Page 1

INSTALLER: LEAVE THESE INSTRUCTIONS WITH THE APPLIANCE THIS TERMINAL IS SERVING.

CONSUMER: RETAIN THESE INSTRUCTIONS FOR FUTURE REFERENCE.

THESE INSTRUCTIONS ARE TO BE USED IN CONJUNCTION WITH THE APPLIANCE AND PVA INSTRUCTIONS.

INSTALLATION

INSTRUCTIONS

1

CERTIFIED UNDER CANADIAN AND AMERICAN NATIONAL STANDARDS: ANSI Z21.88 CSA 2.33 FOR VENTED GAS FIREPLACE HEATERS

AND ANSI Z21. CSA 2.22 FOR VENTED GAS FIREPLACES.

GAS POWER VENT

The GPV is a Direct Vent Terminal

(GPV)

GENERAL INFORMATION

These Installation Instructions must be used in conjunction

with the appliance and appropriate PVA adapter kit Installation

Instructions. Clearances listed in these Instructions supersede

those in the appliance's Installation Instructions.

Power venting of direct vent appliances may result in the

reduction of efficiencies by as much as ten percent. Consider

this in making any venting and heating decisions in any

installation application.

SELECTING AND INSTALLING THE APPLIANCE

When selecting a gas appliance for use with the GPV, take into

consideration the various requirements and limitations in the

venting installation section for the following models:

Models Equipped with an Intermittent Pilot Ignition (I.P.I.)

It is recommended that the GPV be used with a gas appliance

equipped with an Intermittent Pilot Ignition (I.P.I.). Downward

vertical vent runs are permitted with an I.P.I. system. See

venting section in appropriate PVA Installation Instructions.

Models Equipped with Millivolt/ Standing Pilot

Downward vertical vent runs are not permitted with a standing

pilot system. See venting section in appropriate PVA Installation

Instructions.

INSTALLATION TO BE DONE BY A QUALIFIED INSTALLER

to conform with local codes. In absence of local codes install

to the current National Building Code in Canada or to regional

building codes in the United States. It must be electrically

connected and grounded in accordance with local codes. In

the absence of local codes, use the current CSA C22.1

CANADIAN ELECTRICAL CODE in Canada or the ANSI/NFPA

70 NATIONAL ELECTRIC CODE in the United States.

The GPV operates on 120 VAC 60 HZ electrical service which is

supplied at the firebox junction box.

designed to allow installation of

gas appliances where typical vent

configurations cannot be achieved.

Wolf Steel Ltd., 24 Napoleon Rd., Barrie, ON, L4M 4Y8 Canada /

103 Miller Drive, Crittenden, Kentucky, USA, 41030

0211212 fa[022031 ZZZ.napoleonfireplaceV.coP aVk#napoleon.on.ca

ZZZ.continentalfireplaceV.coP aVk#continentalfire.on.ca

$10.00

CERTIFIED

W415-0682 / D / 02.06.12

Page 2

2

TABLE OF CONTENTS

1.0 VENTING 2

1.1 INSTALLATION OVERVIEW 3

1.2 VENT TERMINAL CLEARANCES 4

1.3 VENT LENGTHS 5

1.4 POWER VENT TERMINAL 5

1.4.1 TERMINAL INSTALLATION 5

1.4.2 POWER VENT INSTALLATION 6

1.4.3 INITIAL FIRING PROCEDURES 6

1.4.4 ELECTRICAL CONNECTION 7

1.4.5 HARD WIRING CONNECTION 7

1.4.6 RECEPTACLE WIRING DIAGRAM 7

1.4.7 ELECTRICAL BOX INSTALLATION 8

1.5 RESTRICTOR PLATE INSTALLATION 9

1.6 WIRING DIAGRAM AND INSTALLATION 9

1.6.1 SIT IPI 885 PROFLAME COMPLETE WITH GPV POWER VENT TERMINAL 9

1.6.2 SIT MILLIVOLT 820 NOVA COMPLETE WITH GPV POWER VENT TERMINAL 11

1.6.3 SIT IPI 880/886 PROFLAME COMPLETE WITH GPV POWER VENT TERMINAL 12

1.6.4 DEXEN IPI 6003-3V COMPLETE WITH GPV POWER VENT TERMINAL 13

1.6.5 SIT REMOTE CONTROLLED MILLIVOLT SYSTEM COMPLETE WITH GPV POWER VENT TERMINAL 14

2.0 ADJUSTMENTS 15

2.1 VENTURI ADJUSTMENTS 15

3.0 REPLACEMENTS 15

4.0 TROUBLESHOOTING 16

NOTE: Changes, other than editorial, are denoted by a vertical line in the margin.

1.0 VENTING

There are specifi c adaptors and venting requirements for each appliance, refer to your power vent adaptor

leafl et for more information.

For complete installation instructions refer to the following web sites:

Manufacturer Website

Napoleon - English http://www.napoleonfi replaces.com/Tech/installation_manuals/installations.html

Napoleon - French http://www.napoleonfoyers.com/Fireplaces/powervent.html

Continental http://www.continentalfi replaces.com/fi replaces/gas/powervent.html

W415-0682 / D / 02.06.12

Page 3

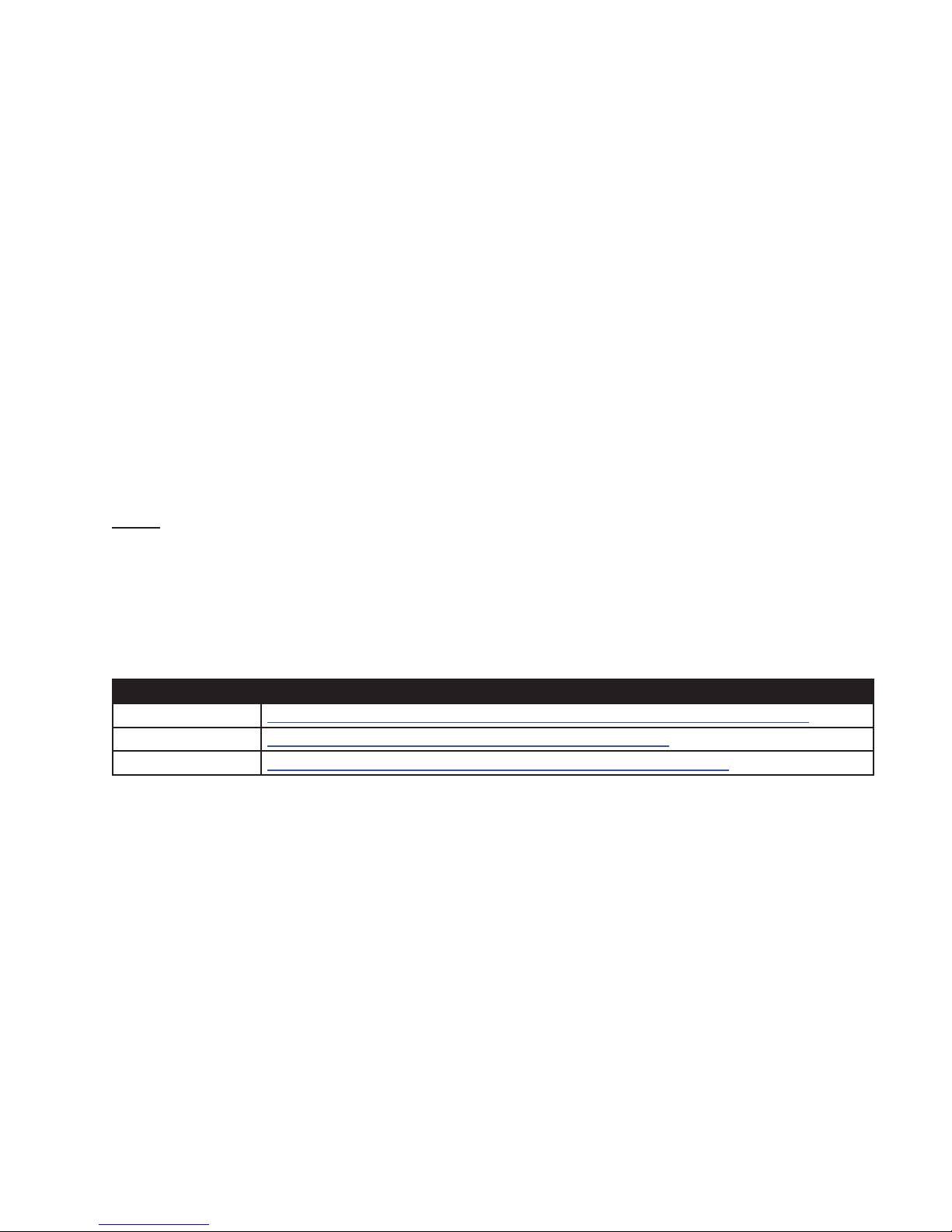

1.1 INSTALLATION OVERVIEW

Reducer, refer to

power vent

adapter kit (PVA)

A typical vent

configuration

for specific venting instructions

where applicable.

LHD50 Illustrated

3

Electrical Box

(velcro to base)

Firestop

Spacer

Gas Power

Vent Terminal

Frame Assembly

Terminal

Access

Cover

W415-0682 / D / 02.06.12

Page 4

4

1.2 VENT TERMINAL CLEARANCES

COVERED BALCONY APPLICATIONS ††*

Q

S

R

G

P

Q

R

INSTALLATIONS

CANADA U.S.A.

A 12” 12” Clearance above grade, veranda porch, deck or balcony.

B 12”

C 12” * 12” * Clearance to permanently closed windows.

D 18” ** 18” **

E 12” ** 12” ** Clearance to unventilated soffi t.

F 0” 0” Clearance to an outside corner wall.

G

H 3’ 3’ ***

I 3’ 3’ *** Clearance to a service regulator vent outlet.

J 12” 9” Clearance to a non-mechanical air supply inlet to the building or a combustion air inlet to any other appliance.

K 6’ 3’ Clearance to a mechanical air supply inlet.

L 7’ ‡ 7’ *** Clearance above a paved sidewalk or paved driveway located on public property.

M 12” †† 12” *** Clearance under a veranda, porch or deck.

N 12” 12” Clearance above the roof.

O 2’ †* 2’ †* Clearance from an adjacent wall including neighbouring buildings.

P 8’ 8’ Roof must be non-combustible without openings.

Q 3’ 3’ See chart for wider wall dimensions.

R 6’ 6’

S 12” 12” Clearance under a covered balcony

Δ

* Recommended to prevent condensation on windows and thermal breakage

** It is recommended to maximize the distance to vinyl clad soffi ts.

*** This is a recommended distance. For additional requirements check local codes.

‡ A vent shall not terminate where it may cause hazardous frost or ice accumulations on adjacent property surfaces..

†† Permitted only if the veranda, porch, or deck is fully open on a minimum of two sides beneath the fl oor.

†* Recommended to prevent recirculation of exhaust products. For additional requirements check local codes.

††* Permitted only if the balcony is fully open on a minimum of one side.

Δ

0” 0” Clearance to an inside non-combustible corner wall or protruding non-combustible obstructions (chimney, etc.).

2” 2” Clearance to an inside combustible corner wall or protruding combustible obstructions (vent chase, etc.).

The terminal shall not be located less than 6 feet under a window that opens on a horizontal plane in a structure with three walls and a roof.

9”

Δ

Clearance to windows or doors that open.

Vertical clearance to ventilated soffi ts located above the terminal within a horizontal distance of 2’ from

the center line of the terminal.

Clearance to each side of the center line extended above the meter / regulator assembly to a maximum

vertical distance of 15’.

See chart for deeper wall dimensions. The terminal shall not be installed on any wall that has an opening between the terminal and the open side of the structure.

R

MIN

MAX

MAX

= 3 feet

= 2 x

Q

feet

12.2C

ACTUAL

W415-0682 / D / 02.06.12

Page 5

1.3 VENT LENGTHS

DETERMINE

THE

CORRECT

HEIGHT

REFER TO POWER VENT ADAPTER KIT (PVA) FOR SPECIFIC VENTING INSTRUCTIONS.

NOTE: If equipped, ACS switch must be disabled if there is any downward venting. Downward venting is not

allowed with appliances that use standing pilots.

1.4 POWER VENT TERMINAL

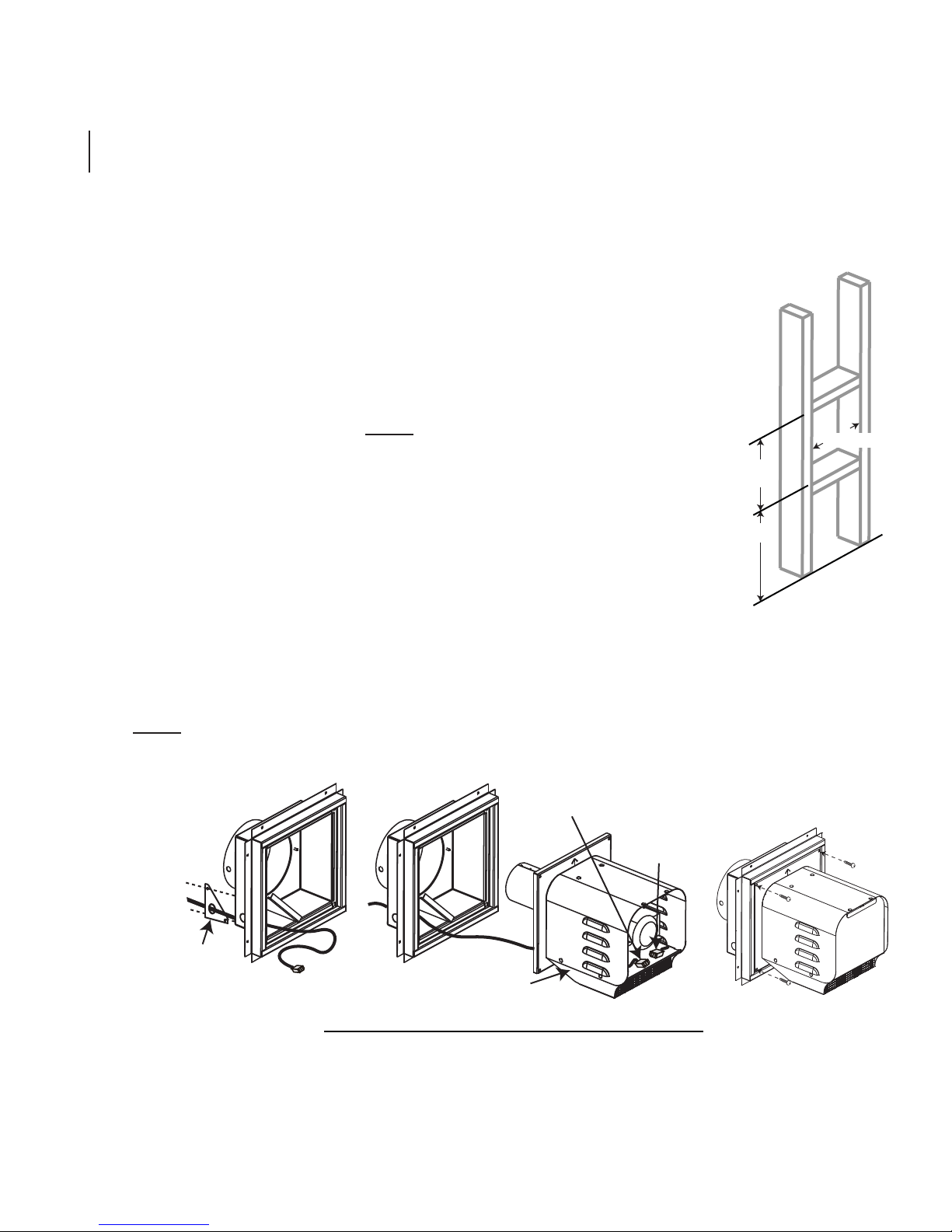

1.4.1 TERMINAL INSTALLATION

This application occurs when venting through an exterior wall. Having determined the correct

height for the terminal location, cut and frame a hole in the exterior wall as illustrated to accommodate the GPV.

A. Remove the electrical access plate from the frame assembly, then remove the

knock out from this plate.

B. Insert the wiring through the electrical access plate and engage the conduit bush-

ing. Re-secure this plate. NOTE: The GPV includes a 20 foot wire

harness cable. If this cable does not reach the appliance, then it

may be cut and a splice added. These connections must conform

with local codes or, in the absence of local codes, use the current CSA

C22.1 Canadian Electrical Code in Canada or the ANSI/NFPA 70

National Electrical Code in the United States.

5

10 1/4”

11 1/4”

C. Remove terminal access cover, see “INSTALLATION OVERVIEW” for

location and route cable through terminal.

D. Assemble gas power vent terminal to frame assembly.

E. Connect the male and female connectors.

F. Replace terminal access cover.

NOTE: Where possible, it is strongly recommended to have an access panel inside the building for

servicing the unit.

MALE MOLEX

ELECTRICAL

ACCESS PLATE

CONNECTOR

TERMINAL

FEMALE

MOLEX

CONNECTOR

20.4

W415-0682 / D / 02.06.12

Page 6

6

1.4.2 POWER VENT INSTALLATION

A. Stretch the inner fl ex pipe to the required length taking

into account the additional length needed for the fi n-

ished wall surface. Slip the vent pipe a minimum of 3”

over the inner sleeve of the terminal and secure with 3

#8 screws. Apply a heavy bead of the high temperature

sealant W573-0007 Mill Pac (not supplied).

B. Using the outer fl ex pipe, slide over the outer combus-

tion air sleeve of the terminal and secure with 3 #8

screws. Seal using high temperature sealant W5730002 (not supplied).

CAULKING

TERMINAL

FIRESTOP

SPACER

C.

D. Route venting through framed opening and fi restop spacer to the

E. The terminal mounting plate may be recessed into the exterior

F. If more vent pipe needs to be used to reach the appliance, couple

G. Install the reducer (if required) or vent and properly secure and

Apply a bead of caulking (not supplied) to the framed

opening and secure the terminal. Ensure the arrows

stamped into the frame assembly are pointing upwards.

NOTE: For fi restop spacer installation instructions,

see PVA kit or the appliance Installation Manual.

appliance.

wall or siding no greater than the depth of its return fl ange.

them together as illustrated. The vent system must be supported

approximately every 3 feet for both vertical and horizontal runs.

Use noncombustible strapping to maintain the minimum clearance

to combustibles.

seal to the unit using high temperature sealant

W573-0007 Mill Pac (not supplied).

HI-TEMP

SEALANT

#10 X 2”

SCREWS

HIGH

TEMPERATURE

SEALANT

RETURN

FLANGE

#8 X 1/2” SELF DRILLING

SCREWS & WASHERS

INNER COUPLER

OUTER COUPLER

1.4.3 INITIAL FIRING PROCEDURES

ALWAYS LIGHT THE PILOT WHETHER FOR THE FIRST TIME OR IF THE GAS SUPPLY HAS RUN OUT

WITH THE GLASS DOOR OPENED OR REMOVED. PURGE SHOULD BE PERFORMED BY A QUALI-

FIED SERVICE TECHNICIAN. ASSURE THAT A CONTINUOUS GAS FLOW IS AT THE BURNER BE-

FORE CLOSING THE DOOR. ENSURE ADEQUATE VENTILATION.

In some instances the system may not light pilot/burner with the door open/removed. Partially blocking the

exhaust fl ue collar will allow the safety pressure switch to activate and allow gas fl ow to the pilot during the

initial test fi ring.

W415-0682 / D / 02.06.12

OUTER

FLEX PIPE

!

WARNING

OUTER

FLEX PIPE

INNER

FLEX PIPE

23.6

Page 7

1.4.4 ELECTRICAL CONNECTION

DO NOT USE THIS APPLIANCE IF ANY PART HAS BEEN UNDER WATER. CALL A QUALIFIED

SERVICE TECHNICIAN IMMEDIATELY TO HAVE THE APPLIANCE INSPECTED FOR DAMAGE TO THE

RISK OF ELECTRICAL SHOCK OR EXPLOSION. DO NOT WIRE 110V TO THE VALVE OR TO THE

APPLIANCE WALL SWITCH. INCORRECT WIRING WILL DAMAGE CONTROLS.

ALL WIRING SHOULD BE DONE BY A QUALIFIED ELECTRICIAN AND SHALL BE IN COMPLIANCE

WITH LOCAL CODES. IN THE ABSENCE OF LOCAL CODES, USE THE CURRENT CSA22.1 CANADIAN

ELECTRIC CODE IN CANADA OR THE CURRENT NATIONAL ELECTRIC CODE ANSI/NFPA NO. 70 IN

ALWAYS LIGHT THE PILOT WHETHER FOR THE FIRST TIME OR IF THE GAS SUPPLY HAS RAN OUT,

WITH THE GLASS DOOR OPENED OR REMOVED.

1.4.5 HARD WIRING CONNECTION

It is necessary to hard wire this appliance.

Permanently framing the appliance with an enclosure, requires the appliance junction box to be hard wired.

This appliance must be electrically connected and grounded in accordance with local codes. In the absence

of local codes, use the current CSA C22.1 Canadian electrical code in Canada or the ANSI/NFPA 70-1996

national electrical code in the United States.

!

WARNING

ELECTRICAL CIRCUIT.

THE UNITED STATES.

7

69.2

1.4.6 RECEPTACLE WIRING DIAGRAM

ELECTRICAL BOX

(BLACK)

3 PRONG

RECEPTACLE

(WHITE)

GROUND

(GREEN)

WIRE

NUTS

L1 (BLACK)

GROUND

(GREEN)

L2 (WHITE)

CABLE

CONNECTOR

SCREW

ELECTRICAL

BOX COVER

W415-0682 / D / 02.06.12

Page 8

8

1.4.7 ELECTRICAL BOX INSTALLATION

NOTE: Before fi nishing in the appliance, the power vent must be installed.

POWER VENT

CONTROL

MODULE

LHD50 ILLUSTRATED

BX SNAP

BUSHING

20’ POWER

VENT CABLE

CONTROL MODULE

A. Start by removing the pre-fi nishing access panel or opening lower louvre.

B. Position the Power Vent Control Module in a convenient location (not on top of the heat shield in the

LHD50) and Velcro it to the base of the appliance.

C. Slide the 20’ power vent cable through the right side of the appliance and connect the box connector to

the side panel, see “INSTALLATION OVERVIEW” section for illustration.

D. Feed the wires through the inside panel, slide the split bushing over the coated wires and snap into

the 7/8” hole to protect the wires as illustrated. Attach the connections as per the appropriate wiring

diagram. See “WIRING DIAGRAM AND INSTALLATION” section.

E. Plug the power vent control module into either the appliance junction box or the control module, if

equipped.

JUNCTION BOX

SPLIT BUSHING

REQUIRED

W415-0682 / D / 02.06.12

Page 9

1.5 RESTRICTOR PLATE INSTALLATION

REFER TO PVA KIT FOR APPLIANCE SPECIFIC INSTRUCTIONS.

1.6 WIRING DIAGRAM AND INSTALLATION

Connect the wiring to the power vent termination as outlined in the previous section, and connect the wiring

to the appliance as outlined in the schematic below. Ensure that the proper clearances are maintained for the

wiring and conduit. When installing the wiring it must never run above the vent run and it must be a minimum 1”

from all venting.

NOTE: The GPV includes a 20 foot wire harness. If this harness does not reach the appliance, then it

may be cut and a splice added. These connections must conform with local codes or, in the absence

of local codes, use the current CSA C22.1 Canadian Electrical Code in Canada or the ANSI/NFPA 70

National Electrical Code in the United States.

1.6.1 SIT IPI 885 PROFLAME COMPLETE WITH GPV POWER VENT TERMINAL

1. Disconnect the wires labeled ON/OFF (White/Green) and TH (Green). Reconnect them to the

corresponding male/female connectors on the Power vent control module.

2. Disconnect the two D/C (Red/Black) wires from each other and reconnect them to the corresponding D/C

connectors on the Power vent control module.

9

3. Disconnect the Orange wire from the gas valve and reconnect it to the Yellow wire (female connector) from

the Power vent control module.

4. Connect the remaining Yellow wire (male connector) from the Power vent control module to the tab on the

gas valve where the Orange wire was removed.

W415-0682 / D / 02.06.12

Page 10

10

BLOWER

WHITE

BLACK

GREEN

VAC SWITCH

YELLOW

YELLOW

1

GPV Terminal

Receiver

120 VOLT FAN AUX OUT

INTO

PLUG

120 VOLT

RED / FCM-COM

GREY / FCM-COM

PURPLE / FCM-COM

GREEN / TH

RED / DC SUPPLY

PINK

BLUE

BLACK / DC SUPPLY

BROWN / MOTOR

BLACK / MOTOR

YELLOW / MOTOR

ORANGE / MOTOR

SPLIT FLOW

(IF INCLUDED

WITH APPLIANCE)

POWER

COM

Control

Module

Vent

Power

Control

Module

Pull connectors apart to

connect to power vent

2

IPI Board

FLAME

SENSOR

BLACK 3/16

BLACK 1/8

CONNECTION

GREEN / ON/OFF

RED / DC SUPPLY

CONNECTION

YELLOW / GREEN

WHITE / TPTH

IMPORTANT: IF USED,

RED

BLACK

WHITE

BLACK / DC SUPPLY

BLACK

YELLOW / GREEN

IT MUST BE

CONNECTED TO A 6

VOLT BATTERY PACK,

HOWEVER MUST NOT

BE USED WHEN USING

THE REMOTE

CONTROL RECEIVER

SWITCH

IPI / CPI (ACS)

(MUST BE DISABLED IF THERE IS

ANY DOWNWARD VENTING.)

GREEN

ORANGE

3

YELLOW

YELLOW

4

SIT Valve

Pilot Assembly

SPARK

ELECTRODE

W415-0682 / D / 02.06.12

Electronic Ignition

TUBE

Page 11

11

1.6.2 SIT MILLIVOLT 820 NOVA COMPLETE WITH GPV POWER VENT TERMINAL

NOTE: Must use double pole switch (supplied) or double pole thermostat (not supplied) with specifi c

power vent adaptor kit.

NOTE: Downward venting is not allowed with appliances that use a standing pilot.

1. Connect the jumper wires to tabs TP/TH and TH on the gas valve.

2. Connect the jumper wire to the two Yellow wires from the Power vent control module.

PILOT

THERMOPILE

BURNER

Pilot Assembly

BLOWER

BLACK

WHITE

GREEN

THERMOCOUPLE

RED

WHITE

SIT Millivolt Gas Valve

JUMPER

1

2

YELLOW

YELLOW

VAC SWITCH

YELLOW

YELLOW

GPV Terminal

IMPORTANT: A RECEPTACLE MAY NEED TO BE INSTALLED AS A POWER SOURCE FOR THE GPV.

GREEN

RED

ORANGE

Double Pole

Switch

WHITE

BLACK

Power Vent

Control

Module

Appliance

Junction Box

W415-0682 / D / 02.06.12

Page 12

12

1.6.3 SIT IPI 880/886 PROFLAME COMPLETE WITH GPV POWER VENT TERMINAL

NOTE: Must use double pole switch (supplied) or double pole thermostat (not supplied) with specifi c

power vent adaptor kit.

1. Connect the jumper wires to the wire labeled ON/OFF (Green/White) and the wire labelled TH (Green).

2. Connect the other end of the jumper wires to the Yellow wires from the Power vent control module.

DC BACK-UP

(NOT ALLOWED

WITH GPV

INSTALLATION)

-

+

+

-

TRANSFORMER

ACS/IPI

SWITCH

(OPTIONAL)

DC SUPPLY

IPI / CPI

1

GROUND

JUMPER

GROUND

EYELET

VALVE

ORANGE

GREEN

VALVE

ELECTRONIC

IPI BOARD

DFC

VAC SWITCH

BLOWER

BLACK

WHITE

GREEN

YELLOW

YELLOW

GPV Terminal

2

YELLOW

YELLOW

Power

Vent

Control

Module

GREEN

RED

ORANGE

WHITE

BLACK

Double Pole

Switch

Appliance

Junction Box

IMPORTANT: A receptacle may need to be

installed as a power source for the GPV.

W415-0682 / D / 02.06.12

Page 13

1.6.4 DEXEN IPI 6003-3V COMPLETE WITH GPV POWER VENT TERMINAL

NOTE: Must use double pole switch (supplied) or double pole thermostat (not supplied) with specifi c

power vent adaptor kit.

NOTE: Downward venting is not allowed with appliances that use a standing pilot.

1. Connect the Brown wires from the Ignition module to the yellow wires from the Power vent control

module.

Battery

Holder

BLACK

Ignition Module

BLUE

BLUE

Ignitor

ORANGE

YELLOW

ORANGE

13

RED

Battery

Relay

VAC SWITCH

BLACK

YELLOW

BROWN

BROWN

BLOWER

BLACK

WHITE

GREEN

YELLOW

YELLOW

GPV Terminal

BLACK

GREEN

1

GREEN

Dexen Gas Valve

YELLOW

YELLOW

Power

Vent

Control

Module

IMPORTANT: A receptacle may need to be installed as a power source for the GPV.

RED

ORANGE

WHITE

Double Pole

Switch

BLACK

Appliance

Junction Box

W415-0682 / D / 02.06.12

Page 14

14

1.6.5 SIT REMOTE CONTROLLED MILLIVOLT SYSTEM COMPLETE WITH GPV

POWER VENT TERMINAL

NOTE: Must use double pole switch (supplied) or double pole thermostat (not supplied) with specifi c

power vent adaptor kits.

NOTE: Downward venting is not allowed with appliances that use standing pilots.

PILOT

THERMOPILE

BURNER

Pilot Assembly

Receiver

BLOWER

BLACK

WHITE

GREEN

THERMOCOUPLE

RED

WHITE

SIT Millivolt Gas Valve

JUMPER

1

2

YELLOW

YELLOW

VAC SWITCH

YELLOW

YELLOW

GPV Terminal

1. Disconnect one of the two wires from the receiver to the valve. Connect it to one of the yellow

wires from the power vent control module.

2. Connect a jumper wire to the valve where the receiver wire was disconnected and to the other yellow

wire from the power vent control module.

W415-0682 / D / 02.06.12

GREEN

RED

ORANGE

Double Pole

Switch

WHITE

BLACK

Power Vent

Control

Module

Appliance

Junction Box

Page 15

2.0 ADJUSTMENTS

2.1 VENTURI ADJUSTMENTS

REFER TO PVA KIT FOR SPECIFIC APPLIANCE INSTRUCTIONS.

3.0 REPLACEMENTS

Contact your dealer or the factory for questions concerning prices and policies on replacement parts. Normally

all parts can be ordered through your Authorized dealer / distributor.

FOR WARRANTY REPLACEMENT PARTS, A PHOTOCOPY OF THE ORIGINAL INVOICE WILL BE

REQUIRED TO HONOUR THE CLAIM.

When ordering replacement parts always give the following information:

• Model & Serial Number of appliance

• Installation date of appliance

• Part number

• Description of part

• Finish

* IDENTIFIES ITEMS WHICH ARE NOT ILLUSTRATED. FOR

FURTHER INFORMA TION, CONTACT YOUR AUTHORIZED DEALER.

15

!

WARNING

FAILURE TO POSITION THE PARTS

IN ACCORDANCE WITH THIS

MANUAL OR FAILURE TO USE ONLY

PARTS SPECIFICALLY APPROVED

WITH THIS APPLIANCE MAY

RESULT IN PROPERTY DAMAGE OR

PERSONAL INJURY.

41.1

COMPONENTS

REF GPV PART NO. DESCRIPTION

1 W062-0026 BLOWER

2 W660-0056 SWITCH, VACUUM

3* W750-0195 WIRE HARNESS, TERMINAL

4* W750-0209 20’ WIRE HARNESS CABLE FROM UNIT TO TERMINAL

5 W010-1924PW PEWTER MAIN BODY

6 W010-1925PW PEWTER FRAME

7 W290-0138 BLOWER GASKET

8 W500-0400 BLOWER MOUNTING PLATE

9 W200-0256PW PEWTER ACCESS COVER

10 W500-0419 DILUTION AIR PLATE

11* W345-0008 HOSE

5

8

7

6

1

9

2

10

W415-0682 / D / 02.06.12

Page 16

16

4.0 TROUBLESHOOTING

ALWAYS LIGHT THE PILOT WHETHER FOR THE FIRST TIME OR IF THE GAS SUPPLY HAS RAN OUT,

WITH THE GLASS DOOR OPEN OR REMOVED.

IN SOME INSTANCES THE SYSTEM MAY NOT LIGHT PILOT/BURNER WITH THE DOOR OPEN/

REMOVED. PARTIALLY BLOCKING THE EXHAUST FLUE COLLAR WILL ALLOW THE SAFETY

PRESSURE SWITCH TO ACTIVATE AND ALLOW GAS FLOW TO THE PILOT DURING THE INITIAL

SYMPTOM PROBLEM TEST SOLUTION

Main burner fl ame is

a blue lazy transparent fl ame.

Carbon is being

deposited on glass or

combustion chamber

surfaces.

White / Grey fi lm

forms.

Exhaust fumes

smelled in room,

headaches.

Main burner will not

light.

Main burner fl ames

are very aggressive.

Main burner won’t

light.

Leak in exhaust vent. - Check exhaust vent pipe and all connection seals.

Incorrect installation. - Refer to PVA kit for appliance specifi c restrictor.

Air shutter has become blocked

or incorrect setting.

Flame is impinging on the logs

or combustion chamber.

Sulphur from fuel is being deposited on glass, logs or combustion chamber surfaces.

Appliance is spilling. - Check door seal and relief fl ap seal.

Main door is not installed. - Install main door.

No restrictor. - Add restrictor.

Vacuum switch not activated. - Remove blockage. In really cold conditions, ice

!

WARNING

TEST FIRING.

- Ensure air shutter opening is free of lint or other

obstructions or has correct setting.

- Check that the media is correctly positioned.

- Open air shutter to increase the primary air.

- Check the input rate: Check the manifold

pressure and orifi ce size as specifi ed by the rating

plate values.

- Check that the door gasket is not broken or

missing and that the seal is tight.

- Check that both 4" and 7" vent liners are free of

holes and well sealed at all joints.

- Check that the proper restrictor is used

- Clean the glass with a gas appliance glass

cleaner. DO NOT CLEAN GLASS WHEN HOT.

- If deposits are not cleaned off regularly, the glass

may become permanently marked.

- Check for proper restrictor.

- Check that the paint curing process is complete.

- Remove restrictor plate on the power vent.

buildup may occur on the terminal and should be

removed as required.

- Test vacuum switch and replace as required.

IMPORTANT: Prove all systems check before completely enclosing unit.

W415-0682 / D / 02.06.12

Loading...

Loading...