Page 1

1

Notice de conduite

Instruction manual

Manuale d'istruzione

Betriebsanleitung

Instructieboek

Manuale de instrucciones

Instruksjonbok

Käyttöohje

P/N 970 312 491

Page 2

2

CONTENTS

1. SAFETY INFORMATION

2. GENERAL INFORMATION

3. ENGINE IDENTIFICATION

• Identification of main components

4. PREPARATION PRIOR TO RUNNING

5. ENGINE OPERATIONS

• Switching on

• Switching off

• Running in / Servicing under guarantee

• List of guarantee check operations

6. MAINTENANCE

• Draining engine oil

• Replacing oil filter

• Fuel filter replacement

• Nozzle holder replacement

• Flushing cooling system

• Replacing water pump

• Electrical/battery equipment

• Adjusting valve clearance

• Reverse reduction gear

• Recommendations

• Periodic Maintenance schedule

• Technical features

• Recommended onboard equipment

*All information and specifications contained in this

manual are based on the technical data in use at the

time of publication.

1 – SAFETY INFORMATION

This operating manual was compiled to help you get

the most out of your engine and its ancillary equipment. It contains important instructions which should

be observed when the engine is running.

It is extremely important that it is read by the

user. It should be always kept in the same location as the engine.

SAFETY SYMBOLS

These symbols are used to indicate that a danger

exists. They are aimed at drawing your attention to

components or operations that could be dangerous

for yourself or other persons using the engine.

Please read the recommendations they contain carefully. It is highly important that you read the safety

instructions and rules before running engine.

I DANGER

Means that an extremely serious danger which could

result in death or major disability if the appropriate

specific measures are not taken.

I WARNING

Means that a danger exists which could cause injury

or death if the appropriate specific measures are not

taken

I CAUTION

Acts as a reminder that safety measures need to be

observed, or draws attention to dangerous actions

which could cause personal injury or damage to the

vessel or its components.

The user should take all necessary precautions in

terms of handling and protection and should seek

advice from a sector professional.

Non-respect of the safety instructions could lead to:

Bodily danger, a danger of environmental pollution

(dangerous substance leaks), danger to equipment

that could cause essential engine operation malfunctions.

• FOLLOW ALL SAFETY RECOMMENDATIONS

- Comply with the engine's warning and caution stickers

- Remove the ignition key and close the battery cut-out

before working on the engine or its ancillary equipment

- Close the engine casing and replace all protective

parts before starting the engine

- Always kept the working area around the engine clean

and uncluttered

- Keep all inflammable liquids outside the engine compartment

- Never run the engine when under the influence of alcohol or medicines

• WEAR PROTECTIVE CLOTHING

- To avoid bodily injury, keep clear of rotating parts and

do not wear loose clothing near the engine when it is

running.

- Use safety clothing and equipment, protective goggles,

gloves, etc. in accordance with circumstances and

when they are required.

• FUELS AND LUBRICANTS

- Switch off the engine before re-fuelling or adding lubrication products

- Do not smoke or use naked flame during re-fuelling

- Wear gloves when looking for a possible leak

- Hot oil can cause burns – let the engine cool before

checking the oil level, or changing the oil or oil filter cartridge

- Always use NANNI DIESEL recommended fuels and

lubricants

ENGLISH

Operating and maintenance manual

Page 3

3

EXHAUST FUME PRECAUTIONS

- Only run the engine away from people and animals

in a well ventilated area–a build-up of exhaust fumes

can be noxious

PRESSURE

- Never open the cooling system cap or oil filler cap

when the engine is running or while it is still hot. Release all pressure in the systems before removing the

caps

- Never check for possible pressure leaks with your

bare hands – wear gloves – leaks of liquids under

pressure can cause serious injuries – in the event of

injury due a liquid leak, see a doctor immediately

BATTERY

- An extremely explosive and volatile oxyhydrogen

gas mixture is created when the battery is being recharged. Never smoke, take a naked flame or cause

a spark near to the battery

- Never short circuit the battery terminals

- The electrolyte in the battery is highly corrosive –

wear gloves and safety goggles.

ELECTRICAL WIRING

- Disconnect the engine ignition and the battery cutout before working on the electrical equipment

- Check the condition of the electrical cables and wiring – short circuits can create a fire hazard

DISPOSAL OF WASTE FLUIDS

- The various fluids used to operate the engine create

a health hazard. Make sure you read the instructions

shown on each product's packaging.

- Comply with the environmental regulations relating

to the disposal of old oil, fuel, cooling liquid, filters

and batteries.

2 –GENERAL INFORMATION

Your NANNI DIESEL engine has been carefully researched and manufactured to the highest quality by

NANNI INDUSTRIES. It is built in accordance with

very precise specifications out of the very finest materials and following strict production procedures.

Your NANNI DIESEL en gi ne i s a reliable and long

term power unit for your vessel.

The installation of your engine in your vessel is highly

important in terms of correct power boating and environmental protection.

NANNI INDUSTRY engineers are among the most

skilful in the sector. Their experience, knowledge

of the sea and mastery of techniques in association with that of engineers from MAN, KUBOTA

and TOYOTA guarantees you the best there is in

terms of performance/reliability economy.

WARNING: It is imperative that you engine is in-

stalled in a Shipyard or by a representative of

NANNI INDUSTRIES, and in compliance with the

installation instructions.

This operating manual contains all the information

required for your engine to operate correctly.

Represented in more than 50 countries via its network of agents and retailers, NANNI INDUSTRIES

guarantees your plain sailing World-wide. Parts, labour or just advice, everything has been thought out

to serve you.

Do not hesitate to contact your nearest NANNI DIESEL approved retailer .

We wish you calm seas and fair weather.

Please read this manual carefully before using your

engine.

Follow all safety recommendations.

I WARNING: Correct operation of your marine en-

gine is dependent on a usage that conforms to the

engine's definition and its transmission (type of vessel, speeds and operating conditions.)

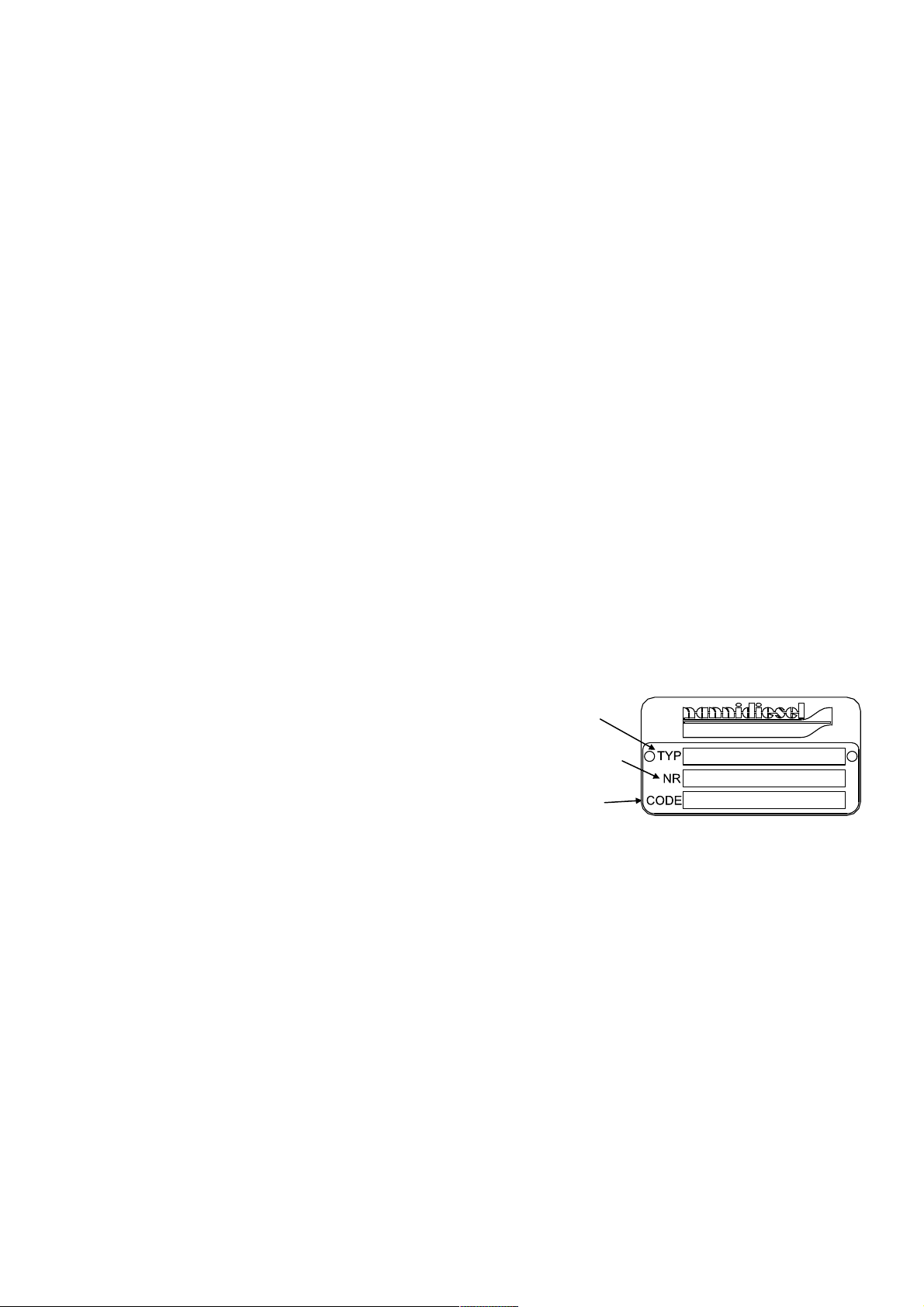

3 – ENGINE IDENTIFICATION

It is imperative that the references shown on the

plates attached to the engine and reversing gear are

quoted in all correspondence, information requests

and orders for spare parts.

IMPORTANT: Make a note of the engine and trans-

mission serial numbers, and the model type, and

keep in a safe place

ENGINE TYPE

SERIAL NUMBER

SPECIFICATION

Page 4

4

IDENTIFICATION DES PRINCIPAUX ORGANES

1. Heat exchanger

2. Cooling liquid filler hole

3. Block drain plug

4. Clear water pump

5. Sea water pump

6. Alternator

7. Flexible fastening

8. Electrical connector

9. Starter

10. Oil gauge

11. Oil filler hole

12. Air filter

13. Water injector exhaust elbow

14. Anode

15. Oil filter

16. Oil pressure transmitter

17. Reversing gearbox reduction gear

18. Injector pump

19. Electrical cut-out

20. Accelerator

21. Air cooler

22. Turbo

23. Exchanger drain

24. Thermostat

25. Turbo drain tap

26. Condensation drain hole

27. Battery minus (-) cable connector

28. Air re-heater relay

29. Diesel filter and water contamination detector air

30. Starter relay

31. Hydraulic oil tank (Stern drive version)

32. Power steering oil coolant (Stern drive version)

33. Neutral safety contact

34. Oil drain port

4 - PREPARATION PRIOR TO RUNNING

When the engine has been installed on board the

vessel and prior to removing the protective covers

over the various openings, clean the engine's surfaces. These operations should be carried out by a

Shipyard or an approved workshop.

GENERAL CHECKS.

See SILVERWAKE® guarantee conditions

- Fill engine and reversing gear with oil

- Fill the exchanger with coolant, degas the turbo volute casing at the highest point

- Check belt tensions

- Check that the various connectors and plugs are

tight (water and oil)

- Check electrical spade connectors, battery terminals, cut-out and extension connectors are tight, plus

the battery electrolyte levels

- Accelerator control.

- Check that the “accelerator and reversing gear”

lever is correctly synchronised (imperative in the case

of a single cable level control.) You should have finished de-clutching we you start to accelerate. In the

event of electrical controls, refer to the specific controls manual provided.

- Carry out a final check on fixing and a visual check

of the marine unit. If necessary, retouch the paintwork on the unit and accessories.

I DANGER :

Never take a naked flame or cause a spark near to

the battery. An extremely explosive and volatile oxyhydrogen gas mixture is created when the battery is

being re-charged - Never cause a short circuit.

Battery electrolyte is highly corrosive: if this acid

come into contact with the skin, wash immediately in

soapy water – in the event that it splashes into the

eyes, rinse abundantly with water and contact a doctor immediately.

- When connecting the battery cable, start with the

positive terminal

- When disconnecting the battery cable, start with the

negative terminal

I WARNING:

Do not drop fuel or lubricants onto the engine

The fluids used to operate the engine create are a

health hazard.

Engine oil cold be harmful to the skin– wear gloves

NOTE: Modern diesel engines are high performance

units which require high quality fuels and lubricants.

ENGINE AND REVERSING GEARBOX LUBRICATION

Engine

Oil pump greasing system, release valve pressure

regulation

Disposable oil filter cartridge

Transmission

See separate specifications

Engine oil levels

Unscrew the oil filler hole cap located on the

rocker cover. Check the oil level using the dipstick. Never fill beyond the maxi level.

NOTE: Oil types and quantities are given in the technical feature table

FUEL SYSTEM

Composition

Disposable main filter cartridge

Injector pump

High pressure injector pipe

Injectors (inside the cylinder head)

ENGLISH

Page 5

5

Fuel system purge

- Check the fuel level in the tank.

- Open the fuel cock, unscrew the purge screw located on the upper part of the filter and pump the system using the incorporated pump. When no more air

bubbles appear, tighten the screw. In the event that

the injection system is not fully primed, carry out the

following procedure:

- Unscrew the No. 1 injector fuel pipe and turn the

engine on the starter until diesel fuel appears. Retighten the nut and follow out the same procedure for

the other injectors.

- Re-start the engine and check for leaks.

I DANGER : Do not smoke, approach with a naked

flame or cause a spark. Wipe up any spilt fuel.

COOLING SYSTEM

This is made up of two different systems: the sealed

cooling system and the sea water cooling system.

Sealed cooling system

This is made up of a pump driven by the crankshaft

via two V shaped belts, a water temperature heat

exchanger, an oil temperature heat exchanger integrated unto the engine block and a thermostat.

Seawater cooling system

This is made up of a pump, a clear - salt water heat

exchanger, supercharger air refrigerant, power steering oil refrigerant (version Stern drive), reversing gear

oil exchanger and an exhaust elbow.

Coolant

Recommendations for initial start up.

- Check that the drain plug located beneath the turbo,

open the breather plug on the top of the turbo liner.

- Create a diluted 50% antifreeze and 50% clear water antifreeze mixture. The quantity required is given

in the table of technical specifications.

- Pour the mixture into the filler hole, close the

breather plug on the top of the turbo liner when the

liquid can be seen and continue filling up to the maximum. Possible top-ups should be made when the

engine is cold and only with clear water. Re-start the

engine and top-up to correct level. Check for leaks.

- Every two years at the beginning of the season,

completely drain the cooling system, flush out using

clear water and re-fill in accordance with the instructions provided above,. (See SILVERWAKE guarantee

terms.)

I

DANGER : Always fill the cooling system when

the engine is off and cold – Do not smoke or approach with a naked flame.

- Keep away from revolving parts when the engine is

running

.

I CAUTION : Never use undiluted antifreeze. The

use of additives and other type of coolant can cause

insulating deposits to be formed, and engine overheating.

Hot water connection

You can install an onboard hot water system by connecting from the interior clear water system to the

engine (Ask your NANNIDIESEL agent).

I CAUTION: Before staring the engine, make sure

that the sea water inlet is open as it only needs the

pump to run dry for several seconds in order to cause

deterioration to the water pump rotor.

After cleaning the sea water filter, carefully close the

cover in order to avoid the water pump sucking in air.

ELECTRICAL EQUIPMENT

5. ENGINE OPERATION

RUNNING

I

DANGER : Make sure that the engine casing is

correctly closed and install all the protective

items before starting the engine.

- Check the fuel level

- Open the diesel supply tap

- Open the sea water inlet valve

- Check engine and transmission oil levels

- Check the coolant level

- Close the battery isolation switch

I CAUTION: Turning the key to the contact position

when starting-up commences the process of preheating inlet air to the engine which can continue

whilst running for approximately 6 minutes. Take

care not to let any part of the body come into contact

with the air pre-heating zone of the engine.

Inlet air pre-heating continues whilst the engine temperature is less than 40°C.

Wiring positions / Color / Function

1 Red (+)12 volt battery

2 Violet D+ Alternator D+ Terminal

3 Grey Oil pressure sensor

4 Yellow Heating unit

5 Pink/Black Oil pressure switch

6 Yellow/Green Water temperature switch

7 Brown Starter

8 Orange/Blue Water temperature sensor

9 Green Water temperature indicator probe

10 Red/Yellow Engine stop solenoid power supply

11 Dark blue (-) engine speed indicator sensor

12 Dark blue (+) engine speed indicator sensor

13 Light blue Water contaminated diesel indicator

14 unused

15 Black (-) 12 volt battery

16 unused

Page 6

6

- Check warning lights and other functions once the

engine has started.

- Stop the engine immediately if the alarm keeps ringing, if the temperature rises abnormally, or if several

warning lights stay lit

.

I CAUTION : Discover and solve the problem be-

fore starting the engine!

Check that the seawater is running through the exhaust correctly.

Let the engine idle for 2 to 3 minutes, then subject it

to a load straightaway.

If the engine does not start at the first attempt, try

again making sure to switch off between each attempt.

IMPORTANT:

In the event of several unsuccessful attempts at starting the engine, look for the reason.

Do not keep on trying as water could be sucked into

the engine through the exhaust system!

I WARNING: Never switch of the electrical system

using the battery cut-out whilst the engine is still running as this could cause damage to the alternator.

IMPORTANT: Do not let the engine idle unnecessarily without load.

STOPPING THE ENGINE

- Move the lever to the idle/neutral position

- Let the engine idle for few seconds so that the temperatures and turbo speed can stabilise.

- Never accelerate the engine before switching

off.

- Turn the key to the "O" position (vertical.)

- Switch of the battery isolation switch, close the sea

water inlet valve as well as the fuel supply.

IMPORTANT: In the event of the vessel being towed,

stop the engine and ensure that the seawater inlet

valve is close so that the engine does not accidentally

fill up with seawater.

TWIN ENGINE VESSELS:

In the event of running on only one engine, close the

sea water inlet of the stopped engine. Do not forget

to re-open it before re-starting the engine.

I CAUTION : Check the engine and the engine

compartment for possible leaks.

RUNNING IN

SERVICING UNDER GUARANTEE

Running in

We recommend that for the first 20 hours of running

you treat your engine gently and only run it at maximum speed for very short periods.

Never race the engine immediately after starting without having let it warm up first.

IMPORTANT : After running, the engine should not

be constantly run at its maximum speed but at 200

RPM below its maximum speed

.

Servicing under guarantee

All preventive maintenance operations as well as

their timescale are given in the: SILVERWAKE. ®

Guarantee Booklet

The guarantee is conditional on these servicing operations. They must be carried out by an approved

NANNI DIESEL representative

All new engines are guarantee against all component

defects in accordance with the terms laid down in the

SILVERWAKE. ® Guarantee Booklet which is given

to the purchaser when the engine is delivered.

6. MAINTENANCE

I DANGER: To avoid any bodily injury, let the en-

gine cool and close the battery isolation switch before

carrying out any work.

Observe safety and environmental protection recommendations

IMPORTANT : These recommendations are vital.

Compliance will lengthen your engines operational

life and ensure that the conditions necessary for

meeting the normal guarantee terms are fulfilled.

Do not make any unapproved modifications to the

engine.

Damage caused by the use of unlisted or non approved spare parts is not covered under the terms of

the guarantee.

All interventions and maintenance work should be

carried out by an approved NANNI DIESEL workshop

If the engine is used for a number of hours that is

less than the indicators provided, maintenance

should be carried out once a year.

In this case, we recommend that maintenance work is

carried out before laying up for the winter, the engine

will then be protected by new, clean lubrication oil.

This does not obviate the wintering operations laid

down in the SILVERWAKE guarantee.

Valve clearance adjustment

This work should be carried out by a specialist workshop (calibrated adjustment shims)

Timescale: in accordance with the maintenance table

(see values in the table of technical features)

ENGLISH

Page 7

7

Water pump rotor replacement

- Close the sea water inlet valve

- Remove the water pump cover

- Remove the worn rotor using adjustable pliers

- Clean remaining components.

- Install a new rotor

- Replace the water pump cover using a new seal.

- Open the sea water inlet valve

- Start the engine and check the system for leaks

Electrical equipment

Regularly check alternator belt tension. Tighten the

belt between the pulleys (190 Nm using the DENSO

checking instrument).

I DANGER : Stop the engine and turn of the battery

isolation switch before doing any work on the electrical system.

Battery

Battery components should be checked once per

season.

Electrolyte density should be between 1,270 and

1,285.

The electrolyte level should be regularly checked.

The level should be kept at 1cm above the plates.

Add distilled water only, if required.

I DANGER : Never approach with a naked flame, or

check the battery by creating a "spark across the terminals" because it gives off inflammable and explosive gases - battery electrolyte is also highly corrosive.

If this acid come into contact with the skin, wash immediately in soapy water. In the event that it

splashes into the eyes, rinse abundantly with water

and contact a doctor immediately. Do not create a

short circuit.

RECOMMENDATIONS

In order to ensure that the alternator an its incorporated regulator work perfectly, Never:

- Switch off the battery cut-out when the engine is

running (risk of damaging the regulator irrevocably).

- Reverse the battery terminals. The terminals are

marked + (positive) and – (negative) respectively;

the negative is the earth; the cable connectors and

the cables themselves should be attached correctly.

- Change the load on the circuit whilst the engine is

running.

To use several batteries, install a load proportioner.

(Ask a NANNIDIESEL representative).

In the event of starting using a back-up battery and

jump leads, carry out the following procedure:

Ignore the main battery circuit, link the backup battery

by connecting to + and - to -.

Once the engine is running, disconnect the jump

leads and do not switch off the main battery circuit.

You should disconnect the 2 battery cables when:

- you are using a battery charger

- before working on any electrical components

- before carrying out any welding on a steel hull

Flushing the cooling system

Clear water system

- Open the filler cap located on the exchanger

- Open the drain plug under the turbo liner

- Unscrew the cross headed screw connector located

on the exhaust manifold

- Remove the engine block drain plug located on the

thermostat mounting

- Drain the used liquid from the heat exchanger and

the engine block

- Fill the clear water system and run the engine for

several minutes

- Use the topping up/priming procedure described in

the Paragraph on: Sealed cooling system

- Drain the water and re-fill with an antifreeze/clear

water mixture

- Fill the cooling system in accordance with the

specifications

NOTE : In the event that the hot water system is connected to the engine, drain this completely also and,

when refilling take the amount of added mixture into

account. Make sure that all air in the system is com-

pletely removed when filling

.

I WARNING: The liquid is under pressure. Do not

open the cap when the engine is hot. Allow the engine to cool and open the cap carefully.

Sea water system

- Close the sea water inlet valve

- Drain all the sea water inlet piping, the filter, sea

water pump, piping, heat exchanger, by undoing their

jubilee clips

- Drain the exhaust system as a certain amount of

water will remain in the silencer "waterlock".

Cleaning the heat and air temperature

exchangers

- Check the exchanger wiring cores.

- Remove the covers.

- Remove the cores and clean them using water and

an commercially available none corrosive product.

Rinse well.

- Replace the O-rings and reinstall the sub assemblies.

I WARNING: Corrosive products are hazardous to

health. Read all instructions on the packaging carefully.

Page 8

8

Diesel fuel filter replacement

The diesel fuel filter is disposable, the fire retardant

envelope and the water contamination sensor should

be kept and replaces in their correct positions (the fire

retardant envelope should not be in contact with the

plastic purge screw.)

- Close the fuel cock

- Unscrew the cartridge from the filter head

- Coat the seal of the new cartridge with clean oil

- Screw the new cartridge onto the filter head and

hand tighten by ¾ of a turn (do not use a tool) replace

the sensor and the purge screw, check the seal

- Open the fuel cock

- Purge the system, check for leaks.

- Start the engine and check all is working correctly.

I CAUTION: - Clean away any spilt fuel.

Observe environmental protection recommendations

Replacing an injector

(Use of the workshop manual is indispensable)

Remove:

- The 6 pipe injection harness

- The distribution cover

- Diesel backflow harness

- The complete injector. The seating and seal (SST

tool)

- Disassemble the injector

- Replace the complete injector, the O ring and the

seating. Replace all diesel backflow harness seals.

Tighten the injector and piping to the recommended

torque.

- Run the engine and check for fuel leaks.

- Do not try to re-condition an injector, this operation

should be carried out by a specialist workshop.

I WARNING: Do not spray diesel onto your skin–

wear gloves

.

IMPORTANT: the re-conditioning of injectors should

be done by an approved NANNI DIESEL workshop.

The injectors should be checked every 400 hours or

every 2 years in accordance with the maintenance

table and the SILVERWAKE® manual.

Draining the engine sump oil

- The oil is extracted using a pump and preferably a

warm engine.

- Pump the oil through the oil dipstick tube until all the

oil has been extracted.

- Refill using new oil. (See characteristics in the

specifications table)

- Check oil level with the dipstick.

- Never exceed the maximum level.

I WARNING: Hot oil can cause burns – Avoid all

skin contact.

Comply with the environmental protection regulations

Oil filter replacement

The cartridge is disposable.

- Unscrew the cartridge from the filter head

- Coat the seal of the new cartridge with clean oil

- Screw the new cartridge onto the filter head and

hand tighten by ¾ of a turn (do not use a tool)

- Start the engine and check for leaks engine.

- Stop the engine, check the oil level and add oil if

required.

I WARNING : Hot oil can cause burns – Avoid all

skin contact.

Comply with the environmental protection regulations.

Reversing gear

Refer to the detailed instructions in the reversing gear

manual enclosed with the operating manual.

Reversing gear mechanical control system

Regularly check the remote controls. The cable

travel should be 35mm from one side to the other of

neutral (O - A = O - B. The lever should be able to

freely travel to its full extent.

Electric control system

Check the connections on the solenoid valves, and

the connections on the control units.

Take note of the position of the levers

I DANGER : To avoid bodily injury, to not run the

engine without an air filter.

ENGLISH

Page 9

9

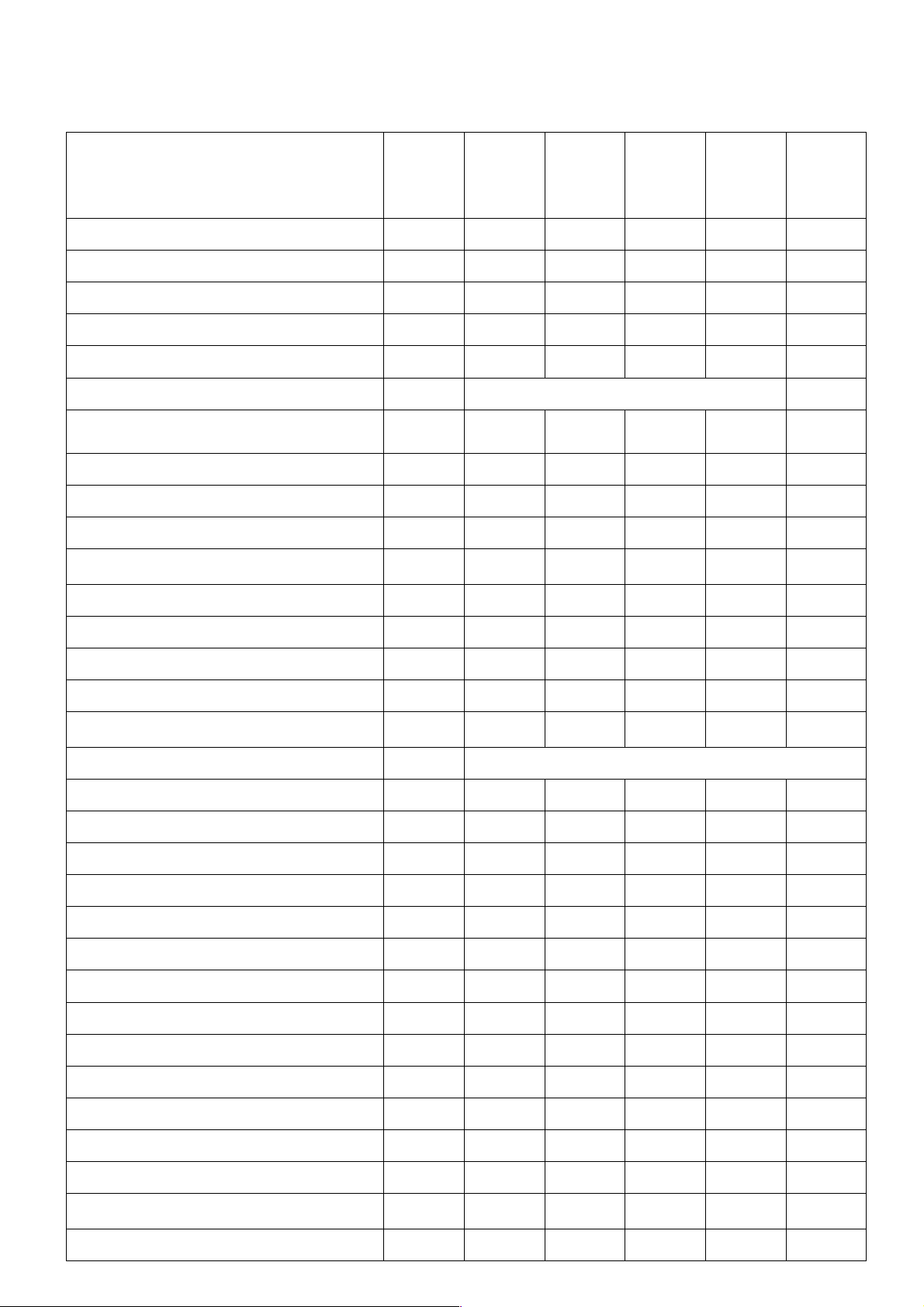

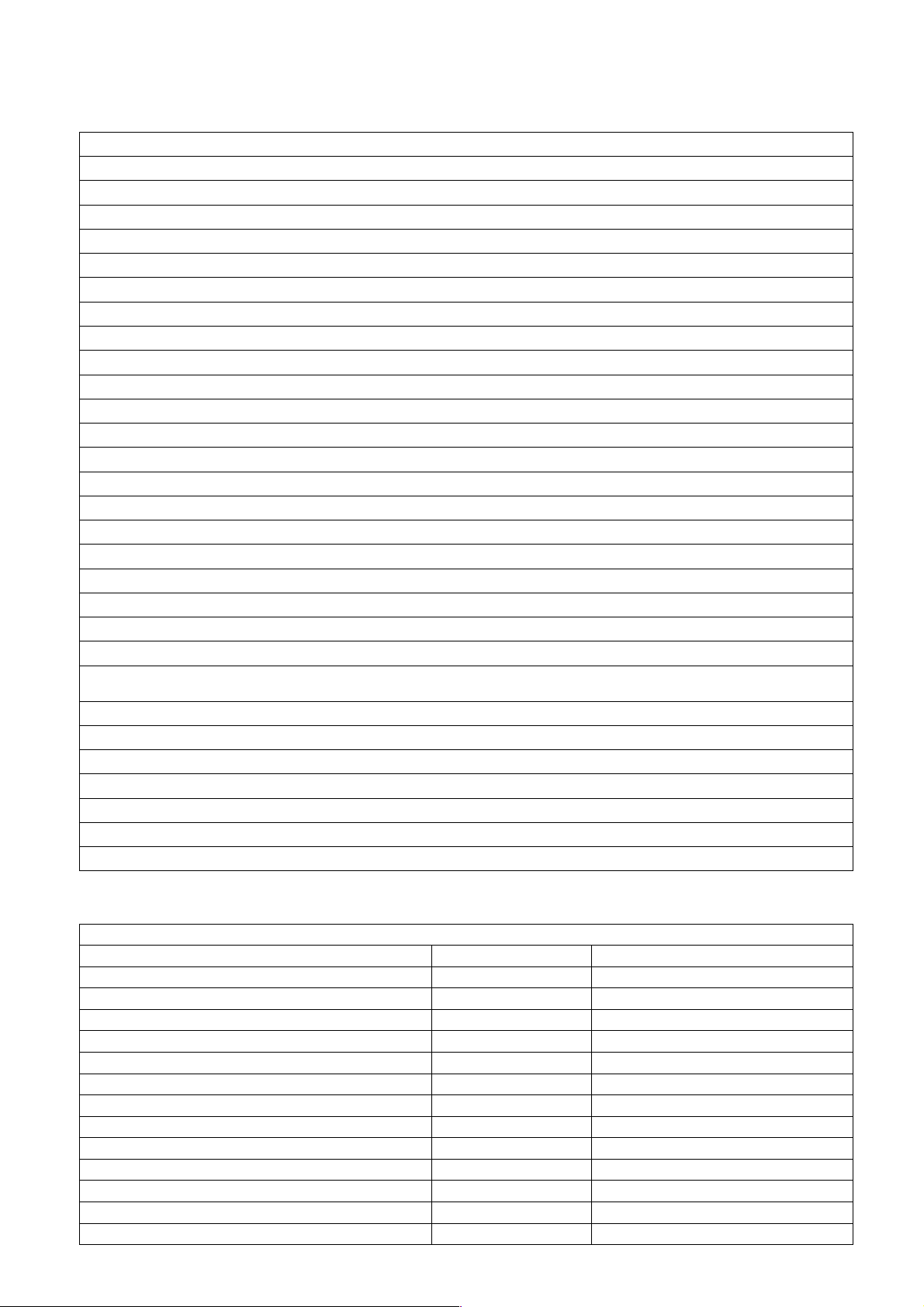

TYPE OF OPERATION

C/R/A

Check

Replace

Adjust

Every day

At

20h

Every

100 h

Every

200h

or every

year

Every

400 h

or every

2 years

Coolant level C/A X X X

Reversing gear oil level C X X X

Motor oil level C X X X

Control panel: indicators and alarms C X X X

Fan belt tension C/A/R X X X

Battery electrolyte level C/A

Control box: inspection of acc./inv. and trolling

cables: General lubrication

C/A X X

Tighten bolts and jubilee clips C/A X X

General sealing C/A X X

Engine alignment suspended fixings. C/A X X

Heat exchanger adjusted cap R X

Coolant R X

Thermostat R X

Heat exchanger wiring loom: cleaning

C X

Air heater: cleaning C X

Air cooling wiring loom: cleaning C X

Sea water filter: cleaning C DEPENDING ON CLEANLINESS

Fuel pre-filter: water purge C/A X X X X X

Fuel filter R X X X

Engine oil filter R X X X

Fuel pre-filter (cartridge) R X X X

Engine oil R X X

Reversing gear oil R X X

Water pump rotor R X

Injector adjustment C/A/R X

Valve clearance A

500 H

Cable gland (if braids are present) C X X X

Air filter, cleaning C X

Turbo: Inspection/Cleaning

C X

Exhaust elbow anode C/R X X X

Air coolant: condensation outlet freeing X

Notched timing belt R X

EVERY 15 DAYS

MAINTENANCE

Periodical Maintenance Table

Page 10

10

Technic al Spe cifica tions

NANNI DIESEL ENGINE Z6.300 T6.300 6.420 TDI

Number of cylinders 6 in line

Max. power* 202.4 kW (275 hp) 224.4 kW (305 hp) 235,6 kW (320 hp)

Nominal operating conditions* 3600 rpm

Idling operating conditions 700 + - 25 rpm

Max. unloaded operating conditions 4200 rpm (+ - 50)

Cycle 4

Bore & stroke 94 x 100

Cylinder size 4.163 cm3

Distribution AC at head 24 belt valves

Compression ratio 15,7

Rotation direction Anti-clockwise (engine wheel view)

Injection order 1-4-2-6-3-5

Injection pump DENSO VE

Injection pressure 01 and 02 17.7 to 18.6 MPa and 34 to 35 MPa

Fuel consumption 216 g/kWh @ 3600 rpm

Injection feed (before TDC) 1.18 à 1.24 mm (comparator lift)

Dry weight 478 kg

Alternator 12 V - 80A

Battery capacity (min.) 100/110 A/h

Cooling circuit By clear water / sea water heat exchange

Sea water pump Neoprene rotor type

Coolant:

50% water + 50 % anti-freeze

27 Litres

Valve clearance (cold) In.0.20 (+ - 0.3) Out.0.50 (+ - 0.3)

Engine oil API CG 4 / SG – SAE 15 W 40

Engine oil capacity, depending on tilt 11,4 litres

Reversing gear ZF 63A oil capacity 3,5 L

Reversing gear ZF 80A oil capacity 5 L

Reversing gear ZF 80 IV oil capacity 7,5 L

Oil characteristics ATF DEXRON II, III

Recommended on-board equipment for engine type 6.420TDI T6 300 Z6 300

DESCRIPTION Quantity Reference

V-belt Set of 2 970 312 725

Engine oil filter

1 970 312 207

Fuel filter

1 970 311 185

Seawater pump rotor kit 1 970 312 432

Diesel return seals

1 970 312 701

Injector seat

1 970 312 695

Thermostat

1 970 311 046

Thermostat seal

1 970 312 796

Air inlet sleeve seal (‘O-ring’)

2 970 312 784

Air exchanger seal

4 970 312 781

Complete injector holder

1 970 312 692

Injector seal

1 970 312 694

Water / water exchanger seal

4 970 312 801

CAUTION: These specifications are designated for pleasure use only.

Recommended cruising speed: 200 rpm below maximum authorised speed.

Page 11

11

2

4

5

1

23

6

7

7

8

9

10

13

15

16

17

18

28

34

21

24

27

29

3

30

33

Page 12

12

10

11

13

2

22

12

31

32

29

14

25

15

20

Page 13

13

ENGINE CONTROL PANEL : SIZE AND CUT OFF FIGURE

Page 14

14

ELECTRICAL SYSTEMS WIRING DIAGRAMS 6.420 TDI, T6 300, Z6 300

Page 15

15 16

Page 16

Nanni Industries S.A.S. 11, Avenue Mariotte - Zone Industrielle BP 107-

33260 La Teste France - Tel : + 33 (0)5 56 22 30 60 - Fax : +33 (0)5 56 22 30 79

E-mail : contact@nannidiesel.com

Certifié ISO

9001 : 2000

Page 17

1

Notice de conduite

Instruction manual

Manuale d'istruzione

Betriebsanleitung

Instructieboek

Manuale de instrucciones

Instruksjonbok

Käyttöohje

P/N 970 312 491

Page 18

2

ÍNDICE GENERAL

1. INFORMACIONES EN MATERIA DE

SEGURIDAD

2. INFORMACIONES GENERALES

3. IDENTIFICACIÓN DEL MOTOR

• Identificación de los principales órganos

4. PREPARACIÓN ANTES DE LA PUESTA EN

SERIVICIO

5. FUNCIONAMIENTO DEL MOTOR

• Puesta en funcionamiento

• Parada del motor

• Rodaje / Inspecciones de garantía

• Lista de las operaciones de verificación de garantía

6. MANTENIMIENTO

• Cambio de aceite del motor

• Reemplazo del filtro de aceite

• Reemplazo del filtro de carburante

• Reemplazo del portainyector

• Enjuague del circuito de refrigeración

• Reemplazo del rotor de la bomba de agua

• Equipo eléctrico / batería

• Ajuste del juego de válvulas

• Inversor reductor

• Recomendaciones

• Cuadro de mantenimiento periódico

• Características técnicas

• Necesario a bordo recomendado

*Todas las informaciones y especificaciones conteni-

das en este manual están basadas en los datos

técnicos aplicados en el momento de la publicación

.

1 – INFORMACIONES EN MATERIA

DE SEGURIDAD

Este manual de utilización ha sido elaborado para

ayudarlo a utilizar su motor y sus equipos. Incluye

instrucciones importantes que se debe seguir cuando

se utiliza el motor.

El usuario debe leer obligatoriamente este manual. Igualmente, este manual debe estar siempre

disponible en el sitio en que se utilice el manual.

SÍMBOLOS DE SEGURIDAD

Se utiliza estos símbolos para indicar un peligro.

Están destinados a llamar su atención sobre elementos u operaciones que pudieren representar un peligro para usted mismo o para otros usuarios de este

motor. Lea atentamente las consignas indicadas por

estos símbolos. Es primordial que lea las instrucciones y las reglamentaciones en materia de seguridad

antes de poner en servicio el motor.

I PELIGRO : Significa que existe un peligro extre-

madamente grave que puede conducir muy probablemente a la muerte o a lesiones irreparables si no se

toman medidas particulares adaptadas.

I ADVERTENCIA : Significa que existe un peligro

que puede provocar lesiones o la muerte si no se

toman medidas particulares adaptadas.

I ATENCIÓN : Recuerda las medidas de seguridad

o llama la atención sobre prácticas peligrosas que

pueden provocar lesiones a personas o causar daños

a la nave o a sus componentes.

El usuario debe tomar todas las precauciones útiles

en materia de manipulación y protección, y pedir consejo a un profesional.

El incumplimiento de las instrucciones de seguridad

puede conducir a:

Peligros corporales, peligros en el ámbito de la contaminación del medio ambiente (fugas de sustancias

peligrosas), peligros materiales con riesgos de fallo

de las funciones fundamentales del motor.

• RESPETAR LAS PRESCRIPCIONES EN MATE-

RIA DE SEGURIDAD

Respete las etiquetas de advertencia y atención dispuestas sobre el motor

Retire la llave de contacto y cierre el corta batería

antes de efectuar cualquier intervención en el

motor y sus equipos

Vuelva a cerrar el capó del motor y coloque en su

sitio los elementos de protección antes de poner en

marcha el motor.

Mantenga siempre limpia la zona de trabajo alrededor del motor

Conserve los líquidos inflamables fuera del comportamiento del motor

Nunca utilice el motor cuando esté bajo los efectos

del alcohol o de medicamentos

• UTILICE ROPA DE PROTECCIÓN

Para evitar lesiones corporales, alejarse de los elementos en movimiento y no llevar ropa holgada cuando esté cerca de un motor en funcionamiento.

Utilice artículos de seguridad como gafas, guantes,

etc. en función de las circunstancias y según las necesidades.

• CARBURANTES Y LUBRICANTES

Detenga el motor antes de llenar los depósitos de

combustible y lubricante.

No fume y no se acerque a una llama mientras llena

el depósito de combustible

Utilice guantes para buscar una eventual fuga

El aceite caliente puede quemar – deje enfriar el motor antes de verificar el nivel de aceite, de cambiar el

aceite o el cartucho del filtro de aceite.

Utilice siempre carburantes y lubricantes recomendados por NANNI DIESEL

ESPAÑOL

Manual de utilización y mantenimiento

Page 19

3

• PREVENCIÓN DE LOS GASES DE ESCAPE

Ponga en funcionamiento el motor en un sitio bien

aireado, lejos de personas y animales; la acumulación de gases de escape puede ser nociva.

• PRESIÓN

Nunca abrir los tapones de líquido de refrigeración y

aceite cuando el motor esté en funcionamiento o caliente. Libere toda la presión de los circuitos antes de

retirar los tapones.

No verificar las fugas eventuales de presión con las

manos desnudas, utilice guantes; los líquidos expulsados bajo presión pueden causar graves lesiones;

en caso de un chorro de fluido, consulte inmediatamente a un médico.

• BATERÍA

Cuando se recarga la batería, se forma una mezcla

de gases extremadamente explosiva, inflamable y

volátil. Nunca fume ni acerque una llama o chispa a

la batería

Nunca ponga en cortocircuito los bornes de la batería.

El electrolito de la batería es muy corrosivo; utilice

guantes y gafas de protección.

• CABLEADO ELÉCTRICO

Interrumpa el contacto del motor y del cortabatería

antes de realizar cualquier intervención en el equipo

eléctrico.

Verifique el estado de los cables y del cableado eléctrico; un cortocircuito puede causar un incendio.

• DESECHO DE LOS FLUIDOS

Los diferentes fluidos utilizados para el funcionamiento del motor representan un peligro para la salud.

Leer bien las instrucciones que figuran en el embalaje de estos productos.

Respete las reglamentaciones en materia de protección del medio ambiente relativas a la eliminación del

aceite, del carburante, del líquido de refrigeración, de

los filtros y de las baterías.

2 – INFORMACIONES GENERALES

Su motor NANNI DIESEL es un producto del estudio

y de la fabricación de calidad de NANNI INDUSTRIES. Está construido con los mejores materiales,

de conformidad con especificaciones precisas, y

según métodos de producción muy estrictos.

Su motor NANNI DIESEL es una fuente de potencia

fiable y duradera para su barco.

La instalación del motor a bordo de su barco tiene

una importancia fundamental para una navegación

segura, así como para el respeto del medio ambiente.

Los ingenieros de NANNI INDUSTRIES son algunos de los más competentes. Su experiencia, sus

conocimientos del mar, su dominio de las técnicas en asociación con los ingenieros de MAN,

KUBOTA y TOYOTA garantizan la mejor adecuación rendimiento/fiabilidad/economía.

I ADVERTENCIA:

La instalación de su motor debe ser efectuada obligatoriamente de un astillero naval o de un representante de NANNI INDUSTRIES, de conformidad con las

instrucciones de montaje a bordo.

Este manual de utilización contiene las informaciones

necesarias para el buen funcionamiento del motor.

NANNI INDUSTRIES está presente en más de 5 países a través de su red de agentes y vendedores, y

garantiza su navegación en todo el mundo. Hemos

pensado en todo para servirle: Piezas, mano de obra

o simples consejos.

No dude en ponerse en contacto con su vendedor

autorizado NANNI DIESEL.

Le deseamos una buena y agradable navegación.

Lea atentamente este manual antes de utilizar el motor. Respete las medidas de seguridad.

I ADVERTENCIA:

El buen funcionamiento de un motor marino depende

de una utilización adaptada a la definición del motor y

de su transmisión (tipo de barco, tiempo y régimen

de utilización).

3 – IDENTIFICACIÓN DEL MOTOR

En toda correspondencia, solicitud de información y

pedido de piezas de repuesto, se debe indicar obligatoriamente las referencias que figuran en las placas

del motor y del inversor.

IMPORTANTE: Anotar el número de serie y la deno-

minación del modelo del motor y de la transmisión.

Conservar una copia de estas informaciones en un

sitio seguro

TIPO DE MOTOR

NÚMERO DE SERIE

ESPECIFICACIÓN

Page 20

4

IDENTIFICACIÓN DE LOS PRINCIPALES ÓRGANOS

1. Cambiador térmico

2. Orificio de llenado de líquido de refrigeración

3. Tapón de cambio de aceite del bloque

4. Bomba de agua dulce

5. Bomba de agua de mar

6. Alternador

7. Suspensión flexible

8. Conector eléctrico

9. Dispositivo de arranque

10. Orificio de llenado de aceite

11. Indicador de nivel de aceite

12. Filtro de aire

13. Codo de escape de inyección de agua

14. Ánodo

15. Filtro de aceite

16. Transmisor de presión de aceite

17. Inversor reductor

18. Bomba de inyección

19. Parada eléctrica

20. Mando de aceleración

21. Enfriador de aire

22. Turbocompresor

23. Empalme de vaciado del cambiador

24. Termostato

25. Grifo de vaciado del turbocompresor

26. Orificio de evacuación de condensación

27. Conexión del cable de menos (-) de la batería.

28. Relé de calentador de aire

29. Filtro de gasóleo y detector de presencia de agua

30. Relé de arranque

31. Depósito de aceite hidráulico (versión Stern drive)

32. Refrigerante de aceite de dirección asistida

(versión Stern drive)

33. Contactor de seguridad de punto muerto

34. Tubo de vaciado de aceite

4 – PREPARACIÓN ANTES DE LA PUESTA

EN SERVICIO

Una vez instalado el motor a bordo, y antes de retirar

las protecciones que obturan los diferentes orificios,

limpiar las superficies exteriores del motor. Estas

operaciones deben ser realizadas por el astillero naval o por un taller autorizado.

VERIFICACIÓN GENERAL.

Ver las condiciones de garantía SILVERWAKE®

- Llenar los depósitos de aceite del motor y del inversor.

- Llenar el depósito de líquido de refrigeración del

cambiador, eliminar los gases en el punto alto de la

voluta del turbocompresor.

- Verificar tensión de las correas

- Verificar el apriete de los diferentes empalmes y

tapones de vaciado (agua y aceite)

- Verificar el apriete de los terminales eléctricos, los

bornes de batería, el cortocircuito, la conexión de las

extensiones, el nivel de electrolito de las baterías.

- Verificar el mando de aceleración.

- Verificar la correcta sincronización de la palanca

“acelerador e inversor” (obligatorio en caso de un

mando con una palanca de cables). Se debe haber

terminado de embragar cuando se comienza a acelerar. En caso de mandos eléctricos, remitirse al manual específico de los mandos suministrados.

- Verificar por última vez la fijación y controlar visualmente el conjunto del grupo marino. Si fuera necesario, efectuar retoques de pintura en el grupo y los

accesorios.

I PELIGRO:

No acercar una llama o una chispa a

la batería. Cuando se recarga la batería, se forma

una mezcla de gases extremadamente explosiva –

No hacer ningún cortocircuito.

El electrolito de la batería es muy corrosivo: si el

ácido entra en contacto con la piel, lavar inmediatamente con agua jabonosa; en caso de salpicaduras

sobre los ojos, enjuagar abundantemente con agua y

consultar inmediatamente a un médico.

- Al conectar el cable a la batería, comience por el

borne positivo.

- Al desconectar el cable de la batería, comience por

el borne negativo.

I ADVERTENCIA:

No derramar carburante o lubricante sobre el motor.

Los fluidos utilizados para el funcionamiento del

motor representan un peligro para la salud.

El aceite de motor puede afectar la piel; utilice

guantes.

NOTA: Los motores diesel modernos son equipos de

precisión que necesitan el empleo de carburantes y

lubricantes de alta calidad.

LUBRICACIÓN DEL MOTOR Y DEL INVERSOR

Motor

Sistema de engrase con bomba de aceite; presión

regulada mediante una válvula de descarga.

Filtro de aceite con cartucho desechable

Transmisión

Ver las especificaciones aparte

Llenado con aceite del motor

Por el orificio de llenado situado en la tapa de los

balancines, destornillando el tapón. Verificar el

nivel con el indicador de nivel. Nunca exceder la

marca de máximo.

NOTA: Las calidades y cantidades de aceite están

indicadas en el cuadro de características técnicas

CIRCUITO DE CARBURANTE

Composición

Filtro principal con cartucho desechable

Bomba de inyección

Tubos de inyección de alta presión

Inyectores (al interior de la culata)

ESPAÑOL

Page 21

5

Purga del circuito de carburante

Verificar el nivel de carburante en el depósito

Abrir el grifo de carburante, abrir el tornillo de purga

situado en la parte superior del filtro, bombear utilizando su bomba incorporada. Cerrar el tornillo cuando desaparezcan las burbujas de aire. En caso de un

descebado total del circuito de inyección, proceder

de la siguiente manera:

Aflojar el tubo de alimentación del inyector N°1, hacer

girar el motor utilizando el dispositivo de arranque

hasta que aparezca gasóleo, volver a apretar la tuerca y continuar con los otros inyectores.

Poner en funcionamiento el motor y verificar que no

haya fugas.

I PELIGRO: No fumar, no acercar una llama o una

chispa. Limpiar siempre el carburante derramado.

CIRCUITO DE REFRIGERACIÓN

Consta en realidad de dos circuitos diferentes: El

circuito cerrado de líquido de refrigeración y el circuito de agua de mar.

Circuito cerrado de líquido de refrigeración

Consta de una bomba accionada por el cigüeñal

mediante dos correas en V, un cambiador térmico

de agua, un cambiador térmico de aceite integrado al bloque y un termostato.

Circuito de agua de mar

Consta de una bomba, un cambiador térmico de

agua dulce-agua de mar, un refrigerante de aire de

sobrealimentación, un refrigerante de aceite de dirección asistida (versión Stern drive), un cambiador de

aceite inversor y un codo de escape.

Líquido de refrigeración

Recomendaciones para la primera puesta en funcionamiento.

- Verificar el apriete del tapón de vaciado situado debajo del turbocompresor, abrir el tapón de ventilación

situado en la parte superior de la voluta del turbocompresor.

- Preparar un mezcla de producto anticongelante permanente con 50% de producto anticongelante y 50%

de agua dulce. La cantidad necesaria está indicada

en el cuadro de especificaciones técnicas. Vertir la

mezcla en el orificio de llenado y, cuando aparezca la

mezcla, cerrar el tapón de ventilación situado en la

parte superior del turbocompresor; después, continuar el llenado hasta alcanzar el nivel máximo. Las

eventuales adiciones de líquido se efectuarán sólo

con agua dulce y con el motor frío. Ponga en funcionamiento el motor y complete hasta alcanzar el nivel.

Verificar que no haya fugas.

- Cada dos años, al inicio de la temporada, vaciar

completamente el circuito de refrigeración, limpiarlo

con agua dulce y llenar según las indicaciones antes

mencionadas. (Ver las condiciones de garantía

SILVERWAKE®).

I

PELIGRO : Llenar con líquido de refrigeración

cuando el motor esté parado y frío; no fumar ni acercar una llama. Alejarse de los elementos que estén

en movimiento cuando el motor esté funcionando.

I ATENCIÓN : Nunca añadir anticongelante puro.

El empleo de aditivos o de otros tipos de líquido de

refrigeración puede provocar la formación de depósitos aislantes y un sobrecalentamiento del motor

Conexión para agua caliente

Se puede conectar al motor una instalación para calentar el agua a bordo, tomándola en el circuito de

agua dulce interior. (Consulte a su agente NANNI

DIESEL).

I ATENCIÓN : Antes de poner en funcionamiento el

motor, asegurarse que la toma de agua de mar esté

abierta dado que basta un funcionamiento en seco,

durante sólo algunos segundos, para deteriorar el

rotor de la bomba de agua.

Después de limpiar el filtro de agua de mar, cerrar

cuidadosamente la tapa para evitar que la bomba de

agua aspire aire.

EQUIPO ELÉCTRICO

5. FUNCIONAMIENTO DEL MOTOR

PUESTA EN MARCHA ESPAÑOL

I PELIGRO : Cerrar bien el capó del motor y vol-

ver a poner en su sitio los elementos de protección antes de poner en marcha el motor.

- Verificar el nivel de gasóleo

- Abrir el grifo de alimentación de gasóleo

- Abrir la válvula de toma de agua en el mar

- Verificar los niveles de aceite, en el motor y en la

transmisión

- Verificar el nivel de líquido de refrigeración

- Cerrar el grifo de batería

Posición de los hilos / Color / Función

1 Rojo (+) Batería de 12 voltios

2 Violeta Borne D+ Alternador

3 Gris Captador de presión de aceite

4 Amarillo Postcalentamiento

5 Rosado/Negro Mano contacto de aceite

6 Amarillo/Verde Termo contacto de agua

7 Marrón Dispositivo de arranque

8 Naranja/Azul Captador de temperatura del agua

9 Verde

Sonda del indicador de la temperatura

del agua

10 Rojo/Amarillo

Alimentación del solenoide de parada

del motor

11 Azul oscuro (-) Captador del indicador de régimen

12 Azul oscuro (+) Captador del indicador de régimen

13 Azul claro Detector de agua en el gasóleo

14 no utilizado

15 Negro (-) Baterías de 12 voltios

16 no utilizado

Page 22

6

- Asegurarse que la palanca de mando del inversor esté en el punto muerto

- Girar la llave de arranque en sentido horario a la

posición «contacto», se encienden los indicadores

luminosos de alerta de aceite y de carga de la batería, suena la alarma acústica. Girar la llave de arranque en sentido horario hasta que arranque el motor.

Soltar inmediatamente cuando el motor haya arrancado.

I ATENCIÓN: El hecho de poner la llave de contac-

to en arranque inicia la acción de calentamiento del

aire de admisión del motor, que continúa durante

aproximadamente 6 minutos con el motor en funcionamiento. Tomar todas las precauciones necesarias

para evitar el contacto entre una parte del cuerpo y la

zona del calentador de aire situado en el motor.

Este calentamiento del aire de admisión está activo

cuando la temperatura del motor es inferior a 40°C.

- Verificar los indicadores luminosos y otras funciones una vez que haya arrancado el motor.

- Parar inmediatamente el motor si suena la alarma;

si la temperatura aumenta anormalmente o si uno o

varios indicadores luminosos quedan encendidos.

I ATENCIÓN : ¡Buscar y suprimir la causa antes de

poner nuevamente en funcionamiento el motor!

- Verificar que el agua de mar fluya correctamente

por el escape.

- Dejar que el motor funcione al régimen mínimo durante 2 a 3 minutos y después volver a ponerlo en

carga inmediatamente.

- Si el motor no arranca al primer intento, repetir a

maniobra interrumpiendo el contacto entre dos intentos.

IMPORTANTE: En caso de varios intentos infructuosos de arranque del motor, buscar la causa.

¡Nunca insistir dado que existe un riesgo de retorno

de agua hacia el motor a través del sistema de escape!

I ADVERTENCIA: Nunca interrumpa el circuito

eléctrico con el cortabatería cuando el motor esté en

funcionamiento. Esto puede dañar el alternador.

IMPORTANTE: No dejar en funcionamiento inútilmente el motor al régimen mínimo sin carga

PARADA DEL MOTOR

Llevar la palanca a la posición de régimen mínimo/

punto muerto

Dejar que el motor funcione al régimen mínimo durante algunos segundos para estabilizar las temperaturas y la velocidad del turbocompresor.

Nunca acelerar el motor antes de cortar el

contacto.

Girar la llave hasta la posición “O” (vertical).

- Cortar el grifo de la batería, cerrar la válvula de

toma de agua en el mar, así como la de alimentación de carburante.

IMPORTANTE: En caso de remolcado del barco,

parar el motor y cerrar obligatoriamente la válvula de

toma de agua en el mar para evitar que se llene accidentalmente el motor con agua del mar.

BARCOS BIMOTORES: En caso de navegación con

un solo motor, cerrar la toma de agua en el mar del

motor que esté parado. No olvidar volver a abrirla

antes de poner en funcionamiento el motor.

I ATENCIÓN : Examinar el motor y el comparti-

miento del motor para detectar eventuales fugas

RODAJE – INSPECCIONES DE GARANTÍA

Rodaje

Durante las primeras 20 horas de funcionamiento, se

recomienda utilizar su motor con precaución y llegar

al régimen máximo sólo durante cortos periodos.

Nunca embalar el motor inmediatamente después del

arranque, sin haberlo dejado calentar.

IMPORTANTE: Después del rodaje, no se debe utilizar el motor de manera permanente a su régimen

máximo, sino a 200 r.p.m. por debajo de este régimen

.

Inspecciones de garantía

Todas las operaciones de mantenimiento preventivo, así como su periodicidad están descritas en

el cuaderno de garantía: SILVERWAKE. ®

Estas inspecciones determinan la validez de la garantía. Estas inspecciones deben ser realizadas por

un representante autorizado de NANNI DIESEL.

Todo motor nuevo está garantizado contra todo defecto material según las modalidades indicadas en el

cuaderno de garantía SILVERWAKE® entregado al

comprador en el momento de la recepción del motor.

6. MANTENIMIENTO

I PELIGRO: Para evitar lesiones corporales, parar

el motor y dejarlo enfriar, y cortar el grifo de la batería

antes de efectuar cualquier intervención.

Respetar las consignas de seguridad y protección del

medio ambiente.

IMPORTANTE :

Estas recomendaciones son obligatorias. Respetarlas conducirá a prolongar la vida de su motor y determinará la realización normal de la garantía ofrecida.

No modificar sin autorización el motor.

Los daños causados por el uso de piezas de repuesto no originales no están cubiertos por la garantía.

Las intervenciones y operaciones de mantenimiento

deben ser efectuadas por un taller autorizado NANNI

DIESEL.

ESPAÑOL

Page 23

7

Si se utiliza el motor durante un número de horas

inferior al de las indicaciones dadas, se deberá

efectuar el mantenimiento una vez por año.

En este caso, se recomienda efectuar las operaciones de mantenimiento antes de la invernada; el motor estará entonces protegido por un aceite de lubricación nuevo y limpio. Esto no dispensa de las operaciones de invernada mencionadas en la garantía

SILVERWAKE.

Ajuste del juego de las válvulas

Estas operaciones deben ser realizadas por un taller

especializado (pastillas de ajuste calibradas).

Periodicidad: Según el cuadro de mantenimiento.

- (Ver los valores en el cuadro de características

técnicas)

Reemplazo del rotor de la bomba de agua

- Cerrar la válvula de toma de agua en el mar

- Retirar la cubierta de la bomba de agua

- Mediante una pinza de tomas múltiples; extraer el

rotor desgastado.

- Limpiar los elementos conservados.

- Instalar un rotor nuevo.

- Volver a instalar la cubierta de la bomba de agua

utilizando una junta nueva.

- Abrir la válvula de toma de agua en el mar.

- Poner en funcionamiento el motor y verificar la estanqueidad del circuito.

Equipo eléctrico

Verificar regularmente la tensión de la correa del alternador. Tensar la correa entre las poleas (190 Nm

utilizando el controlador DENSO).

I PELIGRO : Parar el motor y cortar el grifo de la

batería antes de efectuar cualquier interrupción en el

sistema eléctrico.

Batería

Controlar el estado de los elementos de la batería

una vez por temporada.

La densidad del electrolito debe estar comprendida

entre 1,270 y 1,285.

Se debe controlar periódicamente el nivel de electrolito. Se debe mantener el nivel a 1 cm por encima de

las placas. Añadir sólo agua destilada, si fuera necesario.

I PELIGRO – Nunca acercar una llama, nunca veri-

ficar la batería “a la chispa” dado que los gases que

se liberan son inflamables y explosivos – El electrolito de la batería es muy corrosivo. Si el ácido entra en

contacto con la piel, lavar inmediatamente con agua

jabonosa. En caso de salpicaduras en los ojos, enjuagar abundantemente con agua y consultar a un

médico.

No hacer un cortocircuito.

RECOMENDACIONES

Para asegurar el perfecto funcionamiento del alternador y del regulador incorporado, nunca:

- Interrumpir el cortabatería principal del circuito

cuando el motor esté en funcionamiento (existe un

riesgo de destrucción del regulador).

- Invertir los bornes de la batería. Los bornes están

marcados respectivamente + (positivo) y –

(negativo); este último está conectado a la masa; las

terminaciones de los cables, así como los cables,

deben estar fijados correctamente.

- Cambiar la carga del circuito mientras que el motor

está en funcionamiento.

Para utilizar varias baterías, instalar un repartidor de

carga. Consultar a un representante NANNI DIESEL.

En caso de arranque con una batería de repuesto y

cables de conexión, proceder de la siguiente manera:

Abandonar el circuito de batería principal, conectar la

batería de repuesto a la batería principal conectando

el + al + y el - al -. Una vez que el motor haya arrancado, retirar los cables de conexión y no cortar el

circuito de la batería principal.

Se debe desconectar los 2 cables de batería

cuando:

- Se utiliza un cargador de batería.

- Antes de toda intervención en el equipo eléctrico

- Antes de realizar un trabajo de soldadura en un

casco metálico

Enjuague del circuito de refrigeración

Circuito de agua dulce

- Abrir el tapón de llenado situado en el cambiador.

- Abrir el tapón de vaciado situado debajo de la voluta del turbocompresor.

- Aflojar el empalme de tornillo de cabeza hueca, situado debajo del colector de escape.

- Retirar el tapón de vaciado del bloque, situado sobre el soporte del termostato.

- Evacuar el líquido usado del cambiador térmico y

del bloque motor.

- Llenar el circuito con agua dulce y dejar funcionar el

motor durante algunos minutos.

- Aplicar el procedimiento de llenado/cebado descrito

en el párrafo: Circuito cerrado de refrigeración.

- Vaciar el agua y llenar nuevamente con la mezcla

anticongelante/agua dulce.

- Llenar el circuito de refrigeración según las especificaciones.

NOTA: En caso de que se conectara un circuito de

agua caliente al motor, vaciar también completamente este último y, para el llenado, tomar en cuenta la

cantidad añadida de mezcla. Asegurarse que, durante el llenado, el aire que se encuentra en el circuito

salga completamente.

Page 24

8

I ADVERTENCIA: Líquido bajo presión. No abrir el

tapón cuando el motor está caliente. Dejar que el

motor se enfríe y abrir el tapón con precaución.

Circuito de agua de mar

- Cerrar la válvula de toma de agua en el mar

- Vaciar todos los tubos de toma de agua en el mar,

el filtro, la bomba de agua de mar, el tubo y el cambiador térmico, aflojando los collarines de fijación.

- Vaciar el circuito de escape dado que cierta cantidad de agua queda en el fondo del tubo de escape «waterlock».

Limpieza del cambiador térmico de agua y aire

Verificar los haces de los cambiadores.

- Retirar las cubiertas.

- Retirar los haces y limpiarlos con agua y un producto no corrosivo del comercio. Enjuagar abundantemente.

- Reemplazar las juntas tóricas y volver a montar los

subconjuntos.

I ADVERTENCIA: Los productos corrosivos consti-

tuyen un peligro para la salud. Leer bien las instrucciones que figuran en el embalaje del producto.

Reemplazo del filtro de gasóleo

El cartucho de gasóleo es de tipo desechable; se

debe conservar la envolvente parafuego, así como la

sonda de presencia de agua y se les debe volver a

colocar en posición correcta (el parafuego no debe

estar en contacto con el tornillo plástico de purga).

- Cerrar el grifo de carburante.

- Destornillar el cartucho de la cabeza de filtro

- Untar la junta del nuevo cartucho con aceite limpio.

- Atornillar el nuevo cartucho sobre la cabeza de filtro

y después apretar con la mano ¾ de vuelta (no utilizar herramientas) volver a poner la sonda y el tornillo

de purga, verificar la junta

- Abrir el grifo de carburante.

- Purgar el circuito, verificar la estanqueidad.

- Poner en funcionamiento el motor y verificar el buen

funcionamiento.

I ATENCIÓN: Limpiar siempre el carburante derra-

mado. Respetar las consignas de protección del me-

dio ambiente.

Reemplazo de un inyector. (Es indispensable utilizar el manual de taller)

Retirar :

- La rampa de 6 tubos de inyección.

- La cubierta de distribución.

- La rampa de retorno de gasóleo.

- El inyector completo. El asiento y la junta

(Herramienta SST)

- Desmontar el inyector

- Reemplazar el inyector completo, la junta tórica, así

como el asiento. Reemplazar todas las juntas de retorno de gasóleo. Apretar el inyector y las tuberías

aplicando el par de apriete prescrito. Poner en marcha el motor y verificar que no haya fugas de carburante. No intentar reparar el inyector, esta operación

debe ser realizada por un taller especializado.

I ADVERTENCIA: No pulverizar gasóleo sobre la

piel – utilizar guantes.

IMPORTANTE: Los trabajos de reparación de un

inyector deben ser efectuadas por un taller autorizado NANNI DIESEL. Se debe verificar los inyectores

cada 400 horas o cada 2 años, según el cuadro de

mantenimiento y el cuaderno SILVERWAKE ®.

Cambio de aceite del cárter del motor.

Se extrae el aceite mediante una bomba de vaciado,

preferentemente: con el motor ligeramente caliente.

- Bombear hasta extraer completamente el aceite por

el tubo del indicador.

- Volver a llenar con aceite nuevo. (Ver las características en el cuadro de especificaciones)

- Verificar el nivel con el indicador de nivel.

- No exceder el nivel máximo.

I ADVERTENCIA: El aceite caliente puede quemar

– Evitar todo contacto con la piel. Respetar las regla-

mentaciones en materia de protección del medio ambiente.

Reemplazo del filtro de aceite

El cartucho es de tipo: Desechable.

- Destornillar el cartucho de la cabeza de filtro

- Untar la junta del nuevo cartucho con aceite limpio.

- Atornillar el nuevo cartucho sobre la cabeza de filtro

y después apretar con la mano ¾ de vuelta (no utilizar herramientas)

- Poner en funcionamiento el motor y verificar que no

haya fugas.

- Parar el motor y establecer el nivel de aceite añadiendo aceite, si fuera necesario.

I ADVERTENCIA: El aceite caliente puede quemar.

Evitar todo contacto con la piel. Respetar las reglamentaciones en materia de protección del medio ambiente.

Inversor

Ver las instrucciones detalladas en el manual del inversor adjunto al manual de utilización.

Sistema de mando del inversor mecánico

Verificar regularmente los mandos a distancia. La

carrera del cable debe tener 35 mm de cada lado del

punto muerto (O - A = O – B). La palanca debe hacer

toda su carrera libremente.

Sistema de mando eléctrico.

Verificar las conexiones en las electroválvulas, así

como las conexiones en las cajas de control.

Estar atento a la posición de las palancas

I PELIGRO: Para evitar lesiones corporales, no

poner el motor en marcha sin el filtro de aire.

ESPAÑOL

Page 25

9

TIPO DE OPERACIONES

C/R/A

controlar

reemplazar

ajustar

Todos los

días

A 20 H

Cada

100h

Cada 200h

o cada año

Cada 400h

o cada 2

años

Nivel de aceite del inverso C/A X X

X

Nivel de aceite del moto C X X

X

Tablero de instrumentos: indicaciones y alarmas C X X

X

Tensión de las correa C X X

X

Nivel de electrolito de la batería C/A/R X X

X

Caja de mando: Inspección de cables acelerador/

inversor y trole: Engrase general.

C/A

Apriete de tuercas y collarines C/A X X

Estanqueidad general C/A X X

Suspensiones de fijación del motor, alineación C/A X

X

Tapón tarado de cambiador térmico C/A X X

Líquido de refrigeración R X

Termostato R X

Haz de cambiador: limpieza R X

Calentador de aire: limpieza C X

Haz de enfriador de aire: limpieza C X

Filtro de agua de mar: limpieza C X

Prefiltro de carburante: vaciado de agua C SEGÚN ESTADO DE LIMPIEZA

Filtro de carburant C/A X X X X X

Filtro de aceite del motor R X X X

Prefiltro de carburante (cartucho) R X X X

Aceite del motor R X X X

Aceite del inversor R X X

Rotor de la bomba de agua R X X

Tarado de los inyectores R X

Juego de las válvulas C/A/R X

Prensaestopas (si tiene trenzas) A

500 H

Filtro de aire, limpieza C X X X

Turbocompresor: Inspección/Limpieza C X

Ánodo de codo de escape C X

Refrigerante de aire: libre, desobstruido, condensación

C/R X X X

Correa de distribución con muescas X

Courroie de distribution crantée R X

CADA LAS 15 DIAS

6. MANTENIMIENTO

Cuadro de mantenimiento periódico

Page 26

10

CARACTERÍSTICAS TÉCNICAS

MOTOR NANNI DIESEL Z6.300 T6.300 6.420 TDI

Número de cilindros 6 en línea

Potencia máxima *

202.4 kW (275 ch) 224.4 kW (305 ch) 235,6 kW (320 ch)

Régimen nominal * 3600 r.p.m.

Régimen mínimo 700 + - 25 r.p.m.

Régimen máximo en vacío 4200 r.p.m. (+ - 50)

Ciclo 4 TIEMPOS

Diámetro interno x carrera 94 X 100

Cilindrada 4.163 cm3

Distribución AC en cabeza, 24 válvulas, correa

Relación volumétrica 15,7:1

Sentido de rotación Antihorario (visto desde el volante del motor)

Orden de inyección 1-4-2-6-3-5

Bomba de inyección DENSO VE

Presión de inyección 01 y 02 17.7 a 18.6 MPa y 34 a 35 MPa

Consumo de carburante. 216 g /KWh@ 3600 r.p.m.

Avance de inyección (antes del punto muerto superior) 1,18 a 1,24 mm (subida de comparador)

Peso en seco 436 kg

Alternador 12 V - 80 A

Capacidad de la batería (mínimo) 100/110 A/h

Circuito de refrigeración Por cambiador térmico agua dulce / agua de mar

Bomba de agua de mar Tipo de rotor de neopreno

Líquido de refrigeración:

50% agua + 50 % anticongelante

27 litros

Juego de válvulas (en frío) Adm.0,20 (+ - 0,3) Esc.0,50 (+ - 0,3)

Aceite del motor API CG 4 / SG – SAE 15 W 40

Capacidad de aceite de motor, según la inclinación 11,4 litros

Capacidad de aceite del inversor ZF 63A 3,5 L

Capacidad de aceite del inversor ZF 80A 5 L

Capacidad de aceite inversor ZF 80 IV 7,5 L

Característica del aceite ATF DEXRON II, III

Necesario a bordo, recomendado para el motor tipo 6.420TDI T6 300 Z6 300

DESCRIPCIÓN Ctd. Referencia

Correa trapezoide Juego de 2 970 312 725

Filtro de aceite del motor 1 970 312 207

Filtro de carburante 1 970 311 185

Kit de rotor de bomba de agua de mar 1 970 312 432

Juntas de retorno de gasóleo 1 970 312 701

Asiento de inyector 1 970 312 695

Termostato 1 970 311 046

Junta de termostato 1 970 312 796

Junta de manga de admisión de aire (tórica) 2 970 312 784

Junta de cambiador de aire 4 970 312 781

Porta inyector completo 1 970 312 692

Junta de inyector 1 970 312 694

Junta de cambiador agua/agua 4 970 312 801

ATENCIÓN: Las especificaciones están definidas sólo para uso deportivo y de ocio.

Régimen de crucero recomendado: 200 r.p.m. por debajo del régimen máximo autorizado.

Page 27

11

2

4

5

1

23

6

7

7

8

9

10

13

15

16

17

18

28

34

21

24

27

29

3

30

33

Page 28

12

10

11

13

2

22

12

31

32

29

14

25

15

20

Page 29

13

TABLE R O DE I NSTR U M ENTOS D E L MOTOR: DIMENSIONES Y CORTE

Page 30

14

ESQUEMAS Y PLANOS DE CABLEADO 6.420 TDI, T6 300, Z6 300

Page 31

15 16

Page 32

Nanni Industries S.A.S. 11, Avenue Mariotte - Zone Industrielle BP 107-

33260 La Teste France - Tel : + 33 (0)5 56 22 30 60 - Fax : +33 (0)5 56 22 30 79

E-mail : contact@nannidiesel.com

Certifié ISO

9001 : 2000

Loading...

Loading...