Page 1

R

333 Bayview Avenue

Amityville, New York 11701

For Sales and Repairs, (800) 645-9445

For Technical Service, (800) 645-9440

© NAPCO 2004

SVLBKT

UNIVERSAL SWIVEL BRACKET

INSTALLATION INSTRUCTIONS

WI462A 8/04

The SVLBKT Universal Swivel Bracket is used

to mount Napco space-protection units against

a wall and provide vertical and horizontal tilting.

It will accommodate all current models except

DX-Series Double-Techs and M9000-Series

Monitors, each of which is supplied with its own

integral swivel bracket. The SVLBKT bracket

can mount onto a single-gang box using the

screws supplied, or it may be mounted directly

onto the wall using appropriate screws.

The bracket kit comprises the following parts:

(1) Wall Plate

(2) Housing Brackets (select one)

(1) Ball Bracket

(2) Ball Halves

(1) 6-32x5/8" Hex Head Machine Screw

(2) #6x5/16" Self-Tapping Screws

(3) #6x7/16" Self Tapping Screws

(2) 6-32x1/2" Machine Screws

(1) 6-32x3/8" Thread-Forming Hex Slotted Screw

(1) 1/4" Box Wrench is supplied.

BRACKET ASSEMBLY INSTRUCTIONS

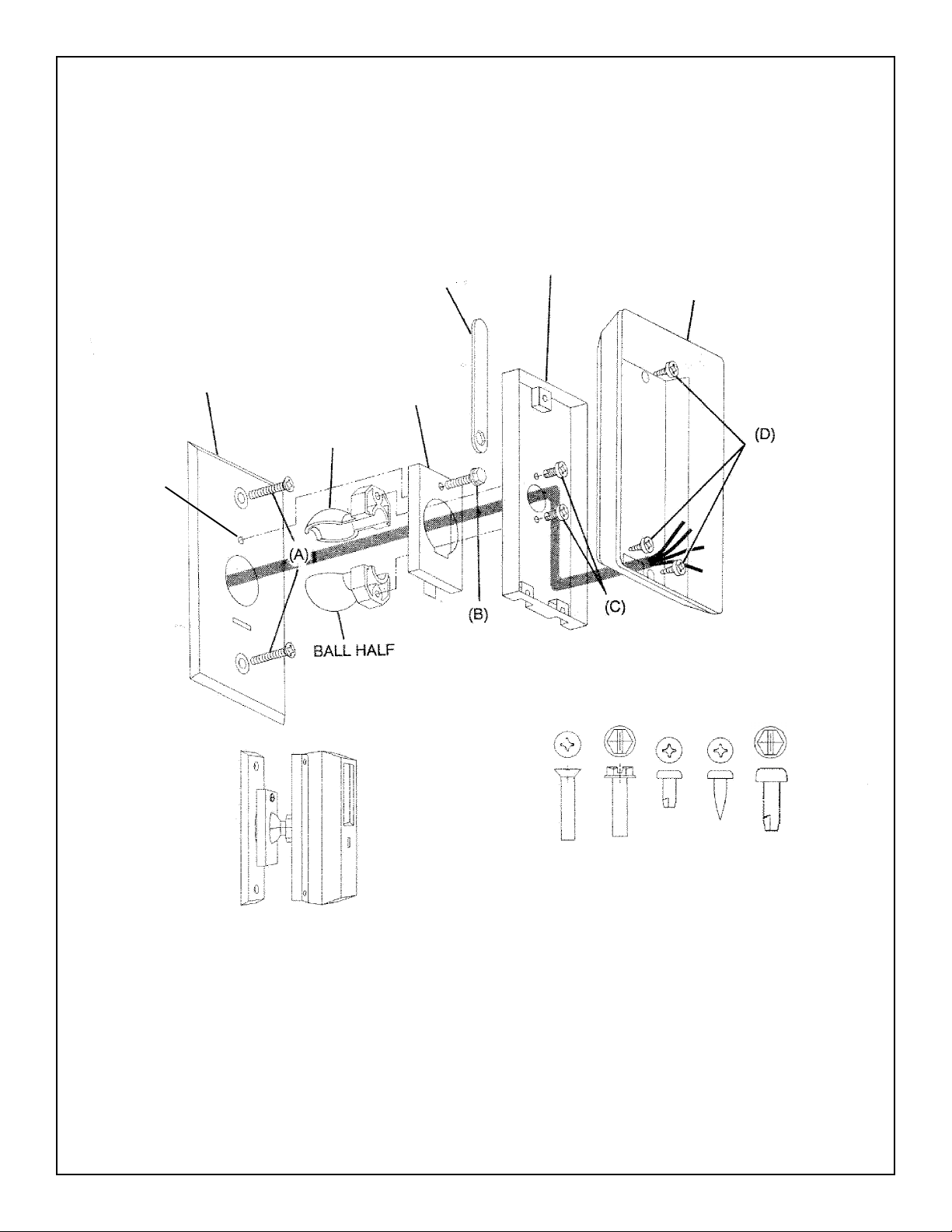

1. Referring to the illustration (see reverse), untapped wall plate hole (E) must first be

tapped with threads by use of the 6-32x3/8"

thread-forming Hex slotted screw. After

threads are tapped into this hole, remove the

Thread-Forming Hex Slotted Screw from the

wall plate hole.

2. Referring to the illustration, slip each Ball Half

through the Ball Bracket, then fit the two

halves together.

3. Insert the tab on the Ball Bracket into the slot

in the Wall Plate. Then, install the 6-32,5/8"

Hex Head Machine Screw through the small

hole in the Ball Bracket and into the Wall

Plate--but do not tighten fully.

4. Select the Housing Bracket that fits the unit to

be mounted. Secure the Housing Bracket to

the ball using the two #6x5/16" Self-Tapping

screws.

5. Pull about 6 inches of cable through the Wall

Plate, the ball and the Housing Bracket. With

Hex-Head screw positioned above the ball,

attach the Wall Plate to a single-gang box using the supplied 6-32x1/2" Machine Screws,

or attach directly to the wall with screws suitable for the mounting surface.

6. Punch out the three mounting holes in the

rear wall of the sensor (one at the top; two at

the bottom) corresponding to those in the

Housing Bracket. Also punch out the wireentry hole at the bottom of the rear wall

(between the two lower mounting holes). Pull

the cable through the wire-entry hole, then attach the rear case of the unit to the Housing

Bracket using the three #6x7/16" SelfTapping Screws.

7. Trim the wires so that approximately 2" enters the case and strip the insulation back

about 1/4". Remove the circuit board by removing the Height Scale Lock Screw; this will

greatly facilitate wiring. Complete the connections to the sensor.

8. Replace the circuit board, setting the Height

Scale to the mounting height of the sensor.

Seal the wire-entry hole using the caulking

material supplied. Replace the front cover

and make the required coverage-pattern tests

and adjustments. Use the supplied wrench to

loosen and tighten the Ball Bracket hex-head

screw between checks.

Page 2

WRENCH

HOUSING BRACKET

SENSOR HOUSING

WALL PLATE

(E)

BALL BRACKET

BALL HALF

(A)

(B)

(C)

(D)

(E)

ASSEMBLED BRACKET WITH SENSOR

SCREW TEMPLATE (ACTUAL SIZES)

(A) 6-32X1/2" MACHINE SCREW

(B) 6-32X5/8" HEX HEAD

(C) #6X5/16" SELF-TAPPING

(D) #6X7/16" SELF TAPPING

(E) 6-32X3/8" THREAD-FORMING HEX SLOTTED

Loading...

Loading...