Napoleon GL24NE, GL18NE, GL30NE Installation Manual

INSTALLER: LEAVE THIS MANUAL WITH THE APPLIANCE.

CONSUMER: RETAIN THIS MANUAL FOR FUTURE REFERENCE.

NEVER LEAVE CHILDREN OR OTHER AT RISK INDIVIDUALS ALONE WITH THE APPLIANCE.

INSTALLATION AND

OPERATING INSTRUCTIONS

1.33A

Wolf Steel Ltd., 24 Napoleon Rd., Barrie, ON, L4M 0G8 Canada /

103 Miller Drive, Crittenden, Kentucky, USA, 41030

Phone (705)721-1212 • Fax (705)720-9081 • www.napoleonfi replaces.com • hearth@napoleonproducts.com

SAFETY INFORMATION

!

WARNING

If the information in these instructions are

not followed exactly, a fi re or explosion

may result causing property damage,

personal injury or loss of life.

- Do not store or use gasoline or other fl ammable

vapors and liquids in the vicinity of this or any

other appliance.

- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier from

a neighbour’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier,

call the fi re department.

- Installation and service must be performed by a

qualifi ed installer, service agency or the supplier.

CERTIFIED FOR CANADA AND UNITED STATES USING ANSI/CSA METHODS.

$10.00

This appliance may be installed in an aftermarket,

permanently located, manufactured home (USA

only) or mobile home, where not prohibited by

local codes.

This appliance is only for use with the type of gas

indicated on the rating plate. This appliance is

not convertible for use with other gases, unless a

certifi ed kit is used.

CERTIFIED

GL18

GL24

GL30

CERTIFIED UNDER: ANSI Z21.60 / CSA 2.26 DECORATIVE GAS APPLIANCES FOR INSTALLATION IN SOLID-FUEL BURNING APPLIANCES

GL18NE, GL24NE, GL30NE

NATURAL GAS

GL18PE, GL24PE, GL30PE

PROPANE

1

W415-1071 / D / 08.08.16

2

TABLE OF CONTENTS

1.0 INSTALLATION OVERVIEW 2

2.0 INTRODUCTION 3

2.1 GENERAL INSTRUCTIONS 4

2.2 GENERAL INFORMATION 5

2.3 MINIMUM APPLIANCE SIZE 5

2.4 RATING PLATE 5

3.0 INSTALLATION 6

3.1 GAS PIPING 6

3.2 DAMPER STOP INSTALLATION 7

4.0 FINISHING 8

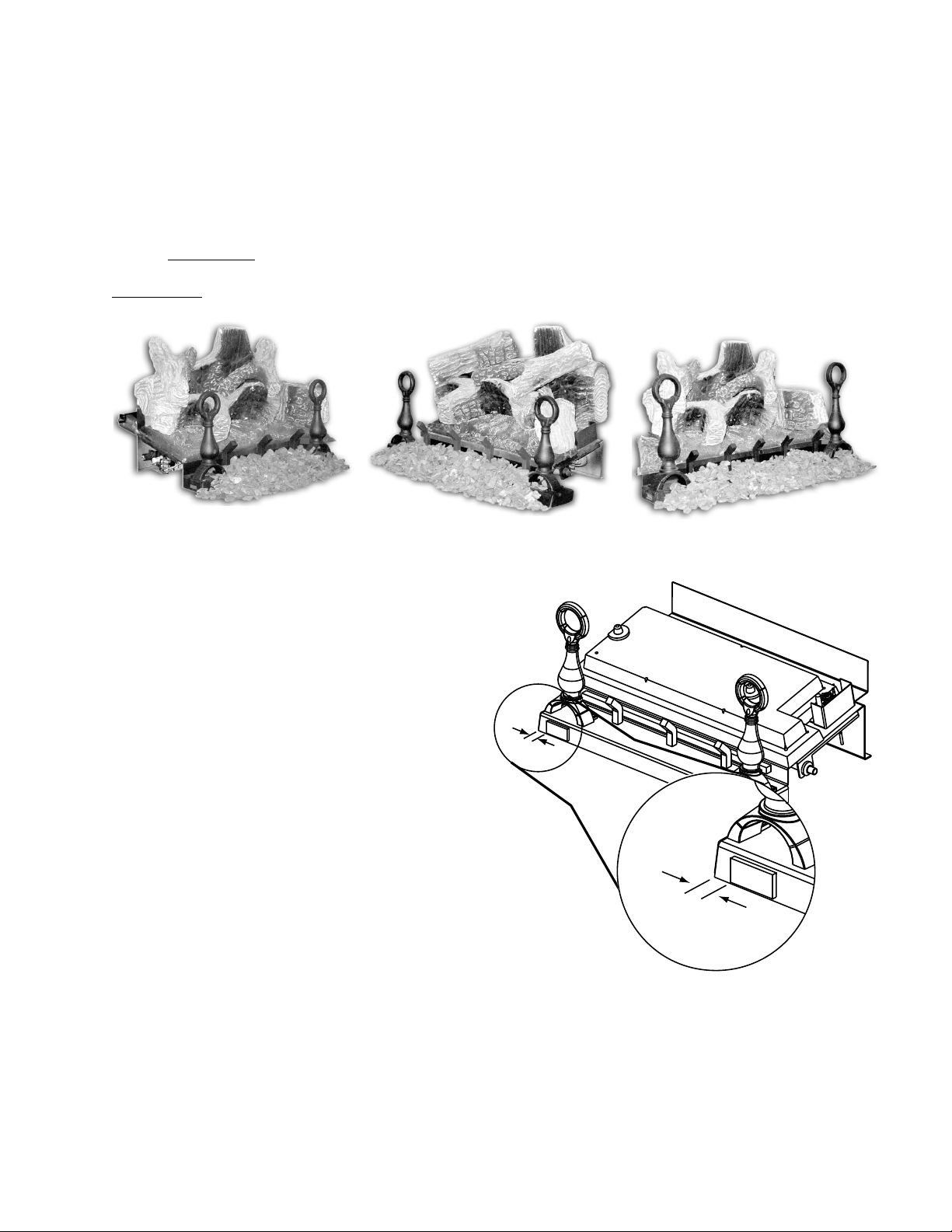

4.1 ANDIRON AND GRATE ASSEMBLY 8

4.2 BATTERY INSTALLATION 8

4.3 LOG PLACEMENT 9

4.4 MEDIA 10

4.5 LOGO PLACEMENT 10

4.6 OPTIONAL ROCK PLACEMENT 11

4.7 OPTIONAL REMOTE INSTALLATION (NOT SUPPLIED) 11

5.0 WIRING DIAGRAM 12

6.0 OPERATION 13

6.1 OPERATING AND LIGHTING INSTRUCTIONS 13

7.0 ADJUSTMENTS 14

7.1 PILOT BURNER ADJUSTMENT 14

7.2 VENTURI ADJUSTMENT 14

7.3 FLAME CHARACTERISTICS 15

8.0 MAINTENANCE 16

9.0 REPLACEMENTS 17

10.0 TROUBLESHOOTING 19

11.0 WARRANTY 20

12.0 SERVICE HISTORY 21

13.0 NOTES 22

NOTE: Changes, other than editorial, are denoted by a vertical line in the margin.

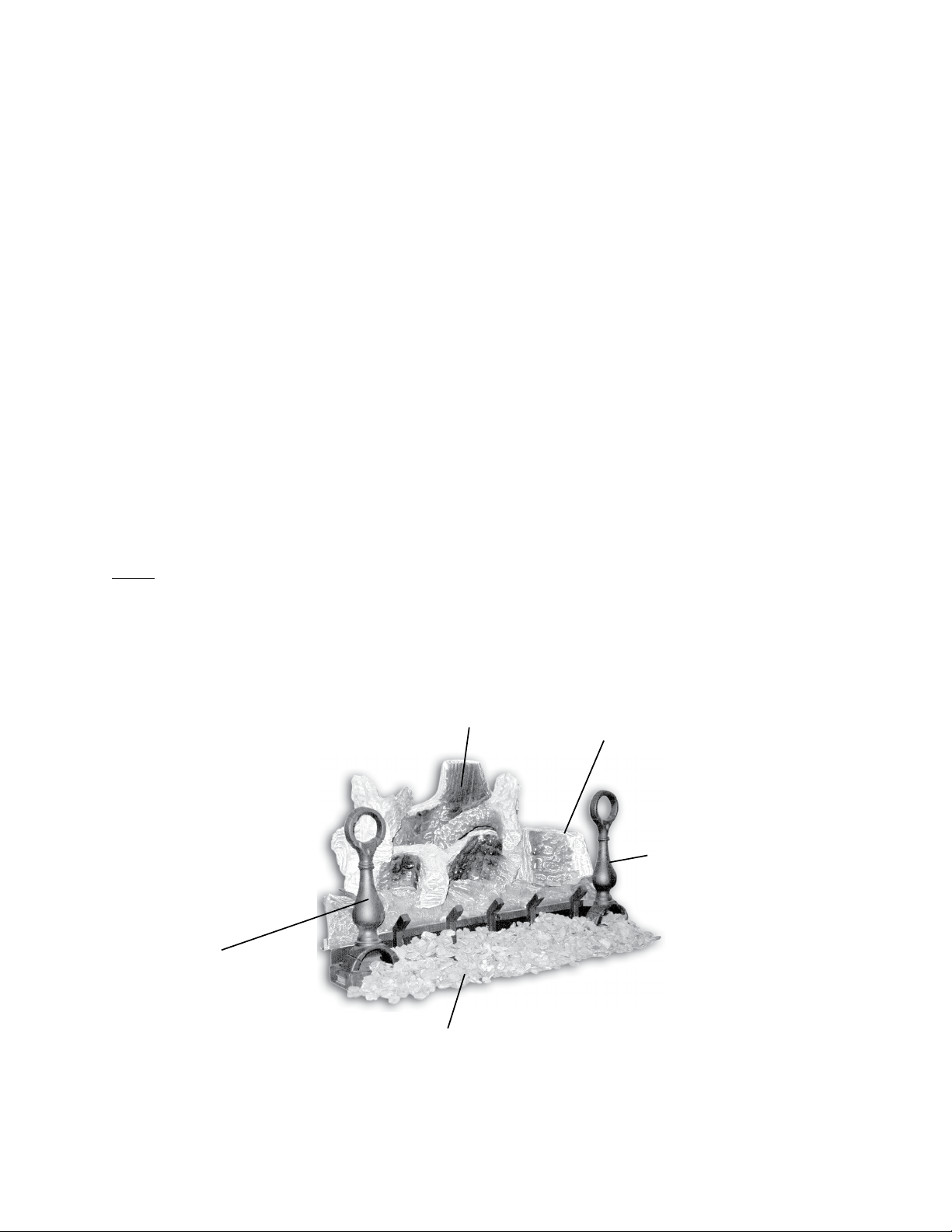

1.0 INSTALLATION OVERVIEW

Logs, see “LOG PLACEMENT” section.

Andiron, see “ANDIRON

AND GRATE ASSEMBLY”

section.

Batteries, see “BATTERY

INSTALLATION” section.

Rating Plate, see “RATING

PLATE INFORMATION”

section.

W415-1071 / D / 08.08.16

Media, see “MEDIA” section.

!

WARNING

Do not use this appliance if any part has been under water. Immediately call a qualifi ed service technician to inspect

2.0 INTRODUCTION

• THIS APPLIANCE IS HOT WHEN OPERATED AND CAN CAUSE SEVERE BURNS IF CONTACTED.

• ANY CHANGES OR ALTERATIONS TO THIS APPLIANCE OR IT’S CONTROLS CAN BE DANGEROUS AND IS

PROHIBITED.

• Do not operate appliance before reading and understanding operating instructions. Failure to operate appliance

according to operating instructions could cause fi re or injury.

• Risk of fi re or asphyxiation do not operate appliance with fi xed glass removed.

• Do not connect 110 volts to the control valve.

• Risk of burns. The appliance should be turned off and cooled before servicing.

• Do not install damaged, incomplete or substitute components.

• Risk of cuts and abrasions. Wear protective gloves and safety glasses during installation. Sheet metal edges may

be sharp.

• Do not burn wood or other materials in this appliance.

• Children and adults should be alerted to the hazards of high surface temperature and should stay away to

avoid burns or clothing ignition.

• Young children should be carefully supervised when they are in the same room as the appliance.

Toddlers, young children and others may be susceptible to accidental contact burns. A physical barrier

is recommended if there are at risk individuals in the house. To restrict access to an appliance or stove,

install an adjustable safety gate to keep toddlers, young children and other at risk individuals out of the

room and away from hot surfaces.

• Clothing or other fl ammable material should not be placed on or near the appliance.

• Due to high temperatures, the appliance should be located out of traffi c and away from furniture and

draperies.

• Ensure you have incorporated adequate safety measure to protect infants/toddlers from touching hot surfaces.

• Even after the appliance is out, the glass and/or screen will remain hot for an extended period of time.

• Check with your local hearth specialty dealer for safety screens and hearth guards to protect children from hot

surfaces. These screens and guards must be fastened to the fl oor.

• Any safety screen, guard or barrier removed for servicing the appliance, must be replaced prior to

operating the appliance.

• This appliance is a vented gas-fi red appliance. Do not burn wood or other materials in this appliance.

• It is imperative that the control compartments, burners and circulating blower and its passageway in the appliance

and venting system are kept clean. The appliance and its venting system should be inspected before use and at

least annually by a qualifi ed service person. More frequent cleaning may be required due to excessive lint from

carpeting, bedding material, etc. The appliance area must be kept clear and free from combustible materials,

gasoline and other fl ammable vapors and liquids.

• Under no circumstances should this appliance be modifi ed.

• This appliance must not be connected to a chimney fl ue pipe serving a separate solid fuel burning appliance.

•

the appliance and to replace any part of the control system and any gas control which has been under water.

• Do not operate the appliance with the glass door removed, cracked or broken. Replacement of the glass should be

done by a licensed or qualifi ed service person, if equipped.

• Do not strike or slam shut the appliance glass door, if equipped.

• Only doors / optional fronts certifi ed with the original wood-burning appliance are to be used in

conjunction with this appliance.

• Keep the packaging material out of reach of children and dispose of the material in a safe manner. As with all

plastic bags, these are not toys and should be kept away from children and infants.

• As with any combustion appliance, we recommend having your appliance regularly inspected and serviced as well

as having a Carbon Monoxide Detector installed in the same area to defend you and your family against Carbon

Monoxide.

• Ensure clearances to combustibles are maintained when building a mantel or shelves above the appliance.

Elevated temperatures on the wall or in the air above the appliance can cause melting, discolouration or damage to

decorations, a T.V. or other electronic components.

• A barrier designed to reduce the risk of burns from the hot viewing glass is provided with the original

wood-burning appliance and shall be installed.

• If the barrier becomes damaged, the barrier shall be replaced with the manufacturer’s barrier for this

appliance.

• Installation and repair should be done by a qualifi ed service person. The appliance should be inspected

before use and at least annually by a professional service person. More frequent cleaning may be required

due to excessive lint from carpeting, bedding material, etc. It is imperative that control compartments,

burners and circulating air passageways of the appliance be kept clean.

3.16D

3

W415-1071 / D / 08.08.16

4

SURFACES AROUND AND ESPECIALLY ABOVE THE APPLIANCE CAN BECOME HOT. AVOID CONTACT

HIGH PRESSURE WILL DAMAGE VALVE. DISCONNECT GAS SUPPLY PIPING BEFORE PRESSURE TESTING GAS

DO NOT USE A BLOWER INSERT, HEAT EXCHANGER INSERT OR ANY OTHER ACCESSORY NOT APPROVED FOR USE

WARNING

We suggest that our gas

hearth products be installed

and serviced by professionals

who are certied in the U.S.

by the National Fireplace

Institute

®

(NFI) as NFI Gas

Specialists

www.ncertied.org

2.1 GENERAL INSTRUCTIONS

ALWAYS LIGHT THE PILOT WHETHER FOR THE FIRST TIME OR IF THE GAS SUPPLY HAS RUN OUT,

WITH THE GLASS DOOR OPENED OR REMOVED.

PROVIDE ADEQUATE CLEARANCE FOR SERVICING AND OPERATING THE APPLIANCE.

NEVER OBSTRUCT THE FRONT OPENING OF THE APPLIANCE.

OBJECTS PLACED IN FRONT OF THE APPLIANCE MUST BE KEPT A MINIMUM OF 48” FROM THE

LINE AT TEST PRESSURES ABOVE 1/2 PSIG. CLOSE THE MANUAL SHUT-OFF VALVE BEFORE PRESSURE

TESTING GAS LINE AT TEST PRESSURES EQUAL TO OR LESS THAN 1/2 PSIG.

USE ONLY WOLF STEEL APPROVED OPTIONAL ACCESSORIES AND REPLACEMENT PARTS WITH THIS APPLIANCE.

USING NON-LISTED ACCESSORIES (BLOWERS, DOORS, LOUVRES, TRIMS, GAS COMPONENTS, VENTING

COMPONENTS, ETC.) COULD RESULT IN A SAFETY HAZARD AND WILL VOID THE WARRANTY AND CERTIFICATION.

!

PROVIDE ADEQUATE VENTILATION.

FRONT FACE OF THE UNIT.

WHEN THE APPLIANCE IS OPERATING.

FIRE RISK. EXPLOSION HAZARD.

WITH THIS APPLIANCE

Thoroughly clean the chimney, flue and existing

appliance before installing the new appliance into

it. Do not burn solid fuels in any appliance that is

equipped with this gas log set.

The installation of this appliance must conform with

local codes or in the absence of local codes, it must

conform to ANSI Z.223.1 or the CAN/CGA B149.

Do not operate appliance in the presence of gasoline

or other flammable liquids and vapours. Keep area

clear of other combustible materials. The appliance

and its shut off must be disconnected from the gas supply piping system before any pressure testing of the

system is done.

Installation practices vary from region to region and it is important to know the specifics that apply to your

area,

For example: in Massachusetts State:

• This product must be installed by a licensed plumber or gas fitter when installed within the

commonwealth of Massachusetts.

• The appliance damper must be removed or welded in the open position prior to installation of a

• The appliance off valve must be a “T” handle gas cock.

• The flexible connector must not be longer than 36 inches.

• The appliance is not approved for installation in a bedroom or bathroom unless the appliance is a

• A carbon monoxide detector is required in all rooms containing gas fired appliances.

No external electricity (110 volts or 24 volts) is required for the gas system operation.

appliance insert or gas log.

direct vent sealed combustion product.

W415-1071 / D / 08.08.16

2.2 GENERAL INFORMATION

!

WARNING

SAMPLE

A

THIS APPLIANCE MUST NOT BE INSTALLED IN A BEDROOM OR BATHROOM.

Altitude (FT) 0-4,500 0-4,500 0-4,500 0-4,500 0-4,500 0-4,500

Max input (BTU/HR) 55,000 55,000 60,000 60,000 65,000 65,000

5

GL18 GL24 GL30

NG LP NG LP NG LP

Min Inlet Gas Supply Pressure 4.5“

Max Inlet Gas Supply Pressure 7“ Water

Manifold Pressure (Under Flow

Conditions)

2.3 MINIMUM APPLIANCE SIZE

LOG SET HEIGHT WIDTH DEPTH

GL18 18” 22” 14”

GL24 20” 28” 14”

GL30 22” 34” 14”

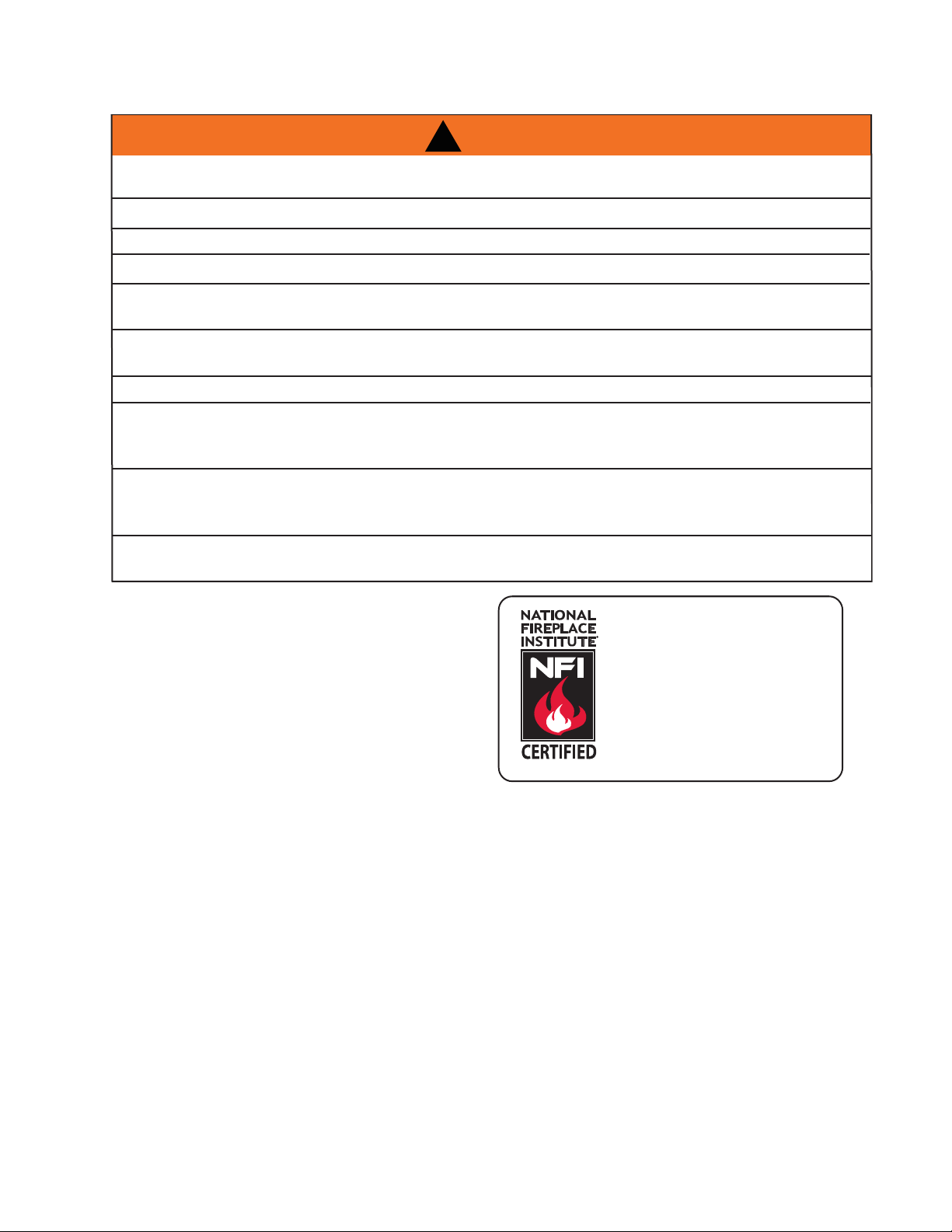

2.4 RATING PLATE

CERTIFIED UNDER / HOMOLOGUE SELON LES NORMES: ANSI Z21.60-2003 CSA 2.26-2003(R2009), DECORATIVE APPLIANCE FOR INSTALLATION IN SOLID-FUEL BURNING APPLIANCES

GL18 NE GL24 NE GL30 NE

55,000BTU/h 60,000BTU/h 65,000BTU/h

34,000BTU/h 35,000BTU/h 36,000BTU/h

Water

Column

Column

3.5“

Water

Column

11“ Water

Column

13“ Water

Column

10“ Water

Column

4.5“

Water

Column

7“ Water

Column

3.5“

Water

Column

11“ Water

Column

13“ Water

Column

10“ Water

Column

4.5“

Water

Column

7“ Water

Column

3.5“

Water

Column

Do not install the gas log set into a cavity smaller than

that referenced in the table.

CERTIFIED

CERTIFIED FOR CANADA/ USA

CERTIFIEE POUR CANADA/ USA

REFERENCE # W/N 15987

GL18 PE

55,000BTU/h 60,000BTU/h 65,000BTU/h

45,000BTU/h 50,000BTU/h 50,000BTU/h

GL24 PE GL30 PE

11“ Water

Column

13“ Water

Column

10“ Water

Column

WOLF STEEL LTD.

24 NAPOLEON ROAD. BARRIE, ONTARIO L4M 0G8 CANADA

WOLF STEEL USA

18”

20”

22”

103 Miller Drive, Crittenden, Kentucky, USA, 41030

SERIAL NUMBER/NO. DE SERIE: GLE

A / W385-1870

THE RATING PLATE IS CHAINED TO THE LEG OF THE BURNER BASE AND SHOULD BE TUCKED

UNDER THE ENTIRE ASSEMBLY.

This rating plate illustration is for reference only. Refer to the rating plate on the appliance for accurate

information.

W415-1071 / D / 08.08.16

6

WARNING

WARNING

3.0 INSTALLATION

THIS APPLIANCE MUST BE INSTALLED IN A SOLID-FUEL BURNING FIREPLACE WITH A WORKING

FLUE AND CONSTRUCTED OF NON-COMBUSTIBLE MATERIAL.

The appliance and gas logs function as a system. If the appliance is not drafting properly and spilling into the

room (check with a match or a smoke stick), reposition the damper clamp until a positive draft is obtained

by opening the damper. If negative pressure in home prevents having a positive draft, consult an air quality

specialist.

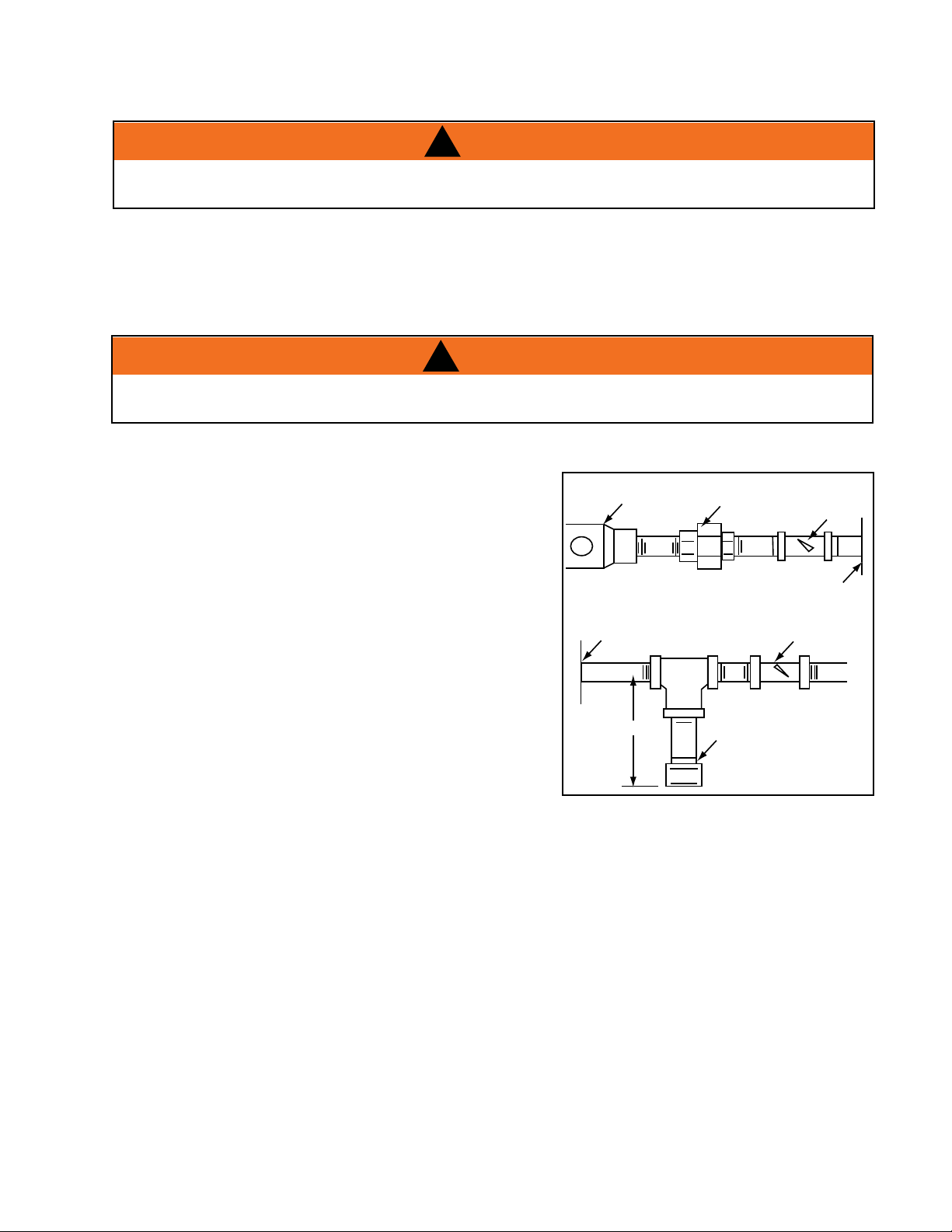

3.1 GAS PIPING

DO NOT CONNECT EITHER THE WALL SWITCH, THERMOSTAT OR GAS VALVE TO ELECTRICITY (110

This appliance must be isolated from the gas supply piping system by closing the individual manual shut off

valve during any pressure testing of the gas supply piping system at test pressure equal to or less than ½ psi

(3.5 kPa)

A. Centre the appliance in the fireplace opening, making

sure the appliance has enough room behind it for the

gas line to run behind the log set under the log support.

!

!

VOLTS).

Regulator

Union

Manual

Shut-Off

Valve

B. Route the gas line and sizing using piping ½” diameter

or greater to allow the full volume of gas to the

appliance. The routing of the gas line has to be done to

local and / or national codes.

C. When rigid pipe is used an ANSI approved manual shut

off and a union must be installed upstream within the

appliance cavity.

D. To ensure the appliance operates reliably, install a

sediment trap upstream of the appliance within the

structures of the piping system.

E. When using propane, a regulator must be used between the tank and the outside wall of the house to

ensure the line pressure does not exceed 14” w.c.

F. Check gas connections with a gas detection device to test for leaks in the system. Soapy water

mixture can also be used to check for leaks.

G. Once all the gas connections are tested for leaks, start the appliance. Follow the lighting instructions

to ensure the appliance is working properly before finishing.

Appliance

3" (76.3mm)

Sediment

Trap

Appliance

Wall

Shut-Off

Key

W415-1071 / D / 08.08.16

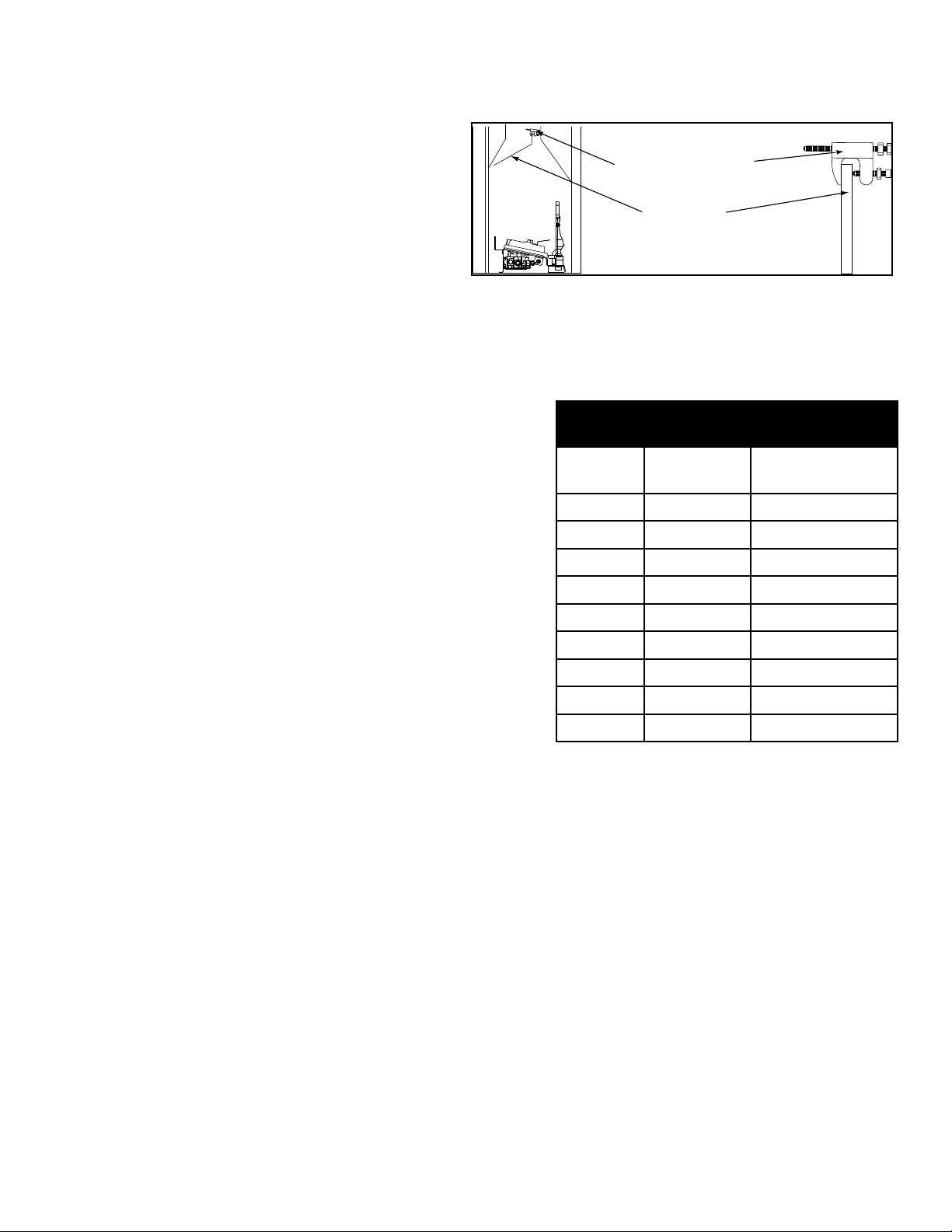

3.2 DAMPER STOP INSTALLATION

The damper must be permanently locked in

position to prevent full closure and to provide

a minimum flue opening. Various methods

for locking the damper may be used but may

be restricted from region to region and it is

important to know the specifics that apply to

your area. For your convenience a damper

stop is provided with the appliance and may

be used where not prohibited by state or local

codes.

Use the 3” adjustable bolt to adjust the damper to the correct opening, based on the enclosed chart.

Should the damper stop not fit, or provide the required permanent opening from the Minimum Damper

Opening table, have the damper cut to provide a minimum permanent opening or install an alternate stop.

7

DAMPER STOP

DAMPER

Creosote, ashes and loose paint must be cleaned from the

chimney flue and firebox by a qualified chimney cleaner,

before installing in a solid fuel burning appliance.

Any outside air ducts and/or ash dumps in the fireplace

shall be permanently closed at time of appliance

installation.

If the damper stop (supplied) is not applicable the damper

may be fixed open by the following method:

• Drill a hole in either end of the damper.

• Using a bolt of sufficient length and adjustment, with 2

nuts, secure to damper through the hole.

• Adjust to correct opening.

MINIMUM DAMPER OPENING

CHIMNEY

HEIGHT

6

8

10

15

20

25

30

35

40

(SQUARE INCHES)

MASONRY

APPLIANCE

33.8”

31.2”

28.7” 22.1”

26.1” 17.3”

23.7” 14.5”

22.7” 12.6”

21.6” 11.3”

FACTORY BUILT

APPLIANCE

10.8”

10.2”

W415-1071 / D / 08.08.16

8

1

2

4.0 FINISHING

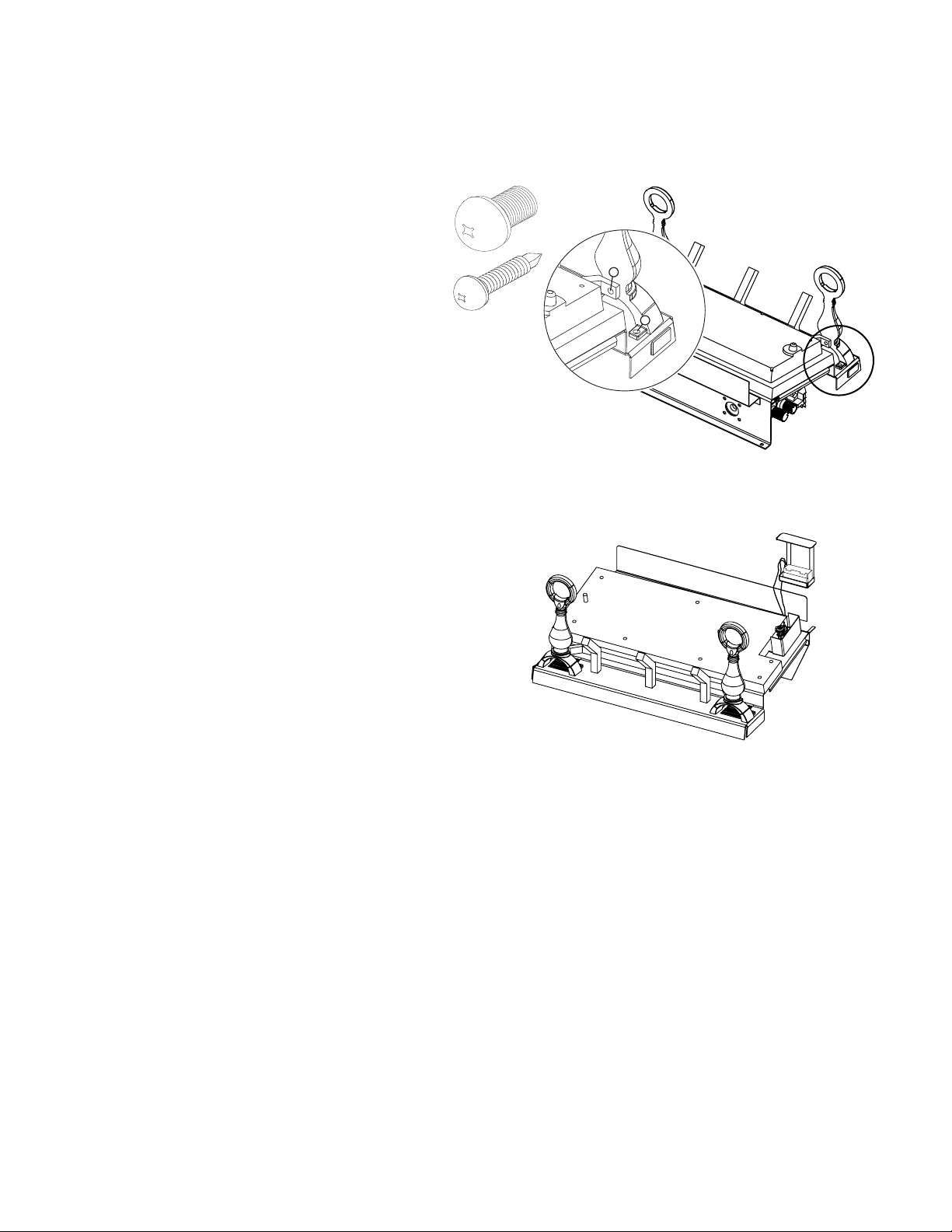

4.1 ANDIRON AND GRATE ASSEMBLY

A. With the 2 andirons laying face

down, secure the grate overtop

using two ¼-20 bolts (supplied in

the manual baggie).

B. Install the grate/andiron assembly

to the burner base using four 1 ¼”

self tapping screws (supplied in the

manual baggie).

USE ONLY ACCESSORIES

DESIGNED FOR AND

LISTED WITH YOUR

SPECIFIC LOG SET.

4.2 BATTERY INSTALLATION

A. Remove all of the logs.

B. The battery pack is located at the rear right corner

of the burner behind the pilot. If there is room, slide

the battery pack out to the right, otherwise lift up

carefully, making sure that the wires connected to

the battery pack do not become entangled.

C. Unfasten the velcro and replace the 4 AA batteries.

D. Replace battery pack and log set (see “LOG

PLACEMENT” section).

W415-1071 / D / 08.08.16

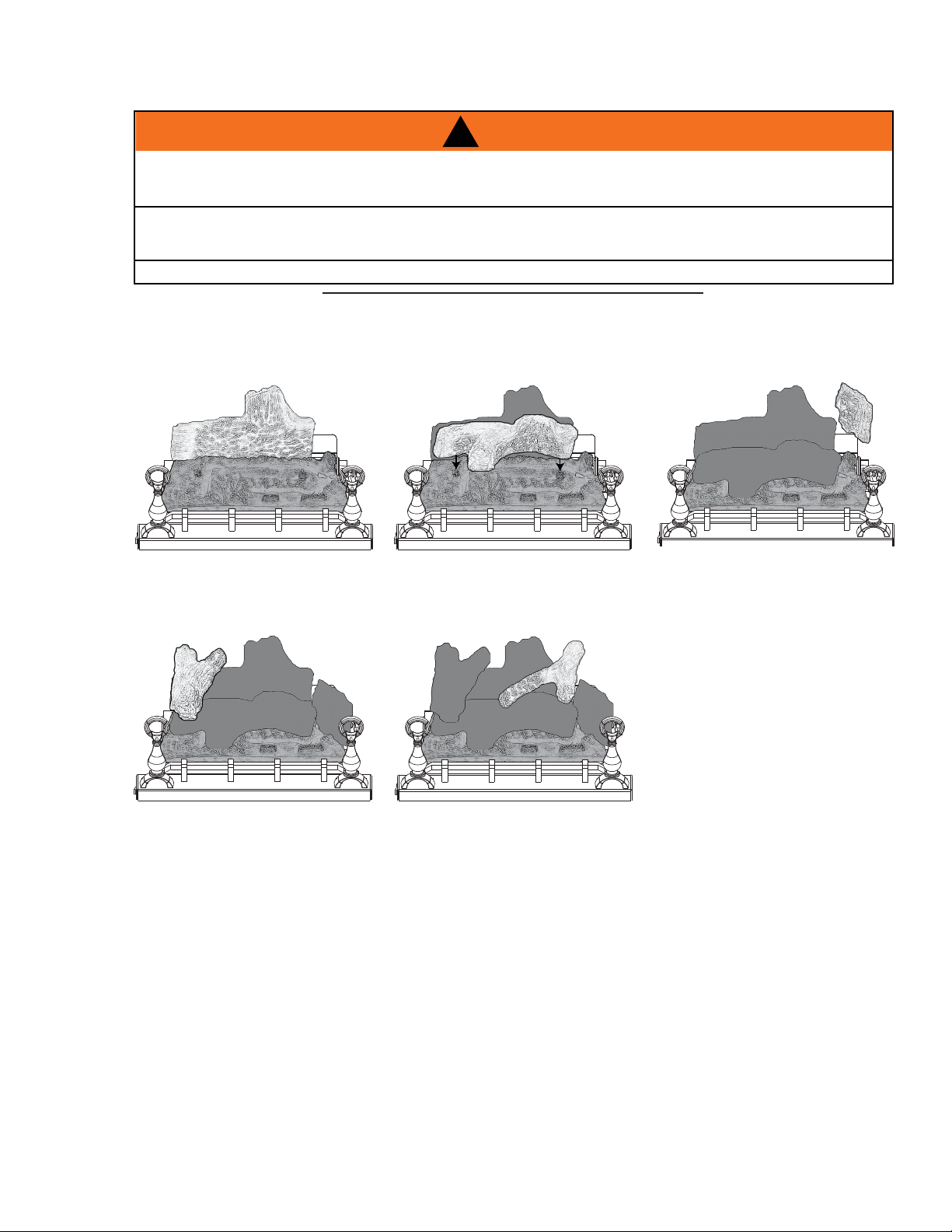

4.3 LOG PLACEMENT

WARNING

FAILURE TO POSITION THE LOGS IN ACCORDANCE WITH THESE DIAGRAMS OR FAILURE TO USE

ONLY LOGS SPECIFICALLY APPROVED WITH THIS APPLIANCE MAY RESULT IN PROPERTY

LOGS MUST BE PLACED IN THEIR EXACT LOCATION IN THE APPLIANCE. DO NOT MODIFY THE

PROPER LOG POSITIONS, SINCE APPLIANCE MAY NOT FUNCTION PROPERLY AND DELAYED

THE LOGS ARE FRAGILE AND SHOULD BE HANDLED WITH CARE.

PhazerTM logs, exclusive to Napoleon, provide a unique and realistic glowing effect that is different in every

installation. Failure to follow these log placement instructions may cause sooting.

9

!

DAMAGE OR PERSONAL INJURY.

IGNITION MAY OCCUR.

76.1A

A. Place the rear log #1 onto

the locating studs on the

rear log support.

D. Position the pins on the

bottom of log #4 into the

holes on the left end of

log #1 and the left end

of log #2.

Log colours may vary. During the initial use of the appliance, the colours will become more uniform as colour

pigments burn in during the heat activated curing process.

Positioning the logs improperly will cause flame impingement and carboning.

Blocked burner ports can cause an incorrect flame pattern, carbon deposits and delayed ignition. Use only

certified Phazer

TM

logs available from your authorized dealer/distributor.

B. Position the holes on

the bottom of log #2

onto the fibre embosses

shown.

E. Place the end of log

#5 on the right end

of log #1. The fork

in the log should

straddle the knot

on top of the log #2.

C. Position the bottom cavity

of log #3 onto the bracket

located in the front right

corner.

W415-1071 / D / 08.08.16

10

LOGO

½"

4.4 MEDIA

A. Place lava or ember rock around the base of the appliance, making sure not to block any burner ports

B. Place formed charcoal lumps around the front and sides of the appliance.

C. Use remaining lava or ember rock to blend with the charcoal lumps.

D. GL30 ONLY: Sprinkle remaining lava rock onto the outer fibre ember beds to hide the seam.

IMPORTANT: DO NOT COVER FRONT SLOTS BENEATH THE ANDIRONS WITH MEDIA.

or valve access. Retain a small amount of lava rock for step 3 and, if applicable, step 4.

GL 18

GL 24 GL 30

4.5 LOGO PLACEMENT

Remove the backing of the logo supplied. Centre the logo

on the front of the appliance, ½” in from the left side, as

shown.

½"

LOGO

W415-1071 / D / 08.08.16

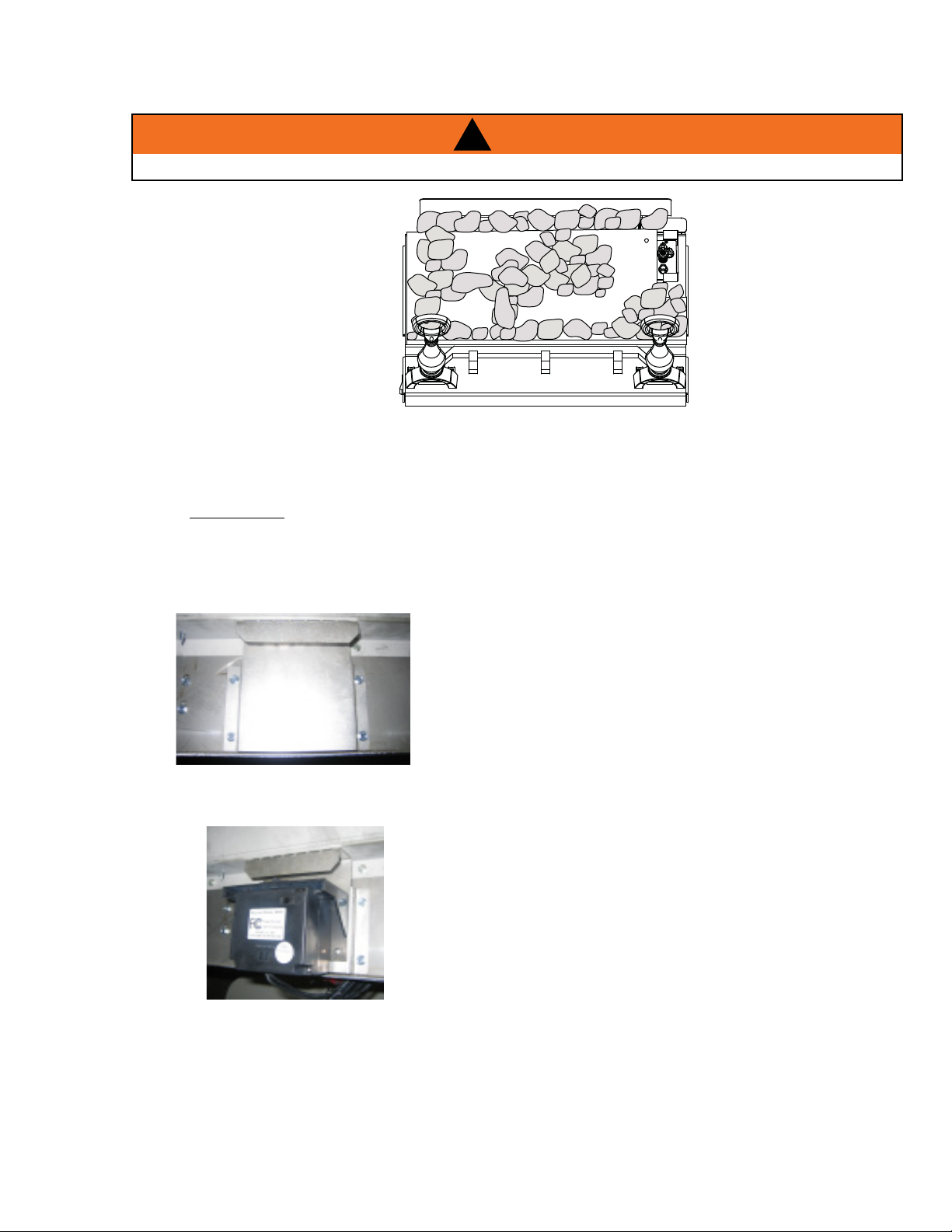

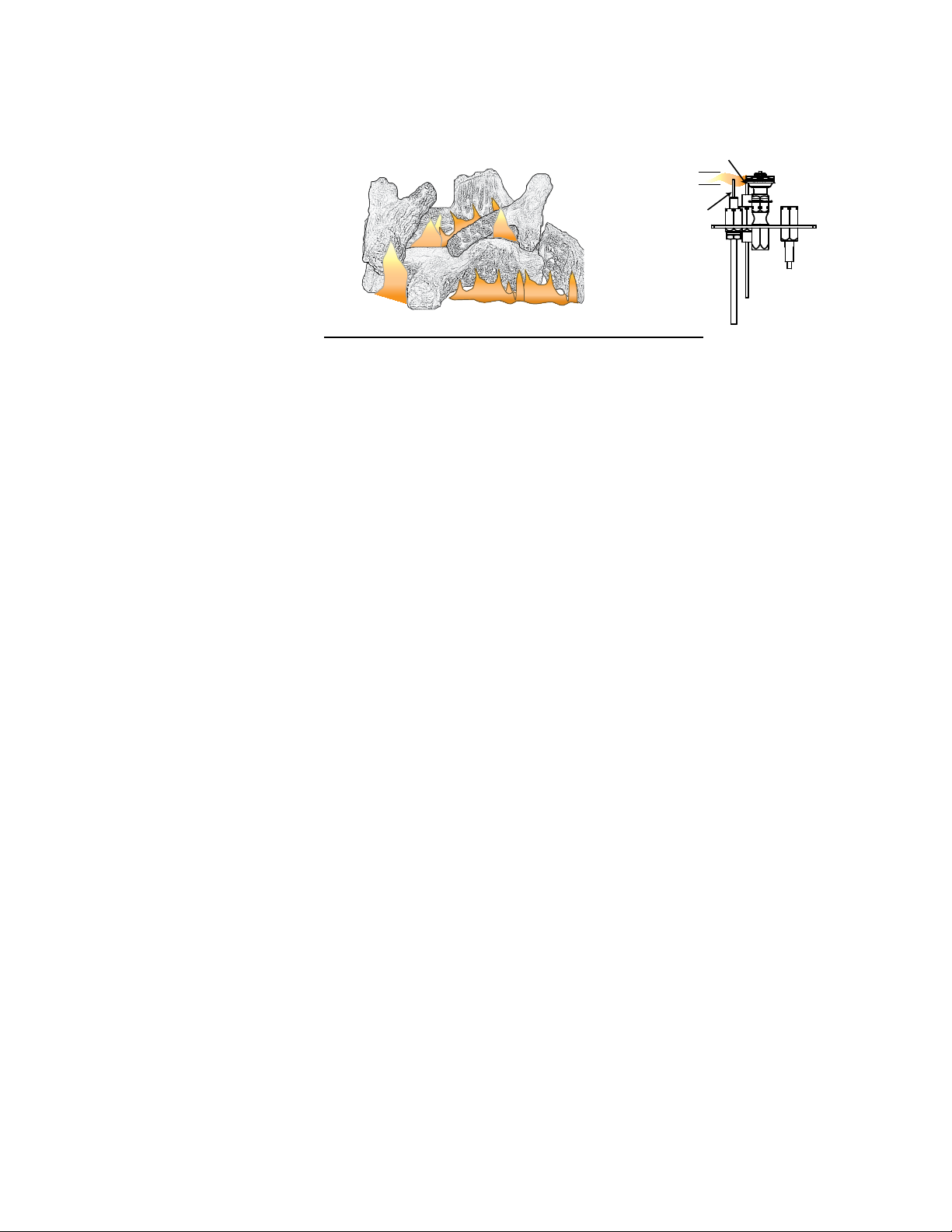

4.6 OPTIONAL ROCK PLACEMENT

!

WARNING

REAL ROCKS MUST NOT BE USED IN THIS APPLIANCE. HEAT WILL CAUSE THEM TO EXPLODE

A. Begin with thin rock clusters on rear log support, then build outward in a pattern, as shown.

Removing a locating pin in the rear support may be required to accommodate the rock clusters. It is

not necessary to use all of the rocks.

IMPORTANT: Do not block burner ports on burner surface. Do not block slots beneath or behind the

andirons.

11

4.7 OPTIONAL REMOTE INSTALLATION (NOT SUPPLIED)

A. The remote receiver must be installed onto the bracket on the back right sides of the burner.

B. Bend the tab on the bracket straight and then using the double sided tape (supplied with the remote

kit), adhere the remote reciever to the bracket.

C. Hook up the wires from the remote receiver to the green and white wires on the wire harness.

W415-1071 / D / 08.08.16

12

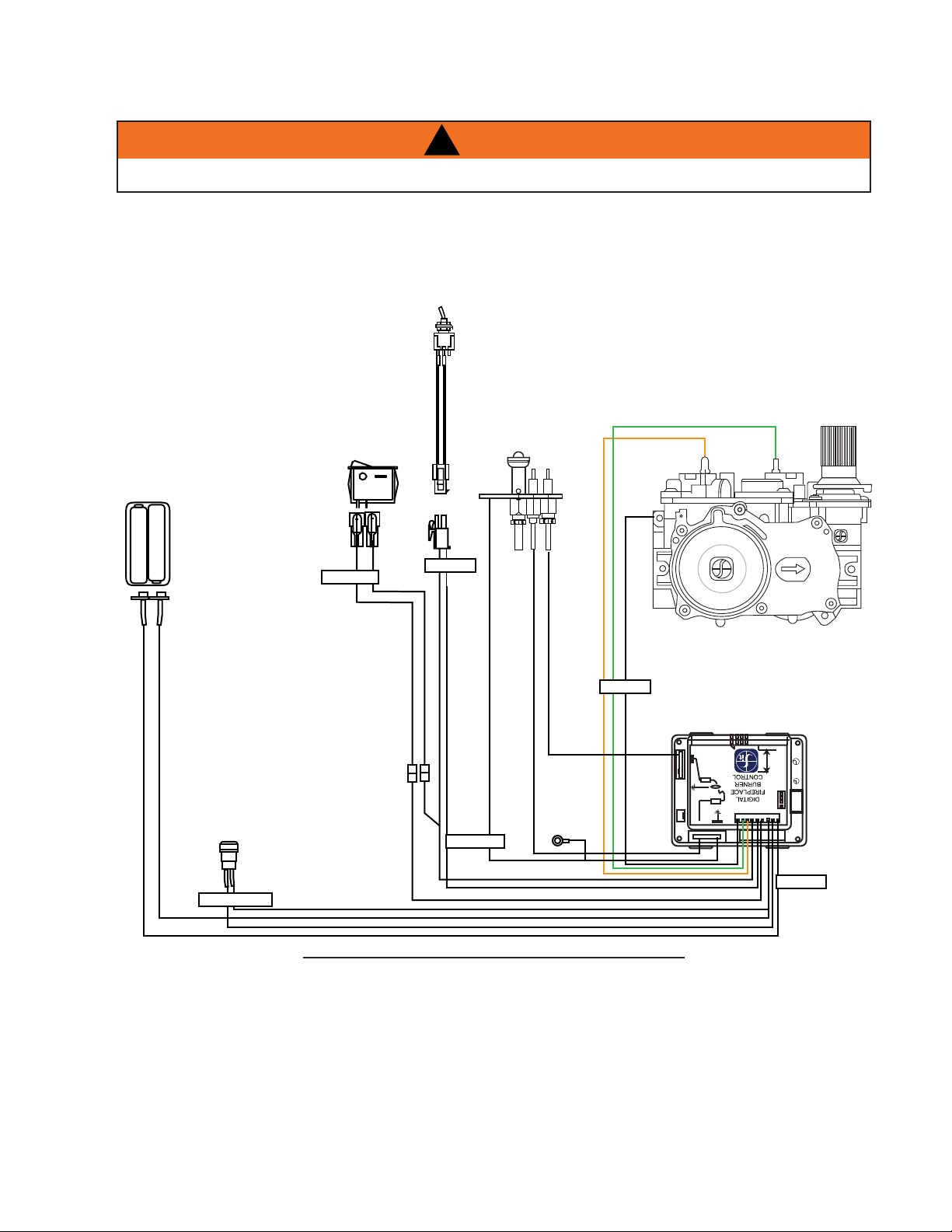

WARNING

This appliance comes equipped with a battery pack. Install four AA batteries into the holder and connect to the

wire harness. Connect the battery holder to the wire harness before using the appliance. It must be connected

to the 6 volt battery pack (supplied).

5.0 WIRING DIAGRAM

!

DO NOT WIRE 110 VOLTS TO THE VALVE OR WALL SWITCH.

ACS/IPI

SWITCH

(OPTION AVAILABLE

ON SPECIFIC

APPLIANCES)

BATTERY

HOLDER

-

+

ON / OFF

SWITCH

ORANGE

GREEN

+

-

DC SUPPLY

ON / OFF

IPI / CPI

VALVE

ELECTRONIC

VALV E

IPI BOARD

GROUND

EYELET

GROUND

DFC

69.6A

W415-1071 / D / 08.08.16

When lit for the fi rst time, the appliance will emit an odour for a few hours. This is a normal temporary condition

caused by the “burn-in” of paints and lubricants used in the manufacturing process and will not occur again.

After extended periods of non-operation such as following a vacation or a warm weather season, the appliance

may emit a slight odour for a few hours. This is caused by dust particles in the cavity burning off. In both cases,

open a window to suffi ciently ventilate the room.

A.

B.

Before operating smell all around the appliance area for gas and next to the fl oor because some gas is

C.

D.

A.

B.

C.

D.

pilot. Do not try to light the pilot by hand.

E.

F.

gas go to the next step.

G.

H.

I.

A.

B.

WARNING

6.0 OPERATION

If the fireplace is equipped with decorative glass doors, they must be fully opened when operating this gas

log set. Keep burner and control compartment clean.

6.1 OPERATING AND LIGHTING INSTRUCTIONS

!

13

IF YOU DO NOT FOLLOW THESE INSTRUCTIONS EXACTLY, A FIRE OR EXPLOSION MAY RESULT

ALWAYS LIGHT THE PILOT WHETHER FOR THE FIRST TIME OR IF THE GAS SUPPLY HAS RUN OUT WITH

CAUSING PROPERTY DAMAGE, PERSONAL INJURY OR LOSS OF LIFE.

THE GLASS DOOR OPENED OR REMOVED.

FOR YOUR SAFETY READ BEFORE LIGHTING:

Do not turn on if children or other at risk individuals are near the appliance.

heavier than air and will settle on the fl oor.

Use only your hand to turn the gas control knob. Never use tools. If the knob will not turn by hand, do

not try to repair it. Call a qualifi ed service technician. Force or attempted repair may result in a fi re or

explosion.

Do not use this appliance if any part has been under water. Immediately call a qualifi ed service

technician to inspect the appliance and replace any part of the control system and any gas control

which has been underwater.

WHAT TO DO IF YOU SMELL GAS:

• Turn off all gas to the appliance.

• Open windows.

• Do not try to light any appliance.

• Do not touch any electric switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbour’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier,

call the fi re department.

LIGHTING INSTRUCTIONS:

Stop! Read the above safety information on this label.

Open the glass door if equipped.

Remove the batteries.

This appliance is equipped with an ignition device which automatically lights the

S

O

MANUAL SHUT-OFF

(SHOWN IN OFF POSITION)

Turn manual shutoff valve clockwise to off. Located behind the appliance.

Wait fi ve (5) minutes to clear out any gas. If you smell gas including near the fl oor,

STOP! Follow “B” in the above safety information on this label. If you don’t smell

Turn manual shutoff valve counter-clockwise to on.

Replace the batteries.

Turn switch on and listen for ignition sound.

Remove the batteries.

Turn manual shutoff valve clockwise to off. Do not force.

TO TURN OFF GAS:

47.19

W415-1071 / D / 08.08.16

14

Adjust the pilot screw to provide properly sized fl ame. Turn in a

39.1E

This appliance has an air shutter that has been factory set open according

SHUTTER

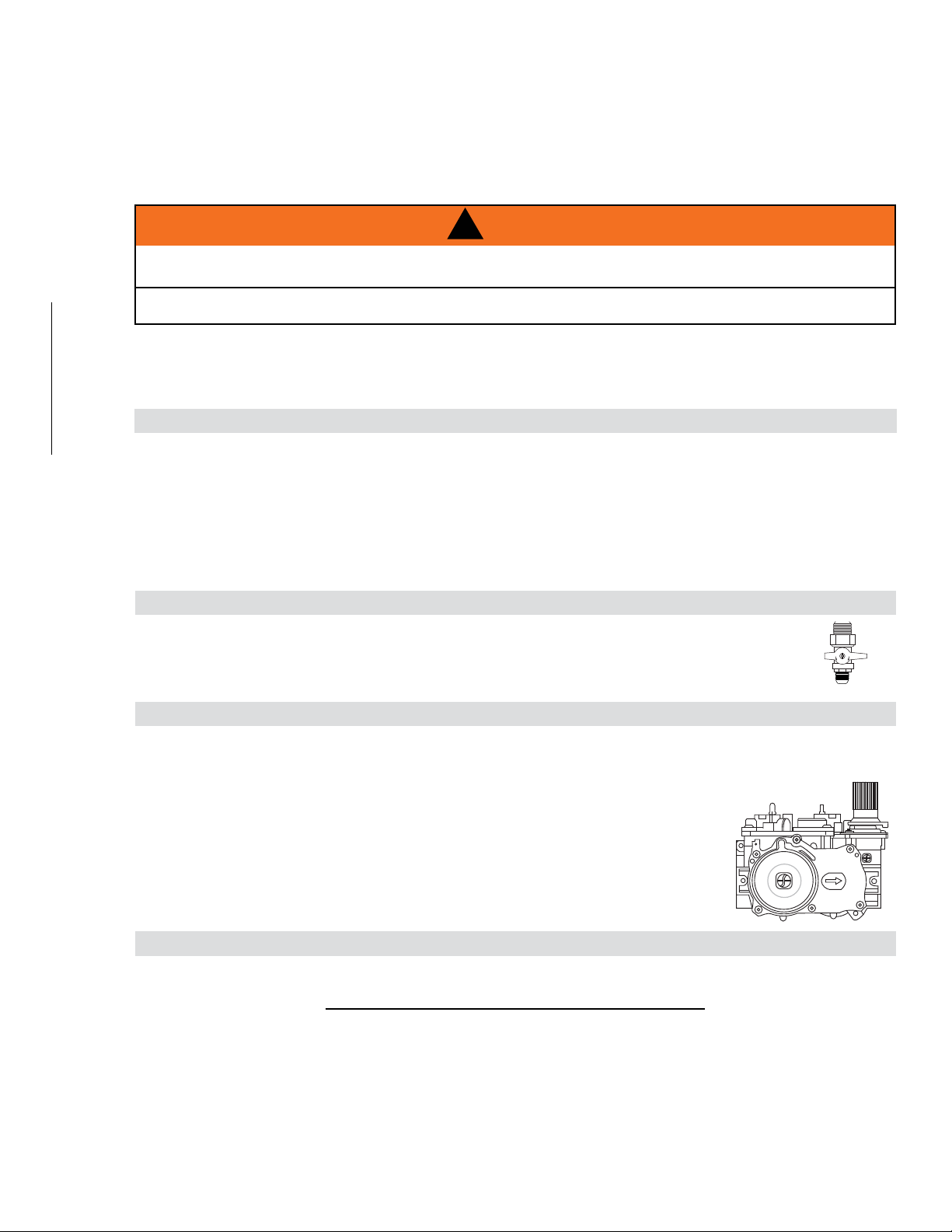

7.0 ADJUSTMENTS

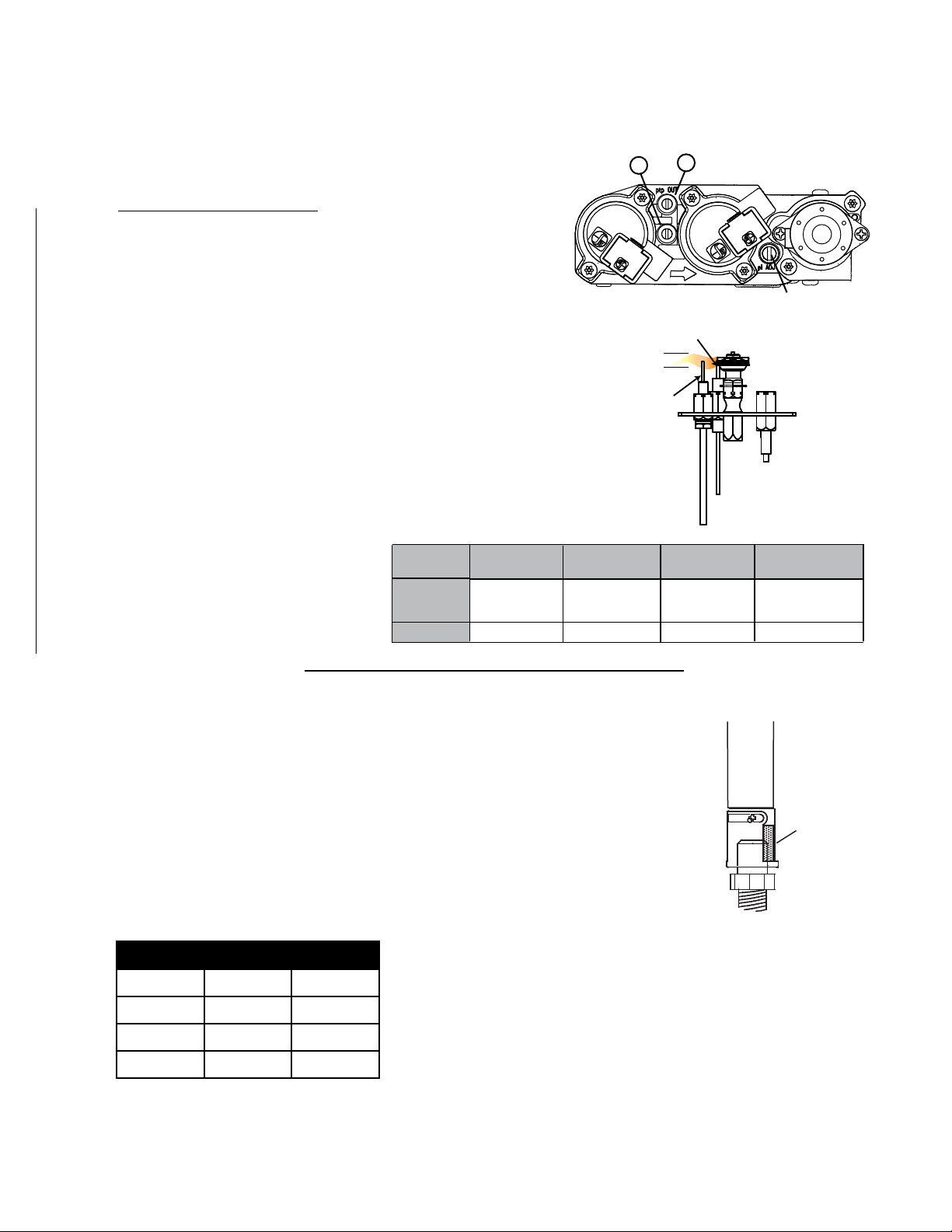

7.1 PILOT BURNER ADJUSTMENT

clockwise direction to reduce the gas fl ow.

Check Pressure Readings:

Inlet pressure can be checked by turning screw (A) counter-

clockwise 2 or 3 turns and then placing pressure gauge tubing

over the test point. Gauge should read as described on the chart

below. Check pressure with main burner operating on “HI”.

Outlet pressure can be checked the same as above using

screw (B). Gauge should read as described on the chart

below. Check pressure with main burner operating on “HI”.

AFTER TAKING PRESSURE READINGS, BE SURE TO

TURN SCREWS CLOCKWISE FIRMLY TO RESEAL. DO

NOT OVERTORQUE.

Leak test with a soap and water solution.

A

ELECTRODE

3/8” - 1/2”

(9.5mm - 12.7mm)

FLAME

SENSOR

B

PILOT SCREW

PILOT

BURNER

Prior to pilot adjustment, ensure that the pilot assembly

has not been painted. If overspray or painting of the pilot

assembly has occurred remove the paint from the pilot

assembly, or replace. Fine emery

cloth or a synthetic scrub pad (such as

Pressure

Scotch-Brite™) can be used to remove

the paint from the pilot hood, electrode

and fl ame sensor.

*Maximum inlet pressure

Inlet

Outlet

not to exceeed 13”.

7.2 VENTURI ADJUSTMENT

to the chart below:

Regardless of venturi orientation, closing the air shutter will cause a more

yellow flame, but can lead to carbonization. Opening the air shutter will

cause a more blue flame, but can cause flame lifting from the burner ports.

The flame may not appear yellow immediately; allow 15 to 30 minutes for

the final flame colour to be established.

AIR SHUTTER ADJUSTMENT MUST ONLY BE DONE BY A QUALIFIED

INSTALLER!

Natural Gas

(inches)

7"

*

(MIN. 4.5")

3.5"

Natural Gas

(millibars)

17.4mb

(MIN. 11.2mb)

8.7mb

Propane

(inches)

13"

(MIN. 11")

10"

VENTURI

BURNER

ORIFICE

FLAME MUST ENVELOP

UPPER 3/8” (9.5mm) TO 1/2”

(12.7mm) OF FLAME SENSOR

Propane

(millibars)

32.4mb

(MIN. 27.4mb)

24.9mb

AIR

OPENING

LOG SET AIR SHUTTER

FUEL NG LP

GL18 1/8” 1/4”

GL24 1/8” 5/16”

GL30 1/8” 3/8”

W415-1071 / D / 08.08.16

7.3 FLAME CHARACTERISTICS

It is important to periodically perform a visual check of the pilot and burner fl ames. Compare them to the

illustration provided. If any fl ames appear abnormal, call a service person.

UPPER 3/8” (9.5mm) TO 1/2”

(12.7mm) OF FLAME SENSOR

15

ELECTRODE

(9.5mm - 12.7mm)

3/8” - 1/2”

FLAME

SENSOR

PILOT

BURNER

FLAME MUST ENVELOP

54.1B

W415-1071 / D / 08.08.16

Loading...

Loading...