Napoleon GPV GAS POWER VENT Installation Instructions Manual

INSTALLER: LEAVE THESE INSTRUCTIONS WITH THE APPLIANCE THIS TERMINAL IS SERVING.

CONSUMER: RETAIN THESE INSTRUCTIONS FOR FUTURE REFERENCE. THESE INSTRUCTIONS

ARE TO BE USED IN CONJUNCTION WITH THE APPLIANCE AND PVA INSTRUCTIONS.

INSTALLATION

INSTRUCTIONS

1

EN

CERTIFIED UNDER CANADIAN AND AMERICAN NATIONAL STANDARDS: ANSI Z21.88 CSA 2.33 FOR VENTED GAS FIREPLACE HEATERS

$1'$16,=&6$)259(17('*$6),5(3/$&(6

The GPV is a Direct Vent Terminal

GAS POWER

designed to allow installation of

VENT

(GPV)

GENERAL INFORMATION

These Installation Instructions must be used in conjunction

with the appliance and appropriate PVA adapter kit Installation

Instructions. Clearances listed in these Instructions supersede

those in the appliance's Installation Instructions.

Power venting of direct vent appliances may result in the

reduction of efficiencies by as much as ten percent. Consider

this in making any venting and heating decisions in any

installation application.

SELECTING AND INSTALLING THE APPLIANCE

When selecting a gas appliance for use with the GPV, take into

consideration the various requirements and limitations in the

venting installation section for the following models:

Models Equipped with an Intermittent Pilot Ignition (I.P.I.)

It is recommended that the GPV be used with a gas appliance

equipped with an Intermittent Pilot Ignition (I.P.I.). Downward

vertical vent runs are permitted with an I.P.I. system. See

venting section in appropriate PVA Installation Instructions.

Models Equipped with Millivolt/ Standing Pilot

Downward vertical vent runs are not permitted with a standing

pilot system. See venting section in appropriate PVA Installation

Instructions.

INSTALLATION TO BE DONE BY A QUALIFIED INSTALLER

to conform with local codes. In absence of local codes install

to the current National Building Code in Canada or to regional

building codes in the United States. It must be electrically

connected and grounded in accordance with local codes. In

the absence of local codes, use the current CSA C22.1

CANADIAN ELECTRICAL CODE in Canada or the ANSI/NFPA

70 NATIONAL ELECTRIC CODE in the United States.

The GPV operates on 120 VAC 60 HZ electrical service which is

supplied at the firebox junction box.

gas appliances where typical vent

configurations cannot be achieved.

Wolf Steel Ltd., 24 Napoleon Rd., Barrie, ON, L4M 4Y8 Canada /

103 Miller Drive, Crittenden, Kentucky, USA, 41030

ID[ZZZQDSROHRQILUHSODFHVFRPDVN#QDSROHRQRQFD

ZZZFRQWLQHQWDOILUHSODFHVFRPDVN#FRQWLQHQWDOILUHRQFD

CERTIFIED

W415-1160 / 03.06.13

2

TABLE OF CONTENTS

EN

1.0 VENTING 2

1.1 INSTALLATION OVERVIEW 3

1.2 VENT TERMINAL CLEARANCES 4

1.3 VENT LENGTHS 5

1.4 POWER VENT TERMINAL 5

1.4.1 TERMINAL INSTALLATION 5

1.4.2 POWER VENT INSTALLATION 6

1.4.3 INITIAL FIRING PROCEDURES 6

1.4.4 ELECTRICAL CONNECTION 7

1.4.5 HARD WIRING CONNECTION 7

1.4.6 RECEPTACLE WIRING DIAGRAM 7

1.4.7 ELECTRICAL BOX INSTALLATION 8

1.5 RESTRICTOR PLATE INSTALLATION 8

1.6 WIRING DIAGRAM AND INSTALLATION 8

1.6.1 SIT IPI 885 PROFLAME 1 9

1.6.2 SIT IPI PROFLAME 2 10

1.6.3 SIT MILLIVOLT 820 REQUIRING A DOUBLE POLE SWITCH 11

1.6.4 SIT MILLIVOLT 820 NOVA FOR SINGLE POLE SWITCH 12

1.6.5 SIT MILLIVOLT 820 NOVA REMOTE CONTROLLED SYSTEM REQUIRING A DOUBLE POLE SWITCH 13

1.6.6 SIT IPI 880/886 PROFLAME REQUIRING A DOUBLE POLE SWITCH 14

1.6.7 SIT IPI 880/886 FOR SINGLE POLE SWITCH 15

1.6.8 DEXEN IPI 6003-3V REQUIRING A DOUBLE POLE SWITCH 16

1.6.9 DEXEN IPI 6003-3V REQUIRING A SINGLE POLE SWITCH 17

2.0 ADJUSTMENTS 18

2.1 VENTURI ADJUSTMENTS 18

3.0 REPLACEMENTS 18

4.0 TROUBLESHOOTING 19

5.0 NOTES 20

NOTE: Changes, other than editorial, are denoted by a vertical line in the margin.

1.0 VENTING

There are specifi c adaptors and venting requirements for each appliance, refer to your power vent adaptor

leafl et for more information.

For complete installation instructions refer to the following web sites:

Manufacturer Website

Napoleon - English http://www.napoleonfi replaces.com/Tech/installation_manuals/installations.html

Napoleon - French http://www.napoleonfoyers.com/Fireplaces/powervent.html

Continental http://www.continentalfi replaces.com/fi replaces/gas/powervent.html

W415-1160 / 03.06.13

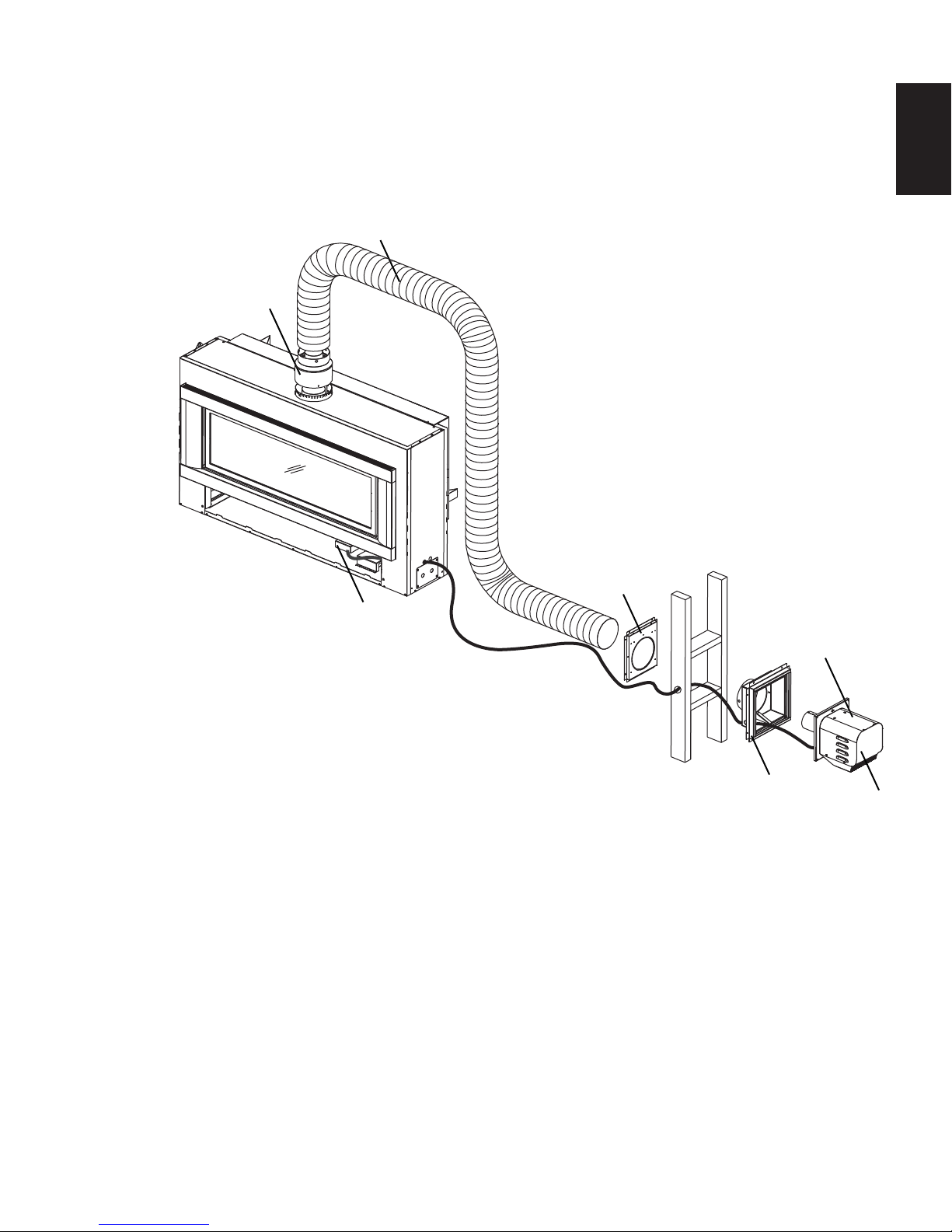

1.1 INSTALLATION OVERVIEW

Reducer, refer to

power vent

adapter kit (PVA)

A typical vent

configuration

for specific venting instructions

where applicable.

3

EN

LHD50 Illustrated

Electrical Box

(velcro to base)

Firestop

Spacer

Gas Power

Vent Terminal

Frame Assembly

Terminal

Access

Cover

W415-1160 / 03.06.13

4

1.2 VENT TERMINAL CLEARANCES

EN

COVERED BALCONY APPLICATIONS ††*

Q

S

R

G

P

A

B

C

D

E

F 0” (0mm) 0” (0mm) Clearance to an outside corner wall.

G

H 3’ (0.9m) 3’ (0.9m)***

I 3’ (0.9m) 3’ (0.9m)*** Clearance to a service regulator vent outlet.

J

K 6’ (1.8m) 3’ (0.9m) Clearance to a mechanical air supply inlet.

L 7’ (2.1m) ‡ 7’ (2.1m)*** Clearance above a paved sidewalk or paved driveway located on public property.

M

N

O 2’ (0.6m) †* 2’ (0.6m) †* Clearance from an adjacent wall including neighbouring buildings.

P 8’ (2.4m) 8’ (2.4m) Roof must be non-combustible without openings.

Q 3’ (0.9m) 3’ (0.9m) See chart for wider wall dimensions.

R 6’ (1.8m) 6’ (1.8m)

S

Δ The terminal shall not be located less than 6 feet (1.8m) under a window that opens on a horizontal plane in a structure with three walls and a roof.

* Recommended to prevent condensation on windows and thermal breakage

** It is recommended to maximize the distance to vinyl clad soffi ts.

*** This is a recommended distance. For additional requirements check local codes.

‡ A vent shall not terminate where it may cause hazardous frost or ice accumulations on adjacent property surfaces..

†† Permitted only if the veranda, porch, or deck is fully open on a minimum of two sides beneath the fl oor.

†* Recommended to prevent recirculation of exhaust products. For additional requirements check local codes.

††* Permitted only if the balcony is fully open on a minimum of one side.

W415-1160 / 03.06.13

INSTALLATIONS

CANADA U.S.A.

12”

(304.8mm)

12”

(304.8mm)

12”

(304.8mm)*

18”

(457.2mm)**

12”

(304.8mm)**

Δ

12”

(304.8mm)

9” (228.6mm)

Δ

12”

(304.8mm)*

18”

(457.2mm)**

12”

(304.8mm)**

0” (0mm) 0” (0mm)

2” (50.8mm) 2” (50.8mm)

12”

(304.8mm)

12”

(304.8mm)††

12”

(304.8mm)

12”

(304.8mm)

9” (228.6mm)

12”

(304.8mm)***

12”

(304.8mm)

12”

(304.8mm)

Q

= 3 feet

MIN

(0.9m)

R

= 2 x

MAX

Q

ACTUAL

R

MAX

IHHW

(4.6m)

Clearance above grade, veranda porch, deck or balcony.

Clearance to windows or doors that open.

Clearance to permanently closed windows.

Vertical clearance to ventilated soffi ts located above the terminal within a horizontal distance of

2’ (0.6m) from the center line of the terminal.

Clearance to unventilated soffi t.

Clearance to an inside non-combustible corner wall or protruding non-combustible obstructions (chimney,

etc.).

Clearance to an inside combustible corner wall or protruding combustible obstructions (vent chase,

etc.).

Clearance to each side of the center line extended above the meter / regulator assembly to a

maximum vertical distance of 15’ (4.6m).

Clearance to a non-mechanical air supply inlet to the building or a combustion air inlet to any other

appliance.

Clearance under a veranda, porch or deck.

Clearance above the roof.

See chart for deeper wall dimensions. The terminal shall not be installed on any wall that has an

opening between the terminal and the open side of the structure.

Clearance under a covered balcony

12.2D

1.3 VENT LENGTHS

DETERMINE

THE

CORRECT

HEIGHT

5

REFER TO POWER VENT ADAPTER KIT (PVA) FOR SPECIFIC VENTING INSTRUCTIONS.

NOTE: If equipped, ACS switch must be disabled if there is any downward venting. Downward venting is not

allowed with appliances that use standing pilots.

1.4 POWER VENT TERMINAL

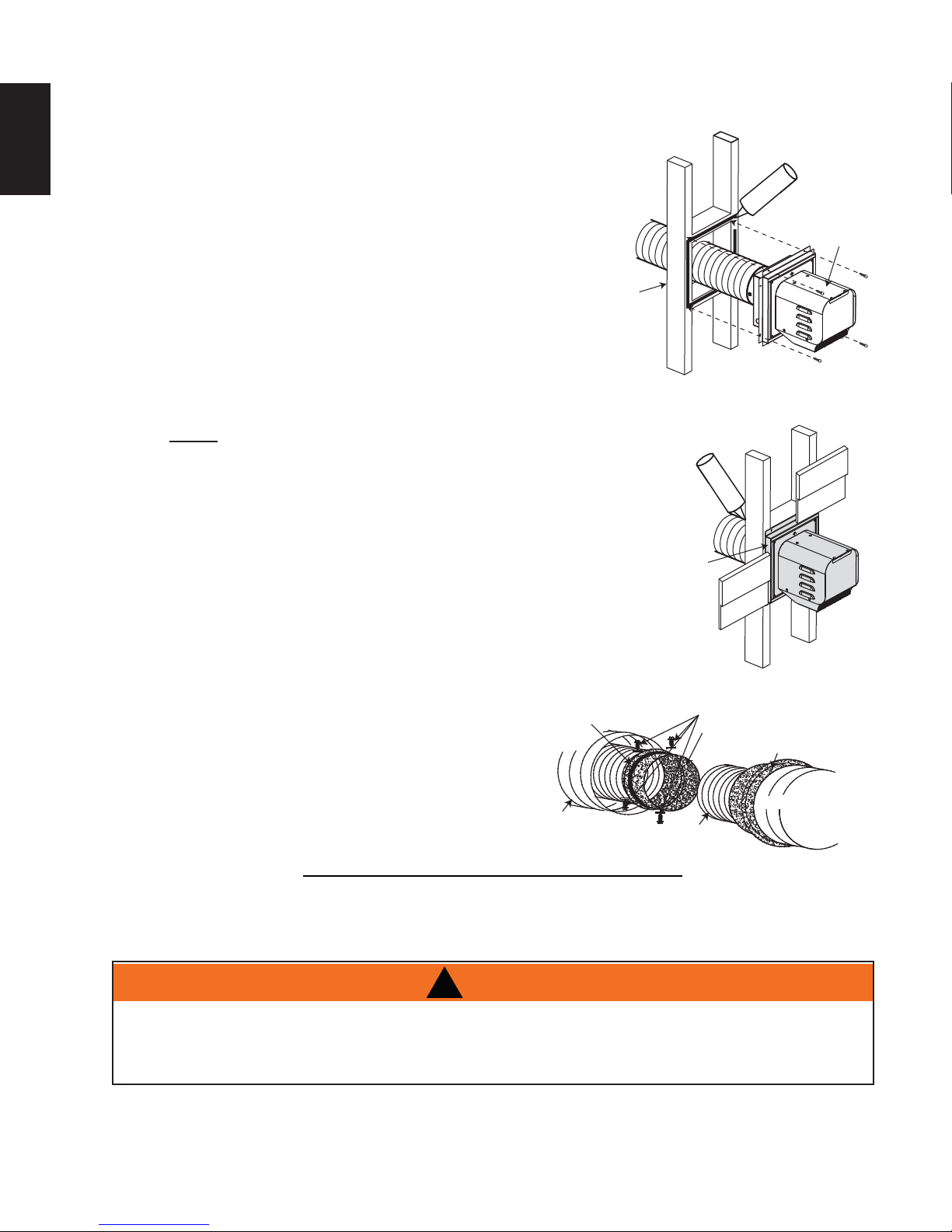

1.4.1 TERMINAL INSTALLATION

This application occurs when venting through an exterior wall. Having determined the correct

height for the terminal location, cut and frame a hole in the exterior wall as illustrated to

accommodate the GPV.

A. Remove the electrical access plate from the frame assembly, then

remove the knock out from this plate.

B. Insert the wiring through the electrical access plate and engage the

conduit bushing. Re-secure this plate. NOTE: The GPV includes a

20 foot (6.1m) wire harness cable. If this cable does not reach

the appliance, then it may be cut and a splice added. These

connections must conform with local codes or, in the absence of

local codes, use the current CSA C22.1 Canadian Electrical Code in

Canada or the ANSI/NFPA 70 National Electrical Code in the United

States.

11 1/4”

(285.8mm)

EN

10 1/4”

(260.4mm)

C. Remove terminal access cover, see “INSTALLATION OVERVIEW” for

location and route cable through terminal.

D. Assemble gas power vent terminal to frame assembly.

E. Connect the male and female connectors.

F. Replace terminal access cover.

NOTE: Where possible, it is strongly recommended to have an access panel inside the building for

servicing the unit.

MALE MOLEX

ELECTRICAL

ACCESS PLATE

CONNECTOR

TERMINAL

FEMALE

MOLEX

CONNECTOR

20.4A

W415-1160 / 03.06.13

6

1.4.2 POWER VENT INSTALLATION

EN

A. Stretch the inner fl ex pipe to the required length taking

into account the additional length needed for the

fi nished wall surface. Slip the vent pipe a minimum of

3” (76.2mm) over the inner sleeve of the terminal and

secure with 3 #8 screws. Apply a heavy bead of the

high temperature sealant W573-0007 Mill Pac (not

supplied).

B. Using the outer fl ex pipe, slide over the outer

combustion air sleeve of the terminal and secure with

3 #8 screws. Seal using high temperature sealant

W573-0002 (not supplied).

C.

D. Route venting through framed opening and fi restop spacer to the

E. The terminal mounting plate may be recessed into the exterior

Apply a bead of caulking (not supplied) to the framed

opening and secure the terminal. Ensure the arrows

stamped into the frame assembly are pointing upwards.

NOTE: For fi restop spacer installation instructions, see PVA

kit or the appliance Installation Manual.

appliance.

wall or siding no greater than the depth of its return fl ange.

FIRESTOP

SPACER

CAULKING

TERMINAL

#10 X 2”

SCREWS

HIGH

TEMPERATURE

SEALANT

RETURN

FLANGE

F. If more vent pipe needs to be used to reach the appliance, couple

them together as illustrated. The vent system must be supported

approximately every 3 feet (0.9m) for both vertical and horizontal

runs. Use noncombustible strapping to maintain the minimum

clearance to combustibles.

G. Install the reducer (if required) or vent and

properly secure and seal to the unit using high

temperature sealant W573-0007 Mill Pac (not

supplied).

1.4.3 INITIAL FIRING PROCEDURES

ALWAYS LIGHT THE PILOT WHETHER FOR THE FIRST TIME OR IF THE GAS SUPPLY HAS RUN

OUT WITH THE GLASS DOOR OPENED OR REMOVED. PURGE SHOULD BE PERFORMED BY A

QUALIFIED SERVICE TECHNICIAN. ASSURE THAT A CONTINUOUS GAS FLOW IS AT THE BURNER

BEFORE CLOSING THE DOOR. ENSURE ADEQUATE VENTILATION.

HI-TEMP

SEALANT

OUTER

FLEX PIPE

!

WARNING

#8 X 1/2” SELF DRILLING

SCREWS & WASHERS

INNER COUPLER

OUTER COUPLER

OUTER

FLEX PIPE

INNER

FLEX PIPE

23.6A

In some instances the system may not light pilot/burner with the door open/removed. Partially blocking the

exhaust fl ue collar will allow the safety pressure switch to activate and allow gas fl ow to the pilot during the

initial test fi ring.

W415-1160 / 03.06.13

Loading...

Loading...