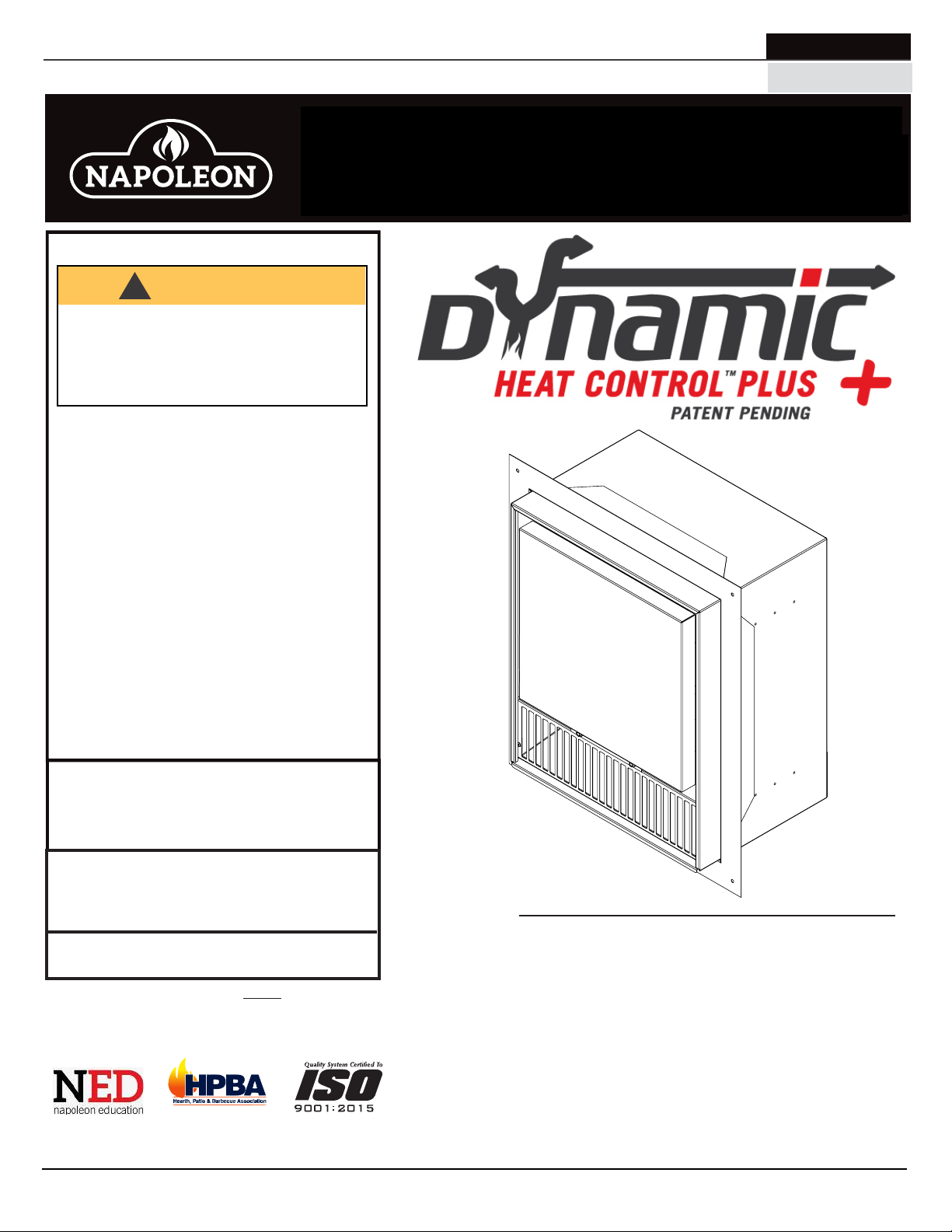

Napoleon DYNAMIC HEAT CONTROL PLUS, DHCP-BK, DHCP-HK, DHCP-EK Installation And Operation Manual

Page 1

NATURAL GAS MODELS:

DHCP-BK / DHCP-EK / DHCP-HK

ADD PRODUCT CODE HERE (TRADE GOTHIC LT STD FONT)

ENGLISH

PROPANE GAS MODELS:

SAFETY INFORMATION

!

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings exactly

could result in serious injury, death, or

property damage.

- Do not store or use gasoline or other

fl ammable vapors and liquids in the vicinity of

this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

neighbour’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call

the fi re department.

FRENCH

PG. 37

INSTALLATION AND

ADD MANUAL TITLE

OPERATION MANUAL

Product Name / Code

(MUST use title from Price Book)

ADD ____ ILLUSTRATED

ADD PRODUCT IMAGE

- Installation and service must be

performed by a qualifi ed installer, service

agency, or the supplier.

This appliance may be installed in an aftermarket,

permanently located, manufactured home (USA

only) or mobile home, where not prohibited by

local codes.

This appliance is only for use with the type of gas

Leave this manual with the appliance.

indicated on the rating plate. This appliance is

not convertible for use with other gases, unless

Retain this manual for future reference.

a certifi ed kit is used.

ENSURE TO ORDER CORRECT KITS.

SEE INSIDE FOR DETAILS.

Leave this manual with the appliance

These installation instructions MUST be used in

conjunction with the Vector™, Luxuria™, and

Retain this manual for future reference

Dynamic Heat Control™ installation manuals.

INSTALLER:

CONSUMER:

INSTALLER:

CONSUMER:

Wolf Steel Ltd., 24 Napoleon Rd., Barrie, ON, L4M 0G8 Canada / 103 Miller Drive, Crittenden, Kentucky, USA, 41030

Phone 1 (866) 820-8686 • www.napoleon.com • hearth@napoleon.com

CSA 2.22 AND ANSI Z21.50 FOR VENTED DECORATIVE GAS APPLIANCES

CSA /

INTERTEK

LOGO

DHCP-BK &

DHCP-EK Illustrated

FOR INDOOR USE ONLY

CERTIFIED TO THE CANADIAN AND AMERICAN NATIONAL STANDARDS:

FOR USE WITH VECTOR™

(with DHC™ installed)

& LUXURIA™ MODELS ONLY

IF INSTALLATION + OPERATION, ADD SERIAL

LV38N/P-1 / LV38N/P2-1 / LV50N/P-2 / LV50N/P2-2 /

IF SEPARATE MANUALS, ADD “PLACE

LVX38N/P / LVX38N/P2 / LVX50N/P / LVX50N/P2 /

BARCODE LABEL ON THE OWNER’S MANUAL”

NUMBER LABEL HERE

LV62N/P / LV62N/P2 / LV74N / LV74N2

LVX62N/P / LVX62N/P2 / LVX74N / LVX74N2

$10.00

W415-1789 / C / 01.29.19

Page 2

EN

table of contents

1.0 installation planning 3

1.1 introduction 3

1.2 installation options 3

1.3 DHC™ Plus kit overview 4

1.3.1 DHCP-BK 4

1.5.1 DHCP-EK 5

1.3.2 DHCP-HK 5

1.4 sound considerations 5

1.5 venting & ducting 5

1.6 placement in enclosure 6

1.7 dimensions 7

1.7.1 DHCP-BK & DHCP-EK 7

1.7.2 DHCP-BK & DHCP-HK 7

2.0 minimum ducting requirements 8

2.1 DHC™ Plus duct outlet 8

3.0 exterior & remote exterior

pre-installation 9

4.0 exterior installation 10

4.1 exterior installation overview 10

4.2 minimum framing requirements 11

4.3 completed installation checklist 13

5.0 remote exterior installation 14

5.1 remote exterior installation overview 14

5.2 minimum framing requirements 15

5.3 ducting installation 15

5.4 completed installation checklist 16

6.0 mounting options 17

6.1 flush 17

6.2 protruding 18

6.3 surface 19

7.0 remote inline pre-installation 20

8.0 remote inline installation 21

8.1 remote inline installation overview 21

8.2 minimum framing requirements 22

8.3 ducting installation 24

8.4 completed installation checklist 25

9.0 electrical information 26

9.1 wiring to SIT control board &

remote control 26

9.1.1 wiring diagram 28

9.2 wiring to wall switch & remote

control (in series) 28

9.2.1 wiring diagram 28

9.3 wiring to wall switch only 29

9.3.1 wiring diagram 29

9.4 blower specifications 29

10.0 operation 30

10.1 on/off switch 30

10.2 using remote control 30

11.0 replacement parts 31

11.1 DHCP-BK overview 32

11.2 DHCP-EK overview 33

11.3 DHCP-HK overview 34

12.0 notes 35

2

note:

The information throughout this manual is believed to be correct at the time of printing. Wolf Steel Ltd. reserves

the right to change or modify any information within this manual at any time without notice. Changes, other than

editorial, are denoted by a vertical line in the margin.

!

WARNING:

known to the State of California to cause cancer, and chemicals including toluene, which are

known to the State of California to cause birth defects or other reproductive harm.

For more information, go to www.P65Warnings.ca.gov.

W415-1789 / C / 01.29.19

This product can expose you to chemicals including chromium, which are

Page 3

1.0 installation planning

!

WARNING

Dynamic Heat Control™ Plus (DHC™ Plus) CANNOT be installed without Dynamic Heat Control™.

DHC™ Plus is ONLY compatible with Dynamic Heat Control™ Installation Option #2 (front opening) or

Installation Option #3 (rear opening).

DHC™ Plus MUST be installed with an air outlet opening or it will become a potential fire hazard.

• Installation must conform to local codes or, in the absence of local codes, the National Gas and Propane

Installation Code CSA B149.1 in Canada, or the National Fuel Gas Code ANSI Z223.1 / NFPA 54 in the United

States.

• An appliance may use only one DHC™ Plus blower kit.

• We recommend installing DHC™ Plus during installation of the appliance BEFORE appliance venting and gas

are installed.

• Installation MUST be performed by a qualified installer who has completed the Dynamic Heat Control™ System

Certification course via Napoleon’s online education portal NEducation.

• Ensure the appliance is completely cool before starting installation.

• To avoid danger of suffocation, keep the packaging bag away from babies and children. Do not use in cribs,

beds, carriages, or play pens. This bag is not a toy. Knot before throwing away.

1.1 introduction

Dynamic Heat Control™ Plus (DHC™ Plus) is a system for managing the heat produced by the appliance at

and around the appliance. The purpose of DHC™ Plus is to move heat away from the appliance and to primarily

distribute some or all of it to the exterior. Where duct lengths are greater than 5 feet or when passing through

uninsulated spaces such as an attic, it is recommended that the duct be insulated.

EN

Whilst it is practically possible to use DHC™ Plus to move heat to another location within the home,

please consider the following points carefully during the planning phase:

• The sound of the DHC™ Plus blower is similar to a bathroom fan (see “sound considerations” section).

• The DHC™ Plus system should not be used in small enclosed rooms with low ceilings, such as a small

bathroom, as the room will be quickly pressurized and the heat transfer from the fireplace will be reduced /

eliminated.

• The DHC™ Plus moves almost all the useable

heat. If the room is small in volume, it can quickly

become very warm. You may move unwanted

heat from one room to another, which may not

satisfy the customer. Therefore, carefully consider

the amount of heat and the size of the room

where it is being transferred to before beginning

installation.

• Where the DHC™ Plus system is used to transfer heat to another room, it is recommended to install a local

on/off switch so that the heat transfer can be disabled from the remote location if desired. The DHC™ Plus

system does not include a remote room thermostat.

1.2 installation options

There are three installation options available for DHC™ Plus, each with its own advantages:

Exterior Installation

DHC™ Plus is installed on the exterior wall of the appliance enclosure. It does not require venting, ducting, or a

bulkhead, and is therefore the simplest installation option. However, careful consideration should be made for the

sound of the DHC™ Plus blower. See “sound considerations” and “exterior installation” sections for details.

Remote Exterior Installation

DHC™ Plus is installed remotely from the appliance enclosure. Though it requires venting and a bulkhead, the

increased distance from the blower ensures sounds from air flow will be significantly less apparent. See “sound

considerations” and “remote exterior installation” sections for details.

Remote Inline Installation

DHC™ Plus is installed inline anywhere between the appliance enclosure and the hot air exhaust assembly.

Similarly to remote exterior installations, this installation requires venting and a bulkhead, with the addition of

ducting. This installation offers the most opportunity for unique configurations, including through multiples rooms

or floor levels. See “remote inline installation” section for details.

W415-1789 / C / 01.29.19

3

Page 4

EN

Hex

Hex

Hex

29/64”

1/8”

1-1/2”

Quadrex Drive

0.141”

Hex

installation planning

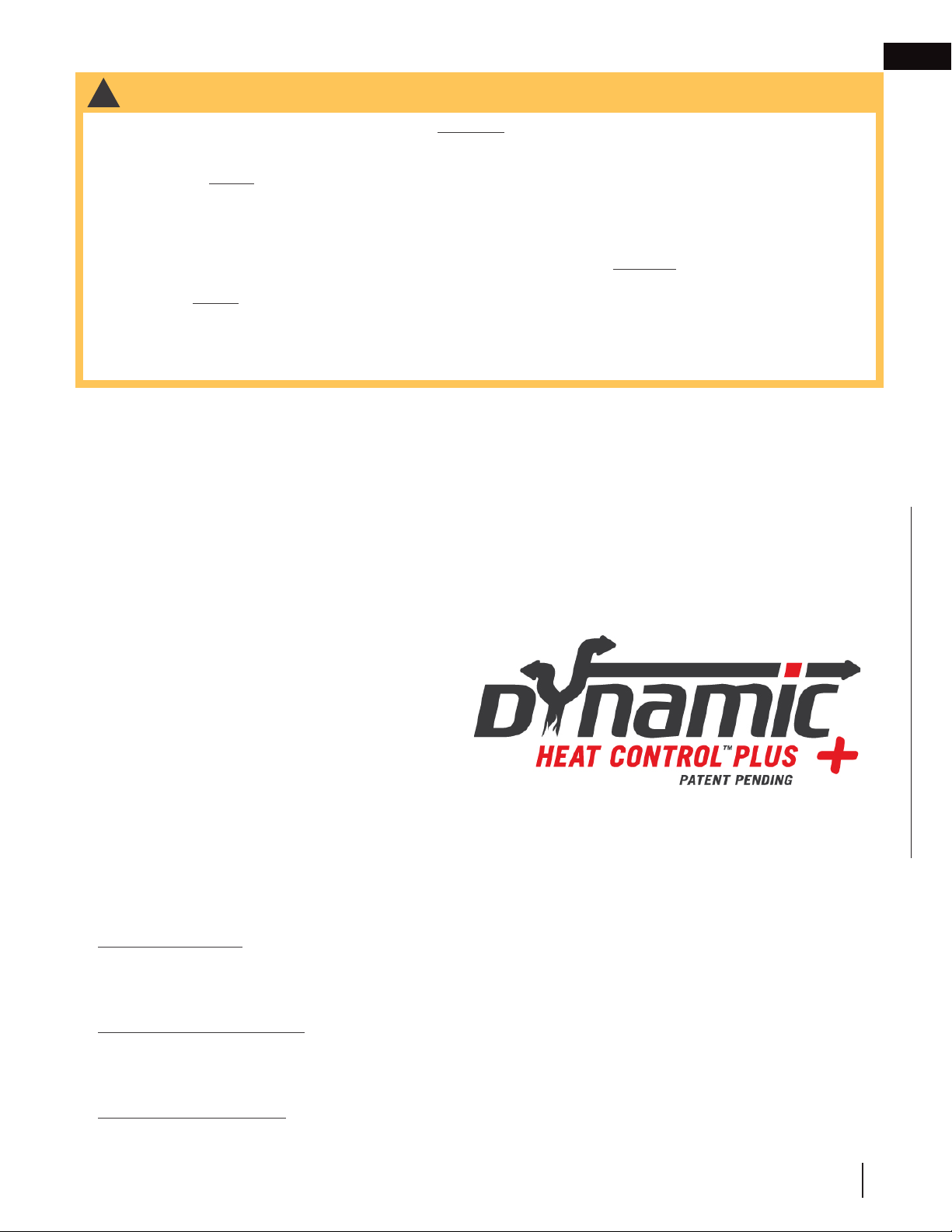

The table below lists kit requirements for each installation option. Please read it carefully.

Installation Type DHCP-BK DHCP-EK DHCP-HK

Exterior

Remote Exterior

Remote Inline

N/A

N/A

N/A

1.3 DHC™ Plus kit overview

Included in each kit:

DHCP-BK DHCP-EK DHCP-HK

1 x blower housing assembly

1x inline cover assembly

1 x air damper assembly

1 x on/off switch / housing

1 x collar connector assembly

1 x collar plate assembly

2 x mounting bracket

1 x bushing

13 x #9x1/2” screws

7 x #8x1/2” screws

note:

These complete kits always comprise of up to 2 boxes. Please read carefully and ensure to order correct application kits for your unique installation.

1 x exterior housing assembly

1 x wall flashing

1 x decorative cover

12 x #9x1/2” screws

1 x hot air exhaust assembly

1 x wall flashing

4 x #9x1/2” screws

2 x #10x1-1/2” screws

#10 Thread, RH

Though not supplied, armoured cable is required for the wiring of the DHC™ Plus (see “electrical information”

section for more information). Therefore, please ensure you have enough armoured cable on-hand to complete

your unique installation.

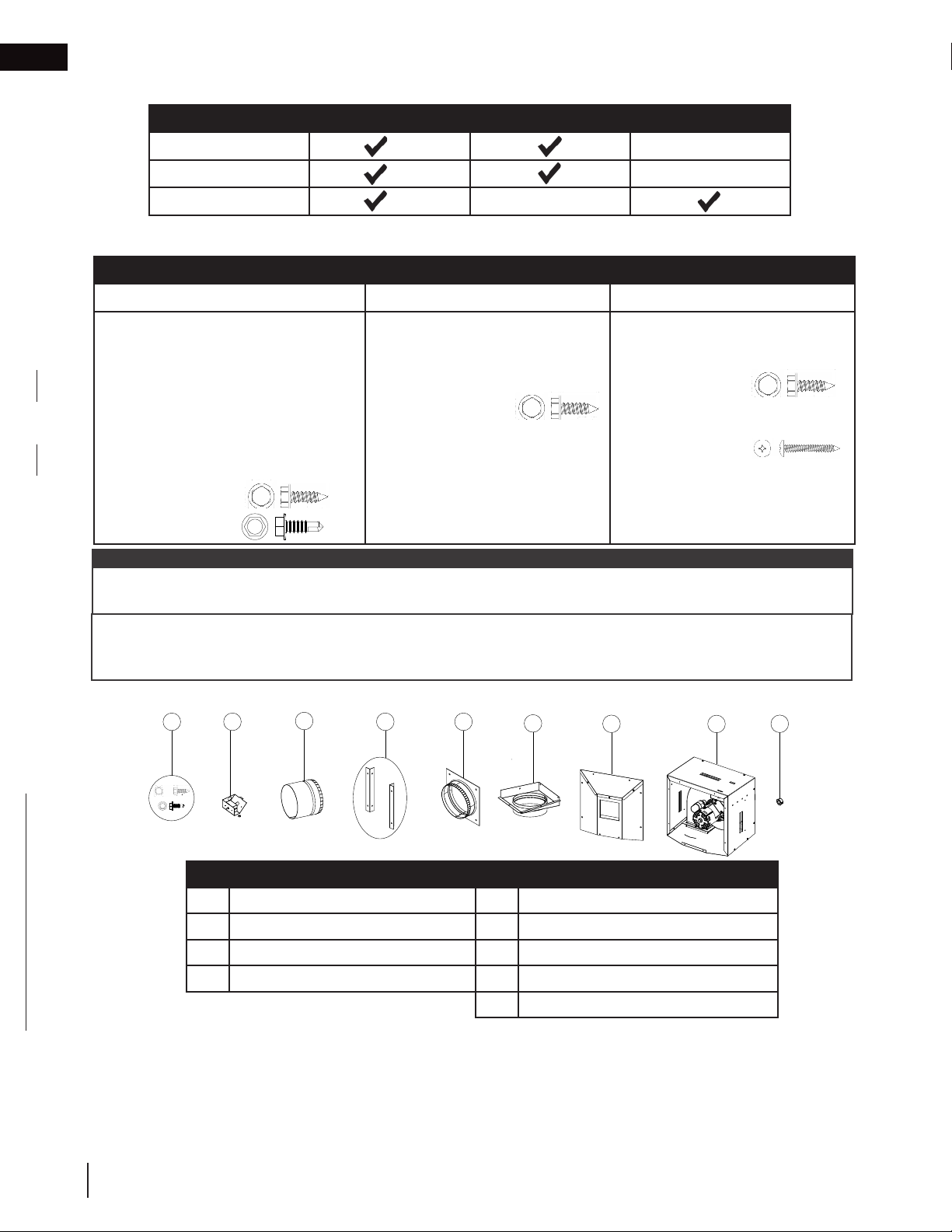

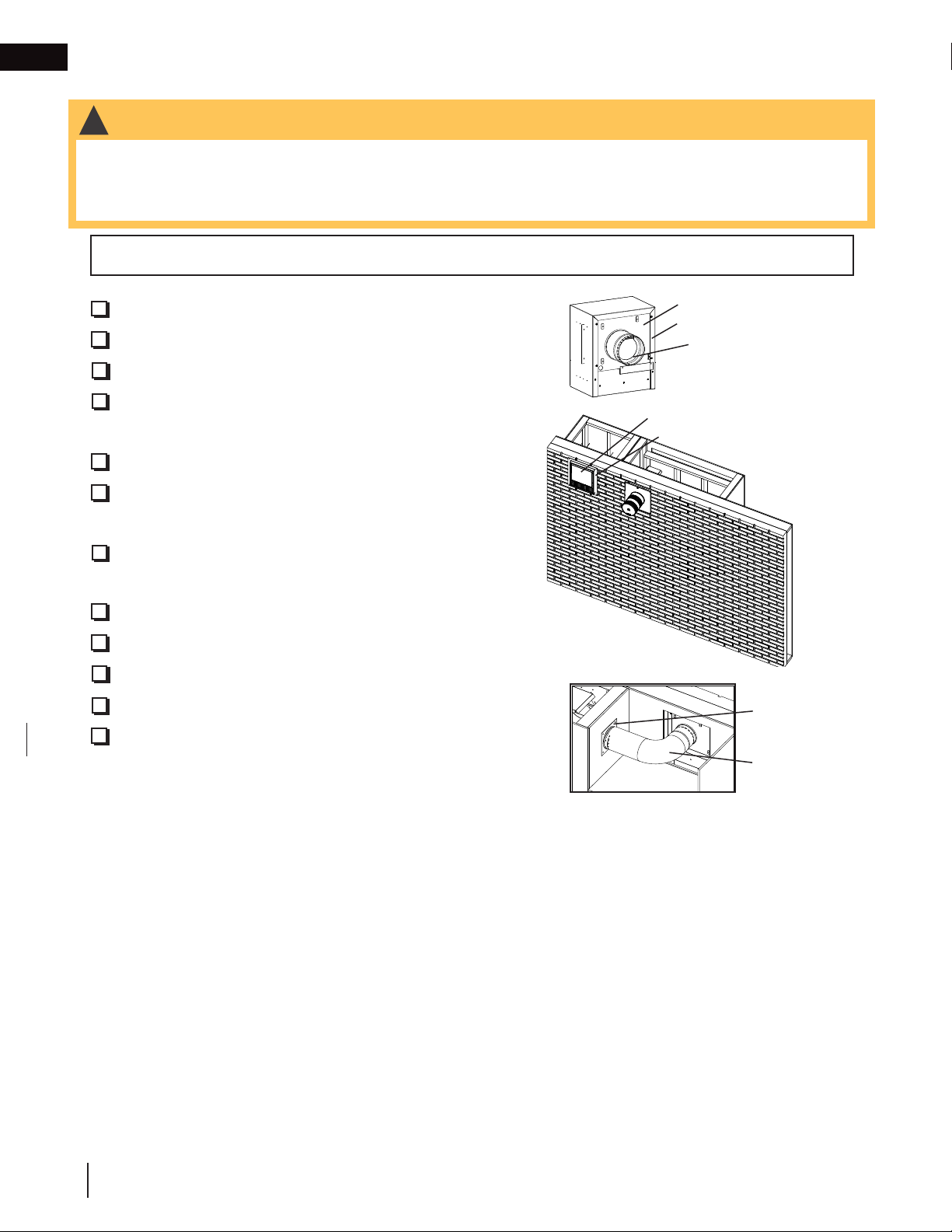

1.3.1 DHCP-BK

1

#9-14 Thread, RH

2

Ref. Description Ref. Description

1 Hardware kit 5 Collar plate assembly

2 On/off switch (with housing and nut) 6 Collar connector assembly

3 Air damper assembly 7 Inline cover assembly

4 Mounting brackets (x2) 8 Blower housing assembly

3

4 5

6

7

8

9

9 Bushing

4

W415-1789 / C / 01.29.19

Page 5

Hex

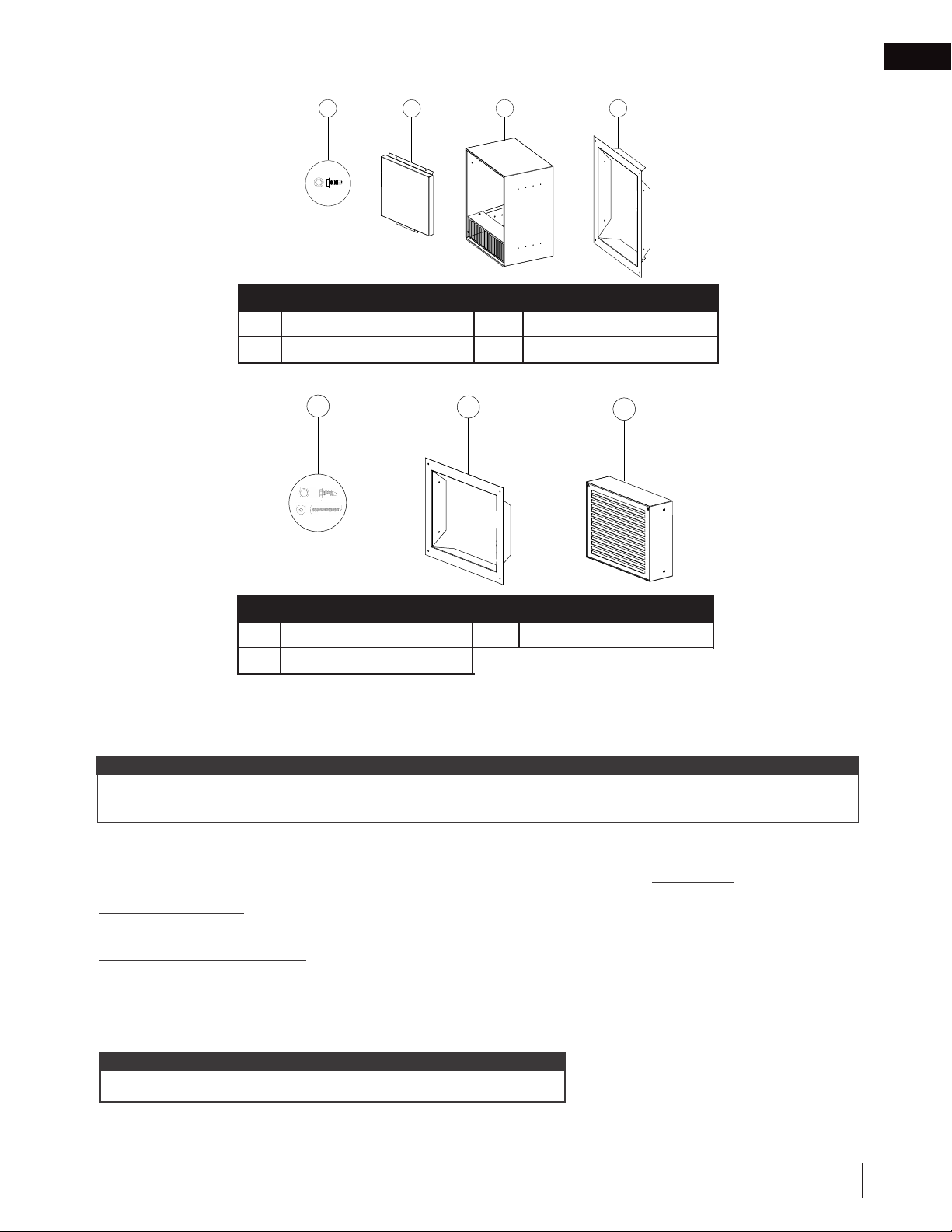

1.5.1 DHCP-EK

1.3.2 DHCP-HK

installation planning

1 3 4

Ref. Description Ref. Description

1 Hardware kit 3 Exterior housing assembly

2 Decorative cover 4 Wall flashing

1

#9-14 Thread, RH

29/64”

1/8”

1-1/2”

#10 Thread, RH

Quadrex Drive

2

2

3

EN

Ref. Description Ref. Description

1 Hardware kit 3 Hot air exhaust assembly

2 Wall flashing

1.4 sound considerations

The DHC™ Plus system uses a high performance fan to move unwanted heat outside. Similar to a bathroom fan

or stove range hood, the use of a fan to move air results in sound.

note:

Consider blower kit location carefully as the air flow sound from the blower is more apparent the closer it is to the

appliance and customer. This is particularly important if using the fan to transfer heat inside a home.

1.5 venting & ducting

Depending on the installation type, DHC™ Plus requires the use of ducting that is not supplied:

Exterior Installation

• N/A

Remote Exterior Installation

• 6” steel rigid venting between appliance enclosure and DHC™ Plus blower kit

Remote Inline Installation

• 6” steel ducting between appliance enclosure and DHC™ Plus blower kit

• 6” steel rigid venting between DHC™ Plus blower kit and hot air exhaust assembly

note:

Always check local codes before installing the DHC™ Plus system.

W415-1789 / C / 01.29.19

5

Page 6

EN

installation planning

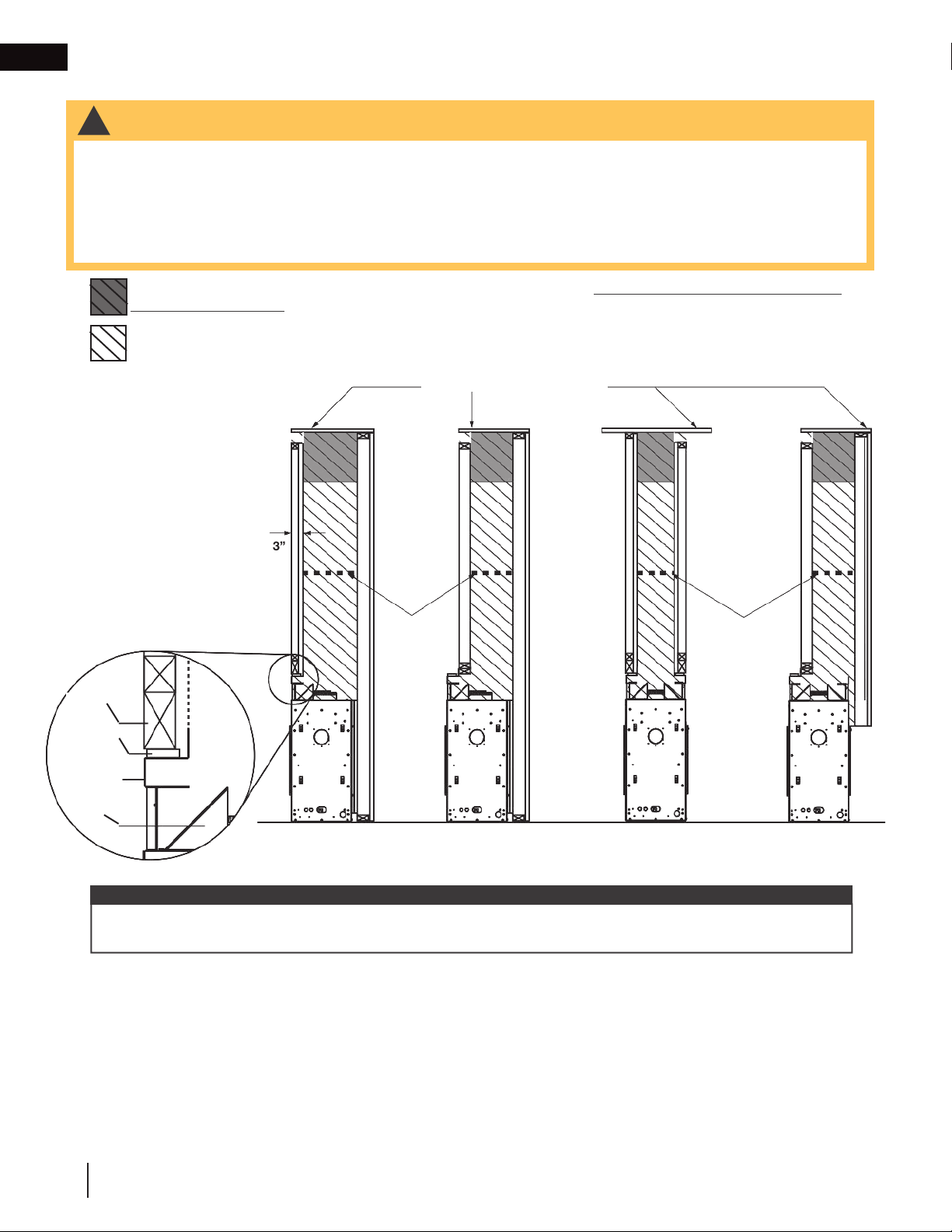

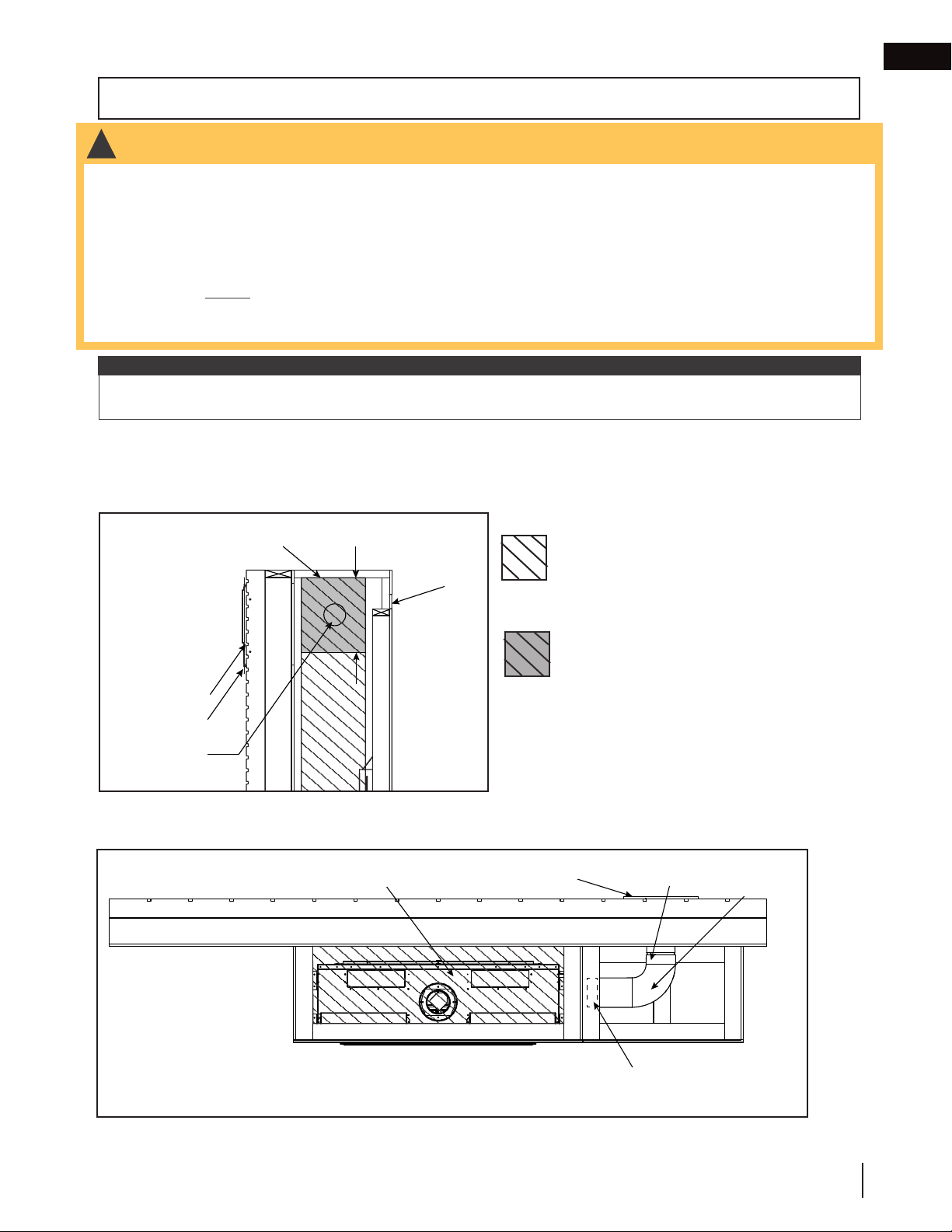

1.6 placement in enclosure

WARNING

!

• Do NOT cover or place any items in the Dynamic Heat Control™ air outlet. Failure to comply with these

instructions could create a fire hazard.

• Ensure a

vent system or the DHC™ Plus system.

The DHC™ Plus system draws air from the appliance enclosure and should be mounted in the

enclosure above the appliance. NEVER make a direct connection to the appliance itself.

ir flow within the air passage is not restricted in any way with the exception of an approved appliance

Recommended DHC™ Plus collar plate assembly installation zone - within the top 12” (30.5cm) of the

appliance enclosure.

No materials of any type permitted in this area with the exception of an approved appliance vent system or

the DHC™ Plus system.

enclosure top and/or ceiling

*

Stud

Stand-Off

Upper

Frame

Deflector

Dynamic Heat

Control™ air

outlet opening

* *

3”

Minimum

33” (83cm)

above

appliance

**

Single-Sided

Single-Sided

(Recessed)***

See-thru

*

Minimum

33” (83cm)

above

appliance

*

**

Single-Sided

(Exterior Recess)

important:

** DHC™ Plus collar plate assembly must be installed above the appliance vent shield (not illustrated) (minimum

33” (83cm) from the top of the appliance).

*** Restrictions also apply to see-thru when one or more recess is used. See your appliance manual for details.

Air flow in the hatched areas must not be restricted in any way with the exception of an approved appliance vent

system or the DHC™ Plus system. No other items are allowed in this area.

See your appliance manual for more information about clearance to combusible materials. No combustible materials allowed in the hatched areas or the space between studs (i.e. no wiring, conduits, electrical bores, combustible framing members, etc.).

6

W415-1789 / C / 01.29.19

Page 7

1.7 dimensions

REV.

025435

C

B

D

8

REV.

DHCP-BK

C

B

D

8

REV.

DHCP-HK

C

B

D

8

1.7.1 DHCP-BK & DHCP-EK

FOR EXTERIOR & REMOTE EXTERIOR INSTALLATIONS ONLY

installation planning

EN

front view right side view

15/16"

25mm

16 3/4"

425mm

18 1/2"

469mm

14 1/16"

357mm

16"

406mm

1.7.2 DHCP-BK & DHCP-HK

FOR REMOTE INLINE INSTALLATIONS ONLY

DHCP-BK

front view right side view

3 3/16"

81mm

6"

152mm

1/2"

13mm

13 3/16"

335mm

14 3/16"

360mm

22mm

7/8"

19 15/16"

507mm

1 1/2"

38mm

ADJUSTABLE FROM FLUSH TO SURFACE MOUNT IN

1 1/2" INCREMENTS. (SHOWN 1 1/2" PROUD OF

FINISHING IN THIS DIAGRAM)

3 1/2"

90mm

11 11/16"

297mm

1 1/2"

[40mm]

168mm

6 3/16"

157mm

6 5/8"

top view

8 1/4"

209mm

6"

152mm

9 7/8"

251mm

1 13/16"

45mm

top view

8"

199mm

6"

152mm

9 5/16"

236mm

1 13/16"

46mm

14 1/4"

362mm

4"

102mm

6"

152mm

3 7/8"

98mm

DHCP-HK

front view right side view

14 1/2"

368mm

3/4"

19mm

12 11/16"

322mm

16"

406mm

279mm

11"

13/16"

21mm

5 13/16"

148mm

1 1/2"

38mm

5 9/16"

142mm

7 3/16"

183mm

top view

6"

152mm

W415-1789 / C / 01.29.19

1 13/16"

46mm

102mm

4"

7

Page 8

EN

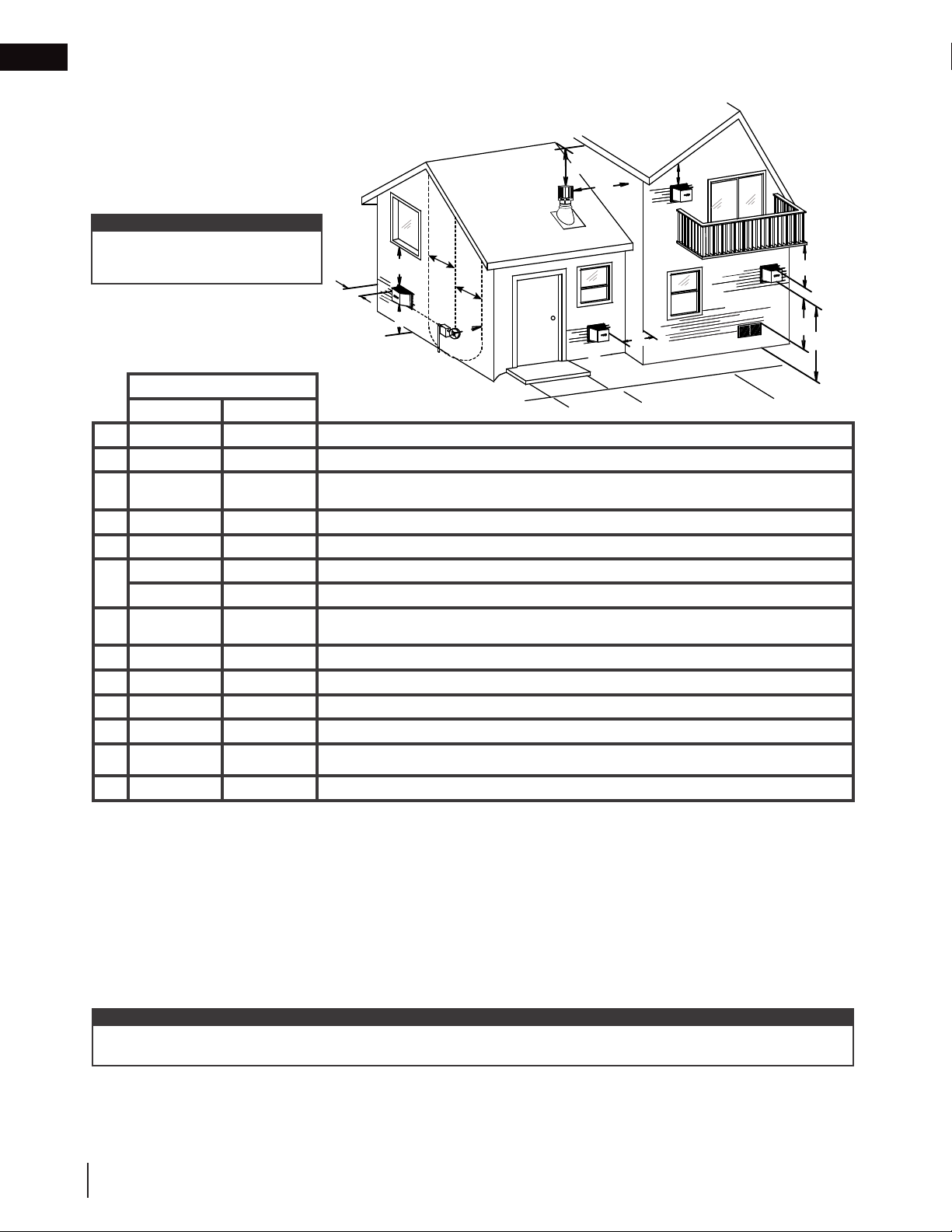

2.0 minimum ducting requirements

2.1 DHC™ Plus duct outlet

note:

Wall terminals are for illustration

purposes only. Size and shapes may

vary.

B

G

C

D

M

C

D

L

E

G

A

H

INSTALLATIONS

CANADA U.S.A.

12” (30.5cm) 12” (30.5cm) Clearance above grade, veranda porch, deck or balcony.

A

12” (30.5cm)* 12” (30.5cm)* Clearance to windows.

B

C

D

E

F

G

H

I

J

K

12”

(30.5cm)**

12” (30.5cm)** 12” (30.5cm)** Clearance to unventilated soffit.

0” (0mm) 0” (0mm) Clearance to an outside corner wall.

0” (0mm) 0” (0mm)

2” (51mm) 2” (51mm) Clearance to an inside combustible corner wall or protruding combustible obstructions (vent chase, etc.).

3’(0.9m) 3’(0.9m)****

3’ (0.9m) 3’ (0.9m)**** Clearance to a service regulator vent outlet.

12” (30.5cm) 9” (229mm) Clearance to a non-mechanical air supply inlet to the building or a combustion air inlet to any other appliance.

6’ (1.8m) 3’ (0.9m) † Clearance to a mechanical air supply inlet.

7’ (2.1m) ‡ 7’ (2.1m) **** Clearance above a paved sidewalk or paved driveway located on public property.

12”

(30.5cm)**

Vertical clearance to ventilated soffits located above the terminal within a horizontal distance of 2’ (0.6m)

from the center line of the terminal.

Clearance to an inside non-combustible corner wall or protruding non-combustible obstructions (chimney, etc.).

Clearance to each side of the center line extended above the meter / regulator assembly to a maximum

vertical distance of 15’ (4.6m).

F

I

J

K

12” (30.5cm)**** 12” (30.5cm)**** Clearance under a veranda, porch or deck.

L

1’ (0.3m)†* 1’ (0.3m) †* Clearance from an adjacent wall including neighbouring buildings.

M

* Recommended to prevent condensation on windows and thermal breakage

** It is recommended to maximize the distance to vinyl clad soffits.

**** This is a recommended distance. For additional requirements, check local codes.

† 3 feet above if within 10 feet horizontally.

‡ A vent shall not terminate where it may cause hazardous frost or ice accumulations on adjacent property surfaces.

†† Permitted only if the veranda, porch, or deck is fully open on a minimum of two sides beneath the floor.

†* Recommended for service. For additional requirements, check local codes.

note:

Clearances are to be in accordance with local installation codes and the requirements of the gas supplier. In their absence, clearances are to

be as listed above and are based on national codes.

8

W415-1789 / C / 01.29.19

Page 9

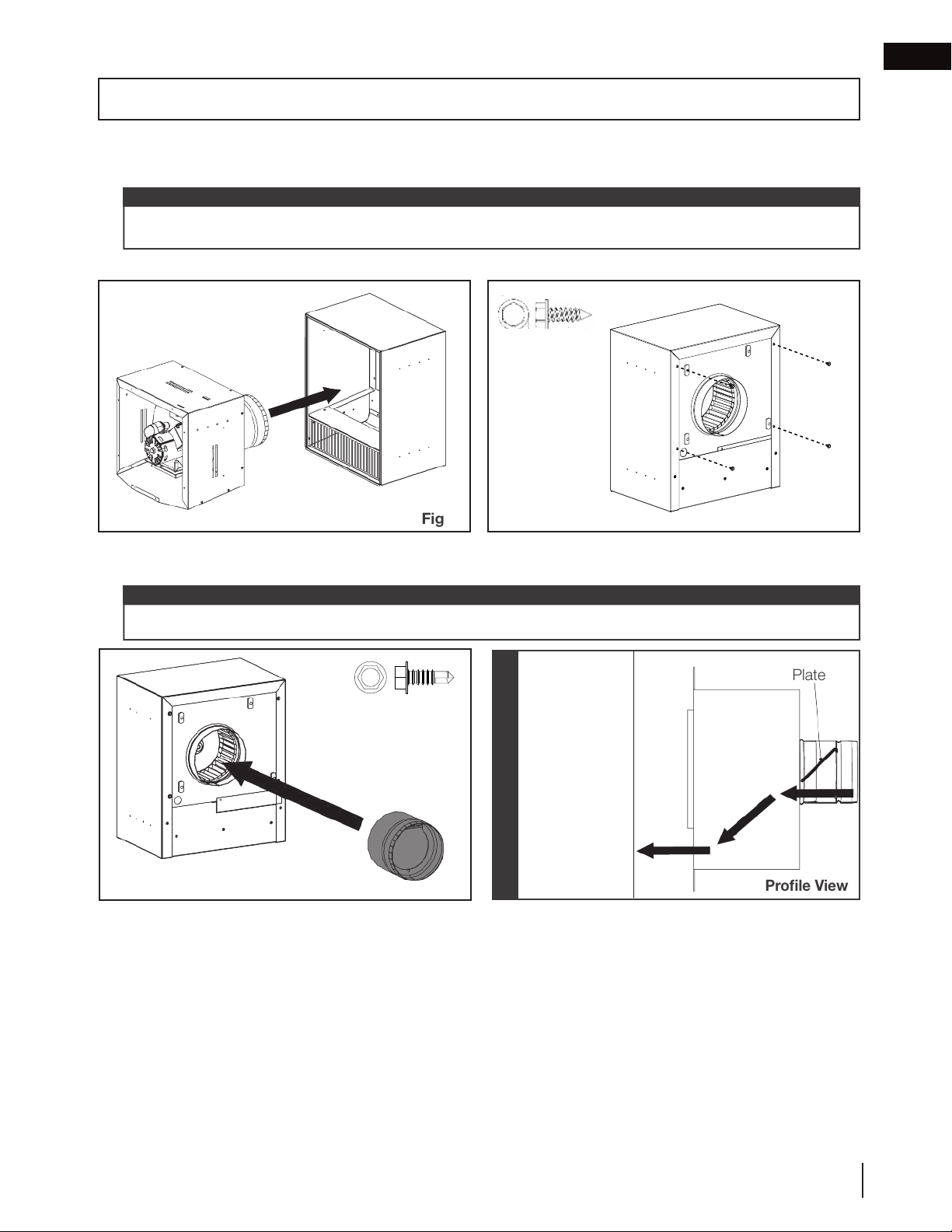

3.0 exterior & remote exterior pre-installation

Hex

FOR EXTERIOR AND REMOTE EXTERIOR INSTALLATIONS ONLY

For exterior and remote exterior installations, you must follow the instructions below before beginning installation.

For inline installations, see “remote inline pre-installation” section.

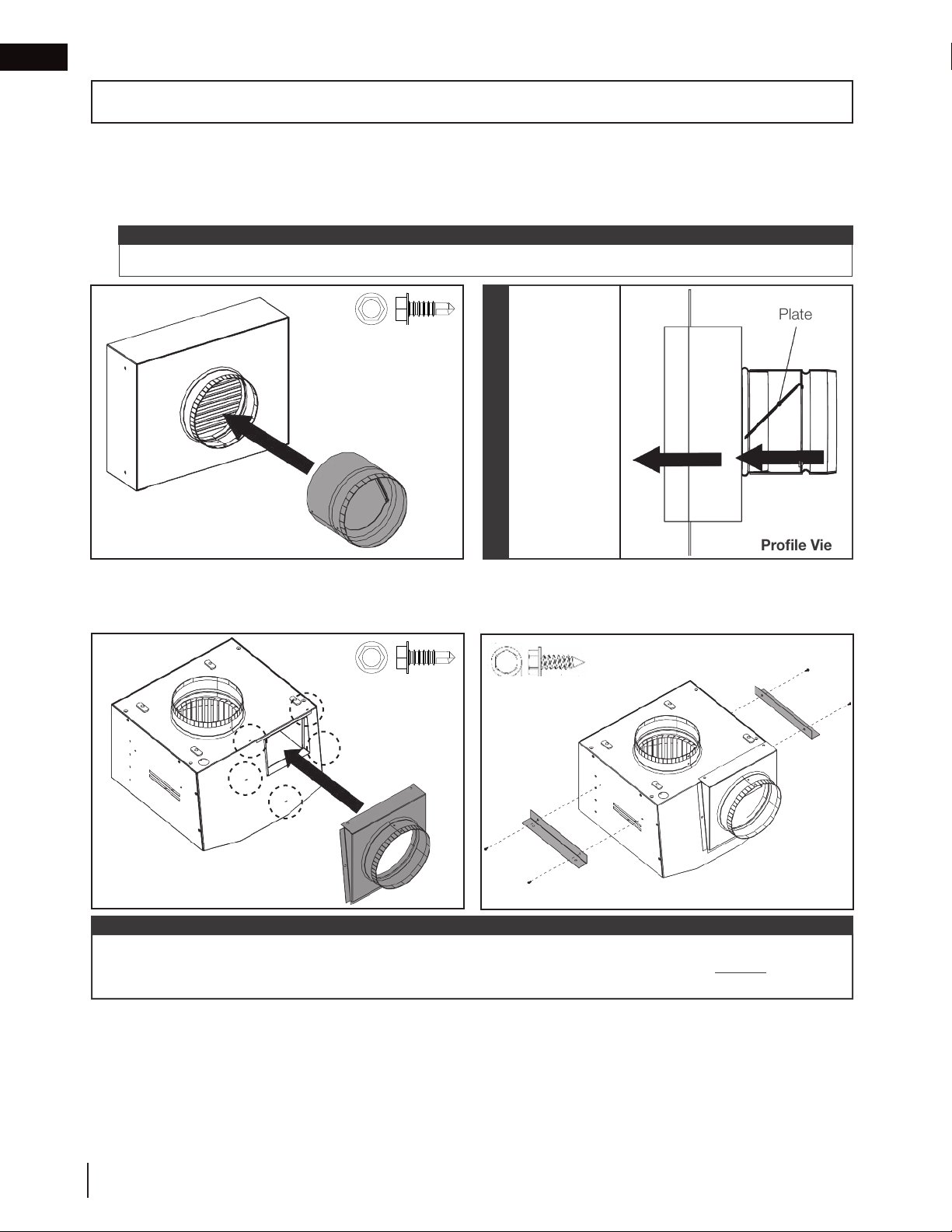

1. Insert the blower housing assembly into the exterior housing assembly. Ensure correct orientation (Fig. 1).

note:

We recommend installing the inline cover assembly and decorative cover last, after all electrical wiring is

complete. See “electrical information” section for installation instructions.

2. Secure the blower housing assembly to the exterior housing assembly using 4 screws (supplied) (Fig. 2).

x 4

EN

Fig. 1

3. Install the air damper assembly onto the collar and secure using self-drilling screws (supplied) (Fig. 3). Rotate

so that the damper closes shut when the blower is not running.

note:

The air damper assembly must be closed when the blower is not running for the system to function correctly.

The plate of

the air damper

x 3

Fig. 3

assembly must

open from the

bottom. Take

care to install

in the correct

orientation so it

IMPORTANT

will open when

the blower operates. Always test

before finishing.

Fig. 2

Plate

Profile View

W415-1789 / C / 01.29.19

9

Page 10

EN

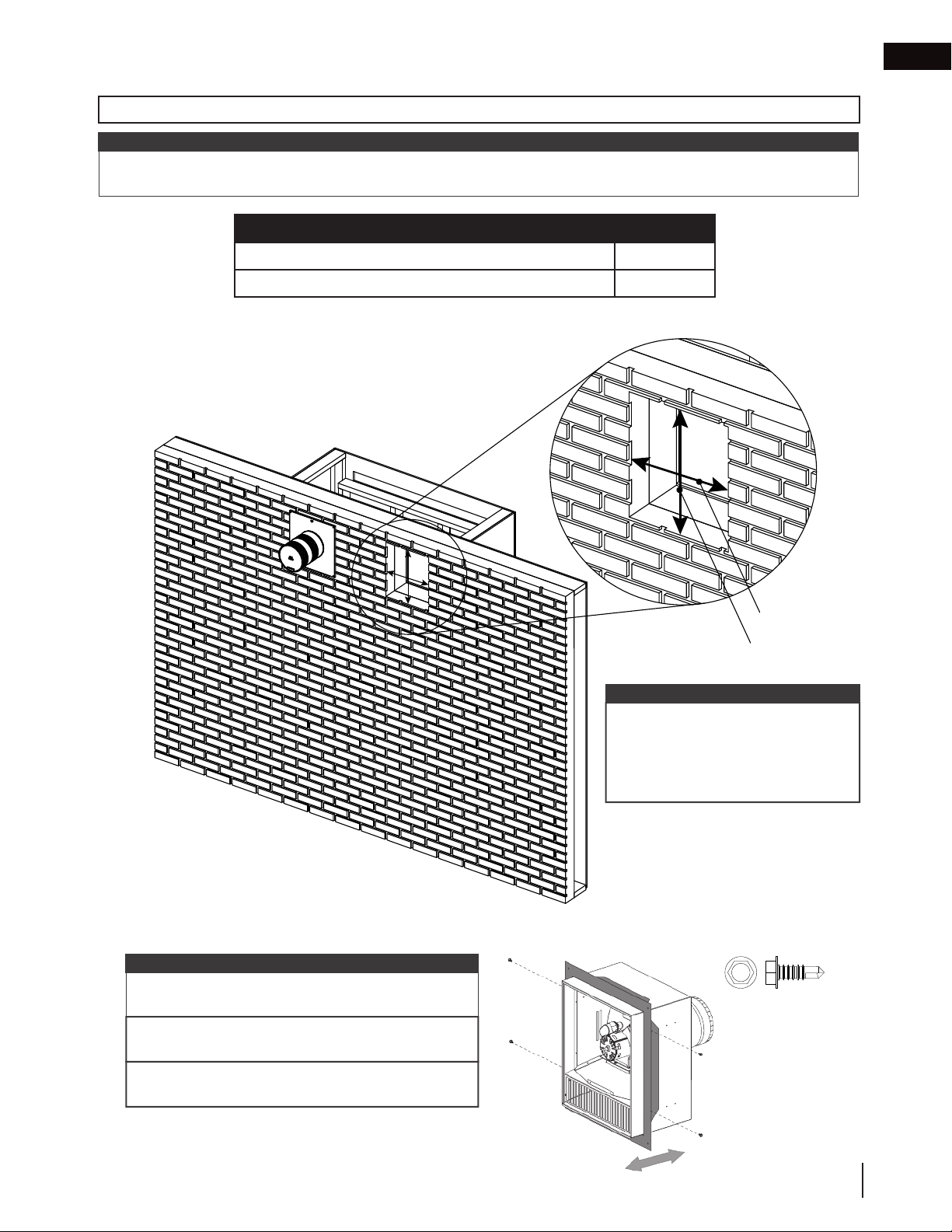

4.0 exterior installation

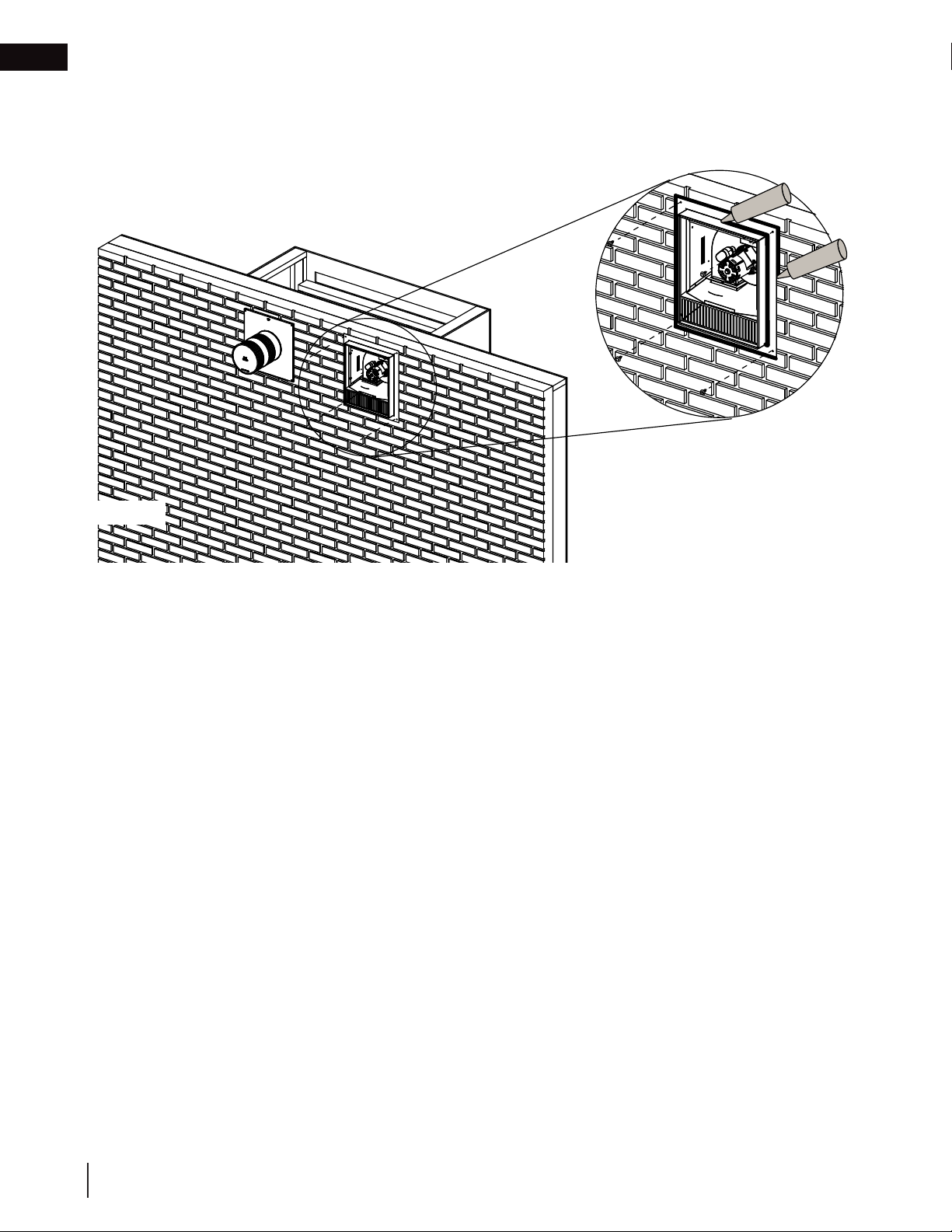

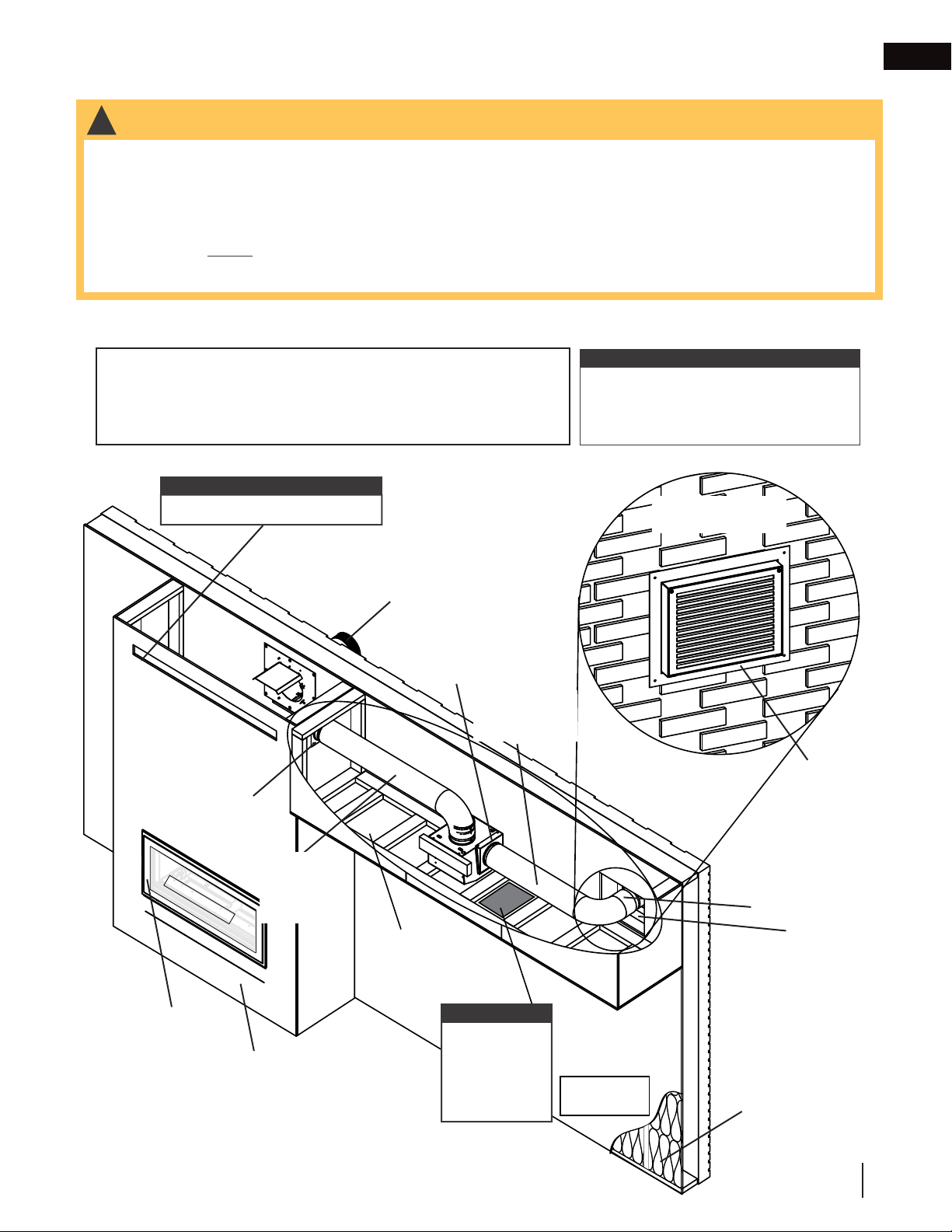

4.1 exterior installation overview

!

WARNING

• Minimum clearance to combustibles must be maintained or a serious fire hazard could result.

• DO NOT cover or place any items in the Dynamic Heat Control™ air outlet opening. Failure to comply with

these instructions will create a fire hazard.

DHC™ Plus CANNOT be mounted directly above or below the appliance vent terminal as this will

cause the system to fail. It MUST be mounted to the left or right of the appliance vent terminal.

• For optimal performance, we recommend installing DHC™ Plus within the top 12” (30.5cm) of the enclosure.

However, it MUST be installed above the appliance.

• The minimum height requirement above the appliance will vary depending on the appliance size. See “minimum

venting requirements” section of your appliance manual for details.

DHC™ Plus exterior installation is the simplest installation option. It is installed on the exterior wall of the appliance enclosure.

Required:

• DHCP-BK

• DHCP-EK

Blower

Housing

Assembly

Air

Damper

Assembly

note:

MUST have air outlet opening.

Wall

Flashing

Decorative

Cover

Appliance

Vent Terminal

(if applicable)

View of Opposite

Exterior Wall

Exterior

Exterior

Housing

Assembly

10

Enclosure

Appliance

note:

Diagram is for illustrative purposes only. Installation must comply with all local codes.

W415-1789 / C / 01.29.19

GLASS GUARD

LVX38 illustrated

Interior

Maintain

distance to

combustibles.

Insulation

Page 11

exterior installation

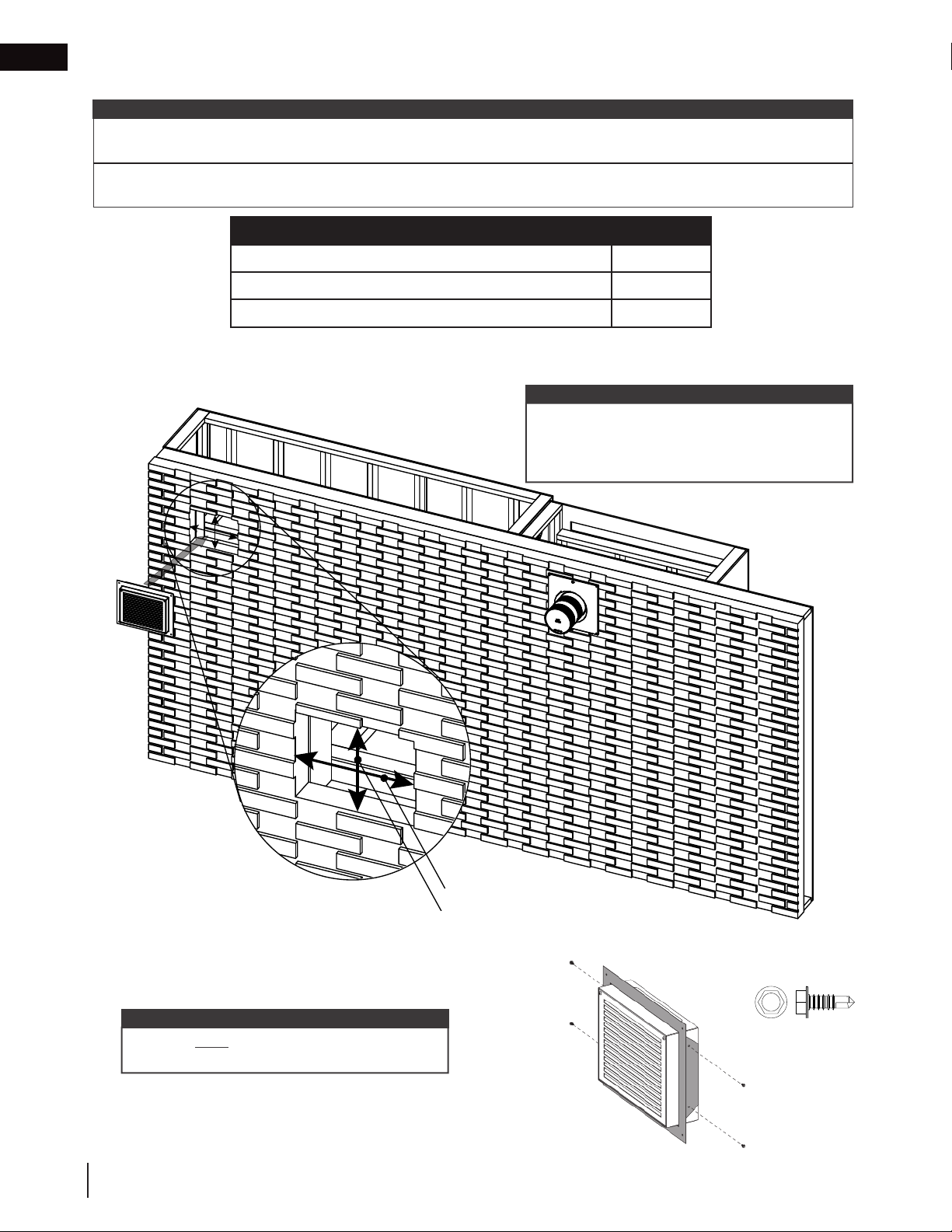

4.2 minimum framing requirements

APPLICABLE FOR EXTERIOR AND REMOTE EXTERIOR INSTALLATIONS

note:

For optimal performance, we recommend installing DHC™ Plus within the top 12” (30.5cm) of the enclosure.

The DHC™ Plus must be mounted above the appliance.

Minimum Clearance to Combustibles Clearance

DHCP-EK 0”

Vent pipe, collars, firestops, etc. 1” (25mm)

1. Determine the desired location of the exterior housing assembly on the exterior wall, and then frame a 14 1/2”

(36.8cm) wide by 17 1/4” (44cm) high opening (Fig. 1).

Interior

Interior

EN

14 1/2” (36.8cm)

17 1/4” (44cm)

note:

It may be necessary to shim the

blower housing in the rough opening

to provide a secure fit. If the blower

Exterior

Exterior

Exterior Installation Illustrated

2. Determine the desired amount of protrusion from the finished exterior wall, and then fasten the wall flashing

using 4 screws (supplied) (Fig. 2). See “mounting options” section for details.

note:

The exterior housing assembly MUST be pre-drilled

with a 1/8” drill bit before installing the wall flashing.

To avoid scratches, we recommend sliding the wall

flashing on from the back.

is not secured properly, excessive

noise and vibration may result.

Fig. 1

x 4

If surface-mounting your DHC™ Plus, this step is

not required (see “mounting options” section).

Fig. 2

W415-1789 / C / 01.29.19

11

Page 12

EN

exterior installation

3. Attach the exterior housing assembly to the exterior wall by securing the wall flashing using the appropriate

fasteners (not supplied) (Fig. 3).

4. Apply silicone to the joint after installation, and caulk or seal the wall flashing appropriately for the finish material (Fig. 4).

SILICONE

Interior

CAULK

Fig. 4

Exterior

Exterior Installation Illustrated

5. We recommend installing the inline cover assembly and decorative cover last, after all electrical wiring is complete. See “electrical information” section for installation instructions.

Fig. 3

12

W415-1789 / C / 01.29.19

Page 13

exterior installation

4.3 completed installation checklist

!

WARNING

• Ensure all items are checked for your respective installation or a serious fire hazard could result.

• Completed installations must conform to local codes or, in the absence of local codes, the National Gas and

Propane Installation Code CSA B149.1 in Canada, or the National Fuel Gas Code ANSI Z223.1 / NFPA 54 in the

United States.

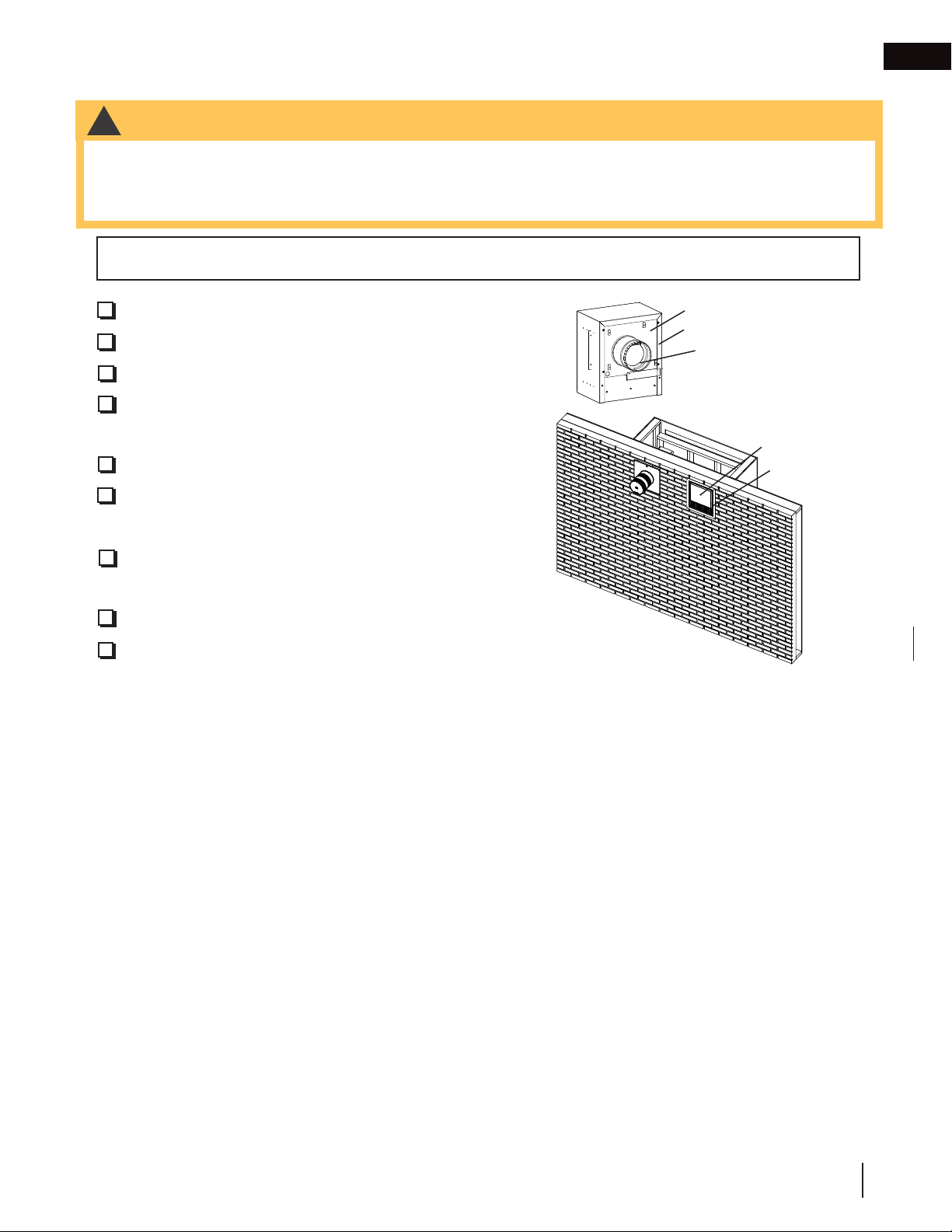

Installer, please tick all boxes for this installation or it IS NOT considered complete.

EN

1. DHCP-BK installed into DHCP-EK.

2. Air damper assembly installed and checked.

3. Rough opening framed into exterior wall.

4. Wall flashing installed and sealed appropriately for finish

material.

5. DHCP-EK attached to exterior wall.

6. Inline cover assembly installed (see “electrical information” section).

7. Decorative cover installed and system operation checked

with appliance (see “electrical information” section).

8. Wiring completed (see “electrical information” section).

9. On/off switch adjusted to fully “on” position.

DHCP-BK

DHCP-EK

Air Damper Assembly

Decorative Cover

Wall Flashing

Interior

Exterior

W415-1789 / C / 01.29.19

13

Page 14

EN

5.0 remote exterior installation

5.1 remote exterior installation overview

!

WARNING

• Minimum clearance to combustibles must be maintained or a serious fire hazard could result.

• DO NOT cover or place any items in the Dynamic Heat Control™ air outlet opening. Failure to comply with

these instructions will create a fire hazard.

DHC™ Plus CANNOT be mounted directly above or below the appliance vent terminal as this will

cause the system to fail. It MUST be mounted to the left or right of the appliance vent terminal.

• For optimal performance, we recommend installing DHC™ Plus within the top 12” (30.5cm) of the enclosure.

However, it MUST be installed above the appliance.

• The minimum height requirement above the appliance will vary depending on the appliance size. See “minimum

venting requirements” section of your appliance manual for details.

DHC™ Plus remote exterior installation can be installed remotely from the appliance enclosure up to 60’ (18.2m)

away.

Required:

• DHCP-BK

• DHCP-EK

• Venting, 6” rigid steel (not supplied)

View of Opposite

Exterior Wall

Exterior Housing

Assembly

note:

MUST have air outlet opening.

Appliance Vent

Terminal (if

applicable)

Enclosure

GLASS GUARD

Blower

Housing

Assembly

Air

Damper

Assembly

Collar Plate

Assembly

6” Rigid Steel

Venting (not

supplied)

Inside View

of Bulkhead

(Some Framing and

Finishing Hidden

for Clarity)

Wall

Flashing

Decorative

Cover

Exterior

14

Appliance

note:

Diagram is for illustrative purposes only. Installation must comply with all local codes.

W415-1789 / C / 01.29.19

LVX 38 illustrated

Maintain

distance to

combustibles.

Interior

Insulation

Page 15

remote exterior installation

12”

5.2 minimum framing requirements

See “minimum framing requirements” in exterior installation section for details.

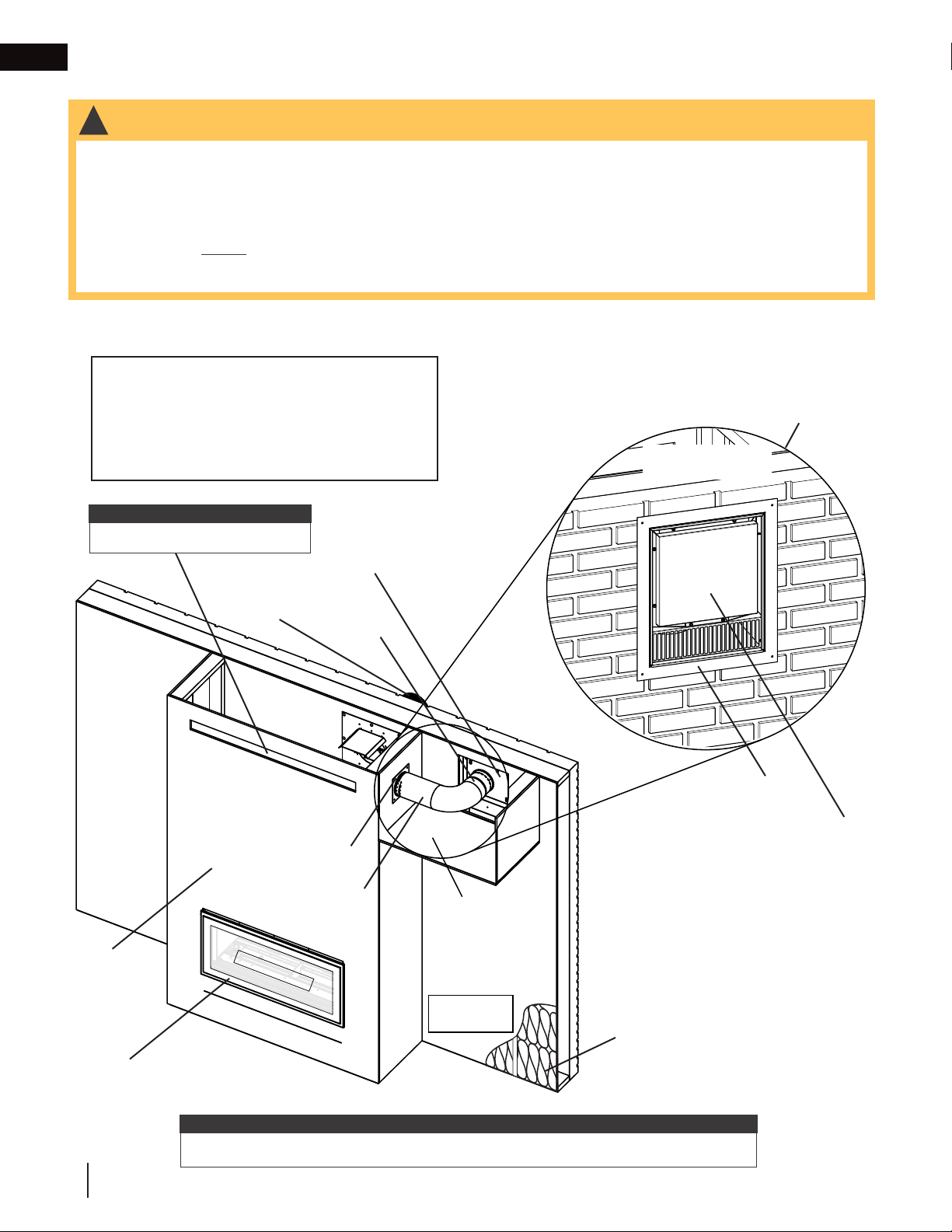

5.3 ducting installation

1. Determine the location for the 6” (152mm) collar plate assembly on the appliance enclosure, and then cut a

hole 6” (152mm) in diameter (Fig. 1).

EN

Top of Enclosure

(152mm)

Exterior

Ø 6”

(30.5cm)

Air Outlet

Opening

Interior

Fig. 1

note:

Ensure to create the Ø 6” (152mm)

hole within the top 12” (30.5cm) of the

enclosure (Fig. 1).

No materials of any type

permitted in this area with

the exception of an approved

appliance vent system or the

DHC™ Plus system.

Recommended DHC™ Plus

collar plate assembly installation

zone (12” [30.5cm]).

Left Side Profile View

2. Using appropriate fasteners (not supplied), secure the 6” (152mm) collar plate assembly over the hole inside

the bulkhead (Fig. 2).

3. Install 6” rigid steel venting (not supplied) from the appliance enclosure to the blower housing assembly (Fig.

3).

Interior

Exterior

GLASS GUARD

LVX 38 illustrated

Fig. 2

Inside View

of Bulkhead

(Some Framing

and Finishing

Hidden for Clarity)

Fig. 3

W415-1789 / C / 01.29.19

15

Page 16

EN

remote exterior installation

5.4 completed installation checklist

!

WARNING

• Ensure all items are checked for your respective installation or a serious fire hazard could result.

• Completed installations must conform to local codes or, in the absence of local codes, the National Gas and

Propane Installation Code CSA B149.1 in Canada, or the National Fuel Gas Code ANSI Z223.1 / NFPA 54 in the

United States.

Installer, please tick all boxes for this installation or it IS NOT considered complete.

1. DHCP-BK installed into DHCP-EK.

2. Air damper assembly installed and checked.

3. Rough opening framed into exterior wall.

4. Wall flashing installed and sealed appropriately for finish

material.

5. DHCP-EK attached to exterior wall.

6. Inline cover assembly installed (see “electrical information” section).

7. Decorative cover installed and system operation checked

with appliance (see “electrical information” section).

8. Ø 6” (152mm) hole cut into appliance enclosure.

9. Collar plate assembly secured.

10. 6” rigid steel venting (not supplied) installed.

11. Wiring completed (see “electrical information” section).

12. On/off switch adjusted to fully “on” position.

DHCP-BK

DHCP-EK

Air Damper Assembly

Decorative Cover

Wall Flashing

Interior

Exterior

6” Collar Plate

Assembly

6” Rigid Steel

Venting

(Not Supplied)

16

W415-1789 / C / 01.29.19

Page 17

6.0 mounting options

FOR EXTERIOR AND REMOTE EXTERIOR INSTALLATIONS ONLY

!

WARNING

• Minimum clearance to combustibles must be maintained or a serious fire hazard could result.

• DO NOT cover or place any items in the Dynamic Heat Control™ air outlet opening. Failure to comply with

these instructions will create a fire hazard.

DHC™ Plus CANNOT be mounted directly above or below the appliance vent terminal as this will

cause the system to fail. It MUST be mounted to the left or right of the appliance vent terminal.

• For optimal performance, we recommend installing DHC™ Plus within the top 12” (30.5cm) of the enclosure.

However, it MUST be installed above the appliance.

• The minimum height requirement above the appliance will vary depending on the appliance size. See “minimum

venting requirements” section of your appliance manual for details.

note:

Consider blower location carefully as the air flow sound from the blower is more apparent the closer it is to the

appliance. See “sound considerations” section for details.

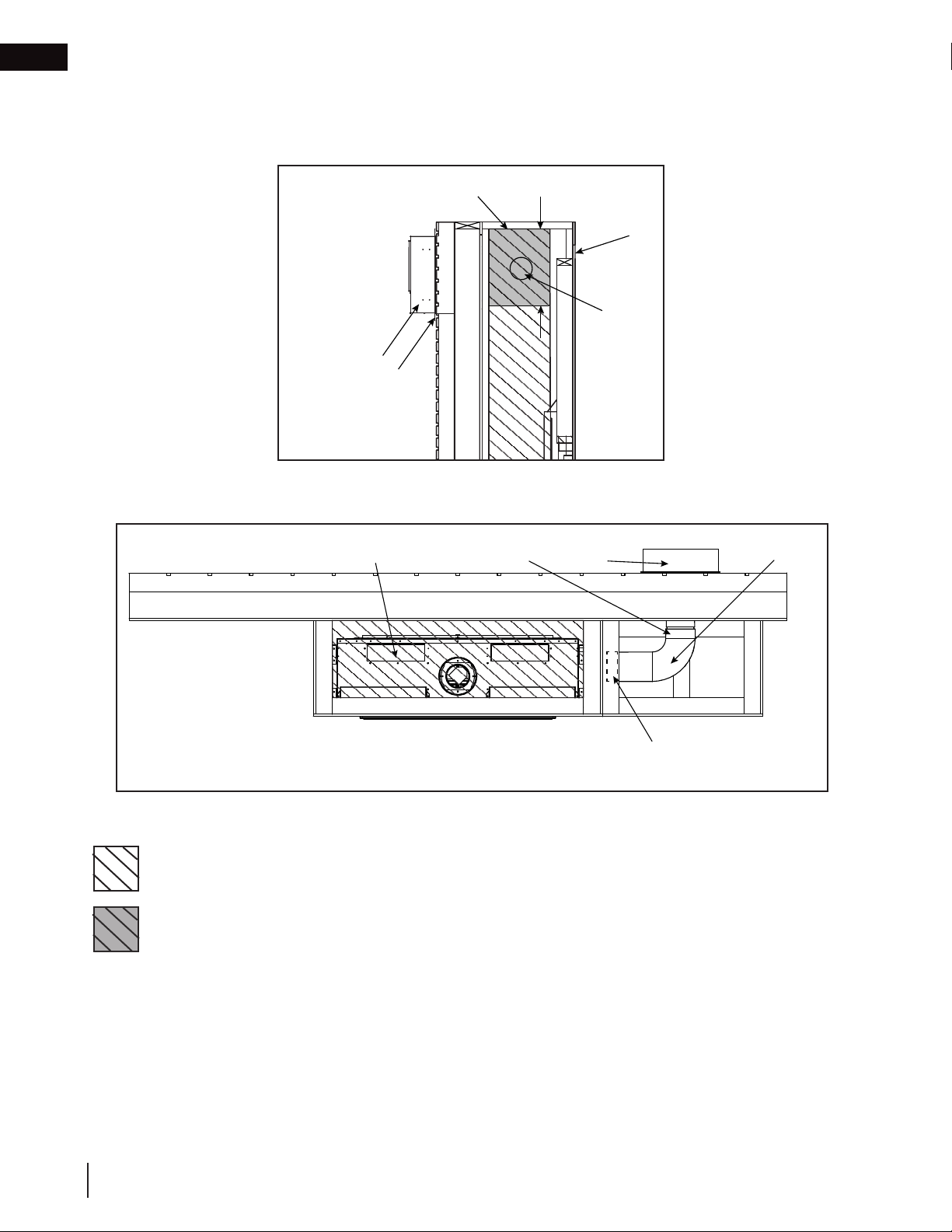

6.1 flush

In this mounting option, the wall flashing and exterior housing assembly are flush with the finished exterior wall.

A

14 1/2” (36.8cm) by 17 1/4” (44cm) rectangular opening must be framed into the exterior wall (see “minimum

framing requirements” section for details).

EN

Top of

Enclosure

Exterior

Exterior Housing

Asssembly

Wall Flashing

Ø 6” (152mm)

Hole & Installed Collar

Plate Assembly

12”

(30.5cm)

Air Outlet

Opening

Interior

Left Side Profile View

(Remote Exterior Installation illustrated. Some components may not apply

to your unique installation.)

Exterior

Appliance

(LVX38 Illustrated)

No materials of any type permitted in this

area with the exception of an approved

appliance vent system or the DHC™ Plus

system.

Recommended DHC™ Plus collar plate

assembly installation zone (12” [30.5cm]).

Exterior Housing

Assembly

Air Damper

Assembly

6’ Rigid

Steel Venting

(not supplied)

Interior

Installed 6” Collar

Plate Assembly

Top Side View

(Remote Exterior Installation illustrated. Some components may not apply to your unique installation.)

W415-1789 / C / 01.29.19

17

Page 18

EN

mounting options

6.2 protruding

In this mounting option, the wall flashing is flush with finished exterior wall but the exterior housing assembly is

protruding from the finished exterior wall. A 14 1/2” (36.8cm) by 17 1/4” (44cm) rectangular opening must be

framed into the exterior wall (see “minimum framing requirements” section for details).

Exterior

Top of

Enclosure

Exterior

Exterior Housing

Asssembly

Wall Flashing

12”

(30.5cm)

Air Outlet

Opening

Interior

Ø 6” (152mm)

Hole &

Installed

Collar Plate

Assembly

Left Side Profile View

(Remote Exterior Installation illustrated. Some components may not apply

to your unique installation.)

Appliance

(LVX38 Illustrated)

Air Damper

Assembly

Exterior Housing

Assembly

6’ Rigid

Steel Venting

Interior

Installed 6” Collar

Plate Assembly

Top Side View

(Remote Exterior Installation illustrated. Some components may not apply to your unique installation.)

No materials of any type permitted in this area with the exception of an approved appliance vent system

or the DHC™ Plus system.

Recommended DHC™ Plus collar plate assembly installation zone (12” [30.5cm]).

18

W415-1789 / C / 01.29.19

Page 19

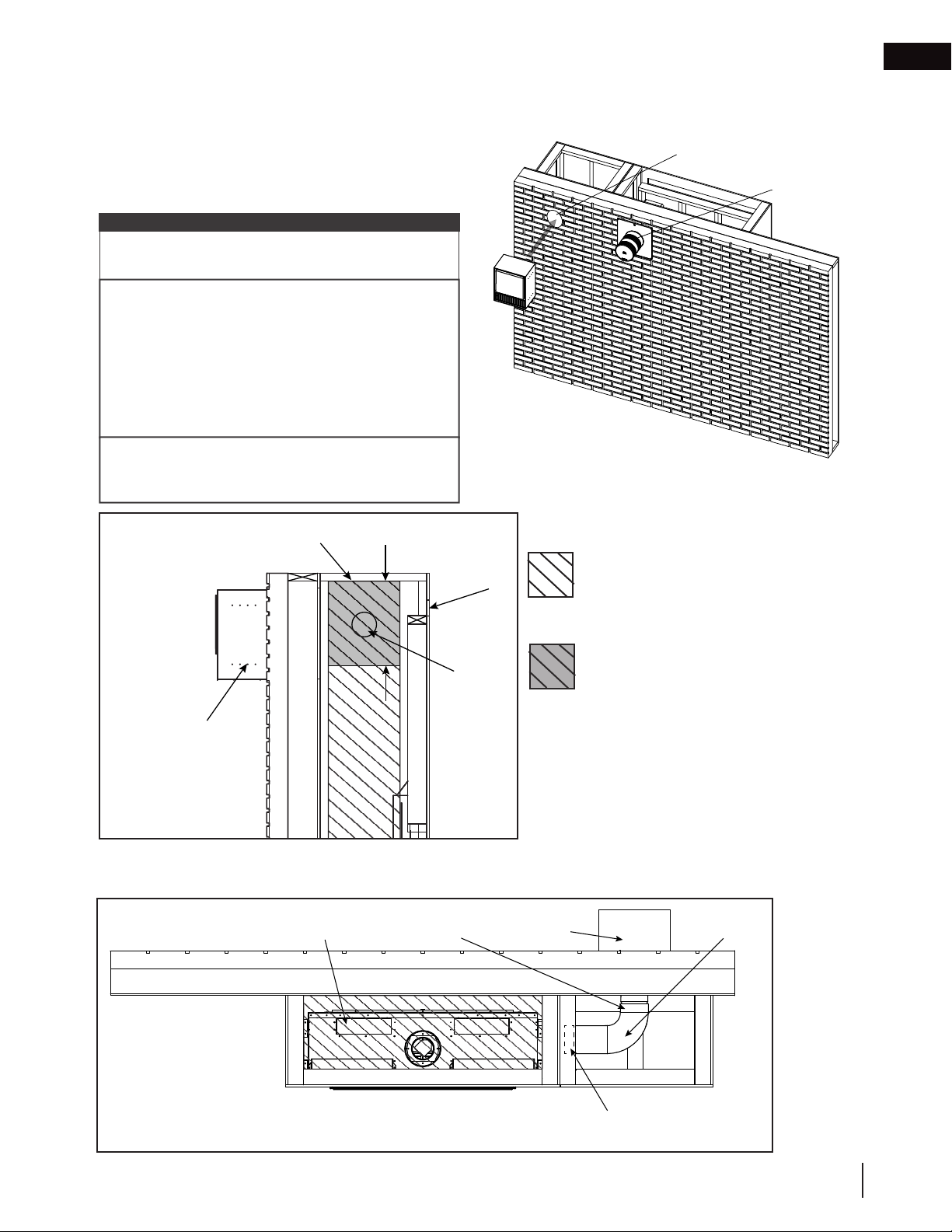

6.3 surface

12”

Top of

Air Outlet

Plate Assembly

In this mounting option, the exterior housing assembly

is surface-mounted to the finished exterior wall

without the use of a wall flashing. S

requires the framing of a minimum Ø 6” (152mm)

clearance hole in the exterior wall for the air damper

assembly (see illustrations).

note:

When surface-mounting DHC™ Plus, ensure to fix

the appliance to studs.

Due to a variety of potential finish materials, brackets

to mount DHC™ Plus need to be fabricated on-site

from suitable materials and attached using selfdrilling fasteners at the dimples provided on the

side of the housing. Suitable flashing, drip edges,

and sealing must be completed in accordance with

good construction practices to weather-proof the

installation.

Care must be taken to fasten the DHC™ Plus

securely, and the weight of the system must not be

supported by the ducting or air damper assembly.

urface-mounting

Exterior

mounting options

Minimum Ø 6”

(152mm)

Clearance Hole

Remote Exterior Installation

illustrated with inline and

decorative covers installed

Ø 6”

(152mm)

hole

Appliance

Appliance

Vent Terminal

Vent Terminal

(if applicable)

(if applicable)

Exterior

Interior

EN

Interior

Enclosure

Exterior

Exterior Housing

Assembly

(30.5cm)

Opening

Interior

Ø 6” (152mm)

Hole &

Installed

Collar Plate

Assembly or

Enclosure

Left Side Profile View

(Remote Exterior Installation illustrated. Some components may not apply to

your unique installation.)

Exterior

Appliance

(LVX38 Illustrated)

Air Damper

Assembly

Exterior Housing

Assembly

No materials of any type permitted in this

area with the exception of an approved

appliance vent system or the DHC™

Plus system.

Recommended DHC™ Plus collar plate

assembly installation zone (12” [30.5cm]).

6’ Rigid

Steel Venting

Interior

Installed 6” Collar

Top Side View

(Remote Exterior Installation illustrated. Some components may not apply to your unique installation.)

W415-1789 / C / 01.29.19

19

Page 20

EN

Hex

7.0 remote inline pre-installation

FOR REMOTE INLINE INSTALLATIONS ONLY

For remote inline installations, you must follow the instructions below before beginning installation. For exterior and

remote exterior installations, see “exterior & remote exterior pre-installation” section.

1. Install the air damper assembly onto the collar of the hot air exhaust assembly and secure with self-drilling screws

(supplied) (Fig. 1). Rotate so that the air damper assembly closes shut when the blower is not running.

note:

The air damper assembly must be closed when the blower is not running for the system to function correctly.

The plate of

x 3

Fig. 1

2. Attach the 6” (152mm) collar connector assembly to the blower housing assembly using self-drilling screws (sup-

plied) (Fig. 2).

3. Attach the mounting brackets to the blower housing assembly using screws (supplied) (Fig. 3).

x 5

the air damper

assembly must

open from the

bottom. Take

care to install

in the correct

orientation so it

IMPORTANT

will open when

the blower operates. Always

test before

finishing.

x 4

Plate

Profile View

20

Blower housing assembly

illustrated on its side.

note:

If desired, grills other than those supplied with the DHC™ Plus may be used for remote inline installations. In

those instances, ensure to maintain a free area of 73.9 sq. in. (47680 sq. mm) minimum and always install the

damper.

4. Attach the inline cover assembly using screws (supplied). See “electrical information” section for more details.

W415-1789 / C / 01.29.19

Fig. 2 Fig. 3

Blower housing assembly

illustrated on its side.

Page 21

8.0 remote inline installation

8.1 remote inline installation overview

!

WARNING

• Minimum clearance to combustibles must be maintained or a serious fire hazard could result.

• DO NOT cover or place any items in the Dynamic Heat Control™ air outlet opening. Failure to comply with

these instructions will create a fire hazard.

DHC™ Plus CANNOT be mounted directly above or below the appliance vent terminal as this will

cause the system to fail. It MUST be mounted to the left or right of the appliance vent terminal.

• For optimal performance, we recommend installing DHC™ Plus within the top 12” (30.5cm) of the enclosure.

However, it MUST be installed above the appliance.

• The minimum height requirement above the appliance will vary depending on the appliance size. See “minimum

venting requirements” section of your appliance manual for details.

DHC™ Plus remote inline installation can be installed inline anywhere between the appliance enclosure and the

hot air exhaust assembly with a total vent length up to 60’ (18.2m).

EN

Required:

• DHCP-BK

• DHCP-HK

note:

MUST have air outlet opening.

Collar Plate

Assembly

• Venting, 6” rigid steel (not supplied)

• Duct, steel 6” (not supplied)

Appliance Vent

Terminal (if

applicable)

6” Collar

Connector

Assembly

6” Rigid Steel

Venting (Not

note:

Diagram is for illustrative purposes

only. Installation must comply with all

electrical and local codes.

View of Opposite

Exterior Wall

Supplied)

Wall

Flashing

GLASS GUARD

Appliance

LVX38 Illustrated

Enclosure

6” Steel

Duct

(Not

Supplied)

Inside View of

Bulkhead (Some

Framing and

Finishing Hidden

for Clarity)

note:

MUST have

access panel

for service or

maintenance of

blower.

Interior

Maintain

distance to

combustibles.

Air Damper

Assembly

Hot Air Exhaust

Assembly

Exterior

Insulation

W415-1789 / C / 01.29.19

21

Page 22

EN

remote inline installation

8.2 minimum framing requirements

note:

For optimal performance, we recommend installing DHC™ Plus within the top 12” (30.5cm) of the enclosure.

The DHC™ Plus must be mounted above the appliance.

A bulkhead may need to be constructed to house the venting and blower housing assembly with appropriate

blower access panel. Always maintain clearance to combustibles.

Minimum Clearance to Combustibles Clearance

DHCP-BK 0”

DHCP-HK 0”

Vent pipe, collars, firestops, etc. 1” (25mm)

1. Determine the desired location for the hot air exhaust assembly on the exterior wall and frame a 14 1/2”

(36.8cm) wide by 11 3/8” (28.9cm) high opening (Fig. 1).

note:

It may be necessary to shim the blower

housing in the rough opening to provide a

secure fit. If the blower is not secured properly,

excessive noise and vibration may result.

Fig. 1

14 1/2” (36.8cm) min.

11 3/8” (28.9cm)

2. Fasten the wall flashing onto the hot air exhaust assembly using

4 screws (supplied) (Fig. 2).

note:

Ensure to NOT install the wall flashing too far

forward or the grill could be damaged.

Exterior

Interior

Interior

x 4

22

Fig. 2

W415-1789 / C / 01.29.19

Page 23

remote inline installation

3. Attach the hot air exhaust assembly to the exterior wall by securing the wall flashing with appropriate fasten-

ers (not supplied) (Fig. 3).

4. Apply silicone to the joint after installation, and

caulk or seal the flashing appropriately for the

finish material (Fig. 4).

SILICONE

EN

CAULK

Fig. 4

Interior

Exterior

5. Determine the location of the blower housing assembly, and then frame two studs spaced at 13 1/4”

(33.6cm). Secure the blower housing assembly to the framing by securing the mounting brackets with appropriate fasteners (not supplied) (Fig. 5).

Underside View

Fig. 3

GLASS

GUARD

LVX38 Illustrated

Inside View of Bulk-

head (Some Framing

and Finishing Hidden

for Clarity)

Access Panel

Interior

Exterior

Fig. 5

W415-1789 / C / 01.29.19

23

Page 24

EN

12”

remote inline installation

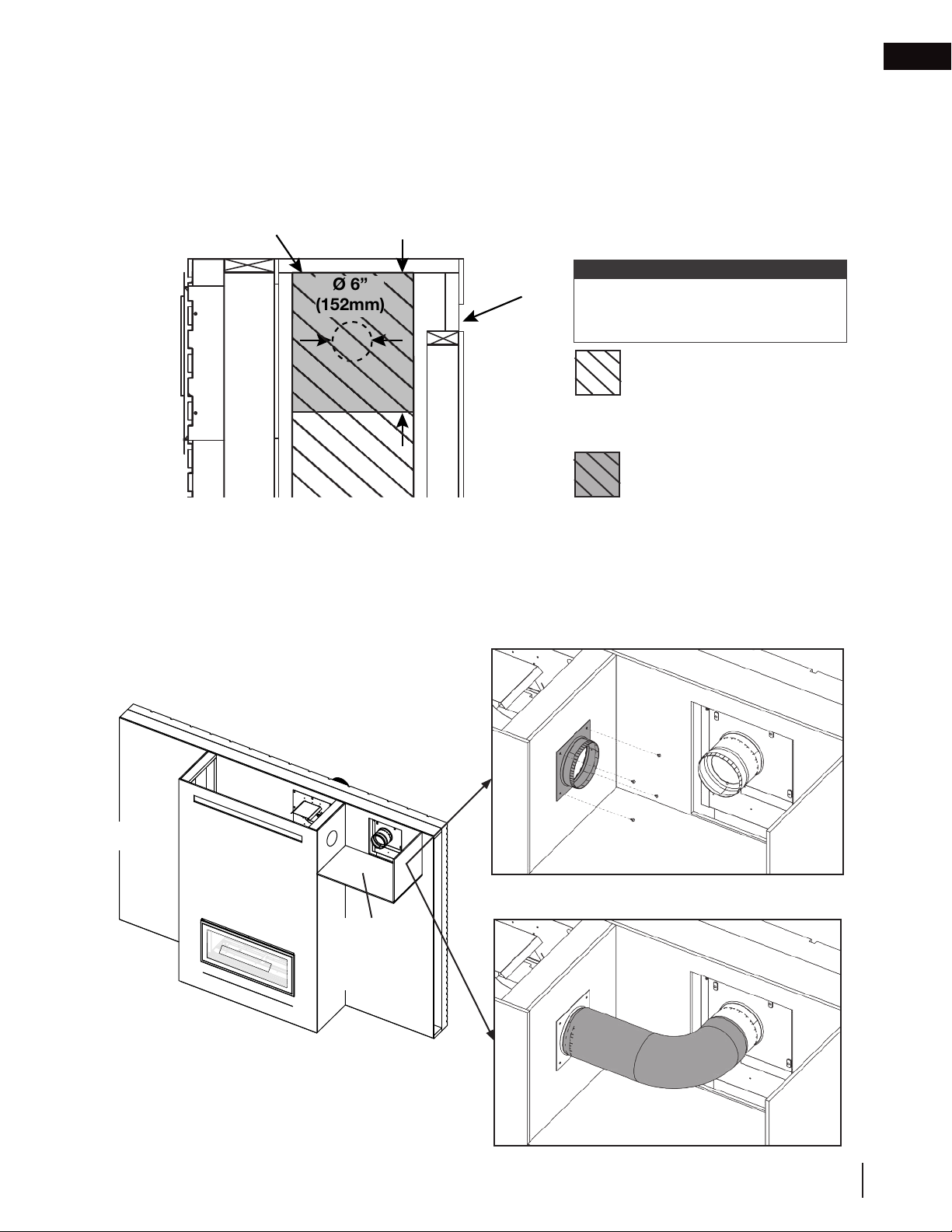

8.3 ducting installation

1. Determine the location for the 6” (152mm) collar plate assembly on the appliance enclosure, and then cut a 6”

(152mm) diameter hole (Fig. 1).

Top of Enclosure

(30.5cm)

Ø 6”

(152mm)

Exterior

Left Side Profile View

2. Secure the 6” (152mm) collar plate assembly over

the hole with the appropriate fasteners (not supplied)

(Fig. 2).

3. Install 6” steel ducting (not supplied) from the appliance enclosure to the blower housing assembly inlet

(Fig. 3).

Air Outlet

Opening

Interior

Fig. 1

note:

Ensure to create the Ø 6” (152mm)

hole within the top 12” (30.5cm) of the

enclosure (Fig. 1).

No materials of any type

permitted in this area with

the exception of an approved

appliance vent system or the

DHC™ Plus system.

Recommended DHC™ Plus

collar plate assembly installation

zone (12” [30.5cm]).

4. Install 6” rigid steel venting (not supplied) from the

blower housing assembly outlet to the hot air exhaust assembly (Fig. 4).

note:

Ensure to maintain 1” (25mm) clearance to

combustibles.

Inside View of

Bulkhead (Some

Framing and

Finishing Hidden

for Clarity)

Access

Panel

Fig. 3

Inside View of

Bulkhead (Some

Framing and

Finishing Hidden

for Clarity)

Access

Panel

Fig. 2

Fig. 4

note:

When constructing a bulkhead, particularly one that passes through multiple rooms or spaces, always ensure that

you adhere to all local building codes and requirements.

24

W415-1789 / C / 01.29.19

Page 25

remote inline installation

8.4 completed installation checklist

!

WARNING

• Ensure all items are checked for your respective installation or a serious fire hazard could result.

• Completed installations must conform to local codes or, in the absence of local codes, the National Gas and

Propane Installation Code CSA B149.1 in Canada, or the National Fuel Gas Code ANSI Z223.1 / NFPA 54 in the

United States.

Installer, please tick all boxes for this installation or it IS NOT considered completed.

EN

1. Air damper assembly installed and checked.

2. Collar connector assembly attached.

3. Mounting brackets installed.

4. Rough opening framed into exterior wall.

5. Wall flashing installed and sealed appropriately for finish

material.

6. DHCP-HK attached.

7. Studs framed.

8. Ø 6” (152mm) hole cut into appliance enclosure.

9. Collar plate assembly secured.

10. 6” steel duct (not supplied) installed.

11. 6” rigid steel venting (not supplied) installed.

12. Wiring completed (see “electrical information” section).

13. On/off switch adjusted to fully “on” position.

DHCP-HK

Wall Flashing

Air Damper

Assembly

Collar Connector Assembly

Mounting Bracket (x2)

Interior

Exterior

6” Collar Plate

Assembly

Access

Panel

6” Steel Duct

(Not Supplied)

6” Rigid Steel

Venting

(Not Supplied)

W415-1789 / C / 01.29.19

25

Page 26

EN

9.0 electrical information

!

WARNING

• All wiring should be done by a qualified electrician, and must be connected and grounded in accordance with

local codes. In the absence of local codes, use the current CSA 22.1 Canadian Electrical Code in Canada or the

ANSI/NFPA 70-1996 National Electrical Code in the United States.

• All electrical wires must be strain-relieved and protected according to local codes and good installation

practices.

• You must used armoured cable for the installation of DHC™ Plus.

9.1 wiring to SIT control board & remote control

BLOWER

BLOWER/LAMP

TERMINAL BLOCK

LAMP

COMFORT

FAN

COMFORT

FAN

LAMP

APPLIANCE CONTROLLER

BLOWER

1. Unplug the blower / lamp terminal block on the SIT control

board, located in the appliance (see appliance manual for

details).

2. Determine the desired location of the wiring knockout (Fig. 1),

and then remove the left or right knockout accordingly. Install

bushing (supplied) into knockout.

3. Loosen blower terminal screws and disconnect wires.

4. Disconnect the blower ground wire, which is screwed to the

base of the appliance.

5. Connect new armoured cable (not supplied) into the blower

terminal block and tighten the blower terminal screws.

6. Plug the blower / lamp terminal block back into the board.

note:

Ensure to ground new armoured cable to the ground screw.

x 1

Right Side

Knockout

REMOVE WIRES TWO BLOWER

WIRES AS SHOWN

Blower

BLOWER/LAMP TERMINAL

BLOCK (TOP VIEW)

Back View of Appliance

Lamp

Left Side

Knockout

Fig. 1

26

7. If applicable, remove the 4 screws securing the decorative cover on the blower housing assembly and set

them aside (Fig. 4, next page). Remove the decorative cover and set it aside.

W415-1789 / C / 01.29.19

Page 27

electrical information

#10 Thread, RH

29/64”

1/8”

1-1/2”

Quadrex Drive

Hex

Hex

8. If applicable, remove the 4 screws securing the inline cover assembly and set them aside (Fig. 3). Remove

the inline cover assembly and set it aside.

9. Install the on/off switch into the on/off switch housing with 2 screws (supplied).

10. Install the pal nut and knob.

11. Install the new armoured cable from the SIT control board to the on/off switch housing inside the blower kit

housing.

12. Connect the hot wire of the new armoured cable to one end of the on/off switch inside the on/off switch

housing.

note:

Ensure to use armoured cable, connectors, and strain reliefs suitable for installation (not supplied).

Armoured cable should be installed in a stud whenever possible. Armoured cable should also be installed as

close to the outside of the enclosure and as far away from the appliance as possible.

13. Connect the opposite end of the on/off switch to the black wire from the blower inside the on/off switch

housing.

14. Connect the neutral wire of the new armoured cable to the white wire from the blower inside the on/off switch

housing.

15. Connect the ground wires from the blower and armoured cable to the ground screw inside the on/off switch

housing.

16. Install the on/off switch housing into the blower kit housing by inserting the tabs into the slots (Fig. 2). Tighten

the nut onto the stud.

17. Install/reinstall the inline cover assembly using 4 screws (supplied) (Fig. 3).

18. Install/reinstall the decorative cover onto the blower housing assembly using 4 screws (supplied) (Fig. 4).

x2

EN

Stud

Nut

Some components

hidden for clarity.

#9-14 Thread, RH

x 4

Fig. 2

#9-14 Thread, RH

x 4

Fig. 3

Fig. 4

W415-1789 / C / 01.29.19

27

Page 28

EN

electrical information

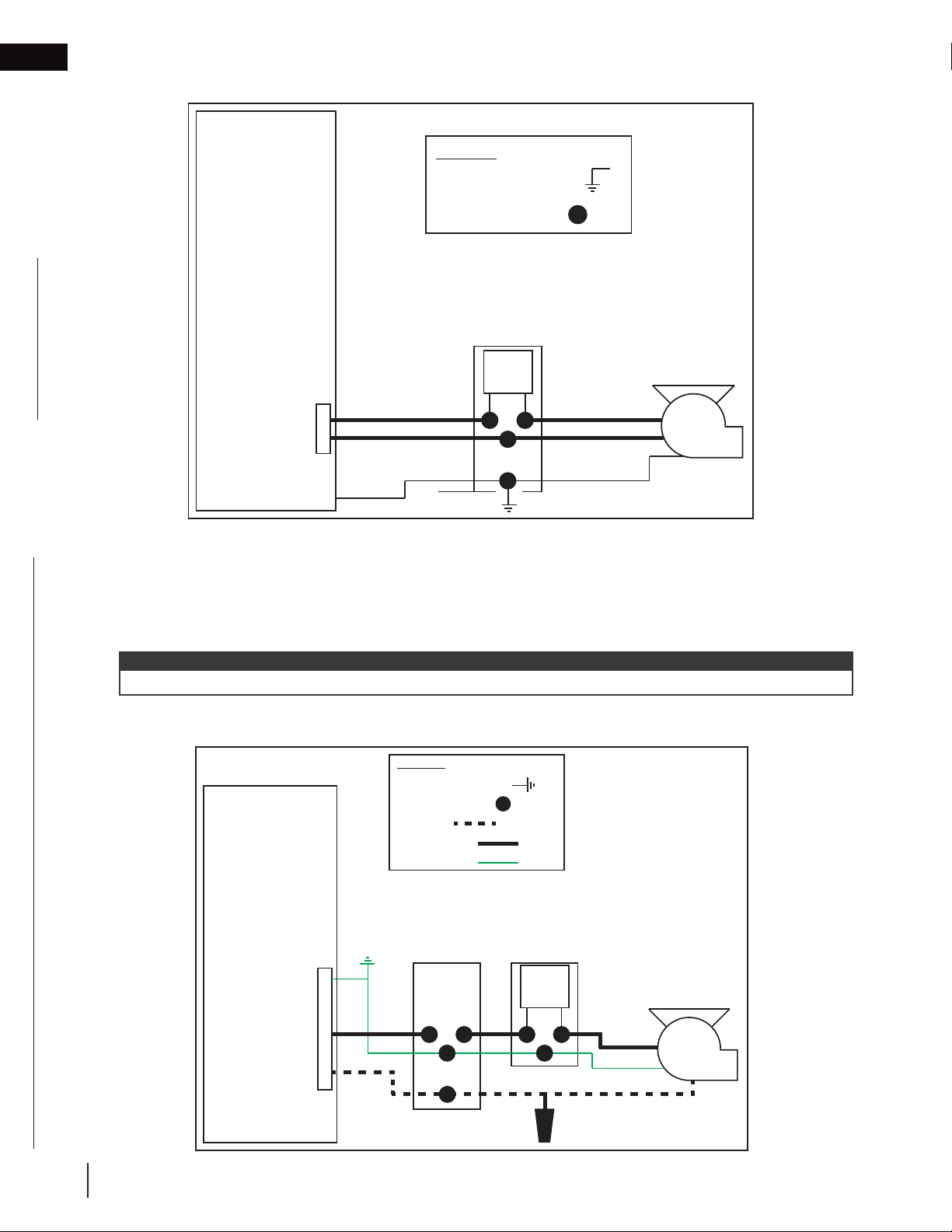

9.1.1 wiring diagram

SIT

Proflame 2

Control Board

14/2 power source

(not supplied)

L

N

Legend:

Ground Connection =

Field Connection =

On/Off Switch

in Blower

Housing

On/Off

Switch

(factory installed)

(supplied)

Blower

9.2 wiring to wall switch & remote control (in series)

1. Determine the location for the wall switch. Install an electrical box (not supplied) at the location.

2. Ensure the hot and neutral wires from the Proflame 2 are properly connected to the wall switch box.

3. Connect the hot wire from the on/off switch to the wall switch.

4. Connect the neutral wires to each other from the blower to the power source neutral (N).

5. Connect the all ground from the SIT Proflame 2 control board to the blower.

note:

Check the blower specifications (see “blower specifications” section) before choosing a suitable wire size.

9.2.1 wiring diagram

Legend:

Ground Connection =

Field Connection =

Neutral =

L1 (120VAC) =

Ground Wire =

SIT

Proflame 2

Control Board

G

Wall

Switch

On/Off Switch

in Blower

Housing

On/Off

Switch

28

W415-1789 / C / 01.29.19

L

N

Blower

Page 29

electrical information

9.3 wiring to wall switch only

1. Turn off the power by locating your housebreaker, and shutting the power off to the room you will be working

in.

2. Determine the location for the wall switch (not supplied). Install an electrical box (not supplied) at the location.

3. Ensure the wires for the wall are properly wired to the switch box and are ready.

4. Connect the hot wire from the on/off switch to the wall switch.

5. Connect the neutral wires to each other from the blower to the power source neutral (N).

6. Connect the all ground from the power source to the blower.

note:

Check the blower specifications (see “blower specifications” section) before choosing a suitable wire size.

9.3.1 wiring diagram

Legend:

Ground Connection =

Field Connection =

Neutral =

L1 (120VAC) =

Ground Wire =

On/Off Switch

in Blower

Housing

Wall

Switch

On/Off

Switch

Blower

120VAC

14/2

Power

Source

G

L

N

EN

9.4 blower specifications

00464504 00469142

Assembled in Mexico

115 V 50/50Hz Class B

0.9A/1.1A 1600 RPM

Cust P/N Sealed Ball Brg

Thermally Protected

No. 70903602

TYPE 90B1

AO

Connection Diagram

Wht Line

Blk Line

Blu

Blu

4 MFD/370 VAC

61299553

W415-1789 / C / 01.29.19

29

Page 30

EN

10.0 operation

10.1 on/off switch

!

WARNING

• This should be performed after both the appliance and DHC™ Plus have been fully installed, including all

venting and finishing materials.

For optimal performance, the on/off switch in the blower housing must ALWAYS be set to the maximum speed

setting.

note:

If a lower speed is selected (at the blower housing or remote) to reduce air flow, the result may be a minor

imbalance of the motor that causes a minor humming. While this will not affect the longevity of the motor, it may

result in a noticeable noise depending on the location of the DHC™ Plus blower kit.

10.2 using remote control

The remote control has 5 different blower speed settings. For optimal performance, the remote control must

ALWAYS be set to the maximum speed setting.

note:

If a lower speed is selected (at the blower housing or remote) to reduce air flow, the result may be a minor

imbalance of the motor that causes a minor humming. While this will not affect the longevity of the motor, it may

result in a noticeable noise depending on the location of the DHC™ Plus blower kit.

30

W415-1789 / C / 01.29.19

Page 31

11.0 replacement parts

WARNING

!

• Failure to position the parts in accordance with this manual or failure to use only parts specifi cally approved

with this appliance may result in property damage or personal injury.

Contact your dealer for questions concerning prices and policies on replacement parts. Normally, all parts can

be ordered through your Authorized dealer / distributor.

For warranty replacement parts, a photocopy of the original invoice will be required to honour the

claim.

When ordering replacement parts always give the following information:

• Model & Serial Number of appliance

• Installation date of appliance

• Part number

• Description of part

• Finish

Parts, part numbers, and availability are subject to change without notice.

Parts identifi ed as stocked will be delivered within 2 to 5 business days for most delivery

destinations.

Parts not identifi ed as stocked will be delivered within a 2 to 4 week period, for most cases.

Parts identifi ed as ‘SO’ are special order and can take up to 90 days for delivery.

EN

W415-1789 / C / 01.29.19

31

Page 32

EN

Items may not appear exactly as illustrated.

Part Number

Description

W010-4481-SER

Air damper assembly

3

4

Ref. No.

Part Number

7

6

2122232527

26

W062-0078-SER

DHC™ Plus blower

W660-0113

W010-4544

Ye s

W010-4482-SER

5

Gasket

W290-0876-SER

8

W350-0908-SER

Inline housing

W010-4483-SER

Collar plate assembly

28

replacement parts

11.1 DHCP-BK overview

32

W415-1789 / C / 01.29.19

Page 33

replacement parts

Part Number

Description

Stocked

2

21

22

W263-0214-SER

Wall flashing

W200-0764-SER

1

EN

11.2 DHCP-EK overview

W415-1789 / C / 01.29.19

33

Page 34

EN

Items may not appear exactly as illustrated.

Ref. No.

Part Number

Description

Stocked

21

22

W263-0213-SER

Wall flashing

W305-0007-SER

Louvered grill

replacement parts

11.3 DHCP-HK overview

34

W415-1789 / C / 01.29.19

Page 35

12.0 notes

EN

W415-1789 / C / 01.29.19

35

Page 36

NAPOLEON CELEBRATING OVER 40 YEARS

OF HOME COMFORT PRODUCTS

7200, Route Transcanadienne, Montréal, Québec H4T 1A3

24 Napoleon Road, Barrie, Ontario, Canada L4M 0G8

214 Bayview Drive, Barrie, Ontario, Canada L4N 4Y8

103 Miller Drive, Crittenden, Kentucky, USA 41030

Phone: 1-866-820-8686

napoleon.com

Page 37

MODÈLES DE GAZ NATUREL

DHCP-BK / DHCP-EK / DHCP-HK

MODÈLES DE PROPANE

ADD PRODUCT CODE HERE (TRADE GOTHIC LT STD FONT)

FRANÇAIS

FRANÇAIS

MANUEL D’INSTALLATION

CONSIGNES DE SÉCURITÉ

AVERTISSEMENT!

RISQUE D’INCENDIE OU D’EXPLOSION

Incapacité à suivre ces avertissements

exactement peuvent entraîner de grave

blessures, des pertes de vie ou des

dommages matériels.

- N’entreposez pas et n’utilisez pas d’essence

ou autres liquides et vapeurs infl ammables à

proximité de cet appareil ou tout autre appareil.

- QUE FAIRE SI VOUS DÉTECTEZ UN

ODEUR DE GAZ:

• N’allumez aucun appareil.

• Ne touchez à aucun interrupteur

électrique; n’utilisez aucun téléphone dans

votre immeuble.

• Appelez immédiatement votre fournisseur

de gaz d’un téléphone voisin. Suivez ses

instructions.

• Si vous ne pouvez pas rejoindre votre

fournisseur de gaz, appelez le service des

incendies.

- L’installation et l’entretien doivent être faits par

un installateur qualifi é, une agence d’entretien

ou le fournisseur.

ADD MANUAL TITLE

ET D’OPÉRATION

Product Name / Code

(MUST use title from Price Book)

ADD ____ ILLUSTRATED

MD

BREVET DÉPOSÉ

ADD PRODUCT IMAGE

Cet appareil peut être installé dans une maison

préfabriquée (mobile) déjà installée à demeure

si les règlements locaux le permettent.

Cet appareil doit être utilisé uniquement

avec le type de gaz indiqué sur la plaque

Laissez ce manuel avec l’appareil.

d’homologation. Cet appareil ne peut être

converti à d’autres gaz, sauf si une trousse de

Conservez ce manuel pour consultation

conversion est utilisée.

ASSUREZ-VOUS DE COMMANDER LES EN-

SEMBLES CORRECTES. VOIR L’INTÉRIEUR

$10.00

Laissez ce manuel avec l’appareil

Conservez ce manuel pour consultation

INSTALLATEUR:

PROPRIÉTAIRE:

ultérieure.

INSTALLATEUR:

PROPRIÉTAIRE:

POUR PLUS DE DÉTAILS.

ultérieure

Wolf Steel Ltd., 24 Napoleon Rd., Barrie, ON, L4M 0G8 Canada / 103 Miller Drive, Crittenden, Kentucky, USA, 41030

Téléphone 1(866)820-8686 • www.napoleon.com • hearth@napoleon.com

DHCP-BK &

DHCP-EK Illustrée

Ces instructions DOIVENT être utilisées conjointement avec

les manuels d’installation des appareils Vector

CERTIFIÉ SELON LES NORMES NATIONALES CANADIENNES ET AMÉRICANES:

CSA 2.22 ET ANSI Z21.50 POUR LES APPAREILS À GAZ DÉCORATIF À ÉVACUATION

LuxuriaMD, et du système Dynamic Heat ControlMD.

POUR USAGE INTÉRIEUR SEULEMENT

MD

et

À UTILISER AVEC LES MODÈLES

VECTORMD (avec système DHCMD) &

LUXURIAMD SEULEMENT

IF INSTALLATION + OPERATION, ADD SERIAL

CSA /

INTERTEK

LOGO

LV38N/P-1 / LV38N/P2-1 / LV50N/P-2 / LV50N/P2-2 /

IF SEPARATE MANUALS, ADD “PLACE

LVX38N/P / LVX38N/P2 / LVX50N/P / LVX50N/P2 /

BARCODE LABEL ON THE OWNER’S MANUAL”

NUMBER LABEL HERE

LV62N/P / LV62N/P2 / LV74N / LV74N2

LVX62N/P / LVX62N/P2 / LVX74N / LVX74N2

W415-1789 / C / 01.29.19

Page 38

table des matières

1.0 planification de l’installation 39

FR

1.1 introduction 39

1.2 options d’installation 40

1.3 vue d’ensemble du système

DHCMD Plus 40

1.3.1 DHCP-BK 41

1.3.2 DHCP-EK 41

1.3.3 DHCP-HK 41

1.4 considérations du niveau de bruit 42

1.5 ventilation & conduits 42

1.6 emplacement dans l’enceinte 43

1.7 dimensions 44

1.7.1 DHCP-BK & DHCP-EK 44

1.7.2 DHCP-BK & DHCP-HK 44

2.0 exigences minimales des

conduits 45

2.1 sortie des conduits pour le

système DHCMD Plus 45

3.0 pré-installation sur un mur

extérieur, à l’intérieur de l’enceinte

ou hors de l’enceinte 46

4.0 installation sur un mur extérieur 47

4.1 vue d’ensemble de l’installation

sur un mur extérieur 47

4.2 exigences minimales en matière

d’ossature 48

4.3 liste de vérification de l’installation 50

5.0 installation sur un mur extérieur

hors de l’enceinte 51

5.1 vue d’ensemble de l’installation

sur un mur extérieur hors de l’enceinte

51

5.2 exigences minimales en matière

d’ossature 52

5.3 installation des conduits 52

5.4 liste de vérification de l’installation 53

6.0 options de fixation 54

6.1 installation à égalité 54

6.2 dépassant 55

6.3 surface 56

7.0 pré-installation en ligne hors de

l’enceinte 57

8.0 installation en ligne hors de

l’enceinte 58

8.1 vue d’ensemble de l’installation en

ligne hors de l’enceinte 58

8.2 exigences minimales en matière

d’ossature 59

8.3 installation des conduits 61

8.4 liste de vérification de l’installation 62

9.0 information électrique 63

9.1 câblage aux panneau de commande

SIT & télécommande 63

9.1.1 schéma de câblage 65

9.2 câblage à l’interrupteur de mur &

télécommande (en séries) 65

9.2.1 schéma de câblage 65

9.3 câblage à l’interrupteur de mur

seulement 66

9.3.1 schéma de câblage 66

9.4 spécifications du ventilateur 66

10.1 l’interrupteur « on/off» 67

10.2 fonctionnement de télécommande 67

10.0 fonctionnement 67

11.0 pièces de rechange 68

11.1 vue d’ensemble de DHCP-BK 69

11.2 vue d’ensemble de DHCP-EK 70

11.3 vue d’ensemble de DHCP-HK 71

38

note:

L’information contenue dans ce manuel est jugée correcte au moment de l’impression. Wolf Steel Ltd. se réserve

le droit de modifier ou de modifier toute information contenue dans ce manuel à tout moment sans préavis. Les

modifications, autres que les éditoriaux, sont désignes par une ligne verticale dans la marge.

!

AVERTISSEMENT:

chrome qui, selon l’État de Californie, causeraient le cancer, et des substances chimiques

incluant le toluène qui, selon d’État de Californie, causeraient des malformations congénitales

ou autres dangers pour la reproduction.

Pour de plus amples renseignements, visitez le www.P65Warnings.ca.gov.

W415-1789 / C / 01.29.19

Ce produit peut vous exposer à des substances chimiques incluant le

Page 39

1.0 planification de l’installation

!

AVERTISSEMENT

Le système Dynamic Heat ControlMD Plus (DHCMD Plus) NE PEUT PAS être installé si l’appareil n’est pas

doté du système Dynamic Heat ControlMD.

• Le système DHCMD Plus est UNIQUEMENT compatible avec l’option d’installation n° 2 du système

Dynamic Heat ControlMD (ouverture avant) ou l’option d’installation n° 3 (ouverture à l’arrière).

Le système DHCMD Plus DOIT être installé avec une sortie d’air; autrement, l’appareil présentera un risque

d’incendie.

• L’installation doit être conforme aux codes locaux ou, en l’absence de tels codes, au Code d’installation du

gaz naturel et du propane CSA B149.1 au Canada ou au National Fuel Gas Code ANSI Z223.1 / NFPA 54 aux

États-Unis.

• Un appareil peut être doté d’un seul ventilateur DHCMD Plus.

• Nous recommandons d’installer le système DHCMD Plus AVANT d’installer les conduits d’évacuation et les

conduits de gaz de l’appareil.

• L’installation DOIT être effectuée par un installateur qualifié qui a suivi le cours sur le système Dynamic Heat

ControlMD sur Napoleon EDucation, le portail de formation en ligne de Napoléon.

• Assurez-vous que l’appareil est complètement refroidi avant de commencer l’installation.

• Afin d’éviter les risques de suffocation, gardez le sac d’emballage loin des bébés et des jeunes enfants. Ne le

laissez pas traîner dans les berceaux, les lits, les poussettes, ou les parcs de jeu. Ce sac n’est pas un jouet.

Nouez-le avant de le jeter.

1.1 introduction

Le système Dynamic Heat ControlMD Plus (DHCMD Plus) est un système de gestion de la chaleur produite par

l’appareil et autour de celui-ci. Le système DHCMD Plus vise à éloigner la chaleur de l’appareil et principalement à

distribuer tout ou partie d’elle à l’extérieur. Lorsque la longueur de conduit est supérieure à cinq pieds ou lorsque les

conduits doivent passer par des espaces non isolés (comme dans un grenier), il est recommandé d’isoler les conduits.

FR

Bien qu’il soit possible d’utiliser le système DHCMD Plus pour déplacer la chaleur vers un autre

emplacement dans la maison, veulliez considéré soigneusement les points suivants lors de la phase de

planification:

• Le niveau sonore du ventilateur DHC

section « considérations du niveau de bruit »).

• Le système DHCMD Plus ne doit pas être utilisé dans de

petites pièces fermées avec des plafonds bas, comme une

petite salle de bain, car la pièce sera rapidement pressurisée

et le transfert de chaleur du foyer sera réduit / éliminé.

• Le système DHCMD Plus déplace presque toute la chaleur

utilisable. Si le volume de la pièce est petit, la pièce peut

rapidement devenir très chaude. Vous pouvez déplacer la

chaleur non désirée d’une pièce à une autre, ce qui risque de ne pas convenir au client. Il est donc important

de bien évaluer la quantité de chaleur et la taille de la pièce dans laquelle la chaleur est transférée avant de

commencer l’installation.

• Lorsque le système DHCMD Plus est utilisé pour transférer de la chaleur dans une autre pièce, il est

recommandé d’installer un interrupteur marche / arrêt dans cette pièce afin que le transfert de chaleur puisse

être désactivé à distance, si désiré. Le système DHCMD Plus ne comprend pas de thermostat.

MD

Plus est semblable à celui d’un ventilateur de salle de bain (voir la

BREVET DÉPOSÉ

W415-1789 / C / 01.29.19

39

Page 40

planification de l'installation

Hex

Hex

Hex

29/64”

1/8”

1-1/2”

FR

1.2 options d’installation

Il y a trois options d’installation possibles pour le système DHCMD Plus, chacune ayant ses avantages:

Installation sur une mur extérieur

Dans cette option, l’installation du système DHCMD Plus se fait sur le mur extérieur de l’enceinte de l’appareil.

Il ne nécessite pas d’évacuation ni de conduit ni de cloison, et est donc l’option d’installation la plus simple.

Cependant, assurez-vous de considérer le bruit de circulation d’air de l’ensemble de ventilateur DHCMD Plus.

Pour plus de détails, consultez les sections « considérations du niveau de bruit » et « installation sur un mur

extérieur ».

Installation sur une mur extérieur hors de l’enceinte

Dans cette option, l’installation du système DHCMD Plus se fait sur un mur extérieur, hors de l’enceinte de

l’appareil. Bien qu’elle nécessite des conduits et une cloison, la distance à laquelle le ventilateur peut être installé

permet de réduire le bruit de circulation d’air de façon significative. Pour plus de détails, consultez les sections «

considérations du niveau de bruit » et « installation sur un mur extérieur hors de l’enceinte ».

Installation en ligne hors de l’enceinte

Dans cette installation, le système DHCMD Plus est installé en ligne hors de l’enceinte, n’importe où entre

l’enceinte de l’appareil et l’ensemble d’évacuation d’air chaud. Comme avec l’installation sur un mur extérieur

hors de l’enceinte, cette installation nécessite une évacuation, une cloison ainsi que l’ajout de conduits. Cette

installation offre le plus de possibilités pour des configurations uniques, y compris à travers plusieurs pièces ou

étages. Pour plus de détails, consultez la section « installation en ligne hors de l’enceinte ».

Le tableau ci-dessous comporte les ensembles requis pour chaque option d’installation. Veuillez lire

attentivement.

Type d’Installation DHCP-BK DHCP-EK DHCP-HK

Mur extérieur

Installation sur un mur extérieur

hors de l’enceinte

Installation en ligne hors de l’enceinte

1.3 vue d’ensemble du système DHCMD Plus

Contenu de chaque ensemble:

DHCP-BK DHCP-EK DHCP-HK

1 x boîtier de ventilateur

1x

l’assemblage du panneau d’accès en ligne

1 x registre d’air

1 x interrupteur « on/off» / boîtier

1 x connecteur de collet

1 x plaque de collet

2 x support de montage

1 x bague

13 x vis #9x1/2 po

7 x vis #8x1/2 po

1 x boîtier extérieur

1 x solin mural

1 x couvercle décoratif

12 x vis #9x1/2 po

N/A

N/A

N/A

1 x ensemble d’évacuation d’air

chaud

1 x solin mural

4 x vis #9x1/2 po

2 x vis #10x1-1/2 po

Quadrex Drive

#10 Thread, RH

note:

Ces ensembles complets sont toujours composés d’au plus deux boîtes. Veuillez lire le manuel d’installation attentivement et veiller à commander les bons ensembles d’installation.

Bien qu’il ne soit pas fourni, il vous faudra un câble armé pour le câblage du système DHCMD Plus (consultez

la section « information électrique » pour plus de détails). Assurez-vous d’avoir suffisamment de câbles armés à

votre disposition pour compléter votre installation.

40

W415-1789 / C / 01.29.19

Page 41

Hex

1.3.1 DHCP-BK

0.141”

Hex

1

#9-14 Thread, RH

Réf. Description Réf. Description

1 Ensemble de quincaillerie 5 Plaque de collet

2 Interrupteur à vitesse variable (avec

3 Registre d’air 7 L’assemblage du panneau d’accès en ligne

4 Supports (x2) 8 Boîtier de ventilateur

1.3.2 DHCP-EK

2

boîtier et écrou)

planification de l'installation

3

1 3 4

4 5

2

6

6 Connecteur de collet

9 Bague

FR

7

8

9

1.3.3 DHCP-HK

Réf. Description Réf. Description

1 Ensemble de quincaillerie 3 Boîtier extérieur

2 Couvercle décoratif 4 Solin mural

1

#9-14 Thread, RH

29/64”

1/8”

1-1/2”

#10 Thread, RH

Quadrex Drive

2

3

Réf. Description Réf. Description

1 Ensemble quincaillerie 3 Ensemble d’évacuation d’air chaud

2 Solin mural

W415-1789 / C / 01.29.19

41

Page 42

planification de l'installation

FR

1.4 considérations du niveau de bruit

Plus

MD

Plus utilise un ventilateur de haute performance pour déplacer la chaleur non désirée à

Le système DHC

l’extérieur. Semblable à un ventilateur de salle de bain ou à une hotte de cuisinière, l’utilisation d’un ventilateur

pour déplacer l’air produire un son.

note:

Déterminez l’emplacement de l’ensemble du ventilateur avec soin, car le bruit du débit d’air émis par ce dernier

est plus perceptible lorsqu’il est situé à proximité de l’appareil et du client. Ceci est particulièrement important si

vous utilisez le ventilateur pour transférer la chaleur à l’intérieur d’une maison.

1.5 ventilation & conduits

Selon le type d’installation, le système DHCMD Plus nécessitera des des conduits qui ne sont pas fournis:

Installation sur une Mur Extérieur

• N/A

Installation sur une Mur Extérieur hors de l’Enceinte

• Un composant d’évacuation rigide en acier de 6 po entre l’enceinte de l’appareil et l’ensemble de ventilateur

DHC

MD

Installation en Ligne hors de l’Enceinte

• Un conduit en acier de 6 po entre l’enceinte de l’appareil et l’ensemble de ventilateur DHC

• Un composant d’évacuation rigide en acier de 6 po entre l’ensemble de ventilateur DHCMD Plus et l’ensemble

d’évacuation d’air chaud

note:

Assurez-vous de consulter toujours les codes locaux avant d’installer le système DHCMD Plus.

MD

Plus

42

W415-1789 / C / 01.29.19

Page 43

planification de l'installation

1.6 emplacement dans l’enceinte

AVERTISSEMENT

!

• NE PAS couvrir ou placer d’objets dans les ouvertures du sortie d’air Dynamic Heat ControlMD. Cela permettra à

l’appareil de manière incorrecte et peut causer un risque d’incendie.

• Assurez-vous que le débit d’air dans la zone de l’enceinte n’est pas restreint d’aucune façon à l’exception de

l’évacuation approuvée ou le système

Le système DHCMD Plus tire l’air de l’enceinte de l’appareil et doit être installé dans l’enceinte, au-

dessus de l’appareil. NE raccordez JAMAIS le système directement à l’appareil.

Zone d’installation recommandée pour la plaque de collet du système DHCMD Plus - dans la section de

12 po (30,5cm) qui se trouve dans le haut de l’enceinte.

Aucun autre type de matériaux ne peut remplir cet espace; seul un système d’évacuation approuvé peut y

être installé ou le système DHCMD Plus.

DHCMD Plus.

sommet de l’enceinte / plafond

FR

Ouverture de

*

sortie d’air

Dynamic Heat

Control

Goujon

Impasse

Cadre

Supérieur

Déflecteur

important:

** La plaque de collet du système DHCMD Plus doit être installer au dessus du bouclier d’évacuation de

l’appareil (non illustré) (33 po [83cm] minimum du haut de l’appareil).

MD

* *

3 po

33 po

(83cm)

minimum

au dessus

de

l’appareil

**

Seul Côté

Seul Côté

(Encastré)***

*

Voir à Travers

*

33 po

(83cm)

minimum

au dessus

de

l’appareil

**

Seul Côté

(Encastré

Extérieur)

*** Des restrictions s’appliquent également à see-thru lorsqu’une ou plusieurs cavités sont utilisées. Consultez le

manuel de votre appareil pour plus de détails.

Le débit d’air dans la zone hachurée ne doit pas être restreint d’aucune façon à l’exception d’un système

d’évacuation approuvée ou le système DHCMD Plus. Aucun autre élément n’est autorisé dans ce domaine.

Consultez le manuel de votre appareil pour plus de détails à propos des dégagements aux matériaux combustibles. Aucun matériau combustible n’est autorisé dans la zone hachurée ou dans l’espace entre les plots (c’est-àdire sans câblage, conduits, perçages électriques, éléments de charpente combustibles, etc.).

W415-1789 / C / 01.29.19

43

Page 44

planification de l'installation

REV.

025435

C

B

D

8

REV.

DHCP-BK

C

B

D

8

REV.

DHCP-HK

C

B

D

8

FR

1.7 dimensions

1.7.1 DHCP-BK & DHCP-EK

POUR UNE INSTALLATION SUR UN MUR EXTÉRIEUR ET SUR UN MUR

EXTÉRIEUR HORS DE L’ENCEINTE SEULEMENT

vue de face vue de côté droite

15/16"

25mm

16 3/4"

425mm

18 1/2"

469mm

14 1/16"

357mm