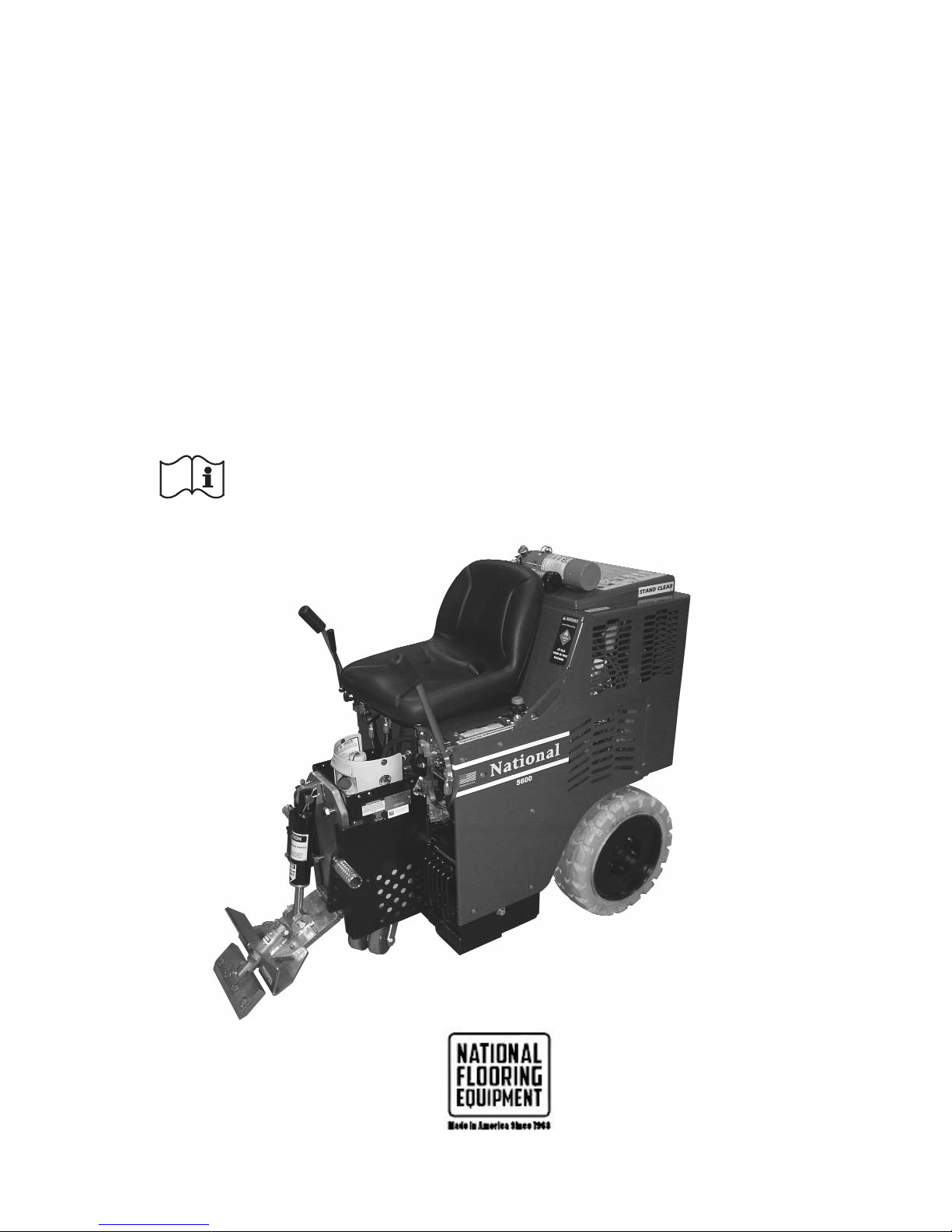

National 5600 Instruction Manual

#5600 PANTHER

®

PROPANE POWERED

FLOOR PREP SYSTEM

INSTRUCTION

MANUAL

Read Manual Before Operating Machine

9250 XYLON AVENUE NORTH • MINNEAPOLIS, MN 55445 • U.S.A.

800-245-0267 • 763-535-8206 • FAX 763-535-8255 • FAX 800-648-7124

WEB SITE: www.nationalequipment.com • E-MAIL: info@nationalequipment.com

National

Flooring Equipment, Inc.

Page 2

TABLE OF CONTENTS

Table of Contents ....................................................................................................2-5

Hydraulic Safe Operation ........................................................................................6-7

A. Maintaining A Safe Work Environment ................................................................6

B. Pressure............................................................................................................6-7

C. Flammability ........................................................................................................7

D. Hydraulic Fluid......................................................................................................7

Rules for Safe Operation........................................................................................8-10

A. General Rules ..................................................................................................8-9

B. Characteristics of a Defensive Operator ............................................................10

Safety Instructions/ Precautions ..........................................................................11-12

Battery Safe Operation ..............................................................................................13

A. First Aid ..............................................................................................................13

B. Ventilation ..........................................................................................................13

Motor Safe Operation ................................................................................................14

Troubleshooting....................................................................................................15-16

Features/Specifications ........................................................................................17-18

A. Vibration/Sound Data ........................................................................................18

Operating Controls ..............................................................................................19-22

A. Start-Up Procedure ............................................................................................19

B. Throttle Control ..................................................................................................19

C. Hydraulic Levers ..........................................................................................19-20

D. Seat Switch ...................................................................................................... 20

E . Cylinder Lift ........................................................................................................20

F . Shut-Down Mode ..............................................................................................21

G. Machine Storage ..............................................................................................21

H . Changing Propane Tank ....................................................................................22

i. Carbon Monoxide Information and Warnings ............................................22

Operational Tips ........................................................................................................23

A. Caster ................................................................................................................23

B. Foot Peg ............................................................................................................23

C. Seat....................................................................................................................23

D. Disarm Machine ................................................................................................23

E. Turn Machine Off................................................................................................23

F. Leakage ............................................................................................................23

G. Angle of the Head is Set Steep ..........................................................................23

H. Raising or Lowering the Slide Plate ..................................................................23

Page 3

TABLE OF CONTENTS

Loading/Unloading ..............................................................................................24-25

A. Dock Heights....................................................................................................24

B. Power-Gate ......................................................................................................24

C. Ramps ..............................................................................................................24

D. Forklift Cups ....................................................................................................25

E. Winches ..........................................................................................................25

F. Transporting ....................................................................................................25

G. Wheel Chocks ..................................................................................................25

Center of Gravity ......................................................................................................26

Job Site Movement ..............................................................................................27-28

A. Taping Wheels..................................................................................................27

B. Leap Frogging Boards......................................................................................27

C. Palletizing ........................................................................................................27

D. Front Wheel Assembly ....................................................................................27

E. To Move Machine Without Power ....................................................................28

F. Moving Machine on Caster ..............................................................................28

Wheel Sizes ..............................................................................................................29

A. Wheel Size ......................................................................................................29

Cutting Heads and Blades....................................................................................30-32

A. Dialing in the Machine......................................................................................30

B. Saving Time with Extra Cutting Heads ............................................................30

C. Adjusting Slide Plate and Cutting Head ..........................................................30

D. Shear Point ......................................................................................................30

E. Weight vs. Sharpness ......................................................................................31

F. Cutting Head Angle ..........................................................................................31

G. Steep Cutting Head Angle................................................................................31

H. Swivel Head ....................................................................................................31

I. Cutting Head Insertion ....................................................................................31

J. Shank Blade Insertion ......................................................................................32

K. Blade Setting....................................................................................................32

L. Self-Scoring Blades..........................................................................................32

M. Blade Insertion or Blade Changing ..................................................................32

Blade Application/Set-Up ....................................................................................33-35

A. Ceramic Set-Up..................................................................................................33

B. Wood Set-Up......................................................................................................33

C. Secondary Backing Carpet Set-Up ....................................................................33

D. Foam Back Carpet Set-Up ................................................................................33

Page 4

TABLE OF CONTENTS

E. Double Stick Carpet Set-Up ..............................................................................33

F. VCT Tile Set-Up ................................................................................................33

G. Rubber Tile Set-Up ............................................................................................33

H. Re-Scraping Set-Up ..........................................................................................34

I. Thin Coating Set-Up ..........................................................................................34

J. Working Over Concrete......................................................................................34

K. Working Over Wood ..........................................................................................34

L. Working Over Soft Sub-Floor ............................................................................34

M. Cross Room Ditching ........................................................................................35

N. Checker Board Ditching ....................................................................................35

Blades ..................................................................................................................36-39

A. Types of Blades..................................................................................................36

B. Blade Sharpening ..............................................................................................37

C. Self-Scoring Blade Sharpening ..........................................................................37

D. Carbide Tipped Blade Sharpening ....................................................................37

E. Blade Selection Chart ..................................................................................38-39

Machine Maintenance ..........................................................................................40-46

A. Maintenance & Inspection List ..........................................................................40

B. Slide Plate ........................................................................................................41

C. Lower Cutting Head Support..............................................................................41

D. Leak Maintenance..............................................................................................41

E. Oil Level & Hydraulic Oil Change Out ................................................................42

F. Hydraulic Cylinder Change Out..........................................................................42

G. Engine Oil Change Out ......................................................................................43

H. Hose Change Out ..............................................................................................43

I. Foot Peg ............................................................................................................43

J. Pump Change Out ............................................................................................43

K. Valve Change Out ..............................................................................................43

L. Engine Change Out............................................................................................44

M. Wheel Motor Change Out ..................................................................................44

N. Wheel Changing ................................................................................................44

O. Changing Hydraulic Fluid Filter ........................................................................45

P. Changing Engine Air Filter ................................................................................45

Q. Caster Maintenance ..........................................................................................45

R. Engine Maintenance ..........................................................................................45

S. Switches ............................................................................................................46

T. Seat Replacement..............................................................................................46

U. Debris Deflector Mounting Instructions ..............................................................47

Page 5

TABLE OF CONTENTS

Complete Parts List ..............................................................................................48-52

Part Numbers and Diagrams ..............................................................................53-66

A. External Parts ..........................................................................................................53

B. External Parts ....................................................................................................54

C. Beeper & Hood Parts ........................................................................................55

D. Gear Pump Parts................................................................................................56

E. Wheel Parts........................................................................................................57

F. Control Lever Parts ..........................................................................................58

G. Single Spool & Hose Parts ................................................................................59

H. Double Spool & Hose Parts................................................................................60

I. Filter & Tank Parts ..............................................................................................61

J. Cylinder Parts.................................................................................................... 62

K. Slide Plate/Deflector, Caster & Foot Peg Parts ..................................................63

L. Propane Tank Parts............................................................................................64

M. Engine Battery....................................................................................................65

N. Battery/Weights ..................................................................................................66

Labels..................................................................................................................67-68

Accessories ..............................................................................................................69

Blades & Cutting Heads ......................................................................................70-71

Wiring Diagrams ......................................................................................................72

Material Safety Data............................................................................................73-78

Fire Extinguisher Material Safety Data................................................................79-85

Guarantee ................................................................................................................86

Return Sheet ............................................................................................................87

Blade Order Form ..............................................................................................88-89

Kawasaki Engine Manual ....................................................................................Insert

Page 6

MAINTAINING A SAFE WORK ENVIRONMENT

Establishing a safe working environment in and around your hydraulic equipment is just common sense.

The easiest and most effective way to avoid problems is to make sure associates understand their

equipment, know how to operate it safely and recognize the danger it represents if handled carelessly. A

few things you must be aware of include:

1. PRESSURE: Hydraulic fluid under pressure is dangerous and can cause serious injury.

2. FLAMMABILITY: When ignited, some hydraulic fluids can explode and/or cause fires.

3. MECHANICAL: Hydraulic fluid creates movement, which causes parts of your equipment to move or

rotate. Always be aware of what you are doing.

4. MOISTURE: Use caution when operating in wet or high moisture conditions. Make sure all electrical

fittings, switches, cords plus strain reliefs are in good condition. Always unplug when not in use and

when doing any service work.

5. ELECTRICAL: Faulty wiring can also be an electrical hazard. A regular preventive maintenance

program should always include a wiring check. Unplug batteries and/or charger before servicing.

6. TEMPERATURE: Because this machine operates at a relatively low pressure, overheating is not

common. If surface of tank becomes too hot to touch by hand (above 130º), shut off machine and

allow to cool off.

PRESSURE

Our system runs at or below 2,000 psi. Never look for a leak when unit is under pressure. Using your

hand could cause serious injury. A few common ways to encounter hydraulic fluid under pressure include:

1. PINHOLE: Fluid under pressure can cause serious injury. It can be almost invisible escaping from a

pinhole, and it can pierce the skin into the body. Do not touch a pressurized hydraulic hose

assembly with any part of your body. If fluid punctures the skin, even if no pain is felt, a serious

emergency exists. Obtain medical assistance immediately. Failure to do so can result in loss of the

injured part or death.

2. LEAK: Keep fittings and hoses tight. Only check and service when not under pressure. Leaking

hydraulic fluid is not only unsightly, it’s hazardous. In addition to making workplace floors slippery and

dangerous, leaks also contaminate the environment. Before cleaning an oil spill, always check EPA,

state and local regulations.

LEAK AT THREAD END/SEAT

Problem: Coupling leaks at thread or seat. This may be caused by any of the following:

a. Missing or damaged O -rings.

b. Damaged threads or seat angle.

c. Thread alignment.

d. Incompatible thread ends or seat angles.

e. Over or under torquing.

Solution: Remove the connection and inspect.

1. Certain couplings require the use of an O-ring. If it is missing, replace it. If an O-ring is used,

check for damage caused by installation or possible material breakdown from heat or fluid

incompatibility. Alternative O-ring materials may be required. Replace if necessary.

2. Check the threads and/or seat angle for damage that may have occurred prior to or during

installation. Any ding or burr may be a potential leak path. Replace if necessary.

HYDRAULIC SAFE OPERATION

Page 7

HYDRAULIC SAFE OPERATION

PRESSURE (continued)

3. If the coupling was misaligned during installation, threads may have been damaged. Replace

and carefully install.

4. Over torquing of a threaded connection can stretch and damage threads and mating seat

angles. Over torquing can also damage the staking area of the nut. Under torquing does not

allow proper sealing.

3. BURST: Whether due to improper selection or damage, a ruptured hose can cause injury. If it bursts,

a worker can be burned, cut, injected or may slip and fall.

4. COUPLING BLOW-OFF: If the assembly is not properly made or installed, the coupling could come

off and hit or spray a worker, possibly resulting in serious injury. Never operate machine without

guards.

FLAMMABILITY

With the exception of those comprised primarily of water, all hydraulic fluid is flammable when exposed to

the proper conditions (including many “fire-resistant” hydraulic fluids).

Leaking pressurized hydraulic fluids may develop a mist or fine spray that can flash or explode upon contact

with a cause of ignition. These explosions can be very severe and could result in serious injury or death.

Precautions should be taken to eliminate all ignition sources from contact with escaping fluids, sprays or

mists resulting from hydraulic failures. Sources of ignition could be electrical discharges (sparks), open

flames, extremely high temperatures, sparks caused by metal -to -metal contact, etc.

HYDRAULIC FLUID

Only use Texaco Rando 46 Hydraulic Oil or Compatible Fluid like IS032. Non-compatible fluids could

cause damage to unit or serious injury.

CAUTION: Never check for leaks over hose or hydraulic connections. Instead, use a piece of

cardboard to locate a pressurized leak. For drips (low pressure leaks), use a rag to clean the area and

determine where the leak originates.

CAUTION: Never touch a pressurized hose assembly. Shut down the hydraulic system before

checking hose temperature.

WARNING: When using electric tools, always follow basic safety precautions to reduce the risk of

electric shock and personal injury.

Page 8

RULES FOR SAFE OPERATION

READ AND SAVE ALL INSTRUCTIONS FOR FUTURE USE. Before use, be sure everyone

operating this equipment reads and understands this manual as well as any labels packaged with or

attached to the machine and components and view the instruction video. Extra copies of the manual and

video are available. In cases where personnel have an insufficient knowledge of the English language,

proper training must be obtained before using the 5600 machine.

1. KNOW YOUR EQUIPMENT: Read this manual and view instruction video carefully to learn

equipment applications and limitations as well as potential hazards associated with this type of

equipment.

2. DISARM MACHINE: Remove cutting head or drop cutting head to the floor when machine is not

in use.

3. DO NOT “SIDE HILL” MACHINE: See Page 24 & 26.

4 . AVOID DANGEROUS ENVIRONMENTS: Do not use in rain, damp or wet locations, or in the

presence of explosive atmospheres (gaseous fumes, dust or flammable materials). Remove materials

or debris that may be ignited by sparks.

5. KEEP WORK AREA CLEAN AND WELL LIT: Cluttered, dark work areas invite accidents.

6. DRESS PROPERLY: Do not wear loose clothing. These may be caught in moving parts. Keep hands

and gloves away from moving parts.

7. USE SAFETY EQUIPMENT: Everyone in the work area should wear safety goggles or glasses

complying with current safety standards. Wear hearing protection during extended use and a dust

mask for dusty operations. Hard hats, face shields, safety shoes, etc. should be worn when specified

or necessary.

8. KEEP BYSTANDERS AWAY: Children and bystanders should be kept at a safe distance from the

work area to avoid distracting the operator. Operator should be aware of who is around them and

their proximity.

9. PROTECT OTHERS IN THE WORK AREA: Provide barriers or shields as needed to protect others

from debris and machine operation.

10. USE PROPER ACCESSORIES: Using accessories that are not recommended may be hazardous.

Be sure accessories are properly installed and maintained. Do not delete a guard or other safety

device when installing an accessory, attachment or servicing.

11. CHECK FOR DAMAGED PARTS: Inspect guards and other parts before use. Check for

misalignment, binding of moving parts, improper mounting, broken parts and any other conditions that

may affect operation. If abnormal noise or vibration occurs, turn the tool off immediately and have the

problem corrected before further use. Do not use damaged equipment. Tag damaged machine “DO

NOT USE” until repaired. A guard or other damaged parts should be properly repaired or replaced.

For all repairs, insist on only identical National replacement parts.

12. REMOVE ALL ADJUSTING KEYS AND WRENCHES: Make a habit of checking the adjusting keys,

wrenches, etc. are removed from the tool before turning it on.

WARNING: Disarm machine when not in use. Remove Cutting Head or lower Cutting Head to the

floor. When exiting machine (getting off machine), remove lower Cutting Head to the floor. When

transporting machine around job site, remove Cutting Head. Failure to follow these instructions could

cause severe bodily injury.

Page 9

RULES FOR SAFE OPERATION

13. GUARD AGAINST ELECTRIC SHOCK: Prevent body contact with grounded surfaces such as pipes,

battery plug connection, radiators, ranges and refrigerators. When scoring or making cuts, always

check the work area for hidden wires or pipes to reduce shock hazards.

14. AVOID ACCIDENTAL STARTING: Be sure equipment is turned off before plugging it in. Do not use

if the power switch does not turn the machine on and off properly.

15. DO NOT FORCE EQUIPMENT: Equipment will perform best at the rate for which it was designed.

Excessive force only causes operator fatigue, increased wear and reduced control.

16. KEEP HANDS AND FEET AWAY FROM ALL CUTTING EDGES AND MOVING PARTS.

17. WEAR GLOVES WHEN CHANGING BLADES.

18. DO NOT OVERREACH. MAINTAIN CONTROL: Stay properly seated. Keep proper footing and

balance at all times. Maintain a firm grip.

19. STAY ALERT: Watch what you are doing, and use common sense. Do not use when you are tired,

distracted or under the influence of drugs, alcohol or any medication causing decreased control.

20. STARTING MACHINE: Insure hydraulic levers are “centered” before turning on ignition switch.

Throttle should be pushed all the way down.

21. SHUT-DOWN MODE: Machine must be in shut-down mode.

22. MAINTAIN EQUIPMENT CAREFULLY: Keep control levers dry, clean and free from oil and grease.

Keep cutting edges sharp and clean. Follow instructions for lubricating and changing accessories.

Periodically inspect battery, charger’s and all plug connections. Have damaged parts repaired or

replaced.

23. STORE IDLE EQUIPMENT: When not in use, store in a dry, secured place. Keep away

from children. Remove blade or keep blade lowered to the floor (disarm machine).

24. MAINTAIN LABELS AND NAME PLATES: These carry important information. If unreadable or

missing, contact National for a free replacement.

25. MACHINE IS HEAVY, DO NOT DROP: Counter weights are heavy. Take caution when removing

or reassembling. Take caution when moving or transporting.

26. COMMERCIAL APPLICATION: Machine is intended for commercial use only.

27. MACHINE IS EQUIPPED WITH A FIRE EXTINGUISHER: Be aware of its proximity and how to

properly use it.

28. PROPER VENTILATION: CARBON MONOXIDE IS A VERY TOXIC, COLORLESS AND

ODORLESS GAS. When engines operate in enclosed spaces, such as warehouses, buildings under

construction, or tunnels, carbon monoxide can accumulate quickly and reach concentrations that are

dangerous for humans. It causes headaches, dizziness, lethargy and death. CO is usually the major

concern whenever LPG engines are used indoors

WARNING: Exposure to dust may cause respiratory ailments. Use approved NIOSH or OSHA

respirators, safety glasses or face shields, gloves and protective clothing. Provide adequate ventilation

to eliminate dust, or to maintain dust level below the Threshold Limit Value for nuisance dust as

classified by OSHA.

WARNING: Ventilation is required in confined work environments.

Page 10

RULES FOR SAFE OPERATION

CHARACTERISTICS OF A DEFENSIVE OPERATOR

• Education

• Alert

• Skills

• Judgment

• Common Sense

• Recognizes the Hazards

• Understands the Defense

• Acts Correctly

A GOOD OPERATOR IS A “DEFENSIVE” OPERATOR

QUALITIES

Education: Learns about the machine and the environment.

Alert: Stays alert at all timesnever lets guard down.

Skills: Only performs duties he/she is qualified to do. Always tries to improve.

Judgment: Plays it safe. Doesn’t take chances.

Common Sense: Does the right thing without having to be told. Applies knowledge.

Recognizes the Hazards: Maintains alertness. Anticipates danger.

Understands the Defense: Knows that safety isn’t an accidentit’s a thinking person’s choice.

Acts Correctly: Does not cave in to pure pressure. Performs correctly when supervised or not.

USE CARBON MONOXIDE DETECTOR WHEN OPERATING MACHINE

Included with the 5600 are a 75007 Lapel CO Monitor and a 75008 Clip. It is recommended that the

operator and anyone in the working vicinity wear the detector. Failure to do so could cause bodily injury

and/or death. The use of detectors helps to verify if work area is safe from Carbon Monoxide poisoning.

The detector has an adhesive strip on the back for mounting or can be worn with the included clip. It can

detect as little as 100ppm (part per million) carbon monoxide gas at approximate relative humidity range

of 33 to 50%. If the humidity is very high it can detect concentrations as low as 20ppm. The presence of

CO will change the impregnated silica color change from red to red/brown and then to gray/black as the

concentration levels increase. Once the detector is exposed to fresh air, it will return back to red. Shelf

life in an unopened pack is approximately two to three years (expiration date is visible through unopened

package on the back). Once opened it should be replaced approximately every ninety days. Write date

opened in provided area on the front of the detector. Read further user directions on the back of the

detector.

Page 11

• Only qualified, trained personnel should operate this unit.

• Loose or damaged parts should be replaced immediately. Failure to do so could cause equipment

damage or serious injury.

• Switches and levers should be inspected. (Disconnect battery charger from wall outlet and machine

from batteries before repairs to prevent electrical shock). Do not use if defective. Power on/off switch

should return to off when lever is released.

• Power control box, motor and switches should be completely enclosed at all times with no

exposed wiring.

• Disconnect negative lead before servicing. Failure to do so can cause damage to electrical

system and/or electrical shock.

• Only use National components. Failure to do so could cause damage or serious injury.

• Always be aware of support personnel and their proximity when in operation. Block off work area.

• Support personnel should never stand next to machine, in front of or behind machine while machine is

running. Failure to do so could cause serious bodily injury or death.

• Manual should be kept with machine in supplied holder for access by operator at all times.

• Always wear eye protection when running machine.

• Never defeat switches or guards.

• Remove blade when machine is not in use and/or lower cutting head to floor. Failure to do so could

cause serious bodily injury.

• Wear gloves when changing blades. Always shut machine off when changing blades.

SAFETY INSTRUCTIONS/ PRECAUTIONS

WARNING: Know and understand before operation. Failure to do so could cause damage to

equipment or bodily injury.

Read and understand operators instruction manual and instructional video

before operating this equipment.

WARNING: Failure to follow any of the above instructions could cause damage to machine,

damage to property or serious bodily injury or death.

The 5600 Propane Ride-On should be inspected for damage and defects at least once during

every working shift. Starting and stopping procedures must be followed in accordance with the

Operating Instructions. Before starting the 5600 Propane Ride-On, be sure that no person is

likely to be endangered by the 5600 Propane Ride-On movement.

WARNING: DANGER-Engine exhaust gases contain poisonous carbon monoxide. Carbon

monoxide is odorless and colorless and can cause injury or death if inhaled. Do not use equipment

indoors without adequate ventilation. Refer to OSHA guidelines and regulations concerning maximum

levels of exposure to carbon monoxide gases and other hazards associated with using internal

combustion engines.

Page 12

SAFETY INSTRUCTIONS/ PRECAUTIONS

Read and understand operators instruction manual and instructional video

before operating this equipment.

The 5600 Propane Ride-On has been equipped with a safety switch under the seat, which requires the

operator to be seated before the 5600 can be operated. Do not attempt the start-up procedure with out

being seated on the machine.

WARNING: Bypassing this or any other safety device may cause property damage and/or bodily injury.

Before carrying out maintenance or repair work:

•Let the engine and the exhaust system, cool down;

•Remove all traces of oil, combustible fuel or cleaning fluids from the scraper, its connections

and fittings in particular;

•Do not use any aggressive cleaning products;

•Be sure that all cleaning rags are fiber free;

•Retighten all loose fittings found during maintenance and repair work.

GASES, DUST, STEAM, SMOKE

Do not weld, flame cut or perform grinding work on the 5600 Propane Ride-On without written

authorization from the manufacturer. The danger of fire or explosion exists when work of this nature is

done. Begin maintenance work only when the machine is in Shut Down Mode (turned off).

SAFETY PRECAUTIONS (OPERATOR/PERSONNEL TRAINING)

Operating and maintenance personnel must verify availability of appropriate fire protection equipment, be

properly trained in the use of the equipment and know how to contact the Fire Department or Emergency

Medical Service if needed.

Page 13

BATTERY SAFE OPERATION

CAUTION - PRECAUTIONS:

a) Contact with electrolytic acid can cause skin irritation and damage clothing. Wear a protective

apron, gloves and goggles when working with batteries. Have plenty of fresh water and soap

nearby in case battery acid contacts your skin, clothing, or eyes.

b) Remove personal metal items such as bracelets, rings, necklaces, and watches when working

with batteries. A battery can produce a short circuit current sufficient enough to weld metal

objects, causing severe burns.

c) Never smoke or allow a spark or flame in the vicinity of the batteries. Caution must be taken

to reduce the risk of dropping metal tools onto the battery. A spark or short circuit may result in

an explosion.

FIRST AID

Immediately flush eyes with cold, fresh water for a minimum of 10 minutes if electrolytic acid comes in

contact with eyes. Seek professional medical attention.

VENTILATION

Blocking louvers or air flow perforations of convection or fan cooled battery chargers and/or machine will

result in damage to the unit. When installing the unit leave space for air to flow freely through the intake

and discharge louvers and/or perforations.

Page 14

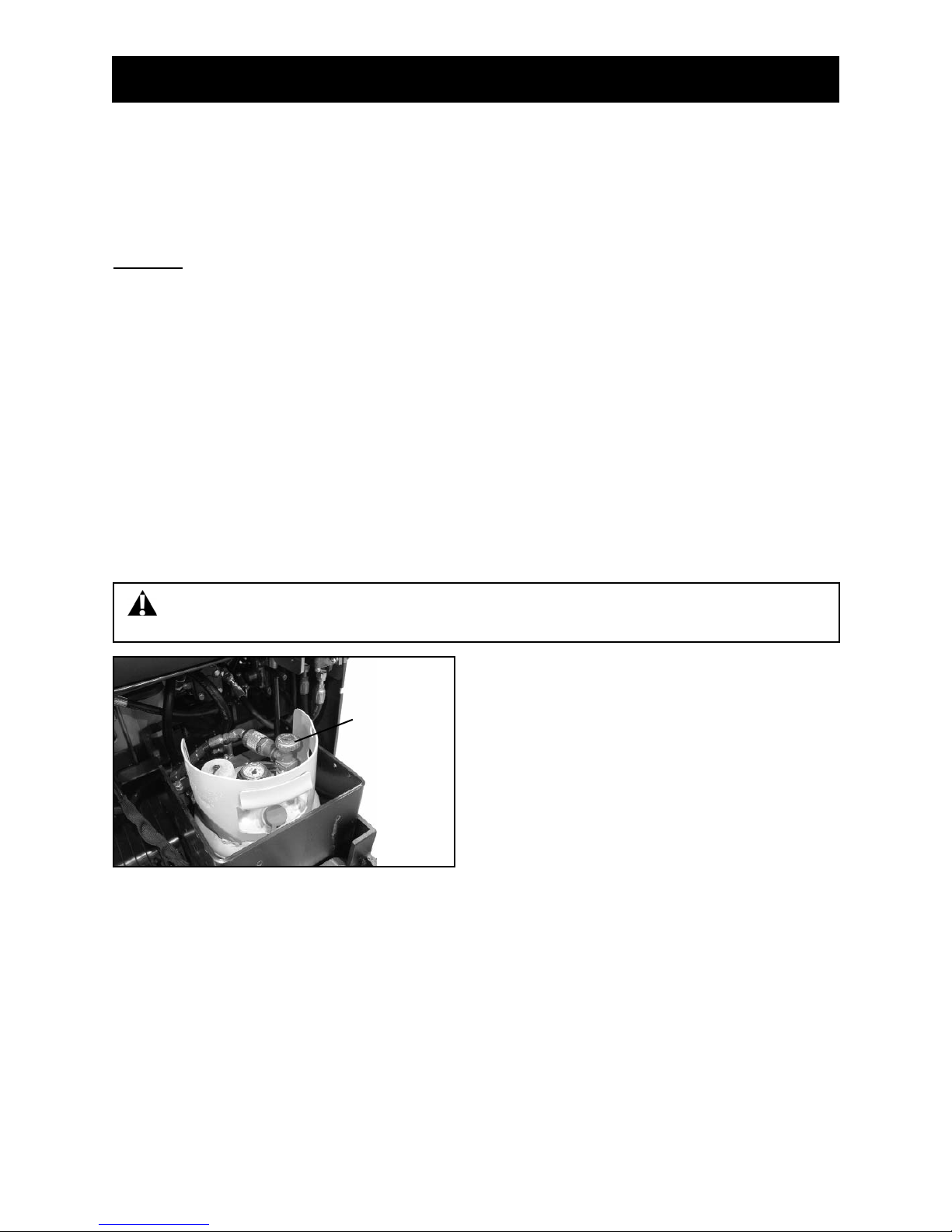

MOTOR SAFE OPERATION

CAUTION - PRECAUTIONS: Before servicing, allow engine to cool down. Failure to do so

could cause bodily injury.

CHECK FLUID LEVELS

Check oil & coolant levels before operating.

CHECK FOR LEAKS

Inspect propane gas line for leaks.

Page 15

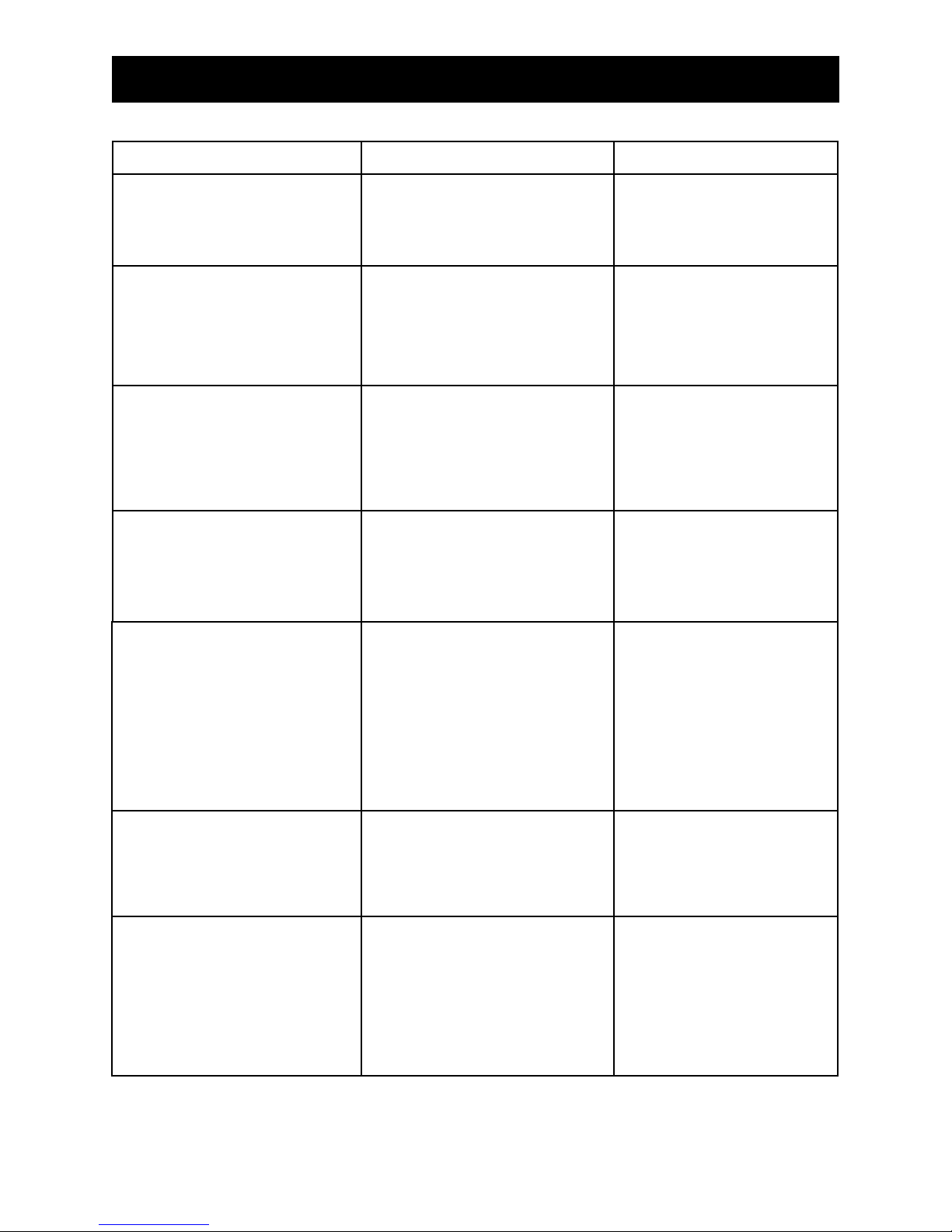

TROUBLESHOOTING

Trouble Possible Cause Remedy

1. The scraper does not work

when the pump is generating

pressure

a. Severe blockage in wheel

drive motor hoses

b. Wheel drive motors defective

a. Check hoses for blockage

and replace hose if necessary

b. Call National Service

Center

2. The hoses are worn a. Hoses rubbing on components

b. Hose has been exposed to

poor environmental conditions

a. Replace and protect the

hose

b. Replace hose and protect

equipment from poor

conditions

3. The machine makes an

unusually loud hissing or

whistling noise

a. Fluid is passing over relief

valves

b. Air in hydraulic circuit

a. If noise is continuous, call

a National Service Center

b. See Trouble 7 and 9

4. Oil deposits are evident on the

inner sides of the driving wheels

a. The shaft seals of the wheel

motors worn out

b. Hose fittings are loose

a. Have the shaft seals

replaced by a specialist

b. Tighten hose fitting.

Replace hose or fitting if

necessary

5. The machine has no power

with the engine running

at 3500 rpm.

a. Check valve adjustment

b. Check hoses for leaks

a & b. Contact National

Service Center immediately

Do not operate in this

condition!!

6. The scraper does not react

when the motion control joystick

is actuated

See possible cause 5a and 5b See remedy 5a and 5b

7. The hydraulic oil is very

cloudy. Excessive air in the

circuit can cause severe

damage to pump. Stop

machine and repair

immediately!

a. Water has entered

hydraulic tank

b. Oil is contaminated with dirt

c. Air has entered the circuit

a. Repair tank if necessary.

Drain and clean tank

thoroughly. Change oil.

b. Drain and clean tank

thoroughly. Change oil.

c. Contact National

Service Center

Page 16

TROUBLESHOOTING

Trouble Possible Cause Remedy

8. Excessive amount of oil

on chassis

a. Outside oil spilled on

chassis

b. Loose hose connections

c. Loose tank fittings

a. Clean machine thoroughly

and see if oil returns

b. Check for loose hoses

c. Check for loose fittings

9. Hydraulic oil and/or oil foam

leaking from oil tank. Excessive

air in the circuit can cause

severe damage to piston pumps.

Stop machine and repair

immediately!

a. Oil level too high

b. Oil level too low

c. Vent in return filter blocked

d. Air getting into hydraulic

circuit

a. Drain tank to correct level

b. Fill tank to correct level

c. Check for blockage

d. Check all suction lines.

Tighten all hose connections

and fittings

10. Engine dies or cuts out a. Fuel tank is empty

b. Oil is low

c. Operator not seated properly

a. Change or fill fuel tank

b. Fill oil to proper level

c. Position on seat correctly

11. Red ignition light stays on a. Oil is Low

b. Machine is overheating

a. Fill engine oil to proper level

b. Let engine cool. Add coolant

to proper level

12. Machine doesn’t start a. Machine needs to be primed a.Press primer button once &

restart machine

WARNING: DO NOT work with machine at idle. Doing so will cause damage to machine!

Page 17

FEATURES/SPECIFICATIONS

SPECIFICATIONS #5600

Width: 24½''

Height with Seat: 46"

Length without Jaw: 52''

Weight (machine only): 1116 lbs.

Added Weight:

Pocket Weight: 464 lbs.

Rear Weight: 83 lbs.

Gross Weight: 1663

Speed: Up to 150 feet

per minute

MOTOR INFORMATION (#5600)

RPM: 2950

Volts: 12 Volt System

HP: 20

Amps-Full Load: NA

Continuous Duty NA

Trailer Hitch

WARNING: Trailer hitch is only intended

to move small trailers on the job site.

Fuel Tank

Control Lever

Forward/Reverse

Neutral Break

Removable

Swivel

Cutting Head

Front Swivel

Caster

Adjustable

Foot Rest

(both sides)

Fork Lift

Cups

(both sides)

Extra weight

compartment

(both sides)

Lower Cutting

Head Support

#5600

Adjustable

Slide Plate

Cutting Head

Cylinder Lift

Fire Extinguisher

Page 18

FEATURES/SPECIFICATIONS

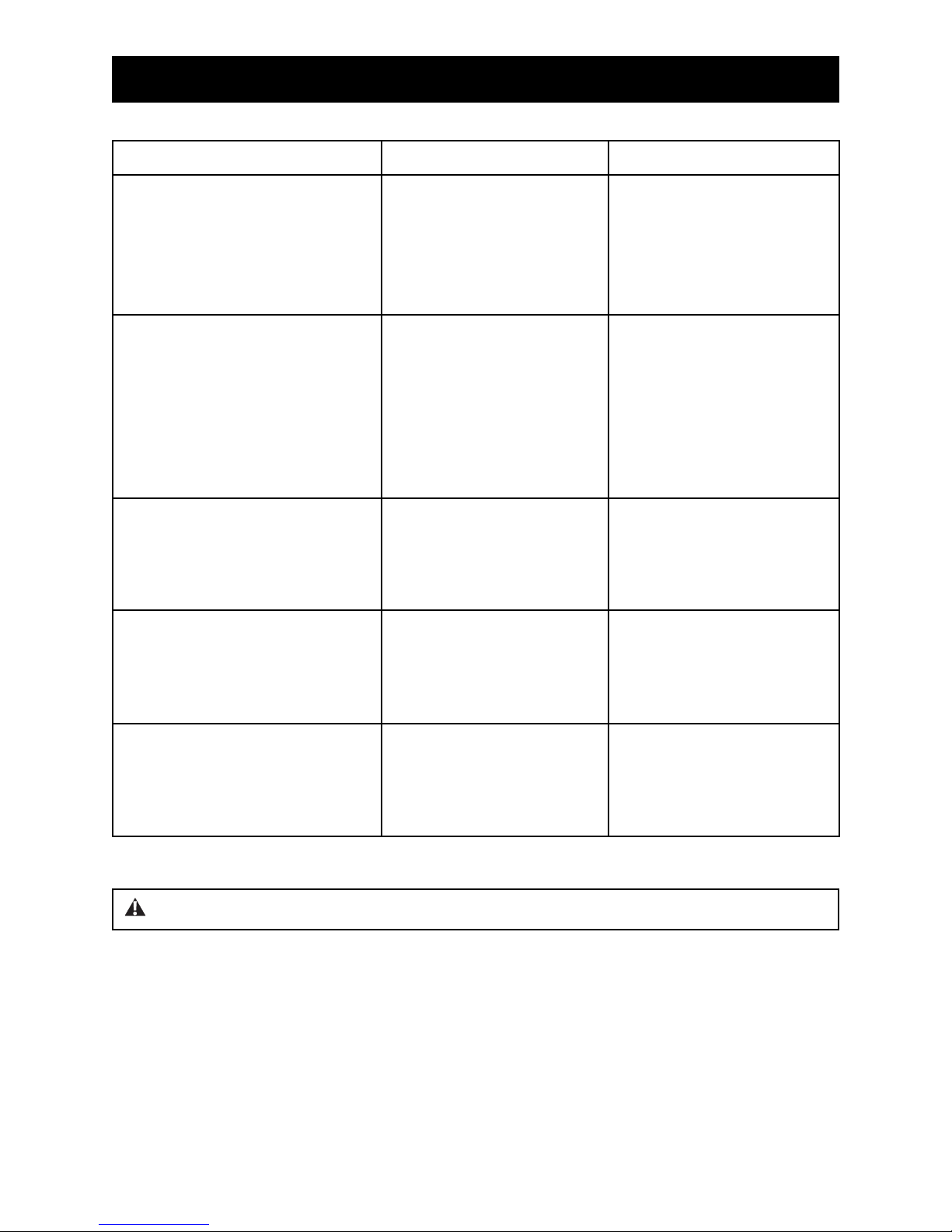

VIBRATION/SOUND DATA

VIBRATION DATA:

Axis

X

Y

Z

Vector

Sum

Stationary

>0.1

0.3

0.4

>0.1

Moving

0.5

0.3

0.1

0.6

Whole Body

Vibration Levels in m/s^2

Axis

X

Y

Z

Vector Sum

Left

0.5

0.3

0.6

0.9

Right

1.4

1.4

0.5

2.0

Hand/Arm

Vibration Levels in m/s^2

Stationary

Moving

dBA

77.0

73.0

Operator Sound Level

dBA ref. 20 Pa

SOUND DATA:

Emissions meets OSHA stantdards

Page 19

OPERATING CONTROLS

START UP PROCEDURE

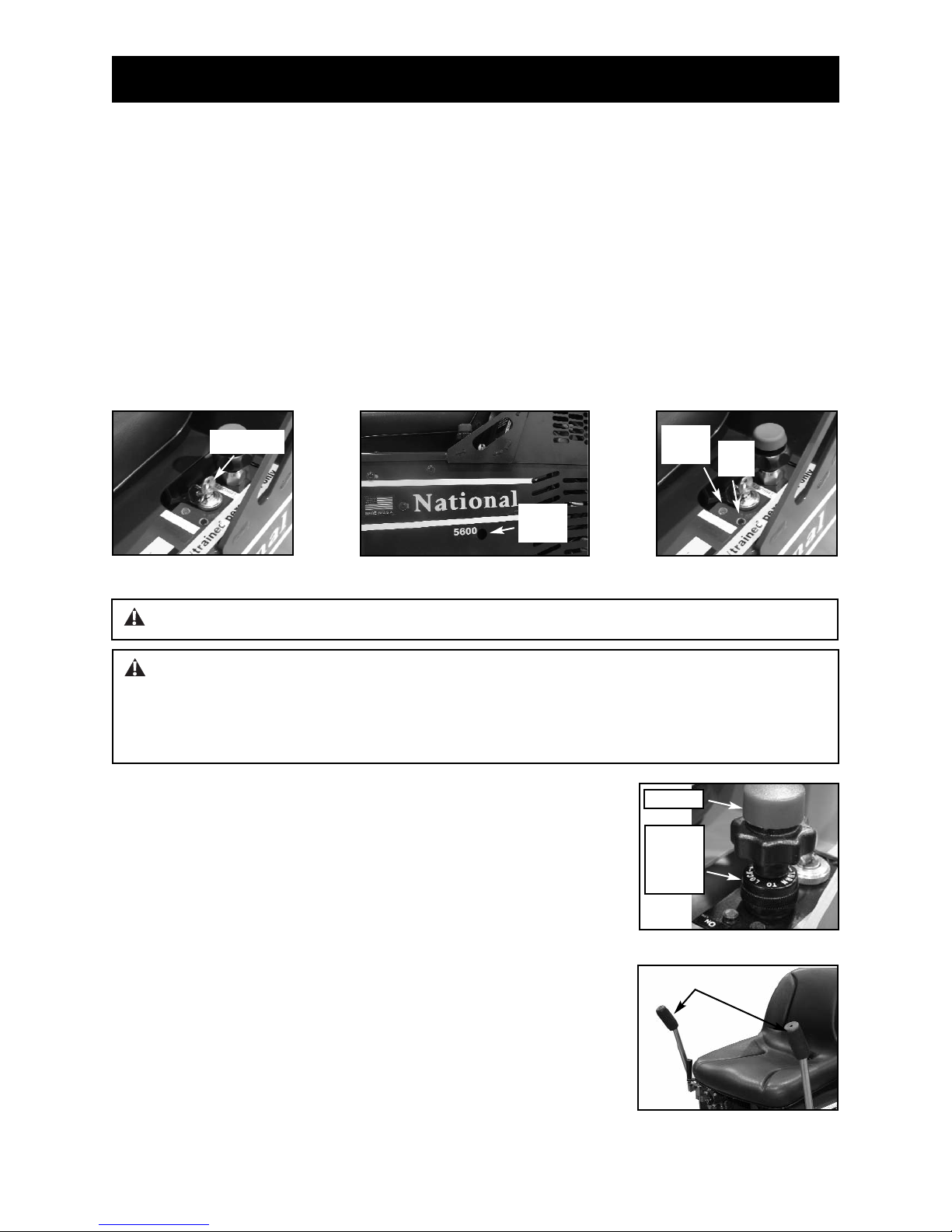

POWER /Key Start (Figure A)

1. Open propane tank valve by turning knob CCW until fully open.

2. Operator must be seated in seat. The machine will not start unless the operator is seated.

3. Insure that hydraulic levers are “centered”.

4. Set throttle at a quarter open.

5. Start with ignition switch.

6. If machine does not start, press primer button once (in hole on side of machine) (Figure B)

7. Start with ignition switch again.

8. Both a Red & Green light will illuminate (Figure C). As soon as engine starts, the red light

will shut off. If the Red light does not shut off, turn machine off.

9. Adjust throttle to move to desired RPM.

Figure A

Figure D

KEY START

THROTTLE

Figure B

PRIMER

BUTTON

Figure E

Hydraulic Levers

WARNING: Ventilation is required in confined work environments. CARBON MONOXIDE IS

A VERY TOXIC, COLORLESS AND ODORLESS GAS. When engines operate in enclosed spaces,

such as warehouses, buildings under construction, or tunnels, carbon monoxide can accumulate

quickly and reach concentrations that are dangerous for humans. It causes headaches, dizziness,

lethargy and death. CO is usually the major concern whenever LPG engines are used indoors

HYDRAULIC LEVERS (FIGURE E)

The hydraulic levers steer the machine. They are feathered spool

valves. For smooth even movement, always move levers slowly. Fast

movement on control levers will result in jerky, uneven movement.

(continued on next page)

THROTTLE CONTROL (FIGURE D)

• Make sure throttle is pushed down

• Start machine

• Adjust throttle to desired RPM by pulling up on the throttle control

• When at desired RPM, turn throttle friction knob counter-clockwise

to hold in position

WARNING: DO NOT work with machine at idle. Doing so will cause damage to machine!

Figure C

GREEN

LIGHT

RED

LIGHT

THROTTLE

FRICTION

KNOB

Page 20

OPERATING CONTROLS

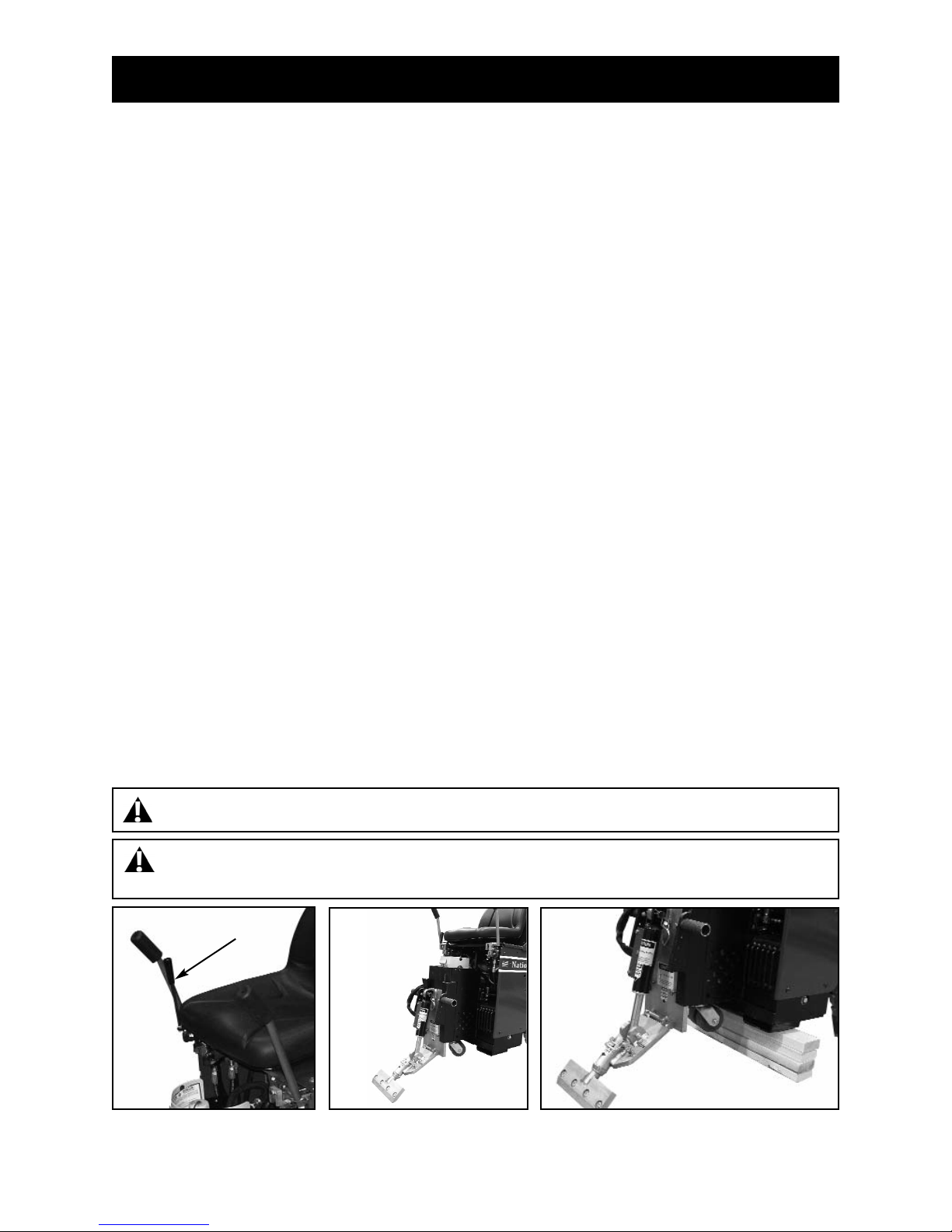

CYLINDER LIFT (FIGURE A)

The cylinder lift lever raises and lowers the cylinder and cutting head. After setting slide plate to proper

height, use the cylinder lift lever to set blade to proper cutting angle. Pull back on the cylinder lift lever

to raise the cutting head. Push the cylinder lift lever forward to lower the cutting head. Continuing to

push the cylinder lift lever forward and it will adjust the angle of the cutting head. This will also jack up the

front of the machine (See Figure B). This will need to be done when doing maintenance on the machine

(ie: wheel changing, front caster maintenance etc). When doing machine maintenance, besides raising

the cutting head angle, place blocks under the machine (See Figure C). Never use the cutting head only.

Figure A

Figure B

WARNING: Disarm machine by removing the cutting head or dropping the cutting head to the

floor when the machine is not in use.

Figure C

SEAT SWITCH

The seat has a safety switch. Operator must be properly positioned for machine to run.

WARNING: Do Not alter a switch or lever. Do Not defeat a safety device.

HYDRAULIC LEVERS (CONTINUED)

• Move levers slowly.

• Both levers forward move the machine forward.

• Both levers backward move the machine backward.

• The left lever forward and the right lever backward

turn the machine quickly to the right.

• The left lever backward and the right lever forward

turn the machine quickly to the left.

• Only using the left or right lever forward , turns the machine slowly to the right or left.

• Only using the left or right lever backwards , turns the machine slowly to the left or right.

• Correcting direction while moving forward is accomplished by slightly reducing pressure on

one lever or the other while moving.

• The center position on levers causes wheels to lock-up.

• Always chock wheels and tie down machine when transporting.

**Control levers are low in vibration.

CYLINDER LIFT

Page 21

OPERATING CONTROLS

WARNING: Engine, exhaust system and hydraulic component temperatures could be in

excess of 200° F causing severe burns if touched.

SHUT DOWN MODE (SHUT DOWN PROCEDURE/ TURNED OFF)

Definition:

State or condition of the 5600 Propane Ride-On that minimizes the danger of mechanical, electrical,

pneumatic or hydraulic hazards.

PUTTING THE 5600 PROPANE RIDE-ONINSHUT DOWN MODE:

• Move the 5600 to level ground

• Turn off the ignition switch and remove the key

• DO NOT move hydraulic levers. The hydraulic system is the brake system. Moving levers could cause

machine to roll, causing damage to machine, property damage and/ or bodily injury

• Wait until motor has stopped completely

• Close propane tank valve (Figure A)

• Let the engine, exhaust system and hydraulic components cool down before performing maintenance

on the machine

Figure A

Propane

Tank Valve

MACHINE STORAGE

• Follow Shut Down Mode procedure

• After engine has completely cooled down, disconnect propane line

• Remove negative terminal on battery

NOTE: IF MACHINE IS NOT RUNNING BUT THE KEY IS IN THE IGNITION AND IN ON POSITION, THE

HOUR METER WILL CONTINUE TO RUN

Page 22

OPERATING CONTROLS

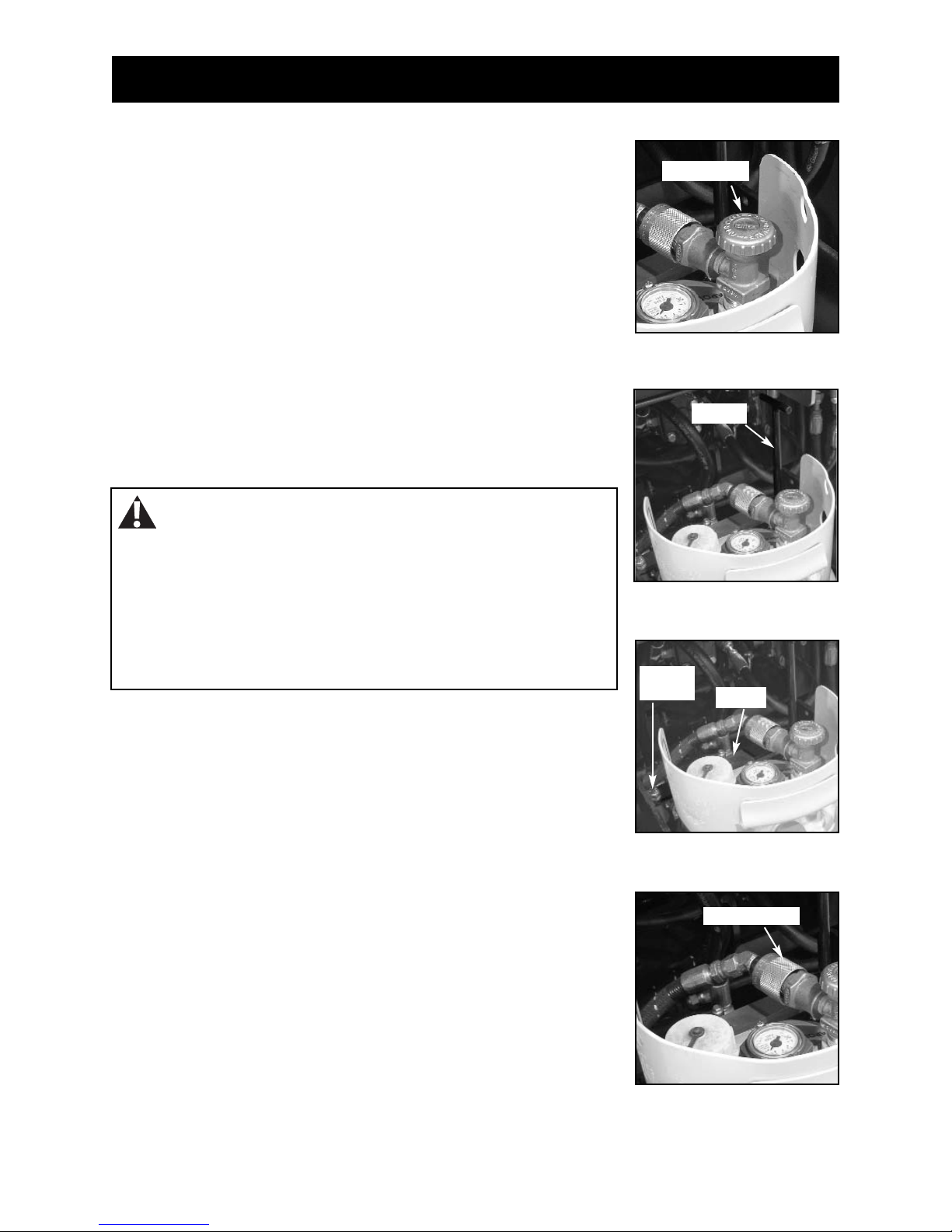

CHANGING PROPANE TANK

TO CHANGE THE PROPANE TANK:

• Turn machine off

• Shut propane tank off (Figure A)

• Release hood strap

• Remove T-handle bolt (Figure B)

• Release tank bracket (bracket does not need to be removed, it

will swing back) (Figure C)

• Disconnect propane hose (Figure D)

• Remove tank and replace

• Follow steps in reverse order

Figure A

Figure B

Figure C

Figure D

Shut Off Valve

T-Handle

T-Handle

Bolt

Bracket

Disconnect Here

WARNING: Ventilation is required in confined work

environments. CARBON MONOXIDE IS A VERY TOXIC,

COLORLESS AND ODORLESS GAS. When engines operate in

enclosed spaces, such as warehouses, buildings under construction,

or tunnels, carbon monoxide can accumulate quickly and reach

concentrations that are dangerous for humans. It causes headaches,

dizziness, lethargy and death. CO is usually the major concern

whenever LPG engines are used indoors

CARBON MONOXIDE DETECTOR

Included with the 5600 are a 75007 Lapel CO Monitor and a 75008 Clip. It is

recommended that the operator and anyone in the working vicinity wear the

detector. Failure to do so could cause bodily injury and/or death. The use of

detectors helps to verify if work area is safe from Carbon Monoxide poisoning.

The detector has an adhesive strip on the back for mounting or can be worn with

the included clip. It can detect as little as 100ppm (part per million) carbon

monoxide gas at approximate relative humidity range of 33 to 50%. If the

humidity is very high it can detect concentrations as low as 20ppm. The

presence of CO will change the impregnated silica color change from red to

red/brown and then to gray/black as the concentration levels increase. Once the

detector is exposed to fresh air, it will return back to red. Shelf life in an

unopened pack is approximately two to three years (expiration date is visible

through unopened package on the back). Once opened it should be replaced

approximately every ninety days. Write date opened in provided area on the

front of the detector. Read further user directions on the back of the detector.

Page 23

OPERATIONAL TIPS

CASTER

Keep clean and free of debris, make sure it can move freely. Clean as needed. Inspect before each use.

Grease once a month.

Moving a "weighted" machine only on the front caster and not on the cutting head or the Front Wheel

Assembly can seem to make the machine turn sluggish. It might turn hard to the right or the left. This is

normal.

FOOT PEG

Keep feet resting and secured on foot pegs when operating machine. Foot pegs are adjustable. Make

sure securing nut is securely tightened

SEAT

Always be properly seated before operating machine. Machine will not run if the operator is not properly

seated

DISARM MACHINE

Remove blade or drop cutting head to the floor when machine is not in use.

TURN MACHINE OFF

Never change cutting head or service blade while machine is running.

LEAKAGE

Keep fittings and hoses tight. If a leak is noticeable, retighten fitting. If leakage persists, remove the

connection and inspect.

ANGLE OF THE HEAD IS SET STEEP

When raising the front of the machine to a steep angle, the bottom of the slide plate should be raised so it

is higher or even with the bottom of the guide channels, 6” to 7” off the floor. This will allow for a steep

blade angle without tipping the machine too far back (usually used for re-scrape). The most common

mode for take up, is the slide plate is almost to the floor (1/4” to 1/2” from the floor).

RAISING OR LOWERING THE SLIDE PLATE

This will only work without a cutting head inserted in the machine. Completely loosen slide plate bolts.

Use cylinder lift lever to raise or lower machine to move slide plate up or down.

WARNING: Always disconnect on board charger before operating machine.

Page 24

LOADING/UNLOADING

• Always remove blade and cutting head when machine is being moved or transported

• Cutting head and slide plate can be removed to make the machine more compact.

• NEVER leave machine unattended on an incline.

• Removing added weights help to make the machine easier and safer to move in and out of a vehicle.

DOCK HEIGHTS

It is best to load or unload the machine from a level/equal dock height (a van from a van dock height, a

truck/semi from a regular dock height).

POWER-GATE

A power-gate can be used when the dock height is not available. Make sure gate is properly rated for

2300 lbs. Make certain the machine is secure so it does not roll off the power-gate. To better secure

machine, raise machine onto the lowered cutting head, raising machine off the caster. Tie machine down,

chock wheels.

RAMPS

To be safe, the ramp needs to be very long to accommodate the machine being loaded/unloaded.

Remove added weight. Make sure ramp is secured. Do not have at a steep incline. The use of a power

winch or hand come-a-long is much safer. For a van, the ramp should be 12 to 18 feet in length

depending on the depth of the incline. For truck height taller than a van, longer ramps will be needed.

See OSHA guidelines. It is not recommended to drive the machine, connected with power, on a ramp.

Make sure ramp is secure and has good contact before using. Failure to do so could cause ramp to fall

away from the vehicle.

Note: See correct and safe operating angles and center of gravity on page 26.

WARNING: Machine has a swivel front caster. Never side hill (See Figure A). The machine on a

incline without power, the front caster will cause machine to swing to the lowest point. If it is necessary

to run machine on an incline, run machine on cutting head. Place at least a 8'' cutting head in

machine. To keep from damaging floor, clamp a piece of carpet into cutting head to slide on the floor.

This will give positive contact with the floor when power is disengaged from the wheels.

Figure A

CAUTION: DO NOT “SIDEHILL”

CAUTION: MACHINE IS BACK HEAVY.

DO NOT RUN ON STEEP INCLINE--

THIS COULD CAUSE MACHINE TO TIP OVER!

Page 25

LOADING/UNLOADING

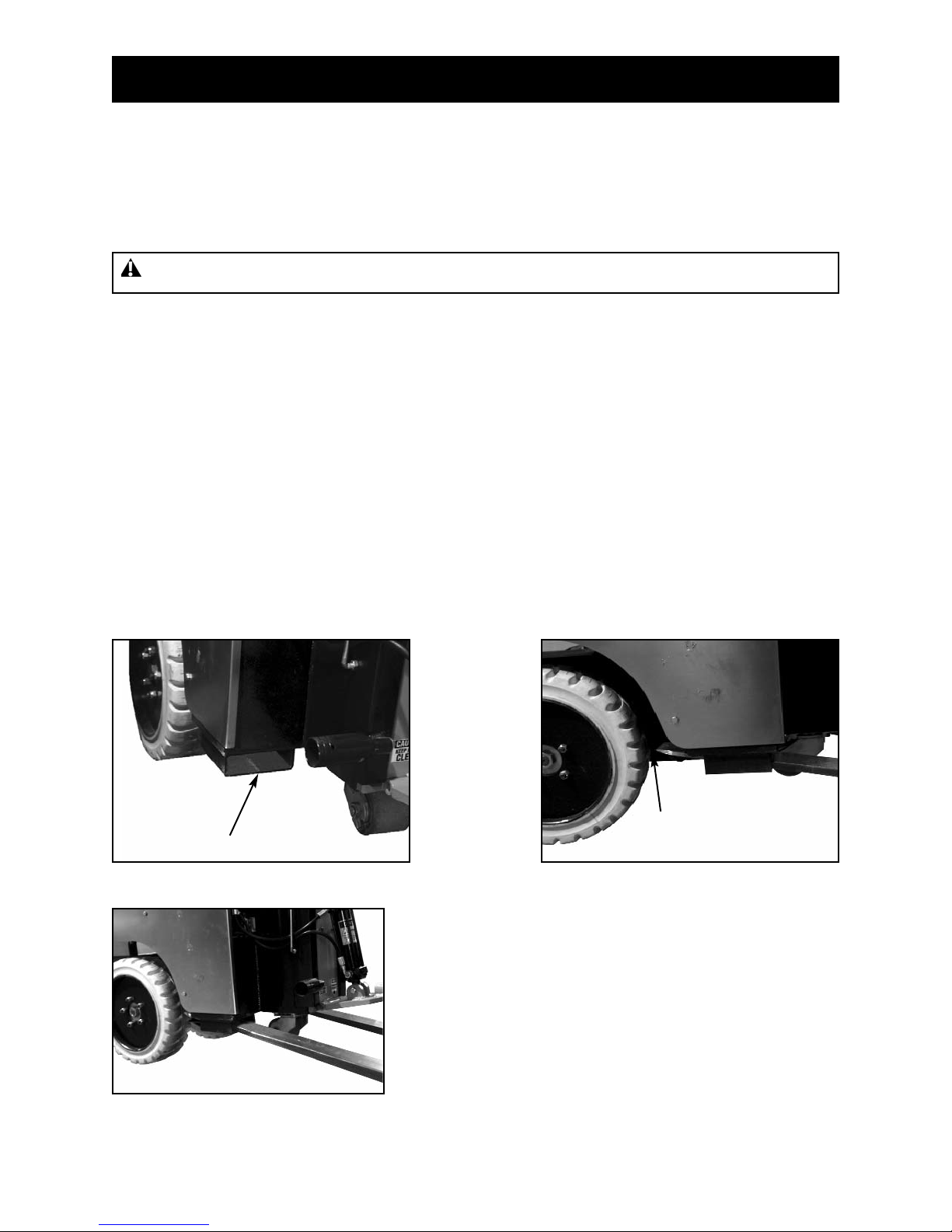

FORKLIFT CUPS

There are two forklift cups mounted under the front of the machine (See Figure A). Slide fork lift forks

through forklift cups. Slide forks all the way back to touch the rear tire (See Figure B). Before lifting

machine, secure machine to fork lift with heavy 3000 lb. or heavier rope or chain. Tilt forks back to lift

machine (See Figure C).

WINCHES

Winches should be used for safety when loading or unloading with ramps. 2000 lb. winch minimum.

TRANSPORTING

Secure machine down with ratchet straps when transporting the machine. Chock wheels to keep

machine from rolling, hydraulic levers should not be locked in the forward or backward position.

Hydraulic levers should be straight up in the "neutral" position. This helps to lock drive wheels. Lift

machine off swivel caster by lowering cutting head for better stabilization. Proper securing straps need to

be rated at least twice the weight of the machine.

WHEEL CHOCKS

Wheel chocks will help to secure the machine but DO NOT use wheel chocks alone to secure the

machine.

Fork Lift Cup

Figure A

Forks on forklift should go

back to the rear wheel

Figure B

Figure C

WARNING: Never tilt machine forward. It could slide off fork lift forks.

Page 26

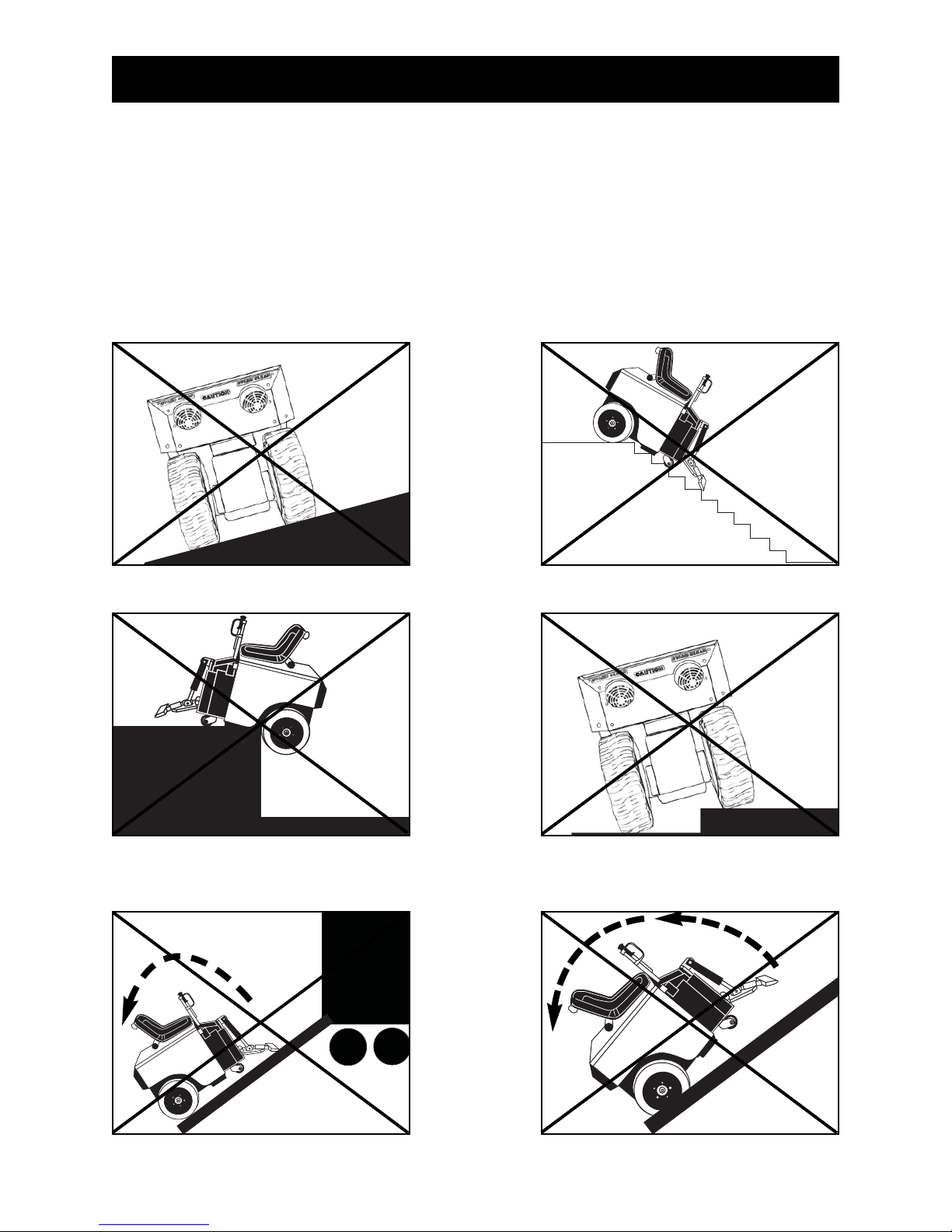

CENTER OF GRAVITY

Be aware of your surroundings and machines operating angles. When changing from a low slide plate to

a high slide plate setting or a low cutting head angle to a high cutting head angle, the operating “attitude”

of the machine changes. When a floor surface is not level (ramps, inclines, large amounts of debris which

would lift the drive wheel of the machine, etc.), the center of gravity changes. Too much of an angle could

make the machine unsafe (a cause for tip-over). Do Not run the machine in unsafe environments.

CAUTION: MACHINE IS BACK HEAVY.

DO NOT RUN ON STEEP INCLINE--

THIS COULD CAUSE MACHINE TO TIP OVER!

CAUTION: MACHINE IS BACK HEAVY.

DO NOT RUN ON STEEP INCLINE--

THIS COULD CAUSE MACHINE TO TIP OVER!

Page 27

JOB SITE MOVEMENT

• Always remove blade and cutting head when machine is being moved or transported

• Cutting head and slide plate can be removed to make the machine more compact.

• NEVER leave machine unattended on an incline.

• Removing added weights help to make the machine easier to move.

TAPING WHEELS

Taping the wheels with a wide masking tape helps to prevent damage and dirt to floors during move-in

and move-out.

LEAP FROGGING BOARDS

Leap frogging boards help to protect floors from damage. Use two or three ¼" luan or plywood sheets,

approximately 27" wide by 6' long. Cover one side of the board with a thin a carpet. With the carpet side

to the floor, place a board in front of the machine. Drive onto the board. Set the next board in front of the

machine. As you drive off one board, pick it up and set it in front of the machine.

PALLETIZING

Only use a solid platform pallet. If a solid platform pallet is not available, place a piece of ¾" plywood on

top of a pallet. Using a forklift with the forks inserted in the forklift cups, place machine on pallet. Use

ratchet straps to secure machine to pallet.

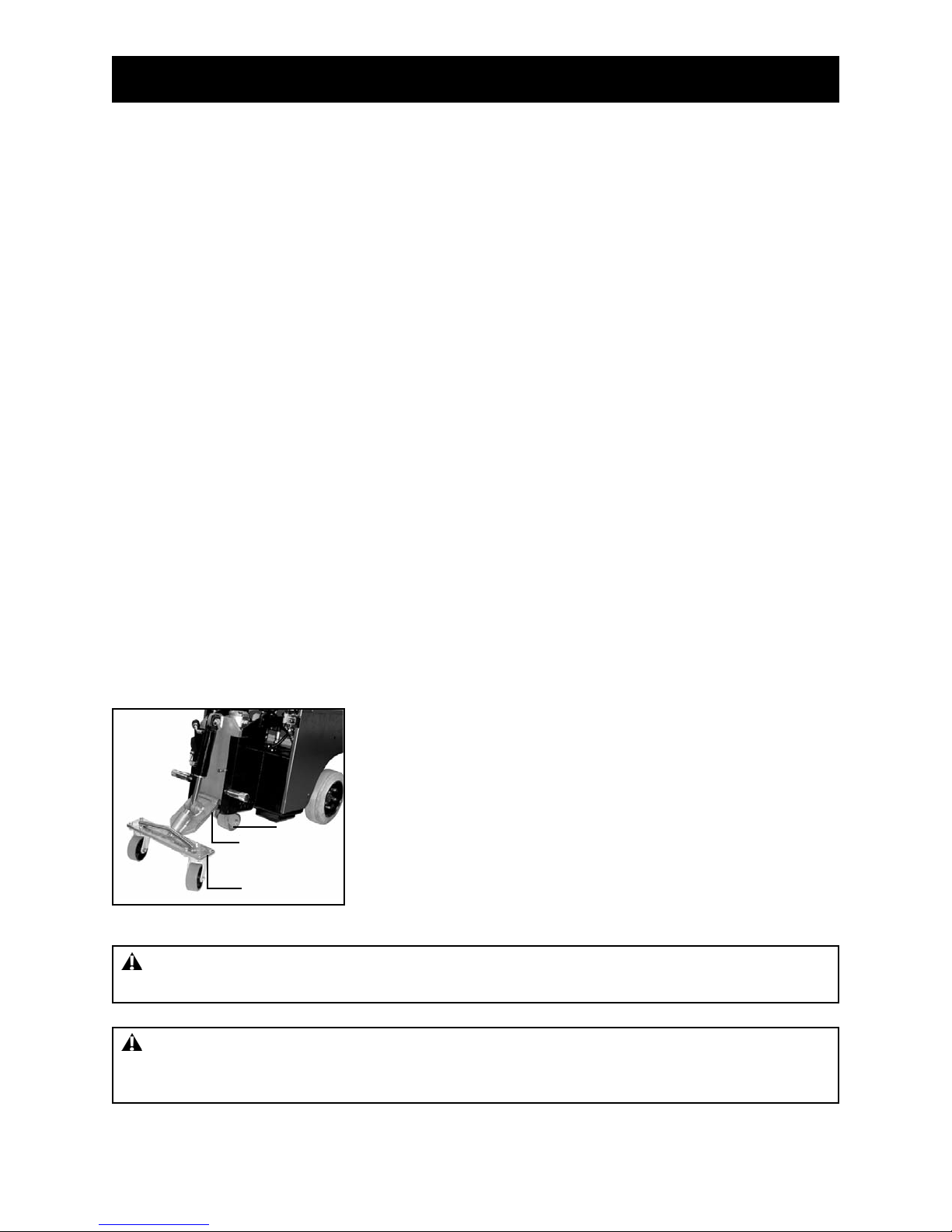

FRONT WHEEL ASSEMBLY (FIGURE A)

The Front Wheel Assembly is an optional attachment (#5110-100) that is very helpful when moving the

machine around on a job-site or loading the machine that is not on a pallet. It allows machine stability and

safe transportation over most surfaces. It is easy and quick to attach or detach. Raise slide plate so the

bottom of the slide plate is higher or even with the bottom of the guide channels. Raise cylinder, insert

Front Wheel Assembly into cutting head. Secure with securing pin.

Figure A

CAUTION: When moving the slide plate, be aware of pinch point at the bottom of the plate.Failure

to do so could cause serious bodily injury.

WARNING: Protect others in work area. Provide barriers or shields as needed to protect

others from debris and machine operation. Operator should be aware of who is around them and

their proximity.

Pinch Point

Note: Make sure the plate is parallel with the floor so the caster

swivels freely.

Caster

Plate

Loading...

Loading...