Napoleon GDS 50 - N, GDI 50 - N, GDI 50 - P, GDS 50 - P, GS 50 - N Installation And Operation Instruction Manual

...

INSTALLER: THESE INSTRUCTIONS MUST BE CONVEYED TO AND REMAIN WITH THE HOMEOWNER.

CERTIFIED UNDER CANADIAN AND AMERICAN NATIONAL STANDARDS, CSA 2.33, ANSI Z21.88 FOR VENTED GAS FIREPLACE HEATERS

GAS-FIRED STOVES

INSTALLATION AND OPERATION INSTRUCTIONS FOR:

VENTED GAS FIREPLACE HEATER

1

NATURAL GAS MODELS

PROPANE GAS MODELS GDS 50 - P and GDI 50 - P PROPANE GAS MODEL GS 50 - P

GDS 50 - N and GDI 50 - N NATURAL GAS MODEL GS 50 - N

Model GS50 is made up of Model GDS50 and B-Vent Adapter Kit GS-150KT

WARNING: If the information in these instructions is not followed exactly, a fire or

explosion may result causing property damage, personal injury or death.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapours and liquids in the vicinity of

this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from

a neighbour's phone. Follow the gas

supplier's instructions.

• If you cannot reach your gas supplier,

call the fire department.

Installation and service must be performed by a qualified installer, service

agency or the gas supplier .

Barrie, ON., Canada L4M 4Y8 (705)721-1212

Fax: (705)722-6031 Email: ask@napoleon.on.ca

Web: www.napoleon.on.ca

Wolf Steel Ltd., RR#1, 9 Napoleon Rd.,

R-2000

WS-415-098 / 04.11.00

2

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE

TABLE OF CONTENTS

Pg 2-4 INTRODUCTION

Warranty

General Instructions

General Information

Care of Glass & Plated Parts

5 LOCATION & CLEARANCES

6-11 DIRECT VENT SPECIFICS

MODEL GDS50

Vent Lengths/Air Terminal Locations

Special Installation Example

Offset Installation Example

Wall & Ceiling Protection

Horizontal Venting Installation

Vertical Venting Installation

Stove Vent Connection

Mobile Home Installation

12 INSERT VENT SPECIFICS

MODEL GDI50

Chimney Connection

Gas Installation

Insert Vent Connection

13-14 B-VENT SPECIFICS

MODEL GS50

Chimney Installation

'B' Vent Installation

Adding Vent Sections

Flashing and Storm Collar Installation

'B' Vent Adaptations

Combustion Air

Pg 15 GAS INSTALLATION

16-17 FINISHING

Door Opening & Closing

Louvre & Trivet Installation

Log Placement

Variable Speed Switch Installation

Flashing Installation

Mantle Clearances

18-1 9 OPERATION / MAINTENANCE

Spill Switch

Venting Action Check

Turbo Burner

Operating Instructions

Maintenance

20 REPLACEMENT BLOWER

21 ADJUSTMENTS

Pilot Burner Adjustment

Venturi Adjustments

22-24 REPLACEMENTS

Ordering Replacement Parts

Terminal Kits

Accessories

Replacement Parts

25-26 TROUBLE SHOOTING GUIDE

27 SERVICE HISTORY

• The stove is a vented gas-fired heater. Do not burn wood or other materials in this stove.

• Adults and especially children should be alerted to the hazards of high surface temperatures and should stay away

to avoid burns or clothing ignition. Supervise young children when they are in the same room as the stove.

• Due to high temperatures, the stove should be located out of traffic and away from furniture and draperies.

• Clothing or other flammable material should not be placed on or near the stove.

• Any safety screen or guard removed for servicing must be replaced prior to operating the stove.

• It is imperative that the control compartments, burners and circulating blower and its passageway in the stove and

venting system are kept clean. The stove and its venting system should be inspected before use and at least annually

by a qualified service person. More frequent cleaning may be required due to excessive lint from carpeting, bedding

material, etc. The stove area must be kept clear and free from combustible materials, gasoline and other flammable

vapours and liquids.

• Under no circumstances should this stove be modified.

• This stove must not be connected to a chimney flue pipe serving a separate solid fuel burning appliance.

• Do not use this stove if any part has been under water. Immediately call a qualified service technician to inspect the

stove and to replace any part of the control system and any gas control which has been under water.

• Do not operate the stove with the glass door opened, cracked or broken. Replacement of the glass should be done

by a licensed or qualified service person.

• Do not strike or slam shut the stove glass door.

WS-415-098 / 04.11.00

WARNING

NAPOLEON gas fireplaces are manufactured under the strict Standard of the world recognized

ISO9002 Quality Assurance Certificate.

NAPOLEON products are designed with superior components and materials, assembled by trained craftsmen

who take great pride in their work. The burner and valve assembly are leak and test-fired at a quality test

station. The complete fireplace is thoroughly inspected by a qualified technician before packaging to ensure that

you, the customer, receives the quality product that you expect from NAPOLEON.

NAPOLEON GAS FIREPLACE PRESIDENT'S LIFETIME LIMITED WARRANTY

3

The following materials and workmanship in your new The following materials and workmanship in your new

The following materials and workmanship in your new

The following materials and workmanship in your new The following materials and workmanship in your new

warranted against defects for as long as you own the fireplace. This covers: combustionwarranted against defects for as long as you own the fireplace. This covers: combustion

warranted against defects for as long as you own the fireplace. This covers: combustion

warranted against defects for as long as you own the fireplace. This covers: combustionwarranted against defects for as long as you own the fireplace. This covers: combustion

chamber, heat exchanger, stainless steel burner, phazer™ logs and embers, ceramic glasschamber, heat exchanger, stainless steel burner, phazer™ logs and embers, ceramic glass

chamber, heat exchanger, stainless steel burner, phazer™ logs and embers, ceramic glass

chamber, heat exchanger, stainless steel burner, phazer™ logs and embers, ceramic glasschamber, heat exchanger, stainless steel burner, phazer™ logs and embers, ceramic glass

(thermal breakage only), gold plated parts against tarnishing, porcelainized enamelled com-(thermal breakage only), gold plated parts against tarnishing, porcelainized enamelled com-

(thermal breakage only), gold plated parts against tarnishing, porcelainized enamelled com-

(thermal breakage only), gold plated parts against tarnishing, porcelainized enamelled com-(thermal breakage only), gold plated parts against tarnishing, porcelainized enamelled components and aluminum extrusion trims.ponents and aluminum extrusion trims.

ponents and aluminum extrusion trims.

ponents and aluminum extrusion trims.ponents and aluminum extrusion trims.

Electrical (110V and millivolt) components and wearable parts such as blowers, gas valves,Electrical (110V and millivolt) components and wearable parts such as blowers, gas valves,

Electrical (110V and millivolt) components and wearable parts such as blowers, gas valves,

Electrical (110V and millivolt) components and wearable parts such as blowers, gas valves,Electrical (110V and millivolt) components and wearable parts such as blowers, gas valves,

thermal switch, switches, wiring, remote controls, ignitor, gasketing, and pilot assembly arethermal switch, switches, wiring, remote controls, ignitor, gasketing, and pilot assembly are

thermal switch, switches, wiring, remote controls, ignitor, gasketing, and pilot assembly are

thermal switch, switches, wiring, remote controls, ignitor, gasketing, and pilot assembly arethermal switch, switches, wiring, remote controls, ignitor, gasketing, and pilot assembly are

covered and covered and

covered and

covered and covered and

of the limited warranty.of the limited warranty.

of the limited warranty.

of the limited warranty.of the limited warranty.

Labour related to warranty repair is covered free of charge during the first year. RepairLabour related to warranty repair is covered free of charge during the first year. Repair

Labour related to warranty repair is covered free of charge during the first year. Repair

Labour related to warranty repair is covered free of charge during the first year. RepairLabour related to warranty repair is covered free of charge during the first year. Repair

work, however, requires the prior approval of an authorized company official. Labour costswork, however, requires the prior approval of an authorized company official. Labour costs

work, however, requires the prior approval of an authorized company official. Labour costs

work, however, requires the prior approval of an authorized company official. Labour costswork, however, requires the prior approval of an authorized company official. Labour costs

to the account of to the account of

to the account of

to the account of to the account of

work must be done through an authorized work must be done through an authorized

work must be done through an authorized

work must be done through an authorized work must be done through an authorized

NAPOLEONNAPOLEON

NAPOLEON

NAPOLEONNAPOLEON

NAPOLEONNAPOLEON

NAPOLEON

NAPOLEONNAPOLEON

will provide replacement parts free of charge during the first yearwill provide replacement parts free of charge during the first year

will provide replacement parts free of charge during the first year

will provide replacement parts free of charge during the first yearwill provide replacement parts free of charge during the first year

are based on a predetermined rate schedule and any repair are based on a predetermined rate schedule and any repair

are based on a predetermined rate schedule and any repair

are based on a predetermined rate schedule and any repair are based on a predetermined rate schedule and any repair

NAPOLEONNAPOLEON

NAPOLEON

NAPOLEONNAPOLEON

NAPOLEONNAPOLEON

NAPOLEON

NAPOLEONNAPOLEON

dealer. dealer.

dealer.

dealer. dealer.

gas fireplace are gas fireplace are

gas fireplace are

gas fireplace are gas fireplace are

CONDITIONS AND LIMITATIONS

NAPOLEON warrants its products against manufacturing defects to the original purchaser only -- i.e., the individual or legal entity (registered customer) whose name appears on the

warranty registration card filed with NAPOLEON -- provided that the purchase was made through an authorized NAPOLEON dealer and is subject to the following conditions and limitations:

This factory warranty is nontransferable and may not be extended whatsoever by any of our representatives.

The gas fireplace must be installed by a licenced, authorized service technician or contractor. Installation must be done in accordance with the installation instructions included with the

product and all local and national building and fire codes.

This limited warranty does not cover damages caused by misuse, lack of maintenance, accident, alterations, abuse or neglect and parts installed from other manufacturers will nullify

this warranty.

This limited warranty further does not cover any scratches, dents, corrosion or discolouring caused by excessive heat, abrasive and chemical cleaners nor chipping on porcelain enamel

parts, mechanical breakage of PHAZER™ logs and embers, nor any venting components used in the installation of the fireplace.

NAPOLEON warrants its stainless steel burners against defects in workmanship and material for life, subject to the following conditions: During the first 10 years NAPOLEON will replace

or repair the defective parts at our option free of charge. From 10 years to life, NAPOLEON will provide replacement burners at 50% of the current retail price.

In the first year only, this warranty extends to the repair or replacement of warranted parts which are defective in material or workmanship provided that the product has been operated

in accordance with the operation instructions and under normal conditions.

After the first year, with respect to this President's Limited Lifetime Warranty , NAPOLEON may , at its discretion, fully discharge all obligations with respect to this warranty by refunding

to the original warranted purchaser the wholesale price of any warranted but defective part(s).

After the first year, NAPOLEON will not be responsible for installation, labour or any other costs or expenses related to the reinstallation of a warranted part, and such expenses are not

covered by this warranty.

Notwithstanding any provisions contained in this President's Limited Lifetime Warranty, NAPOLEON’S responsibility under this warranty is defined as above and it shall not in any event

extend to any incidental, consequential or indirect damages.

This warranty defines the obligations and liability of NAPOLEON with respect to the NAPOLEON gas fireplace and any other warranties expressed or implied with respect to this product,

its components or accessories are excluded.

NAPOLEON neither assumes, nor authorizes any third party to assume, on its behalf, any other liabilities with respect to the sale of this product. NAPOLEON will not be responsible

for: over-firing, downdrafts, spillage caused by environmental conditions such as rooftops, buildings, nearby trees, hills, mountains, inadequate vents or ventilation, excessive venting

configurations, insufficient makeup air, or negative air pressures which may or may not be caused by mechanical systems such as exhaust fans, furnaces, clothes dryers, etc.

Any damages to fireplace, combustion chamber, heat exchanger, brass trim or other component due to water, weather damage, long periods of dampness, condensation, damaging

chemicals or cleaners will not be the responsibility of NAPOLEON.

The bill of sale or copy will be required together with a serial number and a model number when making any warranty claims from your authorized dealer. The warranty registration

card must be returned within fourteen days to register the warranty.

NAPOLEON reserves the right to have its representative inspect any product or part thereof prior to honouring any warranty claim.

ALL SPECIFICATIONS AND DESIGNS ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE DUE T O ON-GOING PRODUCT IMPROVEMENTS. NAPOLEON® IS A REGISTERED

TRADEMARK OF WOLF STEEL LTD. PA TENTS U.S. 5.303.693.801 - CAN. 2.073.41 1, 2.082.915 & DES 417,497(12.07.1999). © WOLF STEEL L TD.

WS-415-098 / 04.11.00

GENERAL INSTRUCTIONS

4

THIS GAS STOVE SHOULD BE INSTALLED AND SERVICED BY A QUALIFIED INSTALLER to conform with local

codes. In absence of local codes, install to the current CAN1B149 Installation Code in Canada or to the National Fuel

Gas Code, ANSI Z223.1-1988, and NFPA 54-1988 in the

United States. Mobile home installation must conform with

local codes or in the absence of local codes, install to the

current standard for gas equipped mobile housing CAN/

CSA Z240 MH Series in Canada or ANSI Z223.1-1988 and

NFPA 54-1988 in the United States.

Purge all gas lines with the glass door of the stove

opened. Assure that a continuous gas flow is at the

burner before c losing the door.

Under extreme vent configurations, allow several minutes (5-15) for the flame to stabilize after ignition.

All horizontal runs must have a ¼ inch rise per foot.

Objects placed in front of the fireplace must be kept a

minimum of 48" away from the front face of the unit.

The stove and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure testing of that system at test pressures in excess of 1/

2 psig (3.5 kPa). The stove must be isolated from the gas

supply piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 psig (3.5

kPa).

A 1/8 inch NPT plug, accessible for test gauge connection,

must be installed immediately upstream of the gas supply

connection to the stove.

The stove, when installed with a blower, must be electrically

connected and grounded in accordance with local codes. In

the absence of local codes, use the current CSA C22.1

CANADIAN ELECTRICAL CODE in Canada or the ANSI/NFPA

70-1990 NATIONAL ELECTRICAL CODE in the United

States. The blower power cord must be connected into a

properly grounded receptacle. The grounding prong must

not be removed from the cord plug.

GENERAL INFORMATION

FOR YOUR SATISF ACTION, THIS STOVE HAS BEEN TESTFIRED TO ASSURE ITS OPERATION AND QUALITY!

Minimum inlet gas supply pressure is 4.5 inches water column for natural gas and 11 inches water column for propane. Maximum inlet gas pressure is 7 inches water column for natural gas and 13 inches water column for propane. Manifold pressure under flow conditions is 3.5 inches

water column for natural gas and 10 inches water column

for propane. When the fireplace is installed at elevations

above 4,500ft, and in the absense of specific recommendations from the local authority having jurisdiction, the certified high altitude input rating shall be reduced at the rate of

4% for each additional 1,000ft.

Change in flame appearance from "HI" to "LO" is more evident in natural gas than in propane. Expansion / contraction

noises during heating up and cooling down cycles are normal and to be expected.

GDS50:GDS50:

GDS50: Maximum input is 44,000 BTU/hr for natural

GDS50:GDS50:

gas and 40,000 BTU/hr for propane. Maximum output for

natural gas is 37,000 BTU/hr at an efficiency of 84% with the

fan on; Maximum output for propane is 34,400 BTU/hr at an

efficiency of 86% with the fan on. Maximum A.F.U.E. (annual

fuel utilization efficiency) rating is 77% for natural gas and

79% for propane. This stove is not approved for closet or

recessed installations. It is approved for bathroom, bedroom and bed-sitting room installations and is suitable for

mobile homes. The natural gas model is suitable for installation in a mobile home that is permanently positioned on

its site and fueled with natural gas.

GDI50: GDI50:

GDI50: This insert must be recessed into a vented

GDI50: GDI50:

noncombustible woodburning fireplace (prefabricated or

masonry) only. The minimum fireplace size in which the

heater is to be installed is:

HEIGHT 21 inches WIDTH 27 INCHES DEPTH 14 inches

The minimum distance, from the bottom of a combustible

mantle projecting 2" maximum from the wall to the top of the

unit, is 18".

Maximum input is 44,000 BTU/hr for natural gas and 40,000

BTU/hr for propane. Maximum output for natural gas is

37,000 BTU/hr at an efficiency of 84% with the fan on; Maximum output for propane is 34,000 BTU/hr at an efficiency of

85% with the fan on. Maximum A.F.U.E. (annual fuel utilization efficiency) rating is 73% for natural gas and 74% for

propane. The insert is approved for bathroom, bedroom

and bed-sitting room installations.

GS50: GS50:

GS50: Maximum input is 44,000 BTU/hr for

GS50: GS50:

natural gas and 40,000 BTU/hr for propane. Maximum output for natural gas is 31,200 BTU/hr at an

efficiency of 77% with the fan on and 71% with the

fan off; and 30,000 BTU/hr for propane at an efficiency of 78% with the fan on and 73% with the fan

off. Minimum A.F.U.E. (annual fuel utilization efficiency) rating is 65% for natural gas and 67% for propane. This stove

is approved for bedroom and bed-sitting room installations.

CARE OF GLASS, AND PLATED PARTS

Do not use abrasive cleaners to clean these parts. Buff

lightly with a clean dry cloth.

The glass is 3/16" ceramic glass available from your Napoleon / Wolf Steel Ltd. dealer. DO NOT SUBSTITUTE MATERIALS. Clean the glass after the first 10 hours of operation

with a recommended gas fireplace glass cleaner. Thereafter clean as required. DO NOT CLEAN GLASS WHEN HOT!

If the glass is not kept clean permanent discolouration and

/ or blemishes may result.

WS-415-098 / 04.11.00

LOCATION AND CLEARANCES

Provide adequate ventilation and combustion air.

Provide adequate accessibility clearance for servicing and operating the stove.

Never obstruct the front opening of the stove.

Objects placed in front of the fireplace must be kept a minimum of 48" away from the front face of the unit.

21-5/8"

GDS50 AND GS50:

As long as clearance to combustibles is

kept within the required distances, the most

desirable and benefical location for a Napoleon stove is in the centre of a building,

thereby allowing the most efficient use of

the heat created. The location of windows,

doors and the traffic flow in the room where

the stove is to be located should be considered. If possible, you should choose a

location where the vent will pass through

the house without cutting a floor or roof

joist.

28¼"

14-1/8"

16-7/8"

WINDOW OPENING

FIGURE 1

13-3/4"

21"

11"

7"ø

AIR INTAKE

4"ø

FLUE

8"

5

MAINTMAINT

MAINT

MAINTMAINT

A. 7"

B. 2"

C. 1"

D. 17½"

E. 6¼"

F. 9½"

*

AIN AIN

THESE MINIMUM CLEARANCES THESE MINIMUM CLEARANCES

AIN

THESE MINIMUM CLEARANCES

AIN AIN

THESE MINIMUM CLEARANCES THESE MINIMUM CLEARANCES

FIGURE 2

GDI50: Clean out ashes

from the inside of the woodburning fireplace. Make

sure that the chimney and

woodburning fireplace are

in a clean and sound condition. Do not remove bricks

or mortar from the woodburning fireplace. If necessary have any repair work

done by a qualified person

before installing the insert.

Remove the existing fireplace damper or lock into an

open position.

** Flashing & trim kits are available in 2 sizes:

WINDOW OPENING

16-7/8"

B"**

FIGURES 3

30-3/4"

TT

O COMBO COMB

T

O COMB

TT

O COMBO COMB

GAS LINE LOCATED

IN PEDESTAL REAR

USTIBLES:USTIBLES:

USTIBLES:

USTIBLES:USTIBLES:

NO ADDITIONAL FLOOR PROTECTION IS REQUIRED

MINIMUM 20" FROM STOVE TOP TO CEILING

*AT A DISTANCE OF 1" FROM THE WALL, ACCESS

TO

THE BLOWER SWITCH, ON-OFF SWITCH OR THE

BLOWER

A"**

POWER CORD MAY NOT BE PRACTICAL.

13/8"

9½"

211/8"

11"

133/4"

263/4"

EXHAUST

3"ø

2½"

63/8"

43/4"

AIR INLET

127/8"

20½"

227/8"

24½

GDI 345-K / GDI-1PB GDI 545-K / GDI-2PB

(7") (10")

Dimension A 273/4" 31"

Dimension B 403/4" 46½"

10¼

28¼"

WS-415-098 / 04.11.00

6

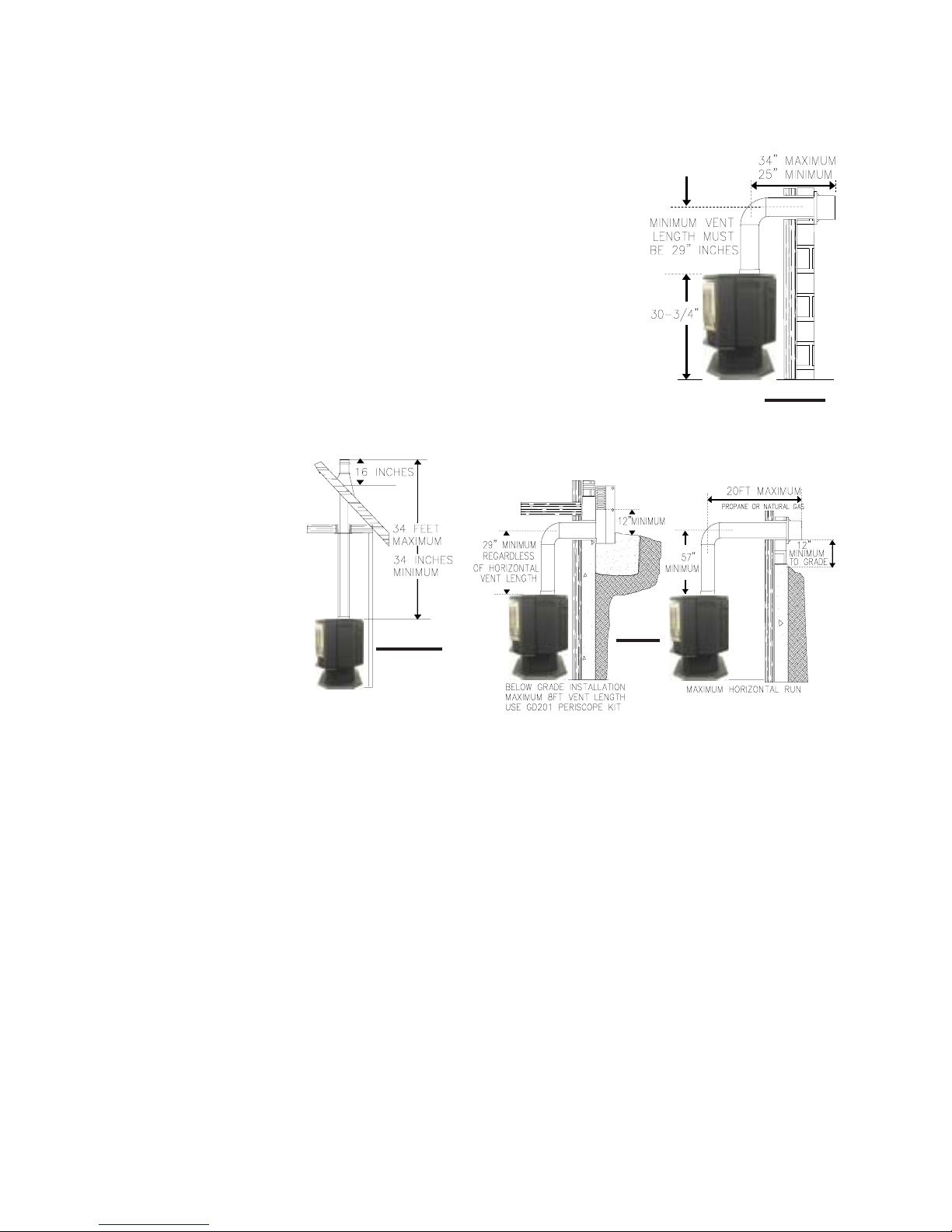

DIRECT VENT SPECIFICS - MODEL GDS50

VENTING LENGTHS AND AIR TERMINAL LOCATIONS

Use only Napoleon or Simpson Dura-Vent Model DV-GS

venting components. Minimum and maximum vent lengths,

for both horizontal and vertical installations, and air terminal locations for either system are set out in this manual

and must be adhered to. For Simpson Dura-Vent, follow

the installation procedure provided with the venting components.

When using Napoleon venting components, use only the

following vent kits: WALL TERMINAL KIT GD175 (7-1/2' of

venting included), or 1/12 TO 7/12 PITCH ROOF TERMINAL

KIT GD110, 8/12 TO 12/12 ROOF TERMINAL KIT GD111,

FLAT ROOF TERMINAL KIT GD1 12 or STOVE PERISCOPE

KIT GD180 (for wall penetration below grade) in conjunc-

tion with the appropriate venting components.

These vent kits allow for either horizontal or vertical venting of the

stove. FIGURES 4, 5, & 6. The maxi-

mum number of 4" flexible connections is two horizontally or three

vertically (excluding the stove and

the air terminal connections).

When terminating vertically, the

minimum vertical rise is 34 inches

above the stove and the maximum

vertical rise is 34 feet. FIGURE 4.

Deviation from the minimum vertical vent length can create difficulty in burner start-up and/or

carboning.

Use an adjustable pipe as the final length of rigid piping

to the stove for ease of installation.

We recommend that exhaust vents that pass through

unheated spaces be wrapped in a protective sleeve to

minimize condensation and re verse flow symptoms . See

Tr oub le Shooting for details.

FIGURE 4

For optimum flame appearance and stove performance, keep the vent

length and number of elbows to a minimum. On

extreme vent configurations, allow several minutes (5-15) for the flame to

stabilize after lighting. The

air terminal must remain

unobstructed at all times.

Examine the air terminal at

least once a year to verify

that it is unobstructed and

undamaged.

The maximum horizontal run is 34 inches with a 90o elbow

located 29" above the stove. FIGURE 5.

The maximum horizontal run with a 57 inch vertical rise

immediately above the stove is 20 feet FIGURES 6.

FIGS 6

HORIZONTAL RUN NOT TO EXCEED VERTICAL RISE

IF VERTICAL RISES GREATER THAN 57 INCHES

ARE NECESSARY, THE INCREASED RISE MUST

BE DEDUCTED FROM THE HORIZONTAL RUN.

FIGURE 5

A terminal shall not terminate directly above a sidewalk or paved driveway which is located betweeen

two single family dwellings and serves both dwellings. Local codes or regulations may require different clearances.

Do not allow the inside liner to bunch up on horizontal or vertical runs and elbows. Keep it pulled

tight. a 1-1/4" air gap all around between the inner

liner and outer stove pipe is required for safe operation. Use a firestop when penetrating interior

walls, floor or ceiling.

All horizontal runs must have a minimum ¼ inch

rise per foot.

WS-415-098 / 04.11.00

AIR AIR

AIR

AIR AIR

FIGURE 7

A

TERMINTERMIN

TERMIN

TERMINTERMIN

INSTALLATIONS

AL INSTAL INST

AL INST

AL INSTAL INST

CANADIAN U.S.A.

12 INCHES

12 INCHES

ALLAALLA

ALLA

ALLAALLA

TIONS:TIONS:

TIONS:

TIONS:TIONS:

Clearance above grade, veranda porch, deck or balcony .

7

B

C

D

E

F

12 INCHES

12 INCHES*

18 INCHES**

12 INCHES**

0 INCHES

0 INCHES***

9 INCHES

12 INCHES*

18 INCHES**

12 INCHES**

0 INCHES

0 INCHES***

G

2 INCHES***

H

I

J

K

L

M

N

O

**

* Recommended to prevent condensation on windows and thermal breakage

**

****

** It is recommended to use a heat shield and to maximize the distance to vinyl clad sof fits.

****

******

*** The periscope GD-201 requires a minimum 18 inches clearance from an inside corner.

******

********

**** This is a recommended distance. For additional requirements check local codes.

********

††

† Three feet above if within 10 feet horizontally.

††

‡‡

‡ A vent shall not terminate directly above a sidewalk or paved driveway that is located between two single family

‡‡

††††

† † Permitted only if the veranda, porch, or deck is fully open on a minimum of two sides beneath the floor.

††††

†*†*

†* Recommenced to prevent recirculation of exhaust products. For additional requirements check local codes.

†*†*

3 FEET

6 FEET

12 INCHES

6 FEET

7 FEET‡

12 INCHES††

16 INCHES

2 FEET†*

dwellings and serves both dwellings.

2 INCHES***

3 FEET****

3 FEET****

9 INCHES

3 FEET†

7 FEET****

12 INCHES****

16 INCHES

2 FEET†*

Clearance to windows or doors that open.

Clearance to permanently closed windows.

Vertical clearance to ventilated sof fit located above the terminal within

a horizontal distance of 2 feet from the centerline of the terminal.

Clearance to unventilated soffit.

Clearance to an outside corner wall.

Clearance to an inside non-combustible corner wall or protruding

non-combustible obstructions (chimney , etc.).

Clearance to an inside combustible corner wall or protruding com-

bustible obstructions ( vent chase, etc.).

Clearance to each side of the centerline extended above the meter

/ regulator assembly .

Clearance to a service regulator vent outlet.

Clearance to a non-mechanical air supply inlet to the building or a

combustion air inlet to any other appliance.

Clearance to a mechanical air supply inlet.

Clearance above a paved sidewalk or paved driveway located on

public property unless fitted with a heat shield kit GD-301.

Clearance under a veranda, porch, deck or balcony .

Clearance above the roof.

Clearance from an adjacent wall including neighbouring buildings.

WS-415-098 / 04.11.00

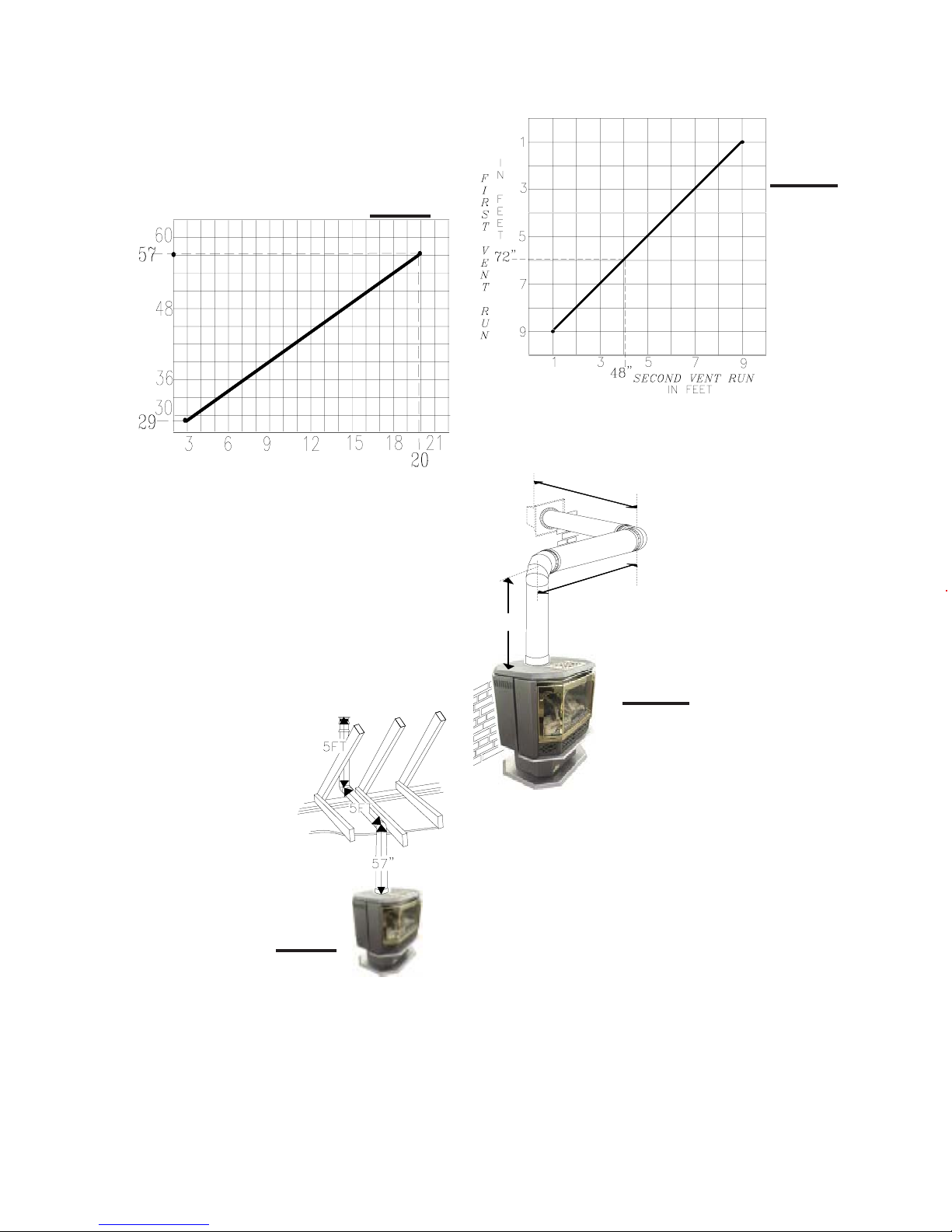

Use the chart on this page to calculate horizontal runs for

8

vertical rises between 29 and 57 inches. FIGURE 8.

When calculating maximum run lengths, include 10 feet for

each 90° elbow or 5 feet for each 45° elbow.

(DO NOT INCLUDE THE FIRST ELBOW DIRECTLY OFF

THE UNIT.)

FIGURE 8

REQUIRED

VERTICAL

RISE FROM

FIREPLACE

TO FIRST

ELBOW IN

INCHES

CALCULATED HORIZONTAL VENT RUN IN FEET

SPECIAL INSTALLATION EXAMPLE

When a horizontal run is introduced, even though the terminal may be vertical, the installation must be considered

HORIZONT AL.

A through the roof installation requires a total 5 foot rise.

FIGURE 9. The location of the fireplace dictates a horizontal

run of 5 feet. What is the required vertical rise to the centre

of the initial 90° elbow?

The total run is: 5 ft. (through the roof vertical rise)

10 ft. (90° elbow)

5 ft. (horizontal run)

20 ft. (total run)

Using the chart, will determine

that a 57 inch minimum vertical

rise immediately off the unit is

required for satisfactory venting

conditions.

OFFSET INSTALLATION EXAMPLE

FIGURE 10

If a first run of 72 inches is

required, using the "First Vent

Run" on the chart shows that

a maximum second run of

48 inches is allowable.

IF NECESSARY, THE

FIRST RUN AND THE SECOND RUN MAY BE REVERSED.

FIGURE 11

57"

48"

s

e

c

o

n

d

r

u

first run

72"

n

ALTHOUGH THE IMMEDIATE VERTICAL

RUN MAY BE GREATER THAN 57

INCHES, THE MAXIMUM COMBINATION OF HORIZONTAL AND VERTICAL

RUNS, BEYOND THE 57 INCHES,

MUST NOT EXCEED 20 FEET.

FIGURE 9

WS-415-098 / 04.11.00

WALL AND CEILING PROTECTION

FOR SAFE AND PROPER OPERA TION OF THE STOVE, FOLLOW THE VENTING INSTRUCTIONS EXACTL Y .

9

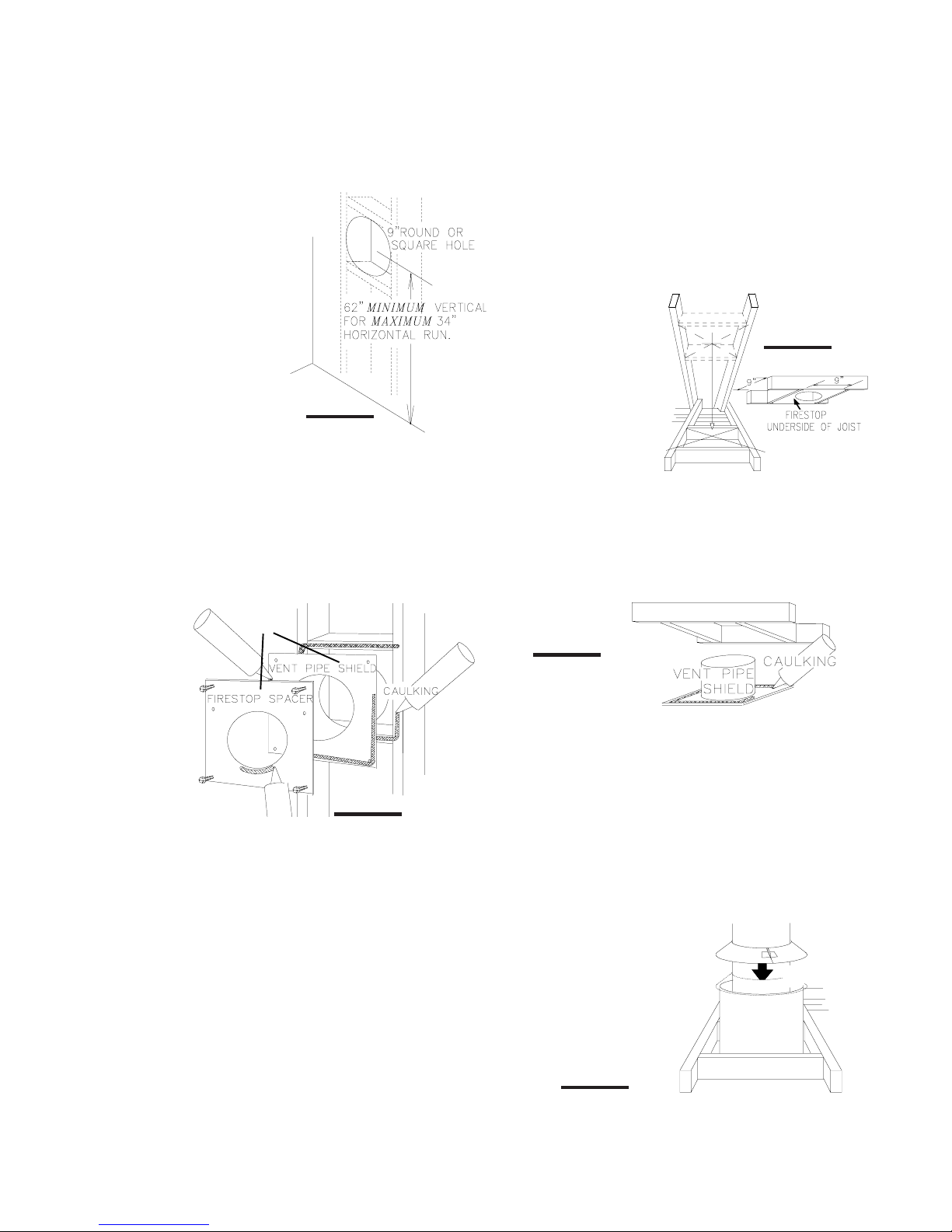

HORIZONTAL INST ALLATION: This application oc-

curs when venting through

an exterior wall. FIGURES

5, 6, & 13. Having determined the air terminal location, cut and frame a hole in

an exterior wall with a minimum square or round opening of 9". (As an alternative

to framing, a vent pipe

shield may be installed, ensuring a 1" clearance to

combustibles. See

Figure 12.)

THE STOVE PIPE MUST RISE ¼" PER FOOT OF RUN.

1. Mark and cut the vent pipe shield to the determined

depth of the combustible wall. Apply a bead of caulking (not

supplied) to the framework or to the shield plate (in the

case of a finished wall) and secure the shield through the

opening to the interior wall. The final location of the vent

pipe shield should maintain the required clearance to the

7" vent pipe. Do not fill this cavity with any type of material.

FIGURE 12

OR

VERTICAL INSTALLATION: This application occurs when

venting through a roof. FIGURE 4. Installation kits for various roof pitches are available from your Napoleon dealer.

See Accessories to order the specific kit required.

1. Determine the air terminal location and move

the stove into position.

Cut and frame 9 inch

openings in the ceiling

and the roof to provide the

minimum 1 inch clearance between the stove

pipe and any combustible

material. Try to center the

exhaust pipe location

midway between two joist

to prevent having to cut

them. Use a plumb bob

to line up the center of the

openings.

Do not fill this space with any type of material.

A vent pipe shield will prevent any materials such as insulation, from filling up the 1" air space around the pipe.

FIGURE 16. Nail headers between the joist for extra support.

FIGURE 15

FIGURE 14

FIGURE 13

Apply a bead of caulking all around and place a firestop

spacer over the vent shield to restrict cold air from being

drawn into the room or around the stove. Ensure that both

spacer and shield maintain the required clearance to combustibles. Once the vent pipe is installed in its final position, apply sealant between the pipe and the firestop spacer.

2. Apply a bead of caulking (not supplied) to the framework or to the Wolf Steel vent pipe shield plate or equivalent

(in the case of a finished ceiling), and secure over the opening in the ceiling. FIGURE 15. A firestop must be placed on

the bottom of each framed opening in a roof or ceiling that

the venting system passes through. FIGURE 14. Apply a

bead of caulking all around and place a firestop spacer

over the vent shield to restrict cold air from being drawn into

the room or around the stove. Ensure that both spacer and

shield maintain the required clearance to combustibles.

Once the vent pipe is installed in its final position, apply

sealant between the pipe and the firestop spacer.

3. In the attic, after the pipe

has been installed, slide the

vent pipe collar down to cover up

the open end of the shield and

tighten. This will prevent any materials, such as insulation, from

filling up the 1" air space around

the pipe.

FIGURE 16

VENT PIPE

SHIELD

VENT

PIPE

COLLAR

WS-415-098 / 04.11.00

Loading...

Loading...