FCC Required Exhibit 12

CMC-TC Wireless I/O-Unit

DK 7320.240

User Manual (UserMan)

Version 1.01

NA-08-0000-0025-1.01

Document Information

CMC-TC Wireless I/O-Unit (UserMan)

Document Information

Document Title: CMC-TC Wireless I/O-Unit (UserMan)

Document Version: 1.01

Published (yyyy-mm-dd): 2008-04-17

Current Printing: 2008-4-17, 1:39 pm

Document ID: NA-08-0000-0025-1.01

Document Status: Released

Disclaimer

Nanotron Technologies GmbH believes the information contained herein is correct and accurate at the time of release. Nanotron

Technologies GmbH reserves the right to make changes without further notice to the product to improve reliability, function or

design. Nanotron Technologies GmbH does not assume any liability or responsibility arising out of this product, as well as any

application or circuits described herein, neither does it convey any license under its patent rights.

As far as possible, significant changes to product specifications and functionality will be provided in product specific Errata

sheets, or in new versions of this document. Customers are encouraged to check the Nanotron website for the most recent

updates on products.

Trademarks

©

nanoNET

names are the sole property of their respective owners.

This document and the information contained herein is the subject of copyright and intellectual property rights under international

convention. All rights reserved. No part of this document may be reproduced, stored in a retrieval system, or transmitted in any

form by any means, electronic, mechanical or optical, in whole or in part, without the prior written permission of Nanotron

Technologies GmbH.

Copyright © 2008 Nanotron Technologies GmbH.

is a registered trademark of Nanotron Technologies GmbH. All other trademarks, registered trademarks, and product

Life Support Policy

These products are not designed for use in life support appliances, devices, or systems where malfunction of these products can reasonably be expected to result in personal injury.

Nanotron Technologies GmbH customers using or selling

these products for use in such applications do so at their own

risk and agree to fully indemnify Nanotron Technologies

GmbH for any damages resulting from such improper use or

sale.

Electromagnetic Interference / Compatibility

Nearly every electronic device is susceptible to electromagnetic interference (EMI) if inadequately shielded, designed, or

otherwise configured for electromagnetic compatibility.

To avoid electromagnetic interference and/or compatibility

conflicts, do not use this device in any facility where posted

FCC User Information

Statement according to FCC part 15.19:

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device

may not cause harmful interference, and (2) this device must

accept any interference received, including interference that

may cause undesired operation.

Statement according to FCC part 15.21:

Modifications not expressly approved by this company could

void the user's authority to operate the equipment.

RF exposure mobil:

The internal / external antennas used for this mobile transmitter must provide a separation distance of at least 20 cm from

all persons and must not be co-located or operating in conjunction with any other antenna or transmitter."

Statement according to FCC part 15.105:

This equipment has been tested and found to comply with the

limits for a Class A and Class B digital device, pursuant to Part

15 of the FCC Rules. These limits are designed to provide

notices instruct you to do so. In aircraft, use of any radio frequency devices must be in accordance with applicable regulations. Hospitals or health care facilities may be using

equipment that is sensitive to external RF energy.

With medical devices, maintain a minimum separation of 15

cm (6 inches) between pacemakers and wireless devices and

some wireless radios may interfere with some hearing aids. If

other personal medical devices are being used in the vicinity

of wireless devices, ensure that the device has been adequately shielded from RF energy. In a domestic environment

this product may cause radio interference in which case the

user may be required to take adequate measures.

CAUTION! Electrostatic Sensitive Device. Precaution should be used when handling the

device in order to prevent permanent damage.

reasonable protection against harmful interference in a residential installation and against harmful interference when the

equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance

with the instructions as provided in the user manual, may

cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. Operation of this equipment in a residential area is likely to cause harmful interference in which

case the user will be required to correct the interference at his

or her own expense.

If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and

receiver.

• Connect the equipment into an outlet on a circuit different

from that to connected.

• Consult the dealer or an experienced technician for help.

Page ii NA-08-0000-0025-1.01 © 2008 Nanotron Technologies GmbH.

EN CMC-TC Wireless I/O-Unit

DK 7320.240

Assembly, Installation and Operation

A38148 09 IT 74

US Representative

Rittal Corporation

One Rittal Place

Springfield, OH 45504

Telefon: +1(937)399 05 00

Fax: +1(937)390 55 99

eMail: rittal@rittal-corp.com

Website: www.rittal-corp.com

Published: 17/04/2008

Microsoft Windows is a registered trademark of Microsoft Corporation.

Acrobat Reader is a registered trademark of Adobe Systems Incorporated.

Table of Contents 1

1 Table of Contents

1 Table of Contents ..............................3

2 Documentation Notes .......................4

2.1 Associated Documents ....................... 4

2.2 Retention of the Documents ............... 4

2.3 Used Symbols ..................................... 4

3 Safety Notes....................................... 4

4 Unit Description.................................5

4.1 Housing ............................................... 5

4.2 Power Supply ...................................... 5

4.3 Connectable Sensors.......................... 5

4.4 Scope of supply................................... 5

4.5 Accessories......................................... 6

4.5.1 Required Accessories ......................... 6

4.5.2 Optional Accessories ..........................6

4.6 Proper Use .......................................... 6

5 Assembly ...........................................7

5.1 Assembly Notes .................................. 7

5.2 Assembling CMC-TC .......................... 7

9 Wireless I/O-Unit as Repeater ........ 17

9.1 Power Supply.................................... 17

9.2 Configuring a Wireless I/O-Unit as

Repeater ........................................... 17

9.3 Repeater Information Page .............. 17

10 Connecting an External Antenna... 18

11 Maintenance and Cleaning............. 18

11.1 18

11.2 Cleaning............................................ 19

12 Storage and Disposal ..................... 19

12.1 Storage ............................................. 19

12.2 Disposal ............................................ 19

13 Customer Service............................ 19

14 Technical Specifications ................ 19

15 Technical Glossary ......................... 20

16 Declarations of Conformity ............ 20

EN

6 Installation..........................................8

6.1 Safety and Other Notes ...................... 8

6.2 Connecting the voltage supply............ 8

6.3 Antenna adjustment ............................ 8

7 Commissioning..................................8

7.1 CMC-TC Wireless I/O-Unit

Commissioning.................................... 8

7.2 Registering Sensors............................ 9

7.3 Removing Sensors............................ 10

7.4 Closing Programming Mode ............. 11

7.5 Tips and Notes for the Sensor

Placement ......................................... 11

7.5.1 Tips for the Calibration of the Sensor

Locations........................................... 11

7.5.2 Introduction to the Wireless Data

Transmission for the Rittal Wireless

Sensor Network................................. 12

7.5.3 Wireless System Range Estimate..... 13

7.5.4 Troubleshooting ................................ 14

8 Operation .........................................15

8.1 Access Using a Browser ................... 15

8.1.1 Login Using a Browser...................... 15

8.1.2 Main Page View ................................ 15

8.1.3 General Overview (Status Window).. 15

8.1.4 Sensor Overview............................... 15

8.1.5 Sensor Configuration ........................16

8.1.6 Sensor Information............................ 16

2 Documentation Notes

EN

2 Documentation Notes

The audience for this guide is the technical specialists familiar with the assembly, installation and operation of the CMC-TC Wireless I/O-Unit.

• You should read this operating guide prior to the

commissioning and store the guide so it is readily

accessible for subsequent use.

Rittal cannot accept any liability for damage and

operational malfunctions that result from the nonobservance of this guide.

2.1 Associated Documents

The guides for other CMC-TC components and their

safety notes also apply together with this guide.

This guide can also be downloaded from

www.rimatrix5.com in the Internet and is also present as file on the CD-ROM of the Processing Unit

II:

German: 7320240VXXd.pdf

English: 7320240VXXe.pdf

To view the guide you require the Acrobat Reader

program; Acrobat Reader can be downloaded from

www.adobe.com

2.2 Retention of the Documents

This guide and all associated documents are part of

the product. They must be given to the operator of

the unit and must be stored so they are available

when needed.

2.3 Used Symbols

The following safety and other notes are used in this

guide:

Symbol for a handling instruction:

• This bullet point indicates that you should perform

an action.

Safety and other notes:

Danger!

Immediate danger to health and life!

Warning!

Possible danger for the product and

the environment!

3 Safety Notes

Observe the subsequent general safety notes for

the installation and operation of the unit:

− Assembly and installation of the CMC-TC Wireless I/O-Unit, in particular for wiring the enclosures with mains power, may be performed only

by a trained electrician. Other tasks associated

with the CMC-TC Wireless I/O-Unit, such as the

assembly and installation of system components

with tested standard connectors, and the operation and configuration of the CMC-TC Wireless

I/O-Unit may be performed only by instructed

personnel.

− Observe the valid regulations for the electrical

installation for the country in which the unit is installed and operated, and the national regulations

for accident prevention. Also observe any company-internal regulations (work, operating and

safety regulations).

− Prior to working at the CMC-TC system, it must

be disconnected from the power supply and protected against being switched on again.

− Use only genuine or recommended parts and

accessories (see Section 4.5 Accessories). The

use of other parts can void the liability for any resulting consequences.

− Do not make any changes to the CMC-TC Wireless I/O-Unit that are not described in this guide

or in the associated guides.

− The operational safety of the unit is guaranteed

only for its approved use. The limit values stated

in the technical specifications (see Section 14

Technical Specifications) may not be exceeded

under any circumstances. In particular, this applies to the permitted ambient temperature range

and to the permitted IP protection category. When

used with a higher required IP protection category, the Rittal CMC-TC must be installed in a

housing or enclosure with a higher IP protection

category.

− The operation of the CMC-TC system in direct

contact with water, aggressive materials or inflammable gases and vapours is prohibited.

− In addition to these general safety notes, also

observe any special safety notes listed for the

specific tasks in the individual sections.

Note!

Useful information and special features.

Unit Description 4

4 Unit Description

The Computer Multi Control Top Concept Wireless

I/O-Unit is an "intelligent" enclosure monitoring system installed in its own housing mounted on the

enclosure. The enclosure monitoring system uses

the various connected sensors to perform the complete physical monitoring of the enclosure, namely,

temperature, humidity, access control and digital

input module. All this information is transferred using

SNMP to a management station where it can be

administered. The CMC-TC Wireless I/O-Unit can

also be used as a repeater. The direct connection of

the CMC-TC power pack starts this function.

4.1 Housing

The CMC-TC Wireless I/O-Unit is contained in its

own housing that can be fastened with the supplied

Velcro strips to the inner side of the side wall, to the

punched sections with mounting flanges or to the

shelf of the enclosure. Mounting units (see Section

4.5.1 "Required Accessories") can also be used to

install the housing.

2

1

3

2 3

1

Fig. 2 CMC-TC Wireless I/O-Unit rear side

Key

1 Antenna connection

2 Power supply (optional)

3 Interface to Processing Unit II

4.2 Power Supply

The CMC-TC Wireless I/O-Unit is supplied with

power from the connected Processing Unit II. The

connection is established using an RJ45 cable. A

selection of various RJ45 cables is described in

Section 4.5 "Accessories".

All connected sensors have their own battery integrated in each sensor.

If you connect the CMC-TC Wireless I/O-Unit directly to a CMC-TC power unit, it operates as a

repeater.

EN

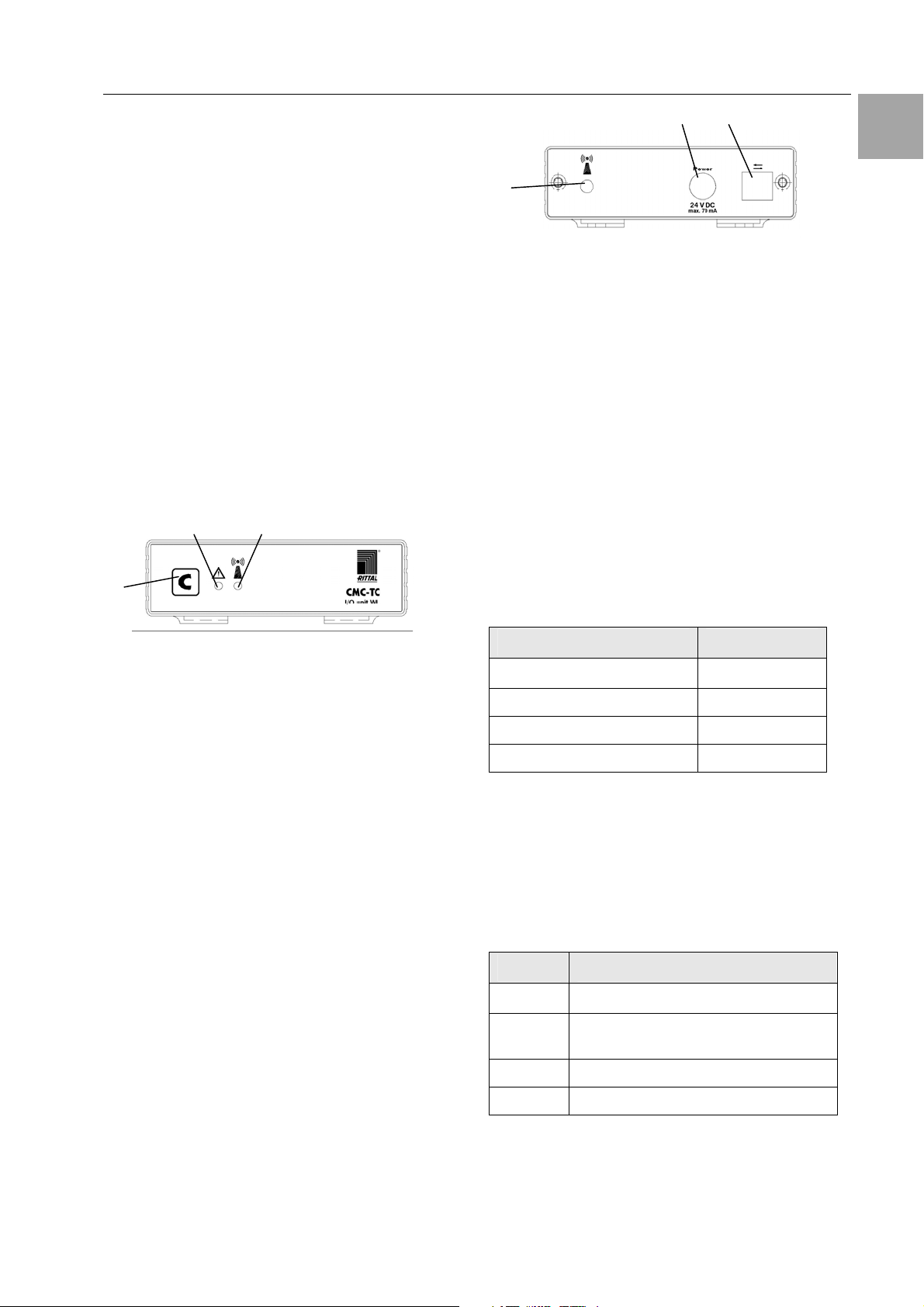

Fig. 1 CMC-TC Wireless I/O-Unit front side

Key

1 Acknowledge key (C key)

2 Status LED

- Off No operating voltage is present or

repeater mode

- Green OK sensor status

- Orange Warning sensor status

- Red Alarm sensor status

- Flashing green/orange/red

Configuration change

- Flashing red System is in reset

3 Wireless connection LED

- Off No operating voltage is present

- Green Normal operation

- Green interrupted briefly for some time [ms] ->

a data package is being sent

- Orange System is in repeater mode

- Red System in repeater mode has lost the

base station

- Flashing red System is in reset

- Flashing green/orange/red

System is in the log-in mode

4.3 Connectable Sensors

Sensor Model No.

Temperature sensor

DK 7320.505

Humidity sensor DK 7320.515

Access sensor DK 7320.535

Digital input module DK 7320.585

Tab. 1 Connectable Sensors

4.4 Scope of supply

The unit will be delivered in a packaging unit in fullyassembled state.

• Check the delivered components for completeness.

• Check that the packaging does not show any

signs of damage.

Quantity Designation

1

2 Self-adhesive Velcro fasteners

1 Antenna

1 Operating instructions

Wireless I/O-Unit

90 x 15 mm

Tab. 2 Scope of supply

4 Unit Description

EN

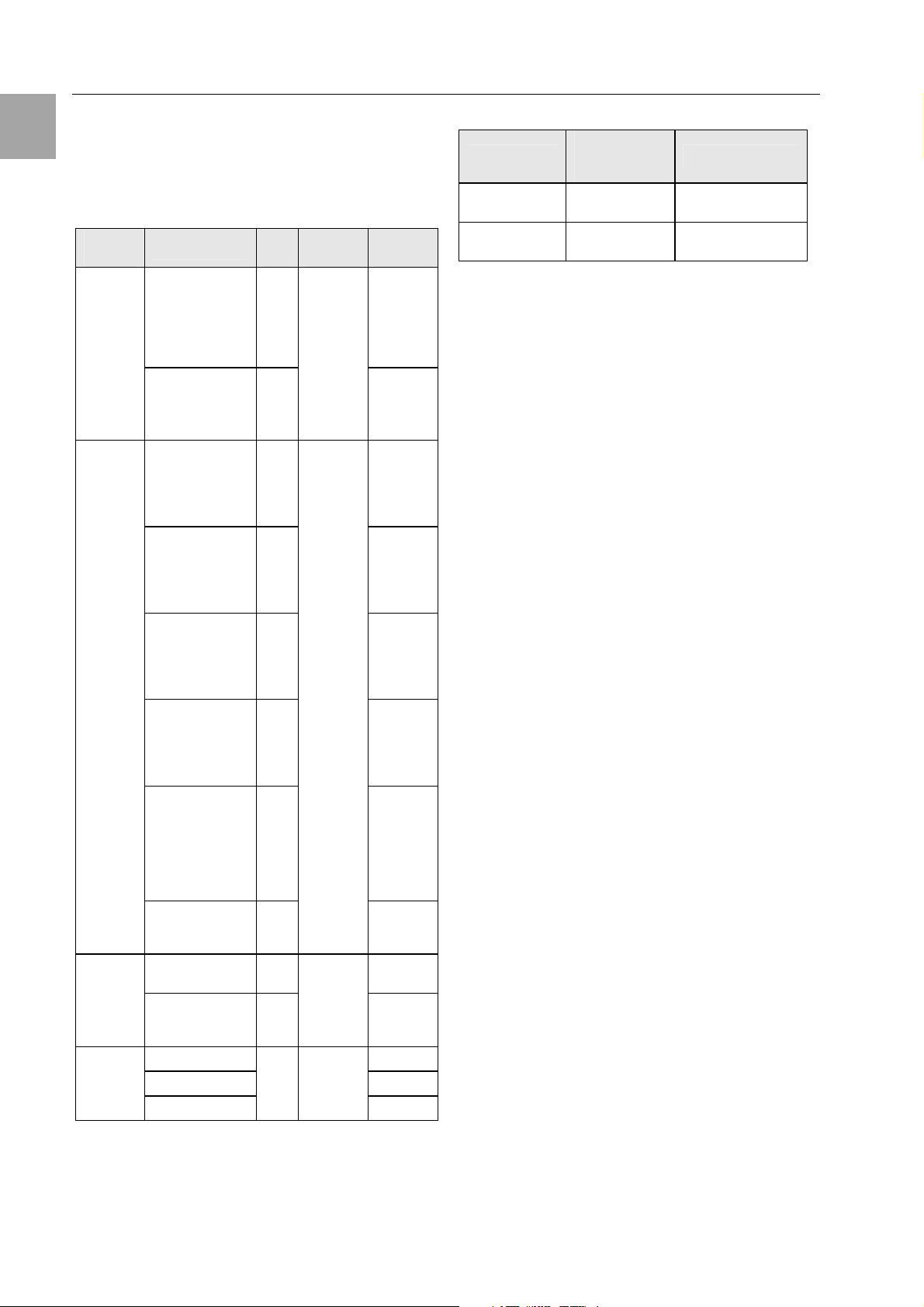

4.5 Accessories

4.5.1 Required Accessories

Depending on the country-specific specifications,

you require an appropriate connection cable for the

power pack of the CMC-TC PU II.

Accessories

Power

supply

for operation

as a

repeater

Connection

cable for

power

pack

Assembly

Connection

cable

Designation

Installation

power pack 24 V

IEC

100-230 V AC,

UL approval, 3 A

SELV

Installation

power pack 24 V

IEC

48 V DC

Connection

cable IEC connector

Country version

D

Connection

cable IEC connector

Country version

GB

Connection

cable IEC connector

Country version

F/B

Connection

cable IEC connector

Country version

CH

Connection

cable IEC connector

Country version

USA/CDN,

UL approval

FT1/VW1

Extension cable

IEC connector

and socket

1 U mounting

unit

1 U single mounting unit with

strain relief

RJ45; 0.5 m 7320.470

RJ45; 2.0 m 7320.472

RJ45; 5.0 m

P.ofRe-

quired

1 7320.425

Yes,

depending on

power

supply

1

1 7200.210

1

1

Yes,

once for

power

1

pack

1

1

1

Optional

1

11

Model

No.

7320.435

7200.211

7200.210

7200.213

7200.214

7200.215

7320.440

7320.450

7320.475

4.5.2 Optional Accessories

Accessories

External antenna

Wireless measuring unit

Tab. 4 Optional accessories

Max. required

number of

items

1 DK 7320.421

1 DK 7320.242

Model No.

4.6 Proper Use

The Rittal CMC-TC Wireless I/O-Unit serves as an

enclosure monitoring system for the monitoring and

administration of various enclosure parameters.

A use different from that described here is considered to be an improper use. Rittal cannot accept any

liability for damage resulting from the improper use

or the non-observance of this guide. The guides for

the used accessories may apply.

Tab. 3 Required accessories

5 Assembly

5.1 Assembly Notes

Install the CMC-TC Wireless I/O-Unit in an enclosure or in a suitable housing system so that it also

has additional protection from external effects. Also

consider the permitted ambient temperature and

humidity operational areas and the applicationrelated required IP degree of protection (see Chapter 14 Technical Specifications).

Note!

If you want to use the unit in

reapeater mode please register the repeater unit at the

I/O-Unit before installation. In

registration mode the range is

limited to 5m.

5.2 Assembling CMC-TC

Assembly 5

EN

Fig. 4 Assembly with Velcro fasteners

• Take the self-adhesive Velcro fasteners from the

supplied accessories and remove the protective

foil from the Velcro fasteners.

• Ensure that the adhesion surfaces are free from

grease and dust.

• Attach the Velcro fasteners to the housing of the

CMC-TC Wireless I/O-Unit and position the CMCTC Wireless I/O-Unit at the required attachment

location.

Fig. 3 Assembly with the mounting module

• Move the CMC-TC Wireless I/O-Unit on the retaining plate of the mounting module. Ensure that

the retaining plate sits between the guide rails of

the CMC-TC Wireless I/O-Unit.

2,4

3

1,5

Fig. 5 Assembly with 1 U mounting unit

1. Remove the two upper screws of the trim piece.

2. Remove the trim piece.

3. Move the CMC-TC Wireless I/O-Unit on the

retaining plate of the mounting unit. Ensure that

the retaining plate sits between the guide rails of

the CMC-TC Wireless I/O-Unit.

4. Replace the trim piece on the mounting unit.

5. Screw the trim piece back on the 1 U mounting

unit.

6 Installation

EN

6 Installation

Danger!

The assembly and installation may be

performed only by trained specialists.

6.1 Safety and Other Notes

− The Rittal CMC-TC system may be operated only

with connected protective earth conductor. The

protective earth conductor connection is made by

plugging in the IEC connection cable. This requires that the IEC connection cable at the power

supply side be connected with the protective

earth conductor.

− The electrical connection voltage and frequency

must conform to the rated values specified at the

rear of the housing and in the technical specifications (see page 19).

− Before commencing work on the Rittal CMC-TC

system, it must be disconnected from the mains

power supply and protected against being reconnected.

− Protect the connection cables using cable ties on

the used housing or enclosure.

− To prevent unnecessary cable losses, the used

cable lengths must not exceed the lengths specified in the technical specifications (see Chapter

14, page 19).

6.2 Connecting the Voltage Supply

1

Key

1 CMC-TC units connection

• Insert the other end of the RJ45 connection cable

in a free RJ45 socket with number 1 to 4 of the

CMC-TC Processing Unit.

After connection to the power supply, the Status

LED of the CMC-TC Wireless I/O-Unit flashes automatically. As soon as it is connected, the Status

LED illuminates alternately red, yellow and green.

6.3 Antenna Adjustment

The antenna of the I/O-Unit should always be adjusted parallel to the antennas of the sensors. If all

sensors are aligned vertical, the I/O-Unit antenna

must be also aligned vertical.

Warning!

FCC certification is valid only for the

2.4 GHz omnidirectional antenna

model IW-144 having a maximum 2 dBi

gain. An antenna having the same

specifications as model IW-144 but

with a gain of less than 2 dBi is an acceptable substitute.

7 Commissioning

7.1 CMC-TC Wireless I/O-Unit Commis-

sioning

Log in to the CMC-TC Processing Unit as described

in Section 8.1.1 Login Using a Browser.

Fig. 6 Connecting the voltage supply

Key

1 Power supply connection

You must connect the CMC-TC Wireless I/O-Unit to

the CMC-TC Processing Unit using the RJ45 connection cable mentioned in Section 4.5.1 "Required

Accessories".

• Insert the plug connector of the RJ45 connection

cable in the socket, as shown above, of the CMCTC Wireless I/O-Unit.

1

Power

12

43

Fig. 7 Connecting to the CMC-TC Processing Unit with

software version as of V. 2.46

P-I C

2

I0I0I

1

24 VDC

max. 2,5 A

1

Fig. 8 Commissioning

Key

1 Status LED

Once the CMC-TC Wireless I/O-Unit has been connected to the power supply, the Status LED of the

CMC-TC Wireless I/O-Unit flashes alternately with

the colours red, yellow and green.

Commissioning 7

1

Fig. 9 Unit detection browser window

Key

1 Status display of the sensor island

The "Unit detected" message appears in the

browser window of the Processing Unit.

Continue to press the C key on the Processing Unit

until the Status LED of the CMC-TC Wireless I/OUnit switches to a continuous green.

1

2

3

Fig. 10 Overview display browser window

Key

1 Overview display

2 Status of the I/O-Unit

3 Clear button

The CMC-TC Wireless I/O-Unit has now been detected.

1

Fig. 12 Wireless sensor (lower side)

Key

1 Status LED

2 Micro pushbutton

2

Press the Sensor micro-pushbutton (Push) located

on the lower side one second. The Status LED on

the sensor illuminates once briefly. If the registration

process was successful, the Wireless Connection

LED of the CMC-TC Wireless I/O-Unit flashes green

for approximately two seconds, then alternately red,

yellow, green. Simultaneously, the Status LED on

the CMC-TC Wireless I/O-Unit flashes alternately

red, yellow and green.

Note!

During the registration process, the distance between the sensor and the Wireless I/O-Unit may not exceed 5 m, because the I/O-Unit operates with reduced

transmission power in this mode.

No other I/O-Unit within a 5 m range must

be in registration mode during the registration process.

EN

7.2 Registering Sensors

1

Fig. 11 Wireless I/O-Unit (programming status)

Key

1 C key

2 Wireless connection LED

Press the C key on the Wireless I/O-Unit for three

seconds. The wireless connection LED now flashes

alternately red, yellow and green. The CMC-TC

Wireless I/O-Unit is now in programming mode.

2

Note!

For the commissioning of the sensors,

please observe information provided in

the Wireless Sensors manual.

1

2

Fig. 13 Sensor identification

Key

1 Status display of the sensor island

2 Clear button

"Configuration changed" appears in the browser

window. Press the Clear button (possibly several

times). The sensor is now registered to the I/O-Unit.

To test the registration, click in the overview display

the name of the I/O-Unit (here: CMC-TC-IOW). The

overview of the registered sensors is now displayed.

7 Commissioning

y

EN

Note!

A newly registered sensor receives the

sensor position with the smallest free

sensor position number.

Sensors have to be registered at the main I/O-Unit,

not at possibly used repeaters.

2

1

Fig. 14 Registered sensors overview

1 Sensor island / I/O-Unit

Click in the sensor overview on the name of the

sensor to be removed.

1

Fig. 16 Sensor Overview

Key

1 Sensor

Key

1 Registered sensors

2 Up button

Click the Up button to return to the overview display.

7.3 Removing Sensors

To remove a sensor from the I/O-Unit, first switch off

the sensor. To do this, press the key on the sensor

for at least five seconds until the Status LED flashes

very quickly.

To perform an immediate removal, switch off the

sensor as described above. On the configuration

page in your web browser, switch to the sensor

configuration.

To do this, click first in the main overview on the

sensor island / I/O-Unit to which the sensor to be

removed is connected (Fig. 15). You must be logged

in as administrator to use this function.

You now see the sensor configuration page.

1

Fig. 17 Sensor configuration

Key

1 Info button

Click the Info button to reach the sensor information

page.

1

Fig. 15 Main page overview

Ke

Commissioning 7

1

Fig. 18 Sensor Information

Key

1 Remove Sensor button

Click the Remove Sensor button to remove the sensor from the I/O-Unit.

Note

The communications timing between the

I/O-Unit and the sensor can require that

Remove Sensor must be clicked several

times before the remove command is accepted.

The sensor has now been removed and will no

longer be listed in the sensor overview. To reconnect the sensor, proceed as described in Section

7.2.

7.4 Closing Programming Mode

1

Fig. 19 Closing programming mode

Key

1 C key

2 Wireless connection LED

To close the programming mode, press the C key

on the CMC-TC Wireless I/O-Unit for two seconds.

The Wireless Connection LED will change to green.

If the programming mode is not closed manually, the

CMC-TC Wireless I/O-Unit returns automatically to

normal mode two minutes after the last registration

action.

2

7.5 Tips and Notes for the Sensor

Placement

To prevent malfunctions and to ensure reliable operation, the sensors should be positioned as described in Subsection 7.5.1. Detailed fundamental

information for the used wireless technology is described in Subsection 7.5.2.

Before starting the measurement, all I/O-Units and

repeaters must be installalled and all antennas must

be aligned.

7.5.1 Tips for the Calibration of the Sen-

sor Locations

To ensure the best possible reception of the individual sensors, the suitability of each sensor location

must be tested in advance using the wireless measuring system sensor (DK 7320.242).

Procedure:

i. Place the I/O-Unit into operation at the

planned location as described in Section

7.1.

Tip: Before starting the calibration, successively connect all sensors to the I/O-Unit.

This causes the sensors to be placed in

front of the measuring system sensor in the

registration list of the Processing Unit II.

This simplifies the subsequent administration.

ii. Connect the wireless measuring system

sensor to the I/O-Unit (see Section 7.2). To

do this, proceed as follows:

Place the I/O-Unit in programming mode

(press the C key for three seconds) > press

the key on the wireless sensor for five seconds (resets the sensor) > press the key on

the wireless sensor 1 second > the LED

flashes once briefly > sensor is registered >

leave programming mode of the I/O-Unit

(press the C key for two seconds, the wireless connection LED on the I/O-Unit lights

up green).

iii. Place the sensor attachment bracket at the

required sensor location (true for all sensor

types). The sensor front side edge must

point later in the I/O-Unit direction.

iv. Place the measuring system sensor on the

attachment bracket. The sensor position

during the measurement must be the same

as the operation position.

v. Perform a one-minute measurement with

the measuring system sensor: Press the

key on the measuring system sensor >

the result of the previous measurement will

be displayed for five seconds > "1" flashes

in the display (indicates the one-minute

measurement) > if a different number is displayed flashing, press the key several times

until the "1" appears > the measurement

EN

7 Commissioning

EN

starts after 5 seconds > the measurement

result (0-9) will be displayed after one minute.

(Details for the measurement and measuring times are contained in the operating instructions of the wireless sensors.)

vi. Measurement result 8-9: The connection is

suitable for the productive operation. Remove the measuring system sensor and

place the required sensor (temperature,

humidity, access or digital input) on the attachment bracket.

vii. Measurement result 0-7: Sensor location

not suitable. Change the position of the

sensor, use a repeater (see Chapter 9) or

use an external antenna. Then repeat the

measurement.

viii. Repeat steps iii. to vii. for each additional

sensor.

The wireless sensors now have an adequate connection to the I/O-Unit. This completes the installation of the system.

If problems in the wireless area occur during the

installation of the system, Subsection 7.5.4 describes the appropriate troubleshooting for correcting the fault.

Signal weakening

Even without obstacles, the sent wireless signal is

subject to a natural attenuation. The electric and

magnetic field strengths reduce by the factor 1/r

This means for distances exceeding approximately

1 m, the signal strength reduces by the factor 4

when the distance is doubled. Consequently, at

10 m distance from the transmitter, only 1/100 of the

signal strength compared with that at 1 m distance

will be received.

Any object through which the wireless signal needs

to penetrate causes an absorption of the signal (optical model: the light will be weaker). Whereas lightweight partition walls and doors cause only small

signal attenuation, masonry walls and coated glass,

persons or animals cause more signal attenuation;

metal causes large signal attenuation. Metal grids

act like metal walls.

2

.

7.5.2 Introduction to the Wireless Data

Transmission for the Rittal Wireless Sensor Network

This section describes the principles of the associated wireless technology that can be useful for setting up the wireless installation.

The sensor system operates with a frequency of

2.4 GHz. This means an optical consideration is

helpful for an initial planning for suitable installation

locations and distances.

The wireless signal is considered as being a light

beam with a dispersion characteristic appropriate for

light.

If you follow this model, it becomes clear that a direct line-of-sight connection between the base and

the sensor is the most favourable installation variant. Walls, furnishings, etc., in the vicinity can, however, act as a "mirror" that reflects the signal like

light. In this case, not only the original signal, but

also reflected signals from various directions arrive

at the receiving point. It is possible that the sent

data are incorrectly combined in the receiver. This

effect is called multi-path reception and can cause

major impairment of the reception quality.

This means even a line-of-sight connection between

the transmitter and the receiver is no guarantee for

a good connection.

Fig. 20 Absorption of the wireless signal by various

materials

Subsection 7.5.3 provides a general estimate of

what ranges can be expected for certain installation

situations.

Commissioning 7

7.5.3 Wireless System Range Estimate

Scenario Sensor range

Single enclosure

Single enclosure (side)

Enclosure suite

Enclosure suite (side)

Table 5 provides an indication of the expected ranges for certain installation scenarios.

for steel door (closed) up to 20m

for steel door (70% vented) up to 35m

for glazed door up to 45m

for steel door (closed) up to 20m

for steel door (70% vented) up to 25m

for glazed door up to 25m

Note: These values are highly dependent on the

ambient reflection

for steel door (closed) up to 6m

for steel door (70% vented) up to 20m

for glazed door up to 30m

for steel door (closed) up to 6m

for steel door (70% vented) up to 10 m

for glazed door up to 10 m

Note: These values are highly dependent on the

ambient reflection

EN

Adjoining room (masonry: thickness 30 cm, concrete)

Corridor (line of sight, LOS)

Outdoor (line of sight, LOS)

for steel door (closed) up to 6m

for steel door (70% vented) up to 8m

for glazed door up to 10 m

up to 50 m

up to 200m

up to 50 m

Industrial building (line of sight, LOS)

Tab. 5 Wireless ranges

7 Commissioning

EN

Key

7.5.4 Troubleshooting

Fault Possible cause Testing and rectification

Sensor signal

is not

received.

Sensor does not send. Send a test packet by briefly pressing the key

on the sensor. LED must flash once.

If necessary, test the battery state using PUII.

Sensor lies outside the

range of the I/O-Unit.

Sensor has been removed or

interchanged.

Incorrect or no sensor registered

to the I/O-Unit.

Test the wireless link using the "wireless measuring system". If the display value is smaller

than "8", change the installation location. Alternatively, use a repeater or an external antenna.

Replace the sensor or/and re-register.

Check the sensor list on the Processing Unit

web page.

If necessary, re-register the sensor.

Sensor is

sometimes not

received.

Antenna not connected correctly. Check the antenna installation, plug connectors

and the laying of the antenna cable.

I/O-Unit is installed in a

shielded area.

Interfering transmitter (continuous transmitter) present.

Sensor lies in the fringe range

of the I/O-Unit.

Sensor lies in the fringe range

of the I/O-Unit.

Intermittent change of the

ambient conditions (enclosure,

door, objects, persons, interfering transmitter, etc.).

Test the wireless link using the "wireless measuring system". If the display value is smaller

than "8", use an external antenna.

Test the wireless link using the "wireless measuring system". Display value should be 8-9 in

the vicinity of the I/O-Unit. If necessary, rectify

the interfering transmitter.

Test the wireless link using the "wireless measuring system". If the display value is smaller

than "8", change the installation location or use

a repeater.

Increase the power reserves of the wireless link:

Mount the base and the sensor as high as possible to minimise the absorbing characteristics

of the floor, and the effect of objects and persons.

Increase the power reserves of the wireless link:

Change the installation location of the sensor or

the I/O-Unit (the other sensors of the I/O-Unit

then must be recalibrated) or use repeaters. If

necessary, rectify the interfering transmitter.

The installation location of the

sensor changes periodically

(mobile sensor).

Interfering transmitter

sometimes present.

Tab. 6 Troubleshooting

Change the installation location of the sensor so

that it lies in the receiving area.

Rectify or switch off the interfering transmitter.

Operation 8

8 Operation

The configuration of the individual sensors is described in the operating manual of the individual

wireless sensors.

8.1 Access Using a Browser

Open your Web browser as usual. Enter the IP

address of the Processing Unit in the address

field and start to build the page.

8.1.1 Login Using a Browser

1

2

3

Fig. 21 Login window

Key

1 User name

2 Password

3 Login or Clear button

Enter in the login window the http user name and

the http password of the Processing Unit. The use

has to have administration rights.

The factory setting of the CMC-TC Processing

Unit:

User name: admin

Password: admin

To confirm the input, click the Login button. To

clear the input, click the Clear button.

8.1.2 Main Page View

1

2

3 IP address of the Processing Unit

4 Link to the main page view

5 Setup link

6 Log link

7 Administration link

8 User name

9 User logout

8.1.3 General Overview (Status Window)

2 43 5

1

6

Fig. 23 I/O-Units overview

Key

1 Connection number and type of the I/O-Unit

2 Name of the I/O-Unit

3 Status display of the I/O-Unit

green: No warning/alarm

yellow: Warning

red flashing: Alarm / error (timeout)

red/yellow flashing: Configuration changed

4 Sensor overview link (see 8.1.4)

5 Sensor configuration link (see 8.1.5)

6 Clear – acknowledge events

Click the Clear button to acknowledge configuration changes of all connected sensors. This

causes the CMC-TC PU to be re-queried and the

Web page rebuilt.

EN

3

4

5

6

7

8

9

Fig. 22 Main page overview

Key

1 Address bar

2 Status window

8.1.4 Sensor Overview

2 3

1

4

Fig. 24 Sensor Overview

Key

4

1 List of all sensors connected to the Processing

Unit.

Clicking the sensor name displays the configuration page of the sensor

2 Link to the sensor configuration

(see 8.1.5)

3 Link to the status window (see 8.1.3)

4 Clear – acknowledge events

8.1.5 Sensor Configuration

You can individually set the attached sensors.

Because the structure of the configuration overview is generally always identical, it is shown here

as an example.

To reach this page, click the

the sensor name directly.

1

2

3

4

5

6

7

8

9

tool icon or click

8 Enter here the numbers 1 to 4 of the email adress

that should receive an email when an alarm is issued. To create the email adress, please consult

the operating manual of the CMC-TC Processing

Unit. The numbers must be entered separated by

an "&" character (e.g. 1&2&3&4).

9 Accepting the changes.

Info page for the specific wireless sensor.

(changes will not be accepted by clicking Info)

Reset all settings to the default values.

Note!

Further setting possibilities are described in the Wireless Sensor operating manual.

8.1.6 Sensor Information

1 2

3

Fig. 25 Configuring the sensor – overview

Key

1 Battery status

OK – battery OK

low – change battery

2 You can set for each sensor whether (enable) or

not (disable) the alarm relay is to be switched for

an alarm.

3 You can set for each sensor whether (enable) or

not (disable) the integrated alarm beeper is to be

activated for an alarm.

4 You can set for each sensor type whether after a

warning or alarm status the CMC-TC PU should

self-acknowledge (auto) or the administrator must

acknowledge manually (manual).

5 By clicking the individual option fields you can

determine to which of the entered trap-receivers

the traps for this sensor are to be sent.

6 By clicking the individual option fields you can set

which alarm configuration is to be enabled or disabled. You can specify the individual functions in

the "Setup – Timer" menu item and assign the

associated scheduler.

7 Enter here the numbers 1 to 4 of the mobile wire-

less numbers that should receive an SMS when

an alarm is issued. To create the mobile wireless

numbers, please consult the operating manual of

the CMC-TC Processing Unit. The numbers must

be entered separated by an "&" character (e.g.

1&2&3&4).

5

Fig. 26 Sensor information

Key

1 Name of the I/O-Unit to which the sensor is regis-

tered.

2 Tabs for additional sensors of the Processing

Unit.

3 Detailed information for the selected sensor

(here: Sensor 1)

Type: Sensor type

Sensor Status: Current measured value or status

of the sensor

Signal Quality: Signal quality of the Sensor –

I/O-Unit connection

Message Text: Message text for alarm messages

Serial Number: Serial number of the sensor

Software Version: Version number of the sensor

software

Transmit Packages: Data packages transmitted

from the sensor to the I/O-Unit

Measurement Cycle: Interval between two

measurements

Lifecheck Cycle: Interval between the

transmission of two Lifecheck packets. An Error

will be reported after 4 consecutive lifecheck signal losses.

Wireless I/O-Unit as Repeater 9

Hoplist: Information path of the sensor signal to

the Wireless I/O-Unit. The individual repeater stations through which the sensor signal passes on

the path to the I/O-Unit are listed here.

4 Button to remove the sensor from the I/O-Unit.

5 Values button returns to the sensor configuration

(see 8.1.5).

9 Wireless I/O-Unit as Re-

peater

The CMC-TC Wireless I/O-Unit can also be used

as a repeater for the Rittal CMC-TC wireless sensor network. This allows a long distance or a large

area to be covered using wireless sensors.

Note!

A maximum of nine CMC-TC Wireless

I/O-Units with repeater function can be

registered with a CMC-TC Wireless I/OUnit using the CMC-TC Processing

Unit.

9.1 Power Supply

1

Fig. 27 Power supply (repeater)

Key

1 Power supply connection

Use for the power supply a power unit described

in Subsection 4.5.1 Required Accessories. Ensure that a country-specific connection cable is

used.

now receive the "Configuration changed" message on the browser window. Click the Clear button two or three times until the message disappears. Click on the sensor overview pageon the

sensor name. The following window now appears.

1

2

3

4

5

6

7

Fig. 28 Repeater status

Key

1 Tab: The repeater will be registered with a free

port on the CMC-TC Wireless I/O-Unit (master).

2 Type: Sensor name (here: WL Repeater).

3 Sensor Status: The status of the CMC-TC Wire-

less I/O-Unit (repeater).

4 Battery Status: --.

5 Message Text: A name for the alarm message of

the CMC-TC Wireless I/O-Unit (repeater) is defined here.

6 Additional cofiguration: see sensor configuration

fig. 26.

7 Accept: Accept all changed settings.

Info: Call the information page of the CMC-TC

Wireless I/O-Unit (repeater) (see 9.3 Repeater

Information Page).

Reset: Reset all changed values.

Note!

During the sensor registration the distance between repeater an Wireless

I/O-Unit must not exceed 5m!

EN

9.2 Configuring a Wireless I/O-Unit

as Repeater

Once you have connected the Wireless I/O-Unit

to the power unit, it functions as a repeater. You

must now register the Repeater Wireless I/O-Unit

with the Wireless I/O-Unit using the CMC-TC

Processing Unit (master). If the repeater has already been registered at a different I/O-Unit, you

have to reset the repeater first. To reset, please

press c key for 10 seconds until the status LED is

flashing.

Press for two seconds the C key on the Wireless

I/O-Unit (master). The wireless connection LED

flashes red, yellow and green. You are now in

programming mode. Now go to the Repeater

Wireless I/O-Unit and press once the C key. You

9.3 Repeater Information Page

The information page shows all important parameters of the CMC-TC Wireless I/O-Unit (repeater).

1

1

2

3

4

5

6

7

8

9

10

11

Fig. 29 Repeater information page

Key

1 Type: The type of the registered unit or the sen-

sor.

2 Sensor Status: The current status of the unit

green: OK

red: Error

3 Signal Quality: The signal strength between the

CMC-TC Wireless I/O-Unit (repeater) and the

CMC-TC Wireless I/O-Unit on the Processing

Unit (master).

4 Message Text: The entered message text for

alarms.

5 Serial Number: The serial number of the CMC-

TC Wireless I/O-Unit (repeater).

6 Software Version: The software version of the

CMC-TC Wireless I/O-Unit (repeater).

7 Transmit Packages: The packages transferred to

the CMC-TC Wireless I/O-Unit (master).

8 Measurement Cycle: The measurement interval

(here every 10 seconds).

9 Lifecheck Cycle: The measurement interval for

querying the reachability to the CMC-TC Wireless I/O-Unit (master). An Error will be reported

after 4 consecutive lifecheck signal losses.

10 Hoplist: Information path of the sensor signal to

the Wireless I/O-Unit. The individual repeater

stations through which the sensor signal passes

on the path to the I/O-Unit are listed here.

11 Values: You can return to the CMC-TC Wireless

I/O-Unit (repeater) status page (see 9.2

Configuring a Wireless I/O-Unit as Repeater).

Hoplist example:

tab 3. You see the following message in the hoplist:

Fig. 31 Hoplist (repeater)

This means that the signals of the CMC-TC wireless humidity sensor on tab 2 using the CMC-TC

Wireless I/O-Unit (repeater) on tab 3 go to the

CMC-TC Wireless I/O-Unit (master).

To unregister the repeater from the I/O-Unit, you

have to reset the repeater. To reset, please press

C key for 10 seconds until the status LED is flashing.

10 Connecting an External An-

tenna

In difficult environments the external antenna can

be used to increase signal perfromance of the

CMC-TC Wireless I/O-Unit (see Subsection 4.5.2

Optional Accessories).

Fig. 32 Connecting an antenna

Key

1 Antenna connection

Unscrew the supplied antenna of the CMC-TC

Wireless I/O-Unit and screw on the antenna plug

of the external antenna.

The antenna of the I/O-Unit should always be

adjusted parallel to the antennas of the sensors. If

all sensors are aligned vertical, the I/O-Unit antenna must be also aligned vertical.

11 Maintenance and Cleaning

The Rittal CMC-TC Wireless Unit I/O-Unit is a

maintenance-free system. The housing does not

need to be opened for the installation or during

operation.

Note!

Opening the housing or any accessory

components will void any warranty and

liability claims.

11.1

Fig. 30 Hoplist example (repeater)

The humidity sensor was registered on tab 2. The

removed CMC-TC Wireless I/O-Unit (repeater) on

Storage and Disposal 12

11.2 Cleaning

Warning!

Danger of damage!

Do not use any aggressive substances, such as white spirit, acid,

etc., for cleaning because such substances can damage the unit.

Use a slightly moistened soft cloth to clean the

housing.

12 Storage and Disposal

12.1 Storage

If the device is not used for a longer period, we

recommend that it is disconnected from the mains

power supply and protected from dampness and

dust.

If the sensors are not used for a longer period,

they should be switched off.

Further information concerning the operating conditions is contained in the technical specifications.

12.2 Disposal

Because the CMC-TC Wireless Unit I/O-Unit consists primarily of the housing and PCB, the unit

must be disposed of through the electronic waste

recycling system when it is no longer required.

14 Technical Specifications

Designation CMC-TC

Housing

Housing type Plastic covering with metal trim

Height 1 U / 44.5 mm

Width 136 mm

Depth 129 mm

Weight without

packaging

Potential equalisation

Earthing -

Protection

category

Interfaces

Pushbuttons 1 membrane pushbutton, ac-

LED display 2 x (active/alarm, wireless con-

Input

Rated voltage /

rated current

approx. 0.6 kg

2)

-

2)

IP 40 to EN 60529

knowledge pushbutton

nection)

24 V DC, internal or

24 V for external power supply

120 mA

EN

13 Customer Service

If you have any technical questions or questions

concerning our product spectrum, contact the

following service address:

Tel.: +49 (0)2772/505-1855

http://www.rimatrix5.com

E-mail: info@rittal.de

Note!

To allow us to process your enquiry

quickly and correctly, please always

specify the article number in the subject

line for e-mails.

Further information and the current operating

manuals and updates of the Rittal CMC-TC can

be downloaded from:

http://www.rimatrix5.de/service_support/download

s.asp

Operational area

Temperature +5 to +45 °C

+42 to +113 °F

Storage temperature

Humidity 10% – 90% rel. humidity, non-

Technical Specifications

1)

Height units

2)

Not required because safety extra-low voltage

24 V DC

-20 to +60 °C

-4 to +140 °F

condensing

15 Technical Glossary

CMC-TC

CMC-TC (Computer Multi Control – Top Concept)

is a Rittal product used to monitor network enclosure components.

Internet browser

An Internet browser can be used to display html

pages (and pages that conform to a similar standard). In the case of CMC-TC PU II, they can be

configured using a user interface displayed with

an Internet browser.

Link

A link causes a jump to another Internet page or

establishes a connection between two Internet

pages.

SNMP (Simple Network Management Protocol)

The SNMP is a simple network management

protocol based on TCP/IP. It was developed to

monitor network components on a central management station.

Trap

Trap is the sending of SNMP messages.

Trap Receiver

The trap receiver is the receiver of SNMP messages.

16 Declarations of Conformity

This device satisfies the requirements of the following EU regulation:

1999/5/EU Regulation for wireless sys-

tems and telecommunications

terminals and the mutual recognition of their conformance

Hereby Rittal declares, that

CMC Wireless I/O-Unit and

CMC Wireless sensor is in

compliance with essential

requirements and other relevant provisions of Directive

1999/5/EC.

In France, the operation is only permitted indoors.

Certification

This device complies with Part 15 of the FCC

Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any

interference received, including interference that

may cause undesired operation.

The internal / external antennas used for this

mobile transmitter must provide a separation distance of at least 20 cm from all persons and must

not be co-located or operating in conjunction with

any other antenna or transmitter."

FCC ID: SIFCMCBASE0108V2

Statement according to FCC part 15.21:

Modifications not expressly approved by this

company could void the user's authority to operate the equipment.

Statement according to FCC part 15.105:

Note: This equipment has been tested and found

to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and

used in accordance with the instruction manual,

may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful interference

in which case the user will be required to correct

the interference at his own expense.

Statement according to FCC part 15.105:

NOTE: This equipment has been tested and

found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates,

uses and can radiate radio frequency energy and,

if not installed and used in accordance with the

instructions, may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to

try to correct the interference by one or more of

the following measures:

. Reorient or relocate the receiving antenna.

. Increase the separation between the equipment

and receiver.

. Connect the equipment into an outlet on a circuit

different from that to which the receiver is connected.

. Consult the dealer or an experienced radio/TV

technician for help.

Revision History

Ver si on Date Description/Changes

1.00 2008-04-15 Initial version.

Revision History

CMC-TC Wireless I/O-Unit (UserMan)

© 2008 Nanotron Technologies GmbH. NA-08-0000-0025-1.00 Page 21

About Nanotron Technologies GmbH

CMC-TC Wireless I/O-Unit (UserMan)

About Nanotron Technologies GmbH

Nanotron Technologies GmbH develops world-class wireless products for demanding applications based

on its patented Chirp transmission system - an innovation that guarantees high robustness, optimal use of

the available bandwidth, and low energy consumption. Since the beginning of 2005, Nanotron's Chirp technology has been a part of the IEEE 802.15.4a draft standard for wireless PANs which require extremely

robust communication and low power consumption.

ICs and RF modules include nanoNET TRX Transceiver, nanoLOC TRX Transceiver, and ready-to-use or

custom wireless solutions. These include, but are not limited to, industrial monitoring and control applications, medical applications (Active RFID), security applications, and Real Time Location Systems (RTLS).

nanoNET is certified in Europe, United States, and Japan and supplied to customers worldwide.

Headquartered in Berlin, Germany, Nanotron Technologies GmbH was founded in 1991 and is an active

member of IEEE and the ZigBee alliance.

Further Information

For more information about this product and other products from Nanotron Technologies, contact a sales

representative at the following address:

Nanotron Technologies GmbH

Alt-Moabit 60

10555 Berlin, Germany

Phone: +49 30 399 954 - 0

Fax: +49 30 399 954 - 188

Email: sales@nanotron.com

Internet: www.nanotron.com

Page 22 NA-08-0000-0025-1.00 © 2008 Nanotron Technologies GmbH.

Loading...

Loading...