Napoleon NPS45 Installation Manual

INSTALLER: LEAVE THIS MANUAL WITH THE APPLIANCE.

CONSUMER: RETAIN THIS MANUAL FOR FUTURE REFERENCE.

NEVER LEAVE CHILDREN OR OTHER AT RISK INDIVIDUALS ALONE WITH THE APPLIANCE.

INSTALLATION AND

OPERATING INSTRUCTIONS

MODEL NPS45/NPI45 MEET THE 2015 U.S ENVIRONMENTAL PROTECTION AGENCY (E.P.A.) PELLET FUEL EMISSION LIMITS FOR PELLET APPLIANCES SOLD

AFTER MAY 15, 2015, 40 C.F. R. PART 60. THESE STOVES HAVE BEEN TESTED AND LISTED BY INTERTEK TESTING SERVICES TO STANDARDS: ASTM E 1509,

ULC/ORD C1482M-90, ULC S627 AND ULC S628.

NPS45

PELLET STOVE

NPI45

PELLET INSERT

CERTIFIED FOR CANADA AND UNITED STATES USING ANSI/CSA

METHODS.

1

EN

FR

PG

57

SAFETY INFORMATION

!

WARNING

PLEASE READ ENTIRE MANUAL

BEFORE YOU INSTALL OR USE THIS

PELLET BURNING APPLIANCE.

If the appliance is not properly installed,

a house fi re may result causing personal

injury or loss of life.

- Authorities having jurisdiction (such as

municipal building department, fi re department, fi re

prevention bureau, etc.) should be consulted before

installation to determine the need to obtain a permit.

- Contact local building or fi re offi cials about

restrictions and installation inspection

requirements in your area.

- This appliance is hot while in operation. Keep

children, clothing and furniture away. Contact may

cause skin burns.

- Do not start a fi re with chemicals or fl uids such as

gasoline, engine oil, etc...

- Do not burn trash or garbage, lawn clippings /

waste, rubber, waste petroleum products, paints

or paint thinners / solvents, plastic, materials

containing asbestos, construction debris, railroad

ties, manure or animal remains, salt water driftwood

or salted materials, unseasoned wood, coloured

paper, cardboard, plywood or particleboard.

!

WARNING

HOT GLASS WILL CAUSE

BURNS.

DO NOT TOUCH GLASS UNTIL

COOLED.

NEVER ALLOW CHILDREN TO

TOUCH GLASS.

Wolf Steel Ltd., 24 Napoleon Rd., Barrie, ON, L4M 0G8 Canada /

103 Miller Drive, Crittenden, Kentucky, USA, 41030

Phone (705)721-1212 • Fax (705)720-9081 • www.napoleonfi replaces.com • hearth@napoleonproducts.com

$10.00

1.12F

W415-1472 / A / 10.11.16

2

TABLE OF CONTENTS

EN

1.0 INSTALLATION OVERVIEW 3

1.1 STOVE 3

1.2 INSERT 4

2.0 INTRODUCTION 5

2.1 DIMENSIONS 6

2.1.1 STOVE 6

2.1.2 NPI45 COMPLETE WITH NI800 FLASHING 6

2.1.3 NPI45 COMPLETE WITH AK8 ADAPTER AND GICSK FLASHING 7

2.1.4 NPI45 COMPLETE WITH AK9 ADAPTER AND CISK FLASHING 8

2.2 SPECIFICATIONS 9

2.2.1 HEATING SPECIFICATIONS 9

2.3 GENERAL INSTRUCTIONS 9

2.4 GENERAL INFORMATION 10

2.4.1 PELLET SPECIFICATIONS 10

2.4.2 SAFETY FEATURES 11

2.4.3 EPA COMPLIANCE 11

2.5 RATING PLATE INFORMATION 12

3.0 INSTALLATION PLANNING 13

3.1 APPLIANCE PLACEMENT 13

3.2 INSTALLATION OPTIONS 13

3.3 STOVE MINIMUM CLEARANCE TO COMBUSTIBLES 14

3.3.1 STRAIGHT INSTALLATION 14

3.3.2 CORNER INSTALLATION 14

3.3.3 ALCOVE INSTALLATION REQUIREMENTS (MINIMUM) 15

3.4 FLOOR PROTECTION REQUIREMENTS INSTALLATION 16

3.5 OUTSIDE AIR 17

3.6 MOBILE HOME 17

4.0 VENTING 18

4.1 TYPE OF VENT 18

4.2 INSTALLING THE PELLET VENT 18

4.3 VENTING THE PELLET APPLIANCE 18

4.4 PELLET VENT TERMINATION 19

4.5 VENT TERMINAL CLEARANCES 19

4.5.1 HORIZONTAL EXHAUST THROUGH WALL INSTALLATION 20

4.5.2 THROUGH THE WALL WITH VERTICAL RISE / HORIZONTAL TERMINATION 20

4.5.3 MINIMUM INSIDE VERTICAL CLEARANCES 21

4.5.4 CLASS A CHIMNEY RETROFIT 21

4.5.5 HEARTH MOUNT INSTALLATION 22

4.6 INSERT VENTING INSTALLATION EXAMPLES 23

4.6.1 TYPICAL EXISTING MASONRY INSTALLATION 23

4.6.2 FACTORY BUILT FIREPLACE 24

5.0 FRAMING (INSERT ONLY) 25

5.1 INSTALLATION INTO A COMBUSTIBLE ENCLOSURE 26

5.2 MINIMUM ENCLOSURE CLEARANCES 27

5.3 MINIMUM CLEARANCE TO COMBUSTIBLES 27

5.4 MINIMUM MANTEL CLEARANCES 28

5.5 REAR TO TOP VENT CONVERSION INSTRUCTIONS 29

6.0 FINISHING 29

6.1 INSTALLING VIEWING DOOR 29

6.2 FLASHING INSTALLATION 30

6.3 TRIVET INSTALLATION 30

7.0 WIRING DIAGRAM 31

8.0 OPERATING INSTRUCTIONS 32

8.1 PROPER PELLET LOADING 32

8.2 START UP CYCLE 32

8.3 LIGHTING APPLIANCE MANUALLY 32

8.4 LIGHTING INSTRUCTIONS 33

8.5 CONTROLS 33

8.6 CONTROL ADJUSTMENT 34

8.7 INSTALLING A THERMOSTAT OR REMOTE CONTROL 35

8.8 SHUTDOWN INSTRUCTIONS 35

9.0 NORMAL OPERATING SOUNDS 36

10.0 MAINTENANCE 37

10.1 DAILY MAINTENANCE 37

10.1.1 MAIN DOOR OPENING 37

10.1.2 ASH DISPOSAL 37

10.1.3 BURN POT INSPECTION 37

10.1.4 CARE OF PLATED PARTS 37

10.1.5 CARE OF GLASS 38

10.1.6 HEAT EXCHANGER TUBES CLEANING 38

10.1.7 PELLET PILE UP MAINTENANCE 38

10.1.8 BURN POT CLEANING 39

10.2 BI-WEEKLY MAINTENANCE (OR EVERY 10 BAGS OF PELLETS) 39

NOTE: Changes, other than editorial, are denoted by a vertical line in the margin.

W415-1472 / A / 10.11.16

10.2.1 FIREBOX MAINTENANCE (VACUUM) 39

10.3 SEMI-ANNUALLY (OR EVERY TWO TONS OF PELLET) 40

10.3.1 VACUUM HOPPER 40

10.3.2 SOOT AND FLY ASH FORMATION 40

10.3.3 VERTICAL EXHAUST DUCT CLEANING 40

10.3.4 EXHAUST HOUSING CLEAN (INSERT ONLY) 41

10.3.5 EXHAUST BLOWER CLEANING 41

10.3.6 SEAL CHECKS 41

10.3.7 VENT CLEANING 42

10.4 IN THE EVENT OF A JAMMED AUGER 42

11.0 REPLACEMENTS 43

12.0 TROUBLESHOOTING 50

13.0 WARRANTY 53

14.0 SERVICE HISTORY 54

11.1 COMMON REPLACEMENT PARTS 46

11.2 NPS45 REPLACEMENT PARTS 47

11.3 NPI45 REPLACEMENT PARTS 48

11.4 COMMON ACCESSORY PARTS 49

11.5 NPI45 ACCESSORY PARTS 49

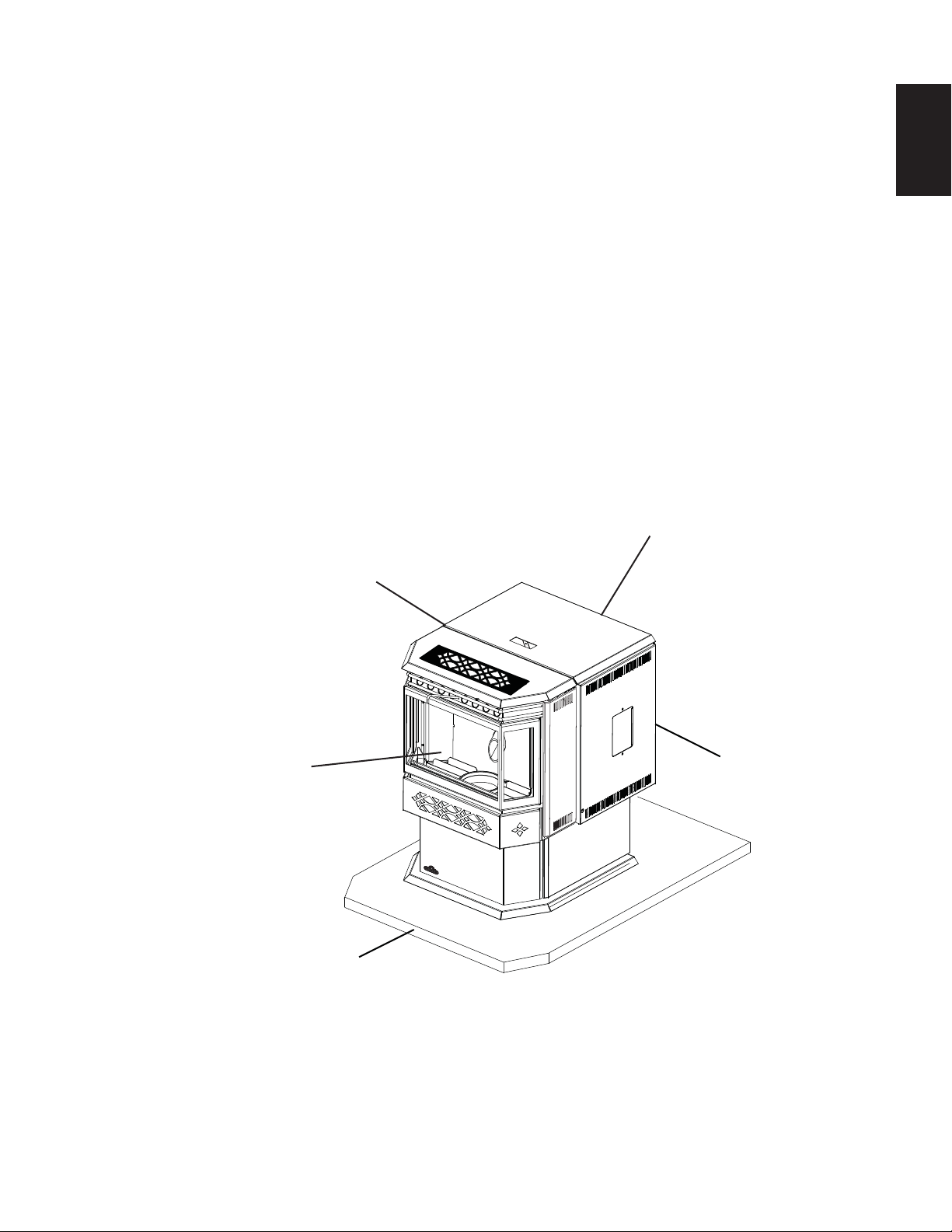

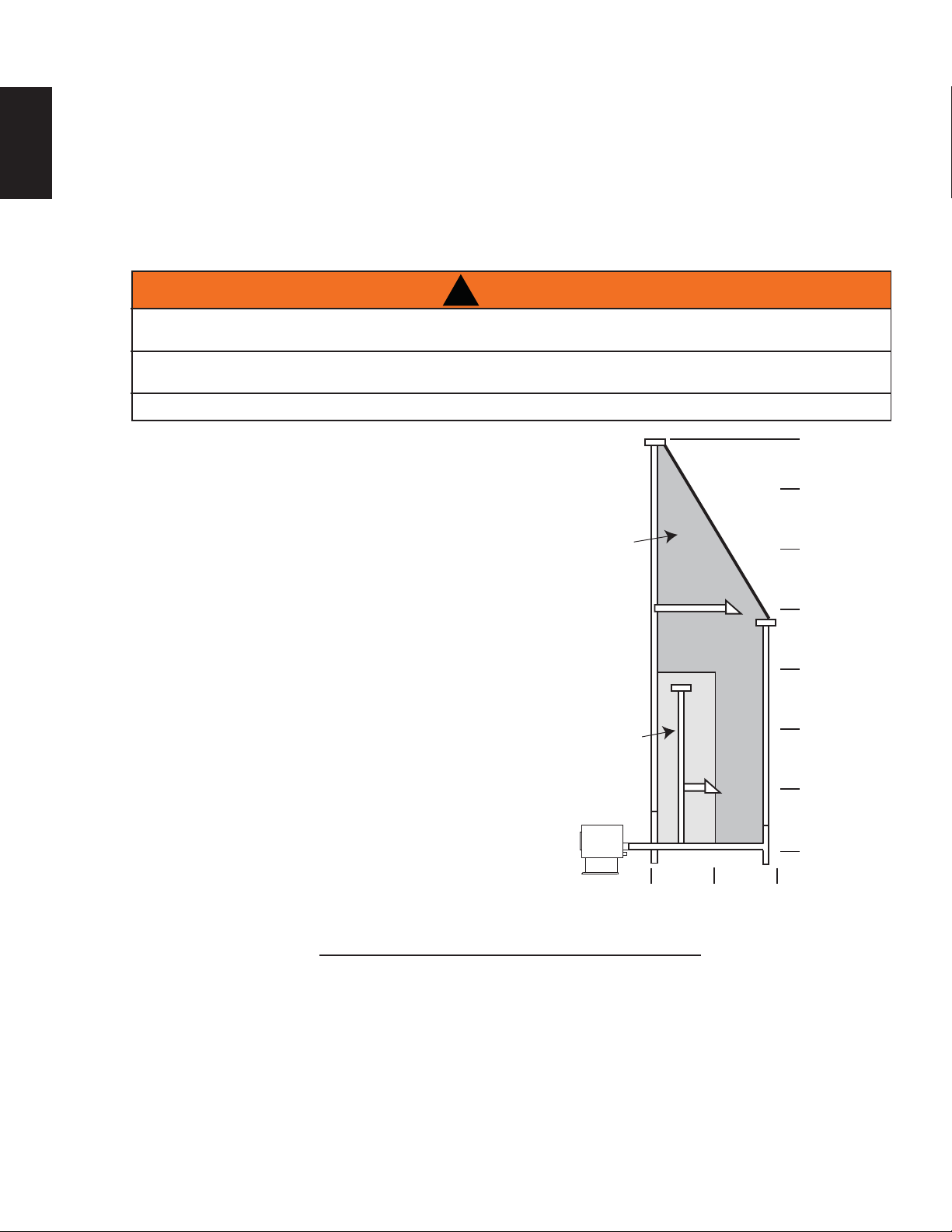

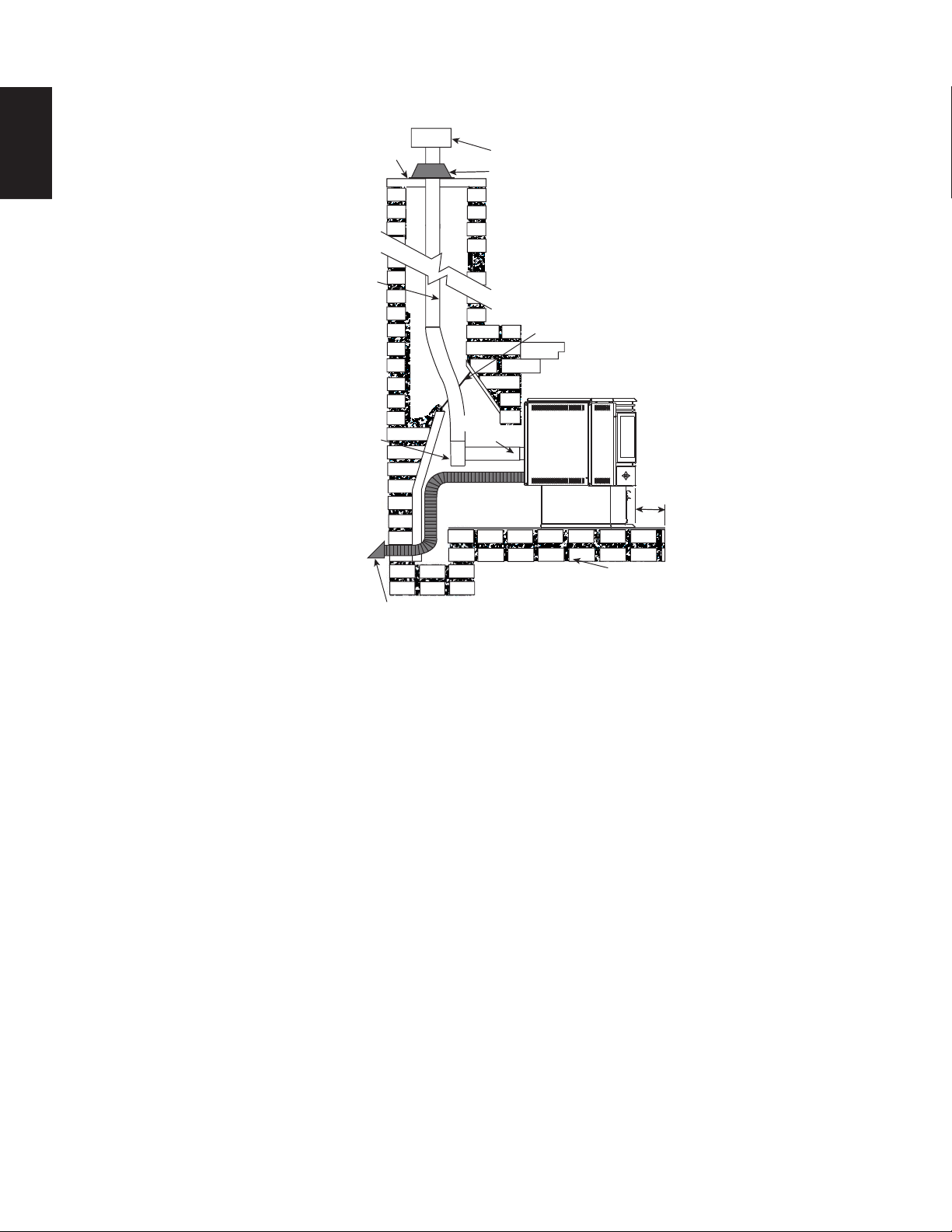

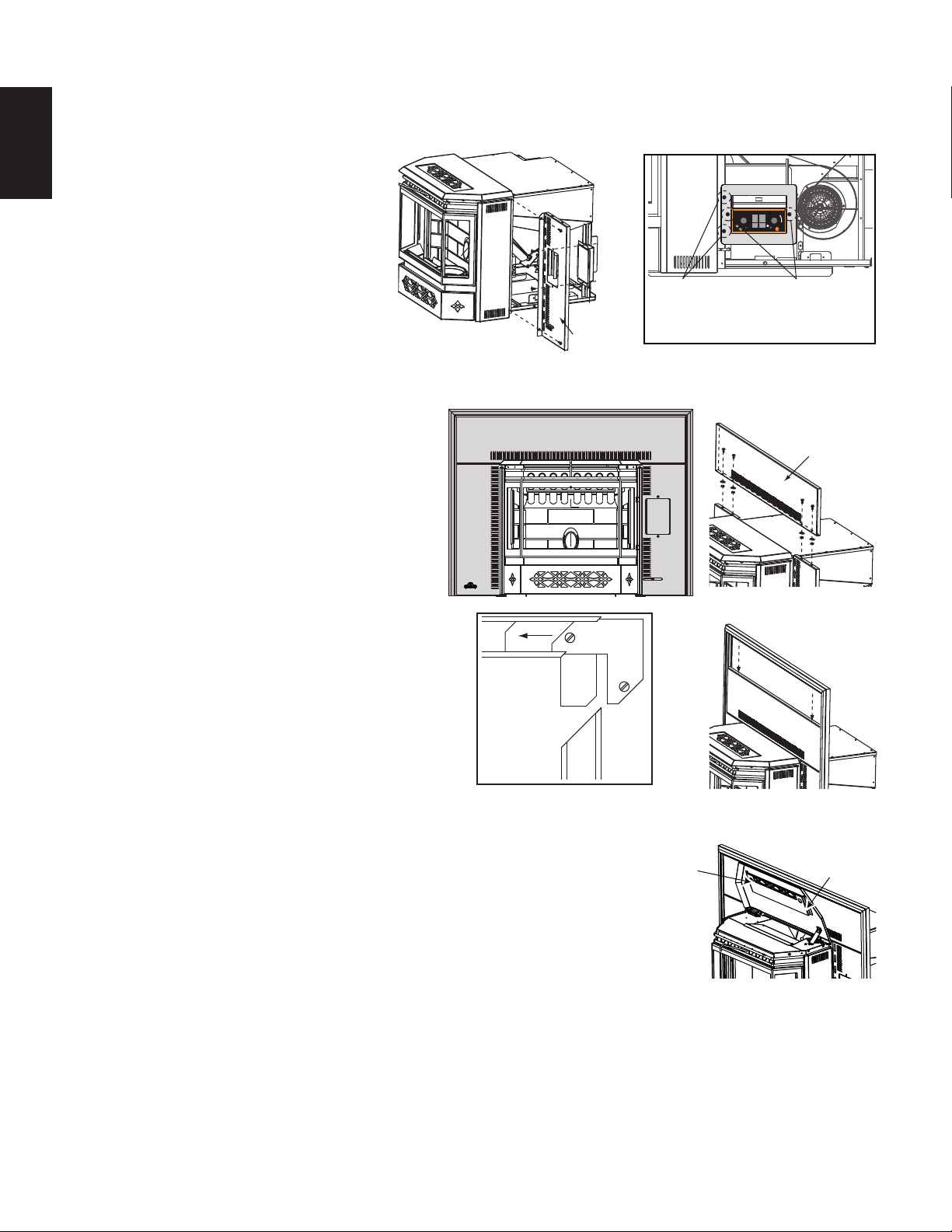

1.0 INSTALLATION OVERVIEW

1.1 STOVE

Venting, see “VENTING”

and “INSTALLATION

Rating Plate, see

“RATING PLATE

INFORMATION”

section.

PLANNING” sections.

3

EN

Door, see

“INSTALLING

VIEWING DOOR”

section.

Floor, see “INSTALLATION

PLANNING - FLOOR

PROTECTION REQUIREMENTS”

section.

See “OUTSIDE

AIR” section.

W415-1472 / A / 10.11.16

4

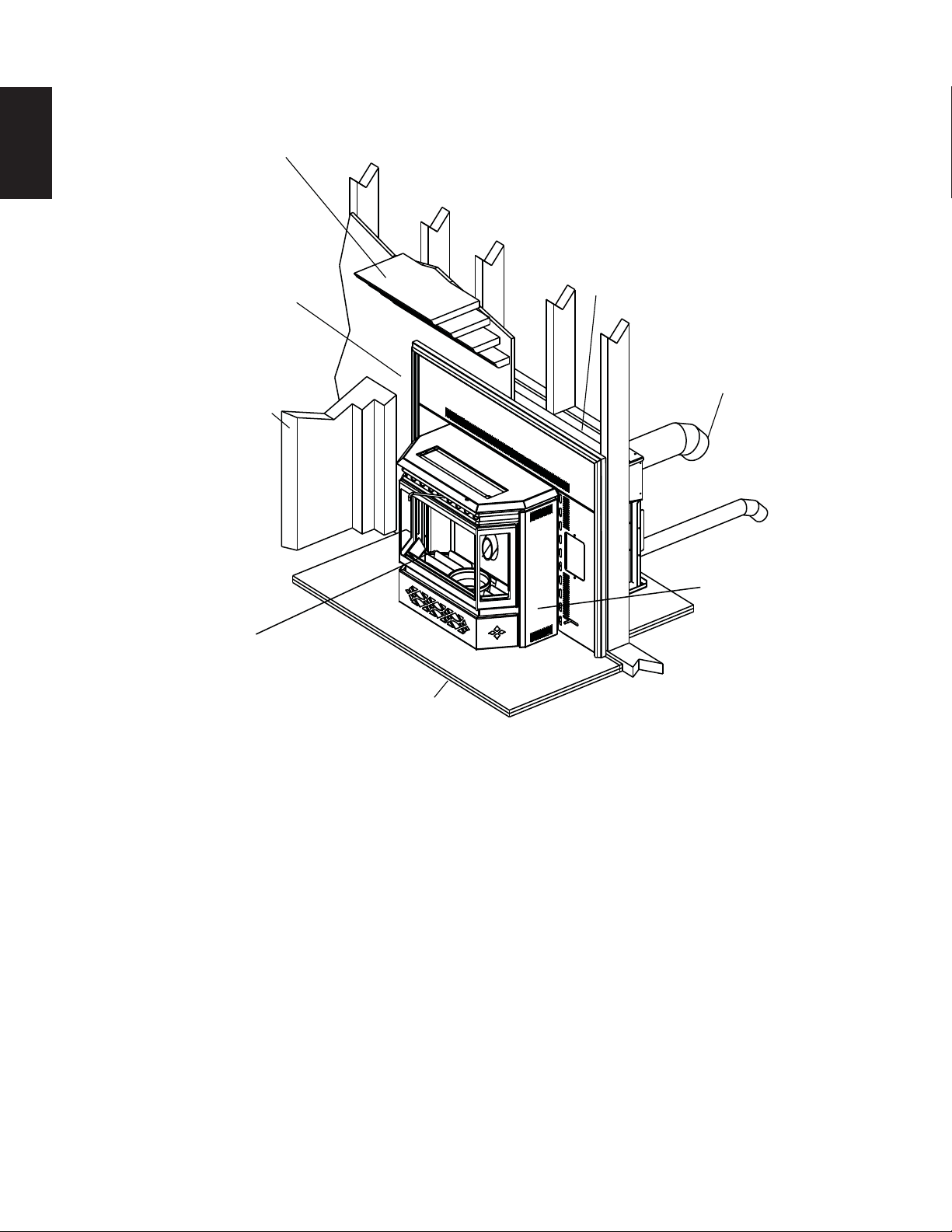

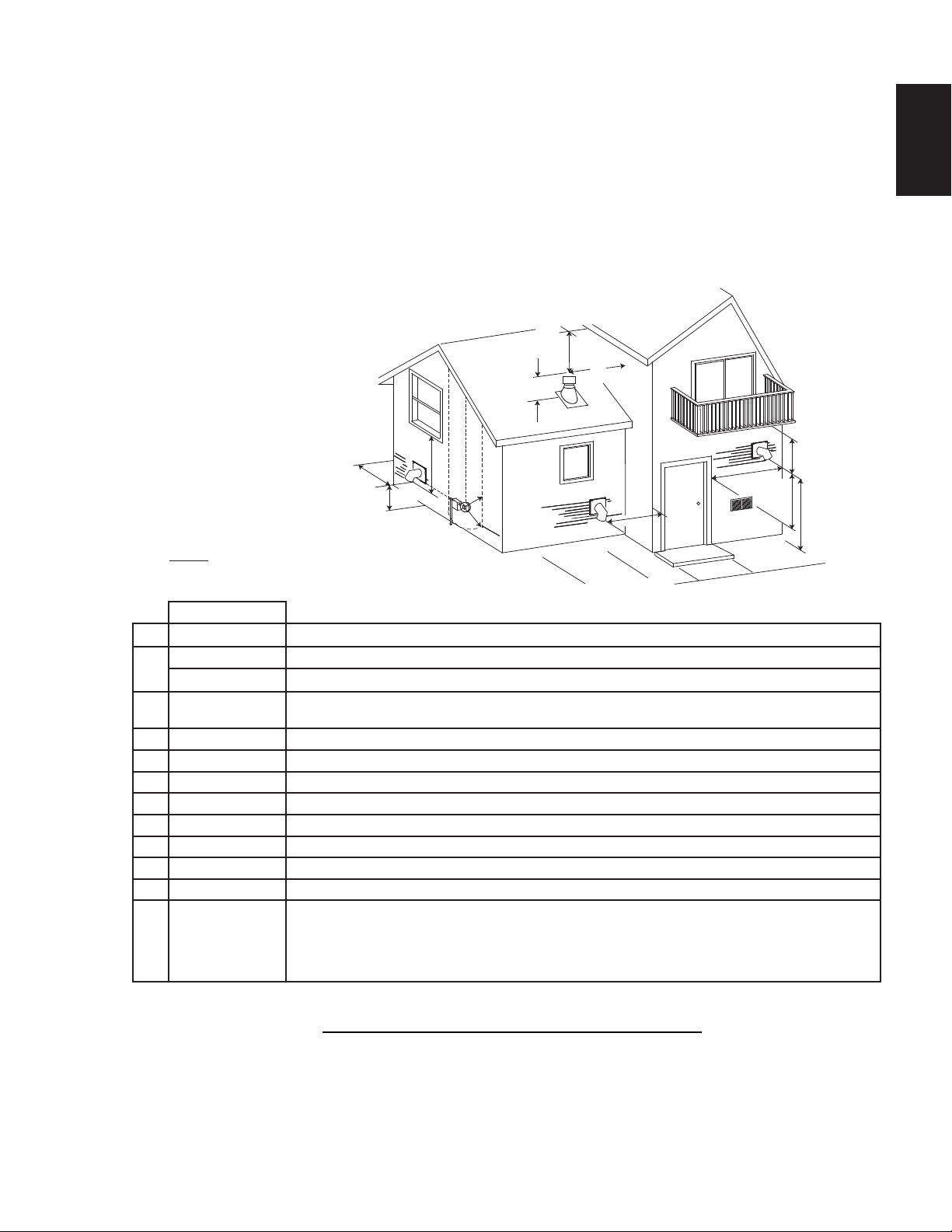

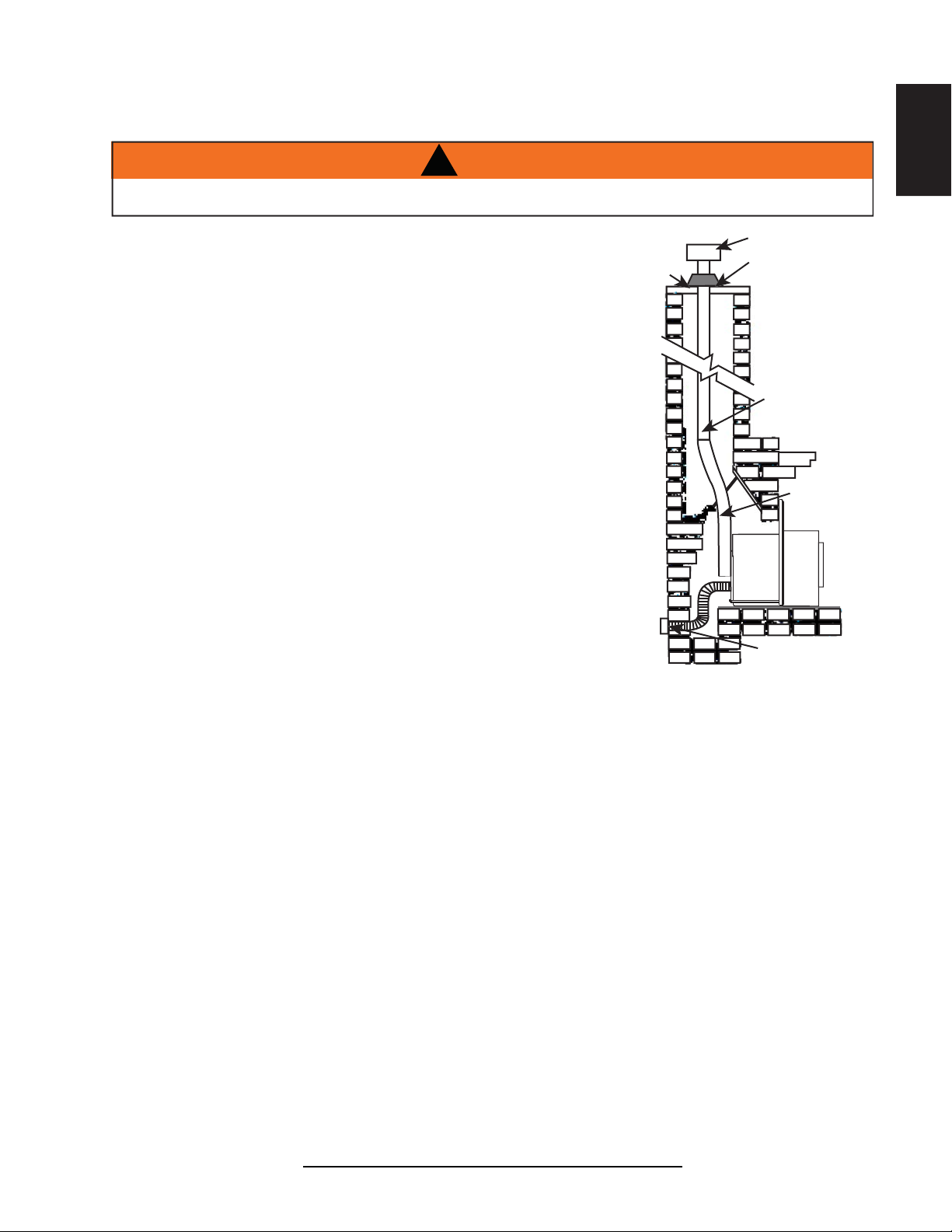

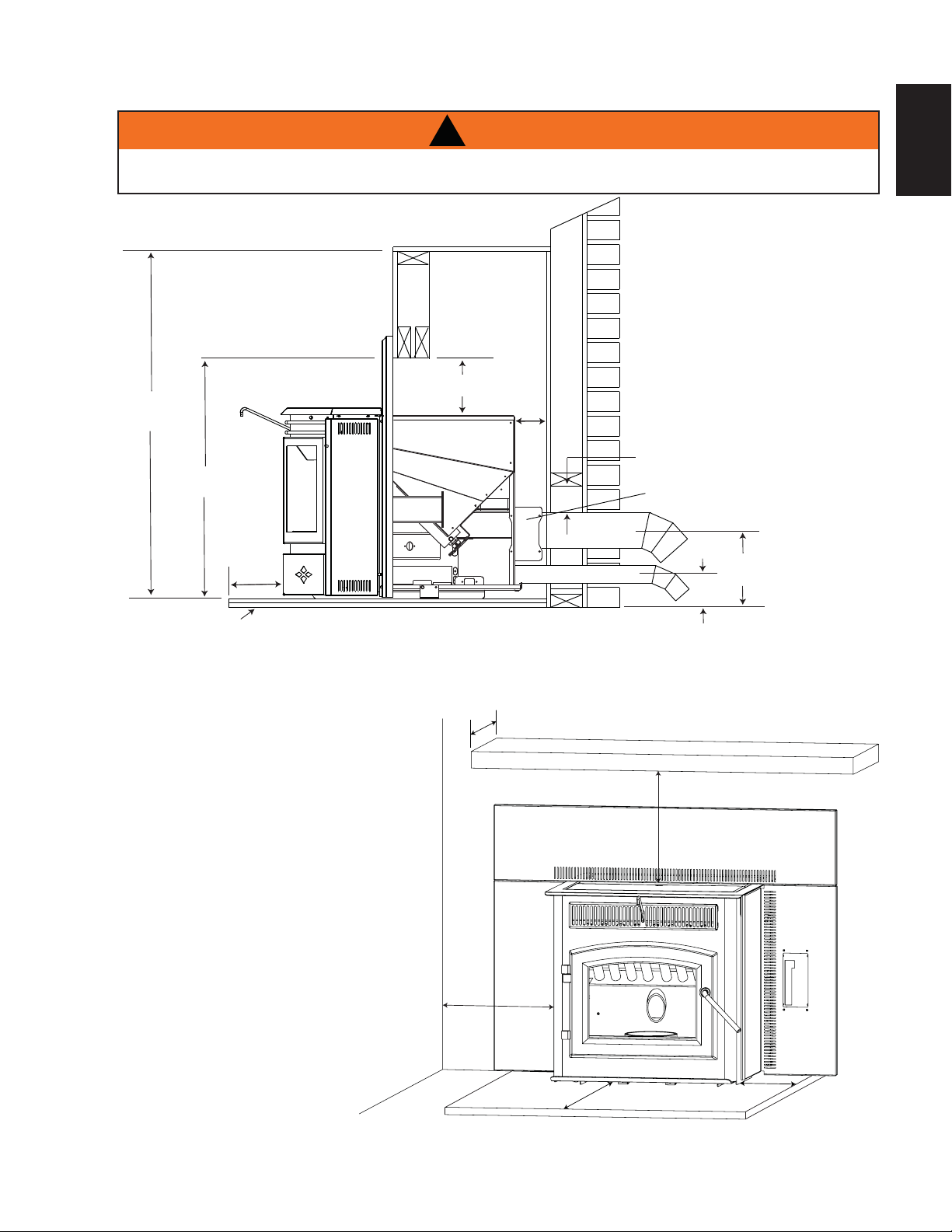

1.2 INSERT

EN

See “MINIMUM MANTEL

CLEARANCES” section.

Drywall

(or other

combustible

material).

See “MINIMUM

CLEARANCES TO

COMBUSTIBLES”

section.

Door, see

“INSTALLING

VIEWING DOOR”

section.

See “ENCLOSURE

CLEARANCES”

section.

See “VENTING”

and “INSTALLATION PLANNING”

sections.

Side

Wall

Rating Plate, see

“RATING PLATE

INFORMATION”

section.

See “INSTALLATION

INTO A BUIL T -IN

ENCLOSURE” section.

W415-1472 / A / 10.11.16

2.0 INTRODUCTION

5

!

WARNING

• THIS APPLIANCE IS HOT WHEN OPERATED AND CAN CAUSE SEVERE BURNS IF CONTACTED.

• Do not operate appliance before reading and understanding operating instructions. Failure to operate appliance according to

operating instructions could cause fi re or injury. Contact the local building or fi re authority and follow their guidelines. Notify

your insurance company of this appliance as well.

• Never try to repair or replace any part of the appliance unless instructions are given in this manual. All other work should be

done by a trained technician.

• Risk of burns. The appliance should be turned off and cooled before servicing.

• Do not operate without fully assembling all components.

• Do not install damaged, incomplete or substitute components.

• Risk of cuts and abrasions. Wear protective gloves and safety glasses during installation. Sheet metal edges may be sharp.

• Children and adults should be alerted to the hazards of high surface temperature and should stay away to avoid burns or

clothing ignition. Toddlers, young children and others may be susceptible to accidental contact burns. A physical barrier is

recommended if there are at risk individuals in the house. To restrict access to an appliance or stove, install an adjustable

safety gate to keep toddlers, young children and other at risk individuals out of the room and away from hot surfaces.

• Clothing or other fl ammable material should not be placed on or near the appliance.

• Due to high temperatures, the appliance should be located out of traffi c and away from furniture and draperies.

• Ensure you have incorporated adequate safety measure to protect infants/toddlers from touching hot surfaces.

• Even after the appliance is out, the glass and/or screen will remain hot for an extended period of time.

• Check with your local hearth specialty dealer for safety screens and hearth guards to protect children from hot surfaces.

These screens and guards must be fastened to the fl oor.

• Any safety screen or guard removed for servicing must be replaced prior to operating the appliance.

• It is imperative that the control compartments, burners and circulating blower and its passageway in the appliance and venting

system are kept clean. The appliance and its venting system should be inspected before use and at least annually by a

qualifi ed service person. More frequent cleaning may be required due to excessive lint from carpeting, bedding material, etc.

The appliance area must be kept clear and free from combustible materials, gasoline and other fl ammable vapors and liquids.

• Under no circumstances should this appliance be modifi ed.

• Do not use this appliance if any part has been under water. Immediately call a qualifi ed service technician to inspect the

appliance and to replace any part of the control system and any gas control which has been under water.

• Do not operate the appliance with the glass door removed, cracked or broken. Replacement of the glass should be done by a

licensed or qualifi ed service person. The viewing door and ashpan must be closed and latched during operation.

• Do not strike or slam shut the appliance glass door.

• Only doors / optional fronts certifi ed with the unit are to be installed on the appliance.

• Keep the packaging material out of reach of children and dispose of the material in a safe manner. As with all plastic bags,

these are not toys and should be kept away from children and infants.

• If the appliance is not properly installed, a house fi re may result. Do not expose the appliance to the elements (ex. rain, etc.)

and keep the appliance dry at all times. Wet insulation will produce an odour when the appliance is used.

• The chimney must be sound and free of cracks. Clean your chimney a minimum of twice a year and as required.

• The heater is designed and approved for pelletized wood fuel only. Any other type of fuel burned in this heater will void the

warranty and safety listing. D

or paint thinners / solvents, plastic, materials containing asbestos, construction debris, railroad ties or treated wood, manure

or animal remains, salt water driftwood or salted materials, unseasoned wood, coloured paper, cardboard, plywood or

particleboard.

• Do not start a fi re with chemicals or fl uids such as gasoline, engine oil, etc.

• Ashes must be disposed in a metal container with a tight lid and placed on a non-combustible surface well away from the

home or structure.

• Your appliance requires periodic maintenance and cleaning. Failure to maintain your appliance may lead to smoke spillage in

your home.

• The exhaust system must be completely straight and properly installed. It is recommended that the pellet vent joints be sealed

with a minimum 500°F (260°C) silicone sealant. Install according to the vent manufacturer’s instructions.

• Ensure clearances to combustibles are maintained when building a mantel or shelves above the appliance. Elevated

temperatures on the wall or in the air above the appliance can cause melting, discolouration or damage to decorations, a T.V.

or other electronic components.

• During a power outage this appliance will not operate. If a power outage does occur, check the appliance for smoke spillage

and open a window if any smoke spills into the room.

• Keep foreign objects out of the hopper.

• Disconnect the power cord before performing any maintenance. NOTE: Turning the pellet feed to “OFF” does not

disconnect all power to the heater.

• Do not throw this manual away. This manual has important operating and maintenance instructions that you will need at a

later time. Always follow the instructions in this manual.

• At no point should you use fi rewood or fi relogs in this appliance. The use of which could cause a house fi re.

• This appliance must be connected to a standard 115 V, 50Hz grounded electrical outlet. Do not use an adapter plug or sever

the grounding prong. Do not route the electrical cord underneath, in front of, or over the appliance.

• When installed in a mobile home, the appliance must be bolted to the fl oor, have outside air, and NOT BE INSTALLED IN THE

BEDROOM (per H.U.D. requirements). Check with local building offi cials.

o not burn trash or garbage, lawn clippings / waste, rubber, waste petroleum products, paints

3.8C

EN

W415-1472 / A / 10.11.16

6

p

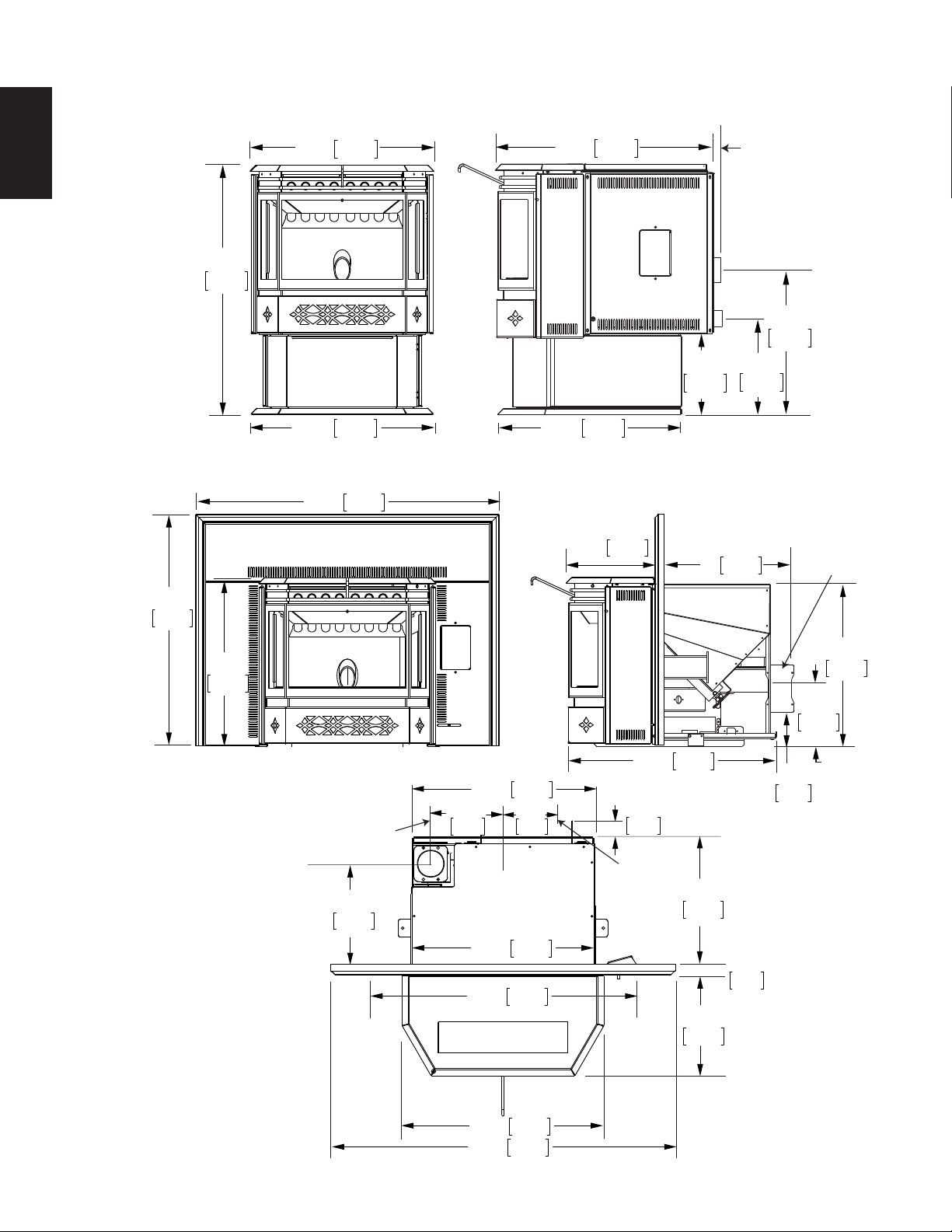

2.1 DIMENSIONS

2.1.1 STOVE

EN

30 1/2"

774mm

22 1/2"

571mm

26 5/8"

676mm

1 1/8”

9 7/8"

251mm

17 3/8"

441mm

11 3/4"

298mm

568mm

22 3/8"

2.1.2 NPI45 COMPLETE WITH NI800 FLASHING

975mm

38 3/8"

29 5/16"

642mm

21 1/2"

546mm

20 3/8"

8"

Center line

of exhaust

11 3/16"

284mm

203mm

Center line of

insert

22 3/8"

518mm

4 1/4"

108mm

568mm

12 1/2"

318mm

673mm

26 1/2"

2 1/4"

57mm

Center line of

air intake

15"

12 3/4"

324mm

381mm

Center line of

Stand-o’s

7 5/8"

194mm

Center line

of exhaust

2 3/4"

70mm

air intake

20 5/8"

524mm

W415-1472 / A / 10.11.16

523mm

20 5/8"

829mm

*32 5/8"

12 1/2"

572mm

22 1/2"

975mm

38 3/8"

*In order to install ashing ush to a nished wall and centered within the opening, the front

ening of the replace or enclosure must be this wide.

o

1 1/4"

32mm

318mm

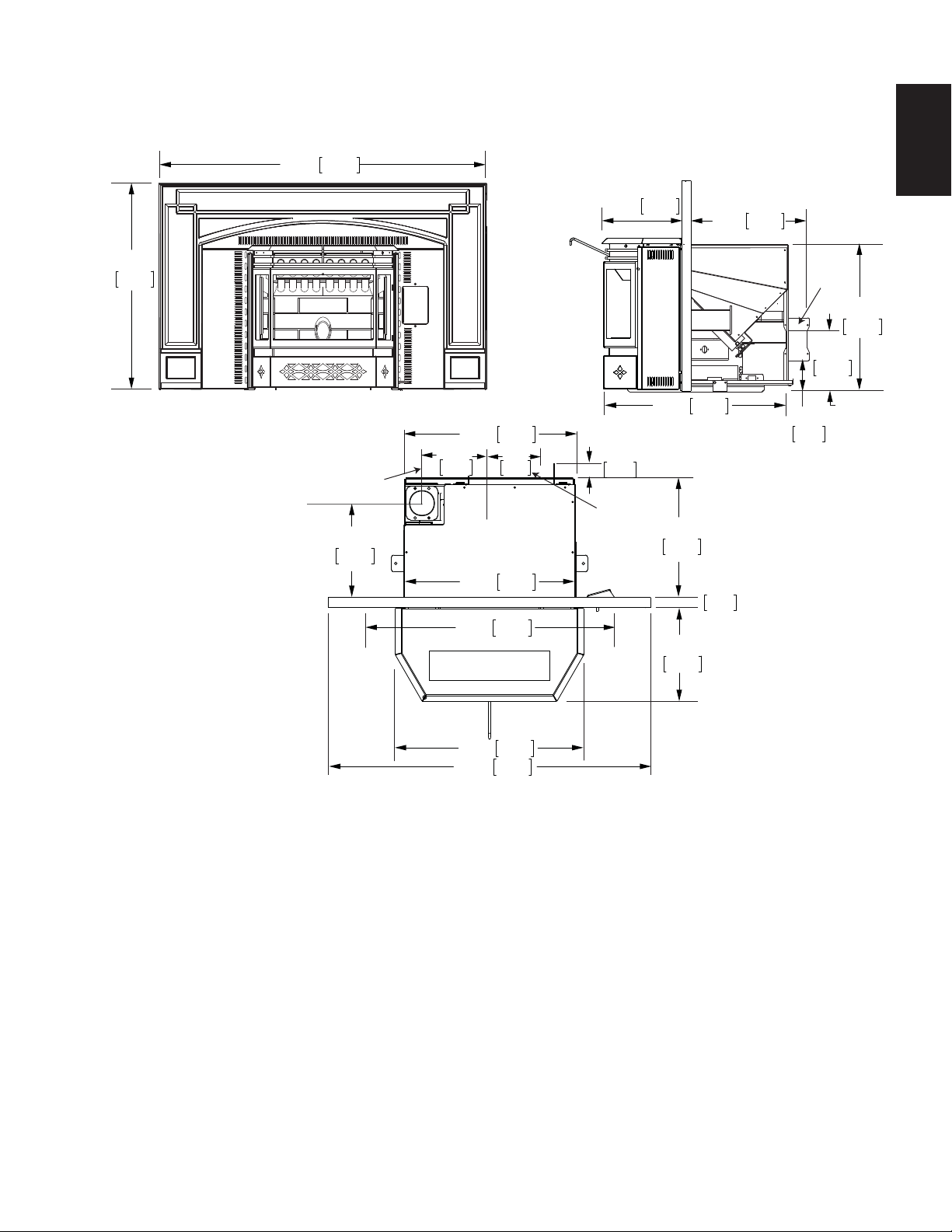

2.1.3 NPI45 COMPLETE WITH AK8 ADAPTER AND GICSK FLASHING

1180mm

46 7/16"

292mm

10 5/16"

29 3/16"

741mm

15 5/8"

7

EN

397mm

Stand-o’s

20 5/8"

524mm

7 5/8"

194mm

26 1/2"

518mm

20 3/8"

8"

Center line

of exhaust

10 1/2"

267mm

*In order to install ashing ush to a nished wall and centered within the opening, the front

203mm

46 7/16"

opening of the replace or enclosure must be this wide.

4 1/4"

108mm

Center line of

insert

523mm

20 5/8"

781mm

*30 3/4"

572mm

22 1/2"

1180mm

2 1/4"

57mm

Center line of

air intake

13 3/8"

340mm

10 5/16"

262mm

673mm

2 3/16"

56mm

Center line

of exhaust

2 3/4"

70mm

Center line of

air intake

W415-1472 / A / 10.11.16

EN

8

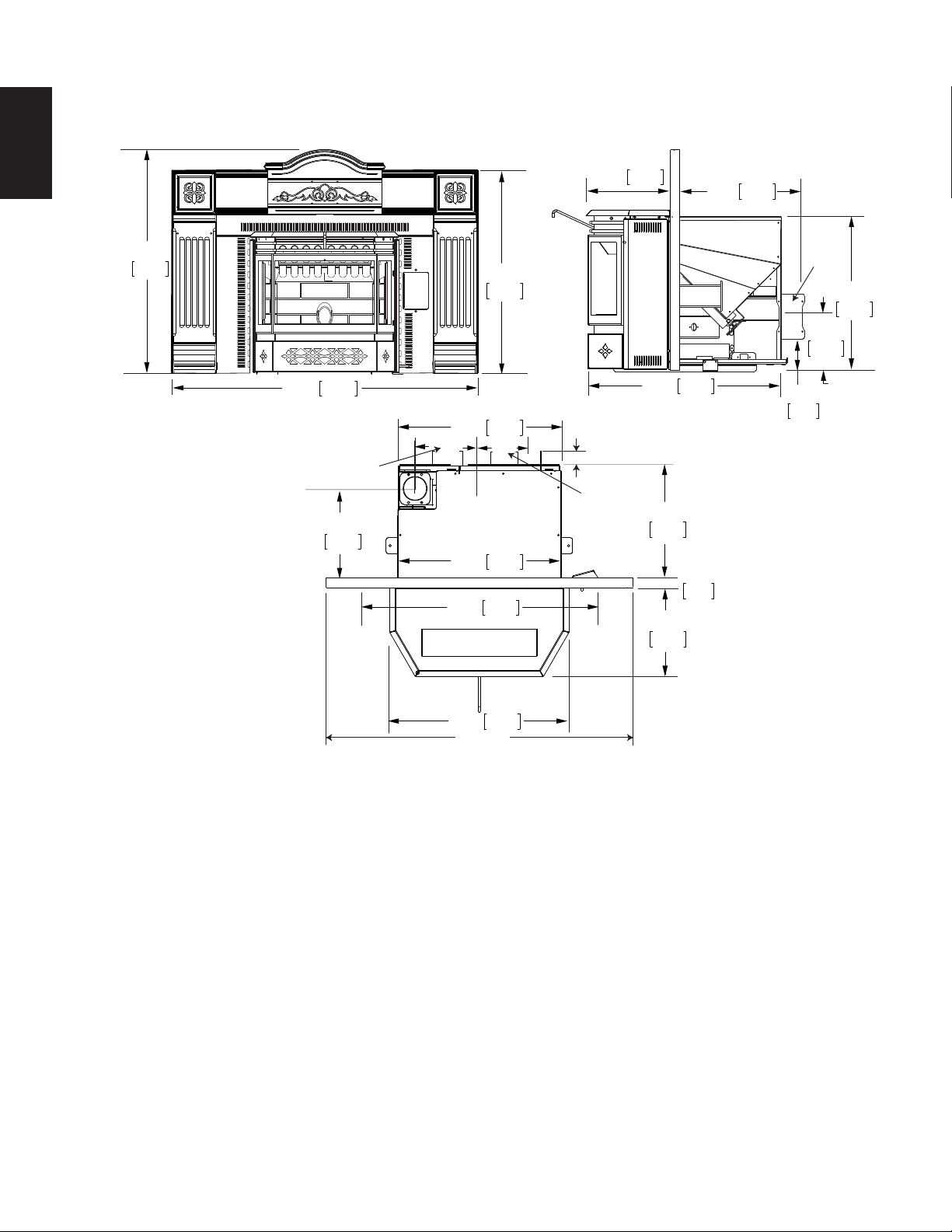

2.1.4 NPI45 COMPLETE WITH AK9 ADAPTER AND CISK FLASHING

270mm

10 5/8"

16 1/2"

419mm

31"

787mm

1180mm

46 7/16"

Center line

of exhaust

11 3/16"

284mm

20 3/8"

8"

203mm

Center line of

insert

20 5/8"

*32 5/8"

28 1/8"

714mm

518mm

4 1/4"

108mm

523mm

829mm

2 1/4”

Center line of

air intake

26 1/2"

14 1/4"

362mm

10 5/8"

270mm

673mm

1 5/8"

42mm

Stand-o’s

20 5/8"

524mm

7 5/8"

194mm

Center line

of exhaust

2 3/4"

70mm

Center line of

air intake

572mm

22 1/2"

46 7/16”

*In order to install ashing ush to a nished wall and centered within the opening, the front

opening of the replace or enclosure must be this wide.

W415-1472 / A / 10.11.16

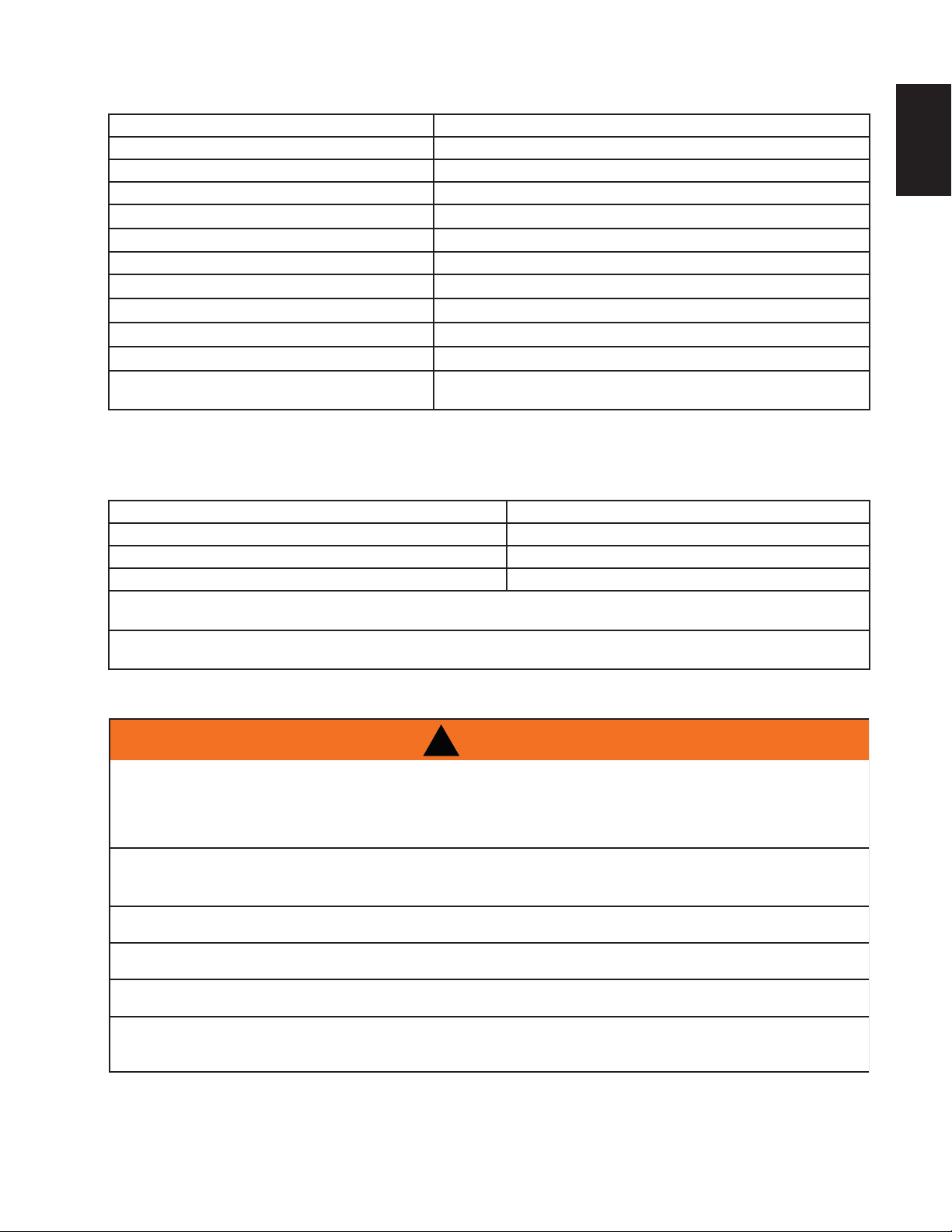

2.2 SPECIFICATIONS

Electrical Rating 115 Volts, 3.6 Amps, 60Hz

Watts During Start-Up Sequence 400 (approximately)

Watts During Operation 180 (approximately)

NPS45 Width 22 3/8" (568mm)

NPS45 Height 30 1/2" (775mm)

NPS45 Depth 26 5/8" (676mm)

Weight 210 Pounds (95kg)

Exhaust Collar 3" (76mm)

Intake Collar 2" (51mm)

NPS45 Hopper Capacity 55 Pounds (25kg)

NPI45 Hopper Capacity 45 Pounds (20kg)

Minimum Appliance Opening Size Front: 32 5/8" (829mm)* W x 20 5/8" (532mm) H x 14 1/4" (362mm)

* In order to install, fl ashing fl ush to fi nished wall and centered within the opening the front opening of the appliance or

enclosure must be 32 5/8" (829mm) wide.

2.2.1 HEATING SPECIFICATIONS

Approximate Maximum Heating Capacity (in square feet)* 800 to 2000 Sq. Feet (243-610 Sq. Meters)

Burn Rate (Pounds per Hour)** 1.0 to 5.0

BTU/hr** 8500 to 42500

Maximum Burn Time on Low Burn** 55 Hours (NPS45), 45 Hours (NPI45)

* Heating capacity will vary depending on the home's fl oor plan, degree of insulation, and the outside temperature. It is

also affected by the fuel size, quality, and moisture level.

** Small pellets will increase or decrease the stated burn rates and burn times. Differences of plus or minus 20%

depending on fuel quality may occur.

9

EN

D Back: 20 3/8" (518mm) W

2.3 GENERAL INSTRUCTIONS

ALL WIRING SHOULD BE DONE BY A QUALIFIED ELECTRICIAN AND SHALL BE IN COMPLIANCE

WITH LOCAL CODES. IN THE ABSENCE OF LOCAL CODES, USE THE CURRENT CSA C22.1

CANADIAN ELECTRIC CODE (IN CANADA) OR THE ANSI/NFPA NO. 70 NATIONAL ELECTRIC CODE

DO NOT CONNECT THIS APPLIANCE TO A CHIMNEY FLUE SERVING ANOTHER APPLIANCE. DO

NOT CONNECT TO ANY AIR DISTRIBUTION DUCT OR SYSTEM.

PROVIDE ADEQUATE CLEARANCE FOR SERVICING AND OPERATING THE APPLIANCE.

NEVER OBSTRUCT THE FRONT OPENING OF THE APPLIANCE.

OBJECTS PLACED IN FRONT OF THE APPLIANCE MUST BE KEPT A MINIMUM OF 48” (1219.2mm)

FROM THE FRONT FACE OF THE APPLIANCE.

!

WARNING

IN THE UNITED STATES.

PROVIDE ADEQUA TE VENTILA TION.

W415-1472 / A / 10.11.16

10

Thank you for purchasing a Wolf Steel Ltd. Pellet Appliance. This appliance is designed for use with Pelletized

Wood Only.

EN

Please read this entire manual before installation and use of this pellet fuel-burning room appliance. Failure to

follow these instructions could result in property damage, bodily injury or even death.

Keep this manual handy for future reference.

This Pellet Appliance, when installed, must be electrically grounded in accordance with the local codes, or in

the absence of local codes, use the current CSA C22.1 Canadian Electrical Code in Canada or the ANSI/NFPA

70 National Electrical Code in the United States.

This appliance will not operate using natural draft or without a power source for the blower systems and fuel

feed system.

These appliances are equipped with levelling screws that penetrate the front corners of the fi rebox. If these

screws are missing it will have a negative infl uence on the performance of this appliance. Ensure that the

levelling screws are tightened into position.

The protective wrap on plated parts is best removed when the assembly is at room temperature but this can be

improved if the assembly is warmed, using a hair dryer or similar heat source.

If the appliance is installed directly on carpeting, vinyl tile or other combustible material other than wood

fl ooring, the appliance shall be installed on a non-combustible hearth pad extending the full width and depth.

2.4 GENERAL INFORMATION

2.4.1 PELLET SPECIFICATIONS

4.5B

!

WARNING

IT IS IMPORTANT TO SELECT AND USE ONLY PELLETS THAT ARE DRY AND FREE OF DIRT

OR ANY IMPURITIES SUCH AS HIGH SALT CONTENT. DIRTY FUEL WILL ADVERSELY AFFECT

THE OPERATION AND PERFORMANCE OF THE APPLIANCE AND WILL VOID THE WARRANTY.

THE PELLET FUEL INSTITUTE (P.F.I.) HAS ESTABLISHED STANDARDS FOR WOOD PELLET

MANUFACTURERS. WE RECOMMEND THE USE OF PELLETS THAT MEET OR EXCEED THESE

STANDARDS. ASK YOUR DEALER FOR A RECOMMENDED PELLET TYPE.

Pellet quality is important, please read the following:

Your Wolf Steel Ltd. Pellet Appliance has been designed to burn premium hard or soft wood pellets only. Do

not use any other type of fuel such as fi re logs or fi re starting pellets, as this will void the warranties stated in

this manual.

The performance and heat output of the pellet appliance is directly related to the quality and moisture of the

pellets. Store pellets in a cool dry area to prevent moisture absorption.

64.1

W415-1472 / A / 10.11.16

P.F.I. PELLET STANDARDS:

11

Inorganic Fines (fi ne

particles)

Bulk Density 38 pound per cubic foot minimum

Size 1/4" (6.4mm) to 5/16" (8mm) diameter, 1/2" - 1 1/2" (13mm

Ash Content No more than 2%

Moisture Content 8% maximum

Chlorides 300 parts per million by weight

Trace Metals Less than 100mg/kg

Heat Content Approximately 8200 BTU per pound minimum

Construction Waste Not to contain any waste materials

1% maximum through a 1/8" (3.2mm) screen

- 38mm) long maximum

If the fuel does not comply to

this standard, the appliance

may not operate as designed.

We recommend the use of

premium grade (1% ash

content) for longer appliance

life and less frequent cleaning.

2.4.2 SAFETY FEATURES

HIGH LIMIT SWITCH: Your appliance is equipped with a high limit switch. In the event that the temperature

of the appliance approaches an unsafe operating temperature, this switch will shut down the pellet feed,

which will eventually shut down the appliance. If this happens, it is important to fi nd out why the appliance

overheated. Contact your local dealer.

LOW LIMIT SWITCH: This switch will automatically shut down the appliance if the fi re goes out or fails to

light within 15 minutes.

EN

HOPPER DOOR INTERLOCK: Your appliance is equipped with a micro switch in the hopper assembly that

shuts off the auger when the hopper door is opened. Closing the door switches the auger back on, allowing

pellets to feed again.

VACUUM SWITCH: This switch will sense lack of air fl ow through the appliance and shut down the pellet

feed. This lack of fl ow could be caused by a blocked vent.

POWER FAILURE: In the event of a power failure, the appliance will shut down. Once power is restored, the

appliance will restart, unless the convection air temperature has gone above the high limit switch setting. If

this happens, contact your local dealer.

2.4.3 EPA COMPLIANCE

We suggest that our woodburning hearth products

be installed and serviced by professionals who are

certified in the U.S. by the National Fireplace

Institute® (NFI) as NFI Woodburning Specialists or

who are certified in Canada by

Wood Energy Technical

Training (WETT).

66.1A

W415-1472 / A / 10.11.16

12

BASE DE PROTECTION

U.S. Environmental Protection Agency:

Certifié conforme à la norme d’ émanation de particles de 2015. Non approuvé pour la

vente après le 15 mai, 2020

: 40 CFR Part 60, Subpart AAA.

2.4 Grammes par heure

U.S. EN ONMENTALPROTECTION AGENCY

Certified to comply with 2015 particulate

emissions standards. Not approved for sale after May 15, 2020.

40 CFR Part 60, Subpart AAA.

2.4g/hr

)(FRONT VIEW)

LOOD MANT

YEAYE

FEDERAL

EDERAL

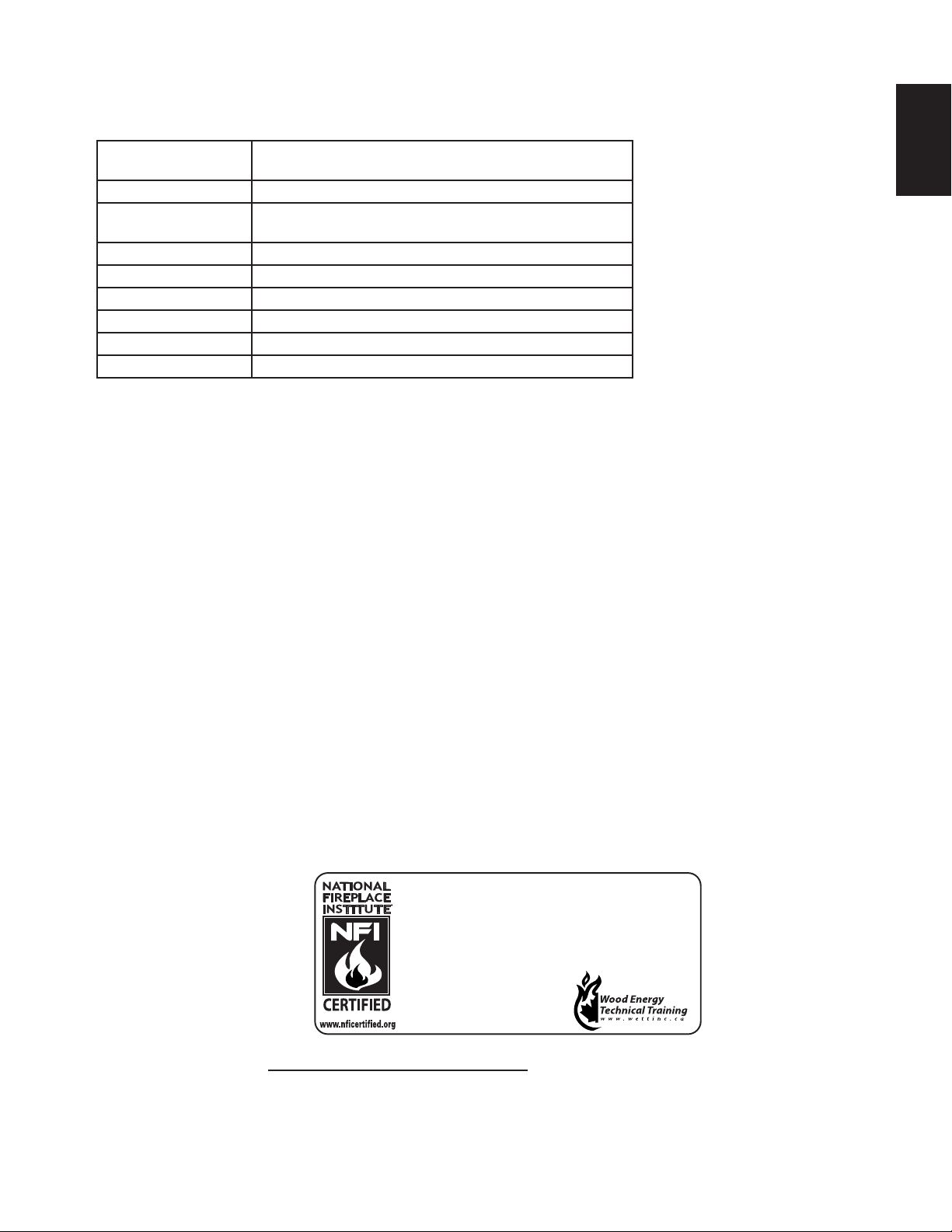

2.5 RATING PLATE INFORMATION

EN

9700539 (WSL)

4001657 (NGZ)

4001658 (NAC)

4001659 (WUSA)

- INSTALL AND USE ONLY IN ACCORDANCE WITH THE

MANUFACTURER’S INSTRUCTIONS AND LOCAL

BUILDING CODES. MINIMUM CEILING HEIGHT: 7FT

(2.13M) HEARTH EXTENSION / COMBUSTIBLE FLOOR

PROTECTION: IF INSTALLED ON A COMBUSTIBLE

FLOOR, UNIT MUST BE PLACED ON A

NON-COMBUSTIBLE FLOOR PROTECTOR EXTENDING

6” IN FRONT.

- DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE

SERVING ANOTHER APPLIANCE.

- REPLACE GLASS WITH ONLY CERAMIC GLASS.

DANGER: RISK OF ELECTRICAL SHOCK. DISCONNECT

POWER BEFORE SERVICING UNIT.

- KEEP VIEWING DOOR TIGHTLY CLOSED DURING

OPERATION.

- CONTACT LOCAL BUILDING AND FIRE OFFICIALS

ABOUT RESTRICTIONS AND INSTALLATION INSPECTION IN YOUR LOCAL AREA.

- SUITABLE FOR USE IN MOBILE HOMES WHEN USED

WITH OUTSIDE AIR INSTALLATION KIT.

- REFER TO INSTALLATION INSTRUCTIONS OR LOCAL

BUILDING CODES WHEN PASSING EXHAUST SYSTEM

THROUGH COMBUSTIBLE WALL OR CEILING.

CAUTION: HOT WHILE IN OPERATION. DO NOT TOUCH.

KEEP CHILDREN, CLOTHING AND FURNITURE AWAY.

CONTACT MAY CAUSE SKIN BURNS.

THIS WOOD APPLIANCE NEEDS PERIOD INSPECTION

AND REPAIR FOR PROPER OPERATION. CONSULT

THE OWNER’S MANUAL FOR FURTHER INFORMA-

TION. IT IS AGAINST UNITED STATES FEDERAL

REGULATIONS TO OPERATE THIS WOOD APPLIANCE

IN A MANNER INCONSISTENT WITH THE OPERATING

INSTRUCTIONS IN THE OWNER’S MANUAL.

WOLF STEEL LTD.

24 NAPOLEON ROAD.

BARRIE, ONTARIO L4M 0G8 CANADA

LISTED PELLET FUEL BURNING ROOM HEATER TESTED TO: ASTM E 1509, UL1482, ULC S628 MODEL NPI45

U.S. ENVIRONMENTAL PROTECTION AGENCY

emissions standards. Not approved for sale after May 15, 2020.

MASONRY FIREPLACE INSTALLATION

MANTEL

B

A

INSERT

C

HEARTH EXTENSION

BUILT-IN FIREPLACE INSTALLATION

WOOD MANTEL

WOOD MANTE

B

(FRONT VIEW)

FRONT VIEW

D

ENCLOSURE

INSERT

E

MANUFACTURE DATE: / DATE DE FABRICATION:

YEAR:

MONTH:

2016

243658710912111

Certified to comply with 2015 particulate

E

2017 2018

40 CFR Part 60, Subpart AAA.

BUILT-IN FIREPLACE INSTALLATION

MANTEL

MINIMUM CLEARANCES TO COMBUSTIBLE

Sidewall A 8”

Mantel B 8”

Floor Protector C 6”

Recess Width D 31 1/2”

Recess Height E 26 1/2”

Recess Depth F 16”

Mantel Depth G 10”

INPUT RATING

MIN 1 LB/HR

MAX 5 LB/HR

ELECTRICAL RATING

120V 3.6A 60HZ

C

(SIDE VIEW)

B

G

ENCLOSURE

F

2019 2020

NPI45

2.4g/hr

For rating plate location, see “INSTALLATION OVERVIEW” section.

This illustration is for reference only. Refer to the rating plate on the appliance for accurate information.

W415-1472 / A / 10.11.16

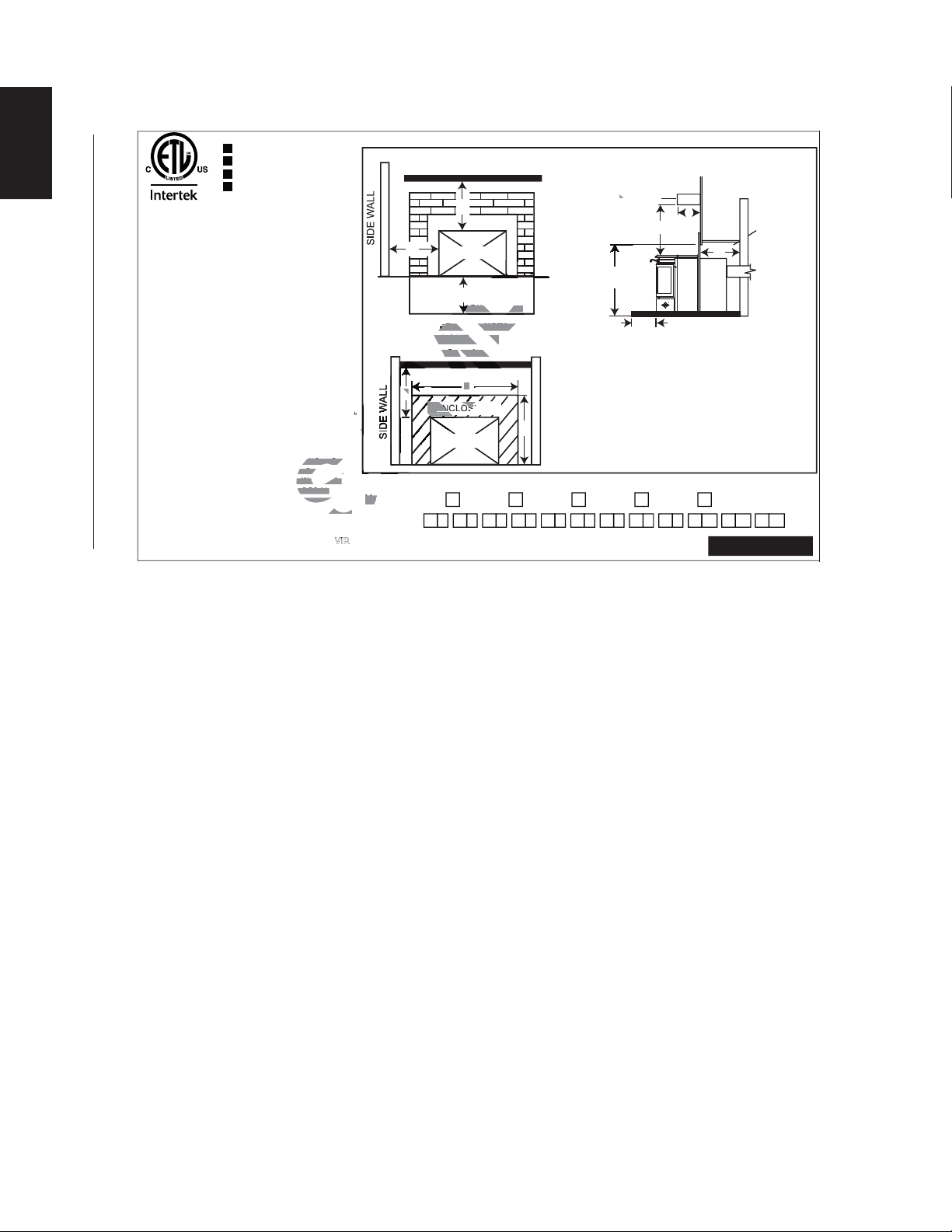

3.0 INSTALLATION PLANNING

13

!

WARNING

READ ENTIRE MANUAL BEFORE YOU INSTALL OR USE THIS APPLIANCE. FAILURE TO FOLLOW THE

INSTRUCTIONS MAY RESULT IN PROPERTY DAMAGE, BODILY INJURY OR EVEN DEATH.

USE ONLY WOLF STEEL APPROVED OPTIONAL ACCESSORIES AND REPLACEMENT PARTS WITH

THIS APPLIANCE. USING NON-LISTED ACCESSORIES AND REPLACEMENT PARTS (BLOWERS,

DOORS, LOUVRES, TRIMS, GAS COMPONENTS, VENT COMPONENTS, ETC.) COULD RESULT IN A

SAFETY HAZARD AND WILL VOID THE LIMITED LIFETIME WARRANTY.

Check with local building offi cials for any permits required for installation of this pellet appliance and notify your

insurance company before proceeding with installation.

Before installing we recommend placing the appliance outside and load 5 lbs (2.3k) of pellets inside the hopper. Plug the appliance in and let it run on HIGH until the pellets run out. This will cure the paint and burn off

most of the oils on the steel, thereby minimizing any smell inside the home.

68.1A

3.1 APPLIANCE PLACEMENT

Have an authorized dealer install the appliance. If you install the appliance yourself, have your dealer review

your installation plans and/or installation.

Draw out a detailed plan of the installation including dimensions and verify the dimensions with the

requirements listed in this manual.

You may wish to adjust the appliance position slightly to ensure the vent does not intersect with a framing

member. Appliance must be positioned so that no combustibles are within, or can swing within (e.g. drapes,

doors), 4 feet (1.2m) of the front of the appliance.

67.1B

EN

3.2 INSTALLATION OPTIONS

NPS45:

To install in a Residential or Mobile Home, see "MOBILE HOME INSTALLATION" section. For alcove installations, see "ALCOVE INSTALLATION REQUIREMENTS" section. For horizontal vent or vertical vent, see

"VENTING" section. For outside air, see "OUTSIDE AIR" section.

NPI45:

To install as an insert into an existing masonry appliance or factory built appliance, see "VENTING" section.

To install into a combustible enclosure, see "INSTALLATION INTO A COMBUSTIBLE ENCLOSURE" section.

W415-1472 / A / 10.11.16

14

3.3 STOVE MINIMUM CLEARANCE TO COMBUSTIBLES

!

EN

DO NOT INSTALL INTO ANY AREA HAVING LESS THAN 48" (1219mm) (CEILING TO APPLIANCE

BOTTOM, EXCLUDING HEARTH HEIGHT).

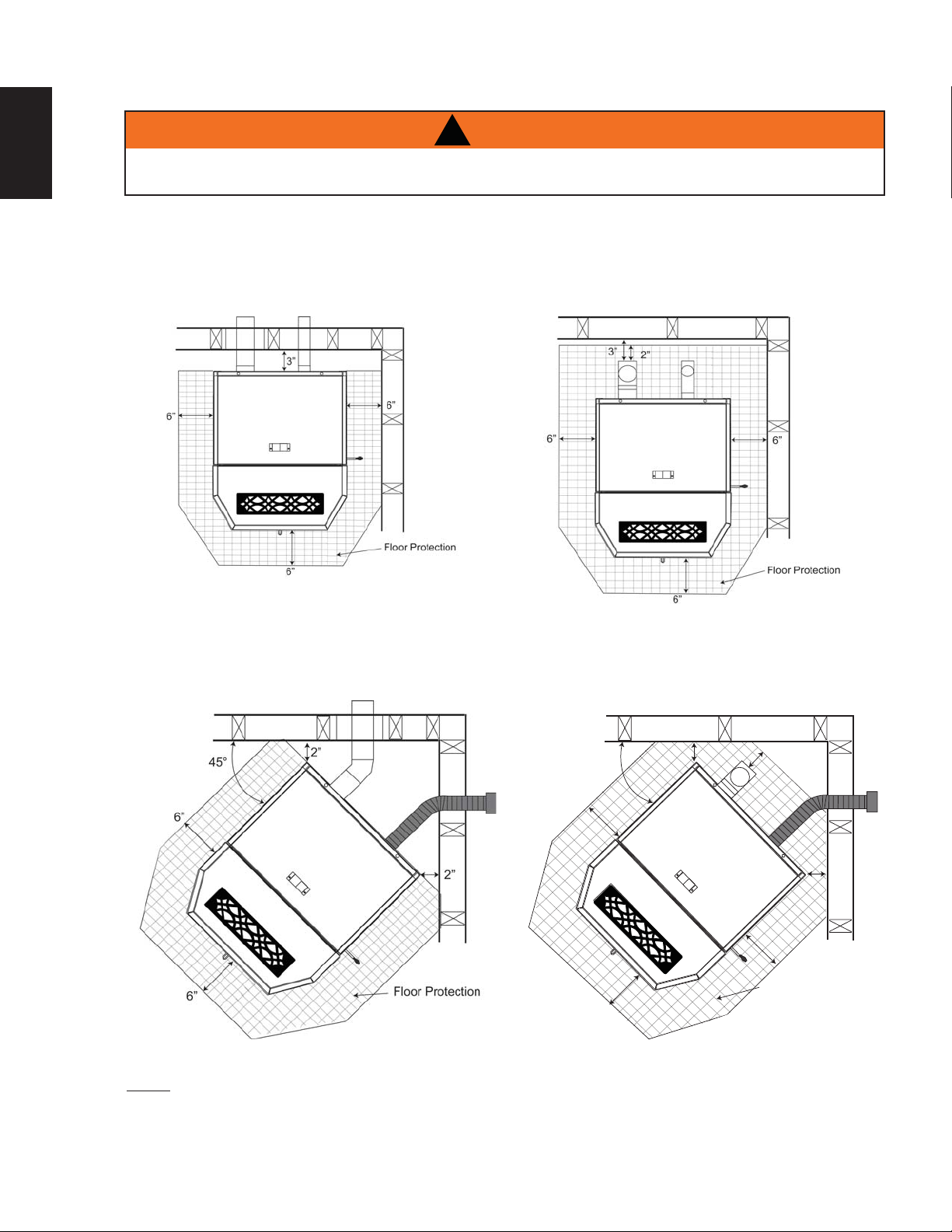

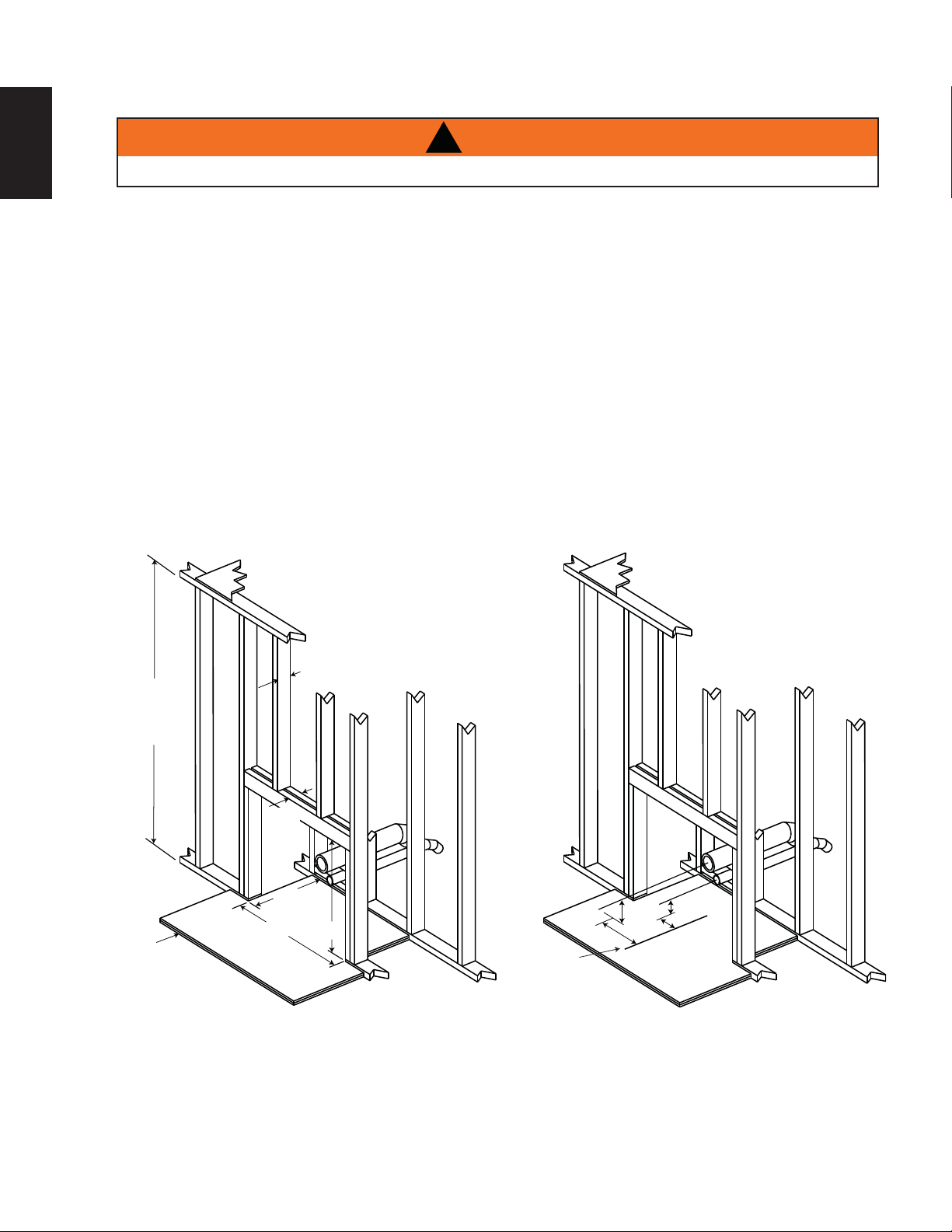

3.3.1 STRAIGHT INSTALLATION

WARNING

Through the Wall Installations complete

with outside air

3.3.2 CORNER INSTALLATION

Through the Wall Vents complete with outside air Interior Vertical Vents

Interior Vertical Vents

2”

2”

45°

6”

2”

6”

Floor Protection

6”

NOTE: If interior vertical pellet vent is used, the clearance to the back wall is determined by the

upward-turning elbow or "Tee". It will vary in depth depending on the brand of pellet vent used (it is

approximately 5" (127mm). Before placing the appliance, connect the elbow or "Tee" and allow for the

minimum 3" (76mm) clearance to the combustible wall.

W415-1472 / A / 10.11.16

3.3.3 ALCOVE INSTALLATION REQUIREMENTS (MINIMUM)

35”

30”

48”

STOVE

15

EN

Minimum Alcove Dimensions

W415-1472 / A / 10.11.16

16

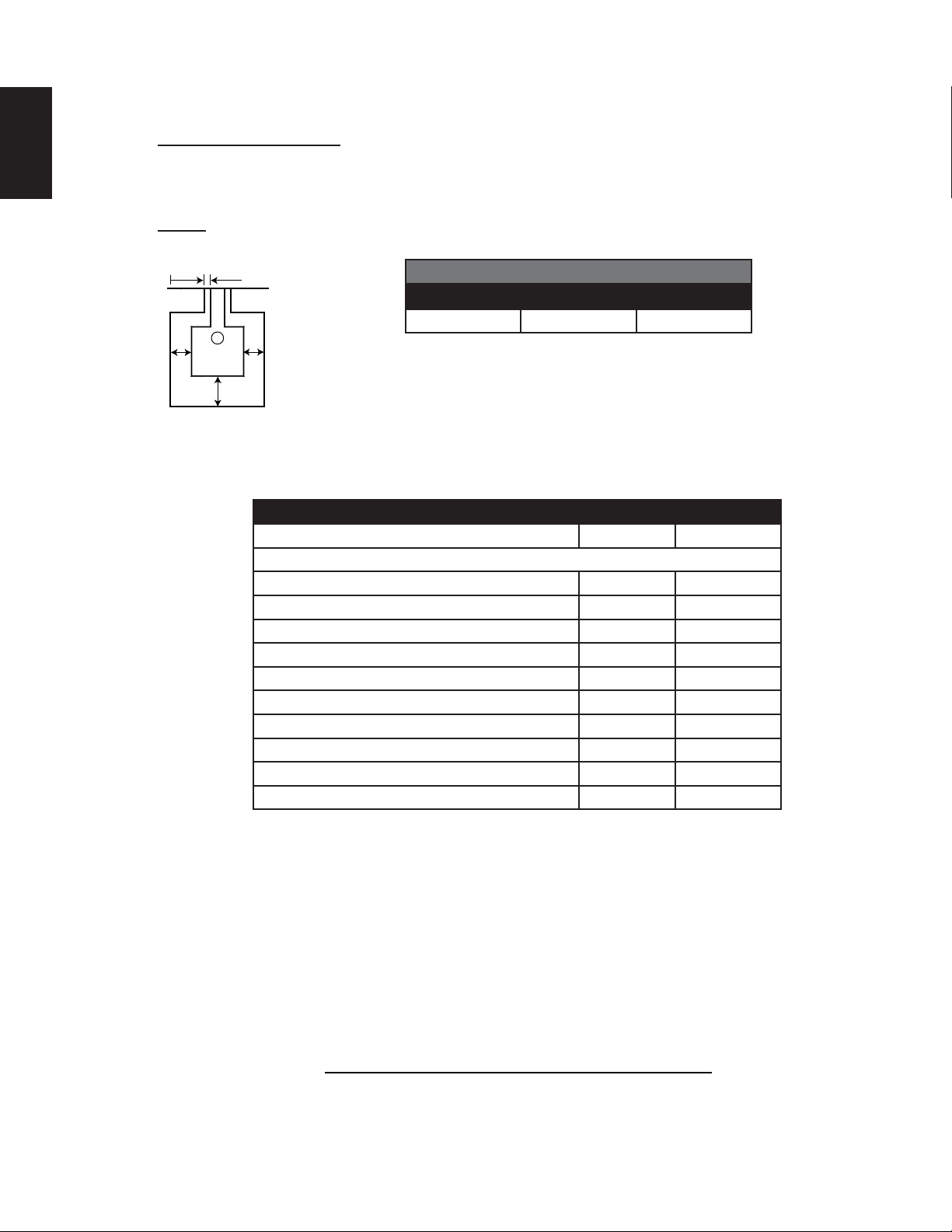

3.4 FLOOR PROTECTION REQUIREMENTS INSTALLATION

EN

THERMAL PROTECTOR:

This appliance must be installed on a non-combustible thermal protector that extends to the front, sides

and back of the appliance as per the minimum requirements below.

NOTE: Floor protection is required for spark and ash shielding, and for limiting fl oor

temperatures from the radiant heat of the appliance.

L

J

R = Thickness / K-Value

K = Thickness / R-Value

With K values, the lower value is a better insulator. With R values, the higher number is better.

J

The thermal protector must have an overall R-Value of 1.0. For multiple layers, add

R-Values for each layer to determine the overall R-Value.

I

CONVERTING MATERIAL SPECIFICATIONS TO R OR K VALUES

COMMON K and R VALUES CHART

MATERIAL K-VALUE R-VALUE

Per inch Per inch

Micore 300 0.43 2.33

Wonderboard (cement board) 1.92 0.52

Common Brick 5.00 0.20

Cement Mortar 5.00 0.20

Ceramic Tile 12.50 0.08

Marble 11.00 0.09

Air Space (ventilated) 0.70 1.43

Sand and Gravel 1.70 0.59

Drywall (gypsum) 1.00 1.00

Rockwool or Fiberglass Batts 0.30 3.33

MINIMUM FLOOR PROTECTION

FRONT (I) SIDES (J) VENT (L)

6” (152mm) 6” (152mm) 2” (51mm)

K-Value Example:

A wood stove may call for thermal protection which has a K factor of 1 or less. A product

such as Micore 300 Board from USG has a K-Value of approximately .43 per inch.

Therefore, a 1/2” (12.7mm) thickness of this board would have a K-Value of .86, which

meets the requirement of our example stove.

R-Value Example:

W415-1472 / A / 10.11.16

This fi replace calls for thermal protection with an R-Value of 0.59. This same board

above is rated as having an R-Value of 2.33 for a 1” (25.4mm) thickness. Therefore,

1/2” (12.7mm) of the Micore 300 Board would have a R-value of 1.165, which meets

the specifi cations for this fi replace.

99.2C

3.5 OUTSIDE AIR

17

Available from your Authorized Dealer (114KT)

Outside air must not be drawn from an enclosed space (garage, unventilated crawl space).

NOTE: Wolf Steel Ltd. strongly suggests using outside air for all residential installations, especially

for those that are energy effi cient, air-tight homes.

Outside air supply must not be over 15' (4.5m) long.

Outside air vents must be made with 1 3/4" (44mm) diameter or larger metal or aluminum duct with a metal

screen attached to the end to keep out rodents (P.V.C. or other materials may not be used).

The outside air inlet must not be above or within 12" (305mm) of the chimney termination, must have a rain

cap or down-turned elbow to prevent the water from entering and be located so that it will not become

plugged by snow or other material.

Outside air is required for all combustible built-in enclosure installations.

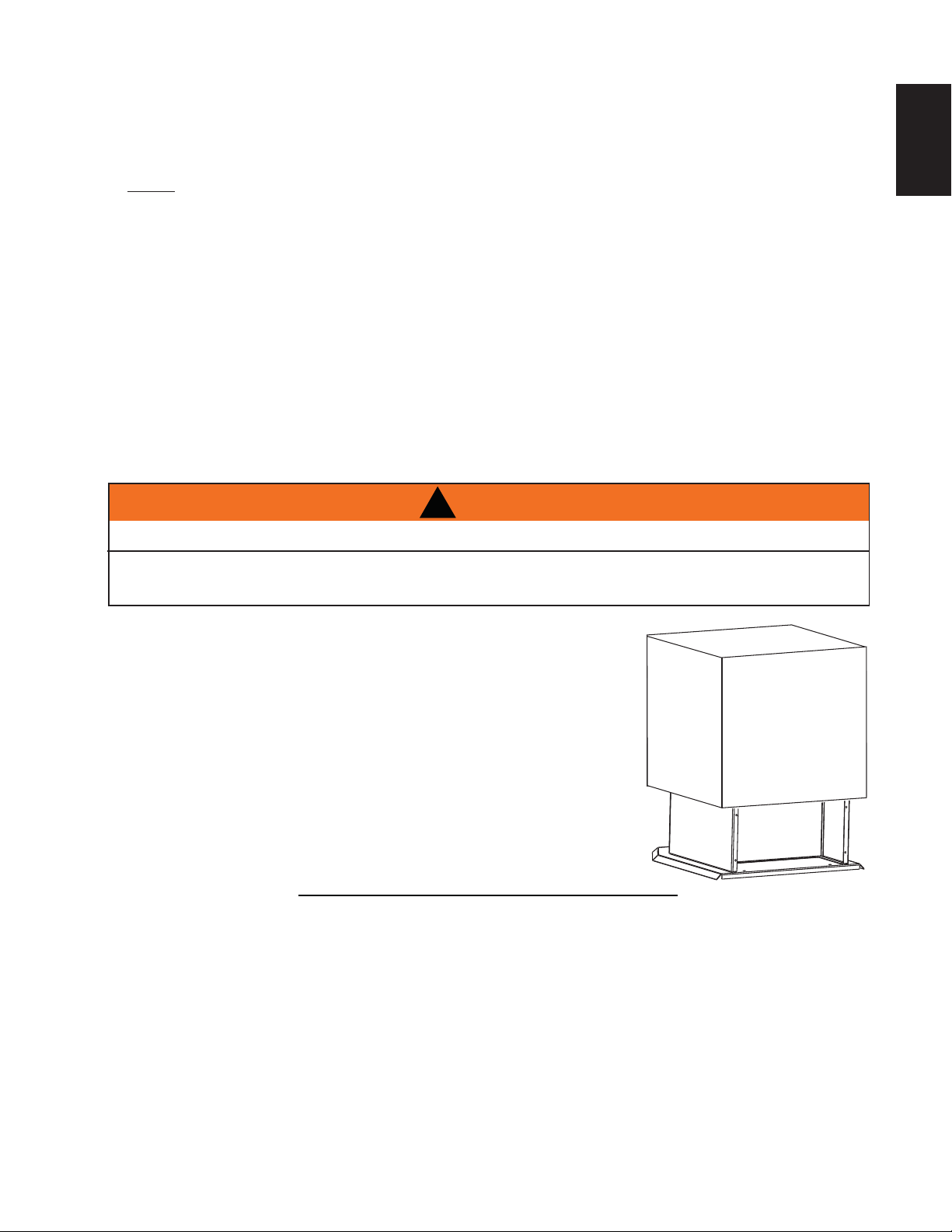

3.6 MOBILE HOME

!

WARNING

DO NOT INSTALL IN A SLEEPING ROOM.

THE STRUCTURAL INTEGRITY OF THE MANUFACTURED HOME FLOOR, WALL, AND CEILING ROOF

MUST BE MAINTAINED.

EN

Installation into a manufactured home or mobile home should be installed in

accordance with the Manufactured Home Construction and Safety Standard,

Title 24 CFR, Part 3280, in the United States or the Mobile Home Standard,

CAN/CSA Z240 MH Series, in Canada.

The appliance must be grounded to the steel chassis of the mobile home

(Some states do not require this; check with your local building department).

STOVE

ILLUSTRATED

29.4A

W415-1472 / A / 10.11.16

18

4.0 VENTING

4.1 TYPE OF VENT

EN

Must be an approved 3" (76mm) or 4" (102mm) diameter Type "L" or "PL" vent, vented to the outside or connect

the vent to a factory built type lined "A" chimney using an adaptor; and/or stainless steel chimney liner for

masonry appliance installations. Use 4" (102mm) diameter vent if vent or liner height is over 15' (4.5m) or if

installation is over 4,000' (1219m) above sea level.

4.2 INSTALLING THE PELLET VENT

PELLET VENT MUST MAINT AIN A MINIMUM 3" (76.2mm) CLEARANCE TO ANY COMBUSTIBLE (INST ALL

DO NOT CONNECT THE PELLET VENT TO A VENT OR CHIMNEY SERVING ANY OTHER APPLIANCE OR

The vent must have a support bracket every 5’ (1.5m)when on

the exterior wall. To achieve optimum performance, keep vent

runs as short as possible, especially on horizontal installations.

MAXIMUM VENTING: Maximum venting height is 33’ (10.1m)

Maximum horizontal without vertical rise is 5’ (1.5m) straight

off the back of the appliance. Use no more than 180° of

elbows (two 90° elbows, or two 45° elbows and one 90°

elbow, etc), excluding the tee and the termination.

VENT INST ALLATION: Termination must exhaust above

the air inlet elevation, and parallel or above the exhaust

output of the pellet appliance. It is recommended that at

least 3’ (0.9m) of vertical pipe be installed to create some

natural draft. This is to help prevent the possibility of smoke

or odour entering the home during the appliance shut down

or in the event of a power outage. Horizontal sections must

have a 1/4” (6.4mm) rise every 12” (304.8mm) of travel if

longer than 3’ (0.9m).

The pellet vent connections must be sealed with HI-Temp

RTV Silicone and screwed together with at least 3 3/8”

(85.7mm) long stainless steel screws. Seal each vent

section by injecting a liberal amount of 500°F (260°C) RTV

silicone sealant into the gap. We recommend sealing the

outside of the vent connections to permit easier access

when servicing.

!

WARNING

VENT AT CLEARANCES SPECIFIED BY THE VENT MANUFACTURER, CHIMNEY LINER EXCLUDED).

HEATER.

DO NOT INST ALL A FLUE DAMPER IN THE EXHAUST VENTING SYSTEM OF THIS UNIT.

33’ (10.1m)

30’ (9.1m)

Use 4”

(101.6mm)

diameter “L”

vent if venting

in this shaded

region.

25’ (7.6m)

20’ (6.1m)

15’ (4.6m)

Use 3” (76.2mm)

or 4” (101.6mm)

diameter “L”

vent if venting

in this shaded

region.

10’ (3.1m)

5’ (1.5m)

0

0

5’

(1.5m)

10’

(3.1m)

4.3 VENTING THE PELLET APPLIANCE

Use an approved wall thimble when passing the vent through walls and a ceiling support / fi restop spacer when

passing the vent through ceilings (maintain a 3" (76mm) clearance to any combustibles).

W415-1472 / A / 10.11.16

7.5D

4.4 PELLET VENT TERMINATION

19

The vent termination must have an approved cap (to prevent water from entering) or a 45° downturn.

If the termination is located on a windy side of the house, a shield is recommended to prevent soot from

building up on the side of the house.

Horizontal terminations must protrude 12" (305mm) from the wall, vertical terminations require a minimum 24"

(610mm) above the highest point that it penetrates through the roof.

Depending on pellet quality, vent confi guration and air settings, black soot may occur on the terminal wall.

4.5 VENT TERMINAL CLEARANCES

D

A

NOTE: Illustration dimensions are to the center of

the exhaust exit point of the vent.

EN

E

C

K

J

G

I

F

H

B

B

L

E

CLEARANCES

A 12” (304.8mm) Clearance above grade, veranda porch, deck or balcony. (Including vegetation and mulch)

9” (228.6mm)* Clearance beside or below any windows or doors that open.

B

12” (304.8mm)* Clearance above any window or door that opens.

C

D 0” (0mm) Clearance to an outside corner wall.

E 3” (0.9m) Clearance to an inside combustible corner wall or protruding combustible obstructions (vent chase, etc.)

F 9” (228.6mm) Clearance to a non-mechanical air supply inlet to the building or a combustion air inlet to any other appliance.

G 3’ (0.9m) Clearance to a mechanical air supply inlet.

H 7’ (2.1m) ** Clearance above a paved sidewalk or paved driveway located on public property.

I 12” (304.8mm)** Clearance under a veranda, porch, deck or balcony.

J 24” (609.6mm) Clearance above the roof.

K 2’ (0.6m) Clearance from an adjacent wall including neighbouring buildings.

L

* Recommended to prevent condensation on windows and thermal breakage

** This is a recommended distance. For additional requirements check local codes.

18”

(457.2mm)

3’ (0.9m) within a

height of 15 feet

(13.7m) above the

meter / regulator

assembly

Vertical clearance to ventilated soffi t located above the terminal within a horizontal distance of 2 feet

(0.6m) from the center line of the terminal.

Clearance to each side of center line extended above natural gas or propane meter / regulator assembly or

mechanical vent.

12.7C

W415-1472 / A / 10.11.16

20

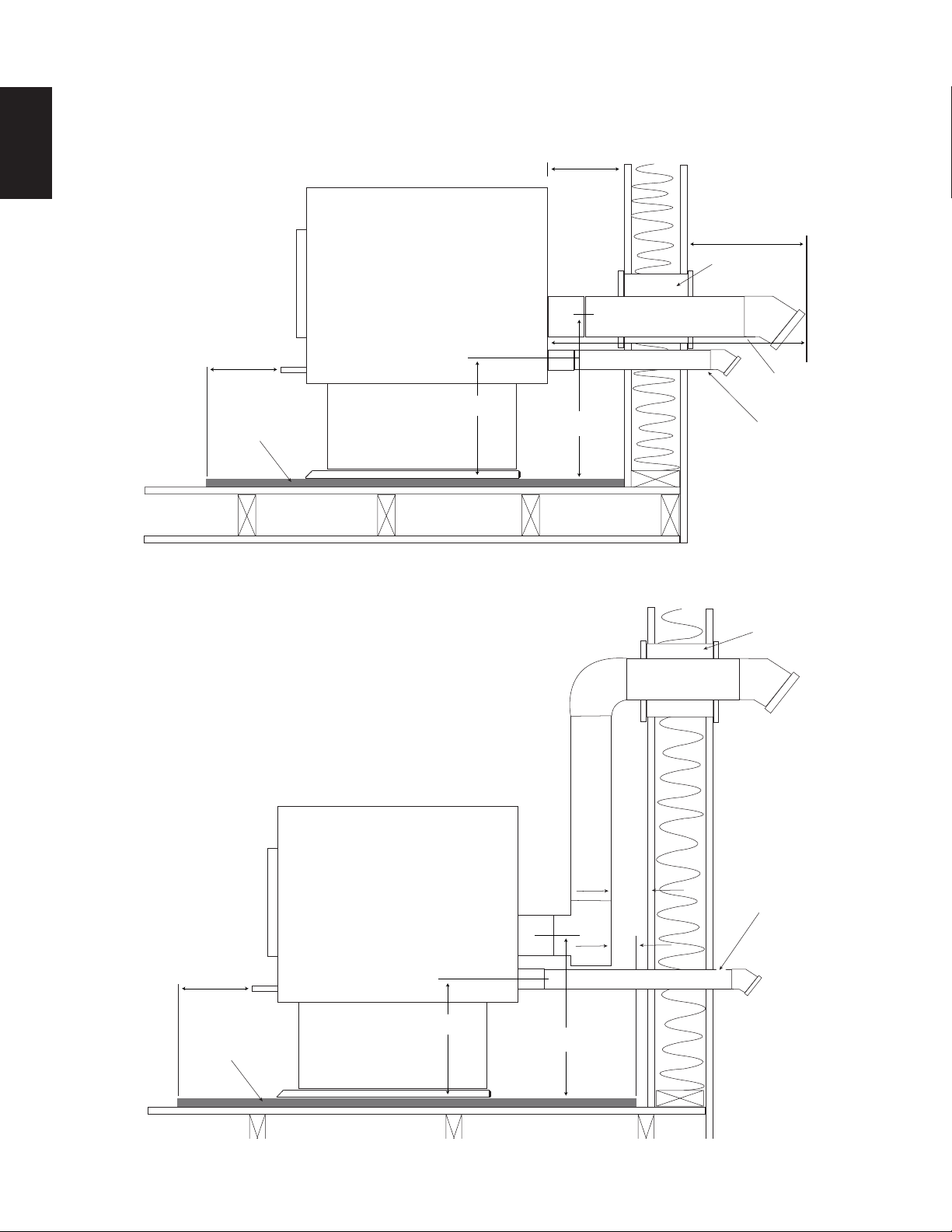

4.5.1 HORIZONTAL EXHAUST THROUGH WALL INSTALLATION

EN

3” Minimum

6”

Minimum

Floor

Protection

4.5.2 THROUGH THE WALL WITH VERTICAL RISE / HORIZONTAL TERMINATION

11 5/8”

17”

12” Minimum

Wall

Thimble

5’ Maximum

Outside Air

(Recommended)

6”

Minimum

Floor

Protection

11 5/8”

17”

2”

3”

Wall Thimble

Outside Air

(Recommended)

W415-1472 / A / 10.11.16

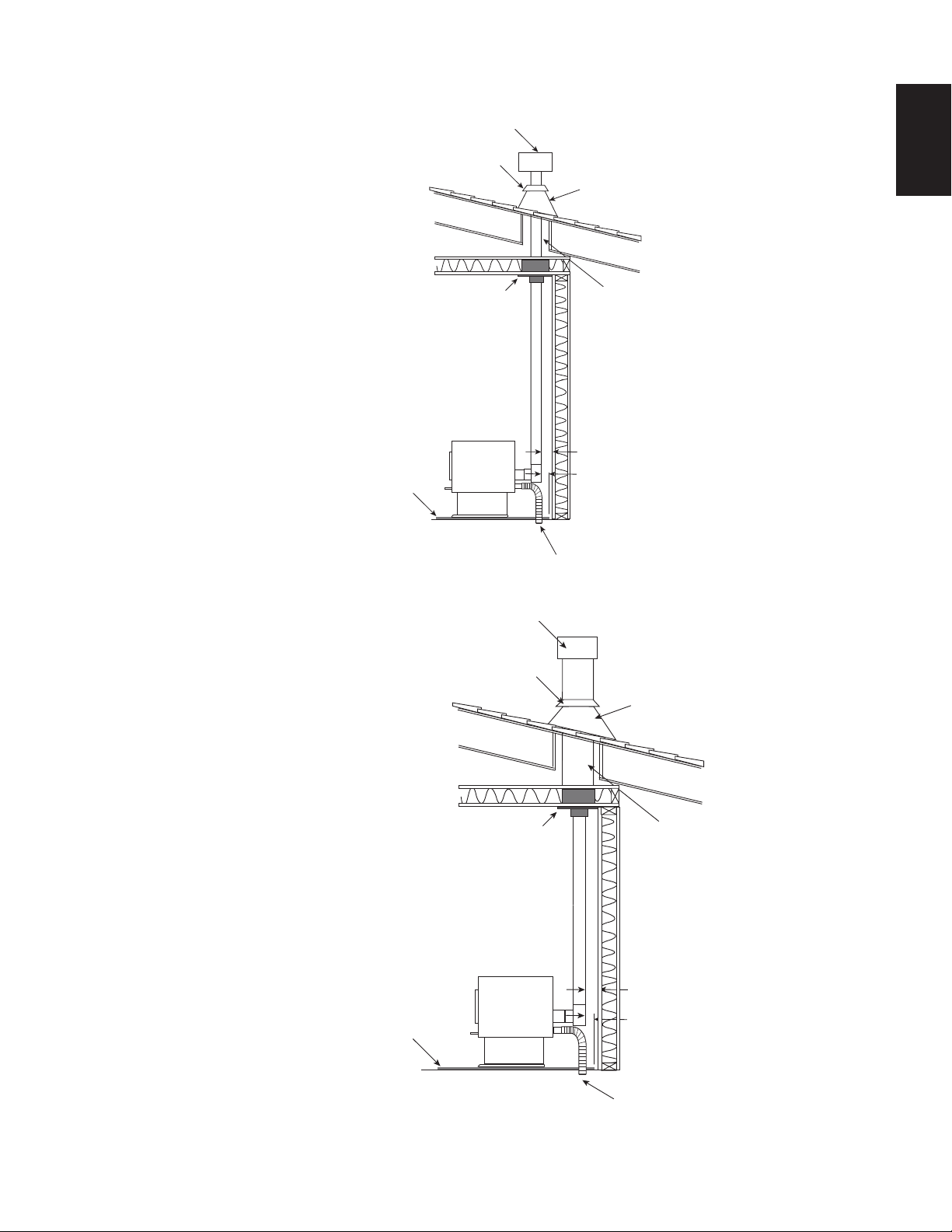

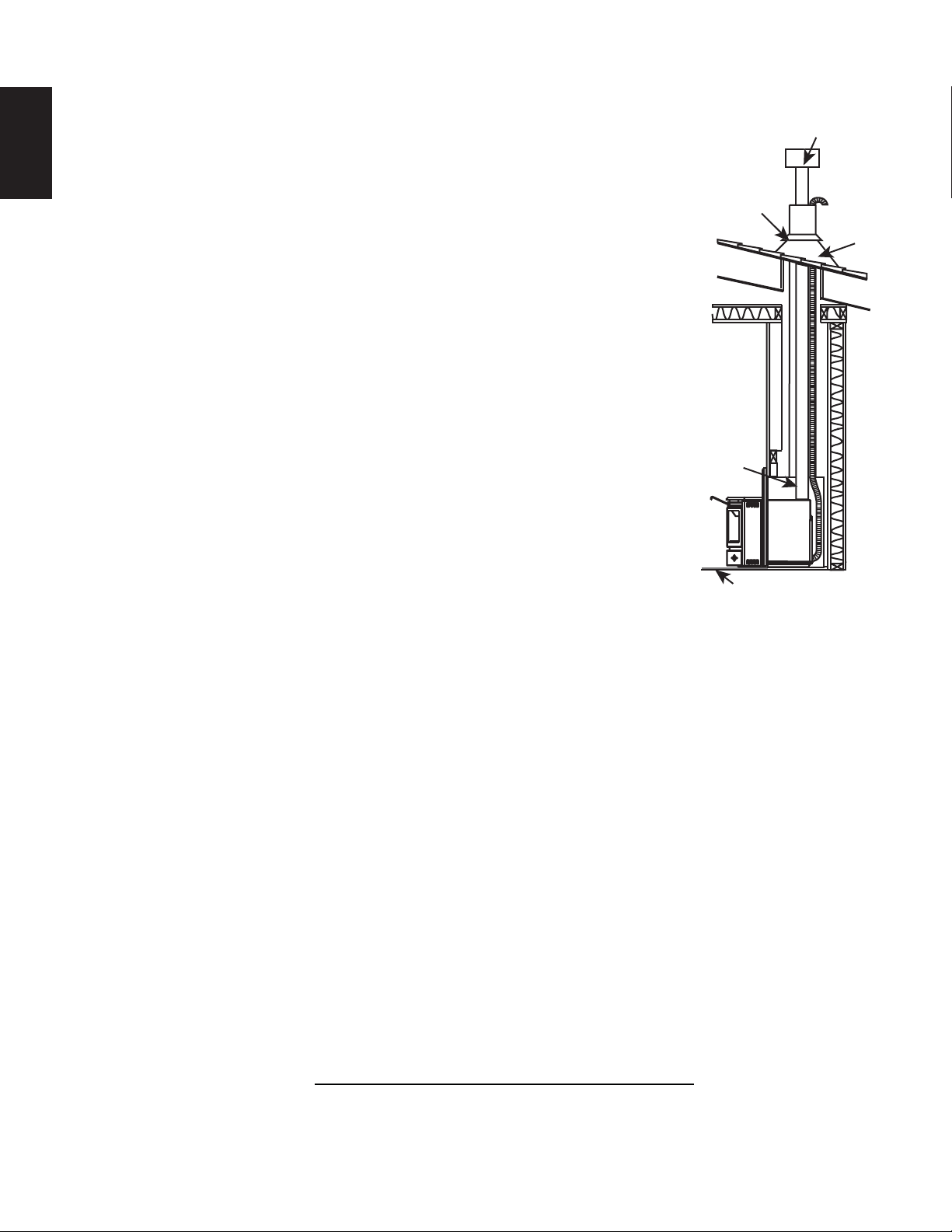

4.5.3 MINIMUM INSIDE VERTICAL CLEARANCES

Vertical Cap

Storm Collar

21

EN

Roof Flashing

Floor Protection

4.5.4 CLASS A CHIMNEY RETROFIT

Ceiling Support

Vertical Cap

Storm Collar

Vent must maintain 3”

clearance to combus-

tibles.

3”

2”

Outside air (Recommended)

(Installation showing inlet of out-

side air in ventilated crawl space)

Roof Flashing

Class A Chimney

Ceiling Support

Floor Protection

Vent must maintain

3” clearance to

combustibles.

3”

2”

Outside air

(Recommended)

(Installation showing inlet of outside

air in ventilated

crawl space)

W415-1472 / A / 10.11.16

22

oootec

t

Co

4.5.5 HEARTH MOUNT INSTALLATION

EN

Chimney Cap

Pellet

Liner

Clean-out

ut

tee

Vertical Cap

Storm Collar

Pellet

Vent

torm

Flue Cover

6”

MIN

Floor Protection

Bring outside air to the heater

Outside Air (Recommended)

For installation instructions, see "TYPICAL EXISTING MASONRY" section.

W415-1472 / A / 10.11.16

4.6 INSERT VENTING INSTALLATION EXAMPLES

l

e

r

o

Cap

Ver

23

4.6.1 TYPICAL EXISTING MASONRY INSTALLATION

!

WARNING

DO NOT REMOVE BRICKS OR MORTAR FROM THE FIREPLACE.

Prior to installation:

When installing the insert into a masonry fi replace, do not

remove any bricks or masonry. Do not weaken the structure,

or reduce the protection for combustible materials to less then

that required by the National Building Code. Bolted or screwed

together pieces (smoke shelf / defl ectors) may be removed,

but must be able to be re-installed if the appliance is removed.

External trim pieces, which do not affect the operation of the

fi replace, may be removed provided they are available to be reinstalled in event the appliance is removed.

A warning label must be attached to the back wall of the fi replace

stating that “This fi replace has been altered to accommodate a

fi replace insert and must be re-inspected by a qualifi ed person

prior to re-use as a fi replace”.

Non-combustible fl oor protection must cover the fl ooring

underneath, as well as extend a minimum of 6” (152.4mm) in

front and to both sides of the appliance.

Cover Plate

Vertical Cap

Storm Collar

rm Colla

t

Pellet

Liner

Cover

Flue

EN

Clean all ashes out of the inside of the fi replace. Make sure

that the chimney and fi replace are free of cracks, loose mortar,

creosote deposits, blockage or other signs of deterioration.

If necessary, have any repair work done by a qualifi ed

professional before installing the appliance.

A. Remove the fi replace damper or fasten it permanently open.

B. Measure the throat of the fi replace and mark this shape on a piece of 24 (0.511mm) gauge sheet meta

(fl ue cover). Cut a hole sized for the pellet liner to lie directly below the fi replace fl ue opening. Allow 2”

(50.8mm) of material for a fl ange on all sides and cut to these measurements. Bend down the fl anges.

If you have never done this before, it might be a good idea to make a cardboard pattern and test it fi rst.

Fasten this fl ue cover in position as high as possible with two masonry screws per side through the

fl anges into the fi replace.

C. If you plan on connecting outside air it is recommended to do so at this time.

D. Install fl oor protection if necessary.

E. Connect the pellet vent with a clean out tee to the back of the insert. Refer to manufacturer’s

installation instructions to see “REAR TO TOP VENT CONVERSION INSTRUCTIONS” section and th

“GENERAL VENTING” section.

F. Run a liner down the chimney and connect to tee.

Outside Air

(Recommended)

G. Position the insert in it’s fi nal location.

H. Pull the excess length of liner out through the top of the chimney. Trim the excess liner, install the cap

and cap the chimney.

62.3B

W415-1472 / A / 10.11.16

24

l

e

4.6.2 FACTORY BUILT FIREPLACE

EN

Prior to installation:

Do not weaken the structure or reduce the protection for

combustible materials to less then that required by the National

Building Code. Bolted or screwed together pieces (smoke shelf /

defl ectors) may be removed, but must be able to be re-installed

if the appliance is removed.

External trim pieces, which do not affect the operation of the

fi replace, may be removed provided they are available to be reinstalled in event the appliance is removed.

A warning label must be attached to the back wall of the

fi replace stating that “This heater has been altered to

accommodate a fi replace insert and must be re-inspected by a

qualifi ed person prior to re-use as a factory built fi replace”.

Non-combustible fl oor protection must cover the fl ooring

underneath, as well as extend a minimum of 6” (152.4mm) in

front and to both sides of the appliance.

Clean all ashes out of the inside of the fi replace. Make sure

that the chimney and fi replace are free of cracks, loose mortar,

creosote deposits, blockage or other signs of deterioration.

If necessary, have any repair work done by a qualifi ed

professional before installing the appliance.

A. Remove the fi replace damper or fasten it permanently

open.

Vertical

Cap

Storm

Collar

The smoke

shelf, damper

and baffles may

be removed

Floor Protection

Do not remove any part that would

alter the integrity in any way.

Roof

Flashing

B. Measure the throat of the fi replace and mark this shape on a piece of 24 (0.511mm) gauge sheet meta

(fl ue cover). Cut a hole sized for the pellet liner to lie directly below the fi replace fl ue opening. Allow 2”

(50.8mm) of material for a fl ange on all sides and cut to these measurements. Bend down the fl anges.

If you have never done this before, it might be a good idea to make a cardboard pattern and test it fi rst.

Fasten this fl ue cover in position as high as possible with two masonry screws per side through the

fl anges into the appliance.

C. If you plan on connecting outside air it is recommended to do so at this time.

D. Install fl oor protection if necessary.

E. Connect the pellet vent with a clean out tee to the back of the insert. Refer to manufacturer’s

installation instructions to see “REAR TO TOP VENT CONVERSION INSTRUCTIONS” section and th

“GENERAL VENTING” section.

F. Run a liner down the chimney and connect to tee.

G. Position the insert in it’s fi nal location.

H. Pull the excess length of liner out through the top of the chimney. Trim the excess liner, install the cap

and cap the chimney.

80.1A

W415-1472 / A / 10.11.16

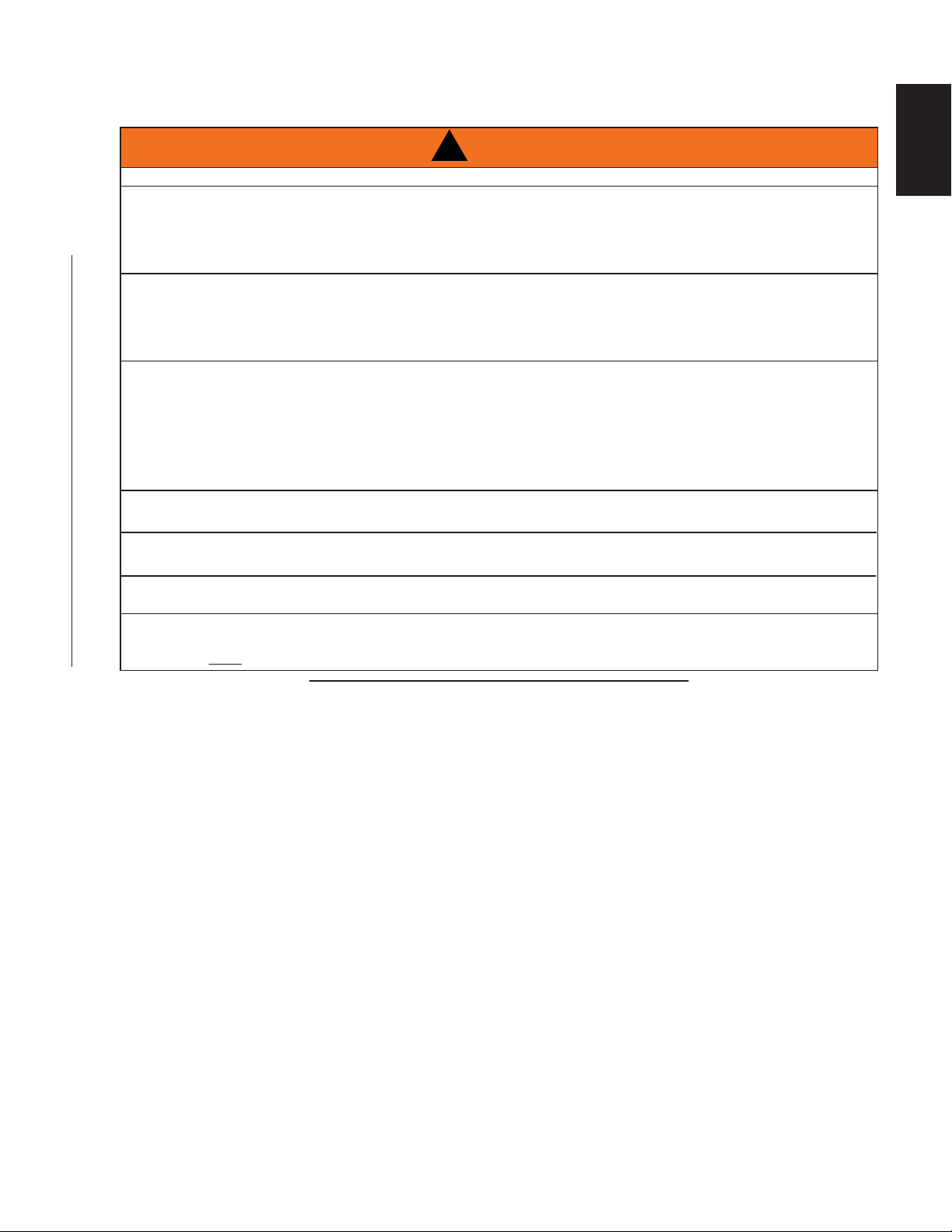

5.0 FRAMING (INSERT ONLY)

25

!

WARNING

RISK OF FIRE!

IN ORDER TO AVOID THE POSSIBILITY OF EXPOSED INSULATION OR VAPOUR BARRIER COMING

IN CONTACT WITH THE APPLIANCE BODY, IT IS RECOMMENDED THAT THE WALLS OF THE

APPLIANCE ENCLOSURE BE “FINISHED” (IE: DRYWALL / SHEETROCK), AS YOU WOULD FINISH

ANY OTHER OUTSIDE WALL OF A HOME. THIS WILL ENSURE THAT CLEARANCE TO

DO NOT NOTCH THE FRAMING AROUND THE APPLIANCE STAND-OFFS. FAILURE TO MAINTAIN

AIR SPACE CLEARANCE MAY CAUSE OVER HEATING AND FIRE. PREVENT CONTACT WITH

SAGGING OR LOOSE INSULATION OR FRAMING AND OTHER COMBUSTIBLE MATERIALS. BLOCK

OPENING INTO THE CHASE TO PREVENT ENTRY OF BLOWN-IN INSULATION. MAKE SURE

WHEN CONSTRUCTING THE ENCLOSURE ALLOW FOR FINISHING MATERIAL THICKNESS TO

MAINTAIN CLEARANCES. FRAMING OR FINISHING MATERIAL CLOSER THAN THE MINIMUMS

LISTED MUST BE CONSTRUCTED ENTIRELY OF NON-COMBUSTIBLE MATERIALS. MATERIALS

CONSISTING ENTIRELY OF STEEL, IRON, BRICK, TILE, CONCRETE, SLATE, GLASS OR PLASTERS,

OR ANY COMBINATION THEREOF ARE SUITABLE. MATERIALS THAT ARE REPORTED AS PASSING

ASTM E 136, STANDARD TEST METHOD FOR BEHAVIOUR OF MATERIALS IN A VERTICAL TUBE

FURNACE AT 1382°F (750°C) AND UL763 SHALL BE CONSIDERED NON-COMBUSTIBLE

MINIMUM CLEARANCE TO COMBUSTIBLES MUST BE MAINTAINED OR A SERIOUS FIRE HAZARD

THE APPLIANCE REQUIRES A MINIMUM ENCLOSURE HEIGHT. MEASURE FROM THE APPLIANCE

IF STEEL STUD FRAMING KITS WITH CEMENT BOARD ARE PROVIDED, OR SPECIFIED IN THE

IF SPECIFIED IN THE INSTALLATION INSTRUCTION FINISHING MUST BE DONE USING A NON-

COMBUSTIBLE MATERIAL SUCH AS NON-COMBUSTIBLE BOARD, CERAMIC TILE, MARBLE, ETC.

DO NOT USE WOOD OR DRYWALL. ANY FIRE RATED DRYWALL IS NOT ACCEPTABLE

COMBUSTIBLES IS MAINTAINED WITHIN THE CAVITY.

INSULATION AND OTHER MATERIALS ARE SECURED.

MATERIALS.

COULD RESULT.

BASE.

INSTALLATION INSTRUCTIONS, THEY MUST BE INSTALLED.

71.1C

EN

W415-1472 / A / 10.11.16

26

5.1 INSTALLATION INTO A COMBUSTIBLE ENCLOSURE

EN

!

WARNING

OUTSIDE AIR IS MANDATORY FOR A COMBUSTIBLE BUILT-IN ENCLOSURE INSTALL.

When installing the insert as a "Built-in" appliance, it is important to maintain the clearances to combustibles,

see "MINIMUM CLEARANCE TO COMBUSTIBLES" section.

A non-combustible hearth must cover the fl ooring underneath, as well as, a minimum of six inches in front

and to both sides of the appliance.

A. Install fl oor protection.

B. Frame structure maintaining minimum clearances. Locate and frame openings for both the exhaust

and outside air. Outside air is mandatory for enclosure installations. See "OUTSIDE AIR" section.

C. Refer to vent manufacturer's installation instructions and to "VENTING" section. Connect the vent.

Install fl ashing, see "FLASHING INSTALLATION" section.

D. Consideration must be taken during installation that removal of the insert is necessary for inspection

and annual maintenance. Install the vent cap.

3 1/2” MAX

40”

MINIMUM

ENCLOSURE

HEIGHT

3 1/2”

MAX

17”

Non

combustible

floor protection.

This protection must

offer an R value of 0.4 (two

layers of 1/2” thick cement board, total 1” with each layer rated with an

R value of 0.2).

For temperature requirements, the enclosure space around and

above the heater must be left unobstructed.

33”

27”

Centerline of

heater opening

7 1/8”

4 7/8”

1 7/8”

2”

W415-1472 / A / 10.11.16

5.2 MINIMUM ENCLOSURE CLEARANCES

!

The stand-offs located on the back of the insert must not be removed when installing the insert into a

built-in combustible enclosure.

6 3/8” Minimum

40”

27”

WARNING

2 1/4”

27

EN

3” all around (Refer to vent

manufacturer’s instructions)

Stand-offs

6”

Non-combustible

floor protection

5.3 MINIMUM CLEARANCE TO COMBUSTIBLES

Side wall to appliance 8" (203mm)

Mantel to top of appliance 8" (203mm)

Top facing to appliance 6 3/8" (162mm)

Side facing to appliance 6" (152mm)

Floor protection* 6"* (152mm)

* Floor Protection: Minimum 6" (152mm)

in front of door and to either side.

10”

Side Wall

7 5/8”

2 3/4”

10” Mantel

8” MIN

8”

MIN

6”

6”

W415-1472 / A / 10.11.16

28

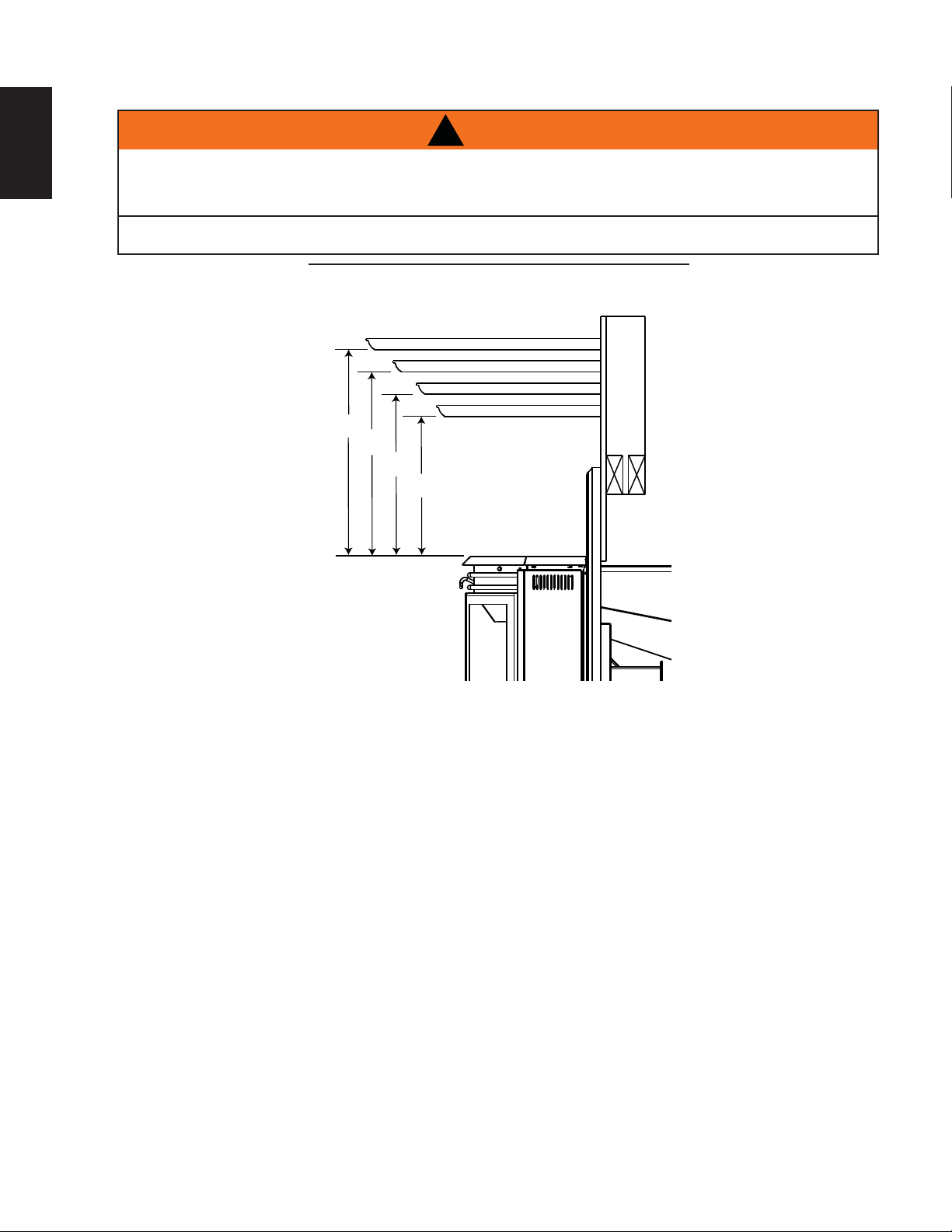

5.4 MINIMUM MANTEL CLEARANCES

EN

RISK OF FIRE, MAINTAIN ALL SPECIFIED AIR SPACE CLEARANCES TO COMBUSTIBLES. FAILURE

TO COMPLY WITH THESE INSTRUCTIONS MAY CAUSE A FIRE OR CAUSE THE APPLIANCE TO

OVERHEAT. ENSURE ALL CLEARANCES (I.E. BACK, SIDE, TOP, VENT, MANTEL, FRONT, ETC.) ARE

WHEN USING PAINT OR LACQUER TO FINISH THE MANTEL, THE PAINT OR LACQUER MUST BE

HEAT RESISTANT TO PREVENT DISCOLOURATION.

16” MANTEL

14”

12”

!

WARNING

CLEARLY MAINTAINED.

14”

12”

10”

10”

8”

73.1

W415-1472 / A / 10.11.16

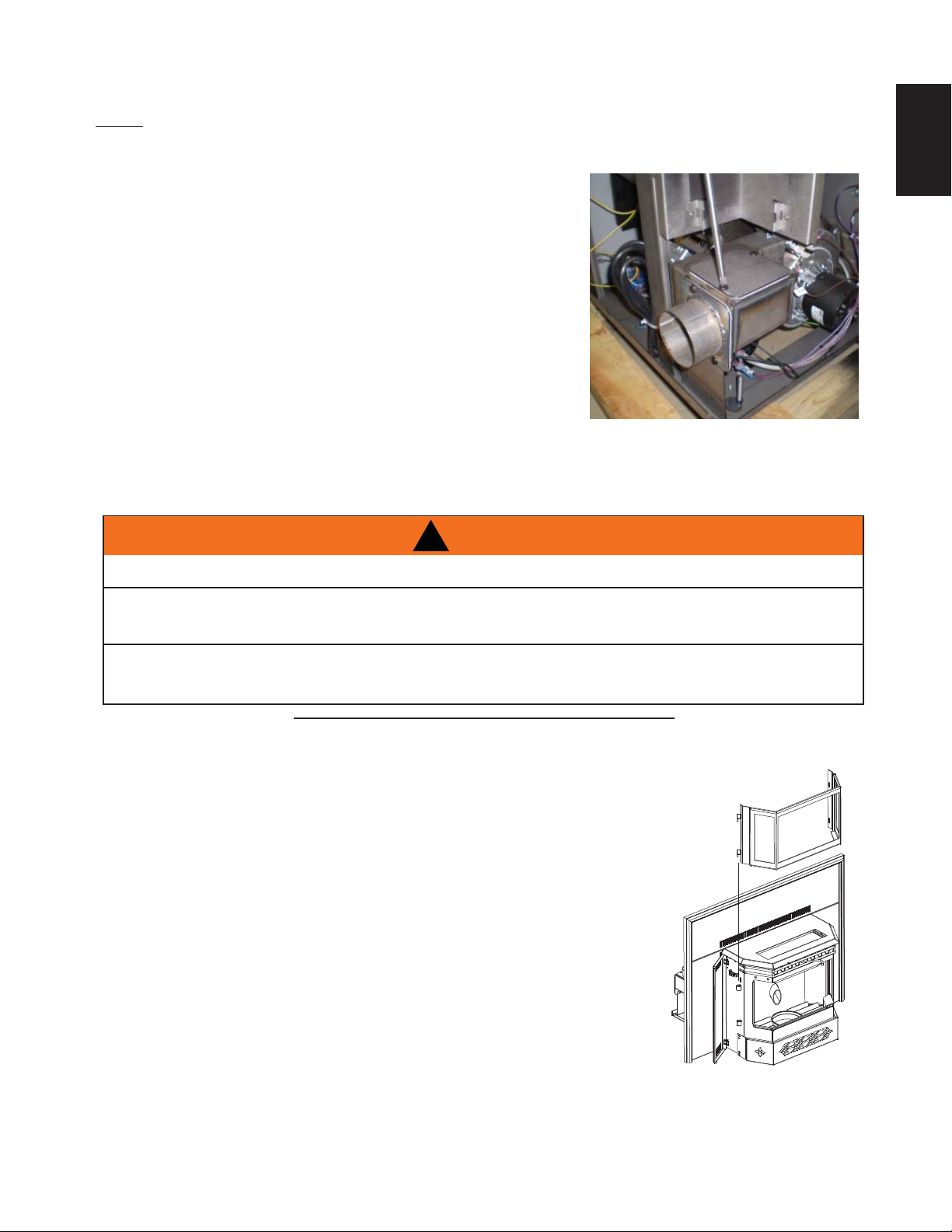

5.5 REAR TO TOP VENT CONVERSION INSTRUCTIONS

NOTE: The insert is factory shipped in a rear vent confi guration. Be careful not to damage the gasket.

If installing 4" (102mm) diameter vent vertically, it will be necessary to start with a 12" (305mm) section of 3"

(76mm) diameter vent to clear the hopper, then increase to 4"(102mm)

diameter vent.

A. To vent exit vertically, remove the two screws holding the

exhaust cover.

B. Remove the two screws holding the exhaust tube.

C. Attach the exhaust tube and gasket in the vertical position.

D. Attach the exhaust cover and gasket over the horizontal exit.

6.0 FINISHING

6.1 INSTALLING VIEWING DOOR

29

EN

!

WARNING

GLASS MAY BE HOT, DO NOT TOUCH GLASS UNTIL COOLED.

THE DOOR LATCHES ARE PART OF A SAFETY SYSTEM AND MUST BE PROPERLY ENGAGED. DO

NOT OPERATE THE APPLIANCE WITH LATCHES DISENGAGED.

BEFORE DOOR IS REMOVED TURN THE APPLIANCE OFF AND WAIT UNTIL APPLIANCE IS COOL TO

THE TOUCH. DOORS ARE HEAVY AND FRAGILE SO HANDLE WITH CARE.

75.2

The main viewing door has been boxed separate from the appliance, but MUST be installed before burning

the appliance.

A. Open both side panels, exposing the bushing on the left and the latches

on the right.

B. Align the pins on the door to the bushing on the left side of the

appliance. Lower into place until both bushings touch.

C. Engage the latch hooks into the door frame. Snap the rear handle hook

to lock the latch closed.

INSERT ILLUSTRATED

W415-1472 / A / 10.11.16

30

6.2 FLASHING INSTALLATION

EN

A. Secure the right fl ashing to the

right side of the appliance using

two of the #8 x 1/2" screws.

B. Remove the two control panel

securing screws, discard the

screws and shipping bracket.

C. Secure the control panel to the

right fl ashing using the two #8

x 3/8" screws. Secure the left

fl ashing with the remaining #8 x

1/2" screws.

D. Align the holes in the top of the

right and left fl ashing with those

on the bottom lip of the Top

Flashing and secure from the

rear using the four #8-32 x 3/8"

screws, washers and nuts.

E. The three pieces of trim are

assembled in the same manner

as a picture frame. Place the

corner brackets (with screw

loosened) into the trim sections.

Tighten the screw spreading

the two pieces apart. Attach the

adjoining section. Repeat with

the opposite side. Tighten all

screws fi rmly.

F. Slide the assembled trim down

over the fl ashing.

G. Affi x the logo to the bottom left

hand corner of the left fl ashing.

TRIM

UNDERSIDE

L

O

W

1

2

3

4

H

5

I

G

H

RIGHT

FLASHING

CONTROL

PANEL

CORNER

BRACKET

SHIPPING

BRACKET

SECURING

SCREWS

PUSH TO START / POUSSEE POUR COMMENCER

OPTIMUM

3

2

3

3

2

2

4

1

4

1

4

1

5

5

5

W385-0355

CONTROL

PANEL

SECURING

SCREWS

TOP

FLASHING

TRIM

ASSEMBLY

6.3 TRIVET INSTALLATION

The trivet for the insert is attached by

two set screws on the inside of the

hopper lid

W415-1472 / A / 10.11.16

SET

SCREW

SET SCREW

Loading...

Loading...