Napoleon Grills PTM450RB User Manual

SERIAL / SÉRIE#______________________

GOURMET GRILLS(PG 2-10)

LE GRILS DU GOURMET(PG 11-19)

MALIBU - PTM450RB

MANUFACTUREDBY / MANUFACTURE PAR:NAPOLEON APPLIANCE CORP.,

214 BAYVIEW DR., BARRIE, ONTARIO, CANADA L4N 4Y8 PHONE: (705)726-4278

FAX: (705)725-2564 EMAIL: ask@nac.on.ca WEBB SITE: www.napoleongrills.com

RETAIN THIS MANUAL FOR FUTURE REFERENCE

GARDER CE LIVRE POUR RÉFÉRENCES FUTURES

N415-0097 / DEC 15/03

TABLE OF CONTENTS

General Instructions page#

Warranty 3

General Information 4

Important Do's and Don'ts 4

Gas Hook-up Instructions 5

Leak Testing Instructions 5

Operating Instructions

Lighting Instructions 6

Cooking Instructions 7

Cleaning Instructions 7

Maintenance Instructions 8

Troubleshooting 9

Ordering Replacement Parts / Returns 10

Assembly and Installation Instructions page#

1. Legs 20

2. Caster and Wheels 20

3. Front Cart Rail and Door Magnet 21

4. Cart Handles and Rear Rail 21

5. Rear Cart Enclosure 22

6. Tank Heatshield (Propane Only) 22

7. Bottom Shelves 23

8. Doors 23

9. Back Panel and Rear Shelf Bracket 24

10. Condiment Trays 24

11. Unit Assembly 25

12. Drippan Assembly 25

13. Warming Pans and Tray 26

14. Right Side Shelf 26

15. Left Side Shelf 27

16. Sear Plates, Grills, and Warming Rack 27

17. Propane Cylinder 28

18. Natural Gas Hose 28

19. Leak Testing Diagram 29

20. Rotisserie Kit Assembly 29

21. Replacement Parts List / Accessories 30

22. Parts Diagram 32

WARNING

Do not try to light this appliance without

reading "LIGHTING" instructions section of this manual.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPOURSAND LIQUIDS

IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE. AN LP CYLINDER NOT

CONNECTED FOR USE MUST NOT BE STORED IN THE VICINITY OF THIS OR ANY

OTHER APPLIANCE. IF THE INFORMATION IN THESE INSTRUCTIONS IS NOT

FOLLOWED EXACTLY,A FIRE OR EXPLOSION MAY RESULT, CAUSING PROPERTY

DAMAGE, PERSONAL INJURY OR DEATH.

WHATTODOIFYOU SMELL GAS:

• Turn off main gas supply.

• Extinguish any open flame.

• Open lid.

• Immediately call your gas supplier, or your fire department if odour continues.

page#

SAFE OPERATING PRACTICES

• This gas grillis not intended tobe installed in or onrecreational

vehicles and/or boats.

• This gas grill must only be used outdoors in a well-ventilated

space and must not be used inside a building, garage or any

other enclosed area.

• Keep any electrical supply cord and fuel supply hose away

from any heated surfaces.

• Inspect the fuel supply hose before each use. If there is evidence of excessive abrasion or wear orthe hose is cut, it must

be replaced, prior to using the gas grill, with a replacement

hose assembly specified by the manufacturer.

• When the propane cylinder is notdisconnected from the appliance, the gas grill and cylinder must be stored outdoors in a

well ventilated space.

• Do not locate in windy settings. High winds adversely affect

the cooking performance of the gas grill.

2

• Adults and especially childrenshould be alertedto the hazards

of high surfacetemperatures. Youngchildren should be supervised near the gas grill.

• Under no circumstances should this gas grill be modified.

• Gas must beturned off at thepropanecylinder or at thenatural

gas supply valve when the gas grill is not in use.

• When the gas grill is to be stored indoors, the connection between the propane cylinder and the gas grill must be disconnected and the cylinder removed and storedoutdoors in a well

ventilatedspaceoutofreachofchildren.Disconnectedcylinders

must not be stored in a building, garage or any other enclosed

area. Natural gas units must be disconnected from the supply

when being stored indoors.

• The top lid is to be closed during the gas grill preheat period

• Do not use the condiment tray to store lighters, matches or

other flammable materials.

• This gas grill is designed for outdoor use only.

R

GOURMET GRILLS

NAPOLEON gas grills are manufactured under the strict Standard of the world recognized

ISO 9001-2000 Quality Assurance Certificate.

NAPOLEON products are designed with superior components and materials, and are assembled by trained

craftsmen who take great pride in their work. The burner and valve assembly are leaktested and test-fired at

a quality test station, and thoroughly inspected by a qualified technician before packaging and shipping to

ensure that you, the customer, receive the quality product you expect from NAPOLEON.

NAPOLEON GAS GRILL PRESIDENT'S LIMITED LIFETIME WARRANTY

NAPOLEON warrants the following materials and workmanship in your new NAPOLEON gas grill

against defects for as long as you own the gas grill. This covers: aluminum castings, stainless steel

burners, stainless steel rod cooking grids, LUXIDIORside shelves, wheels, knobs, porcelain enamelled

lids and stainless steel lids. Subject to the following conditions. During the first ten years NAPOLEON

will provide replacement parts at our option free of charge. From the eleventh year to lifetime NAPOLEON will provide replacement parts at 50% of the current retail price.

Components such as regulator, casters, warming rack, hoses and connectors, igniter (excluding

batteries), fasteners and accessories are covered and NAPOLEON will provide parts free of charge

during the first year of the limited warranty.

Components such as stainless steel sear plates, porcelain enamelled cooking grids, temperature

gauge and brass valves are covered and NAPOLEON will provide parts free of charge during the first

three years of the limited warranty.

NAPOLEON shall not be liable for any transportation charges, labour costs or export duties.

CONDITIONSAND LIMITATIONS

"NAPOLEON warrants its products against manufacturing defects to the original purchaser only (ie., the individual or legal entity (registered customer) whose

name appears on the warranty registration card filed with NAPOLEON), provided that the purchase was made through an authorized NAPOLEON dealer and is

subject to the following conditions and limitations:"

This factory warranty is non-transferable and may not be extended what-so-ever by any of our representatives.

The gas grill must be installed by a licenced, authorized service technician or contractor. Installation must be done in accordance with the installation

instructions included with the product and all local and national building and fire codes.

This limited warranty does not cover damages caused by misuse, lack of maintenance, grease fires, hostile environments, accident, alterations, abuse or

neglect and parts installed from other manufacturers will nullify this warranty.

This limited warranty further does not cover any scratches, dents, painted finishes, corrosion or discolouring by heat, abrasive and chemical cleaners, nor

chipping on porcelain enamel parts, nor any components used in the installation of the gas grill.

Should deterioration of parts occur to the degree of non-performance within the duration of the warranted coverage, a replacement part will be provided.

In the first year only, this warranty extends to the replacement of warranted parts which are defective in material or workmanship provided that the product has

been operated in accordance with the operation instructions and under normal conditions.

After the first year, with respect to this President's Limited Lifetime Warranty NAPOLEON may, at its discretion, fully discharge all obligations with respect to

this warranty by refunding to the original warranted purchaser the wholesale price of any warranted but defective part(s).

NAPOLEON will not be responsible for the installation, labour or any other costs or expenses related to the re-installation of a warranted part, and

such expenses are not covered by this warranty.

Notwithstanding any provision contained in this President's Limited Lifetime Warranty NAPOLEON's responsiblity under this warranty is defined as above and

it shall not in any event extend to any incidental, consequential, or indirect damages.

This warranty defines the obligation and liability of NAPOLEON with respect to the NAPOLEON gas grill and any other warranties expressed or implied with

respect to this product, its components or accessories are excluded.

NAPOLEON neither assumes, nor authorizes any third party to assume, on its behalf, any other liabilities with respect to the sale of this product. NAPOLEON

will not be responsible for: over firing, blow outs caused by environmental conditions such as strong winds, or inadequate ventilation,

Any damages to the gas grill due to weather damage, hail, rough handling, damaging chemicals or cleaners will not be the responsibility of NAPOLEON.

The bill of sale or copy will be required together with a serial number and a model number when making any warranty claims from NAPOLEON. The warranty

registration card must be returned within fourteen days to register the warranty or you can register on-line at www.napoleongrills.com.

NAPOLEON reserves the right to have its representative inspect any product or part prior to honouring any warranty claim.

NAPOLEON shall not be liable for any transportation charges, labour costs, or export duties.

3

GENERAL INFORMATION

THIS GAS BARBECUE IS CERTIFIEDUNDER CANADIANANDAMERICAN NATIONAL STANDARDS, CAN/CGA-1.6-M95 AND

ANSI Z21.58 -1995 RESPECTIVELY FOR OUTDOOR GAS GRILLS AND SHOULD BE INSTALLED to conform with local

codes. In absence of local codes, install to the current CAN1-B149.2 Propane Installation Code in Canada or to the National

Fuel Gas Code, ANSI Z223.1 in the United States.

If a rotisserie motor is used, it must be electrically grounded in accordance with local codes or, in absence of local codes, with

the current CSA C22.1 CANADIAN ELECTRICAL CODE in Canada or the National Electrical Code, ANSI/NFPA70 in the United

States.

USE ONLY THE PRESSURE REGULATOR AND HOSE ASSEMBLY PROVIDED WITH THIS BARBECUE. REPLACEMENT

PRESSURE REGULATORS AND HOSE ASSEMBLIES MUST BE SPECIFIED BY THE MANUFACTURER. DO NOT STORE

PROPANE CYLINDER OR SPARE CYLINDER ON THE SHELF BENEATH THE BARBECUE.

The regulator supplies a pressure of 11 inches water column to the gas grill and has a QCC1 type fitting. Cylinders to be used

with this unit must be supplied with a Sherwood #3349 QCC1 cylinder valve. A QCC1 cylinder has a positive seating connection,

which will not allow gas flow until a positive seal has been achieved. It is also equipped with an excess flow device. In order to

attain full flow to the barbecue, the valves must be in the off position when the cylinder valve is turned on.

PROPANE CYLINDER SPECIFICATIONS: A dented or rusty cylinder may be hazardous and should be checked by your propane

supplier. Never use a cylinder with a damaged valve. Use only a propane supply cylinder constructed and marked in accordance

with the specifications for LP-gas cylinders of the Canadian Transport Commission (CTC) or the US Department of Transportation

(DOT). This appliance has been designed for use with a 20lb. (9.1 kg) size propane cylinder only (not supplied).

The propane cylinder must be provided with a shut-off valve terminating in a propane cylinder valve type QCC1, and a safety relief

device having direct communication with the vapour space of the cylinder. The cylinder supply system must be arranged for vapour

withdrawal and the cylinder shall include a collar to protect the cylinder valve. The cylinder shall incorporate an OPD (overfill

protection device).

IMPORTANT DO'S AND DON'TS

DO'S

Read the entire instruction manual before operating the

gas grill.

Maintain proper clearance to combustibles (16" to rear of

unit, 7" to sides). Additional clearance is recommended near

vinyl siding or large panes of glass.

Leak test the unit before initial use, annually and and

whenever any gas components are replaced.

Follow lighting instructions carefully when operating

grill. Burner controls must be off when turning supply

cylinder valve on.

Ensure sear plates are positioned properly according to

sear plate installation instructions. The holes must be

towards the front of the gas grill.

Clean grease tray and sear plates regularly to avoid

build-up which may lead to grease fires.

Remove warming rack before lighting rear burner. (The

extreme heat will damage the warming rack.)

DON'TS

Do not attempt to use a tank which is not equipped

with a QCC-1 type connection.

Do not route hose underneath drip pan - proper hose

clearance to bottom of unit must be maintained.

Do not use condiment tray to store lighters, matches

or any other combustibles.

Do not locate unit under unprotected combustible

construction.

Do not operate rear burner with main burners

operating.

Do not leave grill unattended when operating.

Do not light burners with lid closed.

Do not move grill when hot or operating.

Do not allow cold water (rain, sprinkler, hose, etc.) to

come in contact with heated unit. Alarge temperature

differential can cause chipping in the porcelain.

4

GAS HOOK-UP INSTRUCTIONS

CYLINDER CONNECTION: Ensure that the gas regulator hose is kink free. Remove the cap or plug from the cylinder fuel

valve. Insert the black QCC1 regulator nipple onto the QCC1 fuel valve. Hand tighten clockwise.

prior to using the barbecue.

system is replaced.

A leak test must be performed annually, and each time a cylinder is hooked up, or if a part of the gas

PROPANE CYLINDER INSTALLATION: Set cylinder into hole in bottom shelf.

IMPORTANT: The regulator must be attached so that no part of the hose touches the underside of the grill or drippan.

A fire will result if these directions are ignored.

NATURAL GAS HOOK-UP: This natural gas grill is supplied with a 10ft supply hose (complete with a quick disconnect) designed

for natural gas andcertified for outdoor use. Thegas grill is designedto operate at aninlet pressure of 7inches water column. Pipingand

valves upstream of the quick disconnect are not supplied.

The quick disconnect must not be installed in an upward direction and a readily accessible manual shut-off valve must be installed

upstream of, and as close to, the quick disconnect as is feasible. The flared end of the hose must be connected to the unit as illustrated

in the

Natural Gas HoseAttachment

using the gas grill.

diagram. These connections must be made by a licensed gas installer. Leak test all joints prior to

Do not use tools. Leak test all joints

MODEL 450RB: Connect the flared end of the hose to the fitting on the end of the manifold tube. Wrench tighten. (

sealer/pipe dope.)

Do not use thread

LEAK TESTING INSTRUCTIONS

Do not use a flame to leak test.

LEAK TESTING: This must be done before initial use, annually and whenever any gas components are replaced or serviced. No

smoking while performing this test, and remove all sources of ignition. See

1. Turn all burners controls to off. T urn supply valve on.

2. Brush a half and half solution of liquid soap and water onto all joints and connections of the regulator, hose, manifolds and

valves.

Leak Testing Diagram

for areas to check.

3. Bubbles will indicate a gas leak. Either tighten the loose joint or replace the part with one recommended by the dealer.

4. If the leak cannot be stopped, shut off the gas supply, disconnect it and have the barbecue inspected by your gas supplier or

dealer. Do not use the appliance until the leak has been corrected.

5. Turn off gas supply.

5

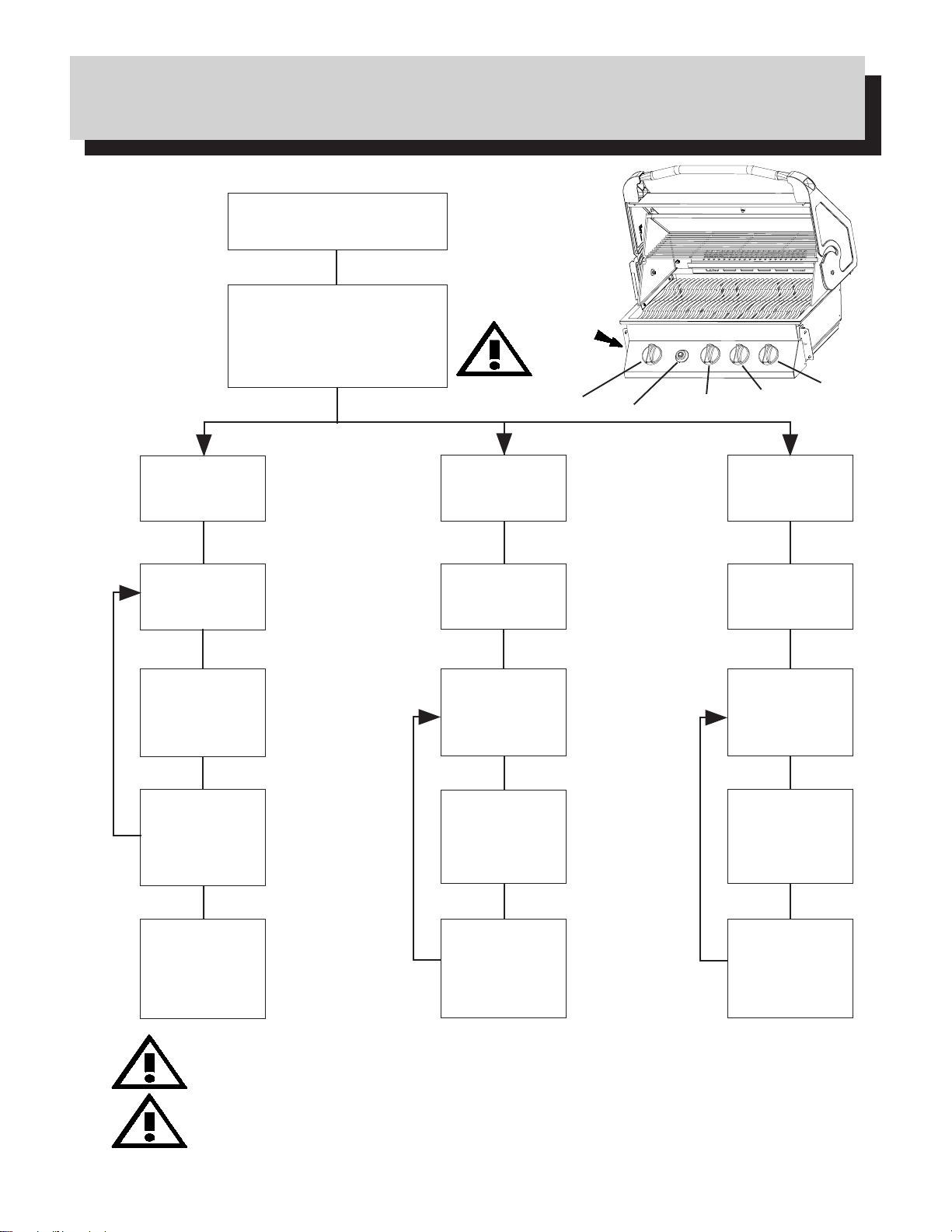

LIGHTING INSTRUCTIONS

Open lid.

Ensuring all burner controls

Main Burner

Lighting

Turn left burner

control to high

position.

Press and hold

igniter button

until lit, or light

by match.

are in the off position,

slowly turn on the gas

supply valve.

LIGHTING HOLE

BURNER

Rear Burner

Lighting

Remove

warming rack.

Turn rear

burner control

to high position.

LEFT

IGNITOR

CENTER

BURNER

RIGHT

REAR

BURNER

Side Burner

Lighting

(optional)

Open burner

cover.

Turn side

burner control

to high position.

BURNER

If ignition is not

immediate, turn

burner control

off. Wait 5

minutes.

With left burner

operating on

high, turn the

centre and/or

right burner to

high.

Press and hold

igniter button

until lit, or light

by match.

If ignition is not

immediate, turn

burner control

off. Wait 5

minutes.

Turn igniter knob

clockwise

several times or

light by match.

If ignition is not

immediate, turn

burner control

off. Wait 5

minutes.

The propane cylinder is equipped with an excess flow device. Unless

all burners are turned off prior to turning the cylinder on, only small

flames and low heat will be achievable.

Do not use back burner while operating main burner.

6

COOKING INSTRUCTIONS

When lit for the first time, the gas grill will emit a slight odour. This is a normal temporary condition caused by the "burn-in" of

internal paints and lubricants used in the manufacturing process and will not occur again. Simply run the main burners on high

for approximately ½ hour.

MAIN BURNER USE: When searing foods, preheating is recommended by operating all main burners in the high position with

the lid closed for approximately 10 minutes. Food cooked for a short period of time (fish, vegetables) may be grilled with the lid

open. Cooking with the lid closed will ensure higher, more even temperatures that will reduce cooking time and cook meat more

evenly. Food that has a cooking time longer than 30 minutes, such as roasts, may be cooked indirectly (with the burner lit

opposite to the food placement). When cooking very lean meats, such as chicken breasts, or lean pork, the grids can be oiled

before pre-heating to reduce sticking. Cooking meat with a high degree of fat content, may create flare-ups. Either trim some

fat or reduce temperatures to prevent this. Should a flare-up occur, move food away from flames, reduce heat. Leave the lid

open. See 'Your All Season Grill' cookbook by Napoleon for more detailed instructions.

REAR BURNER USE:

the rotisserie. This gas grill is equipped with a 19,000BTU rear burner. The rear burner is designed to be used in conjunction

with the rotisserie kit (included with Prestige II units) available from your dealer. See the rotisserie kit assembly instructions. To

use the counterbalance, remove the rotisserie motor from the gas grill. Place the spit with meat being cooked across the

hangers inside the grill. The meat will naturally hang with the heavy side down. Tighten the counterbalance arm and weight, so

that the arm is facing up. Slide the counterweight in or out to balance the load, and tighten in place. Re-install the motor and

begin cooking. Place a dish underneath to collect drippings for basting and naturally delicious gravy. Basting liquid may be

added as required. To seal in juices, first operate rear burner on high until brown, then reduce the heat to thoroughly cook

foods. Keep the lid closed for best results. Your roasts and fowl will brown perfectly on the outside and stay moist and tender

on the inside. For example, a 3 pound chicken on the rotisserie will be done in approximately 1½ hours on medium to high.

See 'Your all Season Grill' cookbook by Napoleon for more detailed instructions.

SIDE BURNER USE: The side burner can be used like any range top burner, for gravies, soups etc. The gas grill should be

located so that the side burner is protected from the wind, because the wind will adversely affect it's performance.

Remove the warming rack prior to use.

Cooking grids should also be removed if they interfere with

CLEANING INSTRUCTIONS

Ensure that the burners are turned off prior to cleaning. Avoid unprotected contact with hot surfaces. Clean grill in an

area where cleaning solutions will not harm decks, lawns or patios. Do not use oven cleaner to clean any part of this gas

grill. Do not use a self cleaning oven to clean cooking grids or any other parts of the gas grill. Barbecue sauce and salt

can be corrosive and will cause rapid deterioration of the gas grill components unless cleaned regularly.

GRIDS AND WARMING RACK - The grids and warming rack are best cleaned during the pre-heat period with a soft brass wire

brush. Steel wool can be used for stubborn stains. Stainless grids will discolour permanently from normal usage, due to the high

temperature of the cooking surface.

CLEANING INSIDE THE GAS GRILL - Remove cooking grids. Use a soft brass wire brush to clean loose debris from casting

sides and insides of the lid. Scrape sear plates with a putty knife or scraper, and use a wire brush to remove ash. Remove sear

plates and brush debris off of burners with a brass wire brush. Brush all debris from inside the gas grill into the removable drip

pan. Ensure that the sear plates are placed properly when they are reinstalled (Check assembly instructions for proper

orientation).

DRIP PAN - Slide the drip pan out for easy cleaning. It should be cleaned frequently (every 4-5 uses) to avoid grease buildup.

Grease and excess drippings pass through to the drip pan, located under the gas grill, and accumulate in the disposable grease

tray below the drip pan. Accumulated grease can cause a fire hazard. Do not line the drip pan with aluminum foil, as it can

prevent the grease from flowing properly. The pan should be scraped out with a putty knife or scraper, and all the debris should be

scraped into the disposable grease tray. This tray should be replaced every two to four weeks, depending on gas grill usage. For

supplies, see your Napoleon Gas Grill dealer.

7

CLEANING THE OUTSIDE OF THE GAS GRILL - Do not use abrasive cleaners to clean any painted, porcelain or stainless steel

parts. Porcelain enamel components must be handled with additional care. The baked on enamel finish is glass like, and will chip

if struck. Touch-up enamel is available from your Napoleon Gas Grill dealer. Exterior grill surfaces should be cleaned while warm

to the touch, with warm soapy water. To clean stainless surfaces, use a stainless steel cleaner or a non-abrasive cleaner. Always

wipe in the direction of the grain. Do not use steel wool, as it will scratch the finish. Stainless steel parts will discolour when

heated, usually to a golden or brown colour. This discolouration is normal and will not affect the performance of the grill.

LUXIDIO SIDE SHELVES - Clean Luxidio with warm soapy water. More difficult stains can be removed with an abrasive cleaner

(Ajax, Vim, or Dutch Cleanser) and a green Scotchbrite scouring pad. Deeper scratches can be removed by using 220 grit

sandpaper on a vibrating or orbital finishing sander. Restore finish using an abrasive cleaner and a green Scotchbrite pad.

MAINTENANCE INSTRUCTIONS

Turn off the gas at the source and disconnect unit before servicing. Maintenance should only be done when the grill is

cool, to avoid the possibility of burns. A leak test must be performed annually, and whenever any component of the gas

train is replaced.

COMBUSTION AIR ADJUSTMENT - (This must be done by a qualified gas installer.) The air shutter is factory set and should

not have to be adjusted under normal conditions. However, some extreme field conditions may exist that require adjustment.

When the air shutter is adjusted correctly, the flames will be dark blue with light blue tips, and occasional yellow tips.

BURNER

LIGHT BLUE

YELLOW TIPPING

DARK BLUE

If the burner is getting too little air, the flames will be lazy yellow, and possibly produce soot. If the burner is getting too much air,

the flames will be lifting erratically from the burner and may cause difficulties when lighting.

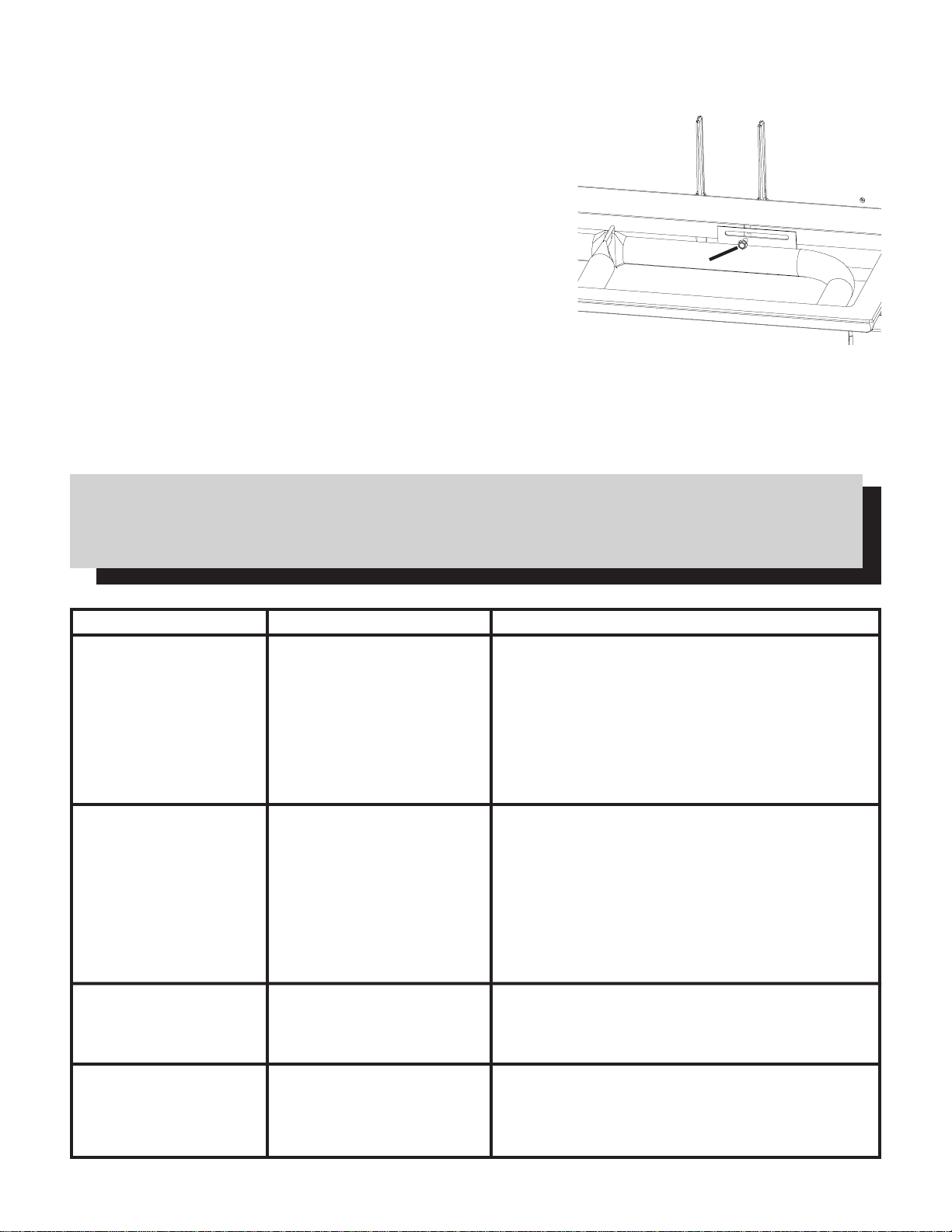

1. To adjust the air shutter, remove cooking grids and sear plates and leave lid open. The back cover must be removed for back

burner air shutter adjustment.

2. Loosen air-shutter lock screw and open or close air shutter as required. The normal settings are:

Main Burner Propane 1/8" Back Burner Propane Full Open

Natural 1/8" Natural 3/8"

BURNER PORT

APPROXIMATELY

1/2"

3. Light burners and set to high. Visually inspect burner flames. When shutters are set, turn burners off, tighten locking screw,

and replace removed parts. Ensure that the insect screens are installed.

HOSE - Check for abrasion, melting, cuts and cracks. If any of these conditions exist, do not use gas grill. Have part replaced by

your Napoleon Gas Grill dealer, or qualified gas installer.

8

BURNER - The burner is made from heavy wall 304 stainless steel, but due to the extreme heat and corrosive environment,

surface corrosion will occur. Use a brass wire brush to remove surface corrosion. Clean any blocked ports using an opened

paper clip. Do not enlarge the burner ports. Spiders and insects are attracted to the smell of propane and natural gas. The

burner is equipped with an insect screen on the air shutter, which will reduce the likelihood of

insects building nests inside the burner, but does not entirely eliminate the problem. The nest or

web will cause the burner to burn with a soft yellow or orange flame or cause a fire (flashback) at

the air shutter underneath the control panel. To clean the inside of the burner, it must be removed

from the gas grill. Remove the 2 screws located above the burner to the left and

right of the centre of the burner. Lift back of burner upwards to remove. Use a

flexible venturi tube cleaning brush to clean out the inside of the burner. Shake

any loose debris out of the burner, through the gas inlet. Ensure that the insect

screen is clean, tight, and free of any lint or other debris. Check also that the

valve orifices are clean. Do not enlarge the orifices. Re-install the burner.

Check that the valve enters the burner when installing. Replace burner cover

and mounting screws to complete installation.

ALUMINUM CASTINGS - Clean castings periodically with warm soapy water.

Aluminum will not rust, but due to high temperatures and weathering, oxidation can occur on aluminum surfaces. This

will appear as white spots on the castings. To refinish the castings, clean them and sand lightly with fine sandpaper. Wipe

surface to remove any residue, and paint with high temperature barbecue paint. Protect surrounding areas from over-spray.

Follow curing directions found on the can.

Screw

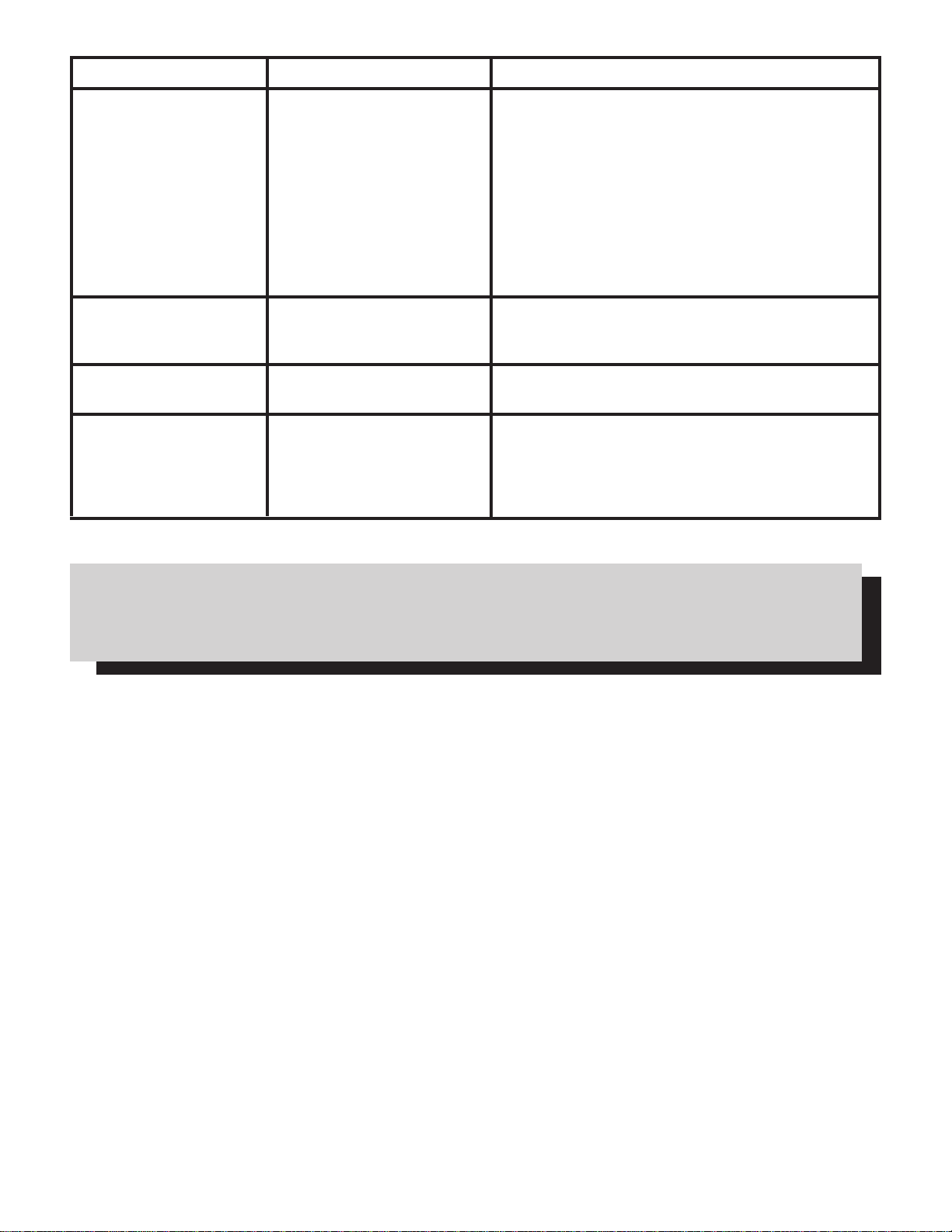

TROUBLESHOOTING

Problem Possible Causes Solution

Low heat / Low flame when

valve turned to high.

Excessive flare-ups/uneven

heat.

For propane - improper lighting

procedure.

For natural gas - undersized supply line.

Forbothgases - improper preheating.

Sear plates installed incorrectly. Ensure sear plates are installed with the holes towards the

Improper pre-heating. Pre-heat grill with both main burners on high for 10 to 15

Excessivegrease and ash build up

on sear plates and in drip pan.

Ensure lighting procedure is followed carefully. All gas grill

valves must be in the off position when the tank valve is

turned on. Turn tank on slowly to allow pressure to

equalize. See lighting instructions.

Pipe must be sized according to installtion code.

Pre-heat grill with both main burners on high for 10 to 15

minutes.

front, and the slots on the bottom. The group of five holes

must be in the centre of the grill. See assembly

instructions.

minutes.

Clean sear plates and drip pan regularly. Do not line pan

with aluminum foil. Refer to cleaning instructions.

Burners burn with yellow

flame, accompanied by the

smell of gas.

Flames lift away from burner,

accompanied by the smell of

gas, and possibly difficulties

in lighting.

Possiblespiderweb or other debris,

or improper air shutter adjustment.

Improper air shutter adjustment. Closeair shutter slightly according to combustion air

Thoroughly clean burner by removing. See general

maintenance instructions. Open air shutter slightly

according to combustion air adjustment instructions.

adjustment instructions.

9

Problem Possible Causes Solution

Burner will not light with the

ignitor, but will light with a

match.

Humming regulator.

Burners will not crosslight

each other.

"Paint" appears tobe peeling

inside lid or hood.

Loose electrode or switch

terminal wires

Loose electrode wire. Check that electrode wire is firmly pushed onto the

Improper gap at electrode tip. Ensure that the collector box is tight, and the gap

Dead battery. Replace the battery with a new one.

Normal occurance on hot days. This is not a defect. It is caused byinternalvibrations

Pluggedportsalongback of burner. Clean burner ports. See burner maintenance

Greasebuildup on inside surfaces. This is not a defect. The finish on the lid and hood is

.

Check that electrode wires are firmly pushed onto the

terminal on ignition module. Check that the lead wires from

the module to the ignition switch are firmly pushed onto their

respective terminals.

terminal on the back of the ignitor.

between the electrode end and the collector box is

between 1/8 - 3/16". The gap can be adjusted by

bending the box in or out.

in the regulator,and does not affect the performance

or safety of the gas grill.

instructions.

porcelain, and will not peel. The peeling is caused

by hardened grease, which dries into paint-like

shards,thatwill flake off. Regular cleaning will prevent

this. See cleaning instructions.

ORDERING REPLACEMENT PARTS

Contactthefactory directly for replacement parts and warranty claims. The customer service department is availablebetween9AMand5PM

(Eastern standard time) at 1-866-820-8686 or fax at 1-705-727-4282. In order to process a claim, we must be provided with the following

information:

1. Model and serial number of the unit.

2. Part number and description.

3. A concise description of the problem ('broken' is not sufficient).

4. Proof of purchase (photocopy of the invoice).

In some cases the customer service representative may request to have the parts returned to the factory for inspection, before providing

replacement parts. The parts must be shipped prepaid to the attention of the customer service department with the following information:

1. Model and serial number of the unit.

2. A concise description of the problem ('broken' is not sufficient).

3. Proof of purchase (photocopy of the invoice).

4. Return authorization number - provided by the customer service representative.

Before contacting customer service, kindly note that the following items are not covered by the warranty:

-costs for transportation, brokerage or export duties

-labor costsfor removal and re-installation

-costs for service calls to diagnose problems

-discoloration of stainless steel parts

-part failure due to lack of cleaning and maintenance, or use of improper cleaners (ovencleaner).

10

Loading...

Loading...