Nanni QLS 65T User Manual

GENSETS NANNI

USER MANUAL

Ref. DGBXXT09047

MODEL

QLS 65T

Q00 TRACKED CHANGES

TRACKED CHANGES

CODE INDEX DATE INITIALS NATURE OF TRANSLATIONS PAGES

DGBXXT09047 - 05/2019 MC Create -

Please note all changes and pages associated.

For further clarity, please add a line in front of each change.

3

S00 SUMMARY

Q00 TRACKED CHANGES 3

TRACKED CHANGES 3

S00 SUMMARY 5

S01 INTRODUCTION 7

INTRODUCTION 7

ABOUT THIS MANUAL 8

CONTENT & UPDATES 8

S02 SAFETY 9

SUMMARY 9

SAFETY SIGNALS 10

SAFETY INFORMATION 10

REPLACEMENT OF MISSING OR DAMAGED SAFETY

SIGNS 10

READ SAFETY INSTRUCTIONS 10

ENGINE-GENSET SAFETY ICONS 11

SAFETY PRECAUTIONS 12

HOT EXHAUST PRECAUTIONS 12

WORK IN VENTILATED AREA 12

WASTE DISPOSAL 12

UNWANTED ENGINE START 12

SAFE MAINTENANCE PRACTICE 12

WORK IN CLEAN AREA 12

PROTECTIVE CLOTHING 12

SERVICE ENGINES SAFELY 13

PROPER USE OF TOOLS 13

SUPPORT ENGINES PROPERLY 13

SAFE ILLUMINATED WORK AREA 13

PROPER LIFTING EQUIPMENT 13

NOISE PROTECTION 13

GENSET OUTPUT GENERATED POWER 13

GUARDS REQUIREMENTS 13

STAYING CLEAR OF ROTATING DRIVELINES 14

PAINT REMOVAL BEFORE HEATING 14

HIGH-PRESSURE FUEL SYSTEM OPENING RISK 14

AVOID HIGH-PRESSURE FLUIDS 14

SAFE COOLING SYSTEM SERVICE 14

AVOID HEAT NEAR PRESSURIZED FLUID LINES 14

WELDING NEAR ELECTRONIC CONTROL UNIT (ECU)

STATIC ELECTRICITY RISK 15

HANDLE FUEL SAFELY - AVOID FIRES 15

BE PREPARED FOR EMERGENCIES 15

HANDLE STARTING FLUID SAFELY (ETHER) 15

HANDLING BATTERIES SAFELY 15

PREVENT BATTERY EXPLOSIONS 16

FROST PROTECTION-WINTERIZATION 16

LIVE WITH SAFETY 16

PREVENT ACCIDENTS 16

S03 FLUIDS 17

SUMMARY 17

FUELS 18

DIESEL FUEL 18

SULPHUR CONTENT 18

WINTER DIESEL 18

WATER IN FUEL 18

MICROORGANISMS IN FUEL 18

INERT IMPURITIES IN FUEL 19

DIESEL LUBRICANTS 19

PRECAUTIONS TO UNDERTAKE 19

OILS RECOMMENDED OR AUTHORIZED 19

GENERALITIES 19

OILS VISCOSITY 20

CORRESPONDENCE BETWEEN API AND ACEA OILS

20

DIESEL SULPHUR CONTENT 20

TO AVOID ENGINE DAMAGE: 20

REDUCE OIL AND FILTER SERVICE INTERVALS BY 50%

WHEN USING BIODIESEL BLENDS GREATER THAN

B20. OIL ANALYSIS MAY ALLOW LONGER SERVICE

INTERVALS. 20

USE ONLY APPROVED OIL TYPES. 20

COOLANTS 21

COOLANT DRAIN INTERVALS 21

WATER PROPERTIES 21

WATER PROPERTIES TO MIX WITH COOLANT CON-

CENTRATE 21

OTHER COOLANTS 22

FREEZE PROTECTION 22

REQUIRED QUANTITY OF COOLANT VS COOLING

SYSTEM CAPACITY 22

OPERATING ENGINE IN WARM TEMPERATURE CLI-

MATES 22

DISPOSING OF WASTE FLUIDS 23

ANNEX 24

ANNEX 1. VOLUME OF GLYCOL 24

S04 WARRANTY 25

ENGINE IDENTIFICATION 25

ENGINE HOMOLOGATION 25

ENGINE RESPONSABILITY 26

WARRANTY 26

PROPOSITION 65 STATE OF CALIFORNIA 26

EPA WARRANTY 27

GENERATOR IDENTIFICATION 27

S05 ENGINE INSTRUMENTS PANEL 28

SUMMARY 28

GENERALITIES 29

LUXE GE FRONT PANEL 29

INSTRUMENTS 30

STARTING BUTTONS 30

ENGINE OIL PRESSURE 30

ENGINE COOLANT TEMPERATURE 30

ALARMS 30

DISPLAYS 30

S06 COMPONENTS 32

SUMMARY 32

GENSET MAIN COMPONENTS 33

ENGINE VIEWS QLS65T 34

ENGINE VIEWS QLS65T 35

S07 STARTING & RUNNING 36

5

S00 SUMMARY

SUMMARY 36

BEFORE STARTING 37

GENSET INSTALLATION 37

FUEL SYSTEM 37

RAW WATER SYSTEM 38

ENGINE ELECTRICAL SYSTEM 38

START THE ENGINE 39

COLD WEATHER OPERATION 39

GENSET ENGINE START 39

ENGINE STARTED 39

STARTING WITH BOOSTER BATTERIES 40

ENGINE RELUCTANT TO START 40

NORMAL ENGINE OPERATION 40

AFTER STOPPING THE GENSET 41

COLD WEATHER PRECAUTIONS 41

S08 MAINTENANCE 42

SUMMARY 42

ABOUT 43

MAINTENANCE 44

GENERALITIES 45

TURBOCHARGER 46

TURBO SERVICE 46

AIR INTAKE 48

CHECK THE AIR FILTER 48

CLEANING THE AIR FILTER 48

FUEL SYSTEM 49

DRAIN WATER IN FUEL PREFILTER 49

REPLACING THE FUEL FILTER 50

AIR BLEEDING 50

LUBRICATION SYSTEM 51

OIL LEVEL - ADDING ENGINE OIL 51

DRAINING THE ENGINE OIL 52

CHANGING THE OIL FILTER 52

COOLING SYSTEM 53

OVERVIEW 53

COOLANT 54

COOLANT LEVEL 54

DRAINING THE COOLANT CIRCUIT 55

COOLANT - FILLING 55

HEAT EXCHANGER SERVICE 56

RAW WATER SYSTEM 57

CHECKING SACRIFICIAL ANODES 57

SIPHON BREAKER 57

EXTRACT THE RAW WATER PUMP IMPELLER

CLEANING THE RAW WATER FILTER 59

RAW WATER SYSTEM - DRAINING 59

RAW WATER SYSTEM 60

RISK OF ICING - PROTECTION AGAINST FROST 60

ELECTRICAL SYSTEM 61

WIRES AND CONNECTORS 61

ENGINE ELECTRICAL WIRING 62

BATTERY 64

KEEP CLEAN THE BATTERY 64

DISCONNECT THE STARTER CABLES 64

58

CONNECT THE CABLES 64

BATTERY ELECTROLYTE LEVEL 64

ELECTROLYTE LEVEL CHECK 65

ALTERNATOR BELT 65

MISCELLANEOUS 66

CAMSHAFT TIMING 66

S09 ALTERNATOR 67

SUMMARY 67

GENERALITIES 68

SAFETY WARNINGS 68

INTERNATIONAL STANDARDS 68

ELECTRICAL PERFORMANCES 68

REINFORCED MECHANICAL STRUCTURE 68

TERMINAL BOX 68

CLASS OF PROTECTION 68

LSAM 44.3 S2 DESCRIPTION 68

CHARACTERISTICS 69

LSAM 44.3 S2 CHARACTERISTICS & RATINGS 69

OUTPUT CONNECTIONS 69

ALTERNATOR SAFETY RULES 70

HANDLING 70

CONNECTIONS CHECKS 70

HOW TO SECURE CABLES 70

CONNECTIONS TO TERMINAL POSTS 71

ROUTINE MAINTENANCE 71

REPAIRS 73

ALTERNATOR STORAGE 73

DISPOSAL AND RECYCLING INSTRUCTIONS 73

S09 STORAGE 74

SUMMARY 74

LONG TERM STORAGE 75

LONG TERM STORAGE PROCEDURE 75

RESTARTING THE ENGINE 76

BATTERY 76

ALTERNATOR 76

S11 TROUBLESHOOTING 77

6

S01 INTRODUCTION

INTRODUCTION

Before operating the genset, make sure that this Manual is applicable to the engine type. Refer to the identication

plate if you are not sure about the engine model designation. If you don’t have the correct manual, please contact your

Nanni authorized dealer.

All the information and specications in this manual are based on the technical data available at time of publication.

Changes and updates may be made by Nanni without notice.

Illustrations are intended as a general guide and may vary from the equipment tted in the engine in some details.

If there are any equipment details that are not shown or described in this Manual, or if you have any question regarding

the operation of any equipment, your authorized Nanni dealer will be glad to inform you of correct care and operating

procedures. Contact a NANNI INDUSTRIES S.A.S. authorized dealer for the servicing of your engine. A list of dealers is

available on our website :

www.nannidiesel.com

Read this Manual carefully to learn how to operate and service your engine correctly. Failure to do so could result

in personal injury or equipment damage. This Manual should be considered as a permanent part of the genset and

should remain with it, even when sold.

Right-hand and left-hand sides are determined by standing at the drive or flywheel end (rear) of the engine and facing

toward the front of the engine.

Write engine and generator serial numbers and option codes. Accurately record all numbers. Your Nanni Agent also

needs these numbers when you order parts. File the identication numbers in a secure place. Some engine accessories such as air cleaner, and instruments are optional. These accessories may be provided by a third party. This Manual

applies only to the engine and those options available through the Nanni distribution network.

7

S01 INTRODUCTION

ABOUT THIS MANUAL

This Manual contains important information, tips, suggestions and warnings. We urge you to read it carefully

and familiarize yourself with the engine before

starting.

For your own safety and longer service life of the genset,

follow the instructions and warnings contained in this

manual and in all documentation provided with the boat.

Ignoring them could result in damage to the engine or

personal injury to you or others.

Please ensure that this Manual is always kept at hand.

It should always be available to anyone else using the

genset, i.e. anyone renting, borrowing or buying the genset from you.

CONTENT & UPDATES

All the informations and specications in this Manual

are based on the technical data applicable at the time of

its publication. Changes and updates may be made by

Nanni without notice.

Illustrations are intended as a general guide, and may

vary from the equipment tted in the engine in some details. Some sections of the Manual do not apply to all

engines. If this is the case, a text indicates which engines it applies to.

If there are any equipment details that are not shown or

described in this Operator’s Manual, or if you have any

questions about the operation of any equipment, your

authorized Nanni Dealer will be glad to inform you of

correct care and operating procedures.

8

S02 SAFETY

SUMMARY

Table des matières

S02 SAFETY 9

SUMMARY 9

SAFETY SIGNALS 10

SAFETY INFORMATION 10

REPLACEMENT OF MISSING OR DAMAGED SAFETY SIGNS 10

READ SAFETY INSTRUCTIONS 10

ENGINE-GENSET SAFETY ICONS 11

SAFETY PRECAUTIONS 12

HOT EXHAUST PRECAUTIONS 12

WORK IN VENTILATED AREA 12

WASTE DISPOSAL 12

UNWANTED ENGINE START 12

SAFE MAINTENANCE PRACTICE 12

WORK IN CLEAN AREA 12

PROTECTIVE CLOTHING 12

SERVICE ENGINES SAFELY 13

PROPER USE OF TOOLS 13

SUPPORT ENGINES PROPERLY 13

SAFE ILLUMINATED WORK AREA 13

PROPER LIFTING EQUIPMENT 13

NOISE PROTECTION 13

GENSET OUTPUT GENERATED POWER 13

GUARDS REQUIREMENTS 13

STAYING CLEAR OF ROTATING DRIVELINES 14

PAINT REMOVAL BEFORE HEATING 14

HIGH-PRESSURE FUEL SYSTEM OPENING RISK 14

AVOID HIGH-PRESSURE FLUIDS 14

SAFE COOLING SYSTEM SERVICE 14

AVOID HEAT NEAR PRESSURIZED FLUID LINES 14

WELDING NEAR ELECTRONIC CONTROL UNIT (ECU) 15

STATIC ELECTRICITY RISK 15

HANDLE FUEL SAFELY - AVOID FIRES 15

BE PREPARED FOR EMERGENCIES 15

HANDLE STARTING FLUID SAFELY (ETHER) 15

HANDLING BATTERIES SAFELY 15

PREVENT BATTERY EXPLOSIONS 16

FROST PROTECTION-WINTERIZATION 16

LIVE WITH SAFETY 16

PREVENT ACCIDENTS 16

9

S02 SAFETY

SAFETY SIGNALS

A signal word—DANGER, WARNING, or CAUTION—is

used in conjunction with the safety-alert symbol.

DANGER identies the most serious hazard with lethal

possible consequences.

WARNING identies serious hazard with possible large

injury consequences.

CAUTION identies precautions to undertake which if

not followed could lead to the above mentioned safety

warnings. Damage to equipement could happen.

NOTICE is used for specic attention to sensitive actions

on equipment. Other signals still applying.

IMPORTANT is a signal with a meaning of care to apply

to equipment.

parts and components sourced from suppliers that is

not reproduced in this Operator Manual.

Keep your equipment in proper working condition.

DANGER !

WARNING !

CAUTION !

NOTE !

SAFETY INFORMATION

This symbol on the engine or in this manual is an alert to

the potential for personal injury. Follow recommended

precautions and safe operating practices.

REPLACEMENT OF MISSING OR DAMAGED

SAFETY SIGNS

Replace missing or damaged safety signs. There can

be additional safety information contained on parts

and components sourced from suppliers that is not

reproduced in this Operator Manual.

READ SAFETY INSTRUCTIONS

Carefully read all safety messages in this manual and on

your genset safety signs.

Keep safety signs in good condition. Be sure new

equipment components and repair parts include the

current safety signs.

IMPORTANT !

Please keep in mind that above safety labels have no

degree of danger. Any irresponsible action could lead to

a real danger situation.

Learn how to operate the equipment and how to use

controls properly. Do not let anyone operate it without

instruction.

Unauthorized modications to the equipment may

impair the function and/or safety and affect its life span.

If you do not understand any part

of this document and need

assistance, contact your Nanni

representative.

Replacement safety signs are available from your dealer.

There can be additional safety information contained on

10

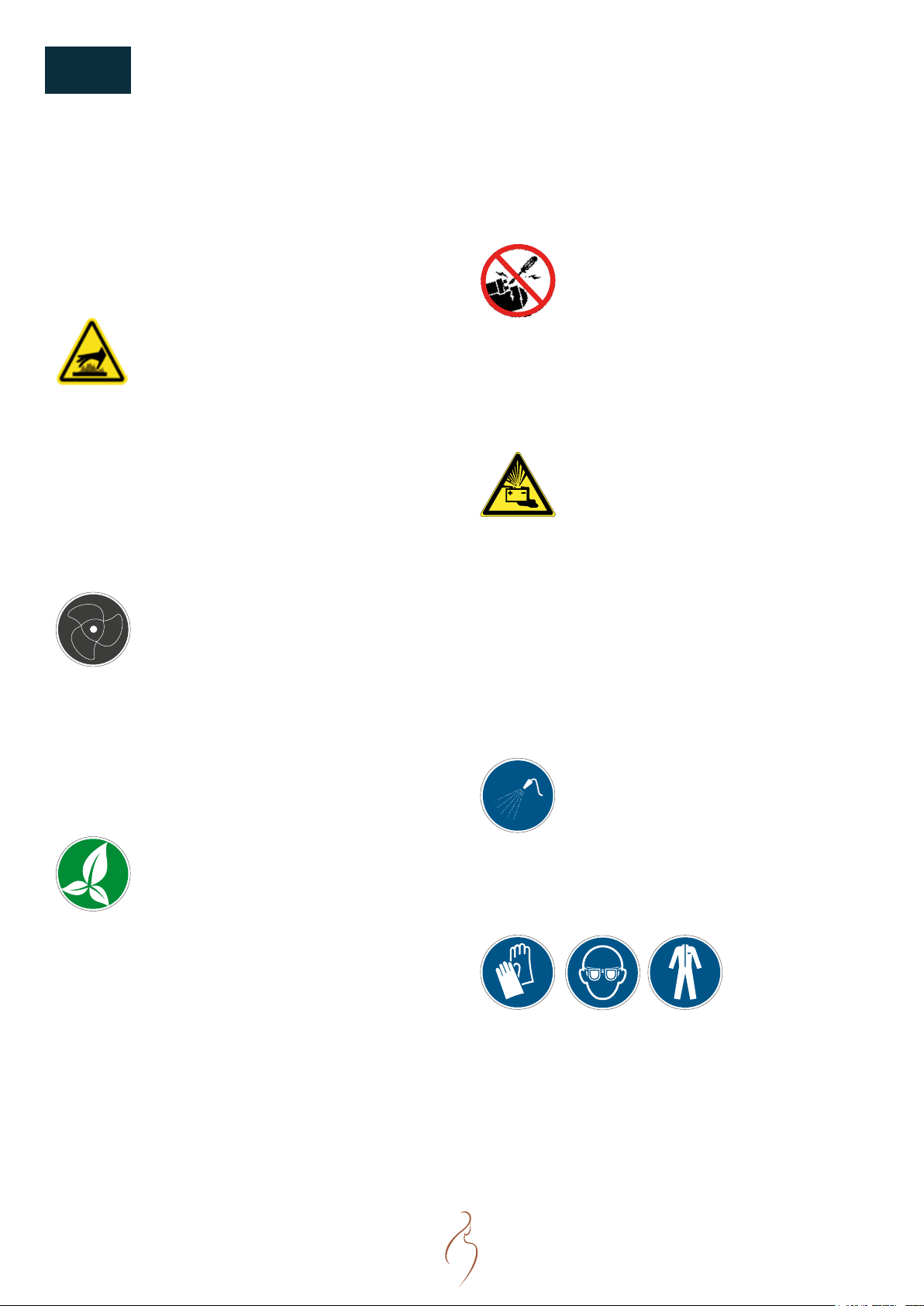

S02 SAFETY

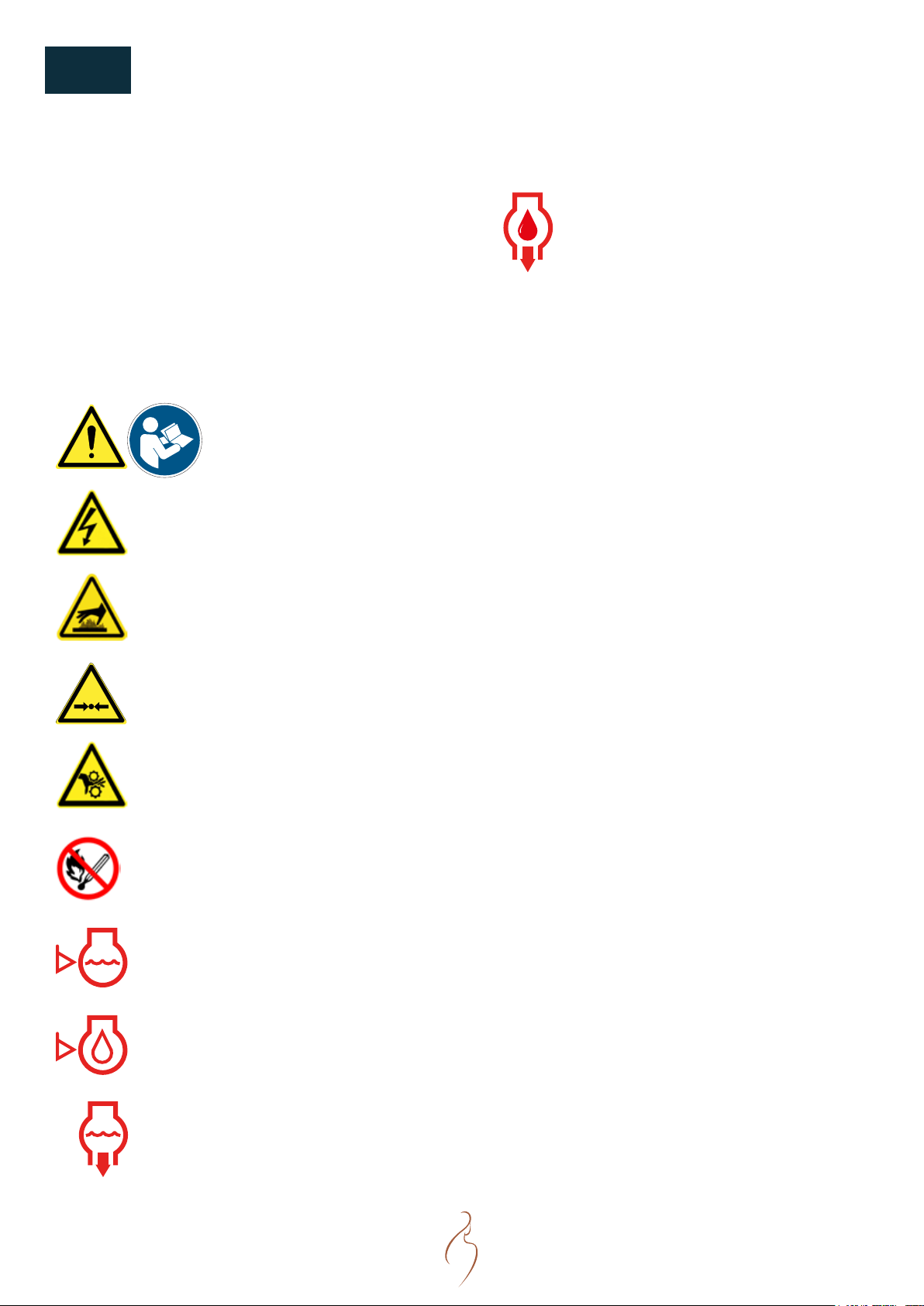

ENGINE-GENSET SAFETY ICONS

Some stickers are xed directly on the engine. They are

intended to help you to quickly identify the location of

certain components and avoid possible hazards when

working on the engine.

Ensure that these stickers are always visible and replace

them if torn or washed up.

Refers to important informations

and instructions to follow before

handling the engine.

Indicates possible electrical hazards.

Indicates the oil drain orice.

Indicates hot parts entailing substantial

risks of burns.

Indicates an area containing pressurised

fluids.

Indicates hazardous rotating parts.

Stipulates that no flames or sparks should

be created in the vicinity.

Indicates where to check the coolant

level.

Indicates where to check the engine oil

level.

Indicates the coolant drain orice.

11

S02 SAFETY

SAFETY PRECAUTIONS

HOT EXHAUST PRECAUTIONS

Servicing machine or attachments with

engine running can result in serious

personal injury. Avoid exposure and skin

contact with hot exhaust gases and

components.

Exhaust parts and streams become very hot during

operation. Exhaust gases and components reach

temperatures hot enough to burn people, ignite, or melt

common materials.

WORK IN VENTILATED AREA

Engine exhaust fumes can cause sickness

or death. If it is necessary to run an engine

in an enclosed area, remove the exhaust

fumes from the area with an exhaust pipe

extension.

UNWANTED ENGINE START

Avoid possible injury or death from engine

runaway. Do not start engine by shorting

across the starter motor solenoid

terminals posts. Engine will start if normal

circuitry is bypassed. Start engine from

operator’s seat.

SAFE MAINTENANCE PRACTICE

Understand service procedures before

doing work. Keep work area clean and dry.

Never lubricate, service, or adjust engine

while it is running. Keep hands, feet, hair

and clothing away from moving parts.

Fix damage immediately. Replace worn or broken parts.

Remove any build up of grease, oil, or debris. On selfpropelled equipment, disconnect battery ground (-)

before making adjustments on electrical systems or

welding.

If you do not have an exhaust pipe extension, open the

doors and get outside air into the area.

WASTE DISPOSAL

Improperly disposing of waste can threaten the environment and ecology. Potentially harmful waste used in engines include such items as oil, fuel, coolant, fluids

lters and batteries.

Use leakproof containers when draining fluids ; Do not

pour waste into the sea, ground, down a drain, or into

any other water source.

Contact your local environmental or recycling center, or

your dealer for information on the proper way to recycle

or dispose of waste.

WORK IN CLEAN AREA

Clean work area and machine before

starting a job. Make sure you have all

necessary tools to do your job. Have the

right parts on hand. Read all instructions

thoroughly ; do not attempt shortcuts.

PROTECTIVE CLOTHING

Wear close tting clothing and safety equipment

appropriate to the job. Operating equipment safely

requires the full attention of the operator. Do not wear

radio or music headphones while operating the engine.

12

S02 SAFETY

SERVICE ENGINES SAFELY

Tie long hair behind your head. Do not

wear a necktie, scarf, loose clothing, or

necklace when you work near moving

parts. If these items were to get caught,

severe injury could result. Remove rings

and other jewelry to prevent electrical

shorts and entanglement in moving parts.

PROPER USE OF TOOLS

Use tools appropriate to the work.

Makeshift tools and unfollowed

procedures can create safety hazards. Do

not use U.S mechanical tools on metric

fasteners (i.e. a 1/2 inch wrench on a 13

mm nut).

Use power tools only to loosen threaded parts and

fasteners. For loosening and tightening hardware,

use the correct size tools. Avoid bodily injury caused

by slipping wrenches. Use only service parts meeting

manufacturer specications.

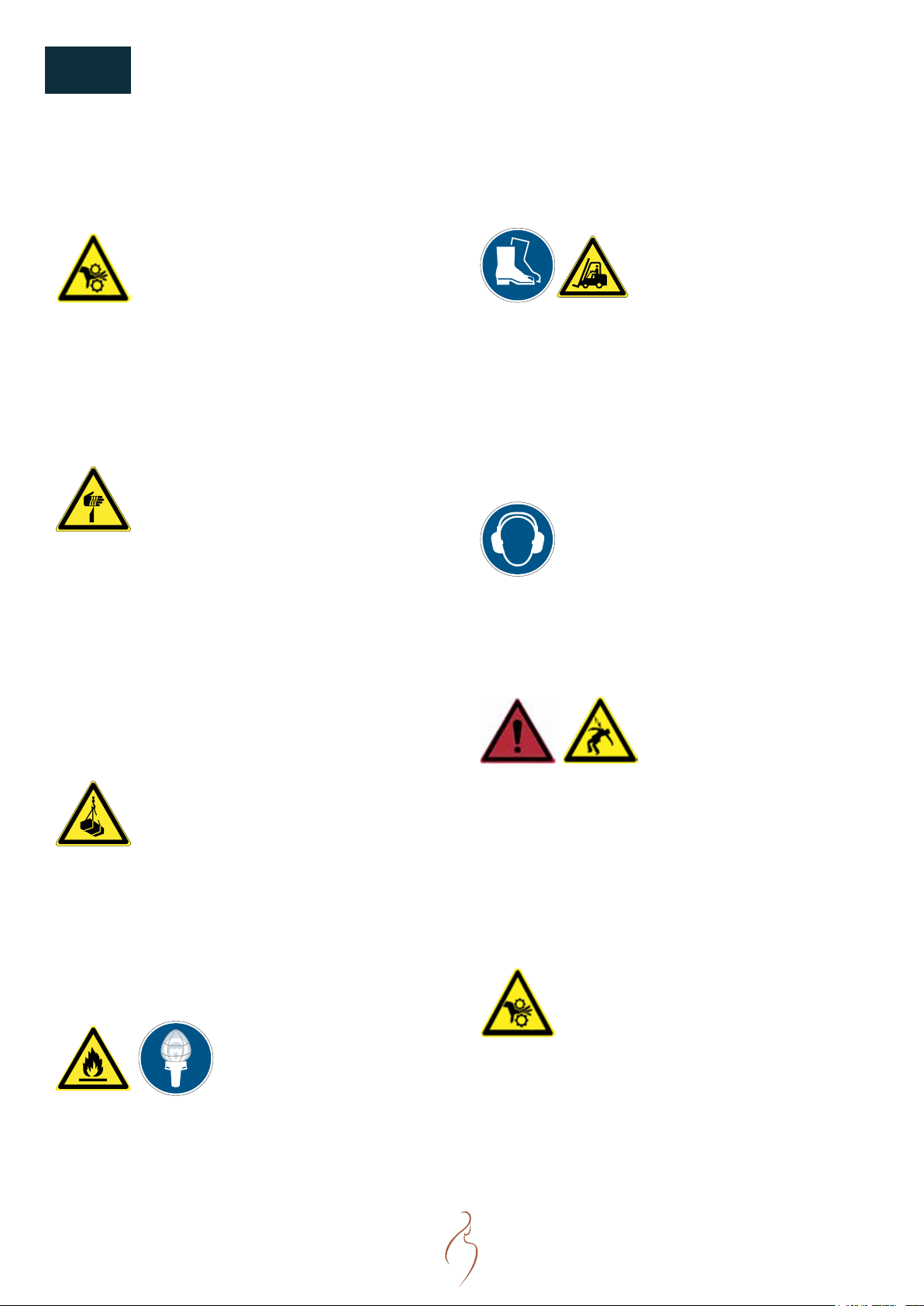

PROPER LIFTING EQUIPMENT

Lifting heavy components incorrectly can cause severe

injury or equipment damage. Use expertise of staff

holding relevant(s) legal capacity to operate heavy

lifting equipment, with the know-how of using slings

and chains.

NOISE PROTECTION

Prolonged exposure to loud noise can

cause impairment or loss of hearing. Wear

a suitable hearing protective device such

as earmuffs or earplugs to protect against

objectionnable or uncomfortable loud

noises.

GENSET OUTPUT GENERATED POWER

SUPPORT ENGINES PROPERLY

Always lower the attachment or implement

to the base before you work on an engine.

If the work requires that the engine be

lifted, provide secure system. If left in a

raised position, hydraulically supported

device can settle or leak down. Do not

support engines on any kind of props that may crumble.

Do not work under an engine that is solely supported by

a jack. Follow recommended procedures in this manual.

SAFE ILLUMINATED WORK AREA

Illuminate your work area adequately and safely. Use a

portable safety light for working inside the engine room.

Make sure the bulb is enclosed by a wire cage. The hot

lament of an accidentally broken bulb can ignite spilled

fuel or oil.

Genset will deliver a sizeable amount of electrical power

which can be lethal if not handled properly. Thus, any

service, connection or repair on the alternator can only

done by a certied marine electrician.

GUARDS REQUIREMENTS

Rotating cooling system fans, belts,

pulleys, and drives can cause serious

injury. Keep all guards in place at all times

during the engine operation. Wear close-

tting clothes. Stop the engine and be sure that fans,

belts, pulleys, and drives are stopped before making

adjustments, connections, or cleaning near fans and

their drive components.

13

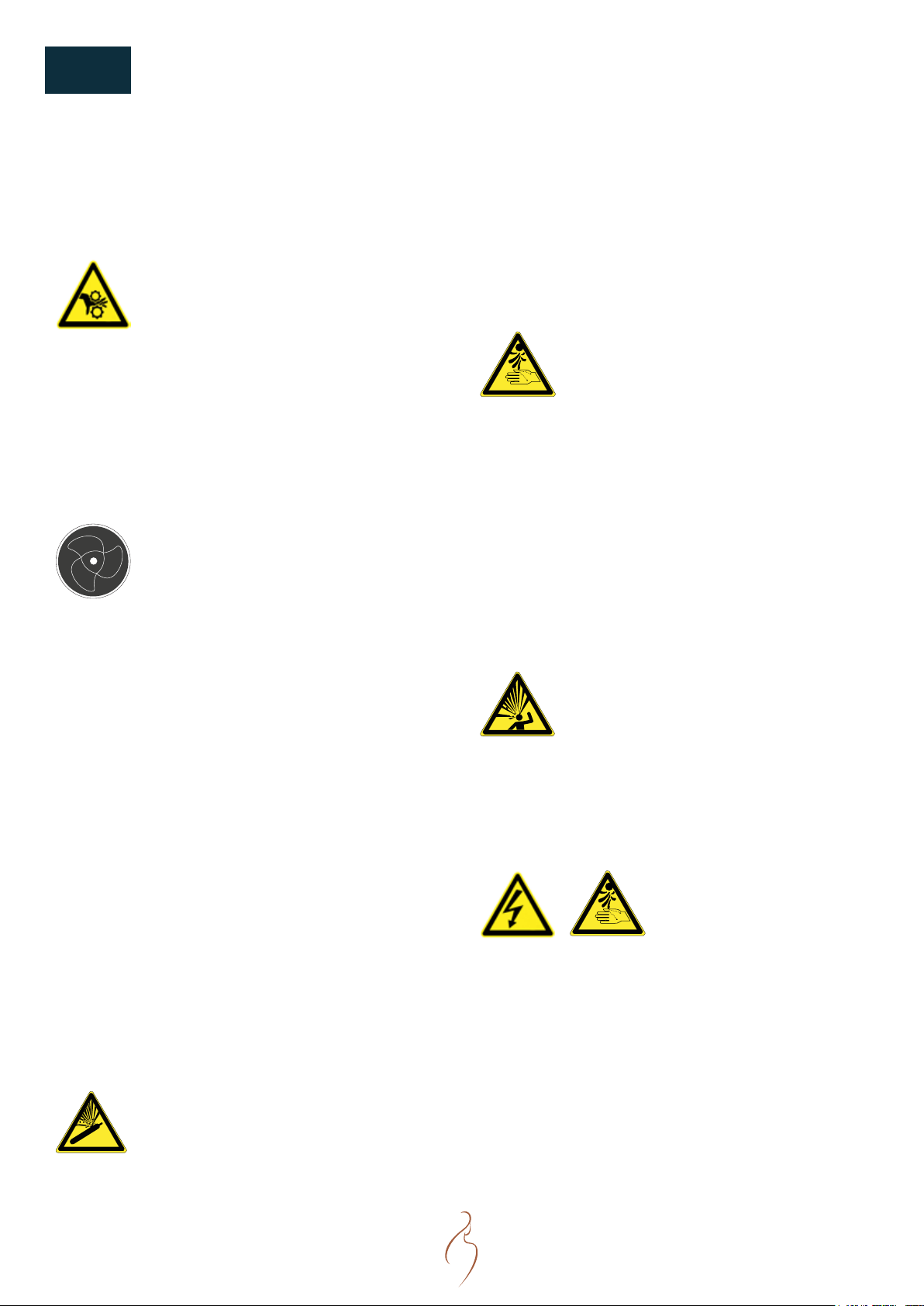

S02 SAFETY

STAYING CLEAR OF ROTATING

DRIVELINES

Entanglement in rotating driveline can

cause serious injury or death. Keep all

shields in place at all times. Make sure

rotating shields turn freely.

Wear close-tting clothing. Stop the engine and be sure

that all rotating parts and drivelines are stopped before

making adjustments, connections, or performing any

type of service on engine or driven equipment.

PAINT REMOVAL BEFORE HEATING

Avoid potentially toxic fumes and dust.

Hazardous fumes can be generated when

paint is heated by welding, soldering, or in

using a torch.

Paint removal :

• Remove paint a minimum of 100 mm (4 in.) from area

to be affected by heating. If paint cannot be removed,

wear an approved respirator mask before heating or

welding.

• If you sand or grind paint, avoid breathing the dust.

Wear an approved respirator.

• If you use solvent or paint stripper, remove stripper

with soap and water before welding. Remove solvent

or paint stripper containers and other flammable

material from area.

• Allow fumes to disperse at least 15 minutes before

welding or heating.

• Do not use a chlorinated solvent in areas where

welding will take place.

• Do all work in an area that is well ventilated to carry

toxic fumes and dust away.

• Dispose of paint and solvents properly.

HIGH-PRESSURE FUEL SYSTEM OPENING

RISK

High-pressure fluid remaining in fuel lines

can cause serious injury. Do not

disconnect or attempt repair of fuel lines,

sensors, or any other components

between the high-pressure fuel pump and

nozzles on engines with High Pressure

Common Rail (HPCR) fuel system. Only technicians

familiar with this type of system can perform repairs.

Consult your engine representative.

AVOID HIGH-PRESSURE FLUIDS

Inspect hydraulic hoses periodically – at

least once per year – for leakage, kinking,

cuts, cracks, abrasion, blisters, corrosion,

exposed wire braid or any other signs of

wear or damage. Replace worn or damaged

hose assemblies immediately with approved

replacement parts. Escaping fluid under pressure can

penetrate the skin causing serious injury.

Avoid the hazard by relieving pressure before

disconnecting hydraulic or other lines. Tighten all

connections before applying pressure. Search for leaks

with a piece of cardboard.

SAFE COOLING SYSTEM SERVICE

Explosive release of fluids from pressurized

cooling system can cause serious burns.

Shut off engine. Only remove ller cap

when cool enough to touch with bare

hands. Slowly loosen cap to rst stop to

relieve pressure before removing completely.

AVOID HEAT NEAR PRESSURIZED FLUID LINES

Flammable spray can be generated by heating near

pressurized fluid lines, resulting in severeburns to

yourself and bystanders. Do not heat by welding,

soldering, or using a torch near pressurized fluid lines or

other flammable materials.

Pressurized lines can accidentally burst when heat goes

beyond the immediate flame area.

Any fluid injected into the skin must be surgically

removed within a few hours or gangrene may result.

Doctors unfamiliar with this type of injury should

reference a knowledgeable medical source.

14

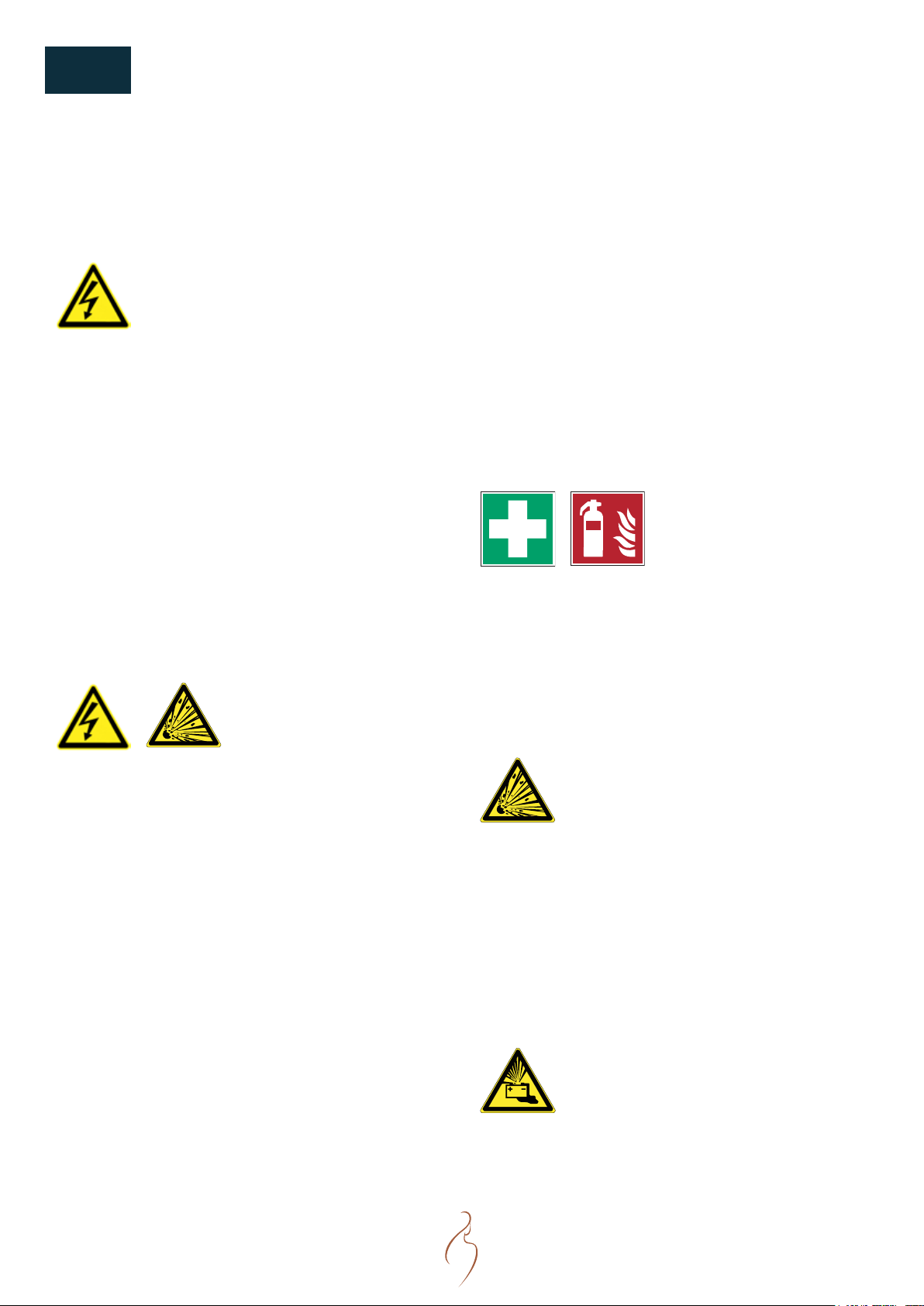

S02 SAFETY

WELDING NEAR ELECTRONIC CONTROL

UNIT (ECU)

If welding is required around the engine, or

in the engine room, ask rst for a

permission from the person in charge. Do

not jump-start engine with arc welding

equipment. Currents and voltages

delivered are too high and may cause permanent

damage. Direct welding onto the engine is forbidden.

1. Disconnect the negative (-) battery cable(s).

2. Disconnect the positive (+) battery cable(s).

3. Connect the positive and negative cables together.

Do not attach to engine support frame.

4. Clear or move any wiring harness sections away

from welding area.

5. Connect welder ground close to welding point and

away from control units.

6. After welding, reverse Steps 1-5.

STATIC ELECTRICITY RISK

HANDLE FUEL SAFELY - AVOID FIRES

Handle fuel with care: it is highly flammable. Do not

refuel the engine while smoking or when near open flame

or sparks.Always stop engine before refueling. Prevent

res by keeping engine room clean of accumulated

trash, grease, and debris. Always clean up spilled fuel.

Use only an approved fuel container for transporting

flammable liquids. Do not store fuel container where

there is an open flame, spark, or pilot light such as within

a water heater or other appliance.

BE PREPARED FOR EMERGENCIES

Be prepared if a re starts. Keep a rst aid kit and

re extinguisher handy. Keep emergency numbers

for doctors, ambulance service, hospital, and re

department near your telephone.

The removal of sulfur and other compounds in Ultra-Low

Sulfur Diesel (ULSD) fuel decreases its conductivity and

increases its ability to store a static charge. Reneries

may have treated the fuel with a static dissipating

additive.

However, there are many factors reducing the

effectiveness of the additive over time. Static charges

can build up in ULSD fuel while it is flowing through fuel

delivery systems. Static electricity discharge in presence

combustible vapors could result in a re or explosion.

Therefore, it is important to ensure that the entire system

used to refuel your engine (fuel supply tank, transfer

pump, transfer hose, nozzle, and others) is properly

grounded and bonded.

Consult your fuel or fuel system supplier to ensure

that the delivery system is in compliance with fueling

standards for proper grounding and bonding practices.

HANDLE STARTING FLUID SAFELY (ETHER)

Starting fluid is highly flammable. Keep all

sparks and flame away if using it. Keep

starting fluid away from batteries and

cables.

To prevent accidental discharge when storing the

pressurized can, keep the cap on the container, and

store in a cool, protected location. Do not incinerate or

puncture a starting fluid container. Do not use starting

fluid on an engine equipped with glow plugs or an air

intake heater.

HANDLING BATTERIES SAFELY

If not handled properly, batteries are a

potential source of hazards. Excess of

gases in batteries may explode. Keep

sparks and flames away from batteries.

Never use a cigarette lighter to observe

electrolyte level. Use a flashlight to do it. Never check

battery charge in shorting posts with a metal part. Use a

voltmeter or hydrometer.

15

S02 SAFETY

Always remove grounded (-) battery clamp rst and

replace grounded clamp last. Sulfuric acid in battery

electrolyte is poisonous and strong enough to burn skin,

eat holes in clothing, and cause blindness if splashed

into eyes.

Avoid hazards and acid burns in :

WARNING !

Battery posts, terminals, and related accessories contain

lead and lead compounds. Rinse hands after handling

batteries.

• Filling batteries in a well-ventilated area

• Wearing eye protection and rubber gloves

• Avoiding use of air pressure to clean batteries

• Avoiding breathing fumes when electrolyte is

• Avoiding spilling or dripping electrolyte

• Using correct battery booster or charger procedure.

If acid is spilled on skin or in eyes:

• Flush skin with water

• Apply baking soda or lime to help neutralize the acid

• Flush eyes with water for 15-30 minutes.

• Get medical attention immediately.

If acid is swallowed:

• Do not induce vomiting

• Drink large amounts of water or milk, but do not

exceed 2 L (2 qt.)

• Get medical attention immediately.

FROST PROTECTION-WINTERIZATION

See Maintenance Section 08 - Raw Water System - Risk

of icing conditions / Protection against frost.

WARNING !

When the engine has been set for winterization, place

“DO NOT OPERATE” labels onto taps, valves, parts of

equipment which have been turned off. Place a large and

visible reminder on the wheelhouse dashboard.

LIVE WITH SAFETY

Before returning engine to customer, make sure engine

is functioning properly, especially the safety systems.

Make sure that all guards and shields are in place.

PREVENT ACCIDENTS

IMPORTANT !

PREVENT BATTERY EXPLOSIONS

Keep sparks, lighted matches, and open

flame away from the top of battery. Battery

gas can explode. Never check battery

charge by placing a metal object across

the posts. Use a volt-meter or hydrometer.

Do not charge a frozen battery: it may

explode. Warm up battery to 16°C (60°F) before doing it.

When engine is OFF, always set the transmission lever to

neutral position.

16

S03 FLUIDS

SUMMARY

Table des matières

S03 FLUIDS 17

SUMMARY 17

FUELS 18

DIESEL FUEL 18

SULPHUR CONTENT 18

WINTER DIESEL 18

WATER IN FUEL 18

MICROORGANISMS IN FUEL 18

INERT IMPURITIES IN FUEL 19

DIESEL LUBRICANTS 19

PRECAUTIONS TO UNDERTAKE 19

OILS RECOMMENDED OR AUTHORIZED 19

GENERALITIES 19

OILS VISCOSITY 20

CORRESPONDENCE BETWEEN API AND ACEA OILS 20

COOLANTS 21

COOLANT DRAIN INTERVALS 21

WATER PROPERTIES 21

WATER PROPERTIES TO MIX WITH COOLANT CONCENTRATE 21

OTHER COOLANTS 22

FREEZE PROTECTION 22

REQUIRED QUANTITY OF COOLANT VS COOLING SYSTEM CAPACITY 22

OPERATING ENGINE IN WARM TEMPERATURE CLIMATES 22

DISPOSING OF WASTE FLUIDS 23

ANNEX 24

ANNEX 1. VOLUME OF GLYCOL 24

17

S03 FLUIDS

FUELS

DANGER !

Fuels and some fluids on board ships are easily

flammable. Handle fuels with care and respect all safety

rules. Do not refuel the tank while the engine is running.

Do not smoke during the lling process or in the engine

compartment. Ventilate the engine compartment before

starting. Wear protective gloves and eye protective

glasses. Avoid synthetic clothing which can melt when

ignited. Always keep a re extinguisher nearby.

DIESEL FUEL

Diesel approved by Nanni Industries on the engines of

the rm are as follows :

• EN 590 (Europe),

• ASTM D975 (U.S.A and territorial waters assimilated,

particularly in the Caribbean and Pacic areas),

• BS 2869 Part 1 Class A1 (G.B),

• JIS KS2204 Fuel N°02 (Japan).

These regulations are in compliance with ISO 8217 DMX.

SULPHUR CONTENT

European Union :

Low-sulphur diesel (<50 mg/kg sulphur) [EN590], or

sulphur-free (<50 mg/kg sulphur [DIN EN590], [ULSD].

Non-European Union :

Sulphur contained in diesel fuel not in accordance with

EN 590 regulation signicantly reduces the performance

of the engine lubricant. More frequent oil changes

are mandatory and also induce much shorter fuel

lter replacement intervals. Request a certicate of

specications from the fuel distributor and forward it

to the nearest Nanni local representative for advice and

action.

Fuels not intended for the operation of marine engines

or with very high sulphur content can cause irreparable

damage to the engine and are not covered by any

warranty from Nanni Industries.

WINTER DIESEL

Without specic mention, these distributed fuels satisfy

the climates in which they are geographically available.

Generally speaking, summer diesel fuel complying with

EN 590 is usable down to a temperature of 0°C [32°F],

and the winter formulated fuel, down to a temperature

of -20 °C [-4°F] (type No. 01-D in U.S.A). In any case,

consult your local distributor to ensure compatibility of

the fuel.

NOTE !

Additions of petroleum distillates, petrol, solvents,

unapproved additives to improve the fluidity of diesel

fuel at very low temperatures can cause irreparable

engine damage and will void all contractual warranties

and responsabilities from Nanni Industries.

WATER IN FUEL

Water is a non-flammable and incompressible liquid.

For this reason, its presence is particularly harmful

to the operation of the engine and to the entire fuel

injection system. Water easily enters the tank by simple

condensation and especially when it is left or partially

empty. Fill up the fuel tank before storage/winter storage.

Check the water-diesel separator regularly and clean it

as required. Anticipate the replacement of the fuel lter.

If a large quantity of water is present in the tank, drain it

and flush the entire fuel and injection system with clean

diesel fuel. Water in the diesel fuel can cause irreparable

damages to the engine and are not covered by any

warranty from Nanni Industries.

MICROORGANISMS IN FUEL

The presence of water in the tank automatically leads

microorganisms and bacteria to grow and will mix with

the fuel. These microorganisms grow rapidly with a

favorable temperature. Depending on their size, they can

pass through lters and penetrate in the fuel injection

system and cause a total engine failure which is not

covered by Nanni Industries warranty. In the event of

fuel contamination, contact the nearest Nanni agent

who may, if necessary, use an approved disinfectant.

18

S03 FLUIDS

INERT IMPURITIES IN FUEL

Others impurities than microorganisms and bacteria do

exist : they are rust debris falling out from the internal

walls of the metal tanks. Some types of berglass tanks

are also subject to osmosis over time and tiny particles

may come off internal walls and circulate in the diesel

fuel. These impurities can pass through the lters and

creep into the injection system and cause a total failure

of the engine which is not covered by Nanni Industries

warranty.

DIESEL LUBRICANTS

PRECAUTIONS TO UNDERTAKE

Engine oils must be handled with care, both for reasons

of safety and the risk of pollution for the environment.

Due to their inertia, hot oils retain a higher temperature

than expected. A hot oil can cause severe burns on

the skin and leave after effects. This phenomenon is

emphasized when draining used oil. Wear protective

gloves and eye protective glasses. Avoid synthetic

clothing.

To avoid introducion of impurities into the engine

during lling or topping up, be sure to thoroughly clean

the ller inlet hole rst and use a container free of any

contamination.

OILS RECOMMENDED OR AUTHORIZED

It is necessary to differentiate the breaking-in oils

from the lubricating oils after running-in. All engine

manufacturers do not have the same recommendations.

User manuals provide information about proper oils

to use for running-in (if recommended) and at which

running hours and of time lapse of run.

GENERALITIES

The oil used in the engine must have a viscosity in

accordance with the ambient temperatures at which

the engine is operated, according to API (American

Petroleum Institute) and SAE (Society of Automotive

Engineers) classications.

Following the entry into force of strict antipollution

regulations, engine oils have been developed for use

with low sulphur fuels (LSD or ULSD). The oils classied

“CF” being now obsolete, use oils “CJ-4, CI-4, CH-4”.

The oils “CH-4” do come in replacement of the “CD, CJ,

CF-4 and CG- 4“. In all cases, the use of high sulphur

fuel signicantly reduces the span between oil changes

whichever oil is used.

19

S03 FLUIDS

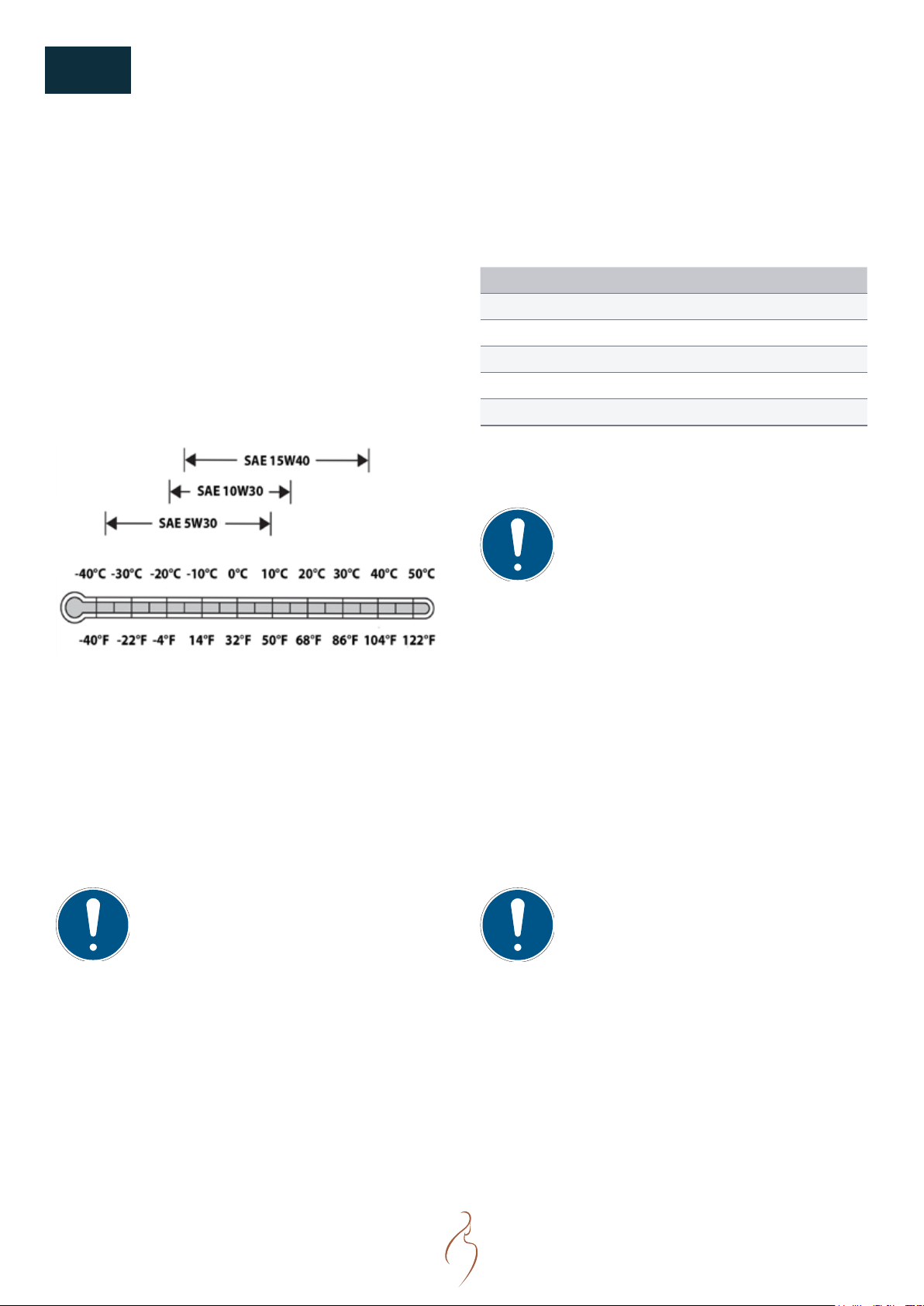

OILS VISCOSITY

Viscosity is a characteristic of oil flow or fluidity, dened

by two numbers: cold and hot. Example :

15W-40: cold viscosity index followed by the letter W

signifying winter. A low value indicates good fluidity at

low temperatures.

15W-40: hot viscosity index (100 °C - summer). A high

value indicates a better lubrication at hot temperatures.

CORRESPONDENCE BETWEEN API AND

ACEA OILS

API ACEA - JAMA

CG-4 ACEA E1

CF-4 ACEA E2 ; ACEA E3

CH-4 ACEA E5 ; JAMA DH 5

CI-4 ACEA E7

CJ-4 ACEA E9 ; JAMA DH 2

DIESEL SULPHUR CONTENT

NOTE

Diesel sulfur content affects engine oil and lter service

intervals.

Normative instances :

• Society of Automotive Engineers (SAE),

• American Petroleum Institute (API),

• Association des Constructeurs Européens

d’Automobiles (ACEA),

• Japanese Automobile Manufacturer Association

(JAMA).

IMPORTANT !

On manufacturers side, oils are subject to constant

improvements, particularly concerning the additives

allowing a better resistance towards oxydation and

fuel economy. Refer to the expertise of the local Nanni

Industries representative regarding the oil that best

suits your engine.

Use of diesel fuel with sulfur content less than 2000 mg/

kg (2000 ppm) is RECOMMENDED.

Use of diesel fuel with sulfur content of 2000-5000 mg/

kg (2000-5000 ppm) REDUCES by 50% the oil and lter

change interval.

Do not use diesel fuel with sulfur content greater than

5000 mg/kg (5000 ppm).

IMPORTANT !

To avoid engine damage:

• Reduce oil and lter service intervals by 50% when

using BioDiesel blends greater than B20. Oil analysis

may allow longer service intervals.

• Use only approved oil types.

20

S03 FLUIDS

COOLANTS

WARNING !

Products not fullling the demands in this section may

lead to faults and damage occurring in the cooling

system. This can lead to the invalidation of Nanni’s

warranty for faults and damage caused by the use of

inappropriate coolant.

COOLANT DRAIN INTERVALS

Drain and flush the cooling system of the engine and

rell with fresh coolant at the indicated intervals, which

depends of the coolant used and of the maintenance

schedule service of the engine.

WATER PROPERTIES

Water properties are important to the efciency of the

cooling system. Distilled, deionized, or demineralized

water is recommended for mixing with ethylene glycol

or propylene glycol base engine coolant concentrate.

WATER PROPERTIES TO MIX WITH

COOLANT CONCENTRATE

Engine coolants are a combination of three chemical

components: ethylene glycol (EG) or propylene glycol

(PG) antifreeze, inhibiting coolant additives, and

adequate “quality” water.

Do not use bottled drinking water as it often contains

higher concentrations of dissolved solids.

Water used in the cooling system should meet the

following minimum specications for quality :

Chlorides < 40 mg / L

Sulfates < 100 mg / L

Total dissolved solids < 340 mg / L

Total hardness < 170 mg / L

pH 5,5-9,0

When mixing coolant concentrate with water, do not

use less than 40 % or greater than 60 % concentration

of coolant. Less than 40 % is inadequate for corrosion

protection. Greater than 60 % can result in coolant

gelation (solidication by cooling) and cooling system

problems. As a general rule, a mixing of 50/50% is

preferred whenever possible.

IMPORTANT !

• Do not use cooling system sealing additives, neither

antifreeze containing sealing additives.

• Do not mix ethylene glycol and propylene glycol base

coolants together.

• Do not mix coolants of various brands and makes

together.

• Do not use coolants containing nitrites.

21

S03 FLUIDS

OTHER COOLANTS

Other ethylene glycol or propylene glycol base coolants

may be used if they meet the following specication :

• Pre-mix coolant meeting ASTM D6210 requirements.

• Coolant concentrate meeting ASTM D6210

requirements in a 40-60 % mixture of concentrate

with appropriate water.

If coolant meeting one of these specications is

unavailable, use a coolant concentrate or pre-mix

coolant that has a minimum of the following chemical

and physical properties :

• Provides cylinder liner cavitation protection

according to a proven and recorded method or a fleet

study run at or above 60 % load capacity.

• Is formulated with a nitrite-free additive package.

• Protects the cooling system metals (cast iron,

aluminum alloys, and copper alloys such as brass)

from corrosion.

FREEZE PROTECTION

The relative concentrations of glycol and water in the

engine coolant determine the freezing protection limit.

REQUIRED QUANTITY OF COOLANT VS

COOLING SYSTEM CAPACITY

See ANNEX 1: VOLUME OF GLYCOL

OPERATING ENGINE IN WARM

TEMPERATURE CLIMATES

Nanni engines are designed to operate with

recommended engine coolants quoted in this chapter.

Always use a recommended engine coolant, even when

operating in geographical areas where freeze protection

is not required (internal engine corrosion protection).

IMPORTANT !

Tap clean water may be used as coolant substitute in

emergency situations only. Contact a Nanni represent-

ative as soon as it is possible for assistance. Get this

water flushed as soon as possible.

Running the engine with water only will make this substitute coolant to foam, aluminum and iron parts of the

engine will be subject to fast internal corrosion, along

with scaling, and cavitation occurances, even with cool-

ant conditioners.

IMPORTANT !

DO NOT use a coolant-water mixture greater than 60%

ethylene glycol or 60% propylene glycol. Refer to the

table below :

Ethylene Glycol Freeze protection limit

40% -24°C (-12°F)

50% -37°C (-34°F)

60% -52°C (-62°F)

Propylene Glycol Freeze protection limit

40% -24°C (-12°F)

50% -37°C (-34°F)

60% -52°C (-62°F)

When cooling system has been drained from the engine,

rell with recommended coolant as soon as possible.

22

S03 FLUIDS

DISPOSING OF WASTE FLUIDS

Prior to contemplate any draining, make sure that all

adequate gear such as : funnel(s), hose(s), suitable

container(s) and so on, are at hand.

Use leakproof containers when draining fluids. Do not

use food or beverage containers that may mislead

someone into drinking from them.

Wear gloves and eye protection glasses. Follow all safety

rules. Wait for engine to cool down.

Do not let waste to drip on the ground, down a city drain,

or into any water source. Improperly disposing of engine

coolants, oils, or other chemical fluids is a threat against

environment and is an offence in many countries.

Inquire on the proper way to recycle

or dispose of waste from your local

environmental or recycling center, or

from your Nanni engine representative or

service dealer.

23

S03 FLUIDS

ANNEX

ANNEX 1. VOLUME OF GLYCOL

% by volume of

Glycol

Ice slush starts

to form at °C

Ice slush starts

to form at °F

Ethylene glycol

3

dm

(litre)

30 35 40 45 50

Cooling

-16 -21 -24 -30 -37

3.2 -5.8 -11.2 -22 -34.6

9 11 12 14 15 30

12 14 16 18 20 40

15 18 20 23 25 50

18 21 24 27 30 60

21 25 28 32 35 70

24 28 32 36 40 80

27 32 36 41 45 90

30 35 40 45 50 100

33 39 44 50 55 110

36 42 48 54 60 120

39 46 52 59 65 130

system

capacity

in dm

3

42 49 56 63 70 140

45 53 60 68 75 150

48 56 64 72 80 160

51 60 68 77 85 170

54 63 72 81 90 180

57 67 76 86 95 190

60 70 80 90 100 200

Volume of glycol below 30% to be avoided.

24

Loading...

Loading...