Page 1

INSTALLER: LEAVE THIS MANUAL WITH THE APPLIANCE.

CONSUMER: RETAIN THIS MANUAL FOR FUTURE REFERENCE.

INSTALLATION AND

OPERATION INSTRUCTIONS

CERTIFIED UNDER CANADIAN AND AMERICAN NATIONAL STANDARDS: CSA 2.33 ● ANSI Z21.88 FOR VENTED GAS FIREPLACE HEATERS.

GD36NTR

BGD36NTR

NATURAL GAS MODEL

GD36PTR

1

BGD36PTR

PROPANE GAS MODEL

CERTIFIED FOR CANADA AND UNITED STATES USING ANSI/CSA METHODS.

SAFETY INFORMATION

!

WARNING

If the information in these instructions are

not followed exactly, a fire or explosion

may result causing property damage,

personal injury or loss of life.

- Do not store or use gasoline or other

flammable vapors and liquids in the vicinity

of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Do not touch any electrical switch; do

not use any phone in your building.

Immediately call your gas supplier from

a neighbor's phone. Follow the gas

supplier’s instructions.

If you cannot reach your gas supplier,

call the fire department.

- Installation and service must be

performed by a qualified installer, service

agency or the supplier.

B

GD36 I

l

l

ust

rated

Wolf Steel Ltd., 24 Napoleon Rd., Barrie, ON L4M 4Y8 Canada • (705)721-1212 • fax(705)722-6031

www.napoleonfireplaces.com • ask@napoleon.on.ca

$10.00

W415-0210 / R / 02.27.08

Page 2

2

TABLE OF CONTENTS

PG 2-5 INTRODUCTION

Warranty

General Instructions

General Information

Care of Glass and Plated Parts

Specifi cations

5-16 VENTING

Venting Lengths

Vent Installations

Typical Vent Installations

Special Vent Installations

Minimum Air Terminal Location Clearances

Venting Application Flow Chart

Venting Specifi cations

Pre-Installation Preparation

17-26 INSTALLATION

Wall and Ceiling Protection

Horizontal Installation

Vertical Installation

Using Flexible Vent Components

Fireplace Vent Connection

Using Rigid Vent Components

Vertical Venting Installation

Restricting Vertical Vents

Mobile Home Installation

Gas Installation

Optional Wall Switch Installation

Framing

Minimum Enclosure Clearances

Minimum Mantel Clearances

Nailing Tab Installation

27-28 FINISHING

Door Removal & Installation

Door Glass Replacement

L36 Louvre Installation

Log Placement

Logo Placement

29

OPTIONAL BLOWER INSTALLATION

30 OPTIONAL FAN INSTALLATION

OPTIONAL THERMOSTATIC SENSOR

31 OPERATION / MAINTENANCE

Operating Instructions

Maintenance

30 ADJUSTMENTS

Pilot Burner Adjustment

Venturi Adjustment

32-34 REPLACEMENTS

Ordering Replacement Parts

Replacement Parts

Accessories

35-36 TROUBLE SHOOTING GUIDE

37 SERVICE HISTORY

38 NOTES

RETAIN THIS MANUAL FOR FUTURE REFERENCE

!

WARNING

• Do not burn wood or other materials in this fi replace.

• Adults and especially children should be alerted to the hazards of high surface temperatures and should stay away to avoid burns or

clothing ignition. Supervise young children when they are in the same room as the fi replace.

• Clothing or other fl ammable material should not be placed on or near the fi replace.

• Due to high temperatures, the fi replace should be located out of traffi c and away from furniture and draperies.

• Ensure you have incorporated adequate safety measure to protect infants/toddlers from touching hot surfaces.

• Even after the fi replace is out, the glass and/or screen will remain hot for an extended period of time.

• Check with your local hearth specialty dealer for safety screens and hearth guards to protect children from hot surfaces. These screens

and guards must be fastened to the fl oor.

• Any safety screen or guard removed for servicing must be replaced prior to operating the fi replace.

• It is imperative that the control compartments, burners and circulating blower and its passageway in the fi replace and venting system

are kept clean. The fi replace and its venting system should be inspected before use and at least annually by a qualifi ed service person.

More frequent cleaning may be required due to excessive lint from carpeting, bedding material, etc. The fi replace area must be kept clear

and free from combustible materials, gasoline and other fl ammable vapours and liquids.

• Under no circumstances should this fi replace be modifi ed.

• This fi replace must not be connected to a chimney fl ue pipe serving a separate solid fuel burning appliance.

• Do not use this fi replace if any part has been under water. Immediately call a qualifi ed service technician to inspect the fi replace and to

replace any part of the control system and any gas control which has been under water.

• Do not operate the fi replace with the glass door removed, cracked or broken. Replacement of the glass should be done by a licensed

or qualifi ed service person.

• Do not strike or slam shut the fi replace glass door.

• This fi replace uses and requires a fast acting thermocouple. Replace only with a fast acting thermocouple supplied by Wolf Steel Ltd.

• Pressure relief doors must be kept closed while the fi replace is operating to prevent exhaust fumes containing carbon monoxide, from

entering into the home. Temperatures of the exhaust escaping through these openings can also cause the surrounding combustible

materials to overheat and catch fi re.

• Only doors / optional fronts certifi ed with the unit are to be installed on the appliance.

NOTE: CHANGES, OTHER THAN EDITORIAL, ARE DENOTED BY A VERTICAL LINE IN THE MARGIN.

W415-0210 / R / 02.27.08

Page 3

3

®

®

®

®

®

®

®

®

®

®

®

®

®

®

®

®®

®

®

®

®

W415-0210 / R / 02.27.08

Page 4

4

GENERAL INSTRUCTIONS

THIS GAS FIREPLACE SHOULD BE INSTALLED AND SERVICED BY A QUALIFIED INSTALLER to conform with local

codes. Installation practices vary from region to region and it is important to know the specifi cs that apply to your area,

for example: in Massachusetts State:

• The fi replace damper must be removed or welded in the open position prior to installation of a fi replace insert or gas log.

• A carbon monoxide detector is required in all rooms containing gas fi red appliances

• The appliance off valve must be a “T” handle gas cock.

• The fl exible connector must not be longer than 36".

• The appliance is not approved for installation in a bedroom or bathroom unless the unit is a direct vent sealed combustion product.

• WARNING: This product must be installed by a licensed plumber or gas fi tter when installed within the commonwealth of

Massachusetts.

In absence of local codes, install to the current National Fuel Gas Code, ANSI Z223.1, or the current CAN/CGA B149, Installation

Codes. Mobile home installation must conform with local codes or in the absence of local codes, install to the current standard

for gas equipped mobile housing CAN/CSA ZA240 MH Series in Canada or the Manufactured Home Construction and Safety

Standard, Title 24 CFR, Part 3280, or the Fire Safety Criteria for Manufactured Home Installations, Sites and Communities

Standard ANSI/NFPA 501A in the United States.

The fi replace and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure

testing of that system at test pressures in excess of 1/2 psig (3.5 kPa). The fi replace must be isolated from the gas supply

piping system by closing its individual manual shutoff valve during any pressure testing of the gas supply piping system at test

pressures equal to or less than 1/2 psig (3.5 kPa).

When the fi replace is installed directly on carpeting, vinyl tile or other combustible

material other than wood fl ooring, the fi replace shall be installed on a metal or

wood panel extending the full width and depth.

If the optional fan or blower is installed, the junction box must be electrically

connected and grounded in accordance with local codes. In the absence of local

codes, use the current CSA C22.1 CANADIAN ELECTRICAL CODE in Canada

or the ANSI/NFPA 70 NATIONAL ELECTRICAL CODE in the United States.

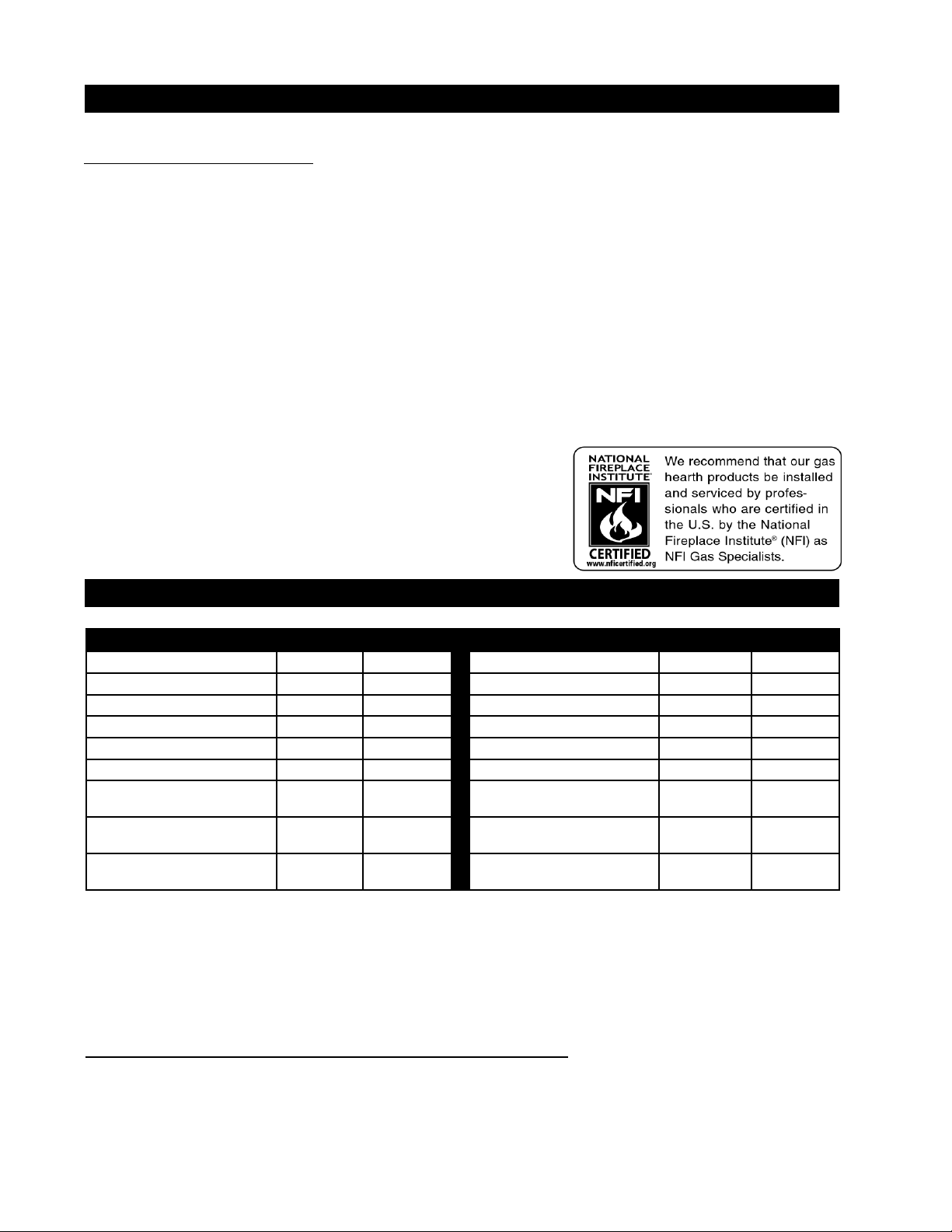

GENERAL INFORMATION

FOR YOUR SATISFACTION, THIS FIREPLACE HAS BEEN TEST-FIRED TO ASSURE ITS OPERATION AND QUALITY!

GD36 RATES AND EFFICIENCIES BGD36 RATES AND EFFICIENCIES

NG LP NG LP

ALTITUDE (FT) 0 - 4,500 0 - 4,500 ALTITUDE (FT) 0 - 4,500 0 - 4,500

MAX. INPUT (BTU/HR) 26,000 26,000 MAX. INPUT (BTU/HR) 18,000 17,000

MAX. OUTPUT (BTU/HR) 22,360 22,880 MAX. OUTPUT (BTU/HR) 11,500 10,900

EFFICIENCY (w/ the fan on) 86% 88% EFFICIENCY (w/ the fan on) 64% 64%

A.F.U.E. 64% 65% A.F.U.E. 53% 53%

MINIMUM INLET GAS SUPPLY

PRESSURE

MAXIMUM INLET GAS SUPPLY

PRESSURE

MANIFOLD PRESSURE

(under fl ow conditions)

This fi replace is approved for bathroom, bedroom and bed-sitting room installations and is suitable for mobile home

installation.

No external electricity (110 volts or 24 volts) is required for the gas system operation.

Expansion / contraction noises during heating up and cooling down cycles are normal and are to be expected.

Provide adequate ventilation air. Provide adequate accessibility clearance for servicing and operating the fi replace.

Never obstruct the front opening of the fi replace.

Objects placed in front of the fi replace must be kept a minimum of 48" away from the front face of the unit.

Use only Napoleon® accessories designed for and listed with the model.

4.5" WATER

COLUMN

7" WATER

COLUMN

3.5" WATER

COLUMN

11" WATER

COLUMN

13" WATER

COLUMN

10" WATER

COLUMN

MINIMUM INLET GAS SUPPLY

PRESSURE

MAXIMUM INLET GAS SUPPLY

PRESSURE

MANIFOLD PRESSURE

(under fl ow conditions)

4.5" WATER

COLUMN

7" WATER

COLUMN

3.5" WATER

COLUMN

11" WATER

COLUMN

13" WATER

COLUMN

10" WATER

COLUMN

W415-0210 / R / 02.27.08

Page 5

CARE OF GLASS AND PLATED PARTS

Do not use abrasive

cleaners to clean

plated parts. Buff

lightly with a clean

dry cloth.

DO NOT SUBSTITUTE MATERIALS. Clean the glass after the fi rst 10 hours

of operation with a recommended gas fi replace glass cleaner. Thereafter

clean as required. DO NOT CLEAN GLASS WHEN HOT! If the glass is not

kept clean permanent discolouration and / or blemishes may result.

GD36 GLASS TYPE BGD36 GLASS TYPE

3/16" Ceramic Glass* 3/16" Tempered Glass*

*Available from your Napoleon® / Wolf Steel Ltd. dealer.

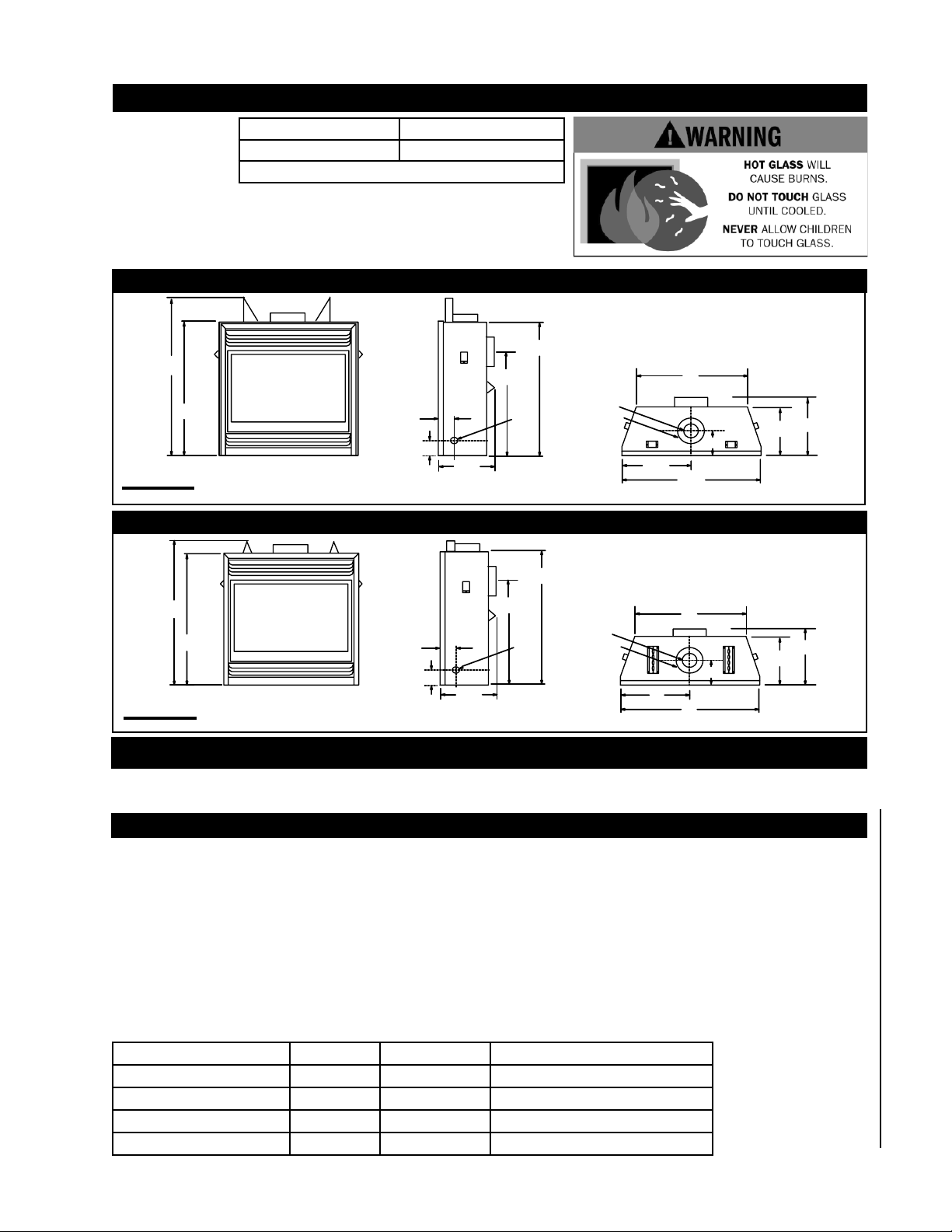

GD36 SPECIFICATIONS

323/8"

381/2"

33"

FIGURE 1a

1

5

/2"

3"

141/4"

ELECTRICAL INLET

LEFT SIDE

24

1

/4"

GAS

INLET

4" DIA.

7" DIA.

18

5

27"

1

1

14

1

7

/2"

5

/8"

1

37

/4"

12

/4"

/4"

BGD36 SPECIFICATIONS

323/8"

1

/4"

14

24

4" DIA.

GAS

7" DIA.

INLET

1

/4"

18"

27"

1

14

/4"

1

12

1

/2"

7

/4"

36"

351/2"

32

FIGURE 1b

3

/8"

1

5

/2"

3"

ELECTRICAL INLET

LEFT SIDE

VENTING

MODELS GD36 AND BGD36 MAY BE VENTED EITHER AS A TOP VENT OR A REAR VENT.

REFER TO THE SECTION APPLICABLE TO YOUR INSTALLATION.

VENTING LENGTHS

Use only Wolf Steel, Simpson Dura-Vent, Selkirk Direct Temp, American Metal Amerivent, or SuperSeal venting components.

Minimum and maximum vent lengths, for both horizontal and vertical installations, and air terminal locations for either system

are set out in this manual and must be adhered to. For Simpson Dura-Vent, Selkirk Direct Temp, American Metal Amerivent,

and SuperSeal follow the installation procedure provided with the venting components.

All outer pipe joints of these venting systems must be sealed using Red RTV and/or Mill Pac high temperature sealant (not

supplied) hereafter referred to as high temperature sealant W573-0002 (Red RTV) and the high temperature sealant W5730007 (Mill Pac).

The connection between the adaptor and for these systems and the fi replace fl ue collar must be sealed using the high

temperature sealant W573-0007 Mill Pac (not supplied).

A starter adaptor must be used with the following vent systems and may be purchased from the corresponding

supplier:

PART 4" / 7" SUPPLIER WEBSITE ADDRESS*

Simpson Dura-Vent W175-0053 Wolf Steel Ltd. www.duravent.com

Selkirk Direct Temp 4DT-AAN Selkirk www.selkirkcorp.com

American Metal Amerivent 4DSC-N2 American Metal www.americanmetalproducts.com

SuperSeal 4DNA Metal-Fab www.mtlfab.com

* For Simpson Dura-Vent,

Selkirk Direct Temp,

merican Metal Amerivent,

and SuperSeal follow the

installation procedure

found on the website for

your venting supplier.

W415-0210 / R / 02.27.08

Page 6

6

For vent systems that provide seals on the inner exhaust fl ue, only the outer air intake joints must be sealed using a red high

temperature silicone (RTV). This same sealant may be used on both the inner exhaust and outer intake vent pipe joints of all

other approved vent systems except for the exhaust vent pipe connection to the fi replace fl ue collar which must be sealed

using the black high temperature sealant Mill Pac.

When using Wolf Steel venting components, use only approved Wolf Steel rigid / fl exible components with the following

termination kits: WALL TERMINAL KIT GD222, or 1/12 TO 7/12 PITCH ROOF TERMINAL KIT GD110, 8/12 TO 12/12 ROOF

TERMINAL KIT GD111 , FLAT ROOF TERMINAL KIT GD112 or PERISCOPE KIT GD201 (for wall penetration below grade).

With fl exible venting, in conjunction with the various terminations, use either the 5 foot vent kit GD220 or the 10 foot vent

kit GD330.

For optimum fl ame appearance and fi replace performance, keep the vent length and number of elbows to a

minimum.

The air terminal must remain unobstructed at all times. Examine the air terminal at least once a year to verify that

it is unobstructed and undamaged.

Wolf Steel rigid and fl exible venting systems must not be combined.

Wolf Steel, Simpson Dura-Vent, Selkirk Direct Temp and American Metal Amerivent venting systems must not be

combined.

These vent kits allow for either horizontal or vertical venting of the fi replace. The maximum allowable horizontal run is 20

feet.

The maximum allowable vertical vent length is 40 feet. The maximum number of 4" vent connections is two horizontally or

three vertically (excluding the fi replace and the air terminal connections) when using fl exible vent pipe.

For optimum performance, it is recommended that all horizontal runs have a 1" rise per foot.

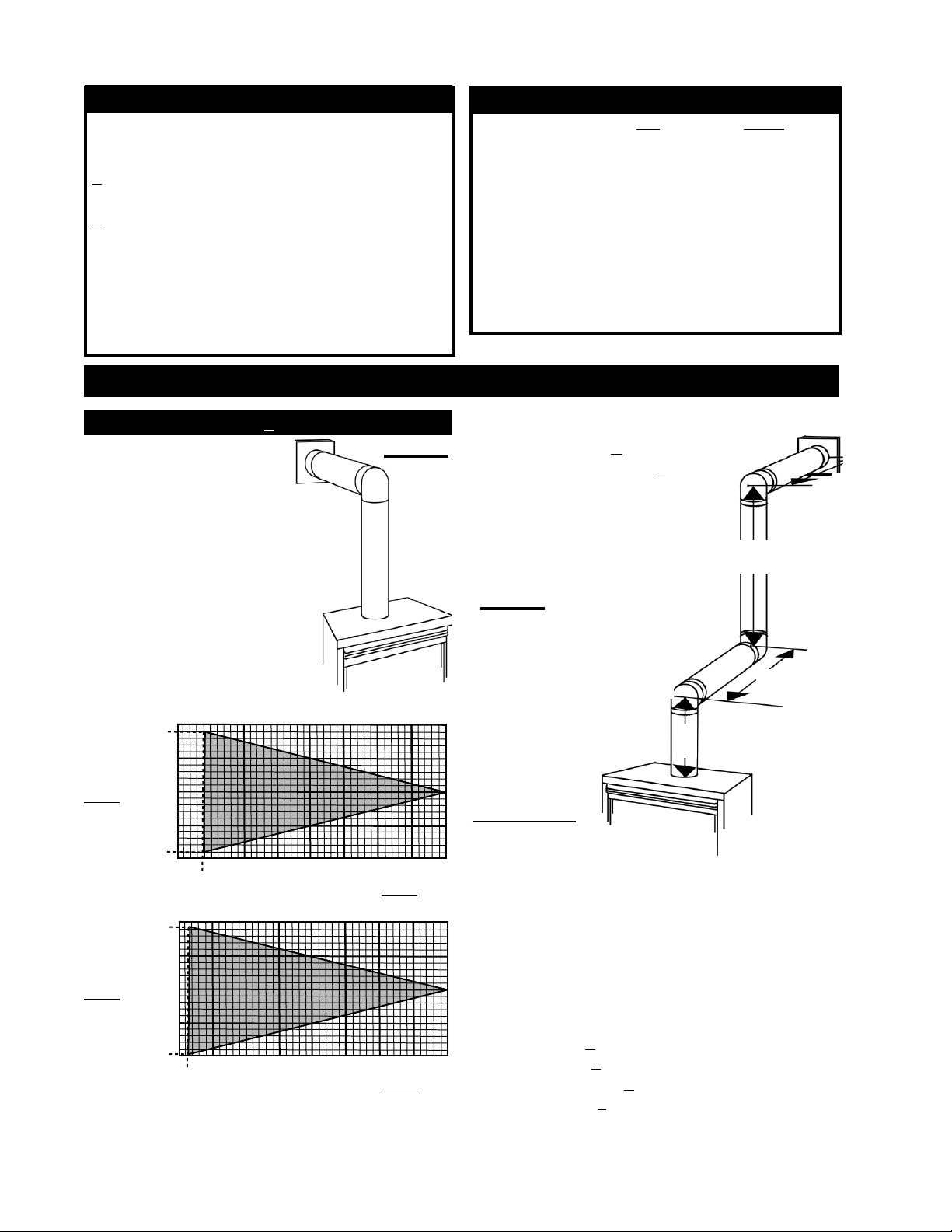

GD36 REQUIRED RISE ON HORIZONTAL VENTING BGD36 REQUIRED RISE ON HORIZONTAL VENTING

REAR VENT

TOP VENT

CORNER VENT

RIGID VENTING 1" / FT **

FLEXIBLE VENTING 1" / FT ** FLEXIBLE VENTING 0" / FT

RIGID VENTING 0" / FT

FLEXIBLE VENTING 0" / FT FLEXIBLE VENTING 0" / FT

RIGID VENTING 6"

FLEXIBLE VENTING 6" FLEXIBLE VENTING 6"

REAR VENT

TOP VENT

CORNER VENT

** When a vertical rise is used as part of the venting confi guration, a 0" rise per foot is acceptable.

RIGID VENTING 0" / FT

RIGID VENTING 0" / FT

RIGID VENTING 0"

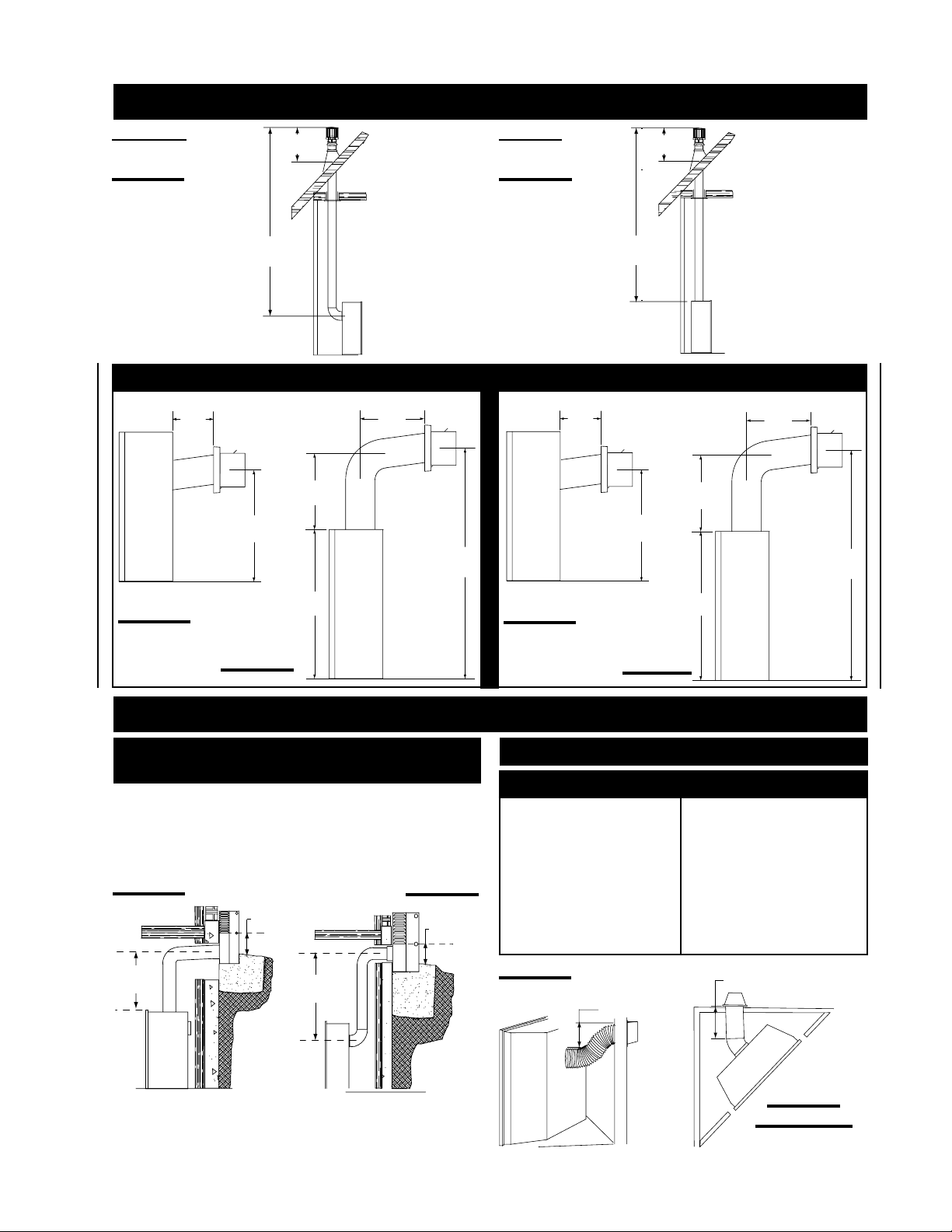

VENT INSTALLATIONS

For safe and proper operation of the fi replace follow the venting instructions exactly.

Deviation from the minimum or maximum vertical vent length can create diffi culty in burner start-up and/or

carboning.

Under extreme vent confi gurations, allow several minutes (5-15) for the fl ame to stabilize after ignition.

Vent lengths that pass through unheated spaces (attics, garages, crawl spaces) should be insulated with the

insulation wrapped in a protective sleeve to minimize condensation.

Provide a means for visually checking the vent connection to the fi replace after the fi replace is installed.

Use a fi restop, vent pipe shield or attic insulation shield when penetrating interior walls, fl oor or ceiling.

GD36 BGD36

HORIZONTAL VENT SECTIONS

A minimum clearance of 1" at the bottom and sides and 2" at

the top of the vent pipe on all horizontal runs to combustibles

is required. Use fi restop spacer W010-1777 (supplied).

VERTICAL VENT SECTIONS

A minimum of 1" all around the vent pipe on all vertical runs

to combustibles is required except for clearances in fi replace

enclosures. See "Minimum Enclosure Clearances" section.

Use fi restop spacer W500-0096 (not supplied).

A minimum clearance of 1" at the bottom and sides and 2" at

the top of the vent pipe on all horizontal runs to combustibles

is required. Use fi restop spacer W010-1774 (supplied).

A minimum of 1" all around the vent pipe on all vertical runs

to combustibles is required except for clearances in fi replace

enclosures. See "Minimum Enclosure Clearances" section.

HORIZONTAL VENT SECTIONS

VERTICAL VENT SECTIONS

Use fi restop spacer W500-0096 (not supplied).

W415-0210 / R / 02.27.08

FOR SPECIFIC VENTING PARAMETERS, REFER TO PAGES 10-15

Page 7

TYPICAL VENT INSTALLATIONS (GD36 AND BGD36)

M

16”

MINIMUM

FIGURE 2a FIGURE 2b

TOP EXITREAR EXIT

16”

MINIMUM

7

40 FT MAXIMUM

20" MAXIMUM

1

/4" MINIMUM

24

PLUS RISE*

* See chart on Page 6

FIGURE 2c

FIGURE 2d

3 FT MINIMUM

GD36

MINIMUM

24"

33"

24" MAXIMUM

57" MINIMUM

PLUS RISE**

40 FT MAXIMUM

3 FT MINIMUM

20" MAXIMUM

1

24

/4" MINIMUM

PLUS RISE*

* See chart on Page 6

FIGURE 2e

BGD36

MINIMUM

FIGURE 2f

10"

32 3/8"

24" MAXIMUM

3

42

/8" MINIMUM

PLUS RISE**

SPECIAL VENT INSTALLATIONS

PERISCOPE TERMINATION

(GD36 AND BGD36)

Use the GD201 periscope kit to locate the air termination

above grade. The periscope must be installed so that when

fi nal grading is completed, the bottom air slot is located a

minimum of 12" above grade. The maximum allowable vent

length is 10 feet.

FIGURE 3a

30”

MINIMUM

MAXIMUM 10FT VENT LENGTH

TOP EXIT INSTALLATION

12”

MINIMUM

30”

MINIMUM

REAR EXIT INSTALLATION

FIGURE 3b

12”

MINIMUM

CORNER TERMINATION

GD36 BGD36

The maximum vent length

for a corner installation

is 24", where only 6" of

vertical rise is used. All

corner installations require

a minimum 6" rise. See

FIGURE 4a.

FIGURE 4a

6” RISE

MINIMU

The maximum vent length for

a corner installation is 20" of

horizontal run, in addition to

the 45° offset. In this case

0" rise is acceptable when

using rigid. See FIGURE

4b. Flexible venting must

maintain a 6" rise. See

FIGURE 4a.

20” MAXIMUM

FIGURE 4b

(BGD36 ONLY)

(WITH RIGID ONLY)

W415-0210 / R / 02.27.08

Page 8

8

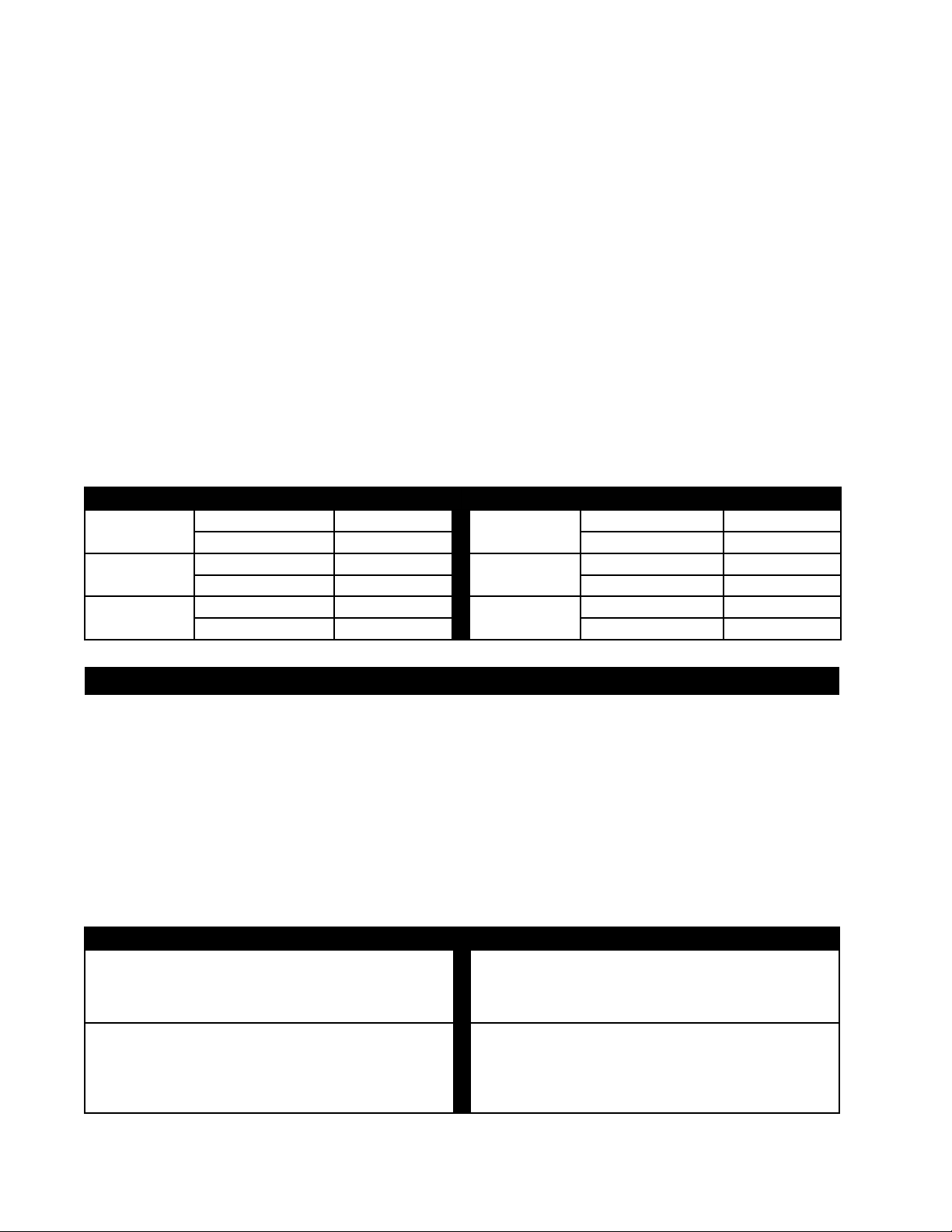

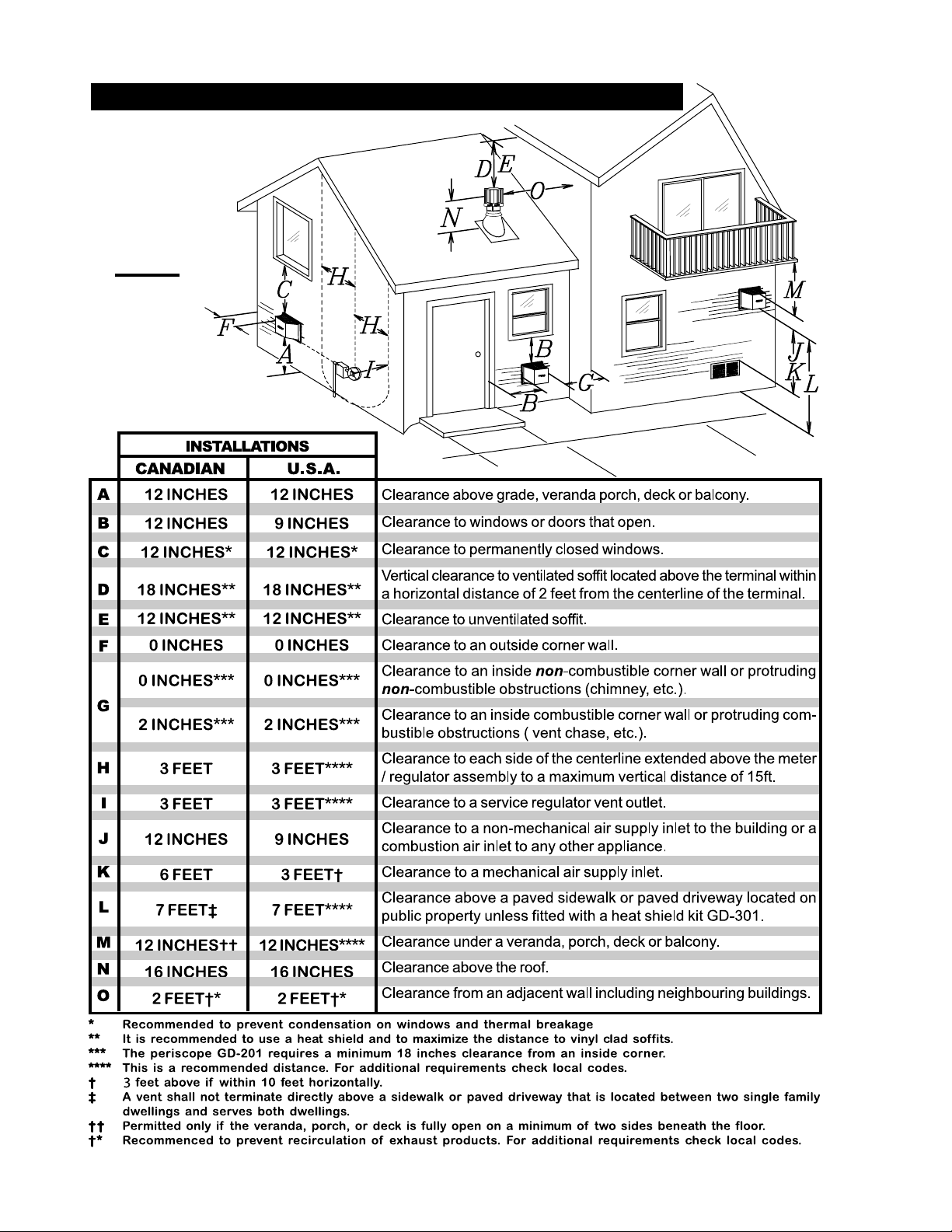

MINIMUM AIR TERMINAL LOCATION CLEARANCES

FIGURE 5

W415-0210 / R / 02.27.08

Page 9

TOP EXIT

Vertical rise

Vertical Termination

Vertical rise

is less than

horizontal

run

Vertical rise

is equal to

or greater

than the

is less than

horizontal

run

9

Horizontal

run + verti-

cal rise to

maximum

of 40 feet

horizontal

run

Horizontal

run + verti-

cal rise to

Horizontal

run + verti-

cal rise to

maximum of

maximum

of 40 feet

24.75 feet

3 times the

vertical rise

equal to or

greater than

the horizon-

4.2 times the

vertical rise

equal to or

greater than

the horizon-

tal run

tal run

VENTING APPLICATION FLOW CHART

Horizontal Termination

FIREPLACE VENT EXIT

Vertical Termination

REAR EXIT

Vertical rise

is equal to

or greater

than the

Vertical rise

is less than

horizontal

Vertical rise

is equal to

or greater

than the

Vertical rise

is less than

horizontal

horizontal

run

horizontal

run

run

run

Horizontal

run + verti-

cal rise to

Horizontal

run + verti-

cal rise to

Horizontal

run + verti-

cal rise to

Horizontal

run + verti-

cal rise to

maximum of

maximum

of 40 feet

maximum

of 40 feet

maximum

of 40 feet

24.75 feet

3 times the

vertical rise

equal to or

greater than

the horizon-

3.5 times the

vertical rise

equal to or

greater than

the horizon-

tal run

tal run

Horizontal Termination

Vertical rise

is equal to

or greater

than the

horizontal

run

Horizontal

run + verti-

cal rise to

maximum

of 40 feet

W415-0210 / R / 02.27.08

Page 10

10

DEFINITIONS

for the following symbols used in the venting calculations

and examples are:

> - greater than

> - equal to or greater than

< - less than

< - equal to or less than

- total of both horizontal vent lengths (HR) and offsets

H

T

(HO) in feet

- combined horizontal vent lengths in feet

H

R

- offset factor: .03(total degrees of offset - 90°*) in

H

O

feet

- combined vertical vent lengths in feet

V

T

TOP EXIT / HORIZONTAL TERMINATION

(HT) < (VT)

FIGURE 6

Simple venting confi guration

(only one 90° elbow)

ELBOW VENT LENGTH VALUES

feet inches

1° 0.03 0.5

15° 0.45 6.0

30° 0.9 11.0

45° 1.35 16.0

90°* 2.7 32.0

* the fi rst 90° offset has a zero value and is shown in the

formula as -90°

For vent confi gurations requiring more than one 90° elbow,

the following formulas apply:

Formula 1: HT < V

Formula 2: HT + VT < 40 feet

T

90°

H

2

See graph to determine the required

vertical rise VT for the required horizontal run HT.

40

38

REQUIRED

VERTICAL

RISE IN

FEET V

30

20

T

10

2

0

2.5 5 7.5 10 12.5 15

2

HORIZONTAL VENT RUN PLUS OFFSET IN FEET H

40

39.2

REQUIRED

VERTICAL

RISE IN

FEET V

30

20

T

10

.8

0

2.5 5 7.5 10 12.5 15

.8

HORIZONTAL VENT RUN PLUS OFFSET IN FEET H

GD36

17.5 20

T

BGD36

17.5

T

20

The shaded area within the lines represents acceptable

values for HT and V

W415-0210 / R / 02.27.08

.

T

V

2

FIGURE 7

90°

H

90°

V

1

Example 1:

V1 = 3 ft

= 8 ft

V

2

VT =

H1 = 2.5 ft

H

H

H

HT = HR + HO = 4.5 + 5.4 = 9.9 ft

H

Formula 1: H

Formula 2: H

20.9 < 40

Since both formulas are met, this vent confi guration is

acceptable.

V1 +

V2 =

3 + 8 = 11 ft

= 2 ft

2

= H1 + H2 = 2.5 + 2 = 4.5 ft

R

= .

O

T

03(three 90° elbows - 90°) = .03(270° - 90°) = 5.4 ft

+ VT = 9.9 + 11 = 20.9 ft

< V

T

T

9.9 < 11

+ VT < 40 feet

T

1

Page 11

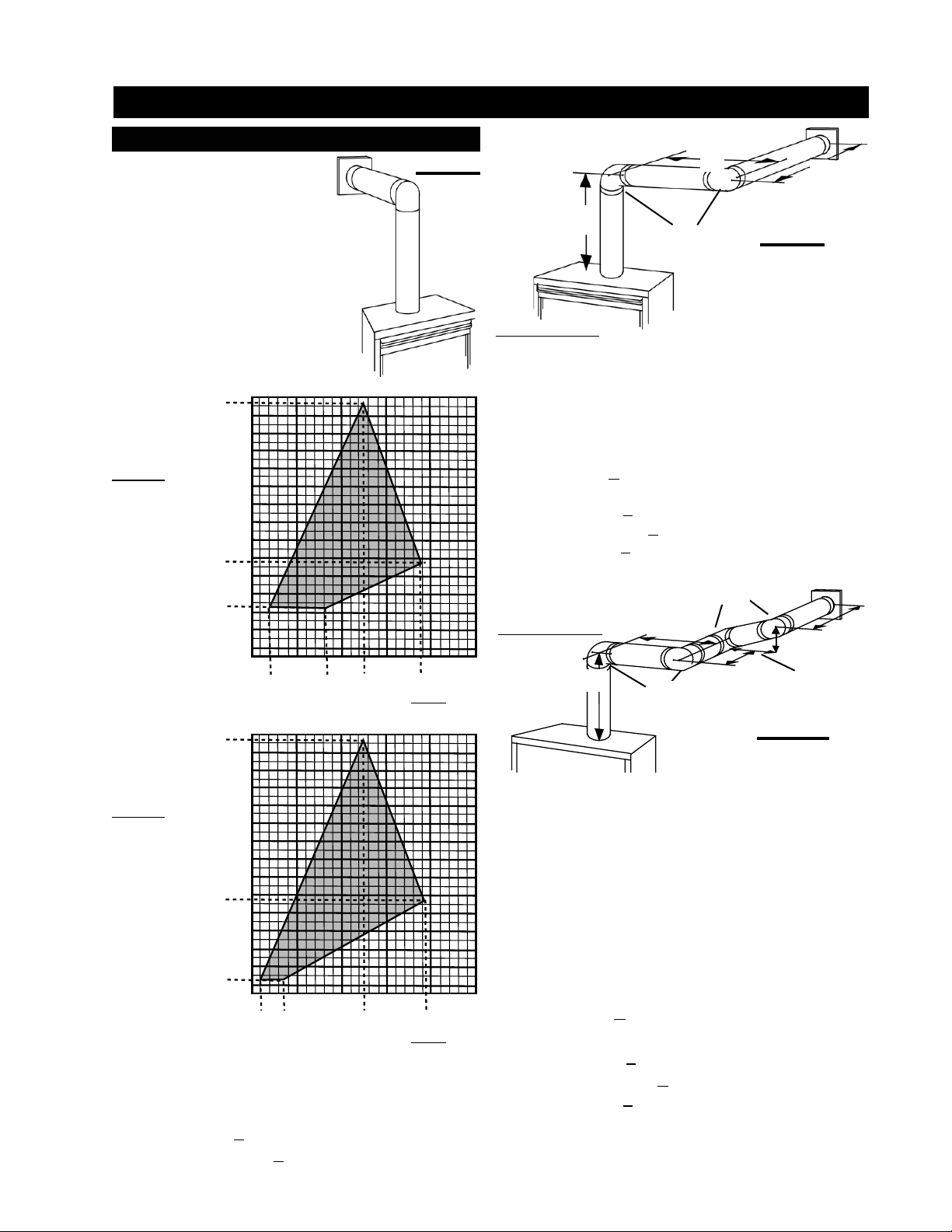

TOP EXIT / HORIZONTAL TERMINATION

11

(HT) > (VT)

FIGURE 8

FIGURE 8

Simple venting confi guration

(only one 90° elbow)

See graph to determine the required

vertical rise VT for the required

horizontal run HT .

GD36

147

150

REQUIRED

VERTICAL

RISE IN

INCHES V

HORIZONTAL VENT RUN PLUS OFFSET IN FEET H

T

147

100

57

50

24

0

150

51525

8.42

19.2512.5

T

BGD36

REQUIRED

VERTICAL

RISE IN

INCHES V

HORIZONTAL VENT RUN PLUS OFFSET IN FEET H

T

100

57

50

10

0

1 19.2512.5

51525

3.5

T

The shaded area within the lines represents acceptable

values for HT and V

.

T

For vent confi gurations requiring more than one 90° elbow the

following formulas apply:

Formula 1: HT < 4.2 V

T

Formula 2: HT + VT < 24.75 feet

H

V

1

1

90°

FIGURE 9

H

2

Example 2:

V

H1 = 3 ft

H2 = 5 ft

HR = H1 + H2 = 3 + 5 = 8 ft

HO = .03(two 90° elbows - 90°) = .03(180° - 90°) = 2.7 ft

HT = HR + HO = 8 + 2.7 = 10.7 ft

HT + VT =

Formula 1: HT < 4.2 V

4.2 V

= VT = 6 ft

1

10.7 + 6 =16.7

T

T

10.7 < 25.2

= 4.2 x 6 = 25.2 ft

Formula 2: HT + VT < 24.75 feet

16.7 < 24.75

Since both formulas are met, this vent configuration is

acceptable.

Example 3:

V

H

1

90°

90°

1

V

H

2

H

H

2

4

3

FIGURE 10

V

1

V

2

= 4 ft

= 1.5 ft

VT = V1 + V2 = 4 + 1.5 = 5.5 ft

H1 = 2 ft

= 1 ft

H

2

= 1 ft

H

3

= 1.5 ft

H

4

HR = H1 + H2 + H3 + H4 = 2 + 1 + 1 + 1. 5 = 5.5 ft

= .03(four 90° elbows - 90°) = .03(360° - 90°) = 8.1 ft

H

O

HT = HR + HO = 5.5 + 8.1 = 13.6 ft

+ VT = 13.6 + 5.5 = 19.1 ft

H

T

Formula 1: HT < 4.2 V

T

4.2 VT = 4.2 x 5.5 = 23.1 ft

13.6 < 23.1

Formula 2: HT + VT < 24.75 feet

19.1 < 24.75

Since both formulas are met, this vent confi guration is

acceptable.

W415-0210 / R / 02.27.08

Page 12

12

REAR EXIT / HORIZONTAL TERMINATION

(HT) < (VT)

Simple venting confi guration

(only two 90° elbows)

FIGURE 11

See graph to determine the required vertical rise VT for the

required horizontal run H

REQUIRED

VERTICAL

RISE IN

FEET V

T

HORIZONTAL VENT RUN PLUS OFFSET IN FEET H

The shaded area within the lines represents acceptable

values for HT and V

For vent confi gurations requiring more than two 90° elbows

the following formulas apply:

Formula 1: HT < V

Formula 2: HT + VT < 40 feet

T

.

T

T

Example 4:

90°

H

V

2

1

FIGURE 12

H

90°

H

2

V

1

90°

V

1

V

2

V

T

H1 = 3 ft

H

2

H

3

HR = H1 + H2 + H3 = 3 + 2 + 1.5 = 6.5 ft

H

O

= .03(90 + 90 + 90 + 90 - 90) = 8.1 ft

HT = HR + HO = 6.5 + 8.1 = 14.6 ft

H

T

Formula 1: H

T

Formula 2: H

29.6 < 40

Since both formulas are met, this vent confi guration is

acceptable.

= 9 ft

= 6 ft

=

V1 +

V2 =

9 + 6 = 15 ft

= 2 ft

= 1.5 ft

= .03(four 90° elbows - 90°)

+ VT = 14.6 + 15 = 29.6 ft

< V

T

T

14.6 < 15

+ VT < 40 feet

T

3

90°

W415-0210 / R / 02.27.08

Page 13

REAR EXIT / HORIZONTAL TERMINATION

13

(HT) > (VT)

FIGURE 13

Simple venting confi guration

(only two 90° elbows)

See graph to determine the required vertical rise VT for the

required horizontal run H

150

147

REQUIRED

VERTICAL

RISE IN

INCHES V

T

100

66

50

12

0

HORIZONTAL VENT RUN PLUS OFFSET IN FEET H

The shaded area within the lines represents acceptable

values for H

and V

T

For vent confi gurations requiring more than two 90° elbows

the following formulas apply:

Formula 1: HT < 3.5V

Formula 2: HT + VT < 24.75 feet

T

51525

3.5 19.2512.5

1

T

.

T

T

Example 5:

90°

45°

H

H

3

4

V

2

90°

H

90°

H

2

V

1

1

90°

FIGURE 14

V

1

V

2

V

T

H1 = 2 ft

H

2

H

3

H

4

HR = H1 + H2 + H3 + H4 = 2 + 1 + 1 + 1.5 = 5.5 ft

H

O

= .03(90 + 90 + 90 + 90 + 45 - 90) = 9.45 ft

HT = HR + HO = 5.5 + 9.45 = 14.95 ft

H

T

Formula 1: H

3.5VT =

Formula 2: H

20.45 < 24.75

Since both formulas are met, this vent confi guration is

acceptable.

= 4 ft

= 1.5 ft

=

V1 +

V2 =

4 + 1.5 = 5.5 ft

= 1 ft

= 1 ft

= 1.5 ft

= .03(four 90° elbows + one 45° elbow - 90°)

+ VT = 14.95 + 5.5 = 20.45 ft

< 3.5V

T

T

3.5 x

5.5 = 19.25 ft

14.95 < 19.25

+ VT < 24.75 feet

T

W415-0210 / R / 02.27.08

Page 14

14

TOP OR REAR EXIT VERTICAL TERMINATION

(HT) < (VT)

FIGURE 15

Simple venting confi gurations

See graph to determine the required vertical rise VT for the

required horizontal run HT.

REQUIRED

VERTICAL

RISE IN

FEET V

The shaded area within the lines represents acceptable

values for HT and V

For vent confi gurations requiring more than zero 90° elbow

(top exit) or one 90° elbow (rear exit), the following formulas

apply:

Formula 1: HT < V

Formula 2: HT + VT < 40 feet

T

HORIZONTAL VENT RUN PLUS OFFSET IN FEET H

.

T

T

T

Example 6:

FIGURE 16

V

1

90°

H

90°

H

V

2

1

V

3

2

90°

90°

V

1

V

2

V

3

V

T

H1 = 8 ft

H

2

HR = H1 + H2 = 8 + 2.5 = 10.5 ft

H

O

= .03(90 + 90 + 90 + 90 - 90) = 8.1 ft

HT = HR + HO = 10.5 + 8.1 = 18.6 ft

H

T

Formula 1: H

Formula 2: H

39.6 < 40

Since both formulas are met, this vent confi guration is

acceptable.

= 5 ft

= 6 ft

= 10 ft

=

V1 +

V2 +

V3=

5 + 6 + 10 = 21 ft

= 2.5 ft

= .03(four 90° elbows - 90°)

+ VT = 18.6 + 21 = 39.6 ft

< V

T

T

18.6 < 21

+ VT < 40 feet

T

W415-0210 / R / 02.27.08

Page 15

TOP OR REAR EXIT VERTICAL TERMINATION

(HT) > (VT)

Simple venting confi gurations

FIGURE 17

See graph to determine the required vertical rise VT for the

required horizontal run HT.

REQUIRED

VERTICAL

RISE IN

FEET V

T

HORIZONTAL VENT RUN PLUS OFFSET IN FEET H

The shaded area within the lines represents acceptable

values for HT and V

.

T

For vent confi gurations requiring more than two 90° elbow

(top exit) or one 90° elbow (rear exit), the following formulas

apply:

Formula 1: HT < 3V

T

Formula 2: HT + VT < 40 feet

90°

V

90°

H

1

1

V

2

H

V

3

2

90°

90°

FIGURE 18

Example 7:

V

1

V

2

V

3

V

T

H1 = 6 ft

H

2

HR = H1 + H2 = 6 + 2 = 8 ft

H

O

= .03(90 + 90 + 90 + 90 - 90) = 8.1 ft

HT = HR + HO = 8 + 8.1 = 16.1 ft

H

T

Formula 1: H

Since this formula is not met, this vent confi guration is

unacceptable.

Formula 2: H

20.6 < 40

Since only formula 2 is met, this vent confi guration is

unacceptable and a new fi replace location or

vent confi guration will need to be established

to satisfy both formulas.

= 2 ft

= 1 ft

= 1.5 ft

=

V1 +

V2 +

V3 =

2 + 1 + 1.5 = 4.5 ft

= 2 ft

= .03(four 90° elbows - 90°)

+ VT = 16.1 + 4.5 = 20.6 ft

< 3V

T

T

3VT =

3 x

4.5 = 13.5 ft

16.1 > 13.5

+ VT < 40 feet

T

90°

T

H

H

45°

2

H

V

1

1

3

90°

FIGURE 19

Example 8:

V

1

V

2

V

T

H1 = 1 ft

H

2

H3 = 10.75 ft

HR = H1 + H2 + H3 = 1 + 1 + 10.75 = 12.75 ft

H

O

= .03(90 + 90 + 90 + 45 - 90) = 6.75 ft

HT = HR + HO = 12.75 + 6.75 = 19.5 ft

H

T

Formula 1: H

3VT =

Formula 2: H

26 < 40

Since both formulas are met, this vent confi guration is

acceptable.

= 1.5 ft

= 5 ft

=

V1 +

V2 =

1.5 + 5 = 6.5 ft

= 1 ft

= .03(three 90° elbows + one 45° elbow - 90°)

+ VT = 19.5 + 6.5 = 26 ft

< 3V

T

T

3 x

6.5 = 19.5 ft

19.5 = 19.5

+ VT < 40 feet

T

V

90°

15

2

W415-0210 / R / 02.27.08

Page 16

16

PRE-INSTALLATION PREPARATION

FAILURE TO INSTALL THE CAP WILL CAUSE THE FIREPLACE TO FUNCTION IMPROPERLY AND

CAN CAUSE INJURY OR PROPERTY DAMAGE.

SEE TOP EXIT PREPARATION FOR DETAILS.

GD36

REAR EXIT REAR EXIT

Remove the baffl e from the back of the fi rebox by removing

the four screws. FIGURE 20a.

FIGURE 20a

BAFFLE

From inside the firebox,

insert the 4" flue pipe /

gasket assembly (provided)

through the rear of the

fi rebox. Secure the gasket

assembly to the rear and

top of the unit using 4 #8

x ¾ inch Hex Head Wildrill

screws supplied.

Do not overtighten. The gasket needs only to be snug

against the fi rebox. FIGURE 20b.

BAFFLE

SCREWS

FIGURE 20b

Before attaching elbows to the collars on the back

of the fi replace, 1½" will need to be trimmed off

the 4" collar.

Re-attach the baffl e to the back of the fi rebox using the four

screws. FIGURE 20a.

TOP EXIT

Remove the baffle from

the back of the firebox by

removing the four screws.

FIGURE 20.

1. Remove the 7" diameter

cap from the top of the

fi replace and re-secure it over

the 7" collar located at the

rear of the unit. Press fi rmly

on the cap while securing to ensure an airtight seal. Do not

damage the gasket.

2. Remove the plate covering the 4" diameter flue

opening (seen inside the top of the 7" diameter collar) and

discard. Try not to disturb the retaining ring or the gasket

beneath. Re-secure the ring and gasket using the screws

removed from the plate.

3. From inside the fi rebox, insert the 4" fl ue pipe / gasket

assembly through the heat shield and out through the

retaining ring. Secure the assembly to the rear and top of the

unit using 4 #8 x ¾" Hex Head Wildrill screws supplied. Do

not overtighten. The gasket needs only to be snug against

the fi rebox. FIGURE 21.

Re-attach the baffl e to the back of the fi rebox using the four

screws. FIGURE 20A.

FIGURE 21

BGD36

From inside the firebox,

insert the 4" flue pipe /

gasket assembly (provided)

through the rear of the

fi rebox. Secure the gasket

assembly to the rear and

top of the unit using 4 #8

x ¾ inch Hex Head Wildrill

screws supplied.

Do not overtighten. The gasket needs only to be snug

against the fi rebox. FIGURE 22.

FIGURE 22

Before attaching elbows to the collars on the

back of the fi replace, 1½" will need to be trimmed

off the 4" collar.

TOP EXIT

1. Remove the 7"

diameter cap from the top

of the fireplace and resecure it over the 7" collar

located at the rear of the

unit. Press fi rmly on the cap

while securing to ensure an

airtight seal. Do not damage

the gasket.

2. Remove the plate covering the 4" diameter fl ue

opening (seen inside the top of the 7" diameter collar) and

discard. Try not to disturb the retaining ring or the gasket

beneath. Re-secure the ring and gasket using the screws

removed from the plate.

3. From inside the fi rebox, insert the 4" fl ue pipe /

gasket assembly through the heat shield and out through

the retaining ring. Secure the assembly to the rear and

top of the unit using 4 #8 x ¾" Hex Head Wildrill screws

supplied. Do not overtighten. The gasket needs only to

be snug against the fi rebox. FIGURE 23.

FIGURE 23

W415-0210 / R / 02.27.08

Page 17

INSTALLATION

WALL AND CEILING PROTECTION

For optimum performance it is recommended that all horizontal runs have a minimum 1" rise per foot using fl exible

venting. For safe and proper operation of the fi replace, follow the venting instructions exactly.

HORIZONTAL INSTALLATION

GD36 FIRESTOP SLEEVE ASSEMBLY

1. Assemble the two halves of the vent sleeve by aligning the holes that come

together to make a rectangular shape (lip to the outside). Secure using 6 of the

screws supplied in the manual baggie.

NOTE: SCREWS NOT REQUIRED IN TWO BLIND HOLES. See Figure 24.

2. Fit the fi restop spacer into one end of the vent sleeve and secure through

the aligned holes on the top, bottom, and sides with the remaining 5 screws

supplied.

If fl exible venting is to be used remove the rigid fi restop spacer. The remaining

hole is sized for fl exible venting.

This application occurs when venting through an exterior wall. Having

determined the air terminal location, cut and frame a hole in the

exterior wall 9 7/8" wide by 11 3/8" high to accommodate the fi restop

sleeve assembly.

NOTE: THE FIRESTOP SLEEVE ASSEMBLY MUST BE INSTALLED

WITH THE 2" CLEARANCE TO THE TOP.

The length of the vent shield may be cut shorter for combustible

walls that are less than 8 1/2" thick but the vent shield must extend

the full depth of the combustible wall.

1. Insert the fi restop sleeve assembly into the wall, mark the wall

depth and trim the vent sleeve to suit. The screws that secure the

vent sleeve may need to be repositioned to ensure a rigid assembly

is maintained. Figure 25.

2. Apply a bead of caulking (not supplied) to the inside surface of the

fi restop fl ange and secure the assembly to the wall. (Ensure that the

rectangular shaped assembly is installed

to maintain 2" from the top of the vent).

Figure 26.

3. Once the vent pipe is installed in it's fi nal

position, apply high temperature sealant

W573-0002 (not supplied) between the pipe

and the fi restop.

NOTE: DO NOT FILL THE CAVITY

BETWEEN THE PIPE AND THE

VENT SLEEVE WITH ANY TYPE OF

MATERIAL.

CAULKING

FLANGE

FIRESTOP

SLEEVE

ASSEMBLY

VENT

SHIELD

TOP

2”

1”

11

3/8

9

”

7/8

FIRESTOP

SPACER

1”

”

DETERMINE

THE

CORRECT

HEIGHT

BLIND

HOLES

FIGURE 24

VENT

SLEEVE

FIGURE 25

17

FIGURE 26

W415-0210 / R / 02.27.08

Page 18

18

FIRESTOP

UNDERSIDE OF JOIST

9

1

/2”

9

1

/2”

SHIELD

VENT

PIPE

COLLAR

VENT PIPE

SHIELD

CAULKING

VENT PIPE

SHIELD

BGD36 FIRESTOP ASSEMBLY

Having determined the correct height for the air terminal location, cut and frame a hole in the exterior wall 9 7/8" wide by 11

3/8" high to accommodate the fi restop assembly. Dry fi t the fi restop assembly before proceeding to ensure the brackets on

the rear surface fi t within the horizontal framing.

The fi restop spacer and shield do not limit the thickness of a wall. For wall construction when using less than 2" x 6" framing

the shield must be cut to suit.

As an alternative to framing, the vent pipe/liner can be enclosed in the wall using

Napoleon® vent sleeve VS47KT.

NOTE: THE FIRESTOP ASSEMBLY MUST BE

INSTALLED WITH THE VENT SHIELD TO THE TOP.

The length of the vent shield may be cut shorter for

combustible walls that are less than 8 1/2" thick but in

these cases the vent shield must extend the full depth of

the combustible wall.

1. Apply a bead of caulking (not supplied) around the

outer edge of the inside surface of the fi restop assembly,

fi t the fi restop assembly to the hole and secure using the

4 screws W570-0026 (supplied in your manual baggie).

2. Once the vent pipe liner is installed in its fi nal position, apply high temperature

sealant W573-0002 (not supplied) between the pipe / liner, and the fi restop.

This restricts cold air from being drawn into the room or around the fi replace.

NOTE: DO NOT FILL THE CAVITY BETWEEN THE PIPE / LINER, FIRESTOP

SLEEVE, AND THE FRAME WITH ANY TYPE OF MATERIAL.

FIGURE 27

VERTICAL INSTALLATION

This application occurs when venting through a roof. Installation kits for various roof pitches are available from your Napoleon®

dealer. See Accessories to order the specifi c kit required.

FIGURE 28

fi replace. Ensure that both spacer and shield maintain the required clearance to combustibles. Once

the vent pipe is installed in its fi nal position, apply sealant

between the pipe and the fi restop assembly.

3. In the attic, slide the vent pipe collar down to cover

up the open end of the shield and tighten. This will prevent

any materials, such as insulation, from fi lling up the 1" air

space around the pipe.

1. Determine the air terminal location, cut and frame a 9½" square opening in the ceiling and the roof

to provide the minimum clearance between the vent pipe and any combustible material. Try to center

the vent pipe location midway between two joists to prevent having to cut them. Use a plumb bob to

line up the center of the openings.

Do not fi ll this space with any type of material.

A vent pipe shield will prevent any materials such as insulation, from fi lling

up the 1" air space around the pipe. Nail headers between the joist for extra

support.

2. Apply a bead of caulking (not supplied) to the framework or to the Wolf

Steel vent pipe shield plate or equivalent (in the case of a fi nished ceiling), and secure over the

opening in the ceiling. A fi restop must be placed on the bottom of each framed opening in a roof

or ceiling that the venting system passes through. Apply a bead of caulking all around and place a

fi restop spacer over the vent shield to restrict cold air from being drawn into the room or around the

W415-0210 / R / 02.27.08

FIGURE 29

FIGURE 30

Page 19

FIGURE 31

ELBOW

USING FLEXIBLE VENT COMPONENTS

For safe and proper operation of the fi replace, follow the

venting instructions exactly.

All 4" fl exible vent pipe and 7" fl exible vent pipe joints

may be sealed using high temperature sealant W573-0002

SPACERS

!

WARNING

Do not allow the 4" flexible vent pipe

to bunch up on horizontal or vertical

runs and elbows. Keep it pulled

tight. A 1 1/4” air gap between the 4"

and 7" flexible vent pipes all around

is required for safe operation. A

spacer is required at the start, middle

and end of each elbow to ensure this

gap is maintained. Spacers are

attached to the 4" flexible vent pipe

at predetermined intervals to

maintain a 1-1/4” air gap to the 7"

flexible vent pipe. These spacers

must not be removed.

(not supplied) or the high temperature sealant W573-0002

Mill Pac (not supplied). However, the high temperature

sealant W573-0007 Mill Pac (not supplied) must be used

on the joint connecting the 4" fl exible vent and the exhaust

fl ue collar.

Use only approved fl exible vent pipe kits marked:

“Wolf Steel Approved Venting” as

identifi ed by the stamp only on the

7” fl exible vent pipe.

Six inches (6”) is the minimum bend radius allowed for the

7” fl exible vent pipe.

19

HORIZONTAL AIR TERMINAL INSTALLATION

1. Stretch the 4" fl exible vent pipe to the required length taking into

account the additional length needed for the fi nished wall surface.

Slip the vent pipe a minimum of 2" over the inner sleeve of the air

terminal and secure with 3 #8 screws. Apply a heavy bead of the high

temperature sealant W573-0007 (not supplied).

NOTE: If using pipe clamps to connect vent components, 3

screws must also be used to ensure the connection cannot slip

off.

2. Using the 7" fl exible vent pipe, slide over the outer combustion

air sleeve of the air terminal and secure with 3 #8 screws. Seal using

high temperature sealant W573-0002 (not supplied).

3. Insert the vent pipes through the fi restop maintaining the required

clearance to combustibles. Holding the air terminal (lettering in an

upright, readable position), secure to the exterior wall and make weather

tight by sealing with caulking (not supplied).

4. If more vent pipe needs to be used to reach the fi replace, couple them

together as illustrated. The vent system must be supported approximately

every 3 feet for both vertical and horizontal runs. Use noncombustible

strapping to maintain the minimum 1" clearance to combustibles.

The air terminal mounting plate may be recessed into the exterior wall

or siding by 1½", the depth of the return fl ange.

FIGURE 32

CAUTION -

ATTEN TI

HOT

ON-

CHAUD

#10x2"

SCREWS

HIGH

TEMPERATURE

SEALANT

7” FLEXIBLE

VENT PIPE

CAULKING

4" FLEXIBLE

2" OVERLAP

HIGH TEMPERATURE

#8 X 1/2”

SELF DRILLING

SCREWS AND

WASHERS

4” COUPLER

4”

FLEXIBLE

VENT PIPE

VENT PIPE

7" FLEXIBLE

VENT PIPE

SEALANT

FIGURE 33

7” COUPLER

7” FLEXIBLE

VENT PIPE

W415-0210 / R / 02.27.08

Page 20

20

VERTICAL AIR TERMINAL INSTALLATION

1. Fasten the roof support to the roof using the screws

provided. The roof support is optional. In this case the

venting is to be adequately supported using either

an alternate method suitable to the authority having

jurisdiction or the optional roof support. Figure 34.

2. Stretch the 4" fl exible vent pipe to the required

length. Slip the 4" fl exible vent pipe a minimum of 2”

over the inner pipe of the air terminal connector and

secure with 3 #8 screws. Seal using a heavy bead of

high temperature sealant W573-0007 (not supplied).

ROOF SUPPORT

Figure 35.

NOTE: If using pipe clamps to connect vent components, 3 screws must also be

used to ensure the connection cannot slip off.

3. Repeat using the 7" fl exible vent pipe, using a heavy bead of high temperature sealant

W573-0002 (not supplied). Figure 35.

4. Thread the air terminal connector / vent pipe assembly down through the roof. The air terminal must be located vertically

and plumb. Attach the air terminal connector to the roof support, ensuring that the top of the air terminal is 16” above the

highest point that it penetrates the roof. Figure 34. DO NOT CLAMP THE FLEXIBLE VENT PIPE.

5. Remove nails from the shingles, above and to the sides of the chimney. Place the fl ashing over the air terminal connector

leaving a min. 3/4” of the air terminal connector showing above the top of the fl ashing. Slide the fl ashing underneath the sides

and upper edge of the shingles. Ensure that the air terminal connector is properly

centred within the fl ashing, giving a 3/4” margin all around. Fasten to the roof. Do

not nail through the lower portion of the fl ashing. Make weather-tight by sealing

with caulking. Where possible, cover the sides and top edges of the fl ashing with

roofi ng material. Figure 36.

6. Aligning the seams of the terminal and air terminal connector, place the terminal

over the air terminal connector making sure the vent pipe goes into the hole in the

terminal. Secure with the three screws provided. Figure 36.

7. Apply a heavy bead of weatherproof caulking 2" above the fl ashing. Note:

Maintain a minimum 2” space between the air inlet base and the storm collar. Install

the storm collar around the air terminal and slide down to the caulking. Tighten to

ensure that a weather-tight seal between the air terminal and the collar is achieved.

Figure 36.

8. If more vent pipe needs to be used to reach the fi replace, couple them together

as illustrated. The vent system must be supported approximately every 3 feet for

both vertical and horizontal runs. Use noncombustible strapping to maintain the

minimum 1" clearance to combustibles. Figure 33.

FIREPLACE VENT CONNECTION

1. Install the 4" fl exible vent pipe to the fi replace. Secure with 3 screws and fl at washers. Seal

the joint and screw holes using the high temperature sealant W573-0007 (not supplied).

2. Install the 7" fl exible vent pipe to the fi replace. Attach and seal the joints using the high

temperature sealant W573-0002 (not supplied).

FIGURE 34

TERMINAL

CONNECTOR

2”

COLLAR

#8 X 1/2”

DRILLING

SCREWS

AIR

STORM

SELF

INNER

PIPE

FIGURE 35

HIGH

TEMPERATURE

SEALANT

4” FLEXIBLE

VENT PIPE

7” FLEXIBLE

VENT PIPE

FIGURE 36

AIR INLET

BASE

CAULKI NG

WEATHER

SEALANT

FLASHING

2” OVERLAP

USING RIGID VENT COMPONENTS

The vent system must be supported approximately every 3 feet

for both vertical and horizontal runs. Use Napoleon® support

ring assembly W010-0370 or equivalent noncombustible

strapping to maintain the minimum clearance to combustibles

for both vertical and horizontal runs.

W415-0210 / R / 02.27.08

#10x2"

SCREWS

ATTENTION-CHAUD

CAUTION -

HOT

CAULKING

FIGURE 37

1"OVERLAP

7"RIGID

VENT

PIPE

4"RIGID

VENT

PIPE

FIGURE 38

HIGH TEMPERATURE

SEALANT

HI-TEMP

SEALANT

#8x1/2"

SELF DRILLING

SCREWS

Page 21

TELESCOPIC

SLEEVE

VENTING

AIR TERMINAL

20"

COUPLER

HORIZONTAL AIR TERMINAL INSTALLATION

1. Move the fi replace into position. Measure the vent length required between terminal and fi replace taking into account the

additional length needed for the fi nished wall surface and any 1¼" overlaps between venting components.

2. Apply high temperature sealant W573-0007 (not supplied) to the outer edge of the 4" inner collar of the fi replace. Attach

the fi rst 4" rigid vent pipe component and secure using 3 self tapping screws. Repeat using the 7" rigid vent pipe.

3. Holding the air terminal (lettering in an upright, readable position), insert into both vent pipes with a twisting motion to

ensure that both the terminal sleeves engage into the vent pipes and the sealant. Secure the terminal to the exterior wall

and make weather tight by sealing with caulking (not supplied).

The air terminal mounting plate may be recessed into the exterior wall or siding by 1½", the depth of the return fl ange.

EXTENDED HORIZONTAL AND CORNER AIR TERMINAL INSTALLATION

A 45° corner installation can have 0" rise between the fi replace combustion air collar and the air

terminal. In this case, vent lengths must be kept to a maximum of 24". For longer vent lengths, a

minimum vertical rise of 24" is required.

1. Follow the instructions for "Horizontal Air Terminal Installations".

FIGURE 39

2. Continue adding components alternating 4" rigid vent pipe and 7" rigid vent pipe. Ensure that all 4"

rigid vent pipe and elbows have suffi cient vent spacers attached and each component is sealed and

securely fastened to the one prior. Attach the 4" telescopic sleeve to the vent run. Repeat using a 7" telescopic

sleeve. Seal and secure as before. To facilitate completion, attach 4" and 7" couplers to the air terminal.

3. Install the air terminal. See item 3, Horizontal Air Terminal Installation. Extend the 4" telescopic sleeve; apply

sealant and connect to the air terminal assembly. Fasten with self tapping screws. Repeat using the 7" telescopic sleeve.

VERTICAL AIR TERMINAL INSTALLATION

NOTE: Before attaching elbows to the collars on the back of the fi replace, 1½" will need to be trimmed off the 4"

collar.

REAR VENT APPLICATION: Attach 4" and 7" elbows to the fi replace. Secure with 3 screws and

seal the joints and screw heads using high temperature sealant. Proceed to step 1 below.

TOP VENT APPLICATION:

1. Move the fi replace into position.

2. Fasten the roof support to the roof using the screws provided. FIGURE 33. The roof support is

optional. In this case the venting is to be adequately supported using either an alternate method

suitable to the authority having jurisdiction or the optional roof support.

AIR

TERMINAL

CONNECTOR

3. Apply high temperature sealant W573-0007 (not supplied) to the outer edge of the inner sleeve

of the air terminal. Slip a 4" diameter coupler a minimum of 2" over the sleeve and secure using

3 screws.

4. Apply high temperature sealant W573-0002 (not supplied) to the outer edge of the of the outside

sleeve of the air terminal connector. Slip a 7" diameter coupler over the sleeve and secure as

before. Trim the 7" coupler even with the 4" coupler end.

5. Thread the air terminal connector / vent pipe assembly down through the roof support and attach,

ensuring that a minimum 16" of air terminal connector will penetrate the roof when fastened.

If the attic space is tight, we recommend threading the Wolf Steel vent pipe collar or equivalent loosely

onto the air terminal connector / vent pipe assembly as it is passed through the attic. The air terminal

connector must be located vertically and plumb.

6. Remove nails from the shingles, above and to the sides of the chimney. Place the fl ashing over the air

terminal connector and slide it underneath the sides and upper edge of the shingles. Ensure that the air

terminal connector is properly centered within the fl ashing, giving a 3/4" margin all around. Fasten to the

roof. Do NOT nail through the lower portion of the fl ashing. Make weather-tight by sealing with caulking.

Where possible, cover the sides and top edges of the fl ashing with roofi ng material.

7. Apply a heavy bead of waterproof caulking 2" above the fl ashing. Note: Maintain a minimum 2" space between the air

inlet base and the storm collar. Install the storm collar around the air terminal and slide down to the caulking. Tighten to

ensure that a weather-tight seal between the air terminal connector and the collar is achieved.

8. Continue adding rigid venting sections, sealing and securing as above. Attach a 4" collapsed telescopic pipe to the last

section of rigid piping. Secure with screws and seal. Repeat using a 7" telescopic sleeve.

9. REAR VENT APPLICATION: Run a bead of high temperature sealant W573-0007 (not supplied) around the outside of

the 4" elbow. Pull the adjustable pipe a minimum 2" onto the elbow. Secure with 3 screws. Repeat with the 7" telescopic

sleeve.

TOP VENT APPLICATION: Run a bead of high temperature sealant W573-0007 (not supplied) around the outside of the

4" collar on the fi replace. Pull the adjustable pipe a minimum of 2" onto the collar. Secure with 3 screws. Repeat with the 7"

telescopic sleeve.

10. In the attic, slide the vent pipe collar down to cover up the open end of the shield and tighten. This will prevent any

materials, such as insulation, from fi lling up the 1" air space around the pipe.

INNER

PIPE

FIGURE 40

HIGH

TEMPERATURE

SEALANT

4” RIGID VENT

PIPE

7” RIGID VENT

PIPE

VENT

PIPE

COLLAR

VENT PIPE

SHIELD

FIGURE 41

W415-0210 / R / 02.27.08

21

Page 22

22

GD36 RESTRICTING VERTICAL VENTS

Vertical terminations running longer than 15 feet may display a very active fl ame. If this appearance is not desirable, the

vent exit must be restricted using restrictor plate kit, RP-KT.

This reduces the velocity of the exhaust gasses, slowing down the fl ame pattern and creating a more traditional appearance.

Specifi c instructions are included with the kit.

MOBILE HOME INSTALLATION

This appliance is certifi ed to be installed as an OEM (Original Equipment Manufacturer) installation in a manufactured

home or mobile home and must be installed in accordance with the manufacturer’s instructions and the Manufactured

Home Construction and Safety Standard, Title 24 CFR, Part 3280, in the United States or the Mobile Home Standard,

CAN/CSA Z240 MH Series, in Canada. This appliance is only for use with the type(s) of gas indicated on the rating plate.

A conversion kit is supplied with the mobile home appliance.

This Mobile/Manufactured Home Listed appliance comes factory equipped with a means to secure the unit. The fi replace is

equipped with two 1/4" diameter holes located in the front left and right corners of the base. For mobile home installations,

the fi replace must be fastened in place. Use #10 hex head screws, inserted through the holes in the base to secure. Always

turn off the pilot and the fuel supply at the source, prior to moving the mobile home. After moving the mobile home and prior

to lighting the fi replace, ensure that the logs are positioned correctly.

This appliance is certifi ed to be installed in an aftermarket permanently located, manufactured (mobile) home, where not

prohibited by local codes.

This fi replace is only for use with the type of gas indicated on the rating plate. This fi replace is not convertible for use with

other gases, unless a certifi ed kit is used.

Conversion Kits

The mobile home appliance is fi eld convertible between Natural Gas (NG) and Propane (LP).

To convert from one gas to another consult your Napoleon® dealer/distributor.

GAS INSTALLATION

Proceed once the vent installation is complete.

NOTE: All gas connections must be contained within the fi replace when complete.

1. Move the fi replace into position and secure to the fl oor through the 1/4" holes located at either side of the base.

2. The fi replace is designed to accept 3/8" gas supply line. The fi replace is equipped with a 3/8" manual shut-off valve.

3. Connect the gas supply in accordance to local codes. In the absence thereof,

install according to the National Installation Code.

MANUAL SHUT-OFF VALVE

4. When fl exing any gas line, support the gas valve so that the lines are not bent

L

or kinked.

5. Check for gas leaks by brushing on a soap and water solution.

DO NOT USE OPEN FLAME.

FIGURE 42

I

L

O

T

O

F

O

I

H

P

F

N

O

P

L

T

I

O

Purge all gas lines with the glass door open. Assure that a continuous gas fl ow is at the burner before closing the

door.

OPTIONAL WALL SWITCH INSTALLATION

For ease of accessibility, an optional remote wall switch may be installed in a

convenient location. A 20ft length of millivolt wire is connected to the gas valve

and wall switch. However, if a greater length is required route 2-strand (solid

core) millivolt wire through the electrical hole located at the bottom left side of

the unit. The recommended maximum lead length depends on wire size:

WIRE SIZE LENGTH

14 Gauge 100 Feet

16 Gauge 60 Feet

18 Gauge 40 Feet

Attach the two leads to terminals 1 and 3 located on the gas valve.

Do not connect either the wall switch, thermostat or gas valve directly to

110 volt electricity.

FIGURE 43

W415-0210 / R / 02.27.08

1

L

O

F

I

H

P

I

L

T

O

O

F

N

O

P

L

T

I

O

3

Page 23

GD36 FRAMING

It is best to frame your fi replace after it is positioned and the

vent system is installed. Frame to local building codes.

It is not necessary to install a hearth extension with this

fi replace system.

When roughing in the fireplace, raise the fireplace to

accommodate for the thickness of the fi nished fl oor materials,

i.e. tile, carpeting, hard wood, which if not planned for will

interfere with the opening of the lower access door and the

installation of many decorative fl ashing accessories.

Note: In order to avoid the possibility of exposed insulation

or vapour barrier coming in contact with the fi replace body,

it is recommended that the walls of the fi replace enclosure

be “fi nished” (ie: drywall/sheetrock), as you would fi nish any

other outside wall of a home. This will ensure that clearance

to combustibles is maintained within the cavity.

Combustible materials may be installed fl ush with the front of

the fi replace but must not cover any of the black face-areas

of the fi replace. Non-combustible material (brick, stone or

ceramic tile) may protrude in these areas.

Minimum clearance to combustible construction from

fi replace and vent surfaces:

Combustible Framing:

- 0" to stand-offs

- 1" to bottom and sides of the vent pipe*

- 2" to top of the vent pipe*

Combustible Finishing:

- 0" to rear

- 0" to front face top and sides

- 14 1/4" recessed depth

Rear Exit

- 42 1/4" to enclosure top from base of the unit

- 72" to ceiling from base of the unit

Top Exit

- 63" to enclosure top from base of the unit

- 72" to ceiling from base of the unit

* HORIZONTAL VENT SECTIONS - A minimum clearance of 1" at the

bottom and sides and 2" at the top of the vent pipe on all horizontal

runs to combustibles is required. Use fi restop spacer W010-1777

(supplied).

* VERTICAL VENT SECTIONS - A minimum of 1" all around the

vent pipe on all vertical runs to combustibles is required except

for clearances in fi replace enclosures. See "Minimum Enclosure

Clearances" section. Use firestop spacer W500-0096 (not

supplied).

23

TOP EXIT INSTALLATION

SHOWN

ENCLOSURE

TOP

FINISHING

MATERIAL

63” (TOP EXIT)

1

42

/4” (REAR EXIT)

141/2”

363/4"

"

/4

3

37

52"

MINIMUM FRAMING DIMENSIONS

!

WARNING

For top exit applications: Do not build into this area - it

14”

MINIMUM

11/2”

MAXIMUM

383/4”

31/2”

MAXIMUM

GAS

INLET

LOCATION

3”

51/2”

373/4”

FIGURE 44 a-d

OUTSIDE

CHASE

373/4"

Combustion protrusions such as mantels and shelves may occur at or after a

minimum distance of 2" away from the side of the fi replace. Thereafter, the

depth of any protrusions must be equal to or less than the distance from the

side of the fi replace up to a depth of 6", after which no greater clearance than

6" is required. This can be considered a side wall with no length boundary.

must be left clear to provide adequate clearance for the

vent. In this 14” wide area centred along the front of

the fireplace, no combustibles are allowed.

STAND-OFF ASSEMBLY

Bend and secure the top stand-off(s) as illustrated:

A

B

141/2"

FIGURE 45

1

14

/2"

373/4"

PROTRUSION

INSIDE

CHASE

2"

4"

6"

C

2"

4"

SIDE

WALL

W415-0210 / R / 02.27.08

Page 24

24

BGD36 FRAMING

It is best to frame your fi replace after it is positioned and the

vent system is installed. Frame to local building codes.

It is not necessary to install a hearth extension with this

fi replace system.

When roughing in the fireplace, raise the fireplace to

accommodate for the thickness of the fi nished fl oor materials,

i.e. tile, carpeting, hard wood, which if not planned for will

interfere with the opening of the lower access door and the

installation of many decorative fl ashing accessories.

Note: In order to avoid the possibility of exposed insulation

or vapour barrier coming in contact with the fi replace body,

it is recommended that the walls of the fi replace enclosure

be “fi nished” (ie: drywall/sheetrock), as you would fi nish any

other outside wall of a home. This will ensure that clearance

to combustibles is maintained within the cavity.

Combustible materials may be installed fl ush with the front of

the fi replace but must not cover any of the black face-areas

of the fi replace. Non-combustible material (brick, stone or

ceramic tile) may protrude in these areas.

Minimum clearance to combustible construction from

fi replace and vent surfaces:

Combustible Framing:

- 0" to stand-offs

- 1" to bottom and sides of the vent pipe*

- 2" to top of the vent pipe*

Combustible Finishing:

- 0" to rear

- 0" to front face top and sides

- 14 1/4" recessed depth

Rear Exit

- 39" to enclosure top from base of the unit

- 72" to ceiling from base of the unit

Top Exit

- 48 3/8" to enclosure top from base of the unit

- 72" to ceiling from base of the unit

* HORIZONTAL VENT SECTIONS - A minimum clearance of 1" at the

bottom and sides and 2" at the top of the vent pipe on all horizontal

runs to combustibles is required. Use fi restop spacer W010-1774

(supplied).

* VERTICAL VENT SECTIONS - A minimum of 1" all around the

vent pipe on all vertical runs to combustibles is required except

for clearances in fi replace enclosures. See "Minimum Enclosure

Clearances" section. Use firestop spacer W500-0096 (not

supplied).

TOP EXIT INSTALLATION

SHOWN

ENCLOSURE

FINISHING

MATERIAL

483/8” (TOP EXIT)

39” (REAR EXIT)

141/2”

363/4"

/2"

1

36

52"

MINIMUM FRAMING DIMENSIONS

!

WARNING

TOP

14”

MINIMUM

11/2”

MAXIMUM

353/4”

31/2”

MAXIMUM

GAS

INLET

LOCATION

3”

51/2”

361/2”

FIGURE 46 a-d

OUTSIDE

CHASE

Combustion protrusions such as mantels and shelves may occur at or after a

minimum distance of 2" away from the side of the fi replace. Thereafter, the

depth of any protrusions must be equal to or less than the distance from the

side of the fi replace up to a depth of 6", after which no greater clearance than

6" is required. This can be considered a side wall with no length boundary.

For top exit applications: Do not build into this area - it

must be left clear to provide adequate clearance for the

vent. In this 14” wide area centred along the front of

the fireplace, no combustibles are allowed.

141/2"

361/2"

14

1

/2"

361/2"

PROTRUSION

INSIDE

CHASE

2"

4"

6"

2"

4"

SIDE

WALL

W415-0210 / R / 02.27.08

Page 25

MINIMUM ENCLOSURE CLEARANCES

25

GD36

REAR EXIT ENCLOSURE

COMBUSTIBLE NON-COMBUSTIBLE

3

9

/4” MINIMUM

1

/4”

42

2”

The fi replace requires a minimum enclosure height of

42 1/4". For temperature requirements, the enclosure space

around and above the fi replace must be left unobstructed.

BRICK

0” IF

NON-COMBUSTIBLE

FINISHING IS USED

2”

1”

24” MINIMUM

PLUS RISE*

SUCH AS BRICK

AND STONE.

FIGURE 47

BGD36

REAR EXIT ENCLOSURE

COMBUSTIBLE NON-COMBUSTIBLE

6” MINIMUM

39”

2”

The fi replace requires a minimum enclosure height of 39".

For temperature requirements, the enclosure space around

and above the fi replace must be left unobstructed.

BRICK

0” IF

NON-COMBUSTIBLE

FINISHING IS USED

2”

1”

24” MINIMUM

PLUS RISE*

SUCH AS BRICK

AND STONE.

FIGURE 49

2” MINIMUM

30”

63”

TOP EXIT ENCLOSURE

COMBUSTIBLE NON-COMBUSTIBLE

BRICK

2”

1”

11/2”

57” MINIMUM

PLUS RISE*

0” IF

NON-COMBUSTIBLE

FINISHING IS USED

SUCH AS BRICK

AND STONE.

TOP EXIT ENCLOSURE

COMBUSTIBLE NON-COMBUSTIBLE

BRICK

48

2” MINIMUM

16”

3

/8”

11/2”

2”

2”

1”

42

The fi replace requires a minimum enclosure height of

48 3/8". For temperature requirements, the enclosure space

around and above the fi replace must be left unobstructed.

0” IF

NON-COMBUSTIBLE

FINISHING IS USED

SUCH AS BRICK

AND STONE.

3

/8” MINIMUM

PLUS RISE*

FIGURE 50

FIGURE 48

2”

The fi replace requires a minimum enclosure height of 63".

For temperature requirements, the enclosure space around

and above the fi replace must be left unobstructed.

* See chart on Page 6

W415-0210 / R / 02.27.08

Page 26

26

MINIMUM MANTEL CLEARANCES

Combustible Mantel clearance can vary according to the Mantel depth. Use the graph to help evaluate the clearance needed.

These same requirements apply to any combustibles protruding on either side of the fi replace.

FIGURES 51 a&b

12

10

M

H

A

E

8

N

I

T

G

6

E

H

4

L

T

2

0

24681012

MANTEL DEPTH

BGD36 NAILING TAB INSTALLATION

1. Attach the nailing tabs to the corner posts

using the 2 sheet metal screws supplied. Secure through the centre of the

top and bottom slots in the nailing tab

and then through the existing holes in

the corner posts.

If there are no existing holes, follow

these instructions:

Position the nailing tab so that the front

face is offset with the front edge of

the corner post (approx. ½"). Centre

the nailing tab vertically on the corner

post.

Figure 53a.

Drill through the centre of the top and

bottom slots in the nailing tab. Secure

using the two sheet metal screws supplied. This allows the nailing tab to slide

back and forth for desired framing.

Figure 53b.

2. To determine the fi nal location of the nailing tab

you must fi rst determine the thickness of your fi nishing

material (i.e. drywall). This will determine the dimension from

the front edge of the corner post to the nailing tab. Once the

nailing tab is in the desired location, drill through the centre

hole of the nailing tab. Secure with a sheet metal screw*.

Figure 53c.

* Additional set screws may be installed.

W415-0210 / R / 02.27.08

FIGURE 52

NAILING

TAB

TOP OF

FIREPLACE

A

8" MANTEL

6"

8"

6"

4"

CORNER POST

NAILING TAB

TOP SLOT

FINISHING

MATERIAL

B

4"

2"

2"

C

CENTRE HOLE

FIGURES 53 a-c

Page 27

DOOR LATCH

HOOD

UPPER

LOUVRE

FINISHING

DOOR REMOVAL AND INSTALLATION

DOOR OPENING AND CLOSING: The upper louvres must be removed to allow the door to

HOOD

UPPER

LOUVRE

DOOR LATCH

1. Place the door frame face down careful not to scratch the paint.

2. Center the gasketed glass inside the door frame with the thick side of the gasket

facing up.

3. Bend the glass retainers located along the edge of the door frame over the gasket

holding the glass in place. Careful not to break the glass.

NOTE: Care must be taken when removing and disposing of any broken glass

or damaged components. Be sure to vacuum up any broken glass from inside

the fi replace before operation.

be opened or closed. To access the lower door latch, open the valve control door. Release

the top and bottom door latches, located at the right side of the door.

Optional plated door trim, and arched door facia are available at your local Napoleon

dealer.

FIGURE 54

NOTE: The protective wrap on plated parts is best removed when the assembly is at room

temperature but this can be improved if the assembly is warmed, using a hair dryer or similar

heat source.

DOOR GLASS REPLACEMENT

GASKET

GLASS

RETAINER

27

GLASS

DOOR FRAME

FIGURE 56 a-c

B

C

FIGURE 55

LOUVRE INSTALLATION

A

CLIPS

A

FLANGE

CENTRE

SLOT

SLOT

TAB

B

C

HINGE

CLIP

SLOT

HOOD

Attach the hood by pressing the

top fl ange into the clips along the

top of the louvre opening. Secure

using a screw through the centre

slot.

UPPER LOUVRES

Insert the louvre tabs into the slots

located at the top left and right

corners of the unit.

LOWER LOUVRES

Insert the hinge clips into the slots

located at the bottom left and right

corners of the unit.

To remove the louvres, pull the

back tabs of the clips forward,

while pushing the louvre assembly back. Lift the clip.

W415-0210 / R / 02.27.08

Page 28

28

LOG PLACEMENT

PHAZERTM logs and glowing embers exclusive to Napoleon

Fireplaces, provide a unique and realistic glowing effect that is

different in every installation. Take the time to carefully position

the glowing embers for a maximum glowing effect.

Log colours

the colours will become more uniform as colour pigments burn

in during the heat activated curing process.

may vary. During the initial use of the fi replace,

FIGURE 57 a-f

4. Position the base end of the center log (#5) against the

middle grate post with the other end of the log resting in the

pocket of the left crossover log.

SIDEVIEW

TAB

2. Move the two small logs (#2 & #3) into position, lining up

the studs located on the burner with the holes on the bottom

of the logs. Ensure that the small logs sit fl at on the burner.

1. Place the back log (#1) onto the log

support tray and in front of the tabs. The

tabs maintain an air space between the log

and fi rebox back to facilitate combustion air

fl ow. Ensure that the back of the log rests

against the brackets on the back wall of the

fi rebox.

5. Place the bottom of the right crossover log (#6) against