NATIONAL CONTROLS DNC-T2310 User Manual

4-14

DUST COLLECTOR CONTROLS

Intelligent, AC-Input, Pulse Cleaning

of Bag House Dust Collectors

Models DNC-T2310 and DNC-T2320

FEATURES

On-board differential pressure sensor

●

4 - 20 mA output for DP

●

8 character alpha-numeric display

●

Microprocessor based control for stable

●

timing from -40°C to 65°C

Enhanced timer option: monitor addi

●

tional devices; record dust collector

data; network timers together remote

network monitor; remote network con

trol

RS232 port for remote monitor and con

●

trol

Automatic output setup capability

●

Expanded cycle mode allows additional

●

dust collector controllers to expand out

put capabilities

High pressure alarm indication

●

Output fault detection

●

Alarm output contacts

●

●

Alarm input sensors

●

Pulse time: line synchronized to elimi

nate 8 ms triac turn off variation per

output

10 A 400 V output triacs for maximum

●

protection against output shorts; 200 VA

load rating

Conformally coated for protection

●

against vibration, humidity, and con

tamination

Metal chassis provided: for mounting

●

directly into nema 4 box

Timer functionally tested to eliminate

●

field failures

Input protection: 30 joule metal oxide

●

varistor

One year warranty: warranted to be

●

free from defects in materials or work

manship for one year from date of man

ufacture

●

Models T2310 and T2320 are microprocessor-based bag house filter controllers

which combine a ten or twenty output

sequencer with a solid state differential

pressure sensor. This offers a small, lowcost replacement to the separate solid state

sequencer and pressure gauge combination

most often used in on-demand pulse jet

cleaning systems. These controllers will

sense the pressure difference across the

filters of a bag house and initiate a cleaning

File #E65038

-

-

-

-

-

cycle when the filters start to impede the air

flow. When the pressure drops to normal the

controller will stop cycling.

Standard Operating Logic: The timers can

operate in the following modes:

●

Auto output: only configured outputs will

be pulsed. Output faults will be detected

and indicated.

●

Manual output: outputs will recycle after

last output used.

●

Output step: a single cleaning pulse can

-

be initiated by pressing the output step

key regardless of pressure input.

●

Continuous cycle: controller will cycle

indefinitely when the bypass/cycle down

input is shorted.

-

●

Cycle down: the outputs will be pulsed

through a user seleced number of com

plete cycles when the bypass/cycle down

input is shorted. This cycle will occur

regardless of pressure input.

Expanded output mode: controller will

●

cycle to output #10 or #20, then will ini

tiate an extended output mode via the

alarm input and output terminals to

NCC’s DNC-T2000 series dust collec

tor controllers. This will facilitate sys

tems which require greater than 10 or 20

outputs.

Standard Timer Operation Status

Indication: The Timer can show the follow-

ing information on its 8-character alphanumeric display during normal operation:

●

DP from 0” to 15” water column

●

High or Low DP Alarms

●

Solenoid Fault Conditions

●

Current Output being Pulsed

●

-

Auxiliary Alarm Input Closures

Upon occurance of any alarm event, the

alarm status is reported on the display

along with the output number that was

pulsed during the time of the event.

●

Alarm Outputs: The isolated Alarm

Output contacts will close for alarm

conditions such as output faults,

high pressure alarm, warm-up failure,

etc. During an alarm condition, a

corresponding message is displayed.

●

Alarm Input: A closure across the Alarm

Input terminals will be indicated on

the display as well as initiate the Alarm

Output.

In addition to the standard operation of the T2310 and T2320,

an enhanced operation option

-

is available with the use of the

DNC-T2300-I/O Remote Input/

Output module in conjunction

with the DNC-T2300-DSP Remote

Annunciator Panel. The T2310

-

and T2320 Timers along with the

DNC-T2300-I/O constitutes the

-

-

Enhanced Timer system which

allows the user to monitor and

record the data parameters associ

ated with a dust collector system.

This system can range in size from

1 to 255 dust collectors, all report

ing to a central location, the DNCT2300-DSP.

Enhanced Timer Operation

Status Indication: The Timer can

show the following information on

its 8 character alpha-numeric dis

play during normal operation:

DP from 0” to 15” water column

●

●

High or Low DP Alarms

●

Solenoid Fault Conditions

●

Current Output being Pulsed

●

Auxiliary Alarm Input Closures

●

DNC-T2300-I/O Analog Input

Status

DNC-T2300-I/O Alarm Input

●

Closures

Upon occurance of any alarm

event, the alarm status is reported

on the display along with the out

put number that was pulsed during

the time of the event.

-

-

-

-

AMETEK National Controls Corp. • 1725 Western Drive • West Chicago, Illinois 60185 • Tel: 800-323-2593 • 630-231-5900 • FAX: 630-231-1377 • www.nationalcontrols.com

CL1L2 1 32 94 65 7 8 10

S

LAST SOLENOID

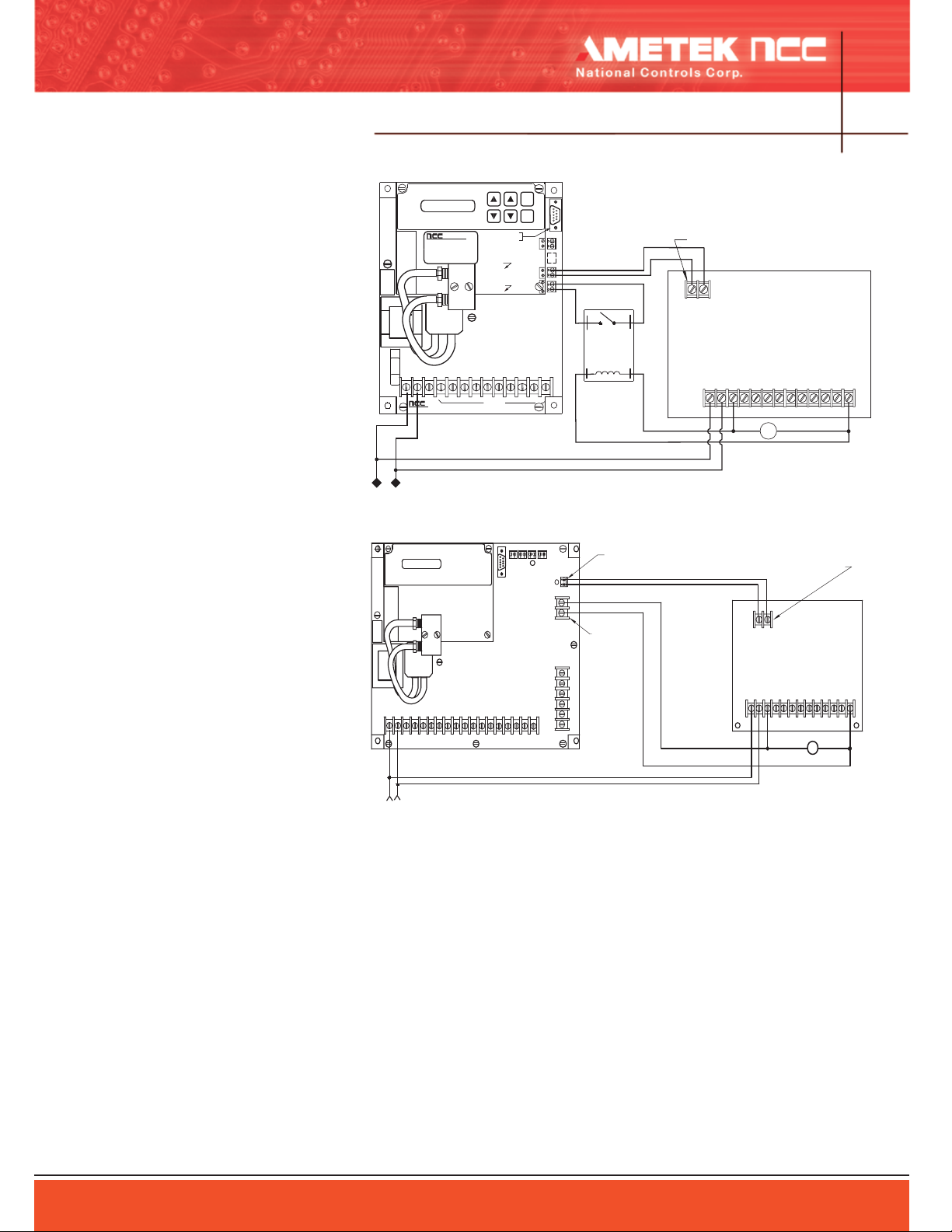

EXPANDED MODE WIRING DIAGRAM FOR DNC-T2320-*10

PRESSURE SWITCH

DNC SERIES DUST

COLLECTOR CONTROLLER

DNC-T2010 MODEL SHOWN

(EXCEPT T2310)

L1

L2

AUX OUTPUT

#4

AUX INPUT

#4

-T2320-

INPUT VOLTAGE 120 VAC

RS232 Port:

FAILURE TO COMPLY WILL VOID ANY

WARRANTY

DO NOT USE SLOW-BLOW OR LARGER SIZE

Model DNC-T2310-010

SOL

COM

L1 L2

3AMP

1

2 3 4

OUTPUTS

5 6

7 8109

HI SIDE

CONNECTIONS:

PRESSURE

LOW SIDE

1725 Western Dr.

S/N:

INTELLIGENT DUST CONTROL

West Chicago, IL. 60185

INPUT VOLTAGE:120 VAC, 10VA

MODEL NO.: DNC-T2310-010

Date Code:

BYPASS

INPU

T

ALARM

OUTPUT

ALARM

INPUT

INCHES OF WATER

DIFFERENTIAL PRESSURE ( P)

National Controls

Corporatio

n

D

OUTPUT

STEP

CANCE

L

ALARM

CONNECTOR

RS232

ITEM VALUE

National Controls

Corporation

S

Last solenoid

DNC-T2003 Through

DNC-T2032 Series

Dust Collector Controller

(DNC-T2010 model shown)

C

10987654321L2

L1

PRESSURE SWITCH INPUT

N

O

. .

CO

I

L

120 VAC Coil

SPST-NO

Relay

EXPANDED MODE WIRING DIAGRAM FOR DNC-T2310-*10

INPUT VOLTAGE 120 VAC

Remote Terminal: An ANSI type ter

●

minal is required for remote monitor

ing and programming of the controller.

Connection to the controller is made via

the RS232 port (9 pin D-Sub connec

tor). All the functions and display status

accessible from the controller are avail

able through the ANSI terminal.

Remote I/O Interface: The 2310/2320

●

controllers are capable of communication

with the DNC-T2300-I/O board via the

RS232 port. This allows the user to moni

tor up to three 4-20 mA analog inputs,

three contact closure type inputs, and

one Type J thermocouple. The I/O mod

ule is programmed via the 2310/2320

keypad and can be user defined to set

alarm points from remote sensors of

parameters such as emission, air flow,

pressure, broken bags, fan motor current,

etc. Refer to the data sheet for the DNCT2300-I/O for additional information.

DUST COLLECTOR CONTROLS

4-15

-

-

-

-

-

-

Programming Logic: The controller as sup

plied from the factory will require user con

-

figuration. Upon application of power the

display will indicate SETUP. The operator

must then configure the various operating

parameters using the six key keyboard of

the controller before normal cleaning opera

tion can begin. The programmable param

-

eters for Standard Operation as displayed

are:

OUTPUT

●

Auto Configuration: will automatically

sense the solenoids connected to the

outputs and will only pulse those outputs

during cleaning cycles.

Manual Configuration: the controller will

pulse each output until the last output

programmed and then recycle to output

For enhanced timer programming information, see IDC Programming Tree on page

4-6.

#1.

LAST: the number of the last output

●

used.

AMETEK National Controls Corp. • 1725 Western Drive • West Chicago, Illinois 60185 • Tel: 800-323-2593 • 630-231-5900 • FAX: 630-231-1377 • www.nationalcontrols.com

LO DP: Low Pressure Setpoint, the pres

●

sure at which the controller will stop its

cleaning cycle.

HI DP: High Pressure Setpoint, the pres

●

sure at which the controller will start its

cleaning cycle.

ON: Output Solenoid On Time.

●

OFF: Off Delay Time Between Output

●

Solenoid Activation.

ALARM: High Differential Pressure Alarm

●

Set-point, the pressure at which the con

troller will close its alarm contacts.

Additional Features: The 2310/2320 con

trollers also provide:

-

-

provide a continuous reading from 4 -20

mA corresponding to the sensed differen

tial pressure range of 0” to 15” water col

umn. This is a standard feature.

24 Hour Time/Day/Month Clock: The

●

4 - 20 mA Output Loop: This output will

●

clock feature will allow a daily automat

ic turn on and turn off command to be

implemented by the controller. It can be

programmed to start and stop the clean

-

week. This is an optional feature found on

ing cycles for up to seven events per

the B-series models.

-

-

-

Caution:

1. Do not mount controls in high vibration areas with

out shock mounts.

2. Do not mount controls in areas of high dust or cor

-

rosive atmospheres without a protective enclosure.

3 Do not use a converter or inverter for the power

source.

4. Do not mount control in high transient voltage

-

areas without an isolation transformer.

5. Do not leave control box open.

6. Do not allow a local repair shop to repair the con

trols, as we employ some very sophisticated compo

nents that could be further damaged. For service, call

us directly: 800-323-2593.

-

-

-

-

Loading...

Loading...