Page 1

INSTALLER : THESE INSTRUCTIONS MUST BE CONVEYED TO AND REMAIN WITH THE HOMEOWNER.

CERTIFIED UNDER U.S. ENVIRONMENTAL PROTECTION AGENCY (E.P.A.) JULY 1990 AND THE OREGON DEPARTMENT OF ENVIRONMENTAL QUALITY (D.E.Q.) PARTICULATE

EMISSION STANDARDS BY E.E.M.C. THESE STOVES HAVE BEEN TESTED AND LISTED BY WARNOCK HERSEY LTD. TO STANDARDS : UL 1482 / ULC-S627.

MODEL 1600C-1 HAS BEEN TESTED AND LISTED FOR INSTALLATION IN MOBILE HOMES.

INSTALLATION AND OPERATION INSTRUCTIONS FOR

LISTED SOLID FUEL BURNING SPACE HEATER

MODEL : 1600C-1

WARNING :

Please read this entire manual before you install and use your new room heater. Failure to follow

instructions may result in property damage, bodily injury, or even death.

If this stove is not properly installed, a house fire may result.

FOR YOUR SAFETY :

Follow the installation directions. This stove can be very hot when burning. Combustible materials such as firewood,

wet clothing, etc. placed too close can catch fire. Children and pets must be kept from touching the stove when it is

hot. The chimney must be sound and free of cracks. Before installing this unit, contact the local building or fire

authority and follow their guidelines.

Operate only with door tightly closed. The door must be kept closed during operation to prevent smoke, embers

from entering the room. Burn wood directly on cast grate supplied. Do not elevate the fire. An opening of at least 14

square inches (90 sq.cm.) of outside air must be admitted to the room. This stove is designed to burn natural wood

only. Higher efficiencies and lower emissions generally result when burning air dried seasoned hardwoods, as

compared to softwoods or too green or freshly cut hardwoods. Do not start a fire with chemicals or fluids such as

gasoline, engine oil, etc. Do not burn treated wood, coal, charcoal, coloured paper, cardboard, solvents or garbage

which tend to produce more pollution than wood. Do not let the stove become hot enough for any part to glow red.

KEEP THE STOVE TOP TEMPERATURE BELOW 700 °F (371 °C). Attempts to achieve heat output rates that

exceed stove design specifications can result in metal distortion and damage.

Fax : (705)722-6031

Wolf Steel Ltd., 24 Napoleon Rd.,

Barrie, ON., Canada L4M 4Y8 (705)721-1212

www.napoleonfireplaces.com

Email : ask@napoleon.on.ca

Document n°1178-1 ~ 02/12/2004

Page 2

NAPOLEON wood fireplaces are manufactured under the strict Standard of the World Recognized

ISO 9001 : 2000 Quality Assurance Certificate.

NAPOLEON products are designed with superior components and materials, assembled by trained craftsmen who take

great pride in their work. The complete fireplace is thoroughly inspected by a qualified technician before packaging to

ensure that you, the customer, receives the quality product that you expect from NAPOLEON.

NAPOLEON WOOD FIREPLACE PRESIDENT’S LIFETIME LIMITED WARRANTY

The following materials and workmanship in your new NAPOLEON wood fireplace are warranted against defects for

as long as you own the fireplace. This covers : combustion chamber, heat exchanger, ceramic glass (thermal

breakage only), porcelainized enamelled components, and cast iron castings.

Electrical (110V) components and wearable parts such as blowers, thermal switch, switches, wiring, firebrick, grate,

baffle, gasketing and high temperature paint are covered and NAPOLEON will provide replacement parts free of

charge during the first year of the limited warranty.

Labour related to warranty repair is covered free of charge during the first year. Repair work, however, requires the

prior approval of an authorized company official. Labour costs to the account of NAPOLEON are based on a

predetermined rate schedule and any repair work must be done through an authorized NAPOLEON dealer.

CONDITIONS AND LIMITATIONS

NAPOLEON warrants its products against manufacturing defects to the original purchaser only — i.e., the individual or legal entity

(registered customer) whose name appears on the warranty registration card filed with NAPOLEON — provided that the purchase

was made through an authorized NAPOLEON dealer and is subject to the following conditions and limitations.

This factory warranty is non-transferable and may not be extended whatsoever by any of our representatives.

The wood fireplace must be installed by an authorized service technician or contractor. Installation must be done in accordance

with the installation instructions included with the product and all local and national building and fire codes.

This limited warranty does not cover damages caused by misuse, lack of maintenance, accident, alterations, abuse or neglect

and parts installed from other manufacturers will nullify this warranty.

This limited warranty further does not cover any scratches, dents, corrosion or discolouring caused by excessive heat, abrasive

and chemical cleaners nor chipping on porcelain enamel parts, nor any venting components used in the installation of the

fireplace.

In the first year only, this warranty extends to the repair or replacement of warranted parts which are defective in material or

workmanship provided that the product has been operated in accordance with the operation instructions and under normal

conditions.

After the first year, with respect to the President’s Limited Lifetime Warranty, NAPOLEON may, at its discretion, fully discharge all

obligations with respect to this warranty by refunding to the original warranted purchaser the wholesale price of any warranted but

defective part(s).

After the first year, NAPOLEON will not be responsible for installation, labour or any other costs or expenses related to the

reinstallation of a warranted part, and such expenses are not covered by this warranty.

Notwithstanding any provisions contained in the President’s Limited Lifetime Warranty, NAPOLEON’S responsibility under this

warranty is defined as above and it shall not in any event extend to any incidental, consequential or indirect damages.

This warranty defines the obligations and liability of NAPOLEON with respect to the NAPOLEON wood fireplace and any other

warranties expressed or implied with respect to this product, its components or accessories are excluded.

NAPOLEON neither assumes, nor authorizes any third party to assume, on its behalf, any other liabilities with respect to the sale

of this product. NAPOLEON will not be responsible for : over-firing, downdrafts, spillage caused by environmental conditions such

as rooftops, buildings, nearby trees, hills, mountains, inadequate vents or ventilation, excessive venting configurations,

insufficient makeup air, or negative air pressures which may or may not be caused by mechanical systems such as exhaust fans,

furnaces, clothes dryers, etc.

Any damages to fireplace, combustion chamber, heat exchanger, brass trim or other component due to water, weather damage,

long periods of dampness, condensation, damaging chemicals or cleaners will not be the responsibility of NAPOLEON.

The bill of sale or copy will be required together with a serial number and a model number when making any warranty claims from

your authorized dealer. The warranty registration card must be returned within fourteen days to register the warranty.

NAPOLEON reserves the right to have its representative inspect any product or part thereof prior to honouring any warranty

claim.

ALL SPECIFICATIONS AND DESIGNS ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE DUE TO ON-GOING PRODUCT IMPROVEMENTS. NAPOLEON® IS A

REGISTERED TRADEMARK OF WOLF STEEL LTD. PATENTS U.S. 5.303.693.801 - CAN. 2.073.411, 2.082.915. © WOLF STEEL LTD.

2

Page 3

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE

TABLE of CONTENTS

INTRODUCTION p. 4

General information p. 4

Principal of operation p. 4

Care of glass p. 4

INSTALLATION p. 5

Alcove installation p. 6

Stove installation p. 6

INSTALLATION WHEN INSTALLED WITH

BLOWER KIT EP63 p. 6

Adding chimney sections p. 7

Outside air p. 7

Flue collar reversal p. 7

Ash fender installation p. 7

Wall pass-through p. 7

Heat shield installation p. 7

MOBILE HOME INSTALLATION p. 8

Venting p. 8

Outside air p. 8

113KT 1600C Adaptor Kit Intallation p. 8

OPERATING INSTRUCTIONS p. 9

When lit for the first time p. 9

Achieving proper draft p. 9

Fire extinguishers / smoke detectors p. 10

Fuel loading and burn cycle p. 10

EP63 OPTIONAL BLOWER KIT p. 10

Ash removal procedures p. 10

EP90-K OPTIONAL SCREEN KIT p. 10

WOOD PILE MAINTENANCE p. 11

STOVE MAINTENANCE p. 11

Creosote formation and removal p. 11

Runaway or chimney fire p. 11

ORDERING PROCEDURES p. 12

)

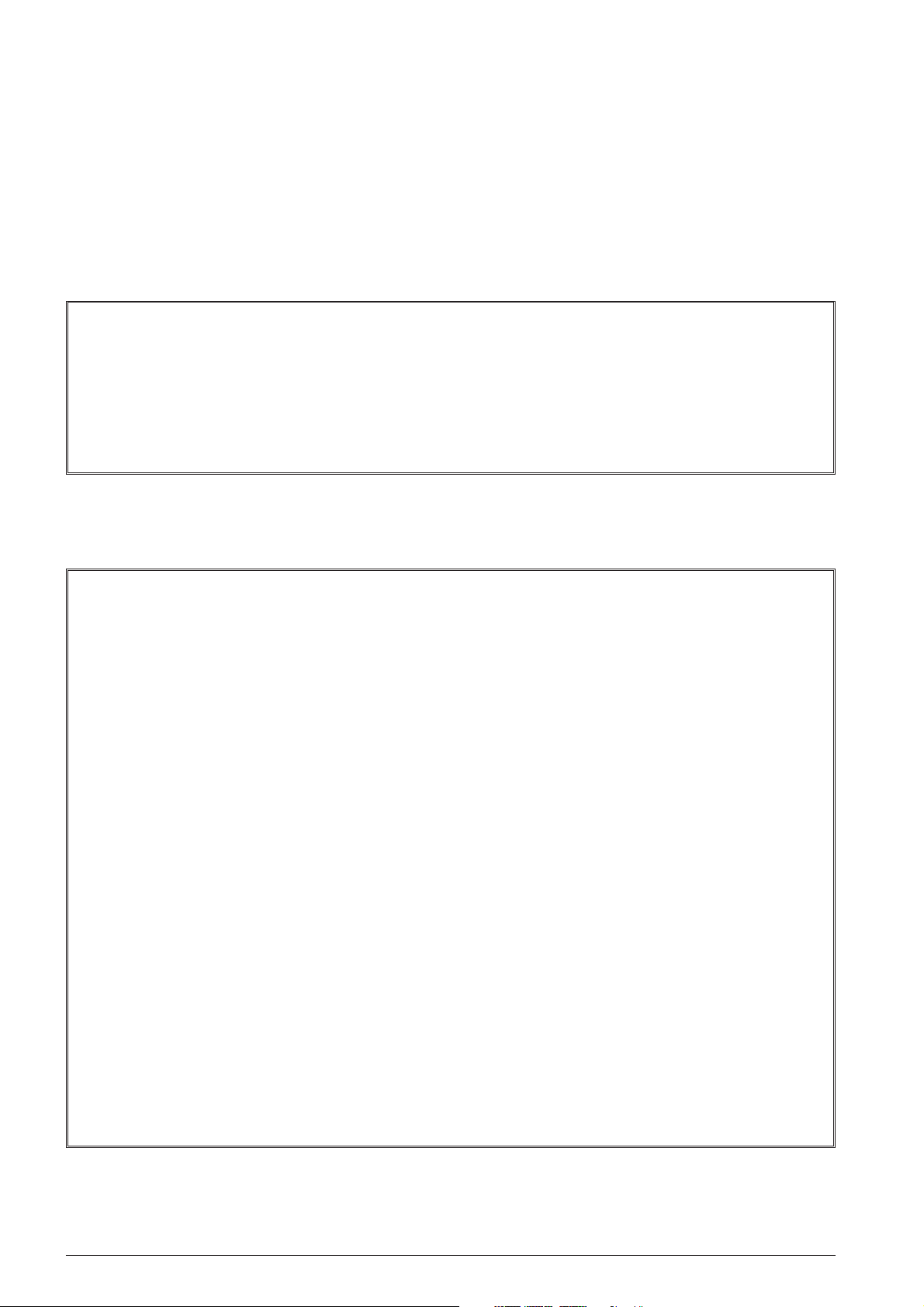

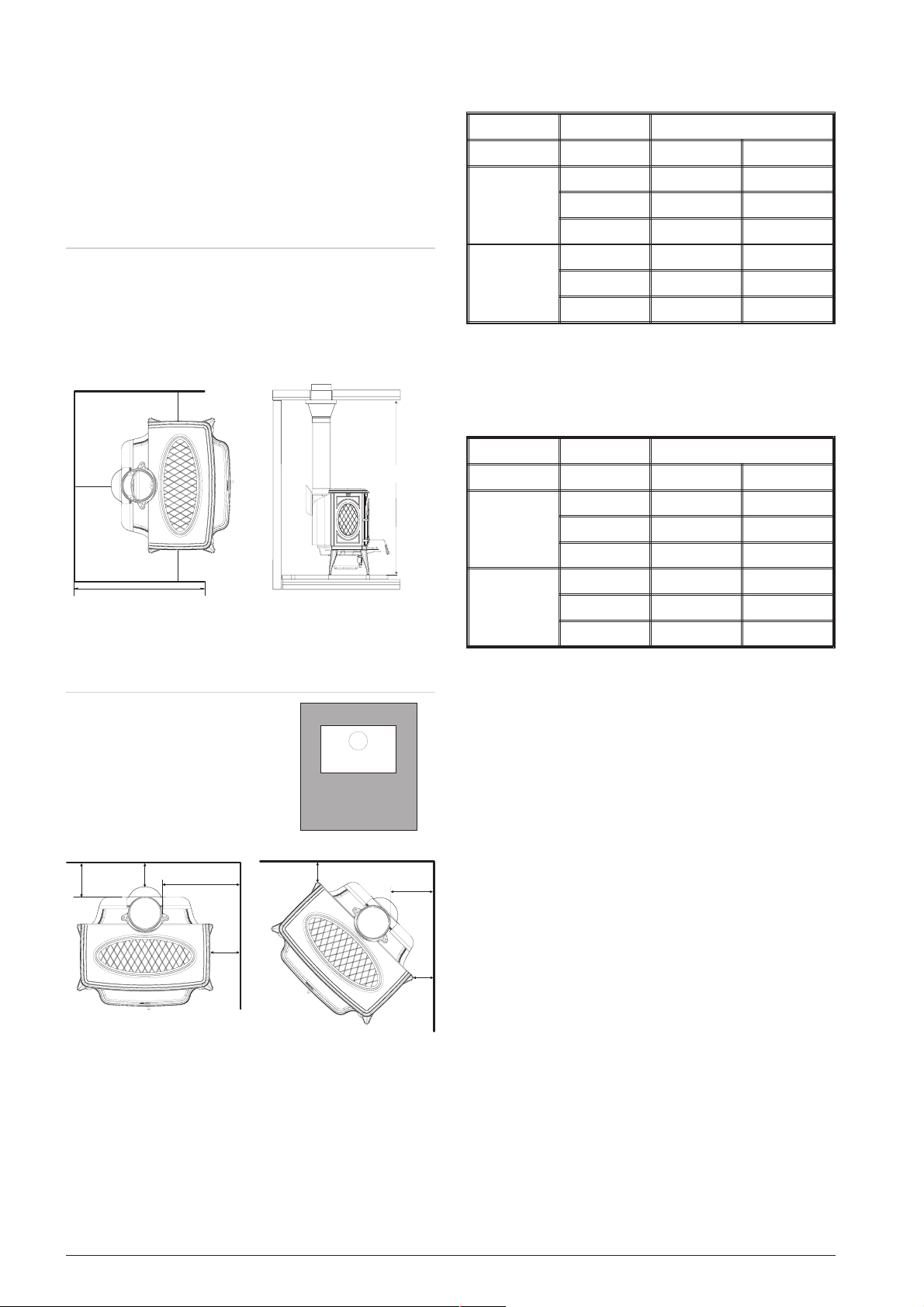

SPECIFICATIONS MODEL 1600C-1

WIDTH X DEPTH 681 X 615 mm 26.8” X 24.2”

HEIGHT 712 mm 28.0”

REAR FLUE HEIGHT (A) 698 mm 27,5”

CHAMBER (D.W.H.) 304 X 520 X 265 mm 11.9” X 20.4” X 10.4”

CAPACITY (LITER) 41.3 L 1.46 ft

APP. AREA HEATED * 56-112 m

HEAT OUTPUT (HIGH BURN) ** 50,000 Btu

DURATION LOW FIRE 7 hr

WEIGHT 150 KG 330 LB

*FIGURES WILL VARY CONSIDERABLY WITH INDIVIDUAL CONDITIONS.

** WOLF STEEL LTD. ESTIMATED REALISTIC BTU/H WITH HARDWOOD LOGS AND REGULAR REFUELING.

2

3

600-1200 ft

2

3

Page 4

INTRODUCTION

General information

The 1600C-1 was specifically designed over many months

of research to meet the 1990 U.S.A. EPA particulate

emission standards and has been extensively tested in

Canadian laboratories. This system is the most efficient,

simple and trouble free we know and works as follows.

The 1600C-1 is designated as a continuous wood burning

heating appliance having a combustion chamber enclosed

with cast brick walls where all fuel is meant to be burnt on

the grate supplied. It is a top and rear vented appliance

capable of being installed near a wall. It has an adjustable

air control for controlling the burning rate as well as a large

ash-pan.

NOTE : The following items supplied with the unit must

be removed from the firebox before attempting to

operate the stove : door handle tool, ash fender and

installation hardware.

After removing the unit from the pallet, use the

securing screws to install the heat shield to the base of

the unit.

Principal of operation

The 1600C-1 is designed to be operated with the door

closed. The heat produced is mainly transmitted through

the window and the body of the unit. Combustion occurs on

the grate with a draft entry through the top of the

combustion chamber. Be sure to provide sufficient

combustion air. There are many other appliances in your

home competing for air such as : a kitchen range hood,

forced air heating devices or a bathroom exhaust fan. Do

not connect this unit to a chimney flue serving another

appliance. Expansion/contraction noises during heating

up and cooling down cycles are normal and to be

expected. After extended periods of non-operation such

as following a vacation or a warm weather season, the

fireplace may emit a slight odour for a few hours. This is

caused by dust particles in the firebox burning off. Open a

window to sufficiently ventilate the room.

If the outside air feature of the stove is utilized, you will

never experience a shortage of combustion air. If you

choose not to utilize outside air and experience draft or

smoking problems, you may need to open a door or

Window.

WARNING: Burning your unit with the ashpan door

open or ajar creates a fire hazard that may result in

internal damage to the stove or a house and/or

chimney fire.

CALIFORNIA PROP 65 WARNING:

Use of this product may produce smoke which

contains chemicals known to the State of California to

cause cancer, birth defects, or other reproductive

harm.

Care of glass

If the glass is not kept clean permanent discolouration

and/or blemishes may result. Normally a hot fire will clean

the glass. The most common reasons for dirty glass

include : not using sufficient fuel to get the stove

thoroughly hot, using green or wet wood, closing the air

control so far that there is insufficient air for complete

combustion. If it is necessary to clean the glass, use a soft

cloth with a nonabrasive cleaner.

DO NOT CLEAN GLASS WHEN HOT !

The glass is very strong but do not let burning fuel rest

against it and always close the door gently. If the glass

should ever crack while the fire is burning, do not open the

door until the fire is out and do not operate the stove again

until the glass has been replaced with a new 4 mm thick

plate of ceramic glass, available from your Napoleon / Wolf

Steel Ltd. dealer.

DO NOT SUBSTITUTE MATERIALS.

To remove the door glass, open the door, remove the

screws and brackets holding the glass in place. Remove all

broken glass. Replace the gasket, if necessary. Place the

new glass in position and replace the brackets and screws.

4

Page 5

INSTALLATION

For reduced clearances installation must comply with

NFPA 211or CAN/CSA-B365.

For clearances when installed with blower kit EP63, refer

to page 6.

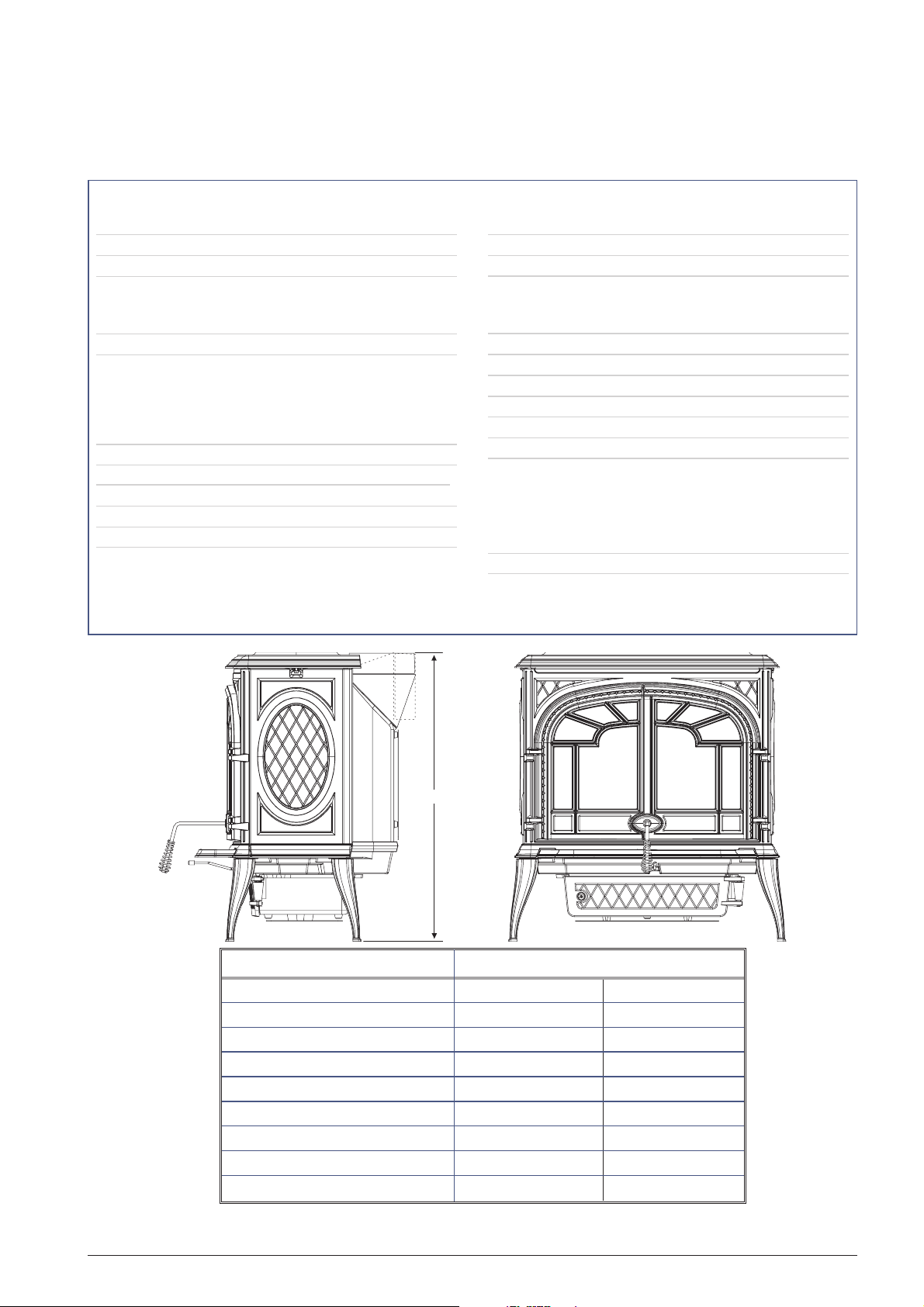

Alcove installation

Model 1600C-1 may be installed into an alcove having a

depth of not more than 4 feet and a height of at least 7 feet,

when using a listed double wall connector that is rated for a

minimum 12” clearance to combustible material.

The minimum clearances are as shown.

Alcove installation

1 6 "

8 4 "

2 2 "

1 6 "

4 f o o t m a x

Walls shall not extend from front of unit when installed

in the alcove configuration.

I l l u s t r a t e d w i t h . 7 5 " h e a r t h p a d .

Stove installation

If the stove is to be installed on a

combustible floor, it must be

placed on a approved

non-combustible hearth pad,

that extends 8" (200mm)

beyond the stove sides and

back, and 18" (455mm) to the

front.

8 "

8 "

8 "

1 8 "

Listed single wall chimney connector

Flue configuration

Type 1 Horizontal Vertical

A 16” 16”

FROM

UNIT

B* 22” 22”

C 15” 15”

D 25” 25”

FROM

PIPE

E ... 22”

* A 22 in. Minimum clearance must be maintained from

combustible wall to the chimney connector.

Double walled connectors listed for a minimum

clearance of 12” or less from combustible materials

must be used to achieve the following clearances.

Flue configuration

Type 2 Horizontal Vertical

A 16” 16”

FROM

UNIT

B 14” 14”

C 15” 15”

D 25” 25”

FROM

PIPE

E ... 16”

B

D

A

C

E

C

5

Page 6

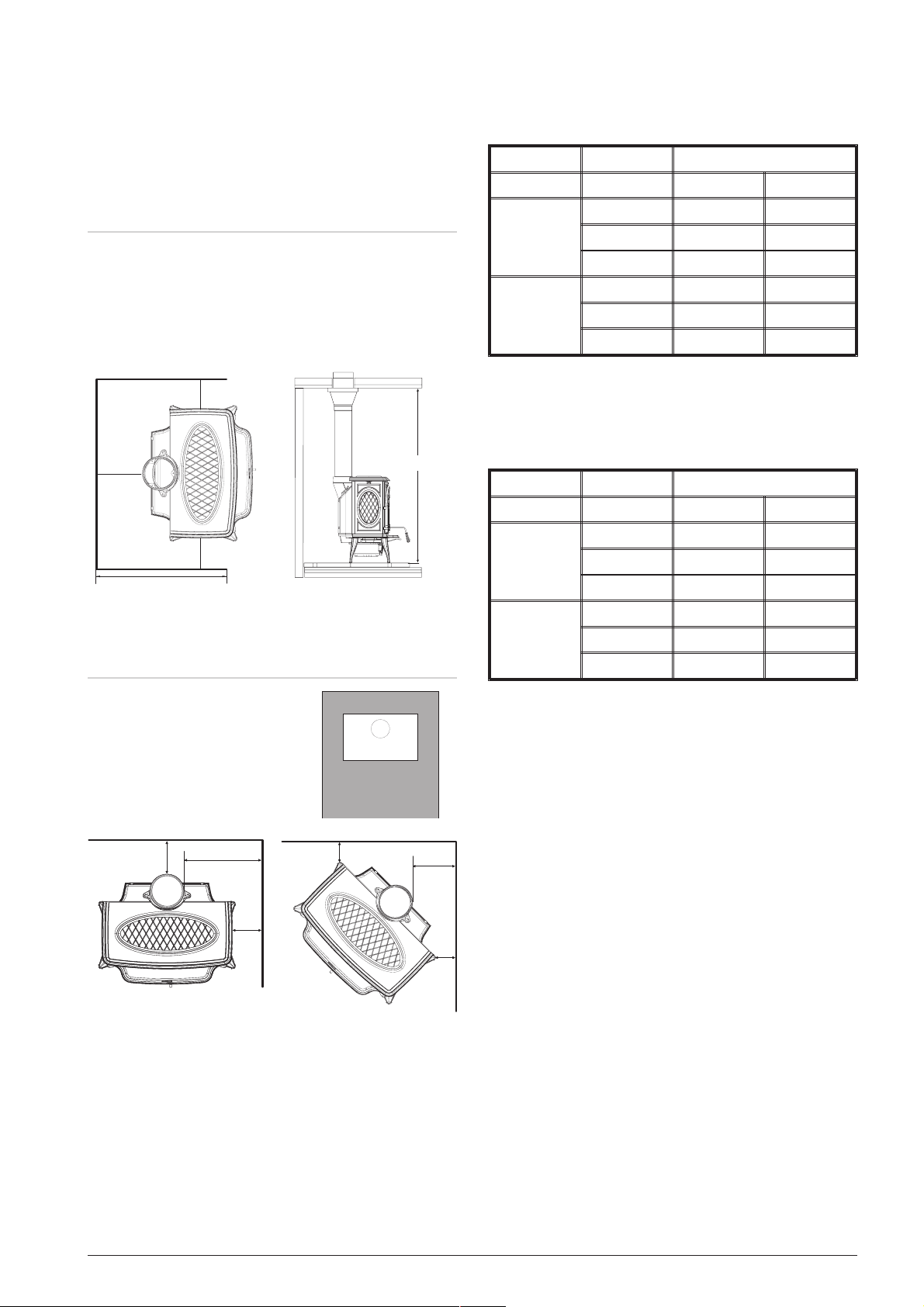

INSTALLATION WHEN

INSTALLED WITH BLOWER

KIT EP63

For reduced clearances installation must comply with

NFPA 211or CAN/CSA-B365.

Alcove installation

Model 1600C-1 may be installed into an alcove having a

depth of not more than 4 feet and a height of at least 7 feet,

when using a listed double wall connector that is rated for a

minimum 12” clearance to combustible material.

The minimum clearances are as shown.

Alcove installation

1 6 "

8 4 "

1 6 "

1 6 "

4 f o o t m a x

Walls shall not extend from front of unit when installed

in the alcove configuration.

I l l u s t r a t e d w i t h . 7 5 " h e a r t h p a d .

Listed single wall chimney connector

Flue configuration

Type 1 Horizontal Vertical

A 16” 16”

FROM

UNIT

B* 10” 16”

C11”11”

D 25” 25”

FROM

PIPE

E ... 18”

F ... 18”

* A 18 in. Minimum clearance should be maintained

from combustible wall to the chimney connector.

Double walled connectors listed for a minimum

clearance of 12” or less from combustible materials

must be used to achieve the following clearances.

Flue configuration

Type 2 Horizontal Vertical

A 16” 16”

FROM

UNIT

B 10” 10”

C11”11”

D 25” 25”

FROM

PIPE

E ... 16”

F ... 12”

Stove installation

If the stove is to be installed on a

combustible floor, it must be

placed on a approved

non-combustible hearth pad,

that extends 8" (200mm)

beyond the stove sides and

back, and 18" (455mm) to the

front.

F

B

D

A

8 "

8 "

1 8 "

C

8 "

E

C

6

Page 7

Chimney connection

A

A 6” diameter single wall stove pipe, used to connect the

stove to the chimney, must be installed with the crimped

end toward the stove. This will ensure that the moisture

which condenses from the burning wood will flow back into

the fire chamber. Each joint in the stove pipe must be

secured with at least three sheet metal screws.

This room heater must be connected to:

1) Achimney complying with the requirements for Type HT

chimneys in the Standard for Chimneys, Factory-Built,

Residential Type and Building Heating Appliance UL 103,

or

2) A code-approved masonry chimney with a flue liner.

Vent the stove into a masonry chimney or an approved,

insulated solid-fuel stainless-steel chimney with as short

and straight a length of six-inch (150mm) diameter smoke

pipe as possible. Connection to a masonry chimney must

be by a metal or masonry thimble cemented in place. An

insulated stainless steel chimney must be supported at the

ceiling or roof and its installation must comply with its

manufacturer’s instructions.

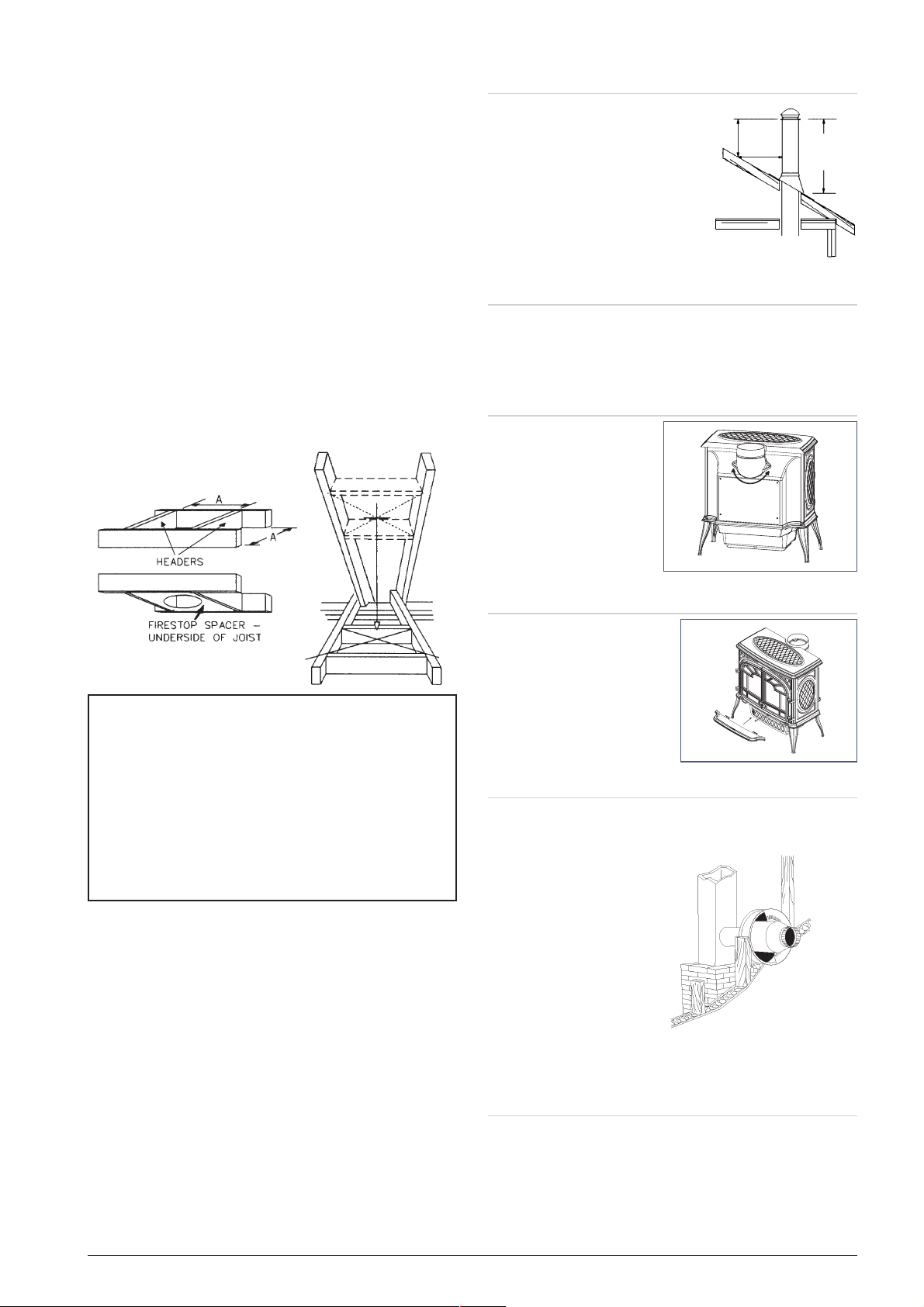

Adding chimney sections

Add chimney sections, according to

manufacturer’s installation

instructions, to the required height.

The chimney must extend, atleast, 3

feet above its point of contact with the

roof and atleast 2 feet higher than any

wall, roof or building within 10 feet. If

your chimney system is enclosed

within the attic area, a rafter radiation

shield is required.

2 F T .

M I N

.

1 0 F T .

3 F T .

M I N

.

Outside air

If possible connect the air intake at the bottom to the

outside with a 4 inch (100mm) diameter fresh air kit

available at your Napoleon/Wolf Steel Ltd. dealer. Follow

detailed instructions under “Mobile Home Outside Air".

Flue collar reversal

The flue collar is oriented

in the Top Exit position.

Remove the two

mounting bolts, and turn

the collar 180 degrees.

Secure the collar using

the same bolts, nuts and

washers.

THE TOTAL HORIZONTAL VENT LENGTH SHOULD

NOT EXCEED 40% OF THE CHIMNEY HEIGHT ABOVE

THE STOVE.

All horizontal smoke pipe must slope slightly

upwards a minimum of 1/4" per foot (6mm/0.3m) and

all connections must be tight and secured by three

sheet metal screws equally spaced.

An uninsulated smoke pipe shall not pass through an

attic, roof space, closet or similar concealed space,

or through a floor, ceiling, wall or partition, or any

combustible construction.

DO NOT USE ANY MAKESHIFT MATERIALS DURING

INSTALLATION.

1. Move the stove into position with the flue centered,

midpoint between two joists to prevent having to cut them.

Use a plumb bob to line up the centre.

2. Cut and frame an opening in the roof to provide a 2"

clearance between the outside of the chimney and any

combustible material.

DO NOT FILL THIS SPACE WITH ANY TYPE OF

MATERIAL.

Nail headers between the joist for extra support.

Firestop spacers must be placed on the bottom of each

framed opening in any floor or ceiling that the chimney

passes through.

3. Hold a plumb bob from the underside of the roof to

determine where the opening in the roof should be. Cut

and frame the roof opening to maintain proper 2"

clearances.

Ash fender installation

To avoid damage during

transport, the ash fender

has been stored behind the

main door. Pivot the ash

fender onto tab “A” and

lower into place.

Wall pass-through

If possible, design the installation so that the connector

does not pass through a combustible wall. If during your

installation you must pass through a combustible wall,

check with your building

inspector before you

begin. Also check with the

chimney connector

manufacturer for any

specific requirements.

Consult with your dealer

regarding special

connection components

available for use for wall

pass-throughs.

This is the preferred

method of passing a flue

pipe through a combustible

wall to a masonry chimney

Use only parts that have been tested and listed for use in a

wall pass-through.

Heat shield installation

The heat shield stored in the unit must be installed under

the stove with 2 provided screws. Please, see page 8 to

respect the orientation of the heat shield.

7

Page 8

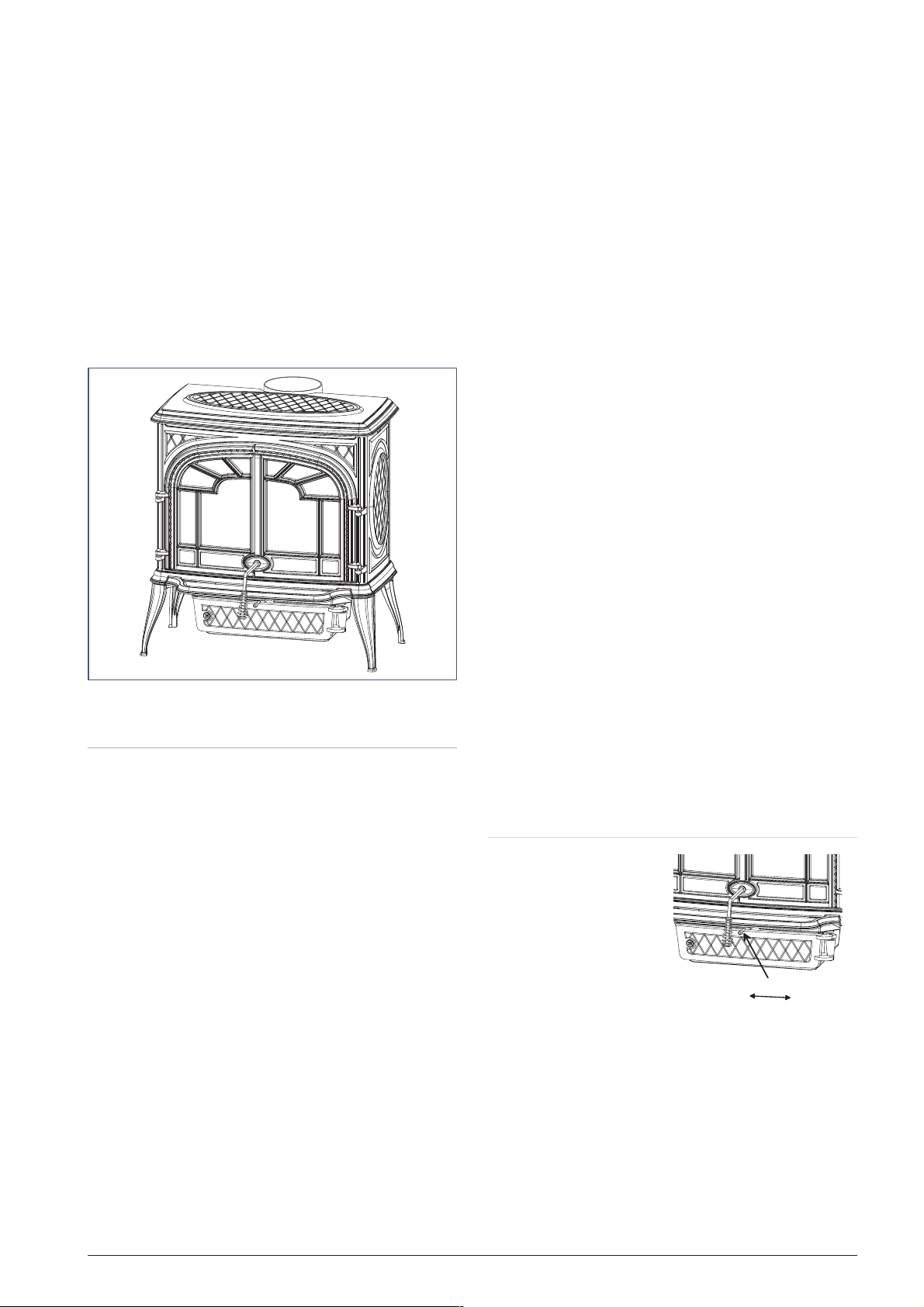

MOBILE HOME INSTALLATION

O

MODEL 1600C-1 IS APPROVED FOR INSTALLATION IN

MOBILE HOMES IN BOTH CANADA AND THE UNITED

STATES.

The stove must be secured to the floor of the mobile home.

Warning!

Do not install this stove in a bedroom/sleeping room.

Do not install the stove in any way that might

compromise the structural integrity of the mobile

home floor, walls, ceiling, or roof.

Venting

Connect the stove to a

chimney system using a

listed double wall

connector with a minimum

clearance rating of 12” or

less. Use chimney system

listedtoULCS629in

Canada or UL103HT in the

USA.

The chimney must be

installed in accordance

with the manufacturer’s

instructions. Use only

specified components with

no substitutions. The

chimney and pipe must

extend at least 8 feet

above the stove and 3 feet

O U T S I D E A I R C O N N E C T I O N T H R O U G H

W A L L O R F L O O R

above the highest point of

the roof. Install a rain cap at the top which will not impede

the smoke exhaust. The chimney must be supported at the

ceiling or roof so that its weight does not rest on the stove.

It must be installed between ceiling joists, with radiation

shield and roof flashing, so that the structural strength,

insulation and waterproof qualities of the home are not

lessened. Seal with silicone to maintain a vapour barrier at

the chimney and outside air pipe penetrations.

C H A P E A U

S O L I N D E T O I T

P O U R M A I S O N M O B I L

É C R A N D E P R O T E C T I

C E I L I N G S U P P O R T

T R I M C O L L A R

S T O V E B O L T E D

T O F L O O R

H E A R T H P A D

113KT 1600C-1 Adaptor Kit Intallation

When installing the 1600C-1 in a mobile home,use the

111KT Outside air kit in conjunction with the 113KT

Outside Air Adaptor Kit.

Remove the two screws from the bottom of the unit and install

the two floor securing brackets using the two screws

removed.

Install the vent connector by inserting the stud retainer into

the hole in the bottom of the fireplace. Position the retainer so

that the studs come through the holes indicated.

Hold the retainer in place and align the holes in the vent

connector with the studs of the retainer.

Secure the vent connector in place using the 2 nuts supplied.

Secure the unit to the floor using the securing brackets and

the two #10x1.5" screws supplied.

Outside air / Floor Securing

Connecting the stove’s air intake to the outside as well

as securing the unit to the floor, is mandatory in

mobile homes only. Use a fresh air kit and the floor

securing brackets.

Avoid cutting away floor joists, wall studs, electrical wires

or plumbing. Seal around the outside pipe with insulation

to prevent drafts.

If room air starvation occurs because the fresh air

intake is blocked with ice, leaves, etc., or because the

stove door was left open, or due to a strong exhaust

fan operating etc., dangerous fumes and smoke from

the operating stove could be drawn into the room.

8

Page 9

OPERATING INSTRUCTIONS

WARNING : Objects placed in front of the fire place

should be kept a minimum of 48” from the front face.

CAUTION : Never use gasoline, gasoline-type lantern

fuel, kerosene, charcoal lighter fluid, or similar liquids

to start or ‘freshen up ’a fire in this heater. Keep all

such liquids well away from the heater while it is in

use.

Your Napoleon EPA listed product is a Hi-Tech unit,

designed with the most advanced technology. The unit is

extremely airtight. It has an exclusive direct outside air

supply (optional kit), a safety feature designed to prevent

spillage, and to keep your house free of carbon monoxide,

in case of a downdrafting chimney or an internal negative

pressure.

When lit for the first time

The stove will emit a slight odour for a few hours. This is a

normal temporary condition caused by the “burn-in” of

internal paints and lubricants used in the manufacturing

process and will not occur again. Simply open a window to

sufficiently ventilate the room during the first few hours of

operation.

To start, a brisk fire is required. Place loosely crumpled

paper on the grate and cover with dry kindling. Open the air

control fully by moving it to the right. Light the paper and

leave the door slightly ajar (one inch) until all kindling is

burning. To maintain a brisk fire, a hot coal bed must be

established and maintained.

Slowly add larger wood (2x4 size pieces). Lay the pieces

lengthwise from side to side in the hot coal bed with a

shallow trench between, so that the primary air can flow

directly into this trench and ignite the fuel above. When the

fire seems to be at its peak, medium sized logs may be

added. Once these logs have caught fire, carefully close

the door. (Closing the door too quickly after refuelling will

reduce the firebox temperature and result in an

unsatisfactory burn.) Remember it is more efficient to burn

medium sized wood, briskly, and refuel frequently than to

load the fireplace with large logs that result in a

smouldering, inefficient fire and dirty glass.

As soon as the door is closed, you will observe a change in

the flame pattern. The flames will get smaller and lazier

because less oxygen is getting into the combustion

chamber. The flames, however, are more efficient. The

flames will remain lazy but become larger again as soon as

the castings have been heated thoroughly and the

chimney becomes heated and provides a good draft.

At this point, the roaring fire that you see when the door is

opened is wastefully drawing heated room air up the

chimney — certainly not desirable. So always operate with

the door fully closed once the medium sized logs have

caught fire.

You can now add larger pieces of wood and operate the

stove normally. Once the stove is entirely hot, it will burn

very efficiently with little smoke from the chimney. There

will be a bed of orange coals in the firebox and secondary

flames flickering just below the top firebrick. You can safely

fill the firebox with wood to the top of the door and will get

best burns if you keep the stove pipe temperatures

between 250 degrees Fahrenheit (121 degrees Celsius)

and 450 degrees Fahrenheit (232 degrees Celsius). A

surface thermometer will help regulate this.

WITHOUT A STOVE THERMOMETER YOU ARE

WORKING BLINDLY AND HAVE NO IDEA OF HOW THE

STOVE IS OPERATING. A STOVE THERMOMETER

OFFERS A GUIDE TO PERFORMANCE.

Can’t get the stove going ?

Use more kindling and paper. Assuming the chimney and

vent are sized correctly and there is sufficient combustion

air, the lack of sufficiently dry quantities of small kindling is

the problem. Thumb size is a good gauge for small kindling

diameter.

Can’t get heat out of the stove ?

One of two things may have happened. The stove door

may have been closed prematurely and the stove itself has

not reached optimum temperature. Reopen the door

and/or draft control to re-establish a brisk fire. The other

problem may have been wet wood. The typical symptom is

sizzling wood and moisture being driven from the wood.

Achieving proper draft

Draft is the force which

moves air from the stove

up through the chimney.

The amount of draft in your

chimney depends on the

length and diameter of

chimney, local geography,

nearby obstructions and

other factors. Adjusting the

air control (Item B)

regulates the temperature.

The draft can be adjusted from a low burn rate with the

control fully closed, to a fast burn rate with the control fully

open.

Inadequate draft may cause back-puffing into the room

through the stove and chimney connector points and may

cause plugging of the chimney. Too much draft may cause

an excessive temperature in the stove, glowing red stove

parts or chimney connectors or an uncontrollable burn

which can lead to a chimney fire or permanent damage to

the unit.

B

_

+

9

Page 10

Fire extinguishers / smoke detectors

All homes with a solid fuel burning fireplace should have at

least one fire extinguisher in a central location known to all,

and at least one smoke detector in the room containing the

fireplace. If it sounds an alarm, correct the cause but do not

deactivate or relocate the smoke detector.

Install the blower and housing using 4 of the screws

supplied.

Loosen the 2 screws securing the thermodisc bracket

and slide the bracket forward until the thermodisc is

touching the heat shield. Secure in place by tightening the

screws.

Fuel loading and burn cycle

For maximum efficiency, when the stove is thoroughly hot,

load it fully to the top of the door opening and burn at a

medium low setting. Maximum heat for minimum fuel

(optimum burn) occurs when the stove top temperature is

between 500°F (260°C) and 600°F (315°C). The

cleanness of the glass is a good indicator of your operating

efficiency. Not enough heat is produced when only one or

two pieces of wood are burned or the wood may not burn

completely. A minimum of three pieces are needed to

encase a bed of coals that sustains the fire.

Loosely stacked wood burns quicker than a tightly packed

load. Wood burns in cycles rather than giving a steady

output of heat. It is best to plan these cycles around your

house hold routine so that only enough coals are left to

start the next load. In the evening, load your stove, at least,

a half-hour before bed to ensure a good fire, hot enough to

close the draft control for an overnight burn. Burn only dry

seasoned wood.

It produces more heat and less soot or creosote. Do not

burn ocean beach wood. Its salt content can produce a

metal eating acid. When refueling open the door slowly to

prevent smoke spillage. Use a pair of long gloves

(barbecue gloves) when feeding the fire. Because these

stoves burn at the front, they are clean and efficient, but

they are also very hot and gloves are useful. Keep a small

steel shovel nearby to use as a poker and to remove

ashes. Do not store the wood within 3 feet (1m) of the

stove.

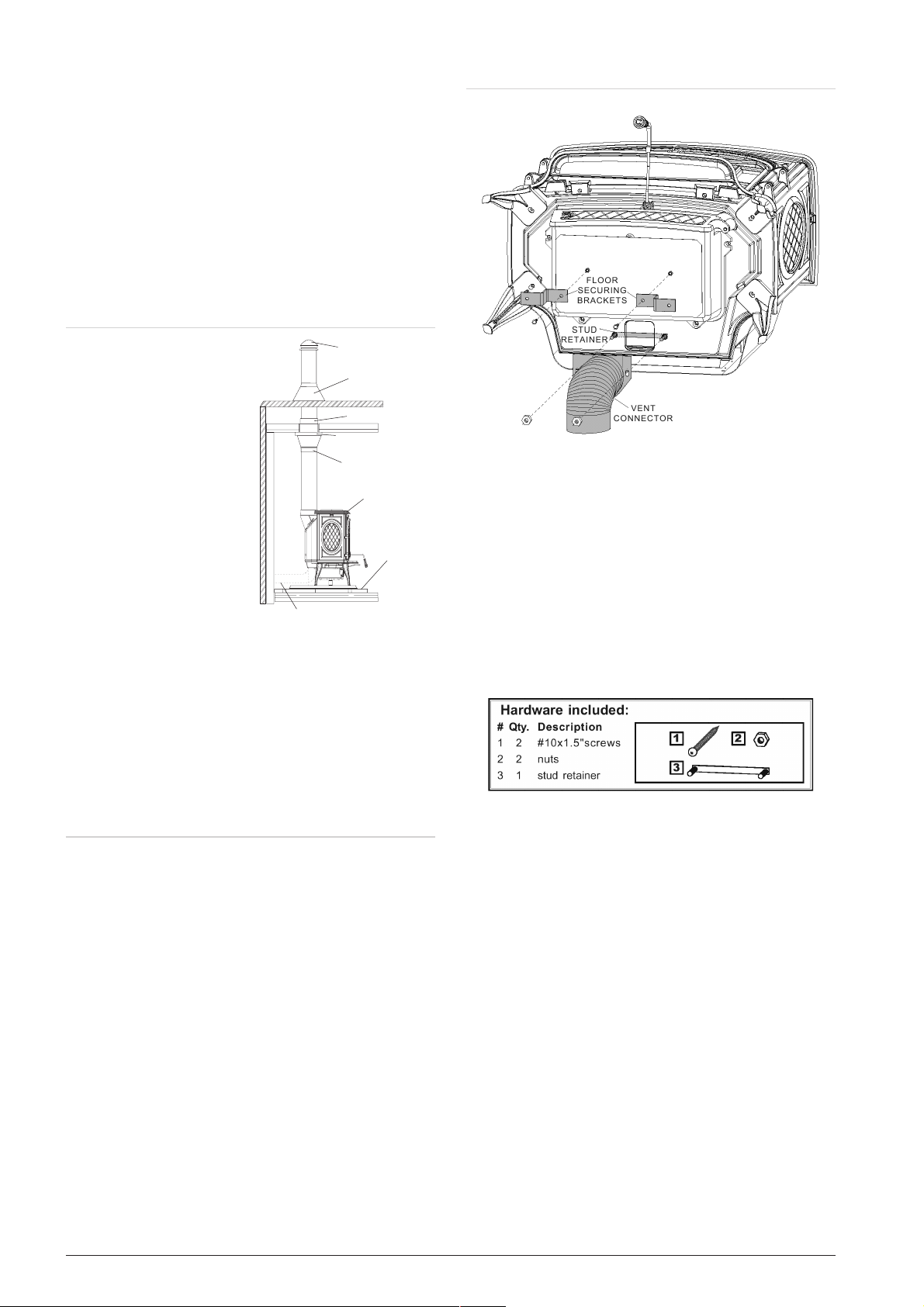

EP63 OPTIONAL BLOWER KIT

Ash removal procedures

CAUTION : Risk of excessive temperatures.

Keep the ash door closed during firing of the

heater.

It is essential to keep the grate free of a heavy build up of

ashes.

When burning solid fuel, always empty the ash pan at least

once a day or whenever it is full of ashes. Never allow the

ashpan to overfill thereby allowing ash to be in contact with

the underside of the grate. If this condition is allowed, the

grate will wear out prematurely.

Hot ashes may be kept in a metal container with a tight

fitting lid. Keep the closed container on a noncombustible

floor or ground, well away from all combustible materials.

The ashes should be retained in the closed container until

all cinders have thoroughly cooled. Cold wood ashes can

be used on the garden or in the compost.

DO’S

1. Build a hot fire

2. Use only dry wood.

3. Several pieces of medium sized wood are better than

a few big pieces.

4. Clean chimney regularly.

5. Refuel frequently using medium sized wood.

6. “Fine Tune” the air settings for optimum performance.

DON’TS

1. Take ash out immediately. Let it accumulate to a depth

of at least one inch. A good ash layer provides for a

longer lasting and better burning fire.

2. Burn wet wood.

3. Close the door too soon or damper down too quickly.

4. Burn one large log rather than two or three smaller,

more reasonably sized logs.

5. Burn at continually “low setting”, if glass door is

constantly blackened. This means the firebox

temperature is too low.

EP90-K OPTIONAL SCREEN KIT

Remove the 4 screws from the rear plate of the stove.

Replace the screws removed with the 4 spacers

supplied.

Install the rear heat shield using the 4 screws removed

and secure to the 4 spacers.

The flue collar shield is only needed if the flue collar is in

the top exit position. If the flue collar is in the rear exit

position, the flue collar shield can be discarded.

Install the flue collar shield to the rear heat shield, using 2

of the screws supplied.

10

The 1600C-1 may only be operated with the doors open

when spark screen EP90-K is used and installed

properly.

This kit is not applicable for mobile homes.

Page 11

WOOD PILE MAINTENANCE

Burn only dry, clean unpainted wood that has been

seasoned. It produces more heat and less soot or

creosote. Freshly cut wood contains about 50% moisture

while after proper seasoning only about 20% of the water

remains. As wood is burned, this water boils off consuming

energy that should be used in heating. The wetter the

wood, the less heat is given off and the more creosote is

produced.

Both hardwood and softwood burn equally well in this

stove but hardwood is denser, will weigh more per cord

and burn a little slower and longer. Firewood should be

split, stacked in a manner that air can get to all parts of it

and covered in early spring to be ready for burning that fall.

Dry firewood has cracks in the end grain. Cut the wood so

that it will fit horizontally, sideways, making for easier

loading and less of a likelihood that the wood will roll onto

the glass.

STOVE MAINTENANCE

Check your chimney and chimney connector for creosote

and soot buildup weekly until a safe frequency for cleaning

is established. If accumulation is excessive, disconnect

the stove and clean both the chimney and the stove. You

may want to call a professional chimney sweep to clean

them. Both have to be cleaned at least once a year or as

often as necessary.

SMOKING : Aproperly installed stove should not smoke. If

yours does, check the following : Has the chimney had

time to get hot ? Is the smoke passage blocked anywhere

in the stove, chimney connector or chimney ? Is the room

too airtight ? Try with a window partly open. Is the smoke

flow impeded by too long a horizontal pipe or too many

bends ? Is it a weak draft perhaps caused by a leaky

chimney, a cold outside chimney, too short a chimney, or a

chimney too close to trees or a higher roof ?

Runaway or chimney fire

Runaway fires can be the result of two major factors :

1. Using incorrect fuel, or small fuel pieces which would

normally be used as kindling.

2. Leaving the door ajar too long and creating extreme

temperatures as the air rushes in the open door.

Solutions :

1. Do not burn treated or processed wood, coal, charcoal,

coloured paper or cardboard.

2. Be careful not to over-fire the unit by leaving the door

open too long after initial start-up. A thermometer on the

chimney connector and/or stove top helps.

What to do if a runaway or chimney fire starts ?

1. Close the draft fully.

2. Call local fire department.

3. Examine flue-pipes, chimney, attic, and roof of the

house, to see if any part has become hot enough to

catch fire. If necessary spray with a fire extinguisher or

water from a garden hose.

4. Do not operate the stove again until you are certain the

chimney and its lining have not been damaged.

Creosote formation and removal

When wood is burned slowly, it produces tar and other

organic vapours which combine with expelled moisture to

form creosote. These vapours condense in the relatively

cooler chimney flue of a slow burning fire and when ignited,

make an extremely hot fire. So, the smoke pipe and

chimney should be inspected monthly during the heating

season to determine if a buildup has occurred. If creosote

has accumulated it should be removed to reduce the risk of

a chimney fire.

11

Page 12

ORDERING PROCEDURES

Contact your dealer or the factory for questions concerning prices and policies on replacement parts. Normally all parts can

be ordered through your Napoleon dealer or distributor. When ordering replacement parts always give the following

information :

1. Model & Serial Number of fireplace

2. Installation date

3. Part Number

4. Description of part

5. Finish

N° Code Description.................P.....N....F ...Qty

1 352165 RJ Top plate .....................................F.....01

1 352165 EF Top plate .......................P...................01

1 352165 77 Top plate ..............................N...........01

2 269443 Deflector .......................P ......N.....F.....01

3 326602 00 Flue baffle ......................P ......N.....F.....01

4 222566 00 Secondary air plate .................P ......N.....F.....01

5 259037 00 Bracket, air plate ..................P ......N.....F.....02

6 310830 RJ Left side panel ..................................F.....01

6 310830 EF Left side panel ....................P...................01

6 310830 77 Left side panel ...........................N...........01

7 305016 EF Liner, left side ....................P ......N.....F.....01

8 252674 Grate cover .....................P ......N.....F.....01

9 309233 EF Grate .........................P ......N.....F.....01

10 322718 EF Air channel cover ..................P......N.....F.....01

11 330018 EF Hearth plate .....................P ......N.....F.....01

12 105275 Ceramic brick liner..................P ......N.....F.....01

13 306285 EF Back panel ......................P......N.....F.....01

14 331001 EF Adaptor........................P ......N.....F.....01

15 303826 EF Flue collar ......................P ......N.....F.....01

16 157968 Rating plate .....................P ......N.....F.....01

17 310734 RJ Right side panel .................................F.....01

17 310734 EF Right side panel ...................P...................01

17 310734 77 Right side panel...........................N...........01

18 305214 EF Liner, right side ...................P ......N.....F.....01

19 319738 EF Grate support (Inner base) .............P ......N.....F.....01

20 332000 EF Air duct, left side...................P ......N.....F.....01

21 315610 EF Air duct, right side ..................P......N.....F.....01

22 270411 00 Air control damper ..................P ......N.....F.....01

23 236131 00 Sealing plate .....................P ......N.....F.....01

24 300491 EF Base .........................P ......N.....F.....01

25 359806 RJ Front plate ....................................F.....01

25 359806 EF Front plate ......................P...................01

25 359806 77 Front plate..............................N...........01

26 327905 RJ Ash tray .....................................F.....01

26 327905 EF Ash tray .......................P...................01

26 327905 77 Ash tray ...............................N...........01

27 158627 Handle, door.....................P ......N.....F.....01

28 179624 Shaft, air control...................P ......N.....F.....01

29 331700 Ash pan housing...................P ......N.....F.....01

30 624045 00 Ash-pan .......................P......N.....F.....01

31 262611 Heat shield (Ash Pan) ................P......N.....F.....01

32 300132 RJ Leg ........................................F.....04

32 300132 EF Leg ..........................P...................04

32 300132 77 Leg..................................N...........04

P = 1600CP (Painted)

N = 1600CN (Brown)

F = 1600CF (Green)

12

Page 13

N° Code Description.................P.....N....F ...Qty

33 301172 RJ Ash pan door...................................F.....01

33 301172 EF Ash pan door.....................P...................01

33 301172 77 Ash pan door ............................N...........01

34 134711 Pin 6X30, ash pan door latch ...........P ......N.....F.....01

35 101055 Axle, ash pan door latch ..............P ......N.....F.....01

36 189825 Screw M 5X6, door latch ..............P......N.....F.....03

37 101057 Hinge DIAM.8, ash pan door ............P ......N.....F.....01

38 134714 Pin 6X24, door latch ................P ......N.....F.....01

39 331800 RJ Door, right side..................................F.....01

39 331800 EF Door, right side ...................P...................01

39 331800 77 Door, right side ...........................N...........01

40 331900 RJ Door, left side ..................................F.....01

40 331900 EF Door, left side ....................P...................01

40 331900 77 Door, left side ............................N...........01

41 110404 Hinge pin 6X30, door ................P ......N.....F.....04

42 181632 Gasket, door glass..................P......N.....F.....2m

43 188829 Ceramic glass 278 X 220 ..............P ......N.....F.....02

44 259015 00 Bracket, glass retainer ...............P ......N.....F.....08

45 142881 Rope .........................P ......N.....F.....08

46 808001 ED Hand tool.......................P ......N.....F.....01

47 101054 Axle, door latch ...................P......N.....F.....01

48 181634 Gasket, door .....................P......N.....F....1,64m

49 181633 Gasket, ash pan door ................P......N.....F....1,33m

50 181625 Gasket, ash pan housing ..............P ......N.....F....3,16m

51 142316 Gasket, flue collar ..................P......N.....F.....1m

52 134107 Glove .........................P ......N.....F.....01

ACCESSORIES

60 EP63 Blower kit.......................P......N.....F

61 EP90-K Screen kit ......................P ......N.....F

90 113KT Adapter kit ......................P......N.....F

111KT Outside air kit ....................P......N.....F

13

Page 14

#

#

"

!

!

$

$

"

#

%

&

#

#

'

'

'

&

%

#

!

$

$

"

14

%

&

#

'

"

"

" &

$

" !

" "

!

" &

! "

#

! !

! $

! #

! $

!

" '

"

! &

" %

" #

!

! '

! $

! %

" $

#

Page 15

INSTALLATEUR : CETTE NOTICE DOIT ÊTRE REMISE AU PROPRIÉTAIRE DU POÊLE ET CONSERVÉE PAR LUI.

HOMOLOGUÉ SELON LES NORMES DE L’AGENCE DE PROTECTION DE L’ENVIRONNEMENT AMÉRICAINE (E.P.A.) JUILLET 1990 ET LE DÉPARTEMENT D’OREGON

DE LA QUALITÉ DE L’ENVIRONNEMENT (D.E.Q.) LES NORMES D’ÉMISSION DE PARTICULES DE E.E.M.C. CE POÊLE A ÉTÉ TESTÉ ET HOMOLOGUÉ PAR WARNOCK

LE MODÈLE 1600C-1 A ÉTÉ TESTÉ ET HOMOLOGUÉ POUR INSTALLATION LES MAISONS MOBILES.

HERSEY LTÉE SELON LES NORMES UL 1482 / ULC-S627.

INSTRUCTIONS D’INSTALLATION ET D’OPÉRATION POUR LES

APPAREILS DE CHAUFFAGE LOCALISÉ À COMBUSTIBLE SOLIDE

MODÈLE : 1600C-1

ATTENTION :

Veuillez lire le manuel d’instructions en entier avant d’installer et d’utiliser votre appareil de chauffage.

Si ces instructions ne sont pas suivies à la lettre, des dommages matériels, des blessures corporelles

ou des pertes de vie pourraient s’ensuivre.

Si cet appareil n’est pas installé adéquatement, un incendie pourrait en résulter.

POUR VOTRE SÉCURITÉ :

Observez les instructions d’installation. Ce poêle peut devenir très chaud pendant la chauffe. Les matériaux

combustibles tels que le bois de chauffage, les vêtements détrempés etc., placés trop près de l’appareil peuvent

prendre feu. Il faut empêcher les enfants et les animaux domestiques de toucher l’appareil lorsqu’il est chaud. La

cheminée doit être en bonne condition et doit être hermétique.Avant d’installer cet appareil, contactez le service du

bâtiment ou le service d’incendie de votre municipalité et suivez leurs directives.

Ne faites fonctionner l’appareil qu’avec la porte hermétiquement fermée. Vous devez garder la porte fermée durant

le fonctionnement pour éviter que la fumée et les braises s’infiltrent dans la pièce. Brûlez le bois directement sur le

chenet en fonte fourni avec l’appareil. Ne surélevez pas le feu. Au moins 14” carrés (90 cm ca.) d’air extérieur doit

être admis dans la pièce. Cet appareil est conçu pour brûler le bois à son état naturel seulement. Comparativement

aux bois mous ou aux bois verts fraîchement coupés, les bois durs et secs produiront des taux d’efficacité plus

élevés et des taux d’émissions plus bas. N’allumez pas l’appareil avec des produits chimiques ou des fluides tels

que de l’essence, de l’huile à moteur etc. Ne brûlez pas de bois traités, du charbon, du charbon de bois, du papier

couleur, du carton, des solvants ou des déchets qui ont tendances à produire plus de pollution que le bois. Ne

laissez pas chauffer l’appareil au point où ses composants seront chauffés au rouge.

GARDEZ LA TEMPERATURE SUR LE DESSUS DE L’APPAREIL SOUS 700°F (371°C). Toute tentative de

dépasser le débit maximum de chaleur tel que mentionné dans les spécifications du design des poêles, pourrait

provoquer la distorsion de l’acier et causer des dommages.

Fax : (705)722-6031

Wolf Steel Ltd., 24 Napoleon Rd.,

Barrie, ON., Canada L4M 4Y8 (705)721-1212

www.napoleonfireplaces.com

Email : ask@napoleon.on.ca

Document n°1178-1 ~ 02/12/2004

Page 16

Les poêles au bois NAPOLEON sont fabriqués conformément aux normes strictes du certificat d’assurance de qualité

mondialement reconnu ISO 9001.

Les produits NAPOLEON sont conçus avec des composants et des matériaux de qualité supérieure, assemblés par

des artisans qualifiés qui sont fiers de leur travail. Le poêle entier est soigneusement inspecté par un technicien

qualifié avant d’être emballé pour garantir que vous, le client recevez le produit de qualité que vous attendez de

NAPOLEON.

LA GARANTIE DU PRÉSIDENT

Les matériaux suivants et la fabrication de votre nouveau poêle au bois NAPOLEON sont garantis contre les

défauts tant que vous en êtes le propriétaire. Ceci couvre : la chambre de combustion, l’échangeur de chaleur, la

vitre en céramique (cassure thermique seulement), les pièces plaquées or contre le ternissement, les composants

en émail de porcelaine et les moulages en fonte.

Les composants électriques (110V)etlespièces portables telles que les ventilateurs, l’interrupteur thermique, les

interrupteurs, l’installation électrique, les briques réfractaires, les grilles, les chicanes, les joints d’étanchéité, et la

peinture résistante aux hautes températures sont couverts et NAPOLEON fournira gratuitement les pièces de

rechange durant la première année de la garantie limitée.

Les coûts de main d’œuvre relatifs aux réparations garanties sont couverts gratuitement durant la première année.

Cependant, les travaux de réparations nécessitent l’approbation préalable d’un représentant autorisé de la

compagnie. Les coûts de main d’œuvre à la charge de NAPOLEON sont basés sur un programme de tarifs

prédéterminé et tout travail de réparation doit être accompli par l’entremise d’un représentant autorisé NAPOLEON.

CONDITIONS ET LIMITATIONS

NAPOLEON garantit ses produits contre les défauts de fabrication à l’acheteur d’origine seulement — l’individu ou la personne

morales (client inscrit) dont le nom apparaît sur la carte d’enregistrement de garantie déposée auprès de NAPOLEON — à

condition que l’achat ait été fait par l’entremise d’un représentant autorisé NAPOLEON et sous réserve des conditions et

limitations suivantes.

Cette garantie d’usine n’est pas transmissible et ne peut être étendue par aucun de nos représentants qu’elle qu’en soit la

raison.Le poêle au bois doit être installé par un installateur ou entrepreneur qualifié. L’installation doit être faite conformément

aux instructions d’installation inclues avec le produit et à tous les codes d’incendie et de construction locaux et nationaux.

Cette garantie limitée ne couvre pas les dommages causés par un usage impropre, un manque d’entretien, un accident, des

altérations, des abus ou de la négligence. L’installation de pièces d’autres fabricants annulera cette garantie.Cette garantie

limitée ne couvre pas non plus, les éraflures, les bossellements, la corrosion ou décoloration causés par une chaleur excessive,

des produits d’entretien chimiques et abrasifs ou l’écaillage des pièces en émail de porcelaine, ou tout composant de ventilation

utilisé dans l’installation du poêle.

Au cours de la première année seulement cette garantie s’étend à la réparation ou le remplacement des pièces garanties dont les

matériaux ou la fabrication sont défectueux sous condition que le produit ait été utilisé conformément aux instructions de

fonctionnement et sous des conditions normales.Après la première année, concernant cette Garantie à Vie Limitée du Président

NAPOLEON peut, à sa discrétion, se débarrasser entièrement de toutes obligations concernant cette garantie en remboursant à

l’acheteur d’origine le prix de gros de toute pièce garantie mais défectueuse.Après la première année, NAPOLEON ne sera pas

responsable de l’installation, main d’œuvre au autres coûts ou dépenses relatives à la ré-installation d’une pièce garantie et de

telles dépenses ne sont pas couvertes par cette garantie.

En dépit de toute disposition contenue dans cette Garantie Limitée à Vie du Président LA RESPONSABILITÉ DE NAPOLEON

sous cette garantie est définie comme ci-dessus et elle ne s’étendra à aucun dommage accidentel, consécutif ou indirect.

Cette garantie définit l’obligation et la responsabilité de NAPOLEON concernant le poêle NAPOLEON et toutes autres garanties

exprimées ou implicites concernant ce produit, ses composants ou accessoires sont exclus.

NAPOLEON n’assume ou n’autorise aucun tiers à assumer en son nom, toutes autres responsabilités concernant la vente de ce

produit NAPOLEON ne sera pas responsable pour : une surchauffe, un mauvais tirage, des déversements causés par des

conditions liées à l’environnement telles que des toits, des bâtiments, la proximité d’arbres, de collines, de montagnes, une

ventilation ou des évents inadéquats, une configuration d’aération excessive, une constitution d’air insuffisante, ou des pressions

atmosphériques négatives qui sont peut-être ou peut-être pas causées par des systèmes mécaniques tels que les ventilateurs

d’évacuation, les fournaises, les séchoirs à linge, etc.

Tous dommages au poêle, à la chambre de combustion, l’échangeur de chaleur, la garniture de cuivre ou autre composant dus à

l’eau, les dommages causés par le temps, de longues périodes d’humidité, de condensation, des produits chimiques ou produits

d’entretien nuisibles ne seront pas de la responsabilité de NAPOLEON.La facture ou sa copie sera requise ainsi qu’un numéro de

série et un numéro de modèle lors d’une réclamation auprès de votre représentant autorisé. La carte d’enregistrement doit être

retournée dans les quatorze jours pour enregistrer la garantie.

NAPOLEON se réserve le droit de demander à son représentant d’inspecter tout produit ou pièce avant d’honorer toute

réclamation.

Toutes les spécifications et les designs peuvent être modifiés sans préavis ou aux améliorations constantes du produit. NAPOLEON® est une marque de commerce déposée DE

WOLF STEEL LTÉE. Brevets U.S. 5.303.693.801 - CAN. 2.073.411, 2.O82.91 5. © WOLF STEEL LTÉE.

2

Page 17

S.V.P. CONSERVEZ CE MANUEL COMME RÉFÉRENCE

TABLE des MATIÈRES

INTRODUCTION p. 4

Informations générales p. 4

Principe de fonctionnement p. 4

Soin de la vitre p. 4

INSTALLATION p. 5

Installation dans une alcôve p. 5

Installation du poêle p. 5

INSTALLATION AVEC

LE KIT SOUFFLERIE EP63 p. 6

Ajout de sections de cheminée p. 7

Air extérieur p. 7

Inversion du collet de conduit d’évacuation p. 7

Installation du récupérateur de cendre p. 7

Évacuation à travers un mur p. 7

Installation de l’écran de dessous p. 7

INSTALLATION MAISON MOBILE p. 8

L’évacuation p. 8

Air extérieur/fixation au plancher p. 8

Adaptateur pour prise d’air extérieur 113KT p. 8

INSTRUCTIONS D’OPÉRATION p. 9

Lors du premier allumage p. 9

Créer un tirage approprié p. 9

Extincteurs et détecteurs de fumée p. 10

Chargement du combustible et cycle de

combustion p. 10

Soufflerie optionnelle EP63 p. 10

Méthodes de décendrage p. 10

Pare-étincelles optionnel EP90K p. 10

ENTRETIEN DU TAS DE BOIS p. 11

ENTRETIEN DU POÊLE p. 11

Formation et enlèvement de créosote p. 11

Feu de cheminée ou feu hors contrôle p. 11

REMPLACEMENTS p. 12

)

SPÉCIFICATIONS MODÈLE 1600C-1

LARGEUR X PROFONDEUR 681 X 615 mm 26.8” X 24.2”

HAUTEUR 712 mm 28.0”

HAUTEUR DÉPART ARRIÈRE (A) 698 mm 27,5”

FOYER (P.L.H.) 304 X 520 X 265 mm 11.9” X 20.4” X 10.4”

CONTENANCE (LITER) 41.3 L 1.46 ft

SURFACE CHAUFFÉE * 56-112 m

PUISSANCE MAXI ** 14 kW

DURÉE 7 hr

POIDS 150 KG 330 LB

*CES DONNÉES VARIENT CONSIDÉRABLEMENT SELON LES CONDITIONS INDIVIDUELLES.

** BTU/H RÉALISTES ESTIMÉS PAR WOLF STEEL LTÉE AVEC BÛCHES DE BOIS DUR ET RAVITAILLEMENTNORMAL.

2

3

600-1200 ft

2

3

Page 18

INTRODUCTION

Informations générales

Le poêle à bois 1600C-1 a été spécifiquement conçu

pendant plusieurs mois de recherches pour satisfaire les

exigences de l’E.P.A. américaine concernant les

émissions standard de particules pour 1990 ; il a été

considérablement testé par les laboratoires canadiens et

américains. Ce système est le plus efficace, le plus simple

et sans problèmes connus; il fonctionne comme suit :

Le “1600C-1” est un appareil de chauffage au bois à

fonctionnement continu ayant une chambre de

combustion fermée avec parois en fonte où tout le

combustible est brûlé sur la grille fournie. C’est un appareil

fonctionnant en départ dessus et arrière et pouvant être

installé près d’un mur. Il dispose d’une commande d’air

permettant de bien contrôler son allure de fonctionnement

et est équipé d’un cendrier de grande contenance.

NOTE : Avant de mettre votre appareil en

fonctionnement, veillez à retirer les articles pouvant

se trouver à l’intérieur : buse de raccordement, outil

d’ouverture de porte, tisonnier, récupérateur de

cendre et matériel d’installation.

After removing the unit from the pallet, use the

securing screws to install the heat shield to the base of

the unit.

Principe de fonctionnement

Le poêle à bois 1600C-1 est conçu pour fonctionner avec

la porte fermée. La chaleur produite est principalement

transmise par la vitre et le corps de l’appareil. La

combustion se produit sur la grille avec une entrée d’air

par le haut de la chambre de combustion. Assurez-vous

qu’il y a assez d’air comburant qui rentre. Il y a beaucoup

d’autres appareils chez vous qui ont besoin d’air, tels : les

hottes des cuisinières, les installations de chauffage à air

pulsé, les ventilateurs d’extraction d’air des salles de bain.

Do not connect this unit to a chimney flue serving another

appliance. Les bruits causés par l’expansion et la

contraction lors des cycles de chauffage et de

refroidissement sont tout à fait normaux et il faut s’y

attendre. Après de longues périodes sans utiliser le poêle,

telles qu’à la suite de vacances ou en automne, il se peut

qu’une légère odeur s’en dégage pendant quelques

heures. Ceci est causé par des particules de poussière

brûlant dans le poêle. Ouvrez une fenêtre afin d’aérer la

pièce de manière suffisante.

Si vous utilisez la prise d’air extérieur de votre poêle, vous

ne manquerez jamais d’air comburant. Si vous choisissez

de ne pas utiliser cette prise d’air extérieur et que vous

avez des problèmes de tirage ou de fumée, vous devrez

ouvrir une fenêtre ou une porte.

AVERTISSEMENT : Faire fonctionner votre appareil

avec la chute à cendres ouverte ou entrouverte

constitue un risque d’incendie et peut résulter en des

dommages internes au poêle, un incendie ou un feu de

cheminée.

AVERTISSEMENT- PROPOSITION 65DE LACALIFORNIE :

L’utilisation de cet appareil peut produire de la fumée

qui contient des substances chimiques qui, selon

l’état de Californie, causeraient le cancer, des

malformations congénitales ou autres dangers pour la

reproduction.

Soin de la vitre

Si vous ne nettoyez pas le dépôts régulièrement, la vitre

risque de rester marquée en permanence. Normalement,

un feu très chaud maintiendra la vitre propre. Les raisons

les plus fréquentes pourquoi la vitre se salit incluent : trop

peu de combustible est utilisé, alors le poêle ne se

réchauffe pas complètement, du bois vert ou humide est

utilisé, le contrôle de tirage est trop fermé, il n’y a alors pas

suffisamment d’air pour réaliser une combustion complète.

S’il est nécessaire de nettoyer la vitre, utilisez des linges

doux, sans abrasifs.

NETTOYEZ SEULEMENT LORSQUE LA VITRE EST

FROIDE !

La vitre est très résistante mais ne laissez pas le bois en

combustion s’appuyer contre la vitre. Fermez toujours la

porte doucement. Si la vitre devait craqueler pendant que

le feu brûle, n’ouvrez pas la porte jusqu’à ce que le feu

s’éteigne et n’utilisez pas l’appareil jusqu’à ce que la vitre

ait été remplacée, préférablement par votre détaillant, par

une nouvelle plaque de verre céramique de 4 mm

d’épaisseur.

N’UTILISEZ PAS DE SUBSTITUT.

Pour enlever la porte, ouvrez la et soulevez-la ; retirez les

vis et les supports qui retiennent la vitre. Enlevez toute la

vitre brisée. Remplacez le joint si nécessaire. Placez

ensuite la nouvelle vitre en position et remplacez les vis et

les supports.

4

Page 19

INSTALLATION

Les installations avec des dégagements réduits doivent se

conformer aux normes NFPA211 ou CAN/CSA-B365.

Pour les dégagements avec le kit EP63 installé, se référer à la

page 6.

Installation dans une alcôve

Le modèle 1600C-1 peut être installé dans une alcôve de

profondeur inférieure à 122 mm et d’une hauteur d’au

moins 213 mm, équipé d’un conduit mural double

enveloppe homologué posé à une distance minimum de

305 mm des matériaux combustibles.

Les distances minimum sont comme indiqu

é.

Installation dans une alcôve

4 0 6 m m

5 5 9

m m

4 0 6 m m

1 2 2 m m m a x

Les murs ne doivent pas se prolonger devant la façade

de l’appareil lorsque installé dans une alcôve.

I l l u s t r é a v e c p r o t e c t i o n a u s o l d e 1 9 m m ( . 7 5 " )

2 1 3 m m

Installation du poêle

Si le poêle est installé sur un

plancher combustible, il doit

être placé sur un protecteur de

plancher incombustible

approuvé qui doit dépasser les

côtés et l’arrière du poêle de

203 mm et se prolonger de

457 mm sur le devant.

2 0 3 m m

2 0 3 m m

4 5 7 m m

2 0 3 m m

Raccord simple paroi

Flue configuration

Type 1 Horizontal Vertical

A 406 mm 406 mm

DU

POÊLE

B* 559 mm 559 mm

C 381 mm 381 mm

D 635 mm 635 mm

DU

CONDUIT

E ... 559 mm

* Une distance minimum de 559 mm sera maintenue

entre le mur combustible et le raccord de cheminée.

Afin d’obtenir ces mesures de dégagement, il faut

utiliser des raccords double parois homologués

pour une distance de 305 mm ou moins par rapport

aux matériaux combustibles.

Flue configuration

Type 2 Horizontal Vertical

A 406 mm 406 mm

DU

POÊLE

B 356 mm 356 mm

C 381 mm 381 mm

D 635 mm 635 mm

DU

CONDUIT

E ... 406 mm

B

D

A

C

E

C

5

Page 20

INSTALLATION AVEC LE

KIT SOUFFLERIE EP63

Les installations avec des dégagements réduits doivent se

conformer aux normes NFPA211 ou CAN/CSA-B365.

Installation dans une alcôve

Le modèle 1600C-1 peut être installé dans une alcôve de

profondeur inférieure à 122 mm et d’une hauteur d’au

moins 213 mm, équipé d’un conduit mural double

enveloppe homologué posé à une distance minimum de

305 mm des matériaux combustibles.

Les distances minimum sont comme indiqu

é.

Installation dans une alcôve

4 0 6 m m

4 0 6

m m

4 0 6 m m

1 2 2 m m m a x

Les murs ne doivent pas se prolonger devant la façade

de l’appareil lorsque installé dans une alcôve.

I l l u s t r é a v e c p r o t e c t io n a u s o l d e 1 9 m m ( . 7 5 " )

2 1 3 m m

Installation du poêle

Si le poêle est installé sur un

plancher combustible, il doit

être placé sur un protecteur de

plancher incombustible

approuvé qui doit dépasser les

côtés et l’arrière du poêle de

203 mm et se prolonger de

457 mm sur le devant.

2 0 3 m m

2 0 3 m m

4 5 7 m m

2 0 3 m m

Raccord simple paroi

Flue configuration

Type 1 Horizontal Vertical

A 406 mm 406 mm

DU

POÊLE

B* 254 mm 406 mm

C 280 mm 280 mm

D 635 mm 635 mm

DU

CONDUIT

E ... 457 mm

F ... 457 mm

* Une distance minimum de 457 mm sera maintenue

entre le mur combustible et le raccord de cheminée.

Afin d’obtenir ces mesures de dégagement, il faut

utiliser des raccords double parois homologués

pour une distance de 305 mm ou moins par rapport

aux matériaux combustibles.

Flue configuration

Type 2 Horizontal Vertical

A 406 mm 406 mm

DU

POÊLE

B 254 mm 254 mm

C 280 mm 280 mm

D 635 mm 635 mm

DU

CONDUIT

E ... 406 mm

F ... 305 mm

F

6

B

D

A

C

E

C

Page 21

Raccordement de la cheminée

A

Un conduit de raccordement à paroi simple de 6" de

diamètre utilisé pour raccorder le poêle à la cheminée doit

être installé avec l’extrémité gaufrée (partie mâle) sur la

buse du poêle. Ceci permettra à l’humidité du bois en

combustion de retourner dans la chambre de combustion.

Chaque joint de raccordement doit être fixé àl’aide de trois

vis à métal.

Cet appareil de chauffage doit être raccordé à :

1) Une cheminée qui se conforme aux exigences des

cheminées préfabriquées de type HT résidentiel et selon le

Building Heating Appliance UL 103.

ou

2) Une cheminée en maçonnerie avec chemisage intégral

conforme aux codes et aux exigences.

Raccorder le poêle à une cheminée de maçonnerie ou une

cheminée isolée en acier inoxydable approuvée. Le tuyau

à fumée de 6" (150 mm) de diamètre doit être aussi court et

aussi droit que possible. Le raccordement à la cheminée

de maçonnerie doit se faire à l’aide d’un manchon

métallique ou de maçonnerie cimenté en place. Une

cheminée métallique isolée doit être supportée au plafond

ou au toit et son installation doit être conforme aux

instructions de son manufacturier.

Ajout de sections de cheminée

Ajoutez des sections de

cheminée selon les

instructions d’installation du

fabricant autant qu’il est

2 F T .

M I N

.

1 0 F T .

3 F T .

M I N

.

requis pour atteindre la

hauteur voulue. Le sommet

de la cheminée doit dépasser

d’au moins 3 pieds le point où

la cheminée émerge du toit et

dépasser d’au moins 2 pieds

toute surface ou structure et située à l’intérieur d’une

distance horizontale de 10 pieds. Si, à l’intérieur de

l’attique, votre cheminée est entourée, un écran protecteur

pour les chevrons est requis.

Air extérieur

Si possible, raccordez la prise d’air à la base de l’appareil

avec une prise d’air extérieur de 4" (100 mm) de diamètre

disponible chez votre détaillant Napoléon/Wolf Steel ltée.

Suivez les instructions de “Air extérieur de maison mobile”.

Inversion du collet de conduit d’évacuation

Le collet de conduit

d’évacuation est orienté pour

une évacuation sur le dessus.

Retirez les deux boulons, et

tournez le collet 180 degrés.

Fixez le collet en place à l’aide

des deux boulons, écrous et

rondelles.

LA LONGUEUR TOTALE DU TUYAU À FUMÉE NE

DEVRAIT PAS EXCÉDER 40’ DE LA HAUTEUR DE LA

CHEMINÉE AU-DESSUS DU POÊLE.

Tout tuyau à fumée doit posséder une pente légère

vers le haut (1/4" au pied/6mmau0.3m)endirection

de la cheminée et toutes les connexions doivent être

hermétiques en plus d’être solidifiées par trois vis à

métal espacées également.

Un tuyau à fumée non isolé ne doit pas traverser un

grenier, un entre-toit, un placard ou autre endroit

dissimulé similaire, ou traverser un plancher, un

plafond, un mur ou une cloison, ou toute autre

construction combustible.

N’UTILISEZ AUCUN MATÉRIAU DE FORTUNE DURANT

L’INSTALLATION.

1. Posez le poêle en position. Repérez le centre du tuyau

de façon à ne pas avoir,si possible,à couper les soliveaux.

Utilisez un fil à plomb pour aligner le centre du tuyau.

2. Découpez et charpentez une ouverture dans le toit. Un

dégagement minimal de 2“ entre la cheminée et les

matériaux combustibles doit être maintenu.

NE REMPLISSEZ CET ESPACE D’AUCUN MATÉRIAUX.

Des boutisses devraient être placées entre les soliveaux

et clouées en place pour assurer un support additionnel.

Pour tout plancher ou plafond traversé par la cheminée,

les espaceurs/coupe-feu doivent être fixés à la base de la

charpente de l’ouverture.

3. Déterminez les dimensions de l’ouverture à découper

dans le toit à l’aide d’un fil à plomb. Dessinez l’ouverture2"

plus grande sur tous les côtés que le diamètre de la

cheminée afin de conserver les dégagements adéquats.

Installation du récupérateur de cendre

Pour éviter des dommages

pendant le transport, le

récupérateur de cendre a

été placé derrière la porte

de l’appareil. Pivotez le

récupérateur de cendre sur

la patte “A” et abaissez pour

le placer.

Évacuation à travers un mur

Si possible, l’installation des

conduits de raccordement ne

doit pas passer à travers un

mur combustible. S’il faut

absolument passer à travers

un mur combustible,

consultez votre inspecteur en

bâtiment avant de procéder.

Consultez aussi le fabricant

des conduits de

raccordement pour toutes

contraintes particulières.

Voici la façon idéale de

passer un conduit de

raccordement à travers un

mur combustible jusqu’à la

cheminée de maçonnerie.

Consultez votre détaillant pour tout composant de

raccordement à travers un mur dont vous auriez besoin.

N’utilisez que les pièces qui ont été testées et certifiées

pour des installations à travers un mur.

Installation de l’écran de dessous

L’écran de dessous placé dans le poêle doit être installé

sous l’appareil avec 2 vis prévues. Reportez vous à la

page 8 afin de respect le sens de montage de l’écran de

dessous.

7

Page 22

INSTALLATION DANS UNE

R

MAISON MOBILE

LE MODÈLE 1600C-1 EST HOMOLOGUÉ POUR

INSTALLATION DANS LES MAISONS MOBILES AU

CANADA ET AUX ÉTATS-UNIS.

Le poêle doit être fixé au plancher de la maison mobile.

Avertissement!

N’installez pas ce poêle dans une chambre à coucher.

N’installez pas ce poêle de façon à compromettre

l’intégrité structurale du plancher, des murs, du

plafond ou du toit de la maison mobile.

L’évacuation

Raccordez le poêle à la

cheminée en utilisant un

conduit de raccordement à

double paroi certifié.

Utilisez un système de

cheminée homologué selon

la norme ULC S629 au

Canada ou l’équivalent aux

États-Unis.

Ces équipements doivent

être installés conformément

aux instructions de leurs

fabricants. N’utilisez que

les composants spécifiés.

Les substitutions ne sont

pas acceptables. La

cheminée et le tuyau de

raccordement doivent se

R A C C O R D E M E N T D E P R I S E D ' A I R E X T É R I E U R

À T R A V E R S U N M U R O U U N P L A N C H E R

prolonger d’au moins 8 pi

au-dessus du poêle et 3 pi au-dessus du point le plus élevé

sur le toit. Au sommet, installez un chapeau qui ne

restreindra pas le passage de la fumée. La cheminée doit

être supportée au plafond ou au toit de façon à ce que son

poids ne repose pas sur le poêle.

Elle doit être installée entre les solives de plafond en

utilisant un écran de protection et un solin de toit pour que

la solidité de l’ossature, l’isolation et l’imperméabilité de la

maison ne soient pas diminuées. Scellez avec du silicone

pour maintenir une barrière thermique à la cheminée et

aux ouvertures par lesquelles pénètrent les conduits d’air

extérieur.

C H A P E A U

S O L I N D E T O I T

P O U R M A I S O N M O B I L E

É C R A N D E P R O T E C T I O N

S U P P O R T D E T O I T

C O L L E T D E F I N I T I O N

P O Ê L E F I X É

A U P L A N C H E R

P R O T E C T I O N

D E P L A N C H E

Adaptateur pour prise d’air extérieur 113KT

Lorsque vous installez le 1600C-1 dans une maison

mobile, utilisez l’ensemble de prise d’air extérieur

111KT conjointement avec l’adaptateur pour prise

d’air extérieur 113KT.

Retirez les deux vis situées en dessous de l’appareil et

installez les deux supports de fixation pour plancher à

l’aide de deux vis retirées.

Installez l’adaptateur pour prise d’air extérieur en insérant

le support goujon de sorte que les goujons passent par les

trous indiqués.

Maintenez le support goujon en place et alignez les trous

de l’adaptateur pour prise d’air extérieur avec les goujons

du support.

Fixez l’adaptateur en place à l’aide des 2 écrous fournis.

Fixez l’appareil au plancher à l’aide des deux supports de

fixation et des deux vis longues fournies.

Air extérieur/fixation au plancher

Le raccordement de la prise d’air du poêle sur

l’extérieur ainsi que la fixation au plancher n’est

obligatoire que pour les maisons mobiles. Utilisez un

ensemble de prise d’air extérieur et des supports de

fixation pour plancher.

Évitez de sectionner les solives de plancher, les montants

muraux, les câbles électriques ou les éléments de

plomberie. Pour prévenir les courants d’air, scellez le

contour du conduit d’air extérieur avec de l’isolation.

Si la pièce est privée d’air parce que la prise d’air

extérieur est obstruée par de la glace, des feuilles etc.

ou parce que la porte du poêle est demeurée ouverte

ou à cause d’un ventilateur puissant en opération etc.,

des vapeurs et des fumées dangereuses pourraient

être aspirées dans la pièce.

8

Page 23

INSTRUCTIONS D’OPÉRATION

AVERTISSEMENT : Objects placed in front of the fire

place should be kept a minimum of 48” from the front

face.

ATTENTION : N’utilisez jamais d’essence, d’huile à

lampe, de kérosène, d’essence à briquets ou autres

liquides similaires pour allumer ou raviver un feu dans

cet appareil. Gardez tous ces liquides loin du poêle

lorsqu’il est en fonction.

Votre appareil Napoléon certifié aux normes EPA, est une

unité de haute technologie, conçue selon les principes

technologiques les plus avancés. Cet appareil est

extrêmement hermétique et est équipé d’une alimentation

directe d’air comburant exclusive (ensemble optionnel), un

dispositif de sécurité qui empêche les écoulements afin de

garder votre maison exempte de monoxyde de carbone,

advenant un refoulement de cheminée ou une pression

négative interne.

Lors du premier allumage

Le poêle émettra une légère odeur pendant quelques

heures. C’est un état provisoire normal provoqué par la

combustion des peintures internes et des lubrifiants

utilisés dans le processus de fabrication et ne se produira

plus par la suite. Ouvrez simplement une fenêtre pour

aérer suffisamment la salle pendant les premières heures

de fonctionnement.

Pour commencer, un feu vif est nécessaire. Placez du

papier chiffonné sur la grille et couvrez debois d’allumage.

Ouvrez la commande d’air entièrement en la déplaçant

vers la droite. Allumez le papier et laissez la porte

légèrement entrebâillée (un pouce) jusqu’à ce que tout le

bois d’allumage soit enflammé. Pour maintenir un feu vif,

un lit de braises chaud doit être établi et maintenu.

Ajoutez lentement du bois de plus grande taille (morceaux

de taille 2" x 4"). Répartir les morceaux de bois en longueur

d’un côté à l’autre du lit de braises chaud séparé par un

fossé peu profond, de sorte que l’air primaire puisse

s’écouler directement dans ce fossé et mettre à feu le

combustible au dessus. Quand le feu semble être à son

point haut, des bûches de tailles moyennes peuvent être

ajoutées. Une fois que ces bûches sont enflammées,

fermez soigneusement la porte (la fermeture de la porte

trop rapide après réapprovisionnement en combustible

réduira la température et engendrera une combustion

insuffisante). Rappelez-vous qu’il est plus efficace de

brûler des bûches de dimension moyenne à feu vif et de

recharger en combustible fréquemment que de charger la

cheminée avec des grandes bûches qui a comme

conséquence un feu couvant, inefficace et une vitre sale.

Dès que la porte sera fermée, vous observerez un

changement de la forme des flammes. Les flammes

deviendront plus petites et plus paresseuses parce qu’il y

moins d’oxygène qui entre dans la chambre de