Page 1

INSTALLER: LEAVE THIS MANUAL WITH THE APPLIANCE.

CONSUMER: RETAIN THIS MANUAL FOR FUTURE REFERENCE.

NEVER LEAVE CHILDREN OR OTHER AT RISK INDIVIDUALS ALONE WITH THE APPLIANCE

INSTALLATION AND

OPERATING INSTRUCTIONS

CONFORMS TO AMERICAN NATIONAL STANDARDS: ANSI Z21.50, CERTIFIED TO CANADIAN CSA 2.22 FOR VENTED GAS FIREPLACES.

EN

FR

PG

53

CERTIFIED FOR CANADA AND UNITED STATES USING ANSI/CSA METHODS.

SAFETY INFORMATION

!

WARNING

If the information in these instructions

are not followed exactly, a fi re or

explosion may result causing property

damage, personal injury or loss of life.

- Do not store or use gasoline or other fl ammable

vapors and liquids in the vicinity of this or any

other appliance.

- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbour’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

fi re department.

- Installation and service must be performed by a

qualifi ed installer, service agency or the supplier.

This appliance may be installed in an aftermarket,

permanently located, manufactured home (USA

only) or mobile home, where not prohibited by

local codes.

This appliance is only for use with the type of gas

indicated on the rating plate. This appliance is

not convertible for use with other gases, unless a

certifi ed kit is used.

Decorative Product: Not for use as a heating appliance.

GDS28N & GS28N

NATURAL GAS

GDS28P & GS28P

Model GS28 is made up of Model GDS28 and Natural Vent

!

A barrier designed to reduce the risk of burns from

the hot viewing glass is provided with this appliance

and shall be installed for the protection of children

and other at-risk individuals.

PROPANE

Adapter Kit GS-150KT

SAFETY BARRIER

DANGER

HOT GLASS WILL CAUSE

BURNS.

DO NOT TOUCH GLASS UNTIL

COOLED.

NEVER ALLOW CHILDREN TO

TOUCH GLASS.

BARRIER

Wolf Steel Ltd., 24 Napoleon Rd., Barrie, ON, L4M 0G8 Canada /

103 Miller Drive, Crittenden, Kentucky, USA, 41030

Phone (705)721-1212 • Fax (705)722-6031 • www.napoleonfi replaces.com • ask@napoleonproducts.com

$10.00

1.28E

W415-1426 / 12.23.14

Page 2

EN

2

TABLE OF CONTENTS

1.0 INSTALLATION OVERVIEW 3

2.0 INTRODUCTION 4

2.1 DIMENSIONS 5

2.2 GENERAL INSTRUCTIONS 5

2.3 GENERAL INFORMATION 7

2.4 RATING PLATE INFORMATION 8

3.0 VENTING 9

3.1 VENTING LENGTHS AND COMPONENTS 10

3.2 TYPICAL VENT INSTALLATION 11

3.3 SPECIAL VENT INSTALLATIONS 12

3.3.1 PERISCOPE TERMINATION 12

3.4 VENT TERMINAL CLEARANCES 13

3.6 VENTING APPLICATION FLOW CHART 14

3.5 DEFINITIONS 14

3.7 ELBOW VENT LENGTH VALUES 14

3.8 TOP EXIT HORIZONTAL TERMINATION 15

3.9 TOP EXIT VERTICAL TERMINATION 17

3.10 VERTICAL THROUGH EXISTING CHIMNEY 19

4.0 INSTALLATION 20

4.1 MINIMUM CLEARANCES TO COMBUSTIBLES 20

4.2 WALL AND CEILING PROTECTION 21

4.2.1 HORIZONTAL INSTALLATION 21

4.2.2 VERTICAL INSTALLATION 22

4.2.3 HORIZONTAL AIR TERMINAL INSTALLATION - MODEL GDS28 22

4.2.4 VERTICAL AIR TERMINAL INSTALLATION 23

4.3 APPLIANCE VENT CONNECTION 24

4.4 MOBILE HOME INSTALLATION - MODEL GDS28 24

4.5 GAS INSTALLATION 25

4.6 OPTIONAL WALL SWITCH / REMOTE 25

4.7 NATURAL VENT SPECIFICS 26

4.7.1 CHIMNEY INSTALLATION 26

4.7.2 INSTALLING NATURAL VENT 27

4.7.3 NATURAL VENT 27

4.7.4 COMBUSTION AIR 28

4.7.5 ADDING VENT SECTIONS 28

5.0 FINISHING 29

5.1 SAFETY SCREEN INSTALLATION AND REMOVAL 29

5.2 DOOR CLOSING AND OPENING 30

5.3 LOG PLACEMENT 31

5.4 GLOWING EMBERS 32

5.5 CHARCOAL EMBERS 32

5.6 LOGO PLACEMENT 32

6.0 OPERATION 33

6.1 OPERATING/LIGHTING INSTRUCTIONS 34

7.0 ADJUSTMENT 35

7.1 PILOT BURNER ADJUSTMENT 35

7.2 VENTURI ADJUSTMENT 35

7.3 FLAME CHARACTERISTICS 36

8.0 MAINTENANCE 37

8.1 ANNUAL MAINTENANCE 38

8.2 CARE OF GLASS 38

8.3 BLOWER REPLACEMENT 39

9.0 REPLACEMENTS 40

10.0 OVERVIEW 41

11.0 VALVE TRAIN ASSEMBLY 42

12.0 ACCESSORIES 43

13.0 VENTING 44

14.0 TROUBLESHOOTING 45

15.0 WARRANTY 48

16.0 SERVICE HISTORY 49

17.0 NOTES 50

NOTE: Changes, other than editorial, are denoted by a vertical line in the margin.

W415-1426 / 12.23.14

Page 3

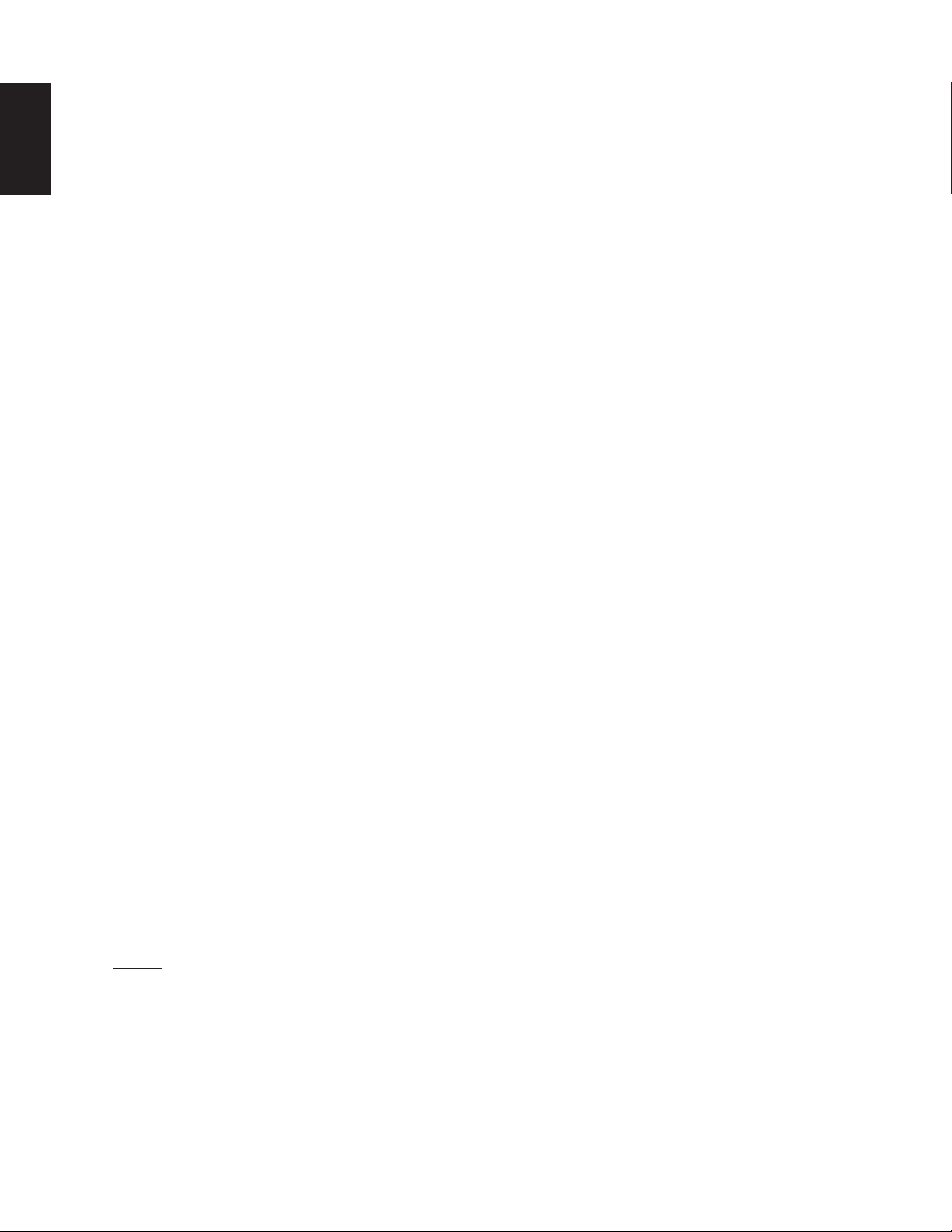

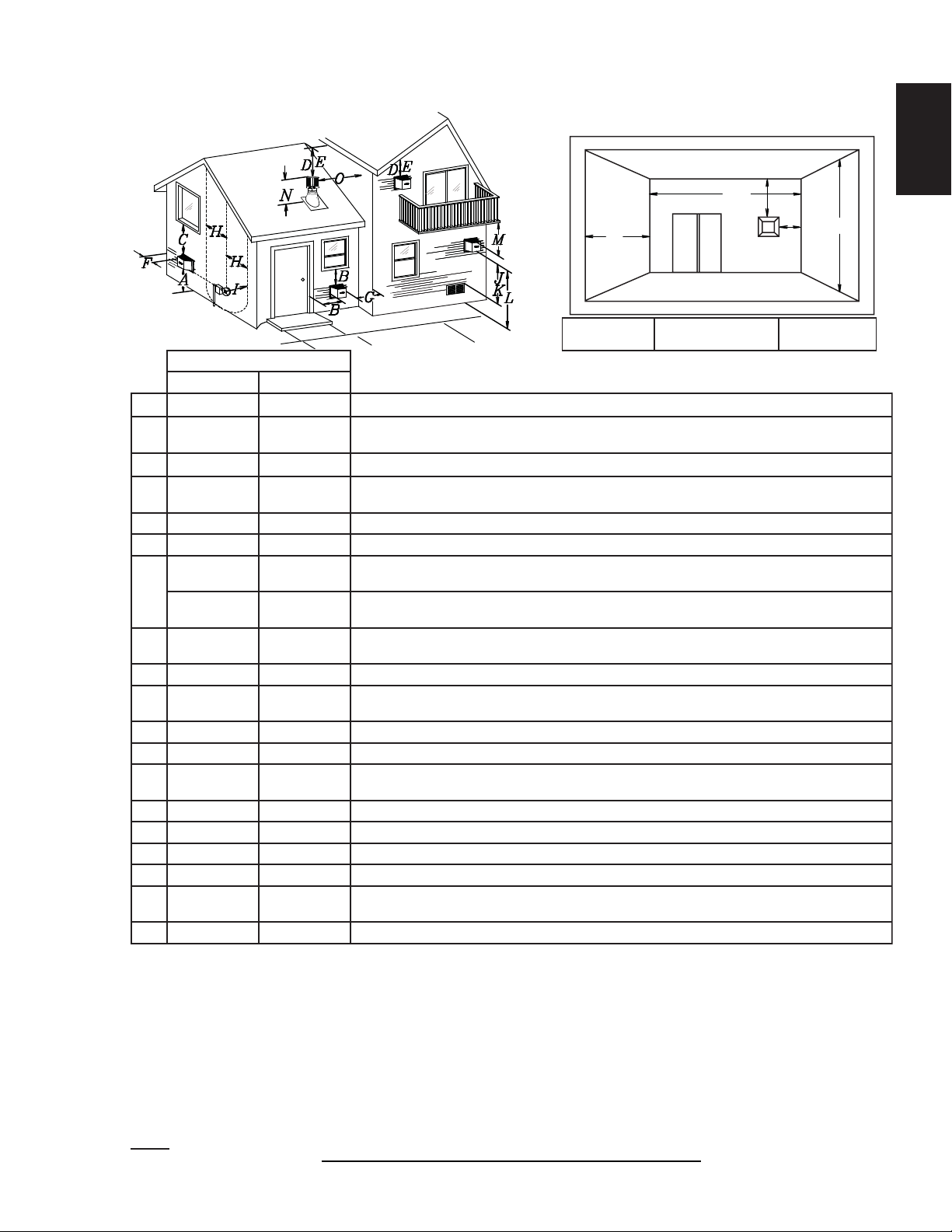

1.0 INSTALLATION OVERVIEW

Vent, see “VENTING” section.

SAFETY BARRIER

3

EN

Logo, see “LOGO

PLACEMENT” section.

Rating plate, see

“RATING PLATE” section.

Door, see “DOOR CLOSING /

OPENING” section.

W415-1426 / 12.23.14

Page 4

4

2.0 INTRODUCTION

EN

• THIS APPLIANCE IS HOT WHEN OPERATED AND CAN CAUSE SEVERE BURNS IF CONTACTED.

• ANY CHANGES TO THIS APPLIANCE OR IT’S CONTROLS CAN BE DANGEROUS AND IS PROHIBITED.

• Do not operate appliance before reading and understanding operating instructions. Failure to operate appliance according to

operating instructions could cause fi re or injury.

• Risk of fi re or asphyxiation do not operate appliance with fi xed glass removed.

• Do not connect 110 volts to the control valve.

• Risk of burns. The appliance should be turned off and cooled before servicing.

• Do not install damaged, incomplete or substitute components.

• Risk of cuts and abrasions. Wear protective gloves and safety glasses during installation. Sheet metal edges may be sharp.

• Do not burn wood or other materials in this appliance.

• Children and adults should be alerted to the hazards of high surface temperature and should stay away to avoid burns

or clothing ignition.

• Young children should be carefully supervised when they are in the same room as the appliance.

Toddlers, young children and others may be susceptible to accidental contact burns. A physical barrier is

recommended if there are at risk individuals in the house. To restrict access to an appliance or stove, install an

adjustable safety gate to keep toddlers, young children and other at risk individuals out of the room and away from hot

surfaces.

• Clothing or other fl ammable material should not be placed on or near the appliance.

• Due to high temperatures, the appliance should be located out of traffi c and away from furniture and draperies.

• Ensure you have incorporated adequate safety measure to protect infants/toddlers from touching hot surfaces.

• Even after the appliance is out, the glass and/or screen will remain hot for an extended period of time.

• Check with your local hearth specialty dealer for safety screens and hearth guards to protect children from hot surfaces. These

screens and guards must be fastened to the fl oor.

• Any safety screen, guard or barrier removed for servicing the appliance, must be replaced prior to operating the

appliance.

• The appliance is a vented gas-fi red appliance. Do not burn wood or other materials in the appliance.

• The appliance area must be kept clear and free from combustible materials, gasoline and other fl ammable vapors and liquids.

• Under no circumstances should this appliance be modifi ed.

• This appliance must not be connected to a chimney fl ue pipe serving a separate solid fuel burning appliance.

• Do not use this appliance if any part has been under water. Immediately call a qualifi ed service technician to inspect the appliance

and to replace any part of the control system and any gas control which has been under water.

• Do not operate the appliance with the glass door removed, cracked or broken. Replacement of the glass should be done by a

licensed or qualifi ed service person.

• Do not strike or slam shut the appliance glass door.

• When equipped with pressure relief doors, they must be kept closed while the appliance is operating to prevent exhaust fumes

containing carbon monoxide, from entering into the home. Temperatures of the exhaust escaping through these openings can also

cause the surrounding combustible materials to overheat and catch fi re.Only doors / optional fronts certifi ed with the unit are to be

installed on the appliance.

• Only doors / optional fronts certifi ed with the unit are to be installed on the appliance.

• Keep the packaging material out of reach of children and dispose of the material in a safe manner. As with all plastic bags, these

are not toys and should be kept away from children and infants.

• As with any combustion appliance, we recommend having your appliance regularly inspected and serviced as well as having a

Carbon Monoxide Detector installed in the same area to defend you and your family against Carbon Monoxide.

• Ensure clearances to combustibles are maintained when building a mantel or shelves above the appliance. Elevated temperatures

on the wall or in the air above the appliance can cause melting, discolouration or damage to decorations, a T.V. or other electronic

components.

• A barrier designed to reduce the risk of burns from the hot viewing glass is provided with this appliance and shall be

installed.

• If the barrier becomes damaged, the barrier shall be replaced with the manufacturer’s barrier for this appliance.

• Installation and repair should be done by a qualifi ed service person. The appliance should be inspected before use and

at least annually by a professional service person. More frequent cleaning may be required due to excessive lint from

carpeting, bedding material, etc. It is imperative that control compartments, burners and circulating air passageways of

the appliance be kept clean.

• This appliance uses and requires a fast acting thermocouple. Replace only with a fast acting thermocouple supplied by Wolf Steel

Ltd.

!

WARNING

3.1D

W415-1426 / 12.23.14

Page 5

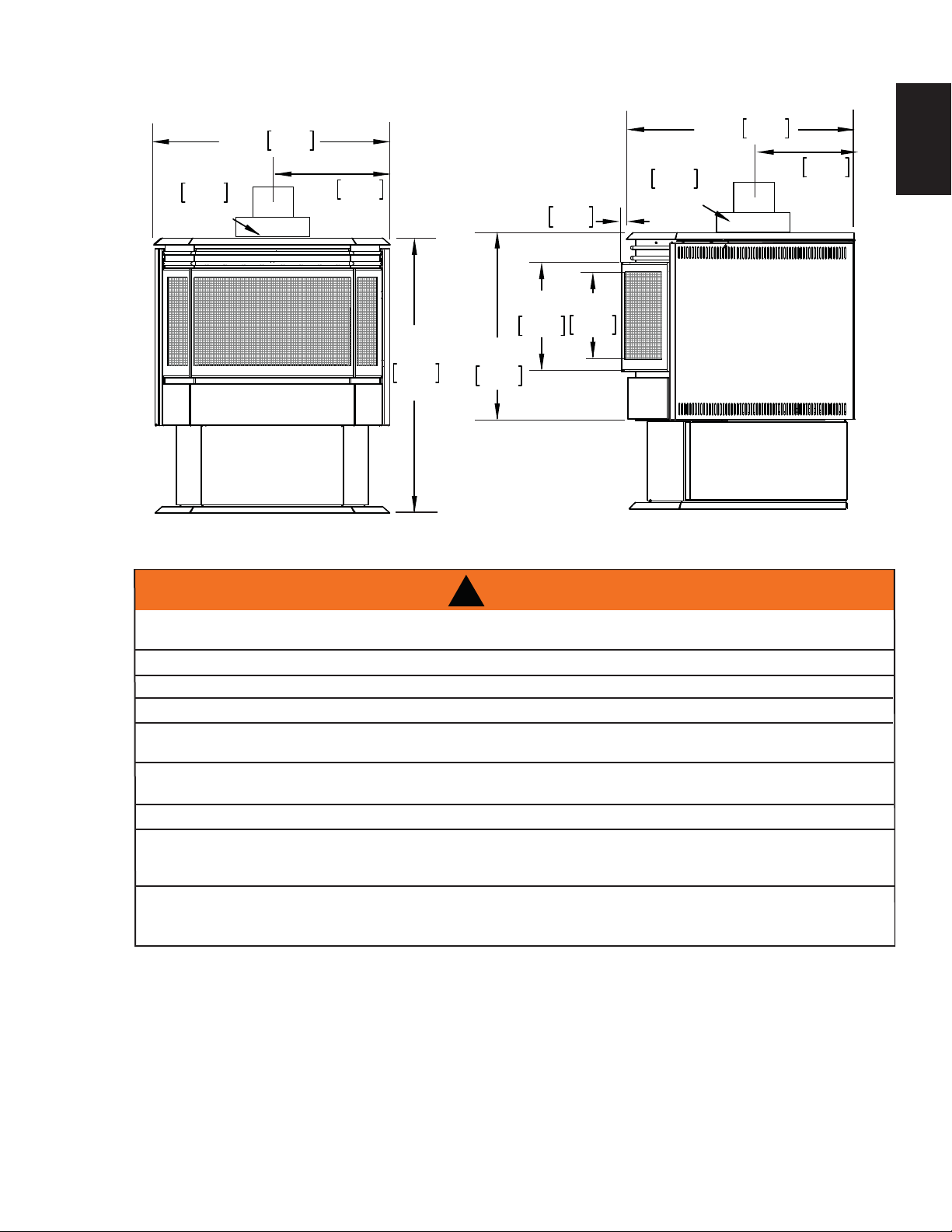

2.1 DIMENSIONS

22 1/2"

178mm

7"

Ø AIR INTAKE

572mm

11 1/4"

286mm

1 3/4"

44mm

102mm

4"

Ø FLUE

18 1/2"

470mm

5 1/2"

5

EN

127mm

SAFETY

BARRIER

2.2 GENERAL INSTRUCTIONS

ALWAYS LIGHT THE PILOT WHETHER FOR THE FIRST TIME OR IF THE GAS SUPPLY HAS RUN OUT,

WITH THE GLASS DOOR OPENED OR REMOVED.

PROVIDE ADEQUATE CLEARANCE FOR SERVICING AND OPERATING THE APPLIANCE.

NEVER OBSTRUCT THE FRONT OPENING OF THE APPLIANCE.

OBJECTS PLACED IN FRONT OF THE APPLIANCE MUST BE KEPT A MINIMUM OF 48” (1219mm) FROM

THE FRONT FACE OF THE APPLIANCE.

SURFACES AROUND AND ESPECIALLY ABOVE THE APPLIANCE CAN BECOME HOT. AVOID CONTACT

WHEN THE APPLIANCE IS OPERATING.

HIGH PRESSURE WILL DAMAGE VALVE. DISCONNECT GAS SUPPLY PIPING BEFORE PRESSURE TESTING GAS

LINE AT TEST PRESSURES ABOVE 1/2 PSIG. CLOSE THE MANUAL SHUT-OFF VALVE BEFORE PRESSURE

TESTING GAS LINE AT TEST PRESSURES EQUAL TO OR LESS THAN 1/2 PSIG (35 mb).

USE ONLY WOLF STEEL APPROVED OPTIONAL ACCESSORIES AND REPLACEMENT PARTS WITH THIS APPLIANCE.

USING NON-LISTED ACCESSORIES (BLOWERS, DOORS, LOUVRES, TRIMS, GAS COMPONENTS, VENTING

COMPONENTS, ETC.) COULD RESULT IN A SAFETY HAZARD AND WILL VOID THE WARRANTY AND CERTIFICATION.

12"

305mm

26 3/4"

680mm

PROVIDE ADEQUA TE VENTILA TION.

FIRE RISK. EXPLOSION HAZARD.

17 3/4"

451mm

!

WARNING

10"

254mm

GAS LINE ACCESS HOLE LOCATED

IN PEDESTAL BASE

THIS GAS APPLIANCE SHOULD BE INSTALLED AND SERVICED BY A QUALIFIED INSTALLER to

conform with local codes. Installation practices vary from region to region and it is important to know the

specifi cs that apply to your area, for example in Massachusetts State:

• This product must be installed by a licensed plumber or gas fi tter when installed within the commonwealth

of Massachusetts.

• The appliance damper must be removed or welded in the open position prior to installation of an appliance

insert or gas log.

• The appliance off valve must be a “T” handle gas cock.

• The fl exible connector must not be longer than 36 inches (914mm).

• A Carbon Monoxide detector is required in all rooms containing gas fi red appliances.

• The appliance is not approved for installation in a bedroom or bathroom unless the unit is a direct vent

sealed combustion product.

W415-1426 / 12.23.14

Page 6

EN

A

A

6

The installation must conform with local codes or, in

absence of local codes, the National Gas and Propane

Installation Code CSA B149.1 in Canada, or the National

Fuel Gas Code, ANSI Z223.1 / NFPA 54 in the United

States. Suitable for mobile home installation if installed in

accordance with the current standard CAN/CSA Z240MH

Series, for gas equipped mobile homes, in Canada or

NSI Z223.1 and NFPA 54 in the United States.

s long as the required clearance to combustibles is

maintained, the most desirable and benefi cial location

for an appliance is in the center of a building, thereby

allowing the most effi cient use of the heat created. The location of windows, doors and the traffi c fl ow in the

room where the appliance is to be located should be considered. If possible, you should choose a location

where the vent will pass through the house without cutting a fl oor or roof joist.

If the appliance is installed directly on carpeting, vinyl tile or other combustible material other than wood

fl ooring, the appliance shall be installed on a metal or wood panel extending the full width and depth.

Some appliances have optional fans or blowers. If an optional fan or blower is installed, the junction box must

be electrically connected and grounded in accordance with local codes, use the current CSA C22.1 Canadian

Electrical Code in Canada or the ANSI/NFPA 70 National Electrical code in the United States.

www.ncertied.org

We suggest that our gas

hearth products be installed

and serviced by professionals

who are certied in the U.S.

by the National Fireplace

®

Institute

(NFI) as NFI Gas

Specialists

4.1B

W415-1426 / 12.23.14

Page 7

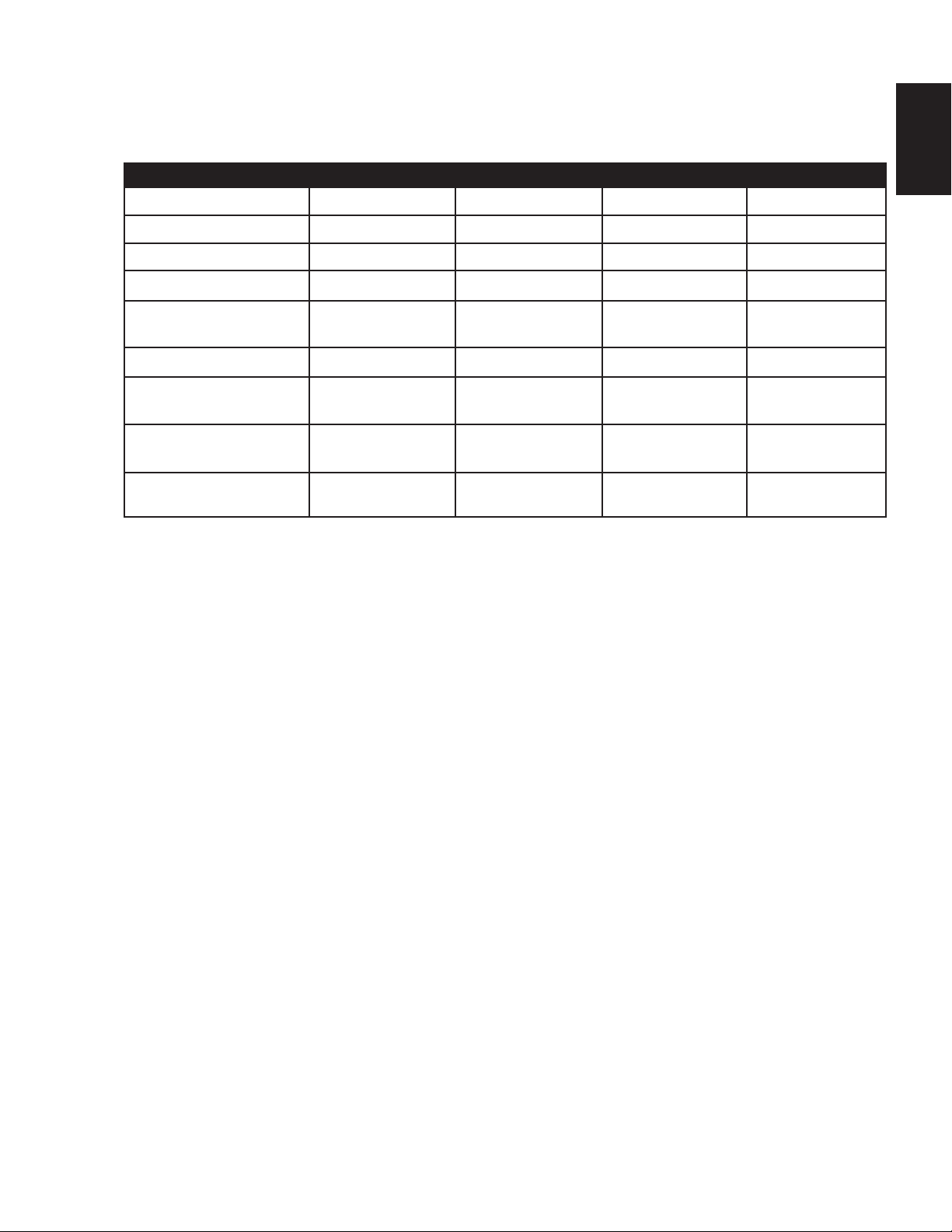

2.3 GENERAL INFORMATION

FOR YOUR SATISFACTION, THIS APPLIANCE HAS BEEN TEST-FIRED TO ASSURE ITS OPERATION

AND QUALITY!

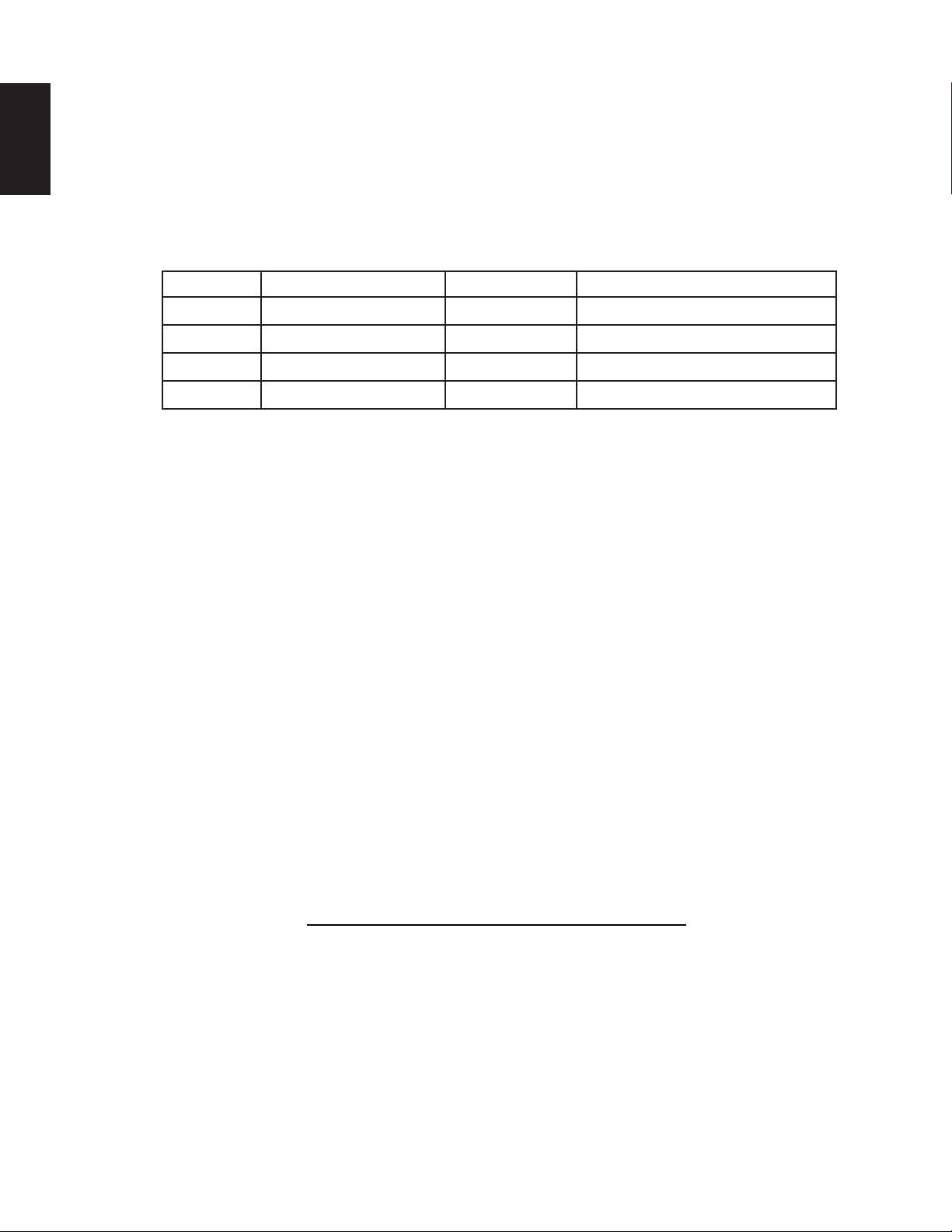

Altitude (FT) 0-4,500 0-4500 0-4500 0-4500

Max. Input (BTU/HR) 30,000 26,000 30,000 26,000

Max. Output (BTU/HR) 25,500 22,360 24,600 21,600

7

EN

GDS28 GS28

NG LP NG LP

Max. Steady State

Effi ciency (w/the fan on)

Max. A.F.U.E. 64% 65%

Min. Inlet Gas Supply

Pressure

Max. Inlet Gas Supply

Pressure

Manifold Pressure

(Under Flow Conditions)

When the appliance is installed at elevations above 4,500 ft (1372m), and in the absence of specifi c recommendations

from the local authority having jurisdiction, the certifi ed high altitude input rating shall be reduced at the rate of 4% for

each additional 1,000 ft (305m).

Change in fl ame appearance from "HI" to "LO" is more evident in natural gas than in propane.

Expansion / contraction noises during heating up and cooling down cycles are normal and to be expected.

This appliance may be installed in an aftermarket permanently located, manufactured mobile home, where not

prohibited by local codes.

This appliance is only for use with the type of gas indicated on the rating plate. This appliance is not convertible

for use with other gases, unless a certifi ed kit is used.

4.5" (11mb) Water

85% 86% 82% 83%

Column

7" (17mb)

Water Column

3.5" (9mb)Water

Column

11" (27mb)

Water Column

13" (32mb) Water

Column

10" (25mb)

Water Column

4.5" (11mb) Water

Column

7" (17mb)

Water Column

3.5" (9mb)Water

Column

11" (27mb)

Water Column

13" (32mb) Water

Column

10" (25mb)

Water Column

This appliance is approved for bedroom and bed-sitting room installations.

W415-1426 / 12.23.14

Page 8

8

/ FOYER À GAZ V/ FOYER À G

ION DIRECTE. HOMOLOGUEON DIRECTE. HOMOLOGU

.

RRIE, ON, L4M 0G8 CA

4001659 659

)(WUSA)

TPUT(MODEL GDS50) RENDEMENT

PUT(MODEL GS50) RENDEMENT

8-P

4 (NG/LP) / (GN/PL):

½"17½"

¼""

OP20" TO CEILING FROM STOVE TOP

:ELECTRICAL RATING / CLASS.:

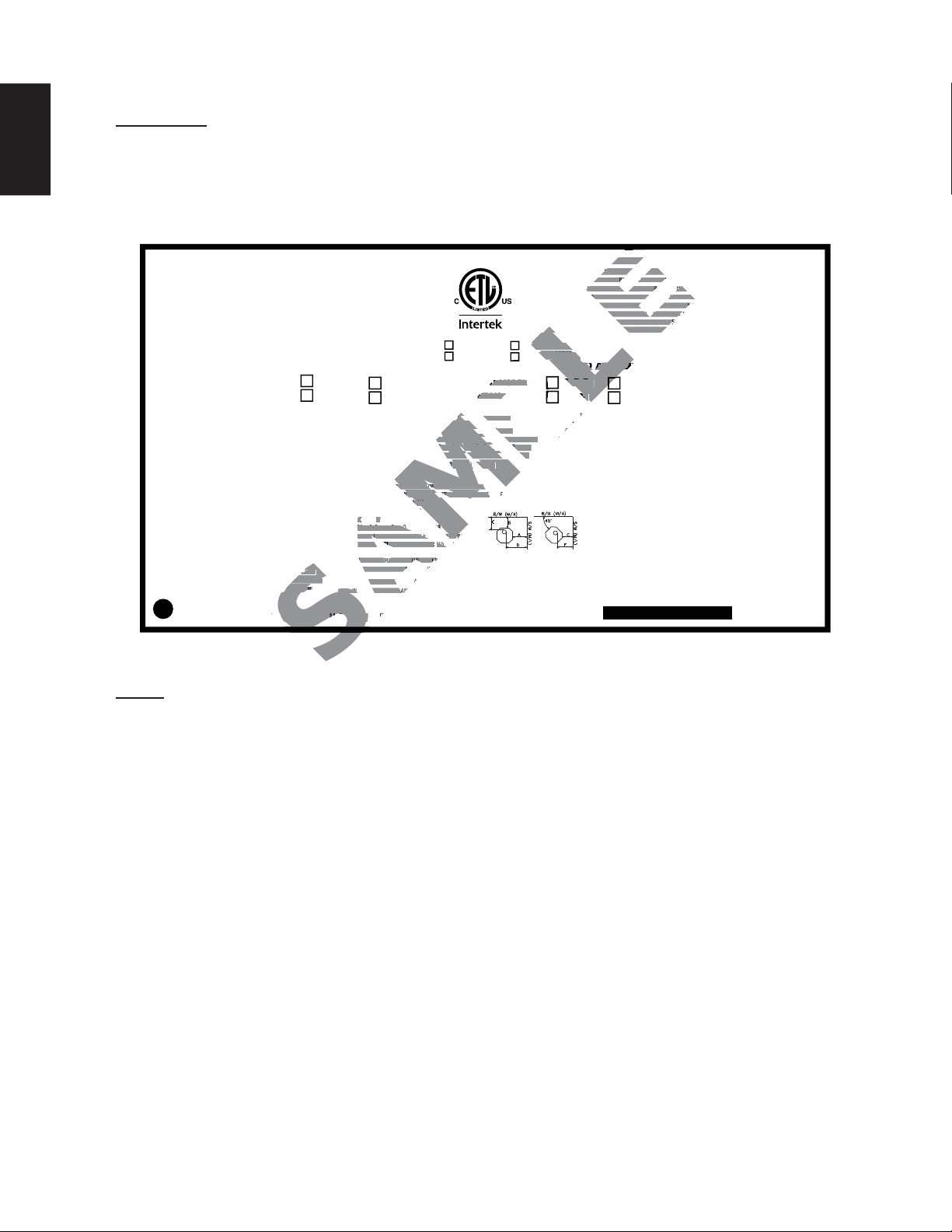

2.4 RATING PLATE INFORMATION

INSTALLER: It is your responsibility to check off the appropriate box on the rating plate according to

EN

the model, venting and gas type of the appliance.

For rating plate location, see “INSTALLATION OVERVIEW” section.

This illustration is for reference only. Refer to the rating plate on the appliance for accurate information.

DIRECT VENT GAS FIREPLACE APPROVED FOR BEDROOM, BATHROOM & BEDSITTING ROOM

INSTALLATION. SUITABLE FOR MOBILE HOME INSTALLATION IF INSTALLED IN ACCORDANCE WITH THE

CURRENT STANDARD CAN/CSA Z240MH SERIES GAS EQUIPPED MOBILE HOMES, IN CANADA OR IN THE UNITED

STATES THE MANUFACTURED HOME CONSTRUCTION AND SAFETY STANDARD, TITLE 24 CFR, PART 3280.

WHEN THIS US STANDARD IS NOT APPLICABLE USE THE STANDARD FOR FIRE SAFETY CRITERIA FOR

MANUFACTURED HOME INSTALLATIONS, SITES AND COMMUNITIES, ANSI / NFPA 501A. FOR USE ONLY WITH

BARRIER W565-0195. FOLLOW THE INSTALLATION INSTRUCTIONS LOCATED IN THE INSTALLATION MANUAL.

9700539 (WSL) 4001657 (NGZ)

MANIFOLD PRESSURE: 3.5 INCHES W.C. (NG)

4001658 (NAC) 4001659 (WUSA)

PRESSION AU COLLECTEUR: 3.5" D'UNE

MIN SUPPLY PRESSURE: 4.5" W.C.(NG)

PRESSION D'ALIMENTATION MIN: 4.5" D'UNE

MAX. SUPPLY PRESSURE: 7" W.C. (NG)

PRESSION D'ALIMENTATION MAX: 7" D'UNE

*ALTITUDE DOWNRATING CONDITIONS APPLY

TO CANADA ONLY /

NOT FOR USE WITH SOLID FUEL

FOR USE WITH GLASS DOORS CERTIFIED WITH THIS UNIT ONLY.

WARNING: DO NOT ADD ANY MATERIAL TO THE APPLIANCE,

WHICH WILL COME IN CONTACT WITH THE FLAMES, OTHER THAN

THAT SUPPLIED BY THE MANUFACTURER WITH THE APPLIANCE.

DECORATIVE PRODUCT: NOT FOR USE AS A HEATING APPLIANCE

B-VENT MODELS GS28/CS280

APPROVED FOR BEDROOM, & BEDSITTING ROOM INSTALLATION.

THIS APPLIANCE MUST BE VENTED USING THE APPROPIATE

NAPOLEON VENT KIT. SEE OWNERS INSTALLATION MANUAL FOR

VENTING SPECIFICS. PROPER REINSTALLATION AND RESEALING IS

NECESSARY AFTER SERVICING THE VENT-AIR INTAKE SYSTEM.

WOLF STEEL LTD.

24 NAPOLEON ROAD, BARRIE, ON, L4M 0G8 CANADA

CONFORMS TO / CONFORME AUX: ANSI Z21.50-2014, CERTIFIED TO / CERTIFIE CSA 2.22-2014 VENTED GAS FIREPLACE / FOYER À GAZ VENTILÉ.

COLONNE D'EAU(GN)

COLONNE D'EAU (GN)

COLONNE D'EAU (GN)

(0-1370m)

30,000 BTU/h *INPUT / ALIMENTATION*

18,000 BTU/h REDUCED INPUT / ALIMENTATION REDUITE

22,500 BTU/h OUTPUT(MODEL GDS50) RENDEMENT

24,000 BTU/h OUTPUT(MODEL GS50) RENDEMENT

NATURAL GAS MODEL

GDS28-N

GS28-N

THIS APPLIANCE MUST BE INSTALLED USING AN ADAPTER KIT GS-150KT. CET APPAREIL DOIT

ETRE INSTALLE EN UTILISANT UN ENSEMBLE ADAPTATEUR GS-150KT.

CDVS280-N

CS280-N

0-4500FT 0-4500FT

57.4%

MINIMUM CLEARANCE TO COMBUSTIBLE MATERIAL /

DEGAGEMENTS MINIMAUX DES MATERIAUX COMBUSTIBLES:

A 7" D 17½"

B 2" E 6¼"

C 1" F 9½"

20" TO CEILING FROM STOVE TOP

" TO CEILING FROM STOVE T

20" ENTRE LE DESSUS DU FOYER ET LE PLAFOND

ELECTRICAL RATING / CLASS.: 115V 1.5AMP 60HZ

ELECTRICAL RATING / CLASS.

MINIMUM AND MAXIMUM HORIZONTAL VENT LENGTHS ARE 25 INCHES AND 20 FEET RESPECTIVELY.

LES LONGUEURS HORIZONTALES MINIMALE ET MAXIMALE SONT 25 POUCES ET 20 PIEDS RESPECTIVEMENT.

DIRECT VENT MODEL

‘B’ VENT MODEL

ALTITUDE / ELEVATION

INPUT / ALIMENTATION*

UTPUT(MODEL GDS50) RENDEMENT

UTPUT(MODEL GS50) RENDEMENT

P4 (NG/LP) / (GN/PL): 57.4%

P4 (NG/LP) / (GN/PL):

7

6

FOYER À GAZ VENTILÉS À ÉVACUATION DIRECTE. HOMOLOGUE POUR INSTALLATION DANS UNE CHAMBRE A COUCHER,

UNE SALLE DE BAIN ET UN STUDIO. APPROPRIE POUR INSTALLATION DANS UNE MAISON MOBILE SI SON INSTALLATION

CONFORME AUX EXIGENCES DE LA NORME CAN/CSA Z240MH SERIE DE MAISONS MOBILES EQUIPEES AU GAZ, EN

VIGUEUR AU CANADA OU AUX ETATS-UNIS DE LA NORME DE SECURITE ET DE CONSTRUCTION DE MAISONS

MANUFACTUREES, TITRE 24 CFR, SECTION 3280. DANS LE CAS OU CETTE NORME D'ETATS-UNIS NE PEUT ETRE

APPLIQUEE, SE REFERER A LA NORME RELATIVE AU CRITERE DE MESURES DE SECURITE CONTRE L'INCENDIE POUR

LES INSTALLATIONS DANS LES MAISONS MANUFACTURES, LES SITES ET LES COMMUNAUTES, ANSI/NFPA 501A. POUR

UNE UTILISER SEULMENT AVEC BARRIÈRE W565-0195. SUIVEZ LES INSTRUCTIONS D'INSTALLATION SE TROUVENT

WUSA

PROPANE MODEL

GDS28-P

DS28-P

GS28-P

28-P

26,000 BTU/h

15,000 BTU/h

19,500 BTU/h

28,800 BTU/h

(0-1370m)

CDVS280-P

CS280-P

*LES CONDITIONS DE BAISSE D’EVALUATION SELON L’ALTITUDE

S’APPLIQUENT AU CANADA SEULEMENT

DANS LE MANUEL D'INSTALLATION.

MANIFOLD PRESSURE: 10 INCHES W.C.(LP)

PRESSION AU COLLECTEUR: 10" D'UNE

COLONNE D'EAU (P)

MIN SUPPLY PRESSURE: 11" W.C. (LP)

PRESSION D'ALIMENTATION MIN: 11" D'UNE

COLONNE D'EAU (P)

MAX. SUPPLY PRESSURE: 13" W.C. (LP)

PRESSION D'ALIMENTATION MAX: 13" D'UNE

COLONNE D'EAU (P)

UN COMBUSTIBLE SOLIDE NE DOIT PAS ETRE

UTILSE AVEC CET APPAREIL

UTILISER AVEC LES PORTES VITREES HOMOLOGUEES SEULEMENT AVEC

CETTE UNITE.

AVERTISSEMENT: N'AJOUTEZ PAS A CET APPAREIL AUCUN MATERIAU

DEVANT ENTRER EN CONTACT AVEC LES FLAMMES AUTRE QUE CELUI QUI

EST FOURNI AVEC CET APPAREIL PAR LE FABRICANT.

PRODUIT DÉCORATIF: NE PAS UTILISER COMME APPARIEL DE CHAUFFAGE

B-VENT MODELS GS28/CS280

HOMOLOGUE POUR INSTALLATION DANS UNE CHAMBRE A COUCHER, & UN STUDIO.

L'APPAREIL DOIT EVACUER SES GAZ EN UTILISANT L'ENSEMBLE D'EVACUATION PROPRE

A NAPOLÉON. REFERER AU MANUEL D'INSTALLATION DE PROPRIETAIRE POUR

L'EVACUATION PRECISE. IL EST IMPORTANT DE BEIN REINSTALLER ET RESCELLER

L'EVENT APRES AVOIR ASSURE LE MAINTIEN DU SYSTEME DE PRISE D'AIR.

SERIAL NUMBER / NO. DESERIE

GDS28

NOTE: The rating plate must remain with the appliance at all times. It must not be removed.

W385-1998

A barrier designed to reduce the risk of burns from the hot viewing glass is provided with the

appliance and shall be installed.

W415-1426 / 12.23.14

Page 9

3.0 VENTING

9

!

WARNING

RISK OF FIRE, MAINTAIN SPECIFIED AIR SPACE CLEARANCES TO VENT PIPE AND APPLIANCE.

IF VENTING IS INCLUDED WITH SPACERS THE VENT SYSTEM MUST BE SUPPORTED EVERY 3FT

(0.9m) FOR BOTH VERTICAL AND HORIZONTAL RUNS. USE SUPPORTS OR EQUIVALENT

NON-COMBUSTIBLE STRAPPING TO MAINTAIN THE REQUIRED CLEARANCE FROM

COMBUSTIBLES. USE WOLF STEEL LTD. SUPPORT RING ASSEMBLY W010-0370 OR EQUIVALENT

NON-COMBUSTIBLE STRAPPING TO MAINTAIN THE MINIMUM CLEARANCE TO COMBUSTIBLES

FOR BOTH VERTICAL AND HORIZONTAL RUNS. SPACERS ARE ATTACHED TO THE INNER PIPE AT

PREDETERMINED INTERVALS TO MAINTAIN AN EVEN AIR GAP TO THE OUTER PIPE. THIS GAP IS

REQUIRED FOR SAFE OPERATION. A SPACER IS REQUIRED AT THE START, MIDDLE AND END OF

EACH ELBOW TO ENSURE THIS GAP IS MAINTAINED. THESE SPACERS MUST NOT BE REMOVED.

THIS APPLIANCE USES A 4” (102mm) EXHAUST / 7” (178mm) AIR INTAKE VENT PIPE SYSTEM.

Refer to the section applicable to your installation.

For safe and proper operation of the appliance follow the venting instruction exactly. Deviation from the

minimum vertical vent length can create diffi culty in burner start-up and/or carboning. Under extreme

vent confi gurations, allow several minutes (5-15) for the fl ame to stabilize after ignition. Although not a

requirement, it is recommended for vent lengths that pass through unheated spaces (attics, garages, crawl

spaces) be insulated with the insulation wrapped in a protective sleeve to minimize condensation. Provide

a means for visually checking the vent connection to the appliance after the appliance is installed. Use a

fi restop, vent pipe shield or attic insulation shield when penetrating interior walls, fl oor or ceiling.

NOTE: If for any reason the vent air intake system is disassembled; reinstall per the instructions

provided for the initial installation.

7.1C

EN

A terminal shall not terminate directly above a sidewalk or paved driveway which is located between

two single family dwellings and serves both dwellings. Local codes or regulations may require different

clearances.

Do not allow the inside liner to bunch up on horizontal or vertical runs and elbows. Keep it pulled

tight. A 1-1/4" (25.4mm - 6.4mm) air gap all around between the inner liner and outer appliance pipe is

required for safe operation. Use a fi restop when penetrating interior walls, fl oor or ceiling.

W415-1426 / 12.23.14

Page 10

10

3.1 VENTING LENGTHS AND COMPONENTS

Use only Wolf Steel, Simpson Dura-Vent, Selkirk Direct Temp, American Metal Amerivent or Metal-Fab venting

EN

components. Minimum and maximum vent lengths, for both horizontal and vertical installations, and air terminal

locations for either system are set out in this manual and must be adhered to. For Simpson Dura-Vent, Selkirk

Direct Temp, American Metal Amerivent and Metal-Fab follow the installation procedure provided with the venting

components.

A starter adaptor must be used with the following vent systems and may be purchased from the corresponding

supplier:

PART 4”/7” (102mm/ 178mm) SUPPLIER WEBSITE

Duravent GDS924N Wolf Steel www.duravent.com

Amerivent 4DSC-N2 American Metal www.americanmetalproducts.com

Direct Temp 4DT-AAN Selkirk www.selkirkcorp.com

SuperSeal 4DNA Metal-Fab www.mtlfab.com

* For Simpson Dura-Vent, Selkirk Direct Temp, American Metal Amerivent and Metal-Fab follow the

installation procedure found on the website for your venting supplier.

For vent systems that provide seals on the inner exhaust fl ue, only the outer air intake joints must be sealed using a

red high temperature silicone (RTV). This same sealant may be used on both the inner exhaust and outer intake vent

pipe joints of all other approved vent systems except for the exhaust vent pipe connection to the appliance fl ue collar

which must be sealed using the black high temperature sealant Mill Pac.

When using Wolf Steel venting components, use only approved Wolf Steel termination kits: wall terminal kit GD175

(7/12’ of venting included), or 1/12 to 7/12 pitch roof terminal kit GD1 10, 8/12 to 12/12 roof terminal kit GD111, fl at

roof terminal kit GD112 or periscope kit GD180 (for wall penetration below grade) in conjunction with the appropriate

venting components.

For optimum fl ame appearance and appliance operation, keep the vent length and number of elbows to a

minimum. It is recommended that all horizontal runs have a minimum 1/4” (6.4mm) rise per foot /meter. The

air terminal must remain unobstructed at all times. Examine the air terminal at least once a year to verify

that it is unobstructed and undamaged. Rigid and fl exible venting systems must not be combined. Different

venting manufacturers components must not be combined.

These vent kits allow for either horizontal or vertical venting of the appliance. The maximum allowable horizontal

run is 20 feet (6m). The maximum allowable vertical vent length is 40 feet (12m). The maximum number of vent

connections is two horizontally or three vertically (excluding the appliance and the air terminal connections) when

using fl exible venting.

Deviation from the minimum vertical vent length can create diffi culty in burner start-up and/or carboning.

Use an adjustable pipe as the fi nal length of rigid piping to the stove for ease of installation.

8.5A

W415-1426 / 12.23.14

Page 11

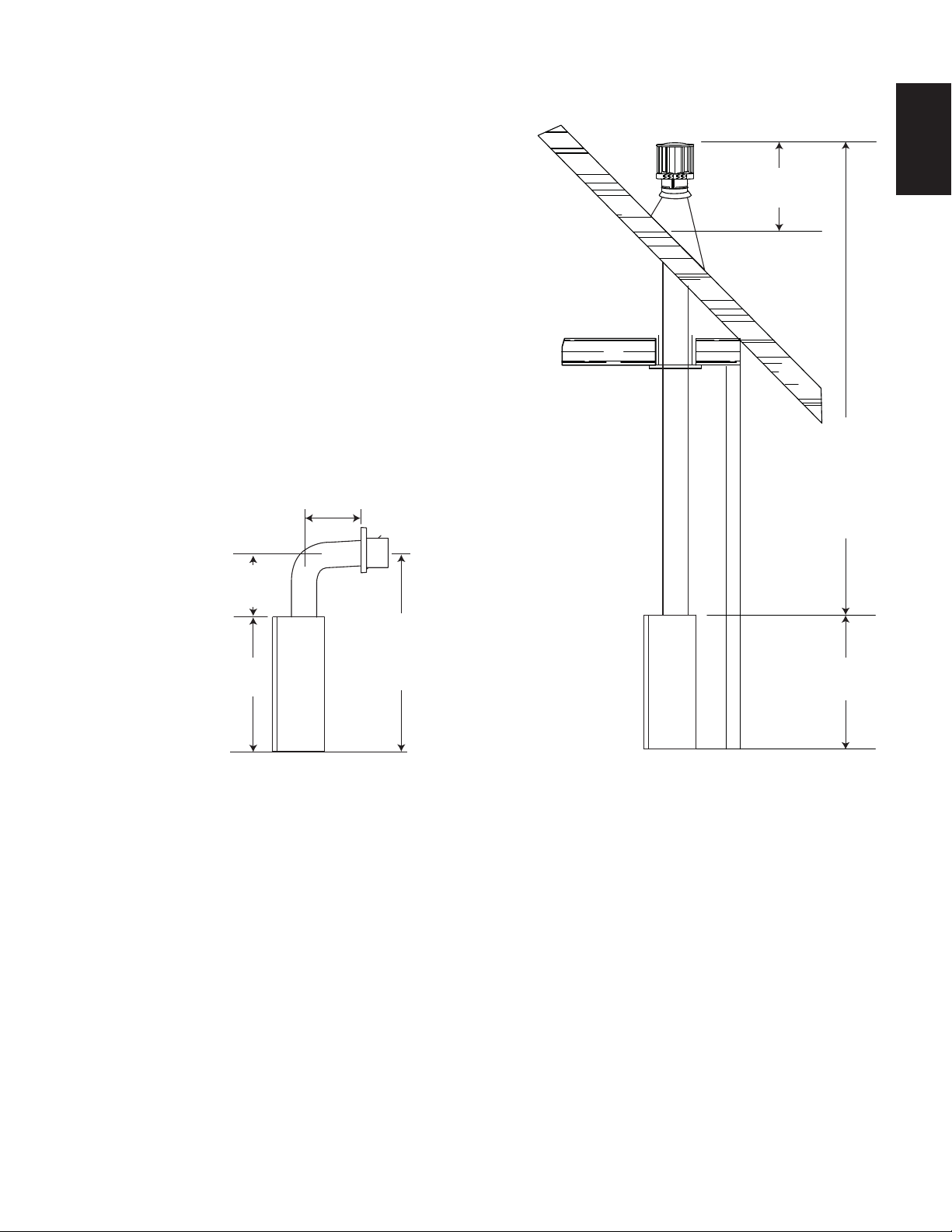

3.2 TYPICAL VENT INSTALLATION

34" (864mm)

MAXIMUM

11

EN

16" (406mm)

MINIMUM

40 FT (12m)

MAXIMUM

3 FT (1m)

MINIMUM

29" (737mm)

MINIMUM

26 3/4"

(680mm)

* See "VENTING" section.

55 3/4" (1416mm)

MINIMUM

PLUS RISE*

26 3/4"

(680mm)

W415-1426 / 12.23.14

Page 12

12

3.3 SPECIAL VENT INSTALLATIONS

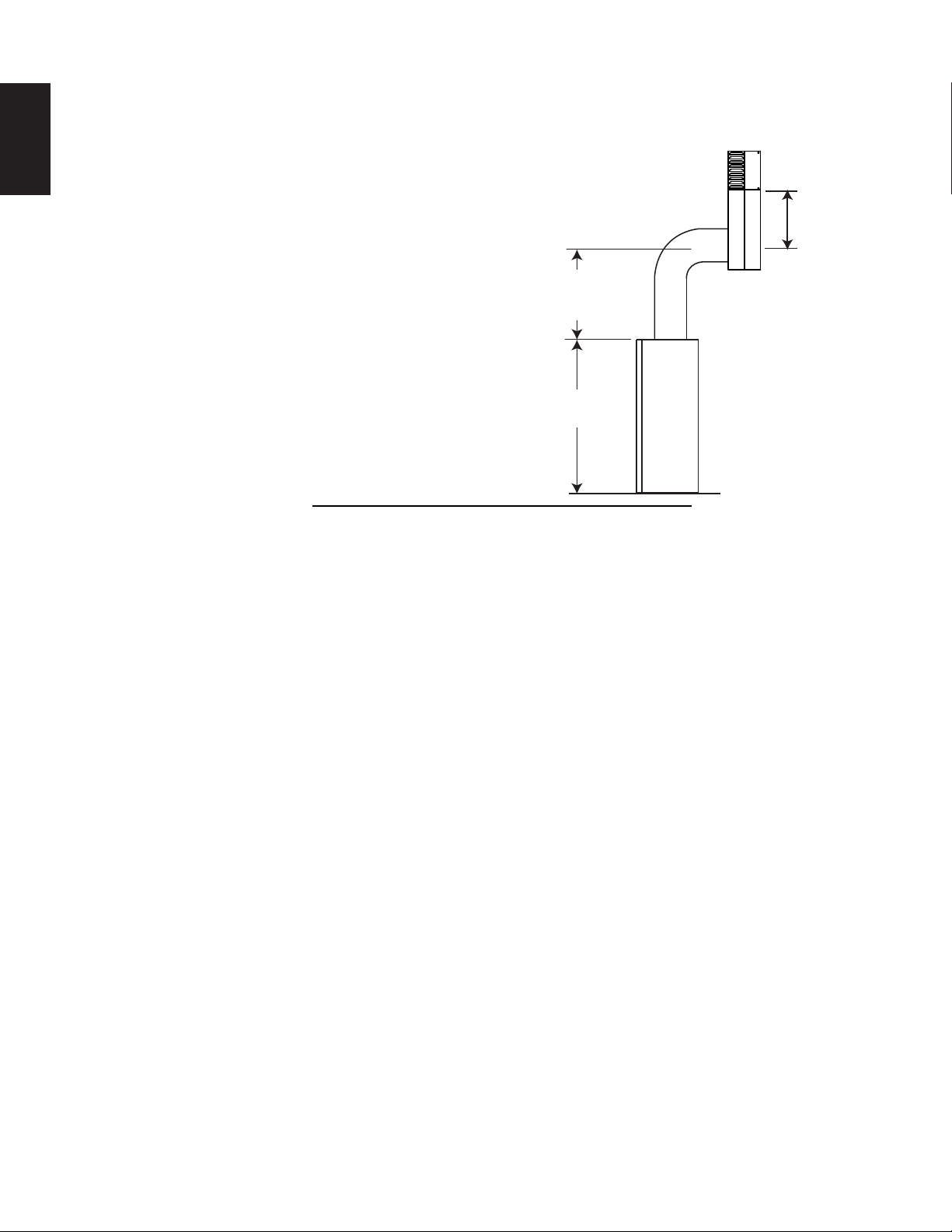

3.3.1 PERISCOPE TERMINATION

EN

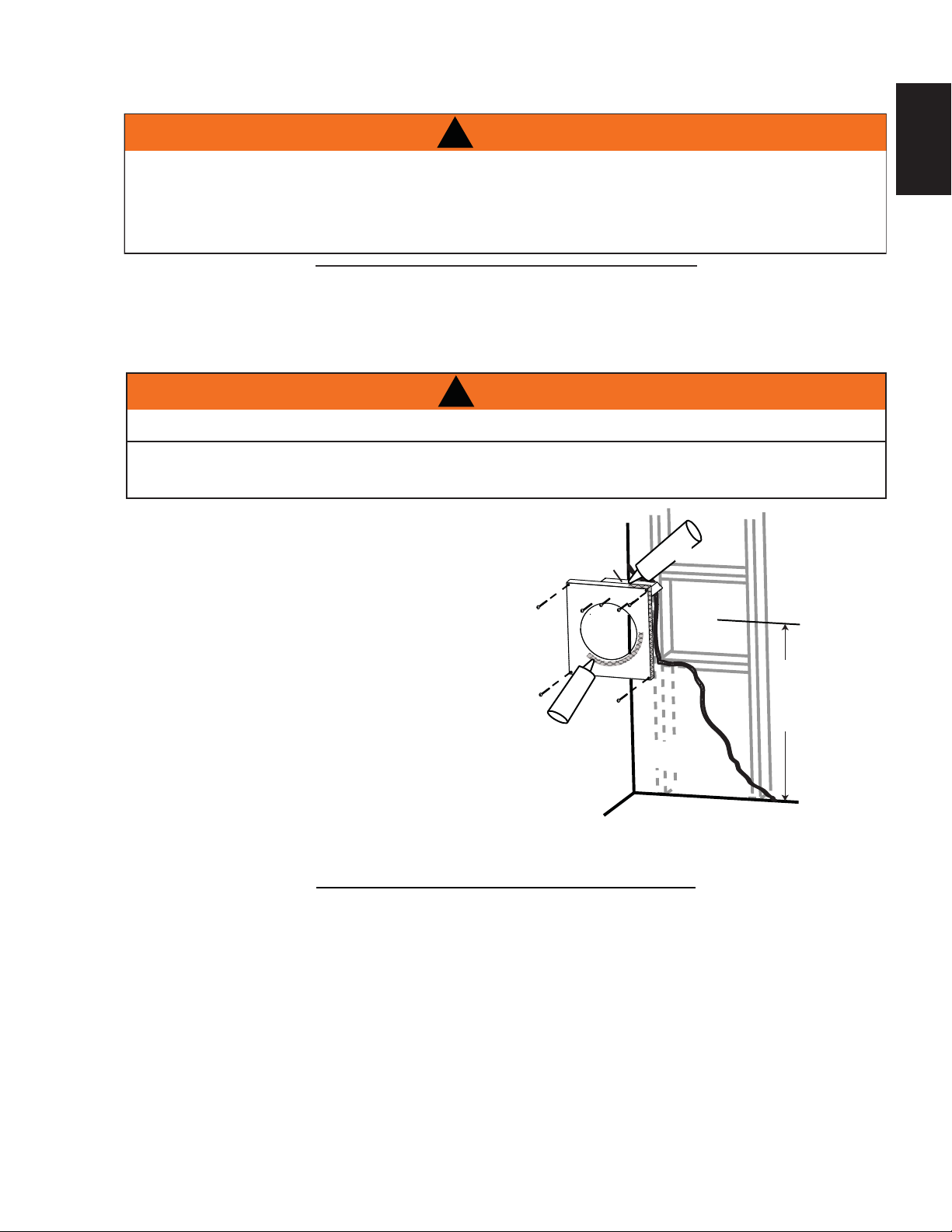

Use the periscope kit to locate the air termination above grade. The periscope must

be installed so that when fi nal grading is completed, the bottom air slot is located a

minimum 12” (305m) above grade. The maximum allowable vent length is 10’ (3m)

for a fi replace and 8’ (2m) for a stove.

12" (305mm)

MIN. TO

GRADE

29" (737mm)

MINIMUM

26 3/4" (680mm)

9.1B

W415-1426 / 12.23.14

Page 13

3.4 VENT TERMINAL CLEARANCES

13

COVERED BALCONY APPLICATIONS ††*

Q

S

R

G

P

EN

Q

= 3 feet

MIN

(0.9m)

R

= 2 x

MAX

Q

ACTUAL

INSTALLATIONS

CANADA U.S.A.

A 12” (305mm) 12” (305mm) Clearance above grade, veranda porch, deck or balcony.

B 12” (305mm)

Δ

9”

(229mm)

Clearance to windows or doors that open.

Δ

C 12” (305mm)* 12” (305mm) * Clearance to permanently closed windows.

D

18”

(457mm)**

18” (457mm)**

Vertical clearance to ventilated soffi ts located above the terminal within a horizontal distance of 2’

(0.6m) from the center line of the terminal.

E 12” (305mm)** 12” (305mm)** Clearance to unventilated soffi t.

F 0” (0mm) 0” (0mm) Clearance to an outside corner wall.

0” (0mm)***

G

2” (51mm)***

0”

(0mm)***

2”

(51mm)***

H 3’(0.9m) 3’ (0.9m)****

Clearance to an inside non-combustible corner wall or protruding non-combustible obstructions (chimney,

etc.).

Clearance to an inside combustible corner wall or protruding combustible obstructions (vent chase,

etc.).

Clearance to each side of the center line extended above the meter / regulator assembly to a

maximum vertical distance of 15’ (4.6m).

I 3’ (0.9m) 3’ (0.9m)**** Clearance to a service regulator vent outlet.

J 12” (305mm) 9” (229mm)

Clearance to a non-mechanical air supply inlet to the building or a combustion air inlet to any other

appliance.

K 6’ (1.8m) 3’ (0.9m) † Clearance to a mechanical air supply inlet.

L 7’ (2.1m) ‡ 7’ (2.1m) **** Clearance above a paved sidewalk or paved driveway located on public property.

M

12”

(305mm)††

12”

(305mm)****

Clearance under a veranda, porch or deck.

N 16” (406mm) 16” (406mm) Clearance above the roof.

O 2’ (0.6m)†* 2’ (0.6m) †* Clearance from an adjacent wall including neighbouring buildings.

P 8’ (2.4m) 8’(2.4m) Roof must be non-combustible without openings.

Q 3’ (0.9m) 3’ (0.9m) See chart for wider wall dimensions.

R 6’ (1.8m) 6’ (1.8m)

See chart for deeper wall dimensions. The terminal shall not be installed on any wall that has an

opening between the terminal and the open side of the structure.

S 12” (305mm) 12” (305mm) Clearance under a covered balcony

The terminal shall not be located less than 6 feet under a window that opens on a horizontal plane in a structure with three walls and a roof.

Δ

* Recommended to prevent condensation on windows and thermal breakage

** It is recommended to use a heat shield and to maximize the distance to vinyl clad soffi ts.

*** The periscope requires a minimum 18 inches clearance from an inside corner.

**** This is a recommended distance. For additional requirements check local codes.

† 3 feet above if within 10 feet horizontally.

‡ A vent shall not terminate where it may cause hazardous frost or ice accumulations on adjacent property surfaces.

†† Permitted only if the veranda, porch, or deck is fully open on a minimum of two sides beneath the fl oor.

†* Recommended to prevent recirculation of exhaust products. For additional requirements check local codes.

††* Permitted only if the balcony is fully open on a minimum of one side.

NOTE: Clearances are in accordance with local installation codes and the requirements of the gas supplier.

12.1D

R

IHHW

MAX

(4.6m)

W415-1426 / 12.23.14

Page 14

14

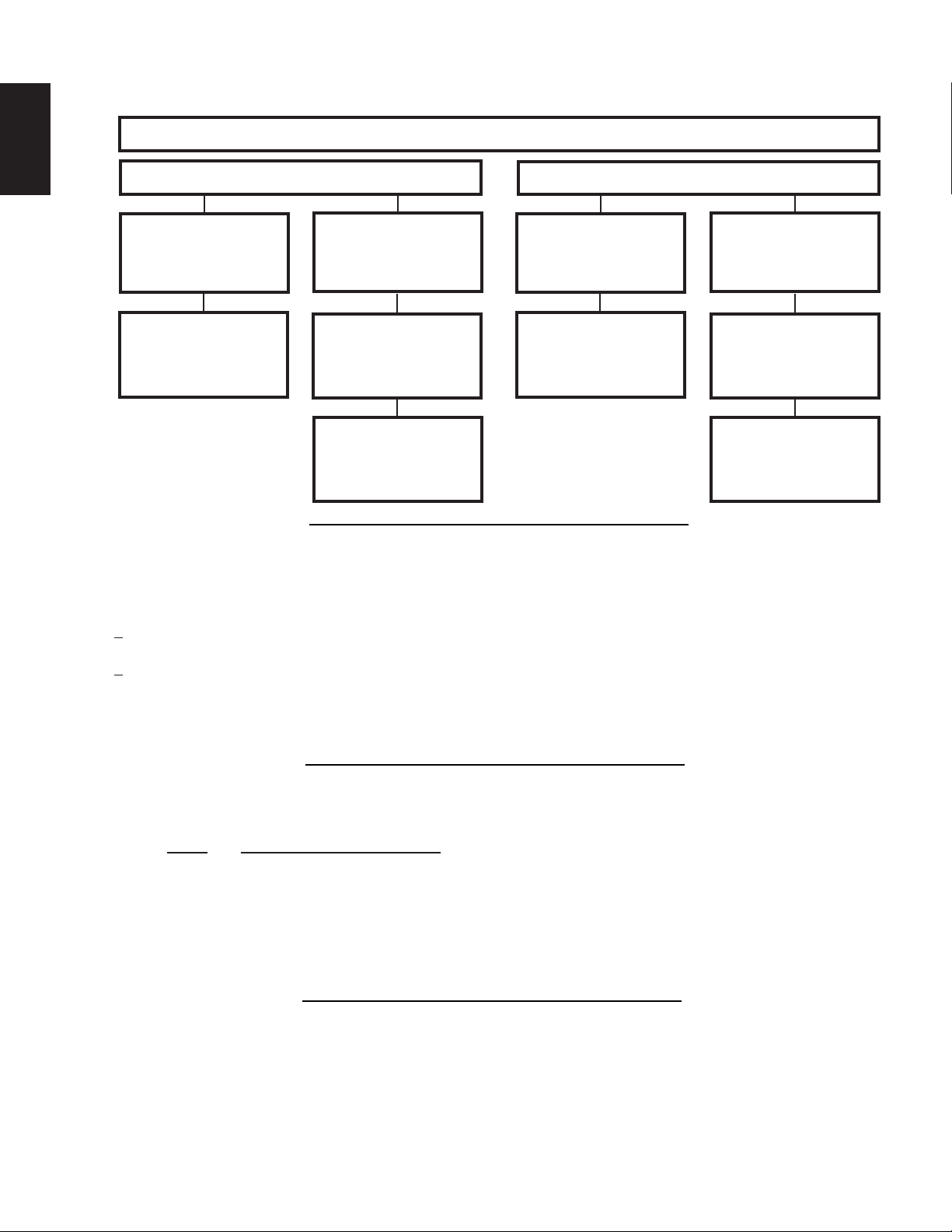

3.6 VENTING APPLICATION FLOW CHART

EN

Vertical rise is equal

to or greater than

the horizontal run

Horizontal run +

vertical rise to

maximum of 40 feet

3.5 DEFINITIONS

Horizontal Termination

Vertical rise is less

than horizontal run

Horizontal run +

vertical rise to

maximum of

(12m)

24.75 feet (7.5m)

4.2 times the

vertical rise equal to

or greater than the

horizontal run

TOP EXIT

Vertical rise is equal

maximum of 40 feet

Vertical Termination

to or greater than

the horizontal run

Horizontal run +

vertical rise to

(12m)

Vertical rise is less

than horizontal run

Horizontal run +

vertical rise to

maximum of 40 feet

(12m)

3 times the vertical

rise equal to or

greater than the

horizontal run

13.1A

For the following symbols used in the venting calculations and examples are:

> - greater than

> - equal to or greater than

< - less than

< - equal to or less than

HT - total of both horizontal vent lengths (Hr) and offsets (Ho) in feet

HR - combined horizontal vent lengths in feet

HO - offset factor: .03 (total degrees of offset - 90°*) in feet

VT - combined vertical vent lengths in feet

3.7 ELBOW VENT LENGTH VALUES

FEET INCHES MILLIMETERS

1° 0.03 0.5 12.7

15° 0.45 6.0 152.4

30° 0.9 11.0 279.4

45° 1.35 16.0 406.4

90°* 2.7 32.0 812.8

* The fi rst 90° offset has a zero value and is shown in the formula as - 90°

14.1

15.1A

W415-1426 / 12.23.14

Page 15

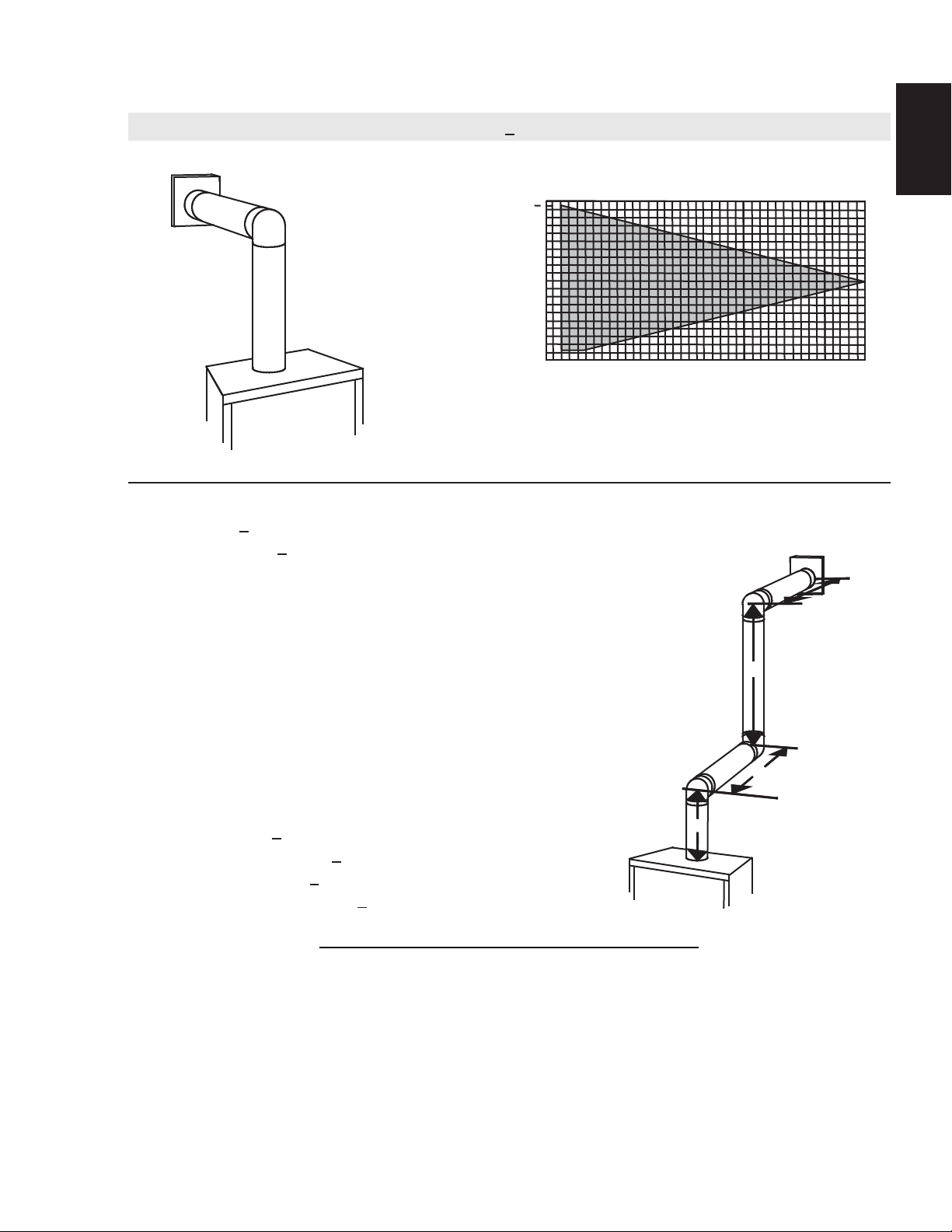

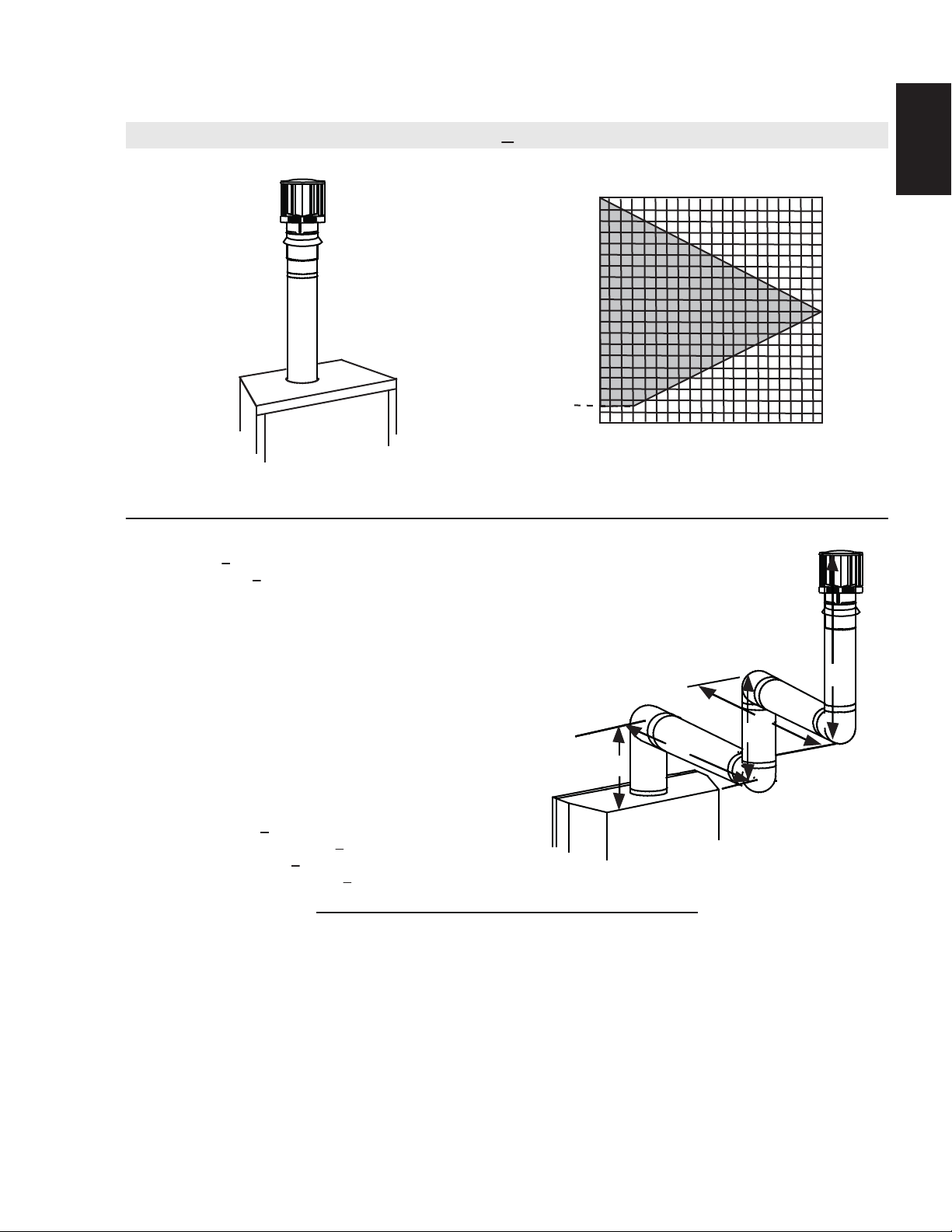

3.8 TOP EXIT HORIZONTAL TERMINATION

15

(HT) < (VT)

Simple venting confi guration (only one 90° elbow)

See graph to determine the required vertical

rise VT for the required horizontal run HT.

40 (12.2)

39 (11.9)

REQUIRED

30 (9.1)

VERTICAL RISE

IN FEET

20 (6.1)

(METERS)VT

10 (3.1)

0

2.5

(0.8)5 (1.5)

7.5

(2.3)10(3.1)

12.5

(3.8)15(5.6)

HORIZONTAL VENT RUN PLUS OFFSET IN

FEET (METERS) H

The shaded area within the lines represents

acceptable values for HT and V

For vent confi gurations requiring more than one 90° elbow, the following formulas apply:

Formula 1: HT < V

T

Formula 2: HT + VT < 40 feet (12.2m)

EN

17.5

(5.3)20(6.1)

T

T

Example:

V1 = 3 FT (0.9m)

V2 = 8 FT (2.4m)

VT = V1 + V2= 3 FT (0.9m) + 8 FT (2.4m) = 11 FT (3.4m)

H1 = 2.5 FT (0.8m)

H2 = 2 FT (0.6m)

HR = H1 + H2 = 2.5 FT (0.8m) + 2 FT (0.6m) = 4.5 FT (1.4m)

HO = .03 (three 90° elbows - 90°) = .03 (270° - 90°) = 5.4 FT (1.7m)

HT = HR + HO = 4.5 FT (1.4m) + 5.4 FT (1.7m) = 9.9 FT (3m)

HT + VT = 9.9 FT (3m) + 11 FT (3.4m) = 20.9 FT (6.4m)

Formula 1: HT < V

T

9.9FT (3m) < 11 FT (3.4m)

Formula 2: HT + VT < 40 FT (12.2m)

20.9 FT (6.4m) < 40 FT (12.2m)

Since both formulas are met, this vent confi guration is acceptable.

90°

V

1

16.10A

90°

90°

H

2

V

2

H

1

W415-1426 / 12.23.14

Page 16

16

EN

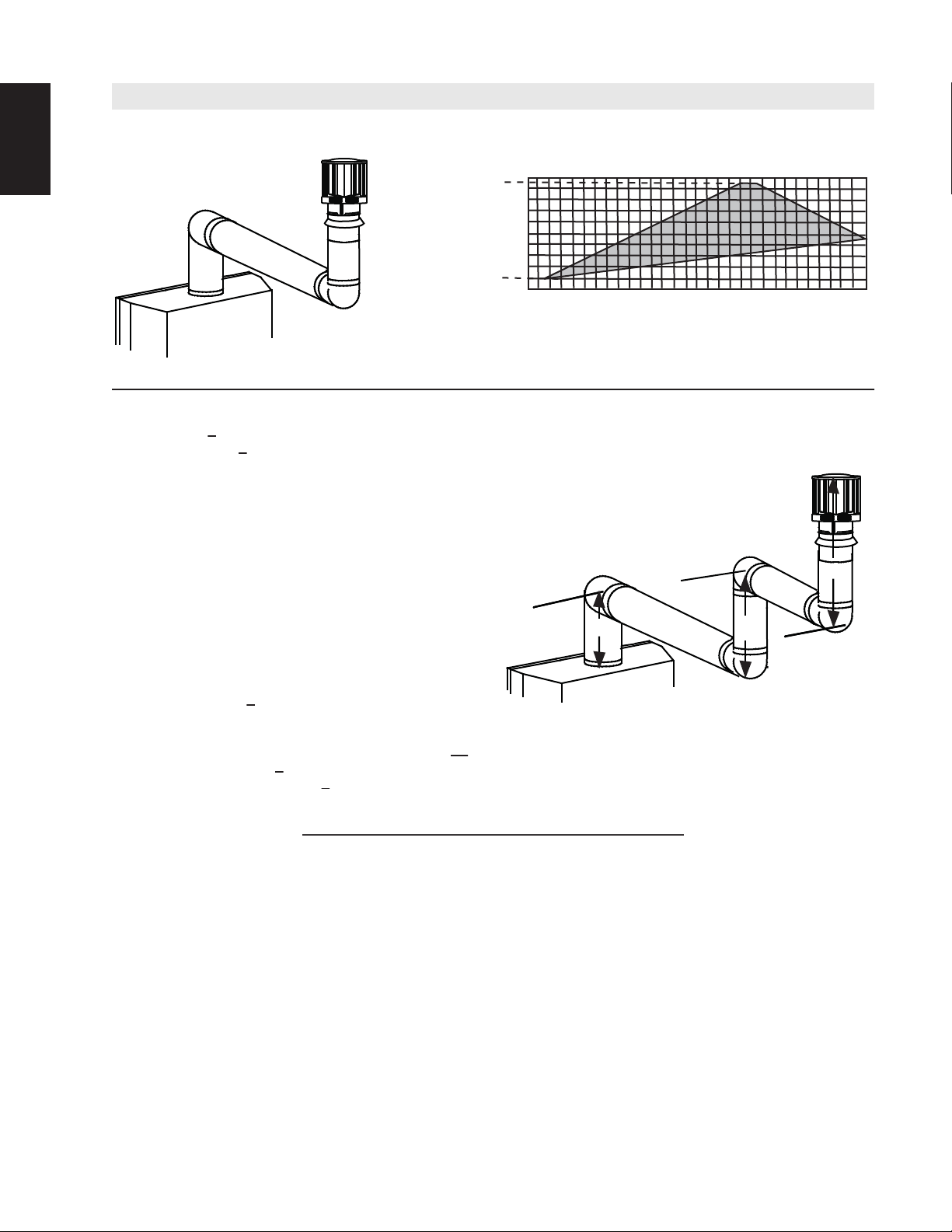

(HT) > (VT)

Simple venting configuration (only one 90° elbow)

See graph to determine the required vertical rise VT for

the required horizontal run H

150 (3810)

147 (3733.8)

REQUIRED

VERTICAL RISE

IN INCHES

(MILLIMETERS) V

T

57 (1447.8)

29 (736.6)

100 (2540)

50 (1270)

5

0

(1.5)

2.8

(0.9)

(3.1)

HORIZONTAL VENT RUN PLUS OFFSET IN FEET (METERS) H

The shaded area within the lines represents acceptable

values for H

and VT

T

For vent configurations requiring more than one 90° elbow, the following formulas apply:

Formula 1: HT < 4.2 V

Formula 2: HT + V

Example:

V

= VT = 6FT (1.8m)

1

H

= 3 FT (0.9m)

1

H

= 5 FT (1.5m)

2

H

= H

+ H

R

H

= .03 (two 90° elbows - 90°) = .03 (180° - 90°) = 2.7FT (0.8m)

O

H

= H

T

H

+ V

T

= 3FT (0.9m)+ 5FT (1.5m) = 8FT (2.4m)

1

2

+ H

= 8FT (2.4m)+ 2.7FT (0.8m) = 10.7FT (3.3m)

R

O

= 10.7FT (3.3m) + 6 FT (1.8m) = 16.7FT (5.1m)

T

T

< 24.75 feet (7.5m)

T

90°

V

1

H

1

10

90°

12.5

(3.8)

(4.6)

.

T

15

20 (6.1)

19.5

(5.9)

T

H

2

Formula 1: HT < 4.2 V

4.2 VT = 4.2FT (1.3m) x 6FT (1.8m) = 25.2 FT (7.7m)

Formula 2: HT + V

16.7 FT (5.1m) < 24.75 (7.5m)

Since both formulas are met, this vent configuration is acceptable.

T

< 24.75 FT (7.5m)

T

90°

Example:

V

= 4 FT (1.2m)

1

V

= 1.5 FT (0.5m)

2

V

= V

+ V

T

H

= 2 FT (0.6m)

1

H

= 1 FT (0.3m)

2

H

= 1 FT (0.3m)

3

H

= 1.5 FT (0.5m)

4

H

= H

R

H

= .03 (four 90° elbows - 90°) = .03 (360° - 90°) = 8.1FT (2.5m)

O

H

= H

T

H

+ V

T

Formula 1: HT < 4.2 V

4.2 VT = 4.2FT (1.3m) x 5.5FT (1.7m) = 23.1FT (7m)

= 4 FT (1.2m) + 1.5 FT (0.5m)= 5.5 FT (1.7m)

1

2

+ H2 + H

1

+ H

R

= 13.6FT (4.2m) + 5.5FT (1.7m) = 19.1FT (5.8m)

T

+ H4 = 2FT (0.6m) + 1FT (0.3m) + 1FT (0.3m) + 1.5FT (0.5m) = 5.5FT (1.7m)

3

= 5.5FT (1.7m) + 8.1FT (2.5m) = 13.6FT (4.2m)

O

T

V

13.6FT (4.2m) < 23.1FT (7m)

Formula 2: HT + V

19.1FT (5.8m) < 24.75 (7.5m)

< 24.75 FT (7.5m)

T

Since both formulas are met, this vent configuration is acceptable.

90°

90°

H

1

90°

1

V

H

H

2

3

16.1_3B

H

4

2

W415-1426 / 12.23.14

Page 17

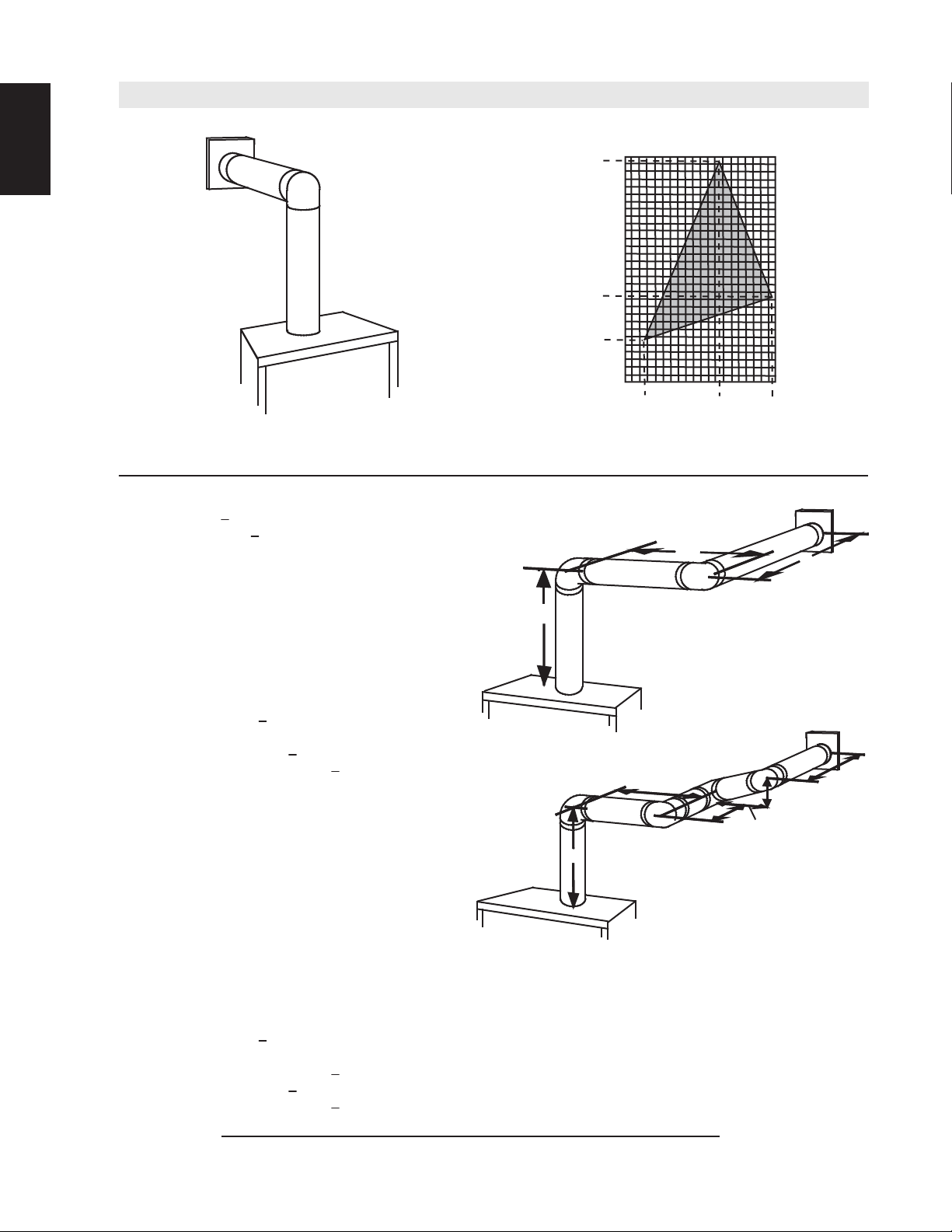

3.9 TOP EXIT VERTICAL TERMINATION

17

(HT) < (VT)

Simple venting configurations.

See graph to determine the required vertical rise V

required horizontal run H

40 (12.2)

30 (9.1)

REQUIRED

VERTICAL

RISE IN FEET

(METERS) V

T

3 (0.9)

20 (6.1)

10 (3.1)

0

5

(1.5)

HORIZONTAL VENT RUN PLUS OFFSET IN FEET (METERS) H

The shaded area within the lines represents acceptable

values for H

T

For vent configurations requiring one or more 90° elbows the following formulas apply:

Formula 1: HT < V

Formula 2: HT + V

T

< 40 feet (12.2m)

T

10

(3.1)

and VT

T

15

(4.6)

EN

for the

20

(6.1)

T

T

.

Example:

V

= 5 FT (1.5m)

1

V

= 6 FT (1.8m)

2

V

= 10 FT (3.1m)

3

V

= V

+ V2 + V3 = 5FT (1.5m) + 6FT (1.8m) + 10FT (3.1m) = 21FT (6.4m)

T

1

H

= 8 FT (2.4m)

1

H

= 2.5 FT (0.8m)

2

H

= H

+ H

R

H

= .03 (four 90° elbows - 90°)

O

= .03 (360° - 90°) = 8.1 FT (2.5m)

H

= H

T

H

+ V

T

Formula 1: HT < V

18.6FT (5.7m) < 21FT (6.4m)

Formula 2: HT + V

39.6FT (12.1m) < 40FT (12.2m)

= 8FT (2.4m) + 2.5FT (0.8m) = 10.5 FT (3.2m)

1

2

+ H

= 10.5FT (3.2m) + 8.1FT (2.5m) = 18.6FT (5.7m)

R

O

= 18.6FT (5.7m) + 21FT (6.4m) = 39.6FT (12.1m)

T

T

< 40 FT (12.19m)

T

Since both formulas are met, this vent configuration is acceptable.

V

90°

1

90°

V

3

H

2

V

H

1

2

90°

90°

18.1A

W415-1426 / 12.23.14

Page 18

18

EN

Simple venting configurations.

(HT) > (VT)

20 (6.1)

19 (5.8)

See graph to determine the required vertical rise V

required horizontal run H

.

T

for the

T

REQUIRED

VERTICAL

RISE IN FEET

(METERS) V

T

3 (0.9)

10 (3.1)

0

5

(1.5)

10

(3.1)

15

(4.6)

20

(6.1)

25

(7.6)

(9.1)

HORIZONTAL VENT RUN PLUS OFFSET IN FEET (METERS) H

The shaded area within the lines represents acceptable

values for H

and VT

T

For vent configurations requiring more than two 90° elbows the following formulas apply:

Formula 1: H

Formula 2: HT + V

< 3V

T

T

< 40 feet (12.2m)

T

Example:

V

= 2 FT (0.6m)

1

V

= 1 FT (0.3m)

2

V

= 1.5 FT (0.5m)

3

V

= V1+V2+V3= 2FT (0.6m) + 1FT (0.3m) + 1.5FT (0.5m) = 4.5FT (1.4m)

T

H

= 6 FT (1.8m)

1

H

= 2 FT (0.6m)

2

H

= H

+ H

R

H

= .03 (four 90° elbows - 90°)

O

= .03 (360° - 90°) = 8.1 FT (2.5m)

H

= H

T

H

+ V

T

= 6FT (1.8m) + 2FT (0.6m) = 8 FT (2.4m)

1

2

+ H

= 8FT (2.4m) + 8.1FT (2.5m) = 16.1FT (4.9m)

R

O

= 16.1FT (4.9m) + 4.5FT (1.4m) = 20.6 FT (6.3m)

T

90°

H

V

1

1

90°

V

H

2

V

2

3

90°

90°

Formula 1: HT < 3V

3VT = 3FT (0.9m) x 4.5FT (1.4m) = 13.5FT (4.1m)

T

16.1FT (4.9m) > 13.5FT (4.1m)

Since this formula is not met, this vent configuration is unacceptable.

Formula 2: HT + VT < 40 feet (12.2m)

20.6FT (6.3m) < 40 (12.2m)

Since only formula 2 is met, this vent configuration is unacceptable and a new appliance location or vent configuration will

need to be established to satisfy both formulas.

18.1_2B

T

30

W415-1426 / 12.23.14

Page 19

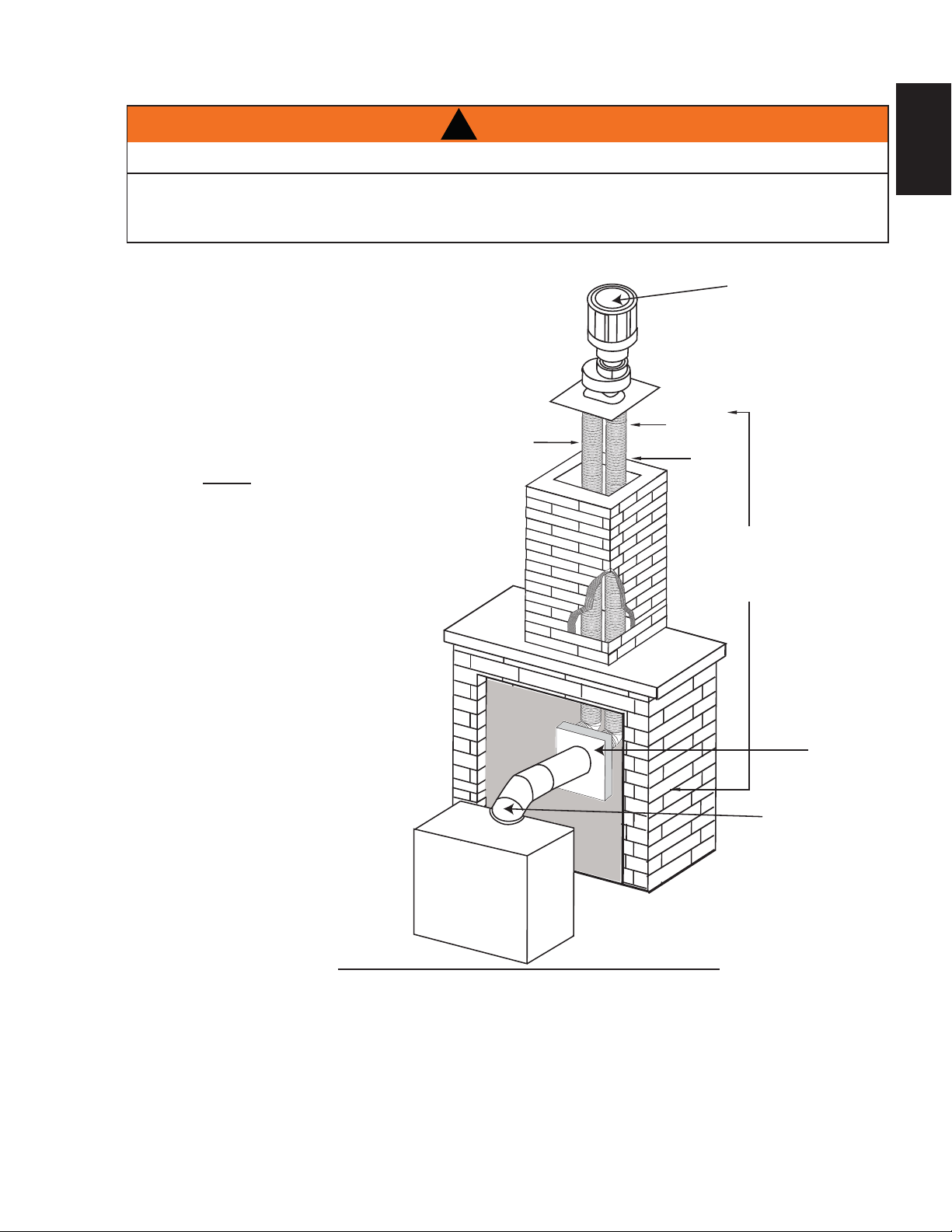

3.10 VERTICAL THROUGH EXISTING CHIMNEY

AIR

INTAKE

EXHAUST

FLUE

FLEX

LINER

* 40 FT (12.2m)

MAX.

10 FT (3.1m)

MIN

COAXIAL TO

CO-LINEAR

ADAPATOR

APPLIANCE

VENT ADAPTOR

TERMINATION

!

WARNING

RISK OF FIRE!

CO-AXIAL TO CO-LINEAR VENTING CONFIGURATIONS MUST ONLY BE USED IN A NON-

COMBUSTIBLE CHIMNEY OR ENCLOSURE. INSTALLATION IN A COMBUSTIBLE ENCLOSURE COULD

RESULT IN A FIRE.

This appliance is designed to be attached to a 3” (76.2mm) co-linear aluminum fl ex vent system running the

full length of a masonry chimney.

The fl ex liners accommodate any contours of a

masonry chimney, however, it is necessary to keep

the fl exible liners as straight as possible. The inlet air

collar of the termination cap must be connected to

the air intake fl ex liner and the exhaust collar must be

connected to the exhaust fl exible liner.

Both Simpson Duravent and Selkirk co-linear to

co-axial adaptors have been approved on this

appliance (NOTE: A vent adaptor will be required

directly off the appliance).

Follow vent manufacturer’s installation instructions.

Different manufacturer’s venting components must

not be combined. Once the preferred manufacturer’s

appliance adaptor has been attached, the

remainder of the system must be that of the

same manufacturer.

19

EN

The only exception to this rule is to use Wolf

Steel’s approved 3” (76.2mm) fl ex liner and

co-linear termination.

* Measured from appliance fl ue collar to

termination fl ue collar

7.6A

W415-1426 / 12.23.14

Page 20

20

4.0 INSTALLATION

EN

!

WARNING

ENSURE TO UNPACK ALL LOOSE MATERIALS FROM INSIDE THE FIREBOX PRIOR TO HOOKING UP

THE GAS AND ELECTRICAL SUPPLY.

IF YOUR APPLIANCE IS SUPPLIED WITH A REMOTE ENSURE THE REMOTE RECEIVER IS IN THE

“OFF” POSITION PRIOR TO HOOKING UP THE GAS AND ELECTRICAL SUPPLY TO THE APPLIANCE.

FOR SAFE AND PROPER OPERATION OF THE APPLIANCE, FOLLOW THE VENTING INSTRUCTIONS

EXACTLY.

ALL INNER EXHAUST AND OUTER INTAKE VENT PIPE JOINTS MAY BE SEALED USING EITHER RED

RTV HIGH TEMP SILICONE SEALANT W573-0002 (NOT SUPPLIED) OR BLACK HIGH TEMP MILL PAC

W573-0007 (NOT SUPPLIED) WITH THE EXCEPTION OF THE APPLIANCE EXHAUST FLUE COLLAR

WHICH MUST BE SEALED USING MILL PAC.

IF USING PIPE CLAMPS TO CONNECT VENT COMPONENTS, 3 SCREWS MUST ALSO BE USED TO

ENSURE THE CONNECTION CANNOT SLIP OFF.

DO NOT CLAMP THE FLEXIBLE VENT PIPE.

RISK OF FIRE, EXPLOSION OR ASPHYXIATION. IMPROPER SUPPORT OF THE ENTIRE VENTING

SYSTEM MAY ALLOW VENT TO SAG AND SEPARATE. USE VENT RUN SUPPORTS AND CONNECT

VENT SECTIONS PER INSTALLATION INSTRUCTIONS.

RISK OF FIRE, DO NOT ALLOW LOOSE MATERIALS OR INSULATION TO TOUCH THE VENT PIPE.

REMOVE INSULATION TO ALLOW FOR THE INSTALLATION OF THE ATTIC SHIELD AND TO

MAINTAIN CLEARANCES TO COMBUSTIBLES.

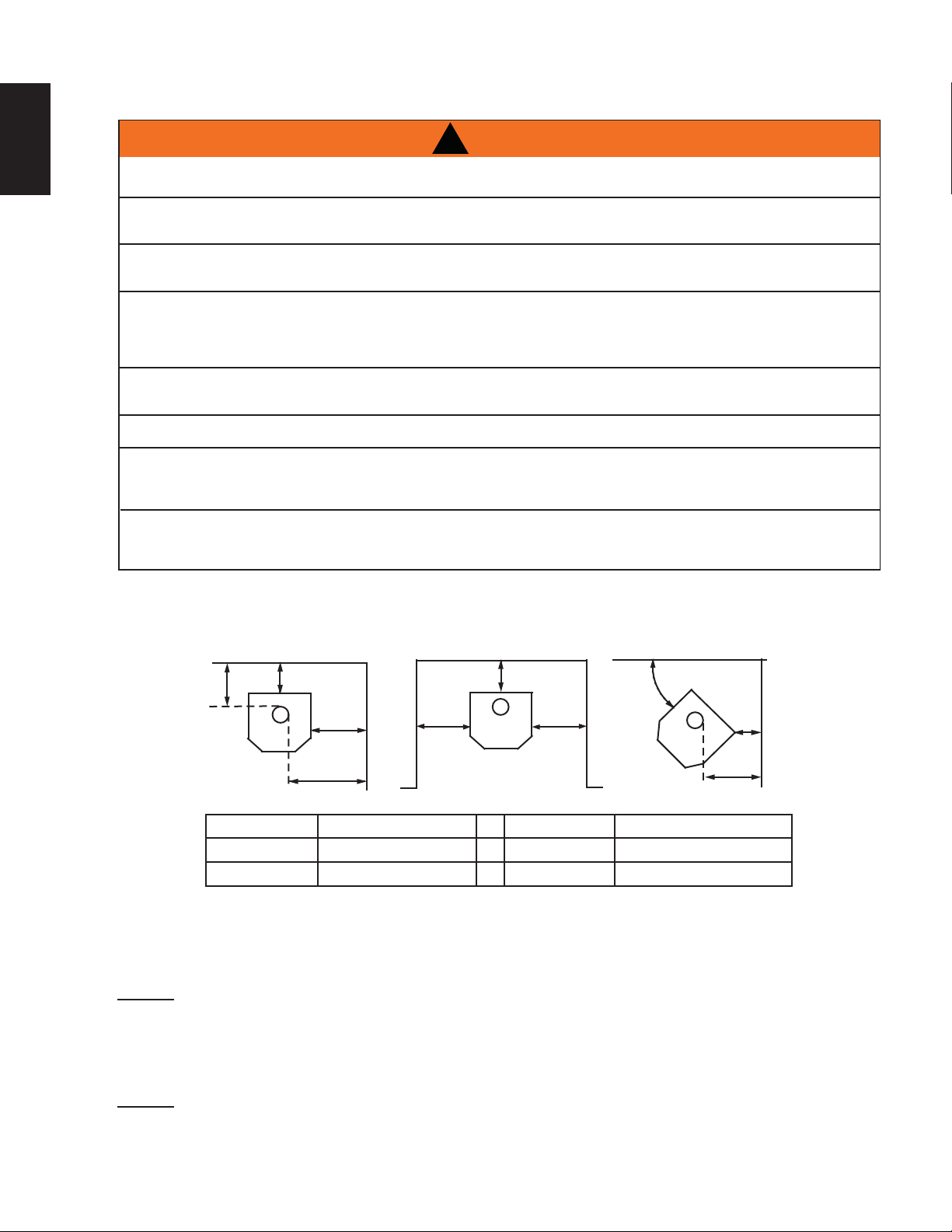

4.1 MINIMUM CLEARANCES TO COMBUSTIBLES

Back Wall

E

- A minimum 20" (508mm) from appliance top to ceiling.

- A minimum 1" (25mm) clearance to combustibles from bottom and sides of vent pipe.

* At a distance of 1" (25mm) from the wall, access to the blower switch, on/off switch or the blower power cord

may not be practical.

GDS28:

HORIZONTAL VENT SECTIONS: A minimum clearance of 2" (51mm) at the top and 1" (25mm) at the bottom

and sides of the vent pipe on all horizontal runs is required.

VERTICAL VENT SECTIONS: A minimum of 1" (25mm) all around the vent pipe on all vertical runs to

combustibles is required.

GDS28:

A minimum of 1" (25mm) all around the B vent pipe on both horizontal and vertical runs to combustibles is

required.

B

A 7" (178mm) D 14 3/4" (375mm)

B 2" (51mm) E 4" (102mm)

C 1" (25mm) * F 9 1/2" (241mm)

Side Wall

A

D

Back Wall

A

Alcove

B

A

Back Wall

Side Wall

45°

Side Wall

C

F

W415-1426 / 12.23.14

Page 21

4.2 WALL AND CEILING PROTECTION

A

21

DO NOT FILL THE SPACE BETWEEN THE VENT PIPE AND ENCLOSURE WITH ANY TYPE OF

MATERIAL. DO NOT PACK INSULATION OR COMBUSTIBLES BETWEEN CEILING FIRESTOPS.

ALWAYS MAINTAIN SPECIFIED CLEARANCES AROUND VENTING AND FIRESTOP SYSTEMS.

INSTALL WALL SHIELDS AND FIRESTOPS AS SPECIFIED. FAILURE TO KEEP INSULATION OR

OTHER MATERIALS AWAY FROM VENT PIPE MAY CAUSE FIRE.

For optimum performance, it is recommended that all horizontal runs have a minimum 1/4" (6.4mm) rise per

foot when venting. For safe and proper operation of the appliance, follow the venting instructions exactly.

4.2.1 HORIZONTAL INSTALLATION

THE FIRESTOP ASSEMBLY MUST BE INSTALLED WITH THE VENT SHIELD TO THE TOP.

TERMINALS MUST NOT BE RECESSED INTO A WALL OR SIDING MORE THAN THE DEPTH OF THE

RETURN FLANGE OF THE MOUNTING PLATE.

This application occurs when venting through an exterior wall.

Having determined the correct height for the air terminal

location, cut and frame a hole in the exterior wall as

illustrated to accommodate the fi restop assembly.

Dry fi t the fi restop assembly before proceeding to

ensure the brackets on the rear surface fi t to the

inside surface of the horizontal framing.

!

WARNING

!

WARNING

VENT

SHIELD

EN

70.1

CAULKING

The length of the vent shield may be cut shorter

for combustible walls that are less than 8 1/2”

(215.9mm)thick but the vent shield must extend the

full depth of the combustible wall.

. Assemble the shield to the spacer as shown,

using the 3 shorter screws supplied.

B. Place the fi restop top so that the vent shield covers the top

of the vent within the opening. Ensure that both spacer and

shield maintain the required clearance to combustibles.

C. Secure the spacer in place using the 4 longer screws supplied. Once the vent pipe is installed in its

fi nal position, apply sealant between the pipe and the fi restop spacer.

FIRESTOP

SPACER

DETERMINE

THE

CORRECT

HEIGHT

FINISHING

MATERIAL

20.5B

W415-1426 / 12.23.14

Page 22

22

4.2.2 VERTICAL INSTALLATION

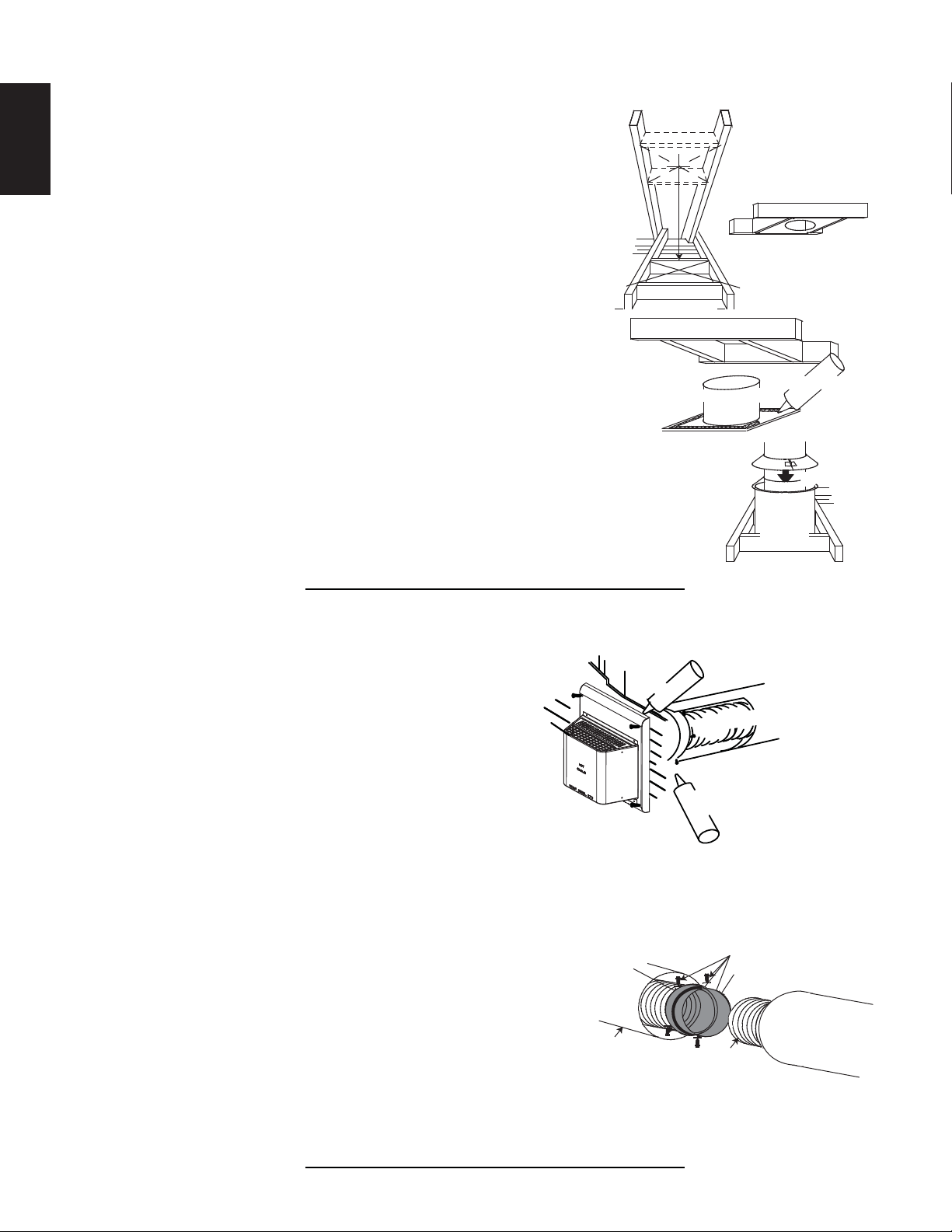

This application occurs when venting through a roof. Installation kits for

EN

various roof pitches are available from your authorized dealer / distributor. See

accessories to order specifi c kits required.

A. Determine the air terminal location, cut and frame a square opening as

illustrated in the ceiling and the roof to provide the minimum 1“ (25mm)

clearance between the vent pipe and any combustible material. Try to center

the vent pipe location midway between two joists to prevent having to cut

them. Use a plumb bob to line up the center of the openings. A vent pipe

shield will prevent any materials such as insulation, from fi lling up the 1”

(25mm) air space around the pipe. Nail headers between the joist for

extra support.

B. Apply a bead of caulking (not supplied) to the framework or to the Wolf

Steel vent pipe shield plate or equivalent (in the case of a fi nished ceiling),

and secure over the opening in the ceiling. A fi restop must be placed on the

bottom of each framed opening in a roof or ceiling that the venting system passes

through. Apply a bead of caulking all around and place a fi restop spacer over

VENT PIPE

SHIELD

the vent shield to restrict cold air from being drawn into the room or around the

fi replace. Ensure that both spacer and shield maintain the required clearance to

combustibles. Once the vent pipe is installed in its fi nal position, apply sealant between the

pipe and the fi restop assembly.

C. In the attic, slide the vent pipe collar down to cover up the open end of the shield and

tighten. This will prevent any materials, such as insulation, from fi lling up the 1” (25mm) air

space around the pipe.

21.1

4.2.3 HORIZONTAL AIR TERMINAL INSTALLATION - MODEL GDS28

A. Stretch the inner fl ex pipe to the required length

taking into account the additional length needed for

the fi nished wall surface. Apply a heavy bead of the

high temperature sealant W573-0007 Mill Pac (not

supplied) to the inner sleeve of the air terminal. Slip

the vent pipe a minimum of 2” (50.8mm) over the inner

sleeve of the air terminal and secure with 3 #8 screws.

B. Using the outer rigid pipe, slide over the outer combustion air

sleeve of the air terminal and secure with 3 #8 screws. Seal

using high temperature sealant W573-0002 (not supplied).

#10x2"

SCREWS

CAULKING

4" (101.6mm) FLEX PIPE

2" (50.8mm) OVERLAP

HIGH TEMP

SEALANT

9" (288.6mm)

FIRESTOP

UNDERSIDE OF

JOIST

CAULKING

VENT

PIPE

COLLAR

VENT

PIPE

SHIELD

7" (177.8mm) RIGID

PIPE

C. Insert the vent pipes through the fi restop maintaining the required clearance to combustibles. Holding the air

D. From inside the house, using silicone, seal between the vent

E. If more vent pipe needs to be used to reach the appliance,

The air terminal mounting plate may be recessed into the exterior wall or siding no greater than the depth of its

return fl ange.

W415-1426 / 12.23.14

terminal (lettering in an upright, readable position), secure to the exterior wall and make weather tight by sealing

with caulking (not supplied).

#8 X 1/2”SELF DRILLING

pipe and the fi restop. Then slide the black trim collar over the

vent pipe up to the fi restop.

couple them together as illustrated. The vent system must

be supported approximately every 3 feet (0.9m) for both

vertical and horizontal runs. Use noncombustible strapping

HI-TEMP

SEALANT

OUTER

RIGID PIPE

SCREWS & WASHERS

INNER COUPLER

OUTER

RIGID PIPE

INNER

FLEX PIPE

to maintain the minimum clearance to combustibles.

23.7C

Page 23

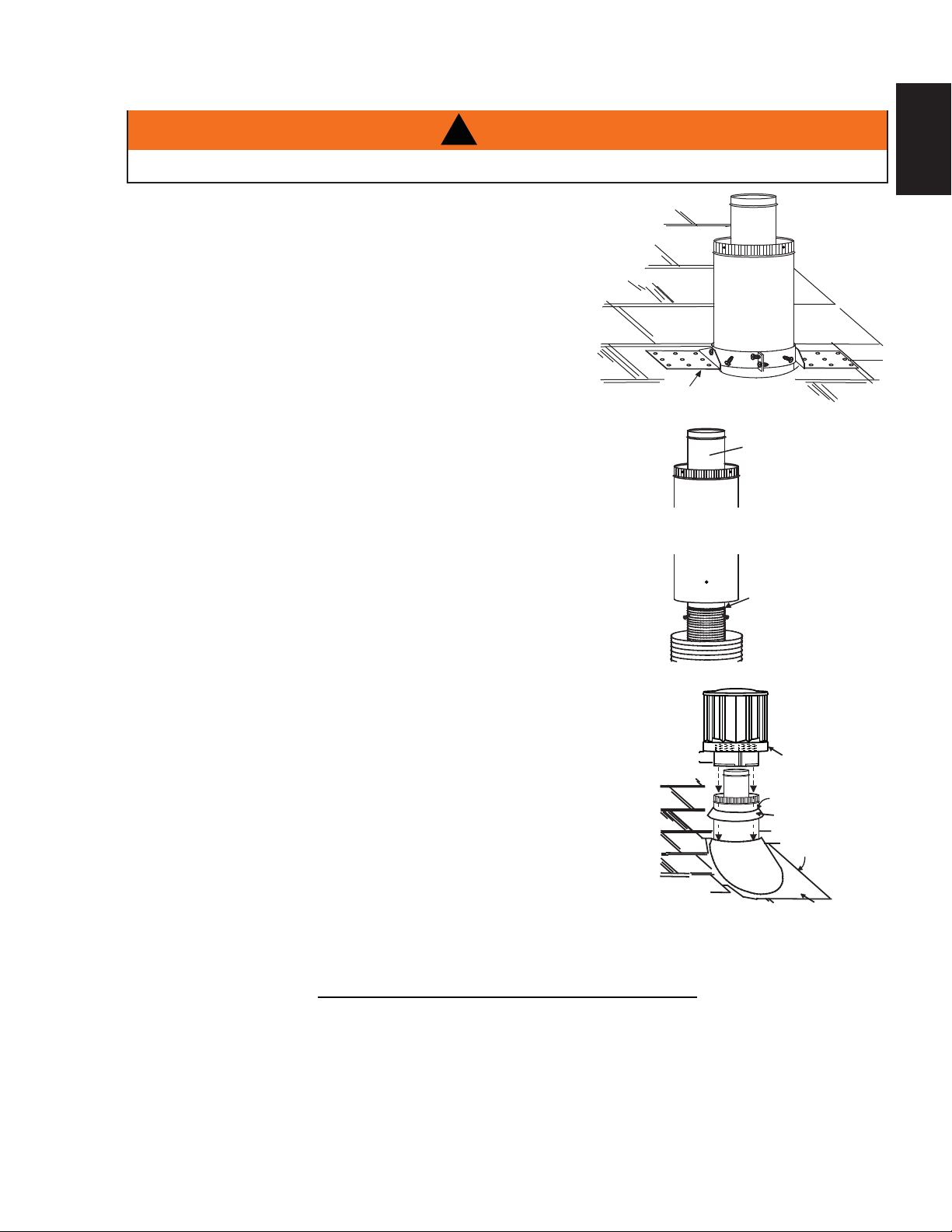

4.2.4 VERTICAL AIR TERMINAL INSTALLATION

!

WARNING

MAINTAIN A MINIMUM 2” (51mm) SPACE BETWEEN THE AIR INLET BASE AND THE STORM COLLAR.

A. Fasten the roof support to the roof using the screws provided. The

roof support is optional. In this case the venting is to be adequately

supported using either an alternate method suitable to the authority

having jurisdiction or the optional roof support.

B. Stretch the inner fl ex pipe to the required length. Slip the

inner fl ex pipe a minimum of 2” (51mm) over the inner pipe

of the air terminal connector and secure with 3 #8 screws.

Seal using a heavy bead of high temperature sealant

W573-0007 (not supplied).

23

EN

C. Repeat using the outer fl ex pipe, using a heavy bead of

high temperature sealant W573-0002 (not supplied).

D. Thread the air terminal connector / vent pipe assembly down through

the roof. The air terminal must be positioned vertically and plumb.

Attach the air terminal connector to the roof support, ensuring that the

top of the air terminal is 16” (406mm) above the highest point that it

penetrates the roof.

E. Remove nails from the shingles, above and to the sides of the air

terminal connector. Place the fl ashing over the air terminal connector

leaving a min. 3/4” (19mm) of the air terminal connector showing

above the top of the fl ashing. Slide the fl ashing underneath the

sides and upper edge of the shingles. Ensure that the air terminal

connector is properly centred within the fl ashing, giving a 3/4”

(19mm) margin all around. Fasten to the roof. Do not nail through

the lower portion of the fl ashing. Make weather-tight by sealing with

caulking. Where possible, cover the sides and top edges of the

fl ashing with roofi ng material.

2” (51mm)

F. Aligning the seams of the terminal and air terminal connector,

place the terminal over the air terminal connector making sure

the vent pipe goes into the hole in the terminal. Secure with

the three screws provided.

G. Apply a heavy bead of weatherproof caulking 2” (51mm) above

the fl ashing. Install the storm collar around the air terminal and

slide down to the caulking. Tighten to ensure that a weathertight seal between the air terminal and the collar is achieved.

ROOF SUPPORT

INNER PIPE

AIR

TERMINAL

CONNECTOR

HIGH

TEMPERATURE

SEALANT

INNER FLEX PIPE

OUTER RIGID

OUTER FLEX PIPE

PIPE

AIR I NL ET

BASE

CAULKING

STORM COLLAR

WEA THER

SEALANT

FLASHING

H. If more vent pipe needs to be used to reach the appliance see “HORIZONTAL

AIR TERMINAL INSTALLATION” section.

24.1A

W415-1426 / 12.23.14

Page 24

24

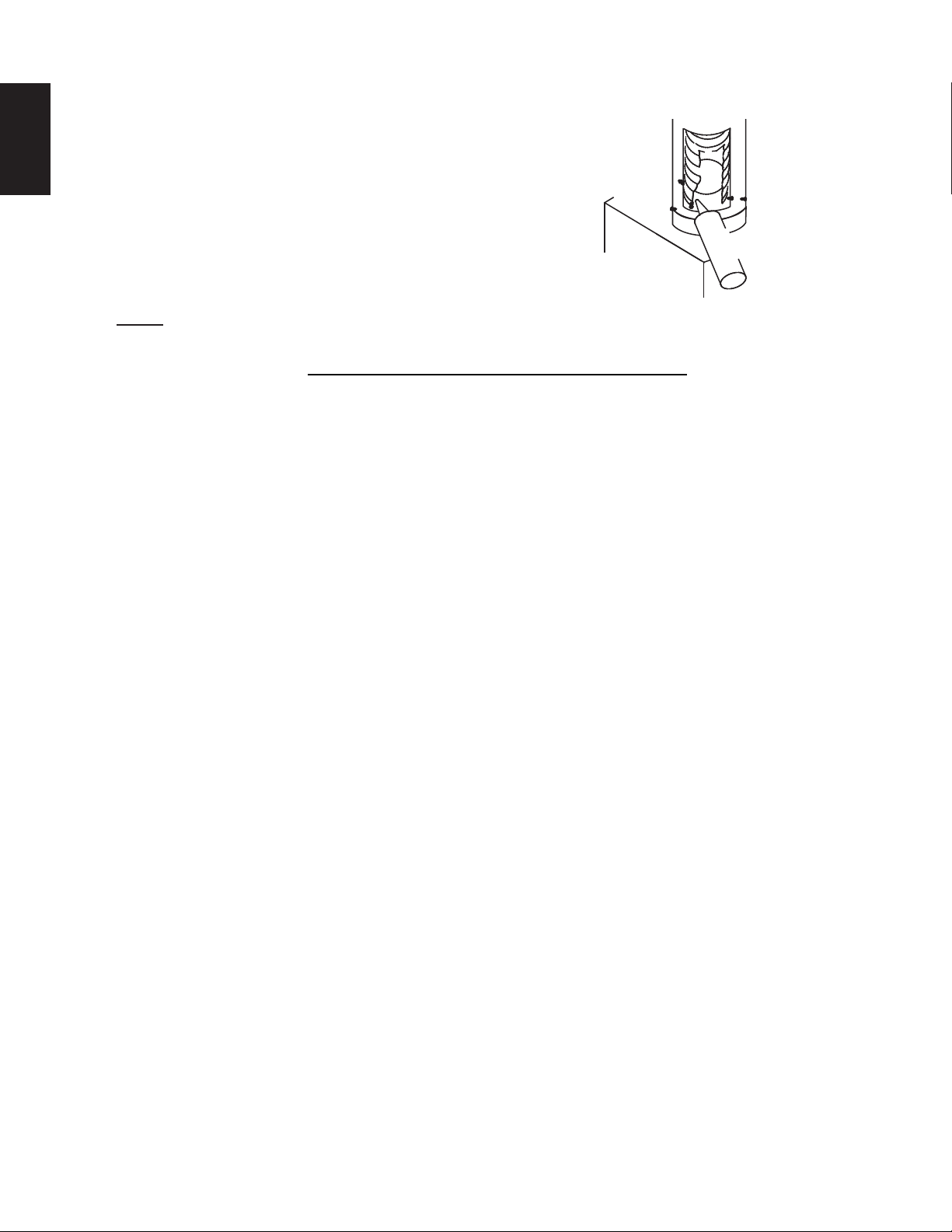

4.3 APPLIANCE VENT CONNECTION

EN

A. Attach the adjustable pipe to the last section of rigid pipe.

Secure with screws and seal.

B. Install the inner fl ex pipe to the appliance. Secure with

3 screws. Seal the joint and screw holes using the high

temperature sealant W573-0007 Mill-Pac (not supplied).

C. Run a bead of high temperature sealant (not supplied) around

the inside of the air intake collar. Pull the adjustable pipe a

minimum 2” (50.8mm) into the air intake collar.

NOTE: Ensure that the sealant is not visible on the exterior pipes once installation is completed. An

optional decorative black band is available for this use. In the event that the venting must be disassembled,

care must be taken to reseal the venting.

4.4 MOBILE HOME INSTALLATION - MODEL GDS28

In Canada, mobile home installation may be vented horizontally or vertically. In the United States, it may only

be installed vertically. See "VERTICAL VENTING" or "HORIZONTAL AIR TERMINAL INSTALLATION" section

for installation.

For mobile home installations, the appliance must be fastened in place. It is recommended that the appliance

be secured in all installations. Use the levelling / securing kit, GDSLL-KT for this purpose.

#8 X 1/2”

SELF

DRILLING

SCREWS

2” (50.8mm)

OVERLAP

HIGH TEMPERATURE

SEALANT

28.3A

W415-1426 / 12.23.14

Page 25

4.5 GAS INSTALLATION

25

!

WARNING

RISK OF FIRE, EXPLOSION OR ASPHYXIATION. ENSURE THERE ARE NO IGNITION SOURCES SUCH AS

SUPPORT GAS CONTROL WHEN ATTACHING GAS SUPPLY PIPE TO PREVENT DAMAGING GAS LINE.

ALWAYS LIGHT THE PILOT WHETHER FOR THE FIRST TIME OR IF THE GAS SUPPLY HAS RUN OUT

WITH THE GLASS DOOR OPENED OR REMOVED. PURGING OF THE GAS SUPPLY LINE SHOULD BE

PERFORMED BY A QUALIFIED SERVICE TECHNICIAN. ASSURE THAT A CONTINUOUS GAS FLOW IS AT

THE BURNER BEFORE CLOSING THE DOOR. ENSURE ADEQUATE VENTILATION. FOR GAS AND

ELECTRICAL LOCATIONS, SEE “DIMENSION” SECTION.

ALL GAS CONNECTIONS MUST BE CONTAINED WITHIN THE APPLIANCE WHEN COMPLETE.

HIGH PRESSURE WILL DAMAGE VALVE. DISCONNECT GAS SUPPLY PIPING BEFORE TESTING GAS

LINE AT TEST PRESSURES ABOVE 1/2 PSIG.

VALVE SETTINGS HAVE BEEN FACTORY SET, DO NOT CHANGE.

Installation and servicing to be done by a qualifi ed installer. Do not use open fl ame.

• Move the appliance into position and secure.

• If equipped with a fl ex connector the appliance is designed to accept a 1/2” (13mm) gas supply.

Without the connector it is designed to accept a 3/8” (9.5mm) gas supply. The appliance is equipped

with a manual shut off valve to turn off the gas supply to the appliance.

• Connect the gas supply in accordance to local codes. In the absence of local codes, install to the

current CAN/CSA-B149.1 Installation Code in Canada or to the current National Fuel Gas Code, ANSI

Z223.1 / NFPA 54 in the United States.

• When fl exing any gas line, support the gas valve so that the lines are not bent or kinked.

• Check for gas leaks by brushing on a soap and water solution.

SPARKS OR OPEN FLAMES.

30.1A

EN

4.6 OPTIONAL WALL SWITCH / REMOTE

!

DO NOT CONNECT EITHER THE WALL SWITCH, THERMOST AT OR GAS VALVE DIRECTLY TO 110

VOLT ELECTRICITY.

For ease of accessibility, an optional remote wall switch or millivolt thermostat may be installed in a convenient

location. Route a 2 strand, solid core millivolt wire from the valve to the wall switch or millivolt thermostat. The

recommended maximum lead length depends on wire size:

WIRE SIZE MAX. LENGTH

14 gauge (1.8mm) 100 feet (30.5m)

16 gauge (1.5mm) 60 feet (18.3m)

18 gauge (1.2mm) 40 feet (12.2m)

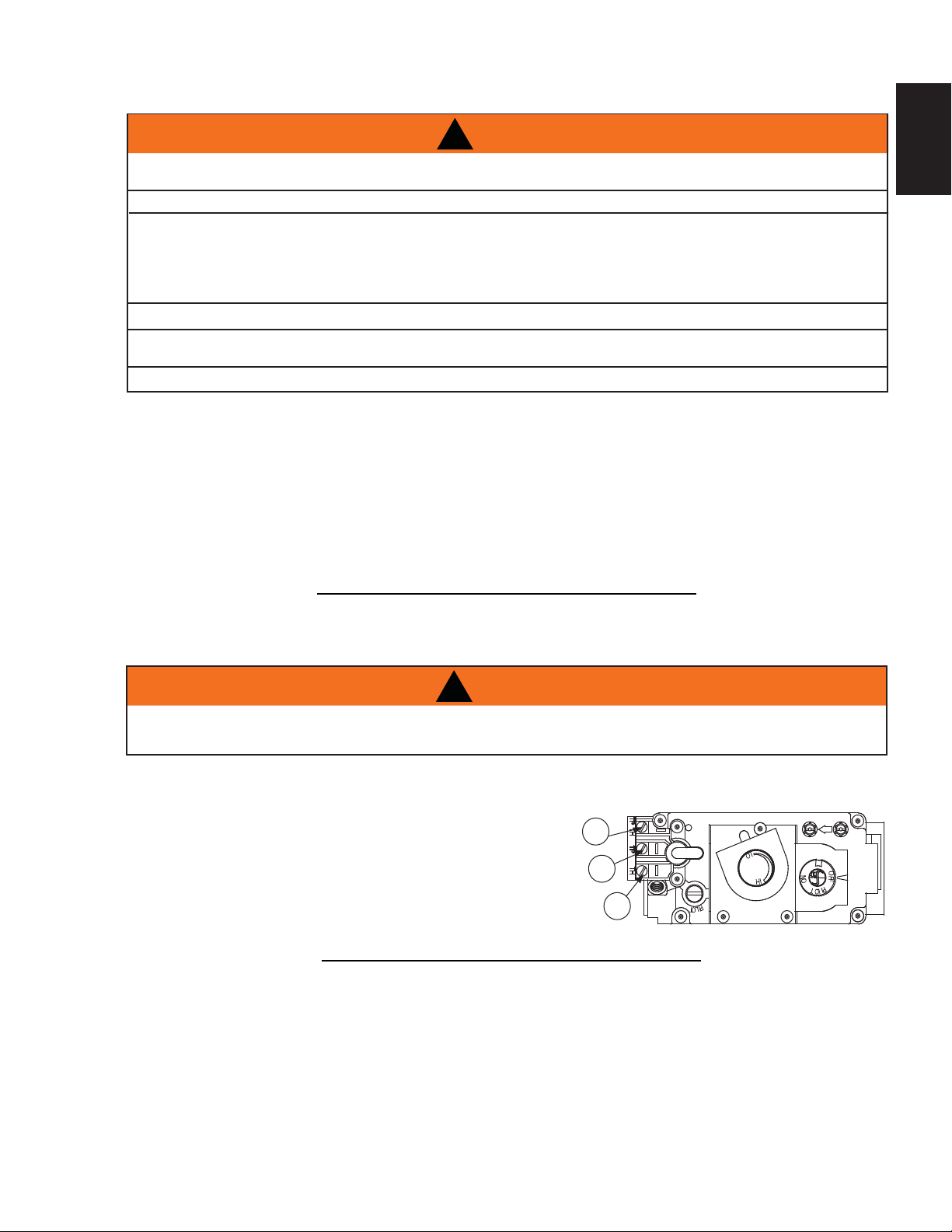

Disconnect the existing wires from terminals 1 and 3 (from the

ON/OFF switch) and replace with the leads from the wall switch / millivolt thermostat.

WARNING

3

2

1

50.1A

W415-1426 / 12.23.14

Page 26

26

4.7 NATURAL VENT SPECIFICS

4.7.1 CHIMNEY INSTALLATION

EN

A CHIMNEY VENTING THIS APPLIANCE SHALL NOT VENT ANY SOLID FUEL BURNING APPLIANCE.

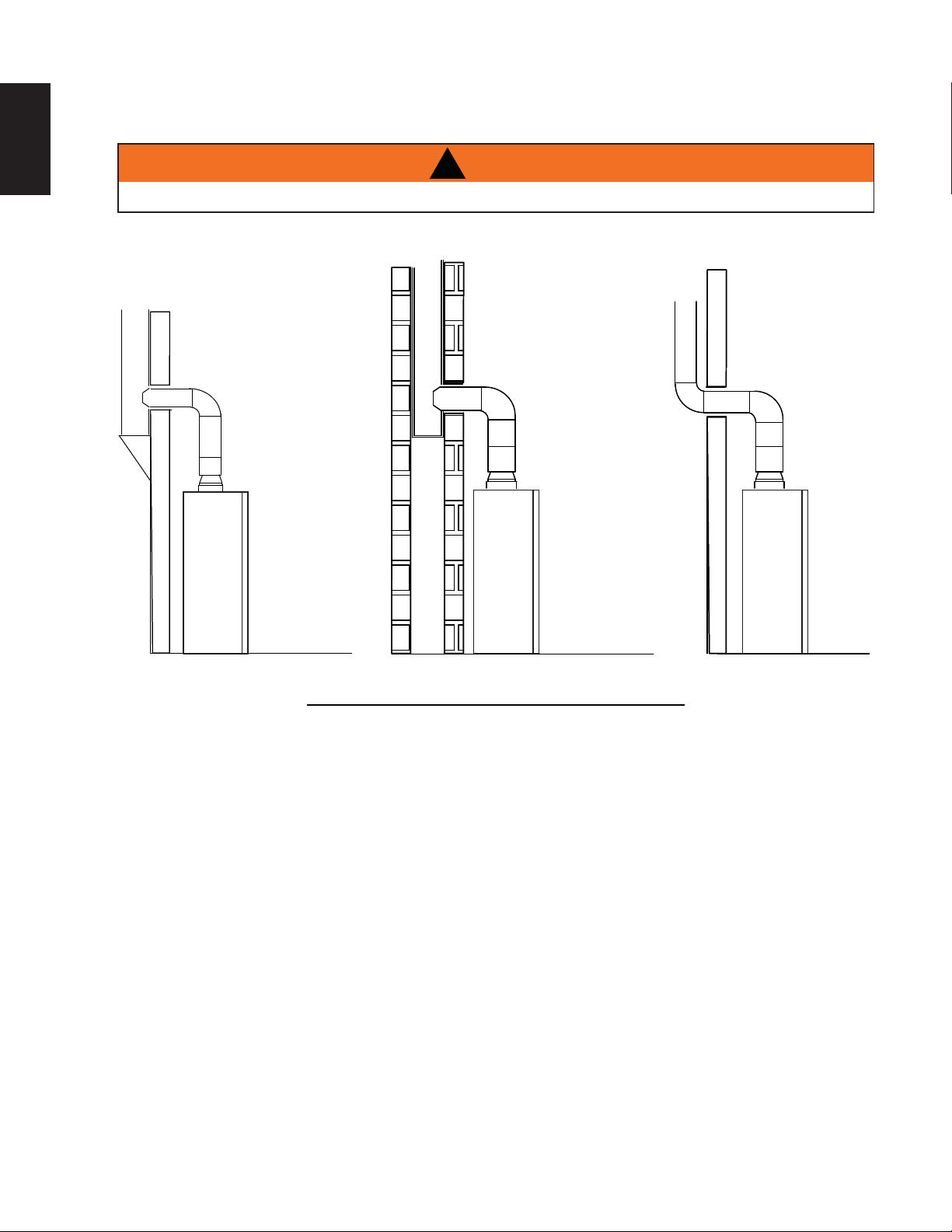

Three types of chimney systems may be used with this appliance.

!

WARNING

MASONRY CLAY LINED

CHIMNEY + VENT

“A” VENT - SOLID

FUEL WOOD BURNING

CHIMNEY & VENT

CONNECTOR

(LINER NEEDED

IF INSIDE

DIAMETER IS 6”

(152mm) OR

LARGER)

SINGLE WALL

OR “B” VENT

A chimney venting this appliance shall not vent any solid fuel burning appliance.

All horizontal runs must have a 1/4" (6.4mm) rise per foot (0.3m).

CONNECTOR

[NO NEW LINER

NEEDED IF OLD

LINER DIAMETER IS

4-5” (102-127mm)]

SINGLE WALL

OR “B” VENT

“B” VENT

GAS BURNING

CHIMNEY

63.7B

W415-1426 / 12.23.14

Page 27

4.7.2 INSTALLING NATURAL VENT

Follow the instructions of the natural vent manufacturer for chimney installation.

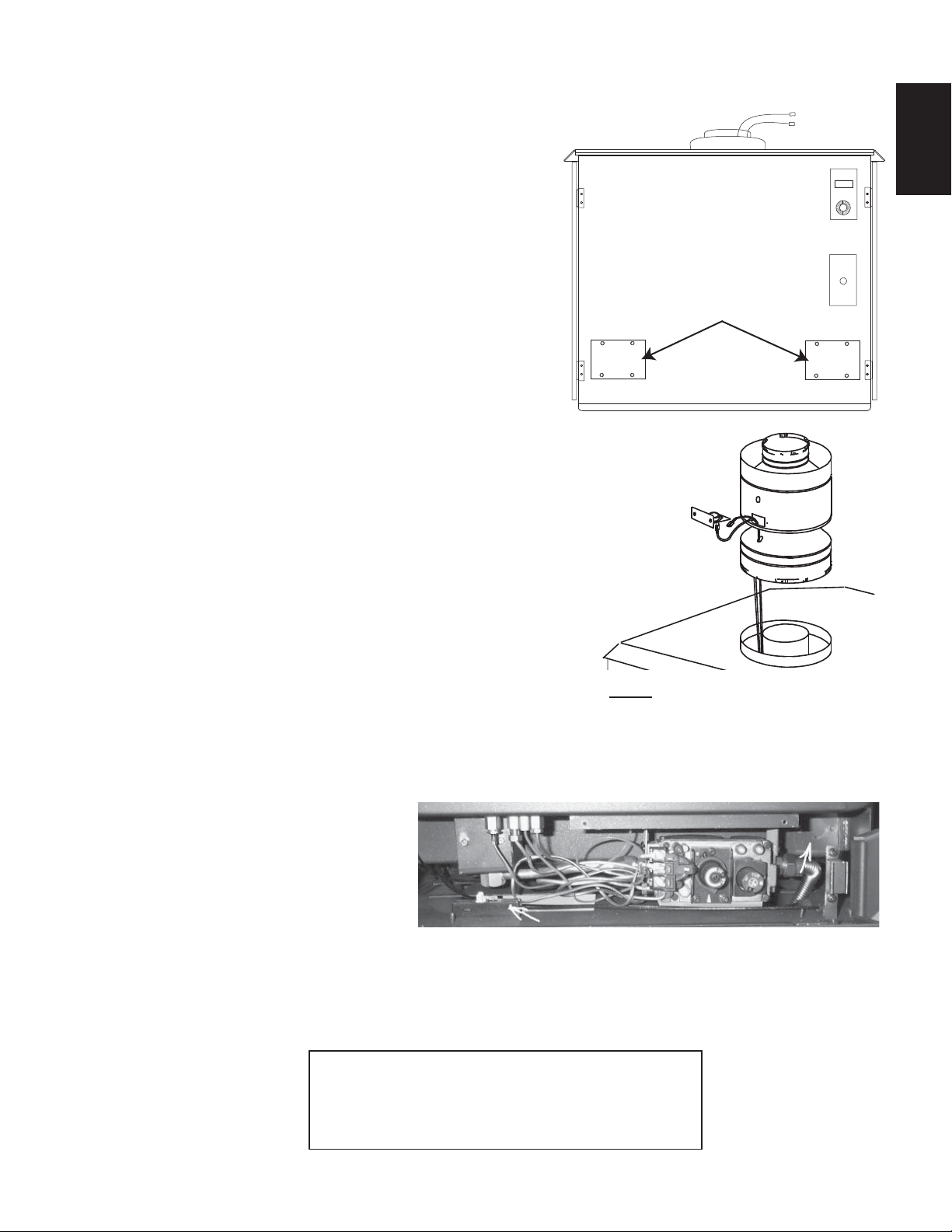

A. Remove and discard the two combustion air cover plates

and gaskets located on the rear panel of the appliance.

B. Replace the four screws per side to secure the rear

panel to the appliance.

27

EN

C. Remove the spill switch bracket from the rear of the

adapter.

D. Gently pull the two wire terminals (located inside the

7" (178mm) fl ue collar at the top of the appliance) out

approximately 8" (203mm).

E. Bring the wires through the lower hole in the adapter and

out the spill switch opening. To pass the wires through the

hole more easily, temporarily tape the two terminals together.

F. With the spill switch opening aligned to the back of the

appliance, push the crimped edge of the adapter in to the

appliance fl ue collar.

G. Connect the wire terminals to the spill switch and re-secure

the bracket.

H. Secure the terminal block into place as shown with the screw

supplied.

I. Unscrew the wire access cover plate from the rear right hand

side below the fi rebox. Remove and discard the gasket.

Remove the knockout from the cover plate and insert the

protective bushing. Pull both spill switch wires through

the bushing taking up any slack. Replace the cover plate.

Connect one wire end to the terminal block and the other

end to terminal 1 of the gas valve. Connect the two wires

running down the left side of the

appliance from the on/off switch to

the remaining tab on the terminal

block and to terminal 3 on the gas

valve.

For aesthetics, the adapter

TERMINAL BLOCK

has been designed to accept a

standard matte black 7" (178mm) stove pipe and the decorative band (standard with the GS-150KT).

Both are available from your local authorized dealer / distributor.

COMBUSTION AIR COVER

PLA TES AND GASKET

ADAPTER

SPILL

SWITCH

NOTE: If not converting, the wires

are rated for high temperatures and

may remain as is in the unit collar.

WIRE ACCESS

COVER PLATE

4.7.3 NATURAL VENT

Attach the Natural Vent label, shown, in the control area of the appliance.

ATTACH THIS LABEL IN THE CONTROL AREA OF THE APPLIANCE.

THIS APPLIANCE HAS BEEN CONVERTED TO A NATURAL VENT

ATTACHEZ CET ETIQUETTE DANS LA REGION DE CONTROLE DUE FOYER.

CET APPAREIL A ÉTÉ CONVERTI À UN MODÈLE À TIRAGE

MODEL.

NATUREL.

A / W385-0160

W415-1426 / 12.23.14

Page 28

28

A

4.7.4 COMBUSTION AIR

This appliance needs air for safe operation and must be installed in such a way that adequate combustion air

EN

4.7.5 ADDING VENT SECTIONS

is available.

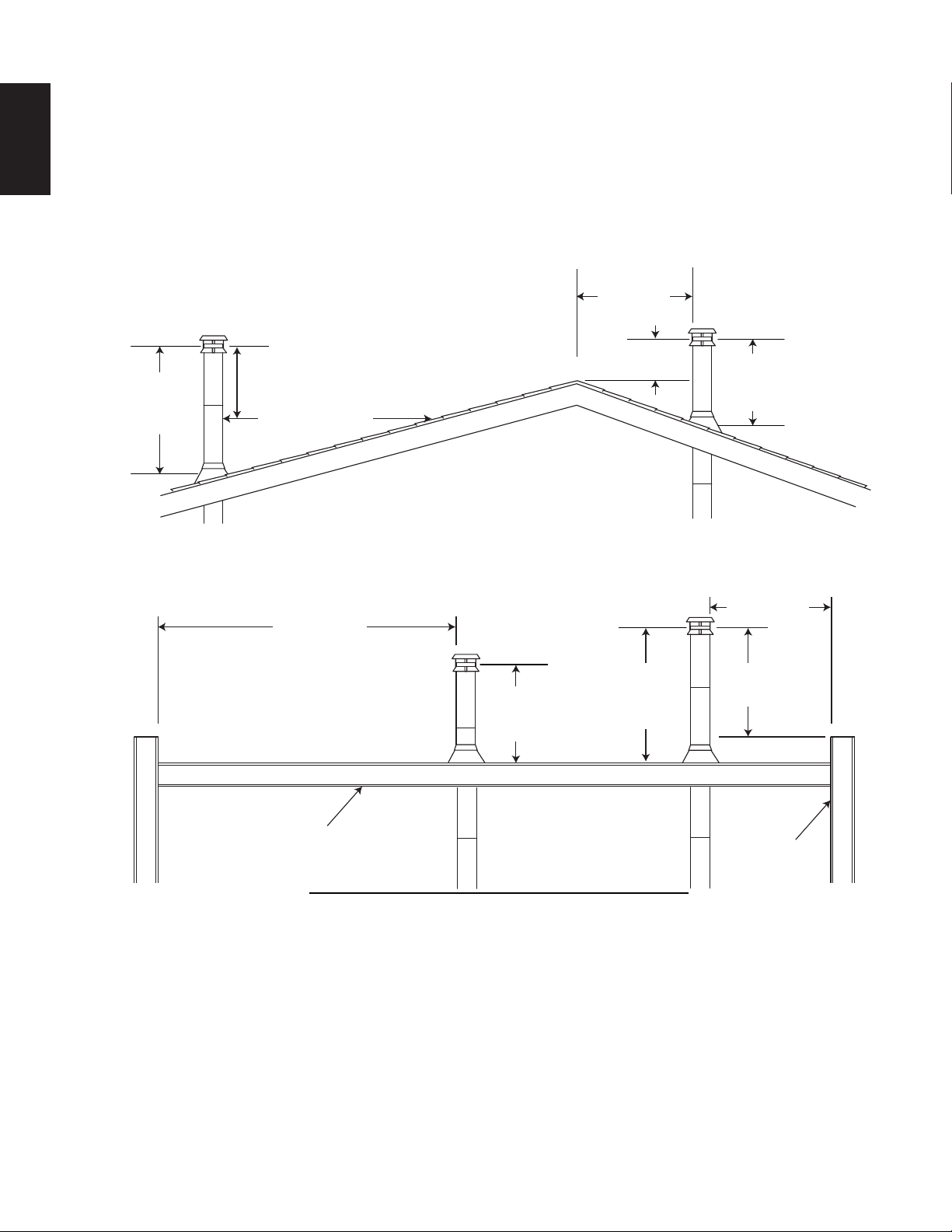

dd chimney sections, according to the manufacturers installation instructions. The chimney must extend at

least, 3 feet (1m) above its point of contact with the roof and at least 2 feet (0.6m) higher than any wall, roof,

building or obstacle within 10 feet (3m) horizontally.

LESS THAN

10 FEET

(3m)

2 FT (0.6m) MIN

3 FT

(1m)

MIN

10 FT (3m)

TO NEAREST

ROOFLINE

RIDGE

2 FT (0.6m)

MIN

3 FT (1m)

MIN

LESS THAN

10 FEET

10 FT (3m)

(3m)

OR MORE

3 FT (1m)

3 FT (1m)

MIN

2 FT (0.6m)

MIN

MIN

W415-1426 / 12.23.14

FLAT ROOF

WALL

59.1B

Page 29

5.0 FINISHING

29

!

WARNING

RISK OF FIRE!

NEVER OBSTRUCT THE FRONT OPENING OF THE APPLIANCE.

DO NOT STRIKE, SLAM OR SCRATCH GLASS. DO NOT OPERATE APPLIANCE WITH GLASS

REMOVED, CRACKED, BROKEN OR SCRATCHED.

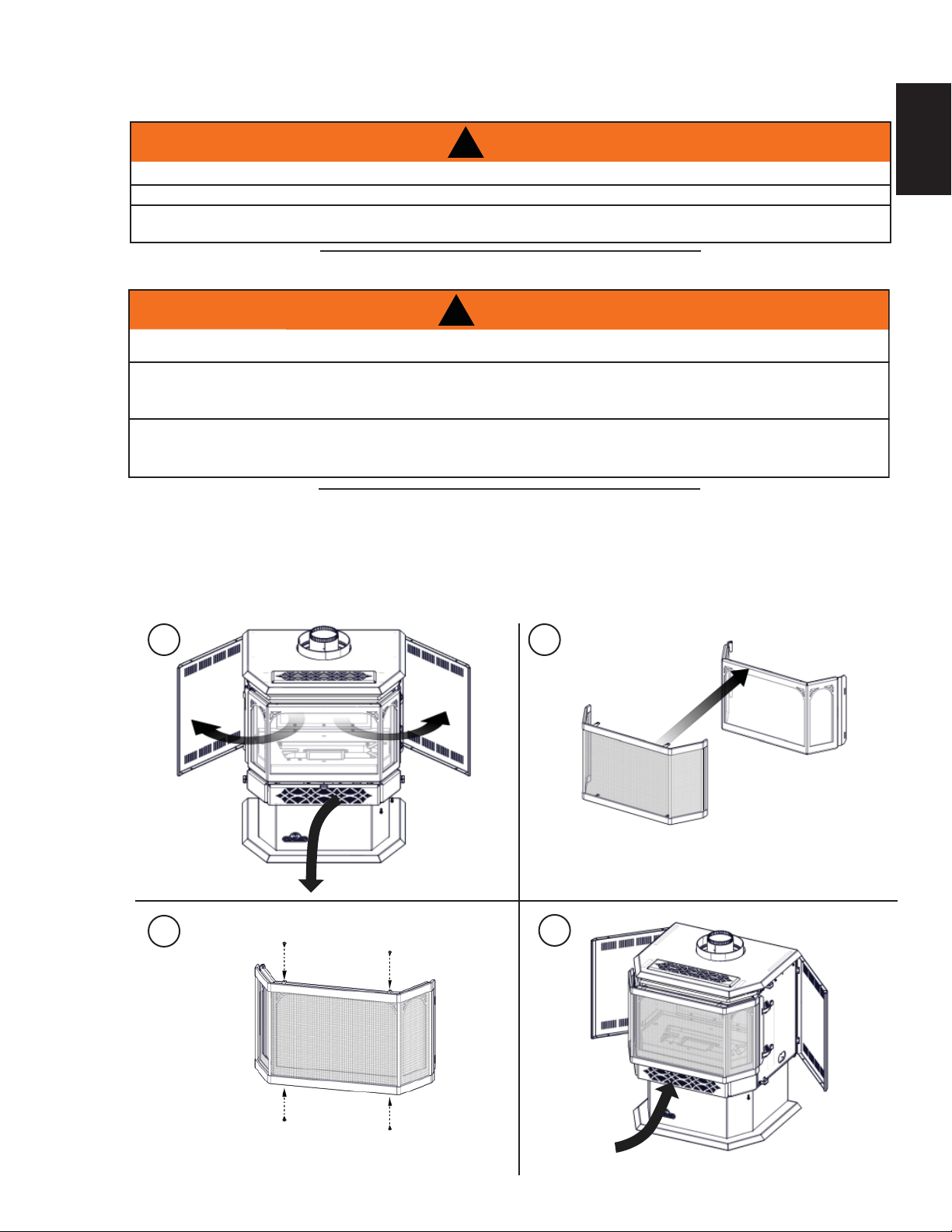

5.1 SAFETY SCREEN INSTALLATION AND REMOVAL

!

WARNING

GLASS MAY BE HOT, DO NOT TOUCH GLASS UNTIL COOLED.

THE DOOR LATCHES ARE PART OF A SAFETY SYSTEM AND MUST BE PROPERLY ENGAGED. DO

NOT OPERATE THE APPLIANCE WITH LATCHES DISENGAGED.

BEFORE DOOR IS REMOVED TURN THE APPLIANCE OFF AND WAIT UNTIL APPLIANCE IS COOL TO

THE TOUCH. DOORS ARE HEAVY AND FRAGILE SO HANDLE WITH CARE.

A barrier designed to reduce the risk of burns from the hot viewing glass is provided with the

appliance and shall be installed.

Open the side panels and control door on the appliance. Place the safety screen onto the door frame. Install

the 4 screws on the top and bottom of the safety screen. Ensure the safety screen is installed correctly before

closing the side panels and control door. Reverse these steps to remove the safety screen.

EN

72.4

75.3

1

3

SAFETY

SCREEN

2

SAFETY

SCREEN

4

SAFETY

SCREEN

W415-1426 / 12.23.14

Page 30

30

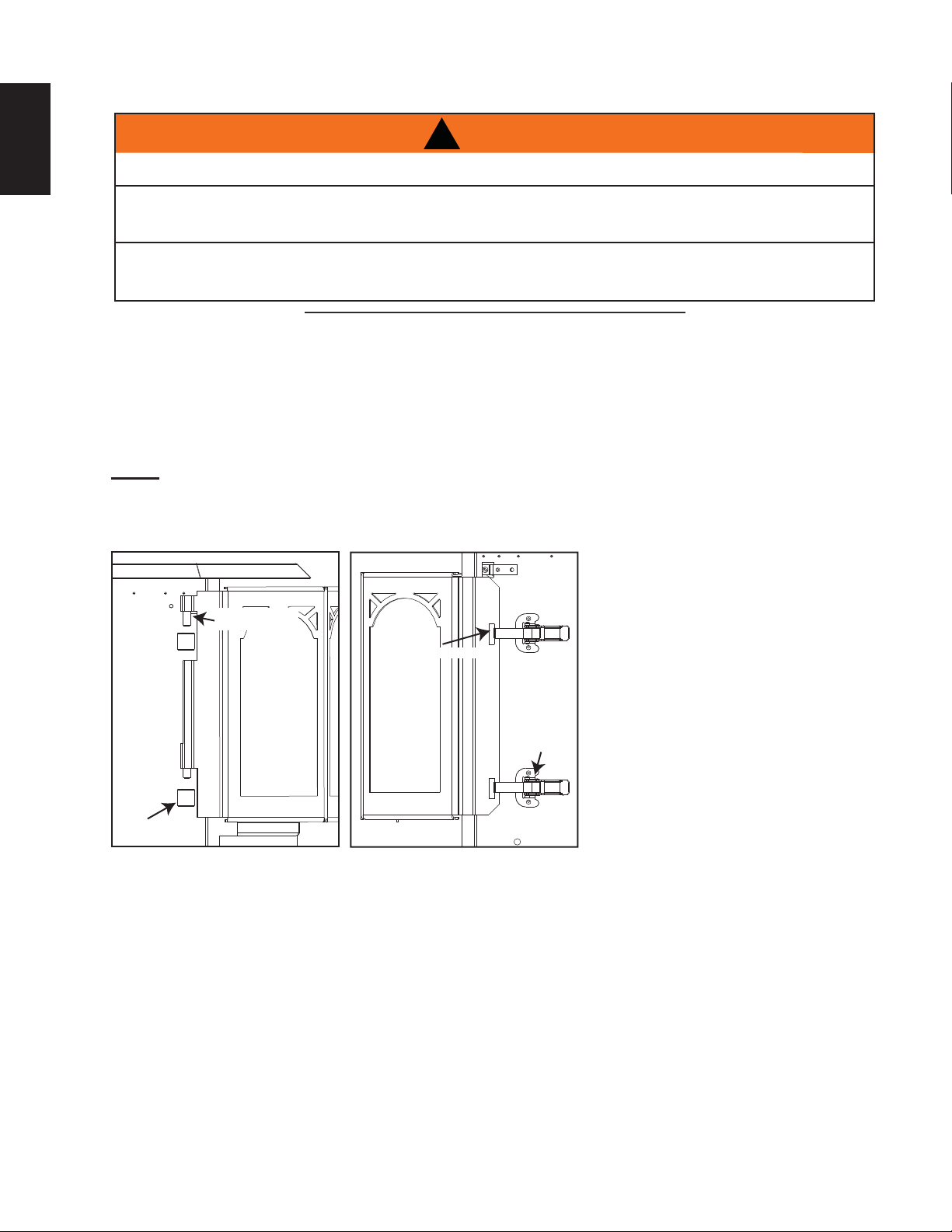

5.2 DOOR CLOSING AND OPENING

EN

!

WARNING

GLASS MAY BE HOT, DO NOT TOUCH GLASS UNTIL COOLED.

THE DOOR LATCHES ARE PART OF A SAFETY SYSTEM AND MUST BE PROPERLY ENGAGED. DO

NOT OPERATE THE APPLIANCE WITH LATCHES DISENGAGED.

BEFORE DOOR IS REMOVED TURN THE APPLIANCE OFF AND WAIT UNTIL APPLIANCE IS COOL TO

THE TOUCH. DOORS ARE HEAVY AND FRAGILE SO HANDLE WITH CARE.

75.3

When installing the fi re viewing door, a simple procedure must be followed in order to not damage the door.

A. Open both side doors, exposing the bushings on the left and the latches on the right.

B. Align the pins on the door to the bushings. Lower into place until both bushings touch.

C. Engage the latch hooks into the door frame. Snap the rear handle hook to lock the latch closed.

NOTE: It may be necessary to lift the door when securing it to ensure that it is in a horizontal position.

To open the door, repeat in reverse order.

BUSHING

HINGE PIN

CATCH SLOT

DOOR

LATCH

W415-1426 / 12.23.14

Page 31

5.3 LOG PLACEMENT

31

!

WARNING

FAILURE TO POSITION THE LOGS IN ACCORDANCE WITH THESE DIAGRAMS OR FAILURE TO USE

ONLY LOGS SPECIFICALLY APPROVED WITH THIS APPLIANCE MAY RESULT IN PROPERTY

DAMAGE OR PERSONAL INJURY.

LOGS MUST BE PLACED IN THEIR EXACT LOCATION IN THE APPLIANCE. DO NOT MODIFY THE

PROPER LOG POSITIONS, SINCE APPLIANCE MAY NOT FUNCTION PROPERLY AND DELAYED

IGNITION MAY OCCUR.

THE LOGS ARE FRAGILE AND SHOULD BE HANDLED WITH CARE.

76.1A

PHAZERTM logs, glowing embers and charcoal embers exclusive to Wolf Steel Ltd. fi replaces, glow when

exposed to direct fl ame and provide a unique and realistic glowing effect that is different in every installation.

Use only certifi ed PHAZERTM logs, glowing embers and charcoal embers available from your local authorized

dealer / distributor.

Log colours may vary. During the initial use of the appliance, the colours will become more uniform as colour

pigments burn in during the heat activated curing process.

A. Place the back log into the fi rebox, pushing it as close

to the fi rebox wall as possible and centered onto the

log support pan.

B. Place the front log on the ember screen lining up the

studs with the holes on the bottom of the log.

C. Set the two cross-over logs into the pockets provided

on both the front and rear logs as shown.

1

EN

2

4

3

W415-1426 / 12.23.14

Page 32

32

5.4 GLOWING EMBERS

EN

DO NOT BLOCK THE BURNER PORTS. BLOCKED PORTS CAN CAUSE AN INCORRECT FLAME

Tear the glowing embers into pieces and place onto the screen beneath the front log. Care should be taken to

shred the embers into thin, small irregular pieces as only the exposed edges of the fi bre hairs will glow when

exposed to direct fl ame.

5.5 CHARCOAL EMBERS

Randomly place the charcoal embers along the front and sides of the log support tray in a realistic manner.

Fine dust found in the bottom of the bag should not be used.

NOTE: Charcoal embers are not to be placed on the burner.

5.6 LOGO PLACEMENT

Remove the backing of the logo supplied and centre over the logo installation holes, as indicated.

!

WARNING

PATTERN, CARBON DEPOSITS AND DELAYED IGNITION.

31.1

32.1

L

O

G

O

W415-1426 / 12.23.14

Page 33

6.0 OPERATION

33

!

WARNING

IF YOU DO NOT FOLLOW THESE INSTRUCTIONS EXACTLY, A FIRE OR EXPLOSION MAY RESULT

CAUSING PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF LIFE.

ALWAYS LIGHT THE PILOT WHETHER FOR THE FIRST TIME OR IF THE GAS SUPPLY HAS RAN OUT

WITH THE GLASS DOOR OPENED OR REMOVED.

TAMPERING WITH THE SPILL SWITCH CAN RESULT IN CARBON MONOXIDE (CO) POISONING AND

POSSIBLE DEATH (GS28 ONLY).

MODEL GS28 ONLY: SPILL SWITCH

This is a thermally activated switch, attached to the back of the chimney adaptor, which senses the change in

temperature and shuts down the gas valve in the event of a blocked or disconnected vent. It acts as a safety

shut-off to prevent a build up of carbon monoxide or an explosion of unburned gases during start up. If the

fl ue is blocked or has no "draw", the spill switch will automatically shut off the supply of gas within about 5-10

minutes.

MODEL GS28 ONLY: VENTING ACTION CHECK

A CHECK FOR CORRECT VENTING ACTION MUST BE MADE BEFORE THE INSTALLED APPLIANCE IS

LEFT WITH THE CUSTOMER. Test in the following manner:

A. Close all doors and windows in the room / start exhaust fans in the home / turn appliance blower off (if

equipped).

B. Set controls to "high" and light the appliance.

C. Wait 5 minutes. Light a match and extend it 1" (25mm) into the hole located above the spill switch

bracket on the adaptor.

D. Venting action is satisfactory if the fl ame stays lit. Venting action is unsatisfactory if the fl ame

extinguishes.

E. If venting action is unsatisfactory, turn the appliance off, wait 10 minutes and try again. If the match

does not stay lit, turn the appliance off and check for vent blockage or restriction. If necessary, consult

with a qualifi ed inspector.

EN

W415-1426 / 12.23.14

Page 34

34

6.1 OPERATING/LIGHTING INSTRUCTIONS

The on-off switch is located on the back of the appliance at the top left corner on models GDS28 and GS28.

EN

When lit for the fi rst time, the appliance will emit a slight odour for a few hours. This is a normal temporary

condition caused by the "burn-in" of paints and lubricants used in the manufacturing process and will not occur

again. Simply open a window to suffi ciently ventilate the room. After extended periods of non-operation such as

following a vacation or a warm weather season, the appliance may emit a slight odour for a few hours. This is

caused by dust particles in the heat exchanger burning off. Open a window to suffi ciently ventilate the room.

OPERATING INSTRUCTIONS

FOR YOUR SAFETY READ BEFORE OPERATING

WARNING: If you do not follow these instructions

exactly, a fi re or explosion may result causing

property damage, personal injury or loss of life.

A. This appliance is equipped with a pilot which must be

lit by hand while following these instructions exactly.

B. Before operating smell all around the appliance area

for gas and next to the fl oor because some gas is

heavier than air and will settle on the fl oor.

C. Use only your hand to turn the gas control knob /

manual shut-off knob. Never use tools. If the knob will

not turn by hand, do not try to repair it. Call a qualifi ed

service technician. Force or attempted repair may

result in a fi re or explosion.

L

O

F

O

F

I

H

N

O

P

L

T

I

P

I

L

O

T

O

GAS KNOB

AT OFF

THERMOCOUPLE

PILOT

BURNER

THERMOPILE

D. Do not use this appliance if any part has been under

water. Immediately call a qualifi ed service technician

to inspect the appliance and replace any part of the

control system and any gas control which has been

under water.

WHAT TO DO IF YOU SMELL GAS:

• Turn off all gas to the appliance.

• Open windows.

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbour's

phone. Follow the gas supplier's instructions.

• If you cannot reach your gas supplier, call the fi re

department.

LIGHTING INSTRUCTIONS

WARNING: The gas valve has an interlock device which will not allow the pilot burner to be lit until the

thermocouple has cooled. Allow approximately 60 seconds for the thermocouple to cool.

When lighting and re-lighting, the gas knob cannot be turned from PILOT to OFF unless the knob is depressed.

1. STOP! Read the safety information on the operating

label.

2. Turn off all electric power to the appliance.

3. Turn the gas knob clockwise

to off.

4. Wait fi ve (5) minutes to clear out any gas. If you smell

gas including near the fl oor, Stop! Follow "B" on the

operating label. If you don't smell gas go to the next step.

5. Find pilot located in front of back log.

6. Turn gas knob counter-clockwise

to pilot.

7. Depress and hold gas knob while lighting the pilot with

the push button ignitor. Keep knob fully depressed for

one minute, then release. If pilot does not continue to

burn repeat steps 3 through 6.

8. With pilot lit, turn the gas knob counter-clockwise

to on.

9. If equipped with remote on-off switch, main burner

may not come on when you turn the valve to on. Remote

switch must be in the on position to ignite burner.

10. Turn on all electric power to the appliance.

TO TURN OFF GAS

1.Turn off all electric power to the appliance if service is to

be performed.

2. Push in gas control knob slightly and turn clockwise

to off. Do not force.

W415-1426 / 12.23.14

Page 35

7.0 ADJUSTMENT

35

7.1 PILOT BURNER ADJUSTMENT

Adjust the pilot screw to provide properly sized fl ame. Turn in a clockwise

direction to reduce the gas fl ow.

Inlet pressure can be checked by turning screw (A)

counter-clockwise until loosened and then placing

pressure gauge tubing over the test point. Gauge should

read 7” (178mm) (minimum 4.5”(114mm)) water column for

natural gas or 13” (330mm) (11” minimum (279mm)) water column

for propane. Check that main burner is operating on “HI”.

Outlet pressure can be checked the same as above using screw (B).

Gauge should read 3.5” (89mm) water column for natural gas or 10”

(254mm) water column for propane. Check that main burner is operating

on “HI”.

AFTER TAKING PRESSURE READINGS, TIGHTEN SCREWS

FIRMLY TO SEAL. DO NOT OVER TORQUE. LEAK TEST.

THERMOCOUPLE

PILOT

BURNER

P

I

L

O

T

39.3

THERMOPILE

L

O

F

O

I

H

F

N

O

P

L

T

I

O

EN

7.2 VENTURI ADJUSTMENT

This appliance has an air shutter that has been factory set open according