Getting Started

with your 8718

This Getting Started Guide is a

duplication made as a reference and

convenience to our customers who

have misplaced the original (printed in

1996) that came with their 8718 RF

Radiation Survey Meter.

Narda’s logo and contact information

has been updated to enable you to

contact us as needed.

narda

Safety Test Solutions

an communications company

3

L

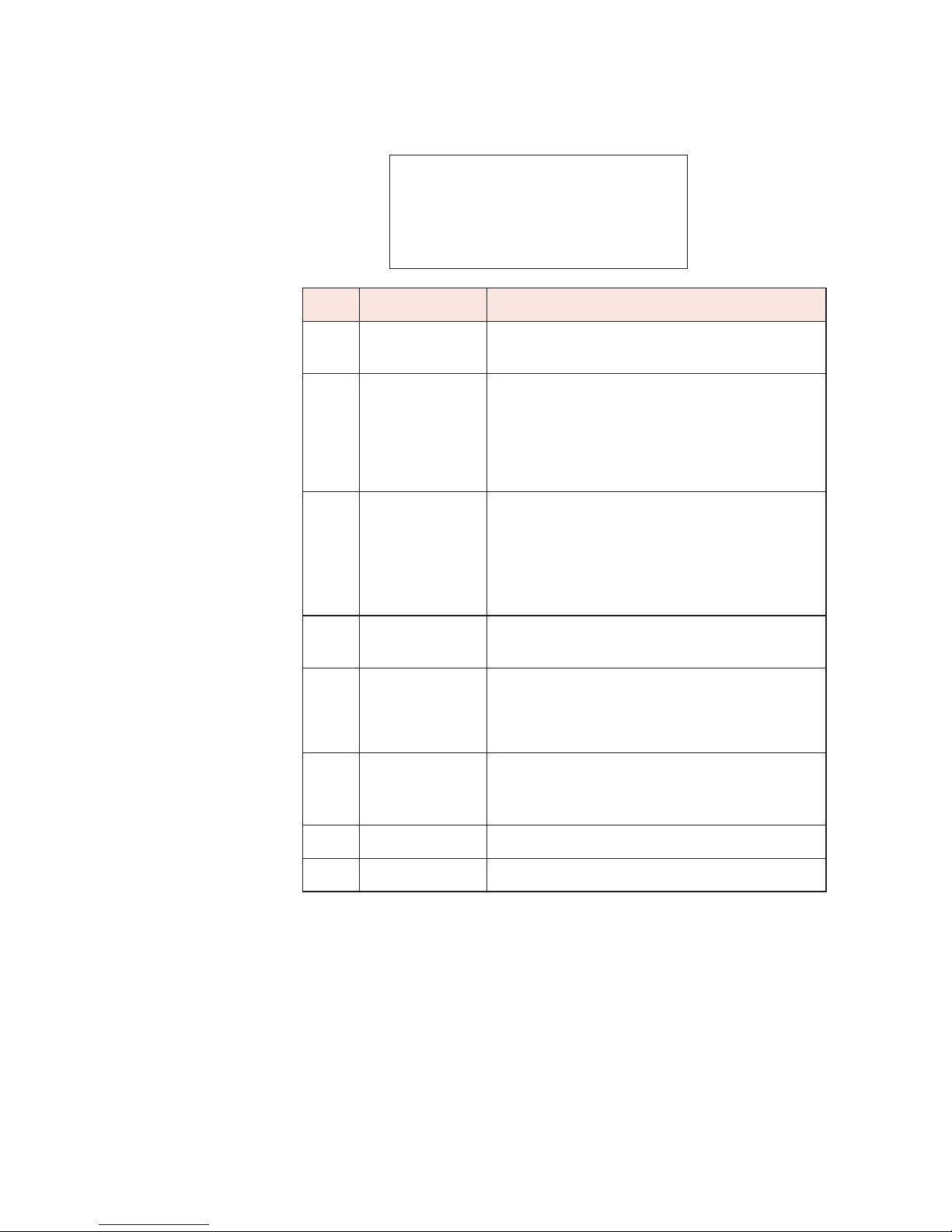

Table of Contents

Section Name................Pg

1 Introduction ............ 3

2 Description ............. 5

3 Getting Ready ...........11

4 Making a Measurement ......13

5 Menu System ...........29

Index ................33

2

1

Introduction

About the Model 8718

Your Model 8718 is a hand-held, battery-powered

meter designed to simplify the measurement of

electromagnetic fields. It can be used with any

Narda 8700 Series probe.

The meter enables you to perform both simple

measurements and more demanding ones that

require averaging and/or data logging. It can be

mounted on a tripod and used with optional fiber

optic links for enhanced accuracy in certain

applications.

This manual will help you as you begin using your Model 8718.

Equipment Supplied

Your Model 8718 is supplied with:

•

Meter

•

Battery Charger/Power Supply

•

Power Cord (220 volt chargers only)

•

Storage Case

•

Interface Software

•

Operation and Maintenance Manual

•

Getting Started Book

3

4

2

Understanding Your Model 8718

General Description

It is important to be familiar with the Model 8718 before you

use it. This section includes descriptive data keyed to

highlighted illustrations to help you locate the various features

of the meter. The descriptions not only identify the features but

tell you how they are used.

Battery Charger and Power Cord

The battery charger and power cord are used to recharge the

battery within the Model 8718.

To recharge the meter, first connect the cable of

the battery charger to the larger jack on the left

side of the meter. Make sure the plug is fully

inserted into the jack (there are two "stops").

Connect the power cord to the wall outlet.

The battery will be fully charged in about 8 hours.

A full charge will give you about 40 hours of

operation (approximately 8 hours if back lighting

is used).

The charger can also be used to power the

Model 8718 when it is to be operated for periods

beyond the capacity of the battery.

5

Probe Connection

To make measurements, use your Model 8718 with

a probe. Connect the cable of the probe to the

probe connector located at the top of the unit.

If you use a fiber optic link, the probe connects to a

fiber optic transmitter. A fiber optic cable connects

the transmitter to the rectangular fiber optic jack on

the left side of the meter.

Audio Alarm

Your Model 8718 is equipped with an audible alarm

that emits sound through a tiny hole on the bottom

of the meter. The alarm sounds whenever the field

strength exceeds the measurement range of the

probe (over ranges).

You can also set the meter to sound its alarm at a

specific level and/or turn on a variable-tone mode.

Probe Test Sources

Your Model 8718 is equipped with two RF sources

for testing your probes. The Test Source key will

turn these sources on. They will stay on for

approximately 20 seconds.

A microwave (waveguide) window on the right side

of the probe is used for testing high frequency

probes.

A contact on the right side of the meter is used for

testing low frequency probes. These probes have

three test points on the head of the probe.

6

Strap and Tripod Mount

A strap is provided on the underside of the Model

8718. It has a hook and loop closure to permit easy

adjustment, around your hand.

Behind the strap is a threaded connector used to

secure the meter to a tripod. Loosen the strap to

access this connector.

Operation With a Computer

To update probe calibration information or retrieve

stored measurements, you must connect your

Model 8718 to a personal computer and use the

Interface Software provided by Narda.

Refer to the Operation and Maintenance Manual for

detailed information regarding computer operations.

Operation With a Recorder

To obtain a continuous record of measurement

over an extended period of time, you can connect a

data recorder to the smaller jack located on the left

side of the meter.

7

Keyboard

The Model 8718 has four groups of keys distinguished by their

color.

Function keys (green)

Numeric keys (yellow)

Special Function keys (white)

Power keys (blue, green)

Power Keys

Two power keys are used to turn the Model

8718 On and Off.

8

Function Keys

Use the four function keys (F1-F4) to select

the options displayed on the bottom line of

the display screen directly above the F1,

F2, F3, and F4 markings. In a few cases the

options will be spelled out on the display.

Numeric Keypad

Use the numeric keypad to enter number data into the Model

8718. You also use the numeric keypad to select an option listed

on the display screen.

Special Function Keys

Six special function keys enable you to perform specific

functions.

Esc Returns you to the previous menu. In a few

cases you must enter a selection rather than

use the Esc key.

Auto Enables you to automatically zero the meter

Zero and probe.

Help Displays a help screen that explains your options.

Test Turns on the built-in low frequency and high

Source frequency probe test sources for approximately

20 seconds.

Range Locks in a specific measurement range for the

bar graph. The digital display is not affected. The

meter automatically displays a digital value over

the probe’s entire measurement range. See Bar

Graph Ranges on page 21.

Enter Stores data you entered with the numeric

keypad. Confirms an option you selected from

a menu screen.

9

10

3

Getting Ready

Introduction

This section will help you get ready to take measurements with

your Model 8718. Information is included for selecting a probe,

connecting the probe to your Model 8718, and connecting the

optional fiber optic link.

Probe Selection

If you have more than one Series 8700 probe, select the probe

best suited for your task. Factors that you should consider:

FREQUENCY

RANGE

POWER

DENSITY

or FIELD

STRENGTH

ELECTRIC

FIELD or

MAGNETIC

FIELD

FLAT

RESPONSE

or SHAPED

FREQUENCY

RESPONSE

The probe frequency range should include the frequencies of all

the emitters to be surveyed at one time.

The measurement range of the probe should be adequate for

the field levels that you anticipate (i.e., do you expect strong

fields or weak fields?).

Most standards recommend that you measure both electric (E)

and magnetic (H) fields below 300 MHz.

Flat response probes are the most common. Narda’s patented

shaped probes read out in Percent of Standard and are

particularly useful in complex, multi-signal environments where

the exposure limits are different for the various emitter

frequencies.

11

Note

Connecting a Probe

Connect the cable of your probe to the probe connector at the

top of your Model 8718. Make certain that the retaining ring of

the connector is securely fastened.

Using a Fiber Optic Link (optional)

A fiber optic link is useful when remote or low frequency

(<30 MHz) readings are to be made with your Model 8718.

To use the fiber optic link...

1. Connect the probe to the fiber optic transmitter and

make certain that the connector retaining ring is

securely fastened.

2. Connect one end of the fiber optic cable to the fiber

optic transmitter and the other end to the rectangular

fiber optic jack on the left side of the meter.

The meter will

remain set to use the

same input (fiber

optic receiver or

cable), even if you

turn the meter off,

until you use the

menu system to

change the input.

3. Turn the meter ON and press F4 to access the menu

system. Press 8 (NEXT) to get to the second menu

screen. Select CABLE/FO (press 1).

4. If the screen shows that the fiber optic receiver is

turned on, you are ready to proceed. If the screen

shows that the fiber optic receiver is turned off, press

F1 (ON).

5. Press Esc twice to return to the opening menu screen.

6. Press F1 to select a probe and begin the measurement

process.

.

12

4

Making a Measurement

Introduction

This section will help you take measurements with your Model

8718. Information is included for turning the meter on, selecting,

zeroing, and testing a probe, plus an explanation of the main

measurement screen of the meter. Some general information is

also included about measurement surveys, precautions you

should observe, and the use of probe correction factors.

Getting Started

Press the ON power key. After a few seconds, the display

screen will show the meter's calibration date and tell you to

CONNECT PROBE NOW.

To Make Measurements...

1. Select the probe you want to use and connect it to

the meter.

2. Press F1 and proceed to enter the probe model

number

To access the meter’s menu system to perform some other

function...

1. Press F4. The first of three menu screens will appear.

See Section 5, Menu System, for details on features

and operation.

13

Entering the Probe Model

Narda's 8700 Series system is completely modular — all 8700

meters work with all 8700 probes. The single most important

thing you must do is "tell" the 8718 meter which probe you

are using.

The Model 8718 has the basic characteristics of every 8700

Series probe stored in its internal memory. All you have to do is

select the correct model number and the meter automatically

sets the correct scales.

The Model 8718 can also store the specific calibration details

for up to six probes. This includes the probe serial number,

calibration date, and the calibration factors marked on the

handle of the probe. Probes with this additional detail stored in

the meter are referred to as probes in memory.

Putting probes into memory has several advantages:

It makes it easier to select a probe

•

Data that is downloaded after using a data logging mode

•

will include a record of the probe’s calibration date and

its serial number.

•

It makes using frequency correction much easier.

Probes are put into the meter’s memory using a personal

computer:

•

By Narda on the day of shipment for all probes shipped

at the same time as the meter.

•

By you at any time when you use the Interface Software

supplied by Narda and a personal computer. Refer to

Operation and Maintenance Manual for detailed

information regarding computer operations.

14

To select from the PROBES IN MEMORY...

1. If you haven’t already, press F1 (MEASURE).

2. The model number and the serial number of the last

probe used will be displayed on the second line of the

display. If you want to use the same probe, press

Enter.

SELECT PROBE

MODEL A8722 SND XXXXX

OR SEL ECT FROM L I S T

87XX 87XX 87XX MORE

F1 F2 F3 F4

3. If you want to use a different probe, look for the model

number in the positions above the F1, F2, or F3

legends. Up to three additional models can be found

by pressing F4 (MORE).

4. Press the appropriate function key and the probe

model and serial number will be displayed on the

second line of the screen. If this is correct, press Enter.

5. A new screen will appear specifying probe model

number, serial number, frequency range, field type,

maximum measurement range, and type of response

(flat or shaped). If this information is correct, press F1.

If this information does not match your requirements,

you need to select another probe. Press F2 and you

will go back to the Select Probe Screen to make

another selection.

A8742D S/N 00001

300 H -3GHzzkE-FLD

600 % STD SHAPED

YES NO MENU

F1 F2 F3 F4

6. Proceed with the probe zeroing process.

15

To use a PROBE that is NOT IN MEMORY...

1. If you haven't already, press F1 (MEASURE).

2. The model number of the last probe used will be

displayed on the second line of the display. If you want

to use the same model probe, press Enter.

SELECT PROBE

MODEL A8722 SND XXXXX

OR SELECT FROM L I ST

87XX 87XX 87XX PROBE

F1 F2 F3 F4

3. If you want to use a different model probe, select

PROBE by pressing F4. If more than three probes are in

memory, you will have to press F4 twice (MORE, then

PROBE). One of three screens that list all 8700 model

probes will appear.

Note

You must turn off the

meter and repeat the

probe selection and

zeroing process if

you want to change

probes.

1 A8722D 5 A8732D

2 B8722D 6 A8742D

3 C8722D

4 D8722D 8 NEXT

F1 F2 F3 F4

4. If you see the model of the probe you want to use, press

the appropriate number key.

5. If you do not see the model number you want, use the

F1 and F2 keys to page forward and backward until you

do. Press the appropriate number key.

6. A new screen will appear specifying probe model

number, frequency range, field type, maximum

measurement range, and type of response (flat or

shaped). If this information is correct, press F1. If this

information does not match your requirements you need

to select another probe. Press F2 and you will go back

to the Select Probe Screen to make another selection.

7. Proceed with the probe zeroing process.

16

A8722D SNXXXXX

300 H - 50GHzzkE-FLD

300 % STD SHAPED

YES NO MENU

F1 F2 F3 F4

Zeroing the Probe

The probe and meter must be “zeroed” together. It is important

that the probe is not exposed to radiated fields during the

zeroing process. The storage case is shielded and provides a

convenient “zero density” environment.

To zero the probe...

Note

Position the probe in

the case with one

test point pointed

downward and the

other two test points

above the foam.

This will insure that

the test points are

not touching the

foam.

1. Place the probe in the storage case. Be careful not

to move the probe while zeroing takes place (on

probes with low frequency test points, you can create

static which will give inaccurate results).

2. When you are ready, press the ENTER key. The

screen will say ZEROING...

3. After zeroing is completed, the main measurement

screen will appear.

If you get a message that the probe could not be zeroed, the

most likely causes are:

•

The probe is not connected properly. Check the

connector and retry.

•

The meter is set for a fiber optic input and you are

using the standard cable input (or vice versa). Turn the

meter off. Turn the meter back on and press

(F4) to access the menu system. Press

8 (NEXT) to get to the Second Menu Screen. Select

CABLE/FO (press 1). Check the CABLE/FO setting to

make sure the fiber optic receiver input (FO) is turned

on. If the screen shows that the fiber optic receiver is

turned off, press F1 (ON) to enable it. Then press Esc

twice to return to the Opening Menu Screen.

17

The field strength is not low enough. Move away from

•

the antenna and use the storage case to zero the probe.

The probe is damaged. Try another probe.

•

To reconfirm the zero while the instrument is in use...

1. Establish a zero density environment for the probe as

before.

2. Press the Auto Zero key. This will automatically “touch

up” the zero and correct for any drift in about 10

seconds.

18

Measurement Display Screen

The Main Measurement Display Screen shows a maximum

value on the third line of the display. The Alternate Measurement

Display Screen provides frequency-specific, real time information

instead of a maximum value.

Main Measurement Display Screen

(Shaped Probes)

MAXIMUM VALUE

• Indicates the

maximum value that

has occurred since

you began making

measurements or

since resetting the

maximum.

• The unit of measure is

the same as for the

instantaneous value

shown on the line

above.

BAR GRAPH

Indicates approximate

•

field strength

100 segment, three

•

10:1 (10 dB) ranges

12.1 % STD

27.5 MAX CF 1.00

LOG MENU %STD FREQ

F1 F2 F3 F4

F1

(LOG) instantly

logs the current

value

F2

Switches you to

the first screen of

the menu system.

The menu system

allows you to set

operating

parameters for the

Model 8718

F4

Allows you to enter

or change the

frequency that you

are correcting for

probe frequency

deviation

F3

Toggles the third line of the display

between a maximum value and an

instantaneous percent of standard

(see Alternate Display Screen). If

you have entered a frequency, you

will switch to the Alternate Display

Screen. You will also reset the

maximum value at the same time. If

you have not entered a frequency

you will reset the maximum value

and the main measurement display

screen will remain.

FIELD STRENGTH

Indicates actual measured value

•

Unit of measure is always % STD

•

for shaped frequency response

probes

PROBE FREQUENCY

CORRECTION

• CF = 1.00 indicates

no correction factor is

being applied

• CF= X.XX indicates

the numeric value that

is being applied

• A frequency displayed

here indicates that the

meter is applying a

correction factor

based on the stored

calibration data for the

specific probe in use.

19

CALCULATED

PERCENT OF

STANDARD

Displays percent of

•

standard that has been

calculated from the

field strength reading

using the referenced

standard and the

indicated frequency

Alternate Display Screen

The Alternate Display Screen is very similar to the Main

Measurement Display Screen with one difference. On the third

line an instantaneous indication of the percent of standard is

shown instead of displaying a maximum value. This screen

should only be used with flat response probes for single

frequency measurements or where all the emitter frequencies

are close and the standard has the same limits.

.26 Wmmc/

6

125 . 2% STD 10 . 00 HzG

LOG MENU MAX FREQ

2

F1 F2 F3 F4

FIELD STRENGTH

Indicates actual

•

measured value

Unit of measure can be

•

changed by going to the

First Menu Screen

To use the Alternate Display Screen...

1. Press F4 (FREQ) and then enter the frequency that

you are measuring. You must fill all four positions. Use

F1, F2,orF3 as required to change the units.

2. Press F4 (SAVE). The probe correction factor will be

displayed briefly if you are using a probe in memory

and you will return to the main measurement screen.

3. Press F2 (MENU), then 8 (NEXT) to access the

second menu screen. Select STNDS (6). Press the

appropriate standard that you want to reference. (You

must use a function key even if the current setting is

correct.) A new screen will appear.

4. Press F1 to verify or F4 to make another selection.

Press Esc twice to go back to the main measurement

screen.

5. From the Main Measurement Screen select %STD by

pressing F3. The meter will now automatically display

the instantaneous measured value in the chosen units

on the second line and at the same time compare that

20

value to the standard at the frequency shown on line 3.

This instantaneous readout of percent of standard is

particularly useful where the allowable level must

normally be calculated. If you are using a probe in

memory or have entered a numeric correction factor,

the meter will also be correcting for probe frequency

deviation.

6. Note that pressing F3 also clears the maximum value

from the meter's memory.

Bar Graph Ranges

The Range key is used to control how the bar graph displays

information. The digital display is not affected and the meter

automatically displays a digital value over the probe’s entire

measurement range. There are four available settings: AUTO,

HIGH, MID, and LOW. The bar graph has 100 divisions.

Note

The Range Key only

affects how the bar

graph displays

information.

You will probably find it convenient to use the AUTO setting

most of the time, but under a few conditions you may find one of

the three fixed ranges useful. The following table illustrates how

the range setting will affect the bar graph. For simplicity, a

probe with a full scale rating of 100 mW/cm

2

is used as an

example.

Range Measurement Range

AUTO As the level increases the bar graph

automatically switches between three ranges:

0.01 to 1, 1 to 10, and 10 to 100.

HIGH 1to100

MID 0.1 to 10

LOW 0.01 to 1

If you exceed the upper limit of either the MID or LOW range, the

bar graph will be replaced with the message RANGE

OVERLOAD. The digital display will continue to show the

correct value.

21

Using Audio Alarms

You can set an audio alarm to sound at a specific value. You can

also activate a variable tone alarm. Both alarms can help you

conduct surveys and can provide a warning of high

electromagnetic fields. You can even use both at the same time.

Under these conditions, the variable tone alarm will change with

the field strength unless the threshold you specified is

exceeded. At this point the continuous tone of the fixed alarm

takes over.

To use the fixed audio alarm...

1. From either measurement screen, press F2 (MENU),

then 7 (AUDIO).

2. Set the alarm level by entering a two digit number

using the numeric keys. This number is equal to the

percentage of full scale rating of the probe that you are

using. For example, if you are using a probe rated at 20

2

mW/cm

mW/cm

and you enter 35, the alarm will sound at 7

2

(35% of 20).

3. Press Enter.

4. Press F1 to turn the fixed alarm ON.

5. Press Esc twice to return to the measurement screen

To use the variable alarm...

1. From either measurement screen, press F2 (MENU),

than 7 (Audio).

2. Press F3 to turn the variable alarm ON.

3. Press Esc twice to return to the measurement screen.

The audio alarm will increase its repetition rate in response to

the intensity of the field being measured. Note that the variable

alarm corresponds to the bar graph. It may be desirable to use

the Range key to select a fixed range setting (see Bar Graph

Ranges on page 21).

22

Testing the Probe

Your Model 8718 is equipped with two RF sources for testing

probes. Press Test Source and both sources will stay on for

approximately 20 seconds.

A contact on the right side of the unit is used for testing low

frequency probes. These probes have three test points around

the head of the probe. Position the probe so that one of the test

points touches the contact on the meter. You should get a

deflection on the bar graph but the amount of deflection is not

important. Repeat for the other two test points to insure that the

probe is working correctly.

A microwave window on the right side of the probe is used for

testing high frequency probes. Hold the probe parallel to the

right side of the meter and position the probe head against the

test window so that one of three arrows on the probe is pointing

towards the window. These arrows indicate the location of the

three sensors inside the probe. A deflection of any magnitude

on the bar graph is acceptable. Repeat for the other two sensors

to insure that the probe is working correctly.

Ultra-broadband probes contain both high frequency and low

frequency sensors. These probes require six checks – three

high frequency and three low frequency.

Using Probe Correction Factors

All probes have a certain amount of frequency sensitivity.

Frequency sensitivity is the amount of deviation from the correct

measured value that a probe yields at various frequencies.

Obviously, the smaller the deviation, the better. But since a

certain amount of frequency deviation is unavoidable, the more

frequencies that you calibrate the probe at, the better. At each

calibration frequency, you have a correction factor.

Multiplying the reading on the meter by a correction factor

marked on the handle of a Narda 8700 Series probe

compensates for the probe’s frequency sensitivity. The Model

8718 is unique because it can perform this task automatically.

23

Correction factors can be used:

When there is only a single emitter being surveyed.

•

When there are multiple emitters all operating at the

•

same frequency (this is often the case with industrial

equipment).

When there are multiple emitters with frequencies that

•

are close to each other and the nearest calibration

frequencies have very similar correction factors.

Correction factors should NOT be used:

When the frequencies of the emitters are diverse.

•

Correction factors may vary considerably and there is no

way to determine the distribution of energy from the

various emitters. It is more accurate not to use a

correction factor under these conditions. See

Measurement Uncertainty on page 26.

To use a correction factor for a probe in memory...

1. Press F4 (FREQ) from the measurement screen. A

new screen will appear to allow you to enter a

frequency.

2. Enter the frequency for which you want to correct for.

Make sure you fill in all four positions. If you make a

mistake just enter more digits until correct. For greater

accuracy, use the units that allow the larger

numbers. For example, enter 10 kHz, not 00.01 MHz.

3. Change the units (if needed) by pressing either

F1 (kHz), F2 (MHz), or F3 (GHz).

4. Press F4 (SAVE). The meter will automatically

calculate the correction factor for the frequency you

have entered from the two closest correction factors

that were stored when you put the probe in memory.

The calculated numeric value will be displayed briefly

before the meter automatically returns to the

measurement screen.

5. The frequency that you are correcting for will be

displayed on the right side of the third line of the

display.

24

To use a correction factor for a probe NOT in memory...

1. Press F2 (MENU). The First Menu Screen will appear.

2. Press 3 (COR FACT). A screen will appear that shows

the correction factor.

3. Use the correction factors on the handle of the probe

to determine the appropriate correction factor and then

use the numeric keys on the meter to enter this value.

Enter a three digit number, ignoring the decimal point,

and rounding to two digits to the right of the decimal

point. If you make a mistake, just enter more digits

until correct. For example, to enter a correction factor

of 1.22, simply enter 1, 2, and then 2 while a correction

factor of 0.94 is entered as 0, 9, and 4.

5. Press Enter to save this correction factor. The meter

automatically returns to the measurement screen.

6. The numeric correction factor will be displayed on

the right side of the third line of the display in the form

CF X.XX.

25

Measurement Uncertainty

The uncertainty of any measurement includes several factors:

Frequency response or frequency sensitivity is typically

•

±1 dB to ±2 dB (from about ±25% to about ±55%).

The correct use of correction factors can greatly reduce

the amount of uncertainty associated with frequency

response.

Ellipse ratio is ±0.75 dB or better, depending on the

•

model of the probe. The ellipse ratio is the ratio of

readings that occur when one rotates the probe around

the axis of its handle. Narda calibrates its probes by

rotating the probe about its axis and using the mean

value to determine the correction factor. If you rotate

the probe around its axis and use the mean value,

ellipse ratio can be eliminated as a source of uncertainty.

Isotropic response is the error that occurs when the

•

probe is pointed in different directions. It includes the

ellipse ratio plus some additional uncertainties.

Although the probes pick up energy from all directions,

they are most accurate when pointed at the source of

energy. Generally speaking, the isotropic response is

no greater than the ellipse ratio providing that the probe

is pointed towards the source.

26

•

Calibration uncertainty represents another 0.5 dB.

•

The Model 8718 meter is accurate within ±3%.

A good rule of thumb is that the total uncertainty is no greater

than ±3 dB when correction factors are not used, providing

that the probe is pointed at the source of energy.

Obtaining a Reading

A reading is obtained by holding your Model 8718 in one hand

and your probe in the other. As you approach the source,

observe the bar graph and measured value of signal strength

on your meter. If you know where the source of energy is, point

the probe towards it. If you do not know where the source is

located or there are multiple sources, hold the probe above

your head pointed up at about 45 degrees above the

horizontal. Rotate the probe in a circle to find the direction

where the maximum indication is obtained. The bar graph is a

useful tool in obtaining the maximum indication.

About Measurement Surveys

When you perform surveys, it is important that you observe a

few guidelines to insure accurate readings:

Make sure you move the probe to obtain a maximum

•

reading.

Keep the arm holding the probe extended out from your

•

body as far as possible with the probe pointed towards

the source of radiation.

•

Low frequency measurements (<50 MHz and especially

<10 MHz) require special techniques because the

human body acts as an antenna and introduces errors.

Using the best technique, place the probe next to the

meter on a non metallic stand such as a wooden ladder

or cardboard box. Stand back and read the meter

without touching it.

The human body has far less affect on magnetic fields and

therefore these measurement techniques are less critical for

magnetic fields than they are for electric fields.

Refer to the operations manual for more complete information

on planning, conducting, and documenting measurement

surveys.

27

Precautions

When making measurements of electromagnetic fields, a

potential exists to expose yourself to excessive levels.

Approach the source of energy slowly and begin making

measurements from a distance at which low field levels exist.

Be prepared to evacuate the area immediately if RF field levels

in excess of the applicable standard are observed.

28

5

Using the Menu System

Introduction

This section will help you use the Model 8718's menu system.

The menu system allows you to enter and store data and to

select various options during operation.

The menu system is always available from any measurement

mode. It is accessed by pressing the appropriate function key

that corresponds to MENU on the bottom line of the display

screen.

The menu system is comprised of three menu screens where all

the basic options are listed. A specific menu item is selected by

pressing the appropriate numeric key that corresponds with that

menu item. Instructions or sub menus appear when one of the

basic menu options is selected. If it isn't clear what to do, press

the Help key.

29

First Menu Screen

1=SETUPS 5=PROBE

2=DISPLAY AV 6=UNITS

3=CORR FACT 7=AUDIO

4=BAT TEST 8=NEXT

Key Menu Options

Up to four sets of measurement situations

can be stored and recalled. Setups are

1

DISPLAY AVG

2

SETUPS

similar to macros in other computer

programs and can save keystrokes when

repeating measurements with the same

meter settings.

Select from four options to determine how

fast the digital information is updated on

the screen.

3

4

5

6

7

COR FACT Enter a numeric correction factor.

Check battery charge status and

estimated use time remaining.

BAT TST

PROBE

UNITS

AUDIO

Turn the back light on or off using F3.

Adjust display contrast (Press Help for

instructions).

Show the model and serial number of the

probe in use.

Select the measurement range when

using Models 8782 and E8782 probes.

Select from all appropriate units of

measure (i.e., mW/cm

the probe in use. Percent of Standard is

the only unit of measure for shaped

probes.

Turn the audio alarm on or off.

Set the alarm threshold in terms of

percent of full scale of the probe in use

(1% to 99%).

Turn the variable tone alarm on or off.

2

, V/m, V2/m2) for

8 NEXT

30

Go to the Second Menu Screen.

Second Menu Screen

1=CABLE/FO 5=RS232

2=TIME AVG 6=STDS

3=DATA LOG 7=BACK

4=TIME SET 8=NEXT

Key Menu Options

1 CABLE/FO

2 TIME AVG

3 DATA LOG

4 TIME SET

5 RS232

6

STNDS

Select between the standard probe cable

input and the fiber optic receiver.

Turn fixed time averaging (various

duration) on or off.

Turn the spatial averaging mode (used for

whole body averaging measurements) on

or off.

Log with time and date stamp.

Log with time and date stamp plus

reference number.

Continuous logging at various specific

rates.

Check or set the meter's internal clock

(time/date).

Turn the RS232 port on or off.

Default is off.

Change the baud rate.

Check or set the standard that is

referenced for various measurement

options.

7

8 NEXT Go to the Third Menu Screen.

BACK

Return to the first menu screen.

31

Third Menu Screen

1=LOCKOUT 3=BACK

2=BLANKOUT

The three menu items provide these options:

Key Menu Options

Lock the keypad so that settings will not

1 LOCKOUT

2 BLANKOUT

3 BACK Return to the Second Menu Screen.

Future firmware options will be added to this screen.

accidentally change. To release, press

ENTER and ESC together.

Blank the display and lock the keypad. To

release, press ENTER and ESC together

and then select another menu item.

32

INDEX

Alarm, Audio

Description .................................................6

Using ........................................................22

AUDIO, menu .............................................30

Auto Zero, key..............................................9

BACK, menu...............................................32

Bar Graph Ranges ......................................21

BAT TST, menu ..........................................30

Battery Charger.............................................5

BLANK OUT, menu ....................................32

CABLE/FO, menu.......................................31

Computer Operation .....................................7

COR FACT, menu ......................................30

Correction Factors, Probe ..........................24

DATA LOG, menu.......................................31

Description, 8718 ..........................................3

DISPLAY AVG, menu .................................30

Display Screen

Alternate ...................................................20

Main..........................................................19

Electric Field................................................11

Enter, key......................................................9

Equipment.....................................................3

ESC, key .......................................................9

F1 through F4, keys.......................................8

Fiber Optic Link, use with ............................12

Field Strength..............................................11

Flat Response .............................................11

Frequency Range .......................................11

Help, key.......................................................9

Keyboard.......................................................8

Keys

Function .....................................................8

Numeric......................................................9

Power .........................................................8

Special Function.........................................9

Magnetic Field.............................................11

Measurements

Making a Measurement ............................13

Precautions ..............................................28

Uncertainty ...............................................26

Menu Screen

First...........................................................30

Second .....................................................31

Third .........................................................32

Menu System ..............................................29

Off, key..........................................................8

On, key..........................................................8

Power Cord ...................................................5

Power Density .............................................11

Power Keys ...................................................8

Precautions .................................................28

Probe

Connection ...........................................6, 12

Correction Factors....................................23

Entering Model .........................................14

Selection ...................................................11

Test Sources ...............................................6

Testing ......................................................23

Zeroing......................................................17

PROBE, menu ............................................30

Range, key....................................................9

Ranges, Bar Graph .....................................21

Recorder Output ...........................................7

RS232, menu ..............................................31

SETUPS, menu...........................................30

Shaped Response ......................................11

STNDS, menu.............................................31

Strap..............................................................7

Surveys

Measurements..........................................27

Obtaining Reading ...................................27

Precautions ..............................................28

Test Source, key ..........................................9

Test Sources .................................................6

TIME AVG ...................................................31

TIME SET....................................................31

Tripod Mount.................................................7

UNITS, menu ..............................................30

Zeroing, probe ............................................17

33

narda

Safety Test Solutions

an communications company

3

L

USA: 435 Moreland Road

Hauppauge, NY 11788

Tel 1-631 231-1700 Fax 1-631 231-1711

E-Mail NardaSTS@L-3COM.com

www.narda-sts.com

GERMANY: Sandwiesenstrasse 7

D-72793 Pfullingen

Tel +49-7121-9732-777 Fax +49-7121-9732-790

E-Mail support@narda-sts.de

www.narda-sts.de

Loading...

Loading...