Page 1

1

INSTALLER: THESE INSTRUCTIONS MUST BE CONVEYED TO AND REMAIN WITH THE HOMEOWNER.

CERTIFIED UNDER CANADIAN AND AMERICAN NATIONAL STANDARDS, CR97-003, CAN1-2.21-M85, IAS U.S. 4-96.

OUTDOOR GAS APPLIANCE

INSTALLATION AND OPERATION INSTRUCTIONS FOR

OUTDOOR GAS FIREPLACE

NATURAL GAS MODEL

PROPANE GAS MODEL

CERTIFIED FOR CANADA AND UNITED STATES USING ANSI / CSA METHODS

GSS36N

GSS36P

WARNING: If the information in these instructions is not followed exactly, a fi re or

explosion may result causing property damage, personal injury or death.

FOR YOUR SAFETY

Do not store or use gasoline or other fl ammable vapours and liquids in the vicinity of

this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Close propane bottle or shut-off gas

supply.

• Do not use any phone in your build

• Immediately call your gas supplier from

a neighbour’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier,

call the fi re department.

ing or near the appliance.

Installation and service must be performed by a qualifi ed installer, service agency or

the gas supplier.

THIS FIREPLACE MUST BE INSTALLED OUTSIDE.

Wolf Steel Ltd., 24 Napoleon Rd., Barrie, ON L4M 4Y8 Canada • (705)721-1212 • fax(705)722-6031

www.napoleonfi replaces.com • ask@napoleon.on.ca

W415-0369 / E / 02.16.07

Page 2

2

TABLE of CONTENTS

PG 3-4 INTRODUCTION

Warranty

General Instructions

General Information

5-6 INSTALLATION

Gas Installation

Combustion and Ventilation Air Provisions

Clearance to Combustibles

Framing

Mantle Clearances

Nailing Tab Installation

9 OPERATION / MAINTENANCE

Operating Instructions

Maintenance

Venturi Adjustment

10 REPLACEMENTS

Ordering Replacement Parts

Replacement Parts

11-12 TROUBLE SHOOTING GUIDE

7-8 FINISHING

Log Placement

Curtain Mesh

Hood Installation

Logo Placement

Louvre Installation

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE

WARNING

• Under no circumstances should this fi replace be modifi ed.

• Provide adequate ventilation and combustion air. Provide adequate accessibility clearance for servicing

and operating the fi replace. Never obstruct the front opening of the fi replace.

• If fi replace keeps shutting off, have it serviced. Keep burner and control compartment clean.

• Do not burn wood or other materials in this fi replace.

• Adults and especially children should be alerted to the hazards of high surface temperatures and should

stay away to avoid burns or clothing ignition. Keep young children and animals away when the fi replace

is hot.

• Clothing or other fl ammable material should not be placed on or near the fi replace.

• Any safety screen or guard removed for servicing must be replaced prior to operating the fi replace.

• It is imperative that the control compartments, burners and circulating air passageways in the fi replace

are kept clean. The fi replace should be inspected before use and at least annually by a qualifi ed service

person. The fi replace area must be kept clear and free from combustible materials, gasoline and other

fl ammable vapours and liquids.

• Furniture or other objects must be kept a minimum of 4 feet away from the front of the fi replace.

• Do not use this fi replace if any part has been under water. Immediately call a qualifi ed service technician

to inspect the fi replace and to replace any part of the control system and any gas control which has been

under water.

• Do not allow wind to blow directly into the fi replace. Avoid any drafts that alter burner fl ame patterns.

• Do not use any accessory not approved for use with this fi replace.

ANY CHANGE TO THIS FIREPLACE OR ITS CONTROLS CAN BE DANGEROUS

AND IS PROHIBITED.

NOTE: Changes, other than editorial, are denoted by a vertical line in the margin.

W415-0369 / E / 02.16.07

Page 3

NAPOLEON® gas appliances are manufactured under the strict Standard of the world recognized

ISO 9001 : 2000 Quality Assurance Certifi cate.

NAPOLEON® products are designed with superior components and materials, assembled by trained

craftsmen who take great pride in their work. e burner and valve assembly are leak and test-fi red at a

quality test station. Once assembled the complete appliance is thoroughly inspected by a qualifi ed technician

before packaging to ensure that you, the customer, receives the quality product that you expect from

NAPOLEON®.

NAPOLEON® GAS APPLIANCE 5 YEAR LIMITED WARRANTY

All stainless steel components of your new NAPOLEON® gas appliance are warranted against defects for

fi ve years.

All parts such as gas valves, logs, gasketing are covered and NAPOLEON® will provide replacement parts

free of charge during the fi rst year of the limited warranty.

Labour related to warranty repair is covered free of charge during the fi rst year. Repair work, however,

requires the prior approval of an authorized company offi cial. Labour costs to the account of NAPOLEON®

are based on a predetermined rate schedule and any repair work must be done through an authorized

NAPOLEON® dealer.

3

CONDITIONS AND LIMITATIONS

NAPOLEON® warrants its products against manufacturing defects to the original purchaser only -- i.e., the individual or legal entity (registered customer) whose name appears

on the warranty registration card fi led with NAPOLEON® -- provided that the purchase was made through an authorized NAPOLEON® dealer and is subject to the following

conditions and limitations:

This limited warranty applies only while the unit remains at the site of original installation, and only if the unit is installed in Canada or the United States.

This factory warranty is nontransferable and may not be extended whatsoever by any of our representatives.

Installation must be done in accordance with the installation instructions included with the product and all local and national building and fi re codes.

This limited warranty does not cover damages caused by misuse, lack of maintenance, accident, alterations, abuse or neglect and parts installed from other manufacturers will

nullify this warranty.

This limited warranty further does not cover any scratches, dents, corrosion or discolouring caused by excessive heat, abrasive and chemical cleaners, mechanical breakage

of logs and embers.

In the fi rst year only, this warranty extends to the repair or replacement of warranted parts which are defective in material or workmanship provided that the product has been

operated in accordance with the operation instructions and under normal conditions.

After the fi rst year, with respect to this Limited Warranty, NAPOLEON® may, at its discretion, fully discharge all obligations with respect to this warranty by refunding to the original

warranted purchaser the wholesale price of any warranted but defective part(s).

After the fi rst year, NAPOLEON® will not be responsible for installation, labour or any other costs or expenses related to the reinstallation of a warranted part, and such expenses

are not covered by this warranty.

Notwithstanding any provisions contained in this Limited Warranty, NAPOLEON’S responsibility under this warranty is defi ned as above and it shall not in any event extend to

any incidental, consequential or indirect damages.

This warranty defi nes the obligations and liability of NAPOLEON® with respect to the NAPOLEON® gas appliance and any other warranties expressed or implied with respect

to this product, its components or accessories are excluded.

This limited warranty does not cover damages resulting from the use of components not supplied with the appliance, or the use of fuel other than those specifi ed.

Any damages to appliance due to weather, long periods of dampness, condensation, damaging chemicals or cleaners will not be the responsibility of NAPOLEON®.

The bill of sale or copy will be required together with a serial number and a model number when making any warranty claims from your authorized dealer. The warranty registration

card must be returned within fourteen days to register the warranty.

NAPOLEON® reserves the right to have its representative inspect any product or part thereof prior to honouring any warranty claim.

W415-0369 / E / 02.16.07

Page 4

4

GENERAL INSTRUCTIONS

THIS GAS FIREPLACE SHOULD BE INSTALLED AND

SERVICED BY A QUALIFIED INSTALLER to conform with

local codes. Installation practices vary from region to region

and it is important to know the specifi cs that apply to your

area.

Installation practices vary from region to region and it is

important to know the specifi cs that apply to your area, for

example: in Massachusetts State:

• The appliance off valve must be a “T” handle gas cock.

• The fl exible connector must not be longer than 36 inches.

• The appliance is not approved for installation in a bedroom

or bathroom unless the unit is a direct vent sealed combustion

product.

• WARNING: This product must be installed by a licensed

plumber or gas fi tter when installed within the commonwealth of

Massachusetts.

• Un-vented room heater shall be installed in accordance with 527

CMR 30.00 and 248 CMR 3.00 through 7.00.

• Sellers of un-vented propane or natural gas-fi red space/room

heaters shall provide to each purchaser a copy of 527 CMR 30.00

upon the sale of the unit from

http://www.napoleonfi replaces.com/Webshare/installation_manuals/

mass_requirements.pdf

• A carbon monoxide detector is required in all rooms containing

gas fi red appliances.

The installation must conform with Local codes or in the

absence of local codes, with the National Fuel Gas Code

ANSI Z223.1/INFPA 54 in the United States or CSA B149.1,

Natural and Propane Installation code in Canada.

The fi replace and its individual shutoff valve must be discon-

nected from the gas supply piping system during any pressure

testing of that system at test pressures in excess of 1/2 psig

(3.5 kPa). The fi replace must be isolated from the gas supply

piping system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping system

at test pressures equal to or less than 1/2 psig (3.5 kPa).

When the fi replace is installed directly on combustible mate-

rial other than wood fl ooring, the fi replace shall be installed on

a metal or wood panel extending the full width and depth.

GENERAL INFORMATION

FOR YOUR SATISFACTION, THIS FIREPLACE HAS BEEN

TEST-FIRED TO ASSURE ITS OPERATION AND QUALITY! Maximum input is 40,000 BTU/hr for natural gas and

propane. When the fi replace is installed at elevations above

2,000ft, and in the absence of specifi c recommendations

from the local authority having jurisdiction, the certifi ed high

altitude input rating shall be reduced at the rate of 4% for

each additional 1,000ft.

It is highly recommended to protect the logs from moisture (rain, snow). Cover the fi rebox when not in use.

This fi replace is only for use with the type of gas indi-

cated on the rating plate. This fi replace is not convertible

for use with other gases, unless a certifi ed kit is used.

Minimum inlet gas supply pressure is 4.5 inches water column for natural gas and 11 inches water column for propane.

Maximum inlet gas pressure is 7 inches water column for

natural gas and 13 inches water column for propane. Manifold

pressure under fl ow conditions is 3.5 inches water column for

natural gas and 10 inches water column for propane.

No external electricity (110 volts or 24 volts) is required

for the gas system operation.

Expansion / contraction noises during heating up and cooling

down cycles are normal and are to be expected.

Use only accessories designed for and

listed with your specifi c fi replace.

W415-0369 / E / 02.16.07

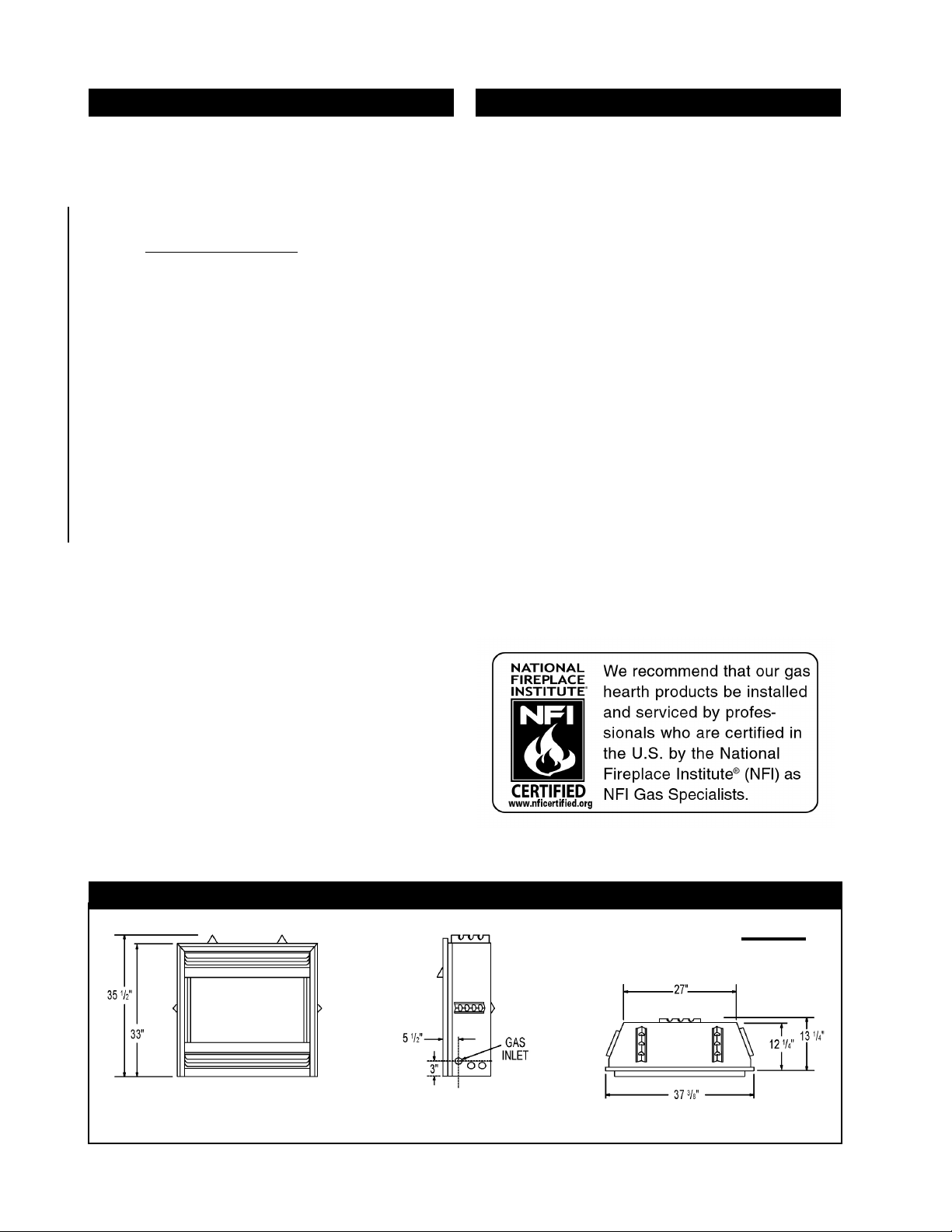

DIMENSIONS

FIGURE 1

Page 5

INSTALLATION

5

GAS INSTALLATION

NOTE: If the unit is installed using a propane cylinder

as a source of fuel, the cylinder must be retained. A

stand for a standard 20lb cylinder is available from your

NAPOLEON® Dealer.

1. Move the fi replace into position and secure using the

nailing tabs and/or secure to the fl oor through the ¼”ø holes

located at either end of the base.

2. Install rigid black pipe, 1/2” type-L copper tubing or, if

local codes permit, a 3/8” fl ex connector and shutoff valve

to the gas line and the fi replace gas valve. Seal and tighten

securely. An adapter fi tting is required between the gas valve

and the copper tubing or fl ex connector.

DO NOT KINK FLEX CONNECTOR.

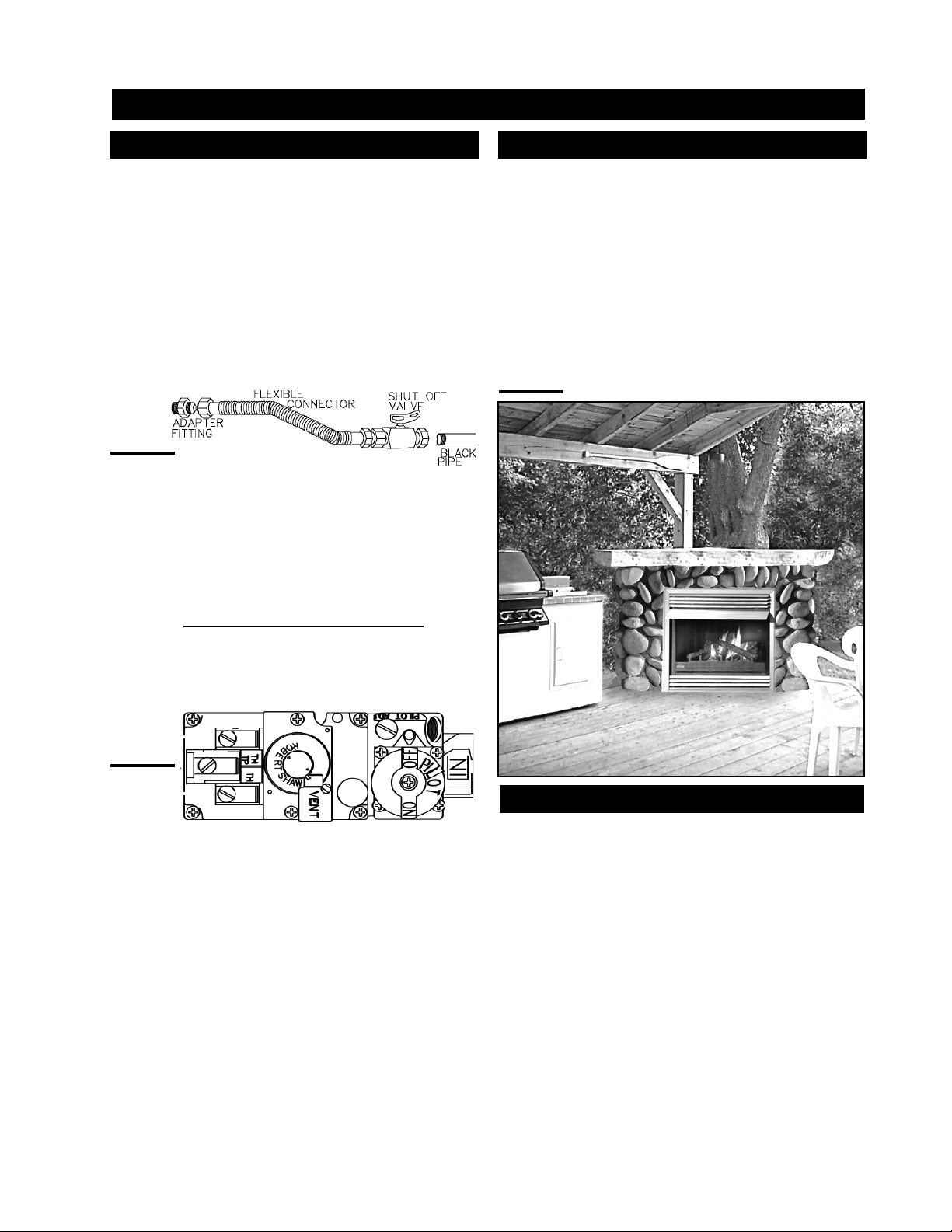

FIGURE 2

3. Check for gas leaks by brushing on a soap and water

solution.

DO NOT USE OPEN FLAME.

4. For ease of accessibility, an optional remote wall switch

may be installed in a convenient location. Route a 2 strand,

solid core millivolt wire through the electrical hole located at

the bottom left side of the unit. The recommended maximum

lead length depends on wire size:

WIRE SIZE MAX. LENGTH

14gauge 100 feet

16gauge 60 feet

18gauge 40 feet

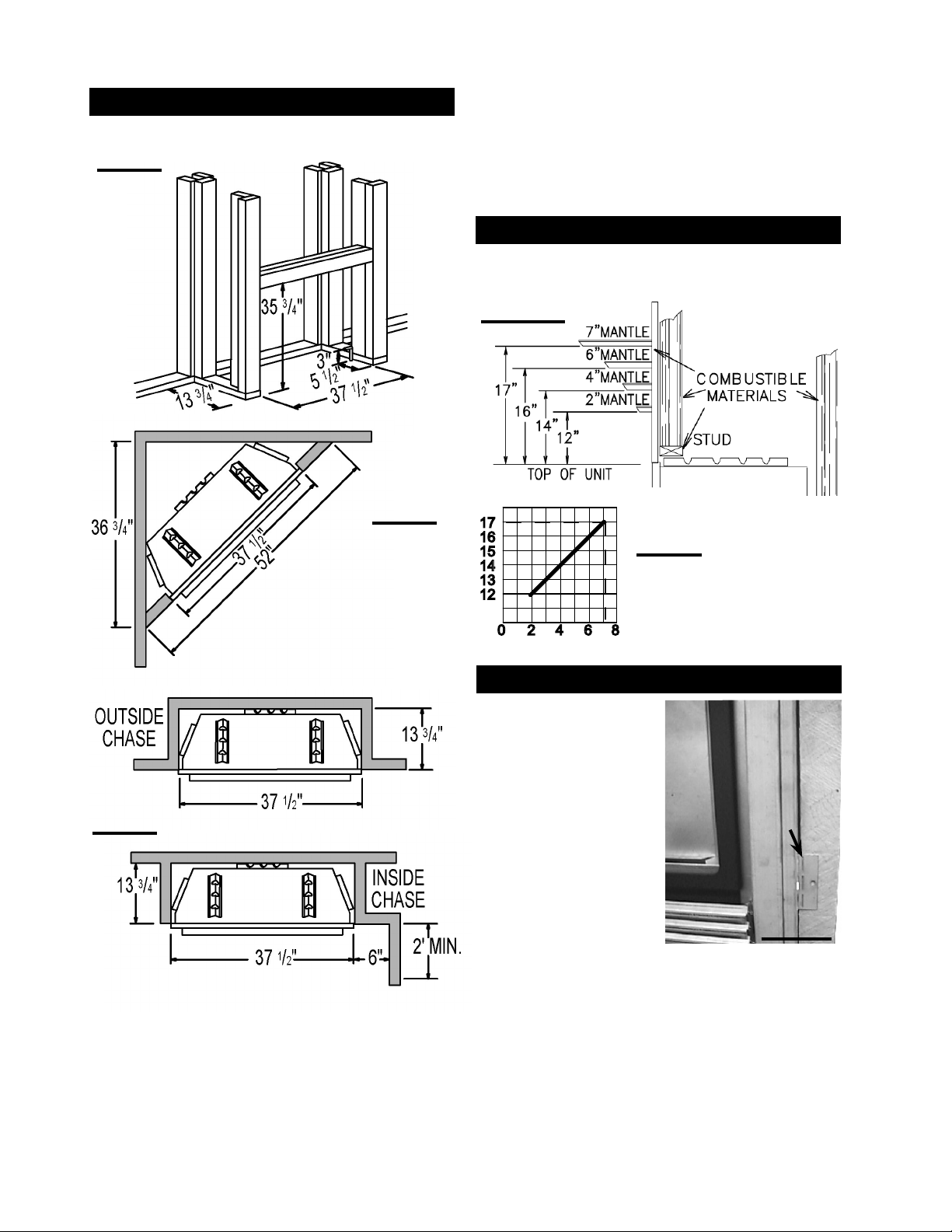

COMBUSTION & VENTILATION AIR

This fi replace is intended for installation on an outdoor patio

or in your yard. It must never be installed inside the warm air

envelope of your structure.

It is highly recommended that this fi replace be installed in a

“sheltered” area. Direct wind will cause an erratic fl ame and

possible pilot or main burner outage.

An erratic fl ame could also lead to excessive carboning

(black soot), this condition is not a safety issue but is visually undesirable.

Typical installation may include covered patio, screened

porch, gazebo or an outside the wall of a house.*

NOTE: Ensure the area has adequate ventilation.

FIGURE 4

Attach the two leads to terminals 1 and 3 located on the

gas valve.

FIGURE 3

Do not connect either the wall switch, thermostat or gas

valve to electricity (110 volts).

CLEARANCE TO COMBUSTIBLES

Sides, back, bottom & top 0 inches

Recessed 13¾ inches

Top of unit to ceiling 48”

It is recommended that the walls of the fi replace enclosure be

fi nished. This would ensure that clearance to combustibles

is maintained within the cavity.

* If installing a propane fi replace the propane cylinder

must always be on the exterior of such a structure.

W415-0369 / E / 02.16.07

Page 6

6

NAILING

TAB

FRAMING

It is best to frame your fi replace after it is positioned. Use

2x4’s and frame to local building codes. FIGURE 4-6.

FIGURE 5

FIGURE 6

When roughing in the fi replace, raise the fi replace to ac-

commodate for the thickness of the fi nished fl oor materials,

i.e. tile, carpeting, hard wood, which if not planned for will

interfere with the opening of the lower access door and the

installation of many decorative fl ashing accessories.

Objects placed in front of the fi replace should be kept a

minimum of 4 feet away from the front face.

MANTLE CLEARANCES

Combustible mantle clearance can vary according to the

mantle depth. Use the graph to help evaluate the clearance

needed.

FIGURE 8a-b

17

16

15

14

13

12

FIGURE 9

FIGURE 7

Combustible materials may be installed fl ush with the front

of the fi replace but must not cover any of the outer frame

face-areas of the fi replace. Non-combustible material (brick,

stone or ceramic tile) may protrude in these areas.

It is not necessary to install a hearth extension with this

fi replace system.

42

MANTLE WIDTH

860

NAILING TAB INSTALLATION

To install the fi replace face

fl ush with the fi nished sur-

face, position the framework

to accommodate the thickness of the fi nished surface.

Bend out the four nailing

tabs, attached on either side

of the fi replace and secure

to the 2x4 framing. The

tabs will facilitate the installation of either a

fi nished surface thickness.

The nailing tabs must not

be removed.

3

/

” or a 1”

4

NAILING

TAB

FIGURE 10

W415-0369 / E / 02.16.07

Page 7

FINISHING

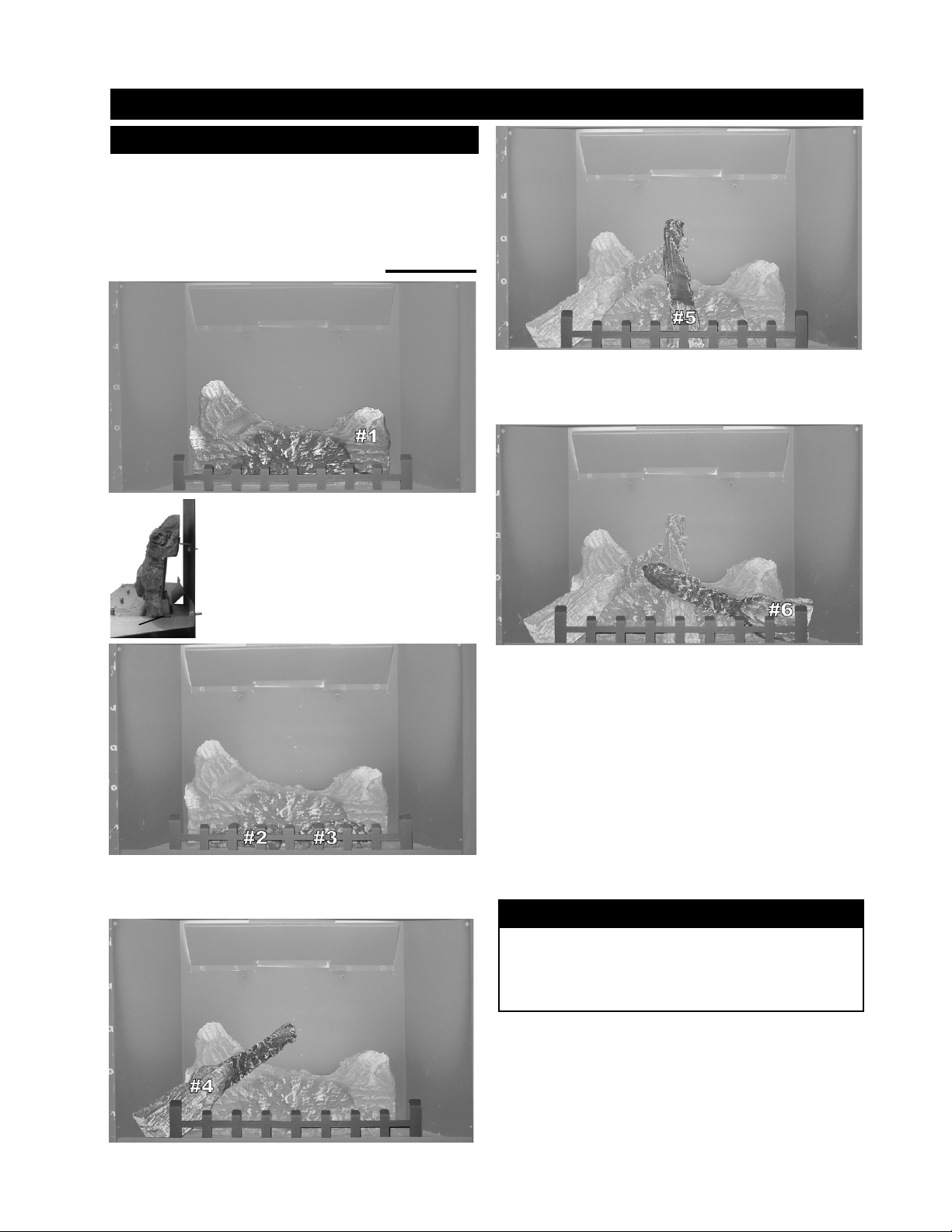

LOG PLACEMENT

PHAZERTM logs are exclusive to NAPOLEON® Fireplaces,

and provide a unique and realistic glowing effect that is different in every installation.

Log colours may vary. During the initial use of the fi replace,

the colours will become more uniform as colour pigments

burn in during the heat activated curing process.

FIGURE 11a-d

7

3. Place the bottom of the left crossover log (#4) against

the left fi rebox side and pulled forward to the grate.

The top of the log should rest in the pocket on the back log.

SIDEVIEW

TAB

2. Move the two small logs (#2 & #3) into position, lining up

the studs located on the burner with the holes on the bottom

of the logs. Ensure that the small logs sit fl at on the burner.

1. Place the back log (#1) onto the log

support tray and in front of the tabs. The

tabs maintain an air space between the

log and fi rebox back to facilitate combus-

tion air fl ow. Ensure that the back of the

log rests against the brackets on the back

wall of the fi rebox.

4. Position the notch located on the end of the center log

(#5) against the middle grate post with the other end of the

log resting in the pocket of the left crossover log.

5. Place the bottom of the right crossover log (#6) against

the right fi rebox side and pulled forward to the grate. The top

of the log should rest in the pocket provided on the center

log (#5).

Blocked burner ports can cause an incorrect fl ame pattern,

carbon deposits and delayed ignition. PHAZER

when exposed to direct fl ame.PHAZERTM logs available from

your NAPOLEON® dealer.

TM

logs glow

IMPORTANT

IT IS HIGHLY RECOMMENDED TO PROTECT

THE LOGS FROM MOISTURE.

COVER THE FIREBOX WHEN NOT IN USE.

W415-0369 / E / 02.16.07

Page 8

8

HOOD

FIGURE 12

HOOD

CURTAIN

MESH

The curtain mesh must be kept fully closed during operation

to help prevent accidental burns from occurring.

LOGO PLACEMENT

Remove the

backing of the

logo supplied

and place on the

screen cover, as

indicated.

FIGURE 14

LOUVRE INSTALLATION

FIGURE 15a-c

BRACKET

SLOT

A

HOOD

LOUVRE

UPPER LOUVRES: Insert

the upper louvres into the

slots on both brackets.

Press the top flange of

the hood into the four clips

located along the top of

the unit as shown.

FIGURE 13

The heater must not be used when the hood is removed. Hook the hood over the lip of the curtain support

plate.

LOWER LOUVRES: Attach each hinge to the

fi rebox with 2 screws.

B

LOWER LOUVRES

(VALVE CONTROL DOOR)

HINGE SCREEN

C

HINGE SCREEN: Position the hinge screen into place and

with the control door open, secure to the fi rebox using three

screws.

W415-0369 / E / 02.16.07

Page 9

OPERATION / MAINTENANCE

If heater keeps shutting off, have it serviced. Keep burner

and control compartment clean.

When lit for the fi rst time, the fi replace will emit a slight

odour for a few hours. This is a normal temporary condition caused by the curing of the logs and the “burn-in” of

internal paints and lubricants used in the manufacturing

process and will not occur again.

FOR YOUR SAFETY READ BEFORE LIGHT-

A. This fi replace is equipped with a pilot which must be lit by hand

while following these instructions exactly.

B. Before operating smell all around the fi replace area for gas

and next to the fl oor because some gas is heavier than air and

will settle on the fl oor.

C. Use only your hand to turn the gas control knob / manual

shut-off knob. Never use tools. If the knob will not turn by hand,

do not try to repair it. Call a qualifi ed service technician. Force or

attempted repair may result in a fi re or explosion.

D. Do not use this fi replace if any part has been under water. Im-

mediately call a qualifi ed service technician to inspect the fi replace

and replace any part of the control system and any gas control

which has been under water.

WHAT TO DO IF YOU SMELL GAS

• Do not use a mobile or land phone.

• If you cannot reach your gas supplier, call the fi re department.

• Turn off all gas to the fi replace.

• Do not try to light any appliance.

• Immediately call your gas supplier from a

neighbour’s phone. Follow the gas supplier’s instructions.

MAINTENANCE

CAUTION: Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and dangerous

operation. Verify proper operation after servicing. This heater

should be inspected and serviced before use and at least annually by a qualifi ed service person. The fi replace area must

be kept clear and free of combustible materials, gasoline or

other fl ammable vapours and liquids. The fl ow of combustion

and ventilation air must not be obstructed.

2. Keep the control compartment, logs, burner, air shutter

opening and the area surrounding the logs clean by vacuuming or brushing, at least once a year.

3. Check to see that all burner ports are burning. Clean out

any of the ports which may not be burning or are not burning properly.

4. Check to see that the pilot fl ame is large enough to engulf

the thermocouple and thermopile and promptly ignites the

main burner.

6. Check to see that the main burner ignites completely on all

openings when the gas knob for the burner is turned on. A 5 to

10 second total light-up period is satisfactory. If ignition takes

longer, consult your NAPOLEON® dealer / distributor.

9

After extended periods of non-operation such as following a vacation or a warm weather season, the fi replace

may emit a slight odour for a few hours. This is caused

by dust particles burning off.

LIGHTING INSTRUCTIONS

When lighting and re-lighting, the gas knob cannot be turned

from pilot to off unless the knob is depressed.

1. Stop! Read the safety information on the operating label.

2. Turn the gas knob clockwise to off.

3. Wait fi ve (5) minutes to clear out any gas. If you smell gas

including near the fl oor, stop! Follow “b” on the operating label.

If you don’t smell gas go to the next step.

4. If fi replace is equipped with fl ame adjustment valve turn

clockwise to off.

5. Find pilot located in front of back log.

6. Turn gas knob counter-clockwise to pilot.

7. Depress and hold gas knob while lighting the pilot with the

push button igniter. Keep knob fully depressed for one minute,

then release. If pilot does not continue to burn repeat steps 3

through 7.

8. With pilot lit, turn gas knob counter-clockwise to

on.

9. If equipped with fl ame adjustment valve, push and turn knob

to high.

10. If equipped with remote on-off switch, main burner may not

come on when you turn the valve to on or high. Remote switch

must be in the on position to ignite burner.

TO TURN OFF GAS

• Push in gas control knob slightly and turn clockwise to

off. Do not force.

Do not use steel wool, as it will scratch the fi nish. Stainless

steel parts will discolour when heated, usually to a golden or

brown colour. This discolouration is normal and will not affect

the performance of the appliance.

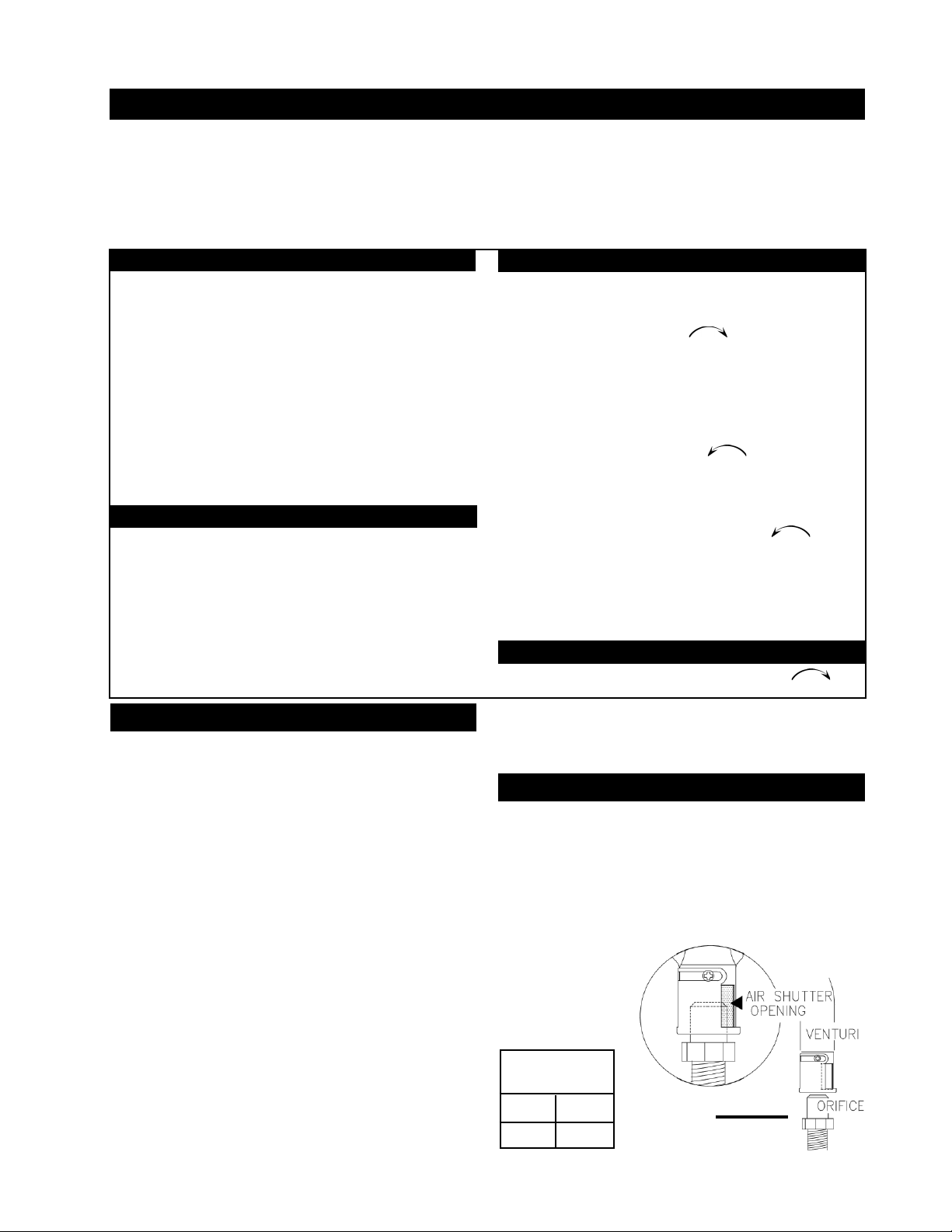

VENTURI ADJUSTMENT

Air shutter adjustment must only be done by a quali-

fi ed gas installer!

Closing the air shutter will cause a more yellow fl ame, but

can lead to carboning. Opening the air shutter will cause a

more blue fl ame, but can cause fl ame lifting from the burner

ports. The fl ame may not appear yellow immediately; allow

15 to 30 minutes for the fi nal fl ame colour to be established.

Opening the air shutter will also reduce exhaust odours. See

Trouble Shooting Guide.

AIR SHUTTER

OPENINGS

Cleaning Stainless Steel: Do not use abrasive cleaners to

clean any painted, porcelain or stainless steel parts. To clean

stainless surfaces, use a stainless steel cleaner or a nonabrasive cleaner. Always wipe in the direction of the grain.

NG 3/16”

LP 1/4”

FIGURE 16

W415-0369 / E / 02.16.07

Page 10

10

REPLACEMENTS

Contact your dealer for questions concerning prices and

policies on replacement parts. Normally all parts can be

ordered through your NAPOLEON® dealer or distributor.

FOR WARRANTY REPLACEMENT PART S, A PHOTOCOPY OF

THE ORIGINAL INVOICE WILL BE REQUIRED TO HONOUR

THE CLAIM.

* IDENTIFIES ITEMS WHICH ARE NOT ILLUSTRATED. FOR FURTHER INFORMATION, CONTACT YOUR NAPOLEON® DEALER.

REPLACEMENT PARTS

# PART NO. DESCRIPTION

1 W357-0001 PIEZO IGNITER

2 W680-0004 THERMOPILE

3 **W680-0005 THERMOCOUPLE

4 W010-0800 NATURAL GAS PILOT ASSEMBLY

4 W010-0801 PROPANE GAS PILOT ASSEMBLY

5 W455-0069 NATURAL GAS PILOT INJECTOR

5 W455-0067 PROPANE GAS PILOT INJECTOR

6 W725-0028 NATURAL GAS VALVE

6 W725-0029 PROPANE GAS VALVE

7* W385-0334 NAPOLEON® LOGO

8 GL-639OD LOG SET

9 W135-0183OD BACK LOG (#1)

10 W135-0184OD LEFT MIDDLE LOG (#2)

11 W135-0185OD RIGHT MIDDLE LOG (#3)

12 W135-0186OD LEFT CROSSOVER LOG (#4)

13 W135-0187OD MIDDLE CROSSOVER LOG (#5)

14 W135-0188OD RIGHT CROSSOVER LOG (#6)

When ordering replacement parts always give the following

information:

ODEL & SERIAL NUMBER OF FIREPLACE

1. M

2. INSTALLATION DATE OF FIREPLACE

3. PART NUMBER

ESCRIPTION OF PAR T

4. D

INISH

5. F

15 W010-1066 PAN BURNER

16 W455-0078 #31 NATURAL GAS BURNER ORIFICE

16 W455-0042 #49 PROPANE GAS BURNER ORIFICE

17 W335-0033 HOOD

18 W565-0062 CURTAIN MESH

19 W555-0040 CURTAIN ROD

20* W080-0614 CURTAIN ROD BRACKET

21 W500-0209 CURTAIN SUPPORT PLATE

22 W630-0010 BLACK TASSELS

23 W200-0135 FIREBOX COVER

24 N325-0036 COVER HANDLE

25* W660-0005 SWITCH

26* W750-0109 3/16” FLAG WIRE ASSEMBLY

27* W750-0110 1/4” FLAG WIRE ASSEMBLY

28 GVFLSS LOUVRE KIT - STAINLESS STEEL

W415-0369 / E / 02.16.07

Replace only with a fast acting thermocouple supplied by Wolf Steel Ltd.

** WARNING: This is a fast acting thermocouple. It is an integral safety component.

Page 11

TROUBLE SHOOTING GUIDE

SYMPTOM PROBLEM TEST SOLUTION

11

Main burner goes

out; pilot stays on.

Pilot goes out when

the gas knob is released.

The gas valve has

an interlock device

which will not allow the pilot burner to be lit until

the thermocouple

has cooled. Allow

approximately 60

seconds for the

thermocouple to

cool.

Pilot burning; no

gas to main burner;

gas knob is on ‘HI’;

wall switch / thermostat is on.

Pilot will not light. - check if pilot can be lit by a match

Pilot fl ame is not large enough

or not engulfi ng the thermo-

pile

Thermopile shorting - clean thermopile connection to the valve. Reconnect.

Remote wall switch wire is too

long; too much resistance in

the system.

Faulty thermostat or switch.

System is not correctly

purged.

Out of propane gas. - fi ll the tank.

Pilot flame is not large

enough

Pilot fl ame is not engulfi ng the

thermocouple.

Thermocouple shorting /

faulty.

Faulty valve.

Themostat or switch is defective.

Wall switch wiring is defective.

Main burner orifi ce is plugged. - remove stoppage in orifi ce.

Faulty valve.

No spark at pilot burner

Spark gap is incorrect

No gas at the pilot burner

- turn up pilot fl ame.

- replace pilot assembly.

- replace thermopile / valve.

- shorten wire to correct length or wire gauge.

- replace.

- purge the gas line.

- turn up the pilot fl ame.

- gently twist the pilot head to improve the fl ame pattern around the

thermocouple.

- loosen and tighten thermocouple.

- clean thermocouple and valve connection.

- replace thermocouple.

- replace valve.

- replace.

- connect a jumper wire across the wall switch terminals; if main burner

lights, replace switch / thermostat.

- disconnect the switch wires & connect a jumper wire across terminals

1 & 3; if the main burner lights, check the wires for defects and / or

replace wires.

- replace.

- check that the wire is connected to the push button ignitor.

- check if the push button ignitor needs tightening.

- replace the wire if the wire insulation is broken or frayed.

- replace the electrode if the ceramic insulator is cracked or broken.

- replace the push button ignitor.

- fi ll the tank.Out of propane gas

- spark gap should be 0.150” to 0.175” (5/32” to 11/64” approx.) from

the electrode tip and the pilot burner. To ensure proper electrode location, tighten securing nut (fi nger tight plus 1/4 turn).

- check that the manual valve is turned on.

- check the pilot orifi ce for blockage.

- replace the valve.

- call the gas distributor.

W415-0369 / E / 02.16.07

Page 12

12

SYMPTOM PROBLEM TEST SOLUTION

Pilot goes out while

standing; Main

burner is in ‘OFF’

position.

Flames are consistently too large or

too small. Carboning occurs.

Carbon is being deposited on, logs or

combustion chamber surfaces.

Remote wall switch

is in “OFF” position;

main burner comes

on when gas knob

is turned to “ON”

position.

Gas piping is undersized. - turn on all gas appliances and see if pilot fl ame fl utters, diminishes or

extinguishes, especially when main burner ignites. Monitor appliance

supply working pressure.

- check if supply piping size is to code. Correct all undersized piping.

High Wind. - unit has been exposed to a high wind condition.

A “sheltered” area is recommended for the installation location.

- close mesh screens.

Unit is over-fi red or under-

fi red.

Air shutter has become

blocked

Flame is impinging on the

logs or combustion chamber.

Wall switch is mounted upside down

ing.

Remote wall switch wire is

grounding.

Faulty valve.

- check pressure readings:

Inlet pressure can be checked by turning screw (A) counter-clockwise

2 or 3 turns and then placing pressure gauge tubing over the test point.

Gauge should read 7” (minimum 4.5”) water column for natural gas or

13” (11” minimum) water column for propane. Check that main burner

is operating on “HI”.

Outlet pressure can be checked the same as above using screw (B).

Gauge should read 3.5” water column for natural gas or 10” water column

for propane. Check that main burner is operating on “HI”.

AFTER TAKING PRESSURE READINGS, BE SURE TO TURN SCREWS

CLOCKWISE FIRMLY TO RESEAL. DO NOT OVERTORQUE.

Leak test with a soap and water solution.

- ensure air shutter opening is free of lint or other obstructions.

- check that the logs are correctly positioned.

- open air shutter to increase the primary air.

- check the input rate: check the manifold pressure and orifi ce size as

specifi ed by the rating plate values.

- close mesh screens.

- reverse.

- replace.Remote wall switch is ground-

- check for ground (short); repair ground or replace wire.

- replace.

W415-0369 / E / 02.16.07

Page 13

13

Service Performed Special ConcernsDealer Name

Name

Service Technician

Wolf Steel Fireplace Service History

This fireplace must be serviced annually depending on usage.

Date

W415-0369 / E / 02.16.07

Page 14

14

NOTES

W415-0369 / E / 02.16.07

Page 15

W415-0369 / 04.23.04

NOTES

14

Page 16

W415-0369 / 04.23.04

Date

Détaillant

Cet appareil doit être entretenu annuellement selon son usage.

Nom du technicien

Historique d’entretien Wolf Steel

Travail effectué

Problèmes particuliers

13

Page 17

W415-0369 / 04.23.04

eur soient telles que spécifiées sur la plaque

- remplacez.

- vérifiez si le fil est bien mis à la terre; réparez ou remplacez le fil.Le fil de l'interrupteur mural

- remplacez.L'interrupteur mural cause

- raccordez à l'endroit.

- fermez le pare-étincelles.

d'homologation.

et la grandeur de l'inject

- vérifiez le débit d'alimentation : vérifiez que la pression du collecteur

d'air primaire.

- augmentez l'ouverture du volet d'air pour augmenter le volume

- vérifiez que les bûches sont positionnées correctement.

des fibres ou autres obstructions.

- assurez-vous que l'ouverture du volet d'air n'est pas bloquée par

une solution d'eau savonneuse.

SCELLER. NE FORCEZ PAS. Vérifiez pour des fuites en appliquant

VOUS DE TOURNER FERMEMENT LES VIS VERS LA DROITE POUR

APRÈS AVOIR PRIS LA LECTURE DES PRESSIONS, ASSUREZque le brûleur principal fonctionne à "HI".

gaz naturel ou 10" de colonne d'eau pour le propane. Assurez-vous

la vis (B). Le manomètre doit indiquer 3,5" de colonne d'eau pour le

La pression de sortie peut être vérifiée de la même façon en utilisant

propane. Assurez-vous que le brûleur principal fonctionne à "HI".

pour le gaz naturel ou 13" (minimum 11") de colonne d'eau pour le

Le manomètre doit indiquer 7" (minimum 4,5") de colonne d'eau

la gauche, puis emboîtez le tube du manomètre sur la pointe d'essai.

Pour vérifier la pression d'arrivée, tournez 2 ou 3 fois la vis (A) vers

- vérifiez la pression :

Soupape défectueuse.

cause un court-circuit.

un court-circuit.

raccordé à l'envers.

L'interrupteur mural est

chambre de combustion.

bûches ou les parois de la

La flamme lèche les

Le volet d'air est bloqué.

faible ou trop forte.

La pression du gaz est trop

placé à "ON".

bouton du gaz est

s'allume lorsque le

brûleur principal

ral est à "OFF"; le

L'interrupteur mu-

bustion.

chambre de comparois de la

bûches ou les

dépose sur les

Du carbone se

carbone.

duit des dépôts de

petites. Il se prograndes ou trop

régulièrement trop

Les flammes sont

- fermez le pare-étincelles.

Un endroit protégé est recommandé pour l’emplacement du foyer.

- l’appareil a été exposé à des vents forts.

codes. Remplacez tous les conduits trop petits.

- vérifiez si la grosseur du conduit d'alimentation est conforme aux

pal s'allume. Vérifiez la pression d'alimentation.

veilleuse vacille, diminue ou s'éteint, surtout quand le brûleur princi-

- allumez tous les appareils au gaz et vérifiez si la flamme de la

Vents forts.

petite.

La conduite de gaz est trop

PROBLÈME SOLUTIONS

"OFF".

principal est à

attente; le brûleur

qu'elle est en

s'éteint alors

La veilleuse

SYMPTÔME

12

Page 18

W415-0369 / 04.23.04

- contactez le fournisseur de gaz.

- remplacez la soupape.

- vérifiez si l'injecteur de la veilleuse est bloqué.

- vérifiez si la soupape manuelle est ouverte.

et tournez 1/4 de tour de plus).

Pour que l'électrode soit bien placée, serrez l'écrou avec les doigts

64" approx.) entre la pointe de l'électrode et le brûleur de la veilleuse.

- la longueur de l'étincelle devrait être de 0,150" à 0,175" (5/32" à 11/

- remplissez le réservoir.Plus de propane.

- remplacez le bouton-pression d’ignition.

- remplacez l'électrode si l'isolateur de céramique est craqué ou brisé.

- remplacez le fil si son isolant est brisé ou effiloché.

- vérifiez si le bouton-pression d’ignition doit être resserré.

- vérifiez si le fil est raccordé au bouton-pression d’ignition.

- vérifiez si la veilleuse peut être allumée avec une allumette.

- remplacez la soupape.

- débloquez l'injecteur.

fils ne sont pas défectueux et/ou remplacez les fils.

entre les bornes 1 & 3; si le brûleur principal s'allume, vérifiez si les

- débranchez les fils de l'interrupteur et reliez un fil de dérivation

le brûleur principal s'allume, remplacez l'interrupteur/thermostat.

- reliez un fil de dérivation entre les bornes de l'interrupteur mural; si

- remplacez la soupape.

- remplacez la soupape.

- remplacez le thermocouple.

- nettoyez le thermocouple et la connexion à la borne de la soupape.

- desserrez et resserrez le thermocouple.

autour du thermocouple.

- tournez légèrement la tête de la veilleuse pour améliorer la flamme

- augmentez la flamme de la veilleuse.

- purgez la conduite de gaz.

- remplacez.

- raccourcissez la longueur du fil ou changez le calibre du fil.

- remplacez la thermopile ou la soupape.

reconnectez.

- nettoyez la connexion de la thermopile à la borne de la soupape et

- remplacez l'assemblage de la veilleuse.

- augmentez la flamme de la veilleuse.

veilleuse.

Pas de gaz au brûleur de la

est incorrecte.

La longueur de l'étincelle

THERMOCOUPLE

THERMOPILE

VEILLEUSE

de la veilleuse.

Aucune étincelle au brûleur

Soupape défectueuse.

pal est bloqué.

L'injecteur du brûleur princi-

rupteur est défectueux.

Le raccordement de l'inter-

rupteur est défectueux.

Le thermostat ou l'inter-

Soupape défectueuse.

court-circuit/est défectueux.

Le thermocouple cause un

couple.

n'enveloppe pas le thermoLa flamme de la veilleuse

n'est pas assez puissante.

La flamme de la veilleuse

Plus de propane. - remplissez le réservoir.

correctement.

Le système n'est pas purgé

rupteur est défectueux.

Le thermostat ou l'inter-

résistance dans le système.

est trop long; trop de

Le fil de l'interrupteur mural

court-circuit.

La thermopile cause un

veloppe pas la thermopile.

pas assez puissante ou n'enLa flamme de la veilleuse n'est

s'allume pas.

La veilleuse ne

mostat est à "ON".

rupteur mural/therest à "HI"; l'interbouton de contrôle

brûleur principal;

pas de gaz au

La veilleuse brûle;

refroidir.

mocouple de se

permettre au ther60 secondes pour

Attendez au moins

couple est refroidi.

lorsque le thermos'allumer que

veilleuse de

qui ne permet à la

d'enclenchement

a un dispositif

La soupape de gaz

gaz est relâché.

quand le bouton du

La veilleuse s'éteint

allumée.

veilleuse reste

pal s'éteint; la

Le brûleur princi-

11

SYMPTÔME PROBLÈME SOLUTIONS

GUIDE DE DÉPANNAGE

Page 19

sécurité. Remplacez uniquement avec un thermocouple à action rapide de Wolf Steel ltée.

* ATTENTION : Ceci est un thermocouple à action rapide. Ceci est un composant intégral de

W415-0369 / 04.23.04

/4"

1

/16"

3

ENSEMBLE DE FIL/RACCORD

PARE-ÉTINCELLES COULISSANT

30* W750-0110 ENSEMBLE DE FIL/RACCORD

29* W750-0109

28* W660-0005 INTERRUPTEUR

26 N325-0036 POIGNÉE DE COUVERCLE

25 W200-0135 COUVERCLE DE FOYER

24 W630-0010 POIGNÉES NOIRES

23 W500-0209 MOULURE HORIZONTALE SUPÉRIEURE

22* W080-0614 SUPPORT POUR TIGE DU PARE-ÉTINCELLES

21 W555-0040 TIGE DU PARE-ÉTINCELLES

20 W565-0062

19 W335-0033 HOTTE

18 W455-0042 INJECTEUR DE BRÛLEUR - PL #49

18 W455-0078 INJECTEUR DE BRÛLEUR - GN #31

17 W010-1066 BRÛLEUR À PLATEAU

16 W135-0188OD BÛCHE TRANSVERSALE DROITE (#6)

15 W135-0187OD BÛCHE TRANSVERSALE CENTRALE (#5)

14 W135-0186OD BÛCHE TRANSVERSALE GAUCHE (#4)

13 W135-0185OD BÛCHE CENTRALE DROITE (#3)

12 W135-0184OD BÛCHE CENTRALE GAUCHE (#2)

11 W135-0183OD BÛCHE ARRIÈRE (#1)

10* W550-0001 BRAISES DE CHARBON DE BOIS

9* W361-0016 BRAISES INCANDESCENTES

8 GL-639OD ENSEMBLE DE BÛCHES

7* W385-0245 LOGO NAPOLÉON

6 W725-0029 SOUPAPE - PROPANE

GAZ NATUREL

6 W725-0028 SOUPAPE 5 W455-0067 INJECTEUR DE VEILLEUSE - PL

5 W455-0069 INJECTEUR DE VEILLEUSE - GN

4 W010-0801 ENSEMBLE DE VEILLEUSE - PL

4 W010-0800 ENSEMBLE DE VEILLEUSE - GN

3 *W680-0005 THERMOCOUPLE

2 W680-0004 THERMOPILE

1 W357-0001 ALLUMEUR PIÉZO

# N° DE PIÈCE DESCRIPTION

LISTE DES PIÈCES DE RECHANGE

* IDENTIFIE LES ARTICLES QUI NE SONT PAS ILLUSTRÉS.POUR PLUS D'INFORMATION, CONTACTEZ VOTRE DÉTAILLANT NAPOLÉON.

..

.

5. LE FINI

DEDE

DE

DEDE

4. DESCRIPTION DE LA PIÈCE

3. NUMÉRO DE LA PIÈCE

UNEUNE

UNE

UNEUNE

AFINAFIN

AFIN

AFINAFIN

,,

,

,,

..

2. DATE D'INSTALLATION DU FOYER

1. M

ODÈLE ET NUMÉRO DE SÉRIE DU FOYER

l'information suivante :

Lorsque vous commandez des pièces, donnez toujours

REQUISEREQUISE

SERASERA

REQUISE

SERA

REQUISEREQUISE

SERASERA

GARANTIEGARANTIE

SOUSSOUS

GARANTIE

SOUS

GARANTIEGARANTIE

SOUSSOUS

DEMANDEDEMANDE

LALA

DEMANDE

LA

DEMANDEDEMANDE

LALA

ALEALE

ALE

ALEALE

PIÈCEPIÈCE

PIÈCE

PIÈCEPIÈCE

ORIGINORIGIN

ORIGIN

ORIGINORIGIN

DEDE

DE

DEDE

HONORERHONORER

HONORER

HONORERHONORER

FF

LL

AA

CTURECTURE

AA

F

A

CTURE

L

A

FF

AA

CTURECTURE

LL

AA

POUVOIRPOUVOIR

POUVOIR

POUVOIRPOUVOIR

DEDE

DE

DEDE

REMPLACEMENTREMPLACEMENT

REMPLACEMENT

REMPLACEMENTREMPLACEMENT

UNUN

UN

UNUN

TT

OCOPIEOCOPIE

T

OCOPIE

TT

OCOPIEOCOPIE

OUROUR

OUR

OUROUR

PHOPHO

PHO

PHOPHO

PP

P

PP

Napoléon.

pièces peuvent être commandées chez votre détaillant

remplacement des pièces. Normalement, toutes les

tions concernant les prix et les politiques de

Contactez votre détaillant ou le fabricant pour les ques-

RECHANGES

10

Page 20

W415-0369 / 04.23.04

FIGURE 16

PL PLEINEMENT OUVERT

GN 7/16"

OUVERTURES DU VOLET D’AIR

pement. Voir le guide de dépannage.

odeurs provenant des gaz d’échap-

Le fait d’ouvrir le volet d’air diminuera les

flamme se stabilise.

ment; allouez de 15 à 30 minutes pour que la couleur finale de la

orifices du brûleur. La flamme peut ne pas être jaune immédiateplus la flamme est bleue et plus elle a tendance à se détacher des

tendance à causer des dépôts de carbone. Plus le volet est ouvert,

Plus le volet est fermé, plus la flamme est jaune et plus elle a

technicien/installateur qualifié pour le gaz seulement!

Le réglage du volet d'air doit être exécuté par un

t qu’elle atteigne

RÉGLAGE DU VENTURI

la performance de l’appareil.

dorée ou brune. Cette décoloration est normale et n’affectera pas

sous l’effet de la chaleur pour habituellement prendre une teinte

pièces en acier inoxydable vont décolorer de façon permanente

N’utilisez pas de laine d’acier car elle égratignerait le fini. Les

tout usage sans abrasif. Frottez toujours dans le sens du grain.

inoxydable, utilisez un nettoyant à acier inoxydable ou un nettoyant

ou en acier inoxydable. Pour nettoyer les surfaces en acier

abrasifs pour nettoyer les pièces peintes, en porcelaine émaillée

Nettoyage de l’acier inoxydable : N’utilisez pas de produits

de temps, consultez votre détaillant Napoléon.

total de 5 à 10 secondes est satisfaisant. Si l’allumage prend plus

que le bouton de contrôle du gaz est à "ON". Un temps d’allumage

5. Vérifiez si le brûleur principal allume sur tous les orifices lors-

principal.

le brûleur par le troisième déflecteur et allume rapidement le brûleur

pour envelopper le thermocouple et la thermopile e

4. Assurez-vous que la flamme de la veilleuse est assez puissante

dont la flamme ne brûle pas adéquatement.

flammes. Nettoyez tous les orifices qui n'ont pas de flamme ou

3. Assurez-vous que tous les orifices du brûleur produisent des

ou en passant l'aspirateur, au moins une fois l'an.

les bûches et l'espace entourant les bûches propres en brossant

2. Garder le compartiment des contrôles, le brûleur, le volet d'air,

d'air comburant et d'air de convection ne doivent pas être obstrués.

d'essence ou autres liquides et vapeurs inflammables. Les apports

le foyer doit être gardé propre et libre de matériaux combustibles,

fois l'an par un technicien de service qualifié. L'espace entourant

devrait être inspecté avant la première utilisation et au moins une

fonctionne adéquatement une fois l'entretien terminé. Cet appareil

fonctionnement et être dangereux. Assurez-vous que le foyer

réinstallation incorrecte des fils pourrait occasionner un mauvais

d'identifier chacun des fils avant de les débrancher. Une

ATTENTION : Lors de l'entretien des contrôles, assurez-vous

ENTRETIEN

à

. Ceci. Ceci

. Ceci

. Ceci. Ceci

eses

es

eses

oo

yy

erer

, comme, comme

o

y

er

, comme

oo

yy

erer

, comme, comme

jusqu’à "OFF". Ne forcez pas.

à "ON".

ne détectez pas d'odeur de

s de l’étape "b" au verso de la

haleurhaleur

..

haleur

.

haleurhaleur

..

aa

gg

e pendant quelques heure pendant quelques heur

a

g

e pendant quelques heur

aa

gg

e pendant quelques heure pendant quelques heur

ee

prpr

oduiroduir

a plusa plus

..

a plus

.

a plusa plus

..

pr

oduir

prpr

oduiroduir

e

ee

vers la droite

• Enfoncez légèrement le bouton de contrôle du gaz et tournez

INSTRUCTIONS POUR COUPER LE GAZ

en position "ON" pour que le brûleur s'allume.

de gaz à "ON" ou à "HIGH". L'interrupteur à distance doit être

principal peut ne pas s'allumer quand vous tournez la soupape

10. Si le foyer est muni d'un interrupteur à distance, le brûleur

enfoncez et tournez le bouton à "HIGH".

9. Si le foyer est muni d’une soupape d’ajustement de flamme,

du gaz vers la gauche

8. Lorsque la veilleuse est allumée, tournez le bouton de contrôle

reste pas allumée, répétez les étapes 3 à 7.

pendant une (1) minute, puis relâchez-le. Si la veilleuse ne

pression d'ignition. Gardez le bouton de contrôle du gaz enfoncé

que vous allumez la veilleuse en appuyant sur le bouton-

7. Enfoncez et maintenez le bouton de contrôle du gaz pendant

"PILOT".

6. Tournez le bouton de contrôle du gaz vers la gauche

5. Trouvez la veilleuse située à l’avant de la bûche arrière.

tournez le bouton vers la droite à "OFF".

4. Si le foyer est muni d’une soupape d’ajustement de flamme,

gaz, passez à l'étape suivante.

plaque d’homologation. Si vous

arrêtez! et suivez les instruction

vous détectez une odeur de gaz incluant au niveau plancher,

3. Attendez 5 minutes pour que le gaz puisse s'échapper. Si

"OFF".

2. Tournez le bouton de contrôle du gaz vers la droite à

de la plaque d’homologation.

1. Arrêtez! Lisez les recommandations de sécurité au verso

l'écl'éc

hanghang

eur de ceur de c

eur de c

eur de ceur de c

l'éc

hang

l'écl'éc

hanghang

est causé par des particules de poussière brûlant dansest causé par des particules de poussière brûlant dans

est causé par des particules de poussière brûlant dans

est causé par des particules de poussière brûlant dansest causé par des particules de poussière brûlant dans

légèrlégèr

e odeur se dége odeur se dég

légèr

e odeur se dég

légèrlégèr

e odeur se dége odeur se dég

à la suite de vacances ou à la fin de l'été, il se peut qu'uneà la suite de vacances ou à la fin de l'été, il se peut qu'une

à la suite de vacances ou à la fin de l'été, il se peut qu'une

à la suite de vacances ou à la fin de l'été, il se peut qu'uneà la suite de vacances ou à la fin de l'été, il se peut qu'une

Après de longues périodes sans utiliser le f

Après de longues périodes sans utiliser le f

Après de longues périodes sans utiliser le f

Après de longues périodes sans utiliser le fAprès de longues périodes sans utiliser le f

..

.

..

caca

tion; elle ne se rtion; elle ne se r

ca

tion; elle ne se r

caca

tion; elle ne se rtion; elle ne se r

..

.

..

et lubrifiants internes utilisés dans le processus de fabri-et lubrifiants internes utilisés dans le processus de fabri-

et lubrifiants internes utilisés dans le processus de fabri-

et lubrifiants internes utilisés dans le processus de fabri-et lubrifiants internes utilisés dans le processus de fabri-

eses

es

eses

rr

r

rr

eses

. Cela. Cela

es

. Cela

eses

. Cela. Cela

opop

op

opop

timent de contrôle prtiment de contrôle pr

timent de contrôle pr

timent de contrôle prtiment de contrôle pr

ee

, f, f

aites-le inspecteraites-le inspecter

e

, f

aites-le inspecter

ee

, f, f

aites-le inspecteraites-le inspecter

peut tourner de "PILOT" à "OFF" à moins de l'enfoncer.

Durant l'allumage et le réallumage, le bouton de la veilleuse ne

INSTRUCTIONS D'ALLUMAGE

contactez le service des incendies.

• Si vous ne pouvez pas rejoindre votre fournisseur de gaz,

fournisseur de gaz et suivez ses instructions.

• De la maison d'un voisin, appelez immédiatement votre

• N’utilisez pas de téléphone cellulaire ou autre téléphone.

• N'allumez aucun appareil.

• Coupez l'alimentation de gaz au foyer.

QUE FAIRE SI VOUS DÉTECTEZ UNE ODEUR DE GAZ

contrôle et du contrôle du gaz qui aurait été submergée.

pour l'inspecter et pour remplacer toute pièce du système de

submergée. Contactez immédiatement un technicien qualifié

D. N'utilisez pas ce foyer si une pièce quelconque a été

nisme pourrait causer un feu ou une explosion.

nicien qualifié. Forcer le bouton ou tenter de réparer le mécamanuellement, n'essayez pas de le réparer. Appelez un techdu gaz. N'utilisez jamais d'outils. Si le bouton ne tourne pas

C. N'utilisez que votre main pour tourner le bouton de contrôle

plancher.

gaz sont plus lourds que l'air et se déposeront au niveau du

afin de vous assurer qu'il n'y a pas de fuite de gaz. Certains

B. Avant d'allumer, sentez autour du foyer et près du plancher

manuellement en observant ces instructions à la lettre.

A. Ce foyer est muni d'une veilleuse qui doit être allumée

AVANT D'ALLUMER LE FOYER :

POUR VOTRE SÉCURITÉ, LISEZ CE QUI SUIT

ditionnement des bûches et l'évaporation des peinturesditionnement des bûches et l'évaporation des peintures

ditionnement des bûches et l'évaporation des peintures

ditionnement des bûches et l'évaporation des peinturesditionnement des bûches et l'évaporation des peintures

est une condition normale temporaire causée par le con-est une condition normale temporaire causée par le con-

est une condition normale temporaire causée par le con-

est une condition normale temporaire causée par le con-est une condition normale temporaire causée par le congg

erer

e odeur pendant quelques heure odeur pendant quelques heur

e odeur pendant quelques heur

e odeur pendant quelques heure odeur pendant quelques heur

açon répétitivaçon répétitiv

açon répétitiv

açon répétitivaçon répétitiv

a une légèra une légèr

g

er

a une légèr

gg

erer

a une légèra une légèr

Lorsqu'il est allumé pour la première fois, le foyer déga-Lorsqu'il est allumé pour la première fois, le foyer déga-

Lorsqu'il est allumé pour la première fois, le foyer déga-

Lorsqu'il est allumé pour la première fois, le foyer déga-Lorsqu'il est allumé pour la première fois, le foyer déga-

GarGar

dede

z le brûleur et le comparz le brûleur et le compar

Gar

de

z le brûleur et le compar

GarGar

dede

z le brûleur et le comparz le brûleur et le compar

Si le fSi le f

oo

yy

er s’éteint de fer s’éteint de f

er s’éteint de f

er s’éteint de fer s’éteint de f

Si le f

o

y

Si le fSi le f

oo

yy

FONCTIONNEMENT/ENTRETIEN

9

Page 21

Fixez

vis.

base du foyer avec deux

chaque charnière à la

INFÉRIEURES :

PERSIENNES

fixez le cache-charnières au caisson à l'aide de trois vis.

place. Avec la porte de contrôle de la soupape ouverte,

CACHE-CHARNIÈRES : Mettez le cache-charnières en

C

CACHE-CHARNIÈRES

DE LA SOUPAPE)

(PORTE DE CONTRÔLE

PERSIENNES INFÉRIEURES

B

Fixez la hotte par-dessus la moulure

W415-0369 / 04.23.04

supérieure horizontale.

est retirée.

L’appareil ne doit pas être utilisé lorsque la hotte

situées

l’appareil, tel qu’illustré.

le long du haut de

quatre attaches

la

hotte/support dans les

chaque support. Insérez

fentes situées sur

supérieures dans les

Insérez les persiennes

SUPÉRIEURES :

PERSIENNES

PERSIENNES

FENTE

SUPPORT

HOTTE

FIGURE 14

A

FIGURES 15a-c

INSTALLATION DES PERSIENNES

qu’indiqué.

horizontale tel

moulure inférieure

placez-le sur la

dorsal du logo et

Retirez le papier

FIGURE 13

fonctionne.

étincelles doit être complètement fermé lorsque le foyer

Afin d’aider à prévenir les brûlures accidentelles, le pare-

COULISSANT

PARE-ÉTINCELLES

HOTTE

FIGURE 12

MISE EN PLACE DU LOGO

HOTTE

8

Page 22

W415-0369 / 04.23.04

rougeoient

MD

minces irréguliers

N’utilisez pas

#6

LE FOYER N’EST PAS UTILISÉ.

RECOUVREZ L’OUVERTURE DU FOYER LORSQUE

PROTÉGER LES BÛCHES CONTRE L’HUMIDITÉ.

IL EST FORTEMENT RECOMMANDÉ DE

IMPORTANT

, disponibles chez votre détaillant Napoléon.

MD

Le blocage des orifices du brûleur

Les braises seront incandescentes

PHAZER

que des braises incandescentes et des bûches certifiées

lorsqu’elles sont exposées à une flamme directe. N’utilisez

et un retard d’allumage. Les bûches PHAZER

peut créer une flamme irrégulière, des dépôts de carbone

les orifices du brûleur.

directe; cependant prenez bien garde de ne pas boucher

seulement lorsqu'elles sont exposées à une flamme

incandescents.

car seuls les côtés exposés des fibres deviendront

très soigneusement en petits morceaux

bûches (#2 & #3). Les braises devraient être déchirées

brûleur en couvrant toute la surface à l’avant des petites

placez-les le long de la première rangée des orifices du

Déchirez les braises incandescentes en morceaux et

BRAISES INCANDESCENTES

pas les braises de charbon de bois sur le brûleur.

la fine poussière qui reste au fond du sac. Ne placez

à bûches de façon à créer un effet réaliste.

Éparpillez les braises à l’avant et sur les côtés du support

BRAISES DE CHARBON DE BOIS

rainure sur la bûche centrale (#5).

jusqu’au chenet. Le haut de la bûche est placé dans la

contre le côté droit de la chambre de combustion et tirez

5. Placez le bas de la bûche transversale droite (#6)

rainure sur la bûche arrière.

tirez vers le chenet. Le haut de la bûche est placé dans la

contre le côté gauche de la chambre de combustion et

3. Placez le bas de la bûche transversale gauche (#4)

#4

soient à plat sur le brûleur.

sous les bûches. Assurez-vous que les petites bûches

en alignant les tiges situées sur le brûleur avec les trous

2. Placez les deux petites bûches (#2 et #3) à leur place,

#2 #3

mur arrière de la chambre de combustion.

dos de la bûche s’appuie sur les supports situés sur le

tion afin de faciliter la circulation d’air. Assurez-vous que le

d’air entre la bûche et l’arrière de la chambre de combuset à l’avant des pattes. Les pattes assurent un espace

1. Placez la bûche arrière (#1) sur le support à bûches

7

#5

#1

la rainure de la bûche transversale gauche.

(#5) contre le poteau central du chenet et l’autre bout dans

4. Placez l’encoche située au bout de la bûche centrale

FIGURES 11a-d

et les braises incandescentes,

MD

LES FINITIONS

le procédé de "cuisson".

mesure que leurs pigments seront "absorbés" pendant

sation du foyer, les couleurs deviendront plus uniformes à

couleur des bûches peut varier. Lors de la première utiliincandescentes pour obtenir le meilleur effet possible. La

stallation. Prenez le temps de bien installer les braises

cent réaliste et unique qui est différent dans chaque inexclusives aux foyers Napoléon, créent un effet incandesLes bûches PHAZER

DISPOSITION DES BÛCHES

Page 23

W415-0369 / 04.23.04

avec ce type de foyer.

Il n'est pas nécessaire d'installer un prolongement d'âtre

peuvent empiéter sur la partie noire.

incombustibles (briques, pierres, tuiles en céramique)

surface peinte en noir du devant du foyer. Les matériaux

lité du devant du foyer mais ils ne doivent recouvrir aucune

Les matériaux combustibles peuvent être installés à éga-

FIGURE 10

FIXATION

4

" ou

/

SUPPORT DE

3

FIGURE 9

pas être retirés.

supports de fixation ne doivent

de 1" d’épaisseur. Les

surface de finition de

faciliteront l'installation d’une

Les supports de fixation

et fixez aux montants 2x4.

vent de chaque côté du foyer

ports de fixation qui se troumur. Dépliez les deux supl'épaisseur de la finition du

d'ossature de façon à prévoir

fini, positionnez les montants

foyer à égalité avec le mur

Pour installer la façade du

INSTALLATION DES SUPPORTS DE FIXATION

FIGURE 6

FIGURES 7

FIGURES 8a-b

nécessaire.

graphique pour vous aider à déterminer le dégagement

varier selon la profondeur de la tablette. Utilisez le

Le dégagement d'une tablette combustible au foyer peut

EMPLACEMENTS DE LA TABLETTE DÉCORATIVE

l'appareil.

une distance minimale de 4 pieds de la façade de

Les objets placés devant le foyer doivent être gardés à

tallation de plusieurs contours.

ront à l’ouverture de la porte d'accès inférieure et à l’instapis ou bois franc car s’ils n’ont pas été prévus, ils nuifaçon à prévoir l’épaisseur du plancher fini, c.-à-d. tuiles,

Lorsque vous mettez le foyer en place, surélevez-le de

OSSATURE

. FIGURES 5-7.

FIGURE 5

ment locaux

sature conformément aux exigences des codes du bâtiest en place. Utilisez des montants 2x4 et construisez l'osIl est préférable de construire l'ossature après que le foyer

6

Page 24

W415-0369 / 04.23.04

combustibles est maintenu.

Ceci assurera que le dégagement aux matériaux

Il est conseillé d’installer le foyer contre des murs finis.

Profondeur de l'enclave 13¾ pouces

Côtés, arrière, dessous et dessus 0 pouce

COMBUSTIBLES

DÉGAGEMENTS AUX MATÉRIAUX

volts).

ou la soupape du gaz à l'alimentation électrique (110

Ne raccordez pas l'interrupteur mural, le thermostat

FIGURE 3

soupape de gaz.

Branchez les deux brins aux bornes 1 et 3 situées sur la

calibre 18 40 pieds

calibre 16 60 pieds

calibre 14 100 pieds

DIAMÈTRE DU FIL LONGUEUR MAX.

longueur maximale dépend du calibre du fil :

électrique située dans le bas, du côté gauche du foyer. La

millivolt à deux brins (noyau solide) dans l'ouverture

peut être installé dans un endroit pratique. Passez un fil

4. Pour faciliter l'accès, un interrupteur mural facultatif

N'UTILISEZ PAS UNE FLAMME NUE.

lution d'eau savonneuse.

3. Vérifiez pour des fuites de gaz en appliquant une so-

5

suie noire). Cette condition

pannes de veilleuse et

FIGURE 4

le mur extérieur de la maison.

tios recouverts, des gazebos ou des installations contre

Des installations typiques peuvent comprendre des pa-

visuellement indésirable.

ne compromet pas la sécurité du foyer mais est

dépôts de carbone excessifs (

Des flammes irrégulières peuvent aussi causer des

de brûleur principal.

irrégulières et possiblement des

endroit

protégé. Les vents directs causeront des flammes

Il est fortement recommandé d’installer ce foyer dans un

à l’intérieur d’une structure fermée et étanche.

sur un patio ou dans votre cour. Il ne doit jamais être installé

Ce foyer est conçu pour être installé à l’extérieur tel que

AIR COMBURANT ET DE CONVECTION

INSTALLATION

FIGURE 2

NE PLIEZ PAS LE RACCORD FLEXIBLE.

flexible.

entre la soupape de gaz et le tuyau de cuivre ou le raccord

serrez solidement. Une bague d'ajustement est requise

à la ligne de gaz et à la soupape de gaz du foyer. Scellez et

/8" et une soupape de sectionnement

3

raccord flexible de

type L de ½" ou, si les codes locaux le permettent, un

2. Installez un tuyau noir rigide, un tuyau de cuivre de

trous de ¼" de diamètre situés de chaque côté de la base.

ports de fixation et/ou fixez-le au plancher en utilisant les

1. Mettez le foyer en place et fixez-le en utilisant les sup-

lb est disponible chez votre détaillant Napoléon.

place. Un support pour des bonbonnes standard de 20

bonbonne de propane, la bonbonne doit être retenue en

NOTE : Si vous branchez votre appareil à une

BRANCHEMENT DU GAZ

Page 25

FIGURE 1

W415-0369 / 04.23.04

DIMENSIONS

.

listés pour votre modèle de foyer

N’utilisez que les accessoires conçus et

fait normaux et il faut s'y attendre.

des cycles de chauffage et de refroidissement sont tout à

Les bruits causés par l'expansion et la contraction lors

système.

24 volts) n'est requise pour le fonctionnement du

Aucune alimentation électrique externe (110 volts ou

pouces de colonne d'eau pour le propane.

est 3,5 pouces de colonne d'eau pour le gaz naturel et 10

propane. La pression au collecteur quand le gaz circule

le gaz naturel et 13 pouces de colonne d'eau pour le

d'alimentation en gaz est 7 pouces de colonne d'eau pour

colonne d'eau pour le propane. La pression maximale

ces de colonne d'eau pour le gaz naturel et 11 pouces de

La pression minimale d'alimentation en gaz est 4,5 pou-

certifié.

tible à moins d’utiliser un ensemble de conversion

foyer ne peut être converti à un autre type de combuscombustible indiqué sur la plaque d’homologation. Ce

Ce foyer est conçu pour fonctionner avec le type de

du foyer lorsque le foyer n’est pas utilisé.

contre l’humidité (pluie, neige). Recouvrez l’ouverture

Il est fortement recommandé de protéger les bûches

supplémentaires.

tude devra être réduit de 4 % pour chaque 1 000 pieds

compétente locale, l'indice certifié du débit à haute altil'absence de recommandations spécifiques de l'autorité

installé à des élévations dépassant 2 000 pieds, et en

pour le gaz naturel et le propane. Lorsque le foyer est

ET SA QUALITÉ! Le débit maximal est de 40 000 BTU/h

L'ESSAI POUR CONFIRMER SON FONCTIONNEMENT

POUR VOTRE SATISFACTION, CE FOYER A ÉTÉ MIS À

INFORMATION GÉNÉRALE

longeant sur toute la largeur et la profondeur.

être monté sur un panneau de métal ou de bois se prode plancher combustible autre que le bois, le foyer devra

Lorsque le foyer est installé directement sur un revêtement

lb/po

(3,5 kPa), ou moins.

2

tème d'alimentation en gaz lorsque la pression est de 1/2

ment manuelle pendant tout essai de pression du sysmentation en gaz en fermant la soupape de sectionnepo

(3,5 kPa). Le foyer doit être séparé de la ligne d'ali-

2

système lorsque les pressions d'essai excèdent 1/2 lb/

mentation en gaz pendant les essais de pression de ce

La soupape du foyer doit être débranchée de la ligne d'ali-

Z223.1/INFPA 54 aux États-Unis.

B149.1 au Canada ou le National Fuel Gas Code, ANSI

au Code d'installation du gaz naturel et du propane CSA

l'absence de codes locaux, l'installation doit être conforme

L'installation doit se conformer aux codes locaux. En

région.

connaître les normes spécifiques qui s’appliquent à votre

vent varier d’une région à l’autre. Il est donc important de

formant aux codes locaux. Les pratiques d’installation peu-

TRETENU PAR UN INSTALLATEUR QUALIFIÉ en se con-

CE FOYER AU GAZ DEVRAIT ÊTRE INSTALLÉ ET EN-

INSTRUCTIONS GÉNÉRALES

4

Page 26

W415-0369 / 04.23.04

l'appareil au gaz NAPOLÉON et toutes autres garanties exprimées ou implicites concernant ce

CONDITIONS ET LIMITATIONS

NAPOLÉON se réserve le droit de demander à son représentant d’inspecter tout produit ou pièce avant d’honorer toute réclamation.

doit être retournée dans les quatorze jours pour enregistrer la garantie.

La facture ou sa copie sera requise ainsi qu’un numéro de série et un numéro de modèle lors d’une réclamation auprès de votre détaillant autorisé. La carte d’enregistrement de garantie

responsabilité de NAPOLÉON.

Tous dommages causés à l'appareil par les intempéries, de longues périodes d’humidité, la condensation, les produits chimiques ou produits d’entretien nuisibles ne seront pas la

Cette garantie limitée ne couvre pas les dommages causés par l'utilisation de composants qui ne sont pas fournis avec l'appareil, ou l'utilisation d'un combustible autre que celui spécifié.

produit, ses composants ou accessoires sont exclus.

Cette garantie définit l’obligation et la responsabilité de NAPOLÉON en ce qui concerne

dommage accidentel, consécutif ou indirect.

Nonobstant toutes les dispositions contenues dans cette Garantie Limitée, la responsabilité de NAPOLÉON sous cette garantie est définie comme ci-dessus et elle ne s’étendra à aucun

telles dépenses ne sont pas couvertes par cette garantie.

Après la première année, NAPOLÉON ne sera pas responsable de l’installation, de la main-d’oeuvre ou autres coûts ou dépenses relatives à la réinstallation d’une pièce garantie, et de

à l’acheteur d’origine le prix de gros de toute pièce garantie qui est défectueuse.

Après la première année, concernant cette Garantie Limitée, NAPOLÉON peut, à sa discrétion, se libérer entièrement de toutes obligations en ce qui concerne cette garantie en remboursant

que le produit ait été utilisé conformément aux instructions de fonctionnement et dans des conditions normales.

Au cours de la première année seulement, cette garantie s’étend à la réparation ou le remplacement des pièces garanties dont les matériaux ou la fabrication sont défectueux sous condition

et abrasifs, le bris par manipulation des bûches et des braises.

Cette garantie limitée ne couvre pas non plus les égratignures, les bossellements, la corrosion ou la décoloration causée par une chaleur excessive, des produits d’entretien chimiques

pièces d’autres fabricants annulera cette garantie.

Cette garantie limitée ne couvre pas les dommages causés par un mauvais usage, un manque d’entretien, un accident, des altérations, des abus ou de la négligence, et l’installation de

L'installation doit être faite conformément aux instructions d’installation incluses avec le produit et à tous les codes d’incendie et du bâtiment locaux et nationaux.

C

ette garantie du fabricant n’est pas transférable et ne peut être prolongée ou étendue par aucun de nos représentants quelle qu’en soit la raison.

Cette garantie limitée s'applique seulement lorsque l'appareil demeure à l'endroit d'installation d'origine et seulement si l'appareil est installé au Canada ou aux États-Unis.

et limitations suivantes :

carte d’enregistrement de garantie déposé auprès de NAPOLÉON -- à condition que l’achat ait été fait par l’entremise d’un détaillant NAPOLÉON autorisé et sous réserve des conditions

NAPOLÉON garantit ses produits contre les défauts de fabrication à l’acheteur d’origine seulement -- c.-à-d. l’individu ou la personne morale (client inscrit) dont le nom apparaît sur la

Napoléon sontNapoléon sont

Napoléon sont

Napoléon sontNapoléon sont

nouvel appareil au gaznouvel appareil au gaz

nouvel appareil au gaz

nouvel appareil au gaznouvel appareil au gaz

doit être accompli par l’entremise d’un représentant autorisé NAPOLÉON.doit être accompli par l’entremise d’un représentant autorisé NAPOLÉON.

doit être accompli par l’entremise d’un représentant autorisé NAPOLÉON.

doit être accompli par l’entremise d’un représentant autorisé NAPOLÉON.doit être accompli par l’entremise d’un représentant autorisé NAPOLÉON.

de NAPOLÉON sont basés sur un programme de tarifs prédéterminé et tout travail de réparationde NAPOLÉON sont basés sur un programme de tarifs prédéterminé et tout travail de réparation

de NAPOLÉON sont basés sur un programme de tarifs prédéterminé et tout travail de réparation

de NAPOLÉON sont basés sur un programme de tarifs prédéterminé et tout travail de réparationde NAPOLÉON sont basés sur un programme de tarifs prédéterminé et tout travail de réparation

préalable d’un représentant autorisé de la compagnie. Les coûts de main-d’oeuvre à la chargepréalable d’un représentant autorisé de la compagnie. Les coûts de main-d’oeuvre à la charge

préalable d’un représentant autorisé de la compagnie. Les coûts de main-d’oeuvre à la charge

préalable d’un représentant autorisé de la compagnie. Les coûts de main-d’oeuvre à la chargepréalable d’un représentant autorisé de la compagnie. Les coûts de main-d’oeuvre à la charge

durant la première année. Cependant, les travaux de réparation nécessitent l’approbationdurant la première année. Cependant, les travaux de réparation nécessitent l’approbation

durant la première année. Cependant, les travaux de réparation nécessitent l’approbation

durant la première année. Cependant, les travaux de réparation nécessitent l’approbationdurant la première année. Cependant, les travaux de réparation nécessitent l’approbation

Les coûts de main-d’oeuvre relatifs aux réparations garanties sont couverts gratuitementLes coûts de main-d’oeuvre relatifs aux réparations garanties sont couverts gratuitement

Les coûts de main-d’oeuvre relatifs aux réparations garanties sont couverts gratuitement

Les coûts de main-d’oeuvre relatifs aux réparations garanties sont couverts gratuitementLes coûts de main-d’oeuvre relatifs aux réparations garanties sont couverts gratuitement

la garantie limitée.la garantie limitée.

la garantie limitée.

la garantie limitée.la garantie limitée.

couverts et Napoléon fournira gratuitement les pièces de rechange durant la première année decouverts et Napoléon fournira gratuitement les pièces de rechange durant la première année de

couverts et Napoléon fournira gratuitement les pièces de rechange durant la première année de

couverts et Napoléon fournira gratuitement les pièces de rechange durant la première année decouverts et Napoléon fournira gratuitement les pièces de rechange durant la première année de

telles que les soupapes de gaz, les bûches et les joints d’étanchéité sonttelles que les soupapes de gaz, les bûches et les joints d’étanchéité sont

telles que les soupapes de gaz, les bûches et les joints d’étanchéité sont

telles que les soupapes de gaz, les bûches et les joints d’étanchéité sonttelles que les soupapes de gaz, les bûches et les joints d’étanchéité sont

Toutes les pièces Toutes les pièces

Toutes les pièces

Toutes les pièces Toutes les pièces

garantis contre les défauts pour une période de cinq ans.garantis contre les défauts pour une période de cinq ans.

garantis contre les défauts pour une période de cinq ans.

garantis contre les défauts pour une période de cinq ans.garantis contre les défauts pour une période de cinq ans.

Tous les composants en acier inoxydable de votre Tous les composants en acier inoxydable de votre

Tous les composants en acier inoxydable de votre

Tous les composants en acier inoxydable de votre Tous les composants en acier inoxydable de votre

GARANTIE LIMITÉE DE 5 ANS DES APPAREILS AU GAZ NAPOLÉON

produit de qualité dont vous vous attendez de NAPOLÉON.

inspecté de nouveau par un technicien qualifié avant d’être emballé pour garantir que vous, le client, recevez le

détection de fuites et d'allumage à une station de test de qualité. Une fois assemblé, chaque foyer est soigneusement

des artisans qualifiés qui sont fiers de leur travail. Le brûleur et le montage de la soupape subissent un test de

Les produits NAPOLÉON sont conçus avec des composants et des matériaux de qualité supérieure, assemblés par

de Qualité mondialement reconnu ISO 9001 : 2000.

Les appareils au gaz NAPOLÉON sont fabriqués conformément aux normes strictes du Certificat d’Assurance

3

Page 27

W415-0369 / 04.23.04

NOTE : Les changements autres que de nature éditoriale sont dénotés par une ligne verticale dans la marge.

ET EST INTERDIT.

TOUTE MODIFICATION APPORTÉE À CE FOYER OU AUX CONTRÔLES PEUT ÊTRE DANGEREUX

• N’utilisez pas d’accessoires qui ne sont pas approuvés pour ce foyer.

de la flamme.

•

Ne laissez pas le vent souffler directement dans le foyer. Évitez les courants d’air qui modifient l’apparence

contrôle du gaz qui aurait été submergée.

de service qualifié pour inspecter l'appareil et pour remplacer toute pièce du système de contrôle et du

• N'utilisez pas ce foyer si une partie quelconque a été submergée. Contactez immédiatement un technicien

• Les meubles ou autres objets doivent être gardés à une distance d'au moins 4 pieds du devant du foyer.

liquides et vapeurs inflammables.

entretien. L'emplacement du foyer doit être gardé libre de tous matériaux combustibles, essence ou autres

Le foyer doit être inspecté avant la première utilisation et au moins une fois l'an par un spécialiste en

• Il est primordial de garder propres les compartiments de contrôle, les brûleurs et les bouches d'air du foyer.

foyer.

• Les pare-étincelles ou écrans enlevés pour faire l'entretien devront être remis en place avant d'utiliser le

• Les vêtements et autres matériaux combustibles ne doivent pas être posés sur ou près du foyer.

leurs vêtements ne prennent feu. Surveillez les jeunes enfants lorsqu'ils sont à proximité du foyer.

surfaces exposées à des températures élevées. Ils doivent s'en tenir éloignés pour éviter de se brûler ou que

• Les adultes et particulièrement les enfants doivent être sensibilisés aux risques que représentent les