Napoleon LVX38, LVX50, LV50-2, LVX62, LVX74 Installation Manual

...

NATURAL GAS MODELS:

ADD PRODUCT CODE HERE (TRADE GOTHIC LT STD FONT)

ENGLISH

PROPANE GAS MODELS:

INSTALLATION MANUAL

SAFETY INFORMATION

!

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly

could result in serious injury, death, or

property damage.

- Do not store or use gasoline or other

fl ammable vapors and liquids in the vicinity of

this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

neighbour’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call

the fi re department.

FRENCH

PG. 27

ADD MANUAL TITLE

PRODUCT NAME™

ADD ____ ILLUSTRATED

ADD PRODUCT IMAGE

- Installation and service must be

performed by a qualifi ed installer, service

agency, or the supplier.

This appliance may be installed in an aftermarket,

permanently located, manufactured home (USA

only) or mobile home, where not prohibited by

local codes.

This appliance is only for use with the type of gas

indicated on the rating plate. This appliance is

not convertible for use with other gases, unless

a certifi ed kit is used.

INSTALLER:

Leave this manual with the appliance

CONSUMER:

Retain this manual for future reference

Wolf Steel Ltd., 24 Napoleon Rd., Barrie, ON, L4M 0G8 Canada / 103 Miller Drive, Crittenden, Kentucky, USA, 41030

Phone 1 (866) 820-8686 • www.napoleonfi replaces.com • hearth@napoleonproducts.com

FOR INDOOR USE ONLY

CERTIFIED TO THE CANADIAN AND AMERICAN NATIONAL STANDARDS:

CSA 2.22 AND ANSI Z21.50 FOR VENTED DECORATIVE GAS APPLIANCES

FOR INDOOR USE ONLY

CERTIFIED TO THE CANADIAN AND AMERICAN NATIONAL STANDARDS:

CSA 2.22 AND ANSI Z21.50 FOR VENTED DECORATIVE GAS APPLIANCES

CSA /

INTERTEK

LOGO

$10.00

W415-1739 / C / 08.03.17

EN

table of contents

1.0 general information 3

2.0 installation planning 4

2.1 installation option 1 - open enclosure (enclosure stops short of the ceiling) 5

2.2 installation option 2 - front opening 5

2.3 installation option 3 - rear opening 6

2.4 installation option 4 - open enclosure with hard combustible valance 7

3.0 appliance overview 8

4.0 Dynamic Heat Control™ installation 9

4.1 high limit switch installation 11

5.0 minimum framing dimensions 13

6.0 minimum clearance to combustible enclosures 14

7.0 rough framing - before appliance installation 16

8.0 finish framing - after appliance installation 17

9.0 fastener placement restriction 21

10.0 finishing 22

11.0 minimum combustible mantel clearances 23

12.0 maximum protrusion 24

13.0 completed DHC installation checklist 25

note:

The information throughout this manual is believed to be correct at the time of printing. Wolf Steel

Ltd. reserves the right to change or modify any information within this manual at any time without

notice. Changes, other than editorial are denoted by a vertical line in the margin.

2

W415-1739 / C / 08.03.17

1.0 general information

WARNING

!

• Dynamic Heat Control™ MUST be installed during the installation of the appliance BEFORE appliance venting and gas

are installed.

• Ensure the appliance is completely cool before starting installation.

• To avoid danger of suffocation keep the packaging bag away from babies and children. Do not use in cribs, bed, carriages,

or play pens. This bag is not a toy. Knot before throwing away.

general information

EN

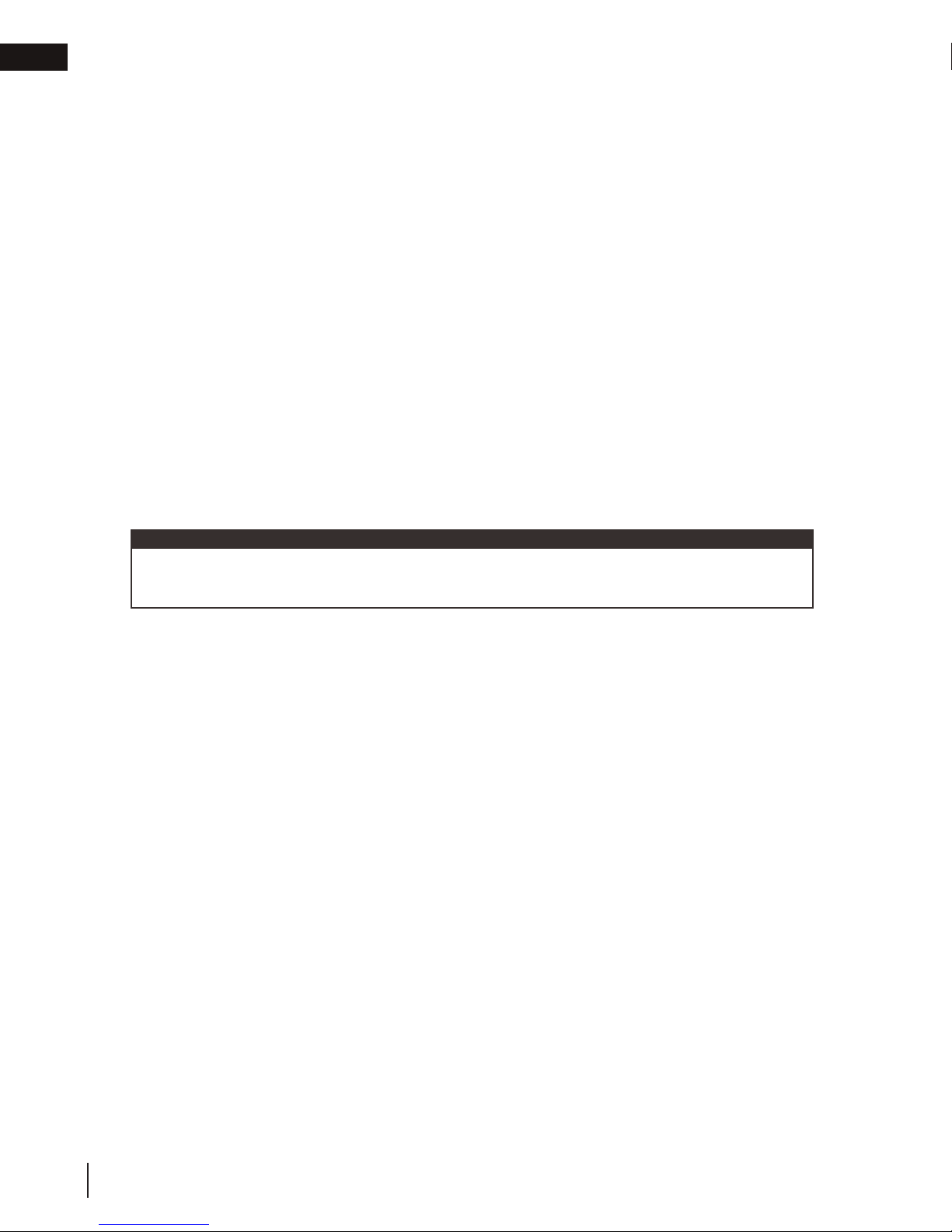

You will need:

Included in this kit

Bracket

Wire Harness

Dynamic Heat Control™ is a system for managing the

heat produced by the appliance at and around the fireplace.

The purpose of the Dynamic Heat Control™ is to move

the heat away from the fireplace to allow it to circulate more

effectively within the living space. By installing the Dynamic

Heat Control™ both the installer and the user gain considerable benefits, see the following;

Screws

Deflectors

High Limit Switch

PATENT PENDING

Installer:

• Ability to use combustible framing and finishing right up to the fireplace opening.*

• High temperatures above the front of the fireplace opening are significantly reduced eliminating potential degrading

to sensitive finish material (cracks or discoloration).

• No additional electrical, fans, ducts, or manifolds are required which keeps installation straightforward.

User:

• Heat is circulated more consistently throughout the living space increasing comfort in front of the fireplace.

• Increased “real world” efficiency as heat is moved in to the room rather than retained inside an enclosure.

• Complete flexibility in selection of finish materials.

• Ability to place a TV, sound bar or artwork above the fireplace.**

The Dynamic Heat Control™ system relies on an optimized flow of air both through the appliance and the enclosure. As such the installation of the Dynamic Heat Control™ system requires certain technical considerations when

compared to traditional fireplaces. Specifically, the Dynamic Heat Control™ requires the enclosure to be ventilated

and requires the installer to ensure that a minimum opening area is provided to allow heat to escape and circulate at

a prescribed minimum height and position. This must be carefully adhered to in the planning and the installation to

ensure the appliance functions safely and to minimize installation time.

*In most common installation configurations, some specific installations require special provisions.

See “Framing with Dynamic Heat Control” section for details. Ensure to strictly adhere to instructions.

** Always check appliance manufacturers recommendations to confirm suitability and any special

environmental limitations. For valuable or antique items, always refer to expert preservation instructions as

some items require specifically controlled temperature and/or humidity

W415-1739 / C / 08.03.17

3

EN

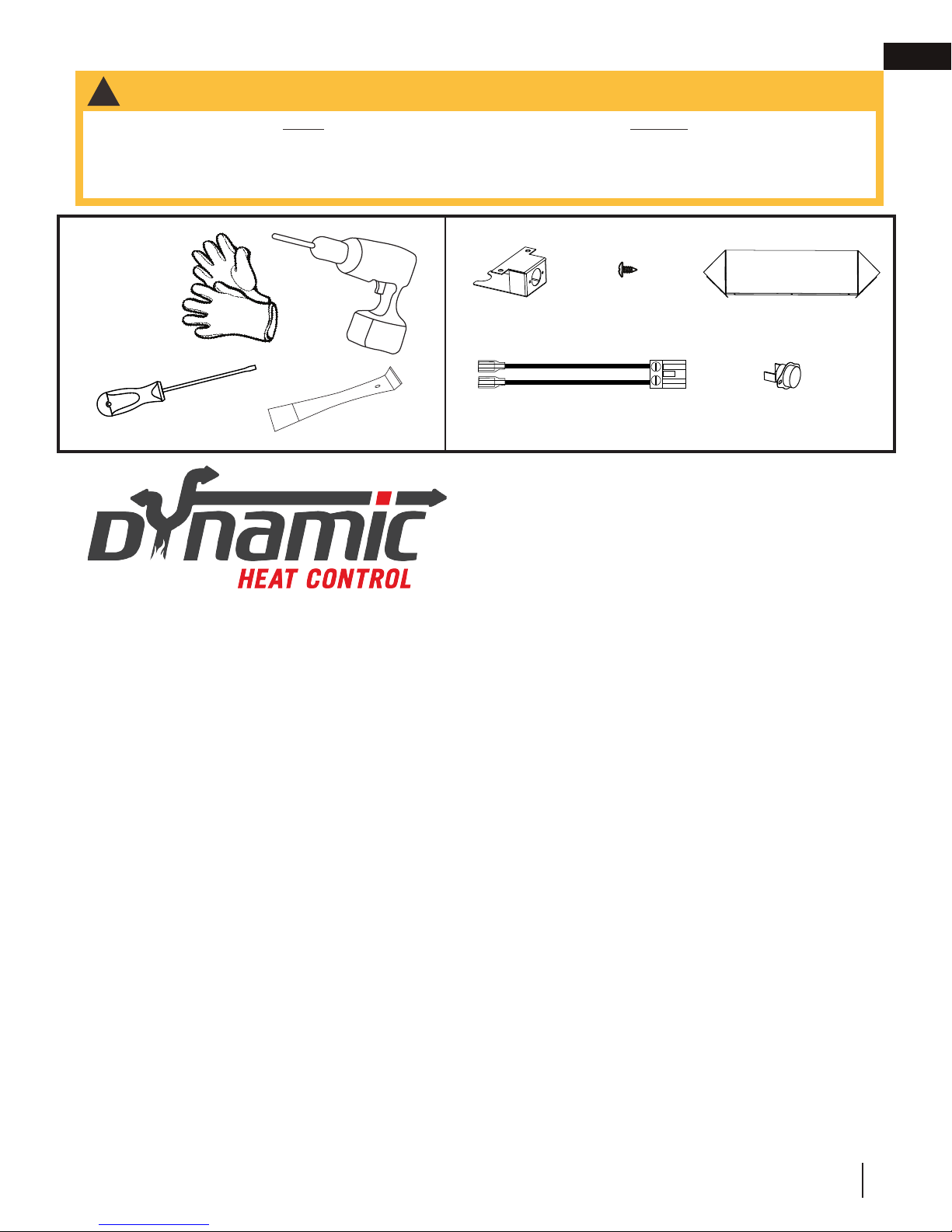

2.0 installation planning

installation planning

WARNING

!

• Do NOT cover or place any items in the Dynamic Heat Control™ air outlet. Failure to comply with these instructions will

create a fire hazard.

• Ensure air flow within the air passage is not restricted in any way with the exception of approved venting.

No materials of any type

are permitted in this area

Stud

Standoff

Upper

Frame

Dynamic

Heat Con-

trol™ air

outlet opening

Combustible

studding MUST

not be used past

the dotted line

3”

enclosure top and/or ceiling

Dynamic

Heat Con-

trol™ air

outlet opening

Dynamic

Heat Con-

trol™ air

outlet opening

Dynamic

Heat Con-

trol™ air

outlet opening

Single-Sided

Single-Sided

See-thru

(Recessed)*

*Restrictions also apply to see-thru when one or more recess is used.

Air flow in the shaded area must not be restricted in any way with the exception of an approved appliance vent system.

No other items are allowed in this area

Shaded framing must use non-combustible materials. No combustible materials allowed in this area or the space

between studs (i.e. no wiring, conduits, electrical bores, combustible framing members, etc.)

4

W415-1739 / C / 08.03.17

installation planning

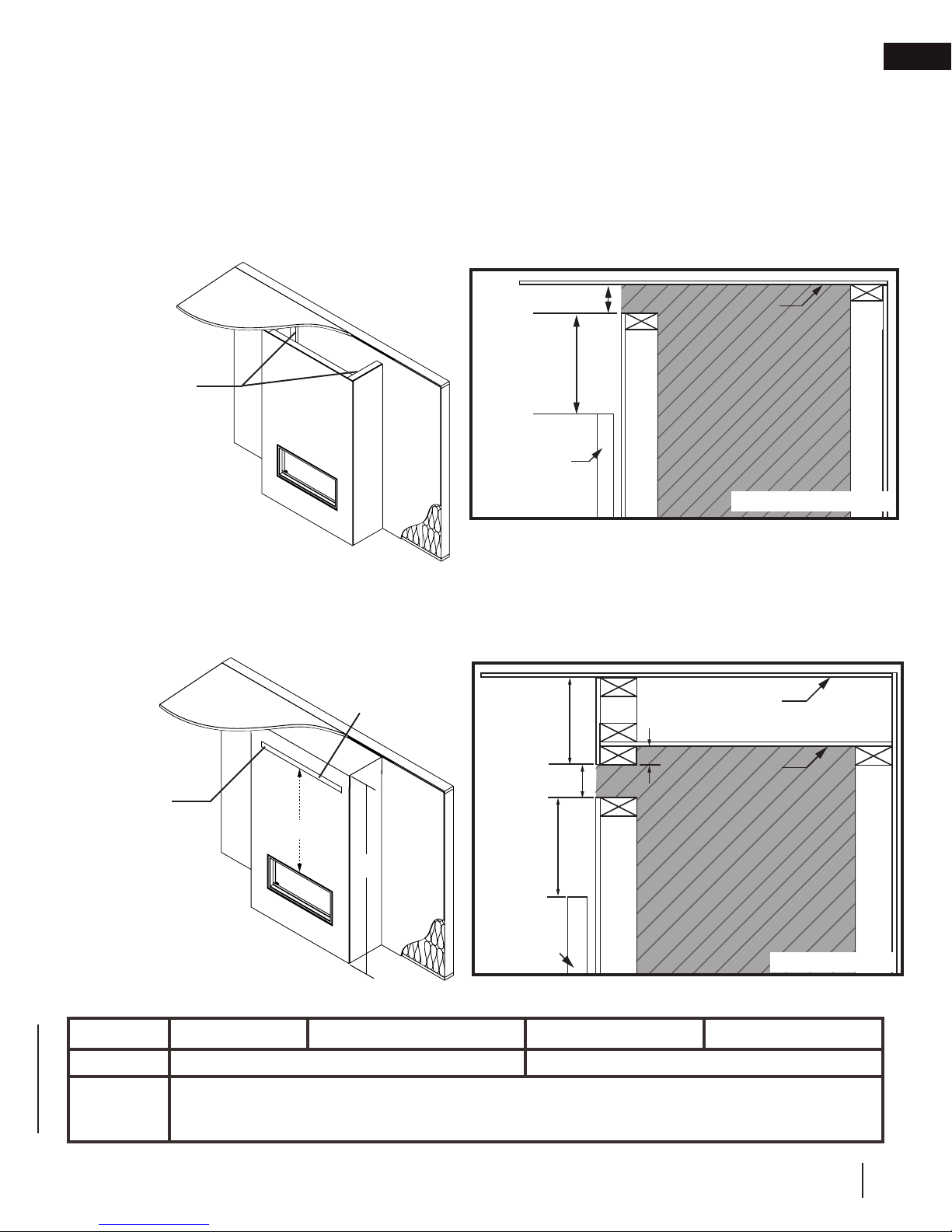

2.1 installation option 1 - open enclosure (enclosure stops short of the ceiling)

NOT Suitable for Dynamic Heat Control™ Plus

It is one option not to finish or close in the top of the enclosure to provide the necessary air circulation path for the

Dynamic Heat Control™ system. Leaving a complete air outlet opening above the enclosure has been found to

be well accepted with respect to final appearance and offer minimal distraction. It also allows for efficient circulation

of air within the room. This option offers the simplest method for framing and installation. (If installing Dynamic Heat

Control™ Plus, refer to option 2 or 3 - DHC Plus cannot be used with option 1). Limit the air outlet opening

height to 4” to reduce the risk of items inadvertly falling into the enclosure. The air outlet opening must extend

around the entire perimeter, or the entire front face of the enclosure, where the enclosure runs from wall

to wall.

EN

DYNAMIC HEAT

CONTROL™ AIR

OUTLET OPENING IS HOT WHEN

APPLIANCE IS

OPERATING!

Air outlet opening

must be located out of reach of

the user. Air outlet must not be

restricted by furnishings or decor.

2-4”

6” min

Wall mounted

object (picture

frame, appli-

ance, etc.)

ceiling

RECOMMENDED

2.2 installation option 2 - front opening

Suitable for Dynamic Heat Control™ Plus

Minimum air outlet opening dimensions must be followed. The opening is required to be framed no more than 1.5” below the

enclosure top (see option 2 diagram) to avoid trapping heat in the upper areas and the air outlet opening centered on the appliance

center. Framing the air outlet opening lower will overheat the appliance, the enclosure, and finishing material.

(Q x R)*

DYNAMIC HEAT

CONTROL™ AIR

OUTLET OPENING IS HOT WHEN

APPLIANCE IS

OPERATING!

S

L

Front air outlet opening must

be located out of reach of the

user. Air outlet must not be

restricted by furnishings or

decor.

Air outlet opening is required to be centered with the appliance.

MINIMUM AIR OUTLET OPENING DIMENSIONS

2 1/2”

min

2-3”

6” min

Wall mounted

object (picture

frame, appli-

ance, etc.)

0-1.5” Max

ceiling

enclosure top

must be installed

ALTERNATIVE

LVX38 LVX50 LVX62 LVX74

(Q x R)* 80 sq. in. minimum (Q must be 2-3”) 160 sq. in. minimum (Q must be 2-3”)

S

*Free area. Any trim edging or finishing must not reduce or restrict minimum area. Grills, grates, louvres, or

other unapproved covers are not permitted and will cause a fire hazard.

This dimension is determined from the enclosure height (L) minus the distance to the top of the Dynamic

Heat Control™ air outlet opening (0”-1.5”), height of the air opening (2”-3”), and the distance from the

base of the appliance to the top of the appliance viewing area (25 11/16”).

W415-1739 / C / 08.03.17

5

EN

installation planning

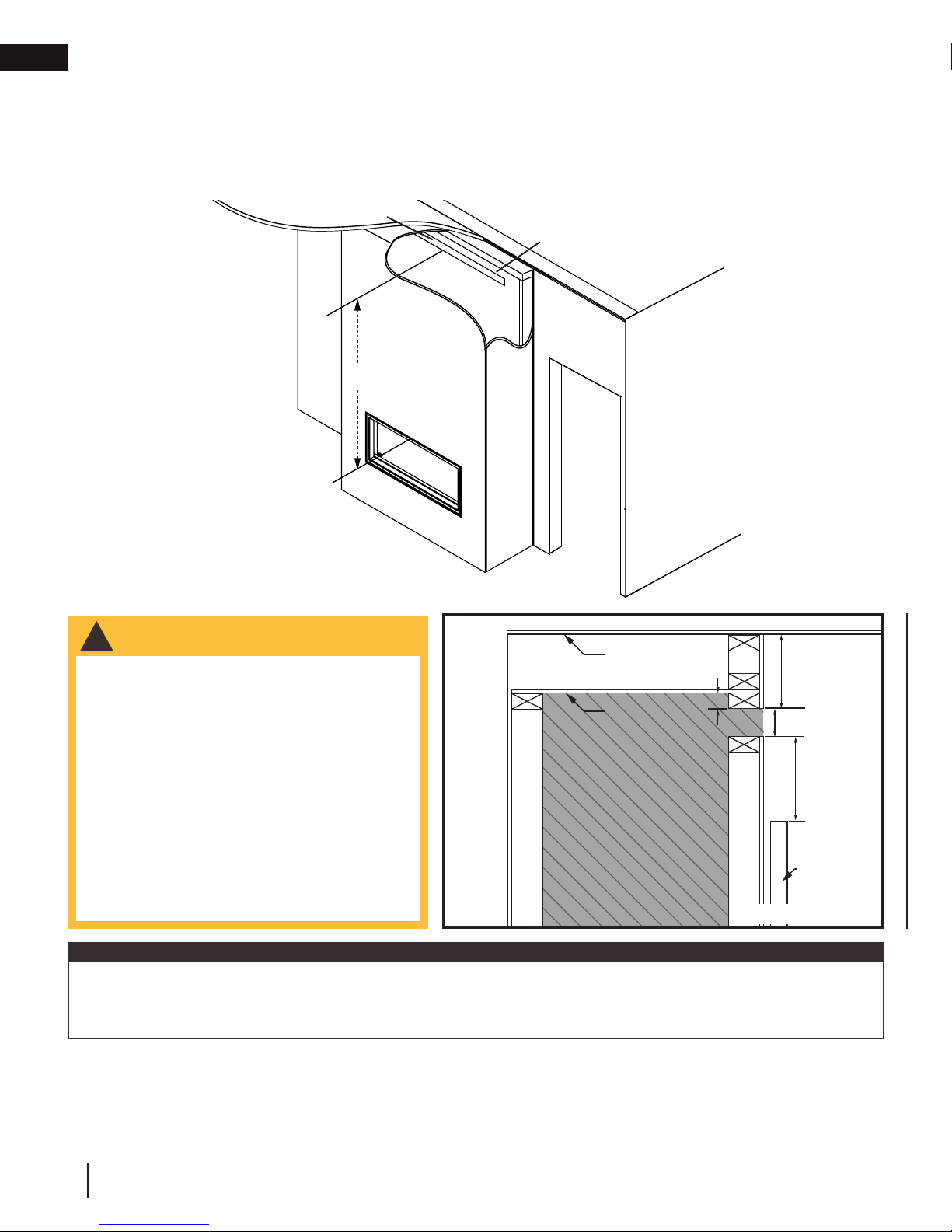

2.3 installation option 3 - rear opening

Suitable for Dynamic Heat Control™ Plus

Minimum air outlet opening dimension must be followed. The opening is required to be framed no more than 1.5” below the

enclosure top (see option 3 diagram) to avoid trapping heat in the upper areas and centered on the appliance center. Framing

the rear opening lower will overheat the appliance, the enclosure, and finishing material.

(Q x R)*

Dynamic Heat

Control™ rear air

outlet opening must

be located out of

reach of the user.

Opening must not

be restricted by furnishings or decor.

Air outlet opening is required to be centered with the appliance.

WARNING

!

S

Room 1

• When using a rear air outlet opening,

it is critical that the adjoining room or

living spaces are in direct air communication (i.e. of an open plan configuration

or connected by a permanently open

doorway or archway). This prevents

the appliance from being in a negative

pressure more than that of the adjoining

room. Failure to follow these requirements can result in reversing the Dynamic Heat Control™ air flow and will

cause the appliance, safety barrier, and

finishing materials to overheat, creating

a fire hazard.

Access

Side of

fireplace

AIR OUTLET

OPENING IS HOT

WHEN APPLIANCE

IS OPERATING!

ceiling

0-1.5” Max

enclosure top

must be installed

Room 2

2 1/2”

min

Other

room

2-3”

6” min

Wall mounted

object (picture

frame, appli-

ance, etc.)

ALTERNATIVE

note:

Increasing the air outlet opening will allow the appliance, the glass barrier (if equipped), the temperatures on the surfaces above the fireplace opening, and the enclosure be at cooler temperatures. It will also allow the air to circulate more effectively in the room. However,

if the appliance is equipped with the Dynamic Heat Control™ Plus, then the opening size must be 80 sq. in. for models

LV38-1, LV50-2, LVX38, and LVX50, or 160 sq. in. for models LV62, LV74, LVX62, and LVX74.

6

W415-1739 / C / 08.03.17

installation planning

note:

See-thru appliances require front or rear air outlet opening. If desired, it can be installed with both front and rear air outlet openings

to allow heat to circulate in two rooms however it is recommended to install the air outlet opening at different heights that meet the

installation parameters for aesthetic purposes. For Dynamic Heat Control™ plus, a second opening MUST NOT be installed

2.4 installation option 4 - open enclosure with hard combustible valance

NOT Suitable for Dynamic Heat Control™ Plus

is similar to option 1 with the addition of a hard combustible valance. Minimum opening dimensions and valance dimensions

must be followed (See option 4 diagram). Restricting air movement within the valance area will overheat the appliance,

the enclosure, and finishing material.

NOTE: Air outlet opening must be at least continuous

around the top of the enclosure for a valance to be permitted. Using the minimum air outlet opening from option 1 or 2

is not permitted and will overheat the appliance.

DYNAMIC HEAT

CONTROL™ AIR

OUTLET OPENING IS HOT WHEN

APPLIANCE IS

OPERATING!

EN

Air outlet opening must be located out of reach of the user.

Air outlet must not be restricted by furnishings or decor.

6” Max.

6” Min.

6” Min.

Wall mounted object

(picture frame, appli-

ance, etc.)

ABSOLUTELY NO OBSTRUCTION OR RESTRICTION ALLOWED IN THE ENTIRE SHADED AREA WITH THE EXCEPTION OF APPROVED VENTING

4” min

ceiling

air outlet opening

must be continuous

around enclosure top.

ALTERNATIVE

W415-1739 / C / 08.03.17

7

EN

installation planning

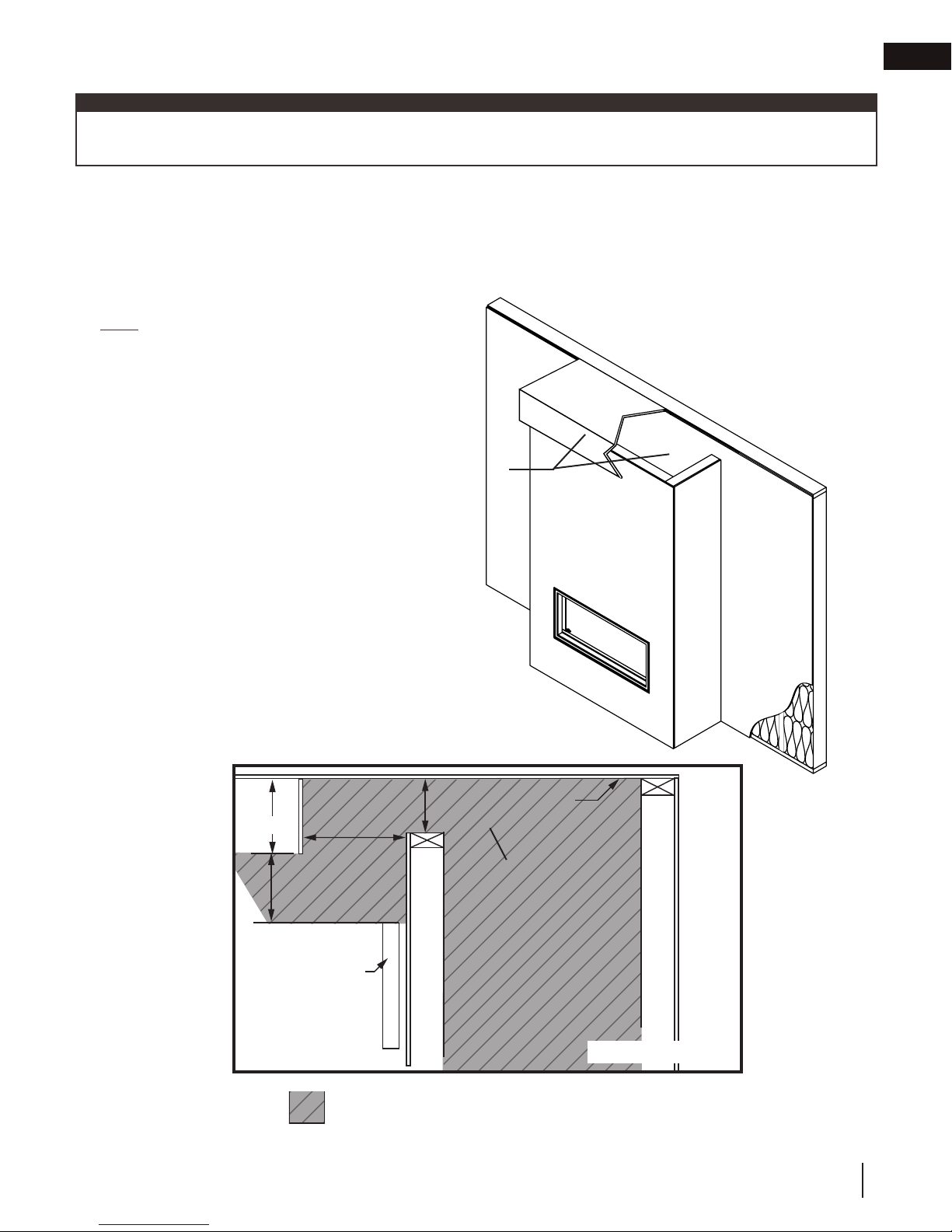

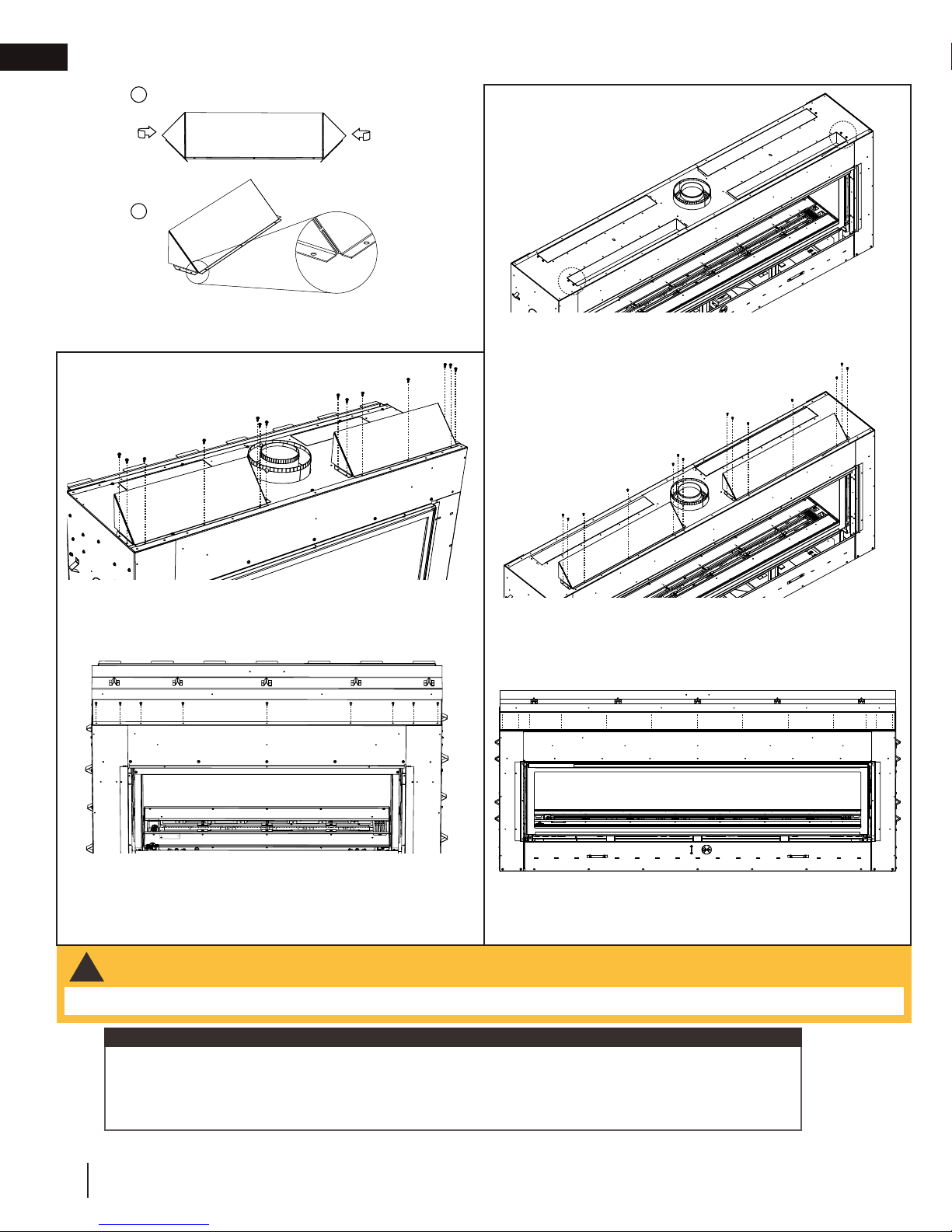

3.0 appliance overview

SINGLE-SIDED INSTALLATION

pilot location

deflectors shown after installation

front frame

access

side

access side

side view

SEE-THRU INSTALLATION

(frame and deflectors not shown)

top view

For knockout plate removal

access side

(access side only), see “DHC

install” section.

fixed side

WARNING: DO NOT REMOVE

FROM FIXED SIDE

pilot location

front frame

access side

8

W415-1739 / C / 08.03.17

access side

side view

pilot location

rear frame

deflectors

shown after

installation

fixed side

pilot location

from viewing

area

pilot location

from viewing

area

fixed side

fixed side

access side

For knockout plate removal (both sides),

see “DHC install” section.

top view

(frame and deflectors not shown)

note:

To determine which side is the access side, the pilot should be located in the left side of

the firebox from the viewing area when the appliance is viewed from the access side.

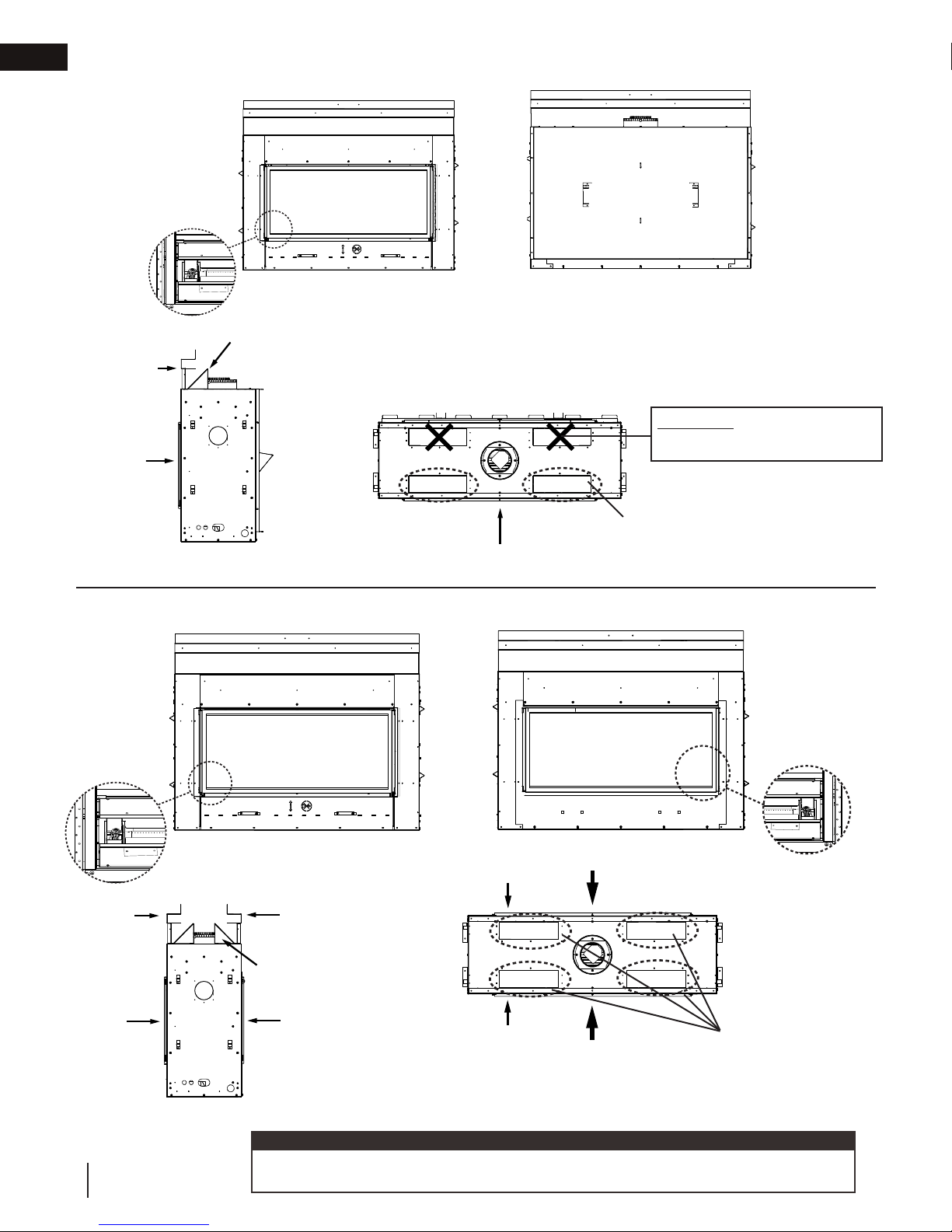

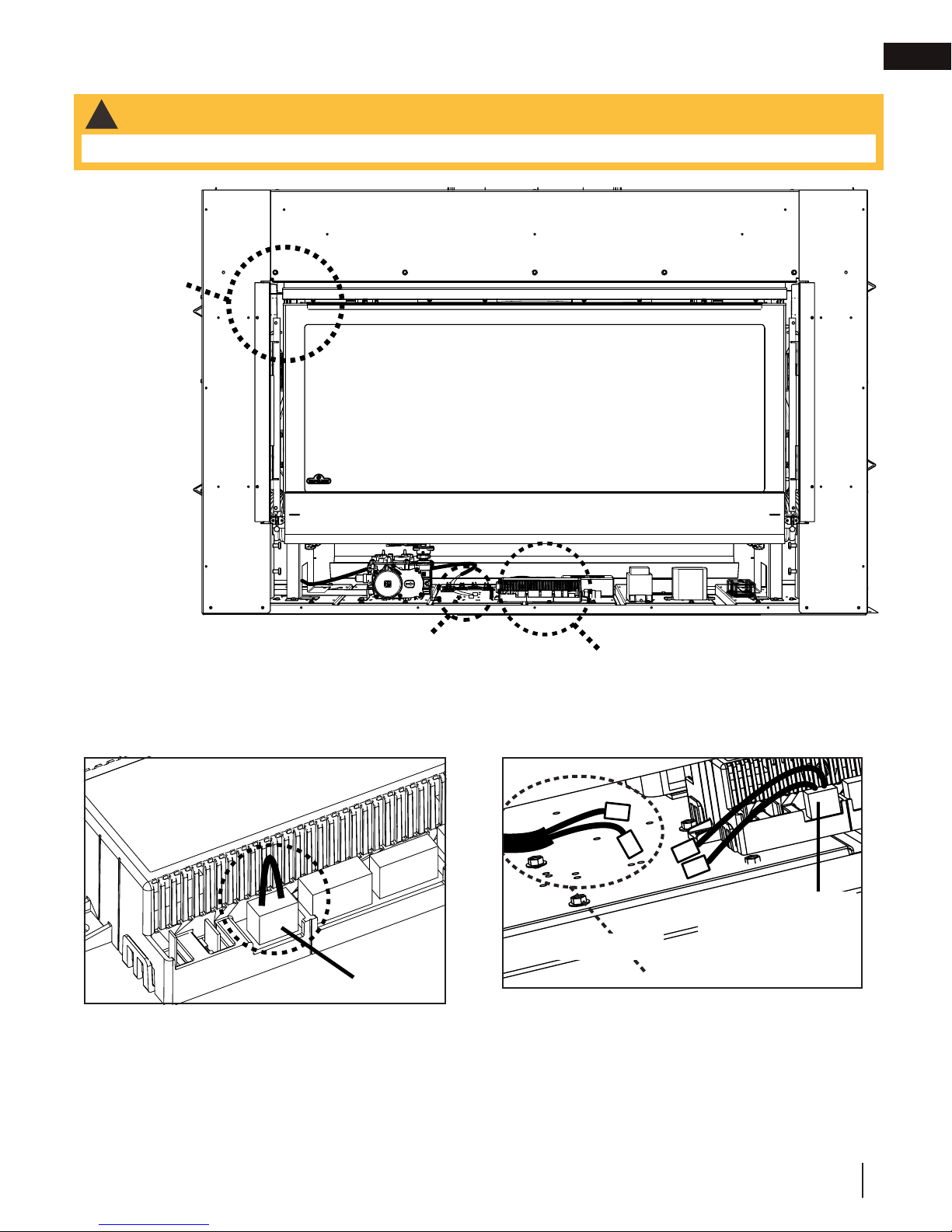

4.0 Dynamic Heat Control™ installation

access side

access side

Before starting the Dynamic Heat Control™ installation, remove safety barrier. Refer to “safety barrier installation/

removal” section in the installation manual

SINGLE-SIDED SHOWN

Front Frame

Dynamic Heat Control™ installation

EN

1.) Remove fasteners securing front frame (and rear

frame for see-thru). Do not discard fasteners.

SINGLE-SIDED SHOWN

2.) Remove knockouts plates (FOR SINGLE-SIDED, ONLY REMOVE

THE TWO KNOCKOUTS PLATES ON THE ACCESS SIDE). Discard

knockout plates. Recommended: Use a flathead screwdriver or a

small pry bar and use prying motion to remove the knockout. Use

a brace such as a piece of wood under the prying tool to avoid distorting

the top

COVER PLATE

Cover Plate

3.) Remove the fasteners securing the cover plates recessed below the knockout plates. For ease of removal, lift the panel from below in

front of the firebox door. Discard cover plates.

IMPORTANT:

Fire Hazard Warning: This step is crucial for your appliance to work properly. If

the knockout plates AND the cover plates are not removed from the viewed side,

the appliance will overheat, the barrier will become excessively hot, and the high

limit switch will constantly trip.

W415-1739 / C / 08.03.17

9

EN

Dynamic Heat Control™ installation

a

b

4.) Bend the sides of the deflectors as shown.

FOR LV38-1 / LV62

FOR LV50-2 / LV74

5.) Remove outer knockout fasteners. Do not discard

fasteners.

5.) Secure deflectors to the appliance with supplied fasteners as

shown.

6.) Re-install front frame using the fasteners removed in step 1.

WARNING

!

6.) Secure deflectors to the appliance with fasteners removed in

step 5 and supplied fasteners.

7.) Re-install front frame using the fasteners previously used

in step 1.

• FOR SEE-THRU APPLIANCES, REPEAT STEPS WITH THE FIXED SIDE.

IMPORTANT:

It is recommended to install venting and vent heat shield(s) before refitting the

front, (and where applicable rear), frame for ease of access. It is critical for see-thru

appliances that ALL 4 knockout plates, ALL 4 cover plates are removed and ALL 4

deflectors are installed.

10

W415-1739 / C / 08.03.17

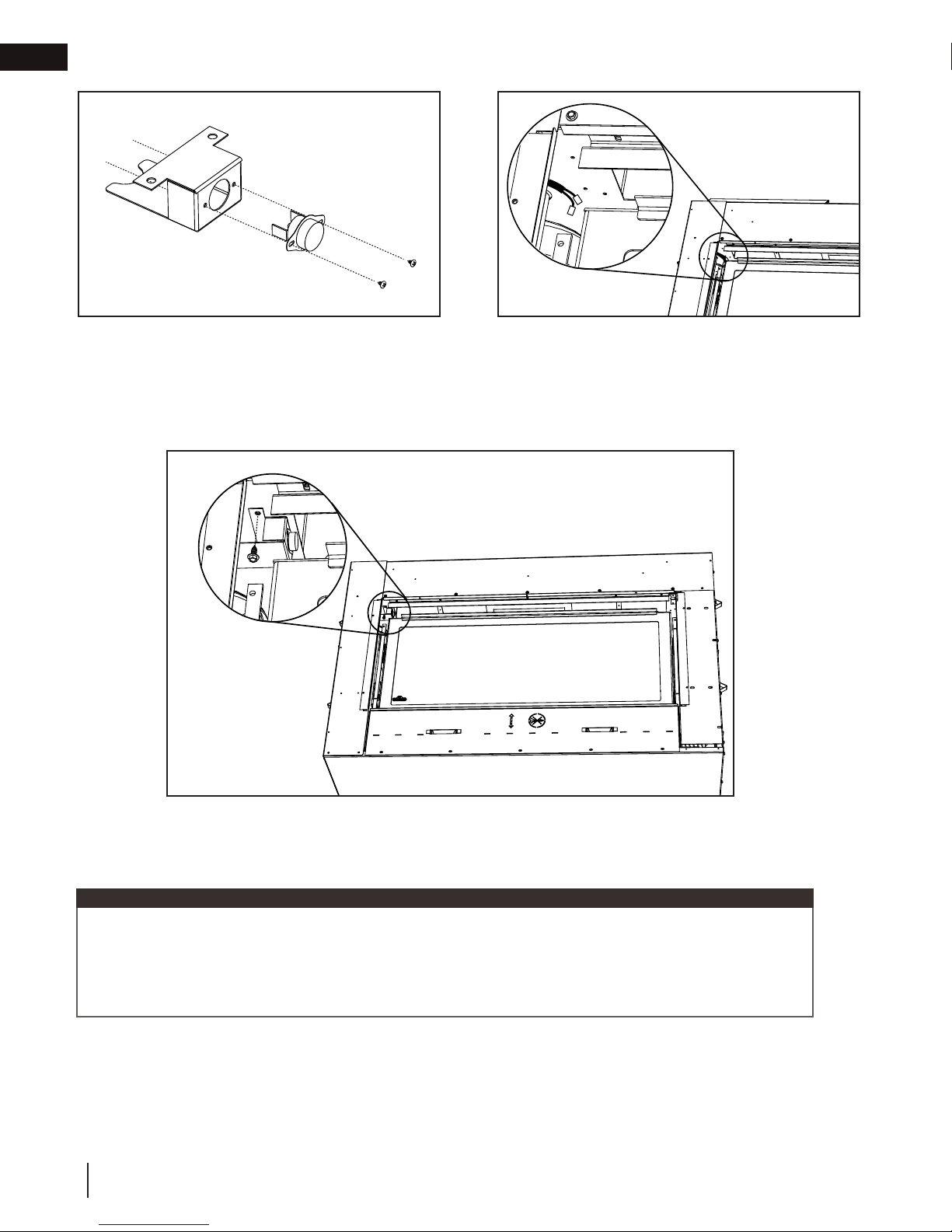

Dynamic Heat Control™ installation

4.1 high limit switch installation

WARNING

!

• High Limit Switch installation is MANDATORY. Failure to correctly install will cause a fire hazard.

Bracket Install

Location

access side

EN

Wire Harness

“X4”

1.) Remove jumper plug from control board (marked “X4”)

and install plug with spade connectors to the control

board. Discard the original jumper plug.

Control Board

Plug with spade

connectors

Wire Harness

W415-1739 / C / 08.03.17

11

EN

Dynamic Heat Control™ installation

3.) Insert the high limit switch into the bracket and secure

with two fasteners (supplied).

4.) Locate the existing wire harness in the upper left corner

of the firebox as shown. Connect wires to the high limit

switch.

access side

5.) Install high limit switch assembly to the bracket install location in the upper left hand corner of the

appliance. Secure high limit switch assembly with a supplied screw as shown.

IMPORTANT:

After installing the Dynamic Heat Control™ Kit, ensure appliance is clean from dust, debris, etc.

before continuing with the appliance installation. Take precautions to ensure framing or finishing

dust and debris does not enter the air outlet openings or deflectors.

Check and clean appliance before operation.

Re-install safety barrier. “Refer to safety barrier installation / removal” in the installation manual.

12

W415-1739 / C / 08.03.17

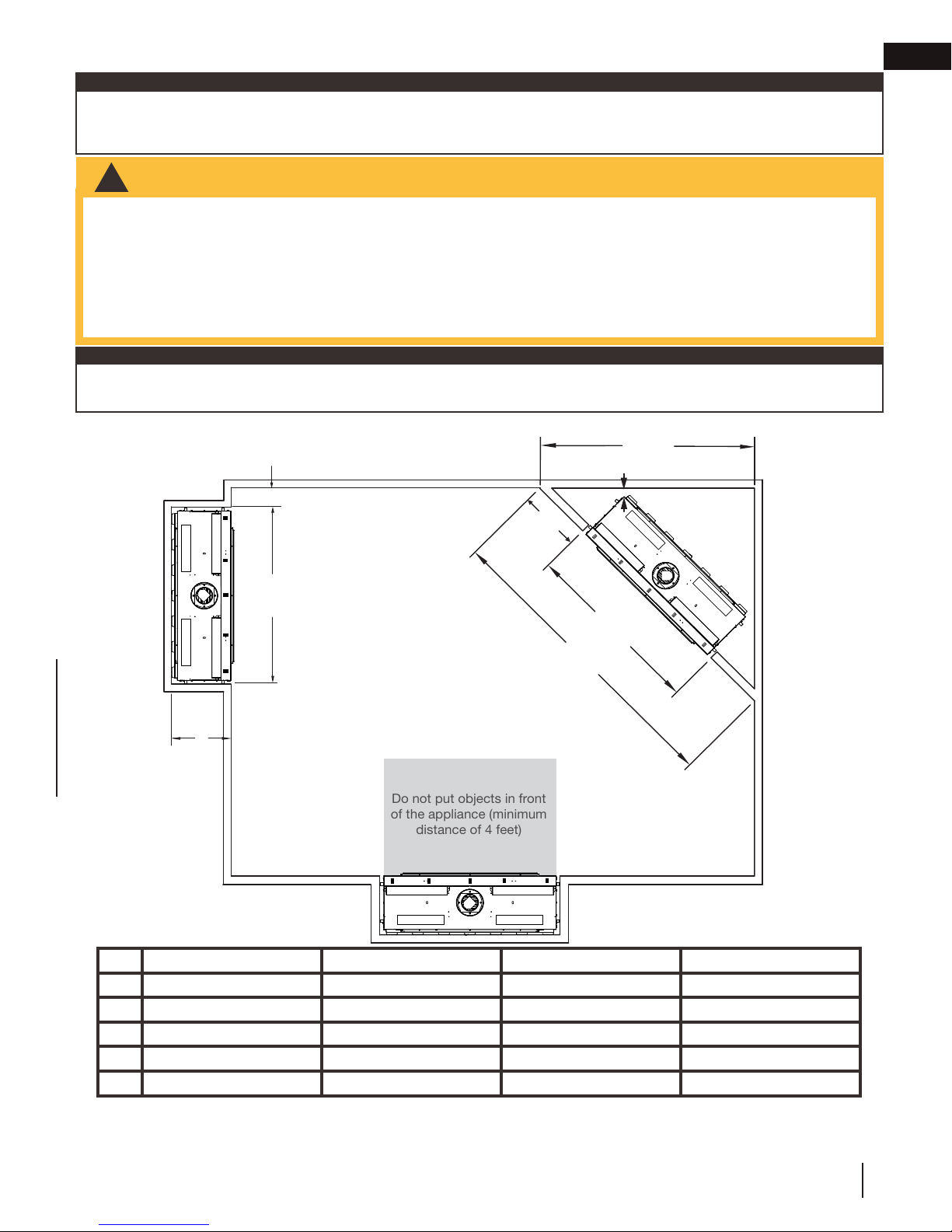

Dynamic Heat Control™ installation

!

WARNING

Do not put objects in front

of the appliance (minimum

distance of 4 feet)

5.0 minimum framing dimensions

note:

When using optional finishing accessories, the framing dimensions and finishing materials may differ from what is outlined in the section below; refer to the leaflet instructions supplied in the accessory kit for specific framing and finishing

specifications.

• Risk of fire!

• In order to avoid the possibility of exposed insulation or vapour barrier coming in contact with the appliance body, it is

recommended that the walls of the appliance enclosure be “finished” (i.e. drywall / sheetrock), as you would finish any

other outside wall of a home. This will ensure that clearance to combustibles is maintained within the cavity.

• Do not notch the framing around the appliance stand offs. Failure to maintain air space clearance may cause over heating

and fire. Prevent contact with sagging or loose insulation or framing and other combustible materials. Block opening into

the chase to prevent entry of blown-in insulation. Make sure insulation and other materials are secured.

• Minimum clearance to combustibles must be maintained or a serious fire hazard could result.

note:

For heavier finishing materials such as marble, we recommend adding extra support to the frame. Ensure there is

adequate floor support for the appliance and finishing material.

EN

minimum framing dimensions

6” (15.2cm) min.

F

E

G

1” (2.54cm) min.

H

F

I

LV38-1 LV50-2 LV62 LV74

E

F

G

H

I

20 1/8” (51.1cm) 20 1/8” (51.1cm) 20 1/8” (51.1cm) 20 1/8” (51.1cm)

53 13/16” (136.7cm) 65 13/16” (167.2cm) 77 13/16” (197.6cm) 89 13/16” (228.1cm)

63 3/4” (162cm) 72 1/4” (183.5cm) 80 11/16” (205cm) 89 1/4” (226.6cm )

18 3/16” (46.2cm) 18 3/16” (46.2cm) 18 3/16” (46.2cm) 18 3/16” (46.2cm)

90 3/16” (229cm) 102 3/16” (259.5cm) 114 1/8” (289.9cm) 126 1/8” (320.4cm)

W415-1739 / C / 08.03.17

13

EN

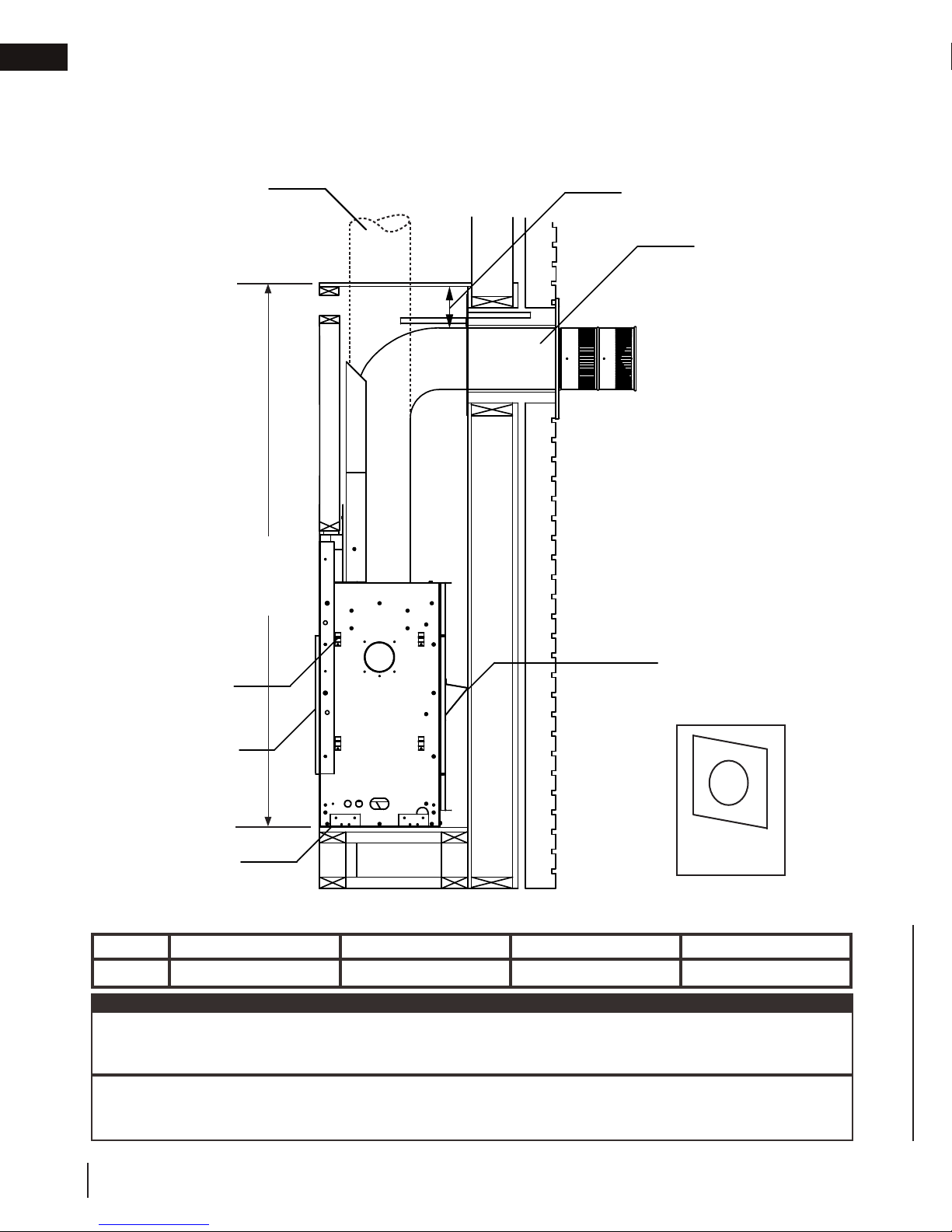

minimum clearance to combustible enclosures6.0 minimum clearance to combustible enclosures

single-sided

1” [25mm] minimum

to sides for vertical

venting.

When passing through

a ceiling, use firestop

spacer W500-0028

(not supplied)

6” [152mm] minimum

3” [76mm] to top

2” [51mm] to sides /

bottom

When passing through

a wall, use firestop

spacer assembly

W010-4178 (supplied)

0” to non-combustible

finishing such as brick

and stone. When using

non-combustible finishing, only use firestop

spacer (W615-0162)

included in the firestop

assembly (W010-4178)

L

0” to back standoffs

0” to side standoffs

1/2” finishing flange

0” to bottom of the

appliance

firestop spacer

(W615-0162)

minimum clearance

Ref LV38-1 LV50-2 LV62 LV74

L

note:

The LV series requires a minimum inside enclosure height of 73” measured from the bottom of the appliance.

For temperature requirements, this area must be left unobstructed. It is mandatory to ventilate the enclosure

according to these instructions.

73” (185.4cm) 73” (185.4cm) 91” (231.1cm) 91” (231.1cm)

Although the minimum enclosure height for the LV series is 73”, some venting configurations that require more

vertical rise will require a larger enclosure to provide minimum vertical clearance between vent pipes and combustibles.

14

W415-1739 / C / 08.03.17

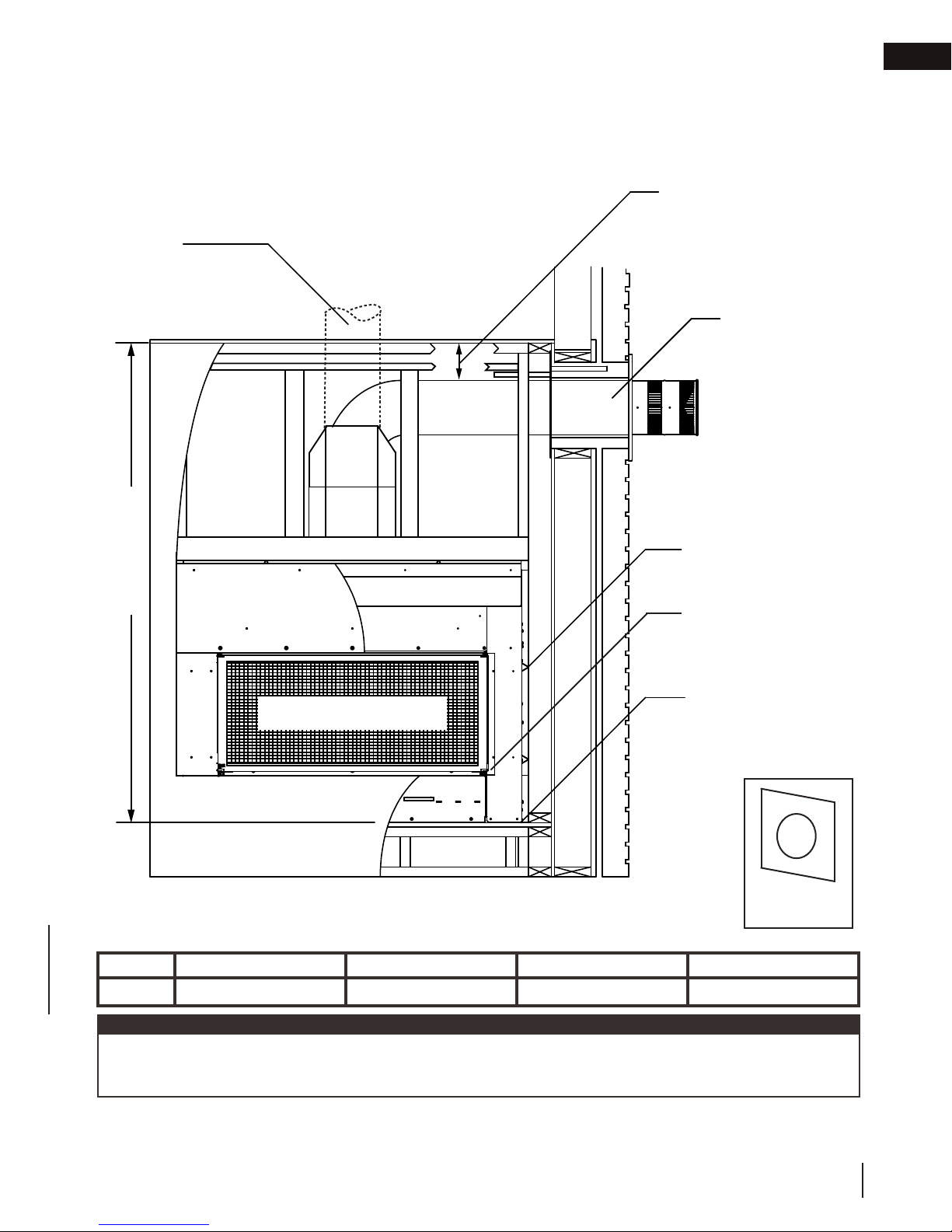

see-thru

1” [25mm]

minimum to

sides for vertical

venting.

When passing

through a

ceiling, use

firestop spacer

W500-0028 (not

supplied)

minimum clearance to combustible enclosures

6” [152mm] minimum

3” [76mm] to top

2” [51mm] to sides /

bottom

When passing through

a wall, use firestop

spacer assembly

W010-4178 (supplied)

0” to non-combustible

finishing such as brick

and stone. When using

non-combustible finishing, only use firestop

spacer (W615-0162)

included in the firestop

assembly (W010-4178)

EN

L

SAFETY BARRIER

0” to side standoffs

1/2” finishing flange

(4 sides)

0” to base of the

appliance

minimum clearance

Ref LV38-1 LV50-2 LV62 LV74

L

73” (185.4cm) 73” (185.4cm) 91” (231.1cm) 91” (231.1cm)

firestop spacer

(W615-0162)

note:

Although the minimum enclosure height for the LV series is 73”, some venting configurations that require more

vertical rise will require a larger enclosure to provide minimum vertical clearance between vent pipes and combustibles.

W415-1739 / C / 08.03.17

15

EN

finish framing - after appliance installation

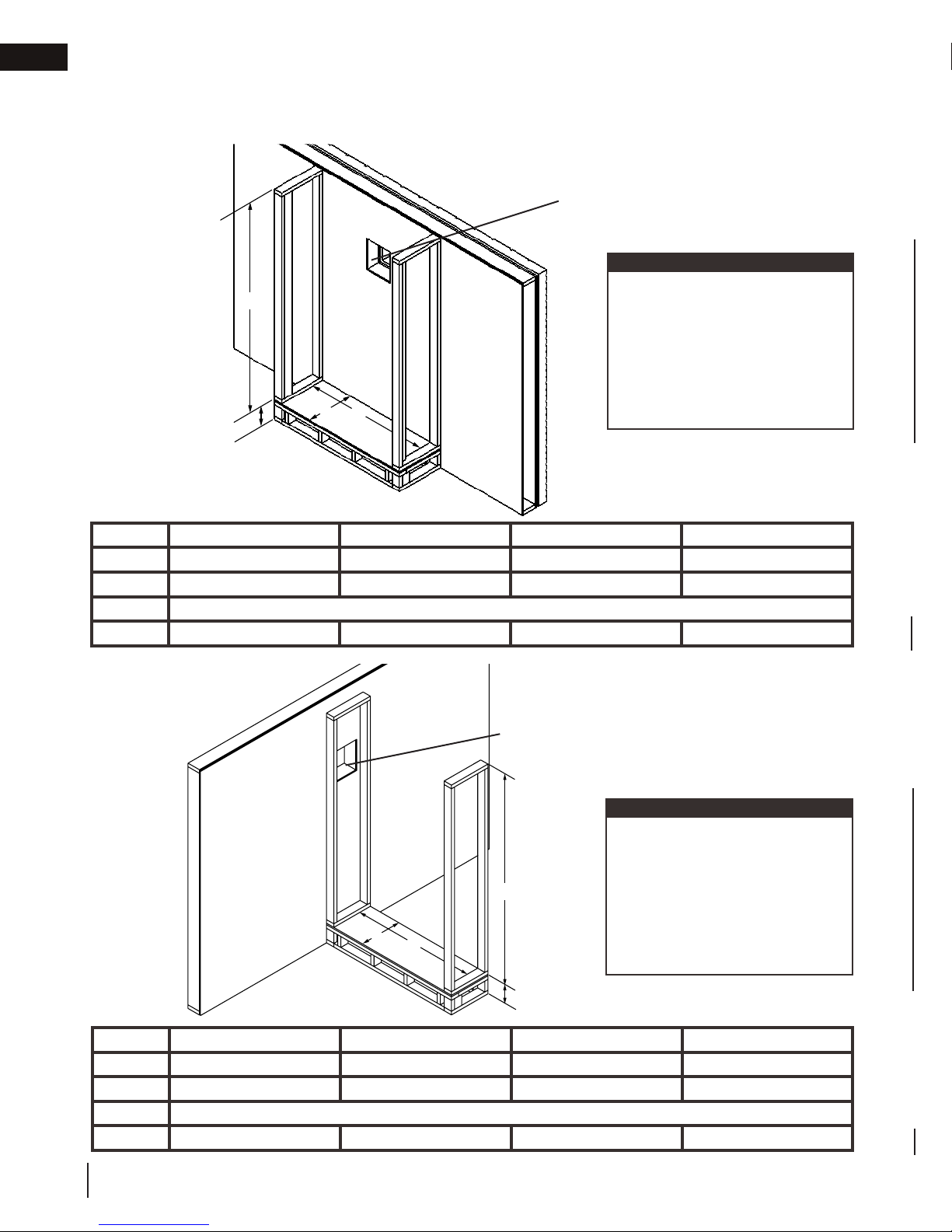

7.0 rough framing - before appliance installation

Before framing your appliance, determine vent requirements before deciding the final location of the appliance.

After rough framing, place the appliance in its final position. Also, see appliance manual for vent shield installation,

nailing tabs installation,electrical installation, gas installation, etc.

single-sided

Before framing the appliance, ensure to install

the firestop first as it will not fit between the

studs if installed after framing.

note:

Although the minimum enclosure

L

height for the LV series is 73”,

some venting configurations

that require more vertical rise

will require a larger enclosure to

provide minimum vertical clearance between vent pipes and

E

J

F

combustibles.

Ref LV38-1 LV50-2 LV62 LV74

E

F

J

L

20 1/8” (51.1cm) 20 1/8” (51.1cm) 20 1/8” (51.1cm) 20 1/8” (51.1cm)

53 13/16” (136.7cm) 65 13/16” (167.2cm) 77 13/16” (197.6cm) 89 13/16” (228.1cm)

Optional - Appliance does not need to be elevated above floor

73” (185.4cm) 73” (185.4cm) 91” (231.1cm) 91” (231.1cm)

see-thru

Before framing the appliance, ensure to install

the firestop first as it will not fit between the

studs if installed after framing.

note:

Although the minimum enclosure height for the LV series is

73”, some venting configurations

L

E

F

that require more vertical rise will

require a larger enclosure to provide minimum vertical clearance

between vent pipes and combustibles.

Ref LV38-1 LV50-2 LV62 LV74

E

F

J

L

16

W415-1739 / C / 08.03.17

16 3/16” (41.1cm) 16 3/16” (41.1cm) 16 3/16” (41.1cm) 16 3/16” (41.1cm)

53 13/16” (136.7cm) 65 13/16” (167.2cm) 77 13/16” (197.6cm) 89 13/16” (228.1cm)

73” (185.4cm) 73” (185.4cm) 91” (231.1cm) 91” (231.1cm)

J

Optional - Appliance does not need to be elevated above floor

Loading...

Loading...