National Comfort Products CPG Installation Manual

Thru-the-Wall Packaged Heating & Cooling

Installation

Guide

Comfort Pack

Universal Series

NATIONAL

®

COMFORT

PRODUCTS

HEATING & A/C EQUIPMENT

80% THERMAL EFFICIENCY

This unit should be installed in an

OUTSIDE WALL for THRU-THE-WALL

INSTALLATION ONLY!

CPG

CPG

U-Models

U-Models

Gas

Heating

Electric

Cooling

Read Installation Guide prior to starting the installation.

National Comfort Products

A Division of National Refrigeration & Air Conditioning Products, Inc.

539 Dunksferry Road | Bensalem, PA 19020 | (215) 244-1400 | 1-800-523-7138 | Fax: (215) 639-1674

®

.

Table of Contents

Safety First ................................................................................................. page 5-6

Before You Start ......................................................................................... page 6

Installation .................................................................................................. page 8

Drainage ...................................................................................................... page 8

Clearance ................................................................................................... page 9

Unit Location Considerations ..................................................................... page 10

Vent Termination Clearances ..................................................................... page 11

Electrical ..................................................................................................... page 12-14

Dimensions ................................................................................................ page 15

Gas Furnace Specifications ......................................................................... page 16

Sequence of Operations (Gas Heat) ............................................................ page 16

Abnormal Functions ................................................................................... page 17

Installation Guide for Comfort Pack (CPG) Units

High Altitude Operation .............................................................................. page 17-18

Gas Piping, Venting & Pressures ............................................................... page 19-20

Ignition System........................................................................................... page 21

Start up ....................................................................................................... page 22-23

Special Notes for Extremely Cold Weather Areas ........................................ page 23-24

Gas Control Valve ........................................................................................ page 24

Maintenance and Service ............................................................................ page 24-29

Slide Out Furnace Instructions .................................................................... page 29-30

Equipment Specifications ............................................................................ page 31

Air Flow ...................................................................................................... page 32-34

Wiring Diagram .......................................................................................... page 36-38

Trouble Shooting ....................................................................................... page 39-40

Replacement Parts Guide ........................................................................... page 41-42

Warranty .................................................................................................... page 43-45

Notes ......................................................................................................... page 46-47

IMPORTANT NOTE: DO NOT DESTROY OR THROW AWAY THIS MANUAL.

IT SHOULD BE KEPT IN A SAFE PLACE FOR FUTURE REFERENCE.

3

Installation Guide for Comfort Pack (CPG) Units

Example: CPG41838-U

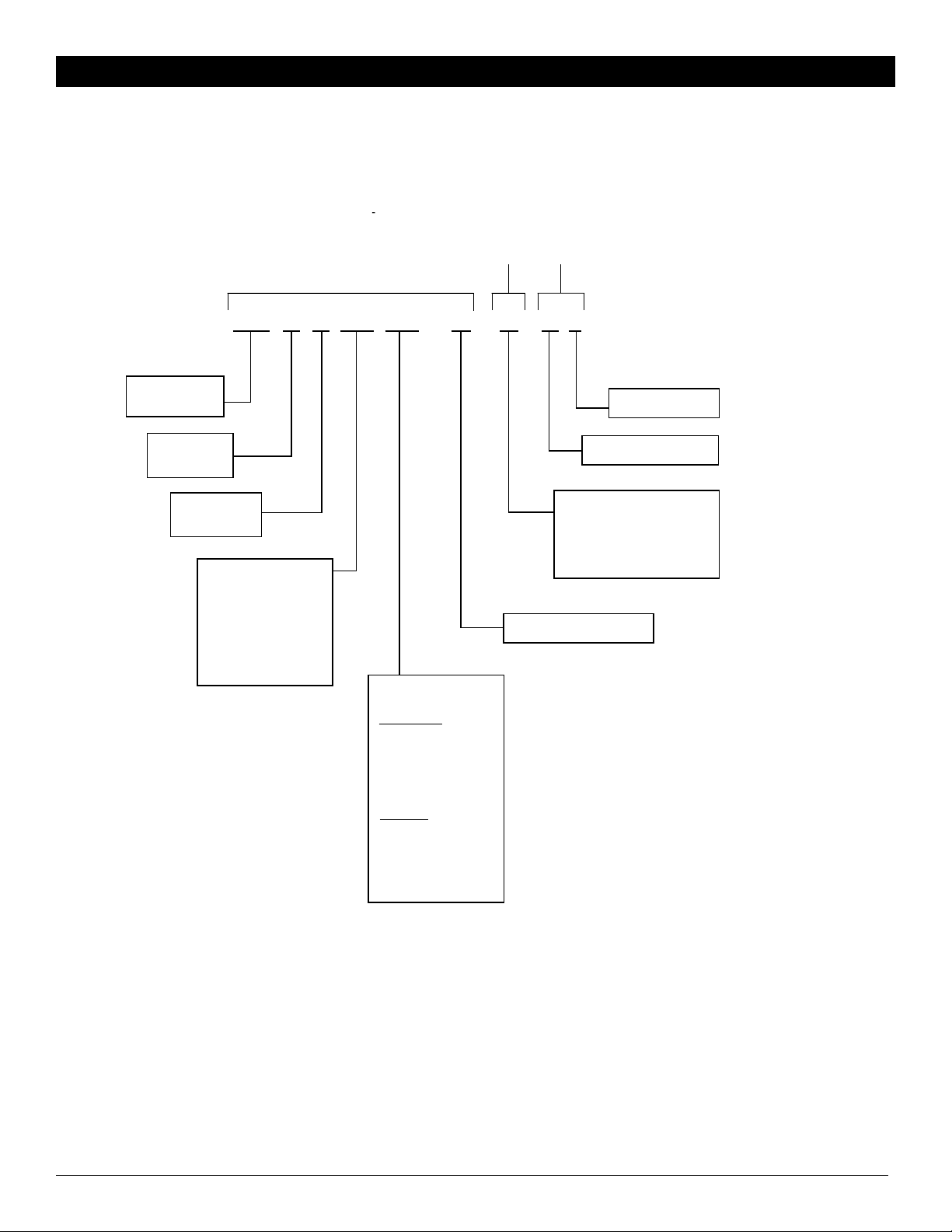

Comfort Pack Nomenclature

Note: Standard units (with no options) will have no letter after the “U” in the name. Example: CPG41838-U

CP=Comfort

Pack

G =Gas

E=Electric

4=410A

Refrigerant

Nominal

Cooling Capacity

12=12,000Btu

18=18,000Btu

24=24,000Btu

30=30,000Btu

Model Number

C P G 4 1 8 3 8 - U

Heating Capacity

Gas Input

28=28,000Btu

38=38,000Btu

51=51,000Btu

64=64,000Btu

Electric

05=5

Kilowatt

Kilowatt

07=7

Kilowatt

10=10

Kilowatt

15=15

Options

(if used)

* *

*

U=Universal Chassis

Last 2 Digits

for factory use

= Edition

*

= Generation

*

A=No Grille

B=Slotted Filter Door

C=No Grille, with

Slotted Filter Door

4

Installation Guide for Comfort Pack (CPG) Units

Safety First!

!

HAZARD INTENSITY LEVELS

1. DANGER: FAILURE TO COMPLY WITH WILL RESULT

IN SEVERE PERSONAL INJURY OR DEATH AND/ OR

PROPERTY DAMAGE.

2. WARNING: FAILURE TO COMPLY COULD RESULT

IN SEVERE PERSONAL INJURY OR DEATH AND/ OR

PROPERTY DAMAGE.

3. CAUTION: FAILURE TO COMPLY COULD RESULT

IN MINOR PERSONAL INJURY AND/OR PROPERTY

DAMAGE.

!

WARNING

FOR YOUR SAFETY, DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS AND LIQUIDS IN THE

VICINITY OF THIS OR ANY OTHER APPLIANCE. SUCH

ACTIONS COULD RESULT IN PROPERTY DAMAGE,

PERSONAL INJURY, OR DEATH.

!

CAUTION

SHOULD OVERHEATING OCCUR, OR THE GAS SUPPLY

FAIL TO SHUT OFF, SHUT OFF THE MANUAL GAS VALVE

TO THE APPLIANCE BEFORE SHUTTING OFF THE

ELECTRICAL SUPPLY.

!

CAUTION

SCROLL COMPRESSORS SHOULD NEVER BE USED TO

EVACUATE THE AIR CONDITIONING SYSTEM. VACUUMS

THIS LOW CAN CAUSE INTERNAL ELECTRICAL ARCING

RESULTING IN A DAMAGED OR FAILED COMPRESSOR.

!

WARNING

THE UNIT MUST BE PERMANENTLY GROUNDED.

FAILURE TO DO SO CAN CAUSE ELECTRICAL SHOCK

RESULTING IN SEVERE PERSONAL INJURY OR DEATH.

“USE COPPER SUPPLY WIRES ONLY”

WARNING

!

IF THE INFORMATION IN THIS MANUAL

IS NOT FOLLOWED EXACTLY, A FIRE

OR EXPLOSION MAY RESULT CAUSING

PROPERTY DAMAGE, PERSONAL INJURY

OR LOSS OF LIFE.

Do NOT store or use gasoline or other ammable

vapors and liquids in the vicinity of this or any other

appliance.

!

WARNING

WARNING: DO NOT USE THIS APPLIANCE IF ANY PART

HAS BEEN UNDER WATER. IMMEDIATELY CALL A

QUALIFIED SERVICE TECHNICIAN TO INSPECT THE

APPLIANCE AND REPLACE ANY GAS CONTROL THAT

HAS BEEN UNDER WATER.

!

WARNING

INSTALLATION AND REPAIR OF THIS UNIT SHOULD

BE PERFORMED ONLY BY INDIVIDUALS MEETING THE

REQUIREMENTS OF AN “ENTRY LEVEL TECHNICIAN”

AS SPECIFIED BY NATIONAL CODES. ATTEMPTING

TO INSTALL OR REPAIR THIS UNIT WITHOUT SUCH

BACKGROUND MAY RESULT IN PRODUCT DAMAGE,

PERSONAL INJURY OR DEATH.

!

WARNING

HIGH VOLTAGE!

DISCONNECT ALL POWER BEFORE SERVING.

FAILURE TO DO SO MAY RESULT IN PROPERTY

DAMAGE, PERSONAL INJURY OR DEATH.

!

CAUTION

USE CARE WHEN HANDLING SCROLL COMPRESSORS.

SOME TEMPERATURES COULD BE HOT!

WHAT TO DO IF YOU SMELL GAS:

• Do NOT try to light any appliance.

• Do NOT touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the re

department.

Installation and service must be performed by a

qualied installer, service agency or the gas supplier.

WARNING

!

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION,

SERVICE, OR MAINTENANCE CAN CAUSE PROPERTY

DAMAGE, PERSONAL INJURY OR LOSS OF LIFE. REFER

TO THE USER’S INFORMATION MANUAL PROVIDED

WITH THIS FURNACE. INSTALLATION AND MATERIALS,

SERVICE MUST BE PERFORMED BY A QUALIFIED

INSTALLER, SERVICE AGENCY OR THE GAS SUPPLIER.

This furnace must be installed in accordance with the

manufacturer’s instructions and local codes. In the absence of

local codes, follow the National Fuel Gas Code, ANSI Z223.1 or

the CAN/CGA-B149 Installation Codes.

To be installed without alteration.

5

Installation Guide for Comfort Pack (CPG) Units

Safety First!

!

WARNING

IF ANY OF THE ORIGINAL WIRE AS SUPPLIED WITH THE

FURNACE MUST BE REPLACED, IT MUST BE REPLACED

WITH WIRING MATERIAL HAVING A TEMPERATURE

RATING OF AT LEAST 90°C.

THIS FURNACE MUST BE INSTALLED SO THERE ARE

PROVISIONS FOR VENTILATING AIR.

SHOULD OVERHEATING OCCUR, OR THE GAS SUPPLY

FAIL TO SHUT OFF, SHUT OFF THE MANUAL GAS

VALVE TO THE FURNACE BEFORE SHUTTING OFF THE

ELECTRICAL SUPPLY.

!

CAUTION

THESE UNITS ARE NOT APPROVED FOR MOBILE

HOME APPLICATIONS. SUCH USE COULD RESULT IN

PROPERTY DAMAGE, PERSONAL INJURY, OR DEATH.

!

WARNING

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO

QUALIFIED, LICENSED SERVICE PERSONNEL FOR

PROPER INSTALLATION, ADJUSTMENT AND OPERATION

OF THIS UNIT. READ THESE INSTRUCTIONS THOROUGHLY

BEFORE ATTEMPTING INSTALLATION OR OPERATION.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY

RESULT IN IMPROPER INSTALLATION, ADJUSTMENT,

SERVICE OR MAINTENANCE POSSIBLY RESULTING

IN FIRE, ELECTRICAL SHOCK, PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

!

WARNING

DO NOT USE OXYGEN TO PURGE LINES OR PRESSURIZE

SYSTEM FOR LEAK TEST. OXYGEN REACTS VIOLENTLY

WITH OIL, WHICH CAN CAUSE AN EXPLOSION

RESULTING IN SEVERE PERSONAL INJURY OR DEATH.

!

WARNING

GAS-FIRED APPLIANCES ARE NOT DESIGNED FOR

USE IN HAZARDOUS ATMOSPHERES CONTAINING

FLAMMABLE VAPORS OR COMBUSTIBLE DUST,

IN ATMOSPHERES CONTAINING CHLORINATED

OR HALOGENATED HYDROCARBONS, OR IN

APPLICATIONS WITH AIRBORNE SILICONE

SUBSTANCES. SEE HAZARD LEVELS BELOW.

Before You Start

This unit is shipped with a cooling chassis installed in the

cabinet. Prior to installing the unit in the wall opening, the

shipping bolts located at the bottom on both sides of the cabinet

must be removed to allow for removal of the cooling chassis.

1/4" hole plugs provided with the unit should be installed in the

holes to prevent air leakage. Shipping bolts are located on both

sides below this sticker:

THE SHIPPING BOLTS MUST BE REMOVED PRIOR

TO INSTALLATION OF THE CABINET TO PERMIT

REMOVAL OF THE CHASSIS. INSTALL THE HOLE

PLUGS PROVIDED.

14299588

This unit is designed and approved for through-the-wall

installation only. The unit must be installed a minimum of 8”

above finish floor. If this unit is installed in a residential

garage, it must be installed so that the ignition source and

burners are located not less than 18 inches (457 mm) above

the floor, and it must be located or protected to avoid physical

damage by vehicles. The entire unit must not be installed

outside. The grille side of the unit should extend 3/4" beyond the

exterior wall to allow moisture that may enter the outdoor

section to drain. The pitch of the internal drain pans toward the

outside will assure proper drainage when the cabinet is installed

level. Masonry walls must have a lintel to support the wall.

The interior of the unit may be installed with zero clearances to

adjacent combustible surfaces. The unit shall not be installed

directly on carpeting, tile or other combustible material,

except wood flooring. In order to be able to remove the chassis,

29" of open area must be left unobstructed in front of the access

panels. The 3/4" O.D. drain pan connection should be connected

to the building drain using the flexible tubing included and

a trap. The secondary drain offers protection from overflow.

The secondary drain feature is piped into the base of the unit

and drains through the weep holes outside. Reconnect 3” piece

of clear flexible tubing to secondary drain on drain pan. Position

secondary drain through grommet of chassis and connect to

flexible tubing (prime trap prior to operating).

The grille side must be kept free of any obstructions that

will reduce or alter the air flow pattern. The unit must be

installed at least 4 feet (1.22 m) from electric meters, gas

meters, regulators, and relief equipment. The vent of the

unit is located at the front grille. Distances from adjacent

public walkways, adjacent buildings, openable windows, and

building openings must be consistent with the National Fuel

Gas Code ANSI Z223.1 and/or CAN/CGA-B149 installation

codes, as well as local codes.

If an optional architectural grille is to be used on standard units,

the stamped and louvered grille provided must be removed.

Consult the factory prior to ordering product(s) that require an

optional architectural grille.

6

Installation Guide for Comfort Pack (CPG) Units

THE CHASSIS BASE AND EVAPORATOR DRAIN PAN, NOT

!

THE INSTALLATION OF THIS APPLIANCE

MUST CONFORM TO THE REQUIREMENTS

OF THE NATIONAL FIRE PROTECTION

ASSOCIATION; THE NATIONAL ELECTRIC

CODE, ANSI/NFPA NO. 70 (LATEST EDITION)

IN THE UNITED STATES; THE CANADIAN

ELECTRICAL CODE PART 1, CSA 22.1 (LATEST

EDITION) IN CANADA; AND ANY STATE OR

PROVINCIAL LAWS OR LOCAL ORDINANCES.

LOCAL AUTHORITIES HAVING JURISDICTION

SHOULD BE CONSULTED BEFORE

INSTALLATION IS MADE. SUCH APPLICABLE

REGULATIONS OR REQUIREMENTS TAKE

PRECEDENCE OVER THE GENERAL

INSTRUCTIONS IN THE MANUAL.

TO REMOVE THE CHASSIS FROM THE CABINET:

TURN OFF POWER TO THE UNIT. REMOVE THE LOWER

ACCESS PANEL FROM THE CABINET. DISCONNECT

THE DRAIN LINE FROM THE EVAPORATOR COIL DRAIN

CONNECTION. DISCONNECT THE SECONDARY DRAIN

FLEXIBLE TUBING & TRAP TO AVOID DAMAGE (PRIME TRAP

WHEN REINSTALLING). DEPRESS AND HOLD THE RELEASE

LATCH ON THE CHASSIS POWER WIRING CONNECTOR

AND UNPLUG IT FROM THE CABINET POWER WIRING

CONNECTOR. DEPRESS AND HOLD THE RELEASE LATCH

ON THE CONTROL WIRING CONNECTOR AND UNPLUG IT

FROM THE CABINET CONTROL WIRING CONNECTOR.

REMOVE THE SCREWS ATTACHING THE CONTROLS

ENCLOSURE TO THE INDOOR COIL COVER. REMOVE THE

SCREWS FROM THE INDOOR BLOWER COVER PLATE.

REMOVE THE PLATE FROM THE UNIT. TEMPORARILY

SECURE THE CHASSIS POWER AND CONTROL WIRING AND

CONNECTORS TO THE TOP OF THE INDOOR COIL COVER

TO PREVENT DAMAGE DURING CHASSIS REMOVAL.

CAREFULLY SLIDE THE CHASSIS OUT OF THE CABINET BY

GRASPING BOTH SIDES OF THE EVAPORATOR COIL DRAIN

PAN AND PULLING TOWARD YOU WHILE KEEPING THE

CHASSIS CENTERED IN THE CABINET. AS THE CHASSIS IS

REMOVED, KEEP THE CHASSIS LEVEL UNTIL THE OUTDOOR

FAN COVER PASSES THE CABINET SEALS. DAMAGE TO

THE CABINET SEALS WILL RESULT IF THE CHASSIS IS

NOT KEPT LEVEL UNTIL THE OUTDOOR FAN COVER HAS

PASSED THE CABINET SEALS. AFTER THE CHASSIS IS

REMOVED, IT SHOULD BE HANDLED USING

CAUTION

BY USING REFRIGERANT PIPING OR THE OUTDOOR FAN

MOUNT. THE BOTTOM OF THE CHASSIS IS NOT SMOOTH

AND WILL DAMAGE FLOORS IF SLID.

TO INSTALL THE CHASSIS INTO THE CABINET:

TURN OFF POWER TO THE UNIT. TEMPORARILY SECURE

THE CHASSIS POWER AND CONTROL WIRING AND TURN

OFF POWER TO THE UNIT. TEMPORARILY SECURE

THE CHASSIS POWER AND CONTROL WIRING AND

CONNECTORS TO THE TOP OF THE INDOOR COIL COVER

TO PREVENT DAMAGE DURING CHASSIS INSTALLATION.

PLACE THE OUTDOOR COIL SECTION OF THE CHASSIS

ONTO THE CABINET RAILS. LIFT THE REAR OF THE CHASSIS

USING THE EVAPORATOR COIL DRAIN PAN SO THAT THE

CHASSIS IS LEVEL AND CENTERED AS IT IS PUSHED IN THE

CABINET. DAMAGE TO THE CABINET SEALS WILL RESULT

IF THE CHASSIS IS NOT KEPT LEVEL UNTIL THE OUTDOOR

FAN COVER HAS PASSED THE CABINET SEALS, AND THE

CHASSIS KEPT CENTERED IN THE CABINET. AFTER THE

CHASSIS IS ALL THE WAY IN THE CABINET, CHECK THAT

THE CHASSIS IS CENTERED IN THE CABINET BY VERIFYING

THAT IT IS IN CONTACT WITH THE CABINET SEALS ON BOTH

SIDES.

INSTALL THE INDOOR BLOWER COVER PLATE AND SECURE

IT WITH SCREWS. INSTALL THE CHASSIS POWER WIRE

CONNECTOR AND THE CONTROL WIRING CONNECTOR

INTO THEIR RESPECTIVE CABINET WIRING CONNECTORS

SO THAT THE CONNECTORS LATCH. POSITION THE

CONTROLS ENCLOSURE AND SECURE IT TO THE INDOOR

COIL COVER WITH SCREWS. CONNECT THE DRAIN LINE TO

THE EVAPORATOR COIL DRAIN CONNECTION. RECONNECT

3” PIECE OF CLEAR FLEXIBLE TUBING TO SECONDARY

DRAIN ON DRAIN PAN. POSITION SECONDARY DRAIN

THROUGH GROMMET OF CHASSIS AND CONNECT TO

FLEXIBLE TUBING (PRIME TRAP PRIOR TO OPERATING).

INSTALL THE LOWER ACCESS PANEL ON THE CABINET.

TURN ON POWER TO THE UNIT.

ALL phases of this installation must comply with NATIONAL,

STATE AND LOCAL CODES. The manufacturer assumes no

responsibility for equipment installed in violation of any code

requirements.

Be sure that the electrical data specified on the unit rating

plate corresponds to what is available at the installation site

and NEC for installation requirements.

This unit MUST be installed in an outside wall for thru-the-wall

installation ONLY.

7

Installation Guide for Comfort Pack (CPG) Units

Be sure that the electrical service provided to the building can

handle the load imposed by the unit.

IMPORTANT — This Document is customer property and is to

remain with this unit. Please refer to service information pack

upon completion of work to register the unit’s warranty. These

instructions do not cover all variations in systems or provide

for every possible contingency to be met in connection with the

installation. Should further information be desired or should

particular problems arise which are not covered sufficiently

for the purchaser’s purposes, the matter should be referred to

your installing dealer or local distributor before contacting the

manufacture.

NOTE: THE UNIT MUST NEVER BE PLACED

ON ITS SIDE OR UPSIDE DOWN AS THE

COMPRESSOR OIL WILL RUN IN THE COOLING

CIRCUIT AND SERIOUSLY DAMAGE THE UNIT.

Installation

NOTE: THESE INSTALLATION AND

MAINTENANCE INSTRUCTIONS SHOULD

BE LEFT WITH THE UNIT FOR FUTURE

REFERENCE.

This unit must be installed in accordance with all applicable

codes. This unit is not to be used for temporary heating of

buildings or structures under construction.

FOR MAXIMUM PERFORMANCE, IT IS IMPERATIVE THAT

THE COOLING CHASSIS AIR DIVIDER BE SEALED TO THE

CABINET AIR SEAL. ANY LEAKAGE WILL ALLOW OUTSIDE

UNCONDITIONED AIR TO INFILTRATE AND MIX WITH THE

CONDITIONED AIR. THIS CONDITION WILL DEGRADE UNIT

PERFORMANCE. ALL UNITS SHOULD BE INSPECTED FOR

THIS CONDITION, AS DURING TRANSPORTATION AND

INSTALLATION THE SEALS CAN BE DISTURBED. IF REQUIRED,

A LIGHT BEAD OF CAULKING IS RECOMMENDED TO SEAL THE

CHASSIS, TO THE AIR SEAL TO ELIMINATE LEAKAGE.

OUTSIDE/UNCONDITIONED AIR MUST NOT BE INTRODUCED

INTO THE RETURN AIR STREAM OF THIS UNIT. THIS

CONDITION WILL ALSO DEGRADE THE PERFORMANCE

OF THE UNIT AND MAY VOID EQUIPMENT WARRANTY.

the possible transmission of sound and vibration, a resilient

material such as rubber or cork should be installed between the

support and the base of the unit. All spaces around the top, sides

and bottom of the exterior grille area should be caulked and

sealed to the wall, making sure that the openings for drainage in

the bottom edge are not blocked.

If the optional wall sleeve is used, caulk the spaces between the

sleeve and the wall. Completely fill the clearance on all sides

between the unit and the wall sleeve with a polyurethane foam

sealant (follow manufacturer’s suggested application manual).

Provide the unit with support inside the building in the area of

the return air opening. Slide the unit into the wall sleeve and

fasten the unit to the sleeve with the five screws provided with

the sleeve.

NOTE: FOR EASE OF INSTALLATION, INSTALL

THE CABINET INTO THE WALL SLEEVE FIRST

WITHOUT THE COOLING CHASSIS. THEN SLIDE

COOLING CHASSIS IN AFTER CABINET IS IN

PLACE.

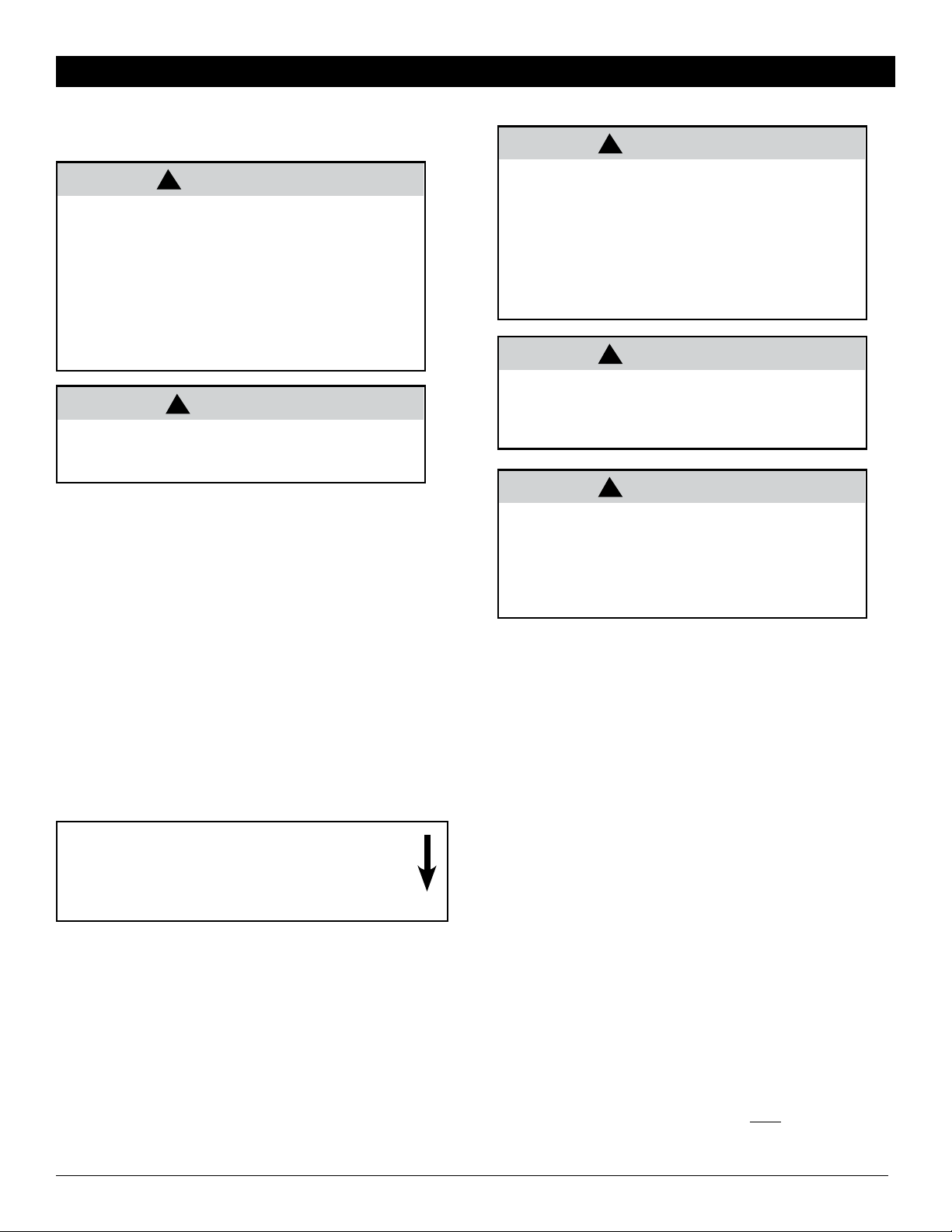

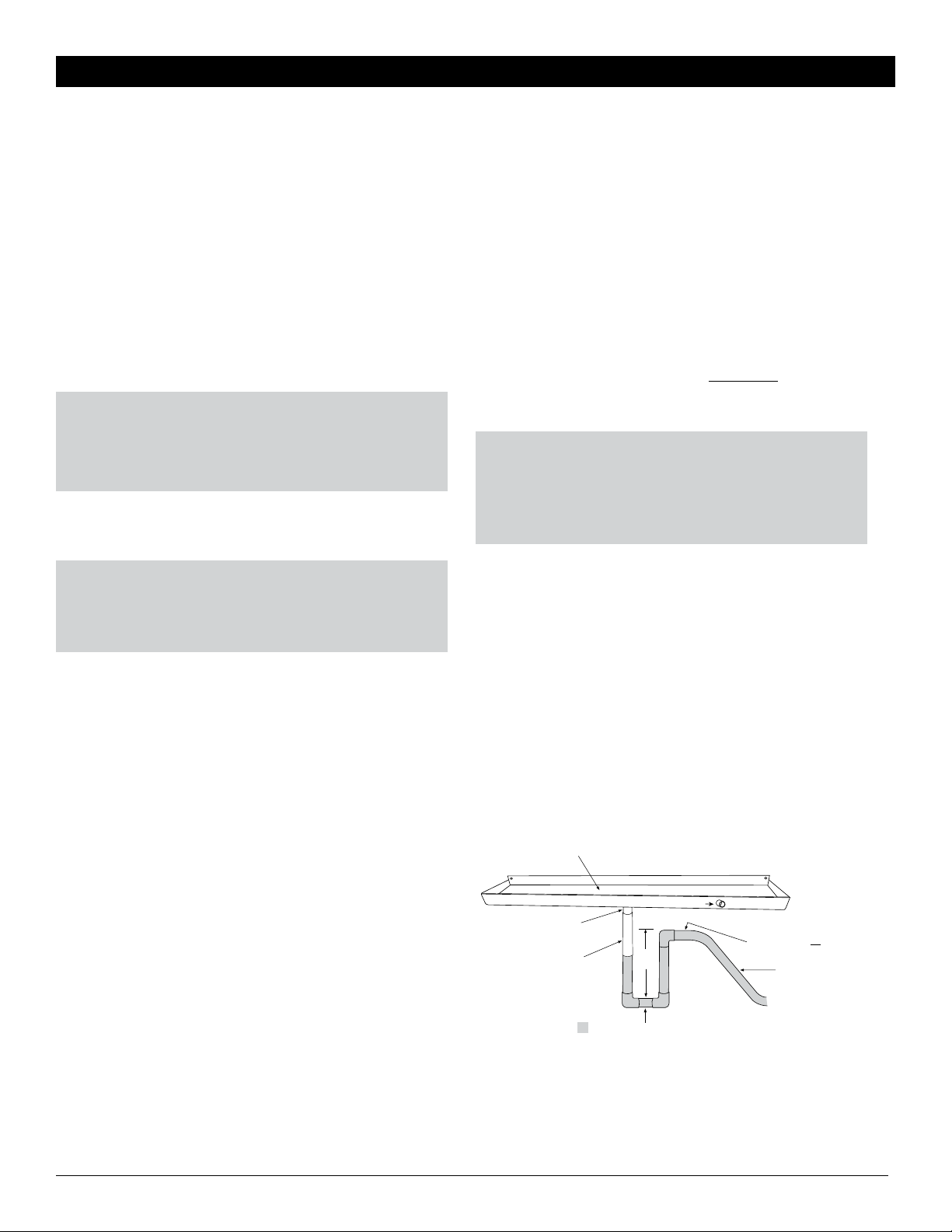

Drainage

The 3/4" I.D. flexible tubing included should be connected to the

Comfort Pack primary drain connection so that it can easily be

disconnected if the cooling chassis must be removed. A trap

at least 2" deep should be provided close to the drain pan. The

tubing should not be higher than the bottom of the unit drain

pan at any point to assure proper drainage and allow chassis

removal. The drain line should pitch downward at least 1" per

10 ft. to an open building drain trap.

Drain Pan

SECONDARY DRAIN TRAP

MUST BE INSTALLED

3/4” O.D. Drain Connection

(Primary Drain)

3/4” I.D. Flexible Tubing Included

2”

min.

Shaded Area Represents Components

Provided and Installed By Others

Highest Point Must Not Be Above

Bottom of Drain Pan

Pitch Downward 1” per 10ft.

The unit should be provided with support inside the building in

the area of the return air opening. The support should be high

enough to allow for return air provisions to the unit. To reduce

8

Loading...

Loading...