Napoleon Luxuria, LVX50N, LVX74N, LVX38N, LVX38N2 Installation Manual

...

NATURAL GAS MODELS:

GLASS GUARD

LVX38N / LVX50N / LVX62N / LVX74N / LVX38N2 / LVX50N2 / LVX62N2 / LVX74N2

ADD PRODUCT CODE HERE (TRADE GOTHIC LT STD FONT)

ENGLISH

PROPANE GAS MODELS:

LVX38P / LVX50P / LVX62P / LVX38P2 / LVX50P2 / LVX62P2

INSTALLATION MANUAL

SAFETY INFORMATION

!

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly

could result in serious injury, death, or

property damage.

- Do not store or use gasoline or other

fl ammable vapors and liquids in the vicinity of

this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

neighbour’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call

the fi re department.

FRENCH

PG. 91

ADD MANUAL TITLE

Product Name / Code

(MUST use title from Price Book)

ADD PRODUCT IMAGE

Luxuria™ Series

(LVX38 illustrated)

ADD ____ ILLUSTRATED

- Installation and service must be

performed by a qualifi ed installer, service

agency, or the supplier.

This appliance may be installed in an aftermarket,

permanently located, manufactured home (USA

only) or mobile home, where not prohibited by

local codes.

This appliance is only for use with the type of gas

indicated on the rating plate. This appliance is

not convertible for use with other gases, unless

a certifi ed kit is used.

INSTALLER:

Leave this manual with the appliance

CONSUMER:

Retain this manual for future reference

Wolf Steel Ltd., 24 Napoleon Rd., Barrie, ON, L4M 0G8 Canada / 103 Miller Drive, Crittenden, Kentucky, USA, 41030

Phone 1 (866) 820-8686 • www.napoleonfi replaces.com • hearth@napoleonproducts.com

CSA 2.22 AND ANSI Z21.50 FOR VENTED DECORATIVE GAS APPLIANCES

CERTIFIED TO THE CANADIAN AND AMERICAN NATIONAL STANDARDS:

CSA 2.22 AND ANSI Z21.50 FOR VENTED DECORATIVE GAS APPLIANCES

CSA /

INTERTEK

LOGO

THIS APPLIANCE IS INSTALLED WITH

FOR INDOOR USE ONLY

CERTIFIED TO THE CANADIAN AND AMERICAN NATIONAL STANDARDS:

FOR INDOOR USE ONLY

IF INSTALLATION + OPERATION, ADD SERIAL

NUMBER LABEL HERE

PLACE BARCODE LABEL ON THE

IF SEPARATE MANUALS, ADD “PLACE

BARCODE LABEL ON THE OWNER’S MANUAL”

OWNER’S MANUAL

$10.00

W415-1710 / B / 08.17.18

EN

HOT GLASS WILL CAUSE

BURNS.

DO NOT TOUCH GLASS UNTIL

COOLED.

NEVER ALLOW CHILDREN TO

TOUCH GLASS.

!

DANGER

A barrier designed to reduce the risk of burns from the

hot viewing glass is provided with this appliance and

shall be installed for the protection of children and other

at-risk individuals.

!

WARNING

safety information

• This appliance is hot when operated and

can cause severe burns if contacted.

• Any changes or alterations to this

appliance or its controls can be

dangerous and is prohibited.

• Do not operate appliance before reading and

understanding operating instructions. Failure

to operate appliance according to operating

instructions could cause fi re or injury.

• Ensure the glass door is opened or removed

when lighting the pilot for the fi rst time and

when the gas supply has run out.

• Risk of fi re or asphyxiation, do not operate

appliance with fi xed glass removed and never

obstruct the front opening of the appliance.

• Do not connect 110 volts to the control valve,

with the exception of models; GSST8 and

GT8.

• Risk of burns. The appliance should be turned off and cooled before servicing.

• Do not install damaged, incomplete or substitute components.

• Risk of cuts and abrasions. Wear protective gloves, protective footwear, and safety glasses during

installation. Sheet metal edges may be sharp.

• Do not burn wood or other materials in this appliance.

• Provide adequate ventilation and combustion air. Provide adequate accessibility clearance for servicing

and operating the appliance.

• High pressure will damage valve. Disconnect gas supply piping before pressure testing gas line at

test pressures above 1/2 psig. Close the manual shut-off valve before pressure testing gas line at test

pressures equal to or less than 1/2 psig (35mb).

• The appliance must not be operated at temperatures below freezing (32°F / 0°C). Allow the appliance

to warm to above freezing prior to operation, with the exception of models; GSS36, GSS42; these

appliances are suitable for 0°F / -18°C.

• Children and adults should be alerted to hazards of high surface temperature and should stay

away to avoid burns or clothing ignition.

• Young children should be carefully supervised when they are in the same room as the

appliance. Toddlers, young children and others may be susceptible to accidental contact

burns. A physical barrier is recommended if there are at risk individuals in the house. To

restrict access to an appliance or stove, install an adjustable safety gate to keep toddlers,

young children and other at risk individuals out of the room and away from hot surfaces.

• Clothing or other fl ammable material should not be placed on or near the appliance.

• Due to high temperatures, the appliance should be located out of traffi c and away from

furniture and draperies.

• Furniture or other objects must be kept a minimum of 4 feet (1.22m) away from the front of the appliance.

• Ensure you have incorporated adequate safety measure to protect infants/toddlers from touching hot

surfaces.

• Even after the appliance is off, it will remain hot for an extended period of time.

• Check with your local hearth specialty dealer for safety screens and hearth guards to protect children

from hot surfaces. These screens and guards must be fastened to the fl oor.

• Any safety screen, guard or barrier removed for servicing the appliance, must be replaced prior

to operating the appliance.

• It is imperative that the control compartments, burners and circulating blower and its passageway in the

appliance and venting system are kept clean. The appliance and its venting system should be inspected

before use and at least annually by a qualifi ed service person. More frequent cleaning may be required

due to excessive lint from carpeting, bedding material, etc. The appliance area must be kept clear and

free from combustible materials, gasoline and other fl ammable vapors and liquids.

• If the appliance shuts off, do not re-light until you provide fresh air. If appliance keeps shutting off, have it

serviced. Keep burner and control compartment clean.

• Under no circumstances should this appliance be modifi ed.

• Do not allow wind or fans to blow directly into the appliance. Avoid any drafts that alter burner fl ame

patterns.

2

W415-1710 / B / 08.17.18

before use and at least annually by a qualifi ed service person. More frequent cleaning may be required

due to excessive lint from carpeting, bedding material, etc. The appliance area must be kept clear and

free from combustible materials, gasoline and other fl ammable vapors and liquids.

• If the appliance shuts off, do not re-light until you provide fresh air. If appliance keeps shutting off, have it

serviced. Keep burner and control compartment clean.

• Under no circumstances should this appliance be modifi ed.

• Do not allow wind or fans to blow directly into the appliance. Avoid any drafts that alter burner fl ame

patterns.

HOT GLASS WILL CAUSE

BURNS.

DO NOT TOUCH GLASS UNTIL

COOLED.

NEVER ALLOW CHILDREN TO

TOUCH GLASS.

!

DANGER

A barrier designed to reduce the risk of burns from the

hot viewing glass is provided with this appliance and

shall be installed for the protection of children and other

at-risk individuals.

!

WARNING

!

WARNING

WARNING

!

WARNING:

Electric

This product can expose you to chemicals including lead and lead compounds,

Gas, Wood

which are known to the State of California to cause cancer, and chemicals including BBP and

DEHP, which are known to the State of California to cause birth defects or other reproductive

harm. For more information, go to www.P65Warnings.ca.gov.

!

AVERTISSEMENT:

Ce produit peut vous exposer à des substances chimiques incluant le

plomb et les composés de plomb qui, selon l’État de Californie, causeraient le cancer, et des

substances chimiques incluant le BBP et DEHP qui, selon d’État de Californie, causeraient des

malformations congénitales ou autres dangers pour la reproduction.

Pour de plus amples renseignements, visitez le www.P65Warnings.ca.gov.

!

ADVERTENICA:

Este producto puede exponerlo a productos químicos, entre ellos, plomo

y compuestos con plomo, que el Estado de California reconoce como causantes de cáncer, y

productos químicos, entre ellos, bencilbutilftalato (BBP, por sus siglas en inglés) y di(2-etilhex-

il) ftalato (DEHP, por sus siglas en inglés), que el Estado de California reconoce como caus-

antes de malformaciones congénitas u otros daños para la reproducción. Para obtener más

información, visite www.P65Warnings.ca.gov.

• Do not use a blower insert, heat exchanger insert or other accessory not approved for use with this

appliance.

• This appliance must not be connected to a chimney fl ue pipe serving a separate solid fuel burning

appliance.

• Do not use this appliance if any part has been under water. Immediately call a qualifi ed service technician

to inspect the appliance and to replace any part of the control system and any gas control which has

been under water.

• Do not operate the appliance with the glass door removed, cracked or broken. Replacement of the glass

should be done by a licensed or qualifi ed service person, if equipped.

• Do not strike or slam shut the appliance glass door, if equipped.

• Only doors / optional fronts certifi ed with the appliance are to be installed on the appliance.

• Keep the packaging material out of reach of children and dispose of the material in a safe manner. As

with all plastic bags, these are not toys and should be kept away from children and infants.

• Carbon or soot should not occur in a vent free appliance as it can distribute into the living area of your

home. If you notice any signs of carbon or soot, immediately turn off your appliance and arrange to have

it serviced by a qualifi ed technician before operating it again.

• If equipped, the screen must be in place (closed) when the appliance is in operation.

• When equipped with pressure relief doors, they must be kept closed while the appliance is operating

to prevent exhaust fumes containing carbon monoxide, from entering into the home. Temperatures of

the exhaust escaping through these openings can also cause the surrounding combustible materials to

overheat and catch fi re.

• Carbon monoxide poisoning may lead to death; early signs of carbon monoxide poisoning resemble the

fl u, with headache, dizziness and/or nausea. If you have these signs, the appliance may not be working

properly. Get fresh air at once! Have appliance serviced. Some people; pregnant women, persons with

heart or lung disease, anemia, those under the infl uence of alcohol, those at high altitudes are more

affected by carbon monoxide than others. Failure to keep the primary air opening(s) of the burner(s) clean

may result in sooting and property damage.

• As with any combustion appliance, we recommend having your appliance regularly inspected and

serviced as well as having a Carbon Monoxide Detector installed in the same area to defend you and

your family against Carbon Monoxide (not applicable for outdoor appliances).

• Ensure clearances to combustibles are maintained when building a mantel or shelves above the

appliance. Elevated temperatures on the wall or in the air above the appliance can cause melting,

discolouration or damage to decorations, a T.V. or other electronic components.

• For appliances equipped with a safety barrier; if the barrier becomes damaged, the barrier

shall be replaced with the manufacturer’s barrier for this appliance.

• Installation and repair should be done by a qualifi ed service person. It is imperative that control

• For outdoor products only: this appliance must not be installed indoors or within any structure that

• If applicable, the millivolt version of this appliance uses and requires a fast acting thermocouple. Replace

compartments, burners and circulating air passageways of the appliance be kept clean.

prevents or inhibits the exhaust gases from dissipating in the outside atmosphere.

only with a fast acting thermocouple supplied by Wolf Steel Ltd.

!

WARNING:

which are known to the State of California to cause cancer, and chemicals including carbon

Add California Prop 65 warning

monoxide, which are known to the State of California to cause birth defects or other reproductive harm. For more information, go to www.P65Warnings.ca.gov.

This product can expose you to chemicals including lead and lead compounds,

safety information

EN

!

FIRE RISK HAZARD / DELAYED IGNITION

High supply pressure will damage the valve / controls.

Disconnect the appliance main gas valve/control

from the supply piping when pressure testing that

system at pressures in excess of 1/2 psi (3.5 kPa).

Isolate the appliance with it’s shut off valve during

any pressure testing of the supply piping at

pressures equal to or less than 1/2 psi (3.5 kPa).

!

W415-1710 / B / 08.17.18

3

EN

table of contents

1.0 general information 5

1.1 rates and efficiencies 6

1.2 installation overview 7

1.3 Dynamic Heat Control™ 8

1.4 rating plate/lighting instruction location

10

1.5 mobile home installation 11

1.6 hardware list 11

1.7 lifting handles installation/removal 11

2.0 dimensions 12

2.1 single-sided 12

2.2 see-thru 13

3.0 minimum venting requirements 14

3.1 typical venting installation 16

3.2 minimum air terminal location

clearances 18

3.3 horizontal termination 19

3.4 vertical termination 22

3.5 LVX38 venting configurations 23

3.6 LVX50 / 62 venting configurations 24

4.0 installation planning 25

4.1 installation option 1 - open enclosure

(enclosure stops short of the ceiling) 27

4.2 installation option 2 - front opening 28

4.3 installation option 3 - Rear Opening 29

4.4 installation option 4 - open enclosure

with hard combustible valance 30

5.0 rough framing - before appliance

installation 31

5.1 minimum framing dimensions 32

5.1.1 minimum clearance to combustible

enclosures 33

6.0 venting installation 36

6.1 firestop spacer assembly 36

6.2 horizontal installation 38

6.3 vertical installation 38

6.4 using flexible vent components 39

6.4.1 horizontal air terminal installation 39

6.5 vertical air terminal installation 40

6.5.1 appliance vent connection 40

6.6 restricting vertical vents 41

6.6.1 LVX38 / LVX50 41

6.6.2 LVX62 / LVX74 41

6.7 vent shield installation 42

7.0 electrical information 43

7.1 hard wiring connection 43

7.2 receptacle wiring diagram 43

7.3 in the event of a power failure 43

7.4 battery holder/switch installation 44

7.5 initializing the battery holder/switch for

the first time 44

7.6 wiring diagram 45

7.7 eFire controller application 45

7.7.1 LVX38/50 wiring diagram 46

7.7.2 LVX62/74 wiring diagram 47

7.8 access panel 48

8.0 gas installation 49

9.0 operation 50

10.0 nailing tab installation 51

11.0 finish framing

- after appliance

installation 52

11.1 framing with Dynamic Heat Control™

52

12.0 finishing 56

12.1 fastener placement restriction 56

12.2 enclosure design 57

12.3 finishing with combustibles 58

12.4 minimum combustible mantel

clearances 60

12.5 optional trim finishing 61

12.6 glass guard installation / removal 62

12.7 firebox glass door installation /

removal 71

12.8 media tray removal 72

12.9 optional media placement 72

12.10 glass media installation / removal 73

13.0 adjustments 74

13.1 restricting vertical vents 74

13.2 venturi adjustment 74

13.3 pilot burner adjustment 75

13.4 flame characteristics 75

14.0 maintenance 76

14.1 annual maintenance 77

14.2 control access 77

14.3 burner removal 78

14.4 valve removal 78

14.5 control module removal 79

14.6 LED replacement 80

14.7 glass / door replacement 81

14.8 care of glass 81

14.9 care of plated parts 81

15.0 replacements 82

15.1 overview 83

15.2 burner components 84

16.0 troubleshooting 86

note:

The information throughout this manual is believed to be correct at the time of printing. Wolf Steel

Ltd. reserves the right to change or modify any information within this manual at any time without

notice. Changes, other than editorial are denoted by a vertical line in the margin.

4

W415-1710 / B / 08.17.18

general information

Installer: please fill out appliance checklist in the

owner’s manual.

1.0 general information

When the appliance is installed at elevations above 4,500ft (1372m), and in the absence of specific recommendations

from the local authority having jurisdiction, the certified high altitude input rating shall be reduced at the rate of 4% for each

additional 1,000ft (305m). Expansion / contraction noises during heating up and cooling down cycles are normal

and are to be expected. Change in flame appearance from “HI” to “LO” is more evident in natural gas than in

propane.

This appliance is approved for bathroom, bedroom and bed-sitting room installations and is certified for mobile

home installation.

This appliance is only for use with the type of gas indicated on the rating plate. This appliance is not

convertible for use with other gases, unless a certified kit is used.

EN

There is a switch that controls the function of the appliance. The battery holder/switch must be placed in the

middle position. If the switch is not placed in the middle position, the appliance will not work.

note:

A glass guard assembly designed to reduce the risk of burns is provided with the appliance and must

be installed. Never operate the appliance without the complete Glass Guard Barrier System installed

and closed.

The protective wrap on plated parts is best removed when the assembly is at room temperature but this can

be improved if the assembly is warmed, using a hair dryer or similar heat source. The protective wrap must be

removed before operating the appliance.

This appliance is a decorative product. It is not a source of heat and not intended to burn solid fuel.

This appliance is equipped with a remote control and a wall switch, which requires batteries to be installed. The

remote takes 3 “AAA” batteries and the wall switch takes 4 “AA” batteries.

Batteries must be disposed of according to the local laws and regulations. Some batteries may be

recycled, and may be accepted for disposal at your local recycling center. Check with your

municipality for recycling instructions.

important:

Some components and/or media are packaged separately and must be installed in accordance with the

information in this manual.

W415-1710 / B / 08.17.18

5

EN

general information

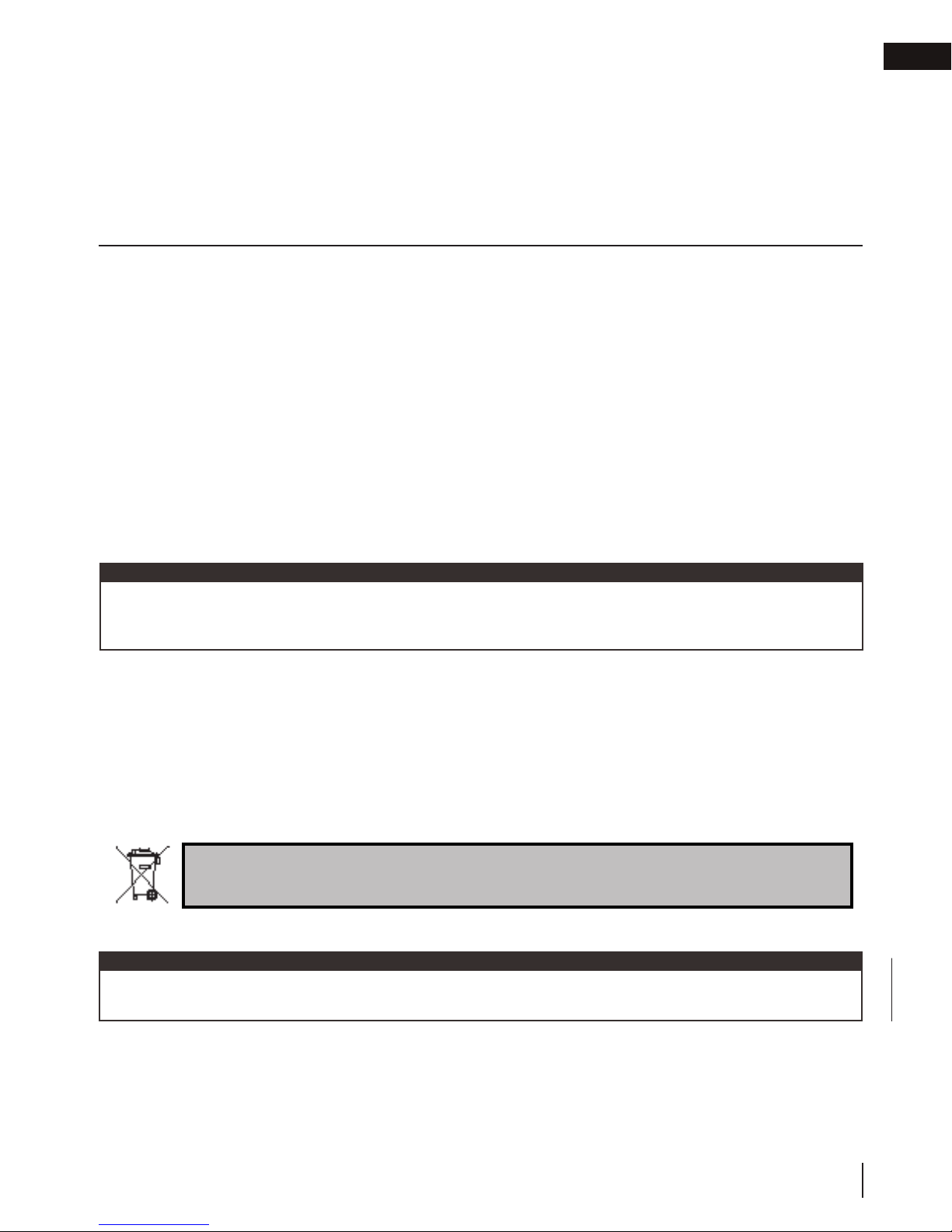

1.1 rates and efficiencies

LVX38

Appliance Type LVX38N LVX38P LVX38N2 LVX38P2

Fuel Type Natural Gas Propane Natural Gas Propane

Altitude (FT) 0-4,500 0-4,500 0-4,500 0-4,500

Max. Input (BTU/HR) 32,000 32,000 32,000 32,000

Min. Input (BTU/HR) 22,000 25,000 23,000 25,000

P4 40.2% 40.2% 40.2% 40.2%

LVX50

Appliance Type LVX50N LVX50P LVX50N2 LVX50P2

Fuel Type Natural Gas Propane Natural Gas Propane

Altitude (FT) 0-4,500 0-4,500 0-4,500 0-4,500

Max. Input (BTU/HR) 38,000 38,000 38,000 38,000

Min. Input (BTU/HR) 26,000 31,000 26,000 31,000

P4 45.5% 45.5% 45.5% 45.5%

LVX62

Appliance Type LVX62N LVX62P LVX62N2 LVX62P2

Single-Sided See-thru

Single-Sided See-thru

Single-Sided See-thru

Fuel Type Natural Gas Propane Natural Gas Propane

Altitude (FT) 0-4,500 0-4,500 0-4,500 0-4,500

Max. Input (BTU/HR) 44,000 38,000 44,000 38,000

Min. Input (BTU/HR) 32,000 31,000 32,000 31,000

P4 55.5% 58.5% 55.5% 58.5%

LVX74

Appliance Type LVX74N LVX74N2

Fuel Type Natural Gas Natural Gas

Altitude (FT) 0-4,500 0-4,500

Max. Input (BTU/HR) 50,000 50,000

Min. Input (BTU/HR) 35,000 32,000

P4 52.5% 52.5%

Single-Sided See-thru

6

W415-1710 / B / 08.17.18

14

10

13

6

5

8

9

4

3

2

GLASS GUARD

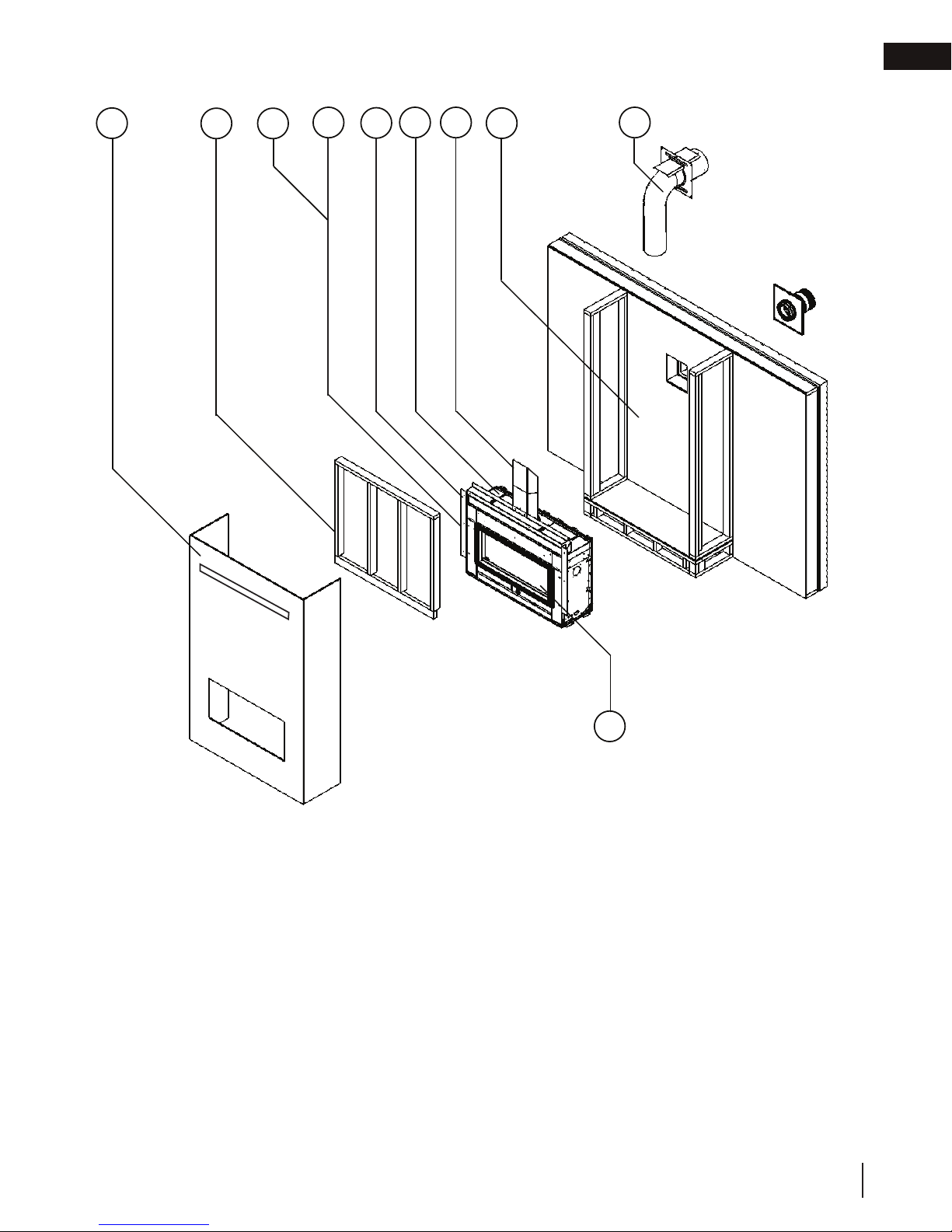

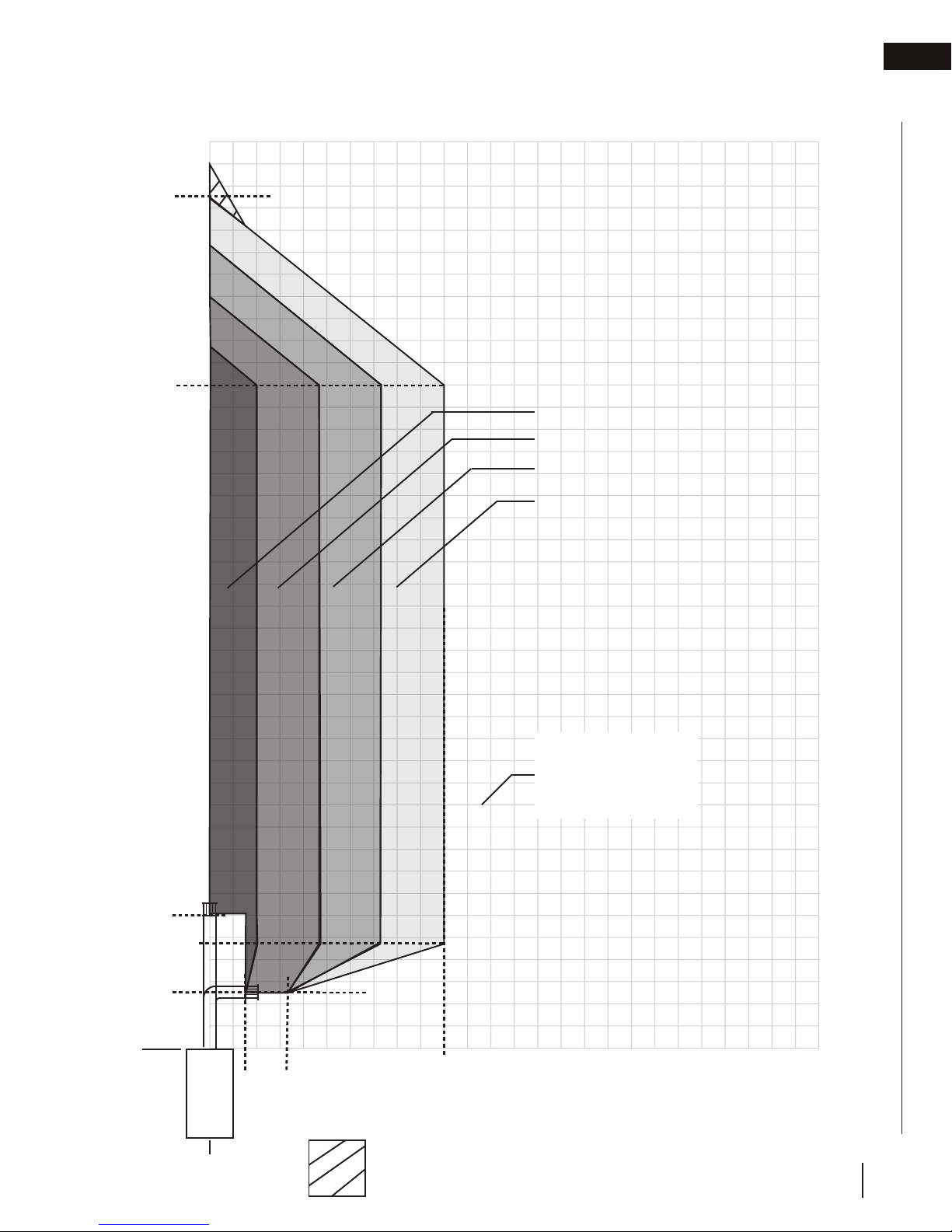

1.2 installation overview

general information

EN

Recommended installation steps:

1. Determine venting requirements before deciding the final location of the appliance

2. Plan out appliance enclosure, framing, fronts, accessories, etc.

3. Install rough framing (refer to “rough framing” section)

4. Place the appliance in its final position

5. Install nailing tabs (refer to “nailing tab installation” section)

6. Install appliance venting (refer to “venting installation” section)

7. Install vent shield (refer to “vent shield installation” section)

8. Install all electrical wirings (refer to “electrical information” section)

9. Install gas lines (refer to “gas installation” section)

10. Fit glass guard (refer to “glass guard assembly installation / removal” section)

11. Test appliance (Glass Guard must be installed while testing the appliance)

12. Remove and protect glass guard. Take great care to store using original packaging.

13. Complete framing (refer to “finish framing” section)

14. Finishing (refer to “finishing” section)

15. If necessary, do final adjustments to glass guard.

16. Complete installation checklist in the owner’s manual and apply the serial number to owner’s manual

W415-1710 / B / 08.17.18

7

EN

general information

1.3 Dynamic Heat Control™

Dynamic Heat Control™ is a system for managing the

heat produced by the appliance at and around the fireplace. The purpose of the Dynamic Heat Control™ is

to move the heat away from the fireplace to allow it to circulate more effectively within the living space. By installing the Dynamic Heat Control™ both the installer and

the user gain considerable benefits, see the following;

PATENT PENDING

Installer:

• Ability to use combustible framing and finishing right up to the fireplace opening.*

• High temperatures above the front of the fireplace opening are significantly reduced eliminating potential degrading to sensitive finish material (cracks or discoloration).

• No additional electricals, fans, ducts, or manifolds are required which keeps installation straightforward.

User:

• Heat is circulated more consistently throughout the living space increasing comfort in front of the fireplace.

• Increased “real world” efficiency as heat is moved in to the room rather than retained inside an enclosure.

• Complete flexibility in selection of finish materials.

• Ability to place a TV, sound bar or artwork above the fireplace.**

The Dynamic Heat Control™ system relies on an optimized flow of air both through the appliance and the enclosure. As such the installation of the Dynamic Heat Control™ system requires certain technical considerations

when compared to traditional fireplaces. Specifically, the Dynamic Heat Control™ requires the enclosure to be

ventilated and requires the installer to ensure that a minimum opening area is provided to allow heat to escape

and circulate at a prescribed minimum height and position. This must be carefully adhered to in the planning and

the installation to ensure the appliance functions safely and to minimize installation time.

*In most common installation configurations, some specific installations require special provisions.

See “framing with Dynamic Heat Control™ section for details. Ensure to strictly adhere to instructions.

** Always check the appliance manufacturer’s recommendations to confirm suitability and any special

environmental limitations. For valuable or antique items, always refer to expert preservation instructions as some items require specifically controlled temperature and/or humidity

8

W415-1710 / B / 08.17.18

general information

roof joist. If the appliance is installed directly on carpeting, vinyl tile or other combustible material other than wood fl ooring, the

WARNING

!

• Always light the pilot whether for the first time or if the gas supply has run out, with the glass door opened

or removed.

• Provide adequate clearance for servicing and operating the appliance.

• Provide adequate ventilation.

• Never obstruct the front opening of the appliance.

• Objects placed in front of the appliance must be kept a minimum of 48” (121.9cm) from the front face of

the appliance.

• Surfaces around and especially above the appliance can become hot. Avoid contact when appliance is

operating.

• Fire risk. Explosion hazard.

• High pressure will damage valve. Disconnect gas supply piping before pressure testing gas line at test

pressures above 1/2 PSIG. Close the manual shut-off valve before pressure testing gas line at test

pressures equal to or less than 1/2 PSIG (35mb).

• Use only Wolf Steel approved optional accessories and replacement parts with this appliance using nonlisted accessories (blowers, doors, louvres, trims, gas components, venting components, etc.) could result

in a safety hazard and will void the warranty and certification.

• The appliance must not be operated at temperatures below freezing (32ºF / 0ºC). Allow the appliance to

warm to above freezing prior to operation.

• This appliance has been designed and certified for indoor use only.

THIS GAS APPLIANCE MUST BE INSTALLED AND SERVICED BY A QUALIFIED INSTALLER to conform with local

codes. Installation practices vary from region to region and it is important to know the specifi cs that apply to your area, for

example in the state of Massachusetts:

• This product must be installed by a licensed plumber or gas fi tter when installed within the commonwealth of

Massachusetts.

• The appliance damper must be removed or welded in the open position prior to installation of an appliance insert or gas

log.

• The appliance off valve must be a “T” handle gas cock.

• The fl exible connector must not be longer than 36 inches (0.9m).

• A carbon monoxide detector is required in all rooms containing gas fi red appliances.

• The appliance is not approved for installation in a bedroom or bathroom unless the unit is a direct vent sealed

combustion product.

The installation must conform with local codes or, in absence of local

codes, the National Gas and Propane Installation Code CSA B149.1

in Canada, or the National Fuel Gas Code, ANSI Z223.1 / NFPA 54

in the United States. Suitable for mobile home installation if installed

in accordance with the current standard CAN/CSA Z240MH Series,

for gas equipped mobile homes, in Canada or ANSI Z223.1 and

NFPA 54 in the United States.

The appliance and its individual shutoff valve must be disconnected

from the gas supply piping system during any pressure testing

of that system at test pressures in excess of 1/2 psig (35 mb).

The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff valve during any

pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psig (35 mb). When installed

with a blower or fan, the junction box must be electrically connected and grounded in accordance with local codes. In the

absence of local codes, use the current CSA C22.1 Canadian Electrical Code in Canada or the ANSI / NFPA 70 National

Electric Code in the United States. In the case where the blower is equipped with a power cord, it must be connected into a

properly grounded receptacle. The grounding prong must not be removed from the cord plug.

The following does not apply to inserts; as long as the required clearance to combustibles is maintained, the most desirable

and benefi cial location for an appliance is in the center of a building, thereby allowing the most effi cient use of the heat

created. The location of windows, doors and, the traffi c fl ow in the room where the appliance is to be located should be

considered. If possible, you should choose a location where the vent will pass through the house without cutting a fl oor or

www.ncertied.org

We suggest that our gas

hearth products be installed

and serviced by professionals

who are certied in the U.S.

by the National Fireplace

®

Institute

(NFI) as NFI Gas

Specialists

EN

appliance shall be installed on a metal or wood panel extending the full width and depth, unless otherwise tested.

W415-1710 / B / 08.17.18

9

EN

NORME DE SECURITÉ ET DE CONSTRUCTION DE MAISONS MANUFACTURÉES, TITRE 24 CFR, SECTION 3280. DANS LE CAS OU CETTE NORME D'ÉTATS-UNIS NE PEUT ÊTRE APPLIQUÉE, SE RÉFÉRER A LA NORME

SAMPLE

general information

1.4 rating plate/lighting instruction location

Both the rating plate and lighting instructions are attached to a chain located on the left side of the control

area near the valve (access side). Remove the glass guard and the control cover to gain access to the

control area.

To replace, slide the instructions back into the control area and slide the glass front into its locked position.

access side

Pilot location

KEEP BURNER AND CONTROL

COMPARTMENT CLEAN. SEE

INSTALLATION MANUAL.

APPLIANCE NEEDS FRESH

AIR FOR SAFE OPERATION

AND MUST BE INSTALLED

WITH ADEQUATE PROVISIONS

FOR COMBUSTION

AND VENTILATION AIR.

GARDEZ LE BRÛLEUR ET LE

COMPARTIMENT DES

CONTRÔLES PROPRES.

CONSULTEZ LE MANUEL

D’INSTALLATION. PAR

MESURE DE SÉCURITÉ.

CET APPAREIL DOIT

ÊTRE ALIMENTÉ EN AIR

FRAIS ET AVEC SUFFISANT

D’AIR COMBURANT ET

DE VENTILATION.

Rating plate

location

WARNING:

IMPROPER INSTALLATION,

ADJUSTMENT, ALTERATION,

SERVICE OR MAINTENANCE

CAN CAUSE PROPERTY DAMAGE,

PERSONAL INJURY OR LOSS OF

LIFE. REFER TO INSTALLATION

MANUAL. INSTALLATION AND

SERVICE MUST BE PERFORMED

BY A QUALIFIED INSTALLER,

SERVICE AGENCY OR THE

GAS SUPPLIER.

ATTENTION:

UN INSTALLATION OU UNE

MODIFICATION INAPPROPRIÉE

DU RÉGLAGE, DU SERVICE ET DE

L’ENTRETIEN POURRAIENT ÊTRE

LA CAUSE DE DOMMAGES À LA

PROPRIÉTÉ DE BLESSURES

CORPORELLES OU MÊME LA

MORT. CONSULTER LE MANUEL

D’INSTALLATION. L’INSTALLATION

ET LE SERVICE DOIVENT

ÊTRE EXECUTÉS PAR UN

INSTALLATEUR QUALIFIÉ POUR

LE GAZ, UNE ENTREPRISE DE

SERVICE OU LE FOURNISSEUR

DE GAZ SEULEMENT.

CAUTION:

HOT WHILE OPERATING. DO NOT TOUCH.

KEEP CHILDREN, CLOTHING, FURNITURE,

GASOLINE OR OTHER FLAMMABLE VAPORS

AWAY.

AVERTISSEMENT:

L’APPAREIL EST CHAUD PENDANT SON

FONCTIONNEMENT. LES ENFANTS, LES

VÊTEMENTS, LES MEUBLES, L’ESSENCE ET

AUTRES LIQUIDES QUI ÉMETTENT DES GAZ

VOLATILS INFLAMMABLES DOIVENT

ÊTRE TENUS ÉLOIGNÉS DE L’APPAREIL.

“This appliance is only for use with the type(s)

of gas indicated on the rating plate and may

be installed in an aftermarket, permanently

located, manufactured home (USA only) or

mobile home, where not prohibited by local

codes. See installation manual for details. This

appliance is not convertible for use with

other gases, unless a certified kit is used.”

«Cet appareil doit être utilisé uniquement

avec les types de gaz indiqués sur la plaque

signalétique et peut être installé dans une

maison préfabriquée (É.-U. seulement) ou

mobile installée à demeure si les règlements

locaux le permettent. Voir le manuel pour

pour plus de renseignements. Cet appareil ne

peut être converti à d’autres gaz, sauf si une

trousse de conversion est utilisée. »

FOR YOUR SAFETY:

DO NOT STORE OR USE GASOLINE

OR OTHER FLAMMABLE VAPORS

AND LIQUIDS IN VICINITY OF THIS

OR ANY OTHER APPLIANCE.

CAUTION: DO NOT OPERATE

THE FIREPLACE WITH THE GLASS

REMOVED, CRACKED OR BROKEN.

REPLACEMENT OF THE GLASS

SHOULD BE DONE BY A LICENSED

OR QUALIFIED PERSON.

POUR VOTRE

SÉCURITÉ:

NE PAS ENTREPOSER NI UTILISER

D’ESSENCE NI D’AUTRES VAPEURS

OU LIQUIDES INFLAMMABLES

DANS LE VOISINAGE DE CET

APPAREIL OU DE TOUT AUTRE

APPAREIL.

AVERTISSEMENT: NE PAS

UTILISER L’APPAREIL SI LE

PANNEAU FRONTAL EN VERRE

N’EST PAS EN PLACE, EST CRAQUÉ

OU BRISÉ. CONFIEZ LE

REMPLACEMENT DU

PANNEAU À UN

TECHNICIEN

AGRÉÉ.

N'AJOUTEZ PAS A

UN COMBUSTIBLE SOLIDE NE

DOIT PAS ÊTRÉ UTILISÉ AVEC

CET APPAREIL. UTILISER AVEC

LES PORTES VITRÉES

HOMOLOGUÉES SEULEMENT

MODEL PROPANE

LHD50PT

0-4500FT (0-1370M)

30,000 BTU/H

ALTITUDE / ÉLÉVATION

INPUT / ALIMENTATION

30,000 BTU/H

0-4500FT (0-1370M)

LHD50NT

GAZ NATURAL

MODEL NATURAL GAS /

VENTED GAS FIREPLACE HEATER. APPROVED FOR BEDROOM, BATHROOM AND BED-SITTING ROOM INSTALLATION. SUITABLE FOR MOBILE HOME INSTALLATION IF INSTALLED IN ACCORDANCE WITH THE

CURRENT STANDARD CAN/CSA Z240MH SERIES GAS EQUIPPED MOBILE HOMES, IN CANADA OR IN THE UNITED STATES THE MANUFACTURED HOME CONSTRUCTION AND SAFETY STANDARD, TITLE 24 CFR,

CERTIFIED UNDER / HOMOLOGUE SELON LES NORMES: CSA 2.33b - 2008, ANSI Z21.88b- 2008 VENTED GAS FIREPLACE HEATER / APPAREIL DE CHAUFFAGE ALIMENTÉ

PART 3280. WHEN THIS US STANDARD IS NOT APPLICABLE USE THE STANDARD FOR FIRE SAFETY CRITERIA FOR MANUFACTURED HOME INSTALLATIONS, SITES AND COMMUNITIES, ANSI / NFPA 501A.

AU GAZ ET VENTILÉ

FOYER DE CHAUFFAGE AU GAZ AVEC ÉVACUATION. HOMOLOGUÉ POUR INSTALLATION DANS UNE CHAMBRE À COUCHER, UNE SALLE DE BAIN ET UN STUDIO. APPROPRIÉ POUR INSTALLATION DANS UNE

MAISON MOBILE SI SON INSTALLATION CONFORME AUX EXIGENCES DE LA NORME CAN/CSA Z240MH SÉRIE DE MAISONS MOBILES ÉQUIPÉES AU GAZ, EN VIGUEUR AU CANADA OU AUX ÉTATS-UNIS DE LA

RELATIVE AU CRITÈRE DE MESURES DE SÉCURITÉ CONTRE L'INCENDIE POUR LES INSTALLATIONS DANS LES MAISONS MANUFACTURÉS, LES SITES ET LES COMMUNAUTÉS, ANSI/NFPA 501A.

W/N 16131

REFERENCE #

DO NOT ADD ANY MATERIAL

:

NOT FOR USE WITH

SOLID FUEL. FOR USE

WITH GLASS DOORS

CERTIFIED WITH THIS

UNIT ONLY.

WARNING

CERTIFIED TO CANADIAN AND AMERICAN NATIONAL STANDARDS: CSA 2.22-2016 AND ANSI Z21.50-2016 FOR VENTED DECORATIVE GAS FIREPLACES.

CERTIFIÉ SELON LES NORMES NATIONALES CANADIENNES ET AMÉRICAINES: CSA 2.22-2016 ET ANSI Z21.50-2016 POUR LES APPAREILS À GAZ VENTILÉS DÉCORATIFS.

DIRECT VENT, VENTED GAS FIREPLACES. APPROVED FOR BEDROOM, BATHROOM AND BED-SITTING

ROOM INSTALLATION. SUITABLE FOR MOBILE HOME INSTALLATION IF INSTALLED IN ACCORDANCE

WITH THE CURRENT STANDARD CAN/CSA Z240MH SERIES GAS EQUIPPED MOBILE HOMES,

IN CANADA OR IN THE UNITED STATES THE MANUFACTURED HOME CONSTRUCTION AND

SAFETY STANDARD, TITLE 24 CFR, PART 3280. WHEN THIS US STANDARD IS NOT

APPLICABLE USE THE STANDARD FOR FIRE SAFETY CRITERIA FOR MANUFACTURED HOME

INSTALLATIONS, SITES AND COMMUNITIES, ANSI / NFPA 501A. THIS APPLIANCE MUST BE

INSTALLED IN ACCORDANCE WITH LOCAL CODES, IF ANY; IF NONE, FOLLOW THE CURRENT

ANSI Z223.1, OR CSA B149, INSTALLATION CODES.

FOLLOW THE INSTALLATION INSTRUCTIONS LOCATED IN THE INSTALLATION MANUAL.

MANIFOLD PRESSURE: 3.5 INCHES W.C. (NG)

PRESSION AU COLLECTEUR: 3.5" D'UNE

COLONNE D'EAU(GN)

9700539 (WSL) 4001657 (NGZ)

MIN SUPPLY PRESSURE: 4.5" W.C.(NG)

4001658 (NAC) 4001659 (WUSA)

PRESSION D'ALIMENTATION MIN: 4.5" D'UNE

LVX38N CLVX38N MODEL CLVX38P LVX38P

COLONNE D'EAU (GN)

MAX. SUPPLY PRESSURE: 7"* W.C. (NG)

PRESSION D'ALIMENTATION MAX: 7"* D'UNE

COLONNE D'EAU (GN)

*MAXIMUM INLET PRESSURE NOT TO EXCEED 13".

*PRESSION D'ALIMENTATION MAXIMALE NE DEVAIT PAS DÉPASSER 13".

NOT FOR USE WITH SOLID FUEL. FOR USE WITH GLASS

DOORS CERTIFIED WITH THIS APPLIANCE ONLY.

WARNING:DO NOT ADD ANY MATERIAL TO THE APPLIANCE, WHICH WILL COME IN CONTACT WITH THE FLAMES, OTHER

THAN THAT SUPPLIED BY THE MANUFACTURER WITH THE APPLIANCE.

MINIMUM CLEARANCE TO COMBUSTIBLE MATERIALS / DÉGAGEMENTS MINIMAUX DES MATÉRIAUX COMBUSTIBLES:

TOP, SIDES & BACK: PER STAND OFF SPACERS FOR FRAMING AND FINISHING MATERIALS. FOR FINISHING MATERIALS

SEE INSTALLATION MANUAL. DESSUS, CÔTÉS & ARRIÈRE: SELON LES ESPACEURS DE DÉGAGEMENT POUR LES MATÉRIAUX

D'OSSATURE SELON LA MANUEL DE PROPRIÉTAIRE POUR LES MATÉRIAUX DE FINITION.

TOP/ DESSUS 0" RECESSED DEPTH ONE SIDED/ PROFONDEUR D'ENCASTRE UNE FACE 17 15/16"

FLOOR / PLANCHER 0" RECESSED DEPTH SEE THRU/ PROFONDEUR D'ENCASTRE TRAVERS 16 3/16"

SIDES / CÔTÉS 0" BACK / ARRIÈRE 0"

VENT TOP / DESSUS DU CONDUIT D’ÉVENT 3"

VENT SIDES & BOTTOM / CÔTÉS ET DESSOUS DU CONDUIT D'ÉVENT 2"

VERTICAL VENT / CONDUIT D’ÉVENT VERTICAL 1"

MANTEL / TABLETTE 0" *

TOP, SIDES & BACK: PER STAND OFF SPACERS FOR FRAMING MATERIALS. FOR FINISHING MATERIALS

SEE INSTALLATION MANUAL. DESSUS, CÔTÉS & ARRIÈRE: SELON LES ESPACEURS DE DÉGAGEMENT POUR LES MATÉRIAUX

D'OSSATURE SELON LA MANUEL DE PROPRIÉTAIRE POUR LES MATÉRIAUX DE FINITION.

* MAXIMUM HORIZONTAL EXTENSION / L'EXTENSION HORIZONTALE MAXIMALE: 2". SEE INSTALLATION MANUAL FOR

GREATER EXTENSIONS. RÉFÉRER AU MANUEL D'INSTRUCTION POUR DES EXTENSIONS PLUS GRANDES.

SEE INSTALLATION MANUAL FOR MINIMUM AND MAXIMUM VENT LENGTHS. RÉFÉRER AU MANUEL D'INSTALLATION

DE PROPRIÉTAIRE POUR LES LONGUEURS D'ÉVACUATION MINIMALE ET MAXIMALE.

WOLF STEEL LTD.

FOR USE WITH SAFETY BARRIER W010-4186.

0-4500FT (0-1370m) ALTITUDE / ÉLÉVATION 0-4500FT (0-1370m)

32,000 BTU/h INPUT / ALIMENTATION 32,000 BTU/h

22,000 BTU/h

24 NAPOLEON ROAD, BARRIE, ON, L4M 0G8 CANADA

W385-2007

AVEC CETTE UNITÉ.

AVERTISSEMENT:

CET APPAREIL AUCUN MATÉRIAU DEVANT

ENTRER EN CONTACT AVEC LES FLAMMES

AUTRE QUE CELUI QUI EST FOURNI AVEC

CET APPAREIL PAR LE FABRICANT.

DÉGAGEMENTS MINIMAUX DES

MATÉRIAUX COMBUSTIBLES:

DESSUS 0”

PROFONDEUR D'ENCASTRÉ 25"

PLANCHER 0”

ÉVENT 2"

CÔTES 0”

MANTEAU 15" *

ARRIÉRE 0”

CLASSIFICATION: 115V 0.82AMP, 60HZ

23,000 BTU/H

#53

10" WATER COLUMN/D'UNE COLONNE D'EAU

11" WATER COLUMN/D'UNE COLONNE D'EAU

13" WATER COLUMN/ D'UNE COLONNE D'EAU

L'APPAREIL DOIT ÉVACUER SES GAZ EN UTILISANT L'ENSEMBLE

D'ÉVACUATION PROPRE A NAPOLEON. RÉFÉRER AU MANUEL

D'INSTALLATION DE PROPRIÉTAIRE POUR L'ÉVACUATION

PRÉCISE. IL EST IMPORTANT DE BIEN RÉINSTALLER ET

ORIFICE / INJECTEUR

RESCELLER L'ÉVENT APRÈS AVOIR ASSURÉ LE MAINTIEN DU

SYSTÉME DE PRISE D'AIR.

MANIFOLD PRESSURE /

DESSUS, COTÉS & ARRIÈRE: SELON LES ESPACEURS DE DÉGAGEMENT POUR LES MATÉRIAUX D'OSSATURE

SELON LE MANUEL DE PROPRIÉTAIRE POUR LES MATÉRIAUX DE FINITION.

* L'EXTENSION HORIZONTALE MAXIMALE: 2". RÉFÉRER AU MANUEL D'INSTRUCTION POUR DES EXTENSIONS

PRESSION AU COLLECTEUR

PLUS GRANDES. RÉFÉRER AU MANUEL D'INSTALLATION DE PROPRIÉTAIRE.

REDUCED INPUT / ALIMENTATION RÉDUITE

MINIMUM SUPPLY PRESSURE /

MAXIMUM SUPPLY PRESSURE /

#38

PRESSION D'ALIMENTATION MINIMALE

PRESSION D'ALIMENTATION MAXIMALE

INTAKE SYSTEM.

23,000 BTU/H

3.5" WATER COLUMN/D'UNE COLONNE D'EAU

SERIAL NUMBER/NO. DE SÉRIE: LV50

4.5" WATER COLUMN/D'UNE COLONNE D'EAU

FOR VENTING SPECIFICS. PROPER REINSTALLATION AND

7.0" WATER COLUMN/D'UNE COLONNE D'EAU

THE APPLIANCE MUST BE VENTED USING THE APPROPRIATE

NAPOLEON VENT KITS. SEE OWNERS INSTALLATION MANUAL

RESEALING IS NECESSARY AFTER SERVICING THE VENT-AIR

TO THE APPLIANCE, WHICH WILL COME

IN CONTACT WITH THE FLAMES, OTHER

THAN THAT SUPPLIED BY THE

MANUFACTURER WITH THE APPLIANCE.

MINIMUM CLEARANCE TO

COMBUSTIBLE MATERIALS:

TOP 0”

FLOOR 0”

RECESSED DEPTH ONE SIDED 23"

RECESSED DEPTH SEE THRU 13.5”

FRAMING (NOT INCLUDING

FACE MATERIAL)

ELECTRICAL RATING: 115V 0.82AMP, 60HZ

SIDES 0”

MADE IN CANADA / FABRIQUÉ AU CANADA

VENT 2"

BACK 0”

MANTLE 15" *

TOP, SIDES & BACK: PER STAND OFF SPACERS FOR FRAMING MATERIALS. FOR FINISHING MATERIALS

SEE OWNERS MANUAL

* MAXIMUM HORIZONTAL EXTENSION / L'EXTENSION

HORIZONTALE MAXIMALE: 2". SEE INSTRUCTION MANUAL FOR GREATER EXTENSIONS.

WOLF STEEL LTD. BARRIE, ONTARIO, CANADA

SEE OWNER'S INSTRUCTION MANUAL FOR MINIMUM AND MAXIMUM VENT LENGTHS.

FOYER À GAZ VENTILÉ. HOMOLOGUÉ POUR INSTALLATION DANS UNE CHAMBRE À COUCHER, UNE

SALLE DE BAIN ET UN STUDIO. APPROPRIÉ POUR INSTALLATION DANS UNE MAISON MOBILE SI

BARRIÈRE W010-4186. SUIVEZ LES INSTRUCTIONS D'INSTALLATION QUI SE TROUVENT DANS LE

REDUCED INPUT / ALIMENTATION RÉDUITE

P4

UN COMBUSTIBLE SOLIDE NE DOIT PAS ÊTRE UTILISÉ AVEC

CET APPAREIL. UTILISER AVEC LES PORTES VITRÉES

HOMOLOGUÉES SEULEMENT AVEC CETTE APPAREIL.

AVERTISSEMENT: N’AJOUTEZ PAS A CET APPAREIL AUCUN MATÉRIAU DEVANT ENTRER EN CONTACT AVEC

LES FLAMMES AUTRE QUE CELUI QUI EST FOURNI AVEC CET APPAREIL PAR LE FABRICANT.

THE APPLIANCE MUST BE VENTED USING THE APPROPRIATE NAPOLEON VENT KITS. SEE OWNER'S INSTALLATION MANUAL

FOR VENTING SPECIFICS. PROPER REINSTALLATION AND RESEALING IS NECESSARY AFTER SERVICING THE VENT-AIR

INTAKE SYSTEM.

L'APPAREIL DOIT ÉVACUER SES GAZ EN UTILISANT L'ENSEMBLE D'ÉVACUATION PROPRE À NAPOLEON. RÉFÉRER AU

MANUEL D'INSTALLATION DE PROPRIÉTAIRE POUR L'ÉVACUATION PRÉCISE. IL EST IMPORTANT DE BIEN RÉINSTALLER ET

RESCELLER L'ÉVENT APRÈS AVOIR ASSURÉ LE MAINTIEN DU SYSTÈME DE PRISE D'AIR.

ELECTRICAL RATING: 115V, 60HZ. LESS THAN 12 AMPERES

SPÉCIFICATIONS ÉLECTRIQUES: 115V, 60HZ. MOINS DE 12 AMPÈRE

DECORATIVE PRODUCT: NOT FOR USE AS A HEATING APPLIANCE

PRODUIT DÉCORATIF: NE PAS UTILISER COMME APPAREIL DE CHAUFFAGE

SERIAL NUMBER/NO. DE SÉRIE: LVX38

SON INSTALLATION CONFORME AUX EXIGENCES DE LA NORME CAN/CSA Z240MH SÉRIE DE

MAISONS MOBILES ÉQUIPÉES AU GAZ, EN VIGUEUR AU CANADA OU AUX ÉTATS-UNIS DE LA

NORME DE SÉCURITÉ ET DE CONSTRUCTION DE MAISONS MANUFACTURÉES, TITRE 24

CFR, SECTION 3280. DANS LE CAS OU CETTE NORME D'ÉTATS-UNIS NE PEUT ÊTRE

APPLIQUÉE, SE RÉFÉRER A LA NORME RELATIVE AU CRITÈRE DE MESURES DE SÉCURITÉ

CONTRE L'INCENDIE POUR LES INSTALLATIONS DANS LES MAISONS MANUFACTURÉS, LES

SITES ET LES COMMUNAUTÉS, ANSI/NFPA 501A. CODES. INSTALLER L’APPAREIL SELON LES

CODES OU RÈGLEMENTS LOCAUX, OU EN L’ABSENCE DE TELS RÈGLEMENTS, SELON LES

CODES D’INSTALLATION ANSI Z223.1 OU CSA-B149 EN VIGUER.

25,000 BTU/h

40.2%40.2%

POUR UTILISATION AVEC

MANUEL D'INSTALLATION.

MANIFOLD PRESSURE: 10 INCHES W.C.(P)

PRESSION AU COLLECTEUR: 10" D'UNE

COLONNE D'EAU (P)

MIN SUPPLY PRESSURE: 11" W.C. (P)

PRESSION D'ALIMENTATION MIN: 11" D'UNE

COLONNE D'EAU (P)

MAX. SUPPLY PRESSURE: 13" W.C. (P)

PRESSION D'ALIMENTATION MAX: 13" D'UNE

COLONNE D'EAU (P)

W385-2185

This illustration is for reference only. Refer to the rating plate on the appliance for accurate information.

note:

The rating plate must remain with the appliance at all times. It must not be removed.

10

W415-1710 / B / 08.17.18

general information

1

2

3

1.5 mobile home installation

This appliance must be installed in accordance with the manufacturer’s instructions and the Manufactured

Home Construction and Safety Standard, Title 24 CFR, Part 3280, in the United States or the Mobile Home

Standard, CAN/CSA Z240 MH Series, in Canada. This appliance is only for use with the type(s) of gas

indicated on the rating plate.

This mobile/manufactured home listed appliance comes factory equipped with a means to secure the appliance. The

shipping brackets that secure the appliance to the pallet can be used to secure the appliance to the floor for mobile

home installation. For mobile home installations, the appliance must be fastened in place.

This appliance is certified to be installed in an aftermarket permanently located, manufactured (mobile) home,

where not prohibited by local codes.

This appliance is only for use with the type of gas indicated on the rating plate. This appliance is not convertible

for use with other gases, unless a certified kit is used.

Conversion Kits

This appliance is field convertible between Natural Gas (NG) and Propane (P). Propane not available for LVX74

models.

To convert from one gas to another, consult your Authorized dealer/distributor.

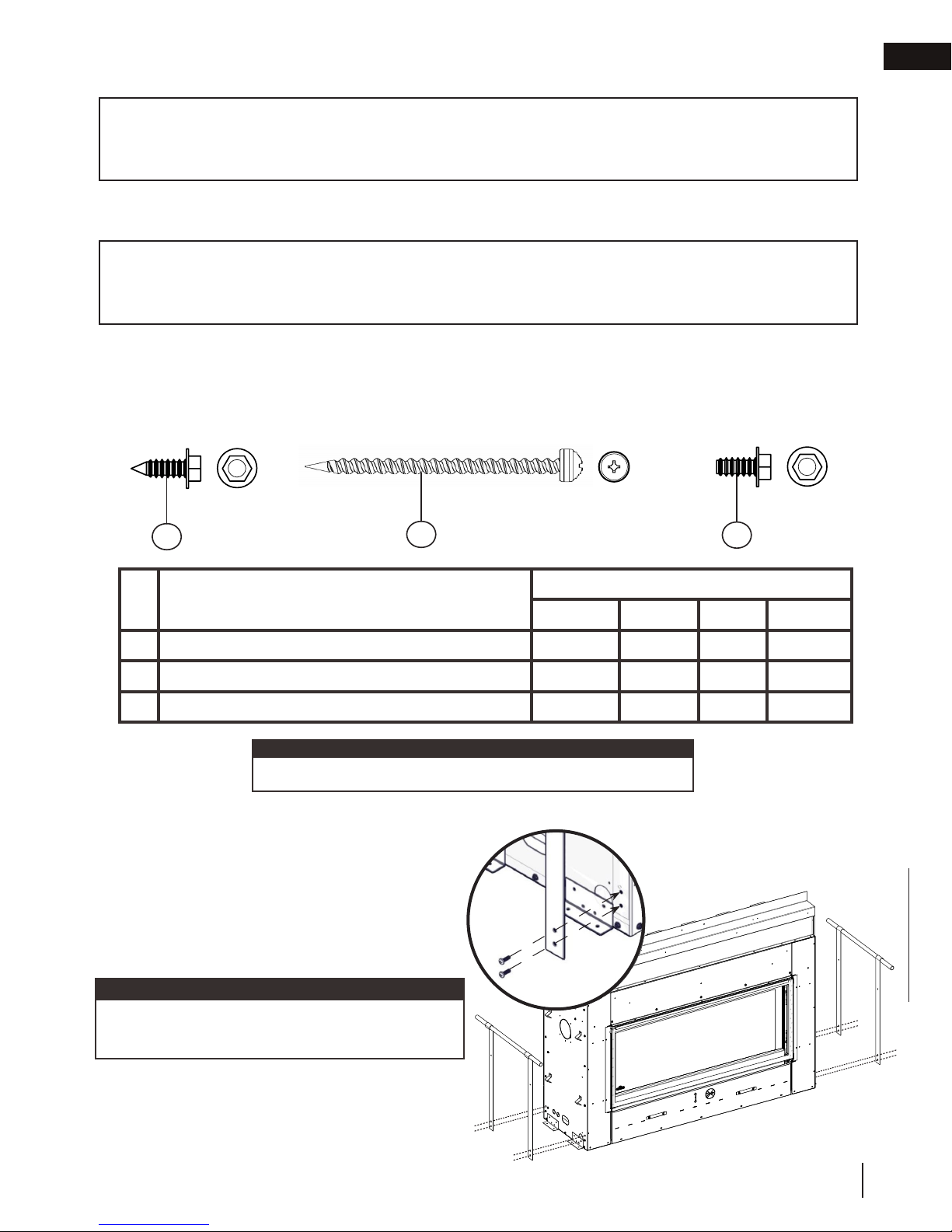

1.6 hardware list

EN

Description Quantity

Hex Head Sheet Metal Screw 22 22 22 22

1

Pan Head Sheet Metal Screw 4 4 4 4

2

Hex Head Sheet Metal Bolt 18 18 18 18

3

note:

Only fasteners supplied with the appliance are illustrated.

1.7 lifting handles installation/removal

Remove 4 screws each side (8 total) then install the

lifting handles to the side of the appliance and secure

using 4 screws each side (8 total). Once the appliance

is in place remove the four screws from each handle to

the appliance. Discard the lifting handles.

note:

The lifting handles MUST be removed prior to rough

framing the appliance.

LVX38 LVX50 LVX62 LVX74

W415-1710 / B / 08.17.18

11

EN

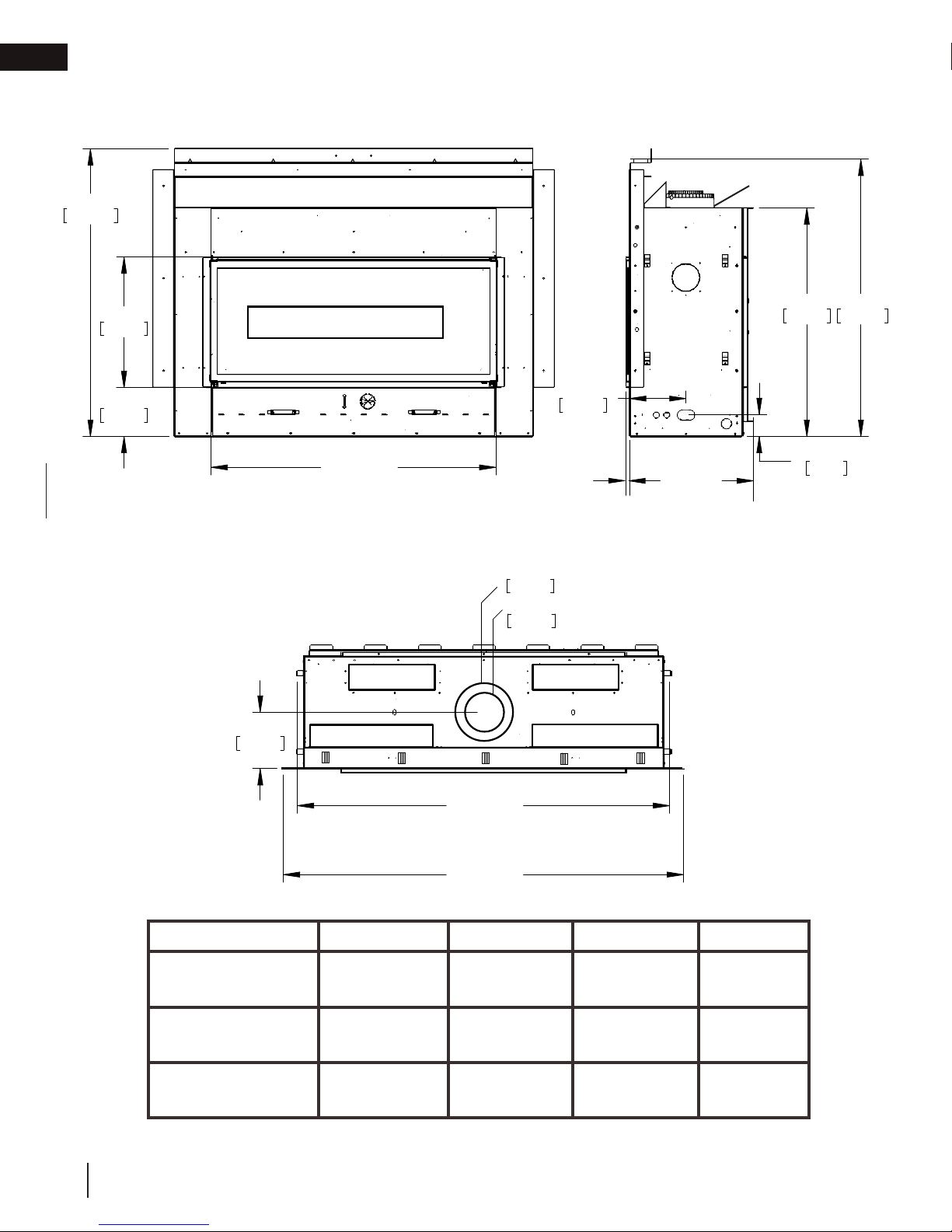

dimensions2.0 dimensions

2.1 single-sided

41 3/16"

1046mm

18 5/8"

473mm

7 1/16"

179mm

GLASS GUARD

A

8 1/16"

205mm

1/2"

[12.7mm]

Base of air collar

32 3/4"

39 11/16"

1008mm

3 1/8"

80mm

832mm

17 3/16"

*

17 11/16”

437mm

(449mm)

8 1/16"

205mm

A

(Finishing Flange)

Ø 8"

Ø 5"

127mm

203mm

B

C

LVX38 LVX50 LVX62 LVX74

42 1/8”

(1070mm)

54 1/8”

(1375mm)

66 1/8”

(1680mm)

78 1/8”

(1984mm)

B

C

*Finishing flange depth (the finishing flange defines the perimeter of the fireplace opening. Framing

or finishing materials must NEVER encroach inside the finishing flange).

12

W415-1710 / B / 08.17.18

53 5/16”

(1354mm)

57 5/16”

(1456mm)

65 5/16”

(1659mm)

69 5/16”

(1761mm)

77 5/16”

(1964mm)

81 5/16”

(2065mm)

89 5/16”

(2269mm)

93 5/16”

(2370mm)

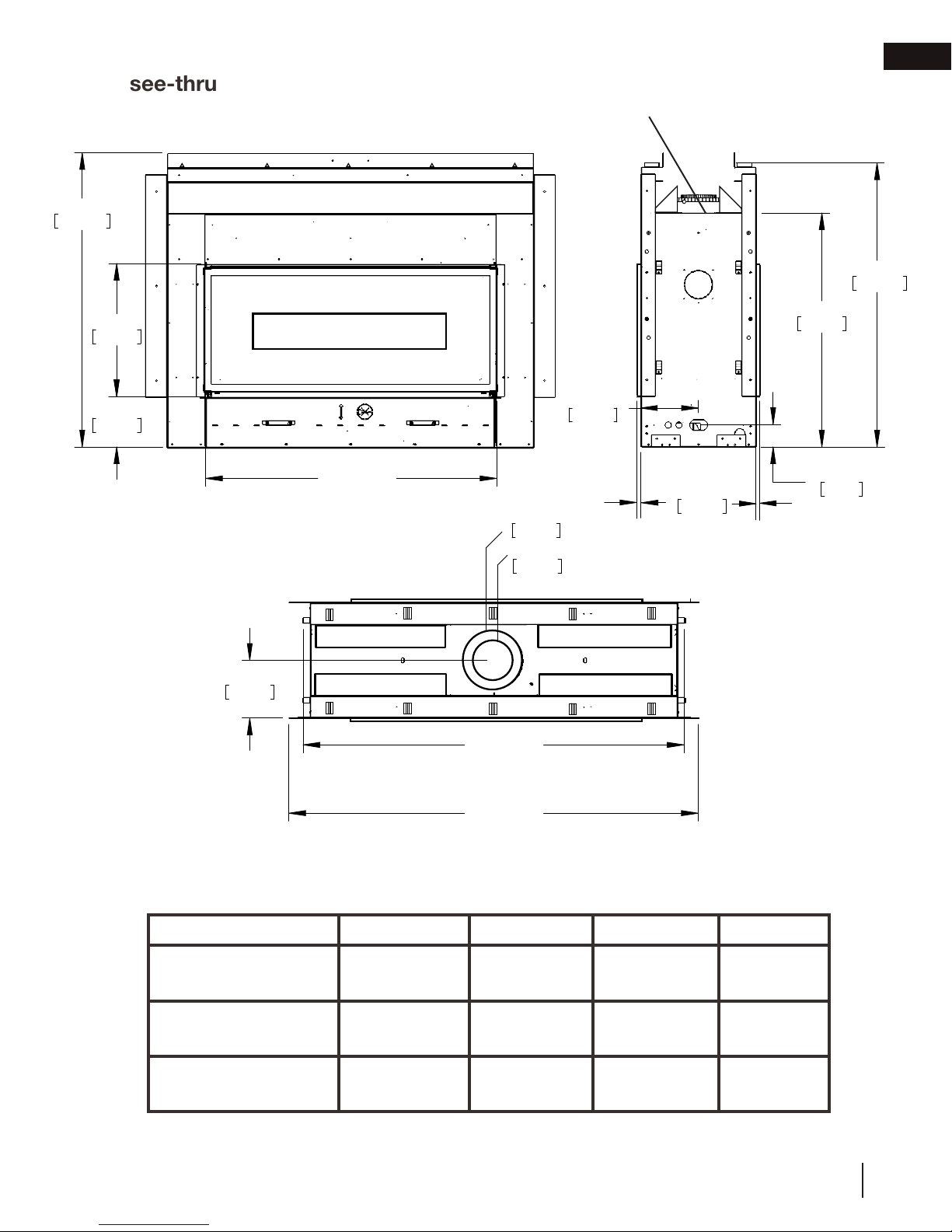

2.2 see-thru

41 3/16"

1046mm

7 1/16"

179mm

18 5/8"

473mm

3 1/8"

80mm

32 3/4"

832mm

39 11/16"

1008mm

16 3/16"

411mm

8 1/16"

205mm

8 1/16"

205mm

Ø 8"

203mm

Ø 5"

127mm

GLASS GUARD

1/2"

[12.7mm]

1/2"

[12.7mm]

A

Base of air collar

dimensions

EN

*

*

(Finishing Flange)

A

(1070mm)

B

C

54 1/8”

LVX38 LVX50 LVX62 LVX74

42 1/8”

(1375mm)

66 1/8”

(1680mm)

78 1/8”

(1984mm)

B

*Finishing flange depth (the finishing flange defines the perimeter of the fireplace opening. Framing or

finishing materials must NEVER encroach inside the finishing flange).

C

53 5/16”

(1354mm)

57 5/16”

(1456mm)

65 5/16”

(1659mm)

69 5/16”

(1761mm)

77 5/16”

(1964mm)

81 5/16”

(2065mm)

89 5/16”

(2269mm)

93 5/16”

(2370mm)

W415-1710 / B / 08.17.18

13

EN

WARNING

3.0 minimum venting requirements

minimum venting requirements

!

• Risk of fi re. Maintain specifi ed air space clearances to vent pipe and appliance.

• The vent system must be supported every 3’(0.9m) for both vertical and horizontal runs. Use support ring

assembly W010-0067 or equivalent non-combustible strapping to maintain the minimum clearance to

combustibles for both vertical and horizontal runs. Spacers are attached to the inner pipe at predetermined

intervals to maintain an even air gap to the outer pipe. This gap is required for safe operation. A spacer is

required at the start, middle, and end of each elbow to ensure this gap is maintained. These spaces must

not be removed.

This appliance uses a 5” (127mm) exhaust / 8” (203.2mm) air intake vent pipe system. Refer to the

section applicable to your installation.

For safe and proper operation of the appliance follow the venting instructions exactly. Deviation from the

minimum vertical vent length can create difficulty in burner start-up and/or carboning. Under extreme vent

configurations, allow several minutes (5-15) for the flame to stabilize after ignition. Although not a requirement,

it is recommended for vent lengths that pass through unheated spaces (attics, garages, crawl spaces) be

insulated with the insulation wrapped in a protective sleeve to minimize condensation.

Provide a means for visually checking the vent connection to the appliance after the appliance is installed.

Use a firestop, vent pipe shield or attic insulation shield when penetrating interior walls, floor or ceiling.

The vent terminal may be painted with high temperature paint to match exterior colours. Use an outdoor paint

suitable for 400°F (200°C). Application and performance of paint is the consumer’s responsibility. Spot testing is

recommended. Appliance should be off.

note:

If for any reason the vent air intake system is disassembled; reinstall per the instructions provided for the

initial installation.

This appliance must be installed with a continuous connection of exhaust and air intake vent pipes. Utilizing

alternate constructions, such as a chimney as part of the vent system, is not permitted.

All vent measurements start at the base of the air collar of the appliance.

important:

For ease of installation, the front frame can be removed. The front frame must be

reinstalled prior to installing the nailing tabs.

Horizontal vent sections: A minimum clearance of 3” (76mm) on the top outside of the enclosure and 2”

(51mm) on the sides and bottom outside of the enclosure all around the vent pipe on all horizontal runs to combustibles is required. Horizontal vent sections within enclosures require a minimum clearance of 6” (152mm) at

the top of the vent pipe.

Vertical vent sections: A minimum of 1” (25mm) all around the vent pipe on all vertical runs to combustibles is

required except for clearances in appliances enclosures. Vertical vent sections within enclosures require a minimum clearance of 1” (25mm) around the vent pipe.

14

W415-1710 / B / 08.17.18

minimum venting requirements

Use only Wolf Steel, Simpson Dura-Vent, Selkirk Direct Temp, American Metal Amerivent or Metal-Fab venting

components. Minimum and maximum vent lengths, for both horizontal and vertical installations, clearances from

vent pipes to combustibles and air terminal locations as set out in this manual apply to all vent systems and

must be adhered to. For Simpson Dura-Vent, Selkirk Direct Temp, American Metal Amerivent and Metal-Fab,

follow the installation procedure provided with the venting components. A starter adaptor must be used with the

following vent systems and may be purchased from the corresponding supplier:

EN

Vent

Manufacturer

Duravent W175-0170 Wolf Steel www.duravent.com

Amerivent 5DSC-N2 American Metal www.americanmetalproducts.com

Direct Temp 5DT-AAN Selkirk www.selkirkcorp.com

SuperSeal 5DNA Metal-Fab www.mtlfab.com

For vent systems that provide seals on the inner exhaust flue, only the outer air intake joints must be sealed using

a red high temperature silicone (RTV). This same sealant may be used on both the inner exhaust and outer

intake vent pipe joints of all other approved vent systems except for the exhaust vent pipe connection

to the appliance flue collar which must be sealed using the black high temperature sealant Mill Pac.

When using Wolf Steel venting components, use only approved Wolf Steel flexible components with the wall

terminal kit GD422R-2, or 1/12 to 7/12 pitch roof terminal kit GD410, 8/12 to 12/12 roof terminal kit GD411,

flat roof terminal kit GD412 or periscope kit GD401 (for wall penetration below grade). With flexible venting, in

conjunction with the various terminations, use either the 5 foot (1.5m) vent kit GD420 or the 10 foot (3.1m) vent

kit GD430.

For optimum flame appearance and appliance performance, keep the vent length and number of elbows to

a minimum.

Horizontal runs may have a 0” (0mm) rise per foot/meter however for optimum performance it is

recommended that all horizontal runs have a minimum 1/4” (21mm) rise per foot/meter using flexible

venting. For safe and proper operation of the appliance, follow the venting instructions exactly.

The air terminal must remain unobstructed at all times. Examine the air terminal at least once a year

to verify that it is unobstructed and undamaged.

Rigid and flexible venting systems must not be combined. Different venting manufacturer components

must not be combined.

Starter Adapter Part

Number

Supplier Website

These vent kits allow for either horizontal or vertical venting of the appliance. The maximum allowable

horizontal run is 20 feet (6.1m). The maximum allowable vertical vent length is 40 feet (12.2m). The maximum

number of vent connections is two horizontally or three vertically (excluding the appliance and the air terminal

connections) when using flexible venting.

A terminal shall not terminate directly above a sidewalk or paved driveway which is located between two single

family dwellings and serves both dwellings. Local codes or regulations may require different clearances.

Do not allow the inside liner to bunch up on horizontal or vertical runs and elbows. Keep it pulled tight. A 1¼”

(31.8mm) air gap all around between the inner liner and outer liner is required for safe operation.

This appliance is certified for use with a power vent kit. Contact your local authorized dealer for more information.

W415-1710 / B / 08.17.18

15

EN

minimum venting requirements

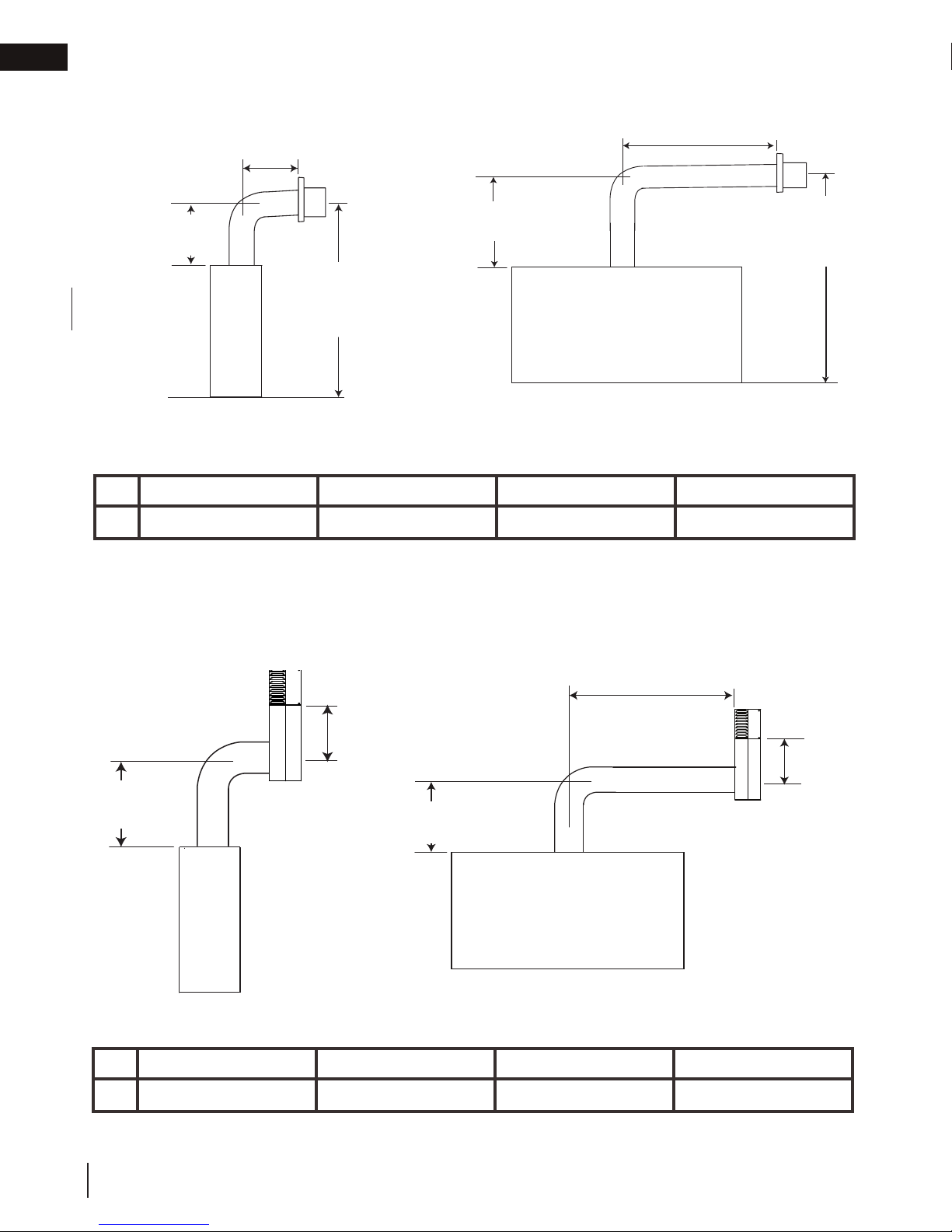

3.1 typical venting installation

18"

(45.7cm)

maximum

D

30”

(76.2cm)

minimum

base of

air collar

(NG only)

62 3/4"

(159.4cm)

minimum plus rise

LVX38 & LVX50: 30” (76.2cm) min

LVX62 & LVX74: 48” (121.9cm) min

base of

air collar

LVX38 & LVX50: 62 3/4” (76.2cm)

min plus rise

LVX62 & LVX74: 80 3/4” (205.1cm)

min plus rise

SEE-THRU

SINGLE-SIDED

LVX38 LVX50 LVX62 LVX74

D

40” (101.6cm) 46 1/2” (118.1cm) 52 1/2” (133.4cm) 58 1/2” (148.6cm)

special vent installation (periscope termination)

Use the periscope kit to locate the air termination above grade. The periscope must be installed so that when

final grading is completed, the bottom air slot is located a minimum 12” (30.5cm) above grade. The maximum

allowable vent length is 10’ (3m).

30”

(76.2cm) min.

base of air collar

SINGLE-SIDED

D

D

12"

(30.5cm)

minimum

to grade

LVX38 & LVX50: 30” (76.2cm) min

base of air collar

SEE-THRU

LVX38 LVX50 LVX62 LVX74

40” (101.6cm) 46 1/2” (118.1cm) N/A N/A

12"

(30.5cm)

minimum

to grade

16

W415-1710 / B / 08.17.18

SINGLE-SIDED OR SEE-THRU

minimum venting requirements

16" (40.6cm)

minimum

EN

note:

A 6’ (1.83m) minimum vertical rise is

considered the minimum practical dimension for the specific appliance enclosure

and a minimal building structure. However,

a greater minimum vertical rise may be

needed to suit the specific application constraints or local codes and / or regulatory

requirements.

40 ft (12m)

maximum

6 ft (1m)

minimum

base of air

collar

W415-1710 / B / 08.17.18

17

EN

Covered balcony applications ††*

minimum venting requirements

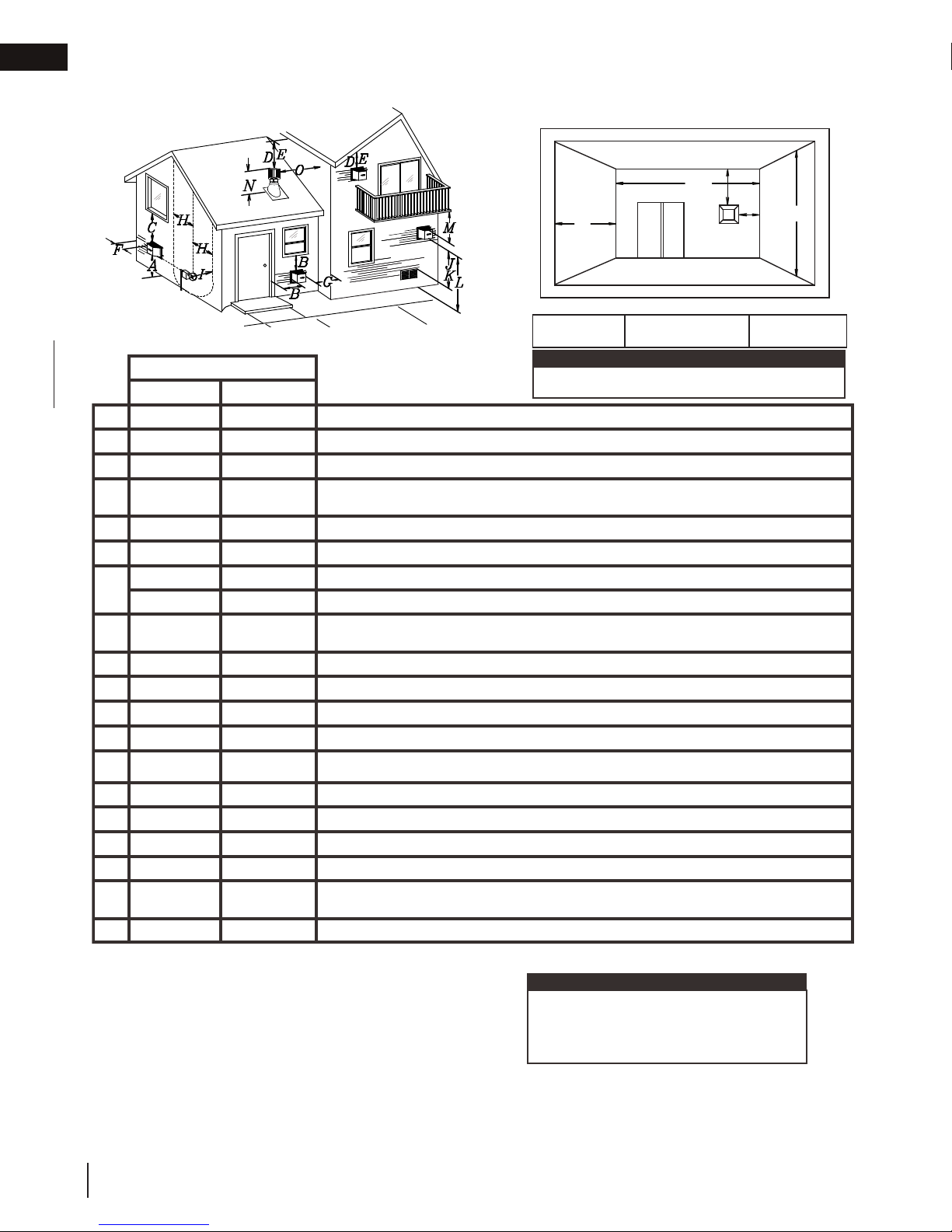

3.2 minimum air terminal location clearances

Q

S

R

Q

= 3 feet

MIN

(0.9m)

INSTALLATIONS

CANADA U.S.A.

12” (30.5cm) 12” (30.5cm) Clearance above grade, veranda porch, deck or balcony.

A

18”

Δ

9” (229mm) ΔClearance to windows or doors that open.

18”

(45.7cm)**

Vertical clearance to ventilated soffi ts located above the terminal within a horizontal distance of 2’ (0.6m)

from the center line of the terminal.

Clearance to an inside non-combustible corner wall or protruding non-combustible obstructions (chimney, etc.).

Clearance to each side of the center line extended above the meter / regulator assembly to a maximum

vertical distance of 15’ (4.6m).

12” (30.5cm)

B

12” (30.5cm)* 12” (30.5cm)* Clearance to permanently closed windows.

C

D

(45.7cm)**

12” (30.5cm)** 12” (30.5cm)** Clearance to unventilated soffi t.

E

0” (0mm) 0” (0mm) Clearance to an outside corner wall.

F

0” (0mm)*** 0” (0mm)***

G

2” (51mm)*** 2” (51mm)*** Clearance to an inside combustible corner wall or protruding combustible obstructions (vent chase, etc.).

H

J

K

L

3’(0.9m) 3’(0.9m)****

3’ (0.9m) 3’ (0.9m)**** Clearance to a service regulator vent outlet.

I

12” (30.5cm) 9” (229mm) Clearance to a non-mechanical air supply inlet to the building or a combustion air inlet to any other appliance.

6’ (1.8m) 3’ (0.9m) † Clearance to a mechanical air supply inlet.

7’ (2.1m) ‡ 7’ (2.1m) **** Clearance above a paved sidewalk or paved driveway located on public property.

note:

Wall terminals are for illustration purposes only. Size and

shapes may vary.

R

= 2 x

MAX

Q

ACTUAL

P

G

R

≤ 15 feet

MAX

(4.6m)

12” (30.5cm)†† 12” (30.5cm)**** Clearance under a veranda, porch or deck.

M

16” (40.6cm) 16” (40.6cm) Clearance above the roof.

N

2’ (0.6m)†* 2’ (0.6m) †* Clearance from an adjacent wall including neighbouring buildings.

O

8’ (2.4m) 8’ (2.4m)

P

3’ (0.9m) 3’ (0.9m) See chart for wider wall dimensions.

Q

6’ (1.8m) 6’ (1.8m)

R

12” (30.5cm) 12” (30.5cm) Clearance under a covered balcony

S

Δ The terminal shall not be located less than 6 feet under a window that opens on a horizontal plane in a structure with three walls and a roof.

* Recommended to prevent condensation on windows and thermal breakage

** It is recommended to use a heat shield and to maximize the distance to vinyl clad soffi ts.

*** The periscope requires a minimum 18 inches clearance from an inside corner.

**** This is a recommended distance. For additional requirements, check local codes.

† 3 feet above if within 10 feet horizontally.

‡ A vent shall not terminate where it may cause hazardous frost or ice accumulations on adjacent property surfaces.

†† Permitted only if the veranda, porch, or deck is fully open on a minimum of two sides beneath the fl oor.

†* Recommended to prevent recirculation of exhaust products. For additional requirements, check local codes.

††* Permitted only if the balcony is fully open on a minimum of one side.

18

W415-1710 / B / 08.17.18

Roof must be non-combustible without openings.

See chart for deeper wall dimensions. The terminal shall not be installed on any wall that has an opening

between the terminal and the open side of the structure.

note:

Clearances are to be in accordance with local

installation codes and the requirements of the gas

supplier. In their absence, clearances are to be as

listed above and are based on national codes.

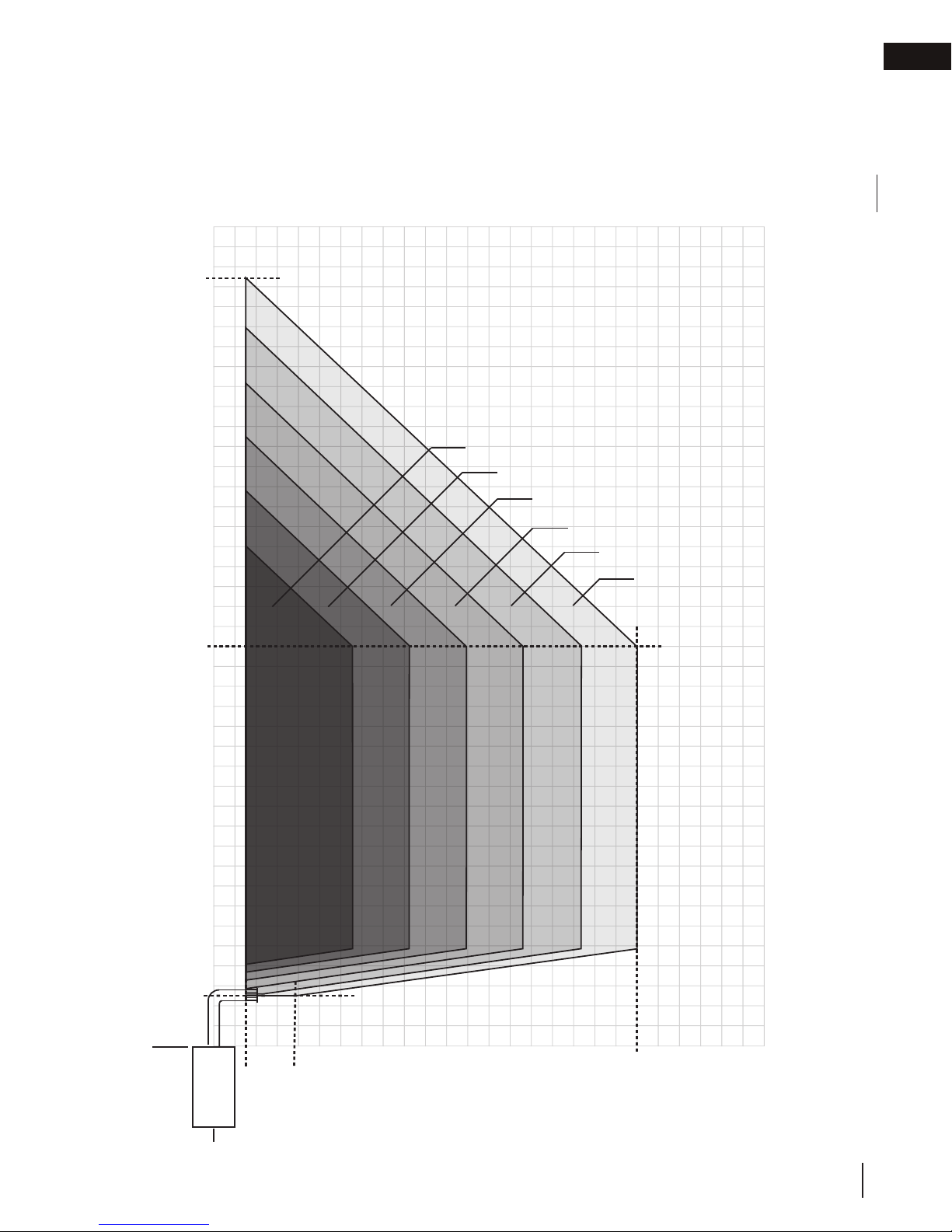

minimum venting requirements - natural gas

3.3 horizontal termination

LVX38 / LVX50 / LVX62 / LVX74 SINGLE-SIDED &

LVX38 / LVX50 SEE-THRU

(NATURAL GAS ONLY)

EN

38 1/2’

(462”)

V

40’

30’

20’

V+H ≤ 40 ft. (For longer vent runs, a power

vent is required).

H ≤ 20 ft.

V + H are measured from the centre of vent

elbows. Elbows are considered as 90º.

Two 45º elbows = One 90º elbow.

1-6 elbow zone

1-5 elbow zone

1-4 elbow zone

1-3 elbow zone

1-2 elbow zone

1 elbow zone

2 1/2’

(30”)

0’

Base of

air collar

15’

10’

5’

5’

3 7/8’

1 1/2’

(46 1/2”)

(18”)

0’

10’

H

15’

20’

25’

W415-1710 / B / 08.17.18

19

EN

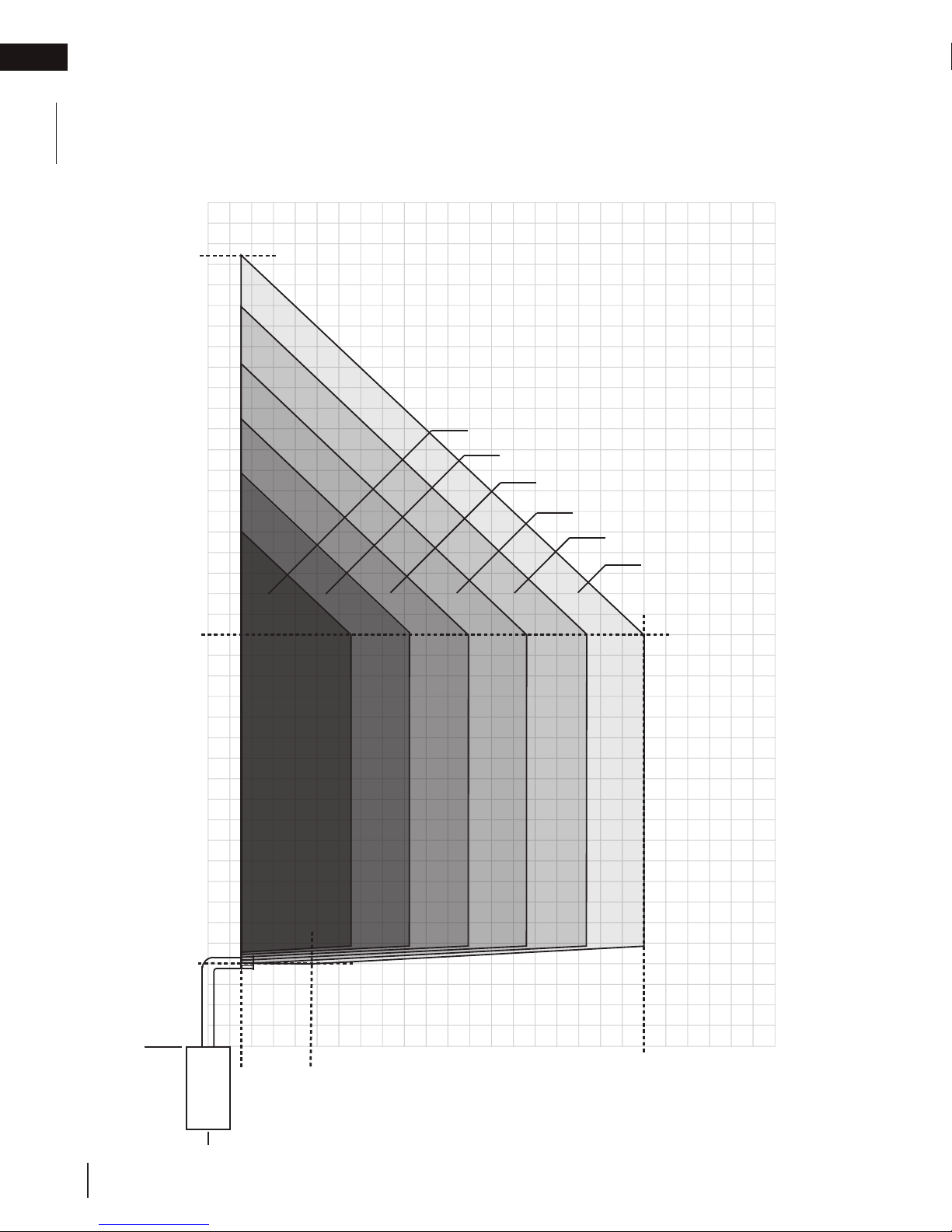

minimum venting requirements - natural gas

LVX62/ LVX74 SEE-THRU

(NATURAL GAS ONLY)

38 1/2’

(462”)

V

40’

30’

20’

V+H ≤ 40 ft. (For longer vent runs, a power

vent is required).

H ≤ 20 ft.

V + H are measured from the centre of vent

elbows. Elbows are considered as 90º.

Two 45º elbows = One 90º elbow.

1-6 elbow zone

1-5 elbow zone

1-4 elbow zone

1-3 elbow zone

1-2 elbow zone

1 elbow zone

20

15’

10’

5’

4’

(48”)

0’

Base of

air collar

0’

W415-1710 / B / 08.17.18

1 1/2’

(18”)

5’

4 7/8’

(58 1/2”)

10’

H

15’

20’

25’

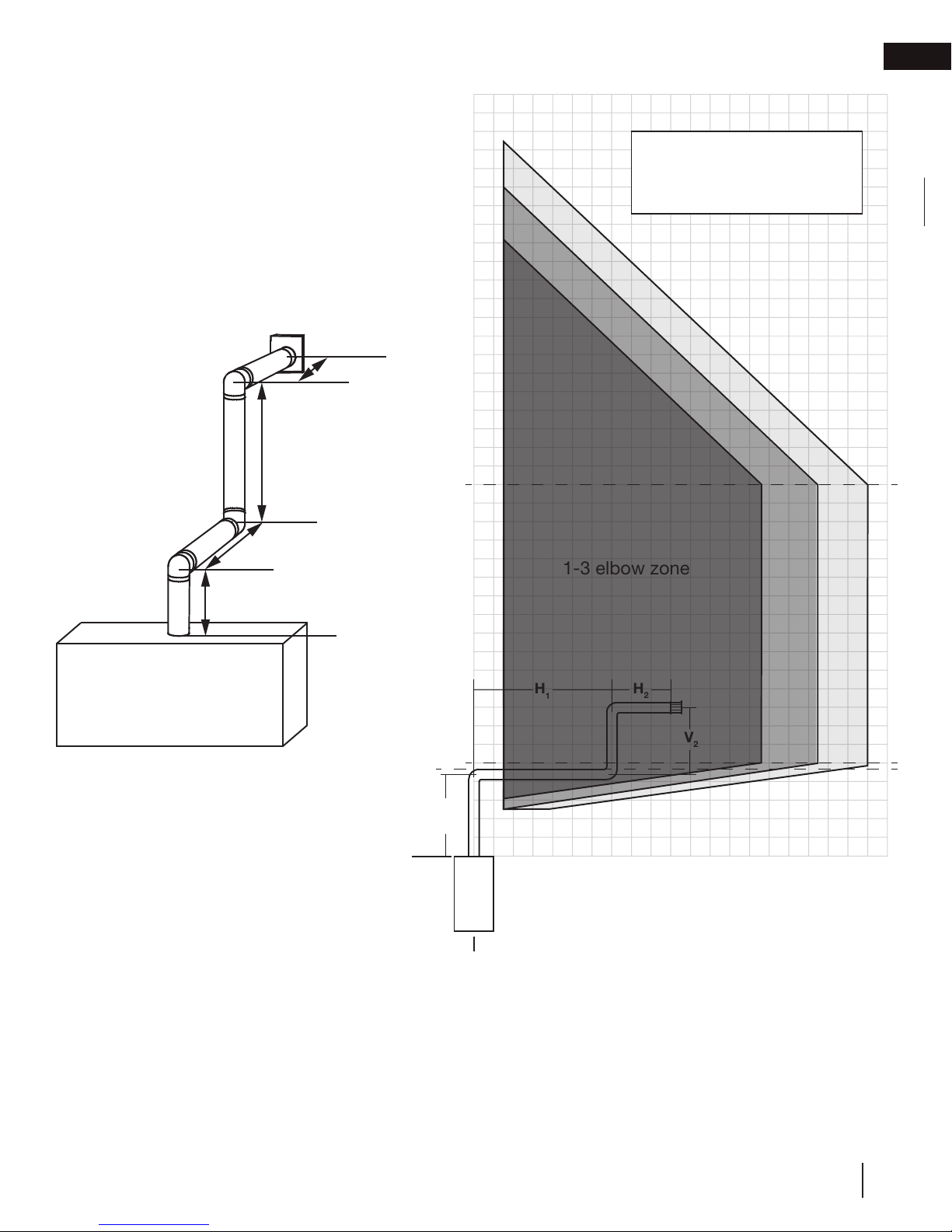

minimum venting requirements - natural gas

40’

EN

(NATURAL GAS ONLY)

H

90°

90°

V

2

H

1

V

1

2

Base of

air collar

V

20’

30’

15’

V = V1 + V2 = 8 ft

H

= H1 + H2

1-3 elbow zone

= 10 ft

10’

H

2

V

2

10’

15’

H

4 3/4”

(57”)

0’

Base of

air collar

H

1

5’

V

1

5’

0’

V and H are measured from the center of the vent elbows

This example represents a vent that has a maximum of three 90º elbows, a combined horizontal vent length (H ) of

Since the vent is located in the dark shaded area, it is within the acceptable vent configuration

10 feet and a combined vertical vent length (V ) of 8 feet.

20’

W415-1710 / B / 08.17.18

21

EN

minimum venting requirements - natural gas

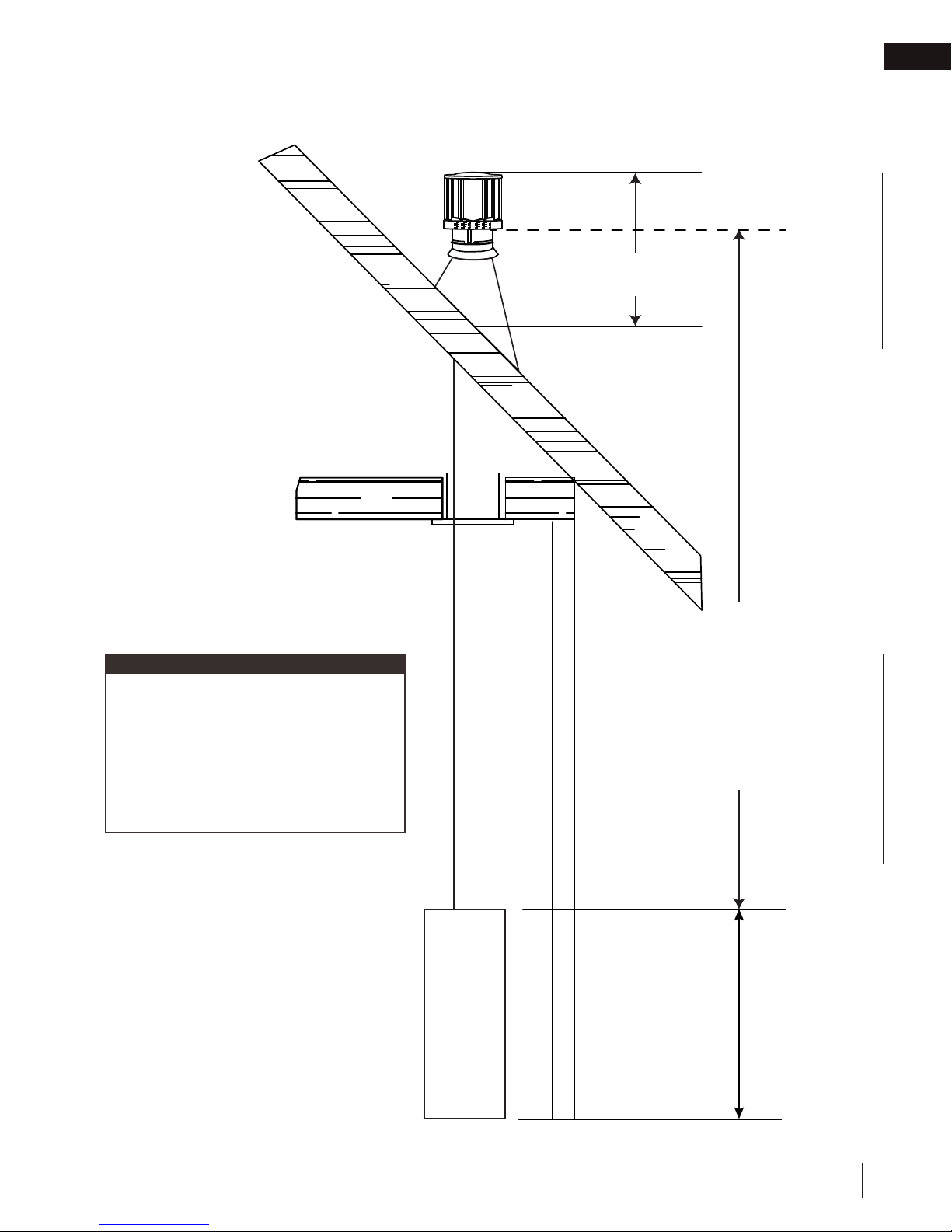

3.4 vertical termination

ALL APPLIANCES

(NATURAL GAS ONLY)

40’

30’

20’

0 elbow zone

V+H ≤ 40 ft. (For longer vent runs,

a power vent is required).

H ≤ 20 ft.

V + H are measured from the

centre of vent elbows. Elbows are

considered as 90º.

Two 45º elbows = One 90º elbow.

2-7 elbow zone

2-6 elbow zone

2-5 elbow zone

2-4 elbow zone

2-3 elbow zone

2 elbow zone

22

15’

10’

6’

5’

0’

Base of

air collar

W415-1710 / B / 08.17.18

5’

note:

A 6’ (1.83m) minimum vertical rise is considered the minimum practical dimension for

the specific appliance enclosure and a minimal building structure. However, a greater

0’

minimum vertical rise may be needed to suit the specific application constraints or

local codes and / or regulatory requirements.

10’

15’

20’

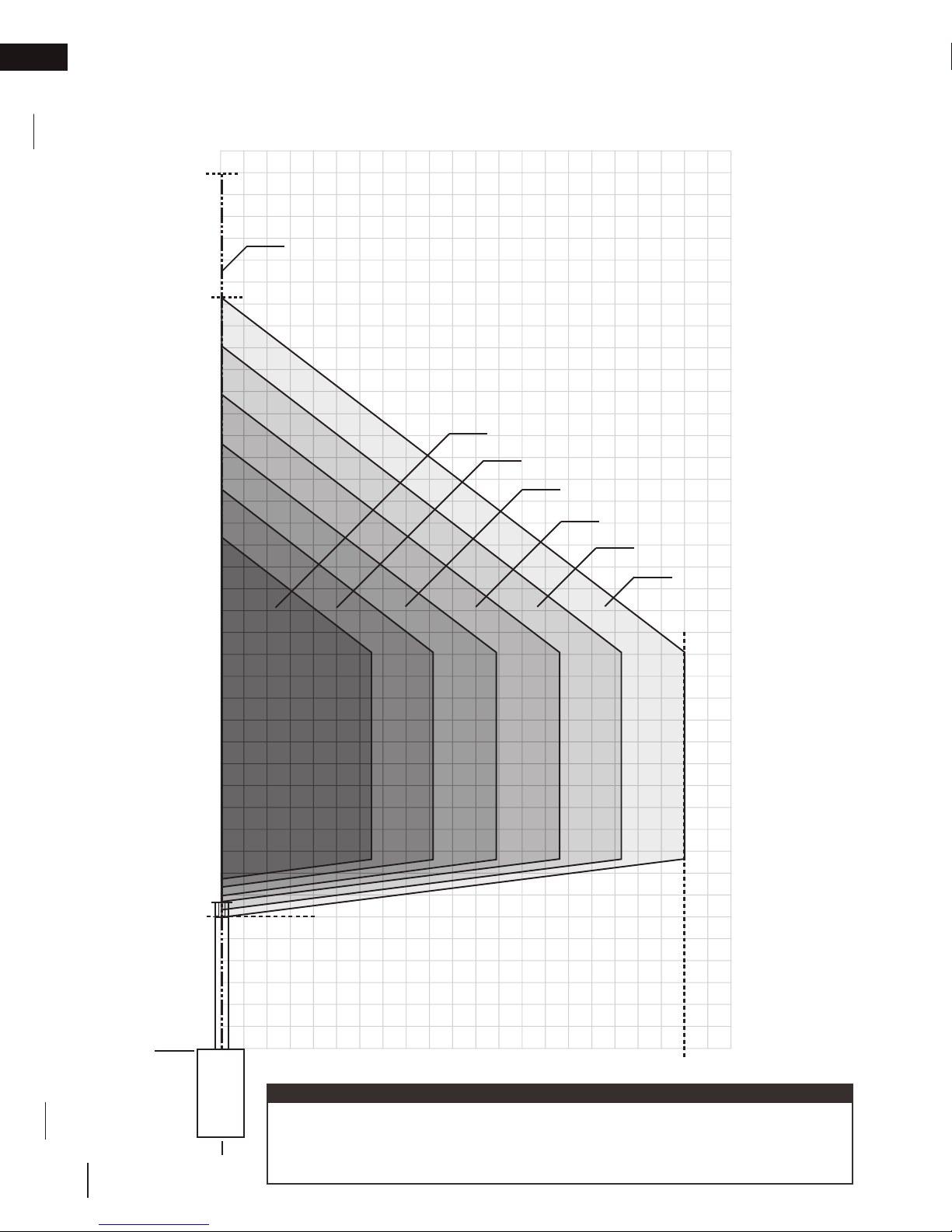

minimum venting requirements - propane

3.5 LVX38 venting configurations

(PROPANE ONLY)

EN

38 1/2’

(462”)

30’

V

40’

V+H ≤ 40 ft. H ≤ 10 ft.

(For longer vent runs, a power vent is

required).

V + H are measured from the centre of vent

elbows. Elbows are considered as 90º.

Two 45º elbows = One 90º elbow.

For 0 elbow configurations, V is a minimum

of 6’ to a maximum of 40’.

1-4 elbow zone

1-3 elbow zone

1-2 elbow zone

1 elbow zone

20’

6’

(72”)

4 3/4’

(57”)

2 1/2’

(30”)

0’

Base of

air collar

5’

15’

10’

Refer to appliance

specific GPV/PVA

instructions for other

venting configurations.

1 1/2’

(18”)

5’

3 1/4’

(40”)

10’

H

15’

20’

25’

Vertical termination only.

0’

No horizontal termination allowed.

W415-1710 / B / 08.17.18

23

Loading...

Loading...