Napoleon Fireplaces EPA 1450 User Manual

1

INSTALLER: LEAVE THIS MANUAL WITH THE APPLIANCE

CONSUMER: RETAIN THIS MANUAL FOR FUTURE REFERENCE

INSTALLATION

AND OPERATION

INSTRUCTIONS

CERTIFIED UNDER U.S. ENVIRONMENTAL PROTECTION AGENCY (E.P.A.) JULY 1990 AND THE OREGON DEPARTMENT OF ENVIRONMENTAL QUALITY (D.E.Q.) PARTICULATE

EMISSION STANDARDS BY E.E.M.C THESE STOVES HAVE BEEN TESTED AND LISTED BY INTERTEK TESTING SERVICES TO STANDARDS: CSA B366.2, ULC S627, UL 1482. MODEL

EPA 1100, 1100L, 1100C, 1150,

1400, 1400L, 1450 & 1900

FREE STANDING MODELS

1100 HAS BEEN TESTED AND LISTED FOR INSTALLATION IN MOBILE HOMES.

EPI 1101, 1402

INSERT MODEL

SAFETY INFORMATION

!

WARNING

If the information in these instructions is not followed exactly, a fire or

explosion may result causing property damage, personal injury or death.

Improper installation, adjustment, alteration, service or maintenance can

cause injury or property damage, bodily injury or even death. Please read

entire manual before you install and use your fireplace.

This fireplace has not been tested with an unvented gas log set. To reduce

risk of fire or injury, do not install an unvented gas log set into the fireplace.

- This fireplace can be very hot when burning.

- Combustible materials such as firewood, wet clothing, etc. placed too close can catch fire.

- Children and pets must be kept from touching the fireplace when it is hot.

- The chimney must be sound and free of cracks. Before installing this unit, contact the local

building or fire authority and follow their guidelines.

- Operate only with the door tightly closed.

- Burn wood behind the log retainer directly on the firebricks.

- Do not use an elevated grate or otherwise raise the fire.

- At least 14 square inches of outside air must be admitted to the room or directly to the unit

through a 4” diameter pipe.

- This fireplace is designed to burn natural wood only. Higher efficiencies and lower emissions

generally result when burning air dried seasoned hardwoods, as compared to softwoods or

to green or freshly cut hardwoods.

- Do not start a fire with chemicals or fluids such as gasoline, engine oil, etc.

- Do not burn treated wood, coal, charcoal, colored paper, cardboard, solvents or garbage.

- Do not let the fireplace become hot enough for any part to glow red.

- KEEP THE STOVE TOP TEMPERATURE BELOW 700°F (371°C). Attempts to acheieve

heat output rates that exceed design specifications can result in steel distortion and

damage.

$10.00

Wolf Steel Ltd., 24 Napoleon Rd., Barrie, ON L4M 4Y8 Canada s (705)721-1212 s fax(705)722-6031

www.napoleonreplaces.com s ask@napoleon.on.ca

W415-0512 / D / 07.16.08

W415-0512 / D / 07.16.08

2

TABLE of CONTENTS

PG 2-4 INTRODUCTION

Warranty

General Information

Care of Plated & Enamelled Parts

Care of Glass

5-6 INSTALLATION

Installing the Legs

Alcove Installation

Stove Installation

Chimney Connection

Adding Chimney Sections

Outside Air

Wall Pass-through

6-7 MOBILE HOME

Venting

Outside Air

7-8 FIREPLACE INSERT

Prior to Installation

Installation into a Masonry Fireplace

Installation into a Factory Built Fireplace

8-9 OPTIONAL BLOWER

Stove Models

Leg Models

Insert Models

1101 Blower Service and Replacement

1402 Blower Service and Replacement

1150 Blower Installation

1150 Features

10-11 FINISHING

Brick Installation

Ornamental Trivet Installation

Door and Handles Installation

Pedestal Trim Installation

Optional Ash Drawer Kit

11-13

OPERATION

Achieving Proper Draft

Fire Extinguishers and Smoke Detectors

Fuel Loading and Burn Cycle

Flash Fire

Extended Fire

Smoking

Ash Removal Procedures

13-14

MAINTENANCE

Creosote Formation and Removal

Runaway or Chimney Fire

Gasket Replacement

Door Removal

14 WOOD PILE MAINTENANCE

15-17 REPLACEMENTS

Ordering Replacement Parts

Replacement Parts

Accessories

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE

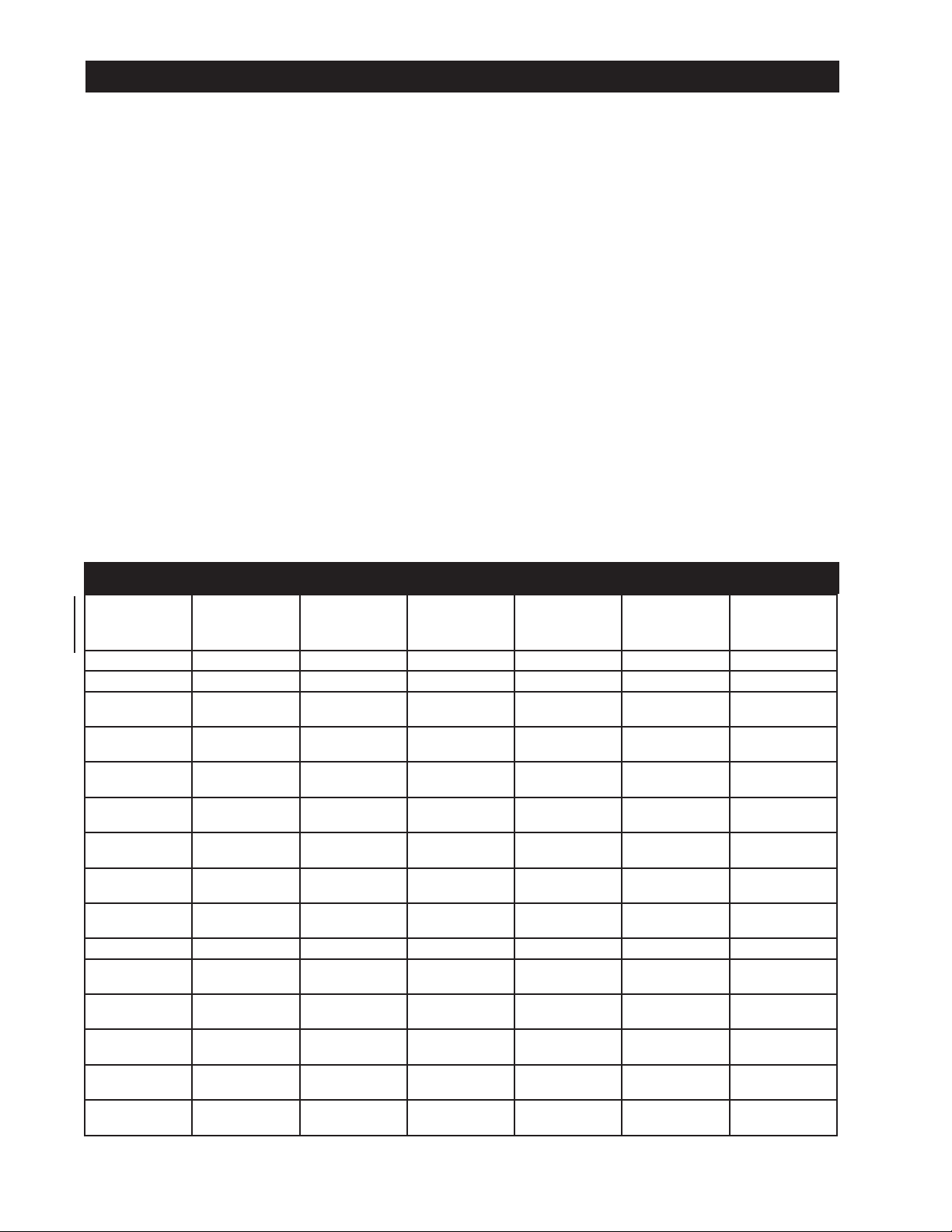

Specifi cations MODEL 1100,

1100C &

1100L

WIDTH 25 1/2” (65 cm) 29 3/8”. (74.6 cm) 28” (71 cm) 25 1/2” (65 cm) 25 1/2” (65 cm) 25 1/2” (65 cm)

DEPTH 22 1/2” (57 cm) 23 3/16” (58.8 cm) 27” (69 cm) 27” (69 cm) 27” (69 cm) 31 1/2” (80 cm)

DEPTH BEHIND

FLASHING

FLUE CENTER-

LINE TO REAR

FLUE CENTER-

LINE TO SIDE

HEIGHT PEDES-

TAL MODEL

HEIGHT CAST

MODEL

HEIGHT LEG

MODEL

CHAMBER

(D.W.H)

CAPACITY 1.7f

APPROX. AREA

HEATED*

HEAT OUTPUT

(HIGH BURN) **

DURATION LOW

FIRE*

WEIGHT w/o

BRICKS

WEIGHT OF

BRICKS

W415-0512 / D / 07.16.08

6 1/2” (16.51 cm) 6 3/4” (17.1 cm) 11” (27.94 cm) 7 1/2” (19.05 cm) 5 1/2” (13.97 cm) 7 1/2“ (19.05 cm)

12 3/4” (32.39 cm) 14 11/16” (37.39

33 1/4” (84 cm) 36 1/2” (92.7 cm) 21 1/4” (54 cm) 33 1/4” (84 cm) 21 1/4” (54 cm) 33 1/4” (84 cm)

28 1/2” (72 cm)

32” (81 cm) 1.7f

13 1/2x18x12”

(34x46x31 cm)

t3

(0.05m3) 1.7ft3 (0.05m3) 2.25ft3 (0.06m3) 2.25ft3 (0.06m3) 3.0ft3 (0.08 m3)

600-1500 f

(56-139 m2)

55,000 BTU 55,000 BTU 55,000 BTU 70,000 BTU 70,000 BTU 85,000 BTU

7 Hours 7 Hours 7 Hours 9 Hours 9 Hours 12 Hours

215 lbs (97.5 kg) 280 lbs (127 kg) 185 lbs (83.9 kg) 250 lbs (113 kg) 250 lbs (113 kg) 285 lbs (129 kg)

110 lbs (54.4 kg) 110 lbs (54.4 kg) 110 lbs (54.4 kg) 145 lbs (65 kg) 145 lbs (65 kg) 114 lbs (52 kg)

*FIGURES WILL VARY CONSIDERABLY WITH INDIVIDUAL CONDITIONS.

** WOLF STEEL LTD. ESTIMATED REALISTIC BTU/H WITH HARDWOOD LOGS AND REGULAR REFUELING.

NOTE: Changes, other than editorial, are denoted by a vertical line in the margin.

MODEL 1150 MODEL 1101

cm)

t3

(0.05m3) 32” (81 cm)

13 1/2x18x12”

(34x46x31 cm)

t2

600-1500 f

(56-139 m2)

t2

MODEL 1400,

(INSERT)

16 1/2 to 21” (42 to

54 cm)

14” (35.56 cm) 12 3/4” (32.39 cm) 12 3/4” (32.39 cm) 12 3/4” (32.39 cm)

13 1/2x18x12”

(34x46x31 cm)

600-1500 f

(56-139 m2)

1400L, & 1450

t2

18x18x12”

(46x46x31 cm)

1000-2000 f

(93-186 m2)

t2

MODEL 1402

(INSERT)

14 1/2” (37 cm)

18x18x12”

(46x46x31 cm)

1000-2000 f

(93-186 m2)

t2

MODEL 1900

22 1/2x18x12”

(57x46x31 cm)

1000-3500 f

(93-325 m2)

t2

NAPOLEON® products are manufactured under the strict Standard of the World Recognized

ISO 9001 : 2000 Quality Assurance Certifi cate.

NAPOLEON® products are designed with superior components and materials, assembled by trained craftsmen

who take great pride in their work. The complete fi replace is thoroughly inspected by a qualifi ed technician before

packaging to ensure that you, the customer, receives the quality product that you expect from NAPOLEON®.

NAPOLEON® WOOD FIREPLACE PRESIDENT’S LIFETIME LIMITED WARRANTY

The following materials and workmanship in your new NAPOLEON® wood fi replace are warranted against

defects for as long as you own the fi replace. This covers: combustion chamber, heat exchanger, ceramic glass

(thermal breakage only), gold plated parts against tarnishing, porcelainized enamelled components, aluminum

extrusion trims ashdrawer, and cast iron castings.

Electrical (110V) components and wearable parts such as blowers, thermal switch, switches, wiring, fi rebrick,

gasketing, stainless steel baffl e retainer, and high temperature paint are covered and NAPOLEON® will provide

replacement parts free of charge during the fi rst year of the limited warranty.

Labour related to warranty repair is covered free of charge during the fi rst year. Repair work, however, requires

the prior approval of an authorized company offi cial. Labour costs to the account of NAPOLEON® are based on a

predetermined rate schedule and any repair work must be done through an authorized NAPOLEON® dealer.

3

CONDITIONS AND LIMITATIONS

NAPOLEON® warrants its products against manufacturing defects to the original purchaser only -- i.e., the individual or legal entity

(registered customer) whose name appears on the warranty registration card fi led with NAPOLEON® -- provided that the purchase

was made through an authorized NAPOLEON® dealer and is subject to the following conditions and limitations:

This factory warranty is non-transferable and may not be extended whatsoever by any of our representatives.

The wood fi replace must be installed by an authorized service technician or contractor. Installation must be done in accordance with

the installation instructions included with the product and all local and national building and fi re codes.

This limited warranty does not cover damages caused by misuse, lack of maintenance, accident, alterations, abuse or neglect and

parts installed from other manufacturers will nullify this warranty.

This limited warranty further does not cover any scratches, dents, corrosion or discolouring caused by excessive heat, abrasive and

chemical cleaners nor chipping on porcelain enamel parts, nor any venting components used in the installation of the fi replace.

In the fi rst year only, this warranty extends to the repair or replacement of warranted parts which are defective in material or workman-

ship provided that the product has been operated in accordance with the operation instructions and under normal conditions.

After the fi rst year, with respect to the President’s Limited Lifetime Warranty, NAPOLEON® may, at its discretion, fully discharge all

obligations with respect to this warranty by refunding to the original warranted purchaser the wholesale price of any warranted but

defective part(s).

After the fi rst year, NAPOLEON® will not be responsible for installation, labour or any other costs or expenses related to the reinstal-

lation of a warranted part, and such expenses are not covered by this warranty.

Notwithstanding any provisions contained in the President’s Limited Lifetime Warranty, NAPOLEON’S responsibility under this warranty is defi ned as above and it shall not in any event extend to any incidental, consequential or indirect damages.

This warranty defi nes the obligations and liability of NAPOLEON® with respect to the NAPOLEON® wood fi replace and any other

warranties expressed or implied with respect to this product, its components or accessories are excluded.

NAPOLEON® neither assumes, nor authorizes any third party to assume, on its behalf, any other liabilities with respect to the sale

of this product. NAPOLEON® will not be responsible for: over-fi ring, downdrafts, spillage caused by environmental conditions such

as rooftops, buildings, nearby trees, hills, mountains, inadequate vents or ventilation, excessive venting confi gurations, insuffi cient

makeup air, or negative air pressures which may or may not be caused by mechanical systems such as exhaust fans, furnaces, clothes

dryers, etc.

Any damages to fi replace, combustion chamber, heat exchanger, brass trim or other component due to water, weather damage, long

periods of dampness, condensation, damaging chemicals or cleaners will not be the responsibility of NAPOLEON®.

The bill of sale or copy will be required together with a serial number and a model number when making any warranty claims from

your authorized dealer. The warranty registration card must be returned within fourteen days to register the warranty.

NAPOLEON® reserves the right to have its representative inspect any product or part thereof prior to honouring any warranty

claim.

ALL SPECIFICA TIONS AND DESIGNS ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE DUE TO ON-GOING PRODUCT IMPROVEMENTS. NAPOLEON® IS A REGISTERED

TRADEMARK OF WOLF STEEL LTD. PATENTS U.S. 5.303.693.801 - CAN. 2.073.411, 2.082.915. © WOLF STEEL LTD.

W415-0512 / D / 07.16.08

4

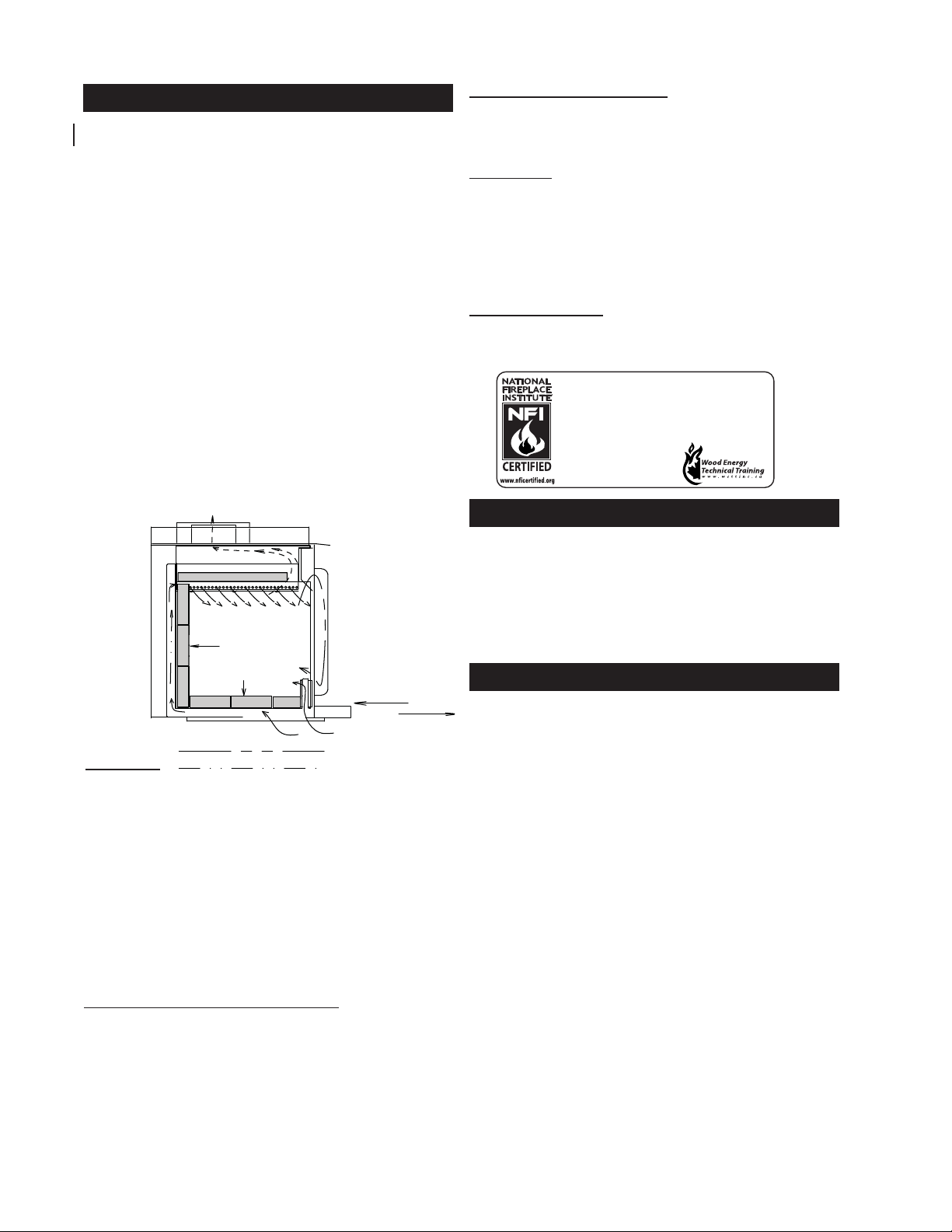

HOT SECONDARY AIR

FIBRE BRICKS

RÉFRACTAIRES

2 SIDES,

BACK

& BOTTOM

SECONDARY AIR

PRIMARY AIR

FLUE GLASS

CERAMIC

GLASS

DRAFT CONTROL

COMBUSTION AIR

INTAKE

OPEN

CLOSED

DÉFLECTEUR EN FIBRE

We suggest that our woodburning hearth products

be installed and serviced by professionals who are

certified in the U.S. by the National Fireplace

Institue® (NFI) as NFI Woodburning Specialists or

who are certified in Canada by

Wood Energy Technical

Training (WETT).

GENERAL INFORMATION

Except for their different depths, models 1100, 1150, 1400,

1900,

1450 and the fi replace inserts 1101, and 1402 are

identical and use the same burning principles. They were

specifi cally designed over many months of research to meet

the 1990 U.S.A. EPA particulate emission standards and

have been extensively tested in Canadian and American

laboratories. This system is the most effi cient, simple and

trouble free we know and works as follows:

Combustion air enters through two holes in the bottom covered by a single draft control. Air from the front hole goes up

on either side of the door into a preheating airwash located

across the top and then down the window to feed the fi re

and also to ensure that the glass remains clean. Air from

this hole also feeds directly into the combustion chamber at

hearth level. Secondary air from the rear hole travels up the

back in the secondary air housing to the manifold located at

the top and shoots out laterally to oxidize the gases below

the smoke exit.

The combustion chamber is lined with high temperature fi re-

brick on 2 sides, the back and across the bottom, with a layer

of fi bre baffl es at the top to maintain a high temperature in the

combustion chamber so that gases mixing with the preheated

air from the secondary air manifold tube are easily ignited and

burned. The stove sides and back are shielded to direct the

heat upwards and forwards into the room.

PEDESTAL MODELS ONLY

If the outside air feature of the stove is utilized, you should

never experience a shortage of combustion air. If you choose

not to utilize outside air and experience draft or smoking

problems, you may need to open a door or window.

WARNING: Burning your unit with the ash dump

door open or ajar creates a fire hazard that may

result in discoloration to the gold plated door,

internal damage to the stove or a house and/or

chimney fire.

To ensure that the ash dump door is tightly closed, allow the

door to snap shut dislodging anything (ashes or pieces of

coal) that may be stuck in the opening.

LEG MODELS ONLY

If you experience smoking problems, you may need to open

a door, a window or otherwise provide some method of supplying combustion air to the unit.

CARE OF ALL PLA TED AND ENAMELED P AR TS

FIGURE 1

Be sure to provide suffi cient combustion air. There are many

other appliances in your home competing for air such as: a

kitchen range hood, forced air heating devices or a bathroom

exhaust fan.

Do not connect this unit to a chimney flue serving another

appliance.

Expansion / contraction noises during heating up and cooling

down cycles are normal and to be expected.

After extended periods of non-operation such as following a

vacation or a warm weather season, the fi replace may emit

a slight odour for a few hours. This is caused by dust particles on the fi rebox burning off. Open a window to suffi ciently

ventilate the room.

CALIFORNIA PROP 65 WARNING:

Use of this product may produce smoke which

contains chemicals known to the State of California

to cause cancer, birth defects, or other reproductive harm.

W415-0512 / D / 07.16.08

Do not use abrasive cleaners to clean these parts. Buff lightly

with a clean dry cloth.

Prolonged high temperature burning with the door ajar may

cause a permanent rainbowing effect on the lower edge of

a gold plated door.

Porcelain enamel components must be handled with care.

The baked-on fi nish is “glass”. If struck, it will chip. T ouch-up

paint is available through your Napoleon dealer.

CARE OF GLASS

If the glass is not kept clean permanent discolouration and / or

blemishes may result. Normally a hot fi re will clean the glass.

The most common reasons for dirty glass include; not using

suffi cient fuel to get the stove thoroughly hot, using green or

wet wood, closing the draft so far that there is insuffi cient air

for complete combustion. If it is necessary to clean the glass,

use a soft cloth with a nonabrasive cleaner.

DO NOT CLEAN GLASS WHEN HOT!

The glass is very strong but do not let burning fuel rest against

it and always close the door gently. If the glass should ever

crack while the fi re is burning, do not open the door until the

fi re is out and do not operate the stove again until the glass has

been replaced with a new 5mm thick plate of ceramic glass,

available from your Napoleon / Wolf Steel Ltd. dealer.

DO NOT SUBSTITUTE MATERIALS.

TO REMOVE THE GLASS: When the unit is cool, open

the door and remove the screws and brackets holding the

glass in place. Remove all broken glass. Wrap the edges

of the new glass with a U-shaped strip of fi berglass gas-

ket, covering 1/4” on each side. Place the glass with the

fi berglass gasket in position and replace the brackets and

screws. When fi nished, you should be able to move the

glass slightly, horizontally and vertically.

9"

6"

14"

23"

ALCOVE

4 FOOT

MAX

STOVE INSTALLATION

BACK WALL

SIDE WALL

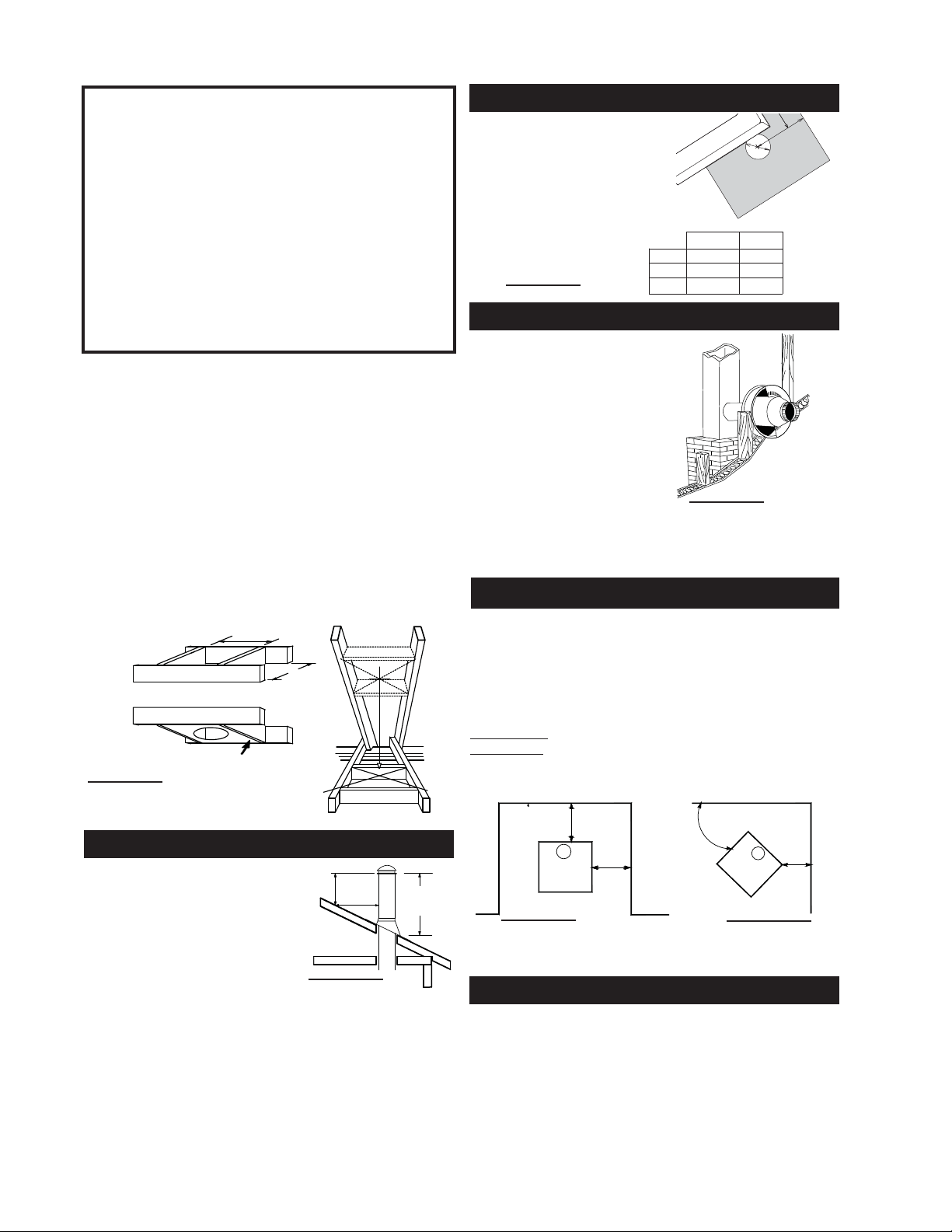

B

A

A 12” (305 mm) 12” (305 mm) 22” (560 mm)

B 10” (254 mm) 12” (305 mm) 12” (305 mm)

C 6” (152 mm) 6” (152 mm) 8” (205 mm)

1100/1100L/1150 1400/1400L 1900

A 10” (254 mm) 10” (254 mm) 22” (560 mm)

B 6” (152 mm) 6” (152 mm) 12” (305 mm)

C 2” (50 mm) 4” (102 mm) 8” (205 mm)

1100/1100L 1400/1400L 1900

C

BACK WALL

45°

SIDE WALL

8"

8"

18"

8"

5

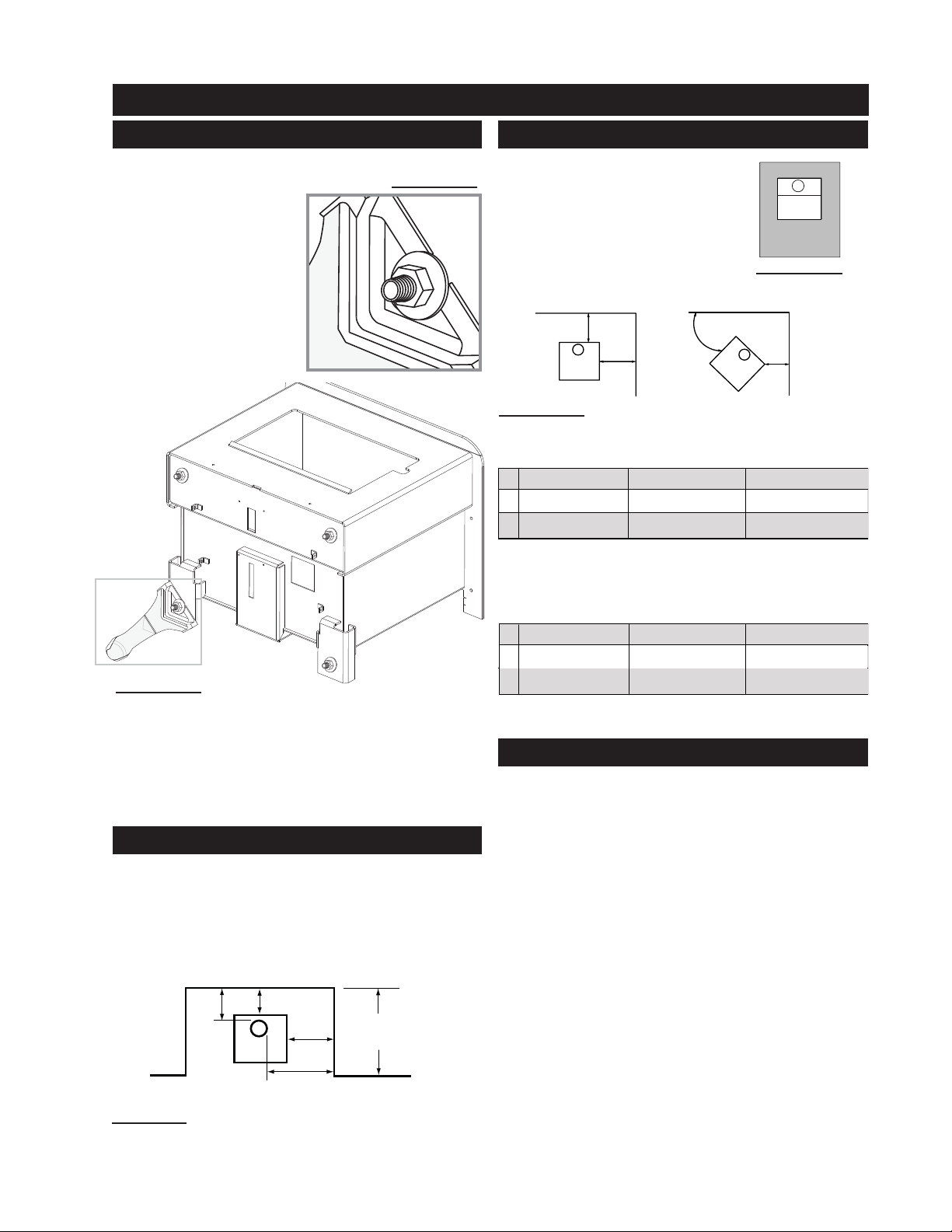

INSTALLING THE LEGS

To avoid being damaged during shipping, the stove has

been bolted to the pallet and

must be unbolted before the

stove can be installed.

1. Remove the 4 nuts and wash-

ers from the underside of the

pallet.

2. Lift the stove up and away

from the pallet to clear the

threaded studs sticking through

the pallet. Place the stove on its

back onto a protective surface

such as a carpet or blanket

to avoid scratches during leg

installation.

FIGURE 2A

STOVE INSTALLATION

If the stove is to be installed on a

combustible fl oor, it must be placed

on an approved non-combustible

hearth pad, that extends 8” (200mm)

beyond the stove sides and back, and

18” (455mm) to the front. It must be

installed with a minimum height of

7’ between the stove base and the

ceiling.

FIGURE 4B

SINGLE WALL CHIMNEY CONNECTOR*

* CLEARANCES CAN BE REDUCED WITH SHIELDING ACCEPTABLE TO LOCAL

AUTHORITIES. REDUCED INSTALLATION MUST COMPY WITH NFPA 211 or

CAN/CSA-B365.

DOUBLE WALL CHIMNEY CONNECTOR

FIGURE 4A

FIGURE 2B

3. Remove the four additional nuts from each of the four

studs.

4. Use four of the nuts and washers removed above to install

the legs as illustrated in FIGURES 2a & 2b.

5. Lift the stove up and gently set down on all four legs. Do

not pivot unit up on its legs, as this could result in damage

to the legs.

ALCOVE INSTALLATION

Model 1 100 only may be installed, using a listed double wall

connector, such as Security DL6 in Canada, the Simpson

Duravent Plus DVL in the USA or an equivalent double wall

connector, into an alcove having a depth of no more than 4

feet and a height of at least 7 feet. The minimum clearances

are as shown in FIGURE 3.

FIGURE 3

NOTE:CLEARANCES ARE UNABLE TO BE REDUCED FOR THE 1150 BY USING

DOUBLE WALL PIPE.

CHIMNEY CONNECTION

A 6” diameter single wall stove pipe, used to connect the

stove to the chimney , must be installed with the crimped end

toward the stove. This will ensure that the moisture which

condenses from the burning wood will fl ow back into the fi re

chamber. Each joint in the stove pipe must be secured with

at least three sheet metal screws.

This room heater must be connected to:

1) A chimney complying with the requirements for Type HT

chimneys in the Standard for Chimneys, Factory-Built, Residential Type and Building Heating Appliance UL 103, or

2) A code-approved masonry chimney with a fl ue liner.

Vent the stove into a masonry chimney or an approved, insulated solid-fuel stainless-steel chimney with as short and

straight a length of six-inch (150mm) diameter smoke pipe

as possible. Connection to a masonry chimney must be by a

metal or masonry thimble cemented in place.

An insulated stainless steel chimney must be supported at

the ceiling or roof and its installation must comply with its

manufacturer’s instructions.

W415-0512 / D / 07.16.08

6

PEDESTAL BASE

4.5"

PEDESTAL BASE

FLOOR AREA BELOW STOVE

B"

A (in.) B(in.)

1100 8 5/8" 9 3/4"

1400 11 1/8" 9 3/4"

1900 14 7/8" 9 3/4"

BACK WALL

6"

SIDE WALL

10"

2"

BACK WALL

45 °

SIDE WAL

L

This is the preferred

method of passing a

flue pipe through a

combustible wall to a

masonry chimney.

THE TOTAL HORIZONTAL VENT LENGTH

SHOULD NOT EXCEED 40% OF THE CHIMNEY

HEIGHT ABOVE THE STOVE.

All horizontal smoke pipe must slope

slightly upwards a minimum of 1/4” per

foot (6mm/0.3m) and all connections must

be tight and secured by three sheet metal

screws equally spaced.

An uninsulated smoke pipe shall not pass

through an attic, roof space, closet or

similar concealed space, or through a fl oor,

ceiling, wall or partition, or any combustible

construction.

DO NOT USE ANY MAKESHIFT MATERIALS DURING INSTALLATION.

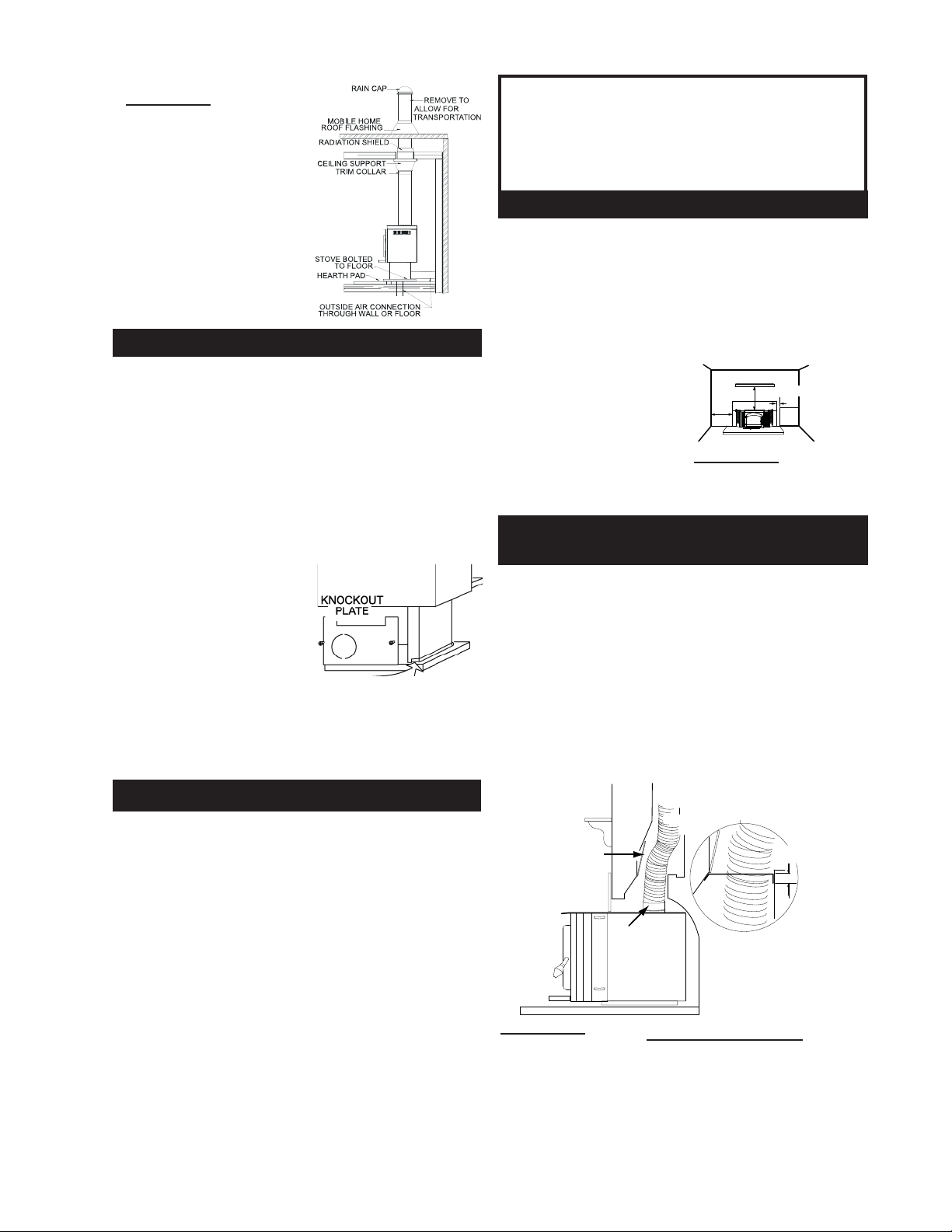

1. Move the stove into position with the fl ue centered, mid-

point between two joists to prevent having to cut them. Use

a plumb bob to line up the centre.

2. Cut and frame an opening in the roof to provide a 2”

clearance between the outside of the chimney and any

combustible material.

DO NOT FILL THIS SPACE WITH ANY TYPE OF

MATERIAL.

Nail headers between the joist for extra support. Firestop

spacers must be placed on the bottom of each framed opening

in any fl oor or ceiling that the chimney passes through.

3. Hold a plumb bob from the underside of the roof to determine where the opening in the roof should be. Cut and frame

the roof opening to maintain proper 2” clearances.

A

A

FIRESTOP SPACER UNDERSIDE OF JOIST

FIGURE 5

HEADERS

PEDESTAL MODELS OUTSIDE AIR

If possible connect the air intake

at the pedestal’s back or bottom

to the outside with a 4 inch

(100mm) diameter fresh air kit

available at your Napoleon/Wolf

Steel Ltd. dealer. Follow detailed

instructions under “Mobile Home

Outside Air”.

FIGURE 7

WALL PASS-THROUGH

If possible, design the installation so that the connector does

not pass through a combustible

wall. If during your installation you

must pass through a combustible

wall, check with your building

inspector before you begin. Also

check with the chimney connector manufacturer for any specifi c

requirements.

Consult with your dealer regarding

FIGURE 8

special connection components

available for use for wall pass-throughs.

Use only parts that have been tested and listed for use in a

wall pass-through.

MOBILE HOME

PEDESTAL MODEL 1100 IS APPROVED FOR INSTALLATION IN MOBILE HOMES IN BOTH CANADA AND THE

UNITED STATES.

1150 IS NOT APPROVED FOR MOBILE HOMES.

PEDESTAL MODEL 1400 IS APPROVED FOR INSTALLATION IN MOBILE HOMES IN THE UNITED STATES

ONLY.

WARNING: DO NOT INSTALL IN SLEEPING ROOM.

CAUTION: THE STRUCTURAL INTEGRITY OF THE MOBILE HOME FLOOR, WALL AND CEILING/ROOF MUST

BE MAINTAINED.

ADDING CHIMNEY SECTIONS

Add chimney sections, according

to the manufacturers installation instructions, securely , to the required

height. The chimney must extend,

at least, 3 feet above its point of

contact with the roof and at least

2 feet higher than any wall, roof or

building within 10 feet. FIGURE 6.

If your chimney system is enclosed within the attic area, a

rafter radiation shield is required.

W415-0512 / D / 07.16.08

2 FT

MIN.

10 FT

FIGURE 6

3 FT

MIN.

FIGURE 9

FIGURE 10

The pedestal base must be fi rmly bolted to the fl oor with 1/4

inch lag bolts. Minimum clearances to combustibles are as

shown in FIGURE 9.

VENTING

Connect the stove to a chimney system using a listed double

wall connector. Use a chimney system listed to ULC S629 in

Canada or UL103HT in the U.S.A.

The chimney must be installed in accordance with the manufacturer’s instructions. Use only specifi ed components with

no substitutions. The chimney and pipe must extend at least

8 feet above the stove and 3 feet above the highest point of

the roof. Install a rain cap at the top which will not impede the

smoke exhaust. The chimney must be supported at the ceiling

or roof so that its weight does not rest on the stove.

7

FIGURE 11

It must be installed between ceiling joists, with radiation shield

and roof flashing, so that the

structural strength, insulation and

waterproof qualities of the home

are not lessened. Seal with silicone to maintain a vapour barrier

at the chimney and outside air

pipe penetrations.

OUTSIDE AIR

Connection from the stove’s air intake to the outside is mandatory in mobile homes only , either through a hole in the wall to

line up with the knockout in the pedestal back, or through a

hole in the fl oor to line up with the hole in the pedestal base.

Use a fresh air kit. Secure the 4 inch diameter aluminum liner

by fl aring the end once it is inserted through the 4-1/2 inch

diameter hole in either the back or base of the pedestal. If the

air intake is through the fl oor, the hole in the pedestal back

must be covered with sheet metal to avoid cold air spillage

into the room. A cover plate is available from your Wolf Steel

Ltd. dealer. Avoid cutting away fl oor joists, wall studs, electrical

wires or plumbing. Seal around the outside pipe with insulation

to prevent drafts.

Attach the rear knockout plate

(located inside the ash pan for

shipping purposes).

If room air starvation occurs because the fresh air

intake is blocked with ice,

leaves, etc., or because

the stove door was left open, or due to a strong

exhaust fan operating etc., dangerous fumes and

smoke from the operating stove could be drawn

into the room.

FIREPLACE INSERT

Y our EPI 1 101 and 1402 insert fi rebox is the exact duplication

of the clean-burning technology found in all Napoleon EPA

certifi ed freestanding stoves and in particular that of the EPA

1 100 and 1400. External modifi cations have been made to al-

low its installation as a “functional fi replace insert” with a heat

circulating blower system and a means of enclosing the solid

fuel burning fi replace cavity for greater heating effi ciency.

The EPI 1101 insert must be installed into a solid fuel burning fi replace that is at least 16 1/2 to 21 inches deep, 28 1/2

inches wide and 21 1/2 inches high with an approved lined

chimney at least 15 feet high (4.6m).

Your EPI

solid fuel burning fi replace that is at least 14 inches deep 26

inches wide and 22 inches high with an approved lined chimney at least 15 feet high (4.6m). This minimum recess can

only be achieved if the opening height is suffi cient enough to

allow the connector to fi t under the noncombustible facing.

The fi replace and chimney must be constructed in accordance

with all national and local building code standards.

1402 fi replace insert must be installed only into a

HINT FOR INSTALLING PORCELAIN

ENAMEL INSERTS:

Ensure the base of the porcelain side panels

are protected from rubbing against the hearth

when sliding your insert into the masonry

fi replace.

PRIOR TO INSTALLATION

Clean all ashes out of the inside of the fi replace. Make

sure that the chimney and fi replace are free of cracks,

loose mortar, creosote deposits, blockage or other signs of

deterioration. If necessary, have any repair work done by a

qualifi ed professional before installing the insert.

Do NOT remove bricks or mortar from the fi replace. In case of

an outside air inlet or ash dump, fi ll with fi berglass insulation.

Adhere to minimum clearances as shown in FIGURE 12.

Do NOT place any combustible materials (furniture, fi rewood, etc.) within

48 inches in front or 36

inches at the side of the

insert.

Combustible material must

not protrude more that 1” to

the side of the insert or between the mantle and the

top of the insert.

FIGURE 12

17"*

28" TO MANTLE

1"*

COMBUSTIBLE

PROTRUDING

SIDE FACINGS

INSTALLATION INTO A MASONRY

FIREPLACE

1. Remove the fi replace damper or fasten it permanently

open.

* We recommend the following method of sealing off the

damper area around the liner.

2. *Measure the throat of the fi replace and mark this shape

on a piece of 24 gauge sheet metal (fl ue cover); cut a six-inch

(6.75”) hole to lie directly below the fi replace fl ue opening.

Allow two inches of material for a fl ange on all sides and cut

to these measurements. Bend down the fl anges. If you have

never done this before, it might be a good idea to make a

cardboard pattern and test it fi rst. Fasten this fl ue cover in

position as high as possible with two masonry screws per side

through the fl anges into the fi replace. FIGURE 13.

LISTED

CHIMNEY

LINER

DAMPER

REMOVED OR

FASTENED

OPEN

FLUE

CONNECTOR

FIGURE 13

In Canada: Install a listed 6 inch diameter fl exible stain-

less steel liner from the top of the chimney to the insert fl ue

collar. Attach a stainless steel liner connector or elbow to the

liner and insert onto the fl ue collar. Fasten with three screws.

Secure the top of the liner to the chimney cap using a liner

support and chimney fl ashing. Cap the top of the chimney

liner assembly using an approved rain cap.

MODEL 1402 Illustrated

FLUE COVER

INSTALLATION

2”

FLANGE

W415-0512 / D / 07.16.08

Loading...

Loading...