NATIONAL CONTROLS DNC-T2310- B220, DNC-T2310-A10 Installation Manual

National Controls Corp.National Controls Corp.

Phone 800-323-2593 ● Fax 630-231-1377 ● Internet www.natcon.com

STANDARD OPERATION MANUAL

TABLE OF CONTENTS

DNC-T2310-A10 / B10

DNC-T2310-A220 / B220

DNC-T2320-A10 / B10

DNC-T2320-A220 / B220

DNC-T2310-A10

DNC-T2320-A10

HOW TO USE THIS GUIDE

OVERVIEW

INSTALLATION INSTRUCTIONS

1.0 MOUNTING THE UNIT

2.0 ELECTRICAL HOOKUP

3.0 ALARM INPUT CONNECTIONS

4.0 ALARM OUTPUT CONNECTIONS

5.0 BYPASS / CYCLE DOWN INPUT CONNECTION

6.0 PRESSURE CONNECTIONS

7.0 4 TO 20 MILLIAMP LOOP

8.0 BEFORE APPLYING POWER TO THE UNIT

9.0 TROUBLESHOOTING

10.0 PLACING THE UNIT INTO “SETUP” MODE

11.0 FACTORY DEFAULT SETTINGS

12.0 USING THE “▲” AND “▼” BUTTONS

13.0 DISPLAY MESSAGES

14.0 PROGRAMMING CONTROLLER PARAMETERS

IDC PROGRAMMING TREE

15.0 RELOADING FACTORY DEFAULT SETTINGS

16.0 ALARMS AND WARNING MESSAGES

17.0 EXPANDED MODE OPERATION

18.0 REMOTE TERMINAL CONNECTION

19.0 OPERATION WITH REMOTE TERMINAL

APPENDIX I - CLOCK PROGRAMMING EXAMPLE

APPENDIX II - CLOCK PROGRAMMING CHART

T2310 / T2320 Operation Manual Page 3

4

5

6

6

8

8

10

10

11

12

12

12

13

13

13

14

15

21

24

25

28

32

33

33

36

National Controls Corp.

National Controls Corp. National Controls Corp.

Phone 800-323-2593 ● Fax 6 30-231-1377 ● Internet www.natcon.com

Phone 800-323-2593 ● Fax 6 30-231-1377 ● Internet www.natcon.com

National Controls Corp.

Phone 800-323-2593

Phone 800-323-2593 ● Fax 630-231-1377 ● Internet www.natcon.com

● Fax 630-231-1377 ● Internet www.natcon.com

HOW TO USE THIS GUIDE

This instruction guide will show you how to install and use the

microprocessor based, Model T2310 and T2320 Pulse-Jet Bag House

Controller. We want you to be pleased with the Controller. If you

have any questions that are not answered in this booklet, please call

National Controls Corp., Customer Service Department.

Product Specifications

■ OPERATING VOLTAGE:

DNC-T2310-A10 / B10.......................................................105-135 VAC 50/60 Hz

DNC-T2310-A220 / B220................................................210-270 VAC 50/60 Hz

DNC-T2320-A10 / B10.......................................................105-135 VAC 50/60 Hz

DNC-T2320-A220 / B220..................................................210-270 VAC 50/60 Hz

■ POWER CONSUMPTION:

120 or 240 volt models ....…..........................10 VA (with no loads connectd)

■ OPERATING TEMPERATURE:......................... -40 to 150 degrees Fahrenheit

■ MAXIMUM SOLENOID LOAD:...........................................200 VA (each output)

■ SOLENOID ON TIME RANGE:.................................................... .01 - .50 Seconds

■ SOLENOID OFF TIME RANGE:...................................................7.0 - 999 Seconds

■ DIFFERENTIAL PRESSURE MEASUREMENT RANGE:................0.0 TO 15.0

Inches of water

■ MAXIMUM AIR PRESSURE APPLIED TO UNIT:......................................10 psi

■ DISPLAY:...............................................................8 Character, vacuum fluorescent

■ SERIAL COMMUNICATION PORT:...............RS-232, Remote ANSI terminal

WARRANTY:

All of National Controls' products are warranted for a period of 1

year against defects and workmanship. Because certain conditions

may apply to different product categories, contact the factory for

detailed warranty information.

IMPORTANT NOTICE TO USERS:

NCC products are capable of use in a wide array of devices and

applications. Any device or system incorporating a NCC product

should be designed that, in the event of failure, malfunction, or

normal wear of the product, the device or system will become

inoperative in a manner which will prevent bodily injury or property damage. In order to keep abreast with the latest technology,

National Controls Corporation reserves the right to change components, design, and specifications without notice.

UNPACKING INSTRUCTIONS:

Examine the unit and the box for damage. If the controller is

damaged "DO NOT" apply power. Contact the carrier on how to file

a damage claim. Contact NCC for information regarding the return

procedure, then return the damaged unit to National Controls

Corporation for evaluation.

OVERVIEW

The Model T2310 and T2320 Series are microprocessor based

Pulse-Jet Bag House Dust Collector Controllers. Their purpose is

to monitor the differential pressure across the dust collectors’ bag

assembly. If the differential pressure exceeds the high-pressure set

point, the controller will initiate a cleaning cycle.

During a cleaning cycle, the controller pulses the solenoids connected to its outputs sequentially. The solenoids in turn, will pulse

high-pressure air to the filter compartments in the dust collector.

The high-pressure air blast is used to clean the filters. The pulsing

of the solenoids will continue until the differential pressure drops

below the low-pressure setpoint. At this time the solenoids will stop

firing.

The controller keeps track of the last output fired. When the

pressure rises above the high-pressure set point again, it will start

the cleaning cycle with the next output to fire.

When the controller is in the auto learning mode, it has the ability

to learn which outputs have solenoids connected to them. If the

controller does not sense a solenoid connected to an output, it will

skip over that output.

T2310 / T2320 Operation Manual Page 4

T2310 / T2320 Operation Manual Page 5

National Controls Corp.

National Controls Corp.

Phone 800-323-2593 ● Fax 6 30-231-1377 ● Internet www.natcon.com

Phone 800-323-2593 ● Fax 6 30-231-1377 ● Internet www.natcon.com

National Controls Corp.National Controls Corp.

Phone 800-323-2593 ● Fax 630-231-1377 ● Internet www.natcon.com

Phone 800-323-2593 ● Fax 630-231-1377 ● Internet www.natcon.com

During normal operation, the solenoids are constantly being

monitored. If a solenoid circuit is open or an output is stuck

"on", the controller shall signal that an alarm condition occurred.

Furthermore, as a troubleshooting aid, the display shall indicate

which output is faulty.

INSTALLATION INSTRUCTIONS

1.0 MOUNTING THE UNIT

It is highly recommended to install this unit in a NEMA-4 type

enclosure. This will protect the precision instrumentation which

is on the controller. National Controls offers NEMA enclosures

for mounting the controller.

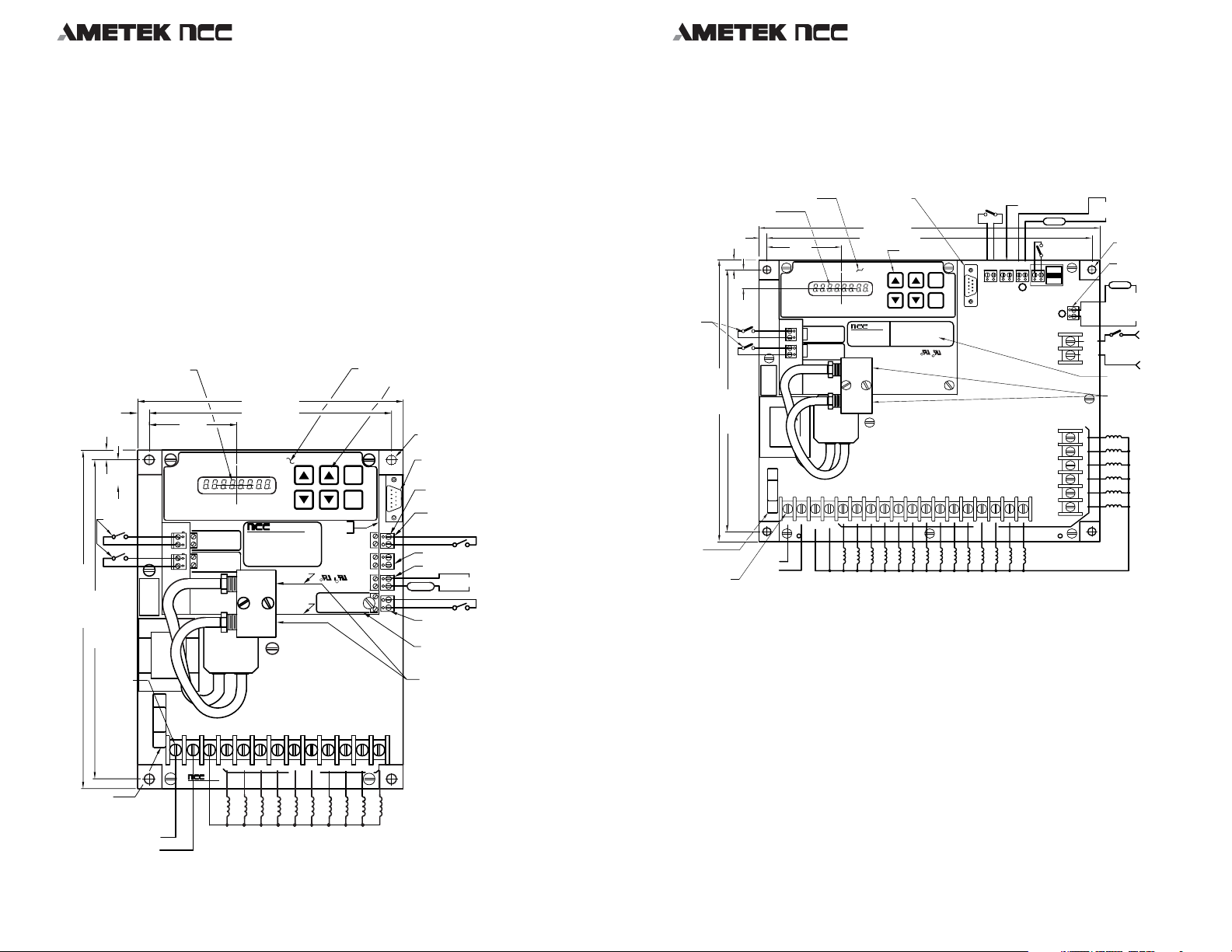

Models DNC-T2310-A10, B10, A220, & B220 Mounting and Wiring Details

VACUUM FLUORESCENT

DISPLAY (8 CHAR.)

(16 SEGMENT)

.312 (7.9)

AUX.

ALARM

INPUTS

SWITCH CLOSURE

INITIATES ALARM

STATUS

(NOT AVAIL. ON

B10 UNITS).

8.75 (222.3)

8.25 (209.5)

#8 SCREW

TERM. 13 PL.

.25

(6.35)

.65

(16.5)

DO NOT USE SLOW-BLOW OR LARGER SIZE

FAILURE TO COMPLY WILL VOID ANY

3AMP

WARRANTY

2.275

(57.8)

INPUT

ALARMALARM

INPUT

32

6.875 (174.6)

6.250 (158.7)

DIFFERENTIAL PRESSURE (d P)

INCHES OF WATER

1725 Western Dr.

ALARM

West Chicago, IL. 60185

INPUT

INTELLIGENT DUST CONTROL

2

MODEL NO.: DNC-T2310-✻✻✻✻

INPUT VOLTAGE:✻✻✻ VAC, 10VA

ALARM

INPUT

S/N:

3

ITEM VALUE

National Controls

Corporation

Date Code:

PRESSURE CONNECTIONS:

HI SIDE

LOW SIDE

POLYESTER OVERLAY

OUTPUT

STEP

ALARM

CANCEL

RS232

CONNECTOR

BYPASS/

CYCLE DOWN

INPUT

(-)

P OUTPUT

D

4-20 mA

(+)

R

ALARM

R

OUTPUT

ALARM

INPUT

1

BUTTONPAD

.25 DIA MOUNTING HOLE

(4 PL.)

RS-232 9 CIRCUIT

MALE CONNECTOR

SEE FIGURE 5

2 POS. SCREW TERMINAL

(6 PL.)

DIFFERENTIAL PRESSURE

CYCLE BYPASS/

CYCLE DOWN INPUT

4-20mA OUTPUT

REMOTE ALARM OUTPUT

ALARM VOLTAGE

ALARM

SOURCE

AUXILIARY ALARM

INPUT

BLACK INK SCREENING

(ALUMINUM COVER)

USER HOOKUP

’’DIRTY AIR PLENUM

& CLEAN AIR PLENUM"

PRESSURE CONNECTIONS

1/8-27 NPT TAPPED HOLE

TUBING FITTING

(2 PL.)

The controller's chassis is pre-drilled to mount directly inside

the NEMA housing. If the unit is going to be mounted inside

another enclosure, use the installation drawings that are shown

in Figures 1 & 2.

Models DNC-T2320-A10, B10, A220, & B220 Mounting and Wiring Details

VACUUM FLUORESCENT

DISPLAY (8 CHAR.)

(16 SEGMENT)

.25 (6.35)

AUX ALARM

INPUTS SWITCH

CLOSURE INITIATES

ALARM STATUS

(NOT AVAILABLE

ON ’-B10’ UNITS

250V 3 AMP

FUSE FOR 120VAC UNITS

(250V 1-1/2 AMP

FUSE FOR 240VAC UNITS)

#6 SCREW TERM.

(26 PL.)

POLYESTER OVERLAY

.59

(15.0)

.312 (7.92)

8.875 (225.4)

8.25 (209.5)

2.325

(59.0)

A

B2

A

B

FAILURE TO COMPLY WILL VOID ANY

DO NOT USE SLOW-BLOW OR LARGER SIZE

3AMP

WARRANTY

L1

L1

L2

RS-232 9 CIRCUIT

MALE CONNECTOR

SEE FIGURE 5

10.75 (273.0)

10.250 (260.35)

DIFFERENTIAL PRESSURE (d P)

INCHES OF WATER

ALARM

National Controls

INPUT

Corporation

1725 Western Dr.

West Chicago, IL. 60185

ALARM

INPUT

3

SOLL2 SOL 1 2 3 4

COM COM

DIRTY AIR PLENUM

CONNECTION

CLEAN AIR PLENUM

CONNECTION

20 -OUTPUTS TO 120 VAC SOLENOID AIR-VALVES

SOL. COM. TERMINALS ARE INTERNALLY CONNECTED TO L2 TERMINAL

DIFFERENTIAL PRESSURE

BUTTON PAD

OUTPUT

ITEM VALUE

ALARM

CANCEL

INTELLIGENT DUST CONTROL

MODEL NO.: DNC-T2320-A10

INPUT VOLTAGE:120 VAC, 10VA

S/N:RDate Code:

C

R

BYPASS/CYCLE DOWN

STEP

8567 9101112 13 14

4-20mA OUTPUT

ALARM

REMOTE ALARM

CONDITION

BYPASS/

RS232

CYCLE DOWN

INPUT

OUTPUTS

INPUT

ALARM

4-20mA

OUTPUT

-

+

ALARM

INPUT 1

REMOTE ALARM

CONDITION OUTPUT

(ALARM VOLTAGE

SOURCE)

.25 DIA. MOUNTING

HOLE (4 PL.)

2 POS. SCREW TERMINAL

(7 PL.)

ALARM

AUX OUTPUT FOR EXPANDED

MODE OR AUX REMOTE ALARM

AUX

CONDITION OUTPUT

OUTPUT

#4

(ALARM VOLTAGE SOURCE)

AUX

120VAC, 50/60HZ

INPUT

#4

(240VAC, 50/60HZ

120VAC

ON 240VAC UNITS)

BLACK INK SCREENING

(ALUMINUM COVER)

USER HOOKUP

’DIRTY AIR PLENUM’

AND ’CLEAN AIR PLENUM’

PRESSURE CONNECTIONS

TAPPED 1/8-27 NPT (2 PL.)

20

19

18

17

16

15

Figure 2

THESE CONTROLLERS ARE NOT DESIGNED TO BE INSTALLED

IN HARSH ENVIRONMENTS WITHOUT SUITABLE

PROTECTION. IMPROPER INSTALLATION WILL VOID THE

WARRANTY.

DO NOT:

L1

L2

AUX INPUT FOR

ALARM OR

EXPANDED MODE

213

456798

OUTPUTS

10

FIGURE 1

Figure 1

250V 3 AMP

FUSE FOR 120 VAC UNITS

250V 1.5 AMP

FUSE FOR 240 VAC UNITS

L1

L2

L2L1

SOL

COM

National Controls

Corporation

10 -OUTPUTS TO 120 or 240 VAC SOLENOID AIR-VALVES (DEPENDING ON MODEL)

SOL .COM. TERMINAL IS INTERNALLY CONNECTED TO L2 TERMINAL

T2310 / T2320 Operation Manual Page 6

Install this unit in an area of high vibration.

Install this unit close to strong magnetic fields.

T2310 / T2320 Operation Manual Page 7

National Controls Corp.

National Controls Corp. National Controls Corp.

Phone 800-323-2593 ● Fax 6 30-231-1377 ● Internet www.natcon.com

Phone 800-323-2593 ● Fax 6 30-231-1377 ● Internet www.natcon.com

National Controls Corp.

Phone 800-323-2593

Phone 800-323-2593 ● Fax 630-231-1377 ● Internet www.natcon.com

● Fax 630-231-1377 ● Internet www.natcon.com

2.0 ELECTRICAL HOOKUP

NOTE: To aid in installation, refer to the corresponding wiring diagram.

Connect this unit to the correct power source, which is listed

on the nameplate. Do not connect this unit to a "converter" or

"inverter" type power source. This unit should be installed on

its own 15-amp circuit. Do not connect this unit to a power

source that is subjected to large switched loads, such as, electric

motors, compressors, electric tools, etc.

WARNING: MAKE SURE THAT THE CIRCUIT THAT YOU ARE

WORKING WITH, IS "TURNED OFF", BEFORE YOU MAKE

THESE CONNECTIONS. SERIOUS INJURY MAY RESULT IF YOU

DO NOT TAKE THE PROPER SAFETY PRECAUTIONS.

On 120 volt models connect the "hot" or "high side" of the

incoming power source to "L1" on the terminal strip. Connect

the "return" to "L2" on the terminal strip.

On 220-volt models, connect one side of the 220-volt line to L1

and connect the other side of the 220-volt line to L2.

Connect the solenoid air valves to the terminal strip. These are

labeled with the word "OUTPUTS" and they are numbered 1

through 10 for the T2310 unit and 1 through 20 for the T2320

unit. You can connect more than one solenoid on each output,

as long as you do not exceed the 200VA (Watt) rating on each

output.

The return wires "commons" from the solenoids will return to

the "SOL COM" connection on the terminal strip.

3.0 ALARM INPUT CONNECTION

CAUTION: DO NOT APPLY ANY TYPE OF LIVE POWER TO

THIS ALARM INPUT. SEVERE DAMAGE TO THE UNIT WILL

OCCUR.

It is recommended that you do not run this wiring in conduit

or cabling raceways, which have high voltage or high current

conductors. It is also recommended that you use a twisted wire

pair for this connection.

3.2 T2320 Models:

There are 4 general-purpose alarm inputs on the DNCT2320-A10 and -A220 controllers. The DNC-T2320-B10 and

-B220 controllers which have the Real Time Clock installed, do

not have alarm inputs #2 and #3 available.

Alarm inputs 1, 2, and 3 will accept any type of sensor, which

has a "normally open, dry contact" switch output. The switch

or contact closure must be suitable for, 24VDC at .010 amps.

A switch or contact closure will indicate an alarm condition to

the controller.

CAUTION: DO NOT APPLY ANY TYPE OF LIVE POWER TO

ALARM INPUTS #1,2, OR 3. SEVERE DAMAGE TO THE UNIT

WILL OCCUR.

"ALARM AUX INPUT #4" is a dual-purpose input. It can

be used as a general alarm input or as the input for the

"EXPANDED MODE" feature, which is described in Expanded

Mode Section. As an alarm input, it requires a switched line

voltage input, 120VAC 50/60 Hz source for the -A10 and -B10

models and 220VAC 50/60 Hz source for the -A220 and -B220

models.

3.1 T2310 Models:

There are three general "ALARM INPUT" connections on the

DNC-T2310-A10 / A220 models and one general "ALARM

INPUT" on the DNC-T2310-B10 / B220. You can connect any

type of sensor to these inputs, which has a "normally open, dry

contact" switch output. The switch or contact on your equipment must be suitable for, 24VDC at .010 amps. A switch or

contact closure will indicate an alarm condition to the controller

T2310 / T2320 Operation Manual Page 8

CAUTION: DO NOT APPLY ANY OTHER VOLTAGE EXCEPT

AS SPECIFIED ABOVE, TO THIS INPUT. DAMAGE TO THE

CONTROLLER WILL OCCUR.

It is recommended that you do not run this wiring in conduit or

cabling raceways, which have high voltage or high current conductors.

It is also recommended that you use a twisted wire pair for this

connection.

T2310 / T2320 Operation Manual Page 9

National Controls Corp.

National Controls Corp. National Controls Corp.

Phone 800-323-2593 ● Fax 6 30-231-1377 ● Internet www.natcon.com

Phone 800-323-2593 ● Fax 6 30-231-1377 ● Internet www.natcon.com

National Controls Corp.

Phone 800-323-2593

Phone 800-323-2593 ● Fax 630-231-1377 ● Internet www.natcon.com

● Fax 630-231-1377 ● Internet www.natcon.com

4.0 ALARM OUTPUT CONNECTION

The "ALARM OUTPUT" connection is used to indicate to a

remote location that an alarm has occurred. All alarms that are

generated by the controller, including ALARM INPUTS #1, 2,

and 3, will activate this output.

This output is a set of "normally open" relay contacts. It is

capable of switching 3 amps at 120/240 VAC. When the controller has an alarm condition, the contacts will close.

The AUX INPUT #4 only controls the AUX OUTPUT #4 on the

T2320 models only. No other alarms will activate this output.

The relay contacts have the same rating as the output for

alarms #1, 2, and 3. A red LED located next to the alarm output

will light when the relay contacts are closed.

It is recommended that you do not run this wiring in conductor

cabling raceways, which have high voltage or high current

conductors. It is also recommended that you use a twisted pair

wire combination for this connection.

5.0 BYPASS/CYCLE DOWN INPUT CONNECTION

5.1 CYCLE DOWN MODE:

The Cycle Down mode allows the user to connect an auxiliary

set of contacts from the ventilation fan in the dust collector to

the Bypass/Cycle Down Input of the “Intelligent” controller in

order to clean the filters “off-line” when the fan shuts down.

If the Cycle Down mode is enabled, normal operation of the

controller occurs when the Bypass/Cycle Down Input is shorted; opening the Bypass/Cycle Down Input will begin a "POWER

CYCLE DELAY" time and will inhibit any cleaning cycles due

to the differential pressure. The display will alternate the words

"POWER", "CYCLE", "DELAY" and "∆P =XX.X".

At the end of this delay, the unit will cycle through all the

selected outputs as determined by the number of cycles selected with the "NO_ CYL XX" programming menu item, beginning

at output number 1. If the unit is being used in expanded

mode, the cleaning cycle of the Cycle Down mode will start

on the external board. When the Bypass/Cycle Down Input is

closed, the unit shall resume normal operation.

5.2 BYPASS MODE:

If the Bypass/Cycle Down Input is shorted with the Cycle Down

mode disabled, a cleaning cycle shall be initiated regardless of

the value of the sensed pressure and will continue until the

circuit is opened. Once the input is opened the cleaning cycle

will either stop or continue based on the value of the sensed

pressure as previously defined.

CAUTION: DO NOT APPLY ANY TYPE OF LIVE POWER TO

THIS BYPASS/CYCLE DOWN INPUT. SEVERE DAMAGE TO THE

UNIT WILL OCCUR.

NOTE: The "ALARM INPUTS", "ALARM OUTPUT", and "BYPASS/CYCLE

DOWN INPUT" do not need to be connected for the operation of the

controller. These connections are optional.

6.0 PRESSURE CONNECTIONS

The controller is equipped with a metal manifold, which is used

to make the differential pressure connections. The manifold is

tapped for 1/8-27 NPT, female pipe fitting.

It is recommended that the tubing be run through a bulkhead

fitting on the NEMA enclosure. This will provide a seal to prevent moisture, dust and particulates from entering the enclosure.

Connect the "HIGH SIDE" or “dirty air” pressure connection

to the inlet of the dust collector. Do not make sharp bends

or kink the tubing when installing. Follow the manufacturers'

installation instructions for the placement of the input pressure

tubing.

CAUTION: THE MAXIMUM PRESSURE THAT CAN BE APPLIED

TO THE PRESSURE INPUTS IS 10 PSI. ANY GREATER

APPLIED PRESSURE, EVEN MOMENTARILY, WILL DAMAGE

THE PRESSURE SENSOR.

Connect the "LOW SIDE" or “clean air” pressure connection

to the outlet of the dust collector. Do not make sharp bends

or kink the tubing when installing. Follow the manufacturers'

installation instructions for the placement of the output pressure tubing.

T2310 / T2320 Operation Manual Page 10

T2310 / T2320 Operation Manual Page 11

National Controls Corp.

National Controls Corp. National Controls Corp.

Phone 800-323-2593 ● Fax 6 30-231-1377 ● Internet www.natcon.com

Phone 800-323-2593 ● Fax 6 30-231-1377 ● Internet www.natcon.com

National Controls Corp.

Phone 800-323-2593

Phone 800-323-2593 ● Fax 630-231-1377 ● Internet www.natcon.com

● Fax 630-231-1377 ● Internet www.natcon.com

7.0 4 TO 20 MILLIAMP CURRENT LOOP

The "4-20mA" output is used for a remote indication of differential pressure. Zero inches of differential pressure will produce

4 milliamps at this output; fifteen inches of differential pressure

will produce 20 milliamps.

There is a plus (+) and minus (-) connection for this output.

Make sure that you observe the polarities when you make the

connections to your equipment.

It is recommended that you do not run this wiring in conductor

cabling raceways, which have high voltage or high current

conductors. It is also recommended that you a twisted pair wire

combination for this connection.

8.0 BEFORE APPLYING POWER TO THE UNIT

■ Recheck all of your electrical connections.

■ Recheck all of your mechanical and pressure

connections.

■ Turn on the circuit breaker.

■ Observe the display on the controller, the word "SETUP" should be on

the display. If not, ignore the message on the display.

9.0 TROUBLESHOOTING

If the display does not show a message after the application of

power, check the following:

■ Check the wiring from the circuit breaker to L1 and L2 on the

controller.

■ Check the fuse on the controller. A blown fuse on the controller

may indicate a problem with the solenoid outputs. Recheck the

connections to the solenoids.

■ A short in the solenoid wiring or a short in a solenoid itself may

not cause the fuse to blow during setup of the controller. If there

is a problem with an output, the fuse may blow during the auto

configuration of the outputs or during the first cleaning cycle.

■ Verify that the correct circuit breaker was turned on.

CAUTION: THE FUSE THAT IS INSTALLED ON THE

CONTROLLER IS A FAST-BLOW FUSE. DO NOT USE A SLOWBLOW OR A LARGER SIZE FUSE. FAILURE TO COMPLY WILL

VOID ANY WARRANTY.

10.0 "SETUP" MODE

After the application of power to a new controller, the word

"SETUP" should be on the display. The controller is shipped

in this mode so that all the programmable parameters are

reviewed before the system is placed in operation.

If you see the message "∆P =xx.x", which is the current differential pressure, this may indicate that the unit has been

previously configured. If you do not have the "SETUP" mode

message and you want to reset the controller to this mode refer

to the section for Reloading Factory Defaults for instructions.

11.0 FACTORY DEFAULT SETTINGS

■ Solenoid output selction:..................................................................................Manual

■ Last solenoid:..…….........................................................................................................10

■ Low pressure setting:...................................................................2.0 inches of water

■ High pressure setting:.................................................................4.0 inches of water

■ Solenoid on time:.......................................................................................0.10 seconds

■ Solenoid off time............................................................................................15 seconds

■ High alarm pressure:.................................................................14.0 inches of water

■ Cycle Down:....................................................................................................................NO

■ Number of Cycles:.............................................................................................................2

12.0 USING THE "ITEM" UP AND DOWN ARROW BUTTONS

By pressing the up or down "ITEM" buttons, you can display

the different messages that are available. The following are two

lists of the display messages as they would appear on your

controller when the unit is in the "SETUP" mode or in the

"OPERATING" mode.

T2310 / T2320 Operation Manual Page 12

T2310 / T2320 Operation Manual Page 13

Loading...

Loading...