Page 1

R

333 Bayview Avenue

Amityville, New York 11701

For Sales and Repairs, (800) 645-9445

For Technical Service, (800) 645-9440

Publicly traded on NASDAQ Symbol: NSSC

© NAPCO 2005

C-100 SAFARI

ADVANCED ADAPTIVE® PIR/MICROWAVE

TECHNOLOGY SENSOR

WEATHER SHIELD HOUSING & SWIVEL BRACKET

MOUNTING KIT

INSTALLATION INSTRUCTIONS

WI1352 1/05

SPECIFICATIONS

General Coverage

GENERAL DESCRIPTION

with standard wide-angle lens, measured in-

doors at 20°C (68° F), typical: 50’x40’

Note:

As with all thermal detectors, the range is dependent

on the difference between the target and the background. In

addition, range changes are more of a possibility because of

the large varying ambient temperature when the sensors are

used outdoors.

Operating Temperature

Mounting

Output Relay

Relay Time

Contact Ratings

: Wall only, 6’ to 10’ max.

: Form A, Normally-Closed

: Approximately 4 seconds

: 100mA, 24Vdc with internal 10Ω current-limiting

: -10° to +50° C (14° to 122° F)

resistor

Trouble

: Open collector current sinking with 39Ω current-limiting

resistor, 20mA max.

Status Input

Self-Test Interval

Power-Supply Requirements

Note:

*: Panel disarmed, >5V; armed, <1.5V.

: 11-16 hours.

:

This unit is intended for operation from a power source

that provides battery backup in the event of a power failure.

: 8-16Vdc

DC

Current Drain at 12Vdc

Microwave Frequency

name indicate the frequency. See table below).

Model Name Microwave Frequency (GHz)

C-100SAFARI52 10.525

C-100SAFARI58 10.587

C-100SAFARI99 9.900

Physical Dimensions

: Idle, 33mA; Alarm, 35mA

: X Band (The last 2 digits of product

: 4.5” x 2.5" x 1.7” (HxWxD) (11.4cm x

6.4cm x 4.3cm)

Shipping Wei ght

: 7oz. (198gm)

CE Required Statement

To meet Flammability Requirements, this unit is to be powered by

an agency-approved power supply meeting the requirements of

EN60950: 2000 clause 2.5 Limited Power Sources.

FEATURE S

Not all models are equipped with all features.

Note:

•

Microprocessor signal processing

Power-up system diagnostic tests virtually all electronics

•

•

Microwave and PIR self test

• Watchdog microprocessor supervision

Microwave circuit supervision

•

•

4-Pulse Mode for hostile environments

• Quick-Response Mode while disarmed

Trouble Output

•

•

Automatic PIR operation on microwave failure

• Dual-element PIR sensor

• High-efficiency, dirt-resistant grooves-in lens

Extensive RFI and EMI filtering ensure optimum immunity to

•

false alarms

• Large lens area assures high PIR sensitivity

• Horizontal as well as vertical aiming capabilities

Selectable Microwave/PIR LED indication visible from virtually

•

any angle, extinguishable after testing

• Small size; modern, unobtrusive design

• Silent operation

Swivel Bracket wall or electrical gang box mountable

•

ORDERING INFORMATION

C-100 Safari Long-Range Dual Technology Detector

SVLBKT Swivel Bracket Kit (Wall/ Gang Box Mounting)

SVL2 Swivel Bracket Kit (Wall Mounting Only)

LENS122 Safari Outdoor Lens (factory installed)

BASIC OPERATION

This unit is a combination passive-infrared sensor and microwave sensor, both contained in a single package. The unit will go

into alarm when both sensors detect intrusion at the same time.

The PIR section operates by detecting a rapid change in temperature when an intruder crosses a protected area. When a

beam experiences a change in heat (projected back through the

lens), a pulse is generated by the sensor element. The microwave transmitter sends out short bursts of RF energy, and the

receiver detects changes in the returned signal caused by motion

within its coverage area.

The microwave section is unaffected by visible light, air drafts,

or temperature changes (as from air conditioners, for example),

but is sensitive to motion. In contrast, infrared is virtually unaffected by vibration.

Thus the two complementary technologies provide an inherent

immunity to false alarms. Dual technology is ideal for use in hostile environments. Since both must trip simultaneously to cause

an alarm, installation is easier and requires less discipline.

TABLE OF CONTENTS

GENERAL DESCRIPTION ...........................................................................1

SPECIFICATIONS ..................................... ............................. ................... 1

FEATURES ..................................... ........................................................... 1

ORDERING INFORMATION ....................................................................1

BASIC OPERATION ..................................................................................1

DETECTION PATTERNS .........................................................................2

STANDARD LENS ....................................................................................2

INSTALLATION .............................................................................................2

CHOOSING A SUITABLE LOCATION .................................................... 2

WIRING ...................................................................................................... 2

TESTING THE COVERAGE AREA ......................................................... 3

COMPLETING THE INSTALLATION ....................................................... 3

ADVANCED FEATURES ..........................................................................3

MOUNTING ....................................................................................................4

SVLBKT SWIVEL BRACKET INSTALLATION ........................................4

SCREW TEMPLATE ................................................................................. 6

SVL2 SWIVEL BRACKET INSTALLATION .............................................7

NAPCO LIMITED WARRANTY ....................................................................8

*For UL installations, Status Input is to be connected only to a UL-listed control panel with a UL-tested Status line.

1

Page 2

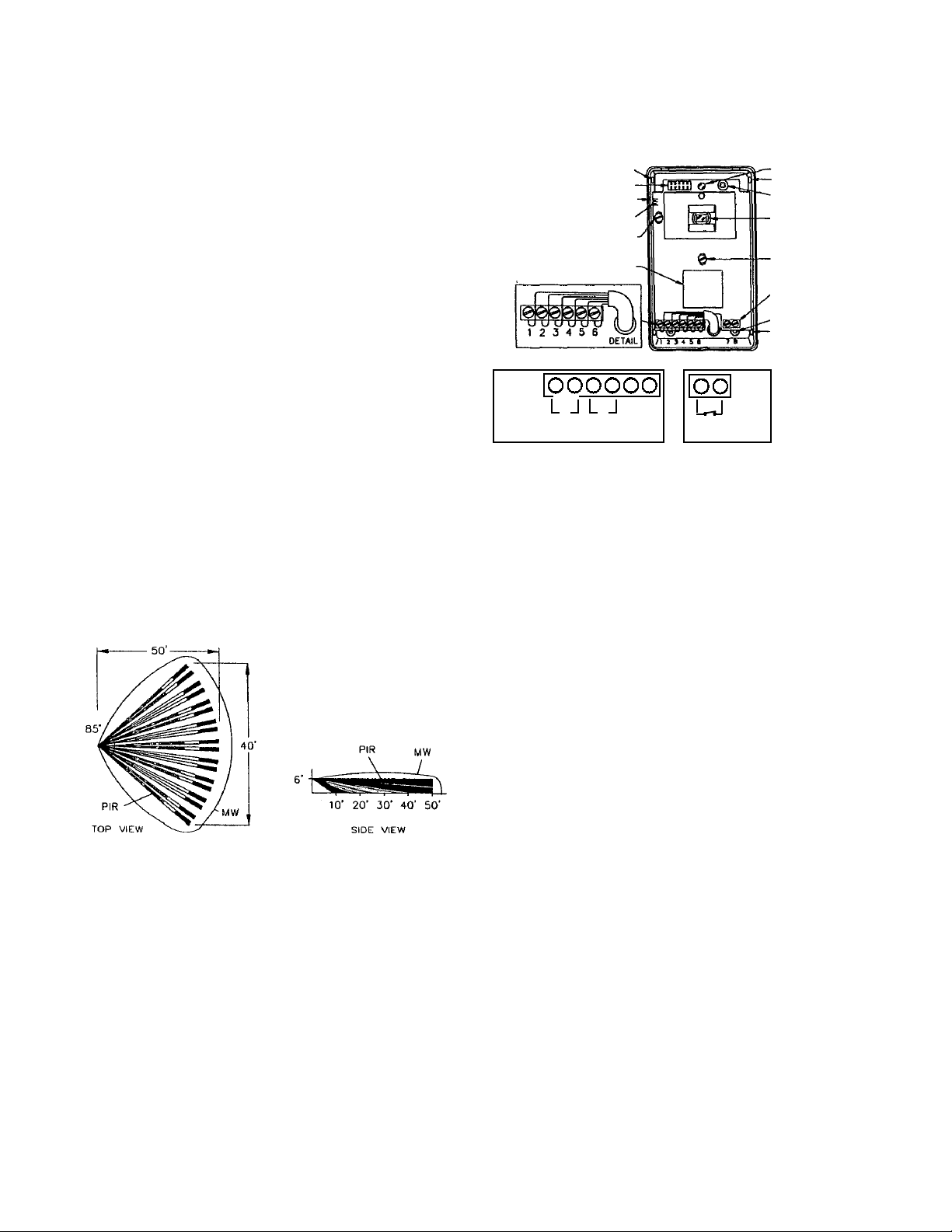

DETECTION PATTERNS

Figure 1 illustrates maximum PIR and microwave detection patterns superimposed on each other. PIR detection patterns are

adjustable, within limits, both vertically and horizontally.

Insensitive Areas

The insensitive area is that area directly beneath the unit within

which an intruder is undetectable. It is shown as a shaded area

in the side-view detection pattern that follows, and assumes that

an intruder will be at least 5’ tall and that the protected area is not

accessible by crawling or crouching. The size of the insensitive

area will increase as the mounting height increases (see Fig. 1,

side view).

STANDARD LENS

This model uses an improved standard wide-angle lens that

yields the 18-zone, 40-beam pattern illustrated in Fig. 1. The coverage pattern is adjustable, within limits, both vertically and horizontally. Stacked optical centers provide tall, dense beam pairs,

making beam aiming easier and less critical. Examples shown

herein are typical and will not apply to all cases. Always test the

coverage pattern after the unit is installed (see

COVERAGE AREA

).

TESTING THE

The supplied lens will perform best in typical applications, thus it

is factory installed. Following are its specifications.

Number of Zone s

Number of Beams

Maximum Coverage

Field of Vie w

Recommended Mounting Height

Minimum Mounting Height

Maximum Mounting Height

: 18 (3 layers: 9/5/4 zones)

: 40 (3 layers: 18/10/12)

: 50’ long x 40’ wide

: 85°

: 6' to 8’

: 6’

: 10’

Fig. 1. C-100 Safari Standard Wide-Angle Lens Pattern.

INSTALLATION

CHOOSING A SUITABLE LOCATION

Select a rigid surface that is relatively free of vibration. Position

the sensor with respect to access pathways so that an intruder

will pass across its field of view, not directly toward or away from

it. Avoid areas with moving objects (such as swaying bushes and

trees) or with devices that may pose a chronic problem to either

sensor. For the dual-technology feature to be truly effective in

rendering the unit free from false alarms, neither sensor should

detect intrusion under normal conditions.

shipped from the factory with Jumper J1 in the Alarm position.

Note:

The unit is

WIRING

Remove the wire entry hole (see

MOUNTING THE SENSOR

to gain access to the terminal strip. (Be sure to caulk around the

wires where they exit the case). Route wires to the terminal strip

as shown in Fig. 2 and connect as follows:

CORNER MOUNT HOLE

JUMPER BLOCK

INDEX NOTCH

HEIGHT SCALE

HEIGHT LOCK SCREW,

C-100STLRE

MICROWAVE CAVITY

PINOUT,

FORM-A

RELAY

*WHERE

EQUIPPED

NOTE: (1) NOT ALL TERMINALS AVAILABLE IN ALL VERSIONS. (2) NC WHEN SET.

1 2 3

+ −

POWER

Power (Terminals 1 [+] & 2 [-]).

5 6 4

NC

STATUS*

ALARM

Fig. 2. Circ uit board layout.

7 8

NC*

TO 24HR

ZONE

TROUBLE*

Apply 12VDC to Terminals 1

LED

CORNER MOUNT HOLE

MICROWAVE RANGE CONTROL

PIR SENSOR

HEIGHT LOCK SCREW, C-100STE

TAMPER TERMINALS

(TAMPER OPTIONAL)

WALL MOUNT HOLE

CORNER MOUNT HOLE

TAMPER

(OPTIONAL)

*WHEN SET

[+] and 2 [-]. The power source may be regulated or unregulated.

Power should be supplied from a control panel or other power

source equipped with a rechargeable battery backup to maintain

operation in the event of a power failure. Refer to

for power-supply requirements.

TIONS

SPECIFICA-

Alarm Relay Contacts (Terminals 3 & 4).

These contacts are

rated at 100mA, 24Vdc and are normally closed. When the sensor is operating, either detection of an intruder or loss of power

will cause the relay contacts to open.

Status and Trouble

(Where equipped)

Wiring to Terminals 5 (Status) and 6 (Trouble) are only required

if using the special features of this unit. Refer to

FEATURE S

Status Input (Terminal 5).

.

Connect to the Status terminal (Arm

ADVANCED

Lug) of the control panel. A low at Terminal 5 tells the sensor

that the panel is armed.

Trouble (Terminal 6).

This is an open-collector output that pro-

duces an active low to signal a trouble condition.

Self Test

The self-test diagnostic simulates motion and tests the PIR sen-

sor, amplifier and related PIR circuitry, the microwave transmitter, receiver, and associated microwave circuitry. This test is

initiated each time the unit is powered up and randomly at 11- to

16-hour intervals after the last alarm to ensure that the unit is

always in operating order. At power-up, the LED will turn on and

both the alarm and trouble outputs will be held “safe’. If the unit

is operating properly, the LED will extinguish after about 1 minute. However, if it fails the self test, the LED will flash rapidly,

indicating a need for service. After the LED goes out, indicating

a successful self-test, proceed as follows:

Setting the Height Scale

For fixed wall mounting (without a Swivel Bracket Kit), the circuit

)

2

Page 3

board Height Scale can be adjusted to compensate for the

mounting height of the sensor, obtaining maximum coverage.

However, because the C-100 Safari itself is adjustable via a

Swivel Bracket Kit, there is no need to use the Height Scale to

compensate for its mounting height. Therefore, to optimize the

optical position of the sensor with respect to the lens, be sure the

circuit board is in its lowest position. Remove the front cover

(the Height scale is printed along the edge of the circuit board in

the upper-left corner). Loosen the Lock Screw (shown in Fig. 2),

and slide the circuit board down. Then tighten the Lock Screw

(

do not over-tig hten!

).

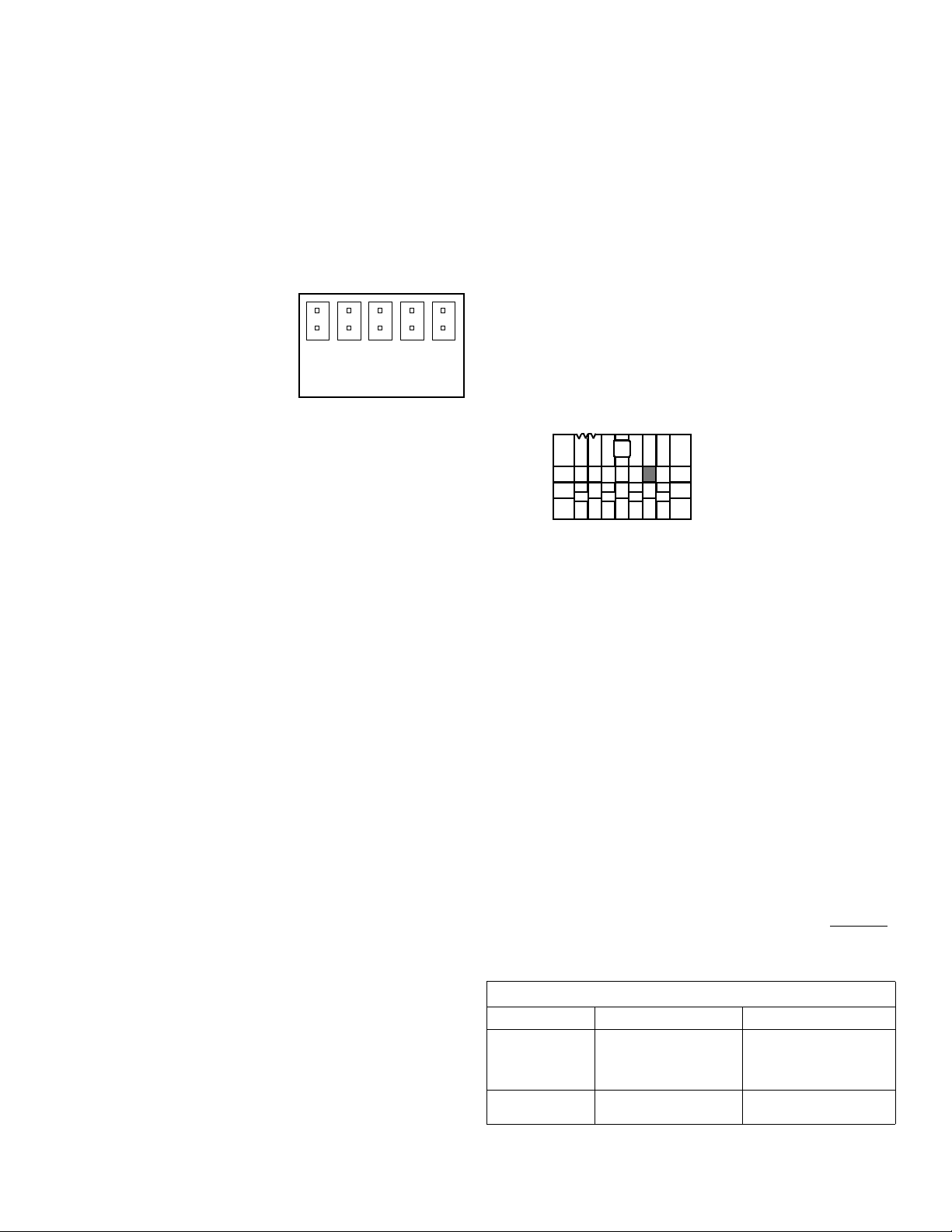

Jumper Block

The Jumper Block (see Fig. 3) is

used to select operating modes,

as follows:

. Install spare jumper for

LENS

Barrier Lens or Long-Range

Pet Alley Lens only.

. LED Disable. Install to dis-

LED

able LED Alarm indication only.

. PIR Walk-Test Mode. LED

PIR

LENS--

Fig. 3. Jumper block

PIR--

LED--

MW--

ALARM--

indicates PIR trips only.

ALARM

. Alarm, LED indicates simultaneous PIR and Micro-

wave trips.

. Microwave Walk-Test Mode. LED indicates microwave

MW

trips only.

The alarm relay will operate only with the LED jumper installed

or the ALARM jumper installed. Therefore, after testing, be sure

to replace the jumper in the ALARM position for normal LED operation, or in the LED position, which prevents the LED from lighting on an alarm condition.

Four-Pulse Mode

. This is the least-sensitive mode, recommended for hostile environments or areas with pets, where an

intruder must cross several beam pairs to trip an alarm. To lock

the unit into the 4-Pulse Mode while maintaining adaptive microwave operation, install both the PIR jumper and the MW jumper.

Microwave Range Adjustment

The microwave RANGE ADJUST control must be set to achieve

the desired coverage such that the Walk-Test LED lights when

motion is detected at the maximum desired range, but does not

light (motion is not detected) beyond the maximum desired range.

To adjust the desired coverage, use the following procedure:

1. Remove the front cover and install the MW jumper.

2. Set the RANGE ADJUST control at mid position and walktest the unit.

3. If the desired range was insufficient, advance the RANGE

ADJUST control slightly clockwise. Repeat the test as necessary, increasing the RANGE ADJUST control each time

until motion is detected at the desired range, but not beyond.

(If the desired range was excessive, reduce the RANGE ADJUST control slightly (counterclockwise) and repeat this

step).

Note:

Be sure to return the jumper to the ALARM or

LED position after adjustment.

TESTING THE COVERAGE AREA

After the unit has been mounted and set up, its coverage should

be tested and, if necessary, altered to accommodate local environmental conditions (within the coverage area). Satisfactory

checks may be made using the Walk-Test LED on the front of the

unit. It is recommended that the coverage area be tested at least

once a year.

Testing the Unit

Complete connections to the terminal strip (see WIRING). The

unit will require a 1-minute “settling” time to adjust itself to the surrounding temperature. After sufficient time has been allowed,

proceed as follows.

Test the range of the coverage

.

Install the PIR Walk-Test jumper and replace the front cover.

Walk out to the maximum determined coverage distance, then

walk across the field of coverage. The LED will remain lit as long

as motion is detected. Repeat this test with the microwave MW

Walk-Test jumper installed. Repeat once again with the ALARM

jumper installed. Confirm that the LED lights at the maximum

desired range,

but not beyon d

.

Zone Masking

A problem zone may be deactivated in order to preserve reliable system operation by zone masking the lens. Carefully apply

a piece of zone-masking foil (supplied) to the grooved inside surface of the lens segment representing the problem zone to block

signal from the offending device (refer to Fig. 4).

Fig. 4. Zone-masking foil (shaded

area) applied to a lens segment to

deactivate a problem zone.

COMPLETING THE INSTALLATION

Jumper J1 must be returned to either the Alarm position

(Terminals J1-4) or the LED Disable position (Terminals J1-2) for

the alarm relay to operate. In the Alarm position, the LED will indicate a condition that would cause an alarm if the system were

armed. To extinguish the Walk-Test LED after testing, remove

the LED Jumper and place across the LED Disable terminals. In

this position, the LED is disabled during normal operation, but is

enabled for alarm memory and diagnostic indications.

ADVANCED FEATURES (

Where available)

Trouble Output

Terminal 6 is an open collector Trouble output; a trouble condition

is indicated by an active low and is maintained. The trouble output may be wired to an unused zone at the panel for local display

at the keypad. While troubles can report to a central station, local

annunciation may be preferable in order to reduce telephone congestion and operating costs.

Quick Response Mode

If Terminal 5 is connected to the Status Terminal (Arm Lug) of the

control panel, the sensor will be inhibited from adapting and will

assume a quick response mode while the panel is disarmed

Note:

The control panels Status Terminal must provide a low

.

output when armed.

TROUBLESHOOTING GUIDE

SYMPTOM

Rapid LED Flash Problem in circuitry or

Unit holding loop in

alarm

PROBABLE CAUSE

internal microprocessor

memory malfunction.

Walk-Test Mode selected. Place jumper in Alarm or

REMEDY

Power down for 5 se conds.

Power up again and wait

1½ minutes. If symptom

persists, return for repair.

LED Disable position.

3

Page 4

MOUNTING

The C-100 Safari Sensor can be mounted in either of two ways:

(

) On to a wall or electrical gang box using a SVLBKT Swivel

A

Bracket , or (B) On to a wall using a SVL2 Swivel Bracket.

Either method makes use of the same Weather Shield Housing,

which is a metal enclosure designed for protecting the Sensor

from a hostile outdoor environment. The C-100 Safari Sensor is

affixed inside this Weather Shield Housing, and sealed against

moisture with an O-Ring that is installed in the base of the sensor.

The images below display each type of assembled bracket, with

the Weather Shield Housing affixed.

(A): SVLBKT Swivel Bracket (above)

(B): SVL2 Swivel Bracket

Mounting hardware for either mounting method is pack-

Note:

aged separately. The hardware used for method "A" is included

in a clear plastic bag marked "A" and hardware for method "B"

is included in a clear plastic bag marked "B". First select a

mounting method for your application, and then be sure to select

the proper mounting hardware as necessary.

For the SVL2 assembly instructions (Section B), go to page 7.

For the SVLBKT assembly instructions (Section A), proceed as

follows:

A: OUTDOOR WEATHER SHIELD HOUSIN G &

SVLBKT SWIVEL BRACKET I NSTA LLA T ION

For Wall or Electrical Gang Box Mount ing

Wall Plate

Weather Shield

Housing

Ball Bracket

A: FINISHED ASSEMBLY (SVLBKT)

The SVLBKT Swivel Bracket is used to mount the spaceprotection unit into the weather shield. The SVLBKT bracket can

mount onto a single-gang box using the screws supplied, or it

may be mounted directly onto the wall using appropriate screws.

For mounting the SVLBKT, gather the following items:

(1) Wall Plate

(1) Ball Bracket

(2) Ball Halves

BAG "A" Containing:

(1) 6-32x5/8" Hex Head Thread Cutting Screw

(2) #6x5/16" Self-Tapping Screws

(2) 6-32x1/2" Oval Head Machine Screws

(1) 1/4" Box Wrench is supplied.

A third bag contains the O-Ring.

ASSEMBLY INSTRUCTIONS

1. Separate the front cover of the sensor from the rear sensor

housing.

2. Remove the PC board from the rear sensor housing.

3. Referring to the image, slip each Ball Half through the Ball

Bracket, then fit the two halves together.

4. Insert the tab on the Ball Bracket into the slot in the Wall

Plate. Then, install the 6-32x5/8" Hex Head Machine Screw

through the small hole in the Ball Bracket and into the Wall

Plate--

but DO NOT ti ghte n ful ly u ntil ai min g is com pl ete

.

DO NOT tighten

fully until aiming

is complete

5. Secure the Weather Shield Housing to the Ball Bracket as-

sembly using the two #6x5/16" Self-Tapping screws (see images on next page).

4

Page 5

6. Pull about 6 inches of cable through the Wall Plate, the Ball

Bracket and the Weather Shield Housing. With Hex-Head

screw positioned above the Ball Bracket, attach the Wall

Plate to a single-gang box using the supplied oval-head 632x1/2" machine screws, or attach directly to the wall with

screws suitable for the mounting surface.

7. In the sensor base, punch out the four mounting holes (two at

the top; two at the bottom) corresponding to the mounting

holes in the Weather Shield Housing (see image below).

Punch

out here

Existing

wire entry

hole

Sensor Base

8.

Importan t:

Wrap the O-Ring around the perimeter of the

inside lip of the sensor base before installing the sensor base

into the Weather Shield Housing (see image above).

The O-Ring will create a watertight seal when the two halves

of the sensor are joined together in step 12.

9. Pull the cable through the existing wire-entry hole, then attach the sensor base to the Weather Shield Housing using

the four 6-32x1/4" Machine Phillips Pan Head Screws (see

next image).

Wrap the O-Ring

around the perimeter of

the inside lip of the

sensor base

attaching the sensor

base to the Weather

Shield Housing

before

10. Trim the wires so that approximately 4" enters the sensor

base and strip the insulation back about 1/4". Caulk the

wire opening using the supplied caulking compound, sealing

the hole where the wires enter the sensor base.

11. Connect wires to the circuit board terminals and replace the

circuit board, setting the Height Scale to the lowest setting.

Height Scale

12. Replace the front sensor cover and make the required coverage-pattern tests and adjustments. Use the supplied

wrench to loosen and tighten the Ball Bracket hex-head

screw between checks.

5

Page 6

SCREW TEMPLATE (ACTUAL SIZES)

(A) 6-32x1/2" MACHINE SCREW OVAL HEAD (BAG "A")

(B) 6-32x5/8" HEX HEAD THREAD CUTTING SCREW (BAG "A")

(C) #6x5/16" SELF-TAPPING SCREW (BAG "A")

(D) #4x1/2 SELF-TAPPING PHILLIPS FLAT HEAD (BAG "B")

(E) 6-32x1/4" MACHINE PHILLIPS PAN HEAD

(A)

(B)

(C)

(D)

(E)

6

SVLBKT FINISHED ASSEMBLY SVL2 FINISHED ASSEMBLY

Page 7

B: OUTDOOR WEATHER SHIELD HOUSING &

SVL2 SWIVE L B RA CKET INSTALLATION

For W all M oun ti ng Only

Weather Shield

Housing

Swivel Mount

Washer

Flat Head

Screw

Rear Sensor

Housing

FINISHED ASSEMBLY (SVL2)

SVL2 Swivel

Mount Bracket

The SVL2 Swivel Bracket is used to mount the spaceprotection unit into the weather shield. The SVL2 bracket can

be mounted directly onto the wall using appropriate screws.

For mounting the SVL2, Find the clear plastic bag marked

"Bag B" which contains the following items:

(1) #4x1/2" Phillips Flat Head Self-Tapping Screw

(1) Swivel Mount Washer

Find a third bag containing the O-Ring and the (4) 6-32x1/4"

Machine Phillips Pan Head Screws.

ASSEMBLY INSTRUCTIONS

1. Separate the front sensor cover from the rear sensor

base.

2. Remove the PC board from

the rear sensor base. In the

Punch

out here

sensor base, punch out the

four mounting holes (two at

the top; two at the bottom)

corresponding to the mounting holes in the Weather

Shield Housing. In addition,

punch out the top hole in the

sensor base as shown.

Existing

wire entry

hole

Sensor Base

3. Attach the Swivel Mount

Bracket to the wall according to

the specified mounting height.

Do NOT mount on ceil-

Note:

ings.

4. Place the sensor base into the Weather Shield Housing.

Importan t:

Wrap the O-Ring around the perimeter of the

inside lip of the sensor base

before

installing the sensor

base into the Weather Shield

Housing. The O-Ring will

create a watertight seal

when the two halves of the

sensor are joined together in

step 9. See image below.

5. Place the Swivel Mount

Washer on the inside of the

sensor base top hole.

6. Insert the Flat Head Screw

into Swivel Mount Washer,

Wrap the O-Ring

around the perimeter of

the inside lip of the

sensor base

attaching the sensor

base to the Weather

Shield Housing

before

Swivel Mount

Washer

through the hole in the sensor base, through the hole in

the Weather Shield Housing

and into the Swivel Mount Bracket. Adjust the unit and

tighten the Flat Head Screw when the desired angle is

obtained.

7. Pull the cable through

the existing wire-entry

hole, then attach the

rear case of the unit to

the Weather Shield

Housing using the four

#6-32x1/4" Phillips Pan

Head machine screws.

8. Trim the wires so that

approximately 4" enters

the case and strip the

insulation back about

1/4". Caulk the wire

opening using the supplied caulking compound, sealing the hole

where the wires enter

Attach rear case

using four 6-

32x1/4" Machine

Screws

the sensor base.

9. Replace the PC board inside the sensor base. Connect

wires to the circuit board terminals and replace the circuit

board, setting the Height Scale to the lowest setting. With

the O-Ring in place (installed in step 4), replace the front

sensor cover and make the required coverage-pattern

tests and adjustments.

7

Page 8

NAPCO LIMITED WARRANTY

NAPCO SECURITY SYSTEMS, INC. (NAPCO) warrants its products to be free from manufacturing defects in materials and workmanship for thirty-six

months following the date of manufacture. NAPCO

will, within said period, at its option, repair or replace

any product failing to operate correctly without charge

to the original purchaser or user.

This warranty shall not apply to any equipment, or any

part thereof, which has been repaired by others, improperly installed, improperly used, abused, altered,

damaged, subjected to acts of God, or on which any

serial numbers have been altered, defaced or removed. Seller will not be responsible for any dismantling or reinstallation charges.

THERE ARE NO WARRANTIES, EXPRESS OR IMPLIED, WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF. THERE IS NO EXPRESS OR IMPLIED WARRANTY OF MERCHANTABILITY OR A WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE. ADDITIONALLY, THIS

WARRANTY IS IN LIEU OF ALL OTHER OBLIGATIONS OR LIABILITIES ON THE PART OF NAPCO.

Any action for breach of warranty, including but not limited to any implied warranty of merchantability, must be

brought within the six months following the end of the

warranty period. IN NO CASE SHALL NAPCO BE LIABLE TO ANYONE FOR ANY CONSEQUENTIAL OR

INCIDENTAL DAMAGES FOR BREACH OF THIS OR

ANY OTHER WARRANTY, EXPRESS OR IMPLIED,

EVEN IF THE LOSS OR DAMAGE IS CAUSED BY

THE SELLER’S OWN NEGLIGENCE OR FAULT.

In case of defect, contact the security professional who

installed and maintains your security system. In order

to exercise the warranty, the product must be returned

by the security professional, shipping costs prepaid

and insured to NAPCO. After repair or replacement,

NAPCO assumes the cost of returning products under

warranty. NAPCO shall have no obligation under this

warranty, or otherwise, if the product has been repaired by others, improperly installed, improperly used,

abused, altered, damaged, subjected to accident, nuisance, flood, fire or acts of God, or on which any serial

numbers have been altered, defaced or removed.

NAPCO will not be responsible for any dismantling, reassembly or reinstallation charges.

This warranty contains the entire warranty. It Is the

sole warranty and any prior agreements or representations, whether oral or written, are either

merged herein or are expressly cancelled. NAPCO

neither assumes, nor authorizes any other person

purporting to act on its behalf to modify, to

change, or to assume for it, any other warranty or

liability concerning its products.

In no event shall NAPCO be liable for an amount in excess of NAPCO's original selling price of the product,

for any loss or damage, whether direct, indirect, incidental, consequential, or otherwise arising out of any

failure of the product. Seller’s warranty, as hereinabove set forth, shall not be enlarged, diminished or

affected by and no obligation or liability shall arise or

grow out of Seller’s rendering of technical advice or

service in connection with Buyer’s order of the goods

furnished hereunder.

NAPCO RECOMMENDS THAT THE ENTIRE SYSTEM BE COMPLETELY TESTED WEEKLY.

Warning:

limited to, any or all of the following; criminal tampering, electrical or communications disruption, it is possible for the system to fail to perform as expected.

NAPCO does not represent that the product/system

may not be compromised or circumvented; or that the

product or system will prevent any personal injury or

property loss by burglary, robbery, fire or otherwise;

nor that the product or system will in all cases provide

adequate warning or protection. A properly installed

and maintained alarm may only reduce risk of burglary,

robbery, fire or otherwise but it is not insurance or a

guarantee that these events will not occur. CONSEQUENTLY, SELLER SHALL HAVE NO LIABILITY

FOR ANY PERSONAL INJURY, PROPERTY DAMAGE, OR OTHER LOSS BASED ON A CLAIM THE

PRODUCT FAILED TO GIVE WARNING. Therefore,

the installer should in turn advise the consumer to take

any and all precautions for his or her safety including,

but not limited to, fleeing the premises and calling police or fire department, in order to mitigate the possibilities of harm and/or damage.

NAPCO is not an insurer of either the property or

safety of the user’s family or employees, and limits its

liability for any loss or damage including incidental or

consequential damages to NAPCO’s original selling

price of the product regardless of the cause of such

loss or damage.

Some states do not allow limitations on how long an

implied warranty lasts or do not allow the exclusion or

limitation of incidental or consequential damages, or

differentiate in their treatment of limitations of liability

for ordinary or gross negligence, so the above limitations or exclusions may not apply to you. This Warranty gives you specific legal rights and you may also

have other rights which vary from state to state.

Despite frequent testing, and due to, but not

8

Loading...

Loading...