Napoleon BGD36CFNTR, BGD36CFGN-1, GD36MN-1, BGD36CFPTR, BGD36CFGP-1 Installation And Operating Instructions Manual

...

INSTALLER: LEAVE THIS MANUAL WITH THE APPLIANCE.

CONSUMER: RETAIN THIS MANUAL FOR FUTURE REFERENCE.

NEVER LEAVE CHILDREN OR OTHER AT RISK INDIVIDUALS ALONE WITH THE APPLIANCE

INSTALLATION AND

EN

OPERATING INSTRUCTIONS

CERTIFIED UNDER CANADIAN AND AMERICAN NATIONAL STANDARDS: CSA 2.22, ANSI Z21.50 FOR VENTED GAS FIREPLACES.

CERTIFIED FOR CANADA AND UNITED STATES USING ANSI/CSA METHODS.

SAFETY INFORMATION

!

WARNING

If the information in these instructions

are not followed exactly, a fi re or

explosion may result causing property

damage, personal injury or loss of life.

- Do not store or use gasoline or other fl ammable

vapors and liquids in the vicinity of this or any

other appliance.

- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbour’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

fi re department.

- Installation and service must be performed by a

qualifi ed installer, service agency or the supplier.

This appliance may be installed in an aftermarket,

permanently located, manufactured home (USA

only) or mobile home, where not prohibited by

local codes.

This appliance is only for use with the type of gas

indicated on the rating plate. This appliance is

not convertible for use with other gases, unless a

certifi ed kit is used.

Decorative Product: Not for use as a heating appliance.

!

BGD36CFNTR,

BGD36CFGN-1 &

GD36MN-1

NATURAL GAS MODEL

BGD36CFPTR,

BGD36CFGP-1 &

GD36MP-1

PROPANE GAS MODEL

BGD36CFNTR ILLUSTRATED

WARNING

HOT GLASS WILL CAUSE

BURNS.

DO NOT TOUCH GLASS UNTIL

COOLED.

NEVER ALLOW CHILDREN TO

TOUCH GLASS.

FR

PG

69

Wolf Steel Ltd., 24 Napoleon Rd., Barrie, ON, L4M 0G8 Canada /

103 Miller Drive, Crittenden, Kentucky, USA, 41030

Phone (705)721-1212 • Fax (705)722-6031 • www.napoleonfi replaces.com • ask@napoleonproducts.com

$10.00

1.28D

W415-1132 / C / 08.20.13

EN

2

TABLE OF CONTENTS

1.0 INSTALLATION OVERVIEW 3

2.0 INTRODUCTION 4

2.1 DIMENSIONS 5

2.1.1 BGD36CF / BGD36CFG 5

2.1.2 GD36M 5

2.2 GENERAL INSTRUCTIONS 5

2.3 GENERAL INFORMATION 7

2.4 RATING PLATE INFORMATION 7

3.0 VENTING 8

3.1 VENTING LENGTHS AND COMPONENTS 8

3.2 TYPICAL VENT INSTALLATIONS 9

3.3 SPECIAL VENT INSTALLATIONS 11

3.3.1 PERISCOPE TERMINATION 11

3.3.2 CORNER TERMINATION 11

3.4 VENT TERMINAL CLEARANCES 12

3.5 VENT APPLICATION FLOW CHART 13

3.6 DEFINITIONS 13

3.7 ELBOW VENT LENGTH VALUES 14

3.8 TOP EXIT HORIZONTAL TERMINATION 14

3.9 REAR EXIT HORIZONTAL TERMINATION 16

3.10 TOP OR REAR EXIT VERTICAL TERMINATION 18

4.0 PRE-INSTALLATION PREPARATION 20

4.1 REMOVING THE VALVE ACCESS DOOR AND TOP DOOR TRIM 20

4.2 DOOR OPERATION 21

4.3 REAR EXIT 21

4.4 TOP VENT 21

5.0 INSTALLATION 22

5.1 WALL AND CEILING PROTECTION 22

5.2 HORIZONTAL INSTALLATION 23

5.3 VERTICAL INSTALLATION 23

5.4 USING FLEXIBLE VENT COMPONENTS 24

5.4.1 HORIZONTAL AIR TERMINAL INSTALLATION 24

5.4.2 VERTICAL AIR TERMINAL INSTALLATION 25

5.4.3 APPLIANCE VENT CONNECTION 26

5.5 USING RIGID VENT COMPONENTS 26

5.5.1 HORIZONTAL AIR TERMINAL INSTALLATION 26

5.5.2 EXTENDED HORIZONTAL AND CORNER TERMINAL INSTALLATION 26

5.5.3 VERTICAL AIR TERMINAL INSTALLATION 27

5.6 VERTICAL THROUGH EXISTING CHIMNEY 28

5.7 MOBILE HOME INSTALLATION 29

5.8 GAS INSTALLATION 29

5.9 OPTIONAL WALL SWITCH EXCLUDING BGD36CFG & GD36M 30

6.0 FRAMING 30

6.1 INSTALLING STAND-OFFS 31

6.2 MINIMUM FRAMING DIMENSIONS 32

6.2.1 STEEL HEADER INSTALLATION FOR CLEAN FACE SURROUND AND STYLO GLASS FACIA 33

6.3 MINIMUM ENCLOSURE CLEARANCES 34

6.3.1 REAR VENT ENCLOSURE 34

6.3.2 TOP VENT ENCLOSURE 35

6.3.3 ALCOVE ENCLOSURE 35

6.3.4 ENCLOSURE INSTALLATION WITH CLEAN FACE SURROUND OR STYLO GLASS FACIA (GD36M) 36

6.4 CLEAN FACE SURROUND FRAMING AND FINISHING EXCLUDING GD36M 37

6.4.1 FINISHED FLOOR INSTALLATION 37

6.4.2 HEARTH INSTALLATION 38

6.5 NON-COMBUSTIBLE FACING MATERIAL 38

6.6 ALCOVE FRAMING 39

6.8 REMOTE RECEIVER PLACEMENT 39

6.7 MINIMUM MANTEL CLEARANCES 39

7.0 FINISHING 40

7.1 DOOR INSTALLATION & REMOVAL 40

7.2 CLEAN FACE TRIM KIT INSTALLATION EXCLUDING GD36M 41

8.0 BGD36CF FINISHING 42

8.1 LOG PLACEMENT 42

8.2 GLOWING EMBERS 43

8.3 CHARCOAL EMBERS 43

8.4 LOGO PLACEMENT 43

8.5 OPTIONAL ROCK KIT 43

9.0 BGD36CFG / GD36M FINISHING 44

9.1 GLASS BURNER INSTALLATION 44

9.2 GD36M GLASS FRONT INSTALLATION / REMOVAL 45

9.3 TOP PRP PANEL INSTALLATION GD36M 45

10.0 OPTIONAL BLOWER INSTALLATION 46

10.1 ACCESSING THE BLOWER 46

10.2 INSTALLING THE BLOWER SWITCH 46

11.0 WIRING DIAGRAM 47

11.1 BGD36CFG / GD36M LIGHT SWITCH 47

11.2 BGD36CFG / GD36M BURNER SWITCH 48

NOTE: Changes, other than editorial, are denoted by a vertical line in the margin.

W415-1132 / C / 08.20.13

11.3 RECEPTACLE WIRING DIAGRAM 49

12.0 OPERATION 49

12.1 BGD36CFG/GD36MN LIGHT OPERATION 49

12.2 BGD36CF 50

12.3 BGD36CFG / GD36M 51

13.0 ADJUSTMENTS 52

13.1 PILOT BURNER ADJUSTMENT 52

13.2 VENTURI ADJUSTMENT 52

13.2.1 BGD36CF VENTURI ADJUSTMENT 52

13.2.2 BGD36CFG / GD36M VENTURI ADJUSTMENT 53

13.3 BGD36CF FLAME CHARACTERISTICS 53

13.4 BGD36CFG / GD36M FLAME CHARACTERISTICS 54

14.0 MAINTENANCE 54

14.1 ANNUAL MAINTENANCE 55

14.2 LED ASSEMBLY REPLACEMENT 56

14.3 GLASS LENS REPLACEMENT 56

14.4 DOOR GLASS REPLACEMENT 57

14.5 CARE OF GLASS 57

14.6 CARE OF PLATED PARTS 57

15.0 REPLACEMENTS 58

16.0 TROUBLESHOOTING 62

16.1 BGD36CF 62

16.2 BGD36CFG / GD36M 64

17.0 WARRANTY 66

18.0 SERVICE HISTORY 67

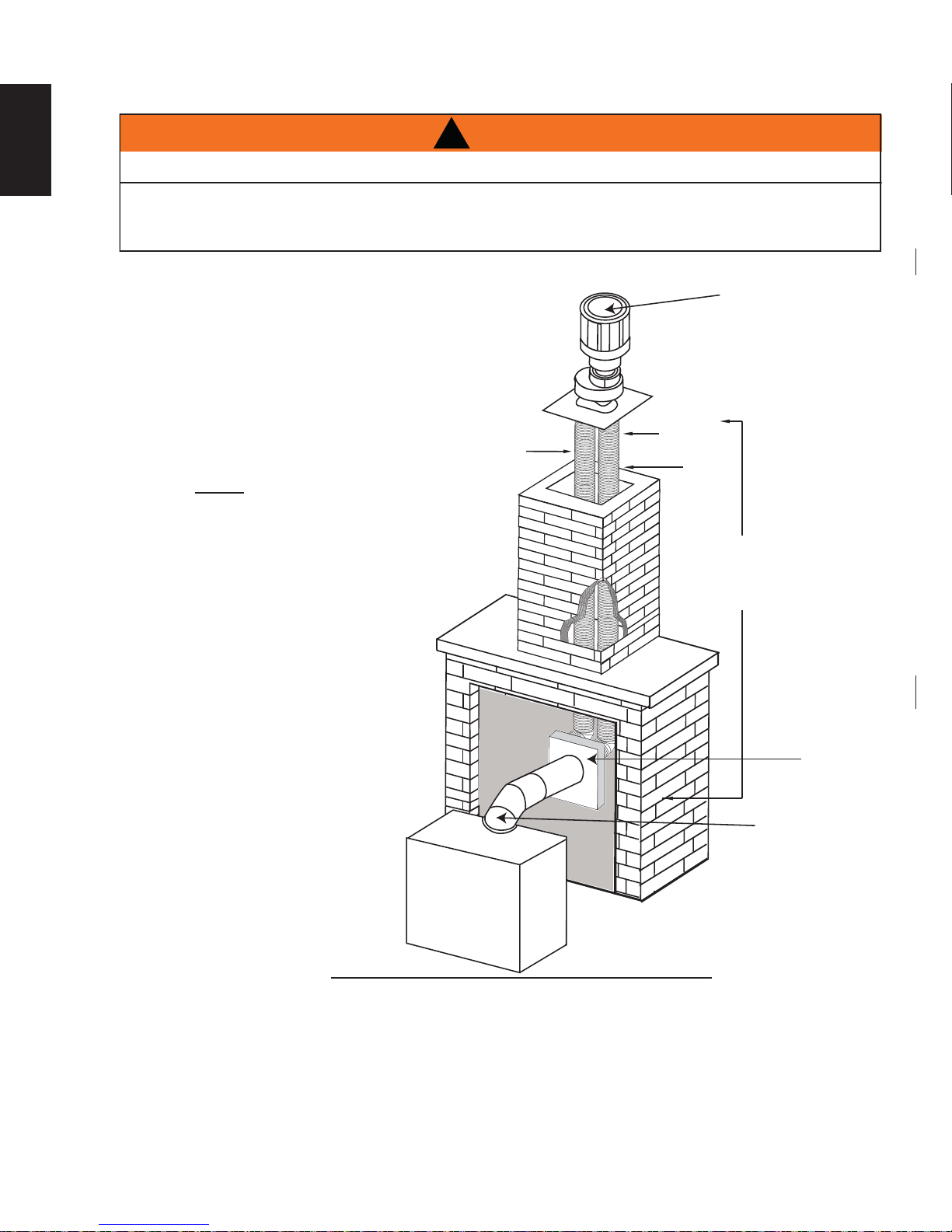

1.0 INSTALLATION OVERVIEW

3

EN

See the sections “MINIMUM

ENCLOSURE CLEARANCES”

for drywall (or other

combustible material)

See the section “MINIMUM

MANTEL AND ENCLOSURE

CLEARANCES”

See the section

“FRAMING”

Side

Wall

See the section

“VENTING” and

“INSTALLATION”

See the section

“INSTALLATION FRAMING”

See the section “GD36M GLASS

FRONT INSTALLATION /

REMOVAL”

W415-1132 / C / 08.20.13

4

2.0 INTRODUCTION

EN

!

WARNING

• THIS APPLIANCE IS HOT WHEN OPERATED AND CAN CAUSE SEVERE BURNS IF CONTACTED.

• ANY CHANGES TO THIS APPLIANCE OR IT’S CONTROLS CAN BE DANGEROUS AND IS PROHIBITED.

• Do not operate appliance before reading and understanding operating instructions. Failure to operate appliance

according to operating instructions could cause fi re or injury.

• Risk of fi re or asphyxiation do not operate appliance with fi xed glass removed.

• Do not connect 110 volts to the control valve.

• Risk of burns. The appliance should be turned off and cooled before servicing.

• Do not install damaged, incomplete or substitute components.

• Risk of cuts and abrasions. Wear protective gloves and safety glasses during installation. Sheet metal edges may be

sharp.

• Do not burn wood or other materials in this appliance.

• Children and adults should be alerted to the hazards of high surface temperature and should stay away to avoid burns or

clothing ignition.

• Young children should be carefully supervised when they are in the same room as the appliance.

young children and others may be susceptible to accidental contact burns. A physical barrier is recommended if there

are at risk individuals in the house. To restrict access to an appliance or stove, install an adjustable safety gate to keep

toddlers, young children and other at risk individuals out of the room and away from hot surfaces.

• Clothing or other fl ammable material should not be placed on or near the appliance.

• Due to high temperatures, the appliance should be located out of traffi c and away from furniture and draperies.

• Ensure you have incorporated adequate safety measure to protect infants/toddlers from touching hot surfaces.

• Even after the appliance is out, the glass and/or screen will remain hot for an extended period of time.

• Check with your local hearth specialty dealer for safety screens and hearth guards to protect children from hot surfaces.

These screens and guards must be fastened to the fl oor.

• Any safety screen or guard removed for servicing must be replaced prior to operating the appliance.

• The appliance is a vented gas-fi red appliance. Do not burn wood or other materials in the appliance.

• It is imperative that the control compartments, burners and circulating blower and its passageway in the appliance

and venting system are kept clean. The appliance and its venting system should be inspected before use and at least

annually by a qualifi ed service person. More frequent cleaning may be required due to excessive lint from carpeting,

bedding material, etc. The appliance area must be kept clear and free from combustible materials, gasoline and other

fl ammable vapors and liquids.

• Under no circumstances should this appliance be modifi ed.

• This appliance must not be connected to a chimney fl ue pipe serving a separate solid fuel burning appliance.

• Do not use this appliance if any part has been under water. Immediately call a qualifi ed service technician to inspect the

appliance and to replace any part of the control system and any gas control which has been under water.

• Do not operate the appliance with the glass door removed, cracked or broken. Replacement of the glass should be done

by a licensed or qualifi ed service person.

• Do not strike or slam shut the appliance glass door.

• When equipped with pressure relief doors, they must be kept closed while the appliance is operating to prevent exhaust

fumes containing carbon monoxide, from entering into the home. Temperatures of the exhaust escaping through these

openings can also cause the surrounding combustible materials to overheat and catch fi re.Only doors / optional fronts

certifi ed with the unit are to be installed on the appliance.

• Only doors / optional fronts certifi ed with the unit are to be installed on the appliance.

• Keep the packaging material out of reach of children and dispose of the material in a safe manner. As with all plastic

bags, these are not toys and should be kept away from children and infants.

• As with any combustion appliance, we recommend having your appliance regularly inspected and serviced as well as

having a Carbon Monoxide Detector installed in the same area to defend you and your family against Carbon Monoxide.

• Ensure clearances to combustibles are maintained when building a mantel or shelves above the appliance. Elevated

temperatures on the wall or in the air above the appliance can cause melting, discolouration or damage to decorations, a

T.V. or other electronic components.

• This appliance uses and requires a fast acting thermocouple. Replace only with a fast acting thermocouple supplied by

Wolf Steel Ltd.

3.1C

Toddlers,

W415-1132 / C / 08.20.13

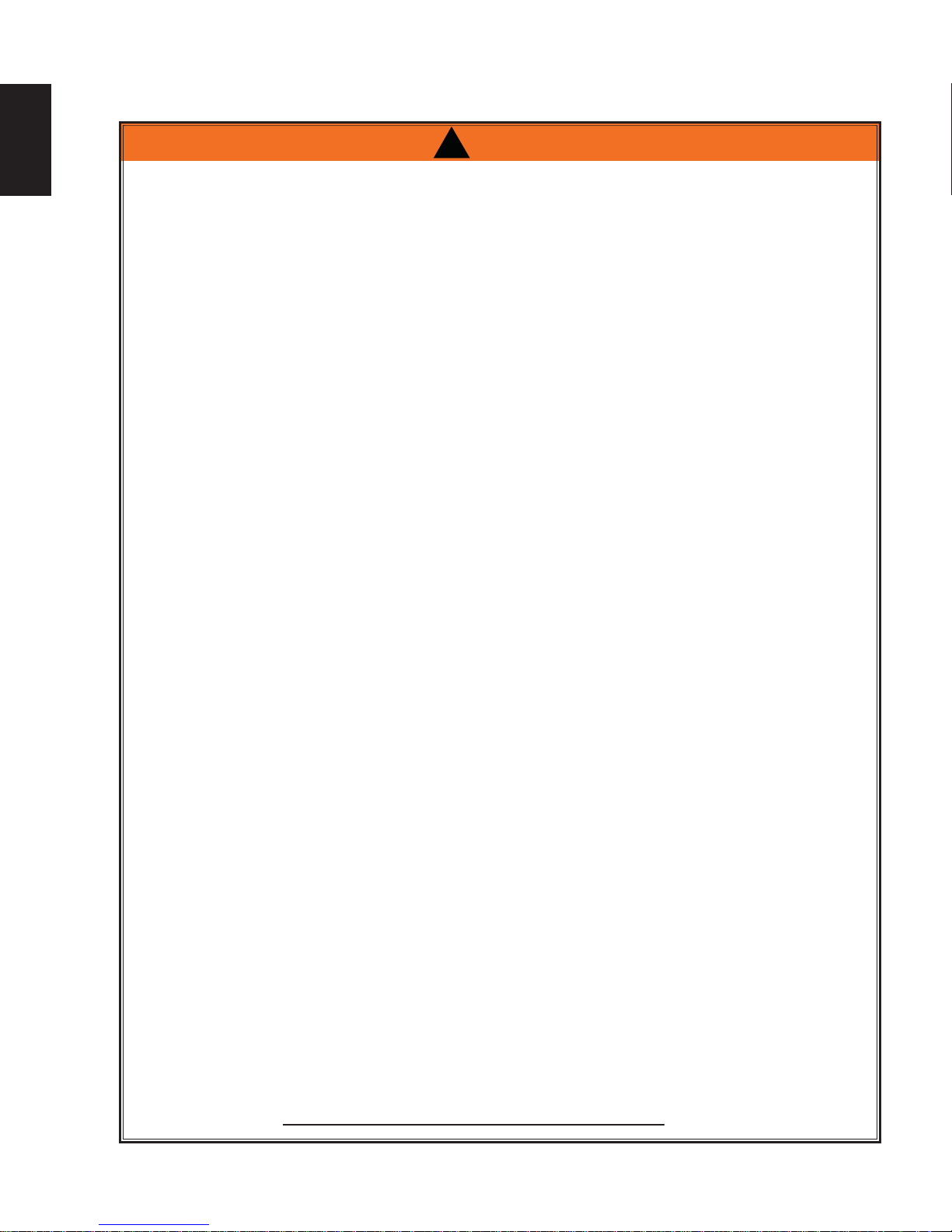

2.1 DIMENSIONS

2.1.1 BGD36CF / BGD36CFG

2.1.2 GD36M

38 1/2"

978mm

34"

864mm

GAS INLET

3"

76.2mm

15"

17"

5"

127mm

8"

203mm

381mm

432mm

24 1/4"

616mm

5"

127mm

686mm

27"

1016mm

40"

5

EN

7"

178mm

4"

102mm

34"

864mm

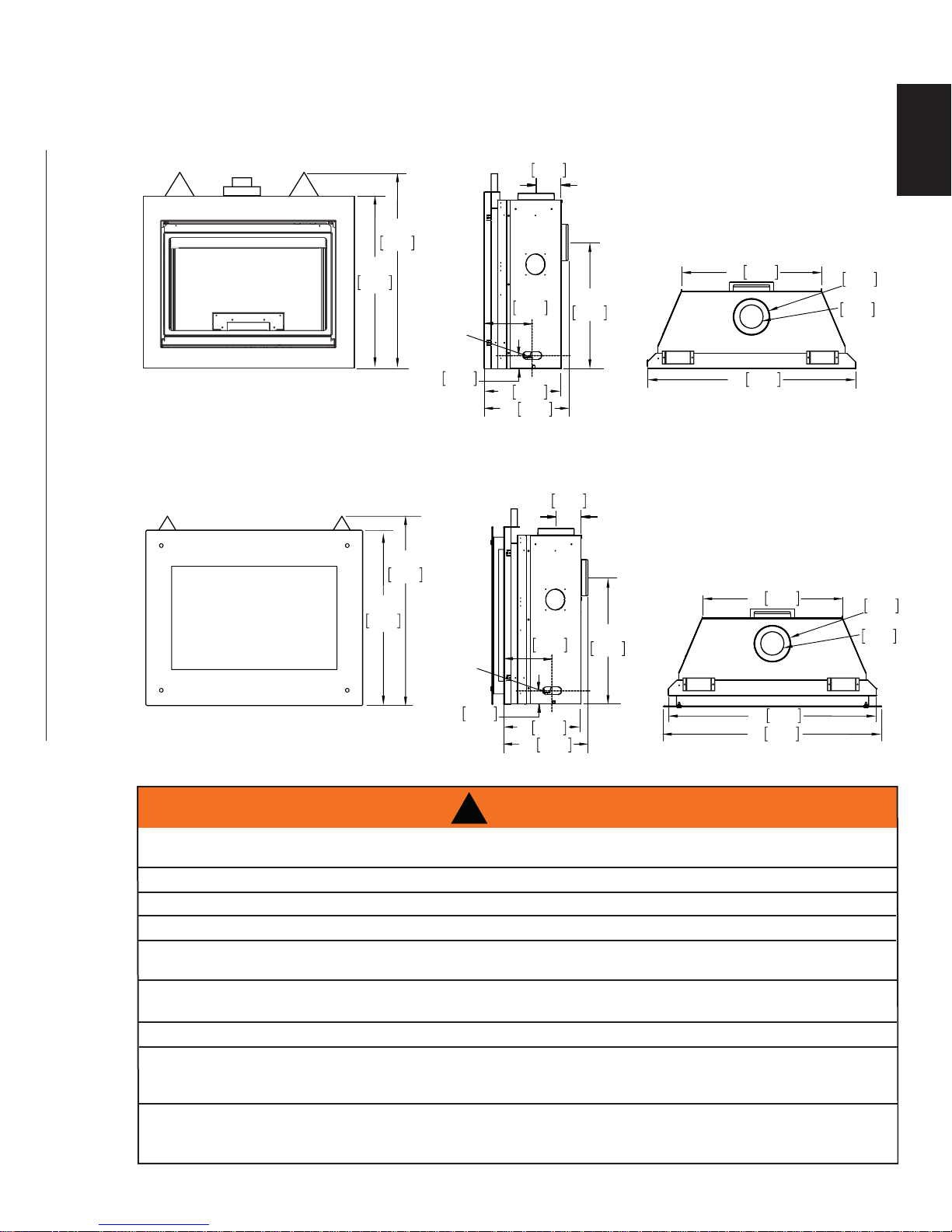

2.2 GENERAL INSTRUCTIONS

ALWAYS LIGHT THE PILOT WHETHER FOR THE FIRST TIME OR IF THE GAS SUPPLY HAS RUN OUT,

WITH THE GLASS DOOR OPENED OR REMOVED.

PROVIDE ADEQUATE CLEARANCE FOR SERVICING AND OPERATING THE APPLIANCE.

NEVER OBSTRUCT THE FRONT OPENING OF THE APPLIANCE.

OBJECTS PLACED IN FRONT OF THE APPLIANCE MUST BE KEPT A MINIMUM OF 48” (1219.2mm)

FROM THE FRONT FACE OF THE APPLIANCE.

SURFACES AROUND AND ESPECIALLY ABOVE THE APPLIANCE CAN BECOME HOT. AVOID CONTACT

WHEN THE APPLIANCE IS OPERATING.

HIGH PRESSURE WILL DAMAGE VALVE. DISCONNECT GAS SUPPLY PIPING BEFORE PRESSURE TESTING GAS

LINE AT TEST PRESSURES ABOVE 1/2 PSIG. CLOSE THE MANUAL SHUT-OFF VALVE BEFORE PRESSURE

TESTING GAS LINE AT TEST PRESSURES EQUAL TO OR LESS THAN 1/2 PSIG (35 mb).

USE ONLY WOLF STEEL APPROVED OPTIONAL ACCESSORIES AND REPLACEMENT PARTS WITH THIS APPLIANCE.

USING NON-LISTED ACCESSORIES (BLOWERS, DOORS, LOUVRES, TRIMS, GAS COMPONENTS, VENTING

COMPONENTS, ETC.) COULD RESULT IN A SAFETY HAZARD AND WILL VOID THE WARRANTY AND CERTIFICATION.

38 1/2"

978mm

203mm

GAS INLET

3"

76.2mm

!

WARNING

15"

17"

381mm

8"

432mm

24 1/4"

616mm

PROVIDE ADEQUA TE VENTILA TION.

FIRE RISK. EXPLOSION HAZARD.

686mm

27"

1016mm

40"

1066mm

42"

7"

178mm

4"

102mm

W415-1132 / C / 08.20.13

EN

A

A

6

THIS GAS APPLIANCE SHOULD BE INSTALLED AND SERVICED BY A QUALIFIED INSTALLER to

conform with local codes. Installation practices vary from region to region and it is important to know the

specifi cs that apply to your area, for example in Massachusetts State:

• This product must be installed by a licensed plumber or gas fi tter when installed within the commonwealth

of Massachusetts.

• The appliance damper must be removed or welded in the open position prior to installation of an appliance

insert or gas log.

• The appliance off valve must be a “T” handle gas cock.

• The fl exible connector must not be longer than 36 inches (914.4mm).

• A Carbon Monoxide detector is required in all rooms containing gas fi red appliances.

• The appliance is not approved for installation in a bedroom or bathroom unless the unit is a direct vent

sealed combustion product.

The installation must conform with local codes or, in

absence of local codes, the National Gas and Propane

Installation Code CSA B149.1 in Canada, or the National

Fuel Gas Code, ANSI Z223.1 / NFPA 54 in the United

States. Suitable for mobile home installation if installed in

accordance with the current standard CAN/CSA Z240MH

Series, for gas equipped mobile homes, in Canada or

NSI Z223.1 and NFPA 54 in the United States.

s long as the required clearance to combustibles is

maintained, the most desirable and benefi cial location

for an appliance is in the center of a building, thereby

allowing the most effi cient use of the heat created. The location of windows, doors and the traffi c fl ow in the

room where the appliance is to be located should be considered. If possible, you should choose a location

where the vent will pass through the house without cutting a fl oor or roof joist.

www.ncertied.org

We suggest that our gas

hearth products be installed

and serviced by professionals

who are certied in the U.S.

by the National Fireplace

®

Institute

(NFI) as NFI Gas

Specialists

If the appliance is installed directly on carpeting, vinyl tile or other combustible material other than wood

fl ooring, the appliance shall be installed on a metal or wood panel extending the full width and depth.

Some appliances have optional fans or blowers. If an optional fan or blower is installed, the junction box must

be electrically connected and grounded in accordance with local codes, use the current CSA C22.1 Canadian

Electrical Code in Canada or the ANSI/NFPA 70 National Electrical code in the United States.

4.1B

All sections of this manual with BGD36CF(G) are common to BGD36CF, BGD36CFG and GD36M. All sections

with BGD36CFG / GD36M are common to both the BGD36CFG and GD36M.

W415-1132 / C / 08.20.13

2.3 GENERAL INFORMATION

IGENCES DE LA NORME CAN/CSA NCES DE LA NORME CAN/CS

EN VIGUEUR AU CANADA OU AUX ETATEUR AU CANADA OU AUX ETAT

S NE PEUT ETRE APPLIQUEE, SE

4001659 (WUSA)4001659 (WUSA)

LEVATIONEVATION

0

)0-4500FT (0-1370m)

h17,000 BTU/h

T / ALIMENTATION REDUITE 12,000 BTU/hT / ALIMENTATION REDUITE 12

M

IFOLD PRESSU

P

PRESSION AU CO

MINIMUM SUPPLY PRESSURE:MINIMUM SUPPLY P

COLONNE D'EAUCOLONNE D'EAU

PRESSION D'ALIMENTATIONPRESSION D'ALIMENT

7.0" WATER COLUMN 7.0" WATER COLUMN

MAXIMUM SUPPLY PRESMAXIMUM SUPPLY PRE

PRESSION D'ALIMENPRESSION D'ALIMEN

ST ACTING THERMOCOUPLE. REPLACE ST ACTING THERMOCOUPLE. REPLACE

T SIDES / COTES DE L'EVENT T SIDES / COTES DE L'EVENT

"1"

VENT BOTTOM / EVENT INFERIEUR

*

ONS. REFERER AU MANUEL D'INSTRUC

CET APPET AP

FOR YOUR SATISFACTION, THIS APPLIANCE HAS BEEN TEST-FIRED TO ASSURE ITS OPERATION AND

QUALITY!

Altitude (FT) 0-4,500 0-4500

Max. Input (BTU/HR) 17,000 17,000

Max. Output Steady State (BTU/HR) 10,900 10,900

Effi ciency (w/the fan on) 64% 64%

A.F.U.E. (Annual Fuel Utilization Effi ciency) 53% 53%

Min. Inlet Gas Supply Pressure 4.5" (11mb) w.c. 11" (27mb) w.c.

Max. Inlet Gas Supply Pressure 7" (17mb) w.c. 13" (32mb) w.c.

Manifold Pressure (Under Flow Conditions) 3.5" (9mb) w.c. 10" (25mb) w.c.

When the appliance is installed at elevations above 4,500 ft (1371m), and in the absence of specifi c recom-

mendations from the local authority having jurisdiction, the certifi ed high altitude input rating shall be reduced

at the rate of 4% for each additional 1,000 ft (305m).

This appliance is approved for bathroom, bedroom and bed-sitting room installations and is suitable for mobile

home installation.

No external electricity (110 volts or 24 volts) is required for the gas system operation.

Expansion / contraction noises during heating up and cooling down cycles are normal and are to be expected.

Use only accessories designed for and listed with your specifi c appliance.

7

EN

APPLIANCE

NG LP

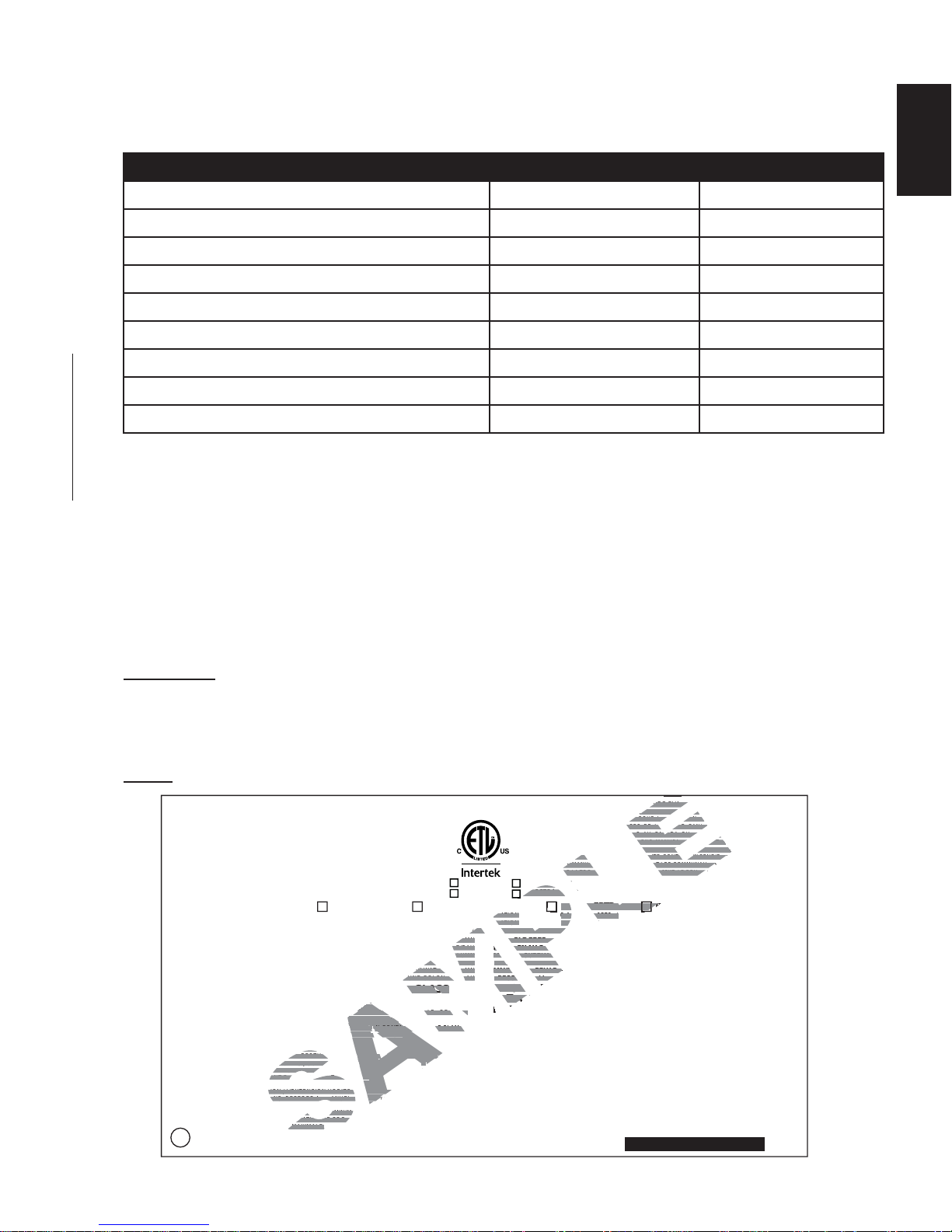

2.4 RATING PLATE INFORMATION

INSTALLER: It is your responsibility to check off the appropriate box on the rating plate according to

the model, venting and gas type of the appliance.

For rating plate location, see “INSTALLATION OVERVIEW” section.

This illustration is for reference only. Refer to the rating plate on the appliance for accurate information.

NOTE: The rating plate must remain with the appliance at all times. It must not be removed.

DIRECT VENT GAS FIREPLACE. SUITABLE FOR BEDROOM, BATHROOM AND BED-SITTING ROOM

INSTALLATION. SUITABLE FOR MOBILE HOME INSTALLA TION IF INST ALLED IN ACCORDANCE

WITH THE CURRENT STANDARD CAN/CSA Z240MH SERIES GAS EQUIPPED MOBILE HOMES,

IN CANADA OR IN THE UNITED STATES THE MANUFACTURED HOME CONTRUCTION AND

SAFETY STANDARD, TITLE 24 CFR, PART 3280. WHEN THIS US STANDARD IS NOT

APPLICABLE USE THE STANDARD FOR FIRE SAFETY CRITERIA FOR MANUFACTURED

HOME INSTALLATIONS, SITES AND COMMUNITIES, ANSI / NFPA 501A. WHEN INSTALLED

WITH SCREEN KIT GD-565KT, THE FIREPLACE COMPLIES WITH CGA CERTIFICATION

REQUIREMENT CR95-006.

NOT FOR USE WITH SOLID FUEL. FOR USE WITH GLASS

DOORS CERTIFIED WITH THIS UNIT ONLY.

WARNING: THIS FIREPLACE USES AND REQUIRES A FAST ACTING THERMOCOUPLE. REPLACE

ONLY WITH A FAST ACTING THERMOCOUPLE SUPPLIED BY WOLF STEEL LTD.

DO NOT ADD ANY MATERIAL TO THE APPLIANCE, WHICH WILL COME IN CONTACT WITH THE FLAMES,

OTHER THAN THAT SUPPLIED BY THE MANUFACTURER WITH THE APPLIANCE.

MINIMUM CLEARANCE TO COMBUSTIBLE MATERIALS /

DEGAGEMENTS MINIMAUX DES MATERIAUX COMBUSTIBLES:

TOP/ DESSUS 0 RECESSED DEPTH / PROFONDEUR D'ENCASTRE 17.25"

FLOOR / PLANCHER 0 VENT SIDES / COTES DE L'EVENT 1"

SIDES / COTES 0 VENT TOP / EVENT SUPERIEUR 2"

BACK / ARRIERE 0 VENT BOTTOM / EVENT INFERIEUR 1"

MANTEL / MANTEAU 12" *

* MAXIMUM HORIZONTAL EXTENSION / L'EXTENSION HORIZONTALE MAXIMALE: 2". SEE INSTRUCTION

MANUAL FOR GREATER EXTENSIONS. REFERER AU MANUEL D'INSTRUCTION POUR DES

EXTENSIONS PLUS GRANDES.

CERTIFIED UNDER / HOMOLOGUE SELON LES NORMES: CSA 2.22b-2009, ANSI Z21.50b-2009 VENTED GAS FIREPLACE / FOYER AU GAZ AVEC EVACUATION.

9700539 (WSL) 4001657 (NGZ)

4001658 (NAC) 4001659 (WUSA)

BGD36CFNTR BCDV36CFNTR MODEL BGD36CFPTR BCDV36CFPTR

17,000 BTU/h INPUT / ALIMENTATION 17,000 BTU/h

12,000 BTU/h REDUCED INPUT / ALIMENTATION REDUITE 12,000 BTU/h

PRESSION AU COLLECTEUR: 3.5" D'UNE COLONNE D'EAU PRESSION AU COLLECTEUR: 10" D'UNE COLONNE D'EAU

MINIMUM SUPPLY PRESSURE: 4.5" WATER COLUMN MINIMUM SUPPLY PRESSURE: 11" WATER COLUMN

PRESSION D'ALIMENTATION MINIMALE: 4.5" D'UNE COLONNE D'EAU PRESSION D'ALIMENTATION MINIMALE: 11" D'UNE COLONNE D'EAU

MAXIMUM SUPPLY PRESSURE: 7.0" WATER COLUMN MAXIMUM SUPPLY PRESSURE: 13" WATER COLUMN

PRESSION D'ALIMENTATION MAXIMALE: 7.0" D'UNE COLONNE D'EAU PRESSION D'ALIMENTATION MAXIMALE: 13" D'UNE COLONNE D'EAU

SEE OWNER'S INSTRUCTION MANUAL FOR MINIMUM AND MAXIMUM VENT LENGTHS.

REFERER AU MANUEL D'INSTALLATION DE PROPRIETAIRE POUR LES LONGUEURS

D'EVACUATION MINIMALE ET MAXIMALE.

WOLF STEEL LTD.

24 NAPOLEON ROAD, BARRIE, ON, L4M 0G8 CANADA

0-4500FT (0-1370m) ALTITUDE / ELEVATION 0-4500FT (0-1370m)

MANIFOLD PRESSURE: 3.5" WATER COLUMN MANIFOLD PRESSURE: 10" WATER COLUMN

IN CONTACT WITH THE FLAMES,

1

FOYER A GAZ VENTILE DIRECT. HOMOLOGUE POUR INSTALLATION DANS UNE CHAMBRE A COUCHER, UNE

SALLE DE BAIN ET UN STUDIO. APPROPRIE POUR INSTALLATION DANS UNE MAISON MOBILE SI SON

INSTALLATION CONFORME AUX EXIGENCES DE LA NORME CAN/CSA Z240MH SERIE DE MAISONS

MOBILES EQUIPEES AU GAZ, EN VIGUEUR AU CANADA OU AUX ETATS-UNIS DE LA NORME DE

SECURITE ET DE CONSTRUCTION DE MAISONS MANUFACTUREES, TITRE 24 CFR, SECTION 3280.

DANS LE CAS OU CETTE NORME D'ETATS-UNIS NE PEUT ETRE APPLIQUEE, SE REFERER A LA NORME

RELATIVE AU CRITERE DE MESURES DE SECURITE CONTRE L'INCENDIE POUR LES INSTALLATIONS

DANS LES MAISONS MANUFACTURES, LES SITES ET LES COMMUNAUTES, ANSI/NFPA 501A. LORSQU'IL

EST INSTALLE AVEC LA TROUSSE POUR ECRAN GD-565KT, LE FOYER EST CONFORME A LA NORME DE

-4500FT (0-1370m

17,000 BTU/

ANIFOLD PRESSURE:

RESSION AU COLLECTEUR:

UN COMBUSTIBLE SOLIDE NE DOIT PAS ETRE UTILISE AVEC

CET APPAREIL. UTILISER AVEC LES PORTES VITREES

HOMOLOGUEES SEULEMENT AVEC CETTE UNITE.

AVERTISSEMENT:

REMPLACEZ UNIQUEMENT AVEC UN THERMOCOUPLE À ACTION RAPIDE DE WOLF STEEL LTÉE.

N’AJOUTEZ PAS A CET APPAREIL AUCUN MATERIAU DEVANT ENTRER EN CONTACT AVEC LES FLAMMES

AUTRE QUE CELUI QUI EST FOURNI AVEC CET APPAREIL PAR LE FABRICANT.

THE APPLIANCE MUST BE VENTED USING THE APPROPRIATE WOLF STEEL VENT KITS. SEE OWNERS

INSTALLATION MANUAL FOR VENTING SPECIFICS. PROPER REINSTALLATION AND RESEALING IS

NECESSARY AFTER SERVICING THE VENT-AIR INTAKE SYSTEM.

L'APPAREIL DOIT EVACUER SES GAZ EN UTILISANT L'ENSEMBLE D'EVACUATION PROPRE A NAPOLEON.

REFERER AU MANUEL D'INSTALLATION DE PROPRIETAIRE POUR L'EVACUATION PRECISE. IL EST

IMPORTANT DE BIEN REINSTALLER ET RESCELLER L'EVENT APRES AVOIR ASSURE LE MAINTIEN DU

SYSTEME DE PRISE D'AIR.

ELECTRICAL RATING / CLASSIFICATION: 115V 0.82AMP, 60HZ

OPTIONAL FAN KIT / ENSEMBLE DE VENTILATEUR FACULTATIF: GZ550-KT, GD65

SERIAL NUMBER/NO. DE SERIE:

CE FOYER UTILISE ET REQUIERT UN THERMOCOUPLE À ACTION RAPIDE.

BGD36CF

CERTIFICATION DE L'ACG CR95-006.

W385-0342 / H

W415-1132 / C / 08.20.13

8

3.0 VENTING

EN

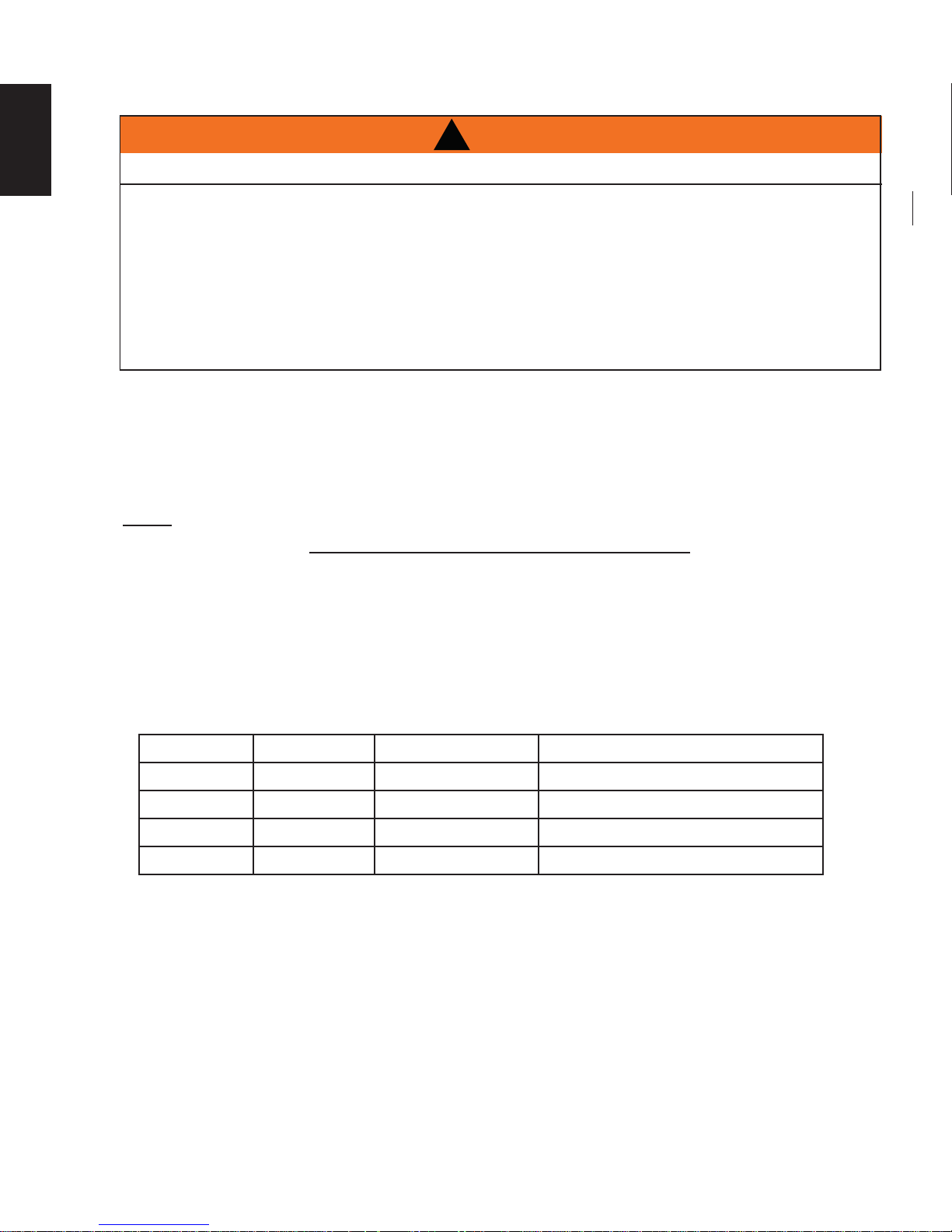

!

WARNING

RISK OF FIRE, MAINTAIN SPECIFIED AIR SPACE CLEARANCES TO VENT PIPE AND APPLIANCE.

IF VENTING IS INCLUDED WITH SPACERS THE VENT SYSTEM MUST BE SUPPORTED EVERY 3FT

(0.9m) FOR BOTH VERTICAL AND HORIZONTAL RUNS. USE SUPPORTS OR EQUIVALENT

NON-COMBUSTIBLE STRAPPING TO MAINTAIN THE REQUIRED CLEARANCE FROM

COMBUSTIBLES. USE WOLF STEEL LTD. SUPPORT RING ASSEMBLY W010-0370 OR EQUIVALENT

NON-COMBUSTIBLE STRAPPING TO MAINTAIN THE MINIMUM CLEARANCE TO COMBUSTIBLES

FOR BOTH VERTICAL AND HORIZONTAL RUNS. SPACERS ARE ATTACHED TO THE INNER PIPE AT

PREDETERMINED INTERVALS TO MAINTAIN AN EVEN AIR GAP TO THE OUTER PIPE. THIS GAP IS

REQUIRED FOR SAFE OPERATION. A SPACER IS REQUIRED AT THE START, MIDDLE AND END OF

EACH ELBOW TO ENSURE THIS GAP IS MAINTAINED. THESE SPACERS MUST NOT BE REMOVED.

THIS APPLIANCE USES A 4” (101.6mm) EXHAUST / 7” (177.8mm) AIR INTAKE VENT PIPE SYSTEM.

Refer to the section applicable to your installation.

For safe and proper operation of the appliance follow the venting instruction exactly. Deviation from the

minimum vertical vent length can create diffi culty in burner start-up and/or carboning. Under extreme vent

confi gurations, allow several minutes (5-15) for the fl ame to stabilize after ignition. Provide a means for

visually checking the vent connection to the appliance after the appliance is installed. Use a fi restop, vent pipe

shield or attic insulation shield when penetrating interior walls, fl oor or ceiling.

NOTE: If for any reason the vent air intake system is disassembled; reinstall per the instructions

provided for the initial installation.

7.1B

3.1 VENTING LENGTHS AND COMPONENTS

Use only Wolf Steel, Simpson Dura-Vent, Selkirk Direct Temp, American Metal Amerivent or Metal-Fab venting

components. Minimum and maximum vent lengths, for both horizontal and vertical installations, and air terminal

locations for either system are set out in this manual and must be adhered to. For Simpson Dura-Vent, Selkirk Direct

Temp, American Metal Amerivent and Metal-Fab follow the installation procedure provided with the venting components.

A starter adaptor must be used with the following vent systems and may be purchased from the corresponding supplier:

PART 4”/7” SUPPLIER WEBSITE

Duravent W175-0053 Wolf Steel www.duravent.com

Amerivent 4DSC-N2 American Metal www.americanmetalproducts.com

Direct Temp 4DT-AAN Selkirk www.selkirkcorp.com

SuperSeal 4DNA Metal-Fab www.mtlfab.com

For Simpson Dura-Vent, Selkirk Direct Temp, American Metal Amerivent and Metal-Fab follow the installation

procedure found on the website for your venting supplier.

For vent systems that provide seals on the inner exhaust fl ue, only the outer air intake joints must be sealed using a red

high temperature silicone (RTV). This same sealant may be used on both the inner exhaust and outer intake vent pipe

joints of all other approved vent systems except for the exhaust vent pipe connection to the appliance fl ue collar which must

be sealed using the black high temperature sealant Mill Pac. High temperature sealant must be ordered separately.

When using Wolf Steel venting components, use only approved Wolf Steel rigid / fl exible components with the following

termination kits: wall terminal kit GD222, GD222R, or 1/12 to 7/12 pitch roof terminal kit GD110, 8/12 to 12/12 roof terminal

kit GD111, fl at roof terminal kit GD112 or periscope kit GD201 (for wall penetration below grade). With fl exible venting, in

conjunction with the various terminations, use either the 5 foot (1.5m) vent kit GD220 or the 10 foot (3.1m) vent kit GD330.

W415-1132 / C / 08.20.13

For optimum flame appearance and appliance performance, keep the vent length and number of elbows to a minimum.

The air terminal must remain unobstructed at all times. Examine the air terminal at least once a year to verify that

it is unobstructed and undamaged.

Rigid and fl exible venting systems must not be combined. Different venting manufacturer components must not

be combined.

These vent kits allow for either horizontal or vertical venting of the appliance. The maximum allowable horizontal run is

20 feet (6.1m). The maximum allowable vertical vent length is 40 feet (12.2m). The maximum number of vent connections

is two horizontally or three vertically (excluding the appliance and the air terminal connections) when using fl exible venting.

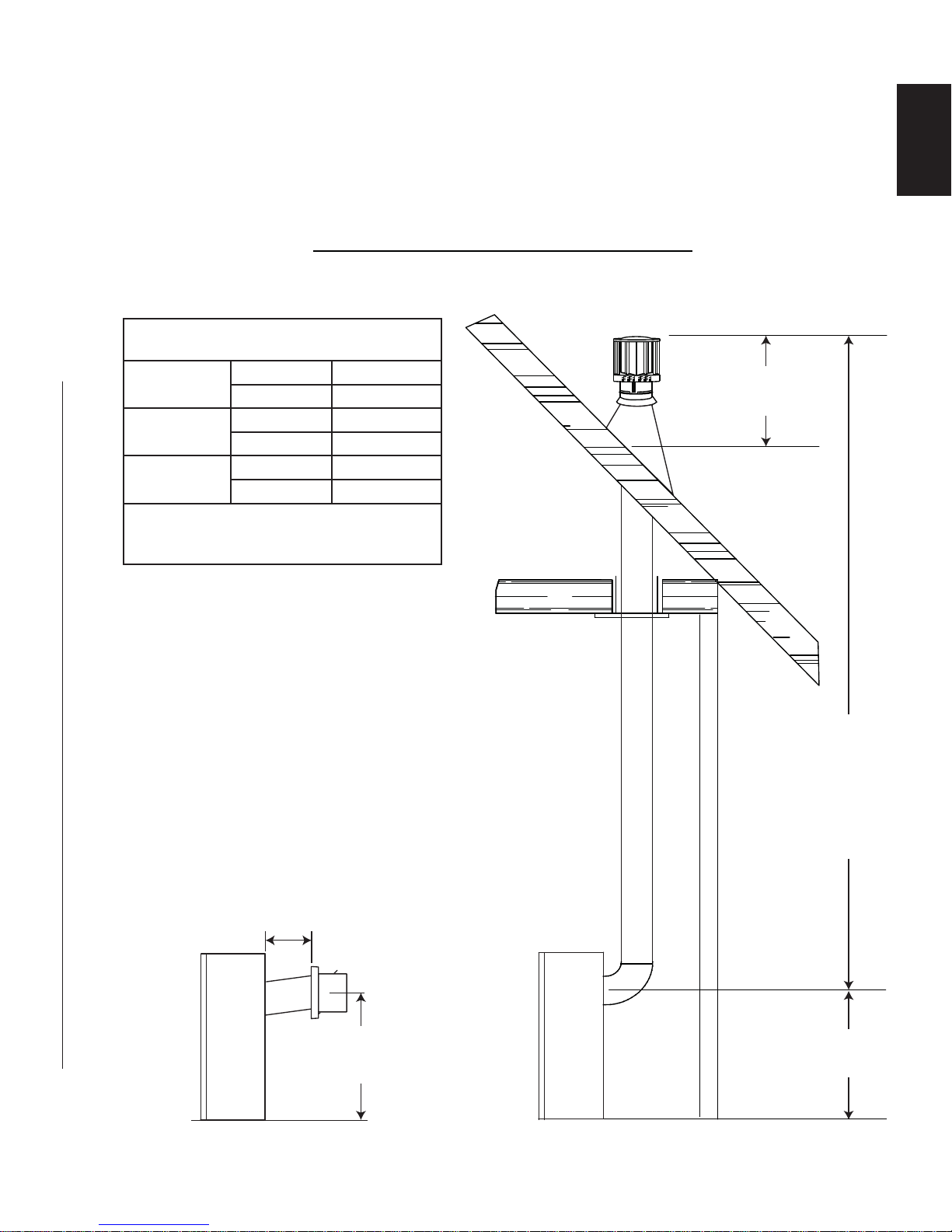

3.2 TYPICAL VENT INSTALLATIONS

REQUIRED RISE ON HORIZONTAL

VENTING

REAR VENT RIGID 0" / FT

FLEXIBLE 0" / FT

TOP VENT RIGID 0" / FT

FLEXIBLE 0" / FT

CORNER

VENT

For optimum performance, it is

recommended that all horizontal runs have

a 1" (25mm) rise per foot.

RIGID 0"

FLEXIBLE 6" (152mm)

9

EN

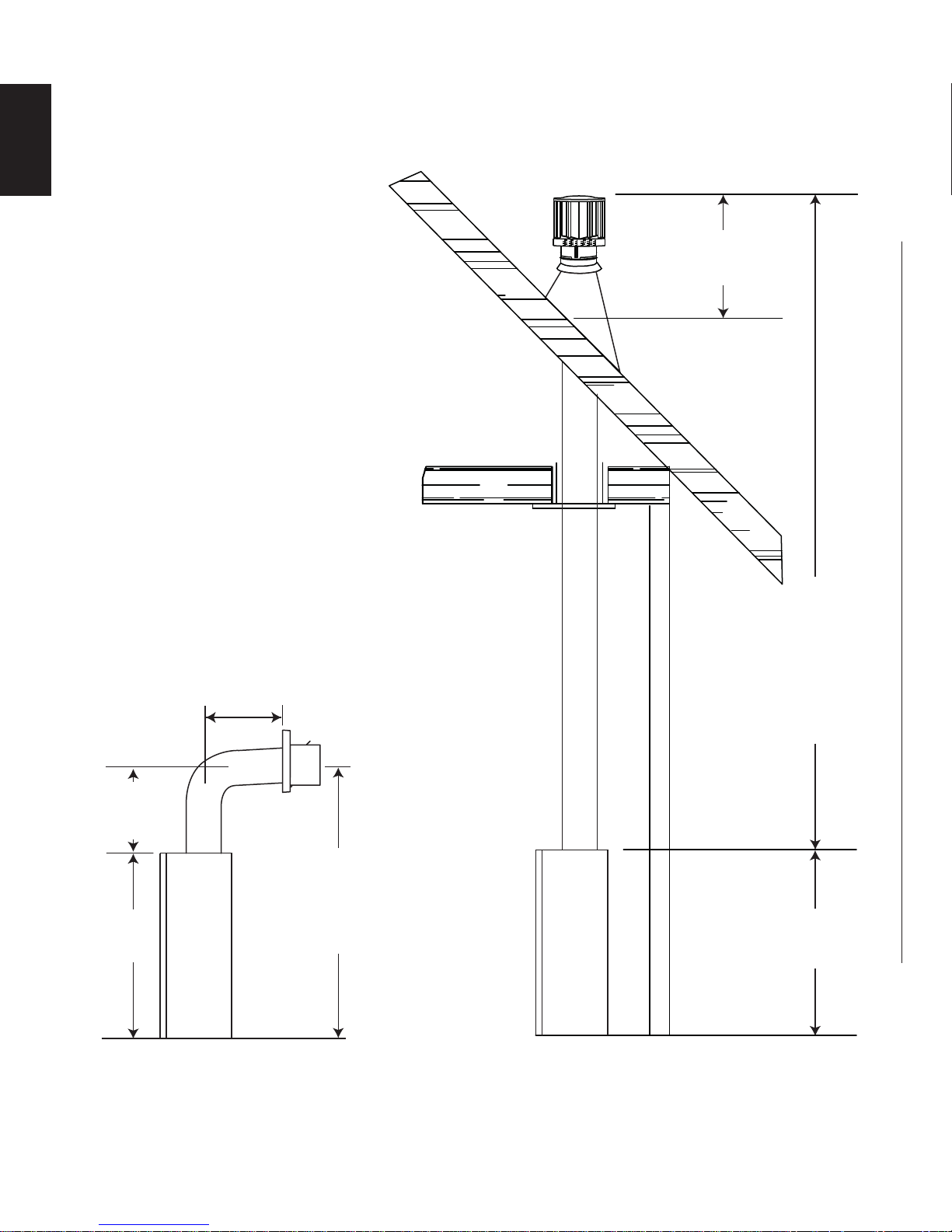

8.1A

16" (406MM)

MINIMUM

20" (508MM)

MAXIMUM

* See "VENTING" section.

24 1/4" (616MM)

MINIMUM PLUS

RISE*

40 FT (12M)

MAXIMUM

3 FT (1M)

MINIMUM

24 1/4"

(616MM)

REAR VENT

W415-1132 / C / 08.20.13

EN

10

16" (406MM)

MINIMUM

10" (254MM)

MINIMUM

34"

(864MM)

24" (610MM)

MAXIMUM

42 3/8"

(1076MM)

MINIMUM

PLUS RISE*

40 FT (12M)

MAXIMUM

3 FT (1M)

MINIMUM

34"

(864MM)

TOP VENT

* See "VENTING" section.

W415-1132 / C / 08.20.13

3.3 SPECIAL VENT INSTALLATIONS

3.3.1 PERISCOPE TERMINATION

Use the periscope kit to locate the air termination above grade. The periscope must be installed so that

when fi nal grading is completed, the bottom air slot is located a minimum 12” (304.8mm) above grade. The

maximum allowable vent length is 10’ (3.1m) for a fi replace and 8’ (2.4m) for a stove.

11

EN

30" (762MM)

MIN

24 1/4"

(616MM)

3.3.2 CORNER TERMINATION

The maximum vent length for a corner installation is 20" (610mm) of horizontal run, in addition to the 45° offset.

In this case zero rise is acceptable when using rigid. Flexible venting must maintain a 6" (152mm) rise.

12" (305MM)

MIN TO

GRADE

12" (305MM)

MIN TO

GRADE

30" (762MM)

MIN

34" (864MM)

9.4A

20" (616mm) MAX

W415-1132 / C / 08.20.13

12

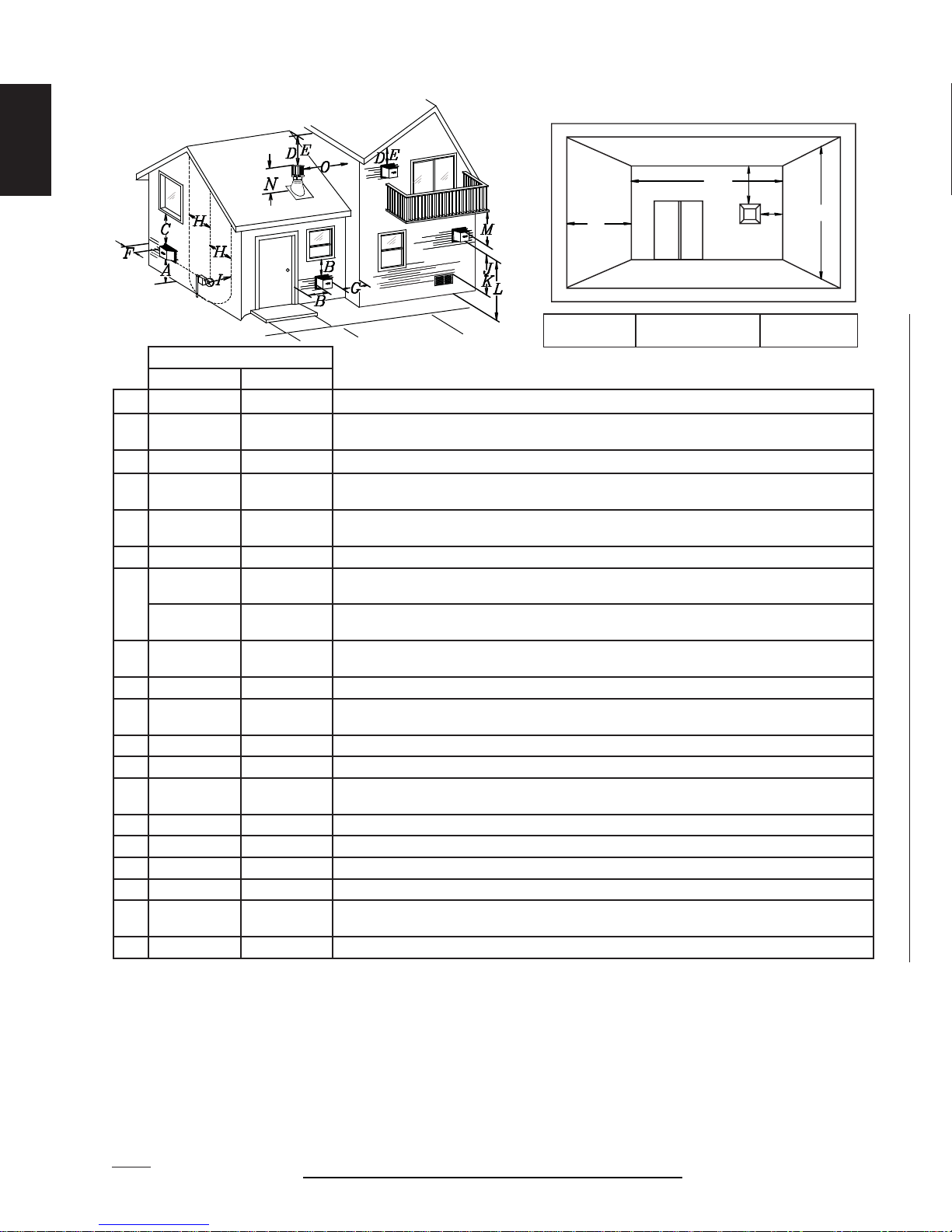

3.4 VENT TERMINAL CLEARANCES

EN

COVERED BALCONY APPLICATIONS ††*

Q

S

R

G

P

Q

= 3 feet

MIN

(0.9m)

R

= 2 x

MAX

Q

ACTUAL

INSTALLATIONS

CANADA U.S.A.

A 12” (305mm) 12” (305mm) Clearance above grade, veranda porch, deck or balcony.

B 12” (305mm)

Δ

9”

(229mm)

Clearance to windows or doors that open.

Δ

C 12” (305mm)* 12” (305mm) * Clearance to permanently closed windows.

D

E

18”

(457mm)**

12”

(305mm)**

18”

(457mm)**

12”

(305mm)**

Vertical clearance to ventilated soffi ts located above the terminal within a horizontal distance of

2’ (0.6m) from the center line of the terminal.

Clearance to unventilated soffi t.

F 0” (0mm) 0” (0mm) Clearance to an outside corner wall.

0” (0mm)***

G

2” (51mm)***

0”

(0mm)***

2”

(51mm)***

H 3’(0.9m) 3’ (0.9m)****

Clearance to an inside non-combustible corner wall or protruding non-combustible obstructions (chimney, etc.).

Clearance to an inside combustible corner wall or protruding combustible obstructions (vent

chase, etc.).

Clearance to each side of the center line extended above the meter / regulator assembly to a

maximum vertical distance of 15’ (4.6m).

I 3’ (0.9m) 3’ (0.9m)**** Clearance to a service regulator vent outlet.

J 12” (305mm) 9” (229mm)

Clearance to a non-mechanical air supply inlet to the building or a combustion air inlet to any other

appliance.

K 6’ (1.8m) 3’ (0.9m) † Clearance to a mechanical air supply inlet.

L 7’ (2.1m) ‡ 7’ (2.1m) **** Clearance above a paved sidewalk or paved driveway located on public property.

M

12”

(305mm)††

12”

(305mm)****

Clearance under a veranda, porch or deck.

N 16” (406mm) 16” (406mm) Clearance above the roof.

O 2’ (0.6m)†* 2’ (0.6m) †* Clearance from an adjacent wall including neighbouring buildings.

P 8’ (2.4m) 8’(2.4m) Roof must be non-combustible without openings.

Q 3’ (0.9m) 3’ (0.9m) See chart for wider wall dimensions.

R 6’ (1.8m) 6’ (1.8m)

See chart for deeper wall dimensions. The terminal shall not be installed on any wall that has an

opening between the terminal and the open side of the structure.

S 12” (305mm) 12” (305mm) Clearance under a covered balcony

The terminal shall not be located less than 6 feet under a window that opens on a horizontal plane in a structure with three walls and a roof.

Δ

* Recommended to prevent condensation on windows and thermal breakage

** It is recommended to use a heat shield and to maximize the distance to vinyl clad soffi ts.

*** The periscope requires a minimum 18 inches clearance from an inside corner.

**** This is a recommended distance. For additional requirements check local codes.

† 3 feet above if within 10 feet horizontally.

‡ A vent shall not terminate where it may cause hazardous frost or ice accumulations on adjacent property surfaces.

†† Permitted only if the veranda, porch, or deck is fully open on a minimum of two sides beneath the fl oor.

†* Recommended to prevent recirculation of exhaust products. For additional requirements check local codes.

††* Permitted only if the balcony is fully open on a minimum of one side.

NOTE: Clearances are in accordance with local installation codes and the requirements of the gas supplier.

W415-1132 / C / 08.20.13

12.1D

R

MAX

IHHW

(4.6m)

3.5 VENT APPLICATION FLOW CHART

13

Horizontal Termination

Vertical rise is equal

to or greater than

the horizontal run

Horizontal run +

vertical rise to

maximum of 40 feet

(12.2m)

TOP EXIT

Vertical rise is less

than horizontal run

Horizontal run +

vertical rise to

maximum of

24.75 feet (7.5m)

4.2 times the

vertical rise equal to

or greater than the

horizontal run

REAR EXIT

Vertical Termination

Vertical rise is equal

to or greater than

the horizontal run

Horizontal run +

vertical rise to

maximum of 40 feet

(12.2m)

EN

Vertical rise is less

than horizontal run

Horizontal run +

vertical rise to

maximum of 40 feet

(12.2m)

3 times the vertical

rise equal to or

greater than the

horizontal run

13.1A

Horizontal Termination

Vertical rise is equal

to or greater than

the horizontal run

Horizontal run +

vertical rise to

maximum of 40 feet

(12.2m)

3.6 DEFINITIONS

For the following symbols used in the venting calculations and examples are:

> - greater than

> - equal to or greater than

< - less than

< - equal to or less than

HT - total of both horizontal vent lengths (Hr) and offsets (Ho) in feet

HR - combined horizontal vent lengths in feet

HO - offset factor: .03 (total degrees of offset - 90°*) in feet

VT - combined vertical vent lengths in feet

Vertical rise is less

than horizontal run

Horizontal run +

vertical rise to

maximum of

24.75 feet (7.5m)

3.5 times the

vertical rise equal to

or greater than the

horizontal run

Vertical Termination

Vertical rise is equal

to or greater than

the horizontal run

Horizontal run +

vertical rise to

maximum of 40 feet

(12.2m)

Vertical rise is less

than horizontal run

Horizontal run +

vertical rise to

maximum of 40 feet

(12.2m)

3 times the vertical

rise equal to or

greater than the

horizontal run

13.2A

14.1

W415-1132 / C / 08.20.13

14

3.7 ELBOW VENT LENGTH VALUES

FEET INCHES MILLIMETERS

EN

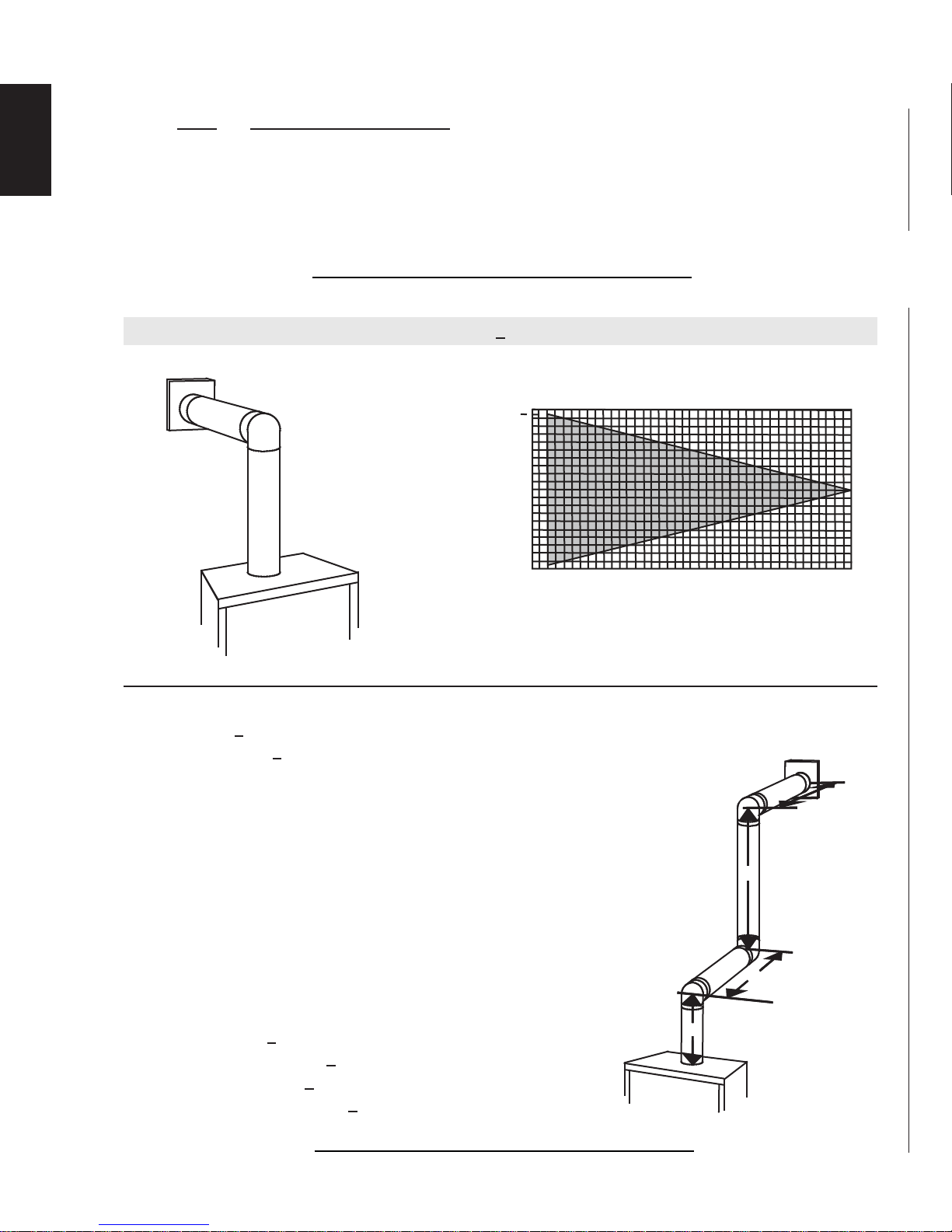

3.8 TOP EXIT HORIZONTAL TERMINATION

1° 0.03 0.5 12.7

15° 0.45 6.0 152.4

30° 0.9 11.0 279.4

45° 1.35 16.0 406.4

90°* 2.7 32.0 812.8

* The fi rst 90° offset has a zero value and is shown in the formula as - 90°

15.1A

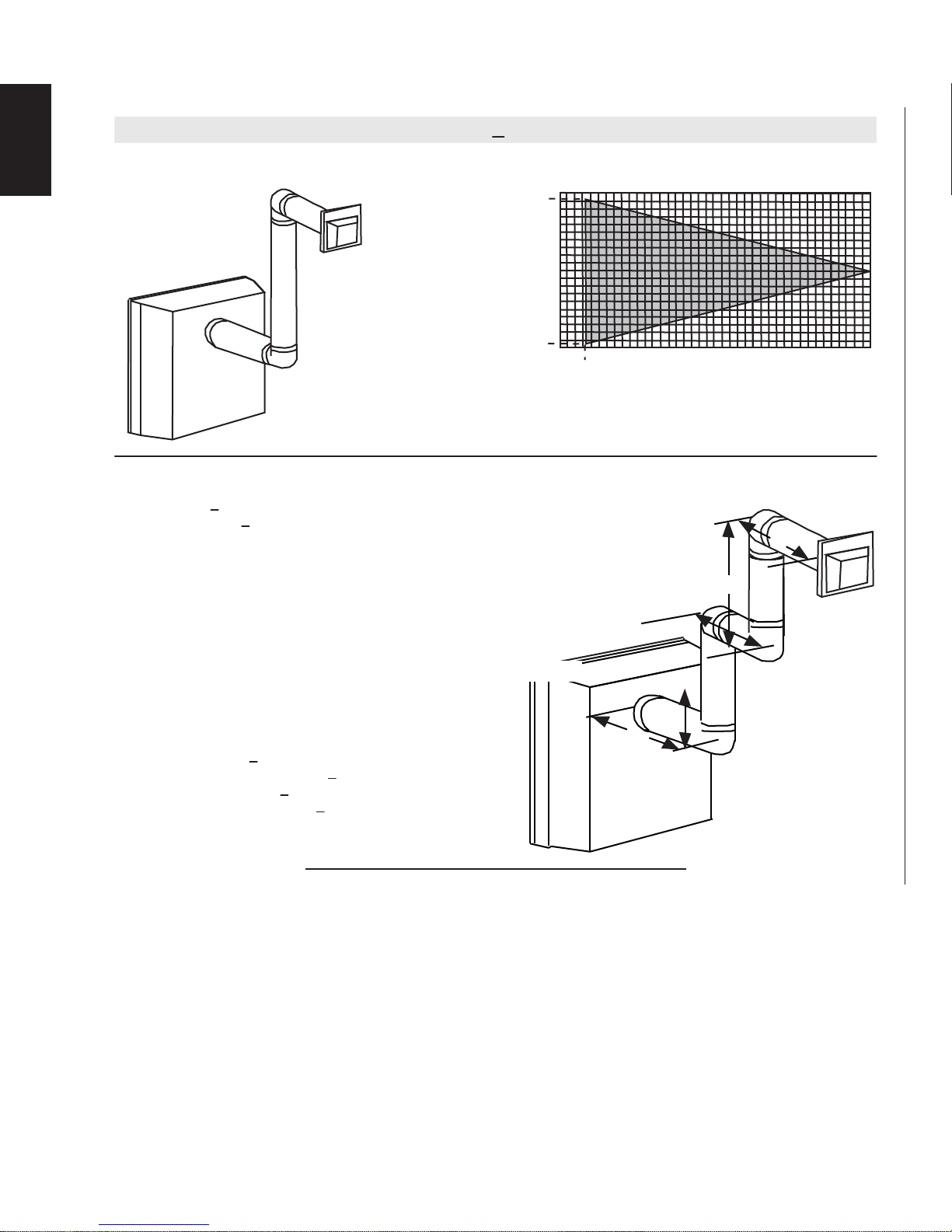

(HT) < (VT)

Simple venting confi guration (only one 90° elbow)

See graph to determine the required vertical

rise VT for the required horizontal run HT.

40 (12.2)

39 (11.9)

REQUIRED

30 (9.1)

VERTICAL

RISE IN FEET

20 (6.1)

(METERS)VT

10 (3.1)

0

2.5

(0.8)5(1.5)

(2.3)

7.5

(3.1)

10

12.5

(3.8)15(4.6)

HORIZONTAL VENT RUN PLUS OFFSET IN

FEET (METERS) H

T

The shaded area within the lines represents

acceptable values for HT and V

For vent confi gurations requiring more than one 90° elbow, the following formulas apply:

Formula 1: HT < V

T

Formula 2: HT + VT < 40 feet (12.2m)

Example:

V1 = 3 FT (0.9m)

90°

V2 = 8 FT (2.4m)

VT = V1 + V2= 3 FT (0.9m ) + 8 FT (2.4m) = 11 FT (3.4m)

V

H1 = 2.5 FT (0.8m)

2

H2 = 2 FT (0.6m)

HR = H1 + H2 = 2.5 FT (0.8m) + 2 FT (0.6m) = 4.5 FT (1.4m)

HO = .03 (three 90° elbows - 90°) = .03 (270° - 90°) = 5.4 FT (1.7m)

= HR + HO = 4.5 FT (1.4m) + 5.4 FT (1.6m) = 9.9 FT (3m)

H

T

H

+ VT = 9.9 FT (3m) + 11 FT (3.4m) = 20.9 FT (6.4m)

T

90°

90°

H

1

17.5

(5.3)20(6.1)

T

H

2

Formula 1: HT < V

T

9.9 FT (3m) < 11 FT (3.4m)

Formula 2: HT + VT < 40 FT (12.2m)

20.9 FT (6.4m) < 40 FT (12.2m)

Since both formulas are met, this vent confi guration is acceptable.

W415-1132 / C / 08.20.13

V

1

16.1B

15

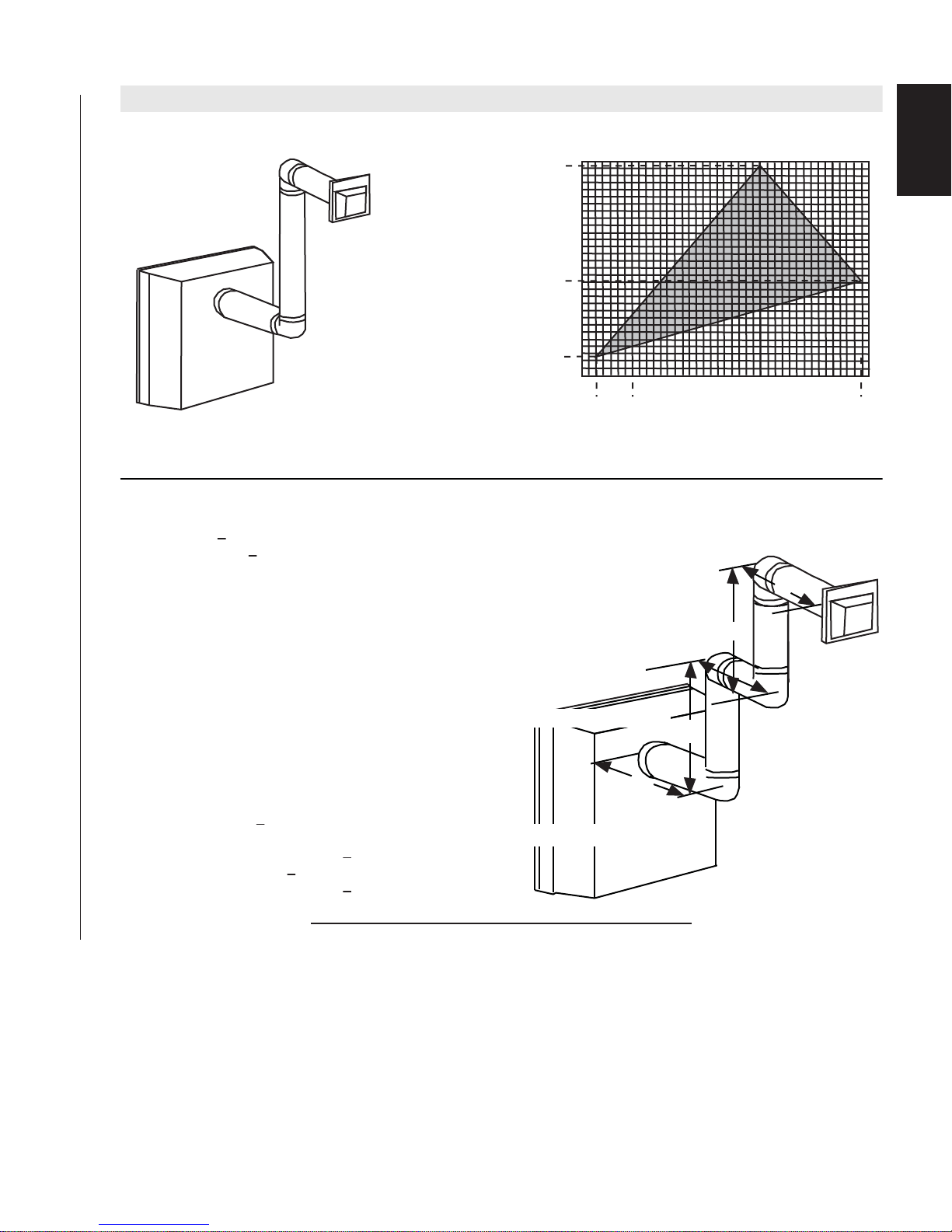

Simple venting configuration

(only one 90° elbow)

(HT) > (VT)

See graph to determine the required vertical rise VT for the required horizontal run HT.

147 (3733.8)

150 (3810)

REQUIRED

VERTICAL

100 (2540)

RISE IN INCHES

(MILLIMETERS) VT

57 (1447.8)

50 (1270)

10 (254)

5

0

(1.5)

2

(0.6)

(3.1)

15

10

(4.6)

12.5

(3.8)

19.5

(5.9)

HORIZONTAL VENT RUN PLUS OFFSET IN FEET (METERS) H

The shaded area within the lines represents acceptable values for H

For vent configurations requiring more than one 90° elbow, the following formulas apply:

Formula 1: H

Formula 2: HT + V

< 4.2 V

T

T

< 24.75 feet (7.5m)

T

90°

H

Example:

V

= VT = 6 FT (1.8m)

1

H

= 3 FT (0.9m)

1

H

= 5 FT (1.5m)

2

H

= H

+ H

R

H

= .03 (two 90° elbows - 90°) = .03 (180° - 90°) = 2.7FT (0.8m)

O

H

= H

T

H

+ V

T

= 3FT (0.9m) + 5FT (1.5m) = 8FT (2.4m)

1

2

+ H

= 8FT (2.4m) + 2.7FT (0.8m) = 10.7FT (3.3m)

R

O

= 10.7FT (3.3m) + 6FT (1.8m) = 16.7FT (5.1m)

T

V

1

20 (6.1)

1

90°

T

and VT

T

H

EN

2

Formula 1: HT < 4.2 V

4.2 VT = 4.2FT (1.3m) x 6FT (1.8m) = 25.2FT (7.7m)

Formula 2: HT + V

16.7 FT (5.1m) < 24.75 FT (7.5m)

Since both formulas are met, this vent configuration is acceptable.

T

< 24.75 FT (7.5m)

T

90°

Example:

V

= 4 FT (1.2m)

1

V

= 1.5 FT (0.5m)

2

V

= V

+ V

T

H

= 2 FT (0.6m)

1

= 1 FT (0.3m)

H

2

H

= 1 FT (0.3m)

3

H

= 1.5 FT (0.5m)

4

H

= H

R

H

= .03 (four 90° elbows - 90°) = .03 (360° - 90°) = 8.1 FT (2.5m)

O

= H

H

T

H

+ V

T

Formula 1: HT < 4.2 V

4.2 VT = 4.2 FT (1.3m) x 5.5 FT (1.7m) = 23.1 FT (7m)

= 4 FT (1.2m) + 1.5 FT (0.5m) = 5.5 FT (1.7m)

1

2

+ H2 + H

1

+ H

R

= 13.6 FT (4.2m) + 5.5 FT (1.7m) = 19.1 FT (5.8m)

T

+ H4 = 2FT (0.6m) + 1FT (0.3m) + 1FT (0.3m) + 1.5FT (0.5m) = 5.5 FT (1.7m)

3

= 5.5 FT (1.7m) + 8.1 FT (2.5m) = 13.6 FT (4.2m)

O

T

V

1

13.6 FT (4.2m) < 23.1 FT (7m)

Formula 2: HT + V

19.1 FT (5.8m) < 24.75 FT (7.5m)

< 24.75 FT (7.5m)

T

Since both formulas are met, this vent configuration is acceptable.

90°

90°

H

1

90°

V

2

H

H

2

3

16.2_3B

H

4

W415-1132 / C / 08.20.13

16

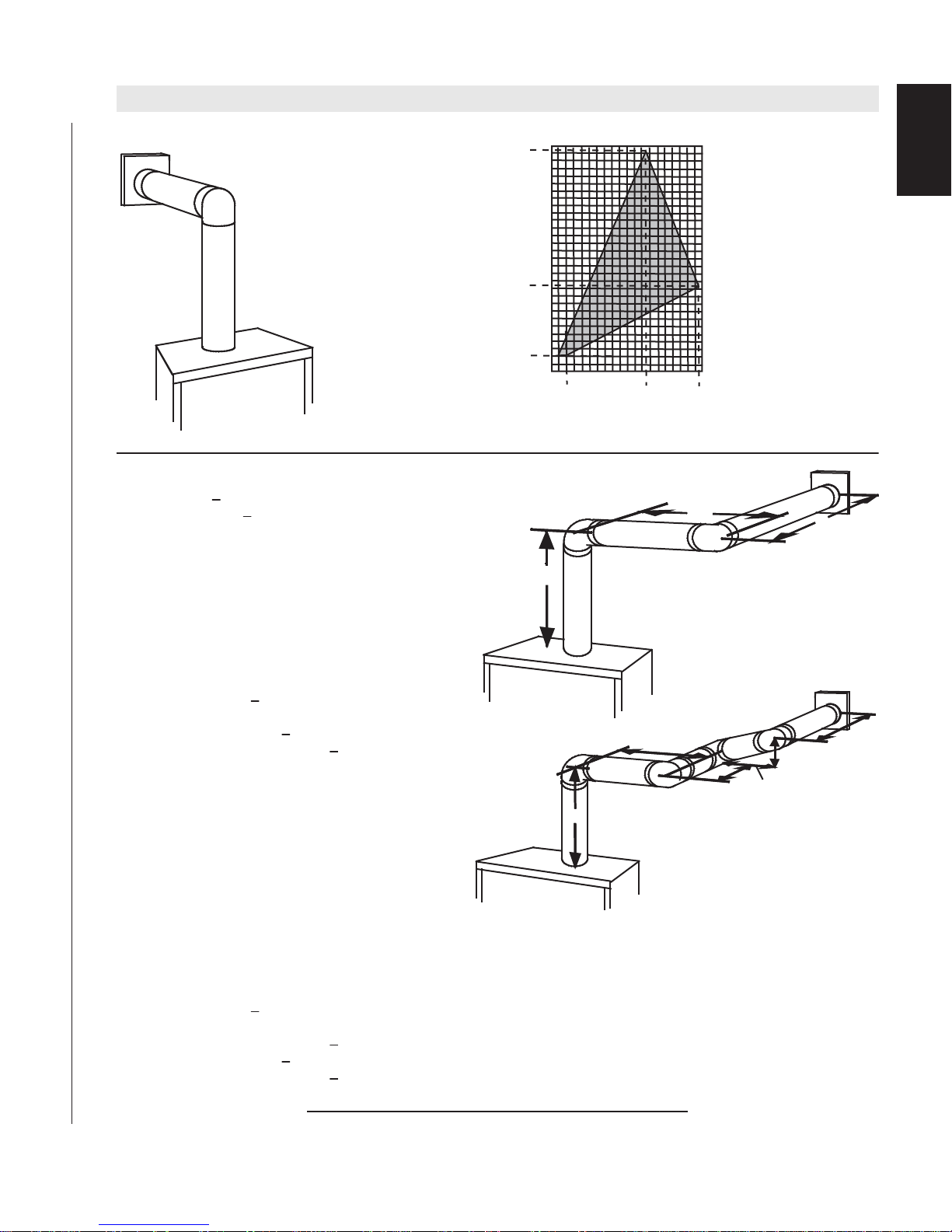

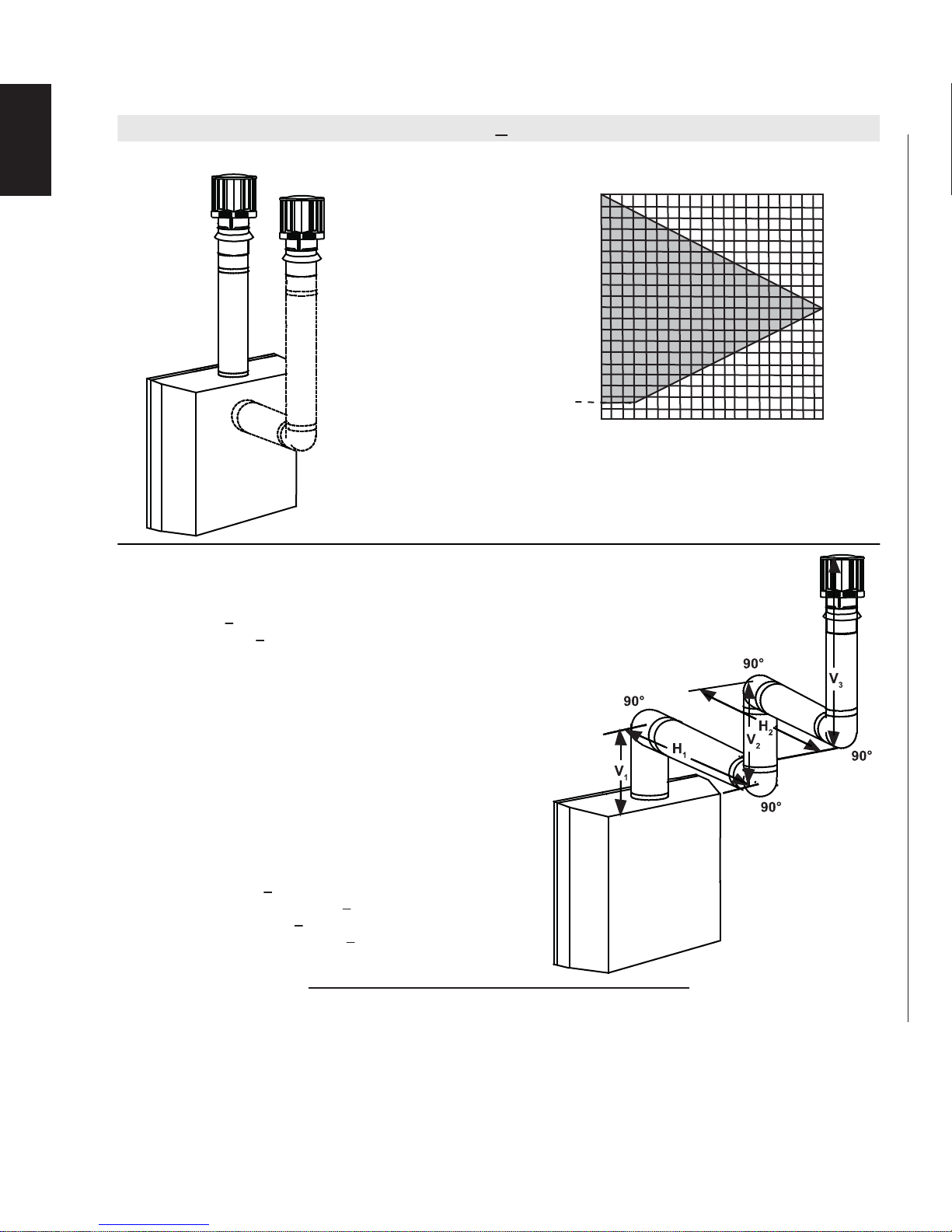

3.9 REAR EXIT HORIZONTAL TERMINATION

EN

Simple venting configuration

(only two 90° elbows)

(HT) < (VT)

See graph to determine the required vertical rise V

REQUIRED

40 (12.2)

38.3 (11.7)

30 (9.1)

horizontal run HT.

VERTICAL

RISE IN

20 (6.1)

FEET

(METERS) V

T

10 (3.1)

1.6 (0.5)

0

2.5

(0.8)5 (1.5)

1.6

(0.5)

7.5

(2.3)

HORIZONTAL VENT RUN PLUS OFFSET IN FEET (METERS) H

The shaded area within the lines represents acceptable values for H

and HT

For vent configurations requiring more than two 90° elbows, the following formulas apply:

Formula 1: H

Formula 2: HT + V

< V

T

T

< 40 feet (12.2m)

T

Example:

V

= 9 FT (2.7m)

1

V

= 6 FT (1.8m)

2

V

= V

+ V

T

H

= 3 FT (0.9m)

1

H

= 2 FT (0.6m)

2

H

= 1.5 FT (0.5m)

3

H

= H

R

H

= .03 (four 90° elbows - 90°) = .03 (360° - 90°) = 8.1 FT (2.5m)

O

H

= H

T

H

+ V

T

Formula 1: HT < V

14.6 FT (4.5m) < 15 FT (4.6m)

Formula 2: HT + V

29.6 FT (9m) < 40 FT (12.2m)

= 9FT (2.7m) + 6FT (1.8m) = 15FT (4.6m)

1

2

+ H2 + H

1

+ H

R

= 14.6FT (4.5m) + 15FT (4.6m) = 29.6 FT (9m)

T

= 3FT (0.9m) + 2FT (0.6m) + 1.5FT (0.5m) = 6.5FT (2m)

3

= 6.5FT (2m) + 8.1FT (2.5m) = 14.6FT (4.5m)

O

T

< 40 FT (12.2m)

T

H

1

90°

V

1

Since both formulas are met, this vent configuration is acceptable.

(3.1)

for the required

T

10

12.5

15

17.5

(3.8)

(4.6)

(5.3)

(6.1)

T

20

T

90°

H

3

V

2

H

2

90°

90°

W415-1132 / C / 08.20.13

16.3A

17

(HT) > (VT)

Simple venting configuration

(only two 90° elbows)

See graph to determine the required vertical rise V

150(3810)

147 (3733.8

required horizontal run H

REQUIRED

VERTICAL RISE IN

100 (2540)

INCHES

(MILLIMETERS)V

T

66

(1676.4)

50 (1270)

12

(304.8)

0

(0.3)

1

2.5

(0.8)5 (1.5)

3.5

(1.1)

(2.3)

7.5

HORIZONTAL VENT RUN PLUS OFFSET IN FEET (METERS) H

The shaded area within the lines represents acceptable

values for H

and HT

T

For vent configurations requiring more than two 90° elbows, the following formulas apply:

Formula 1: H

Formula 2: HT + V

< 3.5V

T

T

< 24.75 feet (7.5m)

T

(3.1)

for the

(4.6)

T

15

17.5

(5.3)

19.25

(5.9)

.

T

10

12.5

(3.8)

(6.1)

EN

20

T

90°

Example:

V

= 4 FT (1.2m)

1

V

= 1.5 FT (0.5m)

2

V

= V

+ V

T

H

= 2 FT (0.6m)

1

H

= 1 FT (0.3m)

2

H

= 1 FT (0.3m)

3

H

= 1.5 FT (0.5m)

4

H

= H1+ H2+H3+H4= 2FT(0.6m) + 1FT(0.3m) + 1FT(0.3m) + 1.5FT(0.5m) = 5.5 FT(1.7m)

R

H

= .03 (four 90° elbows + one 45° elbow - 90°)

O

= .03 (90 + 90 + 90 + 90 + 45 - 90) = 9.45 FT (2.9m)

H

= H

T

H

+ V

T

Formula 1: HT < 3.5V

3.5VT = 3.5FT (1.1m) x 5.5FT (1.7m) = 19.25FT (5.9m)

14.95 FT (4.6m) < 19.25 FT (5.9m)

Formula 2: HT + V

20.45 FT (6.2m) < 24.75 FT (7.5m)

= 4FT (1.2m) + 1.5FT (0.5m) = 5.5 FT (1.7m)

1

2

+ H

= 5.5FT (1.7m) + 9.45FT (2.9m) = 14.95FT (4.6m)

R

O

= 14.95FT (4.6m) + 5.5FT (1.7m) = 20.45FT (6.2m)

T

T

< 24.75 FT (7.5m)

T

Since both formulas are met, this vent configuration is acceptable.

H

3

V

2

90°

H

2

V

1

H

1

90°

90°

16.3_2B

W415-1132 / C / 08.20.13

18

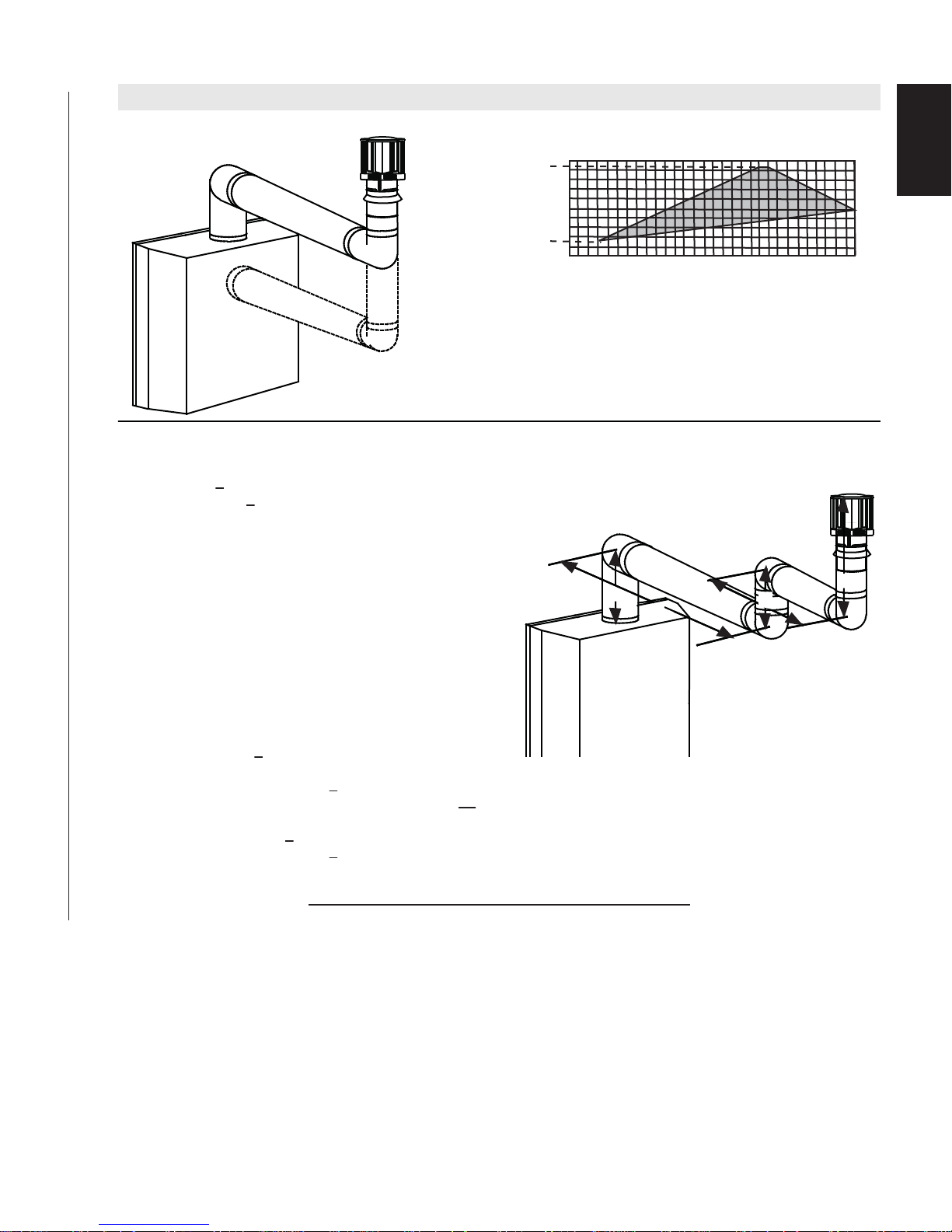

3.10 TOP OR REAR EXIT VERTICAL TERMINATION

EN

(HT) < (VT)

Simple venting configurations.

See graph to determine the required vertical rise V

required horizontal run H

40 (12.2)

30 (9.1)

.

T

REQUIRED

VERTICAL RISE

IN FEET

(METERS)V

T

3 (0.9)

20 (6.1)

10 (3.1)

0

5

(1.5)

10

(3.1)

15

(4.6)

HORIZONTAL VENT RUN PLUS OFFSET IN FEET

(METERS) H

T

The shaded area within the lines represents acceptable

values for H

and HT

T

For vent configurations requiring one or more 90° elbows (top exit) or one or more 90° elbows

(rear exit), the following formulas apply:

Formula 1: H

Formula 2: HT + V

< V

T

T

< 40 feet (12.2m)

T

for the

T

20

(6.1)

Example:

= 5 FT (1.5m)

V

1

V

= 6 FT (1.8m)

2

= 10 FT (3.1m)

V

3

V

= V

+ V2 + V

T

1

H

= 8 FT (2.4m)

1

H

= 2.5 FT (0.8m)

2

H

= H1+ H2 = 8FT (2.4m) + 2.5FT (0.8m) = 10.5FT (3.2m)

R

= .03 (four 90° elbows - 90°)

H

O

= .03 (360° - 90°) = 8.1 FT (2.5m)

H

= H

+ H

T

R

H

+ V

= 18.6FT (5.7m) + 21FT (6.4m) = 39.6FT (12.1m)

T

T

Formula 1: H

18.6 FT (5.7m) < 21 FT (6.4m)

Formula 2: HT + V

39.6FT (12.1m) < 40 FT (12.2m)

= 5FT (1.5m) + 6FT (1.8m) + 10FT (3.1m) = 21 FT (6.4m)

3

= 10.5FT (3.2m) + 8.1FT (2.5m) = 18.6FT (5.7m)

O

< 3.5V

T

T

< 40 FT (12.2m)

T

Since both formulas are met, this vent configuration is acceptable.

18.2A

W415-1132 / C / 08.20.13

19

Simple venting configurations.

(HT) > (VT)

See graph to determine the required vertical rise V

19 (5.8)

20 (6.1)

required horizontal run H

for the

.

T

T

REQUIRED

VERTICAL

RISE IN

FEET

(METERS)V

T

3 (0.9)

10 (3.1)

5

0

(1.5)

10

(3.1)

15

(4.6)

20

(6.1)

25

(7.6)

30

(9.1)

HORIZONTAL VENT RUN PLUS OFFSET IN FEET (METERS)HT

The shaded area within the lines represents acceptable

values for H

and HT

T

For vent configurations requiring more than two 90° elbows (top exit) or one 90° elbow (rear exit), the following

formulas apply:

Formula 1: H

Formula 2: HT + V

Example:

V

= 2 FT (0.6m)

1

V

= 1 FT (0.3m)

2

= 1.5 FT (0.5m)

V

3

V

= V

T

1

= 6 FT (1.8m)

H

1

H

= 2 FT (0.6m)

2

H

= H

R

1

= .03 (four 90° elbows - 90°)

H

O

= .03 (360° - 90°) = 8.1 FT (2.5m)

H

= H

T

R

H

+ V

T

T

< 3 V

T

T

< 40 feet (12.2m)

T

+ V2 + V3 = 2FT (0.6m) + 1FT (0.3m) + 1.5FT (0.5m) = 4.5 FT (1.4m)

+ H

= 6FT (1.8m) + 2FT (0.6m) = 8 FT (2.4m)

2

+ H

= 8FT (2.4m) + 8.1FT (2.5m) = 16.1FT (4.9m)

O

= 16.1FT (4.9m) + 4.5FT (1.4m) = 20.6FT (6.3m)

90°

90°

V

V

1

H

1

V

H

2

2

90°

3

90°

EN

Formula 1: H

3.5 V

16.1FT (4.9m) < 13.5 FT (4.1m)

< 3.5 V

T

T

= 3FT (0.9m) x 4.5FT (1.4m) = 13.5 FT (4.1m)

T

Since this formula is not met, this vent configuration is unacceptable.

Formula 2: HT + V

16.1FT (4.9m) < 13.5 (4.1m)

< 40 FT (12.2m)

T

Since only formula 2 is met, this vent configuration is unacceptable and a new fireplace location or vent configuration will

need to be established to satisfy both formulas.

18.2_2B

W415-1132 / C / 08.20.13

EN

20

Example:

= 1.5 FT (0.5m)

V

1

V

= 5 FT (1.5m)

2

= V

V

H

H

H

H

H

= .03 (360° + 45° - 90°) = 6.75 FT (2.1m)

H

H

+ V2 = 1.5FT (0.5m)+ 5FT (1.5m) = 6.5 FT (2m)

T

1

= 1 FT (0.3m)

1

= 1 FT (0.3m)

2

= 10.75 FT (3.3m)

3

= H

+ H2 + H3 = 1FT (0.3m) + 1FT (0.3m) + 10.75FT (3.3m) = 12.75FT (3.9m)

R

1

= .03 (four 90° elbows + one 45° elbow - 90°)

O

= H

+ H

T

T

+ V

= 12.75FT (3.9m) + 6.75FT (2.1m) = 19.5 FT (5.9m)

R

O

= 19.5FT (5.9m) + 6.5FT (2m) = 26 FT (7.9m)

T

Formula 1:

HT < 3 V

3 V

19.5FT (5.9m) = 19.5FT (5.9m)

T

= 3FT (0.9m) x 6.5FT (2m) = 19.5FT (5.9m)

T

H

1

Formula 2:

HT + V

26 FT (7.9m) < 40 FT (12.2m)

< 40 FT (12.2m)

T

Since both formulas are met, this vent configuration is acceptable.

90°

V

2

H

2

45°

V

1

H

3

90°

90°

18.2_3A

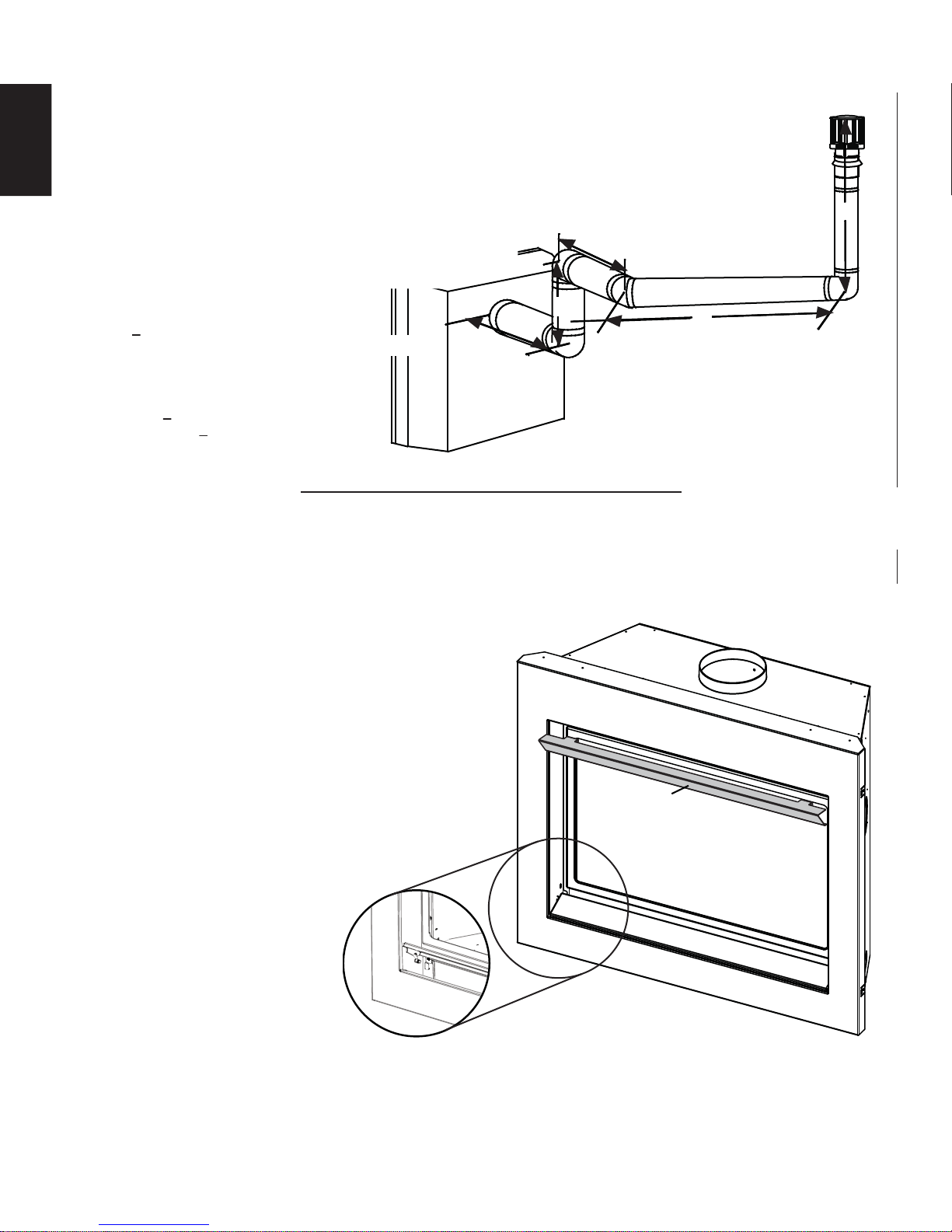

4.0 PRE-INSTALLATION PREPARATION

For optimum performance, it is recommended that all horizontal runs have a 1" (25mm) rise per foot.

4.1 REMOVING THE VALVE ACCESS DOOR AND TOP DOOR TRIM

A. The valve access door rotates on the pins

attached to the side frame. Lift the valve access

door off the pins to operate the main glass door.

B. Lift the top door trim off the top of the door.

T

O

P

DO

O

R TR

IM

W415-1132 / C / 08.20.13

4.2 DOOR OPERATION

To access the lower door latch, open the Valve Access Door as illustrated. Release

the top and bottom door latches, located at the right side of the door.

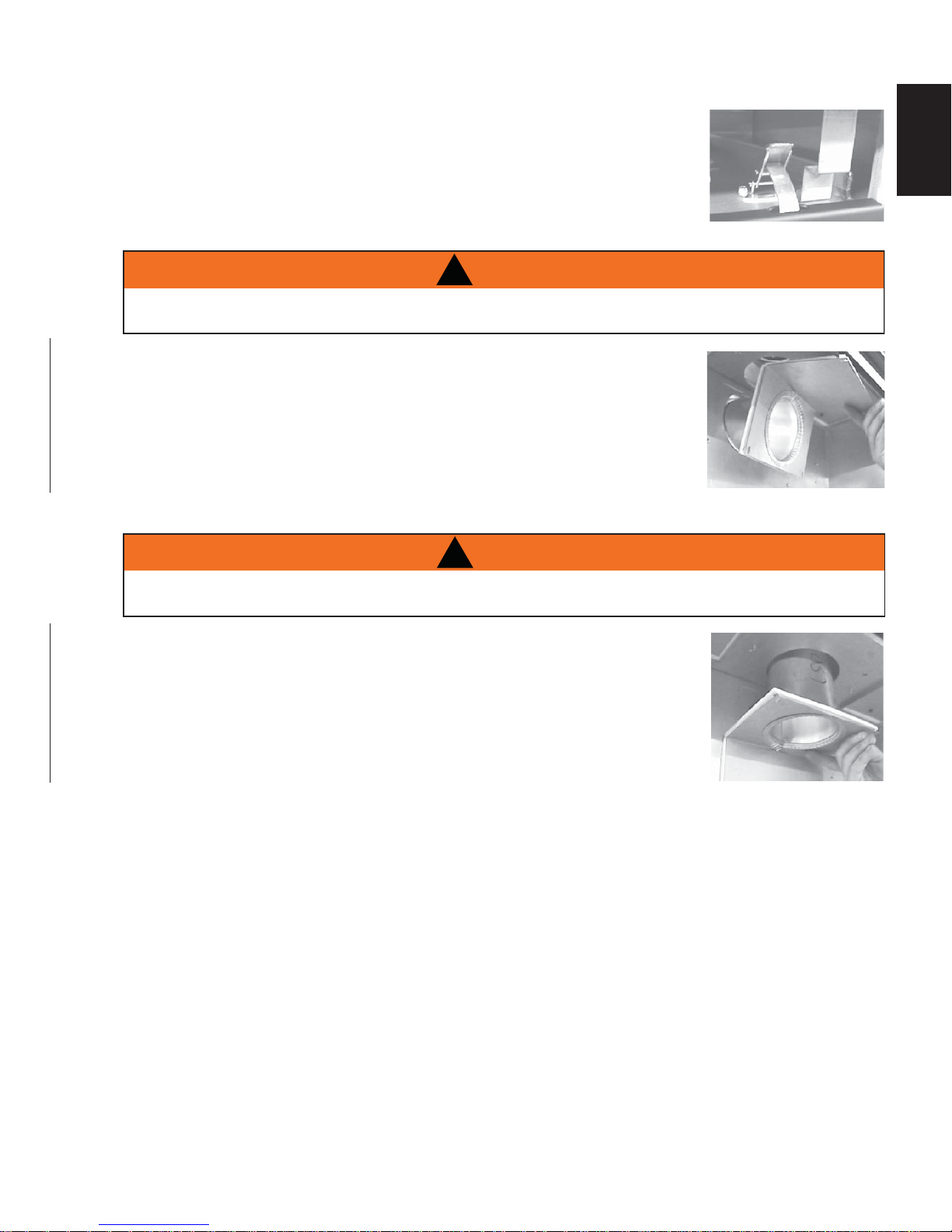

4.3 REAR EXIT

FAILURE TO INSTALL THE CAP WILL CAUSE THE APPLIANCE TO FUNCTION IMPROPERLY AND

From inside the fi rebox, insert the 4" (102mm) fl ue pipe / gasket assembly (provided)

through the rear of the fi rebox. Secure the gasket assembly to the rear and top of the

appliance using 4 #8 x ¾ inch Hex Head Wildrill screws supplied.

Do not overtighten. The gasket needs only to be snug against the fi rebox.

Before attaching elbows to the collars on the back of the appliance, 1½" (38mm) will

need to be trimmed off the 4" (102mm) collar.

!

WARNING

CAN CAUSE INJURY OR PROPERTY DAMAGE.

21

EN

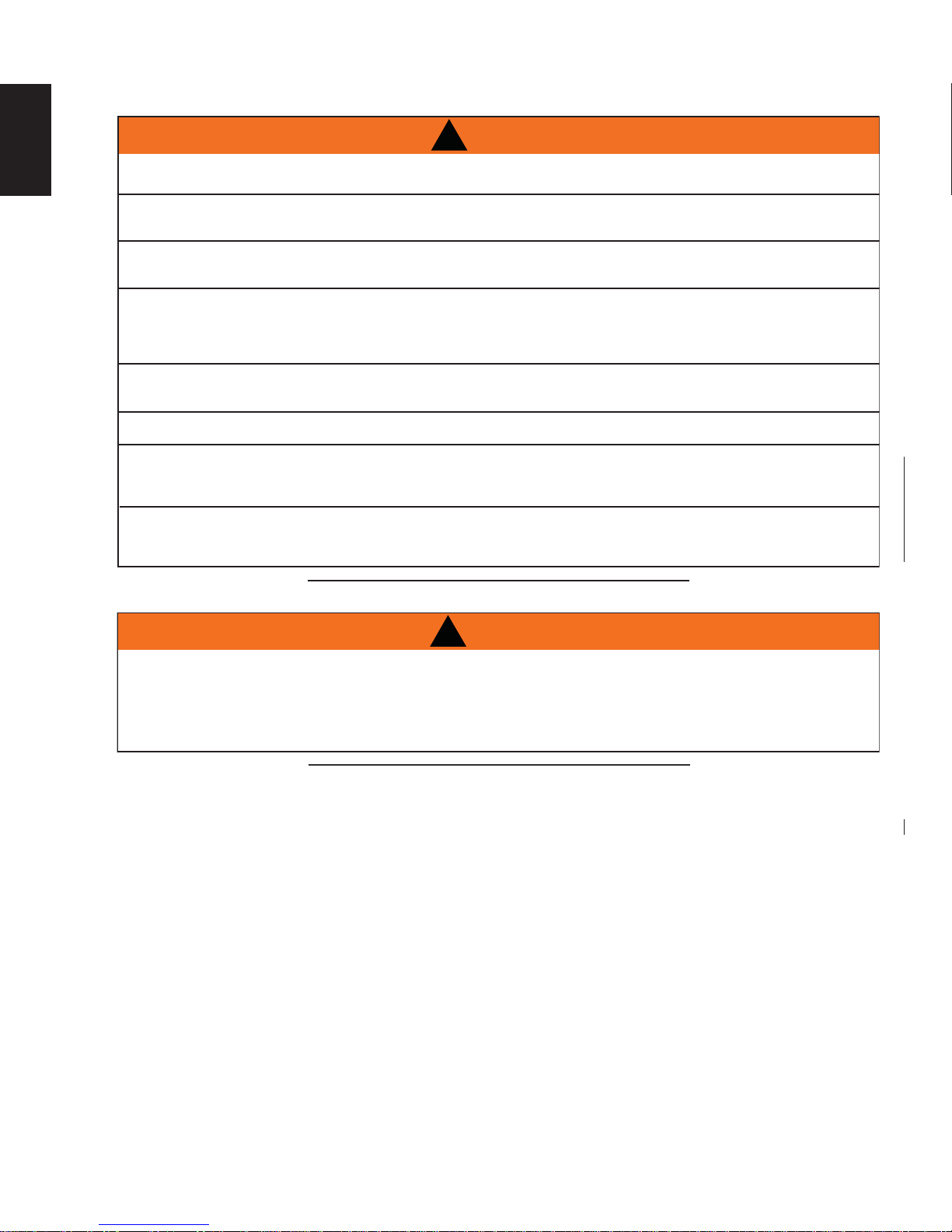

4.4 TOP VENT

FAILURE TO INSTALL THE CAP WILL CAUSE THE APPLIANCE TO FUNCTION IMPROPERLY AND

A. Remove the 7" (178mm) diameter cap from the top of the appliance and

re-secure it over the 7" (178mm) collar located at the rear of the appliance.

Press fi rmly on the cap while securing to ensure an airtight seal. Do not

damage the gasket.

B. Remove the plate covering the 4" (102mm) diameter fl ue opening (seen

inside the top of the 7" (178mm) diameter collar) and discard. Try not to

disturb the retaining ring or the gasket beneath. Re-secure the ring and

gasket using the screws removed from the plate.

C. From inside the fi rebox, insert the 4" (102mm) fl ue pipe / gasket assembly

through the heat shield and out through the retaining ring. Secure the assembly to the rear and top

of the appliance using 4 #8 x ¾" Hex Head Wildrill screws supplied. Do not overtighten. The gasket

needs only to be snug against the fi rebox.

!

WARNING

CAN CAUSE INJURY OR PROPERTY DAMAGE.

W415-1132 / C / 08.20.13

22

5.0 INSTALLATION

EN

ENSURE TO UNPACK ALL LOOSE MATERIALS FROM INSIDE THE FIREBOX PRIOR TO HOOKING UP

THE GAS AND ELECTRICAL SUPPLY.

IF YOUR APPLIANCE IS SUPPLIED WITH A REMOTE ENSURE THE REMOTE RECEIVER IS IN THE

“OFF” POSITION PRIOR TO HOOKING UP THE GAS AND ELECTRICAL SUPPLY TO THE APPLIANCE.

FOR SAFE AND PROPER OPERATION OF THE APPLIANCE, FOLLOW THE VENTING INSTRUCTIONS

ALL INNER EXHAUST AND OUTER INTAKE VENT PIPE JOINTS MAY BE SEALED USING EITHER RED

RTV HIGH TEMP SILICONE SEALANT W573-0002 (NOT SUPPLIED) OR BLACK HIGH TEMP MILL PAC

W573-0007 (NOT SUPPLIED) WITH THE EXCEPTION OF THE APPLIANCE EXHAUST FLUE COLLAR

WHICH MUST BE SEALED USING MILL PAC.

IF USING PIPE CLAMPS TO CONNECT VENT COMPONENTS, 3 SCREWS MUST ALSO BE USED TO

ENSURE THE CONNECTION CANNOT SLIP OFF.

DO NOT CLAMP THE FLEXIBLE VENT PIPE.

RISK OF FIRE, EXPLOSION OR ASPHYXIATION. IMPROPER SUPPORT OF THE ENTIRE VENTING

SYSTEM MAY ALLOW VENT TO SAG AND SEPARATE. USE VENT RUN SUPPORTS AND CONNECT

VENT SECTIONS PER INSTALLATION INSTRUCTIONS.

RISK OF FIRE, DO NOT ALLOW LOOSE MATERIALS OR INSULATION TO TOUCH THE VENT PIPE.

REMOVE INSULATION TO ALLOW FOR THE INSTALLATION OF THE ATTIC SHIELD AND TO

MAINTAIN CLEARANCES TO COMBUSTIBLES.

5.1 WALL AND CEILING PROTECTION

!

WARNING

EXACTLY.

68.2B

!

WARNING

DO NOT FILL THE SPACE BETWEEN THE VENT PIPE AND ENCLOSURE WITH ANY TYPE OF

MATERIAL. DO NOT PACK INSULATION OR COMBUSTIBLES BETWEEN CEILING FIRESTOPS.

ALWAYS MAINTAIN SPECIFIED CLEARANCES AROUND VENTING AND FIRESTOP SYSTEMS.

INSTALL WALL SHIELDS AND FIRESTOPS AS SPECIFIED. FAILURE TO KEEP INSULATION OR

OTHER MATERIALS AWAY FROM VENT PIPE MAY CAUSE FIRE.

70.1

For clearances to combustible materials from the vent pipe, see “FRAMING” section.

For optimum performance it is recommended that all horizontal runs have a minimum 1" (25mm) rise per foot

using fl exible venting. For safe and proper operation of the appliance, follow the venting instructions exactly.

W415-1132 / C / 08.20.13

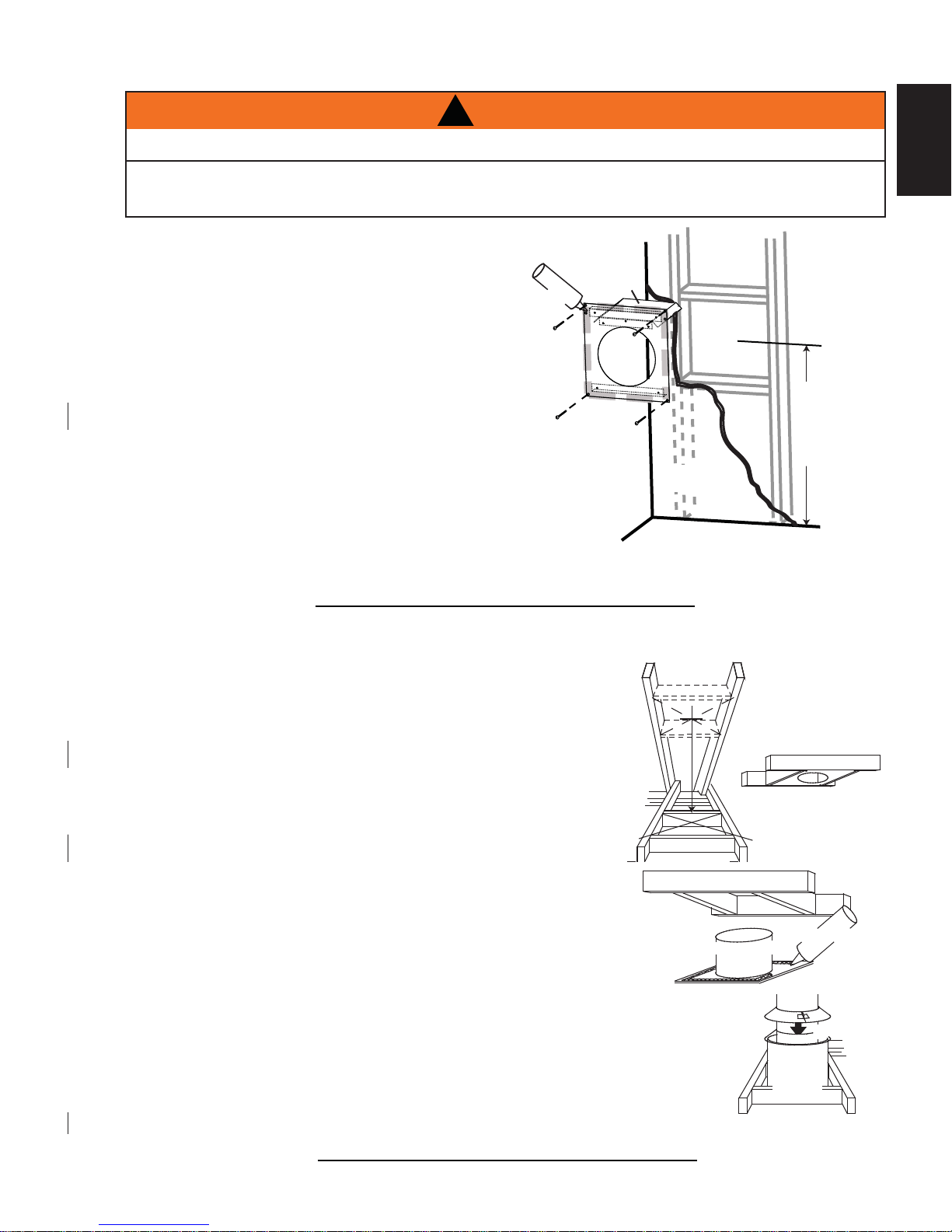

5.2 HORIZONTAL INSTALLATION

THE FIRESTOP ASSEMBLY MUST BE INSTALLED WITH THE VENT SHIELD TO THE TOP.

TERMINALS MUST NOT BE RECESSED INTO A WALL OR SIDING MORE THAN THE DEPTH OF THE

RETURN FLANGE OF THE MOUNTING PLATE.

This application occurs when venting through an exterior wall.

Having determined the correct height for the air terminal

location, cut and frame a hole in the exterior wall as

illustrated to accommodate the fi restop assembly.

Dry fi t the fi restop assembly before proceeding to

ensure the brackets on the rear surface fi t to the

inside surface of the horizontal framing.

The length of the vent shield may be cut shorter

for combustible walls that are less than 8 1/2”

(215.9mm) thick but the vent shield must extend

the full depth of the combustible wall.

A. Apply a bead of caulking (not supplied) around the corner edge of

the inside surface of the fi restop assembly, fi t the fi restop

assembly to the hole and secure using the 4 screws (supplied in your

manual baggie).

!

WARNING

CAULKING

FIRESTOP

SPACER

23

EN

VENT

SHIELD

DETERMINE

THE

CORRECT

HEIGHT

FINISHING

MATERIAL

B. Once the vent pipe is installed in its fi nal position, apply high temperature sealant W573-0007 (not

supplied) between the pipe and the fi restop.

5.3 VERTICAL INSTALLATION

This application occurs when venting through a roof. Installation kits for

various roof pitches are available from your authorized dealer / distributor. See

accessories to order specifi c kits required.

A. Determine the air terminal location, cut and frame a square opening as

illustrated in the ceiling and the roof to provide the minimum 1“ (25mm)

clearance between the vent pipe and any combustible material. Try to center

the vent pipe location midway between two joists to prevent having to cut

them. Use a plumb bob to line up the center of the openings. A vent pipe

shield will prevent any materials such as insulation, from fi lling up the 1”

(25mm) air space around the pipe. Nail headers between the joist for

extra support.

B. Apply a bead of caulking (not supplied) to the framework or to the Wolf

Steel vent pipe shield plate or equivalent (in the case of a fi nished ceiling),

and secure over the opening in the ceiling. A fi restop must be placed on the

bottom of each framed opening in a roof or ceiling that the venting system passes

through. Apply a bead of caulking all around and place a fi restop spacer over

the vent shield to restrict cold air from being drawn into the room or around the

fi replace. Ensure that both spacer and shield maintain the required clearance to

combustibles. Once the vent pipe is installed in its fi nal position, apply sealant between the

pipe and the fi restop assembly.

C. In the attic, slide the vent pipe collar down to cover up the open end of the shield and

tighten. This will prevent any materials, such as insulation, from fi lling up the 1” (25mm) air

space around the pipe.

20.2A

FIRESTOP

UNDERSIDE OF

JOIST

VENT PIPE

SHIELD

SHIELD

CAULKING

VENT

PIPE

COLLAR

VENT

PIPE

21.1

W415-1132 / C / 08.20.13

24

5.4 USING FLEXIBLE VENT COMPONENTS

EN

!

WARNING

DO NOT ALLOW THE INNER FLEX PIPE TO BUNCH UP ON HORIZONTAL OR VERTICAL RUNS AND ELBOWS.

KEEP IT PULLED TIGHT.

SPACERS ARE ATTACHED TO THE INNER FLEX PIPE AT PREDETERMINED INTERVALS TO MAINTAIN AN EVEN

AIR GAP TO THE OUTER FLEX PIPE. THIS GAP IS REQUIRED FOR SAFE OPERATION. A SPACER IS REQUIRED

AT THE START, MIDDLE AND END OF EACH ELBOW TO ENSURE THIS GAP IS MAINTAINED. THESE SPACERS

MUST NOT BE REMOVED.

For safe and proper operation of the appliance, follow the venting

instructions exactly.

All inner fl ex pipe and outer fl ex pipe joints may be sealed using high

ELBOW

SPACERS

temperature sealant W573-0002 (not supplied) or the high temperature

sealant W573-0007 Mill Pac (not supplied). However, the high temperature

sealant W573-0007 Mill Pac (not supplied) must be used on the joint

connecting the inner fl ex pipe and the exhaust fl ue collar.

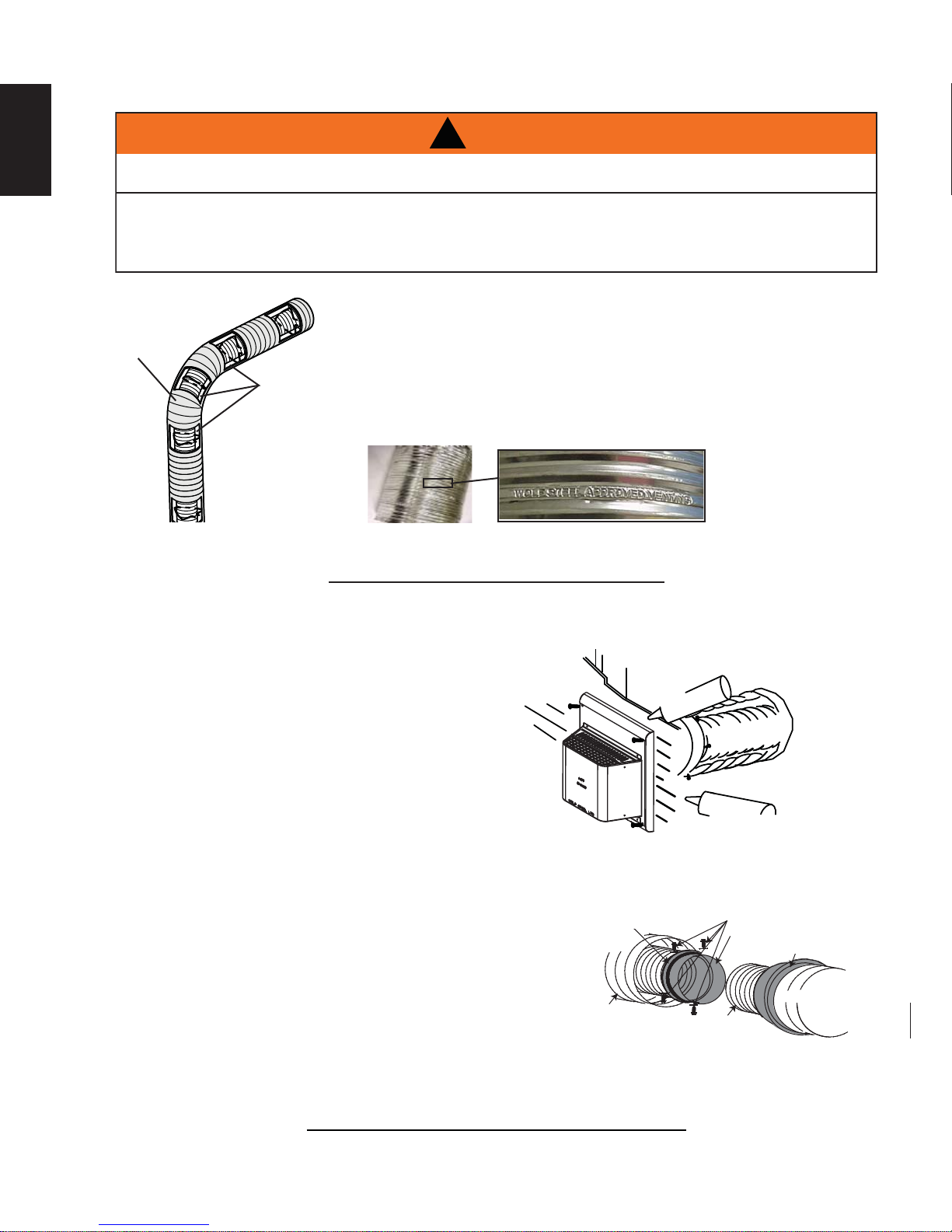

Use only approved fl exible vent pipe kits marked:

“Wolf Steel Approved Venting” as identifi ed

by the stamp only on the outer fl ex pipe.

22.1

5.4.1 HORIZONTAL AIR TERMINAL INSTALLATION

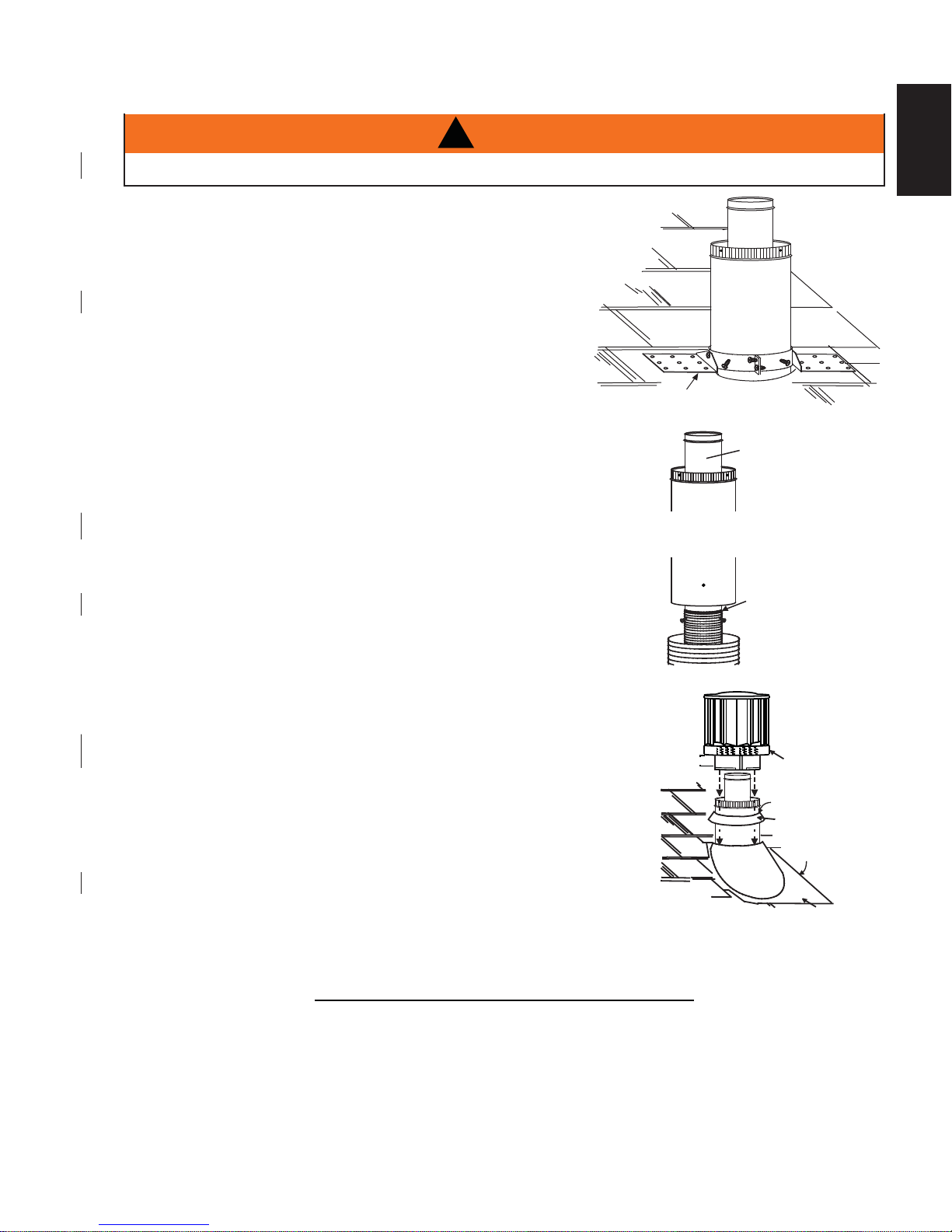

A. Stretch the inner fl ex pipe to the required length taking into

account the additional length needed for the fi nished wall

surface. Apply a heavy bead of the high temperature

sealant W573-0007 Mill Pac (not supplied) to the inner

sleeve of the air terminal. Slip the vent pipe a minimum

of 2” (50.8mm) over the inner sleeve of the air terminal

and secure with 3 #8 screws.

B. Using the outer fl ex pipe, slide over the outer combustion

air sleeve of the air terminal and secure with 3 #8 screws.

Seal using high temperature sealant W573-0002 (not

supplied).

C. Insert the vent pipes through the fi restop maintaining the required

clearance to combustibles. Holding the air terminal (lettering in

an upright, readable position), secure to the exterior wall and

make weather tight by sealing with caulking (not supplied).

D. If more vent pipe needs to be used to reach the fi replace, couple

them together as illustrated. The vent system must be

supported approximately every 3 feet (0.9m) for both vertical

and horizontal runs. Use noncombustible strapping to

maintain the minimum clearance to combustibles.

#10x2"

SCREWS

HI-TEMP

SEALANT

OUTER

FLEX PIPE

CAULKING

INNER FLEX

PIPE

2" (50.8mm) OVERLAP

HIGH TEMPERATURE

#8 X 1/2” SELF DRILLING

SCREWS & WASHERS

INNER

FLEX PIPE

OUTER FLEX PIPE

SEALANT

INNER COUPLER

OUTER COUPLER

OUTER

FLEX PIPE

The air terminal mounting plate may be recessed into the exterior wall or siding no greater than the depth

of its return fl ange.

W415-1132 / C / 08.20.13

23.1B

5.4.2 VERTICAL AIR TERMINAL INSTALLATION

25

!

WARNING

MAINTAIN A MINIMUM 2” (50.8mm) SPACE BETWEEN THE AIR INLET BASE AND THE STORM COLLAR.

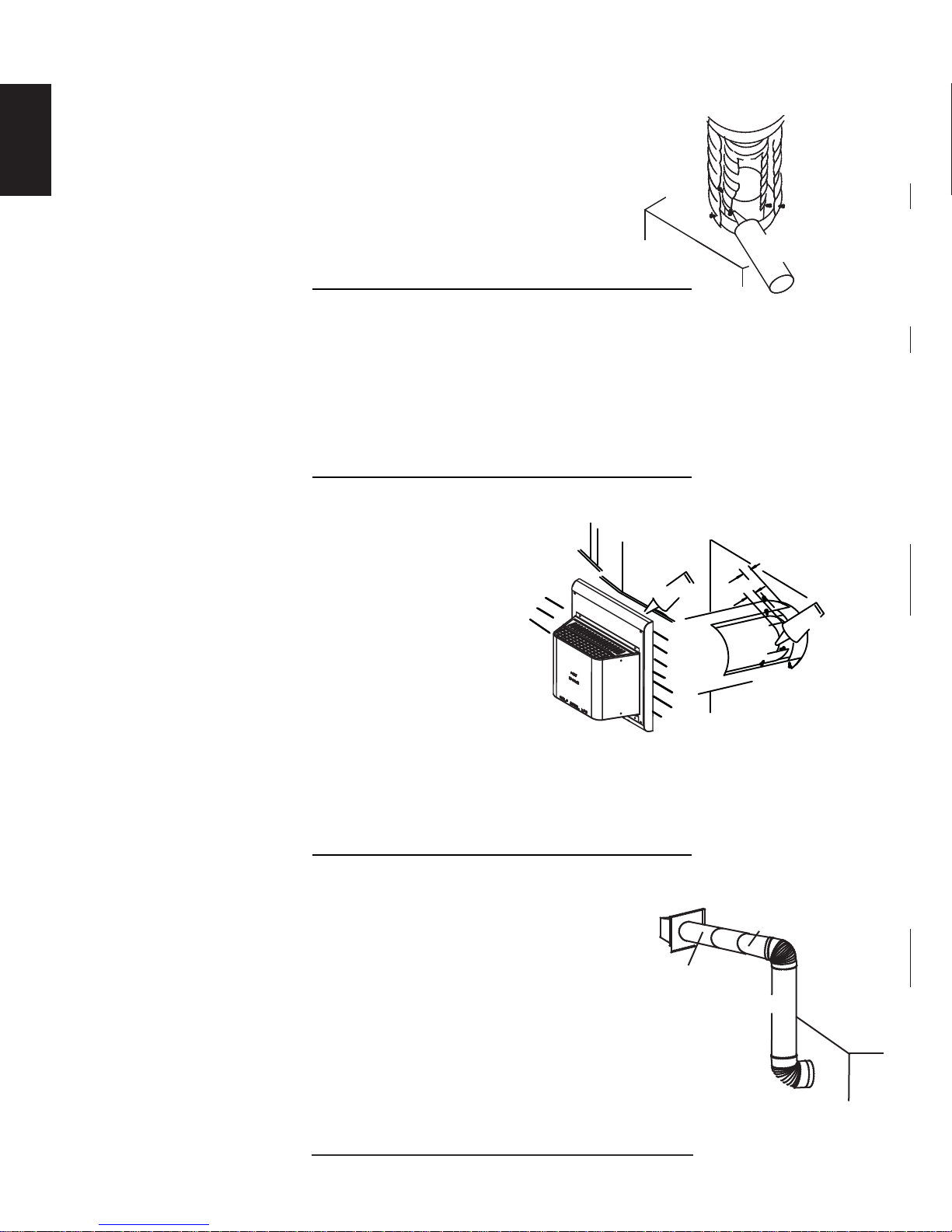

A. Fasten the roof support to the roof using the screws provided. The

roof support is optional. In this case the venting is to be adequately

supported using either an alternate method suitable to the authority

having jurisdiction or the optional roof support.

B. Stretch the inner fl ex pipe to the required length. Slip the

inner fl ex pipe a minimum of 2” (51mm) over the inner pipe

of the air terminal connector and secure with 3 #8 screws.

Seal using a heavy bead of high temperature sealant

W573-0007 (not supplied).

C. Repeat using the outer fl ex pipe, using a heavy bead of

high temperature sealant W573-0002 (not supplied).

D. Thread the air terminal connector / vent pipe assembly down through

the roof. The air terminal must be positioned vertically and plumb.

Attach the air terminal connector to the roof support, ensuring that the

top of the air terminal is 16” (406mm) above the highest point that it

penetrates the roof.

E. Remove nails from the shingles, above and to the sides of the air

terminal connector. Place the fl ashing over the air terminal connector

leaving a min. 3/4” (19mm) of the air terminal connector showing

above the top of the fl ashing. Slide the fl ashing underneath the

sides and upper edge of the shingles. Ensure that the air terminal

connector is properly centred within the fl ashing, giving a 3/4”

(19mm) margin all around. Fasten to the roof. Do not nail through

the lower portion of the fl ashing. Make weather-tight by sealing with

caulking. Where possible, cover the sides and top edges of the

fl ashing with roofi ng material.

F. Aligning the seams of the terminal and air terminal connector,

place the terminal over the air terminal connector making sure

the vent pipe goes into the hole in the terminal. Secure with the

three screws provided.

G. Apply a heavy bead of weatherproof caulking 2” (51mm) above

the fl ashing. Install the storm collar around the air terminal and

slide down to the caulking. Tighten to ensure that a weathertight seal between the air terminal and the collar is achieved.

ROOF SUPPORT

AIR

TERMINAL

CONNECTOR

2”

(50.8mm)

INNER PIPE

HIGH

TEMPERATURE

SEALANT

INNER FLEX PIPE

OUTER FLEX PIPE

AIR I NL ET

BASE

CAULKING

STORM COLLAR

WEA THER

SEALANT

FLASHING

EN

H. If more vent pipe needs to be used to reach the appliance see “HORIZONTAL

AIR TERMINAL INSTALLATION” section.

24.1A

W415-1132 / C / 08.20.13

26

A

5.4.3 APPLIANCE VENT CONNECTION

A. Install the inner fl ex pipe to the appliance. Secure with 3 screws

EN

and fl at washers. Seal the joint and screw holes using the high

temperature sealant W573-0007 (not supplied).

B. Install the outer fl ex pipe to the appliance. Attach and seal

the joints using the high temperature sealant W573-0002 (not

supplied).

5.5 USING RIGID VENT COMPONENTS

The vent system must be supported approximately every 3 feet (0.9m) for both vertical and horizontal runs.

Use Wolf Steel Ltd. support ring assembly or equivalent noncombustible strapping to maintain the minimum

clearance to combustibles for both vertical and horizontal runs.

ll inner exhaust and outer intake vent pipe joints may be sealed using either red high temperature silicone

sealant W573-0002 (not supplied) or black high temperature sealant W573-0007 Mill Pac (not supplied) with

the exception of the appliance exhaust fl ue collar which must be sealed using Mill Pac.

5.5.1 HORIZONTAL AIR TERMINAL INSTALLATION

A. Move the appliance into position. Measure the

vent length required between terminal and

appliance taking into account the additional

length needed for the fi nished wall surface

and any 1¼” (31.8mm) overlaps between

venting components.

B. Apply high temperature sealant W573-0007 (not

supplied) to the outer edge of the inner collar of the

appliance. Attach the fi rst inner rigid pipe component

and secure using 3 self tapping screws. Repeat

using the outer rigid pipe.

#10x2"

SCREWS

#8 X 1/2”

SELF

DRILLING

SCREWS

CAULKING

OUTER

RIGID

PIPE

HIGH TEMP

SEALANT

28.1

25.1A

1" (25.4mm)

INNER

RIGID

PIPE

#8x1/2"

SELF DRILLING

SCREWS

2” (50.8mm)

OVERLAP

OVERLAP

HI-TEMP

SEALANT

C. Insert the vent pipes through the fi restop maintaining the required clearance to combustibles. Holding

the air terminal (lettering in an upright, readable position), secure to the exterior wall and make

weather tight by sealing with caulking (not supplied).

The air terminal mounting plate may be recessed into the exterior wall or siding no greater than the

depth of the return fl ange.

26.1A

5.5.2 EXTENDED HORIZONTAL AND CORNER TERMINAL INSTALLATION

A 45° corner installation can have 0” (0mm) rise between the appliance

combustion air collar and the air terminal. In this case, vent lengths must be

kept to a maximum of 24” (609.6mm) . For longer vent lengths, a minimum

vertical rise of 24” (609.6mm) is required.

A. Follow the instructions for "HORIZONTAL AIR TERMINAL

INSTALLATION" section.

B. Continue adding components alternating inner and outer vent pipes. Ensure that

all inner vent pipes and elbows have sufficient vent spacers attached and each

component is securely fastened to the one prior. Attach the telescopic sleeve to the

vent run. Secure and seal. To facilitate completion, attach inner and outer couplers to

the air terminal.

C. Install the air terminal. See “HORIZONTAL AIR TERMINAL INSTALLATION” section. Extend the outer

telescopic sleeve; connect to the air terminal assembly. Fasten with self tapping screws and seal.

W415-1132 / C / 08.20.13

AIR TERMINAL

20" (508mm)

COUPLER

48.2A

TELESCOPIC SLEEVE

VENTING

5.5.3 VERTICAL AIR TERMINAL INSTALLATION

27

NOTE: Before attaching elbows to the collars on the back of the appliance, 1 1/2” (38.1mm) will need to

be trimmed off the 4” (101.6mm) collar.

REAR VENT APPLICATION: Attach 4” (101.6mm) and 7” (177.8mm) elbows to the appliance. Secure with 3

screws and seal the joints and screw heads using high temperature sealant.

Proceed to step A below.

TOP VENT APPLICATION:

A. Move the appliance into position.

B. Fasten the roof support to the roof using the screws provided. The

roof support is optional. In this case the venting is to be adequately

supported using either an alternate method suitable to the authority

having jurisdiction or the optional roof support.

C. Apply high temperature sealant W573-0007 (not supplied) to the

outer edge of the inner sleeve of the air terminal. Slip the inner

coupler a minimum of 2” (50.8mm) over the sleeve and secure using

3 screws.

D. Apply high temperature sealant W573-0002 (not supplied) to the

outer edge of the of the outside sleeve of the air terminal connector.

Slip the outer coupler over the sleeve and secure as before. Trim the

outer coupler even with the inner coupler end.

E. Thread the air terminal connector / vent pipe assembly down through

the roof support and attach, ensuring that a minimum 16” (406.4mm)

of air terminal connector will penetrate the roof when fastened. If

the attic space is tight, we recommend threading the Wolf Steel vent

pipe collar or equivalent loosely onto the air terminal connector / vent pipe

assembly as it is passed through the attic. The air terminal connector must be

positioned vertically and plumb.

F. Remove nails from the shingles, above and to the sides of the air terminal

connector. Place the fl ashing over the air terminal connector and slide it

underneath the sides and upper edge of the shingles. Ensure that the air

terminal connector is properly centered within the fl ashing, giving a 3/4”

(19.1mm) margin all around. Fasten to the roof. Do NOT nail through the

lower portion of the fl ashing. Make weather-tight by sealing with caulking.

Where possible, cover the sides and top edges of the fl ashing with roofi ng material.

G. Apply a heavy bead of waterproof caulking 2” (50.8mm) above the fl ashing. Install the storm collar

around the air terminal and slide down to the caulking. Tighten to ensure that a weather-tight seal

between the air terminal connector and the collar is achieved.

H. Continue adding rigid venting sections, sealing and securing as above. Attach the inner collapsed

telescopic sleeve to the last section of rigid piping. Secure with screws and seal. Repeat using the

outer telescopic sleeve.

REAR VENT APPLICATION:

I. Run a bead of high temperature sealant W573-0007 (not supplied) around the outside of the inner

elbow. Pull the telescopic sleeve a minimum of 2” (50.8mm) onto the elbow. Secure with 3 screws.

Repeat with the outer telescopic sleeve.

TOP VENT APPLICATION:

J. Run a bead of high temperature sealant W573-0007 (not supplied) around the outside of the inner

collar on the appliance. Pull the telescopic sleeve a minimum of 2” (50.8mm) onto the collar. Secure

with 3 screws. Repeat with the outer telescopic sleeve.

K. In the attic, slide the vent pipe collar down to cover up the open end of the shield and tighten. This will

prevent any materials, such as insulation, from fi lling up the 1” (25.4mm) air space around the pipe

AIR

TERMINAL

CONNECTOR

27.1A

INNER PIPE

HIGH

TEMPERATURE

SEALANT

INNER RIGID

PIPE

OUTER

RIGID PIPE

VENT

PIPE

COLLAR

VENT

PIPE

SHIELD

EN

W415-1132 / C / 08.20.13

28

AIR

INTAKE

EXHAUST

FLUE

FLEX

LINER

* 40 FT (12.2m)

MAX.

10 FT (3.1m)

MIN

COAXIAL TO

CO-LINEAR

ADAPATER

APPLIANCE

VENT ADAPTOR

TERMINATION

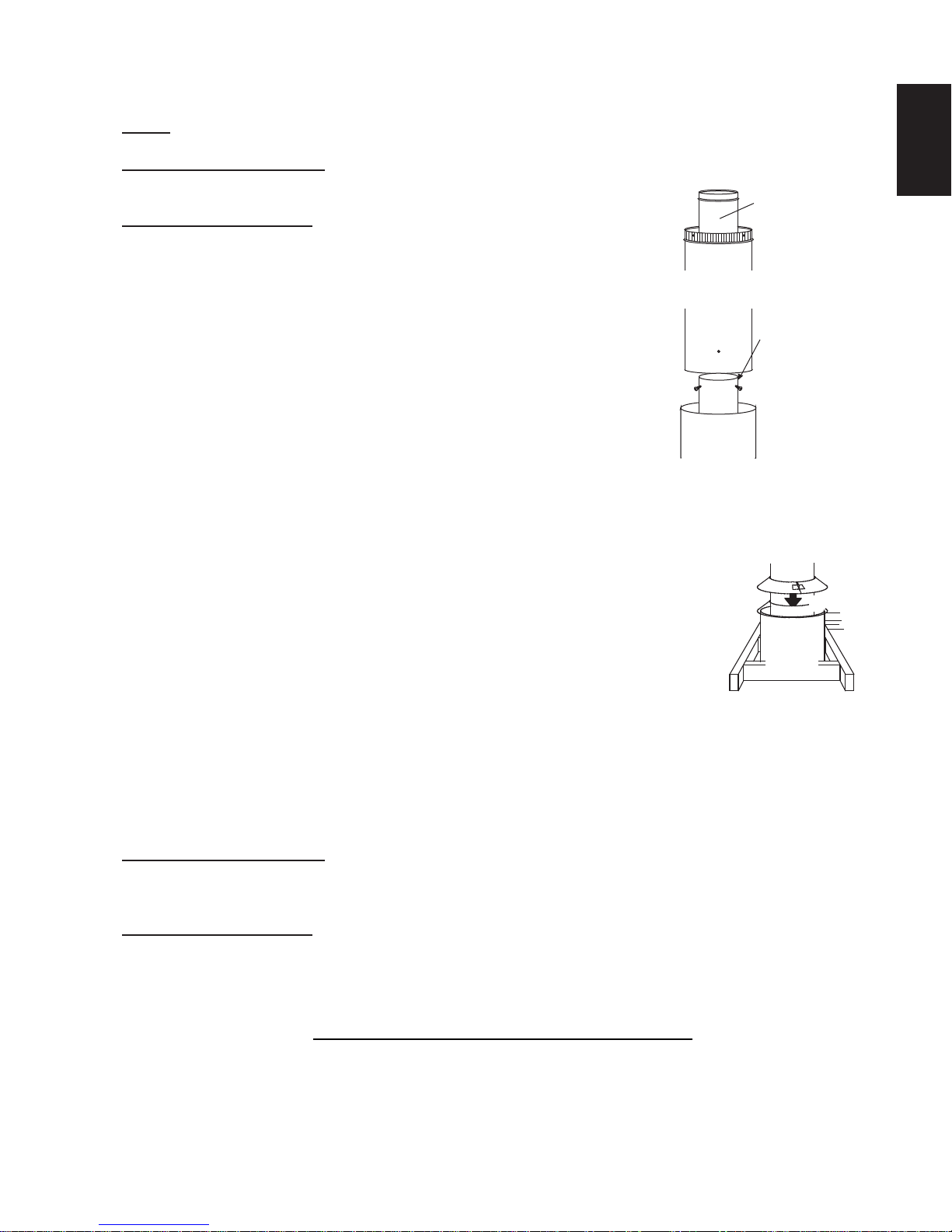

5.6 VERTICAL THROUGH EXISTING CHIMNEY

EN

!

WARNING

RISK OF FIRE!

CO-AXIAL TO CO-LINEAR VENTING CONFIGURATIONS MUST ONLY BE USED IN A NON-

COMBUSTIBLE CHIMNEY OR ENCLOSURE. INSTALLATION IN A COMBUSTIBLE ENCLOSURE COULD

RESULT IN A FIRE.

This appliance is designed to be attached to a 3” (76.2mm) co-linear aluminum fl ex vent system running the

full length of a masonry chimney.

The fl ex liners accommodate any contours of a

masonry chimney, however, it is necessary to keep

the fl exible liners as straight as possible. The inlet air

collar of the termination cap must be connected to

the air intake fl ex liner and the exhaust collar must be

connected to the exhaust fl exible liner.

Both Simpson Duravent and Selkirk co-linear to

co-axial adaptors have been approved on this

appliance (NOTE: A vent adaptor will be required

directly off the appliance).

Follow vent manufacturer’s installation instructions.

Different manufacturer’s venting components must

not be combined. Once the preferred manufacturer’s

appliance adaptor has been attached, the

remainder of the system must be that of the

same manufacturer.

The only exception to this rule is to use Wolf

Steel’s approved 3” (76.2mm) fl ex liner and

co-linear termination.

* Measured from appliance fl ue collar to

termination fl ue collar

7.6A

W415-1132 / C / 08.20.13

5.7 MOBILE HOME INSTALLATION

A

29

This appliance is also certifi ed to be installed as an OEM (Original Equipment Manufacturer) installation

in a manufactured home (U.S. only) or mobile home and must be installed in accordance with the

manufacturer’s instructions and the Manufactured Home Construction and Safety Standard, Title 24 CFR,

Part 3280, in the United States or the Mobile Home Standard, CAN/CSA Z240 MH Series, in Canada. This

appliance is only for use with the type(s) of gas indicated on the rating plate.

This Mobile/Manufactured Home Listed appliance comes factory equipped with a means to secure the unit. Built

in appliances are equipped with 1/4” (6.4mm) diameter holes located in the front left and right corners of the

base. Use #10 hex head screws, inserted through the holes in the base to secure. For free standing products

contact your local authorized dealer / distributor for the appropriate securing kit. For mobile home installations, the

appliance must be fastened in place. It is recommended that the appliance be secured in all installations. Always

turn off the pilot and the fuel supply at the source, prior to moving the mobile home. After moving the mobile home

and prior to lighting the appliance, ensure that the logs are positioned correctly.

This appliance is certifi ed to be installed in an aftermarket permanently located, manufactured (mobile)

home, where not prohibited by local codes.

This appliance is only for use with the type of gas indicated on the rating plate. This appliance is not

convertible for use with other gases, unless a certifi ed kit is used.

conversion kit is supplied with the mobile home appliance.

Conversion Kits

This appliance is fi eld convertible between Natural Gas (NG) and Propane (LP).

To convert from one gas to another consult your Authorized dealer/distributor.

5.8 GAS INSTALLATION

EN

29.1A

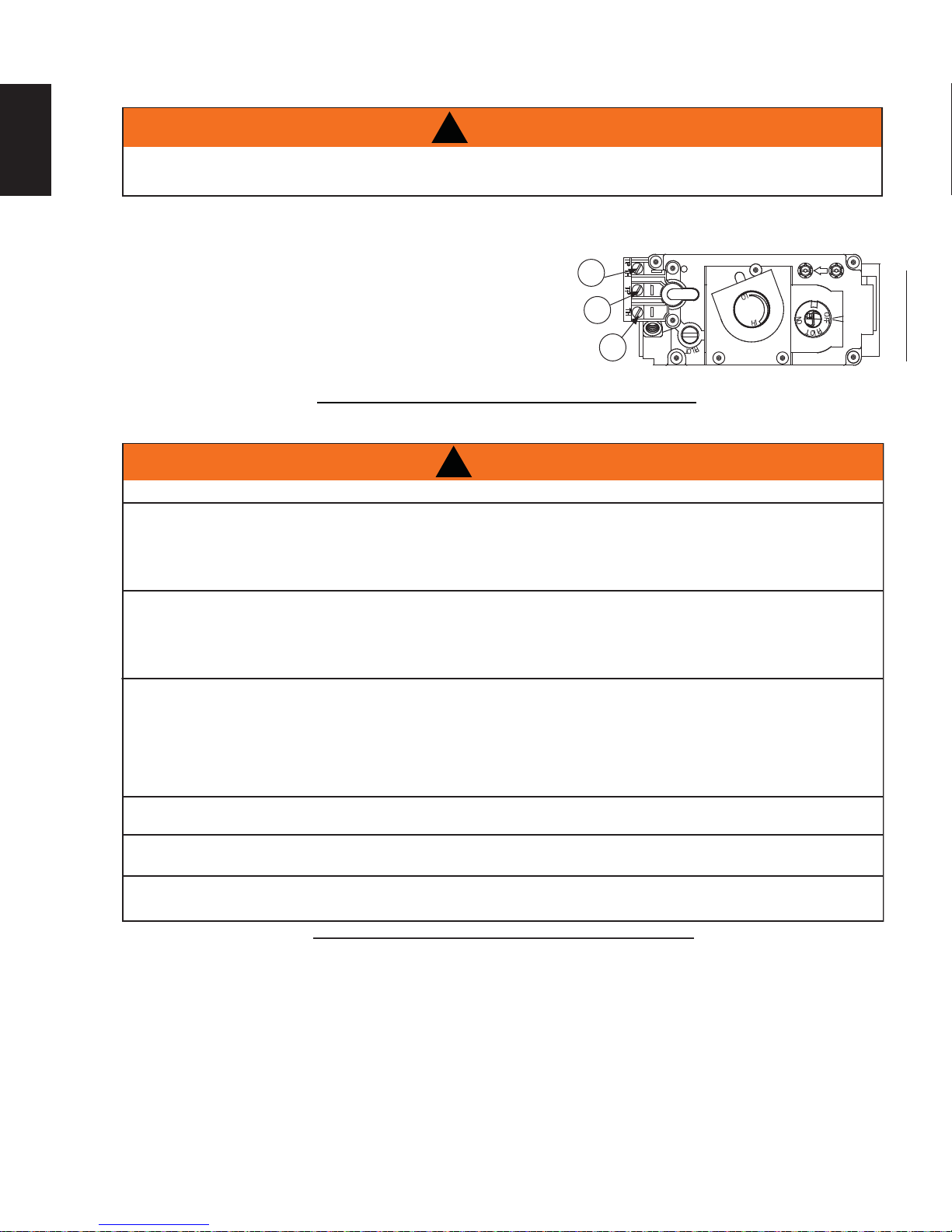

!

WARNING

RISK OF FIRE, EXPLOSION OR ASPHYXIATION. ENSURE THERE ARE NO IGNITION SOURCES SUCH AS

SUPPORT GAS CONTROL WHEN ATTACHING GAS SUPPLY PIPE TO PREVENT DAMAGING GAS LINE.

ALWAYS LIGHT THE PILOT WHETHER FOR THE FIRST TIME OR IF THE GAS SUPPLY HAS RUN OUT

WITH THE GLASS DOOR OPENED OR REMOVED. PURGING OF THE GAS SUPPLY LINE SHOULD BE

PERFORMED BY A QUALIFIED SERVICE TECHNICIAN. ASSURE THAT A CONTINUOUS GAS FLOW IS AT

THE BURNER BEFORE CLOSING THE DOOR. ENSURE ADEQUATE VENTILATION. FOR GAS AND

ELECTRICAL LOCATIONS, SEE “DIMENSION” SECTION.

ALL GAS CONNECTIONS MUST BE CONTAINED WITHIN THE APPLIANCE WHEN COMPLETE.

HIGH PRESSURE WILL DAMAGE VALVE. DISCONNECT GAS SUPPLY PIPING BEFORE TESTING GAS

LINE AT TEST PRESSURES ABOVE 1/2 PSIG.

VALVE SETTINGS HAVE BEEN FACTORY SET, DO NOT CHANGE.

Installation and servicing to be done by a qualifi ed installer. Do not use open fl ame.

• Move the appliance into position and secure.

• If equipped with a fl ex connector the appliance is designed to accept a 1/2” (12.7mm) gas supply.