Page 1

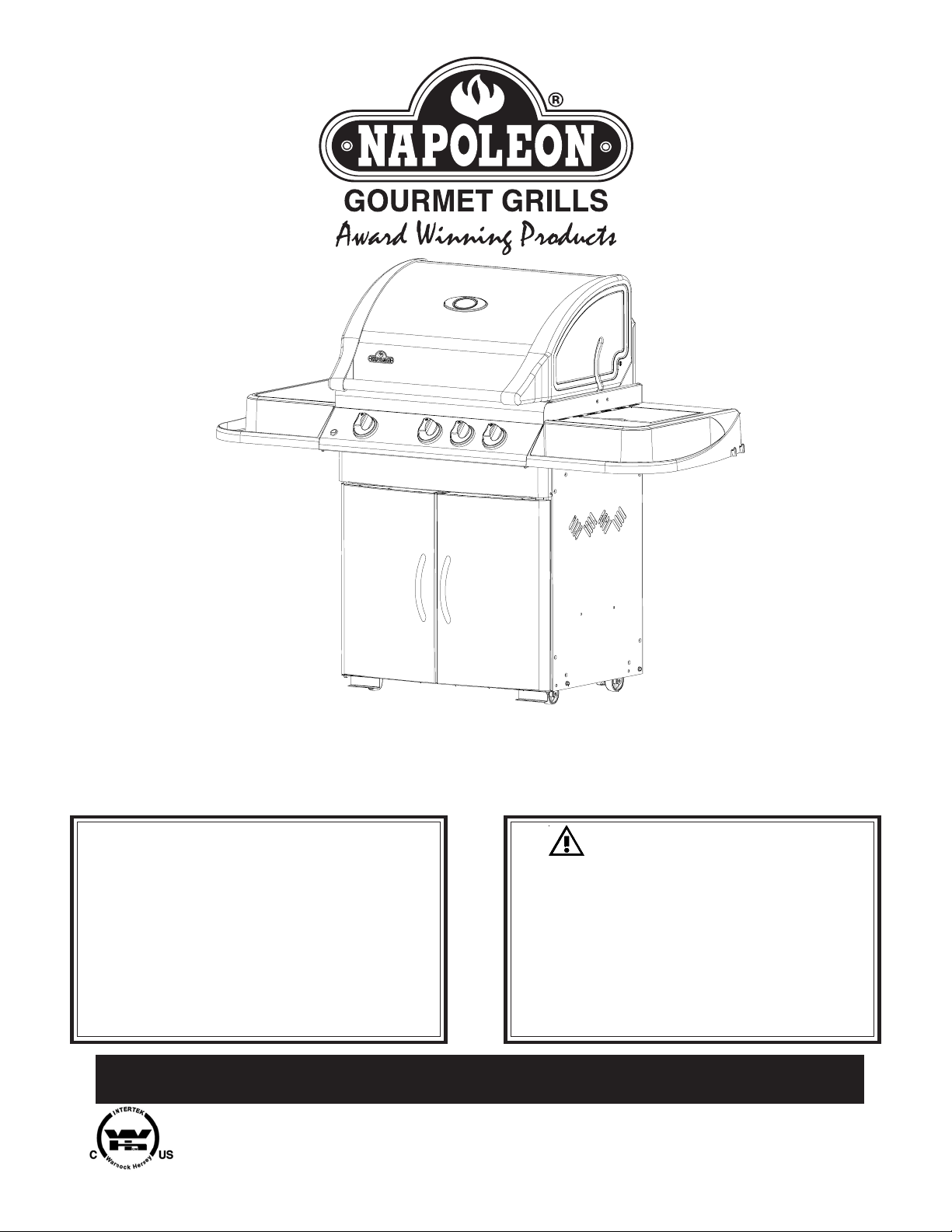

ASSEMBLY AND OPERATING INSTRUCTIONS

MIRAGE 485

OUTDOOR STAINLESS STEEL GAS GRILL

DANGER

NOTICE TO INSTALLER:

LEAVE THESE INSTRUCTIONS

WITH THE GRILL OWNER FOR

FUTURE REFERENCE

DO NOT TRY TO LIGHT THIS APPLIANCE WITHOUT READING LIGHTING INSTRUCTIONS

SECTION OF THIS MANUAL

NAPOLEON APPLIANCE CORPORATION. ,

214 BA YVIEW DR., BARRIE, ONTARIO, CANADA L4N 4Y8 PHONE: (705)726-4278

FAX: (705)725-2564 EMAIL: care@nac.on.ca WEB SITE: www.napoleongrills.com

IF YOU SMELL GAS:

• Shut off gas to the appliance.

• Extinguish any open flame.

• Open lid.

• If odor continues, keep away from the

appliance and immediately call your

gas supplier or your fire department

N415-0156 APR 1 1/07

Page 2

THANK YOU FOR CHOOSING NAPOLEON

NAPOLEON products are designed with superior components and materials, and are assembled by trained

craftsmen who take great pride in their work. The burner and valve assembly are leak tested and test-fired

at a quality test station. This grill has been thoroughly inspected by a qualified technician before packaging

and shipping to ensure that you, the customer, receive the quality product you expect from NAPOLEON.

We at Napoleon are dedicated to you, “our valued customer”. It is our goal to provide you with the

neccessary tools to make this an unforgetable grilling experience. This manual is provided to assist you in

assuring your new grill is assembled, installed, maintained and cared for properly. It is important to read

and understand this entire manual before operating your new grill to ensure you fully understand all safety

precautions and features your grill has to offer. By carefully following the instructions inside this manual you

will enjoy years of trouble free grilling. For whatever reason if we fail to meet your expectations please call

our customer service department at 1-866-820-8686 between 9 AM and 5 PM (eastern standard time) or visit

our website.

NAPOLEON GAS GRILL PRESIDENT'S LIMITED LIFETIME WARRANTY

NAPOLEON warrants the following materials and workmanship in your new NAPOLEON gas grill against

defects for as long as you own the gas grill. This covers: aluminum castings (excluding paint), LUXIDIO trays,

wheels, knobs, stainless steel burners, stainless steel lid inserts, and lid handles. Subject to the following

conditions. During the first five years NAPOLEON will provide replacement parts at our option free of charge.

From the sixth year to lifetime NAPOLEON will provide replacement parts at 50% of the current retail price.

Components such as stainless steel sear plates, stainless steel cooking grids, igniters (excluding batteries),

temperature gauges and brass valves are covered and NAPOLEON will provide parts free of charge during the

first two years of the limited warranty .

Components such as regulators, casters, warming racks, hoses and connectors, fasteners and accessories

are covered and NAPOLEON will provide parts free of charge during the first year of the limited warranty.

NAPOLEON shall not be liable for any transportation charges, labour costs or export duties.

CONDITIONS AND LIMITATIONS

"NAPOLEON warrants its products against manufacturing defects to the original purchaser only (ie., the individual or legal entity (registered customer) whose

name appears on the warranty registration card filed with NAPOLEON), provided that the purchase was made through an authorized NAPOLEON dealer and is

subject to the following conditions and limitations:"

This factory warranty is non-transferable and may not be extended what-so-ever by any of our representatives.

The gas grill must be installed by a licenced, authorized service technician or contractor. Installation must be done in accordance with the installation

instructions included with the product and all local and national building and fire codes.

This limited warranty does not cover damages caused by misuse, lack of maintenance, grease fires, hostile environments, accident, alterations, abuse or

neglect and parts installed from other manufacturers will nullify this warranty.

This limited warranty further does not cover any scratches, dents, painted finishes, corrosion or discolouring by heat, abrasive and chemical cleaners, nor

chipping on porcelain enamel parts, nor any components used in the installation of the gas grill.

Should deterioration of parts occur to the degree of non-performance within the duration of the warranted coverage, a replacement part will be provided.

In the first year only, this warranty extends to the replacement of warranted parts which are defective in material or workmanship provided that the product has

been operated in accordance with the operation instructions and under normal conditions.

After the first year, with respect to this President's Limited Lifetime Warranty NAPOLEON may, at its discretion, fully discharge all obligations with respect to

this warranty by refunding to the original warranted purchaser the wholesale price of any warranted but defective part(s).

NAPOLEON will not be responsible for the installation, labour or any other costs or expenses related to the re-installation of a warranted part, and

such expenses are not covered by this warranty.

Notwithstanding any provision contained in this President's Limited Lifetime Warranty NAPOLEON's responsiblity under this warranty is defined as above and

it shall not in any event extend to any incidental, consequential, or indirect damages.

This warranty defines the obligation and liability of NAPOLEON with respect to the NAPOLEON gas grill and any other warranties expressed or implied with

respect to this product, its components or accessories are excluded.

NAPOLEON neither assumes, nor authorizes any third party to assume, on its behalf, any other liabilities with respect to the sale of this product. NAPOLEON

will not be responsible for: over firing, blow outs caused by environmental conditions such as strong winds, or inadequate ventilation.

Any damages to the gas grill due to weather damage, hail, rough handling, damaging chemicals or cleaners will not be the responsibility of NAPOLEON.

The bill of sale or copy will be required together with a serial number and a model number when making any warranty claims from NAPOLEON. The warranty

registration card must be returned within fourteen days to register the warranty or you can register on-line at www.napoleongrills.com.

NAPOLEON reserves the right to have its representative inspect any product or part prior to honouring any warranty claim.

2

NAPOLEON shall not be liable for any transportation charges, labour costs, or export duties.

Page 3

SAFETY PRECAUTIONS

WARNING

Do not store or use gasoline or other flammable liquids or vapor in the vicinity of this

or any other appliance. An L.P. cylinder not

connected for use must not be stored in the

vicinity of this or any other appliance. Keep

Failure to follow these instructions could

result in property damage, personal

injury or death. Read and follow all

warnings and instructions in this manual

prior to operating grill.

WARNING

area clear and free from combustible

SAFE OPERATING PRACTICES

DANGER: READ ALL INSTRUCTIONS CAREFULL Y BEFORE OPERA TING GRILL. FAILURE T O FOLLOW

THESE INSTRUCTIONS EXACTL Y COULD RESUL T IN A FIRE CAUSING SERIOUS INJURY OR DEA TH.

•Read the entire instruction manual before operating grill.

•Under no circumstance should this gas grill be modified.

•Follow lighting instructions carefully when operating grill.

•Gas must be turned off at the propane cylinder or at the natural gas supply valve when the gas grill is not in use.

•Keep children and pets away from hot grill, DO NOT allow children to climb inside cabinet.

•Do not leave the grill unattended while in use.

•Do not move grill when hot or operating.

•This gas grill is not intended to be installed in or on recreational vehicles and/or boats.

•This gas grill must only be stored outdoors in a well-ventilated area and must not be used inside a building, garage or any enclosed

area.

•Maintain proper clearance to combustibles (16” to rear of unit 7” to sides). Additional clearance is recommended near vinyl siding or

large panes of glass.

•At all times keep the ventilation openings of the cylinder enclosure free and clear from debris.

•Do not locate unit under unprotected combustible construction.

•Do not locate in windy settings. High winds adversely affect the cooking performance of the gas grill.

•When the gas grill is stored indoors, the propane cylinder must be disconnected from the grill and stored outdoors in a well ventilated

area, disconnected cylinders must not be stored in a building, garage or other enclosed area.

•Inspect the fuel line hose before each use. If there is evidence of excessive abrasion or wear, it must be replaced before using the

gas grill, with a replacement hose assembly specified by the manufacturer.

•Never store a spare LP gas cylinder under or near this grill.

•Never fill the cylinder beyond 80 % full.

•Do not attempt to use a cylinder which is not equipped with a QCC1 type connection.

•Leak test all connection before first use, even if the grill was purchased fully assembled, annually or whenever any gas component

has been replaced.

•Never use natural gas in a unit designed for liquid propane gas.

•Never use charcoal briquets or lighter fluid in a gas grill.

•Burner controls must be off when turning supply cylinder on.

•Do not light burner with lid closed.

•Do not operate rear burner with main burner operating.

•The top lid is to be closed during the preheat period.

•Do not route hose underneath drip pan-proper hose clearance to bottom of unit must be maintained.

•Clean grease tray and sear plates regularly to avoid build-up which may lead to grease fires.

•Ensure sear plates are positioned properly according to sear plate installation instructions.

•Do not use side shelves to store lighter, matches or any other combustibles.

•Keep fuel line away from heated surfaces

•Keep electrical supply cords away from water or heated surfaces.

•Inspect infrared burner venturi tube for spider webs and other obstructions periodically. Clean the tubes

completely if you find any such obstructions.

•The outdoor cooking gas appliance and its individual shutoff valve must be disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of 0.5psi (3.5kPa).

•The outdoor cooking gas appliance must be isolated from the gas supply piping system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psi (3.5 kPa).

W ARNING

3

Page 4

CYLINDER SPECIFICATIONS/GAS HOOK UP

This gas barbecue is certified under Canadian and American national standards, CAN/CSA-1.6-2005 and ANSI Z21.58 -2005

respectively for outdoor gas grills and should be installed to conform with local codes. In absence of local codes, install to the

current CAN/CGA-B149.1 Propane Installation Code in Canada or to the National Fuel Gas Code, NFPA54/ANSI Z223.1 in the

United States.

If a rotisserie motor is used, it must be electrically grounded in accordance with local codes or, in absence of local codes, with

the current CSA C22.1 Canadian electrical code in Canada or the National Electrical Code, ANSI/NFPA 70 in the United States.

CALIFORNIA PROPOSITION 65: The burning of gas fuel creates by products, some of which are on the list as substances

known by the State of California to cause cancer or reproductive harm. When cooking with gas, always ensure adequate

ventilation to the unit, to minimize exposure to such substances.

PROPANE CYLINDER SPECIFICATIONS: A dented or rusty cylinder may be hazardous and should be checked by your propane

supplier. Never use a cylinder with a damaged valve. Use only a propane supply cylinder constructed and marked in accordance

with the specifications for LP-gas cylinders of the Canadian Transport Commission (CTC) or the US Department of Transportation

(DOT). This appliance has been designed for use with a 20lb. (9.1 kg) size propane cylinder only (not supplied).

The propane cylinder must be provided with a shut-off valve terminating in a propane cylinder valve type QCC1, and a safety relief

device having direct communication with the vapour space of the cylinder. The cylinder supply system must be arranged for vapour

withdrawal and the cylinder shall include a collar to protect the cylinder valve. The cylinder shall incorporate an OPD (overfill

protection device).

CYLINDER CONNECTION: Ensure that the gas regulator hose is kink free. Remove the cap or plug from the cylinder fuel valve.

Insert the black QCC1 regulator nipple onto the QCC1 fuel valve. Hand tighten clockwise. Do not use tools. Leak test all joints

prior to using the barbecue.

system is replaced.

A leak test must be performed annually, and each time a cylinder is hooked up, or if a part of the gas

CAUTION

PROP ANE CYLINDER INSTALLA TION:

Check that the cylinder valve is closed by turning the knob clockwise.

Check that the grills burner knobs are in the off position.

Open Cabinet doors.

Place the cylinder into the tank holder in bottom of shelf.

Position the cylinder so that the valve faces toward the front of the unit.

Attach regulator hose.

IMPORTANT: Use only the pressure regulator and hose assembly provided with this barbecue. Replacement pressure

regulators and hose assemblies must be specified by the manufacturer. Do not store propane cylinder or spare cylinder on the

shelf beneath the barbecue The regulator must be attached so that no part of the hose touches the underside of the grill or

drippan. A fire will result if these directions are ignored.

The regulator supplies a pressure of 11 inches water column to the gas grill and has a QCC1 type fitting. Cylinders to be used

with this unit must be supplied with a Sherwood #3349 QCC1 cylinder valve. A QCC1 cylinder has a positive seating connection,

which will not allow gas flow until a positive seal has been achieved. It is also equipped with an excess flow device. In order to

attain full flow to the barbecue, the valves must be in the off position when the cylinder valve is turned on.

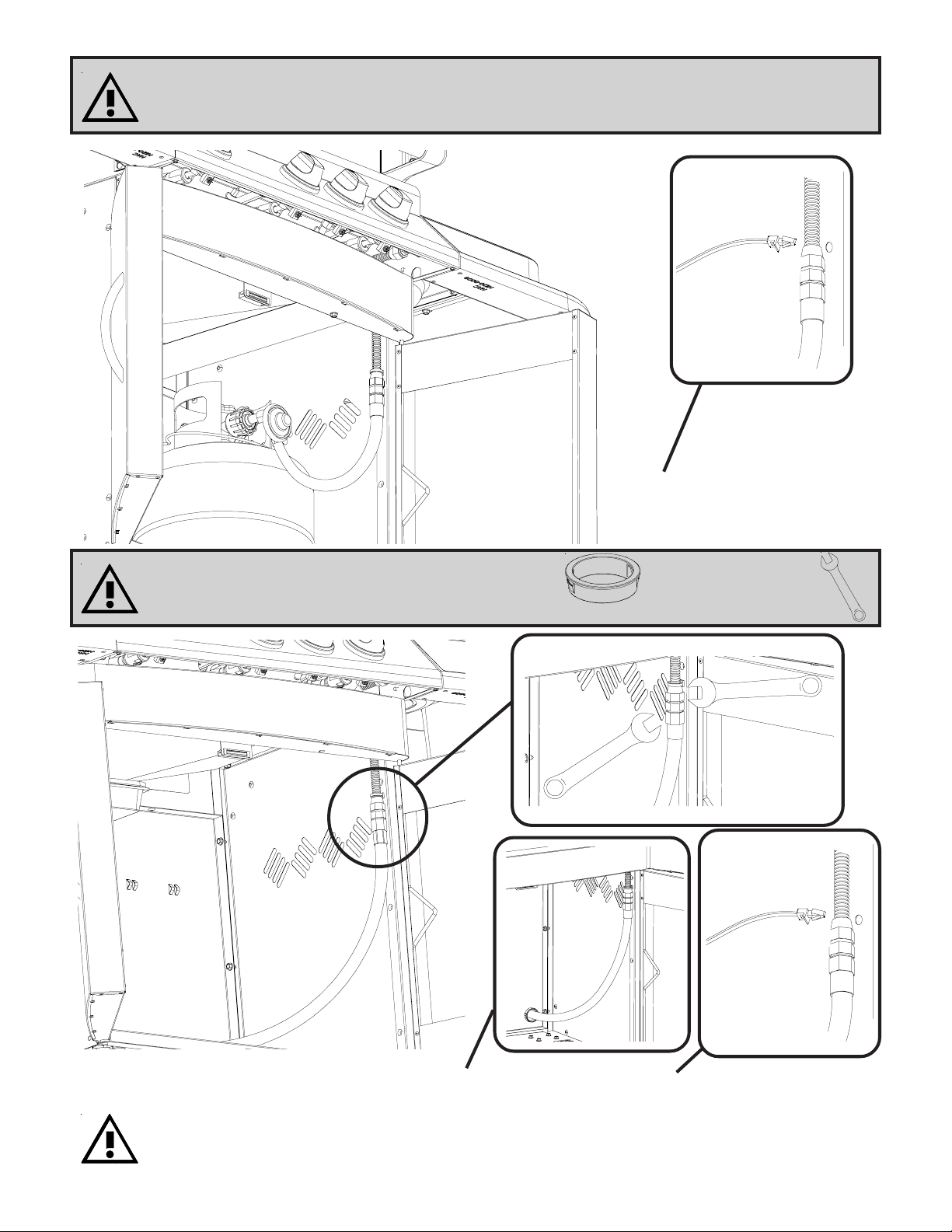

NATURAL GAS HOOK-UP: This natural gas grill is supplied with a 10ft supply hose (complete with a quick disconnect)

designed for natural gas and certified for outdoor use. The gas grill is designed to operate at an inlet pressure of 7 inches water

column. Piping and valves upstream of the quick disconnect are not supplied.

The quick disconnect must not be installed in an upward direction and a readily accessible manual shut-off valve must be

installed upstream of, and as close to, the quick disconnect as is feasible. The flared end of the hose must be connected to the

fitting on the end of the flex tube as illustrated in the

not use thread sealer/pipe dope.)

using the gas grill.

These connections must be made by a licensed gas installer. Leak test all joints prior to

Natural Gas Hose Attachment

diagram. Tighten using two wrenches. (

Do

4

Page 5

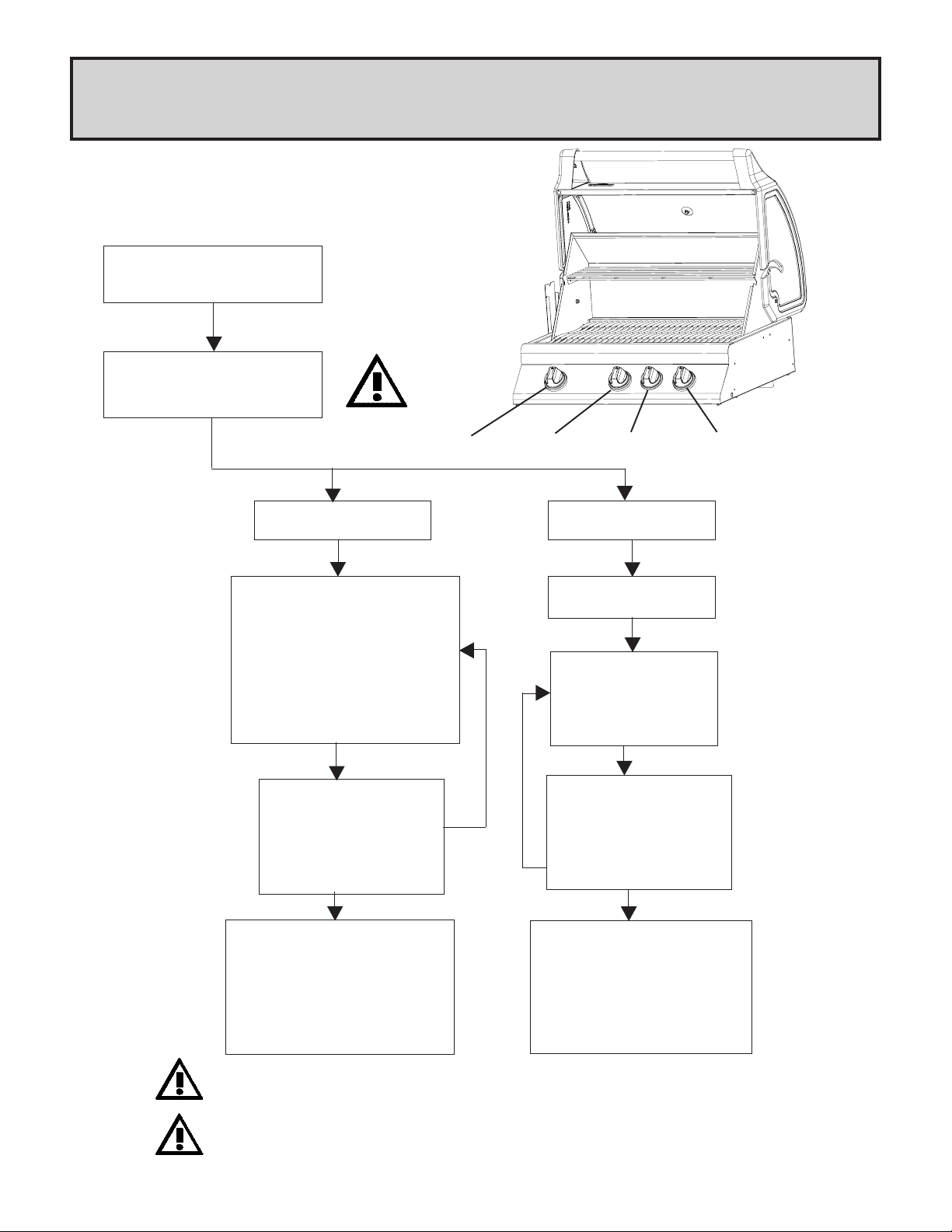

LIGHTING INSTRUCTIONS

OPEN LID.

ENSURING BURNER CONTROLS

ARE IN THE OFF POSITION, TURN

ON THE GAS SUPPLY V AL VE.

LEFT BURNER

MAIN BURNER LIGHTING

1. PUSH AND TURN ANY MAIN

BURNER KNOB SLOWLY TO

THE ’HI’ POSTION. THIS ACTION

WILL IGNITE THE PILOT FLAME

WHICH WILL IN TURN LIGHT THE

SELECTED BURNER. IF THE

PILOT LIGHTS, CONTINUE TO

PUSH DOWN ON THE CONTROL

KNOB UNTIL THE BURNER

LIGHTS AND THEN RELEASE.

2. IF THE PILOT DOES NOT

IGNITE, THEN IMMEDIATEL Y

TURN THE CONTROL KNOB

BACK TO THE ‘OFF POSITION

AND REPEAT STEP 1 SEVERAL

TIMES.

CENTER BURNER

SIDE BURNER LIGHTING

3. IF THE BURNER DOES NOT

IGNITE, THEN IMMEDIATEL Y

TURN THE CONTROL KNOB

BACK TO THE ‘OFF’ POSITION

AND REPEAT STEP 2 SEVERAL

SIDE BURNER

1. OPEN SIDE BURNER

COVER.

2. PUSH AND TURN THE

SIDE BURNER CONTROL

KNOB SLOWLY TO THE

‘HI’ POSITION. THIS

ACTION WILL IGNITE

THE SIDE BURNER

TIMES.

RIGHT BURNER

3. IF THE PILOT AND BURNER WILL

NOT IGNITE WITHIN 5 SECONDS,

TURN THE CONTROL KNOB TO THE

‘OFF’ POSITION AND WAIT 5

MINUTES FOR ANY EXCESS GAS TO

DISSIPA TE. EITHER REPEA T STEPS 1

AND 2 OR LIGHT WITH A MA TCH.

4. IF THE BURNER WILL NOT IGNITE

WITHIN 5 SECONDS, TURN THE

CONTROL KNOB TO THE ‘OFF’

POSITION AND W AIT 5 MINUTES

FOR ANY EXCESS GAS T O

DISSIPA TE. EITHER REPEA T STEPS

2 AND 3 OR LIGHT WITH A MA TCH.

The propane cylinder is equipped with an excess flow device. Unless all burners are

turned off prior to turning the cylinder on, only small flames will be achievable.

If lighting the unit with a match, clip the match into the supplied lighting rod. Hold the

lit match down through the grill and sear plate while turning the corresponding burner

valve to high.

5

Page 6

OPERATING THE GRILL

BURN IN PROCEDURE

When lit for the first time, the gas grill will emit a slight odour. This is a normal temporary condition caused by the "burn-in" of

internal paints and lubricants used in the manufacturing process and will not occur again. Simply run the main burners on high

for approximately ½ hour with the lid closed.

MAIN BURNER USE:

When searing foods, preheating is recommended by operating all main burners in the high position with the lid closed for

approximately 15 minutes. Food cooked for a short period of time (fish, vegetables) may be grilled with the lid open. Cooking with

the lid closed will ensure higher, more even temperatures that will reduce cooking time and cook meat more evenly. When

cooking very lean meats, such as chicken breasts, or lean pork, the grids can be oiled before pre-heating to reduce sticking.

Cooking meat with a high degree of fat content, may create flare-ups. Either trim some fat or reduce temperatures to prevent this.

Should a flare-up occur, move food away from flames, reduce heat. Leave the lid open. See 'Your All Season Grill' cookbook by

Napoleon for more detailed instructions.

DIRECT COOKING:

Place food to be cooked on the grill directly over the heat. This method is generally used for searing or for foods that do not

require prolonged cooking times - hamburgers, steaks, chicken pieces, vegetables, etc. The food is first seared to trap in the

juices and flavor, and then the temperature is lowered to finish cooking the food to your preference.

INDIRECT COOKING:

With one or more burners operating place food to be cooked on the grill over one of the burners that is not operating. The heat

circulates around the food, cooking slowly and evenly. Cooking in this manner is much the same as cooking in your oven and is

generally used for larger cuts of meats such as roasts, chickens or turkeys, but can also be used for cooking foods that are prone

to flare ups. Cooking in this method with lower temperatures and slower cooking times will result in tender foods every time you

grill.

INFRARED MAIN BURNER USE: (optional)

1. Operate on high for 5 minutes with the lid closed or until the ceramic burners glow red.

2. Place food on grills, searing in juices approximately 2 minutes per side.

3. Depending upon your taste, continue cooking over infrared burner on high, medium or low, turning food frequently, or place

food away from infrared burners, close lid, and allow oven temperature to slowly finish cooking your food.

PROTECTION OF YOUR INFRA RED BURNERS - The infrared burners of your grill are designed to provide a long

service life. However, there are steps you must take to prevent cracking of their ceramic surfaces, which will cause the

burners to malfunction.

1. Never let water come in direct contact with your ceramic burner.

2. Avoid impact with hard objects.

3. In order for the burners to function properly, hot air must have a way to escape the grill. If the hot air is not allowed to

escape, the burners may become deprived of oxygen, causing them to crack. Do not cover more than 75% of the cooking

surface with solid metal (ie. griddle or large pan).

Damage caused by failure to follow these steps is not covered by your grill warranty.

IMPORTANT

• Do not allow cold water (rain, sprinkler, hose, etc.) to come in cont act with hot ceramic burners. A large

temperature differential can cause cracking of the ceramic tile.

SIDE BURNER USE:

The side burner can be used like any range top burner, for gravies, soups etc. The gas grill should be located so that the side

burner is protected from the wind, because the wind will adversely affect it’s performance. DO NOT use side burner to deep fry

foods as cooking with oil can create a dangerous situation.

6

Page 7

MAINTENANCE/CLEANING INSTRUCTIONS

It is recommended that this gas grill be thoroughly inspected and serviced annually by a

qualified service person.

• Do not use pressure washer to clean any part of the unit.

Ensure that the burners are turned off prior to cleaning. Avoid unprotected contact with hot surfaces. Clean grill in an

area where cleaning solutions will not harm decks, lawns or patios. Do not use oven cleaner to clean any part of this gas

grill. Do not use a self cleaning oven to clean cooking grids or any other parts of the gas grill. Barbecue sauce and salt

can be corrosive and will cause rapid deterioration of the gas grill components unless cleaned regularly .

Turn off the gas at the source and disconnect unit before servicing. Maintenance should only be done when the grill is

cool, to avoid the possibility of burns. A leak test must be performed annually, and whenever any component of the gas

train is replaced.

COMBUSTION AIR ADJUSTMENT - (This must be done by a qualified gas installer.) The air shutter is factory set and

should not have to be adjusted under normal conditions. However, some extreme field conditions may exist that require

adjustment. When the air shutter is adjusted correctly, the flames will be dark blue with light blue tips, and occasional yellow

tips.

If the burner is getting too little air, the flames will be lazy yellow, and possibly produce soot. If the burner is getting too

much air, the flames will be lifting erratically from the burner and may cause difficulties when lighting.

1. To adjust the air shutter, remove cooking grids and sear plates and leave lid open. The back cover must be removed for

back burner air shutter adjustment.

2. Loosen air-shutter lock screw and open or close air shutter as required. The normal settings are:

3. Light burners and set to high. Visually inspect burner flames. When shutters are set, turn burners off, tighten locking

screw, and replace removed parts. Ensure that the insect screens are installed.

GRIDS AND WARMING RACK - The grids and warming rack are best cleaned during the pre-heat period with a soft brass

wire brush. Steel wool can be used for stubborn stains. Stainless grids will discolour permanently from normal usage, due

to the high temperature of the cooking surface.

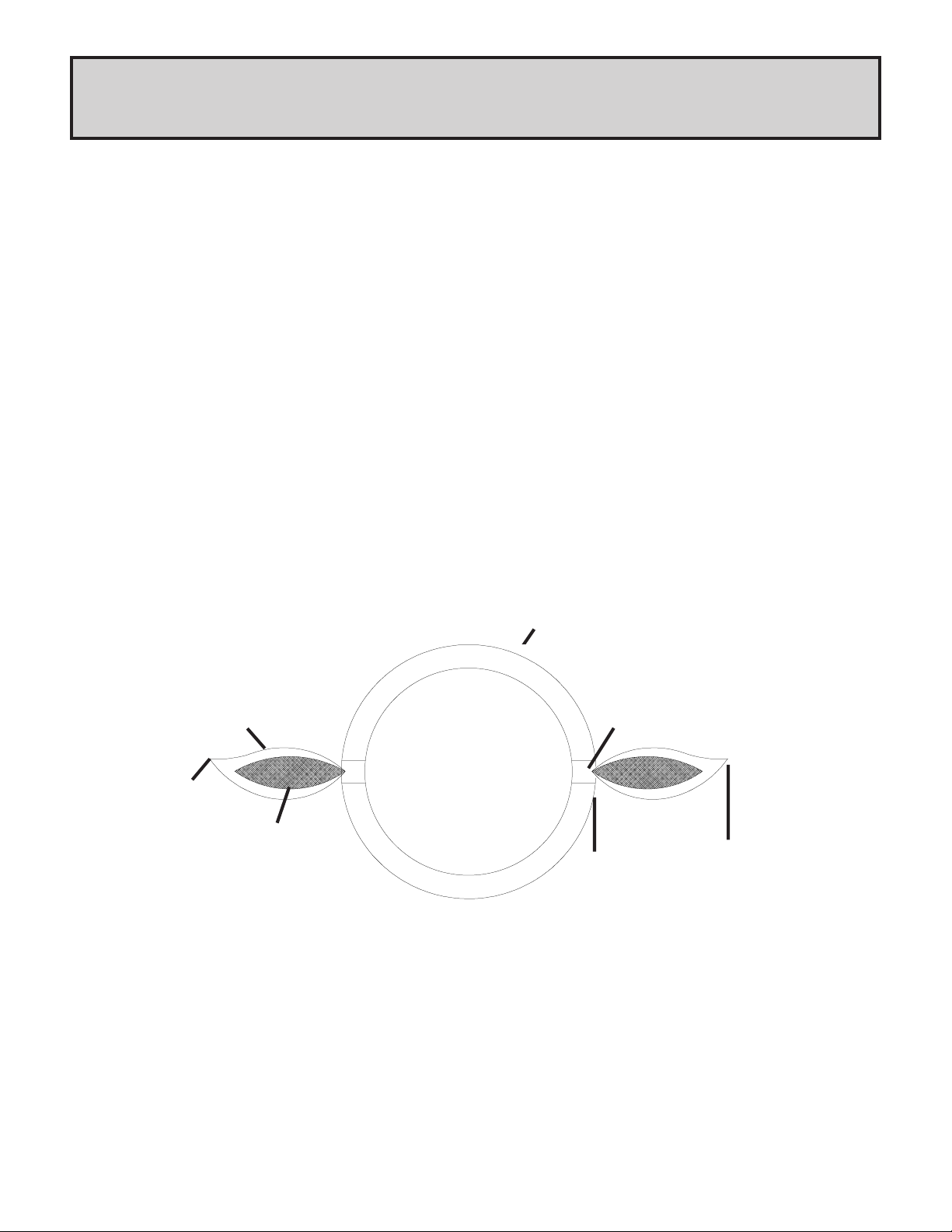

Main Burner Propane 5/32"

Natural 5/32"

LIGHT BLUE

YELLOW TIPPING

DARK BLUE

BURNER

BURNER PORT

APPROXIMA TELY

1/2"

CLEANING INSIDE THE GAS GRILL - Remove cooking grids. Use a soft brass wire brush to clean loose debris from casting

sides and insides of the lid. Scrape sear plates with a putty knife or scraper, and use a wire brush to remove ash. Remove

sear plates and brush debris off of burners with a brass wire brush. Brush all debris from inside the gas grill into the

removable drip pan. Ensure that the sear plates are placed properly when they are reinstalled (Check assembly instructions

for proper orientation).

DRIP PAN - Slide the drip pan out for easy cleaning. It should be cleaned frequently (every 4-5 uses) to avoid grease

buildup. Grease and excess drippings pass through to the drip pan, located under the gas grill, and accumulate in the

disposable grease tray below the drip pan. Accumulated grease can cause a fire hazard. Do not line the drip pan with

aluminum foil or sand, as it can prevent the grease from flowing properly. The pan should be scraped out with a putty knife or

scraper, and all the debris should be scraped into the disposable grease tray. This tray should be replaced every two to four

weeks, depending on gas grill usage. For supplies, see your Napoleon Gas Grill dealer.

7

Page 8

MAINTENANCE/CLEANING INSTRUCTIONS

HOSE - Check for abrasion, melting, cuts and cracks. If any of these conditions exist, do not use gas grill. Have part

replaced by your Napoleon Gas Grill dealer, or qualified gas installer.

CLEANING THE OUTSIDE OF THE GAS GRILL - Do not use abrasive cleaners to clean any painted, porcelain or stainless

steel parts. Porcelain enamel components must be handled with additional care. The baked on enamel finish is glass like,

and will chip if struck. Touch-up enamel is available from your Napoleon Gas Grill dealer. Exterior grill surfaces should be

cleaned while warm to the touch, with warm soapy water. To clean stainless surfaces, use a stainless steel cleaner or a nonabrasive cleaner. Always wipe in the direction of the grain. Do not use steel wool, as it will scratch the finish. Stainless steel

parts will discolour when heated, usually to a golden or brown colour. This discolouration is normal and will not affect the

performance of the grill.

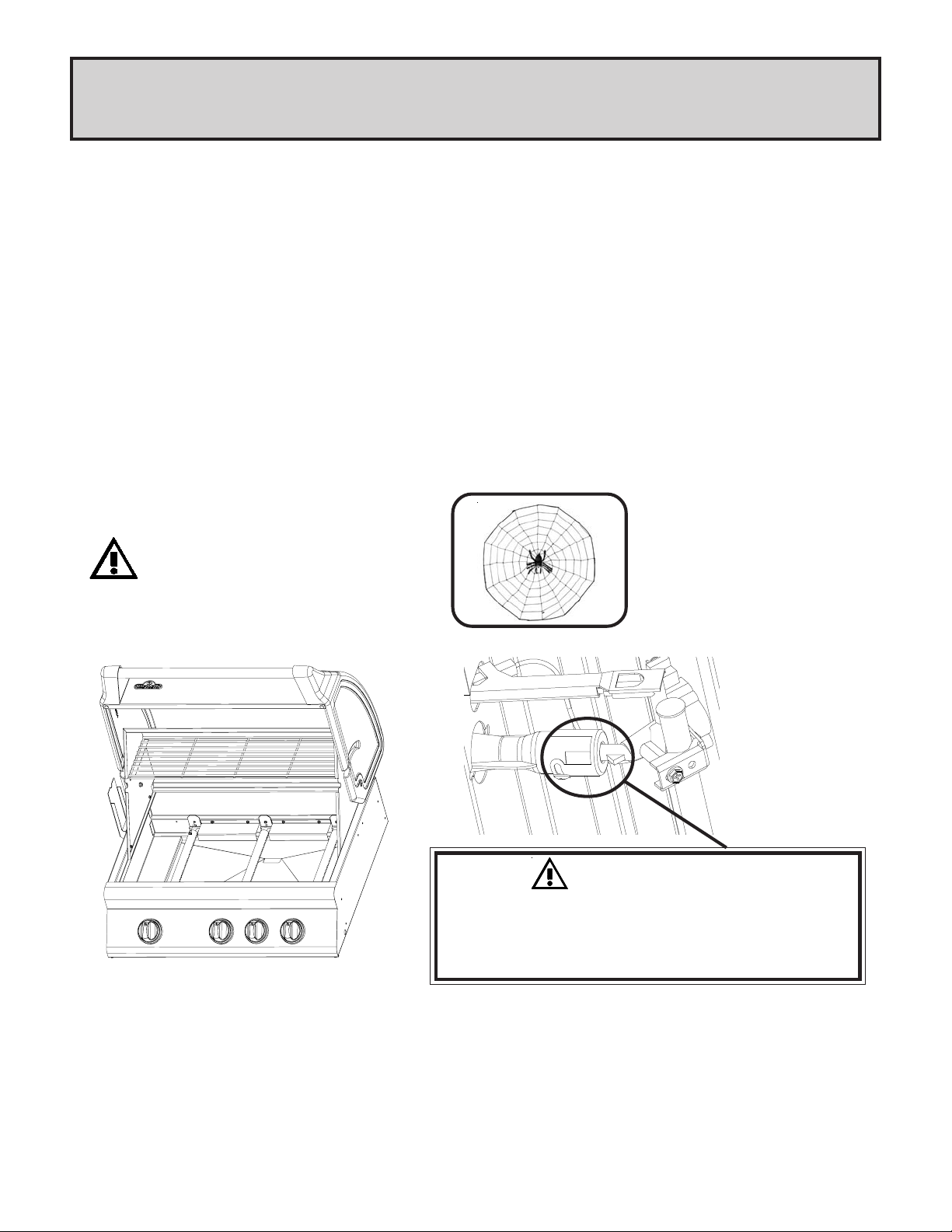

TUBE BURNER - The burner is made from heavy wall 304 stainless steel, but due to the extreme heat and corrosive

environment, surface corrosion will occur. Use a brass wire brush to remove surface corrosion. Clean any blocked ports

using an opened paper clip. Do not enlarge the burner ports. Spiders and insects are attracted to the smell of propane and

natural gas. The burner is equipped with an insect screen on the air shutter, which will reduce the likelihood of insects

building nests inside the burner, but does not entirely eliminate the problem. The nest or web will cause the burner to burn

with a soft yellow or orange flame or cause a fire (flashback) at the air shutter underneath the control panel. To clean the

inside of the burner, it must be removed from the gas grill. Remove the screw located in the center of each burner. Lift the

back of the burner upwards to remove. Use a flexible venturi tube cleaning brush to clean out the inside of the burner. Shake

any loose debris out of the burner, through the gas inlet. Ensure that the insect screen is clean, tight, and free of any lint or

other debris. Check also that the valve orifices are clean. Do not enlarge the orifices. Re-install the burner.

CAUTION BEWARE OF SPIDERS

WARNING

It is very important when re-installing the burner after

cleaning that the valve/orifice enters the burner tube before

lighting your gas grill. If the valve is not inside the burner

tube a fire or explosion could occur.

INFRA RED BURNER - Because of the high intensity of the infrared burner, most drippings and food particles that fall onto the

burner surface are immediately incinerated. However, some debris and residue may remain. To remove this residue after

cooking, turn the grill on high with lid closed for 5-10 minutes. Never use a brush or pressure washer to clean the infra red

burners.

8

Page 9

TROUBLESHOOTING

Problem Possible Causes Solution

Low heat / Low flame when

valve turned to high.

Excessive flare-ups/uneven

heat.

Burners burn with yellow

flame, accompanied by the

smell of gas.

Flames lift away from

burner, accompanied by the

smell of gas, and possibly

difficulties in lighting.

For propane - improper lighting

procedure.

For natural gas - undersized

supply line.

For both gases - improper

preheating.

Sear plates installed incorrectly.

Improper pre-heating.

Excessive grease and ash build

up on sear plates and in drip

pan.

Possible spider web or other

debris, or improper air shutter

adjustment.

Improper air shutter adjustment.

Ensure lighting procedure is followed carefully. All gas grill

valves must be in the off position when the tank valve is

turned on. Turn tank on slowly to allow pressure to

equalize. See lighting instructions.

Pipe must be sized according to installation code.

Pre-heat grill with both main burners on high for 10 to 15

minutes.

Ensure sear plates are installed with the holes towards the

front, and the slots on the bottom. See assembly

instructions.

Pre-heat grill with both main burners on high for 10 to 15

minutes.

Clean sear plates and drip pan regularly. Do not line pan

with aluminum foil. Refer to cleaning instructions.

Thoroughly clean burner by removing. See general

maintenance instructions. Open air shutter slightly

according to combustion air adjustment instructions.

Close air shutter slightly according to combustion air

adjustment instructions.

Regulator ‘Hums’ when

unit is operating.

Burners will not crosslight

each other.

"Paint" appears to be

peeling inside lid or hood.

Normal occurence on hot days.

Plugged ports at back of burner.

Grease build up on inside

surfaces.

This is not a defect. It is caused by internal vibrations in the

regulator, and does not affect the performance or safety of

the gas grill. Humming regulators will not be replaced.

Clean burner ports. See burner maintenance instructions.

This is not a defect. The finish on the lid and hood is

stainless steel, and will not peel. The peeling is caused

by hardened grease, which dries into paint-like shards,

that will flake off. Regular cleaning will prevent this. See

cleaning instructions.

9

Page 10

ORDERING REPLACEMENT PARTS

WARRANTY INFORMATION

MODEL:

DA TE OF PURCHASE:

KEEP YOUR RECEIPT AS

PROOF OF PURCHASE

TO VALIDATE YOUR

WARRANTY

SERIAL NUMBER:

(record information here for easy reference)

Before contacting the customer service department, check the NAC web site for more extensive cleaning, maintenance,

troubleshooting and part replacement instructions at www.napoleongrills.com. Contact the factory directly for replacement parts

and warranty claims. The customer service department is available between 9 AM and 5 PM (Eastern standard time) at 1-866820-8686 or fax at 1-705-727-4282. In order to process a claim, we must be provided with the following information:

1. Model and serial number of the unit.

2. Part number and description.

3. A concise description of the problem ('broken' is not sufficient).

4. Proof of purchase (photocopy of the invoice).

In some cases the customer service representative may request to have the parts returned to the factory for inspection, before

providing replacement parts. The parts must be shipped prepaid to the attention of the customer service department with the

following information:

1. Model and serial number of the unit.

2. A concise description of the problem ('broken' is not sufficient).

3. Proof of purchase (photocopy of the invoice).

4. Return Authorization number - provided by the customer service representative.

Before contacting customer service, kindly note that the following items are not covered by the warranty:

-costs for transportation, brokerage or export duties

-labor costs for removal and re-installation

-costs for service calls to diagnose problems

-discoloration of stainless steel parts

-part failure due to lack of cleaning and maintenance, or use of improper cleaners (ovencleaner).

NAPOLEON APPLIANCE CORPORATION

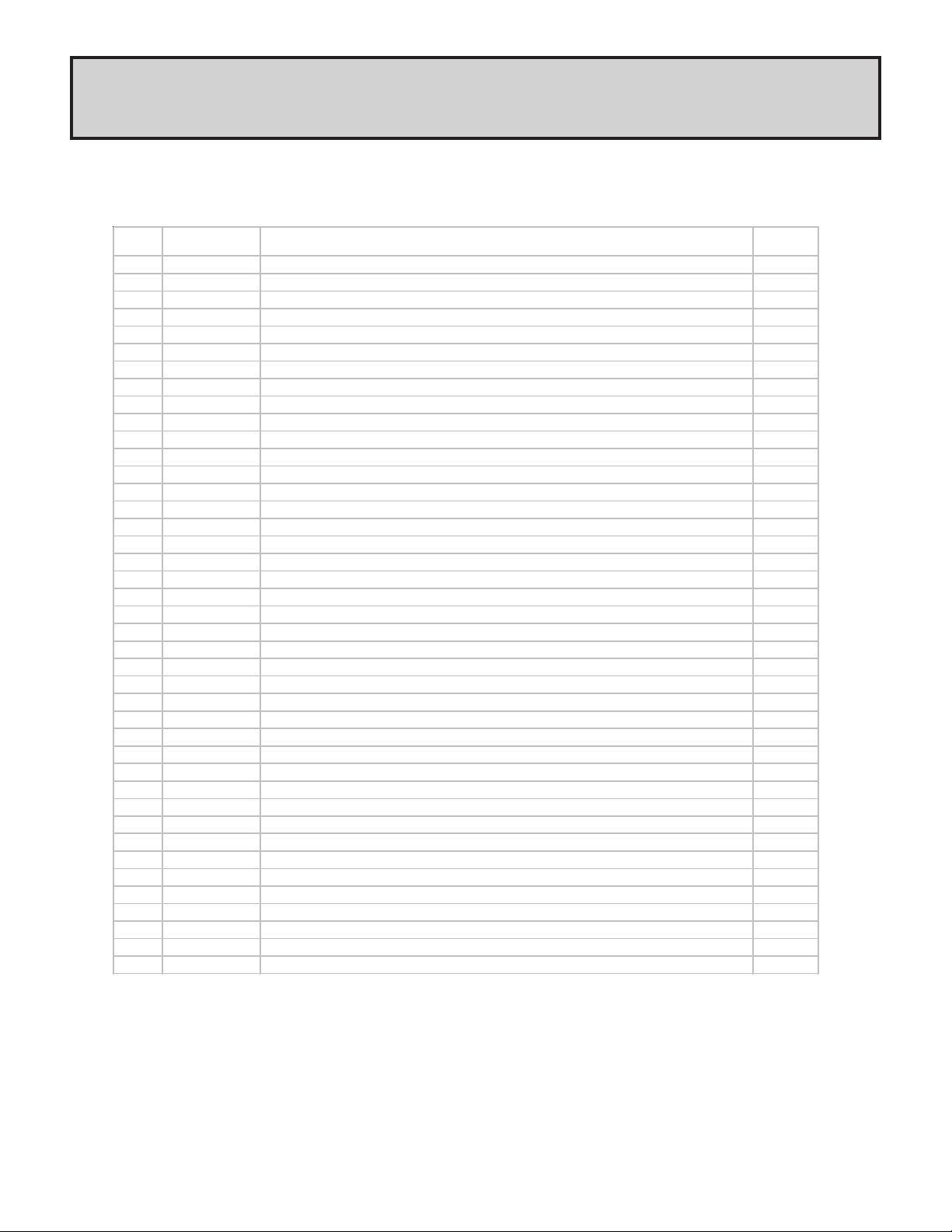

ACCESSORIES / PARTS ORDER FORM

FAX TO: 1-705-727-4282

PLEASE PRINT CLEARL Y

CUSTOMER NAME:

ADDRESS:

TELEPHONE:

VISA OR MASTERCARD #: EXPIRY DA TE:

QUANTITY

PRODUCT NUMBER

DA TE:

MODEL #:

SERIAL #:

DESCRIPTION

T AXES & SHIPPING CHARGES MAY APPL Y

10

Page 11

ASSEMBLY INSTRUCTIONS

CAUTION: During unpacking and assembly it is recommended that you wear work gloves

and safety glasses for your protection. Although we make every ef fort to make the assembly

process as problem free and safe as possible, it is characteristic of fabricated steel parts that the

edges and corners may be sharp and can cause cuts if handled incorrectly during assembly .

GETTING STARTED

1. Remove all cart panels, hardware, and grill head from carton. Raise lid and remove any components

packed inside. Use the parts list to ensure all necessary parts are included.

2. Do not destroy packaging until grill has been fully assembled and operating to your satisfaction.

3. Assemble BBQ where it is to be used, lay down cardboard or a towel to protect parts from being

lost or damaged while assembling.

4. Most stainless steel parts are supplied with a protective plastic coating that must be removed prior

to using grill.

5. Follow all instructions in the order that they are layed out in this manual.

6. T wo people are required to lift the grill head onto the assembled cart.

TOOLS REQUIRED FOR ASSEMBLY (tools not included)

3/8(10mm)

WRENCH

OR RATCHET

7/16 WRENCH

3/8

OR RATCHET

FLAT AND PHILIPS

7/16

SCREWDRIVERS

HAMMER

If you have any questions about assembly or grill operation, or if there are

damaged or missing parts please call our customer service department at 1-

866-820-8686 between 9 AM and 5 PM (eastern standard time)

11

Page 12

1 x N430-0002

MAGNET CA TCH

1

Magnet Installation

Snap magnet into slot in front of bottom shelf.

16 X

16 X

7/16

3/8

N570-0073 (1/4-20 X 3/8”)

2

Caster/Bracket Installation

N450-0027 (1/4-20)

Attach (4) casters, using (4) 1/4 - 20 X 3/8” screws and (4) 1/4-20 lock nuts

for each caster. Attach brackets under front casters as illustrated. Tighten

securely.

12

non revolving caster- left side

Page 13

PROPANE ONLY

3

Insert propane tank ring into slots in bottom shelf as shown. Fold tabs over to

secure in place.

4 X

N570-0080 (#14 X 1/2")

4

Propane Tank Ring Installation

3/8

Left and Right Cart Panel Installation

Install end cart panels ensuring slots in panel are to the top, rest panel on bottom

shelf and line up holes. Fasten using (4) #14 x 1/2” screws.

13

Page 14

6 X

N570-0080 (#14 X 1/2")

3/8

5

Fit rear cart panel between the two end panels, ensure large hole in panel is to

the bottom right hand corner as illustrated. Fasten using (6) #14 x 1/2” screws,

three on each side.

Rear Cart Panel Installation

14

6

Rotate basket slightly to allow wire to enter the holes in the side panel. Push

through and upwards, rotating to allow the bend in the wire to pass through the

holes. Lay basket flat against the side panel. Clip top propane tank mount into

slots in back panel. Insert one end at a time, gently bending wire. (When not

in use tank mount will lay flat against back panel).

Condiment Basket / Propane Tank Mount Installation

PROPANE ONLY

Page 15

6 X

N570-0080 (#14 X 1/2")

1 x N430-0002

3/8

MAGNET CATCH

7

Front Cabinet Support Installation

Fasten top rail assembly to the front of side panels using (4) #14 x 1/2” screws.

For ease of installation start all screws before tightening completely. Attach

magnet bracket to bottom of top rail using (2) #14 x 1/2” screws, and snap magnet into place as shown.

2 X

N570-0080 (#14 X 1/2")

8

Propane Tank Heat Shield Installation

PROPANE ONLY

Attach propane tank heat shield above propane tank ring. Attach one end under lip of back panel and other end to underside of front cabinet support.

3/8

15

Page 16

6 x

N570-0073 (1/4-20 x 3/8”)

3/8

9

Grill Head Installation

PROPANE ONLY - To avoid assembly difficulties, prior to mounting the grill

head, remove zip tie holding regulator up under control panel. This was installed

at the factory to protect the regulator hose during shipping and is no longer required. (Take care when removing the tie not to damage the hose).

Lift grill head and place on assembled cart, lining up holes in top of side cart

panels with holes in bottom of base. Fasten from inside using (4)1/4-20 x 3/

8”screws, two per side. Install battery pack below vent slots on left hand panel

using double sided tape supplied with battery pack. Plug wire from LED (lights)

located underneath control panel into wire from battery pack. Install rotisserie

mount bracket to left side of barbecue as shown using (2) 1/4-20 x 3/8” screws.

16

TWO PEOPLE ARE REQUIRED

FOR THIS STEP

Page 17

10 x

N570-0073 (1/4-20 x 3/8")

3/8

10

Assembling End Caps to Side Shelf / Side Burner

Peel protective coating from side shelf / side burner. Attach corresponding end

cap as shown using (5) (1/4-20 x 3/8”) screws.

Bend tabs on front of shelf up with a flat head

screw driver, insert screw through t ab and into

end cap.

4 X

N570-0082 (1/4-20 x 5/8")

4 X

N735-0001 (1 1/16” insulated washer)

3/8

11

Side Shelf Installation

Insert (4) 1/4-20 x 5/8” screws through washers into threaded holes in side of

base, do not tighten all the way. Slide assembled side shelf over screw heads

and finish tightening.

17

Page 18

4 X

N570-0082 (1/4-20 X 5/8")

1 X

N160-0016

4 X

N735-0001 (1 1/16” insulated washer)

3/8

12

Side Burner Installation

Insert (4)1/4-20 x 5/8” screws through washers into threaded holes in side of base.

Do not tighten all the way. Slide assembled side burner over screw heads and

finish tightening. Attach 1/2” flex connector hose from manifold to fitting on end of

side burner hose. Fit orifice into burner tube and secure with hose retainer clip

supplied. Attach wire from manifold to side burner electrode.

18

Page 19

4 x N570-0073

(1/4-20 X 3/8")

4 X N735-0003

(1/4” LOCK W ASHER)

2 x N105-0011

DOOR BUSHING

3/8

13

Cabinet Door Installation

Install door handle onto front of door using (2) 1/4-20 x 3/8” screws and (2) 1/4”

lock washers per door.

Insert pivot rod through hole on inside top of door. Holding door in one hand,

direct pivot rod into hole in underside of front cabinet support. Once secure, let

rod slide down and through hole in bottom of door and into bushing in bottom

shelf.

BUSHING

19

Page 20

3 X N305-0057

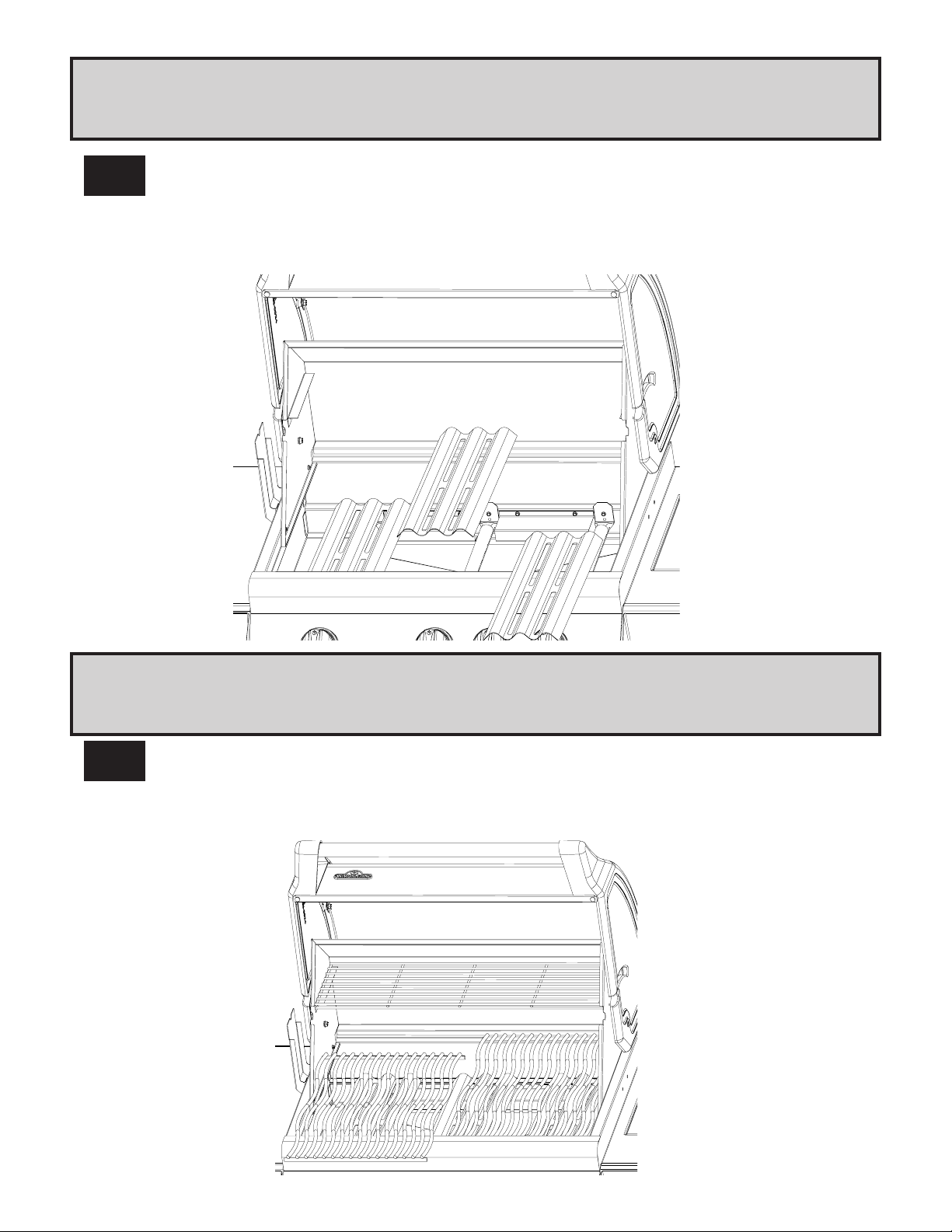

14

Insert sear plates into base, position one over each tube burner with slots down

to allow drippings to travel through.

Sear Plate Installation

1 X N520-0023

2 X N305-0058

15

Postion grills and warming rack into base as shown. Rest warming rack on

brackets inside hood and grills on front and back lip of base.

Grill and Warming Rack Installation

20

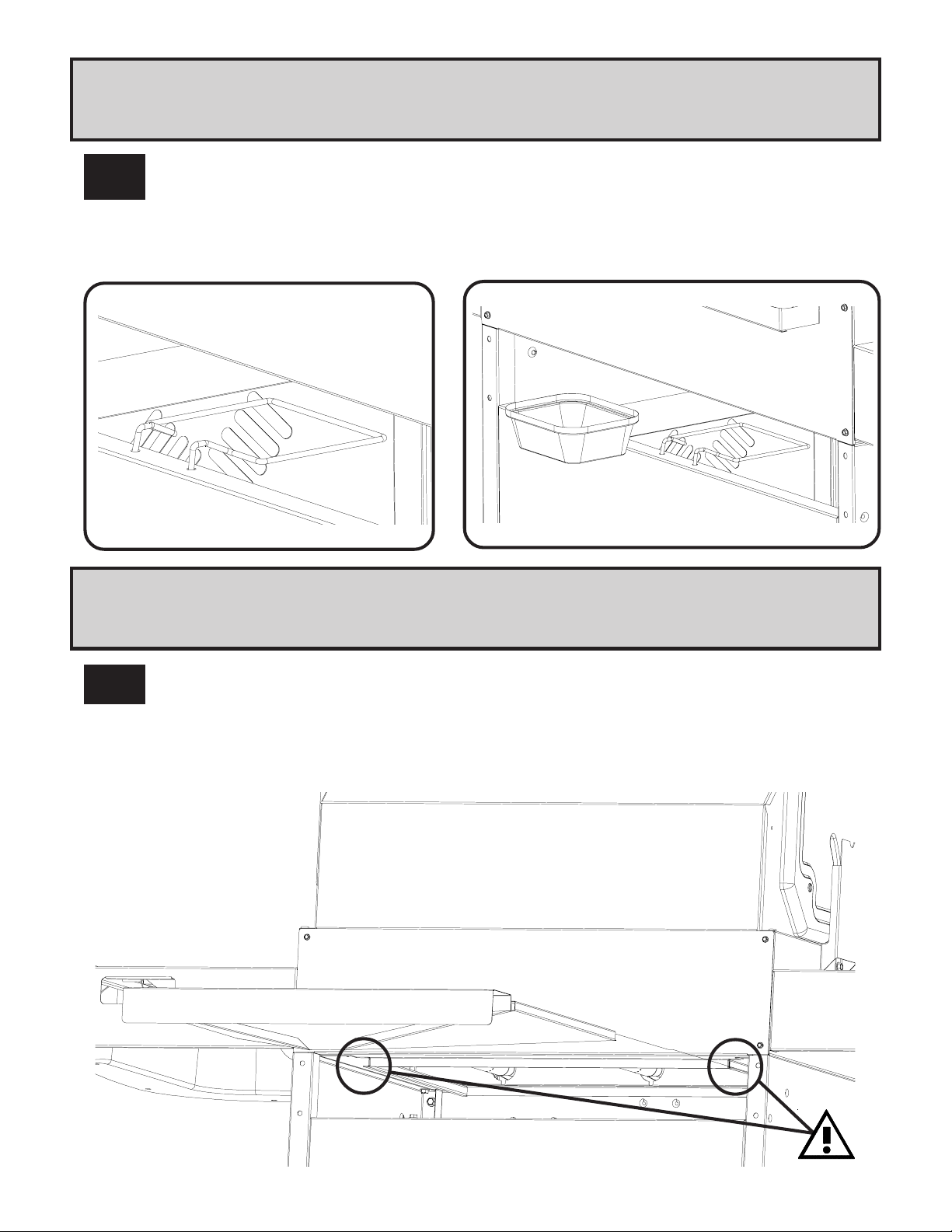

Page 21

16

Clip the wire grease tray holder into the two holes located in the center of the

back panel. Place the aluminum grease tray into the grease tray holder

Grease Tray and Holder Installation

17

Slide drip pan into rear of base as shown. Ensure drip pan rides along rails on

bottom of base.

Drip Pan Installation

21

Page 22

PROPANE ONLY

CLIP HOSE TO SIDE P ANEL USING

HOSE RET AINER CLIP SUPPLIED

NATURAL GAS ONLY

3/4

2 X

1xN105-0002

22

INST ALL BUSHING INTO

BACK P ANEL

THIS MUST BE PERFORMED BY A LICENSED GAS FITTER.

DO NOT USE PIPE DOPE OR TEFLON T APE ON THIS CONNECTION

CLIP HOSE TO SIDE P ANEL USING HOSE

RET AINER CLIP SUPPLIED

Page 23

LEAK TESTING INSTRUCTIONS

DO NOT USE A FLAME TO LEAK TEST.

LEAK TESTING: This must be done before initial use, annually and whenever any gas components are replaced or serviced. No

smoking while performing this test, and remove all sources of ignition. See

1. Turn all burner controls to off. Turn supply valve on.

2. Brush a half and half solution of liquid soap and water onto all joints and connections of the regulator, hose, manifolds and

valves.

3. Bubbles will indicate a gas leak. Either tighten the loose joint or replace the part with one recommended by the dealer.

4. If the leak cannot be stopped, shut off the gas supply, disconnect it and have the barbecue inspected by your gas supplier or

dealer. Do not use the appliance until the leak has been corrected.

5. Turn off gas supply.

A LEAK TEST MUST BE PERFORMED A T THE

FOLLOWING TIMES:

•BEFORE INITIAL USE EVEN IF THE GRILL W AS

DEALER ASSEMBLED.

•A T LEAST ONCE PER YEAR.

•WHENEVER ANY GAS COMPONENT HAS BEEN

REPLACED.

Leak Testing Diagram

for areas to check.

23

Page 24

PARTS LIST

Item Part # Desc ription 485

1 N135-0024K left side lid casting x

2 N385-0129 NAPOLEON logo x

3 W450-0005 logo spring clips x

4 N510-0010 black silicone lid bumper x

5 N685-0003 tempe rature gauge x

6 N051-0004 tempe rature gauge bezel x

7 N335-0042 stainless steel lid insert x

8 N585-0040 heat shield lid x

9 N010-0504 lid handl e x

10 N135-0025K right side lid casting x

11 N570-0015 lid pivot screw x

12 N010-0502 hood assembly x

13 N570-0008 #8 x 1/2" screw x

14 N570-0073 1/4-20 x 3/8" screw x

15 N735-0003 1/4" lockwasher x

16 N520-0023 w arming rack x

17 N305-0058 cooking grids - stainless rod x

18 N305-0057 sear plate x

19 N010-0529 stainless steel side shelf - right x

20 N120-0009 LU XIDI O side shelf end cap, right x

21 N570-0082 1/4-20 x 5/8" screw x

22 N010-0528 stainless steel side shelf - left x

23 N120-0008 LU XIDI O side shel f end cap, left x

24 N500-0035K side burner pla te x

25 N100-0037 side burner x

26 N335-0043 side burner lid x

27 N305-0059 side burner grate x

28 N555-0019 side burner lid pivot rod x

29 N100-0036 main burner x

30 N080-0202 main burner cross light bracket x

31 N475-0199 rotisserie mount x

32 N010-0500 base x

33 N010-0501 drip pan x

34 N160-0014 grease tray holder x

35 62007 replacement grease trays (5 pieces) x

36 N200-0077P back cover x

37 N475-0181 control panel x

38 N380-0011 control knob x

39 N051-0003 control knob bezel x

40 N530-0003 1-outlet regula tor p

N345-0001 10ft n/g hose c/w quick disconnect n

41 N010-0507 manifold assembly c/w valves p

24

x - standard p - propane units only p - appareils propane seulement

x - compris n - natural gas units only n - appareils gaz naturel seulement

ac - accessory ac - accessoires

Page 25

PARTS LIST

Item Part # Description 485

N010-0508 manifold assembly c/w valves n

42 N720-0044 manifold flex connector x

43 N255-0027 union fitting 3/8" - 3/8" x

44 N725-0034 main burner valve c/w #56 orifice p

N725-0035 main burner valve c/w #52 orifice n

45 N725-0032 side burner valve p

N725-0033 side burner valve n

N455-0049 side burner orifice #62 p

N455-0050 side burner orifice #54 n

N720-0055 side burner supply tube x

47 N475-0183P left/right side panel cabinet enclosure x

48 N555-0018 door pivot rod x

49 N010-0506 cart door assembly x

50 N325-0048 door handle x

N570 -0073 door ha ndl e screws x

52 N590-0147P bottom shelf x

53 N010-0505 front cabinet support x

54 N475-0184P rear cart panel x

55 N585-0041P heat shield p

56 N105-0002 snap bushing x

57 N105-0011 door bushings x

58 N655-0094P tank ring support p

59 N430-0002 magnetic catch x

N02 0-0122 main assembly baggie x

61 N750-0020 wirin g ha rness led, x

62 N190-0001 battery pack x

W043-0 002 ba ttery "AA' x

64 N735-0001 insulated washer x

N105-0001 bushing 7/8" x

66 N640-0001 hose retainer clip x

67 N160-0015 propane tank clip p

68 N130-0012 revolving caster x

69 N450-0027 locking nut 1/4-20 x

70 N080-0212 stabilizer brackets x

71 N590-0164 condiment basket x

72 N130-0013 non revolving caster x

N370-0454 rotisserie kit ac

N555-0020 rotisserie spit ac

63485 vinyl cover ac

56017 stainless steel griddle ac

67730 charcoal tray ac

x - standard p - propane units only p - appareils propane seulement

x - compris n - natural gas units only n - appareils gaz naturel seulement

ac - accessory ac - accessoires

25

Page 26

26

Page 27

NOTES

27

Page 28

NOTES

28

Loading...

Loading...