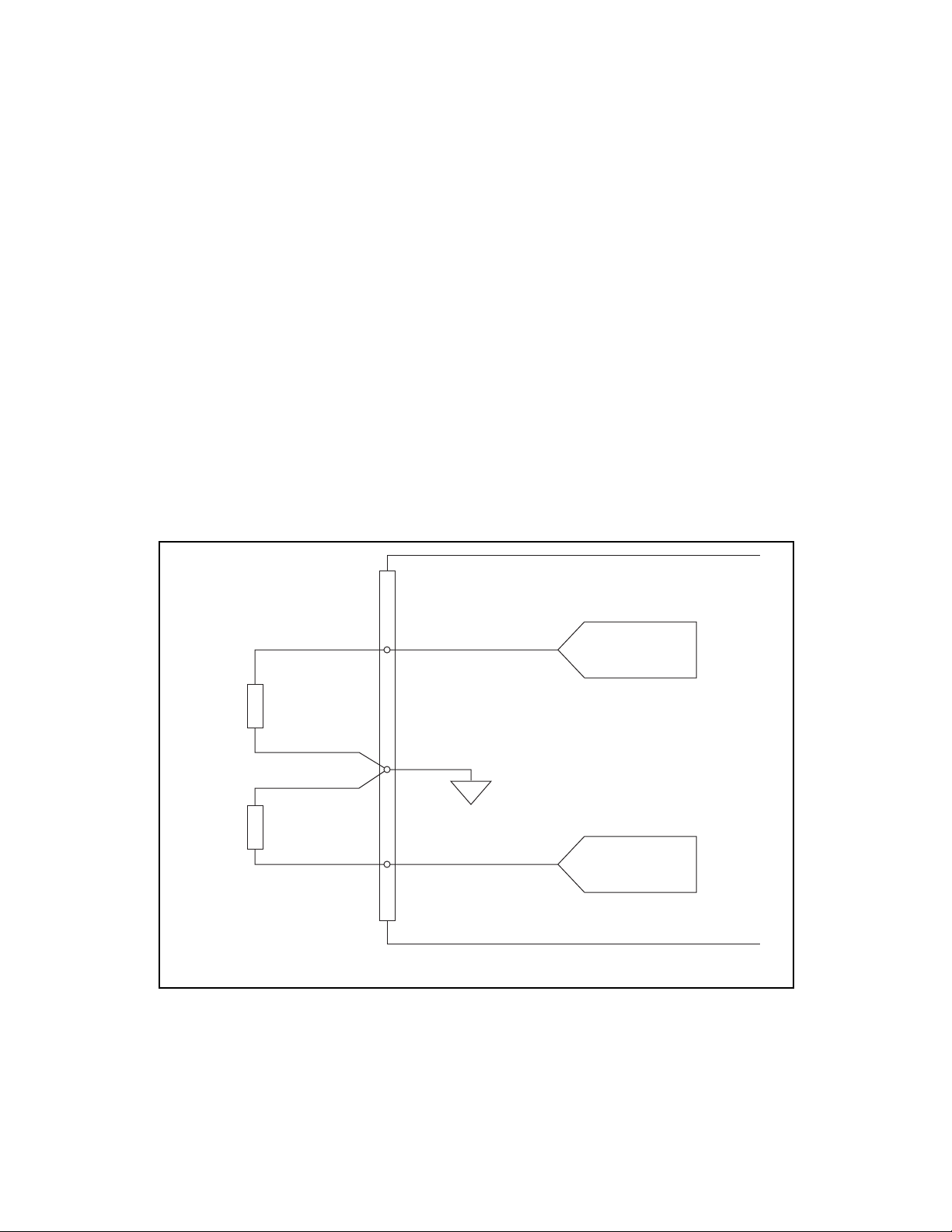

Board Configuration

The Lab-NB contains three jumpers for changing the analog input and output configuration of

the board. The jumpers are shown in the parts locator diagram in Figure 2-1. Jumpers W1 and

W2 configure the two analog outputs. Jumper W3 (not labeled on the board) is used to select the

analog input range. Because of space constraints on the board, the jumper post labels are

missing. To distinguish between the A, B, and C posts of the jumpers, hold the board so that the

component side is facing you, the NuBus connector is down, and the 50-pin I/O connector is on

your right. The posts are then in the order A-B-C from left to right on all three of the horizontal

jumpers, as shown in Figure 2-1.

Note: This same orientation of the board is also assumed in the figures illustrating the

jumper connections (Figures 2-2 and 2-3).

© National Instruments Corporation 2-1 Lab-NB User Manual

Page 20

Configuration and Installation Chapter 2

3

2

1W1

2W2

3W3

1

Figure 2-1. Parts Locator Diagram

Lab-NB User Manual 2-2 © National Instruments Corporation

Page 21

Chapter 2 Configuration and Installation

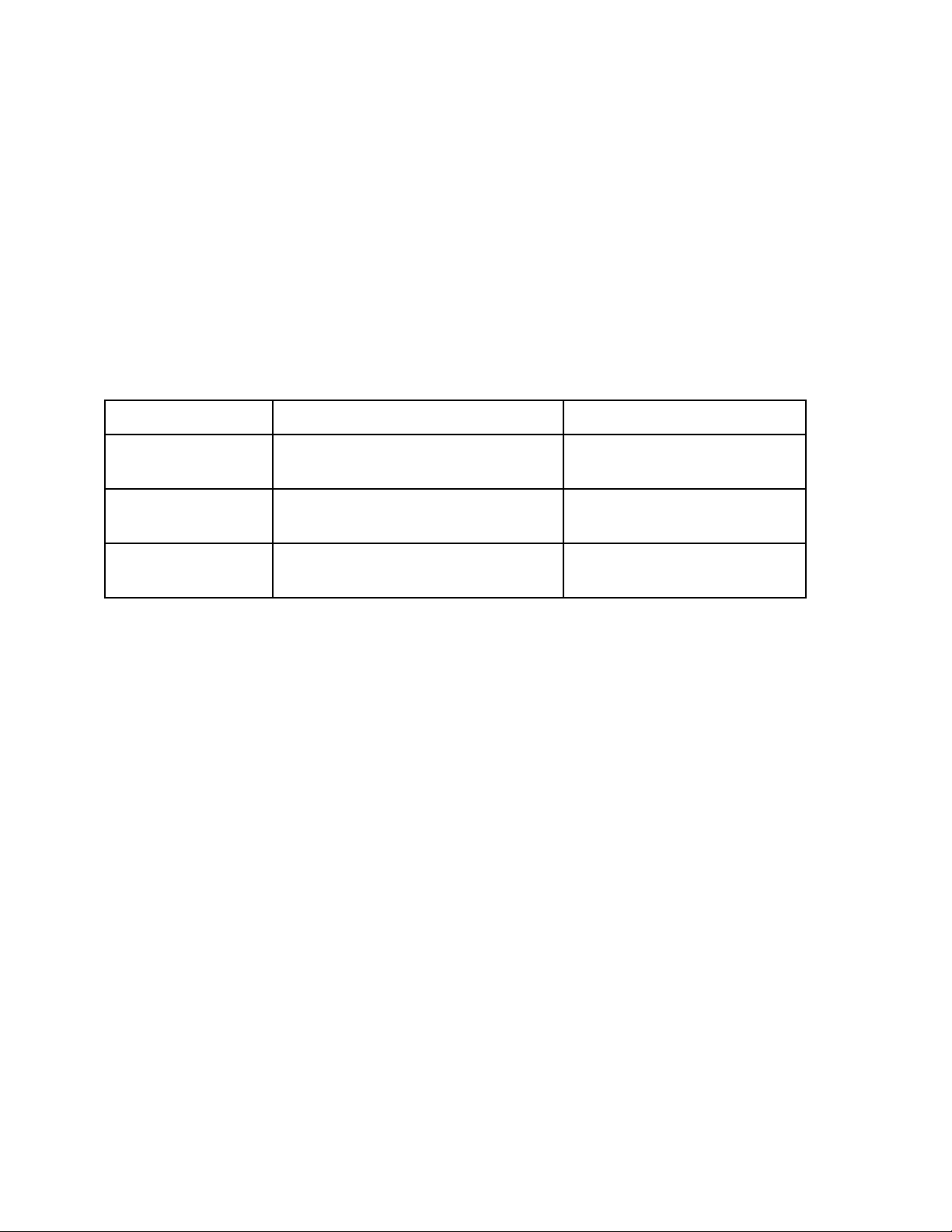

Factory Default Jumper Settings

The Lab-NB is shipped from the factory with the following configuration:

• Jumpers W1 and W2–bipolar analog output

• Jumper W3–bipolar analog input

Table 2-1 lists all the available jumper configurations for the Lab-NB with the factory defaults

noted.

Table 2-1. Lab-NB Jumper Settings

Configuration Jumper Setting

Output CH0

Polarity

Output CH1

Polarity

Input Range Bipolar: ±5 V (factory setting)

Bipolar: ±5 V (factory setting)

Unipolar: 0 to 10 V

Bipolar: ±5 V (factory setting)

Unipolar: 0 to 10 V

Unipolar: 0 to 10 V

W1: A-B

W1: B-C

W2: A-B

W2: B-C

W3: A-B

W3: B-C

Analog Output Configuration

Two ranges are available for the analog outputs: bipolar (±5 V) and unipolar (0 to 10 V).

Jumper W1 controls output channel 0, and W2 controls output channel 1.

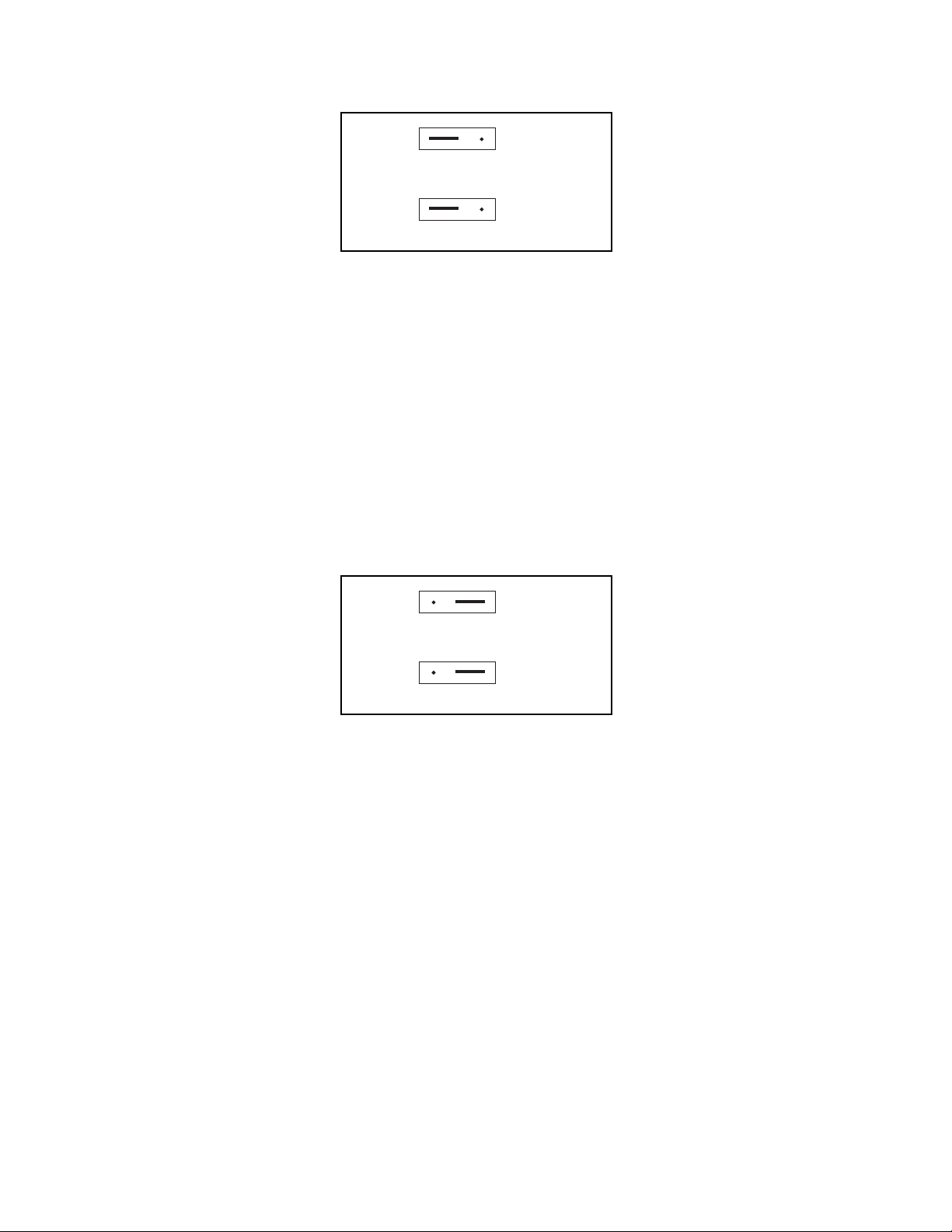

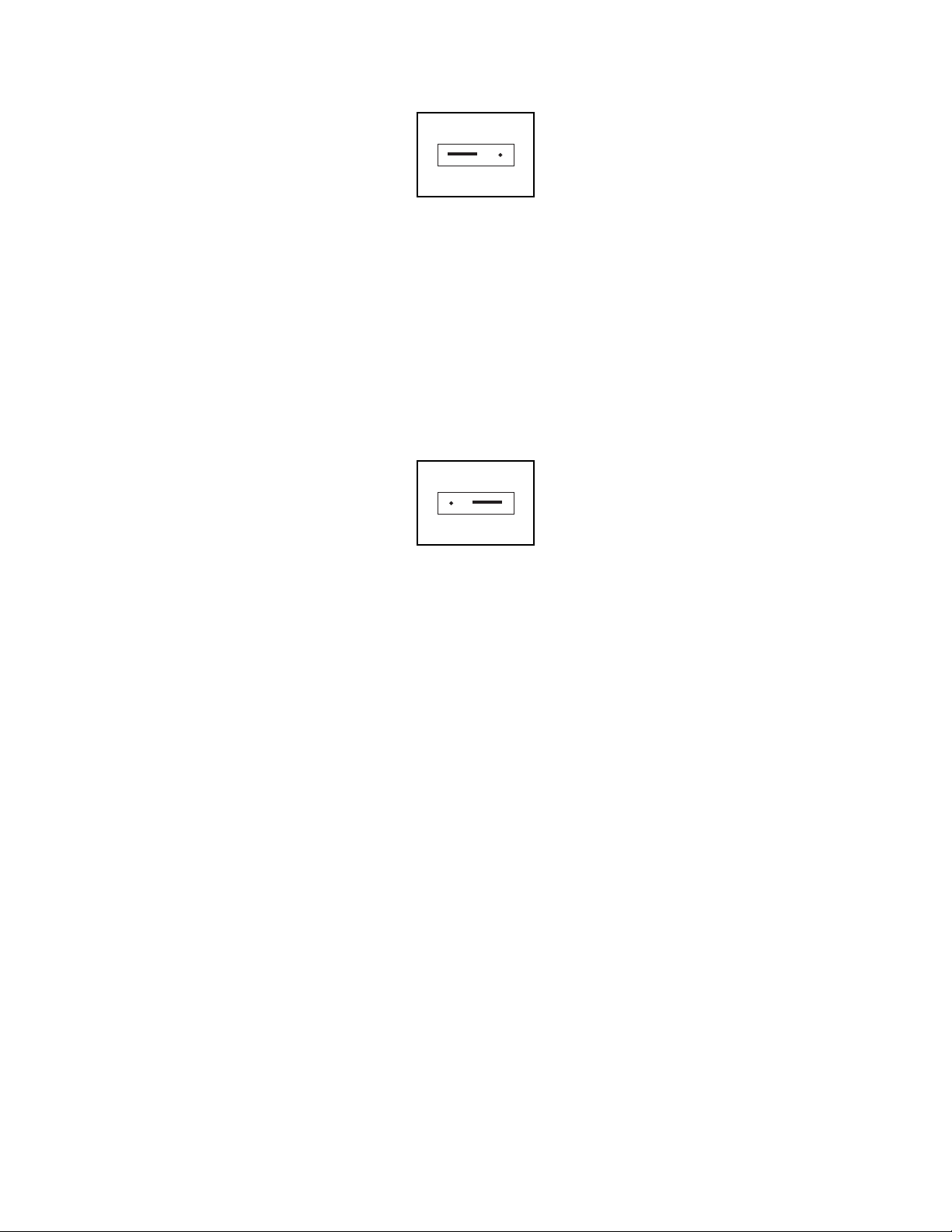

Bipolar Output Selection

You can select the bipolar (±5 V) output configuration for either analog output channel by

setting the following jumpers:

Analog Output Channel 0 W1 A-B

Analog Output Channel 1 W2 A-B

This configuration is shown in Figure 2-2.

© National Instruments Corporation 2-3 Lab-NB User Manual

Page 22

Configuration and Installation Chapter 2

W1

ABC

W2

ABC

Channel 0

Channel 1

Figure 2-2. Bipolar Output Jumper Configuration

Unipolar Output Selection

You can select the unipolar (0 to 10 V) output configuration for either analog output channel by

setting the following jumpers:

Analog Output Channel 0 W1 B-C

Analog Output Channel 1 W2 B-C

This configuration is shown in Figure 2-3.

W1

ABC

W2

ABC

Channel 0

Channel 1

Figure 2-3. Unipolar Output Jumper Configuration

Analog Input Configuration

Two ranges are available for the analog inputs: bipolar (±5 V) and unipolar (0 to 10 V). Jumper

W3 controls the input range for all eight analog input channels.

Bipolar Input Selection

You can select the bipolar (±5 V) input configuration by setting the following jumper:

Analog Input W3 A-B

This configuration is shown in Figure 2-4.

Lab-NB User Manual 2-4 © National Instruments Corporation

Page 23

Chapter 2 Configuration and Installation

W3

ABC

Figure 2-4. Bipolar Input Jumper Configuration

Unipolar Input Selection

You can select the unipolar (0 to 10 V) input configuration by setting the following jumper:

Analog Input W3 B-C

This configuration is shown in Figure 2-5.

W3

ABC

Figure 2-5. Unipolar Input Jumper Configuration

Note: If you are using a software package such as NI-DAQ or LabVIEW, you may need to

reconfigure your software to reflect any changes in jumper or switch settings.

Installation

Find the section in your Macintosh documentation that explains how to install an expansion

board in your computer. You can use this procedure as a universal board installation guide.

First, read the entire procedure. Then, install your Lab-NB board in the Macintosh by following

the outlined procedure.

Signal Connections

I/O Connector Pin Description

Figure 2-6 shows the pin assignments for the Lab-NB I/O connector. This connector is located

on the back panel of the Lab-NB board and is accessible at the rear of the Macintosh computer

after the board has been properly installed.

© National Instruments Corporation 2-5 Lab-NB User Manual

Page 24

Configuration and Installation Chapter 2

Warning: Connections that exceed any of the maximum ratings of input or output signals on

the Lab-NB may result in damage to the Lab-NB board and to the Macintosh

computer. This includes connecting any power signals to ground and vice versa.

National Instruments is

NOT liable for any damages resulting from any such

signal connections.

ACH0

ACH2

ACH4

ACH6

AIGND

AOGND

DGND

PA1

PA3

PA5

PA7

PB1

PB3

PB5

PB7

PC1

PC3

12

34

56

78

9

10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25 26

27 28

29 30

31 32

33 34

ACH1

ACH3

ACH5

ACH7

DAC0 OUT

DAC1 OUT

PA0

PA2

PA4

PA6

PB0

PB2

PB4

PB6

PC0

PC2

PC4

PC5

PC7

EXTUPDATE*

OUTB0

OUTB1

CLKB1

GATB2

+5V

35 36

37 38

39 40

41 42

43 44

45 46

47 48

49 50

PC6

EXTTRIG

EXTCONV*

GATB0

GATB1

OUTB2

CLKB2

DGND

Figure 2-6. Lab-NB I/O Connector Pin Assignments

Lab-NB User Manual 2-6 © National Instruments Corporation

Page 25

Chapter 2 Configuration and Installation

Signal Connection Descriptions

Pin Signal Name Description

1-8 ACH<0..7> Analog input channels 0 through 7 (single-ended).

9 AIGND Analog input ground.

10 DAC0 OUT Voltage output signal for analog output channel 0.

11 AOGND Analog output ground.

12 DAC1 OUT Voltage output signal for analog output channel 1.

13 DGND Digital ground.

14–21 PA<0..7> Bidirectional data lines for port A. PA7 is the MSB, PA0 the LSB.

22–29 PB<0..7> Bidirectional data lines for port B. PB7 is the MSB, PB0 the LSB.

30–37 PC<0..7> Bidirectional data lines for port C. PC7 is the MSB, PC0 the LSB.

38 EXTTRIG External control signal to start a timed conversion sequence.

39 EXTUPDATE* External control signal to update DAC outputs.

40 EXTCONV* External control signal to trigger A/D conversions.

41 OUTB0 Counter B0 output.

42 GATB0 Counter B0 gate.

43 OUTB1 Counter B1 output.

44 GATB1 Counter B1 gate.

45 CLKB1 Counter B1 clock.

46 OUTB2 Counter B2 output.

47 GATB2 Counter B2 gate.

48 CLKB2 Counter B2 clock.

49 +5 V +5 V out, 1 A maximum.

50 DGND Digital ground.

Note: Pin 49 is connected to the NuBus +5 V supply via a 1 A fuse. A replacement fuse is available

from Allied Electronics, part number 845-2007, and Littelfuse, part number 251001.

* Indicates that the signal is active low.

The connector pins can be grouped into analog input signal pins, analog output signal pins,

digital I/O signal pins, and timing I/O signal pins. Signal connection guidelines for each of these

groups are included later in this chapter.

Analog Input Signal Connections

Pins 1 through 8 are analog input signal pins for the 12-bit ADC. Pin 9, AIGND, is an analog

common signal. This pin can be used for a general analog power ground tie to the Lab-NB. Pins

1 through 8 are tied to the eight single-ended analog input channels of the input multiplexer

through 4.7-kΩ series resistances. Pin 40 is EXTCONV* and can be used to trigger conversions.

A conversion occurs when this signal makes a high-to-low transition. It can only be used to

© National Instruments Corporation 2-7 Lab-NB User Manual

Page 26

Configuration and Installation Chapter 2

cause conversions to occur; it cannot be used as a monitor to detect conversions caused by the

onboard sample-interval timer.

The following input ranges and maximum ratings apply to inputs ACH<0..7>:

Input impedance 0.1 GΩ in parallel with 45 pF

Input signal range Bipolar input: ±(5 / gain) V

Unipolar input: 0 to (10 / gain) V

Maximum input voltage rating ±45 V powered on or off

Exceeding the input signal range for gain settings greater than 1 will not damage the input

circuitry as long as the maximum input voltage rating of ±45 V is not exceeded. For example,

with a gain of 10, the input signal range is ±0.5 V for bipolar input and 0 to 1 V for unipolar

input, but the Lab-NB is guaranteed to withstand inputs up to the maximum input voltage rating.

Warning: Exceeding the input signal range will result in distorted input signals. Exceeding

the maximum input voltage rating may result in damage to the Lab-NB board and

to the Macintosh computer. National Instruments is

NOT liable for any damages

resulting from any such signal connections.

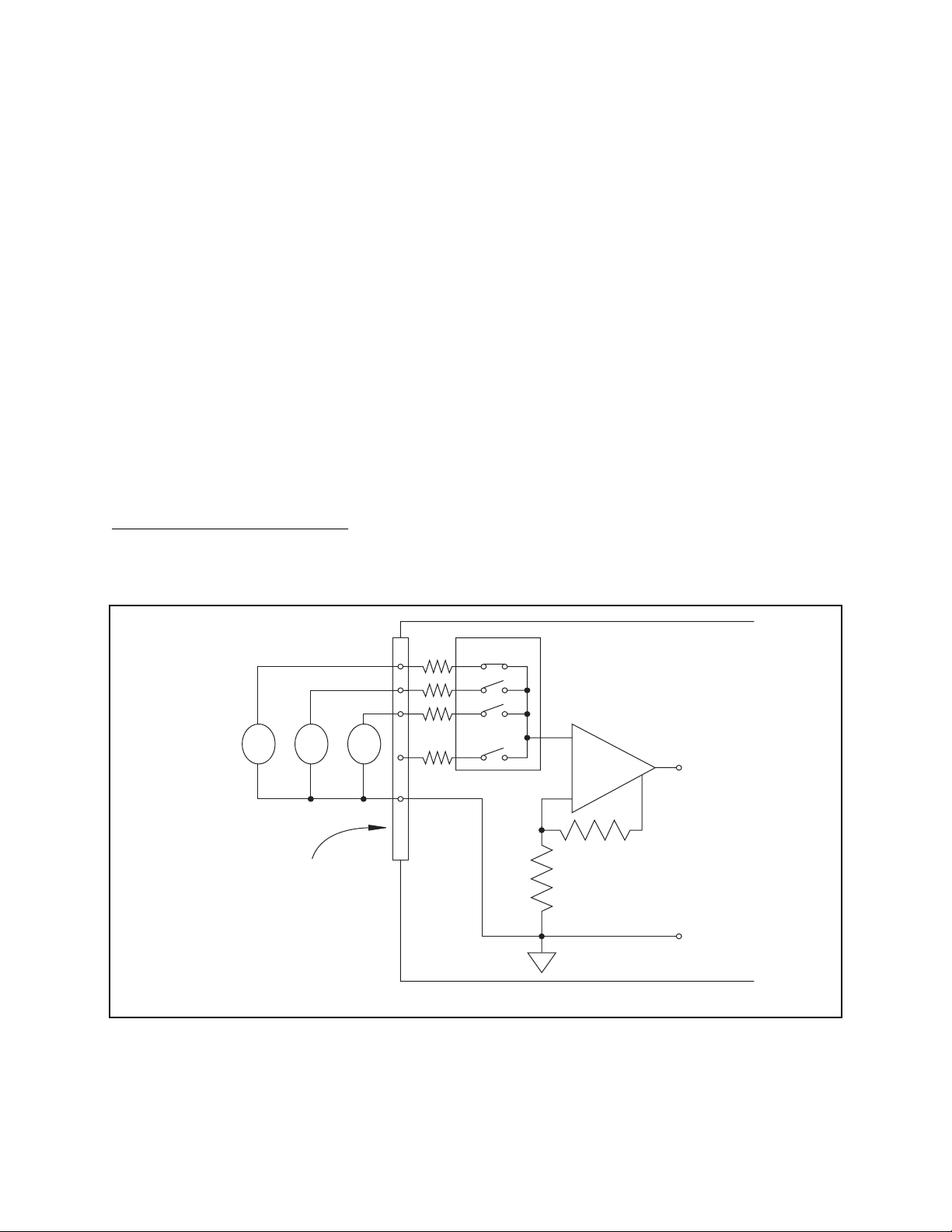

Connections for Signal Sources

Figure 2-7 shows how to connect a signal source to a Lab-NB board. When you connect

grounded signal sources, observe the polarity carefully to avoid shorting the signal source output.

ACH<0..7>

•

•

•

Input Multiplexer

AIGND

+

-

R

f

R

a

Programmable Gain

Amplifier

+

M

Measured

-

V

Voltage

Signal

Source

+++

S1

V

V

I/O Connector

S2

V

S3

1

2

3

8

--9

Lab-NB Board

Figure 2-7. Analog Input Signal Connections

Lab-NB User Manual 2-8 © National Instruments Corporation

Page 27

Chapter 2 Configuration and Installation

Analog Output Signal Connections

Pins 10 through 12 of the I/O connector are analog output signal pins.

Pins 10 and 12 are the DAC0 OUT and DAC1 OUT signal pins. DAC0 OUT is the voltage

output signal for Analog Output Channel 0. DAC1 OUT is the voltage output signal for Analog

Output Channel 1.

Pin 11, AOGND, is the ground reference point for both analog output channels as well as analog

input.

The following output ranges are available:

Output signal range Bipolar input: ±5 V

Unipolar input: 0 to 10 V

*

Maximum load current = ±1 mA for 12-bit linearity

Figure 2-8 shows how to make analog output connections.

DAC0 OUT10

+

Load

Load

VOUT 0

VOUT 1

-

-

+

11

12

AOGND

DAC1 OUT

*

*

Channel 0

Channel 1

Analog Output Channels

Lab-NB Board

Figure 2-8. Analog Output Signal Connections

© National Instruments Corporation 2-9 Lab-NB User Manual

Page 28

Configuration and Installation Chapter 2

Digital I/O Signal Connections

Pins 13 through 37 of the I/O connector are digital I/O signal pins. Digital I/O on the Lab-NB is

designed around the 82C55A integrated circuit. The 82C55A is a general-purpose PPI

containing 24 programmable I/O pins. These pins represent the three 8-bit ports (PA, PB, and

PC) of the 82C55A.

Pins 14 through 21 are connected to the digital lines PA<0..7> for digital I/O port A. Pins 22

through 29 are connected to the digital lines PB<0..7> for digital I/O port B. Pins 30 through 37

are connected to the digital lines PC<0..7> for digital I/O port C. Pin 13, DGND, is the digital

ground pin for all three digital I/O ports.

The following specifications and ratings apply to the digital I/O lines.

Absolute maximum voltage input rating +5.5 V with respect to DGND

-0.5 V with respect to DGND

Digital input specifications (referenced to DGND):

V

input logic high voltage 2.2 V min

IH

VIL input logic low voltage 0.8 V max

I

input current load,

IH

logic high input voltage 1.0 µA max

input current load,

I

IL

logic low input voltage -1.0 µA max

Digital output specifications (referenced to DGND):

output logic high voltage 3.7 V min

V

OH

VOL output logic low voltage 0.4 V max

I

output source current,

OH

logic high -2.5 mA max

output sink current,

I

OL

logic low 2.5 mA max

Lab-NB User Manual 2-10 © National Instruments Corporation

Page 29

Chapter 2 Configuration and Installation

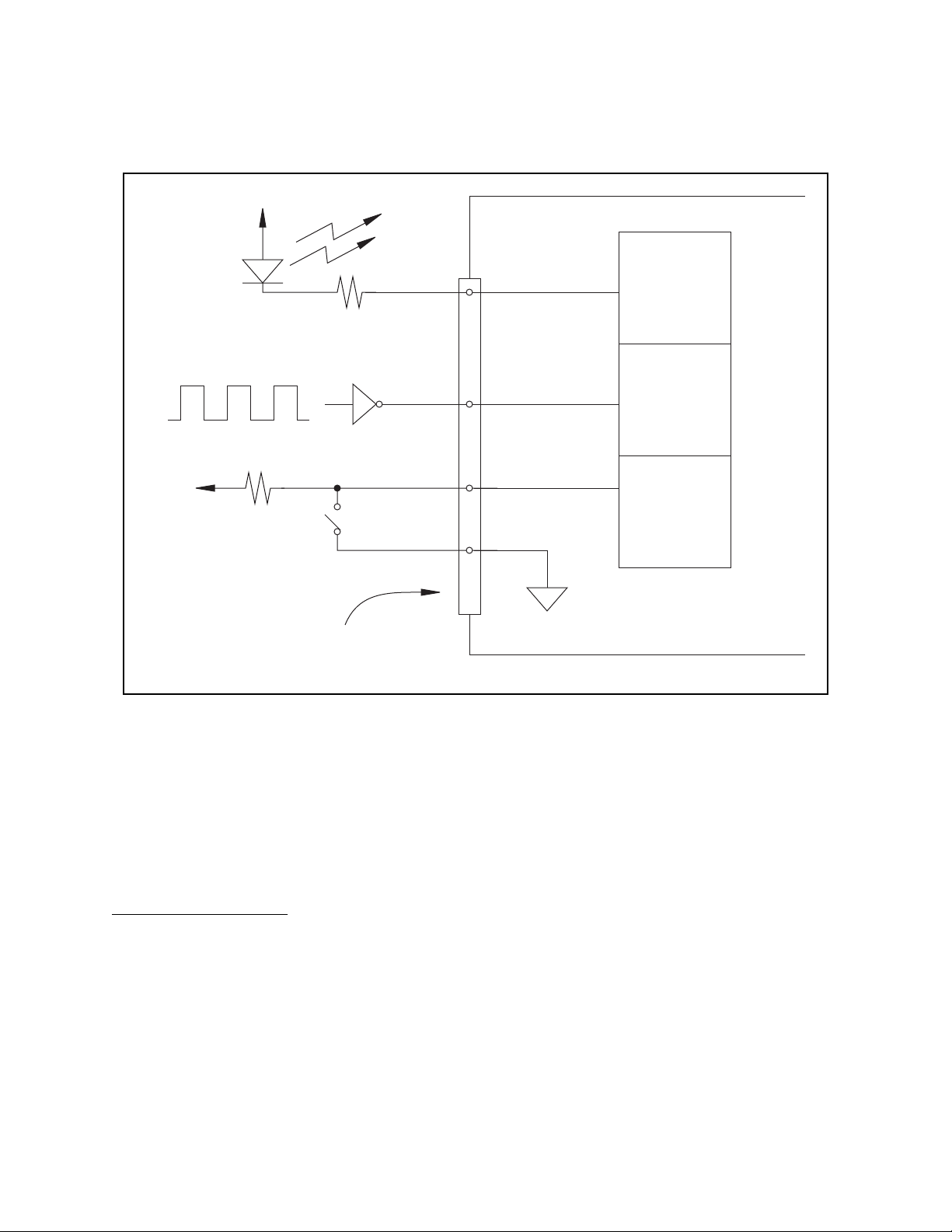

Figure 2-9 illustrates signal connections for three typical digital I/O applications.

+5 V

LED

+5 V

Switch

I/O Connector

14 PA0

Port A

P A<7..0>

Port B

22 PB0

PB<7..0>

TTL Signal

30 PC0

Port C

PC<7..0>

13

DGND

Lab-NB Board

Figure 2-9. Digital I/O Connections

In Figure 2-9, port A is configured for digital output, and ports B and C are configured for digital

input. Digital input applications include receiving TTL signals and sensing external device states

such as the switch in Figure 2-9. Digital output applications include sending TTL signals and

driving external devices such as the LED shown in Figure 2-9.

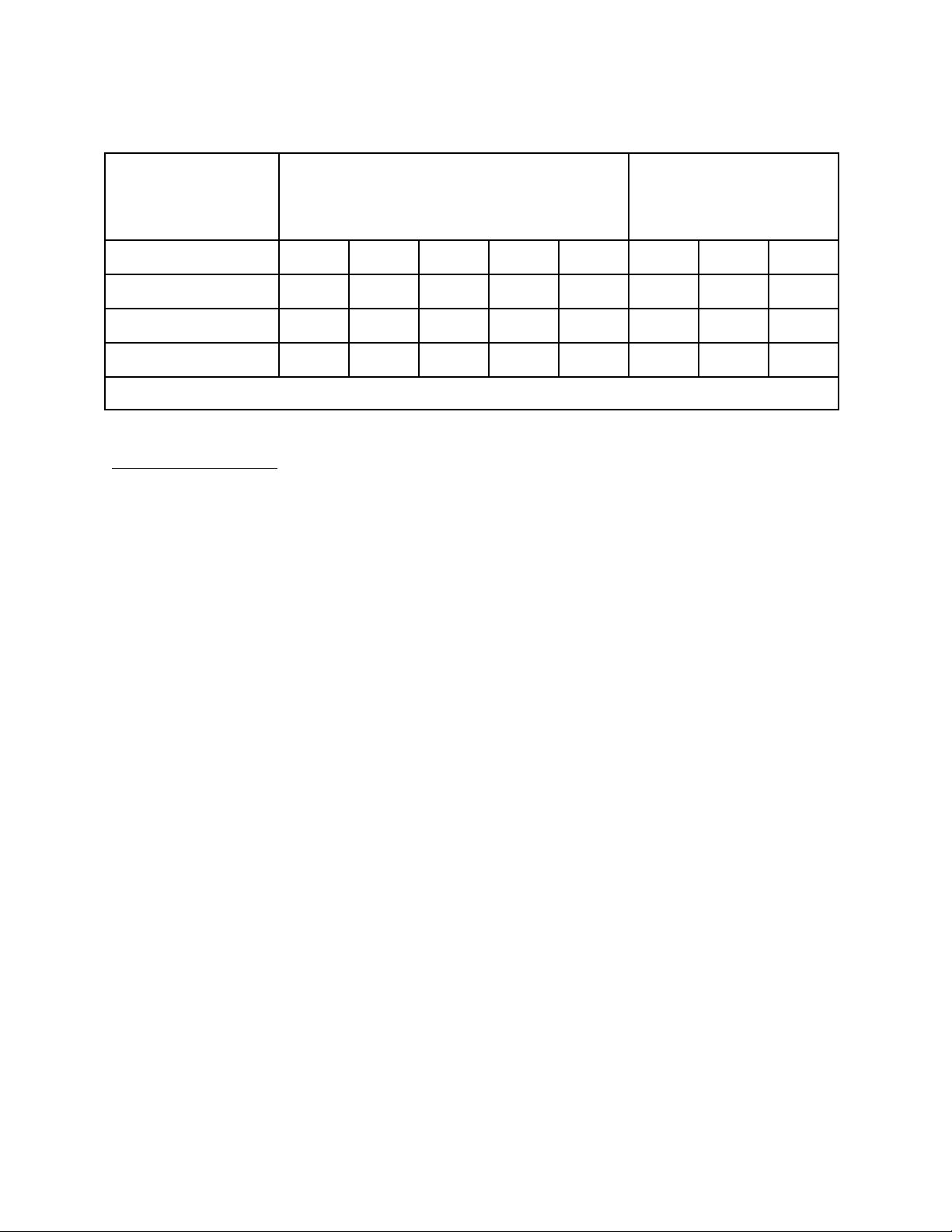

Port C Pin Connections

The signals assigned to port C depend on the mode in which the 82C55A is programmed. In

mode 0, port C is considered as two 4-bit I/O ports. In modes 1 and 2, port C is used for status

and handshaking signals with two or three I/O bits mixed in. The following table summarizes

the signal assignments of port C for each programmable mode. See Chapter 4, Register-Level

Programming, for programming information.

Warning: During programming, note that each time a port is configured, output ports A

and C are reset to 0, and output port B is undefined.

© National Instruments Corporation 2-11 Lab-NB User Manual

Page 30

Configuration and Installation Chapter 2

Table 2-2. Port C Signal Assignments

Programming

Group A Group B

Mode

PC7 PC6 PC5 PC4 PC3 PC2 PC1 PC0

Mode 0

Mode 1 Input

Mode 1 Output

Mode 2

* Indicates that the signal is active low.

I/O I/O I/O I/O I/O I/O I/O I/O

I/O I/O IBF

OBFA* ACKA* I/O I/O INTR

OBFA* ACKA* IBF

STBA* INTR

A

STBA* INTR

A

STBB* IBFB

A

ACKB* OBFB* INTR

A

I/O I/O I/O

A

INTR

B

Timing Specifications

The handshaking lines STB* and IBF are used to synchronize input transfers. The handshaking

lines OBF* and ACK* are used to synchronize output transfers.

B

B

Lab-NB User Manual 2-12 © National Instruments Corporation

Page 31

Chapter 2 Configuration and Installation

The following signals are used in the timing diagrams shown later in this chapter:

Pin Direction Description

STB* Input Strobe Input—A low signal on this handshaking line loads data into the

input latch.

IBF Output Input Buffer Full—A high signal on this handshaking line indicates that

data has been loaded into the input latch. This is basically an input

acknowledge signal.

ACK* Input Acknowledge Input—A low signal on this handshaking line indicates

that the data written from the specified port has been accepted. This

signal is basically a response from the external device that it has received

the data from the Lab-NB.

OBF* Output Output Buffer Full—A low signal on this handshaking line indicates that

data has been written from the specified port.

INTR Output Interrupt Request—This signal becomes high when the 82C55A is

requesting service during a data transfer. The appropriate interrupt

enable signals must be set to generate this signal.

RD* Internal Read Signal—This signal is the read signal generated from the control

lines of the NuBus.

WR* Internal Write Signal—This signal is the write signal generated from the control

lines of the NuBus.

DATA Bidirectional Data Lines at the Specified Port—This signal indicates when the data on

the data lines at a specified port is or should be available.

© National Instruments Corporation 2-13 Lab-NB User Manual

Page 32

Configuration and Installation Chapter 2

Mode 1 Input Timing

The following figure illustrates the timing specifications for an input transfer in mode 1.

T1

T2

STB *

IBF

INTR

RD *

T3

DATA

T4

T6

T5

Name Description Minimum Maximum

T1 STB* pulse width 100 –

T2 STB* = 0 to IBF = 1 – 150

T3 Data before STB* = 1 20 –

T4 STB* = 1 to INTR = 1 – 150

T5 Data after STB* = 1 50 –

T6 RD* = 0 to INTR = 0 – 200

T7 RD* = 1 to IBF = 0 – 150

T7

All timing values are in nanoseconds.

© National Instruments Corporation 2-14 Lab-NB User Manual

Page 33

Chapter 2 Configuration and Installation

Mode 1 Output Timing

The following figure illustrates the timing specifications for an output transfer in mode 1.

T3

WR*

T4

OBF*

INTR

ACK*

DATA

T1

T5

T2

T6

Name Description Minimum Maximum

T1 WR* = 0 to INTR = 0 – 250

T2 WR* = 1 to output – 200

T3 WR* = 1 to OBF* = 0 – 150

T4 ACK* = 0 to OBF* = 1 – 150

T5 ACK* pulse width 100 –

T6 ACK* = 1 to INTR = 1 – 150

All timing values are in nanoseconds.

© National Instruments Corporation 2-15 Lab-NB User Manual

Page 34

Configuration and Installation Chapter 2

Mode 2 Bidirectional Timing

The following figure illustrates the timing specifications for bidirectional transfers in mode 2.

T1

WR *

T6

OBF *

INTR

ACK *

STB *

IBF

RD *

DATA

T3

T4

T2

T5

T7

T8

Name Description Minimum Maximum

T1 WR* = 1 to OBF* = 0 – 150

T2 Data before STB* = 1 20 –

T3 STB* pulse width 100 –

T4 STB* = 0 to IBF = 1 – 150

T5 Data after STB* = 1 50 –

T6 ACK* = 0 to OBF = 1 – 150

T7 ACK* pulse width 100 –

T8 ACK* = 0 to output – 150

T9 ACK* = 1 to output float 20 250

T10 RD* = 1 to IBF = 0 – 150

T10

T9

All timing values are in nanoseconds.

Lab-NB User Manual 2-16 © National Instruments Corporation

Page 35

Chapter 2 Configuration and Installation

Timing Connections

Pins 38 through 48 of the I/O connector are connections for timing I/O signals. The timing I/O of

the Lab-NB is designed around the 8253 Counter/Timer integrated circuit. Two of these integrated

circuits are employed in the Lab-NB. One, designated 8253(A), is used exclusively for DAQ

timing, and the other, 8253(B), is available for general use. Pins 38 through 40 carry external

signals that can be used for DAQ timing in place of the dedicated 8253(A). These signals are

explained under DAQ Timing Connections later in this chapter. Pins 41 through 48 carry generalpurpose timing signals from 8253(B). These signals are explained under General-Purpose

Timing Connections later in this chapter.

DAQ Timing Connections

Counter 0 on the 8253(A) Counter/Timer (referred to as A0) is used as a sample-interval counter

in timed A/D conversions. Counter 1 on the 8253(B) Counter/Timer (referred to as A1) is used as

a sample counter in conjunction with counter 0 for data acquisition. These counters are not

available for general use. In addition to counter A0, EXTCONV* can be used to externally time

conversions. See Chapter 4, Register-Level Programming, for the programming sequence needed

to enable this input. Figure 2-10 shows the timing requirements for the EXTCONV* input. An

A/D conversion is initiated by a falling edge on the EXTCONV*. If EXTCONV* stays low

more than 12

following rising edge on EXTCONV*. If EXTCONV* stays low less than 12

this conversion is latched into the FIFO memory after 12

µsec, the data from this conversion is not latched into the FIFO memory until the

µsec, the data from

µsec.

t

EXTCONV*

V

IH

V

IL

t

w

A/D Conversion starts within

125 nsec from this point

w

tw 250 nsec minimum

(worst-case)

(100 nsec typical)

Figure 2-10. EXTCONV* Signal Timing

Another external control, EXTTRIG, is used for either starting a DAQ sequence or terminating an

ongoing DAQ sequence, depending on the settings of the EXTTRIGEN and PRETRIG bits in the

ADC Configuration Register.

If EXTTRIGEN is set, EXTTRIG serves as an external trigger to start a DAQ sequence. In this

mode, posttrigger mode, the sample-interval counter is gated off until a rising edge is sensed on

the EXTTRIG line. EXTCONV*, however, is enabled on the first rising edge of EXTCONV*,

following the rising edge on the EXTTRIG line. Further transitions on the EXTTRIG line have no

© National Instruments Corporation 2-17 Lab-NB User Manual

Page 36

Configuration and Installation Chapter 2

effect until a new DAQ sequence is established. Figures 2-11 and 2-12 illustrate two possible

posttrigger DAQ timing cases. In Figure 2-11, the rising edge on EXTTRIG is sensed when the

EXTCONV* input is high. Thus, the first A/D conversion occurs on the second falling edge of

EXTCONV*, after the rising edge on EXTTRIG. In Figure 2-12, the rising edge on EXTTRIG is

sensed when the EXTCONV* input is low. In this case, the first A/D conversion occurs on the

first falling edge of EXTCONV*, after the rising edge on EXTTRIG. Notice that Figures 2-11

and 2-12 show a controlled acquisition mode DAQ sequence; that is, Sample Counter A1 disables

further A/D conversions after the programmed count (3 in the examples shown in Figures 2-11

and 2-12) expires. The counter is not loaded with the programmed count until the first falling edge

following a rising edge on the clock input; therefore two extra conversion pulses are generated as

shown in Figures 2-11 and 2-12. EXTTRIG can also be used as an external trigger in freerun

acquisition mode.

t

w

V

IH

EXTTRIG

EXTCONV*

V

IL

t

w

tw 50 nsec minimum

CONVERT

Sample

Counter

EXTTRIG

EXTCONV*

CONVERT

Sample

Counter

XX3210

Figure 2-11. Posttrigger DAQ Timing

(EXTCONV* High When Trigger Sensed)

t

w

V

IH

V

IL

t

w

tw 50 nsec minimum

td 50 nsec minimum

X 3210

Figure 2-12. Posttrigger DAQ Timing

(EXTCONV* Low When Trigger Sensed)

Lab-NB User Manual 2-18 © National Instruments Corporation

Page 37

Chapter 2 Configuration and Installation

If PRETRIG is set, EXTTRIG serves as a pretrigger signal. In pretrigger mode, A/D conversions

are enabled via software before a rising edge is sensed on the EXTTRIG input. However, the

sample counter, counter A1, is not gated on until a rising edge is sensed on the EXTTRIG input.

Additional transitions on this line have no effect until a new DAQ sequence is set up.

Conversions remain enabled for the programmed count after the trigger; therefore, data can be

acquired before and after the trigger. Pretrigger mode works only in controlled acquisition

mode, that is, counter A1 is required to disable A/D conversions after the programmed count

expires. Thus, the maximum number of samples acquired after the trigger is limited to 65,535.

The number of samples acquired before the trigger is limited only by the size of the memory

buffer available for data acquisition. Figure 2-13 shows a pretrigger DAQ timing sequence.

t

w

V

EXTTRIG

EXTCONV*

IH

V

IL

t

w

tw 50 nsec minimum

CONVERT

Sample

Counter

4

3210

Figure 2-13. Pretrigger DAQ Timing

Because both pretrigger and posttrigger modes use EXTTRIG input, only one mode can be used

at a time. If neither PRETRIG nor EXTTRIGEN is set high, this signal has no effect.

The final external control signal, EXTUPDATE*, is used to externally control the updating of

the output voltage of the 12-bit DACs or to generate an externally timed interrupt on the NuBus.

If the TMRWGEN bit in the DAC Configuration Register is set, the DAC voltage is updated by a

low level on the EXTUPDATE* signal. If the TMRINTEN bit in the Interrupt Control Register

is set, an interrupt is generated whenever a rising edge is detected on the EXTUPDATE* bit .

Therefore, externally timed, interrupt-driven waveform generation is possible on the Lab-NB.

Figure 2-14 illustrates a waveform generation timing sequence using the EXTUPDATE* signal.

Notice that the DACs are updated by a low level on the EXTUPDATE* line. Any writes to the

DAC Data Registers while EXTUPDATE* is low therefore result in immediate update of the

DAC output voltages.

© National Instruments Corporation 2-19 Lab-NB User Manual

Page 38

Configuration and Installation Chapter 2

EXTUPDATE*

DAC OUTPUT

UPDATE

TMRINTUP

DACWRT

t

ext

t

Minimum 50 nsec

ext

Figure 2-14. Waveform Generation Timing with the EXTUPDATE* Signal

Since a rising edge on the EXTUPDATE* signal always sets the TMRINTUP bit in the Interrupt

Status Register, the EXTUPDATE* signal can also be used for periodic interrupt generation

timed by an external source. The TMRINTUP bit is cleared by writing to either of the two

DACs or to the TMRINTCL bit location. Figure 2-15 illustrates a timing sequence where

EXTUPDATE* is being used to generate a NuBus interrupt.

EXTUPDATE*

TMRINTUP

and

NuBusNMR

TMRINTCLR

Figure 2-15. NuBus Interrupt Generation with the EXTUPDATE* Signal

The following specifications and ratings apply to the EXTCONV*, EXTTRIG and

EXTUPDATE* signals.

Absolute maximum voltage input rating -0.5 to 7.0 V with respect to DGND

Lab-NB User Manual 2-20 © National Instruments Corporation

Page 39

Chapter 2 Configuration and Installation

8253 digital input specifications (referenced to DGND):

input logic high voltage 2.2 V min

V

IH

V

input logic low voltage 0.8 V max

IL

Input load current ±10 µA max

8253 digital output specifications (referenced to DGND):

output logic high voltage 2.4 V min

V

OH

V

output logic low voltage 0.45 V max

OL

I

output source current, at V

OH

I

output sink current, at V

OL

OH

OL

400 µA max

2.2 mA max

General-Purpose Timing Signal Connections

The general-purpose timing signals include the GATE, CLK, and OUT signals for the three

8253(B) counters. The 8253 Counter/Timers can be used for general-purpose applications such

as pulse and square wave generation; event counting; and pulse-width, time-lapse, and frequency

measurement. For these applications, CLK and GATE signals are sent to the counters, and the

counters are programmed for various operations. The single exception is counter B0, which has

an internal 2-MHz clock.

The 8253 Counter/Timer is described briefly in Chapter 3, Theory of Operation

. For detailed

programming information, consult Appendix C, AMD 8253 Data Sheet.

Pulse and square wave generation are performed by programming a counter to generate a timing

signal at its OUT output pin.

Event counting is performed by programming a counter to count rising or falling edges applied

to any of the 8253 CLK inputs. The counter value can then be read to determine the number of

edges that have occurred. Counter operation can be gated on and off during event counting.

Figure 2-16 shows connections for a typical event-counting operation where a switch is used to

gate the counter on and off.

© National Instruments Corporation 2-21 Lab-NB User Manual

Page 40

Configuration and Installation Chapter 2

+5 V

4.7 kΩ

CLK

OUT

GATE

Switch

Signal

Source

Counter (from Group B)

13

I/O Connector

DGND

Lab-NB Board

Figure 2-16. Event-Counting Application with External Switch Gating

Pulse-width measurement is performed by level gating. The pulse to be measured is applied to

the counter GATE input. The counter is loaded with the known count and is programmed to

count down while the signal at the GATE input is high. The pulse width equals the counter

difference (loaded value minus read value) multiplied by the CLK period.

Time-lapse measurement is performed by programming a counter to be edge gated. An edge is

applied to the counter GATE input to start the counter. The counter can be programmed to start

counting after receiving a low-to-high edge. The time lapse since receiving the edge equals the

counter value difference (loaded value minus read value) multiplied by the CLK period.

Frequency measurement is performed by programming a counter to be level gated and by

counting the number of falling edges in a signal applied to a CLK input. The gate signal applied

to the counter GATE input is of known duration. In this case, the counter is programmed to

count falling edges at the CLK input while the gate is applied. The frequency of the input signal

then equals the count value divided by the gate period. Figure 2-17 shows the connections for a

frequency measurement application. A second counter could also be used to generate the gate

signal in this application.

Lab-NB User Manual 2-22 © National Instruments Corporation

Page 41

Chapter 2 Configuration and Installation

+5 V

4.7 kΩ

CLK

OUT

GATE

Signal

Source

I/O Connector

Gate

Source

13

Counter

DGND

Lab-NB Board

Figure 2-17. Frequency Measurement Application

The GATE, CLK, and OUT signals for counters B1 and B2 are available at the I/O connector. In

addition, the GATE and CLK pins are pulled up to +5 V through a 4.7 kΩ resistor. The input

and output ratings and timing specifications for the 8253 signals are given next.

The following specifications and ratings apply to the 8253 I/O signals:

Absolute maximum voltage input rating -0.5 to 7.0 V with respect to DGND

8253 digital input specifications (referenced to DGND):

input logic high voltage 2.2 V min

V

IH

V

input logic low voltage 0.8 V max

IL

Input load current ±10 µA max

8253 digital output specifications (referenced to DGND):

output logic high voltage 2.4 V min

V

OH

V

output logic low voltage 0.45 V max

OL

I

output source current, at V

OH

I

output sink current, at V

OL

© National Instruments Corporation 2-23 Lab-NB User Manual

OH

OL

400 µA max

2.2 mA max

Page 42

Configuration and Installation Chapter 2