Napoleon GVFS20P, GVFS20N Installation And Operating Instructions Manual

INSTALLER: LEAVE THIS MANUAL WITH THE APPLIANCE.

CONSUMER: RETAIN THIS MANUAL FOR FUTURE REFERENCE.

INSTALLATION AND

OPERATING INSTRUCTIONS

CERTIFIED UNDER CANADIAN AND AMERICAN NATIONAL STANDARDS: ANSI Z21.11.2B, VOLUME II FOR UNVENTED ROOM HEATERS.

GVFS20P

PROPANE

GVFS20N

NATURAL GAS

UNVENTED MILLIVOLT

1

SYSTEM

CERTIFIED FOR THE UNITED STATES USING ANSI METHODS.

SAFETY INFORMATION

!

WARNING

If the information in these instructions are

not followed exactly, a fi re or explosion

may result causing property damage,

personal injury or loss of life.

- Do not store or use gasoline or other fl ammable

vapors and liquids in the vicinity of this or any

other appliance.

- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbour’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

fi re department.

- Installation and service must be performed by a

qualifi ed installer, service agency or the supplier.

- This is an unvented gas-fi red heater that

uses air (oxygen) from the room in which it is

installed. Provisions for adequate combustion and

ventilation air must be provided.

Wolf Steel Ltd., 24 Napoleon Rd., Barrie, ON, L4M 4Y8 Canada /

103 Miller Drive, Crittenden, Kentucky, USA, 41030

Phone (705)721-1212 • Fax (705)722-6031 • www.napoleonfi replaces.com • ask@napoleonproducts.com

10.00$

1.23

W415-0559 / C / 10.04.10

2

TABLE OF CONTENTS

1.0 INSTALLATION OVERVIEW 3

2.0 INTRODUCTION 4

3.0 INSTALLATION 8

4.0 FINISHING 12

5.0 OPTIONAL BLOWER INSTALLATION 14

6.0 OPERATION 15

7.0 ADJUSTMENT 16

8.0 MAINTENANCE 17

9.0 REPLACEMENTS 19

10.0 TROUBLE SHOOTING 21

11.0 WARRANTY 24

12.0 SERVICE HISTORY 25

2.1 DIMENSIONS 5

2.2 GENERAL INSTRUCTIONS 5

2.3 GENERAL INFORMATION 6

2.4 RATING PLATE INFORMATION 7

3.1 COMBUSTION AND VENTILATION AIR PROVISIONS 8

3.2 DETERMINING CONFINED OR UNCONFINED SPACE 9

3.3 GAS INSTALLATION 10

3.4 OPTIONAL WALL SWITCH / THERMOSTAT 11

3.5 MOBILE HOME INSTALLATION 11

4.1 CAST FRONT INSTALLATION AND REMOVAL 12

4.2 SCREEN INSTALLATION AND REMOVAL 12

4.3 LOGO PLACEMENT 12

4.4 LOG PLACEMENT 13

5.1 BLOWER INSTALLATION AND CONNECTION 14

5.2 SWITCH CONNECTIONS 14

7.1 VENTURI ADJUSTMENT 16

7.2 FLAME CHARACTERISTICS 16

8.1 OXYGEN DEPLETION SENSOR PILOT CLEANING 17

8.3 PILOT INDICATOR LIGHT BATTERY REPLACEMENT 18

8.2 ORIFICE REPLACEMENT 18

NOTE: Changes, other than editorial, are denoted by a vertical line in the margin.

W415-0559 / C / 10.04.10

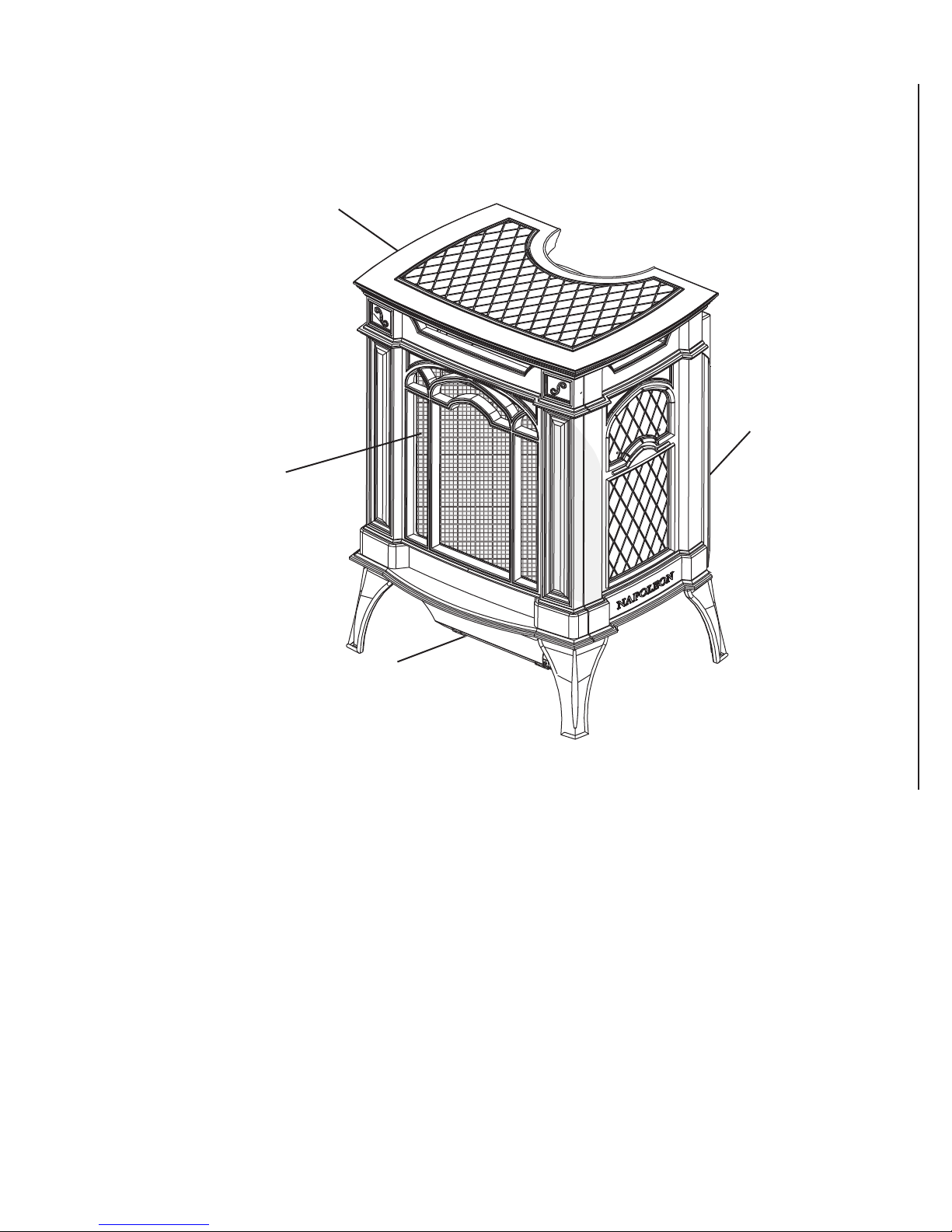

1.0 INSTALLATION OVERVIEW

Cast top, see “FINISHING - CAST

FRONT INSTALLATION AND

REMOVAL” section.

Door, see “FINISHING

- SCREEN

INST ALLA TION AND

REMOVAL” section.

3

Blower, see “OPTIONAL

BLOWER

INSTALLATION” section.

Rating Plate, see

“RATING PLATE

INFORMATION”

section.

W415-0559 / C / 10.04.10

4

2.0 INTRODUCTION

• THIS APPLIANCE IS HOT WHEN OPERATED AND CAN CAUSE SEVERE BURNS IF CONTACTED.

• ANY CHANGES TO THIS APPLIANCE OR ITS CONTROLS CAN BE DANGEROUS AND IS PROHIBITED.

• Under no circumstances should this appliance be modifi ed.

• Do not operate appliance before reading and understanding operating instructions. Failure to operate

appliance according to operating instructions could cause fi re or injury.

• Risk of burns. The appliance should be turned off and cooled before servicing.

• Do not install damaged, incomplete or substitute components.

• Risk of cuts and abrasions. Wear protective gloves and safety glasses during installation. Sheet metal edges

may be sharp.

• Provide adequate ventilation and combustion air. Provide adequate accessibility clearance for servicing and

operating the appliance. Never obstruct the front opening of the appliance.

• If the appliance shuts off, do not re-light until you provide fresh air. If appliance keeps shutting off, have it

serviced. Keep burner and control compartment clean.

• Do not burn wood or other materials in this appliance.

• Children and adults should be alerted to the hazards of high surface temperature and should stay away to

avoid burns or clothing ignition.

• Young children should be carefully supervised when they are in the same room as the appliance. Toddlers,

young children and others may be susceptible to accidental contact burns. A physical barrier is recommended

if there are at risk individuals in the house. To restrict access to an appliance, install an adjustable safety gate

to keep toddlers, young children and other at risk individuals out of the room and away from hot surfaces.

• Due to high temperatures, the appliance should be located out of traffi c and away from furniture and

draperies.

• Ensure you have incorporated adequate safety measures to protect infants/toddlers from touching hot

surfaces.

• Clothing or other fl ammable material should not be placed on or near the appliance.

• Check with your local hearth specialty dealer for safety screens and hearth guards to protect children from

hot surfaces. These screens and guards must be fastened to the fl oor.

• Any safety screen or guard removed for servicing must be replaced prior to operating the appliance.

• It is imperative that the control compartments, burners and circulating blower and its passageway in the

appliance are kept clean. The appliance should be inspected before use and at least annually by a qualifi ed

service person. More frequent cleaning may be required due to excessive lint from carpeting, bedding

material, etc. The appliance area must be kept clear and free from combustible materials, gasoline and other

fl ammable vapours and liquids.

• Furniture or other objects must be kept a minimum of 4 feet away from the front of the appliance.

• Do not use this appliance if any part has been under water. Immediately call a qualifi ed service technician

to inspect the appliance and to replace any part of the control system and any gas control which has been

under water.

• Do not allow fans to blow directly into the appliance. Avoid any drafts that alter burner fl ame patterns.

• Do not use a blower insert, heat exchanger insert or other accessory not approved for use with this appliance.

• Carbon or soot should not occur in a vent free appliance as it can distribute into the living area of your home.

If you notice any signs of carbon or soot, immediately turn off your appliance and arrange to have it serviced

by a qualifi ed technician before operating it again.

• Keep the packaging material out of reach of children and dispose of the material in a safe manner. As with all

plastic bags, these are not toys and should be kept away from children and infants.

• As with any combustion appliance, we recommend having your appliance regularly inspected and serviced as

well as having a Carbon Monoxide Detector installed in the same area to defend you and your family against

Carbon Monoxide.

• The appliance screen must be in place when the appliance is operating.

• Ensure clearances to combustibles are maintained when building a mantel or shelves above the appliance.

Elevated temperatures on the wall or in the air above the appliance can cause melting, discolouration or

damage to decorations, a T.V. or other electronic components.

!

WARNING

3.4B

W415-0559 / C / 10.04.10

2.1 DIMENSIONS

19 1/4"

9

5

/8"

25 3/8"

15 3/4"

2.2 GENERAL INSTRUCTIONS

* CARBON MONOXIDE POISONING MAY LEAD TO DEATH

EARLY SIGNS OF CARBON MONOXIDE POISONING RESEMBLE THE FLU, WITH HEADACHE,

DIZZINESS AND/OR NAUSEA. IF YOU HAVE THESE SIGNS, THE HEATER MAY NOT BE WORKING

PROPERLY. GET FRESH AIR AT ONCE! HAVE HEATER SERVICED.

SOME PEOPLE---PREGNANT WOMEN, PERSONS WITH HEART OR LUNG DISEASE, ANEMIA,

THOSE UNDER THE INFLUENCE OF ALCOHOL, THOSE AT HIGH ALTITUDES--- ARE MORE

AFFECTED BY CARBON MONOXIDE THAN OTHERS.

!

WARNING

5

THE APPLIANCE IS ONLY FOR USE WITH THE TYPE OF GAS INDICATED ON THE RATING PLATE.

THIS APPLIANCE IS NOT CONVERTIBLE FOR USE WITH OTHER GASES.

OBJECTS PLACED IN FRONT OF THE HEATER SHOULD BE KEPT A MINIMUM OF 48” AWAY FROM

THE FRONT FACE OF THE APPLIANCE.

USE ONLY WOLF STEEL APPROVED OPTIONAL ACCESSORIES AND REPLACEMENT PARTS WITH

THIS APPLIANCE. USING NON-LISTED ACCESSORIES AND REPLACEMENT PARTS (BLOWERS,

LOUVRES, TRIMS, GAS COMPONENTS, VENT COMPONENTS, ETC.) COULD RESULT IN A SAFETY

HAZARD AND WILL VOID THE LIMITED LIFETIME WARRANTY.

NOT DESIGNED FOR USE WITH A GLASS DOOR. SCREEN MUST BE CLOSED WHEN APPLIANCE IS

IN OPERATION.

THIS APPLIANCE MUST NOT BE INSTALLED IN A BEDROOM OR BATHROOM.

This gas appliance should be installed and serviced by a qualifi ed installer to conform with local codes.

Installation practices vary from region to region and it is important to know the specifi cs that apply to your

area, for example: in Massachusetts State:

• The appliance off valve must be a “T” handle gas cock.

• The fl exible connector must not be longer than 36“.

• The appliance is not approved for installation in a bedroom or bathroom unless the appliance is a direct

vent sealed combustion product.

• A carbon monoxide detector is required in all rooms containing gas fi red appliances.

• WARNING: This product must be installed by a licensed plumber or gas fi tter when installed within the

commonwealth of Massachusetts.

• Un-vented room appliance shall be installed in accordance with 527 CMR 30.00 and 248 CMR 3.00

through 7.00.

• Sellers of un-vented propane or natural gas-fi red space / room appliances shall provide to each purchaser

a copy of 527 CMR 30.00 upon the sale of the appliance from http://www.napoleonfi replaces.com/

Webshare/installation_manuals/mass_requirements.pdf

W415-0559 / C / 10.04.10

6

In absence of local codes, install the appliance to the current National Fuel Gas Code, ANSI Z223.1

Installation Code which can be obtained from:

American National Standards Institute Inc. or National Fire Protection Association Inc.

1430 Broadway Batterymarch Park

New York, NY 10018 Quincy, MA 02269

The appliance and its individual shutoff valve must be disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in excess of 1/2 psig (3.5 kPa). The appliance must be

isolated from the gas supply piping system by closing its individual manual shutoff valve during any pressure

testing of the gas supply piping system at test pressures equal to or less than 1/2 psig (3.5 kPa). When

installed with a blower the junction box must be electrically connected and grounded in accordance with local

codes. In the absence of local codes, use the current ANSI / NFPA 70 National Electric Code. In the case

where the blower is equipped with a power cord it must be connected into a properly grounded receptacle.

The grounding prong must not be removed from the cord plug.

We suggest that our gas

As long as the required clearance to combustibles is maintained,

the most desirable and benefi cial location for the appliance is in the

center of a building, thereby allowing the most effi cient use of the

heat created. The location of windows, doors and the traffi c fl ow in

the room where the appliance is to be located should be considered.

www.ncertied.org

hearth products be installed

and serviced by professionals

who are certied in the U.S.

by the National Fireplace

®

Institute

Specialists

(NFI) as NFI Gas

If the appliance is installed directly on carpeting, vinyl tile or other

combustible material other than wood fl ooring, the appliance shall be installed on a metal or wood panel

extending the full width and depth. NOTE: This does not apply to stoves.

* Air shortage caused by an inadequate air supply, improper log positions, the addition of foreign or

unapproved materials or the failure to properly maintain the appliance, may result in incomplete combustion of

the fuel. Incomplete combustion results in soot being deposited inside the fi rebox as well as surfaces outside

the appliance. If any soot deposits are observed, shut off the appliance immediately and arrange for it to be

serviced by a qualifi ed technician.

2.3 GENERAL INFORMATION

FOR YOUR SA TISFACTION, THIS APPLIANCE HAS BEEN TEST-FIRED TO ASSURE ITS OPERATION AND

QUALITY!

Altitude (FT) 0-2,000 0-2,000

Max. Input (BTU/HR) 23,000 23,000

Min. Inlet Gas Supply Pressure 4.5" Water Column 11" Water Column

Max. Inlet Gas Supply Pressure 7" Water Column 13" Water Column

Manifold Pressure (Under Flow Conditions) 3.5" Water Column 10" Water Column

When the appliance is installed at elevations above 2,000ft, and in the absence of specifi c recommendations from

the local authority having jurisdiction, the certifi ed high altitude input rating shall be reduced at the rate of 4% for each

additional 1,000ft. Expansion / contraction noises during heating up and cooling down cycles are normal and to be

expected.

4.2C

GVFS20

NG LP

No external electricity (1 10 volts or 24volts) is required for the gas system operation.

This appliance is equipped with a pilot light safety system referred to as an oxygen depletion sensor and is designed to

turn off the appliance if not enough fresh air is available.

W415-0559 / C / 10.04.10

2.4 RATING PLATE INFORMATION

OF THIS OF THIS

RNING:RNIN

DO NOT ADD ANY MATERIAADD ANY MATERIA

WILL COME IN CONTACT WILL COME IN CONTAC

THAT SUPPLIED BY THE MANTHAT SUPPLIED BY THE MA

SCREEN MUST BE IN PLACEEEN MUST BE IN PLAC

00

mm

))

BTUBTU

//hh0000

TBT

UU

//

hh

WWATERER

COLUMCOLUM

NN111WWAATETE

RR

CCOOLUM

N

RESSUREESSURE

::

3"13"

WATT

ERER

CCOOLUMLUM

820.63366ILOT ILOT

O

COXYPROTEC

TT

OROR::# 8#

4366

YYHHAAVVII

NN

GGJJURURISIS

D

I

CC

TIOTIO

FUEL

..

PP

TARIO L4M 4Y8 CANADA

RIO L4M 4Y8 CANAD

CONFORMS TO: ANSI Z21.11.2a-2008, UNVENTED GAS FIRED ROOM HEATER

THIS IS A GAS-FIRED UNVENTED

ROO M HEATER THAT REQUIRES

ADEQUATE COMBUSTION

AND VENTILATION AIR.

THIS APPLIANCE IS NOT FIELD

CONVERTIBLE FOR USE WITH

MODEL GVFS20-N

**0-2000FT (0-610m)

23,000 BTU/h

18,000BTU/h

MANIFOLD PRESSURE: 3.5" WATER COLUMN

MINIMUM SUPPLY PRESSURE: 4.5" WATER COLUMN

MAXIMUM SUPPLY PRESSURE: 7.0" WATER COLUMN

OPERATING PILOT OXYPROTECTOR: # 8214

**ABOVE 2,000FT, CONSULT LOCAL AUTHORITY HAVING JURISDICTION

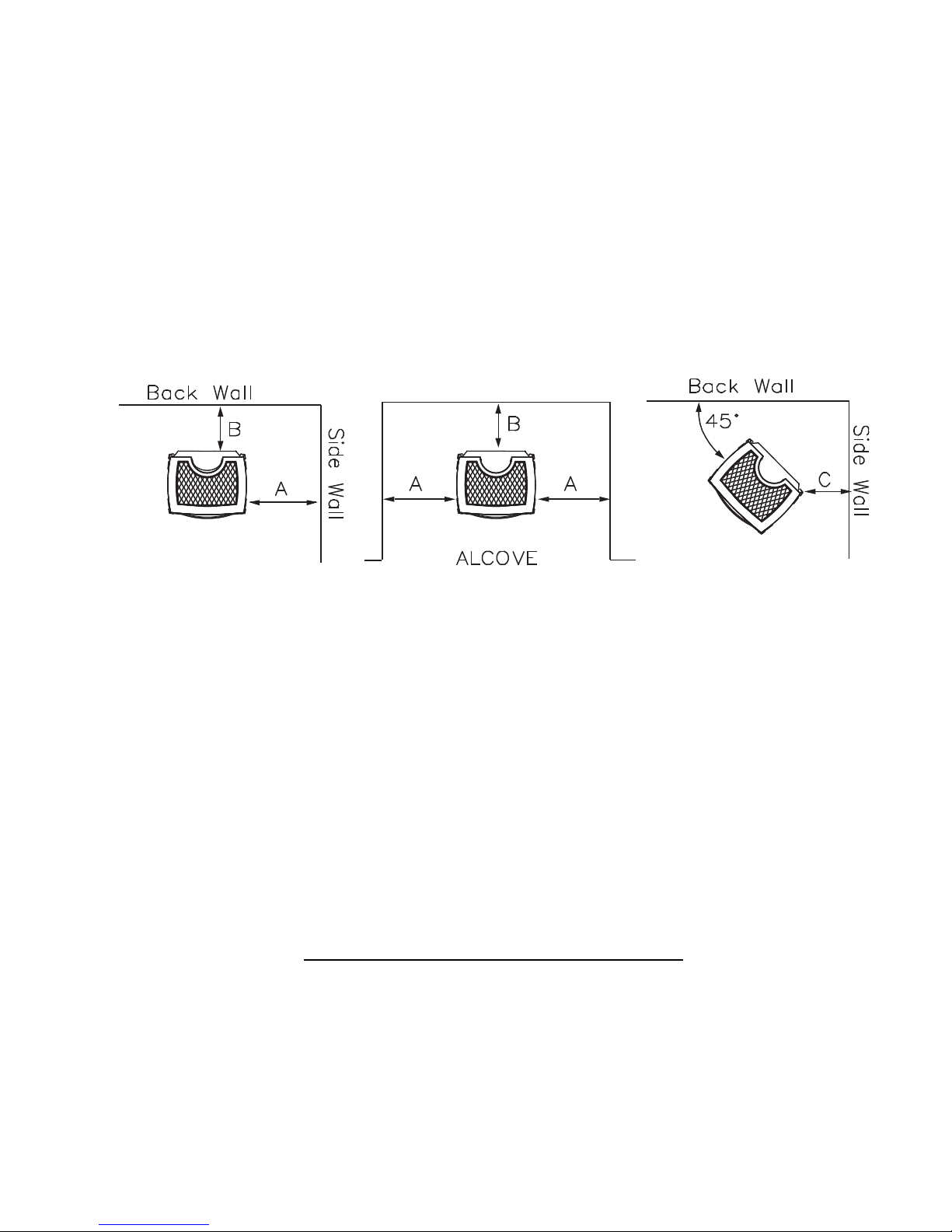

MINIMUM CLEARANCE TO COMBUSTIBLE MA TERIALS

A 4”

B 2"

C 2"

48” MIN I M U M TO CEILING FROM STOVE TOP

WOLF STEEL LTD.

24 NAPOLEON ROAD. BARRIE, ONTARIO L4M 4Y8 CANADA

OTHER FUELS.

ALTITUDE

INPUT

REDUCED INPUT

MANIFOLD PRESSURE: 10" WATER COLUMN

MINIMUM SUPPLY PRESSURE: 11" WATER COLUMN

SIT CONTROL: # 820.638

MAXIMUM SUPPLY PRESSURE: 13" WATER COLUMN

SIT CONTROL: # 820.636

OPERATING PILOT OXYPROTECTOR: # 8436

NOT FOR USE WITH SOLID FUEL.

WARNING: DO NOT ADD ANY MATERIAL TO THE APPLIANCE, WHICH

o

B

45

A

C

THAT SUPPLIED BY THE MANUFACTURER WITH THE APPLIANCE.

SCREEN MUST BE IN PLACE WHILE THE APPLIANCE IS IN OPERATION.

WILL COME IN CONTACT WITH THE FLAMES, OTHER THAN

THIS UNIT IS NOT APPROVED FOR

BEDROOM, BATHROOM AND

BED-SITTING ROOM

INSTALLATION.

MODEL GVFS20-P

**0-2000FT (0-610m)

23,000 BTU/h

B

18,000BTU/h

1

XYPROTE

D

FUEL

ELECTRICAL RATING: 115V 0.82AMP, 60HZ

SERIAL NUMBER

OPTIONAL FAN KIT: GS-64KT

GVFS20

DIAGRAM TO AID THE OPERATION

OF THIS FIREPLACE

FLAME

ADJUSTMENT

ON / OFF

CONTROL

IGNITOR

W385-0337 / J

7

INSTALLER: It is your responsibility to check off the appropriate box on the rating plate according to

the model, venting and gas type of the appliance.

For rating plate location, see “INSTALLATION OVERVIEW” section.

This illustration is for reference only. Refer to the rating plate on the appliance for accurate information.

W415-0559 / C / 10.04.10

8

3.0 INSTALLATION

THIS GAS HEATER SHOULD BE INSTALLED AND SERVICED BY A QUALIFIED INSTALLER to conform

with local codes. Installation practices vary from region to region and it is important to know the specifi cs that

apply to your area.

Provide adequate ventilation and combustion air. Provide adequate accessibility clearance for servicing

and operating the heater. Never obstruct the front opening of the heater.

As long as clearances to combustibles is kept within the required distances, the most desirable and benefi cial

location for a heater is in the centre of a building, thereby allowing the most effi cient use of the heat created.

The location of windows, doors and the traffi c fl ow in the room where the heater is to be located should be

considered.

MAINTAIN THESE MINIMUM CLEARANCES TO COMBUSTIBLES:

A. 4" B. 2"* C. 2"

Heater should not be installed directly on carpeting.

Minimum 48" from top to ceiling.

* If less than 5" clearance is maintained between the back of the heater and the back wall, it will be necessary

to disconnect the gas pipe to move the heater out for installation or service of the blower.

3.1 COMBUSTION AND VENTILATION AIR PROVISIONS

This appliance shall not be installed in a confi ned space or unusually tight construction unless provisions are

provided for adequate combustion and ventilation air.

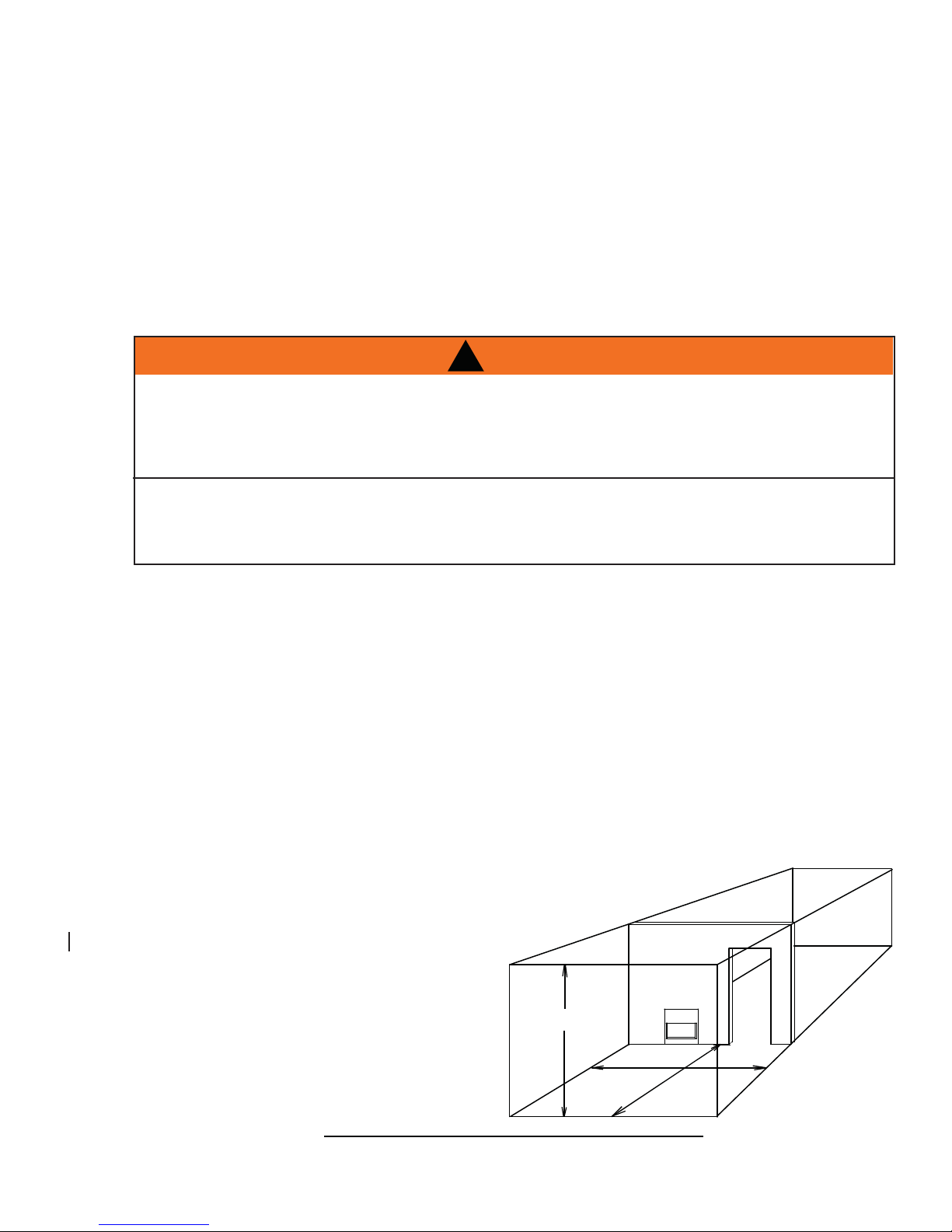

The National Fuel Gas Code, ANSI Z223.1 / NFPA 54 defi nes a confi ned space as a space whose volume is

less than 50 cubic feet per 1,000 Btu per hour (4.8 m3 per kw) of the aggregate input rating of all appliances

installed in that space and an unconfi ned space as a space whose volume is not less than 50 cubic feet per

1,000 Btu per hour (4.8 m3 per kw) of the aggregate input rating of all appliances installed in that space.

Rooms communicating directly with the space in which the appliances are installed, through openings not

furnished with doors are considered a part of the unconfi ned space.

The GVFS20 is rated at 23,000 BTU's per hour for natural gas and propane gas and therefore requires a

minimum unconfined space of 1,150 cubic feet.

17.1A

W415-0559 / C / 10.04.10

9

A

A

LENGTH

HEIGHT

ROOM 2

ROOM 1

WIDTH

3.2 DETERMINING CONFINED OR UNCONFINED SPACE

To determine the volume of the room where the appliance is to be installed, multiply the width x the length x

the ceiling height of that room measured in feet. If any adjoining rooms are connected by grilles or openings

such as kitchen pass-throughs, etc., the volume of those rooms may be added to the total.

Multiply the room volume by 1000 and divide this amount by 50 to determine the maximum BTU/hr that the

space can support with adequate combustion and ventilation air.

dd the Btu/hr of all fuel burning appliances located within the space such as gas furnace, gas water

appliance, etc. Do not include direct vent gas appliances which draw their input and output air from and to the

outdoors.

Unusually tight construction is defi ned as construction where:

A) Walls and ceilings exposed to the outside atmosphere have a continuous water vapour retarder with a

rating of 1 perm (6 x 10-11 kg per pa-sec-m2) or less with openings gasketed or sealed, and

!

WARNING

IF THE AREA IN WHICH THE APPLIANCE MAY BE OPERATED IS SMALLER THAN THAT DEFINED AS

AN UNCONFINED SP ACE OR IF THE BUILDING IS OF UNUSUALLY TIGHT CONSTRUCTION, PROVIDE

ADEQUA TE COMBUSTION AND VENTILATION AIR BY ONE OF THE METHODS DESCRIBED IN THE

NA TIONAL FUEL GAS CODE ANSI Z223.1/ NFPA 54 , AIR FOR COMBUSTION AND VENTILATION, OR THE

APPLICABLE LOCAL CODE.

IF THE AREA IN WHICH THE APPLIANCE MAY BE OPERATED DOES NOT MEET THE REQUIRED VOLUME

FOR INDOOR COMBUSTION AIR, COMBUSTION AND VENTILATION AIR SHALL BE PROVIDED BY ONE

OF THE METHODS DESCRIBED IN THE ANSI Z223.1 / NFPA 54, THE INTERNATIONAL FUEL GAS CODE,

OR APPLICABLE LOCAL CODES.

B) Weather stripping has been added on openable windows and doors, and

C) Caulking or sealants are applied to areas such as joints around window and door frames, between sole

plates and fl oors, between wall-ceiling joints, between wall panels, at penetrations for plumbing, electrical,

and gas lines, and at other openings.

n unvented room appliance is recommended for use as a secondary heat source rather than as a primary

source. Gas combustion produces water vapour which could occur at the rate of approximately one ounce of

water for every 1,000 BTU/hr of gas input. During the cold weather season, indoor humidity levels tend to be

low. Consequently, this water vapour can enhance the living space. However if a problem should occur:

A) Ensure suffi cient combustion and circulation air

B) Use a dehumidifi er

C) Do not use the unvented room appliance as a primary heat source

Without suffi cient fresh air for proper operation, poor fuel combustion can result. Carbon Monoxide is a result

of poor combustion.

If additional fresh air is required, use one of the methods described in the National Fuel

Gas Code, ANSI Z223.1 / NFPA54 or the applicable local code.

Room Volume = Length x Width x Height

Max BTU/hr = Room Volume x 1000 / 50

If for example:

The length of the rooms is 10 feet,

The width of Room 1 is 10 feet,

The width of Room 2 is 15 feet,

The height of the rooms is 8 feet.

The volume of Room 1: 10x10x8 = 800 cubic feet

The volume of Room 2: 10x15x8 = 1200 cubic feet

19.1B

W415-0559 / C / 10.04.10

Loading...

Loading...