Page 1

TM

SCXI

SCXI Chassis User Manual

SCXI Chassis User Manual

May 2004 Edition

Part Number 320423H-01

Page 2

Worldwide Technical Support and Product Information

ni.com

National Instruments Corporate Headquarters

11500 North Mopac Expressway Austin, Texas 78759-3504 USA Tel: 512 683 0100

Worldwide Offices

Australia1800300800, Austria4306624579900, Belgium32027570020, Brazil551132623599,

Canada (Calgary) 403 274 9391, Canada (Ottawa) 613 233 5949, Canada (Québec) 450 510 3055,

Canada (Toronto) 905 785 0085, Canada (Vancouver) 514 685 7530, China 86 21 6555 7838,

Czech Republic 420 224 235 774, Denmark 45 45 76 26 00, Finland 3850972572511,

France330148142424, Germany490897413130, Greece302104296427, India918051190000,

Israel972036393737, Italy3902413091, Japan81354722970, Korea820234513400,

Malaysia 603 9131 0918, Mexico 001 800 010 0793, Netherlands 31 0 348 433 466,

New Zealand 0800 553 322, Norway 47 0 66 90 76 60, Poland 48 22 3390150, Portugal 351 210 311 210,

Russia 7 095 783 68 51, Singapore 65 6226 5886, Slovenia 386 3 425 4200, South Africa 27 0 11 805 8197,

Spain34916400085, Sweden460858789500, Switzerland41562005151, Taiwan886225287227,

Thailand 662 992 7519, United Kingdom 44 0 1635 523545

For further support information, refer to the Signal Conditioning Technical Support Information document.

To comment on the documentation, send email to techpubs@ni.com.

© 1991–2004 National Instruments Corporation. All rights reserved.

Page 3

Important Information

Warranty

The SCXI chassis (SCXI-1000, SCXI-1000DC, and SCXI-1001) are warranted against defects in materials and workmanship for a period of

one year from the date of shipment, as evidenced by receipts or other documentation. National Instruments will, at its option, repair or replace

equipment that proves to be defective during the warranty period. This warranty includes parts and labor.

The media on which you receive National Instruments software are warranted not to fail to execute programming instructions, due to defects

in materials and workmanship, for a period of 90 days from date of shipment, as evidenced by receipts or other documentation. National

Instruments will, at its option, repair or replace software media that do not execute programming instructions if National Instruments receives

notice of such defects during the warranty period. National Instruments does not warrant that the operation of the software shall be

uninterrupted or error free.

A Return Material Authorization (RMA) number must be obtained from the factory and clearly marked on the outside of the package before

any equipment will be accepted for warranty work. National Instruments will pay the shipping costs of returning to the owner parts which are

covered by warranty.

National Instruments believes that the information in this document is accurate. The document has been carefully reviewed for technical

accuracy. In the event that technical or typographical errors exist, National Instruments reserves the right to make changes to subsequent

editions of this document without prior notice to holders of this edition. The reader should consult National Instruments if errors are suspected.

In no event shall National Instruments be liable for any damages arising out of or related to this document or the information contained in it.

E

XCEPT AS SPECIFIED HEREIN, NATIONAL INSTRUMENTS MAKES NO WARRANTIES, EXPRESS OR IMPLIED, AND SPECIFICALLY DISCLAIMS ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. CUSTOMER’S RIGHT TO RECOVER DAMAGES CAUSED BY FAULT OR NEGLIGENCE ON THE PART OF

N

ATIONAL INSTRUMENTS SHALL BE LIMITED TO THE AMOUNT THERETOFORE PAID BY THE CUSTO MER. NATIONAL INSTRUMENTS WILL NOT BE LIA BLE FOR

DAMAGES RESULTIN G FROM LOSS OF DATA, PROFITS, USE OF PRODUCTS, OR INCIDENTAL OR CONSEQUENTIAL DAMAGES, EVEN IF ADVI SED OF THE POSSIB ILITY

THEREOF. This limitation of the liability of National Instruments will apply regardless of the form of action, whether in contract or tort, including

negligence. Any action against National Instruments must be brought within one year after the cause of action accrues. National Instruments

shall not be liable for any delay in performance due to causes beyond its reasonable control. The warranty provided herein does not cover

damages, defects, malfunctions, or service failures caused by owner’s failure to follow the National Instruments installation, operation, or

maintenance instructions; owner’s modification of the product; owner’s abuse, misuse, or negligent acts; and power failure or surges, fire,

flood, accident, actions of third parties, or other events outside reasonable control.

Copyright

Under the copyright laws, this publication may not be reproduced or transmitted in any form, electronic or mechanical, including photocopying,

recording, storing in an information retrieval system, or translating, in whole or in part, without the prior written consent of National

Instruments Corporation.

Trademarks

CVI™, LabVIEW™, Measurement Studio™, National Instruments™, NI™, ni.com™, NI-DAQ™, and SCXI™ are trademarks of National

Instruments Corporation.

Product and company names mentioned herein are trademarks or trade names of their respective companies.

Patents

For patents covering National Instruments products, refer to the appropriate location: Help»Patents in your software, the patents.txt file

on your CD, or ni.com/patents.

WARNING REGARDING USE OF NATIONAL INSTRUMENTS PRODUCTS

(1) NATIONAL INSTRUMENTS PRODUCTS ARE NOT DESIGNED WITH COMPONENTS AND TESTING FOR A LEVEL OF

RELIABILITY SUITABLE FOR USE IN OR IN CONNECTION WITH SURGICAL IMPLANTS OR AS CRITICAL COMPONENTS IN

ANY LIFE SUPPORT SYSTEMS WHOSE FAILURE TO PERFORM CAN REASONABLY BE EXPECTED TO CAUSE SIGNIFICANT

INJURY TO A HUMAN.

(2) IN ANY APPLICATION, INCLUDING THE ABOVE, RELIABILITY OF OPERATION OF THE SOFTWARE PRODUCTS CAN BE

IMPAIRED BY ADVERSE FACTORS, INCLUDING BUT NOT LIMITED TO FLUCTUATIONS IN ELECTRICAL POWER SUPPLY,

COMPUTER HARDWARE MALFUNCTIONS, COMPUTER OPERATING SYSTEM SOFTWARE FITNESS, FITNESS OF COMPILERS

AND DEVELOPMENT SOFTWARE USED TO DEVELOP AN APPLICATION, INSTALLATION ERRORS, SOFTWARE AND

HARDWARE COMPATIBILITY PROBLEMS, MALFUNCTIONS OR FAILURES OF ELECTRONIC MONITORING OR CONTROL

DEVICES, TRANSIENT FAILURES OF ELECTRONIC SYSTEMS (HARDWARE AND/OR SOFTWARE), UNANTICIPATED USES OR

MISUSES, OR ERRORS ON THE PART OF THE USER OR APPLICATIONS DESIGNER (ADVERSE FACTORS SUCH AS THESE ARE

HEREAFTER COLLECTIVELY TERMED “SYSTEM FAILURES”). ANY APPLICATION WHERE A SYSTEM FAILURE WOULD

CREATE A RISK OF HARM TO PROPERTY OR PERSONS (INCLUDING THE RISK OF BODILY INJURY AND DEATH) SHOULD

NOT BE RELIANT SOLELY UPON ONE FORM OF ELECTRONIC SYSTEM DUE TO THE RISK OF SYSTEM FAILURE. TO AVOID

DAMAGE, INJURY, OR DEATH, THE USER OR APPLICATION DESIGNER MUST TAKE REASONABLY PRUDENT STEPS TO

PROTECT AGAINST SYSTEM FAILURES, INCLUDING BUT NOT LIMITED TO BACK-UP OR SHUT DOWN MECHANISMS.

BECAUSE EACH END-USER SYSTEM IS CUSTOMIZED AND DIFFERS FROM NATIONAL INSTRUMENTS' TESTING

PLATFORMS AND BECAUSE A USER OR APPLICATION DESIGNER MAY USE NATIONAL INSTRUMENTS PRODUCTS IN

COMBINATION WITH OTHER PRODUCTS IN A MANNER NOT EVALUATED OR CONTEMPLATED BY NATIONAL

INSTRUMENTS, THE USER OR APPLICATION DESIGNER IS ULTIMATELY RESPONSIBLE FOR VERIFYING AND VALIDATING

THE SUITABILITY OF NATIONAL INSTRUMENTS PRODUCTS WHENEVER NATIONAL INSTRUMENTS PRODUCTS ARE

INCORPORATED IN A SYSTEM OR APPLICATION, INCLUDING, WITHOUT LIMITATION, THE APPROPRIATE DESIGN,

PROCESS AND SAFETY LEVEL OF SUCH SYSTEM OR APPLICATION.

Page 4

Conventions

The following conventions are used in this manual:

» The » symbol leads you through nested menu items and dialog box options

to a final action. The sequence File»Page Setup»Options directs you to

pull down the File menu, select the Page Setup item, and select Options

from the last dialog box.

This icon denotes a note, which alerts you to important information.

This icon denotes a caution, which advises you of precautions to take to

avoid injury, data loss, or a system crash. When this icon is marked on the

product, refer to the Read Me First: Safety and Radio-Frequency

Interference document, shipped with the product, for precautions to take.

When symbol is marked on a product it denotes a warning advising you to

take precautions to avoid electrical shock.

When symbol is marked on a product it denotes a component that may be

hot. Touching this component may result in bodily injury.

bold Bold text denotes items that you must select or click in the software, such

as menu items and dialog box options. Bold text also denotes parameter

names.

italic Italic text denotes variables, emphasis, a cross reference, or an introduction

to a key concept. This font also denotes text that is a placeholder for a word

or value that you must supply.

monospace Text in this font denotes text or characters that you should enter from the

keyboard, sections of code, programming examples, and syntax examples.

This font is also used for the proper names of disk drives, paths, directories,

programs, subprograms, subroutines, device names, functions, operations,

variables, filenames, and extensions.

SCXI chassis Refers to the SCXI-1000, SCXI-1000DC, and SCXI-1001. When

information pertains to only one chassis, that chassis is named explicitly;

for example, the SCXI-1001 has 12 module slots.

SCXIbus Refers to the backplane in the chassis. A signal on the backplane is referred

to as the SCXIbus <signal name> line (or signal). The SCXIbus descriptor

may be omitted when the meaning is clear.

Slot 0 Refers to the power supply and control circuitry in the SCXI chassis.

Page 5

Contents

Chapter 1

Introduction

About the SCXI Chassis ................................................................................................1-1

What You Need to Get Started ......................................................................................1-1

Software Programming Choices ....................................................................................1-2

NI-DAQ...........................................................................................................1-2

National Instruments ADE Software...............................................................1-3

National Instruments Documentation ............................................................................1-4

Optional Equipment.......................................................................................................1-5

Chapter 2

Configuring and Installing the SCXI Chassis

Chassis Description........................................................................................................2-1

Chassis Uses ....................................................................................................2-7

Configuring the SCXI Chassis.......................................................................................2-8

Selecting Chassis Addresses............................................................................2-8

SCXI-1000/1001 ...............................................................................2-8

SCXI-1000DC...................................................................................2-9

Selecting Voltage and Replacing the Fuse for the SCXI-1000

and SCXI-1001.............................................................................................2-11

Selecting the Voltage ........................................................................2-12

Replacing the Power Entry Module Fuse .........................................2-13

Replacing and Checking Backplane Fuses on the SCXI-1000

and SCXI-1001 ..............................................................................2-13

Replacing the Fuses on the SCXI-1000DC.....................................................2-14

Replacing the Power Entry Fuse and +5 VDC Fuse.........................2-14

Replacing and Checking Backplane Fuses .......................................2-15

Installing the SCXI Chassis ...........................................................................................2-16

Installing the SCXI-1000 and SCXI-1001 Chassis .........................................2-16

Installing the SCXI-1000DC Chassis..............................................................2-16

Installing Filler Panels ...................................................................................................2-17

Installing Front Filler Panels ...........................................................................2-17

Installing Rear Panels......................................................................................2-18

Maintaining the Fan Filter .............................................................................................2-18

© National Instruments Corporation v SCXI Chassis User Manual

Page 6

Contents

Appendix A

Specifications

Appendix B

Common Questions

Glossary

Index

Figures

Figure 2-1. SCXI-1000 Front View Diagram.......................................................... 2-2

Figure 2-2. SCXI-1000DC Front View Diagram .................................................... 2-3

Figure 2-3. SCXI-1001 Front View Diagram.......................................................... 2-4

Figure 2-4. SCXI-1000 Rear View Diagram........................................................... 2-5

Figure 2-5. SCXI-1001 Rear View Diagram........................................................... 2-6

Figure 2-6. SCXI-1000DC Rear View Diagram ..................................................... 2-7

Figure 2-7. Address Setting Examples .................................................................... 2-9

Figure 2-8. SCXI-1000DC Chassis Address Jumper Settings................................. 2-10

Figure A-1. Physical Dimensions of the SCXI-1001 ............................................... A-3

Figure A-2. Physical Dimensions of the SCXI-1000 and SCXI-1000DC ............... A-4

Tables

Table 2-1. SCXI Chassis Front View Items........................................................... 2-1

Table 2-2. SCXI-1000/1001 Chassis Rear View Items ......................................... 2-4

Table 2-3. SCXI-1000DC Chassis Rear View Items ............................................. 2-6

Table 2-4. SCXI-1000/1001 Voltage Selection and Fuse Ratings by Region ...... 2-11

SCXI Chassis User Manual vi ni.com

Page 7

Introduction

This manual describes the electrical and mechanical aspects of the

SCXI-1000, SCXI-1000DC, and SCXI-1001 chassis and contains

information concerning their operation. The SCXI chassis supply power

to and contain control circuitry for the SCXI series of modules. The

SCXI-1000 and SCXI-1000DC hold up to four modules. The SCXI-1001

holds up to 12 modules.

This chapter describes the SCXI chassis, lists what you need to get started,

and describes the optional software and equipment.

About the SCXI Chassis

The SCXI-1000 and SCXI-1001 chassis are powered with standard AC

power. The SCXI-1000DC is powered by any 9.5 to 16 VDC source such

as the optional SCXI-1382 battery pack or the SCXI-1383 power supply.

Every SCXI chassis supplies a low-noise environment for signal

conditioning, supplying power and control circuitry for the modules. It is

a general-purpose chassis that you can use with current SCXI modules.

1

Refer to Appendix A, Specifications, for detailed SCXI-1000,

SCXI-1000DC, and SCXI-1001 specifications.

What You Need to Get Started

To set up and use the SCXI chassis, you need the following items:

❑ Hardware

– One of the following SCXI chassis:

• SCXI-1000

• SCXI-1000DC

• SCXI-1001

© National Instruments Corporation 1-1 SCXI Chassis User Manual

Page 8

Chapter 1 Introduction

– One of the following, depending on your application:

• Power cord (120, 220, or 240 VAC)

• SCXI-1382 battery pack (SCXI-1000DC only)

• SCXI-1383 (VDC) power supply (SCXI-1000DC only)

– A computer

❑ Software

–NI-DAQ

– One of the following software packages:

•LabVIEW

™

™

•LabWindows

• Measurement Studio

/CVI

❑ Documentation

– SCXI Chassis User Manual

– Read Me First: Safety and Radio-Frequency Interference

– SCXI Quick Start Guide

– Documentation for your hardware

– Documentation for your software

You can download documentation from

ni.com/support.

Software Programming Choices

There are several options to choose from when programming the NI plug-in

DAQ and SCXI hardware. You can use LabVIEW, LabWindows/CVI,

Measurement Studio, or NI-DAQ.

NI-DAQ

NI-DAQ has an extensive library of functions that you can call from the

application development environment (ADE). These functions allow you

to use all the features of NI measurement products.

NI-DAQ carries out many of the complex interactions, such as

programming interrupts, between the computer and the DAQ hardware.

NI-DAQ maintains a consistent software interface among its different

versions so that you can change platforms with minimal modifications

SCXI Chassis User Manual 1-2 ni.com

Page 9

Chapter 1 Introduction

to your code. Whether you are using LabVIEW, LabWindows/CVI,

Measurement Studio, VI Logger, or other ADEs, your application uses

NI-DAQ.

You can download the most recent version of NI-DAQ from

downloads

.

National Instruments ADE Software

LabVIEW features interactive graphics, a state-of-the-art interface, and

a powerful graphical programming language. The LabVIEW Data

Acquisition VI Library, a series of virtual instruments for using LabVIEW

with National Instruments DAQ hardware, is included with LabVIEW.

LabWindows/CVI is a complete ANSI C ADE that features an interactive

user interface, code generation tools, and the LabWindows/CVI Data

Acquisition and Easy I/O libraries.

Measurement Studio, which includes tools for Visual C++ and tools for

Visual Basic, is a development suite that allows you to design test and

measurement applications. For Visual Basic developers, Measurement

Studio features a set of ActiveX controls for using National Instruments

DAQ hardware. These ActiveX controls provide a high-level programming

interface for building virtual instruments (VIs). For Visual C++ developers,

Measurement Studio offers a set of Visual C++ classes and tools to

integrate those classes into Visual C++ applications. The ActiveX controls

and classes are available with Measurement Studio and the NI-DAQ

software.

ni.com/

VI Logger is an easy-to-use yet flexible tool specifically designed for data

logging applications. Using dialog windows, you can configure data

logging tasks to easily acquire, log, view, and share your data. VI Logger

does not require any programming; it is a stand-alone, configuration-based

software.

Using LabVIEW, LabWindows/CVI, Measurement Studio, or VI Logger

greatly reduces the development time for your data acquisition and control

application.

© National Instruments Corporation 1-3 SCXI Chassis User Manual

Page 10

Chapter 1 Introduction

National Instruments Documentation

The SCXI Chassis User Manual is one piece of the documentation set for

the data acquisition and SCXI system. You could have any of several types

of documents, depending on the hardware and software in the system. Use

the documents you have as follows:

• Getting Started with SCXI—Read this manual first. It gives an

overview of the SCXI system and contains the most commonly needed

information for the modules, chassis, and software.

•The SCXI Quick Start Guide—This document describes how to set up

an SCXI chassis, install SCXI modules and terminal blocks, and

configure the SCXI system in Measurement & Automation Explorer

(MAX).

• The SCXI hardware user manuals—Read these manuals next for

detailed information about signal connections and module

configuration. They also explain in greater detail how the module

works and contain application hints.

• The DAQ hardware user manuals—These manuals have detailed

information about the DAQ hardware that plugs into or is connected to

the computer. Use these manuals for hardware installation and

configuration instructions, specification information about the DAQ

hardware, and application hints.

• Software documentation—Examples of software documentation you

may have are the LabVIEW, Measurement Studio, and NI-DAQ

documentation sets. After you set up the hardware system, use either

the application software (LabVIEW or Measurement Studio) or the

NI-DAQ documentation to help you write your application. If you have

a large, complicated system, it is worthwhile to look through the

software documentation before you configure the hardware.

• Accessory installation guides or manuals—If you are using accessory

products, read the terminal block and cable assembly installation

guides or accessory user manuals. They explain how to physically

connect the relevant pieces of the system. Consult these guides when

you are making the connections.

• If you are designing your own module, the SCXIbus System

Specification is available from NI upon request. The specification

describes the physical, electrical, and timing requirements for the

SCXIbus.

SCXI Chassis User Manual 1-4 ni.com

Page 11

Optional Equipment

NI provides a full line of modules that amplify, filter, isolate, and multiplex

a wide variety of signal types, such as thermocouples, resistance

temperature detectors (RTDs), strain gauges, high-voltage inputs, current

inputs, analog outputs, and digital I/O signals. Cables and terminal blocks

with screw terminals, BNC connectors, or thermocouple plugs are

available to connect signals to the modules.

Chapter 1 Introduction

Refer to the latest NI catalog and

of sensors and I/O types supported in SCXI.

ni.com/catalog for a complete listing

© National Instruments Corporation 1-5 SCXI Chassis User Manual

Page 12

Configuring and Installing

the SCXI Chassis

This chapter contains instructions for configuring and installing the SCXI

chassis. It describes the following:

• Chassis address selection

• Voltage and fuse selection

• Chassis, modules, and accessories installation

• Fan filter maintenance

Chassis Description

Table 2-1 describes the front view items shown in Figures 2-1, 2-2,

and 2-3.

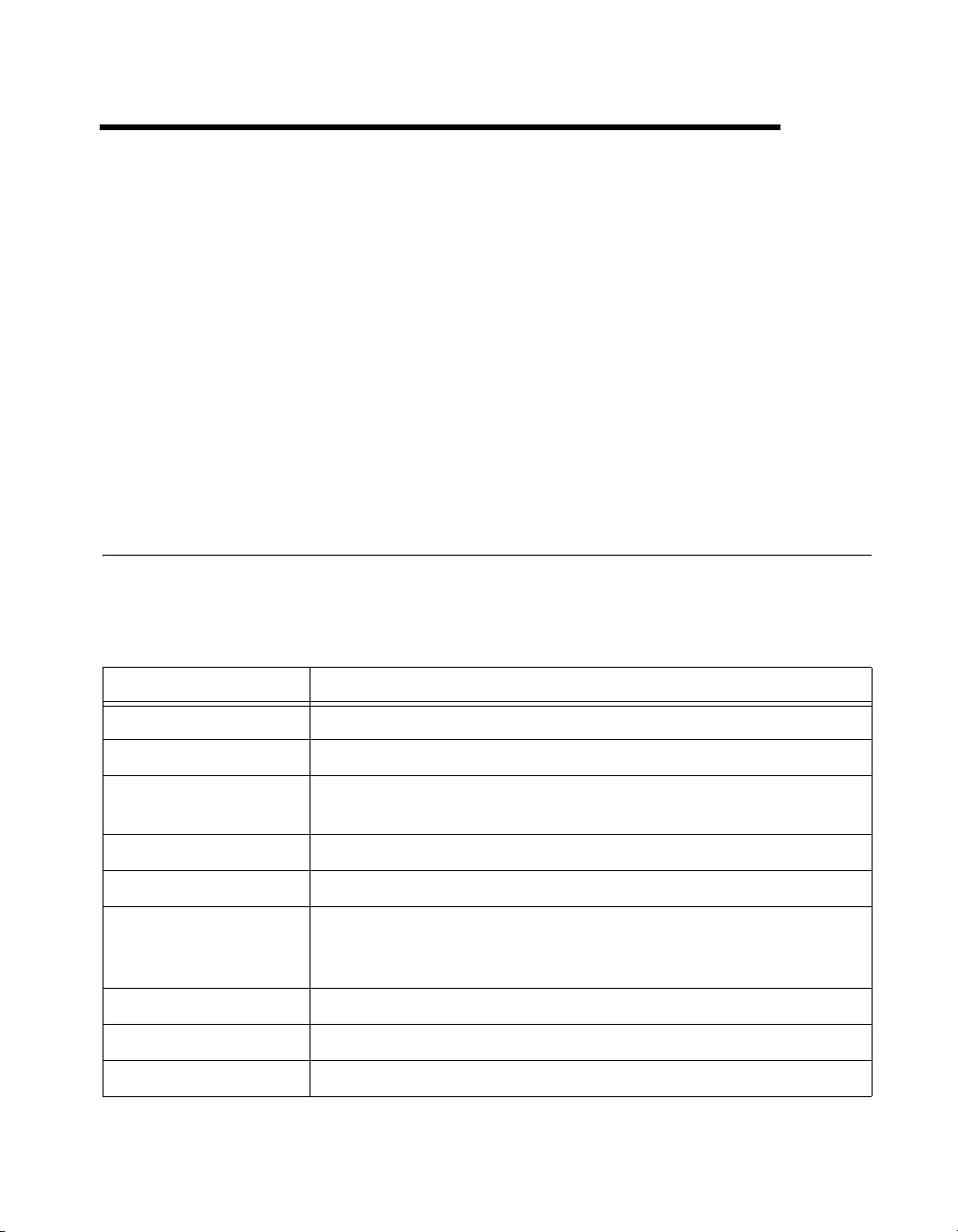

Table 2-1. SCXI Chassis Front View Items

Item Definition

2

Power switch Powers the chassis on and off

Indicator light When lit, indicates that the chassis is powered on

Reset button Reinitializes Slot 0 and all modules to their power-on state when

pressed

Slot 0/power supply Contains the power supply and control circuitry for the chassis

Address DIP switches Determine the chassis address—SCXI-1000 and SCXI-1001

Address selection

jumpers (located behind

the front panel)

Module guides Guide modules to connect with the SCXIbus connector

Backplane Brings power, control lines, and analog bus connections to modules

Front threaded strips Secure modules in the chassis and attach front panels

© National Instruments Corporation 2-1 SCXI Chassis User Manual

Determine the chassis address—SCXI-1000DC only

Page 13

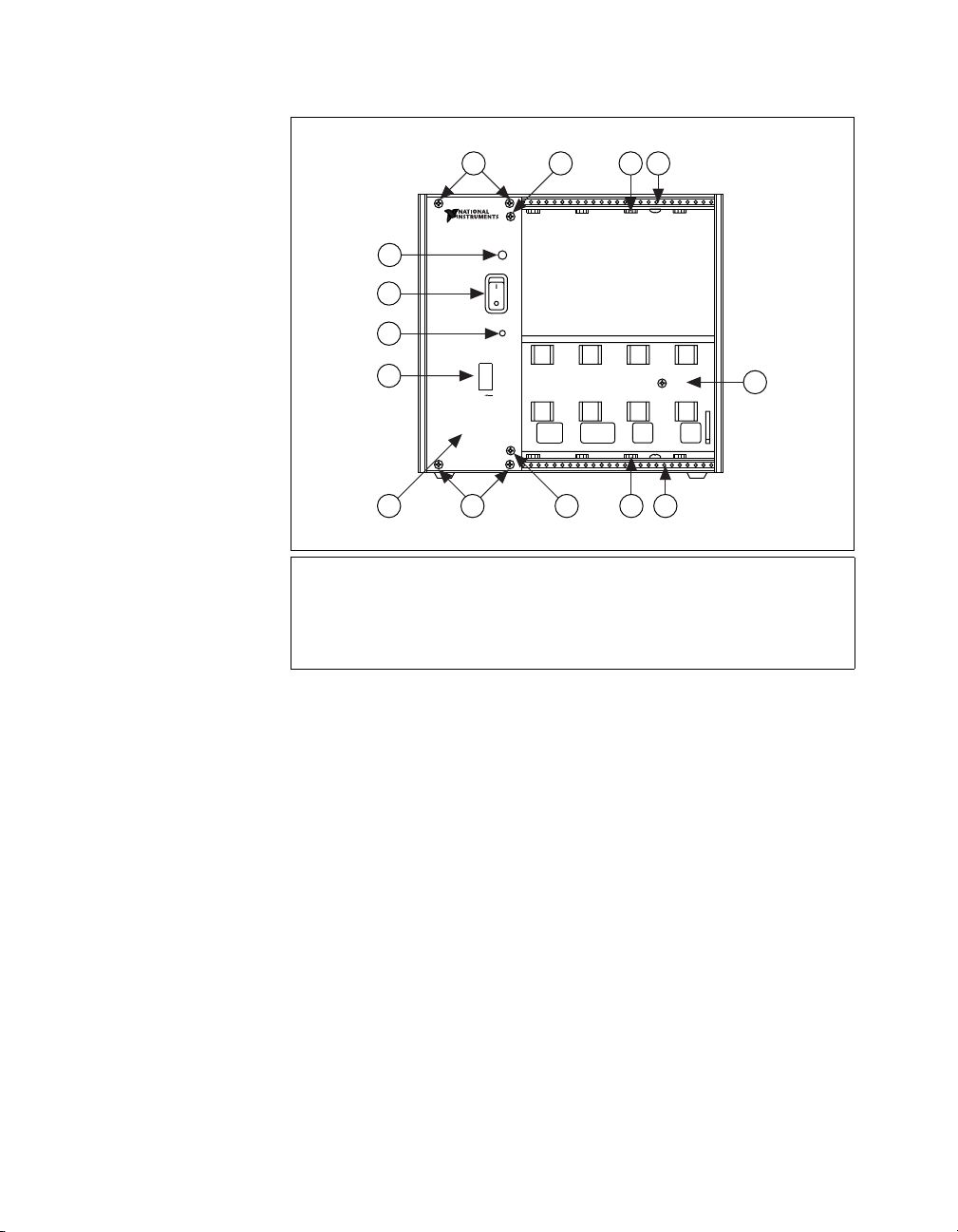

Chapter 2 Configuring and Installing the SCXI Chassis

4

3

2

1

10

1 Address DIP Switches

2 Reset Button

3 Power Switch

4 Indicator Light

5 Front Panel Screws

(flathead on some revisions)

Figure 2-1. SCXI-1000 Front View Diagram

5 6

5

4

3

2

1

ADDRESS

ON

8

7

65

87

6 Front Panel Screws

(early revisions only)

7 Module Guides

8 Front Threaded Strips

9 Backplane

10 Slot 0/Power Supply

9

SCXI Chassis User Manual 2-2 ni.com

Page 14

Chapter 2 Configuring and Installing the SCXI Chassis

5 6

4

3

2

1

10

1 Address Selection Jumpers

(behind front panel)

2 Reset Button

3 Power Switch

4 Indicator Light

5 Front Panel Screws

(flathead on some revisions)

Figure 2-2. SCXI-1000DC Front View Diagram

8

7

65

6 Front Panel Screws

7 Module Guides

8 Front Threaded Strips

9 Backplane

10 Slot 0/Power Supply

87

(early revisions only)

9

© National Instruments Corporation 2-3 SCXI Chassis User Manual

Page 15

Chapter 2 Configuring and Installing the SCXI Chassis

4

3

2

5

4

3

1

2

1

ADDRESS

ON

7 85 6

10

65

1 Address DIP Switches

2 Reset Button

3 Power Switch

4 Indicator Light

5 Front Panel Screws (flathead on some revisions)

9 7 8

6 Front Panel Screws (early revisions only)

7 Module Guides

8 Front Threaded Strips

9 Backplane

10 Slot 0/Power Supply

Figure 2-3. SCXI-1001 Front View Diagram

Tables 2-2 and 2-3 describe the rear view items shown in Figures 2-4, 2-5,

and 2-6.

Table 2-2. SCXI-1000/1001 Chassis Rear View Items

Item Description

Power entry module IEC receptacle for power input, voltage selection board, and fuse

Fuse Protects both you and the SCXI chassis in case of a fault in the chassis

Voltage tumbler Configures the chassis for the AC line voltage

Fan(s) Cools the chassis

Filter(s) Prevents dirt from contaminating the circuitry in the chassis

Fan screws Secure the fan(s) to the chassis

SCXI Chassis User Manual 2-4 ni.com

Page 16

Chapter 2 Configuring and Installing the SCXI Chassis

Table 2-2. SCXI-1000/1001 Chassis Rear View Items (Continued)

Item Description

Backplane fuses Protect the power supply from shorts on modules

Rear connector space For module space, connector mounting brackets, or adapters

Rear threaded strips Secure cable connections, mounting brackets, or filler panels to

the chassis

3

2

1 Fan and Filter

2 Fan Screws

3 Rear Threaded Strips

4 Rear Connector Space

5 Rear Panel Screws

(flathead on some revisions)

Figure 2-4. SCXI-1000 Rear View Diagram

4 6

1

6 Voltage Tumbler

7 Power Entry Module

8 Fuse (concealed)

9 Backplane Fuses (behind fan)

120Vac

5

7

8

5

9

© National Instruments Corporation 2-5 SCXI Chassis User Manual

Page 17

Chapter 2 Configuring and Installing the SCXI Chassis

3

1

1 Fans and Filters

2 Fan Screws (each fan)

3 Rear Threaded Strips

4 Rear Connector Space

5 Rear Panel Screws (flathead on some revisions)

Table 2-3. SCXI-1000DC Chassis Rear View Items

Item Description

Power entry

Receptacle for power input; uses a 9.5 to 16 VDC power source

connector J1

4

2

6 Voltage Tumbler

7 Power Entry Module

8 Fuse (concealed)

9 Backplane Fuses (behind fan)

Figure 2-5. SCXI-1001 Rear View Diagram

5

6

120Vac

7

8

5

1

9

Fuse F1 Power input fuse (6.3 A), protects both you and the SCXI chassis in case

of a fault in the chassis

Fuse F2 +5 VDC internal power supply fuse (3.15 A), protects the power supply

from shorts on modules

Fan(s) Cools the chassis

Fan screws Secure the fan(s) to the chassis

Backplane fuses Protect the power supply from shorts on modules

Rear connector

For module space, connector mounting brackets, or adapter boards

space

Rear threaded strips Secure cable connections, mounting brackets, or filler panels to the chassis

SCXI Chassis User Manual 2-6 ni.com

Page 18

Chapter 2 Configuring and Installing the SCXI Chassis

3

2

1 Fan and Filter

2Fan Screws

3 Rear Threaded Strips

4 Rear Connector Space

5 Rear Panel Screws

(flathead on some revisions)

Figure 2-6. SCXI-1000DC Rear View Diagram

4

5

J1

+

6

7

6.3A

F1

250V

3.15A

F2

250V

1

8

5

9

6 Power Entry Connector

7 Power Input Fuse

8 +5 VDC Internal Power Supply Fuse

9 Backplane Fuses (behind fan)

Chassis Uses

Before you configure the chassis, decide whether you are going to use it in

multiplexed mode or parallel mode.

In multiplexed mode, analog input (AI) channels are multiplexed into one

module output so that the cabled E Series DAQ device has access to the

multiplexed output of the module and the outputs of all other multiplexed

modules in the chassis.

In parallel mode, you need a separate E Series DAQ device for each module

to send each of its output channels directly to a separate AI channel of the

E Series DAQ device connected to the module.

© National Instruments Corporation 2-7 SCXI Chassis User Manual

Page 19

Chapter 2 Configuring and Installing the SCXI Chassis

Configuring the SCXI Chassis

Configuring the chassis involves selecting a chassis or high-level data link

control (HDLC) address, line voltage, and fuse value on any chassis.

Note Refer to the Read Me First: Safety and Radio-Frequency Interference document

before removing equipment covers or connecting or disconnecting any signal wires.

Selecting Chassis Addresses

These sections provide information about how to select addresses for the

SCXI chassis.

SCXI-1000/1001

Unless you are using multiple chassis and need to configure one or more

SCXI chassis for a different address, you can skip this section, and the

SCXI chassis retains factory-default address of 0.

You can configure the SCXI chassis for one of 32 different addresses so that

you can connect multiple SCXI chassis to the same control source. The five

switches on the front panel of Slot 0 determine the chassis address.

Switches one through five represent the values 1, 2, 4, 8, and 16, when set

to the ON position. When set to the OFF position, their value is zero. The

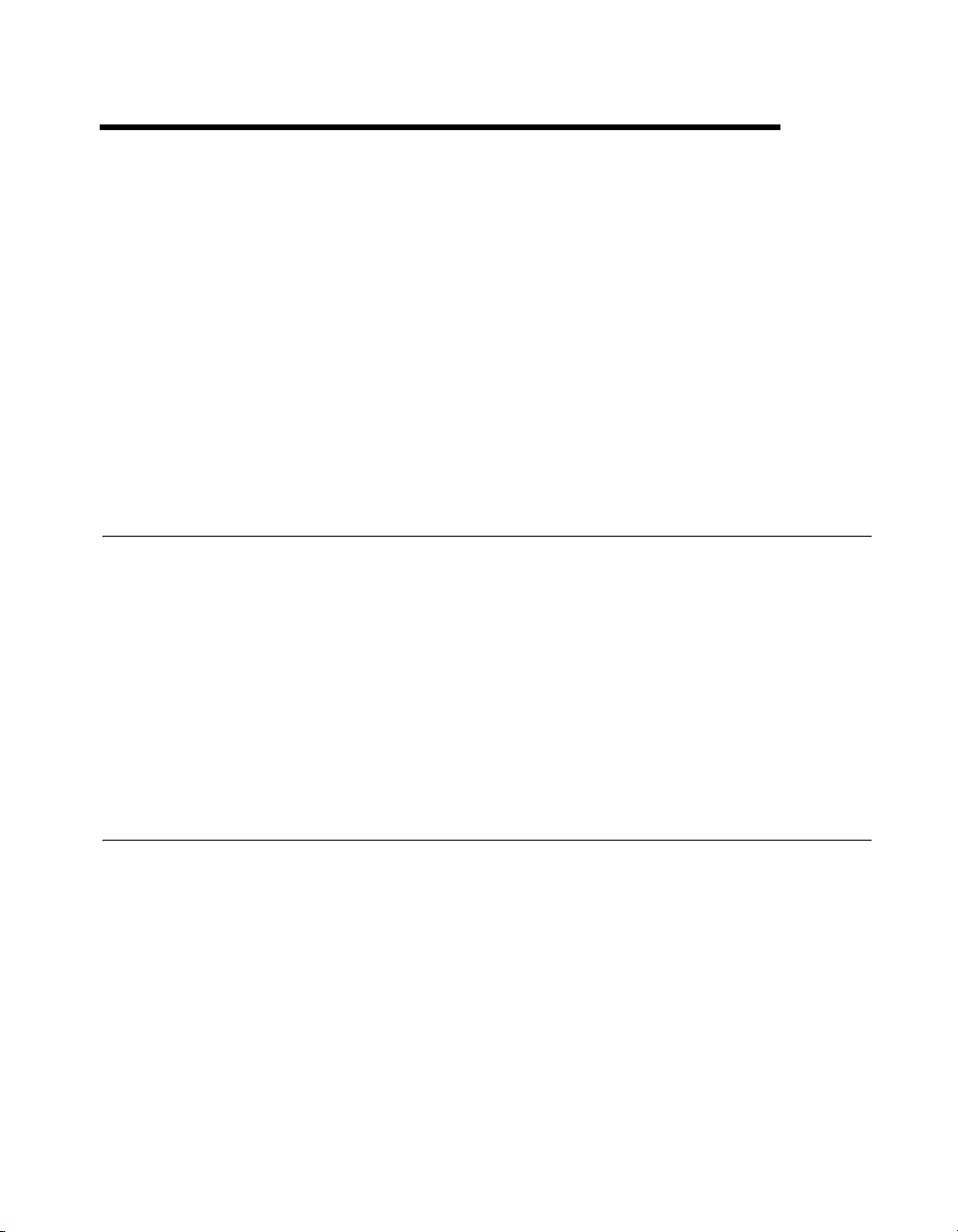

chassis address is the sum of the switch values. Figure 2-7 shows examples

of both the factory-default setting of the chassis address 0 and the switch

setting for chassis address 19.

Note SCXI-1000 chassis through revision D do not have address jumpers or switches and

respond to any address, but you cannot use them in multichassis systems. Revision E

chassis use jumpers on Slot 0 for chassis addressing. Revision F and later chassis use a DIP

switch for chassis addressing.

SCXI-1001 chassis through revision D use jumpers on Slot 0 for chassis addressing.

Revision E and later chassis use a DIP switch for chassis addressing.

SCXI Chassis User Manual 2-8 ni.com

Page 20

Chapter 2 Configuring and Installing the SCXI Chassis

5

4

3

2

1

ON

Chassis Default

Address = 0

ON

Address = 19

5

4

3

2

1

Figure 2-7. Address Setting Examples

SCXI-1000DC

Unless you are using multiple chassis and need to configure one or more

SCXI chassis for a different address, you can skip this section, and the

SCXI chassis retains the factory-default address of 0.

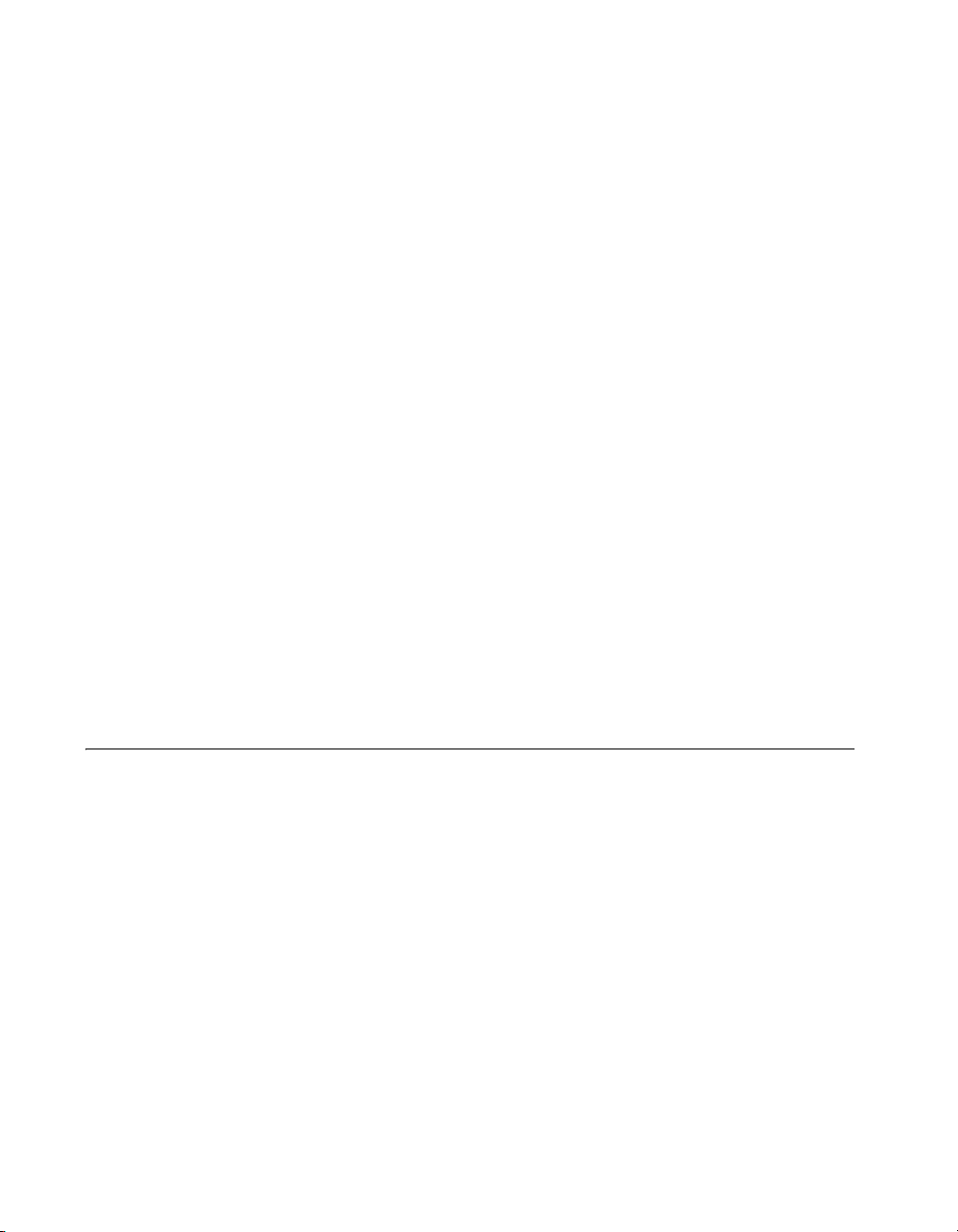

You can configure the SCXI chassis for one of 32 different addresses so that

you can connect multiple SCXI chassis to the same control source. Three

jumpers that determine the chassis address are located behind the front

panel of Slot 0 just below the Reset button. The chassis address is the sum

of the values of all the jumpers. Figure 2-8 shows examples of both the

factory-default setting of address 0 and the jumper settings for address 19.

Note SCXI-1000DC chassis through revision C do not have address jumpers or switches

and respond to any address, but you cannot use them in multichassis systems. Revision D

and later chassis use jumpers on Slot 0 for chassis addressing.

© National Instruments Corporation 2-9 SCXI Chassis User Manual

Page 21

Chapter 2 Configuring and Installing the SCXI Chassis

W1

0

2

4

6

W2

W3

Chassis Address 0

Factory Setting

1

3

5

7

+8

+16

W1

0

2

4

6

W2

W3

Chassis Address 19

Example Setting

1

3

5

7

+8

+16

Figure 2-8. SCXI-1000DC Chassis Address Jumper Settings

Changing the Chassis Address

While referring to Figures 2-2 and 2-6, complete the following steps to

change the chassis address of the SCXI-1000DC:

1. Power off the chassis and remove the power cord from the power entry

module.

2. To prevent a shock hazard, wait at least one minute before proceeding

to step 3.

3. Using a screwdriver, remove the four (six on some revisions) panhead

screws from the front panel of Slot 0.

4. Remove the six screws from the rear panel.

5. Remove the controller from Slot 0.

6. Set all three jumpers for the chassis address you want.

7. Replace the controller in Slot 0.

8. Replace the four (six on some revisions) screws. Do not overtighten.

9. Replace the six screws in the rear panel. Do not overtighten.

SCXI Chassis User Manual 2-10 ni.com

Page 22

Chapter 2 Configuring and Installing the SCXI Chassis

Selecting Voltage and Replacing the Fuse for the SCXI-1000 and SCXI-1001

If you ordered the chassis with the appropriate part number (the -0x

extension of the kit part number corresponds to your geographical region),

the voltage tumbler and fuse are correct for operation in your geographical

region. Check the voltage on the voltage tumbler to ensure that you have

the correct voltage tumbler setting and fuse.

The SCXI chassis can operate with line voltages of 100, 120, 220, and

240 VAC. The voltage tumbler in the power entry module determines the

voltage for which the chassis is configured. You can identify the operating

voltage by looking at the number on the power entry module when the door

that covers the tumbler is closed. The fuse is 5 × 20 mm, which has a

current rating relative to the operating voltage. Table 2-4 shows the proper

voltage selections and fuse ratings for different regions.

Caution For continued protection, replace fuses only with fuses of the same type and

rating.

Table 2-4. SCXI-1000/1001 Voltage Selection and Fuse Ratings by Region

SCXI

Chassis

Ty pe

SCXI-1000 100 V Japan 1 3/4 A 250 V 5 mm ×

Region/Voltage

120 V 1 1/2 A 250 V 5 mm ×

220 V Swiss 1 1/4 A 250 V 5 mm ×

240 V Australia 1 1/4 A 250 V 5 mm ×

240 V Europe 1 1/4 A 250 V 5 mm ×

240 V North American 1 1/4 A 250 V 5 mm ×

240 V U.K. 1 1/4 A 250 V 5 mm ×

Main

Power Fuse

Quantity

Main Power

Fuse Type

20 mm SLO-BLO

20 mm SLO-BLO

20 mm SLO-BLO

20 mm SLO-BLO

20 mm SLO-BLO

20 mm SLO-BLO

20 mm SLO-BLO

Backplane

Fuse

Quantity

2 1.5 A 125 V LittleFuse

2 1.5 A 125 V LittleFuse

2 1.5 A 125 V LittleFuse

2 1.5 A 125 V LittleFuse

2 1.5 A 125 V LittleFuse

2 1.5 A 125 V LittleFuse

2 1.5 A 125 V LittleFuse

Backplane

Fuse Type

R251 01.5 TI

R251 01.5 TI

R251 01.5 TI

R251 01.5 TI

R251 01.5 TI

R251 01.5 TI

R251 01.5 TI

© National Instruments Corporation 2-11 SCXI Chassis User Manual

Page 23

Chapter 2 Configuring and Installing the SCXI Chassis

Table 2-4. SCXI-1000/1001 Voltage Selection and Fuse Ratings by Region (Continued)

SCXI

Chassis

Ty pe

SCXI-1001 100 V Japan 1 2.0 A 250 5 mm ×

Region/Voltage

120 V 1 1.6 A 250 5 mm ×

220 V Swiss 1 1.0 A 250 5 mm ×

240 V Australia 1 1.0 A 250 5 mm ×

240 V Europe 1 1.0 A 250 5 mm ×

240 V North American 1 1.0 A 250 5 mm ×

240 V U.K. 1 1.0 A 250 5 mm ×

Main

Power Fuse

Quantity

Main Power

Fuse Type

20 mm SLO-BLO

20 mm SLO-BLO

20 mm SLO-BLO

20 mm SLO-BLO

20 mm SLO-BLO

20 mm SLO-BLO

20 mm SLO-BLO

Selecting the Voltage

Complete the following steps to select a voltage:

1. Power off the chassis.

2. Remove the power cord from the power entry module.

3. Using a flathead screwdriver, pry the door to the tumbler open from

the top.

4. Remove the voltage tumbler.

5. Rotate the tumbler to the appropriate voltage and reinsert it into the

power entry module.

6. Close the door.

7. Check to make sure that the voltage showing on the selection tumbler

is correct.

8. Reinsert the power cord.

Backplane

Fuse

Quantity

2 4 A 125 V LittleFuse

2 4 A 125 V LittleFuse

2 4 A 125 V LittleFuse

2 4 A 125 V LittleFuse

2 4 A 125 V LittleFuse

2 4 A 125 V LittleFuse

2 4 A 125 V LittleFuse

Backplane

Fuse Type

R251 01.5 TI

R251 01.5 TI

R251 01.5 TI

R251 01.5 TI

R251 01.5 TI

R251 01.5 TI

R251 01.5 TI

SCXI Chassis User Manual 2-12 ni.com

Page 24

Chapter 2 Configuring and Installing the SCXI Chassis

Replacing the Power Entry Module Fuse

Caution Disconnect all power before removing the cover.

Complete the following steps to replace the power entry module fuse:

1. Power off the chassis.

2. Remove the power cord from the power entry module.

3. Using a flathead screwdriver, pry the door to the voltage selection

tumbler open from the top.

4. Pull out the fuse drawer.

5. Remove the fuse.

6. Install the new fuse in the drawer.

7. Reinsert the fuse drawer in the right-hand slot with the arrow pointing

to the right.

8. Close the door.

9. Reinsert the power cord.

Replacing and Checking Backplane Fuses on the SCXI-1000 and SCXI-1001

In addition to the power entry module fuse, the analog supply lines on the

backplane are fused at 1.5 A on the SCXI-1000 chassis and at 4 A on the

SCXI-1001 chassis.

If you are making your own modules, fuse the module at 250 mA to avoid

blowing the backplane fuses. Fusing the module also better protects the

module because a failure can result in a large amount of current drawn, but

not enough current drawn to blow the backplane fuses.

On the SCXI-1000, the backplane fuses are located behind the fan. On the

SCXI-1001, the backplane fuses are located behind the right-hand fan, near

the power entry module, as viewed from the rear of the chassis.

© National Instruments Corporation 2-13 SCXI Chassis User Manual

Page 25

Chapter 2 Configuring and Installing the SCXI Chassis

Complete the following steps to check or replace fuses:

1. Remove the appropriate fan and filter from the rear of the chassis by

following the instructions in the Maintaining the Fan Filter section.

Make sure to switch the power off and remove the power cord.

2. The fuse marked with a copper + on the backplane is for the positive

analog supply, and the fuse marked with a copper – is for the negative

analog supply. To check whether a fuse is blown, connect an ohmmeter

across the leads. If the reading is not approximately 0 Ω, replace

the fuse.

3. Using a pair of needle-nose pliers, carefully extract the fuse.

4. Take a new fuse and bend its leads so the component is 12.7 mm

(0.5 in.) long, the dimension between the fuse sockets, and clip the

leads to a length of 6.4 mm (0.25 in.).

5. Using the needle-nose pliers, insert the fuse into the socket holes.

6. Repeat, if necessary, for the other fuse.

7. Check the fan filter and, if it is dirty, clean it as described in the

Maintaining the Fan Filter section.

8. Reinstall the fan and filter.

Replacing the Fuses on the SCXI-1000DC

There are two fuses located on the rear panel of the SCXI-1000DC. The

input power fuse (F1) is a 6.3 A, 5 × 20 mm time-lag fuse. The internal

+5 VDC supply is fused by a 3.15 A, 5 × 20 mm time-lag fuse (F2).

Replacing the Power Entry Fuse and +5 VDC Fuse

Caution For continued protection against fire, replace fuses only with fuses of the same

type and rating.

Complete the following steps to replace the rear panel fuses:

1. Power off the chassis.

2. Remove the power cord from power entry connector J1.

3. Turn the fuse holder counter-clockwise with a screwdriver and pull out

the fuse holder to expose the fuse in the housing.

4. Remove the fuse.

5. Install the new fuse.

SCXI Chassis User Manual 2-14 ni.com

Page 26

Chapter 2 Configuring and Installing the SCXI Chassis

6. Push the fuse holder back into the housing and screw it clockwise until

it is tight.

7. Reinsert the power cord.

Replacing and Checking Backplane Fuses

In addition to the power entry and the +5 V supply fuses, the analog supply

lines on the backplane are fused at 1.5 A on the SCXI-1000DC chassis.

If you design a special/prototype module, use the SCXI-1181 module and

fuse the module at 250 mA to avoid blowing the analog backplane and

+5 V supply fuses. Fusing the module better protects the module because a

failure can result in a large amount of current drawn, but not enough to blow

the backplane and +5 V fuses.

On the SCXI-1000DC, the backplane fuses are located behind the fan.

Complete the following steps to check or replace fuses:

1. Remove the appropriate fan and filter from the rear of the chassis by

following the instructions in the Maintaining the Fan Filter section.

Be sure to switch the power off and remove the power cord.

2. The fuse marked with a copper + on the backplane is for the positive

analog supply, and the fuse marked with a copper – is for the negative

analog supply. To check whether a fuse is blown, connect an ohmmeter

across the leads. If the reading is not approximately 0 Ω, replace the

fuse.

3. Using a pair of needle-nose pliers, carefully extract the fuse.

4. Take a new fuse and bend its leads so the component is 12.7 mm

(0.5 in.) long, the dimension between the fuse sockets, and clip the

leads to a length of 6.4 mm (0.25 in.).

5. Using the needle-nose pliers, insert the fuse into the socket holes.

6. Repeat, if necessary, for the other fuse.

7. Check the fan filter and, if it is dirty, clean it as described in the

Maintaining the Fan Filter section.

8. Reinstall the fan and filter.

© National Instruments Corporation 2-15 SCXI Chassis User Manual

Page 27

Chapter 2 Configuring and Installing the SCXI Chassis

Installing the SCXI Chassis

These sections provide information about installing the SCXI chassis.

Installing the SCXI-1000 and SCXI-1001 Chassis

Complete the following steps to install the SCXI-1000 and SCXI-1001

chassis:

1. If necessary, change the chassis address of the box by following the

instructions in the Selecting Chassis Addresses section. Unless you are

using multiple chassis, skip this step and leave the address at its

factory-default setting of 0.

2. Place the SCXI chassis on a sturdy, level surface. Leave at least 10 cm

(4 in.) of space behind the chassis for adequate air circulation.

3. Power off the chassis.

4. Make sure the voltage selection tumbler in the power entry module is

set for the line voltage of the outlet. Refer to the Selecting the Voltage

section if necessary.

5. Insert the female end of the power cord into the power entry module.

6. Insert the male end of the power cord into the wall outlet.

7. Install the modules into the chassis.

8. Install the necessary cabling for the modules. Consult the SCXI

module user manual for cabling installation instructions.

9. Install any front and rear filler panels.

10. Power on the chassis.

11. Power on the computer connected to the modules.

12. Refer to the SCXI Quick Start Guide to complete the SCXI system

installation.

Installing the SCXI-1000DC Chassis

Complete the following steps to install the SCXI-1000DC chassis:

1. If necessary, change the chassis address by following the instructions

in the Selecting Chassis Addresses section. Unless you are using

multiple chassis, skip this step and leave the address at its

factory-default setting of 0.

2. Place the SCXI chassis on a sturdy, level surface. Leave at least 10 cm

(4 in.) of space behind the chassis for adequate air circulation.

3. Place the chassis power switch in the off position.

SCXI Chassis User Manual 2-16 ni.com

Page 28

4. Make sure the voltage of the power source is between 9.5 and 16 VDC.

5. Insert the power plug into the header J1.

Caution Revision A SCXI-1000DC chassis have screw terminals on the rear panel to

connect the power source. Wire the power source to these screw terminals. Observe the

correct polarity, as connecting the power source with the wrong polarity can cause

permanent damage to the chassis. NI is not liable for any damage or injuries resulting from

improper power connections.

6. Install the modules into the chassis.

7. Install the necessary cabling for the modules. Consult the SCXI

module user manual for cabling installation instructions.

8. Install any needed front and rear filler panels.

9. Power on the chassis.

10. Power on the computer connected to the modules.

11. Refer to the SCXI Quick Start Guide to complete the SCXI system

installation.

Installing Filler Panels

Chapter 2 Configuring and Installing the SCXI Chassis

The front and rear filler panel accessories protect the inside of the chassis

and the installed modules by preventing unwanted material from entering

the chassis and damaging modules, or forming conductive paths that can

degrade performance. Install all modules first, then start installing filler

panels from the edge of a front panel.

Installing Front Filler Panels

Complete the following steps to install front filler panels:

1. Place the panel with the captive screws to the right of the chassis front.

Line up the screws with the threaded strip holes.

2. Using a flathead screwdriver, screw the captive screws into the

threaded strip holes.

© National Instruments Corporation 2-17 SCXI Chassis User Manual

Page 29

Chapter 2 Configuring and Installing the SCXI Chassis

Installing Rear Panels

Complete the following steps to install rear panels:

1. Place the panel at the rear of the chassis between the two threaded

strips. Align the panel so that the serial number faces into the chassis

and the screw holes are on the right.

2. Using a flathead screwdriver, screw the two screws through the rear

panel into the threaded strip holes.

Maintaining the Fan Filter

The brushless fan(s) on the rear of the SCXI chassis cool the chassis and

modules. To keep the fan effective, the fan filter(s) must be clean. Dust and

dirt accumulation reduces airflow, making the inside of the chassis hotter,

shortening the life of the chassis and modules. Complete the following

steps to clean the fan filter(s):

1. Power off the chassis.

2. Remove the power cord from the power entry module.

3. Place the chassis face down on a flat surface so that the fan is on top.

If the chassis is so heavily cabled that you cannot easily place it in this

position, leave the chassis as it is, but be careful to support the fan

during removal and reinstallation to avoid breaking the fan wires.

4. Remove the fan filter. Remove the four screws that secure the fan and

filter to the rear of the chassis. When removing the last screw, be

careful to hold the fan to avoid breaking the fan wires.

5. Clean the fan filter by moving the filter around under a gentle stream

of cold tap water until all the dust is removed. Dry the filter.

6. Replace the fan filter by aligning the fan and filter with the fan holes,

making sure that the label side of the fan is face down. Reinstall the

four screws and make sure the assembly is secure.

SCXI Chassis User Manual 2-18 ni.com

Page 30

Specifications

This appendix lists the specifications of the SCXI chassis. These are typical

at 25 °C unless otherwise stated.

Electrical Characteristics

V+

Supplies

SCXI-1000/

1000DC

A

SCXI-1101

Tolerance limits include

peaks

Ripple (peak-to-peak) 1.5 V 1.5 V

Max load 680 mA 2.04 A

V–

Tolerance limits include

peaks

Ripple (peak-to-peak) 1.5 V 1.5 V

Max load 680 mA 2.04 A

+5 V

Tolerance limits include

peaks

Ripple (peak-to-peak) 50 mV 50 mV

Max load 250 mA 600 mA

Power dissipation ................................... 7 W per slot

+18.5 to +25 V +18.5 to +25 V

–18.5 to –25 V –18.5 to –25 V

+4.75 to +5.25 V +4.75 to +5.25 V

© National Instruments Corporation A-1 SCXI Chassis User Manual

Page 31

Appendix A Specifications

Maximum loads are the supply current for the entire chassis. Scaling the

maximum power gives the allotted current per slot, as follows.

Supplies SCXI-1000/1000DC SCXI-1001

V+ 170 mA 170 mA

V– 170 mA 170 mA

+5 V 50 mA 50 mA

Source Power Requirements

Physical

Line Voltage,

47–63 Hz

120 VAC, ±10% 0.6 A 1.25 A

100 VAC, ±10% 0.5 A 1.25 A

240 VAC, ±10% 0.25 A 0.75 A

220 VAC, ±10% 0.25 A 0.75 A

SCXI-1000 SCXI-1001

Max AC Current

SCXI-1000DC

Input voltage...........................................12 VDC nominal

(9.5 to 16.0 VDC)

Max DC operating current

at 9.5 VDC..............................................5.5 A

Weight

SCXI-1000..............................................3.9 kg (8 lb 10 oz)

SCXI-1000DC ........................................3.3 kg (7 lb 5 oz)

SCXI-1001..............................................6.8 kg (14 lb 14 oz)

Refer to Figures A-1 and A-2 for the physical dimensions of the four-slot

chassis (SCXI-1000 and SCXI-1000DC) and the 12-slot chassis

(SCXI-1001).

SCXI Chassis User Manual A-2 ni.com

Page 32

Appendix A Specifications

Figure A-1. Physical Dimensions of the SCXI-1001

© National Instruments Corporation A-3 SCXI Chassis User Manual

Page 33

Appendix A Specifications

Figure A-2. Physical Dimensions of the SCXI-1000 and SCXI-1000DC

SCXI Chassis User Manual A-4 ni.com

Page 34

Environmental

Safety

Note For UL and other safety certifications, refer to the product label, or visit

ni.com./hardref.nsf, search by model number or product line, and click the

appropriate link in the Certification column.

Appendix A Specifications

Operating temperature............................ 0 to 50 °C

Storage temperature ............................... –20 to 70 °C

Humidity ................................................ 10 to 90% RH, noncondensing

Maximum altitude.................................. 2,000 meters

Pollution Degree (indoor use only)........ 2

The chassis are designed to meet the requirements of the following

standards of safety for electrical equipment for measurement, control,

and laboratory use:

• IEC 61010-1, EN 61010-1

• UL 3111-1, UL 61010B-1

• CAN/CSA C22.2 No. 1010.1

Electromagnetic Compatibility

Emissions ............................................... EN 55011 Class A at 10 m.

FCC Part 15A above 1 GHz

Immunity................................................ EN 61326-1:1997 + A2:2001,

Table 1

EMC/EMI............................................... CE, C-Tick, and FCC Part 15

(Class A) Compliant

Note For EMC compliance, operate this device with shielded cabling.

© National Instruments Corporation A-5 SCXI Chassis User Manual

Page 35

Appendix A Specifications

CE Compliance

Note Refer to the Declaration of Conformity (DoC) for this product for any additional

regulatory compliance information. To obtain the DoC for this product, visit

ni.com/hardref.nsf, search by model number or product line, and click the

appropriate link in the Certification column.

The chassis meet the essential requirements of applicable European

Directives, as amended for CE marking, as follows:

Low-Voltage Directive (safety)..............73/23/EEC

Electromagnetic Compatibility

Directive (EMC) .....................................89/336/EEC

SCXI Chassis User Manual A-6 ni.com

Page 36

Common Questions

My chassis worked fine until I inadvertently removed and reinserted a

module while the chassis was on. Now my chassis does not power on.

What can I do?

SCXI modules are not hot swapable, so you may have blown a fuse. Refer

to Chapter 2, Configuring and Installing the SCXI Chassis, for information

on fuse replacement. If replacing the fuse does not correct the problem, you

may have damaged the digital bus circuitry or the SCXI module. Please

contact NI Technical Support at

My chassis power is on, my modules are configured for multiplexed

mode, and I am not getting good data. All the channels read the same

voltage even though I know I am putting different voltages into each

channel. What is causing this problem?

The SCXI chassis has backplane fuses. One or both of these fuses could be

blown. Refer to the Replacing and Checking Backplane Fuses on the

SCXI-1000 and SCXI-1001 section of Chapter 2, Configuring and

Installing the SCXI Chassis, for fuse replacement information.

B

ni.com/support for assistance.

Can I programmatically detect whether or not my chassis is

powered on?

Not exactly. You can determine whether or not you can communicate with

configured modules through

a LabVIEW VI that you can obtain from

info code

My chassis will not power on. What should I check?

Check the to make sure the power cord is attached and connected to a power

source. Look at the voltage selection tumbler above the power cord

receptacle and make sure it is set to the correct voltage. Make sure the

power switch is powered on. Verify that the main power fuse is good.

© National Instruments Corporation B-1 SCXI Chassis User Manual

rdtscp.

SCXI_ModuleID_Read in NI-DAQ or using

ni.com/express by entering the

Page 37

Glossary

Symbol Prefix Value

ppico10

m milli 10

k kilo 10

Numbers/Symbols

° degrees

– negative of, or minus

Ω ohms

± plus or minus

+ positive of, or plus

% percent

+5 V (signal) +5 VDC source signal

A

–12

–3

3

A amperes

A/D analog-to-digital

AC alternating current

C

CCelsius

© National Instruments Corporation G-1 SCXI Chassis User Manual

Page 38

Glossary

D

D/A digital-to-analog

DAQ data acquisition—(1) collecting and measuring electrical signals from

sensors, transducers, and test probes or fixtures and processing the

measurement data using a computer; (2) collecting and measuring the same

kinds of electrical signals with A/D and/or DIO boards plugged into a

computer, and possibly generating control signals with D/A and/or DIO

boards in the same computer

F

F (1) Fahrenheit—a temperature measurement scale;

(2) farad—a measurement unit of capacitance

FIFO first-in first-out memory buffer

fuse a protective device that breaks a circuit when a current exceeds a rated value

G

GND ground

H

HDLC high-level data-link control

Hz hertz—cycles per second of a periodic signal

I

I/O input/output—the transfer of data to/from a computer system involving

communications channels, operator interface devices, and/or data

acquisition and control interfaces

IEC International Electrotechnical Commission

in. inch or inches

SCXI Chassis User Manual G-2 ni.com

Page 39

K

kg kilograms

L

lb pounds

O

oz ounces

S

s seconds

SCXI Signal Conditioning eXtensions for Instrumentation

Glossary

V

Vvolts

VAC volts, alternating current

VDC volts, direct current

W

W watts

© National Instruments Corporation G-3 SCXI Chassis User Manual

Page 40

Index

Symbols

+5 VDC fuse replacement, SCXI-1000DC, 2-14

A

address selection, 2-8

jumper settings

SCXI-1000 and SCXI-1001

(figure), 2-9

SCXI-1000DC (figure), 2-10

jumperless chassis (note), 2-8

SCXI-1000 and 1001, 2-8

SCXI-1000DC, 2-9

B

backplane fuse replacement and check procedure

SCXI-1000 and 1001, 2-13

SCXI-1000DC, 2-15

C

cables, optional equipment, 1-5

CE compliance specifications, A-6

chassis address selection. See address selection

configuration

See also installation

address selection

SCXI-1000 and SCXI-1001, 2-8

figure, 2-9

SCXI-1000DC, 2-9

figure, 2-10

chassis descriptions

front view diagrams, 2-2, 2-3, 2-4

front view items (table), 2-1

rear view diagrams, 2-5, 2-6, 2-7

rear view items (table), 2-4, 2-6

chassis usage considerations, 2-7

fuse replacement and check procedure,

backplane

SCXI-1000 and SCXI-1001, 2-13

SCXI-1000DC, 2-15

fuse replacement for power entry module

+5 VDC fuse replacement,

SCXI-1000DC, 2-14

voltage selection for SCXI-1000 and

SCXI-1001

procedure, 2-12

voltage selection and fuse ratings by

region (table), 2-11

conventions used in the manual, iv

D

documentation

conventions used in the manual, iv

National Instruments documentation, 1-4

related documentation, 1-4

E

electromagnetic compatibility

specifications, A-5

environmental specifications, A-5

equipment, optional, 1-5

F

fan filter maintenance, 2-18

filler panel installation

front filler panel, 2-17

rear filler panel, 2-18

frequently asked questions, B-1

© National Instruments Corporation I-1 SCXI Chassis User Manual

Page 41

Index

fuse replacement

backplane fuse replacement and check

procedure

SCXI-1000 and SCXI-1001, 2-13

SCXI-1000DC, 2-15

fuse ratings by region (table)

SCXI-1000 and SCXI-1001, 2-11

fuse replacement for power entry module

+5 VDC fuse replacement,

SCXI-1000DC, 2-14

SCXI-1000DC, 2-14

fuse, blown, B-1

I

installation

chassis descriptions

front view diagrams, 2-2, 2-3, 2-4

front view items (table), 2-1

rear view diagrams, 2-5, 2-6, 2-7

rear view items (table), 2-4, 2-6

fan filter maintenance, 2-18

filler panel installation, 2-17

SCXI-1000 and SCXI-1001, 2-16

SCXI-1000DC, 2-16

M

maintenance of fan filter, 2-18

P

problems and solutions, B-1

S

safety specifications, A-5

SCXI chassis

common questions, B-1

hardware and software requirements, 1-1

optional equipment, 1-5

overview, 1-1

SCXI chassis descriptions

front view diagrams

SCXI-1000, 2-2

SCXI-1000DC, 2-3

SCXI-1001, 2-4

front view items (table), 2-1

rear view diagrams

SCXI-1000, 2-5

SCXI-1000DC, 2-7

SCXI-1001, 2-6

rear view items (table)

SCXI-1000 and 1001, 2-4

SCXI-1000DC, 2-6

SCXI modules

troubleshooting and common

questions, B-1

SCXI-1000

address selection, 2-8

jumper settings (figure), 2-9

front view diagram, 2-2

fuse replacement

backplane fuse replacement and

check procedure, 2-13

fuse ratings by region (table), 2-11

power entry module, 2-13

installation, 2-16, A-3

physical dimensions (figure), A-4

rear view diagram, 2-5

rear view items (table), 2-4

source power requirements, A-2

voltage selection, 2-11

procedure, 2-12

voltage selection and fuse ratings by

region (table), 2-11

SCXI-1000DC

address selection, 2-9

jumper settings (figure), 2-10

front view diagram, 2-3

SCXI Chassis User Manual I-2 ni.com

Page 42

Index

fuse replacement

+5 VDC fuse replacement, 2-14

backplane fuse replacement and

check procedure, 2-15

power entry fuse and +5 VDC, 2-14

installation, 2-16

physical dimensions (figure), A-4

rear view diagram, 2-7

rear view items (table), 2-6

source power requirements, A-2

SCXI-1001

address selection, 2-8

jumper settings (figure), 2-9

front view diagram, 2-4

fuse replacement

backplane fuse replacement and

check procedure, 2-13

fuse ratings by region (table), 2-11

power entry module, 2-13

installation, 2-16

physical dimensions (figure), A-3

rear view diagram, 2-6

rear view items (table), 2-4

source power requirements, A-2

voltage selection, 2-11

procedure, 2-12

voltage selection and fuse ratings by

region (table), 2-11

software programming choices, 1-2

source power requirements

SCXI-1000 and 1001, A-2

SCXI-1000DC, A-2

specifications

CE compliance, A-6

electrical characteristics (table), A-1

electromagnetic compatibility, A-5

environmental, A-5

physical dimensions

SCXI-1000 and SCXI-1000DC

(figure), A-4

SCXI-1001 (figure), A-3

safety, A-5

source power requirements

SCXI-1000 and 1001, A-2

SCXI-1000DC, A-2

weight, A-2

V

voltage selection

See also fuse replacement

SCXI-1000 and SCXI-1001, 2-11

procedure, 2-12

voltage selection and fuse ratings by

region (table), 2-11

W

weight specifications, A-2

© National Instruments Corporation I-3 SCXI Chassis User Manual

Loading...

Loading...