NANO NDL-060,NDL-070,NDL-080,NDL-090,NDL-100,NDL-110,NDL-120,NDL-130, NDL-100, NDL-110, NDL-120, NDL-080 Maintance Manual

...

D-Series

1

HEATLESS COMPRESSED AIR DRYER

MAINTENANCE & SERVICE MANUAL

www.n-psi.com

NDL-060

NDL-070

NDL-080

NDL-090

NDL-100

NDL-110

NDL-120

NDL-130

Page 2

Copyright

This manual is copyrighted, all rights reserved. It may not, in whole or in part, be copied, photocopied,

reproduced, translated, or reduced to any electronic medium or machine readable form without prior consent

in writing from nano-purification solutions. It may not be distributed through the internet or computer bulletin

board systems without prior consent from nano-purification solutions.

GENERAL INFORMATION

©2012 nano-purification solutions

eHeatless Desiccant Air Dry r: D-Series1 (060-130) Service Manual

Models: NDL-060, 070, 080, 090, 100, 110, 120, 130 (Including ES Model)

Document number: n-psi-D1(060-130)-OM-US-01

Issue: 001

Document Introduction

This manual provides manufacturers prescribed procedures for the maintenance and service procedures for a

nano-purification solutions compressed air dryer. The procedures illustrated in this document are only to be

performed by authorised personnel. For further information regarding the procedures outlined in this document

contact nano-purification solutions before proceeding. Read this document carefully before attempting to

service the dryer.

General Safety

For your own safety, when carrying out maintenance work on the dryer, all relevant national safety regulations

must be complied with relating to pressurised and electrical systems. Only authorised, competent and trained

personnel should maintain the dryer, this user guide is intended solely for such personnel and is to be used

only as a reference, it should not be used to replace conventional training.

NOTES: highlight important sections of information where particular care and attention should

be paid.

CAUTIONS: indicate any situation or operation that may result in potential damage to the

product, injury to the user, or render the product unsafe.

Warranty Guidelines

All dryers are supplied with a 5 year manufacturer’s warranty from the date of purchase. The dryer should be

installed, operated and maintained in accordance with the manufacturer’s guidelines. Only genuine service

parts should be used and no modifications made. For further information please contact us at

support.n-psi.com.

Page 3

nano-purification solutions

11330 Vanstory Blvd

Huntersville, NC 28078

Telephone: (704) 897-2182

Internet: www.n-psi.com

E-mail: support@n-psi.com

Title

1. Service Intervals

2. Product Assembly

3. Recommended Tools

4. Dryer Shutdown Procedure

5. Service A Instructions – Cartridge Replacement (NDL-060 – NDL-120)

5.1 Service A Instructions – Cartridge Replacement (NDL-130 only)

6. Service B Instructions – Inlet Control & Exhaust Valve Replacement (NDL-060 - NDL-090)

6.1 Service B Instructions – Inlet Valve Replacement (NDL-100 - NDL-130)

6.2 Service B Instructions – Inlet Control & Exhaust Valves Replacement (NDL-100 TO NDL-130)

6.3 Service B Instructions - Outlet Valve Replacement (NDL-060 TO NDL-130)

7. Service C Instructions – ES Models Only

8. Re-setting the Dryer Controller

9. Manifold Tightening Sequences

10. Dryer Start-up Procedure

11. Other Dryer Checks & Non-serviceable Items

12. Troubleshooting

13. Service Record & Notes

MANUFACTURERS DETAILS

CONTENTS

Page(s)

4

5-6

7

7

8

9

10-11

12-13

14-15

16

17-18

19

20

21

22

23

24-25

Page 4

The following table details the recommended service intervals for this product and the service kits to be used.

1. SERVICE INTERVALS

Additional For ES Models Only

Recommended Service Intervals

Required Service Kits

Dryer

Model

Service A Service B Service C

Service

Type

B

A

P P P P PP

P

PP PP PP PP PP

C

1

Year

2

Years

3

Years4 Years

5

Years

6

Years

7

Years 8 Years 9 Years

11

Years

10

Years

12

Years

2 Years

(12,000 Hrs)

4 Years

(24,000 Hrs)

6 Years

(36,000 Hrs)

8 Years

(48,000 Hrs)

10 Years

(60,000 Hrs)

NDL-070

NDL-060

NDL-080

NDL-090

NDL-100

NDL-110

NDL-120

NDL-130

NDK-060

NDK-070

NDK-080

NDK-090

NDK-100

NDK-110

NDK-120

NDK-130

NDK-060 + NVK-090

NSK-130

NDK-070 + NVK-090

NSK-130

NDK-080 + NVK-090 NSK-130

NDK-090 + NVK-090 NSK-130

NDK-100 + NVK-130 NSK-130

NDK-110 + NVK-130 NSK-130

NDK-120 + NVK-130 NSK-130

NDK-130 + NVK-130 NSK-130

P P

12 Years

(72,000 Hrs)

PP

Page 5

2. PRODUCT ASSEMBLY

TOP COVER

INLET/OUTLET

(TOP) MANIFOLD

ASSEMBLY

DESICCANT

CARTRIDGES

DRYER

CONTROLLER

DRYER

SHROUD

DRYER

COLUMN

BOTTOM

MANIFOLD

ASSEMBLY

DRYER LEGS

SILENCER

BOX

MODELS NDL-060 TO NDL-090

EXHAUST VALVE

INLET VALVE

Page 6

2.1 PRODUCT ASSEMBLY

MODELS NDL-100 TO NDL-130

TOP COVER

OUTLET (TOP)

MANIFOLD

ASSEMBLY

DESICCANT

CARTRIDGES

DRYER

CONTROLLER

DRYER

COLUMN

INLET (BOTTOM)

MANIFOLD

ASSEMBLY

DRYER LEGS

SILENCER

BOX

DRYER

SHROUD

EXHAUST VALVE

VALVE

BLOCK

INLET

BLOCK

Page 7

3. RECOMMENDED TOOLS

The following tools will be required to service the dryer:

TERMINAL SCREW DRIVER

ALLEN KEY 3mm

ALLEN KEY 4mm

ALLEN KEY 6mm

ALLEN KEY 8mm

TORQUE WRENCH (8-60NM)

TORQUE SOCKET 6mm

TORQUE SOCKET 8mm

20mm PIN SPANNER

BEARING PULLER

4. DRYER SHUT DOWN PROCEDURE

Before performing any maintenance or service operations on this product, ensure the product

is isolated from the compressed air supply and fully depressurised. Also ensure the product is

switched off and/or isolated from the mains power.

PROCEDURES

• Closetheinletandoutletvalves.

The dryer might still be pressurised! In order to depressurise the dryer; ensure the dryer is isolated from the

compressed air source:

o Cycle the dryer twice to ensure the dryer exhausts and is completely depressurised.

o When fully depressurised the ‘clicking’ of the exhaust valves will be heard but no air

exhausted.

• Whenthedryerisfullydepressurised,isolatefromthepowersupply.

Page 8

5. SERVICE ‘A’ INSTRUCTIONS

REPLACING DESICCANT CARTRIDGES NDL-060 to NDL-120

(Every 12,000 hrs or 24 months)

Please refer to figure 1

1. Ensure the dryer is shutdown and

fully depressurised before attempting any

maintenance work. (See page 7)

2. Remove the 4x M5 screws as shown to

remove the dryer top cover.

3. Remove the 8x M12 cap head screws and

8x washers to remove the top manifold from

the dryer column.

4. Discard the gasket seal.

5. Lift the wire handle and remove the

cartridge from the dryer column.

(See figure 2).

6. Check and clean the top manifold and dryer

column as required, paying particular attention

to the gasket sealing faces.

7. Remove the new cartridges and gasket

seal from the service kit provided.

8. Insert 2x new desiccant cartridges and

press them down until they stop and the

cartridge is below the top surface of the dryer

column.

9. Insert the new gasket seal placing it into the

gasket groove in the top manifold ensuring it

is fully retained.

10. Ensure both handles are folded flat.

11. Replace the top manifold and secure with

the 8x M12 cap head screws tightening to a

torque setting of 80Nm.

NOTE: Refer to the page 20 and follow the

correct tightening sequence.

12. The seal between the dryer column and

top manifold should be checked for leaks prior

to fitting the top cover and operating the dryer

13. Replace the dryer top cover and secure

with the 4x M5 screws. These screws should

be hand tightened only or tightened to a

torque setting of less than 1Nm.

If service A is complete reset the dryer, refer

to page 19.

Care must be taken when removing the

desiccant cartridges not to damage the top face

of the dryer column. This is a sealing face!

(Sealing face shown as the shaded area)

Figure 2.

Figure 1.

GASKET SEAL

TOP MANIFOLD

8x M12 CAP

HEAD SCREWS

TOP COVER

DESICCANT CARTRIDGES

4x M5 SCREWS

Page 9

5.1 SERVICE ‘A’ INSTRUCTIONS

REPLACING DESICCANT CARTRIDGES (NDL-130 ONLY)

(Every 12,000 hrs or 24 months)

Figure 3

Please refer to Service ‘A’ instructions on page

8 of this service guide.

NOTE: NDL-130 dryer has 2x cartridges per

side. (See Figure 3)

DRYER CARTRIDGE

(UPPER)

DRYER CARTRIDGE

(LOWER)

CARTRIDGE JOINING

RINGS

REPLACING DESICCANT CARTRIDGES

1. Lift handle and remove the upper cartridges

from the dryer and discard them.

NOTE: Ensure the upper cartridges have

disconnected from the cartridge joining rings

and the lower cartridges before attempting to lift

from the dryer.

2. Remove the lower cartridges from the dryer

and discard.

3. Identify upper and lower cartridges from the

service kit.

4. Insert joining ring into the head of the lower

cartridge.

5. Insert lower cartridges separatey into dryer.

6. Insert upper cartridges separately into dryer.

7. See page 8 for reassembling top manifold.

Page 10

6. SERVICE ‘B’ INSTRUCTIONS

REPLACING INLET CONTROL AND EXHAUST VALVES (NDL-060 TO NDL-90)

(Every 24,000 hrs or 4 Years)

Figure 1.

Figure 3.

2. Detach each of the solenoid

plugs from the solenoids by

removing the 4x plug screws and

releasing the plugs.

(See Figure 1)

SOLENOID

PLUG

PLUG

SCREW

3. Remove the solenoid coils

by unclipping and sliding the

coils from the valve stems.

(See Figure’s 2 & 3)

Figure 2.

RETAINING

CLIP

SOLENOIDS

COILS

VALVE

STEM

1. Ensure the dryer is shutdown

and fully depressurised before

attempting any maintenance work.

(See page 7)

Page 11

VALVE

DIAPHRAGM

EXHAUST

VALVE

M5 SOCKET

HEAD SCREWS

6. SERVICE ‘B’ INSTRUCTIONS

REPLACING INLET CONTROL AND EXHAUST VALVES (NDL-060 TO NDL-090)

(Every 24,000 hrs or 4 Years)

Figure 4.

4. Remove the 16x M5 socket head screws and the 16x spring washers and discard them. Remove and

discard the exhaust valve bodies from the bottom manifold. (See Figure 4)

5. Remove and discard the 4x diaphragms from the bottom manifold. (See Figure 4)

6. Replace the 4x diaphragms and 4x exhaust valves from the service kit and replace the 16x M5 socket head

screws and spring washers from the service kit and tighten to a torque setting of 6Nm. (See Figure 4)

NOTE: Refer to the page 20 and follow the correct tightening sequence.

7. Reattach the 4x solenoid coils and 4x solenoid plugs. (See Figure 1)

When service B is complete reset the dryer, refer to page 18.

BOTTOM

MANIFOLD

Page 12

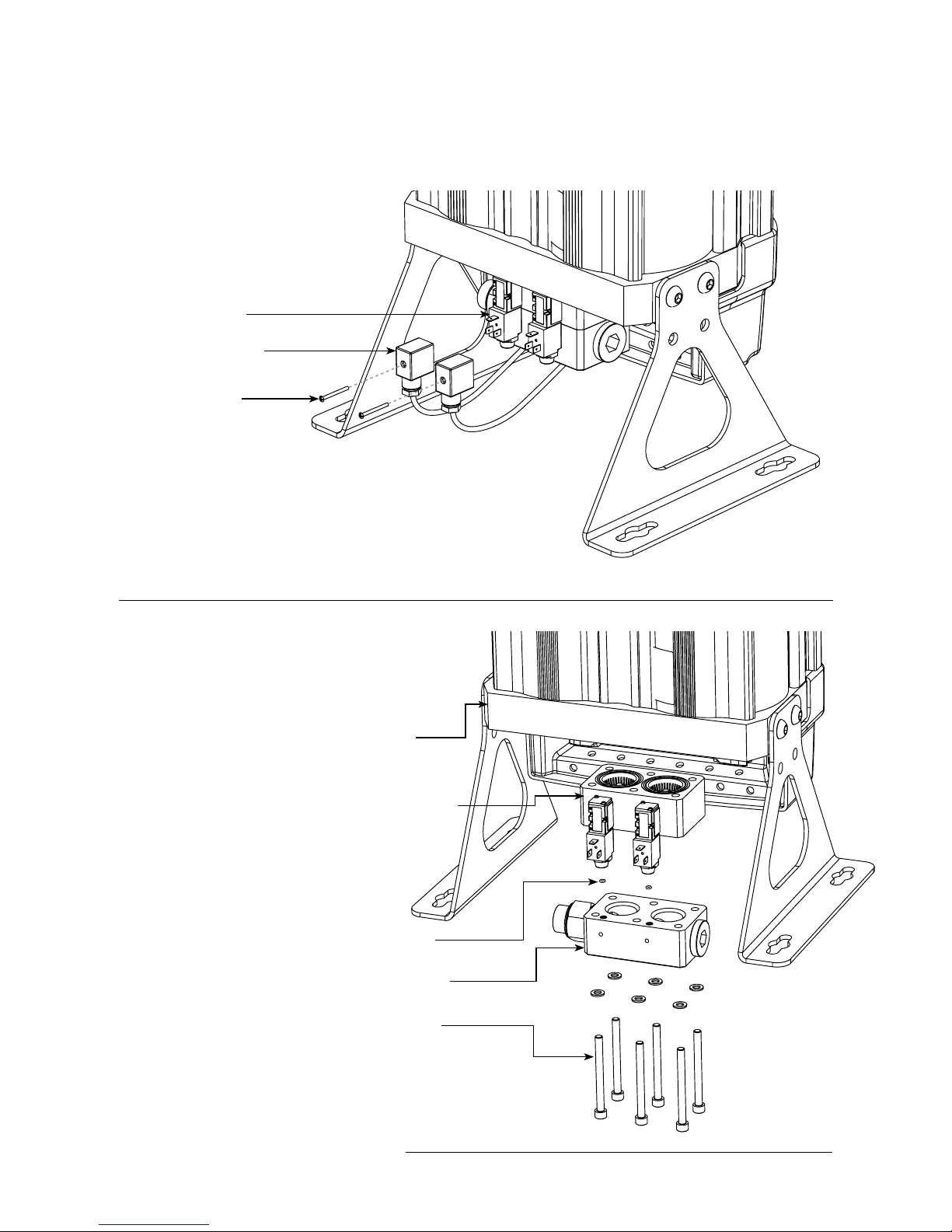

6.1 SERVICE ‘B’ INSTRUCTIONS

REPLACING INLET VALVES NDL-100 TO NDL-130 ONLY

(Every 24,000 hrs or 4 Years)

Figure 2.

VALVE BLOCK

3. Remove the 6x M8 socket

head cap screws and 6x washers

from the inlet block to release

both the valve block and inlet

block from the bottom manifold

and from each other.

(See Figure 2)

INLET BLOCK

1. Ensure the dryer is shut down

and fully depressurised before

attempting any maintenance

work. (See page 7)

Figure 1.

6x M8 HEAD

CAP SCREWS

2. Remove the screws and

release the solenoid plugs from

the inlet control valves.

(See Figure 1)

INLET CONTROL

VALVES

SOLENOID

PLUG

SCREW

BOTTOM

MANIFOLD

2x O RINGS

4. Remove and discard the 2x

O rings from the inlet block and

replace them from the service kit.

(See Figure 2)

Page 13

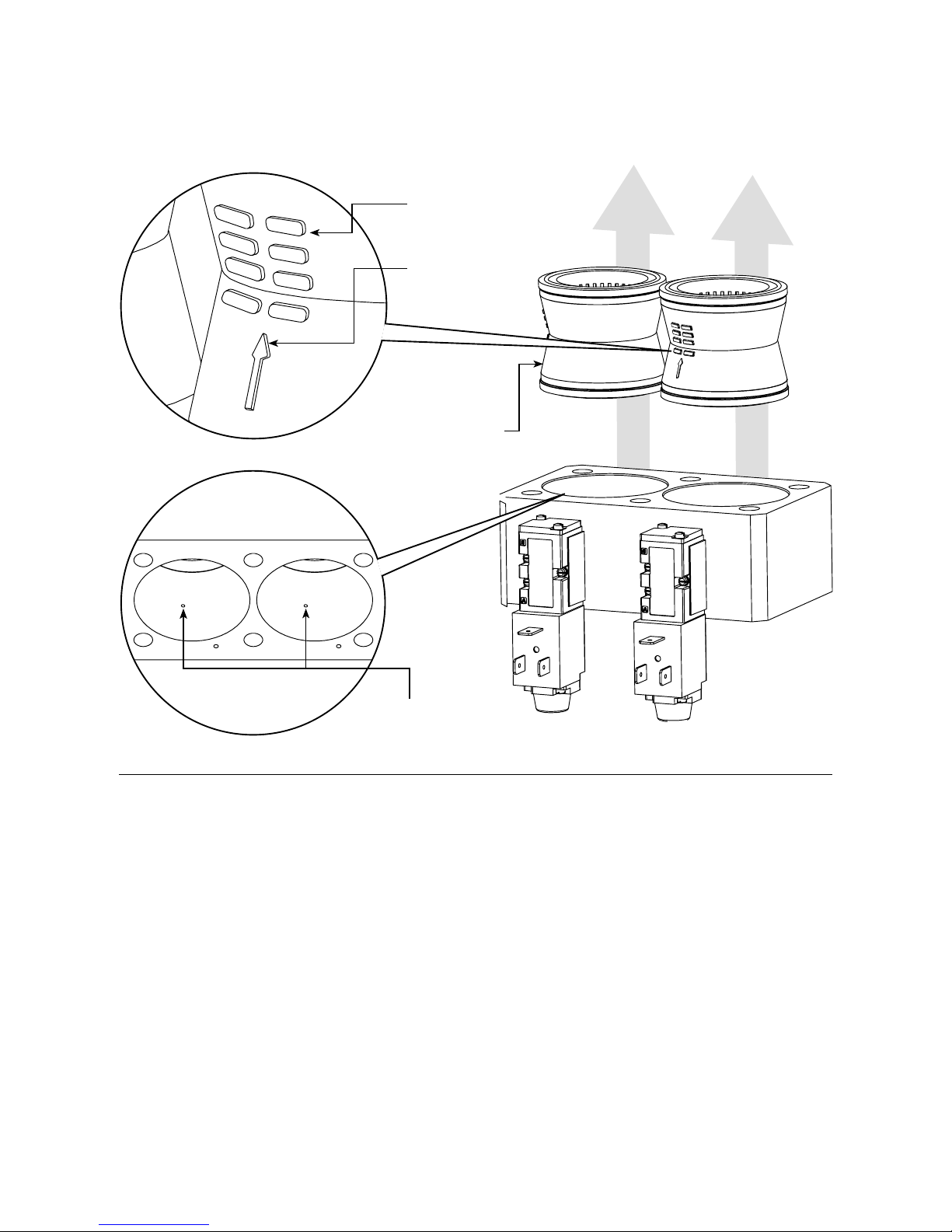

Figure 3.

INLET VALVES

FLOW DIRECTION

ARROW

7. Insert the new inlet valves into the valve block ensuring the flow direction arrow is pointing as shown and

the valve ridge details cover the spill port. (See Figures 4 & 5)

Figure 4.

5. Remove the inlet valves from the valve block by pushing them out. (See Figure 3).

6. Discard the old inlet valves.

Figure 5.

SPILL PORT

VALVE RIDGE

DETAILS

8. Replace the 6x M8 socket head cap screws and 6x washers and tighten at a torque setting of 20Nm.

(See Figure 2)

6.1 SERVICE ‘B’ INSTRUCTIONS

REPLACING INLET VALVES NDL-100 TO NDL-130 ONLY

(Every 24,000 hrs or 4 Years)

NOTE: The spill ports are

1.5mmØ holes within the

valve block.

9. Reattach the solenoid plugs and the screw to complete the assembly. (See Figure 1)

When service A is complete reset the dryer, refer to page 18.

Page 14

6.2 SERVICE ‘B’ INSTRUCTIONS

REPLACING INLET CONTROL AND EXHAUST VALVES (NDL-100 TO NDL-130)

(Every 24,000 hrs or 4 Years)

Figure 1.

VALVE

GASKET

INLET

CONTROL

VALVE

SCREWS

1. Remove the 6x fixing screws and 6x washers to release the inlet control valves from the valve block.

(See Figure 1)

2. Discard the valve gaskets and inlet control valves and replace from the service pack.

3. Replace the 6x fixing screws and 6x washers.

4. Replace the solenoid plug and screw (See Figure 1 on page 12)

When service B is complete reset the dryer, refer to page 18.

Page 15

(Every 24,000 hrs or 4 Years)

6.2 SERVICE ‘B’ INSTRUCTIONS

REPLACING INLET CONTROL AND EXHAUST VALVES (NDL-100 TO NDL-130)

Figure 1.

O RING

SILENCER BOX

VALVE DIAPHRAGM

EXHAUST VALVE

Figure 2.

SILENCER

FIXING

NUT

M5 SOCKET HEAD

SCREWS

1. Ensure the dryer is shutdown

and fully depressurised before

attempting any maintenance work.

(See page 7)

2. Unscrew the silencer fixing nut

using a 20mm pin spanner and

remove the O ring to release the

silencer box from the assembly.

(See Figure 1)

3. Remove the 8x M5 socket head

screws and the 8x spring washers

and remove the exhaust valve

bodies and diaphragms from the

inlet (bottom) manifold.

(See Figure 2)

4. Replace the 2x diaphragms and

2x exhaust valves from the service

kit.

5.Replace the 8x M5 socket head

screws and spring washers and

tighten at a torque setting of 6Nm.

Reattach the 2x solenoid valves

and 2x plugs. (See Figure 2)

NOTE: Refer to the page 20

and follow the correct tightening

sequence.

Page 16

8x M12 CAP

HEAD SCREWS

TOP

MANIFOLD

(Every 24,000 hrs or 4 Years)

6.3 SERVICE ‘B’ INSTRUCTIONS

REPLACING OUTLET VALVES (NDL-060 TO NDL-130)

Please refer to figure 1

1. Ensure the dryer is shutdown and fully depressurised before attempting any maintenance work.

(See page 7)

2. Remove the 4x M5 screws to remove the dryer top cover.

3. Remove the 8x M12 cap head screws and 8x washers to remove the top manifold from the dryer column.

4. Using a pair of circlip pliers, remove each circlip.

5. Remove the valve seat using a pair of bearing pullers and then remove the valve.

6. Remove the DU bush and replace it from the service kit.

7. Replace the valve and valve seat from the service guide and re-insert the circlip.

8. Place the manifold back on top of the dryer column and insert the 8x M12 cap head screws and 8x washers

and tighten at a torque setting of 80Nm.

NOTE: Refer to the page 20 and follow the correct tightening sequence.

9. Replace the top cover and insert the 4x M5 screws to secure it in place.

CIRCLIP

VALVE SEAT

VALVE

DU BUSH

FITTING

Figure 1.

Page 17

M4

SCREWS

7. SERVICE ‘C’ INSTRUCTIONS

ES MODELS ONLY

(Every 6,000 hrs or 12 months)

Figure 1.

Figure 3.

Figure 4.

2. Remove the 4x M5 screws to remove

the top cover. (See Figure 1)

4. Remove the screw from the sensor

plug and detach it from the dew point

sensor assembly. (See Figure 3 & 4)

SENSOR

PLUG

SCREW

SENSOR

PLUG

CONTROLLER

CHASSIS PLATE

1. Ensure the dryer is shutdown and

fully depressurised before attempting any

maintenance work. (See page 7)

Figure 2.

3. Release the catches located at the top

and bottom of the shroud to open it.

(See Figure’s 1 & 2)

Page 18

Figure 6.

Figure 7.

6. Unscrew the dew point sensor from the sensor block and

replace with the new or re-calibrated sensor. (See Figure 7)

7. SERVICE ‘C’ INSTRUCTIONS

ES MODELS ONLY

(Every 6,000 hrs or 12 months)

7. Reattach the new or re-calibrated dew point sensor and sensor

block assembly to the controller chassis plate using the 2x fixing

screws.

8. Replace the sensor plug and screw to complete the sensor

assembly. (See Figure 3 & 4)

9. Close the shroud and ensure the latches are in position.

10. Replace the top cover and insert the 4x M5 screws. These

screws should be hand tightened only. (See Figure 1)

DEW POINT SENSOR

SENSOR BLOCK

Figure 5.

5. Remove the 2x fixing screws from the controller chassis plate

and release the dew point sensor assembly. (See Figure 5 & 6)

When service C is complete reset the dryer, refer to page 19.

Page 19

8. RESETTING THE DRYER CONTROLLER

Figure 1.

CONTROLLER

RESET AREA

1. Ensure the dryer is on and running, see dryer start up procedure on

page 18.

2. Place a magnet over the controller reset area shown in Figure 1 for

8-10 seconds until the dryer re-sets. (See Figure 1)

3. Once re-set the hours run counter will show ‘00000’.

NOTE: Magnet not included in the service kit.

Page 20

9. MANIFOLD TIGHTENING SEQUENCES

1

2

3

4

5

6 7

8

1

2

3

4

5

6 7

8

Top manifold

Bottom manifold

FOR MODELS NDL-060 TO NDL-130

Page 21

10. DRYER START-UP PROCEDURE

Do not allow the dryer to flow air unless powered up, switched on and cycling. Resulting effect

could be cartridge contamination; requiring replacement cartridges.

•Connecttomainspower

•Connectallpipework.

- Ensure the inlet operating pressure parameters are between 4-16 barg.

- Ensure the inlet air temperature is between 1.5°C-50°C.

•Opentheinletandoutletvalves.

•Turnonelectricalpowertothedryer.

•Thedryerwilldisplayitsstatusandcommencenormaloperation.Whenthedryerispoweredupthedisplay

will show “initialising dryer” for approximately 20 seconds, ensuring the dryer is in equilibrium state before

commencing operation.

Page 22

11. OTHER DRYER CHECKS & NON-SERVICEABLE

ITEMS

DAILY CHECKS

Visual and functional check of the dryer should be carried out daily:

• Check the dryer for any external damage.

Assess and eliminate any defects found.

• If the red service light appears, the dryer must be serviced.

Contact the service department and request a dryer service kit.

• Remove any loose dust or dirt from the dryer; clean all surfaces that appear to have attracted unwanted

contaminants.

• Check the dewpoint sensor display (where applicable). If the dew point is not achieved the dewpoint

reading on the display will alternate with “dewpoint alarm” every 5 seconds. The no-volt alarm will also

activate.

Contact the service department and request a product service.

MAINTENANCE GUIDELINES

• Maintenance operations only to be conducted when the system has been shut down and fully

depressurised.

• All connections must be undone with care, paying particular attention to the areas that become

pressurised.

• Do not modify or adjust the control settings.

• Only certified n-psl approved replacement parts to be used.

• Always check all connections for leakage and secure seating.

• Ensure all loose parts are removed or secured to the dryer before operation.

Page 23

13. TROUBLESHOOTING

1. Insufficient inlet pressure

2. Electrical Fault

3. Moist or contaminated desiccant

4. Too high air consumption

5. Excessive inlet air temperature

6. Insufficient purge air

7. Exhaust silencer blocked

1. Inlet pressure min 4 barg. If not adjust inlet pressure

settings.

2. Ensure the power is on and the dryer front panel is

illuminated; check the dryer is cycling correctly.

3. Eliminate the cause of contamination. Replace cartridges

– do not re-use.

4. Ensure the performance of the dryer matches the required

system air consumption.

5. Check against technical specification.

6. Purge incorrectly adjusted. Consult service personnel to

adjust settings (Factory pre-set).

7. Consult service personnel.

Poor dew point

performance

Problem CausedProblem Solution

8. Controller not functioning correctly

9. Controller not illuminated

10. Insufficient inlet pressure

11. Failure to de-pressurise when

cycling

12. Outlet flow stops

8. Ensure the controller is powered; check the on screen

column status to ensure it is powering the solenoid valves

during normal cyclic operation.

9. Check power to unit & fuse: T2A 250V (located at Fig 8.A).

10. Inlet pressure = min 4 barg. If not adjust inlet pressure

settings.

11. Solenoid valve not functioning correctly; if there is power

to the coil, replace valve. A correctly working valve outputs an

audible click when it energises.

12. Check inlet air supply.

Failure of dryer to

cycle

13. Failure to initialise dryer

14. Erratic air flow from exhaust

13. Switch off and restart dryer. Ensure dryer is pressurised

before powering dryer to allow dryer to initialise before

commencing operation.

14. Faulty or damaged valve; service required.

Constant

depressurisation

REFERENCE TO KNOWN ISSUE

Opening the inlet valve too quickly

Valve should be opened slowly allowing the pressure to build up gradually.

Inlet/outlet head pipe

Diameter too small.

Pipe work unsupported.

Inlet pipe work from low point in system, allowing bulk water to collect and enter the dryer.

Electrical controller

Incorrect fuse fitted or fuse blown. Check the plug and fuse located on top of the controller back plate inside

the dryer front cover.

Additional Items

Use of non-authorised components.

Untrained / unauthorised maintenance / installation personnel used.

Increase in air consumption without relation to the flow capacity of the dryer.

Purging the dryer with cleaning agents that could damage the components or the desiccant.

Covers removed or loose during operation.

Failure to carry out a service when indicated by the dryer.

Do not allow the dryer to flow air unless powered up, switched on and cycling. Resulting effect could be

cartridge contamination; requiring replacement cartridges.

Page 24

14. SERVICE RECORD & NOTES

The following table allows the customer to document the service history of the product and

to make notes related to each service.

DRYER SERVICE RECORD

PRODUCT CODE:

............................................................

PRODUCT SERIAL NO.

..........................................................................

SERVICE TYPE

A / B / C

DATE

SERVICED BY

(PRINT/SIGN)

NOTES

Page 25

NOTES:

.................................................................................................

.................................................................................................

.................................................................................................

.................................................................................................

.................................................................................................

.................................................................................................

.................................................................................................

.................................................................................................

.................................................................................................

.................................................................................................

.................................................................................................

.................................................................................................

.................................................................................................

.................................................................................................

.................................................................................................

.................................................................................................

Page 26

11330 Vanstory Blvd

Huntersville, NC 28078

Telephone: (704) 897-2182

Internet: www.n-psi.com

E-mail: support@n-psi.com

Loading...

Loading...