Napoleon W415-0118 Service Manual

Wolf Steel’s Service Manual Index

Part 1: Troubleshooting: Direct Vents

Pilot Not Lighting Flowchart ..............................................................................................................4

Pilot Not Holding Flowchart .............................................................................................................5

Pilot Failure Flowchart....................................................................................................................6

Main Burner Not Lighting Flowchart............................................................................................7

Main Burner Delayed Ignition Flowchart.........................................................................................8

Main Burner Low Flame Flowchart...................................................................................................9

Main Burner Failure Flowchart........................................................................................................... 10

Complete Unit Shutdown.................................................................................................................. 11

Odour Flowchart.............................................................................................................................. 12

Part 2: Troubleshooting: Natural Vents

Pilot Not Lighting Flowchart...........................................................................................................14

Pilot Not Holding Flowchart............................................................................................................15

Pilot Failure Flowchart......................................................................................................................16

Main Burner Not Lighting Flowchart............................................................................................17

Main Burner Delayed Ignition Flowchart............................................................................................18

Main Burner Low Flame Flowchart..................................................................................................19

Main Burner Failure Flowchart........................................................................................................20

Complete Unit Shutdown.................................................................................................................21

Odour Flowchart..............................................................................................................................22

Part 3: Troubleshooting: Vent Free

Pilot Not Lighting Flowchart.............................................................................................................24

Pilot Not Holding Flowchart..............................................................................................................25

Pilot Failure Flowchart......................................................................................................................26

Main Burner Not Lighting Flowchart.................................................................................................27

Main Burner Delayed Ignition Flowchart...........................................................................................28

Main Burner Low Flame Flowchart...................................................................................................29

Complete Unit Shutdown.................................................................................................................30

Odour Flowchart..............................................................................................................................31

Part 4: Troubleshooting: Other Issues

Carboning Flowchart.......................................................................................................................33

Oil-Canning Flowchart.....................................................................................................................34

Blower Flowchart.............................................................................................................................35

Remote Control Guide.....................................................................................................................36

Part 5: Testing & Adjustments

Testing: Pressures...........................................................................................................................38

Testing: Gasket................................................................................................................................39

T esting: Switches - Spill Switch.........................................................................................................39

Testing: Switches - T .stat/Toggle.......................................................................................................39

Testing: Millivolts - Thermocouple - Robertshaw Valve...................................................................40

Testing: Millivolts - Thermocouple - SIT 820 Nova Valve................................................................41

Testing: Millivolts - Thermopile........................................................................................................42

Testing: Function - Magnet Coil - Robertshaw Valve......................................................................43

Testing: Function - Operator Coil - Robertshaw Valve....................................................................44

Testing: Function - Magnet Coil - SIT 820 Nova Valve....................................................................45

Testing: Function - Operator Coil - SIT 820 Nova Valve.................................................................46

Testing: Pilot Flame.........................................................................................................................47

Adjustments: Pilot Flame..................................................................................................................48

Adjustments: Spill Switch - Robertshaw Valve....................................................................................49

Adjustments: Spill Switch - SIT 820 Nova Valve..................................................................................50

Adjustments: Venturi/Air Shutter.....................................................................................................51

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

ISO-176 W415-0118 / B / 10.25.06

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

© WOLF STEEL LTD.

PART 1: TROUBLESHOOTING: DIRECT VENTS

Pilot Not Lighting Flowchart..........................................................................................................4

Pilot Not Holding Flowchart..........................................................................................................5

Pilot Failure Flowchart..................................................................................................................6

Main Burner Not Lighting Flowchart.............................................................................................7

Main Burner Delayed Ignition Flowchart......................................................................................8

Main Burner Low Flame Flowchart...............................................................................................9

Main Burner Failure Flowchart....................................................................................................10

Complete Unit Shutdown...........................................................................................................11

Odour Flowchart.........................................................................................................................12

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

ISO-176 W415-0118 / B / 10.25.06

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

© 2005 WOLF STEEL LTD.

4

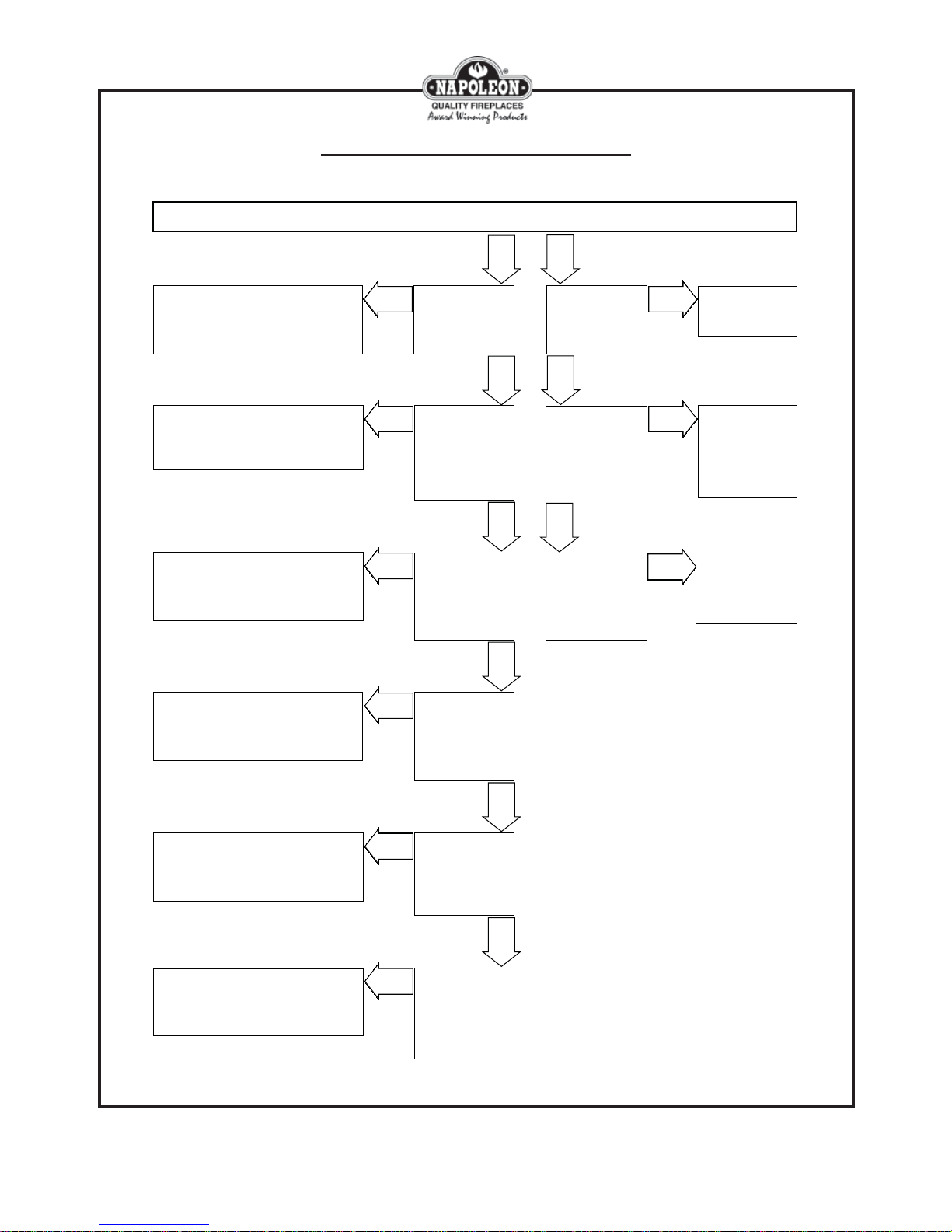

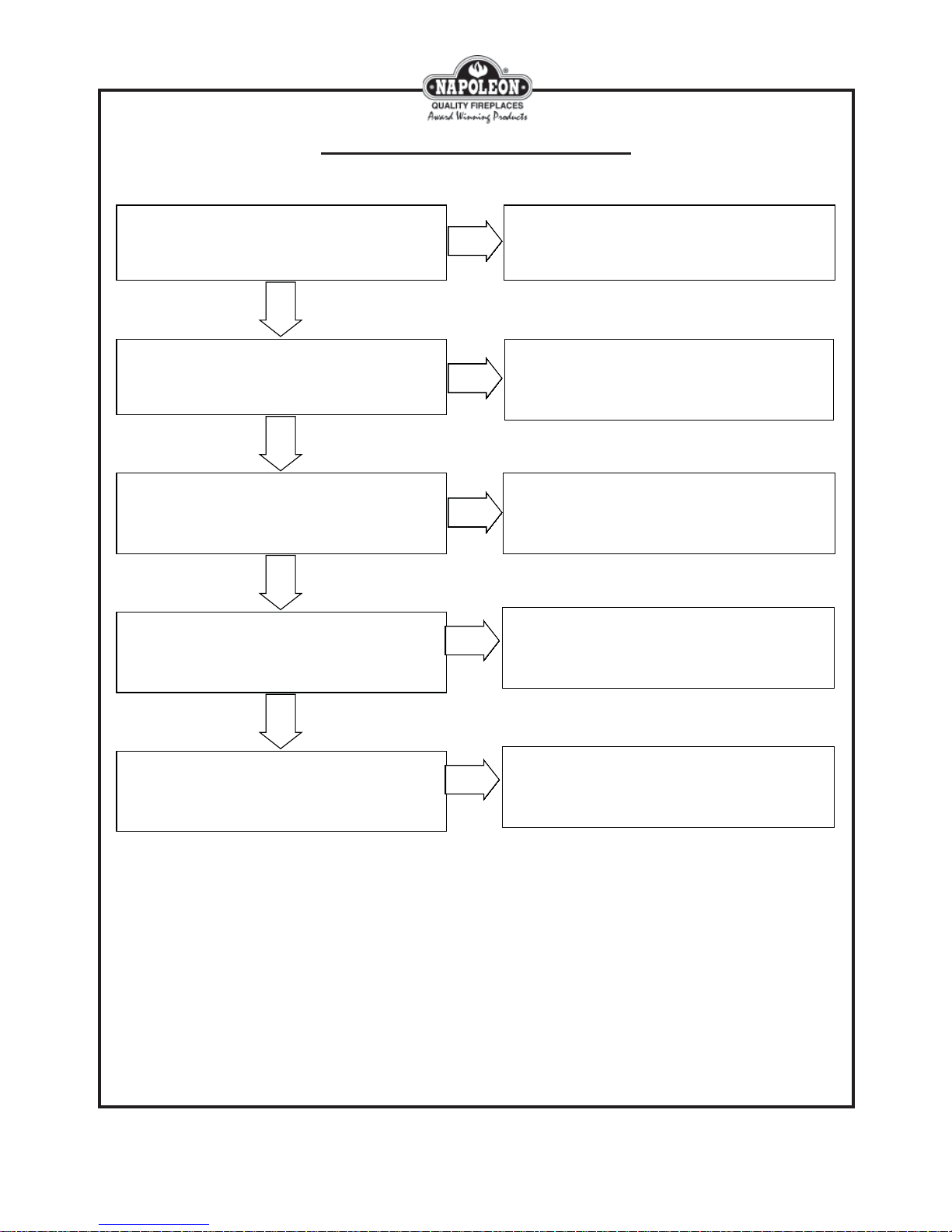

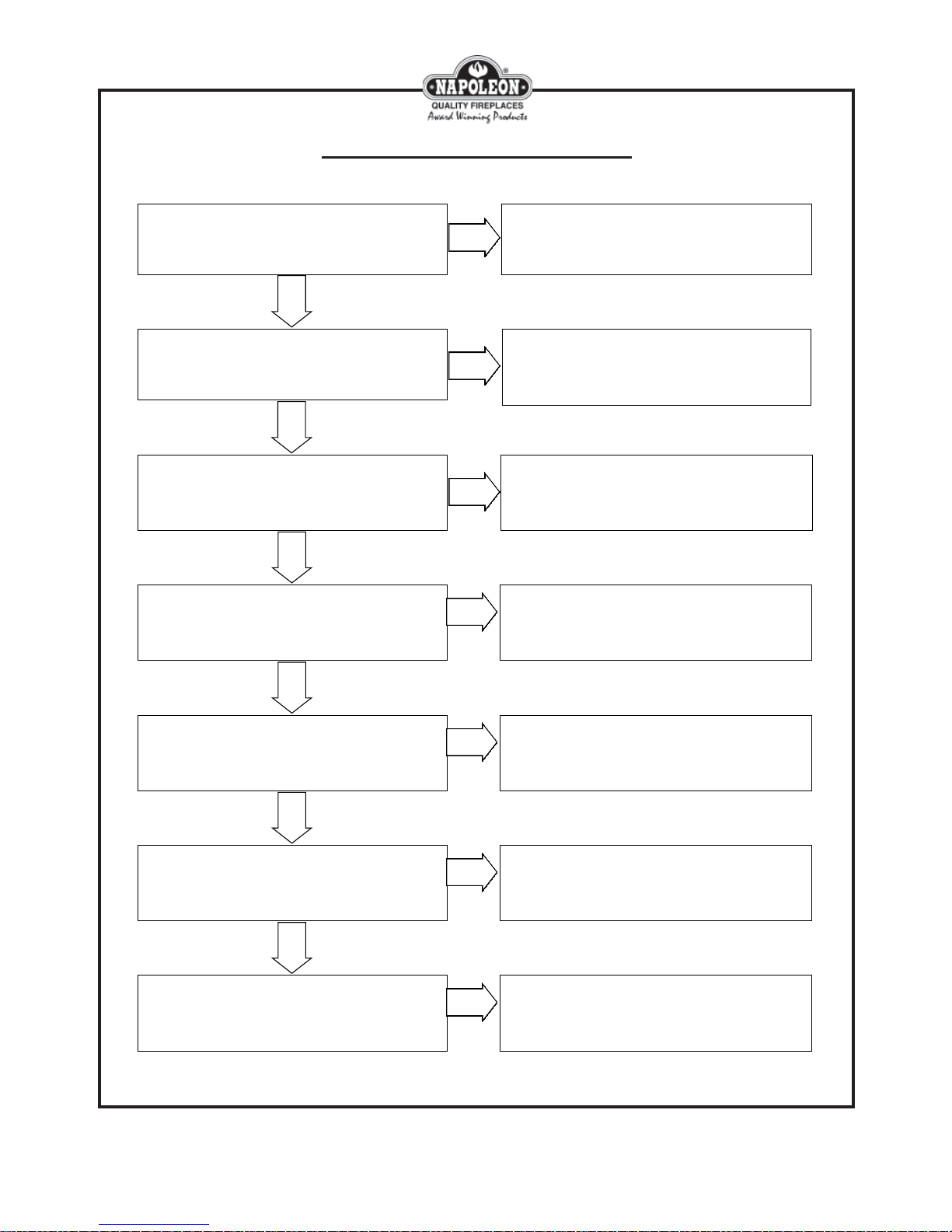

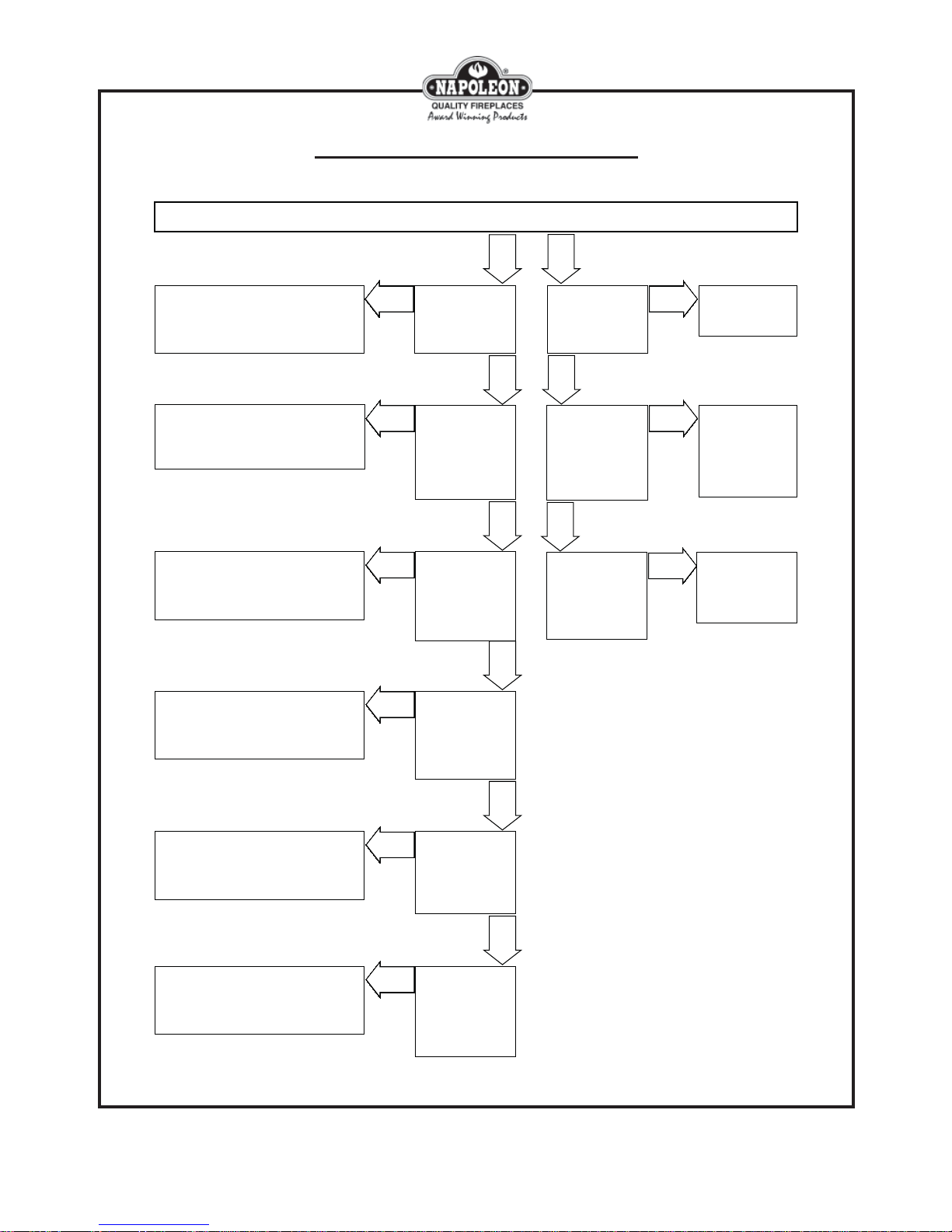

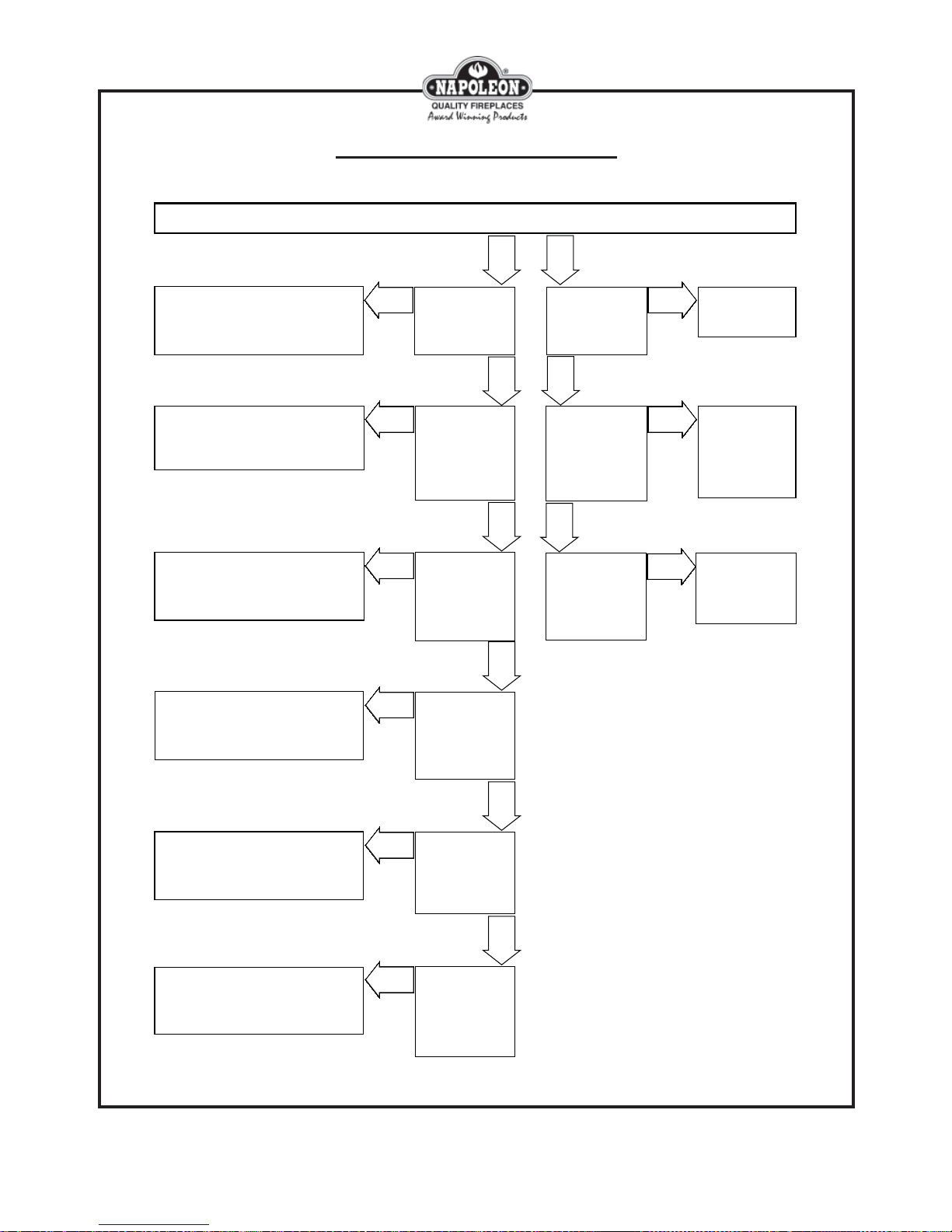

Troubleshooting: Direct Vents

Pilot Not Lighting Flowchart

Is there a s park at the electrode when the pus h button igniter is pres s ed?

Check to ensure proper supply

pressures are available for ignition.

(See "Testing: Procedures")

Ensure the adjustment screw has not

been tightened closed. Adjust as

necessary. (See "Adjustments: Pilot

Flame")

Remove the tube and orifice and clean,

make sure no debris has compacted the

inside, inhibiting the flow of gas .

T ig hte n / sec u re to prev e nt le a k s .

NO

Has the inline gas

pressure been

NO

adjustment screw

been checked?

NO

Ha ve th e pilo t tub e

& pilo t orific e been

NO

Ar e the fittings on

the pilot tu be

te s ted ?

Has the pilot

checked for

blocka ges?

secure?

YES

YES

YES

YES

NO

Is the electrode

wire c onnection

secure?

YES

Is there a 1/8" gap

between the

electrode and the

pilot hood?

YES

Has the electrode

been examined for

damage? (i.e.

chipped/broke n)

NO

NO

NO

Secure / Replace

as necessary.

Adjust position so

the r e is no

grea ter than a

1/8" gap.

Replace if

damaged or

broke n.

Un-kink the tube to prevent blockage, or

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

replace leaking tube.

E nsure the opening is not blocked or

plugged. C lea r if necess ary.

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

ISO-176 W415-0118 / B / 10.25.06

NO

Ha s the pilo t tube

been checked for

NO

Has the primar y

air opening on the

been checked for

YES

kinks / leaks?

YES

pilot assembly

blocka ges?

© 2005 WOLF STEEL LTD.

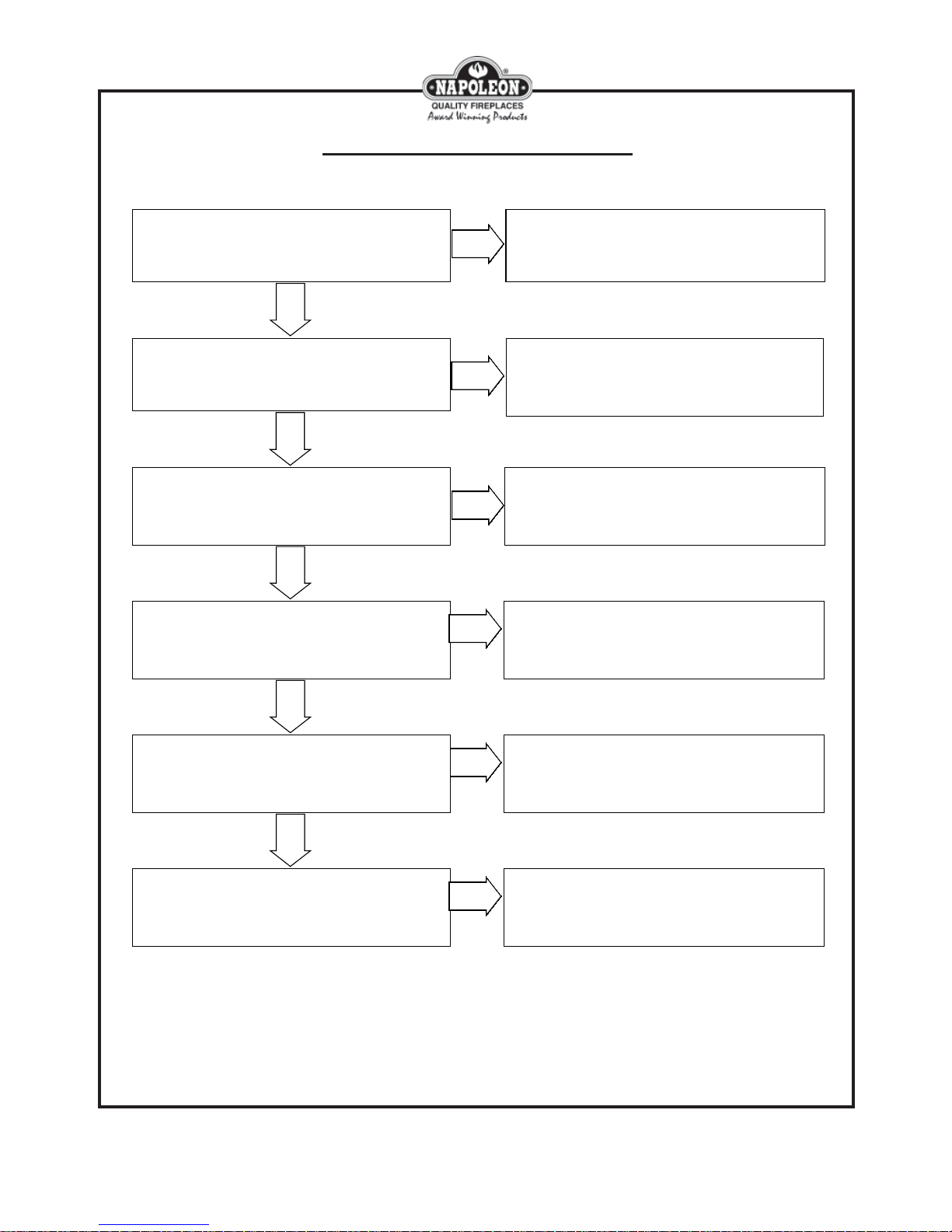

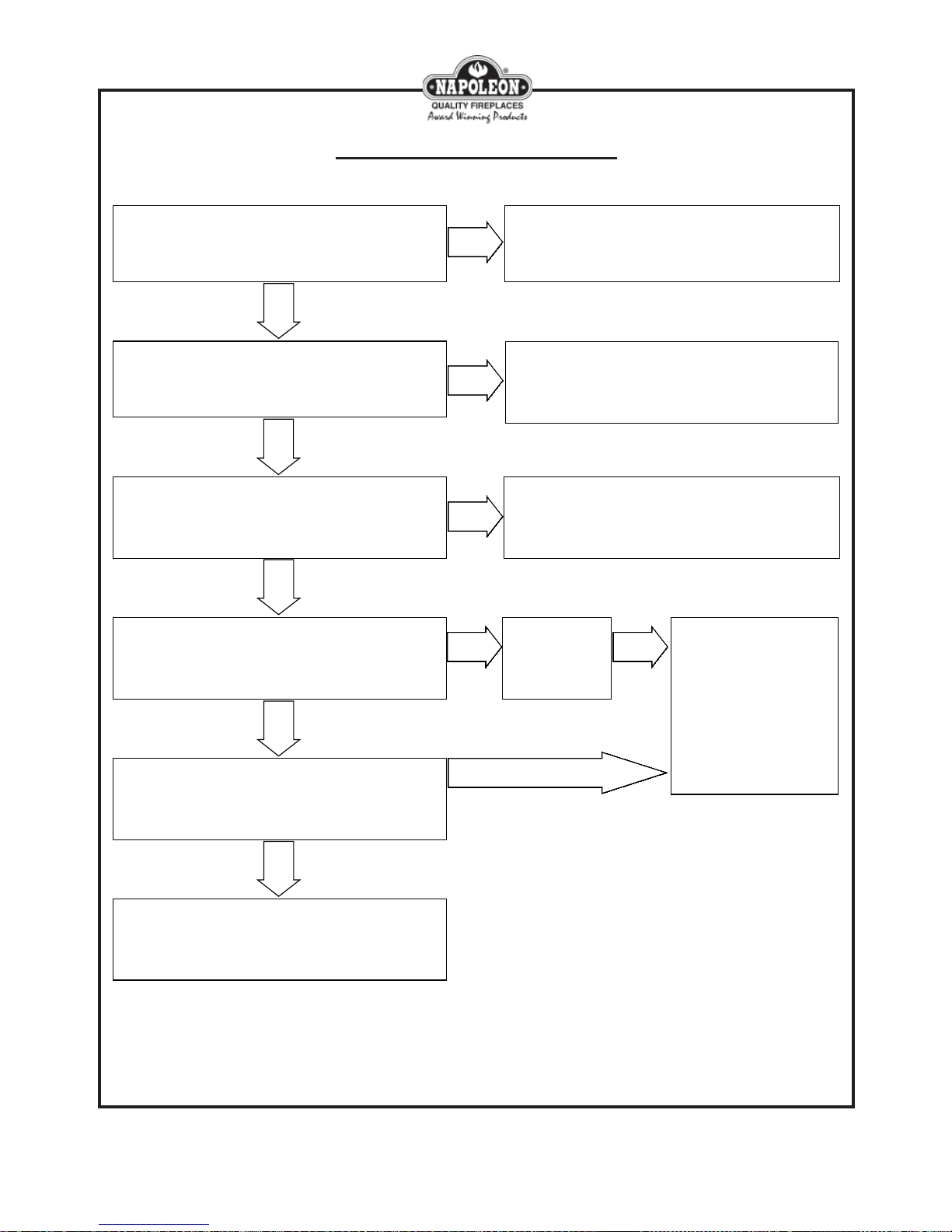

Troubleshooting: Direct Vents

Pilot Not Holding Flowchart

5

Has the thermocouple connection been checked?

Is the tip of the thermocouple clean?

YES YES

Has the thermocouple been tested for millivolt

generation?

YES

Has the magnet coil of the valve been checked for

function?

NO

NO

NO

NO

Tighte n therm oc ou ple t o e nsure prop e r m illivolt

delivery.

Clean any buildup off of the tip of the

therm ocouple to m aximize it's exposure to the

flame.

Test the therm ocouple to ensure it is within

specifications. (See "Testing: Millivolts -

Thermocoup le")

Te st the m agne t c oil to ensure it is w ithin

specification. (See "Testing: Function - Magnet

Coil")

YES

Is the supply line size ade quate for the

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

ISO-176 W415-0118 / B / 10.25.06

installatio n?

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

NO

© 2005 WOLF STEEL LTD.

Check the local code requirements and replace as

ne ce ssar y.

6

Troubleshooting: Direct Vents

Pilot Failure Flowchart

Is the pilot flame p attern, position and size

correct?

YES

Is the pilot flame shrinking when the burner is

turned on?

NO

Has the thermocouple been tested for millivolt

generation?

YES

Has the function of the magnet coil been

checked?

NO

YES

NO

NO

Check to m ake sure the p ilot is large enough and in

the proper p osition, to properly heat the

thermocouple. (See "Testing: Pilot Flame")

Check to m ake sure the pressure is not dropping

off on activation. (See "Testing: Pressures")

Test the therm ocouple to ensure it is within

spe c ific ations. (See "Testing: Millivolts -

Thermocoup le")

Te st the m agne t c oil to e nsure it is w ithin

specification. (See "Testing: Function - Magnet

Coil" )

YES

Has the vent system been examined for problems?

NO

(See "Complete Unit Shutdown" Flowchart)

YES

Are the logs properly positioned?

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

ISO-176 W415-0118 / B / 10.25.06

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

NO

© 2005 WOLF STEEL LTD.

Out of place logs can alter the flow of air within

the combustion chamber, causing an erratic pilot.

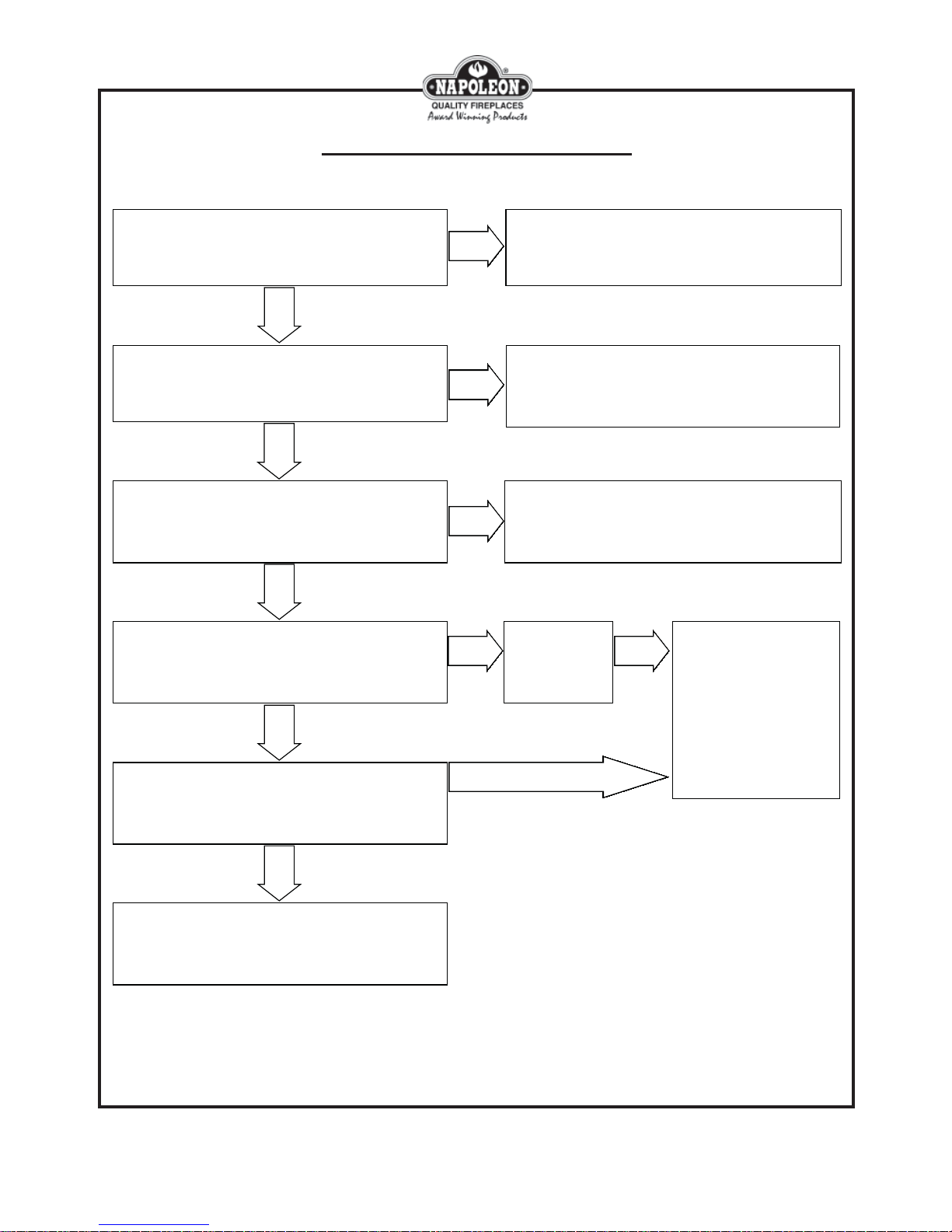

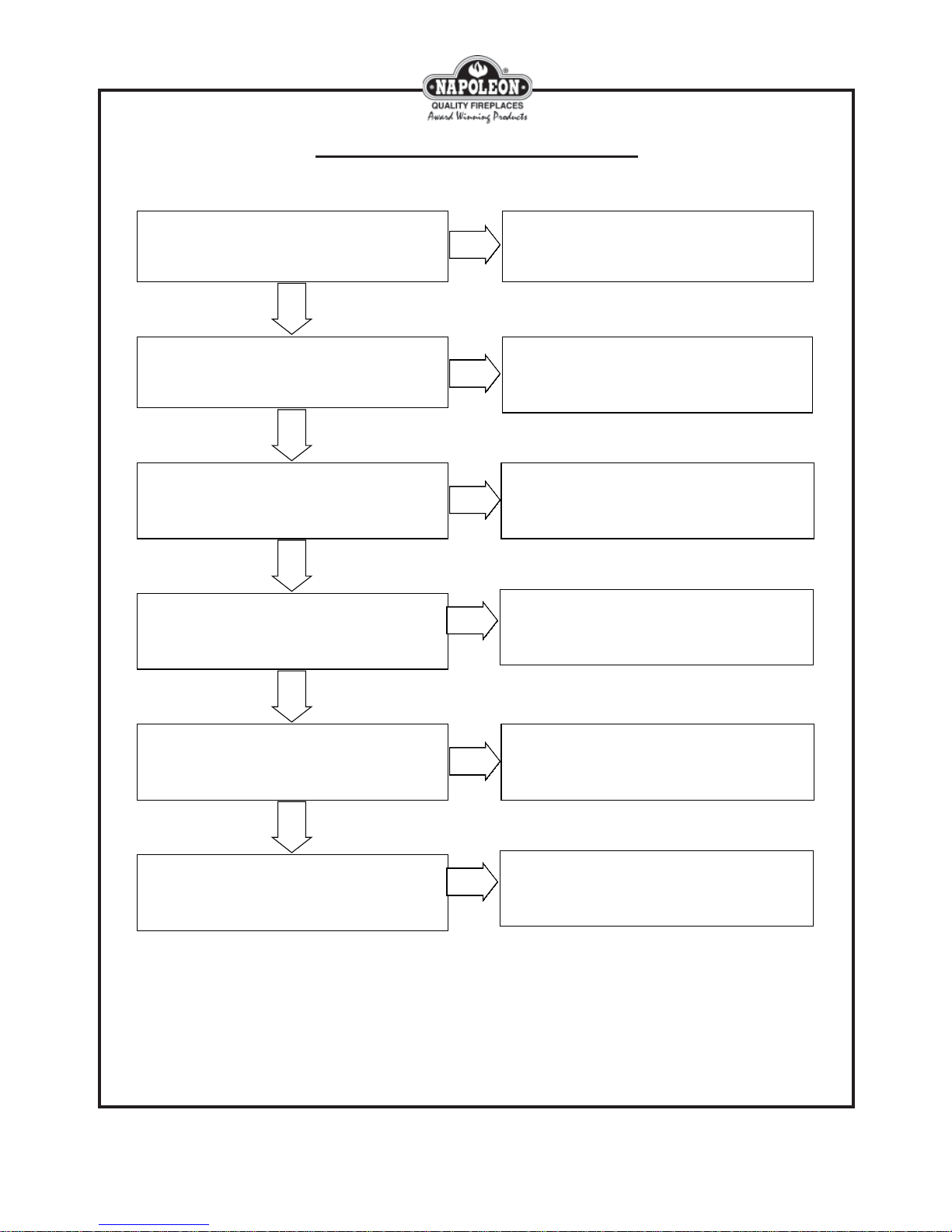

Troubleshooting: Direct Vents

Main Burner Not Lighting Flowchart

7

Have the thermopile leads been connected to the

1st & 2nd term inals on the valve (THTP & TP)?

YES

Has the thermopile been tested for millivolt

generation?

YES

Has the burner & orifice been checked for

blockages?

YES

Is there a sw itch or remote connected on

te rm inals 1 & 3?

YES

NO

NO

NO

NO

Connect the thermopile leads to the 1st & 2nd

term inals on the valve (THTP & TP).

Test the thermopile to ensure it is within

spe c ifications. (See "Testing: Millivolt s -

Check and clean as required.

Conn e c t a

sw it ch or

rem ote to

te rm inals 1 & 3.

Thermopile").

NO

Test the operator coil of

the valve for resistance.

Replace the valve if out

of spec ification. (See

"Testing: Function -

Op era to r Coil")

Disc on ne c t sw itch or re m o te a t v alv e and re p lace

with a jumper wire. Did the burner activate?

YES

See "Testing: Switches - T.Stat/Toggle"

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

ISO-176 W415-0118 / B / 10.25.06

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

NO

© 2005 WOLF STEEL LTD.

8

Troubleshooting: Direct Vents

Main Burner Delayed Ignition Flowchart

Has the pilot flame position and size been examined?

YES

Has t he inline ga s pre ssur e b ee n t est e d?

YES

Has the main burner & orifice been checked for blockages?

YES

Has th e m ain bu rne r o rif ice bee n e xam ined to see if it is the

right size?

YES

Has the venturi (air shutter) been checked & adjusted?

YESYESYES

Has the venturi access door been checked?

YES

Has the burner been checked to ensure it is level?

NO

NO

NO

NO

NO

NO

NO

Check to m ake sure the pilot is large

enough and in the proper position,

to reach the ignition ports. (See

"Testing: Pilot Flame")

Check to ensure the proper supply

pre ssures are available for ignition.

(See "Testing: Pressures")

Chec k to m ake sure nothin g is

blocking the flow of gas through the

burne r a nd orif ice, c ont rib utin g to

the de lay. Clean as nec essary.

Check the size of the orifice and

ensure it meets manufacturers

spe cific atio n.

Check the venturi setting and adjust

as necessary to improve the ignition

time. (See "Ad justing: Venturi")

Check to e nsure the door is tightly

sealed and not allowing any air into

the air-shutter cham be r, and that the

gasket is intac t.

Examine and level as nece ssary.

Has the positioning of the logs been checked?

Have the c harcoal / glowing em bers (w here app licable) been

checked?

NO

NO

Out of place logs can alter the flow

of air within the com bustion

chamber, causing an erratic pilot.

Check to make sure no e mb er

material is clogging the ports, and

contributing to the delay.

YES

Has the venting been examined?

NO

Ensure the ve nting is sealed and

there are no leaks.

YES

Has the main door seal been checked?

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

© 2005 WOLF STEEL LTD.

NO

Check to m ake sure no air is leaking

in around the seal, which can affe ct

the flow of air in the combustion

chamber.

ISO-176 W415-0118 / B / 10.25.06

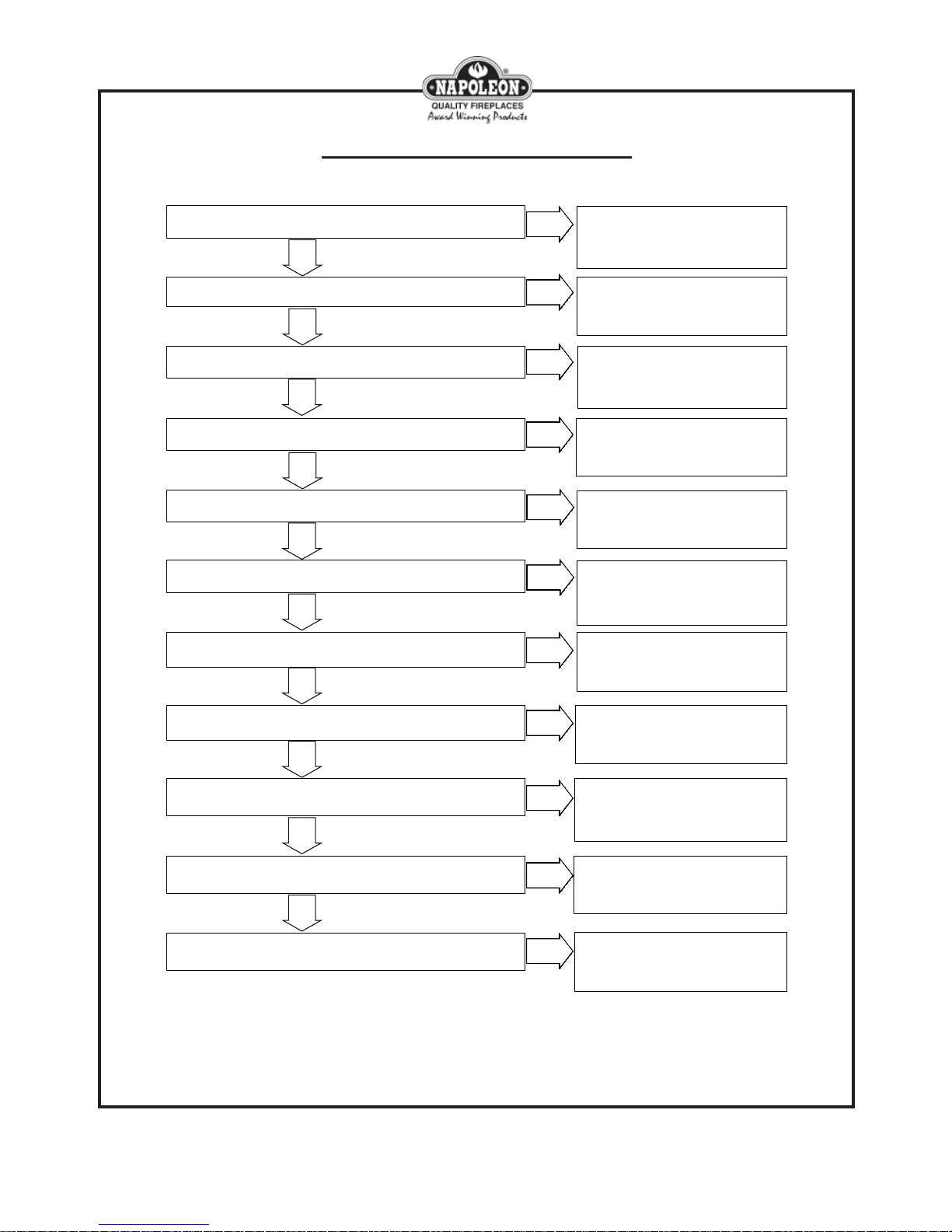

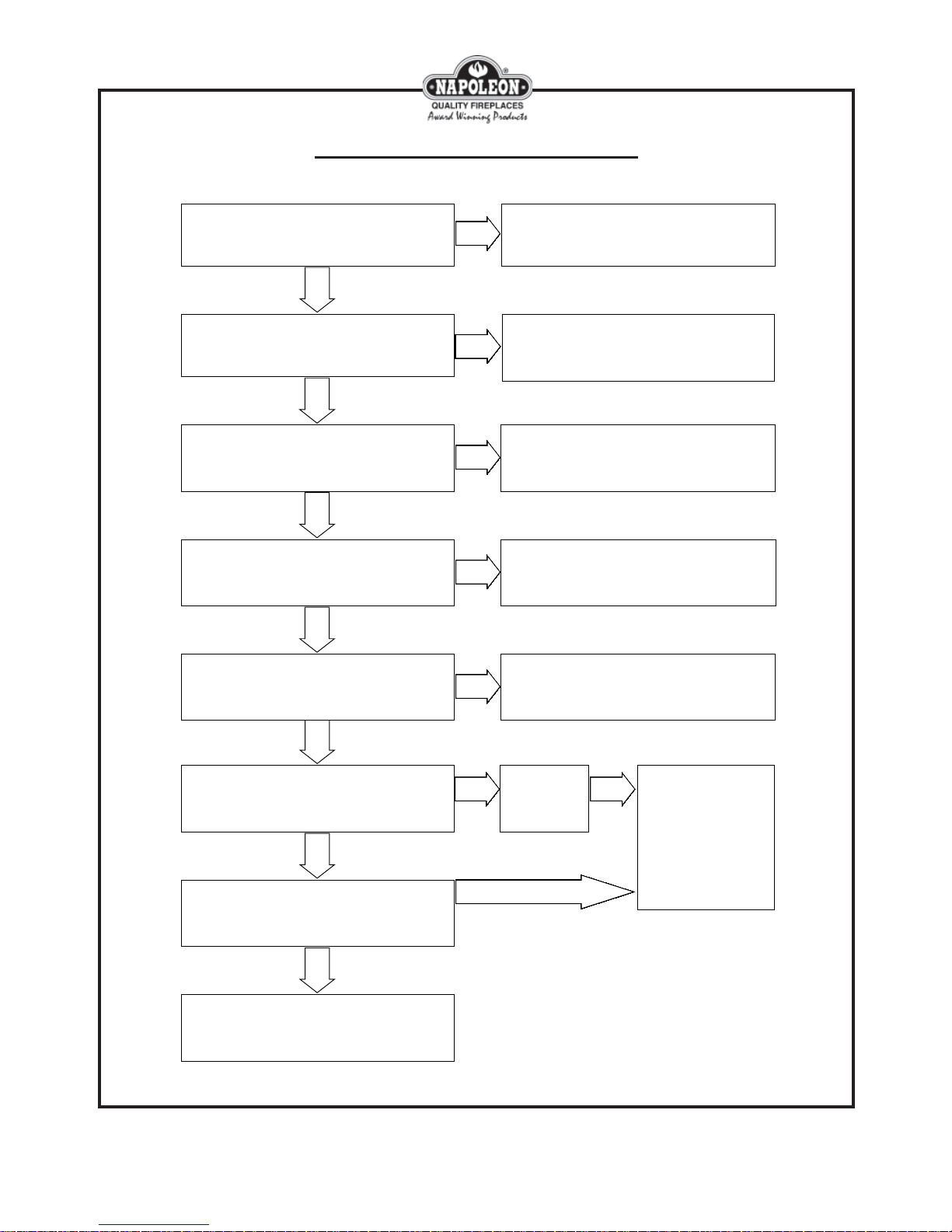

Troubleshooting: Direct Vents

Main Burner Low Flame Flowchart

9

Does the fireplace have a modulating remote?

NO

Is the h i- lo knob s et to a high s e tting ?

YES

Have the inlet + outlet gas pressures been tested?

YES

Ha s the main burn er orifice be en examine d to see if it is

the r igh t s ize?

YES

NO

NO

NO

Check to see if the remote has power. When power is

un a va ilable , the r e mote def a ults to a low-fla me mo de until

it's re s tored.

T u rn the k no b to its higher s e ttin g.

Check to ensure the proper supply and flow condition

pressures for optimal burn. (See "Testing: Pressures")

Check the size of the orifice and ensure it meets

manufacturers specification.

YES

Has the main burner and orifice been checked for

blocka ges?

NO

Check to make sure nothing is blocking the flow of gas

through the burner and orifice, which could res ult in low

flame. Clean as necessary.

YES

Has the venturi (air shutter) been checked + adjusted?

NO

C heck the v e ntu ri s etting a nd a dju s t a s nec e s s ar y to

improve the flame appearance. (See "Adjustments:

Venturi")

YES

Has the manifold tube been checked for blockages?

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

ISO-176 W415-0118 / B / 10.25.06

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

NO

© 2005 WOLF STEEL LTD.

R emo ve the tu be to ma ke s ure no deb ris ha s comp a cted

inside, inhibiting the flow of gas . C lea n as nec es sa ry.

10

Troubleshooting: Direct Vents

Main Burner Failure Flowchart

Is the burner flame spontaneously going out without any change in flame

appearance?

NO

Is the burner flame going

ghostly and blue before

extinguishing?

YES

(See "Complete Unit

Shu td ow n"

Flowchart)

Check to m ake sure the pilot flame is

adeq uately covering the therm opile

+ thermocouple. (See "Testing: Pilot

Clean, tighten, or re place as

Flame)

NO

ne ce ssary .

Has the pilot

NO

flame position

and size been

examined?

Are the electrical

connections

(the rm opile, sw itch,

rem ote, thermostat),

clean/secure /unb roken?

YES

YES

YES

Check to ensure that the length

and gauge of the w ire have not

exceeded their listed

maximums, and that the wire is

not coiled at any p oint.

Has the w iring for the

NO

therm ostat/switch (if

applicable) been

checked for proper

len gth/size?

YES

Test the thermop ile to ensure it is

w ithin sp ecif icat ions. (See "Te sting:

Millivolts - Ther mo pile" )

NO

therm opile

been tested for

gener ation?

Has the

m illivolt

YES

Has the

Test the operator coil to ensure it is

w ithin sp ecif icat ion. (See "Testin g:

Function - Operator Coil")

NO

operator c oil of

the valve been

checked for

re sistan ce ?

YES

Is the m ain

Does the main burner flame shrink

shortly after activation?

YES

Che ck to m ake sure the pre ssure is

not dropp ing off on activation.

(See "Testing: Pressures")

Remove and

replace w ith a

m illivolt sw itch.

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

NO

burner flame

sta ying the

sam e size wh en

turned on?

Doe s the

unit have a

connected

NO

m illivolt

sw itch ?

© 2005 WOLF STEEL LTD.

sw itch

to it?

Is it a

YES

Doe s the

NO NO

unit have a

therm ostat

connected

to it?

YES

YES

Is it a

m illivolt w all

therm ostat?

NO

Remove and

replace w ith a

m illivolt w all

therm ostat.

Does the unit have a

remote connected to

it?

YES

Is it a Wolf Steel

approved remote?

(Advantage/Skytech)

NO

Rem ove and re place

with a Wolf Steel

approved remote.

ISO-176 W415-0118 / B / 10.25.06

Troubleshooting: Direct Vents

Complete Unit Shutdown

11

Is the burner flame going blue and see-through before

extinguishing?

Have the seals on the venting, main door, relief doors,

around the burner and the pilot assembly been checked

for le aks ?

YES YES

Has the termination been checked for blockages and

obstructions?

YES

Is the ve nting within the s pe c ifications of the installa tion

manual and local code requirements?

NO

NO

NO

NO

(S ee: "Pilot F a ilure " F lowchart)

Check and seal/replace as necessary. (See "Testing:

Gasket")

E nsure tha t nothing is obs tructing the flow of air &

exhaust from the terminal. C lear as necessary.

Check the venting requirements and return to

s pec ifica tion.

YES

Has the venting been sealed on the inner and outer vent

pipe connections?

NO

S ea l all inner a nd outer vent pipe connections.

YES

Does the venting meet the fireplace parameters

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

ISO-176 W415-0118 / B / 10.25.06

regarding length and rise?

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

NO

© 2005 WOLF STEEL LTD.

E nsure tha t the ve nting is within s pec ified pa ra me ters .

12

Troubleshooting: Direct Vents

Odour Flowchart

Has th e u nit had its re qu ire d 'Burn-in' p eriod ?

YES

Has the unit been checked for leaks around the

d oor se al, re lie f-doo r se als, ve nt c olla r (if possib le ),

and firebox?

YES

Is the unit be ing used f requently?

Run the unit on its highest setting for 8-10 hours

NO

NO

NO

w ith the blow er shut off. (Note: Som e low e r BTU

units may req uire more than 1 burn-in period.)

Remember to ventilate the area.

Check for leaks and seal as necessary. (See

"Testing: Gasket")

Chec k to see if the unit is du sty and is bur ning off

accumulated dust from prolonged inactivity.

YES

Is the front of the fireplace clear of the presence

of any combustible materials?

YES

If the unit has a mantle - have the m antle

clearances been referenced for accuracy?

YES

Has th e u nit b e en installe d in a f inishe d w all?

YES

Have the required clearances to combustibles

been maintained?

YES

Ensure that com bustible mate rials are kept at least

NO

NO

NO

NO

four feet away from the front of the fireplace.

Check the mantle clearances listed in the manual

against th e spe cif ics o f the installation. Ad just or

rem ove the mantle as necessary.

Check for the presence of vapor barrier, insulation,

or other m aterial / construction-d ebris in contact

with the outer shell of the firebox.

Referenc e installation manual and restore to

manufacturers specifications as necessary.

Is the unit an inser t?

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

ISO-176 W415-0118 / B / 10.25.06

NO

© 2005 WOLF STEEL LTD.

Check the existing chimney for the presence of

creosote, w hich can, w hen heated, p roduce an

odour.

PART 2: TROUBLESHOOTING: NATURAL VENTS

Pilot Not Lighting Flowchart............................................................................................................14

Pilot Not Holding Flowchart............................................................................................................15

Pilot Failure Flowchart....................................................................................................................16

Main Burner Not Lighting Flowchart...............................................................................................17

Main Burner Delayed Ignition Flowchart........................................................................................18

Main Burner Low Flame Flowchart................................................................................................19

Main Burner Failure Flowchart......................................................................................................20

Complete Unit Shutdown................................................................................................................21

Odour Flowchart............................................................................................................................22

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

ISO-176 W415-0118 / B / 10.25.06

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

© 2005 WOLF STEEL LTD.

14

Troubleshooting: Natural Vents

Pilot Not Lighting Flowchart

Is ther e a s park at the electrode when the push button igniter is pres s ed?

Check to ensure proper supply

pressures are available for ignition.

(See "Testing: Procedures")

Ensure the adjustment screw has not

been tightened closed. Adjust as

necessary. (See "Adjustments: Pilot

Flame")

R emove the tube and or ifice a nd c lean ,

make sure no debris has compacted the

ins ide , inh ibiting the flo w of g a s .

T ig hte n / sec u re to pre vent le a ks .

NO

Has the inline gas

pressure been

NO

adjustment screw

been checked?

NO

Ha ve th e pilo t tub e

& pilo t orific e been

NO

Ar e the fittings on

te s ted ?

Has the pilot

checked for

blocka ges?

the pilot tu be

secure?

YES

YES

YES

YES

NO

Is the electrode

wire c onnection

secure?

YES

Is there a 1/8" ga p

between the

electrode and the

pilot hood?

YES

Has the electrode

been examined for

damage? (i.e.

chipped/broke n)

NO

NO

NO

Secure / Replace

as necessary

Adjust position so

the r e is no

gr eater than a

1/8" gap.

Replace if

damaged or

broke n.

Un-kink the tube to prevent blockage, or

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

replace leaking tube.

Ensure the opening is not blocked or

plugged. C lea r if necess ary.

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

ISO-176 W415-0118 / B / 10.25.06

NO

Ha s the pilo t tube

been checked for

NO

Has the primar y

air opening on the

pilot assembly

been checked for

© 2005 WOLF STEEL LTD.

YES

kinks / leaks?

YES

blocka ges?

Troubleshooting: Natural Vents

Pilot Not Holding Flowchart

15

Has the thermocouple/thermopile connection

been checked?

Has the thermocouple/thermopile been tested for

millivolt generation?

YES YES

Have the pilot tube/pilot orifice been checked for

blockages?

YES

Is th e sup p ly line size a dequ at e fo r t he

installatio n?

NO

NO

NO

NO

Check and tighten thermocouple/thermop ile to

ensure p rope r millivolt de live ry.

Test the thermocouple/thermopile to ensure they

are within specifications. (See "Testing: Millivolts -

The rm ocouple", and "Testing: Millivolt s -

Thermopile")

Remove the tube & orifice and clean, to make sure

no de bris has com pacted inside, inhibiting the

flow of gas.

Check the local code requirements and replace as

ne ce ssar y.

YES

Has the spill switch connection been checked?

NO

Verify that the spill switch is connected and that

the re is c ont inuit y on the sw itc h..

YES

Has the magnet coil of the valve been checked for

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

ISO-176 W415-0118 / B / 10.25.06

function?

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

NO

© 2005 WOLF STEEL LTD.

Test the magnet coil to ensure it is within

specification. (See "Testing: Function - Magnet

Coil" )

16

Troubleshooting: Natural Vents

Pilot Failure Flowchart

Is the pilot fl ame patte rn, pos ition a nd s ize c orr ec t?

YES

C hec k to ma ke s ure the p ilot i s l ar ge en ough an d in the

proper position, to properly heat the thermocouple. (S ee

NO

"Testing: Pilot F lame")

Is the pilot flame s hrinking when the burner is turned on?

NO

Has the thermocouple been tested for millivolt

gener ation?

YES

Has the thermopile (on single-generator systems) been

tes ted for millivolt ge ner atio n?

YES

Are the connections on the thermopile, spill s witch, and

switches secure?

YES

Has the function of the spill switch been checked?

YES

Has the function of the magnet coil been checked?

Check to ma ke sure the pressure is not dropping off on

YES

NO

NO

NO

NO

NO

activation. (See "Testing: Pressures")

T es t the ther mocou ple to ens ure it is within s pecifica tions .

(See "Tes ting: Millivolts - Thermocouple")

Test the thermopile to ensure it is within specifications.

(See "Tes ting: Millivolts - Thermocouple")

Tighten / secure the connections.

Check the function of the spill switch. (See "Tes ting:

T es t the magn et c oil to en su re it is within s pecifica tion.

Switches - Spill Switch")

(See "Tes ting: Function - Magnet Coil")

Are the units venting parame ter s within s pec ifica tion?

Has the unit been checked for spilling?

Has the positioning of the logs been checked?

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

ISO-176 W415-0118 / B / 10.25.06

YES

YES

YES

NO

NO

NO

© 2005 WOLF STEEL LTD.

Che ck local code requirements for natural-vent

appliances and adjust as necessary.

C hec k the s pill- tube for dra ft (a s d eta ile d in th e

ins tallation manual) and open a window to alleviate

negative pressure in the area.

O ut of pla ce logs ca n a lter the flow of a ir within the

combustion chamber, causing an erratic pilot.

Troubleshooting: Natural Vents

Main Burner Not Lighting Flowchart

Has the pilot flame position and size been examined?

YES

Check to make sure the pilot is large enough and in the

NO

pr ope r po s ition to r e ach the ign itio n po rts . ( S ee

"A dju s tmen ts : P ilot F la me ")

17

Has the thermopile been tested for millivolt generation?

YES

Has the inline gas pressure been tested?

YES

Have the spill & vent safety switches been checked for

proper function?

YES

Has the burner & orifice been checked for blockages?

YES

NO

NO

NO

NO

T est the the rmopile to e ns ure it is within spec ifica tions,

and that it is connected. (See "Testing: Millivolts -

Check to ensure the proper supply pressures are

available for ignition. (See "Testing: Pressures")

Test s witches to ensure function and verify connection.

(See "Tes ting: Switches - Spill Switch")

Thermopile")

Check & clean as required.

Is there a switch or remote connected on terminals 1 & 3?

Disconnect at valve and replace with a jumper wire. Did

See "Tes ting: Switches - T.S tat/Toggle"

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

(T HTP & T H)

the bu rn er a c tiva te?

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

ISO-176 W415-0118 / B / 10.25.06

YES

YES

Connect a switch

NO

terminals 1 & 3.

© 2005 WOLF STEEL LTD.

or re mote to

NO

NO

T est the operator coil of the

valve for resistance.

Replace the valve if out of

s pec ification . ( S ee

"T es ting: F unction -

Operator Coil")

18

Troubleshooting: Natural Vents

Main Burner Delayed Ignition Flowchart

Has the pilot flame position and size been examined?

YES

Has the inline gas pressure been tested?

YES

Has the main burner & orifice been examined to see if it is the right size?

YESYES

Has the main burner and orifice been checked for blockages?

YES

Ha s th e ve ntu ri (air s hutte r ) be en c he c ke d & a djus ted?

Ha s th e pos ition ing of the lo gs bee n ch e cke d?

YES

NO

NO

NO

NO

NO

NO

C hec k to ma ke s ur e the pilot is lar ge

e no ugh a nd in the pr op er pos ition, to

reach the ignition ports. (See

"A dju s tme nts : P ilot F lame")

C heck to e ns ur e the pr op er s upply

pressures are available for ignition. (See

"Testing: Pressures")

Check the size of the orifice to ensure it

meets manufacturers specification.

Check to make sure nothing is blocking

the flow of ga s thro ugh the b ur ne r a nd

orifice, contributing to the delay. Clean

as necessary.

C heck the v enturi s ettin g a n d a djus t a s

ne ce s s a ry to improve the ign ition time.

(S ee "Adjusting: Venturi")

O ut o f pla ce logs ca n alter the f low of a ir

within the c omb us tion c hambe r, c a us ing

an erratic pilot.

Have the charcoal / glowing embers (where applicable) been checked?

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

© 2005 WOLF STEEL LTD.

NO

Check to make sure no ember material is

cloggin g th e por ts , a nd contrib utin g to the

delay.

ISO-176 W415-0118 / B / 10.25.06

Troubleshooting: Natural Vents

Main Burner Low Flame Flowchart

19

Does the fireplace have a modulating remote?

NO

Is the hi-lo knob set to a high setting?

YES

Have the inlet + outlet gas pressures have been

tested?

YES

Has the main burner orifice been examined to see

if it is the righ t size ?

YES

YES

NO

NO

NO

Check to see if the remote has power. When

pow er is unavailable, the remote defaults to a

low -f lam e m od e u ntil it's re stor ed .

Turn the knob to its higher setting.

Check to ensure the proper supply and flow

condition pressures for optimal burn. (Se e

"Test ing: Pr essure s")

Check the size of the orifice and ensure it meets

manufacturers specification.

Check to make sure nothing is blocking the flow of

Has the main burner and orifice been checked for

blockages?

NO

gas through the burner and orifice, which could

re sult in low fla me. Cle an as nec essary.

YES

Has the venturi (air shutter) bee n checke d +

adjusted?

NO

Check the venturi setting and adjust as necessary

to improve the flame appearance. (See

"Adjustments: Venturi")

YES

Has the manifold tube been checked for

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

blockages?

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

NO

© 2005 WOLF STEEL LTD.

Remove the tube to m ake sure no de bris has

com pacte d inside, inhibiting the flow of gas. Clean

as nec e ssary.

ISO-176 W415-0118 / B / 10.25.06

20

Troubleshooting: Natural Vents

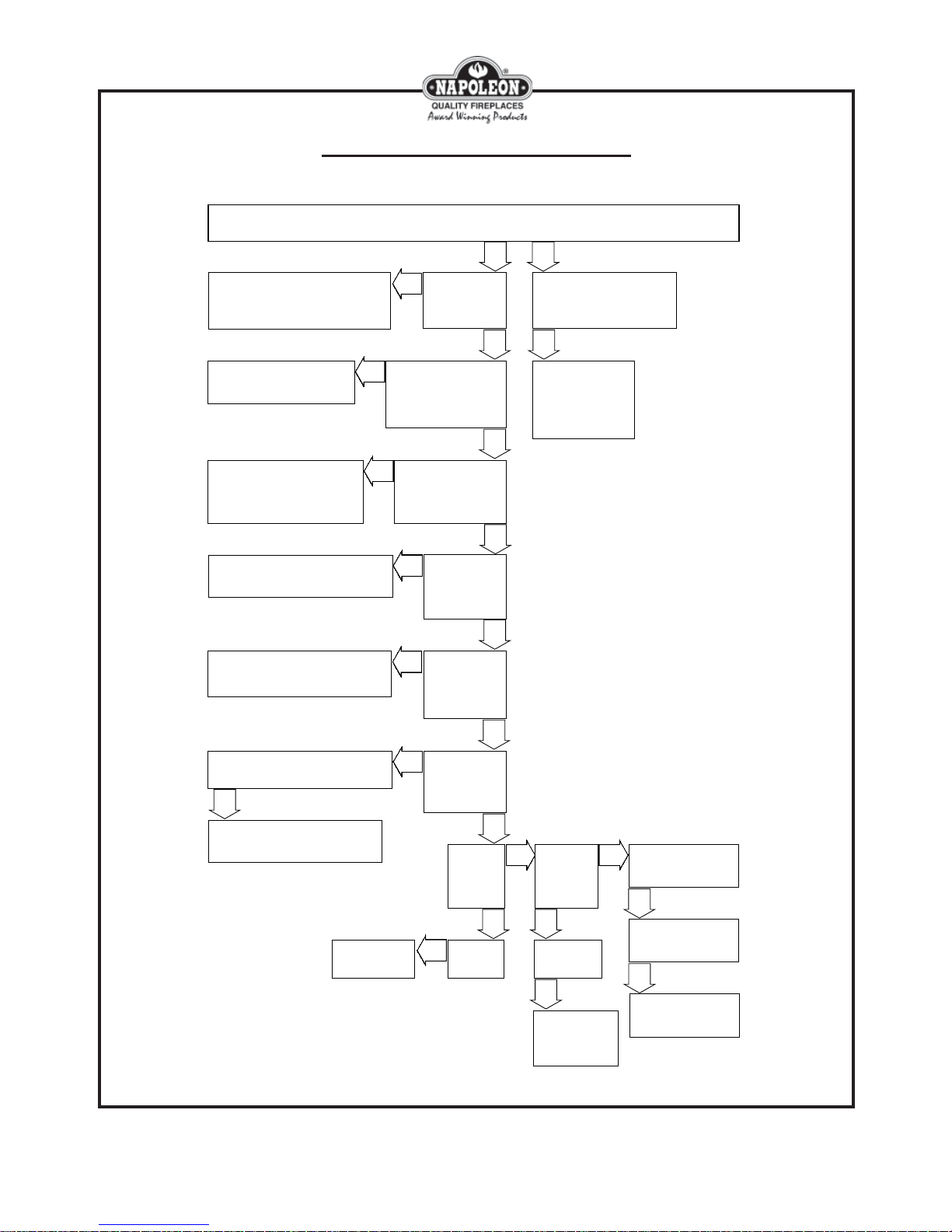

Main Burner Failure Flowchart

Is the burner flame spontaneously going out without any change in flame appearance?

Check to make sure the p ilot flame is

adeq uately covering the therm opile

+ thermocouple.

Clean, tighten, or re place as

ne ce ssary .

Check to ensure that the length

and gauge of the w ire have not

exceeded their listed

maximums, and that the wire is

not coiled at any p oint.

Test the thermopile to ensure it is

w ithin sp ecif icat ions. (See "Te sting:

Millivolt s - Therm opile ")

Test the operator coil to ensure it is

w ithin sp ecif icat ion. (See "Testin g:

Function - Operato r Coil")

NO

Has the pilot

NO

flame position

and size been

examined?

Are the electrical

connec tions

(the rm opile , swit ch,

remote, thermostat),

clean/secure/unbroken?

Has the w iring for the

NO

therm ostat/switch (if

applicable) been

checked for proper

len gth/size?

Has the

NO

therm opile

been tested for

millivolt

gener ation?

Has the

NO

operator c oil of

the valve been

checked for

resistance?

YES

YES

NO

Is the burner flame going

ghostly and blue b efore

YES

(See "Complete Unit

Shu td ow n"

Flowchar t)

YES

YES

YES

extinguishing?

YES

NO

Check the function of the spill switch.

(See "Testing: Switches - Spill Switch")

Has the function

of the spill

sw itc h b ee n

checked?

YES

Check to ensure the unit is not spilling

and it is estab lishing a goo d d raf t.

NO

been checked

Has the unit

for proper

draft?

YES

Doe s the

unit have a

sw itch

connec ted

to it?

YES

Remove and

replace w ith a

m illivolt sw itch.

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

© 2005 WOLF STEEL LTD.

NO

Is it a

millivolt

sw itch ?

Doe s the

NO NO

unit have a

therm ostat

connected

to it?

YES

Is it a

millivolt wall

therm ostat?

NO

Remove and

replace w ith a

millivolt wall

therm ostat.

Does the unit have a

rem ote connected to

it?

YES

Is it a Wolf Steel

approved remote?

(Advantage/Skytech)

NO

Rem ove and re place

with a Wolf Steel

approved remote.

ISO-176 W415-0118 / B / 10.25.06

Troubleshooting: Natural Vents

Complete Unit Shutdown

21

Is the burner flame going blue and see-through

before extinguishing?

YES

Is the venting within the specifications of the

installation m anual and loc al c od e re q uir ements?

NO

NO

(See: "Pilot Failure" Flowchart)

Check the venting requirements and return to

spe c ificat ion.

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

ISO-176 W415-0118 / B / 10.25.06

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

© 2005 WOLF STEEL LTD.

22

Troubleshooting: Natural Vents

Odour Flowchart

Has th e unit ha d it s req uired 'Burn-in' perio d?

YES

Run the unit on its highest setting for 8-10 hours

w ith the blow er shut off . (Note: Some low er BTU

NO

units may req uire more than 1 burn-in period.)

Remember to ventilate the area.

Has the area been checked for the presence of

contaminants in the air? (i.e. pet hair, excess of

d ust, ex cess o f sm oke , e tc .)

YES

Is the unit being used frequently?

YES

Is the front of the fireplace clear of the presence

of any combustible materials?

YES

If the unit has a mantle - have the m antle

clearances been referenced for accuracy?

YES

Has th e unit b ee n installe d in a finishe d w all?

NO

NO

NO

NO

NO

The presence of air pollutants can give off an

odour when combusted by the fireplace.

Chec k to see if t he unit is d usty and is b urning of f

accumulated dust from prolonged inactivity.

Ensure that com bustible mate rials are kep t at least

four feet away from the front of the fireplace.

Check the mantle clearances listed in the manual

against the specifics of the installation. Adjust or

remove the mantle as necessary.

Check for the presence of vapor barrier, insulation,

or other m aterial / construction-deb ris in contact

with the oute r shell of the fireb ox.

Have the required clearances to combustibles

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

been maintained?

Is the unit an insert ?

Is the unit bu rning cle an?

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

ISO-176 W415-0118 / B / 10.25.06

YES

YES

YES

NO

NO

NO

© 2005 WOLF STEEL LTD.

Reference installation manual and restore to

manuf acturers specifications as necessary.

Check the existing chimney for the presence of

creosote, which can, w hen heated, p roduce an

A un it th at is sooting, or ha s its air shutte r

im p rop erly ad juste d , c an r esult in inc omp let e

combustion and produce a de finite odour.

odour.

PART 3: TROUBLE SHOOTING: VENT FREE

Pilot Not Lighting Flowchart..............................................................................................24

Pilot Not Holding Flowchart..............................................................................................25

Pilot Failure Flowchart......................................................................................................26

Main Burner Not Lighting Flowchart...................................................................................27

Main Burner Delayed Ignition Flowchart............................................................................28

Main Burner Low Flame Flowchart...................................................................................29

Complete Unit Shutdown.................................................................................................30

Odour Flowchart...............................................................................................................31

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

ISO-176 W415-0118 / B / 10.25.06

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

© 2005 WOLF STEEL LTD.

24

Troubleshooting: Vent Free

Pilot Not Lighting Flowchart

Is there a s park at the electrode when the pus h button igniter is pres s ed?

Check to ensure proper supply

pressures are available for ignition.

(See "Testing: Procedures")

Ensure the adjustment screw has not

be e n tighte ned clos ed. A djus t a s

necessary. (See "Adjustments: Pilot

Flame")

R emove the tube and or ifice a nd c lean ,

make sure no debris has compacted the

inside, inhibiting the flow of gas.

Tighten / secure to prevent leaks.

NO

Has the inline gas

pressure been

NO

Has the pilot

adjustment screw

been checked?

NO

Ha ve th e pilo t tub e

& pilot orifice been

NO

Ar e the fittings on

the pilot tu be

te s ted ?

checked for

blocka ges?

secure?

YES

YES

YES

YES

NO

Is the electrode

wire c onnection

secure?

YES

Is there a 1/8" gap

between the

electrode and the

pilot hood?

YES

Has the electrode

been examined for

damage? (i.e.

chipped/broke n)

NO

NO

NO

Secure / Replace

as necessary

Adjust position so

the r e is no

grea ter than a

1/8" gap.

Replace if

damaged or

broke n.

Un-kink the tube to prevent blockage, or

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

replace leaking tube.

Ensure the opening is not blocked or

plugged. C lea r if necess ary.

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

ISO-176 W415-0118 / B / 10.25.06

NO

Ha s the p ilo t tube

been checked for

NO

Has the primar y

air opening on the

pilot assembly

been checked for

© 2005 WOLF STEEL LTD.

YES

kinks/leaks?

YES

blocka ges?

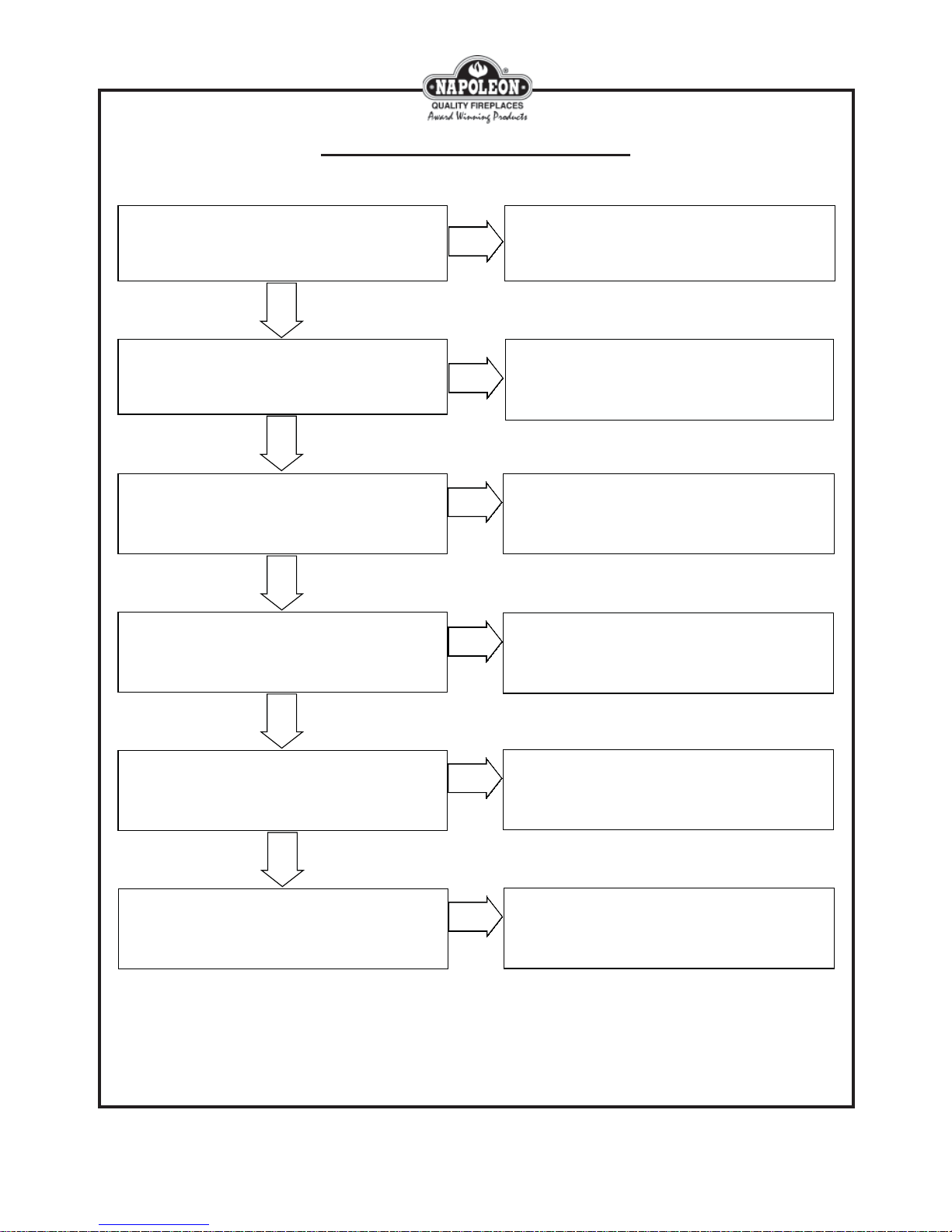

Troubleshooting: Vent Free

Pilot Not Holding Flowchart

25

Has the thermocouple/thermopile connection been

Has the thermocouple/thermopile been tes ted for millivolt

checked?

generation?

YES YES

Has the magnet coil of the valve been checked for

func tion?

YES

Have the pilot tube/pilot orifice been checked for

blocka ges?

YES

Is the supply line size adequate for the installation?

NO

NO

NO

NO

NO

C he ck an d tig hte n th ermoco uple to ens ur e prope r

C he ck an d tig hte n th e the rmo co up le/the rmo pile to

T est the magne t coil to e nsure it is within s pe cific ation.

(S ee "T es ting: F unction - Magnet C oil")

Remove the tube & orifice and clean to make sure no

debris has compa cted inside , inhibiting the flow of gas.

Check local code requirements and replace as

millivolt de live ry .

en sure pro per millivolt de live ry .

necessary.

YES

Is the unit sustaining pressure when the burner is

a ctiv a ted ?

Check to make sure the pressure is not dropping off on

NO

activation. (See "Testing: Pressures")

YES

Is the primary air opening for the ODS system clean?

NO

Clean the air opening to prevent the pilot flame from

ca ndling a nd lifting off o f the ther moco uple .

YES

E ns ur e th a t the logs ha ve be en po s itione d a c co rd ing to

Has the positioning of the logs been checked?

NO

the spec ifica tions in the ma nua l.

YES

T oo much pre ssure ca n pus h the pilot out past the

thermopile re s ulting in lower millivolts . T oo low pre s s ure

Has the inline gas pressure been tested?

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

NO

© 2005 WOLF STEEL LTD.

can prevent the pilot from lighting. (See "Testing:

pressures")

ISO-176 W415-0118 / B / 10.25.06

26

Troubleshooting: Vent Free

Pilot Failure Flowchart

Is the pilot flame p attern, position and size

correct?

YES

Is the pilot flame shrinking when the burner is

turned on?

NO

Has the thermocouple been tested for millivolt

generation?

YES

Has the function of the magnet coil been

checked?

YES

Has the inline gas pressure been tested?

YES

Check to make sure the pilot is large enough and in

NO

YES

NO

NO

NO

the proper position, to properly heat the

therm ocouple. (See "Testing: Pilot Flame ")

Check to make sure the pressure is not dropping

off on activation. (See "Testing: Pressure s")

Test the therm ocouple to ensure it is within

spe cific atio ns. (See "Te sting: Millivo lts -

Thermoc ouple")

Te st the m agnet coil to ensu re it is w ithin

specification. (See "Testing: Function - Magnet

Coil" )

Too much pressure can push the pilot out past the

the rmo pile result ing in low e r m illivo lts. To o low

pressure can prevent the pilot from lighting. (See:

"Test ing : Pre ssur e s)

Has the ODS been examined for dirt/debris in it's

prim ary air o penin g?

YES

Has th e u nit b e en installed in a room w hich me e ts

its minimum unconfined space requirement.

YES

Are the logs properly positioned?

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

ISO-176 W415-0118 / B / 10.25.06

NO

NO

NO

© 2005 WOLF STEEL LTD.

the combustion chamber, causing an erratic pilot.

Check the ODS and clean as required.

Check the requirem ents for the unit as per the

manual, and the n provide make-up air as

ne ce ssary.

Out of place logs can alter the flow of air within

Troubleshooting: Vent Free

Main Burner Not Lighting Flowchart

27

Ha v e the thermo pile lea ds been c on ne c te d to the 1 s t &

2nd termin a ls on th e va lve ( T HT P & T P )?

YES

Has the thermopile been tested for millivolt generation?

YES

Has the burner & orifice been checked for blockages?

YES

Is there a switch or remote connected on terminals 1 & 3?

(T HTP & T H)

YES

NO

NO

NO

NO

C o nn e ct the thermo pile lea ds to the 1s t & 2nd termina ls

Test the thermopile to ensure it is within specifications.

C onnect a s witch

or remote to

terminals 1 & 3.

on the valve (THTP & TP).

(See "Testing: Millivolts - Thermopile").

Check & clean as required.

NO

T es t the operator coil of the

valve for resistance.

Replace the valve if out of

s pe cifica tion. ( S ee

"T es ting: F unction -

Operator Coil")

Disconnect at valve and replace with a jumper wire. Did

the burner activate?

YES

See "Testing: S witches - T.S tat/T oggle"

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

ISO-176 W415-0118 / B / 10.25.06

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

NO

© 2005 WOLF STEEL LTD.

28

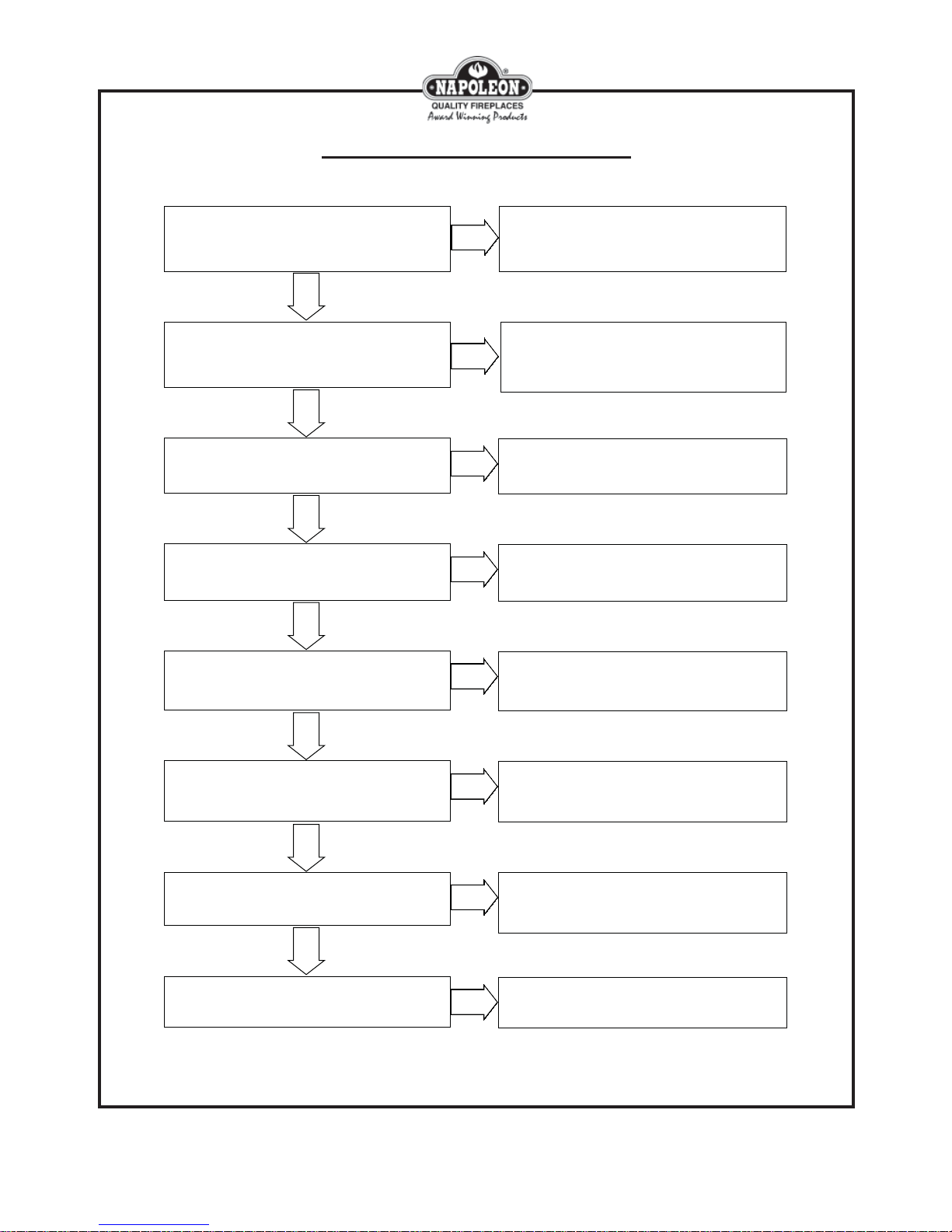

Troubleshooting: Vent Free

Main Burner Delayed Ignition Flowchart

Has the pilot flame position and size been examined?

YES

Has the inline gas pressure been tested?

YES

Has the main burner & orifice been checked for blockages?

YES

Has the main burner orifice been examined to see if it is the

right size?

YES

Has the venturi (air shutter) been checked & adjusted?

YESYES

Has the burner been checked to ensure it is level?

NO

NO

NO

NO

NO

NO

Check to m ake sure the pilot is large

enough and in the proper position,

to reach the ignition ports. (See

"Testing: Pilot Flame")

Check to ensure the proper supply

pre ssures are available for ignition.

(See "Te sting: Pr e ssur e s")

Check to make sure nothing is

blocking the flow of gas through the

burner and orif ice , c ontrib uting to

the de lay. Clean as ne ce ssary.

Check the size of the orifice and

ensure it meets manufacturers

spe c ificat ion.

Check the venturi setting and adjust

as necessary to improve the ignition

time. (See "Ad justing: Venturi")

Examine and level as necessary.

Has the positioning of the logs been checked?

NO

Out of place logs can alter the flow

of air within the combustion

chamber, causing an erratic pilot.

YES

Have the charcoal/glowing embers (where applicable) been

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

ISO-176 W415-0118 / B / 10.25.06

checked?

© 2005 WOLF STEEL LTD.

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

NO

Check to make sure no ember

material is clogging the ports, and

contributing to the de lay.

Troubleshooting: Vent Free

Main Burner Low Flame Flowchart

29

Does the fireplace have a modulating remote?

NO

Is the hi-lo knob set to a high setting?

YES

Have the inlet & outlet gas pressures have been

tested?

YES

Has the main burner orifice been examined to see

if it is the right size ?

YES

NO

NO

NO

Check to see if the remote has p ow er. Whe n

pow er is unavailable, the remote de faults to a

low -fla me m ode until it' s re stored .

Turn the knob to its higher setting.

Check to ensure the proper supply and flow

condition pressures for optimal burn. (See

"Test ing : P re ssure s")

Check the size of the orifice and ensure it meets

m an uf ac ture rs spec if ic ation.

YES

Check to make sure nothing is blocking the flow of

Has the main burner and orifice been checked for

blockages?

NO

gas through the burne r and orifice, w hich could

result in low flame. Clean as necessary.

YES

Has the venturi (air shutter) been checked &

adjusted?

NO

Check the venturi setting and adjust as necessary

to improve the flame appearance. (See

"Adjustments: Venturi")

YES

Has the manifold tube been checked for

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

blockages?

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

NO

© 2005 WOLF STEEL LTD.

ISO-176 W415-0118 / B / 10.25.06

Remove the tub e to make sure no d ebris has

compacted inside, inhibiting the flow of gas. Clean

as nece ssar y.

30

Troubleshooting: Vent Free

Complete Unit Shutdown Flowchart

Is the burner flam e going ghostly and blue before extinguishing?

Clean, tighten, or replace as

ne ce ssar y.

Test the operator coil to ensure it is

w ithin spec ificat ion. (See "Testing:

Function - Operator Coil")

Does the main burner flame shrink

shortly after activation?

NO

YES

Check to make sure the pressure is

not dropping off on activation. (See

"Test ing: P re ssu re s")

Increase available room air or

relocate as necessary to meet

requirements

Are the electrical

connections

(the r m op ile , sw itc h,

rem ote, therm ostat),

clean/secure/unbroken?

NO

NO

NO

Has the

operator coil

been checked

for re sistance ?

Does t h e m ain

burner flame

remain a

consistent size

when activated?

Have t h e

com bustion and

ventilation air

pr ovisio n

guidelines been

checked to see if

the room is of

sufficient volume

to sustain th e

unit ?

NO

YES

YES

YES

YES

Does the unit have a catalytic

door?

YES

Ensure that the air

intakes for the

catalytic door are

not plugged or

covered.

ALL RIGHTS RESERVED, NO PART OF THIS BOOK MAY BE REPRODUCED OR TRANSMITTED IN ANY FORM OR BY ANY MEANS - GRAPHIC, ELECTRONIC OR MECHANICAL WITHOUT THE

PRIOR WRITTEN PERMISSION FROM WOLF STEEL LTD., BARRIE, ONTARIO, CANADA

ISO-176 W415-0118 / B / 10.25.06

© 2005 WOLF STEEL LTD.

Loading...

Loading...