Page 1

HANDLING,

TRANSPORTING

AND

ERECTION

SATURN

INSTRUCTIONS

S-l

STAGE,

SA-1

,

J

:

....

GEORGE

."

C.

MARSHALL

SPACE

HTTP://HEROICRELICS.ORG

HUNTSVILLE

FLIGHT

ALABAMA

CENTER

Page 2

TITLE

Handling, T

Erect

ion

ranspor ing,

Inst

ructions, Sat urn S

Stage

~

SA

=1

And

T

ABLE

=1

OF CONTENTS

GEORGE

MARSHALL

SPACE FLIGHT

PROCEDURE

DATE

PAGE

1

1

OF

c.

CENTER

147

Paragraph

LIST

INTRODUCTION

10

OF

CHAPTER

PREPARING

ILLUSTRATIONS

0

000

000

Q

I T

RANSPORTATION,

BOOSTER

VOOOGOOOOOOOOOOOOOOOO

<:)

I,)

U 0 0

(J

0

HANDL

FOR

ERECTION

000000

0 0 0 0 0 0

ING,

AND

ooooooooo

101 Positioning Transporter (J=AF= 2004)

102

"103

2 0 ER

2

2~2

30

Installing

and

Removal

ECTI.NG

01

Posit~oning

Removing

T

hrus t Ring

REMOVING

Bumper

Two

Cable Asse mblies (J=1

Procedu

BOOSTER

Transpor t

Booster

BOOSTER

Assembly (D=

re

Rear Ring Sec

0 I,)

(J

0 0 0 v 0 0 0 0 0 0 0

er

from T

0,)

a 0 0 0

()

0 0 0 0 0 0 a 0

FROM

TEST TOWER

10426438) ,

0424771)

'ti

(.0

(J 0 (J

and At

tachin

ransporter

()

U 0 0 0 0 a 0 0 0 0

ons (J=AF91200

0 0 u 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 • a 0 0 0 0 • 0 0 Q

and Pos

Ovooooouooooooooooooooo

O .

OOOCOOOOOQO

I)

0 0

00000.)

0 0 0 0 0

ERECTION

o

oooooooooooooooouoooooooooooo

AT STATIC TES

oooooooooooooo

Two

Bumpers

oo oo

ooo

g Erection

itioni

(J

C.

0 0 0 0 0 v 0 0 0 0 0 GOO. 0 a 0 0 0 0 0 0 0

Page

OOO

OOOOOOOOOOOO

(.I

0 0

000

000000

o

ooopoooooooooo

(D=

. o o

oouoooooooooo

4=2

=0 000000000000000

0000

T T

OWER

10426434) ,

.

0 0

ooooo

(I

OO

O

000

000

o'o

I)

C 0 20

11

Cables 000000000000000 20

ng

on

Tower

(I

0 0 0 28

o

ooooooooooouo

35

3

5

7

7

7

7

3

01

Prepar

302

Removing

Trans

303

304

Installation

Removing

and

CHAPTER

10

PREPARING

1

01

Preparing

102

103

Positioning

Insta

(J

ing

Booster for

Booster from Towe

porter

Bumper

Two Cable

II

TRANSPORTATION,

BOOSTER

Servi ce St ruct

Tran

lli

ng

Beam

""",

1 0426668) 0 0

Removal

ooooovooo"oooo

r Thrus t Ring and

0 0 0

0.)

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 a 0 0 0 0 " 0

Proced

ure

Assem

Rear Ring Sect

bly

(D=1

0426438) , Two

Assemblies (J=10424771)

HANDLING9 AND

FOR

ERE

CTIO

N 00000000000000000000000000

ure for Er

sporter

Weldmen

()

0 0 0 0 0 u 0 v 0 0 0 0 0 Q 0 0 0 0 0

(J=AF= 2004 0000000000000000000 .

t (J=10426675) and Forward

ion

ERECTION

ecti

on

coo

o

ooo

ooooo

Pos

itioni

\.'I

0 0 0 0 0 0 0 0 0 0 0 0 0 0

s (J=AF=1

2004=2=0) 000

Bumpers

0000000000

AT

CAPE

ooocooOoooooooooooooo,ooo

0 0 0

I)

0 0 0 0 0 0 0

ooooooooooooo

ng

on

(J

0 0 0 0

ooo

0;1

0000000

(D=

10426434)

00 00

000.' 0 0000000000

CANAVERAL

00000

00000

00000000

oooo

000000000000

Sling

Assemblies

I;)

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 51

35

0 0 37

40

44

47

47

47

47

Page 3

EORGE C.

PROCEDURE

MARSHALL

EP=141

SPACE

PAGE

FLIGHT

CENTER

OF

2 1

47

TABLE

OF

CONTEN

TS

(Con

o)

Paragraph Page

104

105 Removal

:2

2

,2

30

40

4

4~2

Remova

0

EREC

TING

01

Posit

2

Removing

0

REMOVING

REMOVING

RING DET

.1

Removing

front Trans porter

Preservi

l Procedure Forward Ri

Procedure Rear Ring Secti

BOO STER

ioning

Booster

BOOSTER

RING

AILS

Forwa

ng

Forward and Rear Ring Deta

I)

0 0 0 0 0 0 0 0 0 0 0 0 8 0 0 0

Transport er and A

from Transpor t

FROM

LAUNCH

SECTIONS

AND ATT

WITH

ACHING

rd and Rear Ring Sect i ons w

I)

0 0

(.)

0 0 0 0 0 0 0 0 0 0 0 0

ng

Sectio

tta

er

PEDESTAL

ns (J=AF=12

ons (J=AF=1

(I

Q 0 0 0 0 0 0 0 0 0 0 0 0 G

ching Cab

and

Pos

les

iti

00000000000000000000000

2004=2=O)

0000000000000000000000000 64

oning on Launch

FIN I IDENTIFICATION

HARDWARE

0000000000000000000000

ith

Fin

4)

0 0 0

00

0 0 0 0 0 0 u 0 0 0 0 • 0 0 0 0 0 0 0 0

i!L

s and Attachi

004

=3=O)

000000

0000000

0000000000000000

OO

0 0 0 0 0 0 Q 0 0 0 0 0 " 0 0 0 e 0 0 0

Pedestal 0 72

00000000

AND

PRESERVING

ALL

0.000000000

I Ident

ification

ng

Hardware a 0

I)

I.) 0 0 0 0 0 0 0

54

60

64

0.

79

80

8D

eo

0 0

82

CHAPTER III

GENERAL

INSTRUCTIO

NS

FOR THE

8=1

T

RANSPORTER 0000

0000

000

0000

00

83

Page 4

LIST

OF

ILLUSTRATIONS

PAGE

OF

EP-141 3 147

Figure

1.

2"

3.

40

Positioning

Removing Doors and

Installing Bumpers

Positioning

Equipment at

Horizontal

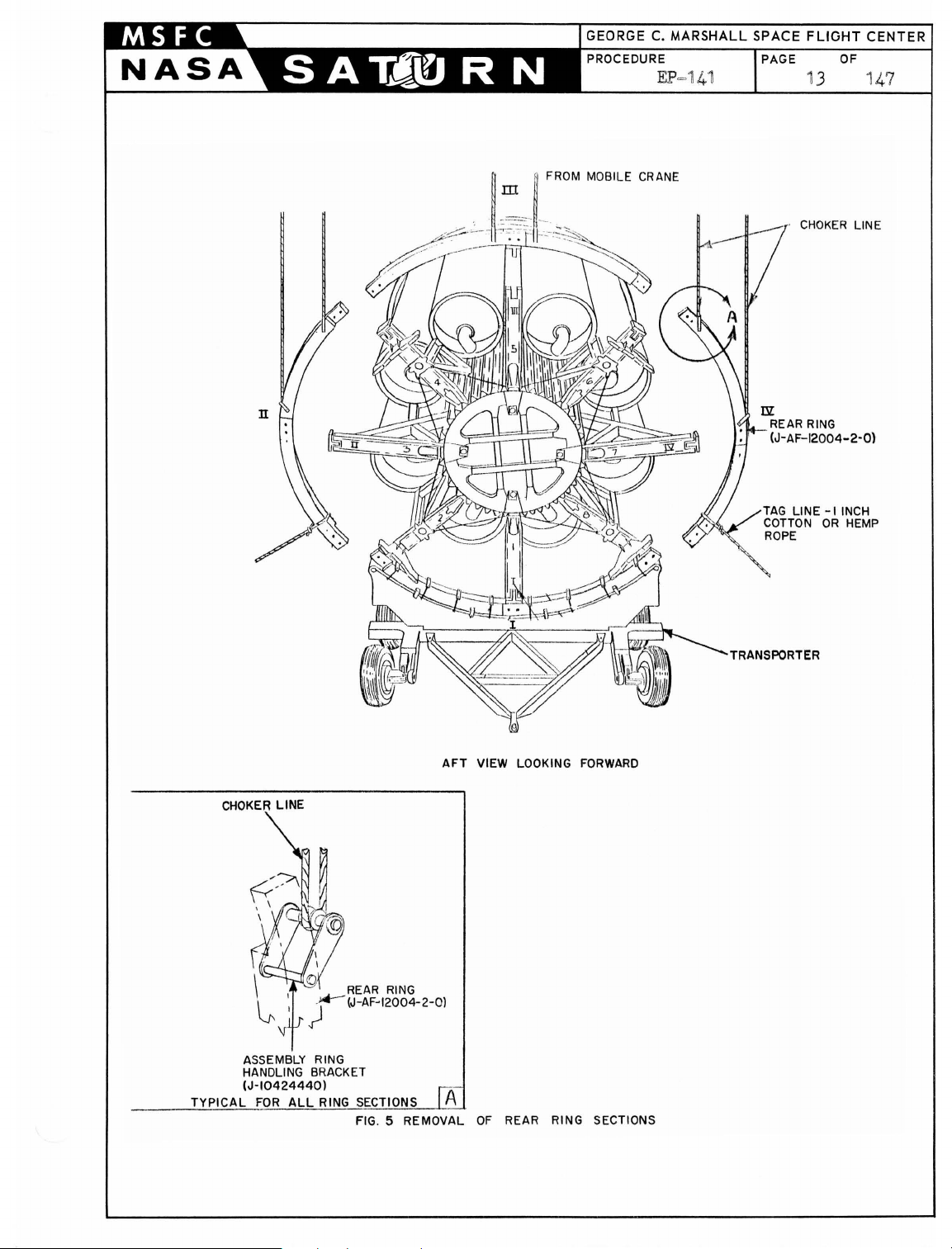

5. Removal of Rear Ring Sec

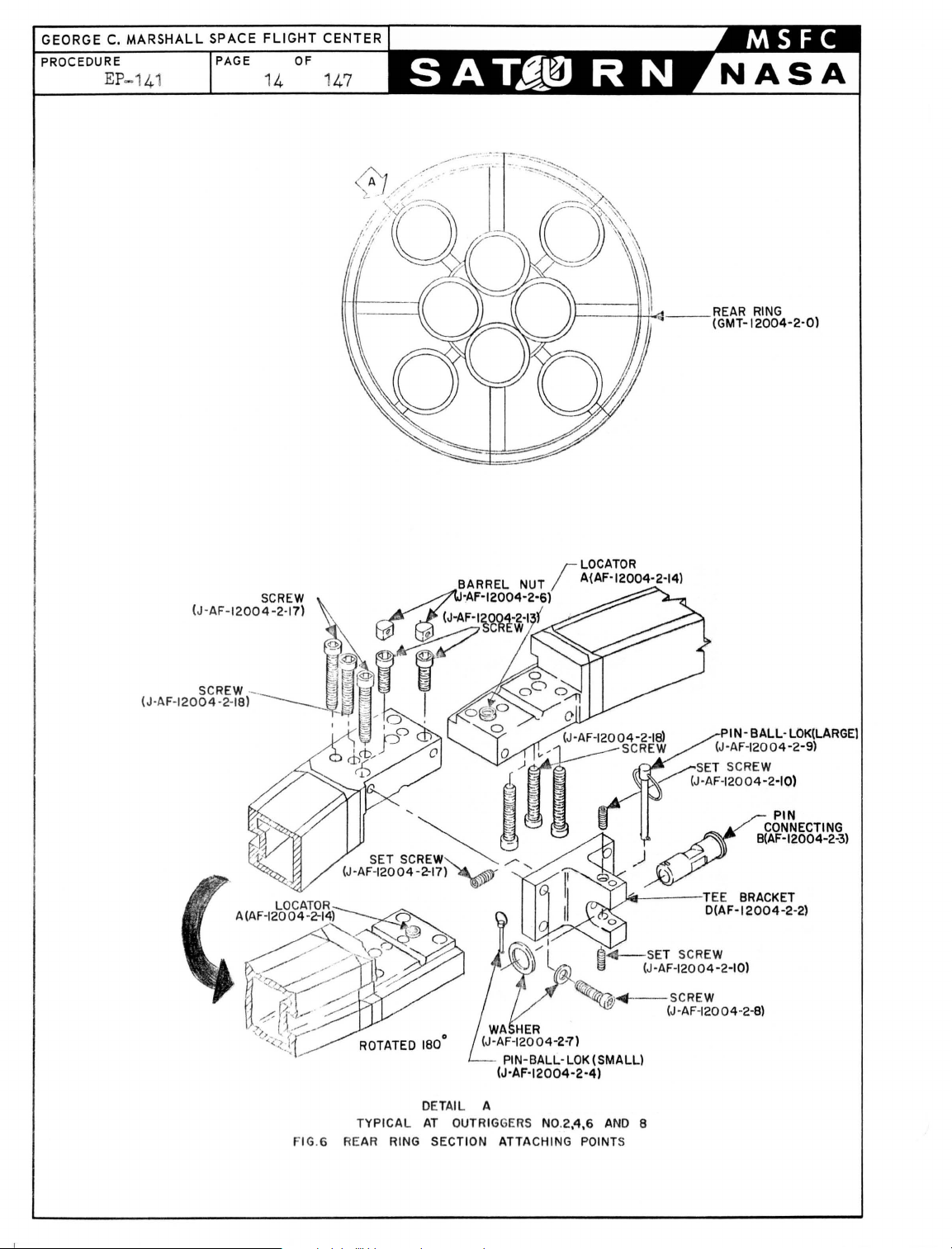

6.

7.

8.

9Q Erect

100

11

• Connect

2.

1

Rear Ring Sect

Removal

of

Identification

ion

Attaching

ion Attaching

Rear Ri

of

Beam

Ins t

Erection

ng

Fin

allation

ing Aft Cable Assembly

Forward Support Clamps

Static

Plates

oooe

and Cable

Pla

tform and

ti

ons

Section

Line

and Out

Beam

and Cable Assemblies 0' 0000'

o.

0 0 • 0 0 • 0 • 0 0 0 0

Title

Test

Tower 0000

o o o

oooo

o

ooocooooooo

Assemblies

0.000 •• 0

Personnel

(J=AF=12004-2~0

Poin

ts

•••

000. 0. 0.00.0 •• 0,'0

at Outrigger

rigger

oeeoooooooooo

••• 00. o

Noo 2

Numbers

ooooo •••

••

0 ••• 0 0 0 0 • 0 0 • 0 0 • 0

•.•

0 0 0 • 0

•• 00. 0 •• 0

o

CJOOOOOClOOOO

••• 0 ••••

•••

• 0 •.

O O O O 9

00

•. 000.0 10

000000.00"00'.00..

)

0.0

00000.00 •••••

.'0

•• 0" 0 14

••• 0 .. 0 .....

0'0.0.00.00

oo

• • o

ooooo

00.0.

•• 0

ooeoo

0000000'0 0" 0 23

.•

0 . 0 0,' • 0 0 0 .' 0

••• 0 00

. 0 • • 25

•••

0 • • •

00

0.

..

oo

Page

8

12

13

18

19

21

27

13 0

14. Boost

15.

16

0

17.

18.

19.

20.

21.

22.

23

. Forward Ring Section Removal

24 .

Lifting

Boost

Positioning Boost

Preparing

Boost

er

Stabilization

er

in

er

Vert

Serv

ice Structure

off

Transporter

ical

Position

er

on

Preparatory

Positioning Equipment at

Preparing

Installa

ti

Boost

on

of

er

Beam

for

Erection 0 0 •• • •• 0 • •• 0

Weldmen

Removing Forward Ring Sect

Forward Ring

Attaching Aft

Section Attaching

and Forward

0 •• 0 • •

0000000

t o

Lifting

••••

000

..• 0 .•.•

0. 0 •• •• •• 0. 0. 0.0 0.· •

Support Bracket s 0.00 . 0

for

Erection

Firing Sit e 0

.000.00 •••

•••. 000. 0

•.

t and Forward

ions

(J=AF-12004~3~0) .~

Poin

t s

Procedures

Sling

Assemblies .000

•••

Sling

0 .

.0 .0

.... 00. 0 ••

••••

00

•• 0. 0000.000 •• 29

off

Transporter

0000

000

00

••

0. 0

•.••••..

. 0

••••••.

••• •• 0......

• . 0. 31

•••

•• 0 33

0 •• 36

0. 0

..

0 0 0 0 0 • 0 • 0 ••• p 0 0 0 0 . . •

Assemblies

0.

00

•••

00

00

••••

• 0.

•••• 00

.. 0 ••••• 00..

00

••

0' o . 00" 0

......

00

. • 00. 0

0 •• 0 56

00

48

49

52

53

55

57

65

Page 5

GEORGE

C.

PROCEDURE

MARSHALL SPACE FLIGHT CENTER

EP

,·,1

41

PAGE

4

OF

147

Figure

Connec

26

27

28

0

.

.

L

8-1

Removing

29. Booster-

30.

31 0 Rear Ri ng Support Cl

P

ti

ng

ifti

ng Boost

Stage

Af t Cable Assembly and

Pedestal

to-

ositioning

Erect

ing

er

off

Cen'ter-or-Gravi

0

III

0 .

000

Launch

Boost

LIST OF

Beam

Transpor

••

0.0

ILLUSTRATIONS

Ti t

le

and Forward

er

0

•• 0 ••••

ty Di agram

Positioni

Q 0 • • " 0 • • 0 e • • 0 II 0 . 0 0 0 .

(Con

Sling Assemblies

• 0 • • 0

••••••

ng

o)

• 0 • • 0 • •

Booster

....

Pedestal Orientation Diagram..

er

on

Support A

amp

s Q. 0 0 • 0 0 • ·0 u •

rms

and Holddown

••

0

••

0 •

III

0 • 0

••

0 •

•••••

••••

...

0 0

. ..........

Arms

•••

••••

0 •

•• ••

on

!oJ

00000

.0...

•

•

•• 0..

•••••

00.

• 0 • •

Launch

•••

" 0 0

••

...

....

III

•••

0 • • • • • • 81

Page

• • • 69

••

• • 71

00

. 75

..

..

68

77

78

Page 6

ER

Thi s

manual provide

erecting

and

chapt

II

ta

ers 0 Chapter

con

tai

ns

i ns

opera

ins

t i ng

Chapter I consi st s

sections,

va

tion

of

t he

Chapter

rear

pedes t

position

of tooling

rear ring sect i ons t o t he

II

ring

sections, posi t i oning and

al,

and

A complet e

T

ransporter

and Int

roducti

Equipmen

t ower and

por

t e

r, towing tractor

ranspor

t

handling

and i ncluding a

t e

at t he Cape Canaveral f

tat i on ring pl a t forms .

of

t he Boost er d

s t he necessary in

t he Saturn S

=I

Booste r

I cont ai ns instructi

t ruct i ons at t he

ins

t ructions

of

st ep=by=st ep procedures

i ng and erecting the

, pos

iti

oning

cons i st s

preserva

man

ual

of

t i on

con

taini

st ep=by=st ep

of tool

on i s inserted i n

ssential

t o proper ha

, gant

urin

INTRODU

~

ef

Cape Canaveral

for

t he Sat

t he Boost

Booster aft

erecting 'the Boost

i ng

ng ge

separa

neral inst

t e Tab l e

thi

s manual

ndling of

irin

g site i

ry

cra

ne, mobil

Sp

eci

al

g r e

mov

al

CTI

ON

st r uct i ons

fectivity SA

ons at t he

f i ri

urn

S=I T

ransporter

Boost

er

on t he t

er

i n t he

er sta

procedures

for shipp ing.

ructions

of

Con

t ent s ,

as

Chap

t he Boost

nclu

des t he fol

e c

rane, fork

hardware

and

erection.

assures

for transporting,

=1

and

is divided int o t

static tes

ng sit e.

t tower.

Chapter

.

for

r e

moving

t he

static test t ower ,

ransp

or t

er,

and

t i c test

for

for

firing

removi ng t he

er

from t he

t he Sat

List of

t er

III

.

er

at t he

lowing: trans

l i f t ,

safe

horizontal

and

handling

Chapter

III

rear ring

reassembly

.

forward

launch

urn

S=I

Ill

ustrati

static tes

efficient

hree

con=

pres

and

ons,

t

=

and

,

er -

Divi

T

his

sions

publ

0

i cat i

on

i s a

com

bin

ed

effort

of

t he M=

LOD, M=T

EST,

and M-

F&AE

Page 7

PROCEDURE

PAGE

OF

Page 8

CHAPTER

I

1.

PREPARING

1.1

1

Pos

1.1.

1.

.2

Installing

and

1.

1.2.2

TRANSPORTATION,

BOOSTER

iti

oning

1 Pos

r i ght

FOR

Transporter

iti

on transporter

angle

bridging

1.2

area

Lock t

around

(See

figure 1 for

ransporter

Bumper

Two

Cable Assemblies

2.1

Move tractor

boos t

Using

er

fork

personnel

(D-10426438) , t

(J-10424771) . (See

HANDLING,

TEST T

ERECTION

0

(J=AF=12004

on nort h

t o

deflector pit

at a di stance which

t he t

ransporter

the rel ative

brakes

and chock wheels .

Assembly (D-10426438).

(J-10424771~

and t

ow

bar

.

lift,

raise transpor

to a height necessary

wo

bumpers (D-10426434

figure 2.)

AND

OWER

)o

for

clear

ERECTION

side

of

and

aline

will

provi de

t he mobile

positions

Two

of the

tat

ion

for att

AT

STATIC

sta

tic tes

wit h

sufficien

of

Bumpers

forward

ring

aching

),

and

t t ower at a

deflector pit

t working

crane

and

fork

t he equipment. )

(D-1042643~

end

of

t he

pla

t form and

bumper assembly

cable

assemblies

)

lift

!

.

1.

2.1 .1

1.

2. 1. 2

1.201

.3

1.201.4

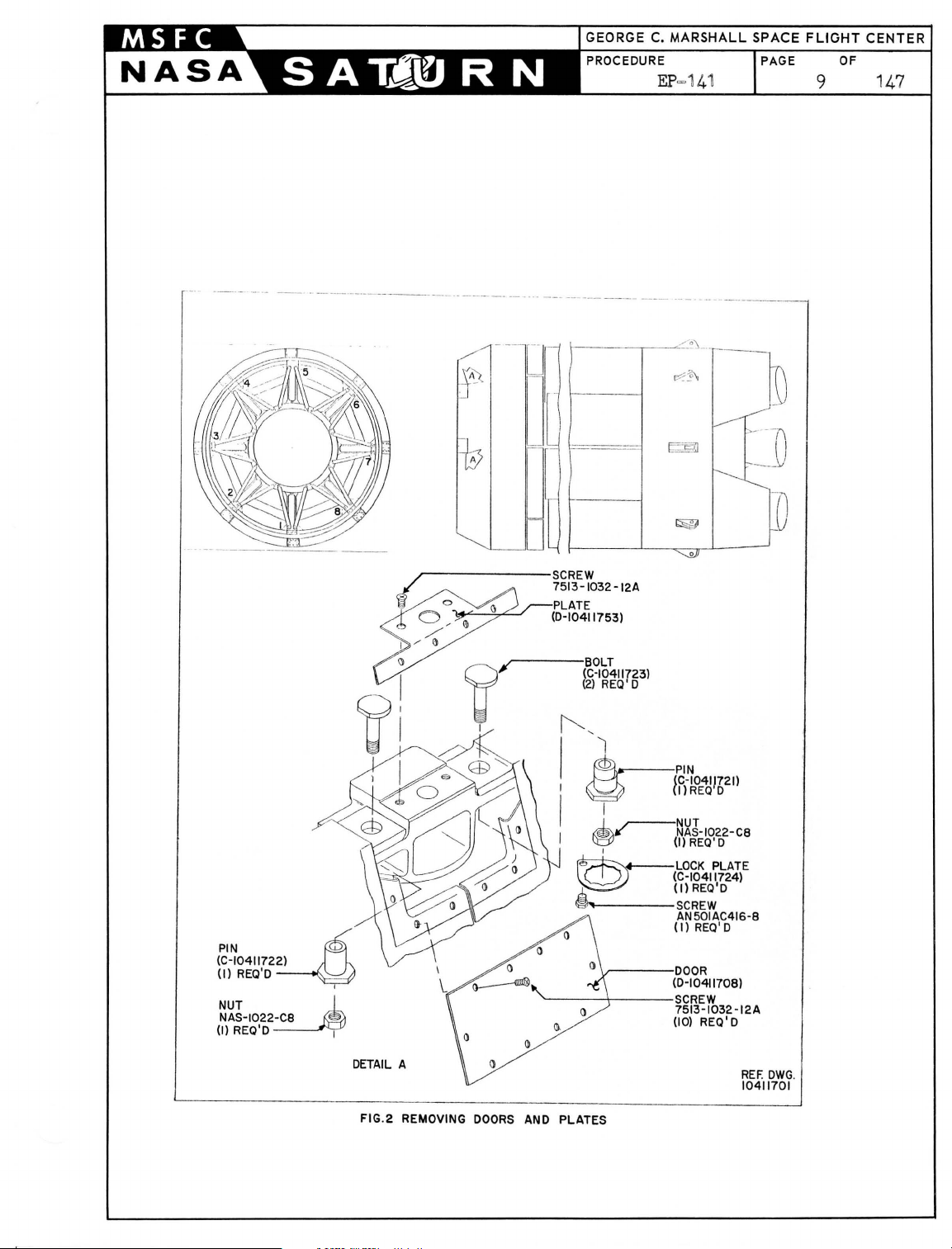

Remove

attached

adapter

doors

t o int

~o

gain

assembly attac

I=beams

Remove att

fairing

for

shown

NOTE:

and st

boost

No.3,

aching

t o second stage adapt

bumper

in

All

figure

assemblies

doors

oredo Th

er

has been

figure 2 for

Install

bump

wi t h detai l

Install

B

~

bumpers (D-10426434)

figure

3.

(D-10411708) and pl at

er

st age

access

hing

4,

fairing

t o bumper and

poi

nt s . Attaching

5,

6,

and 7.

hardware t hat

er

es

and second st

secures int

at at

and forward sli ng

2.

and a

i s hardwar e wi

erec

list of attaching

tta

t ed

ching

in

hardware t o be packaged

ll

be

t he test t ower. See

hardware.

er assembly (D-10426438)

A,

figure

3.

in

accordance

(D-10411753)

age

forward

poin

t s

ers

sling

are

tage

taching poi nt s

assemblies

installed aft

in

accordance

wi

t h

at

as

er the

detail

Page 9

PROCEDURE

EP

=141

PAGE

OF

8 1

47

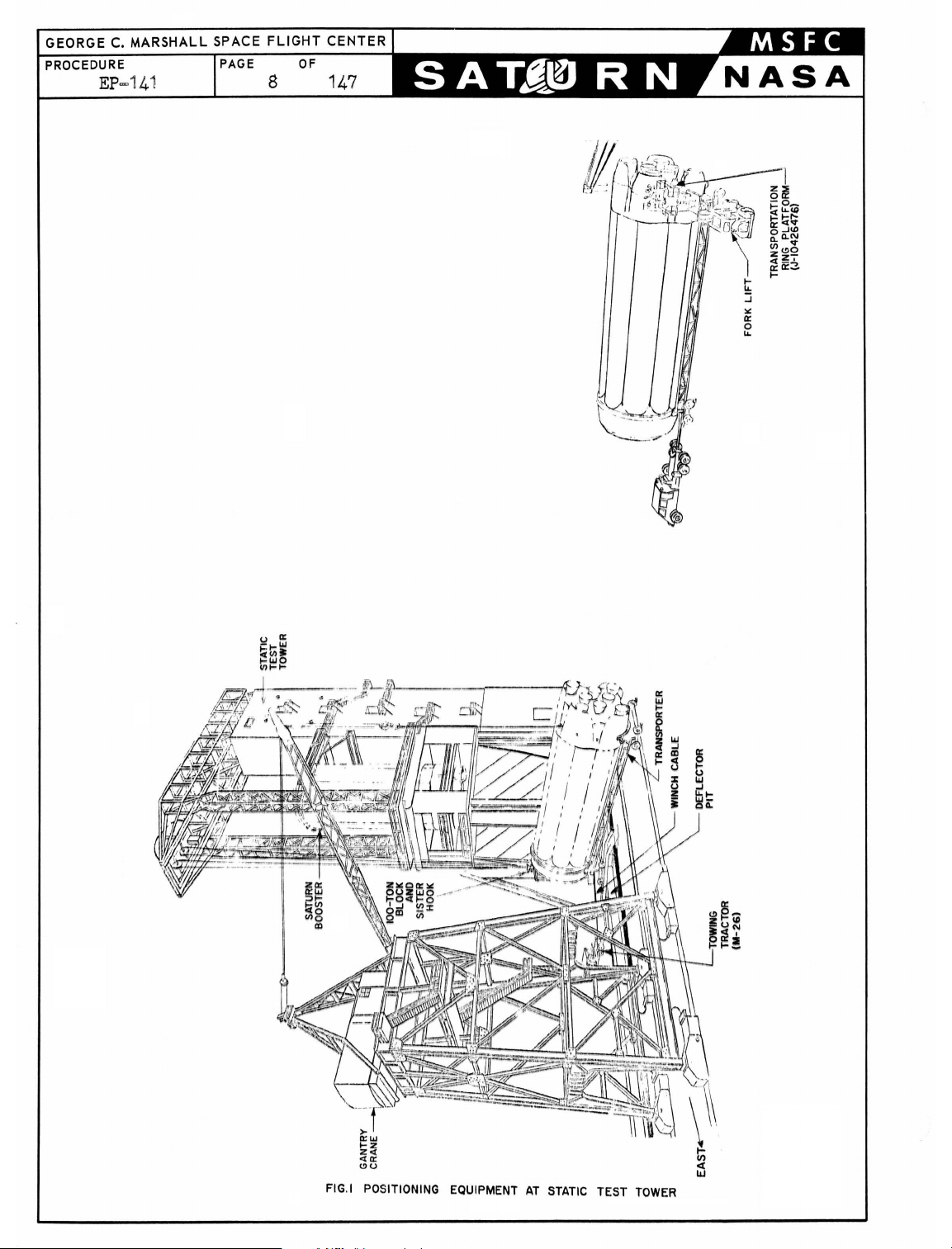

FIG.I POSITIONING EQUIPMENT

AT

STATIC

TEST

TOWER

Page 10

-----

--,--

--

---------------

---

---_._-._----------

...

_-----

[I

--

L

---------

-------

--------

"~?,-.-

1%2'\

----

E§

--

---

7\

-

__

U

PIN

(C-10411722)

(I)

NUT J_

NAS-1022

(I)

~

REQ'O

~

REQ'O I

U

D

~------SCREW

/ 7513-1032 -12A

i

~

~

S>

~

I /

I)

I)

~

I

l1

i ' 1

Q '

~

I I

.r-PLATE

~

(0-10411753)

(~~~~1I723)

~

REQ'O

'1

~

I I

~

I

I)

'-----~-----SCREW

r-~~J-1022-C8

~

,

~

,,1,

.....

~

I-----SCREW

~---OOOR

{f)-~OE4J!621l

(I)

REQ'O

LOCK

PLATE

(C-10411724)

(Il

REQ'O

AN501AC416-8

(I)

REQ

' O

(0-10411708)

7513

-1032-12A

(10)

REQ' 0

-0

DETAIL

A

FIG.2 REMOVING

DOORS

AND PLATES

REF.

OWG

10411701

.

Page 11

GEORGE

PROCEDURE

C.

EP=141

MARSHALL

SPACE

PAGE

10 147

FLIGHT

OF

CENTER

ill

R

BUMPER

UNSCREW

SEATED

BRACKET.

AGAINST

[~

.

~-jJ~ ,-~:~ =-i-~.:-

~~

IS

BOTH

SECURED

BOLTS

BOLT

BUMPER

BY

BOLT

AN12-14,

(AN8-6A)UNTIL

HOLDING

(D~0426438)(REF)

EACH

SHROUD

IS

TO

_-~-=~1r'

---Q--

~

"

BOLT

AN8-6A

TANI2-14

WASHER

NOTE:

WHENEVER

BOLTS,WASHER,AND

TO

BE

DISCARDED

NOTE: WIPE OFF

CLEAN RAGS

WITH

ASSEMBLIES

TOROUE

LUBRICATE

BEFORE

2-

22-WASHER NASI43-16C,RFF.

2-

HEAD

INSTALLATION

CABLE

ASSY

BOLT

NAS156-68,

WASHER

NAS~3-I.'R?

CABLE

.

ALL

OF

BOLT

THREADS,

(J-1042477il,

NUTS

SHANK

REF

AT

(NAS

fi

ASSEMBLY

SHALL

LUBRICANT FROM BOOSTER PARTS

TIME

156-68)

OF

WITH

R

_

~

1042477

BY

INSTALLED,USED

OF

REMOVAL

TO

BOLT,

AND

MOLYKOTE

_

6000

EACH

TYPE

INSTALL

PULL

IS

ATTACHED,NEW

HARDWARE

OF

SLING

INC

LBS(500FT

SIDE

OF

"G'.'

LUG

OF

IN

CABLE-

WASHERS

LINE

. LBS.).

OF

SEE

A-A

BOLT

AN14-14

WASHER

FIG

AN945-14

. 3 .

INSTALLING

2-NUT(A-10424915),

BUMPERS

AND

~

~

R

~

CABLE

ASSEMBLIES

Page 12

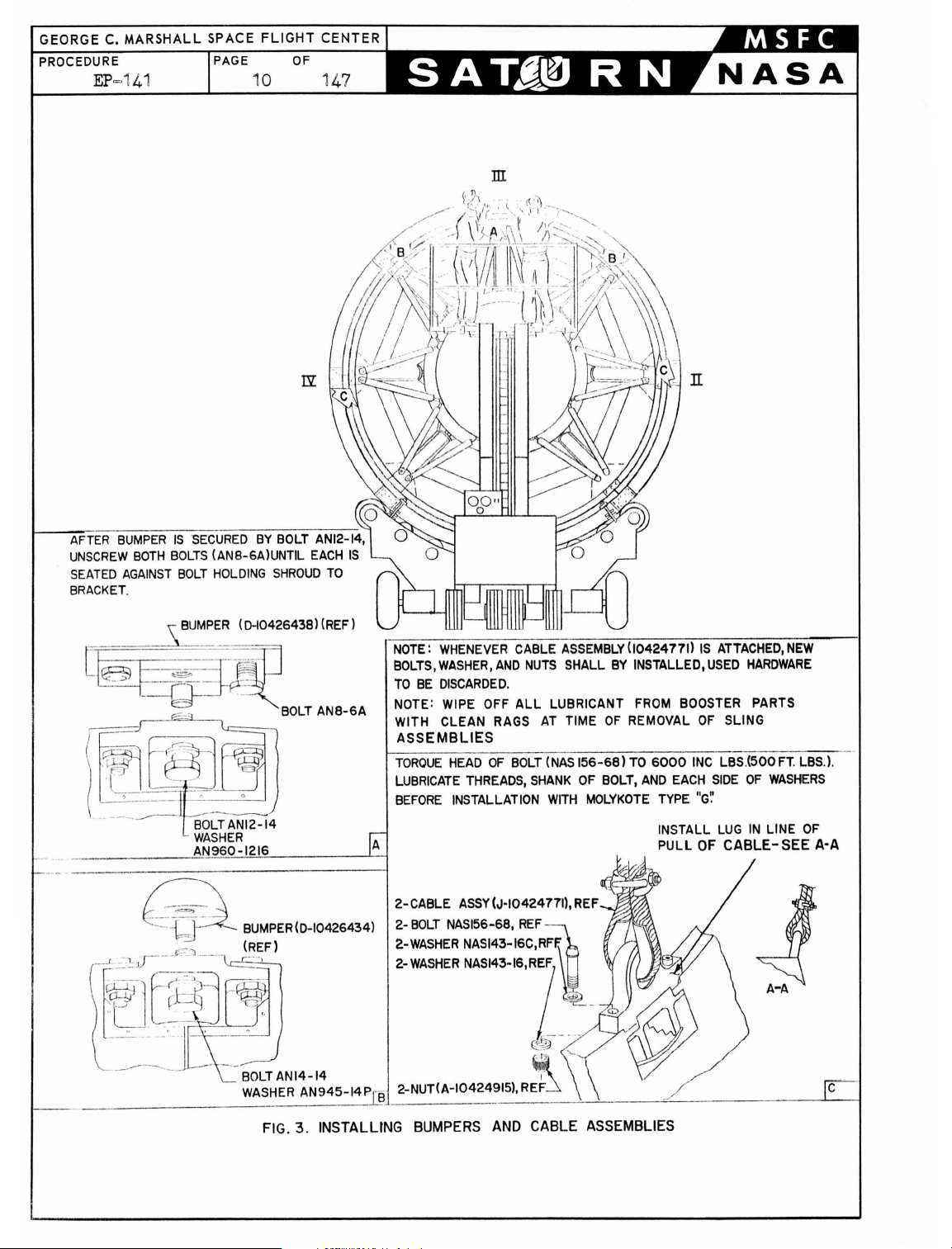

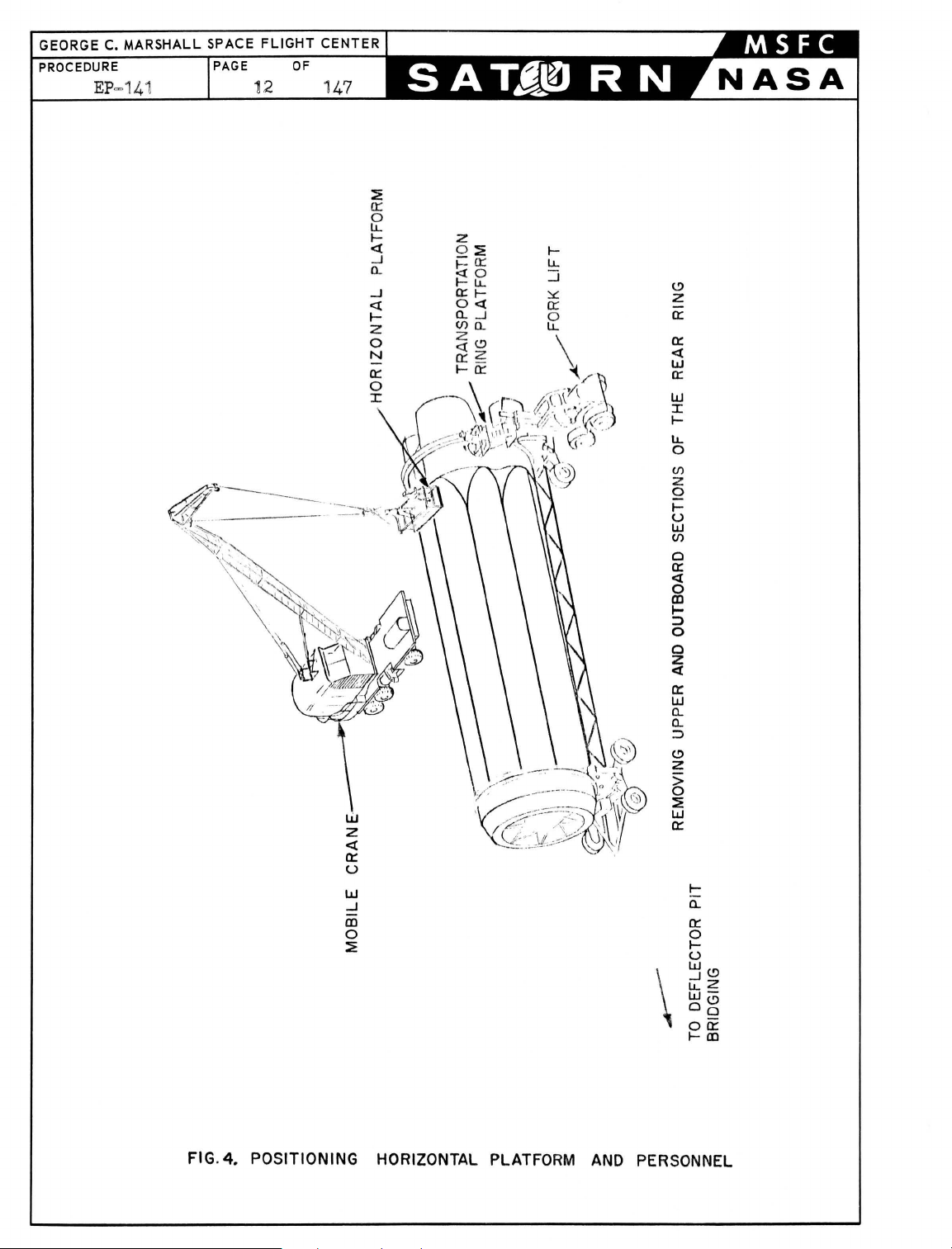

1020105 Install

w

ith instructI

assemblie

cab l e

s toget

assemblie

s (J=10424771)

ons i n deta

her

t o prevent damage to boos

il

C~

f i g

ure

in acc

30 T

ordan

ie

tero

cabl

ce

e

1

1.

03

302

2

1

0

0

01

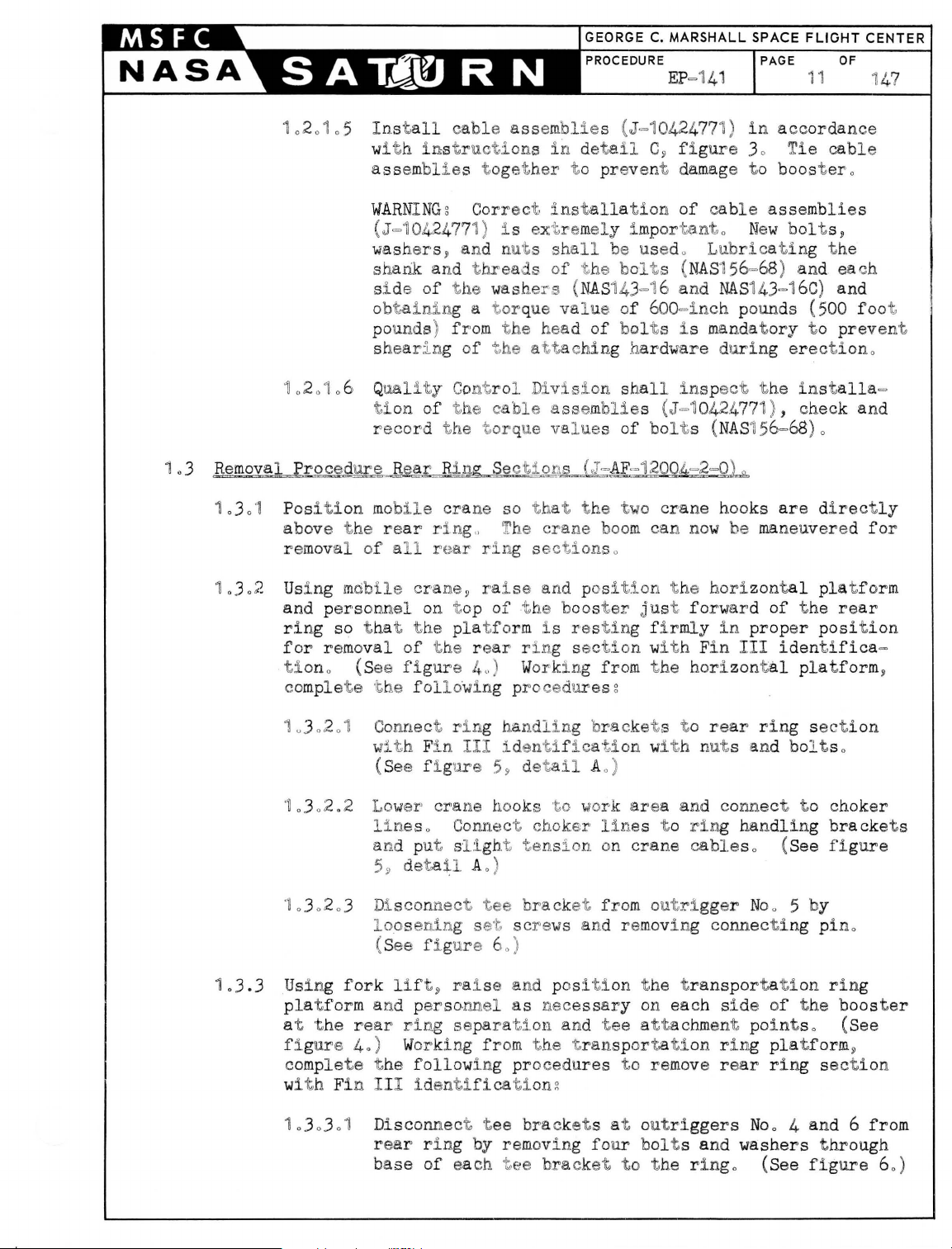

Posi t i on m

abov e t he r e

mov

r e

Using m

and p

ring so t hat

for

ti

ono (See f i

comple

WARNIN

(J=,10424771) i s ext,remel

washers

shank and

si de

Gg

Cor

~

and nut s sha

thr

of t he

rect

eads

wash

el~

inst

allat

ion

y importa.nto New

ll

be used o

of t he bol t s (

s

(

NAS

143=16 and

of

cab

le

assemblies

Lubricatin

NAS

156=68) and ea eh

NAS14J=16C

obtaining a torque va l ue of 600=inch pounds (500 foot

po

sh

10

6 Q

ti

r e

al

of a 1 r e

obile

er

son

removal

te

t he

unds) f r

earin

uality

on of

cord

obile

ar rin

crane~

nel

the

of

followi ng p

om

the

hea d

g of

the

attac

Control Divisio

the

cab

le assemblies (.T=1

the

tor

que val ues

cra

ne so t hat t he two

g" The

ar

ring section

raise and

on t,op

t he re

gur

pla

e

tf o

4,,

of

t he boos

rm

ar

r i ng sec

) W

i s res

orkin

rocedure

hin

crane

pos

g f

of bol

t s i s

mandatory

g hardware du

n sha

ll insp

ect

0424771 ) , check and

of bolt

boom

crane

can n

s (

NAS156=68

hooks

ow

s o

ition

t he

hori

ter just forward

ting firmly

tio

n with F

rom

t he horizont

in

in

s g

ring

t he installa

are directly

be

maneuvered for

zontal

of

prop

III

identifica

al

bolt

s,

g t he

) and

t o preven't

erectiono

)0

pla

t form

the

rear

er

position

platform

=

=

~

1

.3.3

10

302

'~

.302

10

30203 Di

Using

pla

t f

1 Connect ri ng

0

wi

th

F

in

.2

Lower

1ine

and p

loosenin

fork

orm

and perso

(See f i g

5

~

scon

(S

ee

lift~

ure

crane hook

s o Connect choker

ut sli

deta

il

nect

g s

fi. gur e 6

ra

handling 'bra

III

iden

59

ght

A 0 )

tee

et scre

0)

i se and p

nnel

as

at 'the rear rlng separat,;i

f i g

ure 40) Working from

c

omplete

wi

t h Fi n I II

10303

t he following proce

identif

01

Disconnect t ee

re

ar

ri ng by removing

base

of

each t ee

ica

t iong

t i fica t,

detail

s ,

to

ion wit

A 0 )

work area and conne

line

ten

si on on

bracket fro

ws

and re

osition

nece

ssary

on and

t he t

tee attachment point

ransportation ring

dures

bracket

s at o

four bol

bracket

cket s t o

rear

ring

sec t

h nuts and bolt s 0

ct

to

s t o

ring handling

crane

cable

s o (See figu

m outrigger Noo 5 by

moving conn ecting pino

t he t

ransportati

on each si de of

on

the

s o (See

p

latf orm

to remov

utri

e re

ggers

ar

ring sectio

4

No

o

and 6 from

t s and washers t hrough

to

t he ringo (See f i

ion

choker

brackets

re

ring

booster

~

n

gure 60)

Page 13

GEORGE C. MARSHALL SPACE FLIGHT CENTER

PROCEDURE

EP

=141

PAGE

OF

12 147

::E

0::

o

LL

I-

«

0..

--.l

«

I-

w

z

«

0:

U

W

--.l

Ql

o

::E

--.l

l-

LL

::J

~

0::

o

LL

\

(.!)

Z

0:

0:

«

w

0:

W

I

l-

LL

o

(/)

z

Q

I-

U

W

(/)

o

0:

«

o

Ql

~

:)

o

o

z

«

0:

W

0..

0..

::J

(.!)

Z

>

o

::E

w

0:

I-

0..

0:

o

I-

U

W<!)

~Z

W-

og

00:

I-Ill

FIG.

4.

POSITIONING

HORIZONTAL PLATFORM

AND

PERSONNEL

Page 14

PROCEDURE

EP=141

FLIGHT

OF

13 147

.

CHOKER

CENTER

LINE

CHOKER

TYPICAL

LINE

\ I

~

;

)""-IJ-AF-12004-2-01

ASSEMBLY

HANDLING

IJ-I04244401

F.:OR

BRACKET

ALL

REAR

RING

RING

RING SECTIONS

FIG

. 5 REMOVAL

AFT

VIEW LOOKING

OF

TRANSPORTER

FORWARD

REAR RING SECTIONS

Page 15

GEORGE

PROCEDURE

C.

EP

MARSHALL

-141

SPACE FLIGHT CENTER

PAGE

OF

14 147

(J"AF-12004 -2"17)

SCREW

ROTATED

180·

) B(AF-12004-2"3)

,

~

C6~~ECTING

~

~

---

·TEE

BRACKET

D(AF"12004-2"2)

TYPICAL

FIG.6 REAR

DETAIL

AT

OUTRIG

RING

SECTION ATTACHING

A

GERS NO

.2.4.6

POINT

AND

S

8

Page 16

1.303.2

Remove

holes

holes

t he 4!=

of each

on opposi

screws t o

di sco

l ocat

of

are

rear

r i

and

nnectin

NO

TEg

or (A=AF=1

each ring

c

onn

ring

ng

at

locators

One 4!=

ect,ed~

each splic

sections o

inch

scr

ews

ring sectiony inser

te

si de

of

pull locato

g pos

inch

rs

(A=AF=1

iti

ono (See fi g

screw (J=AF=1

2004=2=14)

section; t

herefore,

one screw i s on t he

and one s cr ew i s

e j o

into

(A=AF=1

2004=2=14) rema

(J=AF=

12004=2=18) from

t t

hese

ring sections

2004=2=14) t o t he

ure 60)

2004=2-18) and one

are

loca

t ed

when

forward

on

t he aft

Screws

(J=AF=1200

in wit h t he

screws

in

, and t i ght en

in

t he end

t he

ring

sections

side

side

of

of

t he

4~2~18)

ring

end

hole

t he

rear

1

.3.4

103.3.3 Dis

connect

ti

on from

6 by remov

six

screws (J=AF=1

5 and 60)

1

0303

04

Co

nne.d tag

iden

t ifica

work

ing areao Use tag line

men

t 0 (See f i

10

3.3.5 Disconnect r

ion wit h F

t

lines

10

30306 Using

p

Us

ing

fork

and

personne

section wit h

from t he t

pro

cedur es g

10

3.4

.1

Con

Fin

f i g

from mobile cra

mob

er

sonnel

lif

t , raise

l t o a hei ght

Fin

ranspor

nect

IV

ure

rear

ring sectio

rear rin

in

g t

wo

g s

barrel

2004=2=17) at

line

tio

to

r e

n and hoi st

gure 50

ing handling

in

III

i dent i f

ile

crane, lower

t o

the

gro

und 0

and posi t

as

nece

IV

i d

entification.

tation ring pla

ring

handling

identification

5. )

n with Fi n

ecti

ons at out ri

nut s (J=AF=1

ar ring secti

off

of

t o cont

)

brackets

icatio

ne hooks .

horizon

ion transporta

ssary

for

(See

tform, compl

bracke

with

t s t o r ear

bolts

III

identific

ggers

No

. 4 and

2004=2=6) and

each

boost,er

end. (See

on w

ith Fin III

and lower i nt o

rol

swinging

from

rear

ring

figures

move

sec

n and remove choker

tal

pl at form and

t i

on

ring

removal

figure 4.)

ete

t he

pla

of

rear

Work

following

i ng

ring sectio

and

nut

s.

(See

a-

-

=

tform

ring

n with

1

.3.4.2

1.3.4

Using mobil e

to

work

03

Connect

ri

ng sect i on wit h F

t

ension

area

cho

on

crane wit

and con

ker

l i

crane

h t

wo

nect

nes

t o ring hand

in

IV

hooks,

t o choker

i d

enti

lower

lineso

ling

bracke

fication and put

cables. (See figure 5.)

crane

t s on

hooks

rear

sligh

t

Page 17

GEORGE C.

PROCEDURE

MARSHALL

EP=141

SPACE FLIGHT CENTER

PAGE

1

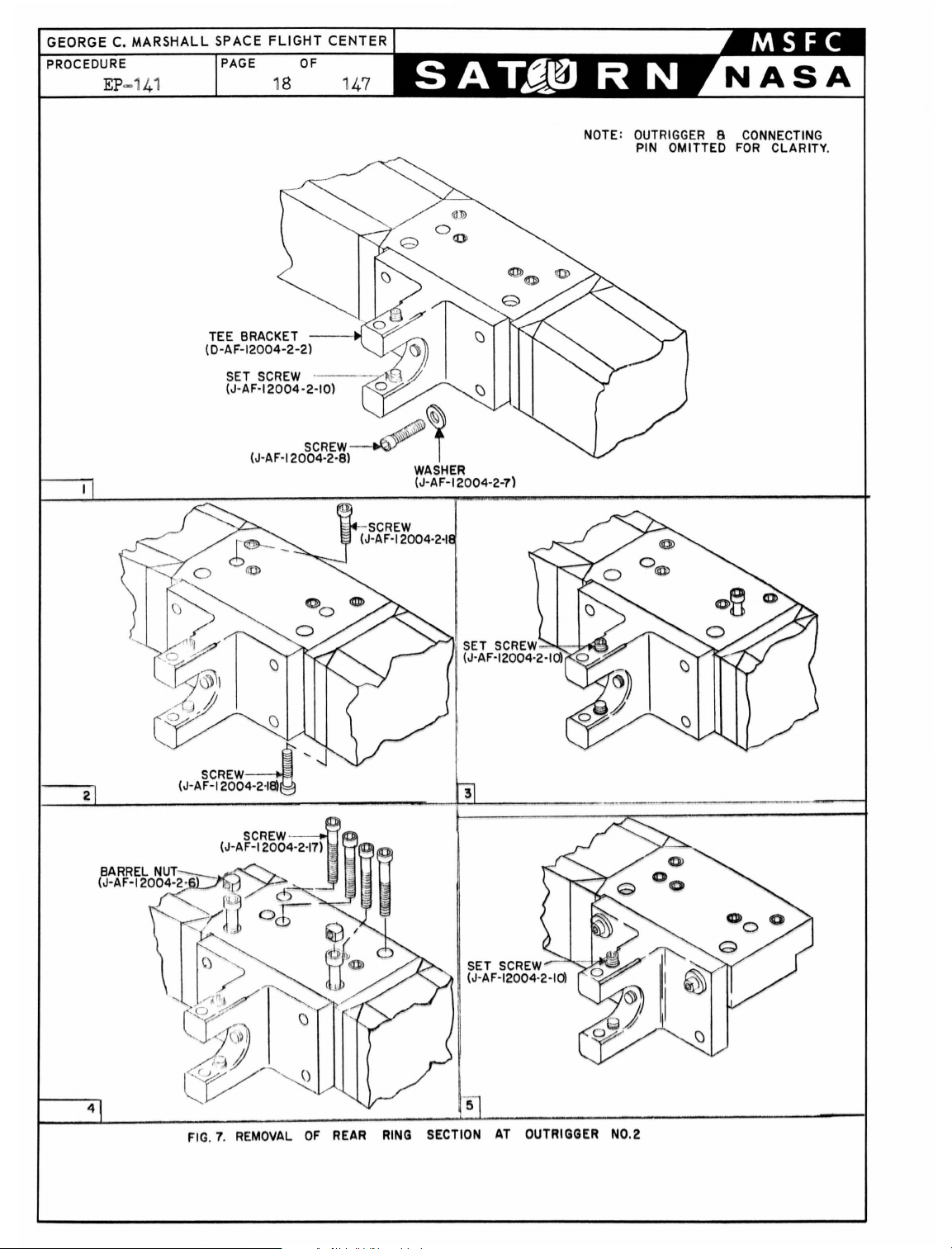

.3.4.4

OF

16 1

Disconnect

47

outrigger

t

ee.

Remove

at out ri gger No. 8. (See

tee

No.7

two

bracket

from

by removing

bol

t s only from base

rear

ring

four

bolts

figure 6.)

section

from base

of

t ee

bracket

at

of

1

.3.4.5

10

304.6

1.3.

4.7

1.3.4.8

1.3.4.9

NOTEg The

t ee

bra

until

erection

forces

Disconnect

t

ion

by performing

in

paragraphs 1

Connect tag

wi

t h

Fin

Lower personnel and t

fork

lif

hoisting

Wi

t h

personnel

lift rear

of

t he bOOster and lower int o working

crane.

Disconnect

ti

on

and remove choker

remaining t

wo

cket at outrigger

are

cables

obtained

rear

ring

are

from t he t

section

the

.3.3

.2 and 1

line

to

lower end

rv

identification.

ransportation

t and

rear

clear

ring

immediat e

section

positioned

ring

(See

section wit h

figure

ring

handling

5. )

bol

t s t hrough t he base

No

0 8

connect ed and

with

applicable

.3.3.3.

(See

free

t o

maintain a taut tag

Fin

brackets

lines

from mobile crane hooks.

will

remain

ower

and

Fin

procedures

of

rear

figure

ring

area

preparatory

of

booster

IV

identification

from

of

t he

installed

slight lifting

gantry

IV

identifica-

cranes.

outlined

ring

section

5.)

platform wit h

t o

.

line,

free

area with mobile

rear

ring

sec-

1

.3.5

103.4.10 Using

and

fork

lif

personnel

t ee bracket s from out

se

t screws and removing connecting

6. )

1.

3.4.

11

Lower transportati

t he ground with f ork lift.

Using fork lift, raise

form and

ring

Working

following

1.3. 5

1.

3.5

personnel

section wit h

t o a hei ght

Fin

from t he t ranspor t ation ring

.1

procedu

Connect

wi

th

figure

Fin

5.)

res

ring

II

:

.2 Using mobile crane wi

t o work

area

t , rai

t o a

and

II

se transpor

height as

riggers

on ring

position

as

necessary

Noo 6 and 7

pla

tform and pereonnel

transportation

neceSSary

identification.

platform

handling

bracket s t o

identification wit h

th two

hooks, lower crane hooks

and connect choker

tat

ion

(See

rear

bolts

lines.

ring

pins.

pla

and

disconnect

by

(See

tform

loosening

ring

for

removal

figure

4.)

, complet e t he

ring

and

nuts.

(See

section

figure

figure

to

platof

rear

(See

5. )

Page 18

T

CENTER

147

1.3.5.3

1.

3. 5

1.

3.5. 5 Disconnect r ear ring sect

Connect choker lines t o

ring s

ension

t

04

Disconnect t ee

out r i

of

by

ecti

on

on

crane

ggers NOe

each t ee

bra

performing

wi t h F

t he app

in

cables.

brackets

2 and 3 by removing

cke

t.

paragraphs 103.3.2 and 10303.

1.3.5.6

1.

3. 5.7

figure 8 for

numbers

.)

Connect tag l i ne t o lower end

Fin

II

ide

Inser

t t

section wit

and

secure tee

bol

t s . (See

NO

TEg The t

bracke

t at out r i

t he er ection

for

ces

are obtaine

identification

ntifica

wo

barrel nut

h Fi n I

brack

fig

wo bol

cables are connecte

t iono (See

identification at out r i

ur e 6

t s t hrough t he

gger

d from t he t ower and gant

ring handling bra

II identification

(See f i gu

from

rear ring sections at

re 5.)

four

(See f i

gure 6.)

ion wit h Fi n

licable

pro ced

30

of

Fin

of

ure

(See

Li nes and outrigger

rear ring

figure

s (J=AF=12004=2=6)

et

t o

rear ring

0)

base

Noo 2 w

ill

r emai n

d and

cket s on

and put

bol

II

identification

sligh

t s at

s outlined

figure 70)

section wit h

5.

)

in

rear

ring

gger No. 2

section wit h t

of

t he t ee

installed unt

slight

lifting

ry

cranes

rear

t

base

in

(See

wo

il

o

1.

305.8 Lower pe

fork lif t a

hois

t i ng

10

30509

Wi

t h pe

lift rear ring sec

of boos t

crane

1.

3. 5010 Disconnect

t

ion

10

3050

11

Using

pe

rso

bracke

screws

1.

305.12

Low

er pe

wi

t h

ransporter ont o t he

t

NO

TEg The aft end

hree

t

ring

No

o 2 and 8 at out

are sti

wo

of

t

sections stHl

rsonn

el and trans

nd cle

rear

rso

nne l positioned t o maintain

ar

ring sec

t i on with Fin

er

and lower i nt o worki

imme

t i

portat

dia

t e

on

free

ion

ring

area

preparatory

of

boos tero

II

i d

ng

area wit h mobile

0 (See figur e 50)

ring handling bracket

s from

and remove choker lines from mobi

fork

lif

t~

raise t

nnel

t o a hei ght

t s from out ri ggers

and r e

fork

points

moving conn

rsonnel

l i ft and

~

and t

t ee

brackets Noo

section with Fin I identifica

riggers

ll

connect ed t o t

t he four bolt

install

ransportati

as

necessary

Noo 3 and 4 by

ectin

g pins o (See

ransportation ring

clear

the

area

deflector pit

of

t he boost

er

1,

No

o 2 and 8,

heir

out

rigg

s t hrough t

ed o Tee

heir

bracket Noo 1

on r i

and di sconnect t

preparatory

bridgingo

is

2 and 8

t i on o Tee

er beams and have

base

pla

t form wit h

t o

a taut t ag l i

enti

fication

rear

l e

crane

ng

ring sec

hooks

pla

tform

loosening set

figure 60)

pla

t form

to

now

resting

of

t he

bracke

respe

ctively

t o t he ri

is

ne,

free

·=

and

ee

moving

on

rear

t s

y

ng

inta

o

ct

Page 19

GEORGE

PROCEDURE

C.

EP

MARSHALL

~141

SPACE FLIGHT CENTER

PAGE OF

18 1

47

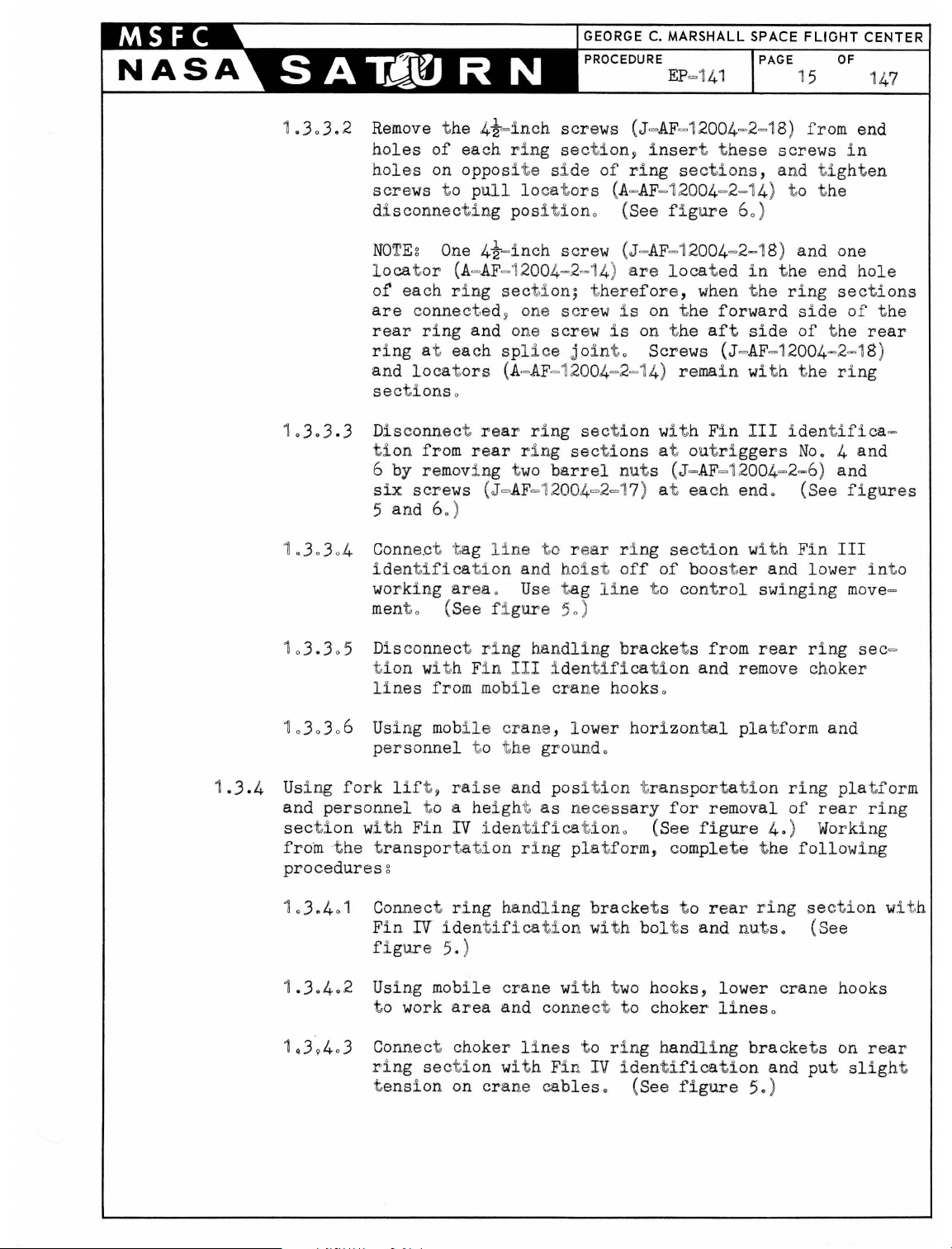

TEE BRACKET

(D-AF-12004-2-2)

(J-AF-12004-2-8)

SCREW

-~

,

WASHER

(J-AF-12004-2-7)

NOTE: OUTRIGGER 8 CONNECTING

PIN OMITTED

FOR

CLARITY

.

SET

SCREW...::...J

(J-AF-12004-2-10l

l-

lrl1!

~

FIG. 7. REMOVAL

OF

REAR

RING

SECTION

AT

OUTRIGGER NO.2

Page 20

U>

b

z

a:

w

<.!)

<.!)

r--.

b

z

a:

w

<.!)

<.!)

a:

I-

::>

0

CD

b

z

a:

w

<.!)

<.!)

PAGE

OF

19 147

10

b

z

a:

w

<.!)

<.!)

a:

I-

::>

0

~S

<.!)

z

0:

z

0

i=

~

a:

0

0..

en

z

<I:

a:

Il-

LL

<I:

~

b

z

a:

w

<.!)

<.!)

a:

I-

::>

0

f()

b

Z

a:

W

<.!)

<.!)

a:

I-

::>

0

b

z

a:

w

<.!)

<.!)

a:

l-

::>

0

b

z

~H

LL

0

a:

<t

~

a:

0

LL

<.!)

Z

:lI::

0

0

...J

~

W

:;:

l-

LL

<t

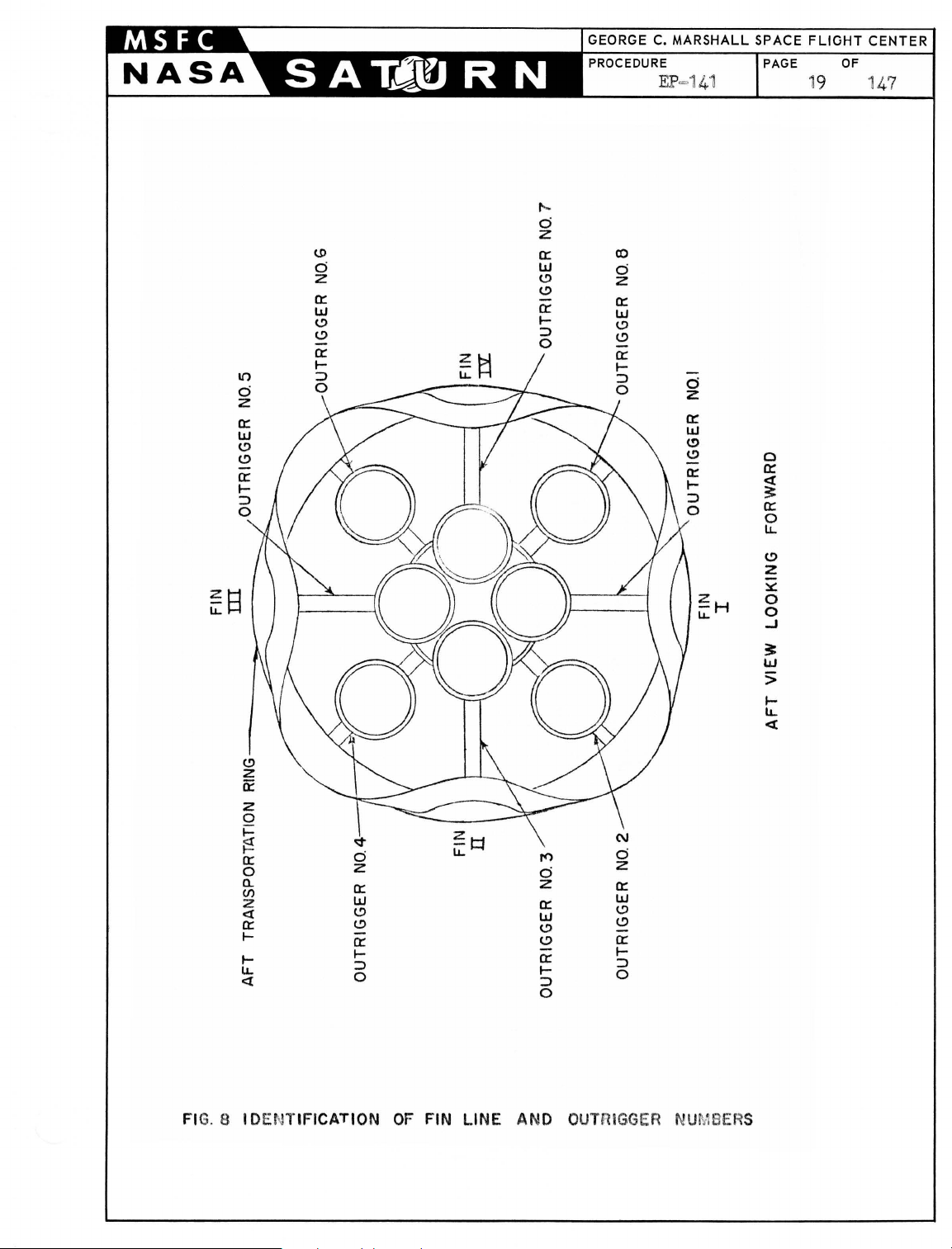

FI

G.

8 I

DE

NTIFICATION

OF

FIN LINE AND

OUT

RiGGER

NUMBERS

Page 21

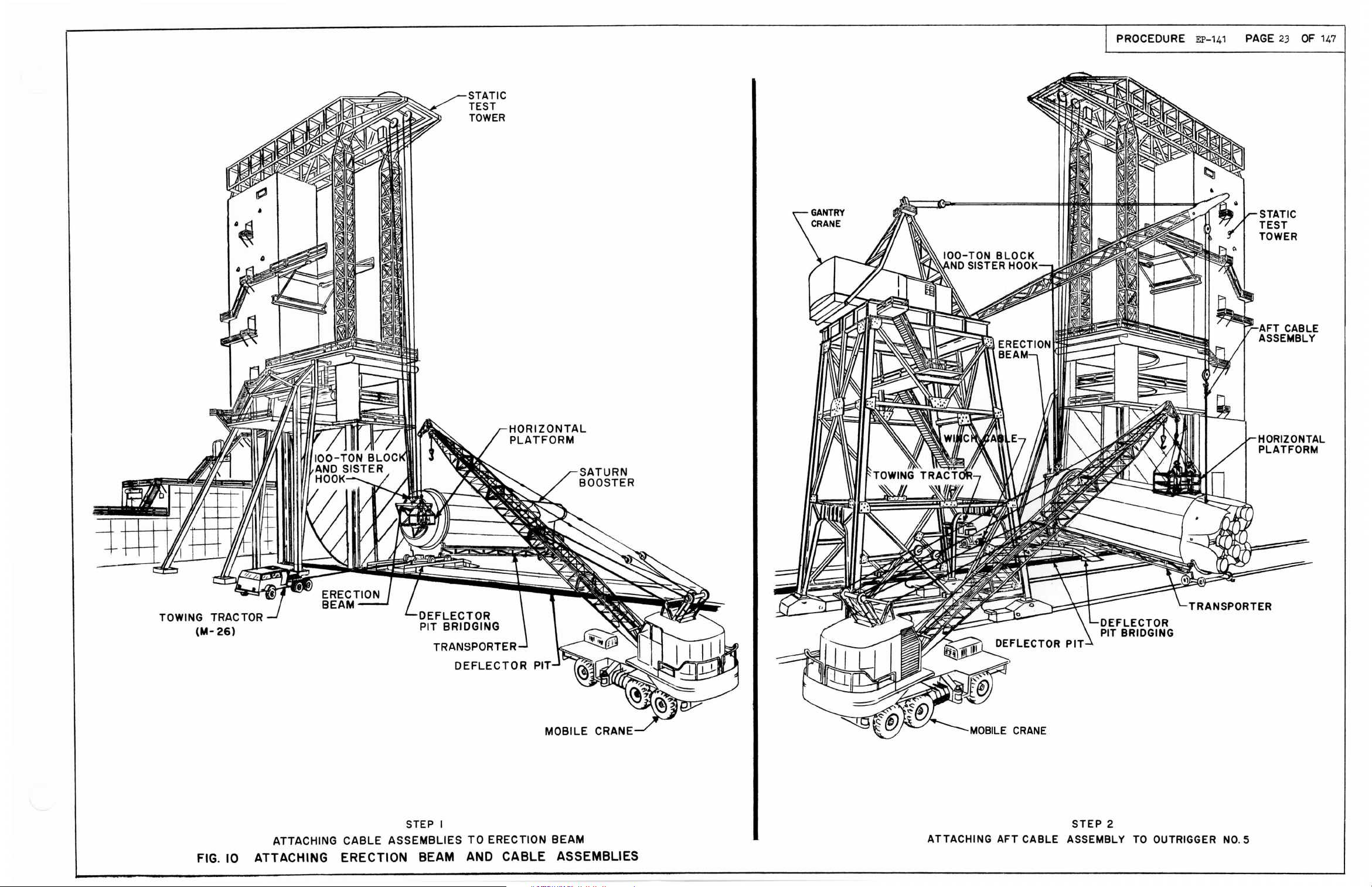

GEORGE C.

PROCEDURE

MARSHALL

EP

=141

SPACE FLIGHT CENTER

PAGE 2 OF 1

0

47

20

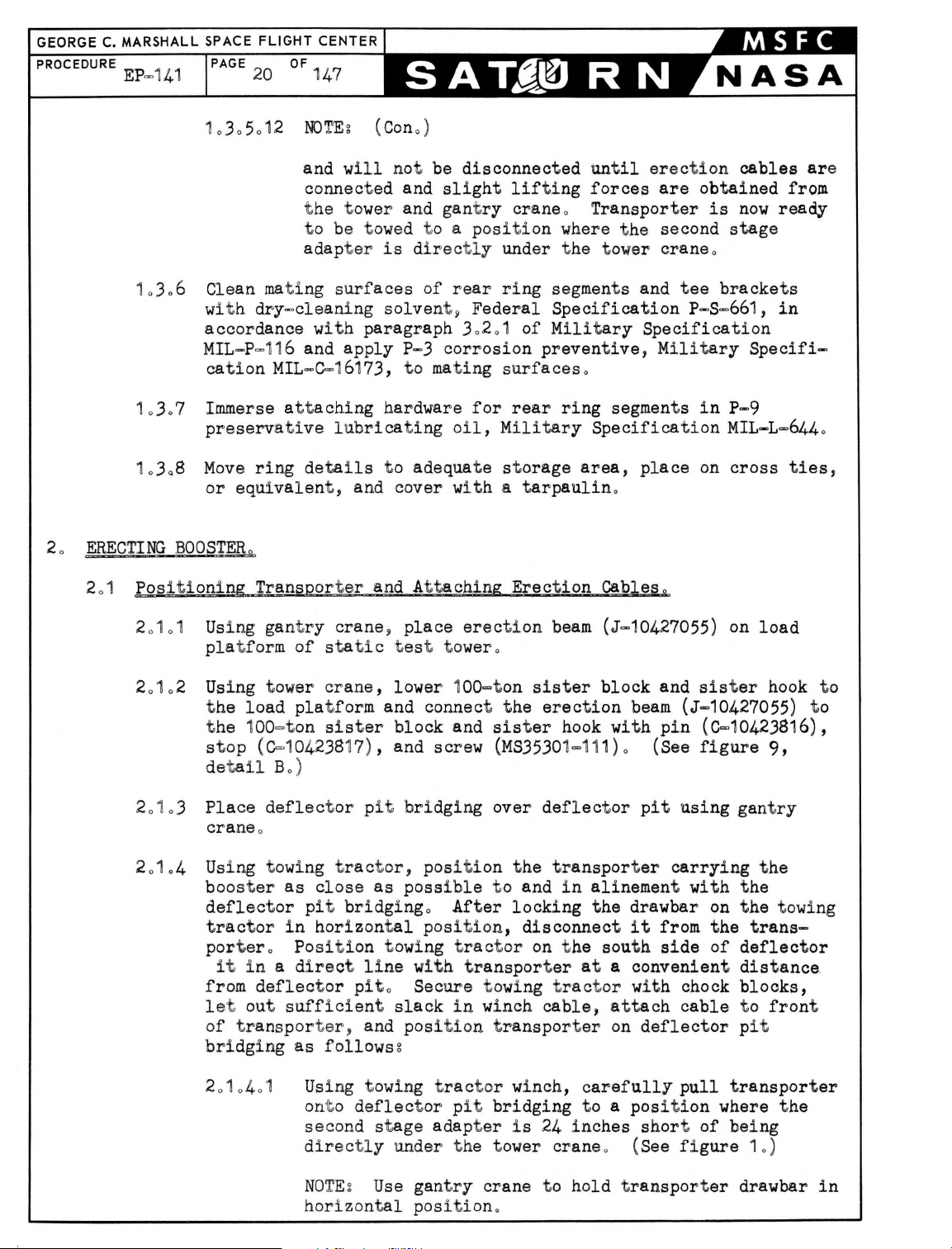

10306

10307

10

308

ERECTING

2

01

Pos

2

0101

and wil l not be

connec t ed and

th

e t

ower

and gant

t o be t

adap t

Clean mating

wi

t h

dry~cleaning

owed

er

is directl

surfaces

solven

accordance wit h paragraph 302

MIL-P=11

cation

Immerse attaching

preserv

Move ring

or

BOOSTER

iti

oning T

Using gant

pla

6 and

MIL

-C=1

ati

ve

details

equivalen

o

ransporter

ry

t form

of

apply

6173, t o mat

hardware

lubricating oil ,

t o adequat e st orage

t , and cover w

and A

crane

static

~

t es t t

disconnected unt

slight

t o a

lifting

ry

crane 0

position

y under t he t

of

P-3

rear

t~

corrosion

ring

Federal

01

ing

surfaces

for

of

rear

Military

ith

a t

arpaulin

tta

ching Erect

place erection

ower

o

il

erection

forces

are

Transporter

where t he second

ower

crane

cables

obtained

is

now

stage

o

segment s and tee bracke t s

Specification

Military

prevent

ive,

p-s=66

1,

Specification

Military

Specifi-

o

ring

segment s

Specification

area,

place

in

P-9

MIL-L

on

cross ties,

0

ion

beam

Cab1es

(J~10427055)

g

on

load

are

from

ready

in

=6440

10

2 Using t

2

0

t he l oad

t he 100=t

st

de

20103 Place

cra

2

0104 Using t owing t

boost

ower

pla

on

op

(C=10423817) , and screw

tail

Bo)

defl

ne

o

er

as

deflector pit

t

ractor

portero

it

from

l

et out

in

Position towing tractor

i n a dl

def

lect

sufficient slack

of transporter , and pos

bridging

as

crane,

t form and connect

sister

lower 1

00=ton

block and

sister

the

sister

(MS3530

ect

or pit

ractor,

close

bridgingo After

horizontal

bridging

as

poss

over

position

ibl

e t o and

pos

ition

t he t

locking

, disconnect

on

rect line with transporter

or pito Secure towi

in

ng tractor with chock

winch

ition transporter

follows

Using t owing

onto deflect

second

d

irectly under t

g

stage

t

ractor

or pit

bridging

adapter i s

he tower

winch,

block

erection

hook wit h

1=11

1) 0 (See

deflector pit

ransporter

in

alinement wit h t he

the

t he south

at a

and

sister

beam

(J=10427055)

pin (C=1

figure

using

carrying

drawbar

it

from

side

on

the

of

convenient

0423816),

gant

t he towi

deflector

dis

blocks,

cable, attach

on

carefully

t o a

24 inches

cable

deflector pit

pull transporter

position

short of

where t he

being

t o

crane 0 (See fi gure 10)

hook t o

9,

ry

t he

trans-

t ance.

fron

to

ng

t

NO

TEg

hori zon

Use

tal

gant

ry

crane t o hold t

position.

ransporter

drawbar

in

Page 22

= _ '

_0

r~

O

__

y-

~

A / ' '

~

--£

~'I .-=~"

"

~

r

-

o-"

~

4-

~

"-

"

TON

100

SISTER

HOOK

BLOCK

ERECTION

BEAM

(J-10427055)

"-

f11

- -

' -

BUMBER ASSY (0-

2-BUMPER

~~~~

]

!

~

I

I

10426438)

(0-10426434)

PIN (C-10424412)

~424

:

~)

PAGE

21 147

1\~,\

A

/-

GANTRY

\

).1

BLOCK

https://manualmachine.com/-

AFT

r ASSEMBLY

Il

(0-10423292)

111

(

CONNECTING

{/'

(~~~424657)

1

i~

A

__ 1

~

OF

CRANE

ASS'Y

CABLE

f---------

CONNECTING

TYPICAL

__

NOTE:

BUMPER

NEVER

HAS SOME VISABLE

"-----

------

-----

_____

ERECTION

~

~

·

PIN

----~

FORWARD

TWO

__

.. ______________

ASSEMBLY

BE

LESS THAN

~:

CABLE ASSEMBLY

(J-10424

PLACES

10426438

SPACE

(J-10427055)

~~

ERECTING

771)

IS

90°

FROM

BETWEEN IT

--

2-CABLE

ASSY

(J-10424771

~1

_

~

~

-

-----

f~-

---.---

BEAM

COTTER PIN

--

:::~

J

-

I

_

__________

NOT

DESIGNED

THE

HORIZONTAL CENTERLINE

---

AND

------

FIG.9 ERECTION BEAM INSTALLATION

...

J

~

__

TO

RESIST

EXCESSIVE LOADS,

THE

BUMPER ASSEMBLY_ C

--------"

._.-

--

L--::::::

\

~

[

OF

THE

--

-

---------------

-----.

BOOSTER

,

TOWER

CRANE CABLES SHALL

SO

THAT THE SISTER

8

HOOK

Page 23

GEORGE

PROCEDURE

C.

MARSHALL SPACE FLIGHT CENTER

EP

=141

PAGE

22

OF

"1

47

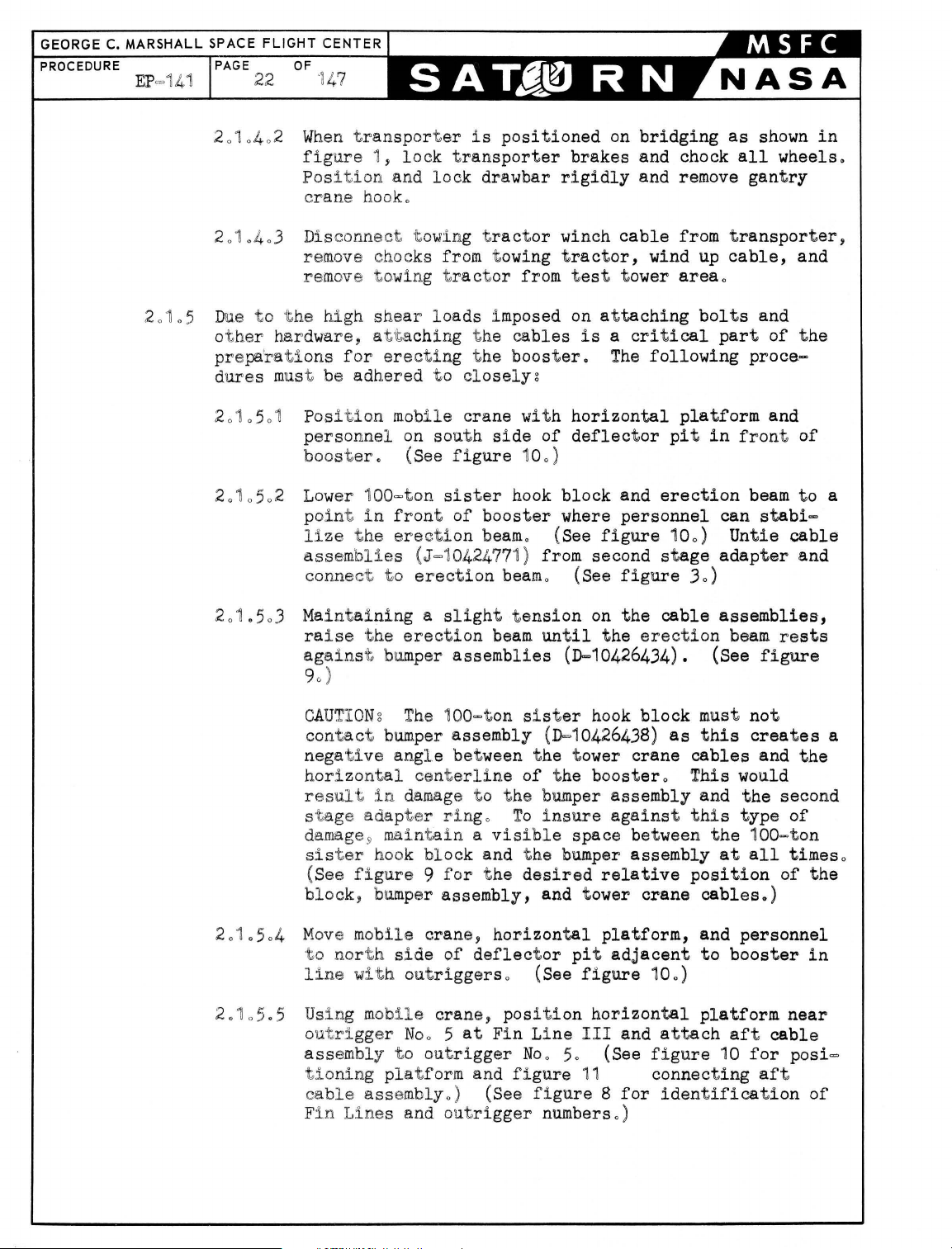

20105

2010402 When tran

fig

ure

1,

Position

c

ran

e hook.

2010403

Disconnect t owing

remove chocks from t owing

remove towi

Due to

ot

prepa'rations

dures

2

0"10501

her

the

high

hardwar

mus

t be

Pos

shear

e, at'ta

for

adhered

ition mobi

personnel

booster.

2

010502 Lower

100=ton

point in

l

:l.ze the

201.5

03

assemb

conne

Mai

ra

lies

ct

ntai

ning a slight

ise the

against bum

90 )

sporter i s

lock

and

lock

tran

drawbar

positioned

sporter

tract

ng t

ractor

l oads imposed

chi

ng

the

erecting the

to

closelyz

l e

crane

on south

(See

side

figure 100

sister

front of

booster

erection beamo

(J=1

0424771 ) from second

to

erection

erection

per

beam

assemblies

or

from t

cables

booster.

with

of

)

hook

(See

beam

o (See

tension

until

on

bridging

brakes

rigidly

winch

and chock

and remove

cable

tractor,

est

tower

on

attaching

is a critical

The

horizontal

deflector

block

where

and

personnel

figure

wind

following

pit

erection

100)

stage

as

from

area

transporter,

up

cable,

o

bolts

part

platform

in

can

Untie

adapter

figure 30)

on

the

the

cable

erection

assemblies,

beam

(D-10426434). (See

shown

all

wheels.

gantry

and

and

of

the

proce-

and

front of

beam

to

stabi=

cable

and

rests

figure

in

a

2

0'10

2.105

CA

UTIO

Ng

The

contact bum

per

negative ang l e between

horizontal

res

ul t in

centerl

damage

stage adapter

darnage9 maintain a visi

sister

(See f i

hook

gure 9 for

block, bumper

504

Mov

e mobile

t o nor t h

side

line with outriggerso

.5

Using m

o

utrigger Noo 5

assembly

tioning

ca

F

in

ble

Line

obUe

to

pla

tform and

assemblyo

s and out

100=ton si

ster

hook

assembly (D-10426438)

the

t ower

ine

of the boostero This would

t o

the

bumper assembly and

ringo

block

assembly,

crane,

of

crane,

at

outrigger

) (See

To

insure

ble

space between

and t he bumper assembly

t he

desired

and tower

horizontal

deflector

position

Fin

pit adjacent

(See

figure

horizontal

Line

III

Noo 50

figure

11

figure 8 for

rigger

numberso )

block

crane

as

cables

must

this

not

creates

the

against this type

the 100

at

all

relative

platform,

crane

position

cables.)

and

personnel

to

booster

100)

platform

and

(See

attach

figure

aft

10

for

connecting

identification

and

second

of

=to

times

of

near

cable

aft

a

the

n

o

the

in

posi=

of

Page 24

STATIC

TEST

TOWER

PROCEDURE

EP-141

PAGE

23

STATIC

TEST

TOWER

FT

ASSEMBLY

OF

CABLE

147

TOWING TRACTOR

(M-

26)

DEFLECTOR

PIT BRI DGING

TRANSPORTER

DEFLECTOR

HORIZONTAL

PLATFORM

MOBILE

HORIZONTAL

PLATFORM

SATURN

BOOSTER

TRANSPORTER

DEFLECTOR

PIT BRIDGING

CRANE

FIG.

STEP I

ATTACHING

10

ATTACHING ERECTION BEAM AND CABLE ASSEMBLIES

CABLE

ASSEMBLIES

TO

ERECTION

BEAM

ATTACHING

AFT

CABLE ASSEMBLY

STEP

2

TO

OUTRIGGER

NO.5

Page 25

~

GANTRY

BLOCK

CRANE

ASSEMBLY

- - - -

---

-

---

CONNECTING

---

PIN~

~

--------AFT

.

~

...

-----

CABLE

ASSEMBLY

(0-10423292)

COTTER

PIN

CONNECTING

(0-10424657)

NUT

OUTRIGGER-------.y-

LINK

(DOG

BONE)

~

.

~

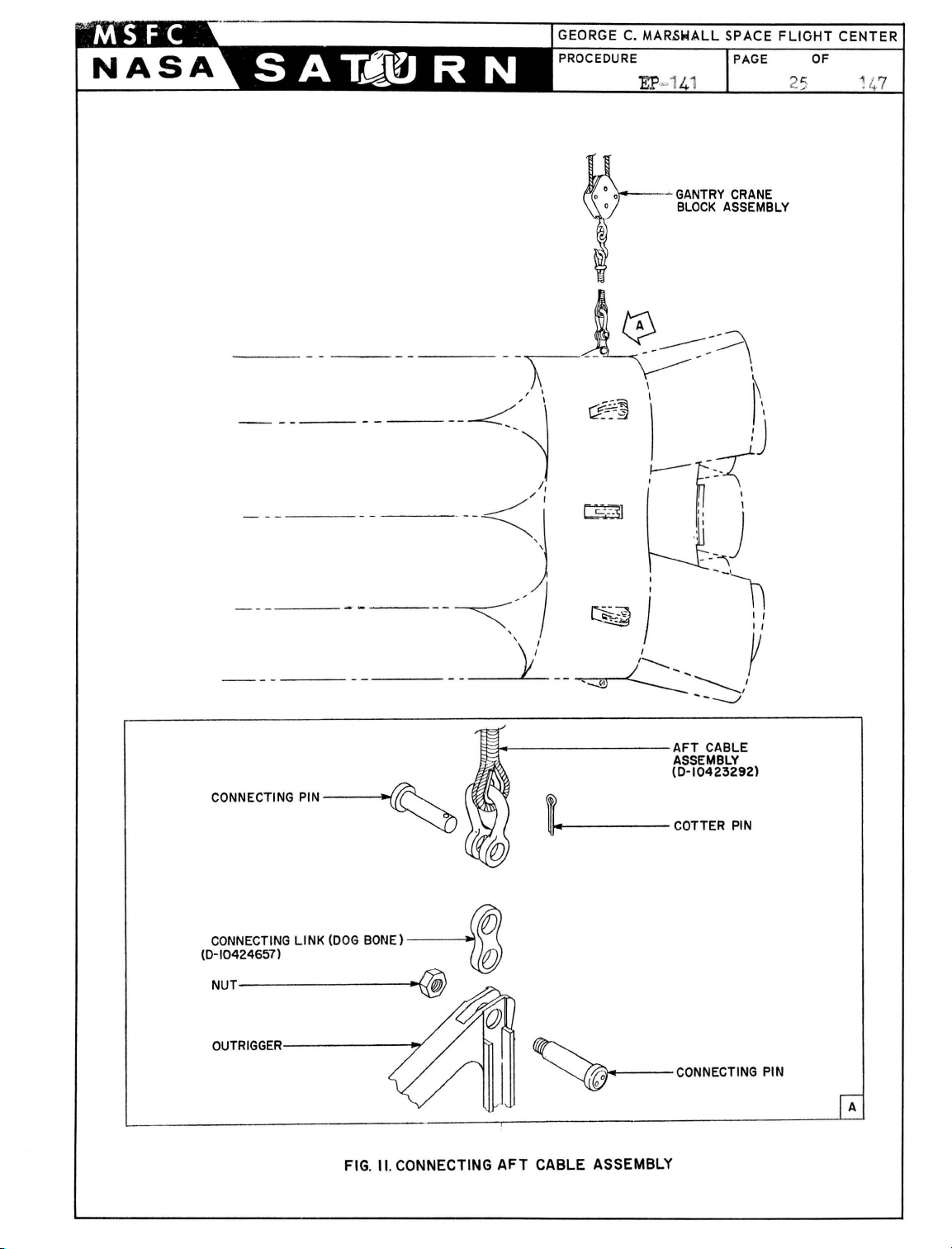

FIG. II. CONNECTING

@;

AFT

~

CABLE ASSEMBLY

CONNECTING

PIN

A

Page 26

PROCEDURE

EP-141

PAGE

26 147

OF

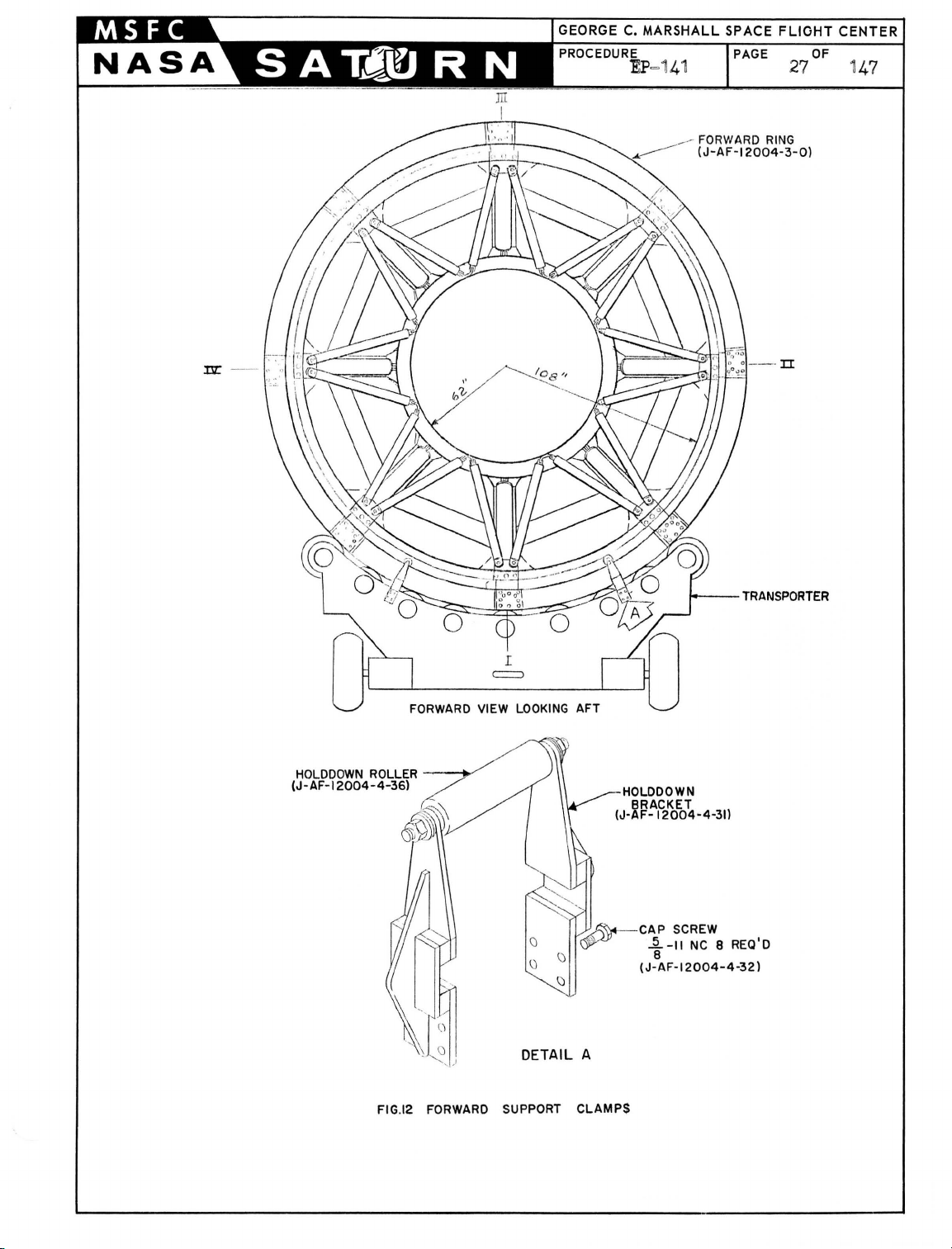

201.5

2.1.5

2

.1.

508 Using

2.105

2.1.50

.6 Lower gan t

assembly

NOTE:

lifting

ry

gant

forces

t he boos t

ry

t o

Prior

forces

cranes

should not,

er

ware yet t o be r e

07

Remove

aft se

set

Connecting

figure

ring

of

.9

Remove two

bracke

large

t screws

screw t hrough

pin

60

)

fork

pla

lif

t form and

t he boos t

rema

t at out ri

10 Disconnect t ee

loosening

(See

figure

set

crane

block

to

as

Bal~lok

er

block

assembly

assembly. (See f

t he

following

must be

obtained

t o support t he

however, be

t hi s would

moved

in

t ee

base

remains

t ,

raise

cause

from t he

pin

and

bracke

of

t he t ee

in

out

and

position

personnel

at outriggers

ini

ng bol

ggers

brackets

t s t

No

2 and 8.,

o

from outriggers

and at

igure 100)

proceduresy substantial

from t he tower and

booster

great

.

enough t o

binding

forward

loosen

t at out

rigg

t he

rigger

is

t o remain

er Noo

t he transportation

as

necessary

No.2

hro

ugh b

and 8

ase

(See f

screws and removing connecting

60

)

tach aft

The

lifting

of

t he

and

rear

forward

No.1.

10

(See

on

each

of

rear

of

each tee

igure 60)

No

2 and 8 by

o

lif

hard-

fixed

pins.

cable

t

rings

and

The

.

side

ring

o

.

NOTE:

lower

porter.

2.1

05.11 At

tach two

NOTE~

equal,

201.5.12

Place

Lower

201.5.

13

fork

Remove

lif

porter

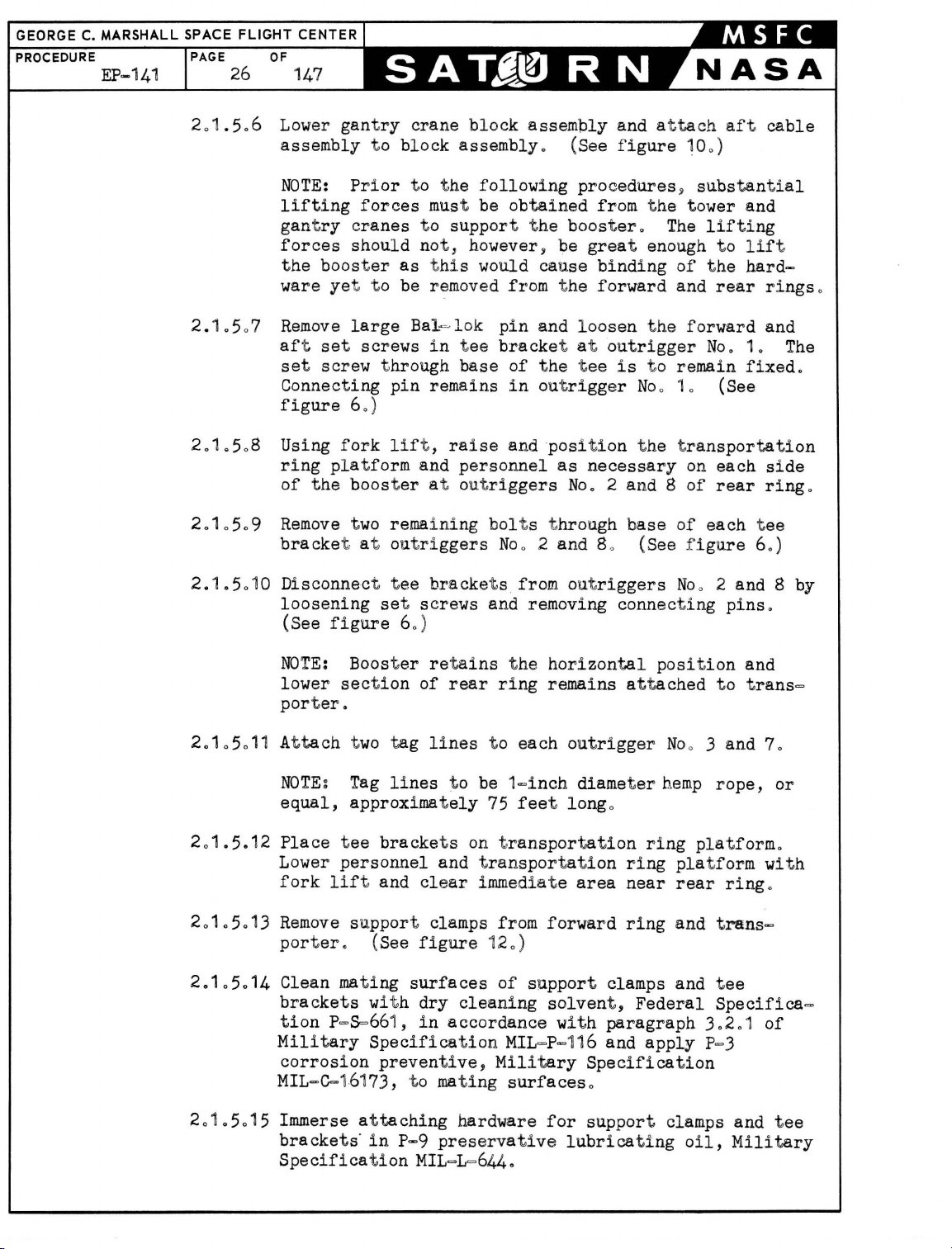

2.1.5.14

Clean mat

brackets wit h

tion

p=s=661,

Military

corrosion

MIL=C=

01.5.1 5 Immerse at

2

bracke

Specification

Boost

section

approximately

tee

personnel

er retai

tag

Tag

lines

bracke

t and cle

of

rear

lines

t o be

t s on t

and t

ar

ns

ring

t o

75

ransportati

immediat e

support clamps from

. (See

ing

figure

surfaces

dry

cleaning

in

accordance

12

of

Specification

preventive,

161

73,

taching

t s'

in

t o mati

P-9

preservative

MIL

Military

ng

hardware

=L=644.

the

horizontal

remains attached

each

outrigger

1=i

nch diamet

feet

long

o

ransportation

on

area

forward

0)

support

clamps and

solvent,

with

paragraph

MIL

=P-116 and

Specification

surfaces

for

0

support

lubricating

position

Noo 3 and 70

er

hemp

ring

ring

near

ring

pla

rear

and

Federal

apply

clamps and

oil,

and

t o t

rans=

pla

rope,

tformo

or

tform wit h

ring

o

trans=

tee

Specifica=

3.2.1

of

P=3

tee

Military

Page 27

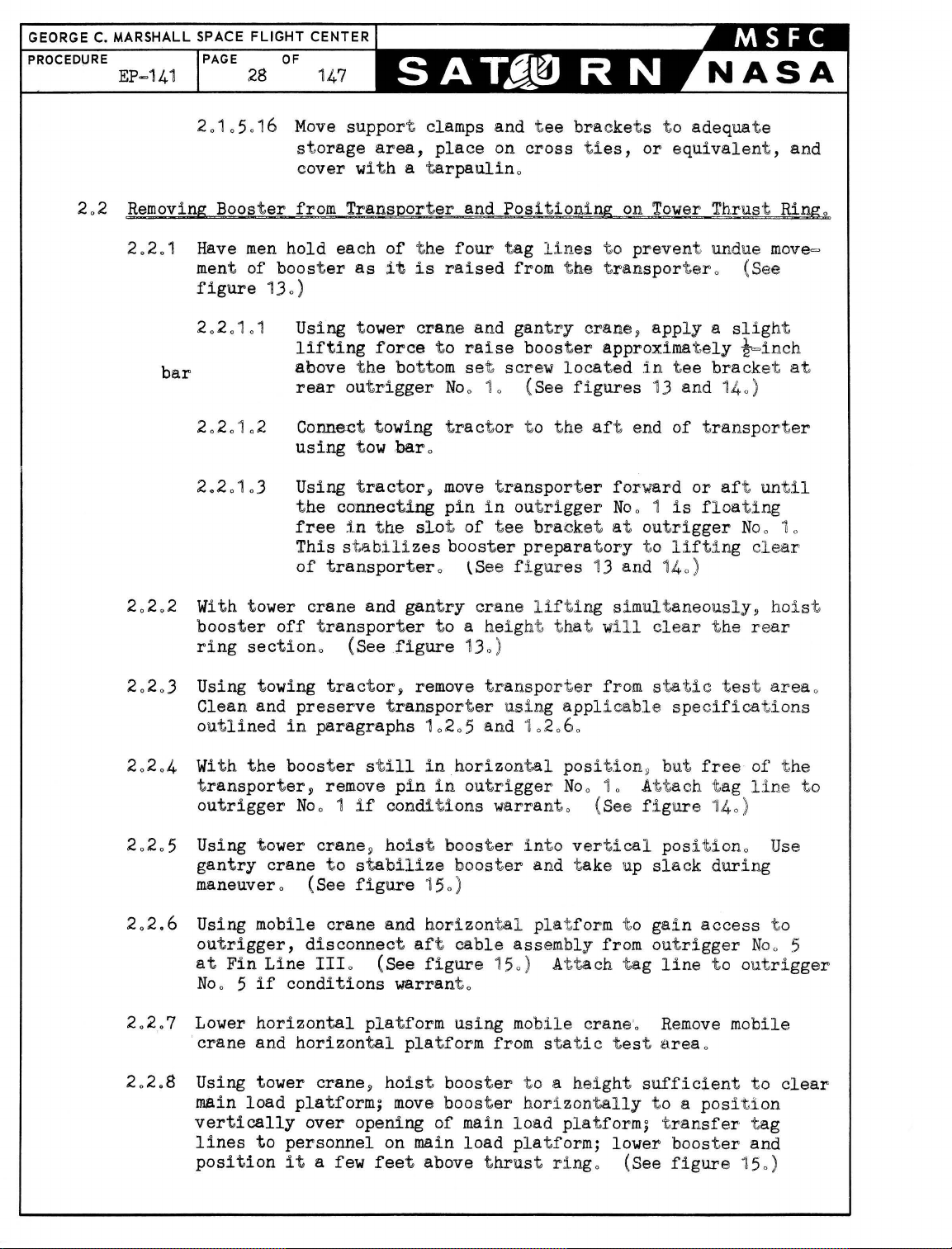

GEORGE C.

_-

________ . (J-AF-12004-3-0)

FORWARD

RING

HOLDDOWN

(J-AF-12004

FORWARD

ROLLER -

- 4-36)

--1

V

=

VIEW

LOOKING

DETAIL A

AFT

-HOLOOOWN

BRACKET

(J-AF-12004-4-31l

Y/~

CAP

~

(J-

1----

SCREW

i-II

NC 8 REa'o

8

AF-12004-4-32)

TRANSPORTER

FIG.12

FORWARD

SUPPORT CLAMPS

Page 28

GEORGE C. MARS

PROCEDURE

202

Removing Boost

L SPACE

PAGE

201

0

FLIGHT

28

5016

er

CENTER

OF

147

Move

storage

c

ov

from

support clamps and t ee

area,

er

with a tarpaulin

Transporter

place

and

on

Positioning

bra

cross ties,

0

cket s t o adequat e

or equivalent, and

on

Tow

er Th

rus

t Ringo

2.201

Have

ment of

figure

bar

20

20102

2020103 Using t

202

02 With tower

booster

ring

20203

Using towing

Clean and

ou

tl

men

hold

boost

13

0)

Using t ower

lifting

above t he

rear

Gonne:c

using tow

the

free

This st.

of

crane

off transporter

section

o

preserve transporter

ined

in

paragraphs

each

er

as

of

it

force

bottom set scr ew

out

rigger

t towing t

bar

rac

t orjl

connecting

In t he

l9.b.ilizes

transporter

and

gantry cra

(See

figure

tractor,

t he

four

is

raised

cra

ne and gant

t o

tag

from t he

raise boo

lin

ry

ster

es

to

transporter o (See

crane~

approximately t=inc

located

No

10

o

ractor

0

(See f i

t o t he aft end

move transporter

pin

in

out

slot of

t ee

booster

prepara

bracket

rigger

gur

es 13 and 140)

f orward

No

at out

t ory t o liftin

o tSee f i gur es 13 and 14

ne lif t i ng

to

a hei gh't that wi

sim

ll cle

130)

remove tran

10205

sporter f rom

us i ng app

and

10

2060

licab

prevent undue move=

appl y a

slig

ht

h

in tee

bra

of

t ransporter

cket

at

or aft unt i l

0 1 i s

floating

rigger Noo

10

g clear

0)

ultane ous

ar

stat

le specifi ca

ly~

hoist

t he r e

ar

i c test ar ea

tion

s

o

20204

Wi

t h

the

booster still

t

ransportery remove

out

rigger

No

20205 Using tower

202.6

202,.7

20

2.8

gantry

maneuver

Using mobile

outrigger,

at

No

Lower

'

crane

Using tower

main

vertically

lines

position

Fin

if

5

o

horizontal

and

load

to

crane

0 (S

Line

conditions

horizontal

platform,

personnel

i t a few

in

horizont,a

pin

in

out

rigger

0 1

if

crane

t o

ee

crane

cond! t

~

hois

sta

bi lize booster and take up sl ack

figure

and hori zontal pl at form t o gai n

ions

t boost

150)

warra

er into

disconnect aft cable ass

1110 (See f i

gure

150) A

warranto

pl at form

pla

craney hoist booster

move

over

opening

on main

fee

t above t

using mobile c

tform from stat i c test H

t o a he

boost

of

er hori zon

main

load

load

pla

hrus

l

posi

t.i

on~

but free

No

10

At

o

nt

0 (See f i g

vertical positi

tach tag line t o

ure

14

0)

ono

duri

access

embly from outrigg

er Noo 5

ttach tag line t o outr i gg

ran

e'. Re

ight suffici

tall

pla

tform, transfer tag

t form; lower boost

move mobile

rea

o

ent

y t o a posiUon

er

t ringo (See f i gur e

of t,he

Use

ng

t o

to cle

and

150

)

er

ar

Page 29

TOWER

CRANE

HOIST

PROCEDURE

EP-14f

AGE

29

OF

stATIC

TEST

TOWER

147

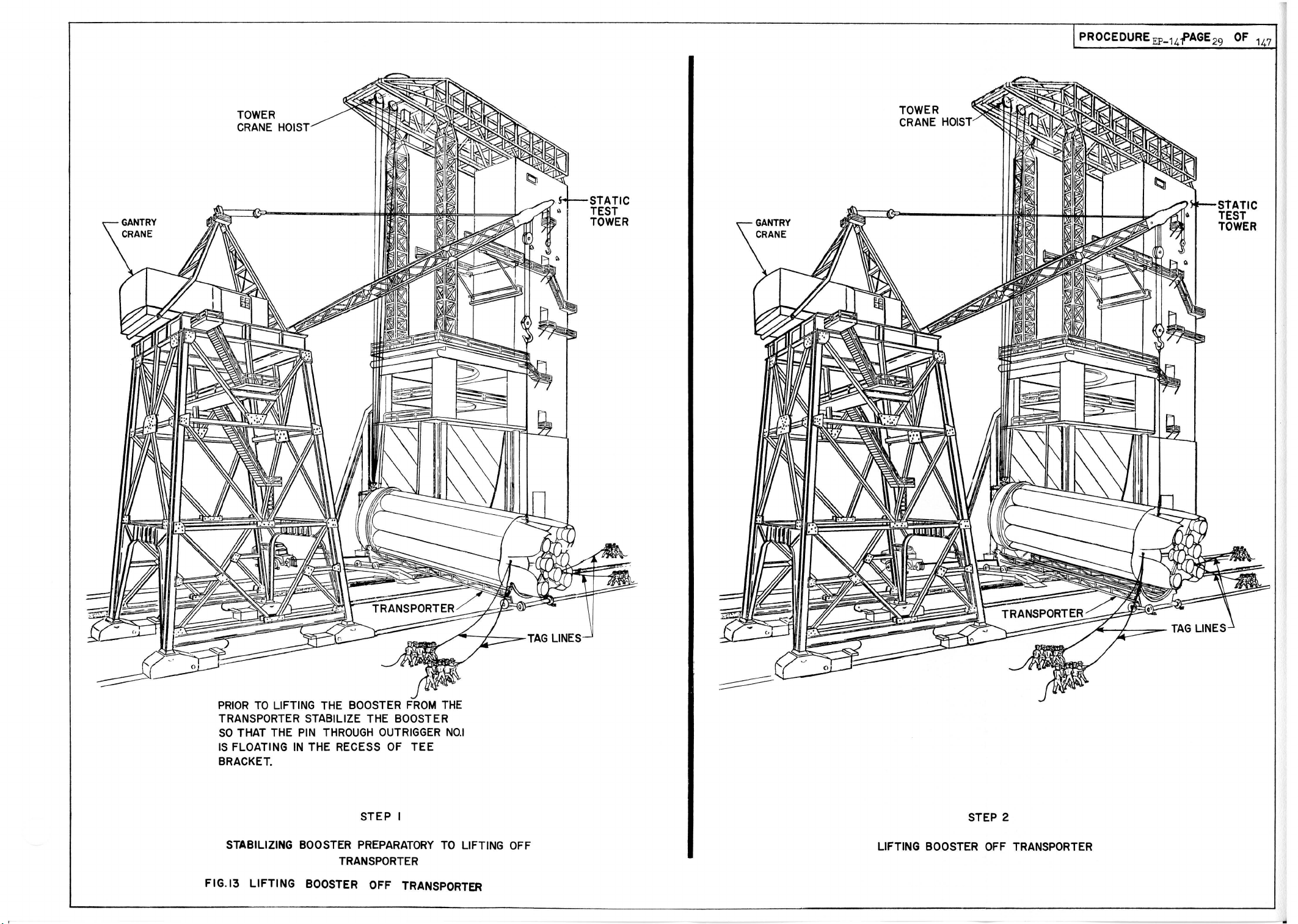

PRIOR

TO

LIFTING THE BOOSTER

FROM

TRANSPORTER STABILIZE THE BOOSTER

SO

THAT THE

IS

FLOATING

PIN

THROUGH

IN

THE RECESS

OUTRIGGER

OF

TEE

BRACKET.

STABILIZING BOOSTER

STEP

PREPARATORY

I

TRANSPORTER

FIG.13

LIFTING

BOOSTER OFF TRANSPORTER

THE

NO.1

TO

LIFTING OFF

STEP 2

LIFTING BOOSTER

OFF

TRANSPORTER

Page 30

OUTFllGCiER

[\10.

1

PIN CONNEC

(B-AF-12004-2-3)

FIG.14. BOOSTER

TING

STABILIZATION

PREPARATORY

TO

LIFTING

OFF

TRANSPORTER

Page 31

PROCEDURE

PAGE

OF

Page 32

GANTRY

CRANE

TOWER

CRANE HOIST -

IOO-TON BLOCK

AND

SISTER HOOK

ERECTION

BEAM

AFT

CABLE

ASSEMBLY -

NO

.5 OUTRIGGER

--------1+-f---+!I

.......,.

....

~~~~~~

~

~~

PROCEDURE

OUTRIGGER

TEST

TOWER

PIN

~

ASHE

~<9

~

~\

~

~

NUT

A TYPICAL 8 PLACES

~

TIEROD

EP_1~GE

33

OF

SUPPORT

BRACKET

NUl)

WASHE~~

D

147

DETACHING

STEP I

AFT

OUTRIGGER

CABLE ASSEMBLY FROM

NO

.5

MOBILE

CRANE

o

STEP 2

POSITIONING BOOSTER

ON

TEST

TOWER

FIG.

15

BOOSTER

IN

VERTICAL

P{)SITION

Page 33

CENTER

20209 Us

tower

2020

'W

Remove tag

on

outrig

202

011

Inser t t est t ower pins (

accordance wit h inst ructions from M

202012 Us

'tower

202.13

202

Remove ga

014

Disconnect cable

adapt

cl e

CAUTION

blies t o prevent

202

015

The removal of bumper

(D=10426434)

I=>beams No

insi~ructions

(See fi gur es 3 a

in

g tag

t o t,h

in

g gant

er 0 Ra

ar

lines

support

rus

t ringy usi

gers

ry

area

0

~

brac

lin

es

int

o suppor t

crane,

aline

ket s

and lower booster through main

ntry crane

assem

i se

erection

of

boost

er

and lower t o t he groundo (See

g Care must be

damage

an

d t he

0 3

~

4)

5)

as

out

nd

boost er out r i

o

ng p

bracke

figure

remove

(See f i

ersonnel

defl

gure

t s o (See

16)

ect

or pit

from test t ower

blie

s (

J=1

0424771) from

beam

with

exer

ci sed

in

t o t he second

assembly

installation

(D=1042643

of

6 ~ and 7 1s essenti

line

d i n

paragraphs

4

0)

ggers wit h

15

0)

t o s

tea

dy

booster

figure

in

support

=TEST

LAB

o

bridging

area

o

cable

assemblies atta

disconnecting

stage

adapter o

8) and bumpers

original

ally

1020101

respective

load

pla

and

)

16

0

bracke

t s

from test

se

cond

stage

figure

cable

hardware at

t he

reverse

thr

ough 1

tes

tform

guide

in

ohed

3

0)

asseffi=

of

2

1

0

0

0

t

40

30

202016 C

REl10VI NG

.3

0 1

Pr

epar i

30

101

3

010

3

0103

3

0104

0105

3

le

ar

t,est t ower

BOOSTER

FROM

ng BOQ,ster

Pla ce

deflect

crane 0

< U

sing

t owing t

possi bl e t o and

A

ttac

h gant

horizo

ntal

Di sconnec t t

so

uth

si de of

and i n

lin

Attach wi nch

pos

,ition on t he

When transport

as shown

wh

eel

so

area

TEST TOWER

for

Rem

or pit

ractor

in alinemen

ry cra

ne t o drawbar and support t he drawbar

positio

ractor

the

e

with

the transporter 0 (See fig

to tra

defl

er

i s posi t i oned on

in

f igure

,

o

ovaL

bridging ov

, p

osi

t i on t he t

t with t he

no

from t ransport

def

lector pit

nsport

er

draw

ect or pi t b

1j

l ock tran

er deflect

ransporter

deflector pit

er

and move t he t

with

bar

ridgin

the tractor

and winch t

go (See

deflector

sporter

brakes

or pit

as clo

ure

1

ransporter int o

figure

pi t br idgin

and chock

using

bridging

ractor

wi nch

0)

gant

se

in

facing

10

)

g

ry

as

o

a

t o t he

all

Page 34

GEORGE C. MARSHALL SPACE FLIGHT CENTER

PROCEDURE

EP~141

PAGE

36

OF

1

47

NOTE:

SHROUD

NOT

SHOWN

A TYPICAL 8 PLACES

FOR

CLARITY

FIG. IS-POSITIONING BOOSTER

OUTRIGGER

------~--.-

ON

-

SUPPOR

T BRACKET

.---~--

.

..

--

- ----.

Page 35

MARSHALL

SPACE FLiOH

PAGE

37

OF

1

47

301.6 Lock

Move tractor

of t

30

107

010

3

30'09

.3

0 10 '

Uslng tower cra

wi

t h

to

a position

8 R

emove doors

4

~

5,

Install

A

~

fi gure

10

Ins

tall

f i gur e 30

30'

;11

Low

a

nd

washers,

f i gure 30

WARNING

i s ext remely impor

'U

sedo Lu

and each si de of t he

obtaining

from

a

tta

and posi t i oning

dra~bar

in

t o nor'th

ransporter o

erection

and

6

~

a

nd 7 as outlined in

bumper assem

.3

0

bumpers (0=,1042

er er

ection beam with

i ns

tall cable

and

nuts

g Corr

bricating the

a torq

th

e head

chme

nt

hardware

rigid

ne, low

beam

pos

iti

on

side

of test t ower and at

er 100=ton si st

and

cable

assemblies

and disconnect gant

tach

er block and

(J=1

0424771)

directly above t he second st age adapt

necessary fli

ght hardware at out

riggers

paragraphs1020L1 and 10201.20

bly

ect

of

(D=104

6434)

assem

blies (J=1042477

in

accordance wit h

ins

tal

lati

tan

to

shanks and t hreads

~ashers

ue

value

bolts

is

durin

on

trans

port ero

in

cable

26438)

accordance wit h

assemblies attached

in

accordance

1)

using

detail

new

instructions

on

of cable assemblies

Ne

w bol t s, washers, and nut s

of

bol

t s

(

NAS

143=16 and

of

6000

inc

h pounds (500 foot pounds)

mandat ,ory t o preve

g removal

of

boost

NAS143=

nt

shearing

er

from test t ower

ry

crane.

t o

aft

sister

er

a

tta

0

hook,

ched~

No

with

detail

B,

in

position

bolts,

in

detail

(J=1042

4771

sheil

(NAS156-68)

16c) and

of

ehd

o

C,

be

t he

3

~

)

.30101:2 Qua

30101

.3 0 '1014

.3 G 10

.3

02 Hemo

30201

lit

y Cont

cable ass

valUes of bolts (

3 Re

mova

l of test

~il

l

be performed i n

LAB

0

Use

per sonn

rol

emblies

el

to steady boost

Division

(

J=10424771

NAS156=68)o

t ower pins f r

accorda

thrust ring support bracket so

15 AJl;,t

ving Boost,er from T

.ach t wo t ag

7, and one e

NOTEg

approximat

Tag

ely

ach

lines ,to

75

Prior t o remoYi

following

t he

par

lin

es t o outrigg

to outrigg

be 1=inch diameter

feet longo

owe

r Thrust Ring and Posi t

ng

boo

s'ter f

t s

are

shall inspect t he

) ~

check and

om

t hrust ring support bracket s

nce wit h

instructions

er and t o guide out ri

ers

No 0 .3 ~ t

er s

No

o

an

d 5 i f conditions warranto

1

rom tower thrust ri

ava

ilableg

installation

record the t

wo

t o

hemp rope,

ionin

g on T

ng, check that

of

orq

ue

from M=TES

ggers

free

outriggers

or

equal,

ransporter o

t he

T

of

No

0

Page 36

GEORGE C.

PROCEDURE PAGE OF

MARSHALL

EP=141

SPACE

302.

FLIGHT

38

101

Rear

id

CENTER

147

ring

ent

ifi cati

section with Fin I

on

(1)

required

NOTE

30201. 2

302

010

3

302

010

4

g Rear

is

attached

Rear

rIng

i

dentification

Rear

rIng

identifi

Rear

ring

ring section wit h Fin I

to

transporter 0

sec

t i on wit h

sect

ion wIt h

ca

t i

on

section wit h

identification

3020105

installed

NOTE

sec

bracket is attac

F

in

3

020106 Screw

brackets wit h s

(J=AF=12004=2=

~

One

t ee

t i

on wIt h

III

identifica

(J=AFr=12004=2~".s

Fin I id

et

bra

cket

ent

hed t o r e

tion

)

Tee

3020107 Screw (J=AF=12004=2=13)

3

02

0108 Screw (J=AF=12004=2=17)

Fin

II

Fin

III

Fin

IV

screws

2)

is attached

ification

ar

ring

o

identification

(1 )

(1

)

(1 )

(6)

t o

rear

ring

and one t ee

sec

t i

on wit h

(32)

(8)

(32)

required

requi

red

requ.ired

required

required

required

required

020109 Barrel

3

30201

3020101

01

0 Connect i

1 Washer

30201012 Bal=

302

01013 Bal=

302

3020

302.

302

3020

3020

30201.

302

14

01

0

'01

5 Screw

1016 Bo

01017

101

8 Washer

1019

20

01021

Bracket

l t (J=AF=12004=4-33)

Washer (J=

Roller

Tubing (J=AF=12004

Hex Nut

nut

(J=AF=12004=2=6)

ng

pin

(B=AF~.1

(J=AF=12004~2=5)

lok pin (J=AF=12004

lok pin

(J-AF=1200

(J=AF=12004=2

(J=AF=

12004=4=31)

4=4~32)

AFd12004=4=34)

(J~AF~'12004='4 =35)

(D=AF=120

04~4=36

=4=37)

(J=

AF=12004~4=38)

2 004<'>2=3)

.'3

2=9)

=24.

)

)

(8)

req¢.red

(8) required

(8)

required

(8)

required

(8) required

(4)

required

(1

6)

require

(2) required

(4)

required

(4

.)

required

(2)

required

(2)

required

(2)

required

d

Page 37

302

302

302

302

02

Cl

ean mat

support

ven

t~

ing

cla

F

ederal

paragraph

a l

igh

t coat

Spec