Page 1

INSTALLER: LEAVE THIS MANUAL WITH THE APPLIANCE.

CONSUMER: RETAIN THIS MANUAL FOR FUTURE REFERENCE.

INSTALLATION AND

OPERATING INSTRUCTIONS

CERTIFIED UNDER CANADIAN AND AMERICAN NATIONAL STANDARDS: CSA 2.33, ANSI Z21.88 FOR VENTED GAS FIREPLACE HEATERS.

HD81

RIVER ROCK / STONE

BURNER ASSEMBLY

B81NS

NATURAL GAS

1

B81PS

PROPANE

CERTIFIED FOR CANADA AND UNITED STATES USING ANSI/CSA METHODS.

SAFETY INFORMATION

!

WARNING

If the information in these instructions are

not followed exactly, a fi re or explosion

may result causing property damage,

personal injury or loss of life.

- Do not store or use gasoline or other fl ammable

vapors and liquids in the vicinity of this or any

other appliance.

- WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use

any phone in your building.

• Immediately call your gas supplier from a

neighbour’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

fi re department.

- Installation and service must be performed by a

qualifi ed installer, service agency or the supplier.

Wolf Steel Ltd., 24 Napoleon Rd., Barrie, ON, L4M 4Y8 Canada /

103 Miller Drive, Crittenden, Kentucky, USA, 41030

Phone (705)721-1212 • Fax (705)722-6031 • www.napoleonfi replaces.com • ask@napoleon.on.ca

$10.00

1.2

W415-0808 / 06.16.09

Page 2

2

TABLE OF CONTENTS

1.0 GENERAL INFORMATION 2

2.0 INSTALLATION 2

3.0 ADJUSTMENT 6

3.0 REPLACEMENTS 7

4.0 NOTES 8

2.1 ACCESS PANEL 2

2.2 BURNER ASSEMBLY 2

2.3 BULKHEADS 3

2.4 NIGHT LIGHT™ INSTALLATION 3

2.5 PORCELAIN BASE INSTALLATION 4

2.6 BURNER COVER INSTALLATION 4

2.7 ROCK INSTALLATION 5

3.1 FLAME CHARACTERISTICS 6

3.2 VENTURI ADJUSTMENT 6

NOTE: Changes, other than editorial, are denoted by a line in the margin.

1.0 GENERAL INFORMATION

This rock burner assembly is approved for use in the HD81 gas appliance only. It is not approved for use as a

stand alone appliance or in conjunction with any other appliance.

2.0 INSTALLATION

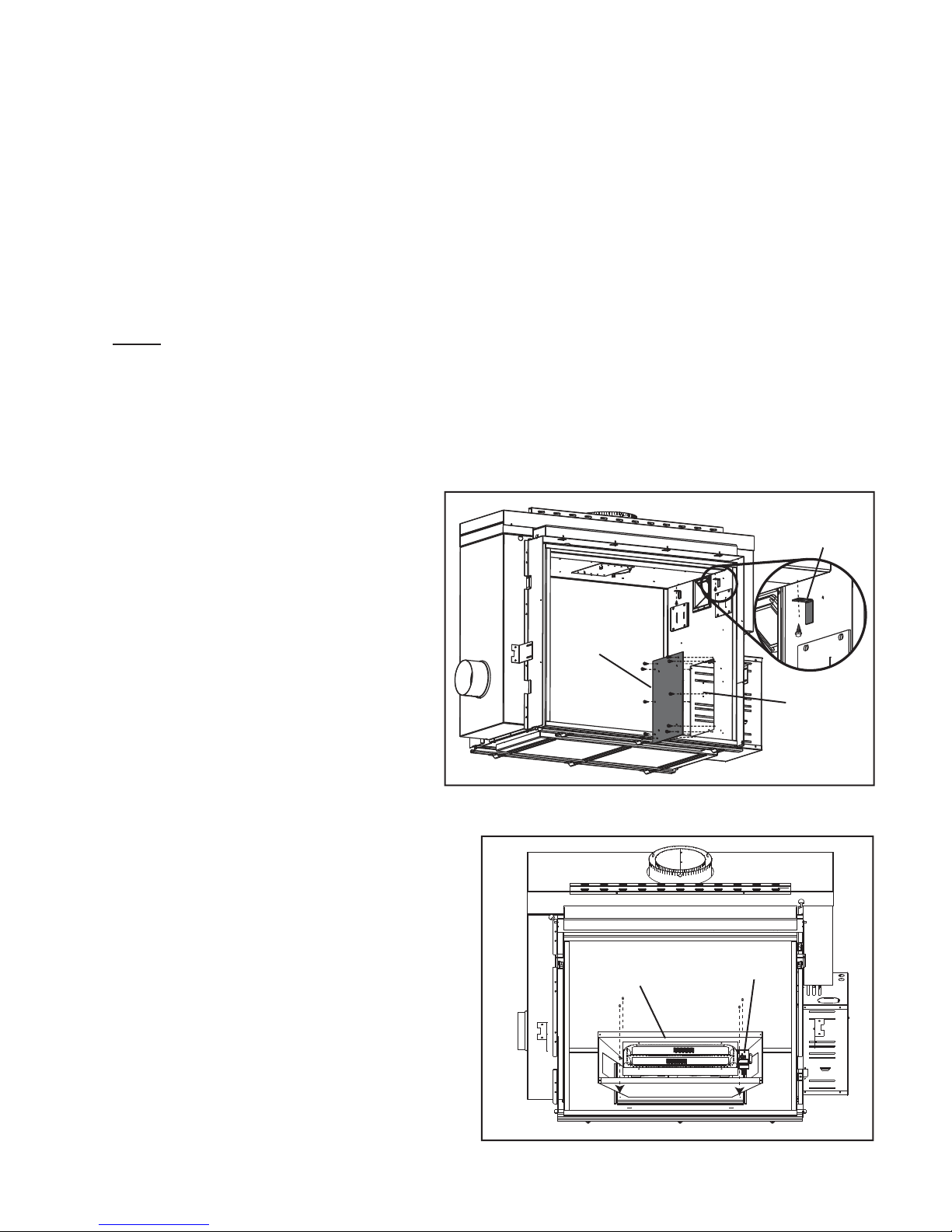

2.1 ACCESS PANEL

2.1.1 Once either door is removed (see

HD81 Installation Instructions), remove the valve access panel and the

4 retaining brackets located at the top

of the fi rebox.

2.2 BURNER ASSEMBLY

2.2.1 Attach the burner assembly to the fi rebox

base with the screws supplied, making sure

the pilot assembly is closest to the valve access opening.

ACCESS

PANEL

BURNER

ASSEMBL Y

RETAINING

BRACKETS

VALVE

ACCESS

OPENING

PILOT

ASSEMBLY

W415-0808 / 06.16.09

Page 3

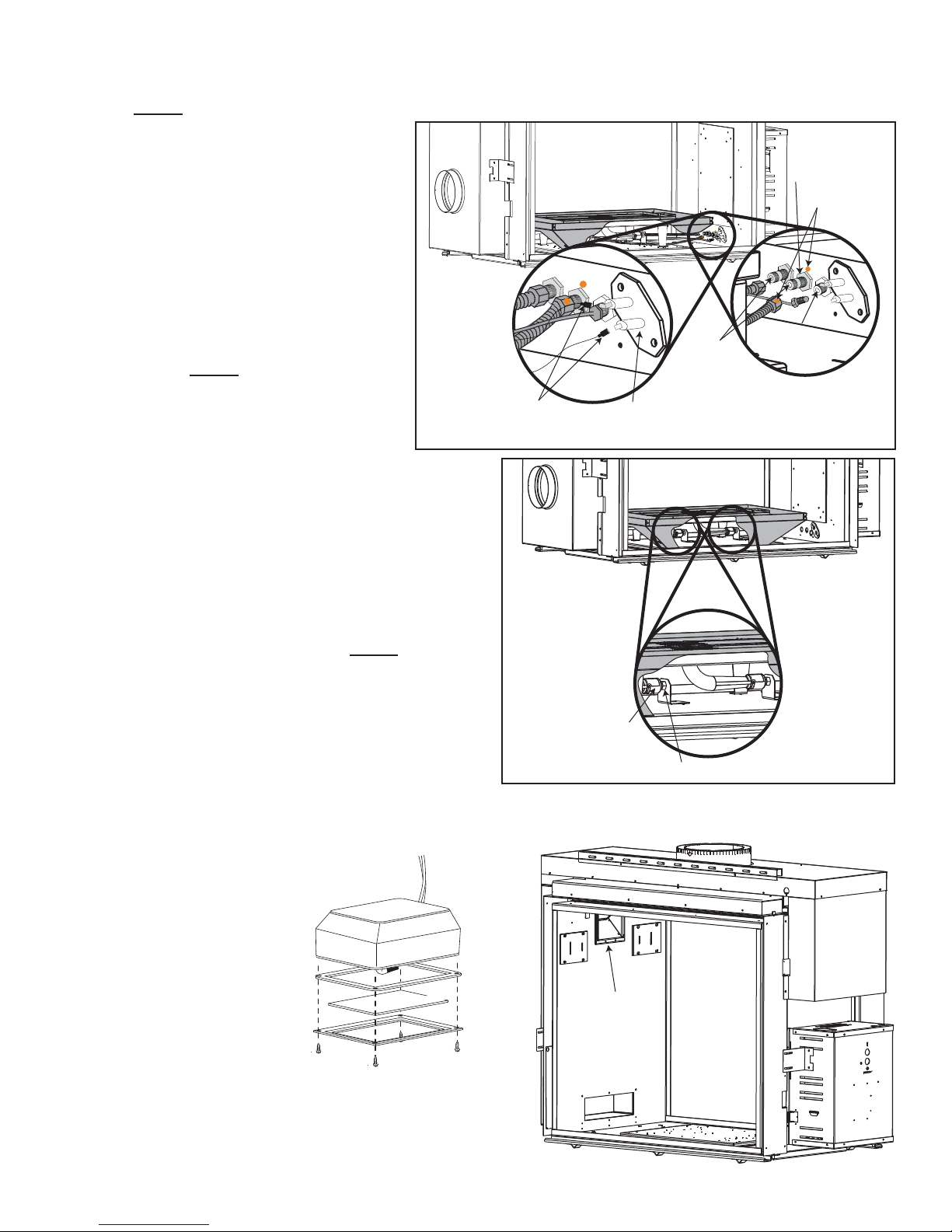

2.3 BULKHEADS

NOTE: Bulkhead covers need to be removed.

3

2.3.1 Connect the gas fl ex lines

and the pilot line to the gas

bulkheads located under the

valve access opening. Be sure

to match up the gas manifold

marked with an orange dot

with the center bulkhead, also

marked with an orange dot.

Care must be taken to ensure

the pilot line isn’t damaged and

ensuring gas tight connections

are made.

NOTE: The middle tube is the

primary burner and can not

be turned off. The outside

burner can be turned on and

off with the remote. If this

isn’t the case then switch the

fl ex lines.

2.3.2 Connect the pilot electrode leads to the

bulkhead. The leads can only fi t one way.

You need to match the 1/4” fl ag with the 1/4”

bulkhead spade and the 3/16” fl ag with the

3/16” spade.

PILOT

ELECTRODE

LEADS

PILOT

ELECTRODE

GAS

BULKHEADS

PRIMARY

BURNER

ORANGE

DOTS

PILOT

BULKHEADS

2.3.3 Ensure the 2 venturi tubes are over the

orifi ces before lighting. NOTE: It is recom-

mended at this stage to do an operational check before fi nishing installation.

2.3.4 Check for gas leaks by brushing on a soap

and water solution. Do not use open fl ame.

2.3.5 After leak test has been performed re-install

access panel with gasket.

2.4 NIGHT LIGHT™ INSTALLATION

Your HD81 comes

equipped with 2 “Night

Lights™”.

The lights have been prewired and are controlled

from the remote control.

Included with the burner

assembly are the frames,

lenses and gaskets that

need to be installed as

illustrated.

THE FIREBOX MUST

BE SEALED.

Over tightening the screws could break the lens.

“Light Leakage” from the holes in the housing lamp may

be observed. The holes in the lamp housing are necessary for ventilation and must not be covered.

COLOURED SIDE UP

GASKET

LENS

FRAME

VENTURI

TUBE

ORIFICE

NIGHT

LIGHT

W415-0808 / 06.16.09

Page 4

4

2.5 PORCELAIN BASE INSTALLATION

INSTALL IN THE FOLLOWING ORDER:

2.5.1 Side porcelain panels or brick panels must

be installed prior to porcelain base cover

plates. For side porcelain panel installation

see “PRP81 PORCELAIN REFLECTIVE

RADIANT PANEL” leafl et and for brick panel

installation see “GD844KT DECORATIVE

BRICK P ANEL - SANDSTONE” leafl et.

2.5.2. Slide the porcelain cover plates through the

front opening being careful not to scratch

the porcelain panels. The cover plates must

slide under the burner cover as shown.

Secure to the burner base with the screws

provided and repeat on other side. Porcelain wire shields sit on the cover plates as

illustrated.

PORCELAIN

COVER PLATE

PORCELAIN

WIRE SHIELD

2.6 BURNER COVER INSTALLATION

2.6.1 Lower the burner cover down onto the

burner tray and porcelain base, making

sure the pilot is properly seated through

the slot on the right side.

2.6.2 Attach burner cover with four screws as

illustrated.

2.6.3 Empty the sand into the burner tray.

Spread the sand evenly over the burner

tray.

W415-0808 / 06.16.09

Page 5

2.7 ROCK INSTALLATION

REAL ROCKS MUST NOT BE USED IN THIS APPLIANCE. HEAT WILL CAUSE THEM TO EXPLODE.

!

WARNING

5

2.7.1 Position the two rock clusters in front of the

center burner tube, ensuring the clusters are

sitting fl at on the burner and making sure not

to cover burner ports.

2.7.3 Position the four large rocks randomly along

the front, making sure not to cover burner

ports.

2.7.2 Place the large cut out rocks along the edge

of the burner, making sure not to cover any

burner ports. (There are no set locations).

2.7.4 Place the medium rocks randomly between

the other rocks, making sure not to cover

the burner ports.

2.7.5 Position the remaining little rocks randomly,

making sure not to cover the burner ports.

2.7.6 Repeat on other side.

W415-0808 / 06.16.09

Page 6

6

A

3.0 ADJUSTMENT

3.1 FLAME CHARACTERISTICS

It’s important to periodically perform a visual check of the pilot and burner fl ames. Compare them to the illustra-

tions provided. If any fl ames appear abnormal call a service person.

3.2 VENTURI ADJUSTMENT

This model has an air shutter that has been factory set open according to the chart

below:

Closing the air shutter will cause a more yellow fl ame, but can lead to carboning.

Opening the air shutter will cause a more blue fl ame, but can cause

fl ame lifting from the burner ports. The fl ame may not appear yellow

immediately; allow 15 to 30 minutes for the fi nal fl ame color to be

established.

ELECTRODE

FLAME

SENSOR

PILOT

BURNER

FLAME MUST ENVELOP

UPPER 3/8” TO 1/2” OF

FLAME SENSOR

3/8” - 1/2”

54.1

AIR

SHUTTER

OPENING

IR SHUTTER ADJUSTMENT MUST ONLY BE DONE BY A QUAL-

IFIED INSTALLER!

LP 7/16”

NG 3/16”

VENTURI

ORIFICE

BURNER

49.4

Air Shutter Openings both Burners

W415-0808 / 06.16.09

Page 7

3.0 REPLACEMENTS

Contact your dealer or the factory for questions concerning prices and policies on replacement parts. Normally

all parts can be ordered through your Authorized dealer / distributor.

FOR WARRANTY REPLACEMENT PARTS, A PHOTOCOPY OF THE ORIGINAL INVOICE WILL BE

REQUIRED TO HONOUR THE CLAIM.

When ordering replacement parts always give the following information:

• Model & Serial Number of appliance

• Installation date of appliance

• Part number

• Description of part

• Finish

* IDENTIFIES ITEMS WHICH ARE NOT ILLUSTRATED. FOR FURTHER INFORMATION, CONTACT YOUR

AUTHORIZED DEALER.

REF NO. HD81 DESCRIPTION

1 W280-0071 NIGHT LIGHT LENS FRAME

2 W290-0080 NIGHT LIGHT GASKET

3 W300-0086 CERAMIC BLUE NIGHT LIGHT LENS

4 W350-0460 ROCK BURNER HOUSING

5 W100-0113 DOUBLE TUBE BURNER

6* W175-0227 CONNECTOR, 3/8” STAINLESS STEEL FLEX

7* W175-0289 CONNECTOR, 3/8” STAINLESS STEEL FLEX (24”)

8* W550-0007 FINE AGGREGATE

9 W010-1861 2-WAY NATURAL GAS PILOT ASSEMBLY

9 W010-1862 2-WAY PROPANE GAS PILOT ASSEMBLY

10 W565-0109 GLASS BURNER SCREEN

11 W120-0064 ROCK BURNER WIRE SHIELD

12 W750-0200 FLAME SENSOR

13 W750-0201 ELECTRODE

14 W455-0070 NATURAL GAS PILOT INJECTOR

14 W455-0065 PROPANE GAS PILOT INJECTOR

15* W455-0058 #35 ORIFICE NATURAL

15* W455-0050 #55 INSIDE ORIFICE PROPANE

15* W455-0087 #52 OUTSIDE ORIFICE PROPANE

16 W200-0274 ROCK BURNER COVER

COMPONENTS

7

!

WARNING

Failure to position the parts in

accordance with this manual or failure

to use only parts specifically approved

with this appliance may result in

property damage or personal injury.

41.1

12

13

14

11

5

10

9

1

2

4

16

3

W415-0808 / 06.16.09

Page 8

8

4.0 NOTES

W415-0808 / 06.16.09

44.1

Loading...

Loading...