Nanni N4.47MD, N4.43HD, N4.40, N4.50 User Manual [de]

Nanni marine engine

Operator’s manual

Engines

N4.40

N4.43HD

N4.47MD

N4.50

English

You can download a copy of this manual in English on nannidiesel.com.

Français

Vous pouvez télécharger ce manuel en Français sur notre site Web à

l’adresse www.nannidiesel.com.

Italiano

Scarica una copia del manuale in lingua Italiano sul nannidiesel.com.

Deutsch

Sie können eine Kopie dieses Handbuchs in Deutsch Sprache auf nannidiesel.com.

CONTENTS

1

Introduction ............................. 1

About this manual .........................2

Safety ........................................ 3

Emergency kit ..............................3

Safety alert symbols .....................3

Safety icons ..................................4

Safety precautions .......................5

Overview .................................. 9

About the engine ..........................9

About the propeller .....................14

Behaviour of the boat .................14

Engine main components ..........15

Instruments panel ................. 19

Standard panel ...........................19

Instrumentation ..........................20

Operation ............................... 25

Before starting ............................25

Starting the engine .....................26

During operation ........................28

Stopping the engine ...................30

Maintenance .......................... 32

Service schedule .........................33

General inspection ......................35

Fuel system ................................37

Lubrication system .....................41

Cooling system ..........................43

Raw water system ......................47

Electrical system ........................51

Battery ........................................52

Corrosion protection ...................54

Long term storage ......................57

Troubleshooting .................... 59

Technical data ....................... 61

Thank you for choosing a Nanni product!

Contact a Nanni authorized dealer for the servicing of your product. A list of

dealers can be found on our web site:

www.nannidiesel.com

Nanni engines are the product of many years of experience in the development of marine engines and equipment designed for use in open seas.

Your engine is built with the finest materials in accordance with precise

specifications and strict production methods.

Before operating the engine , make sure that this manual is applicable to the

engine. Refer to the Identification plate if you are not sure about the engine

model designation. If you don’t have the correct manual, please contact

your Nanni authorized Dealer.

Correct installation of the engine on your boat is of the greatest importance

for safe navigation and protection of the environment. The installation

should be carried out by an authorized Nanni workshop in accordance with

the installation instructions.

1

INTRODUCTION

2

About this manual

This Operator’s Manual contains

important information, tips, suggestions and warnings. We urge you

to read it carefully and familiarize

yourself with the engine before

starting.

For your own safety and longer

service life of the engine, follow

the instructions and warnings

contained in this manual and in all

documentation provided with the

boat. Ignoring them could result in

damage to the engine or personal

injury to you or others.

Please ensure that this Manual is

always kept in the boat. It should

always be available to anyone

else using the engine, i.e. anyone

renting, borrowing or buying the

engine from you. Throughout the

document, the following symbols

are used to ease the reading:

Indicates that the text is continued on the following page.

Indicates the end of a section.

Content and updates

All the informations and specifications in this Manual are based on

the technical data applicable at the

time of its publication. Changes and

updates may be made by Nanni

without notice.

Illustrations are intended as a

general guide, and may vary from

the equipment fitted in the engine in

some details. Some sections of the

Manual do not apply to all engines.

If this is the case, a text indicates

which engines it applies to.

If there are any equipment details

that are not shown or described

in this Operator’s Manual, or if

you have any questions about the

operation of any equipment, your

authorized Nanni Dealer will be

glad to inform you of correct care

and operating procedures.

2

Read this chapter carefully as it

concerns your safety. Most accidents are caused by failing to follow

basic safety rules. Be aware of the

possible risks involved in handling

the engine and make sure to take

the necessary precautions to protect yourself, those around you and

the equipment.

Read all informations supplied with

the boat before starting the engine

for the first time.

Always ensure that the maintenance of the boat and all equipment has been done in accordance

with the instructions stated in the

relevant Manual. Have all mandatory and necessary safety equipment

handy in the boat and serviceable.

Emergency kit

You can order an emergency kit

from any Nanni authorized dealer.

The engine emergency kit contains

several components to carry out

simple repair in the event of a fault.

Always have an complete emergency kit onboard and necessary

tools to carry out any repairs.

Safety alert

symbols

General rules of safety precautions

to follow are indicated in this Manual. They are indicated as follows:

I DANGER

Indicates a hazardous situation

which, if not avoided, will result

in death or serious injury.

I WARNING

Indicates a hazardous situation

which, if not avoided, could result in death or serious injury.

I CAUTION

Indicates a hazardous situation

which, if not avoided, could result in minor or moderate injury,

or could cause property damage.

NOTICE: Indicates important information in order to facilitate handling

or avoid property damage.

3

SAFETY

3

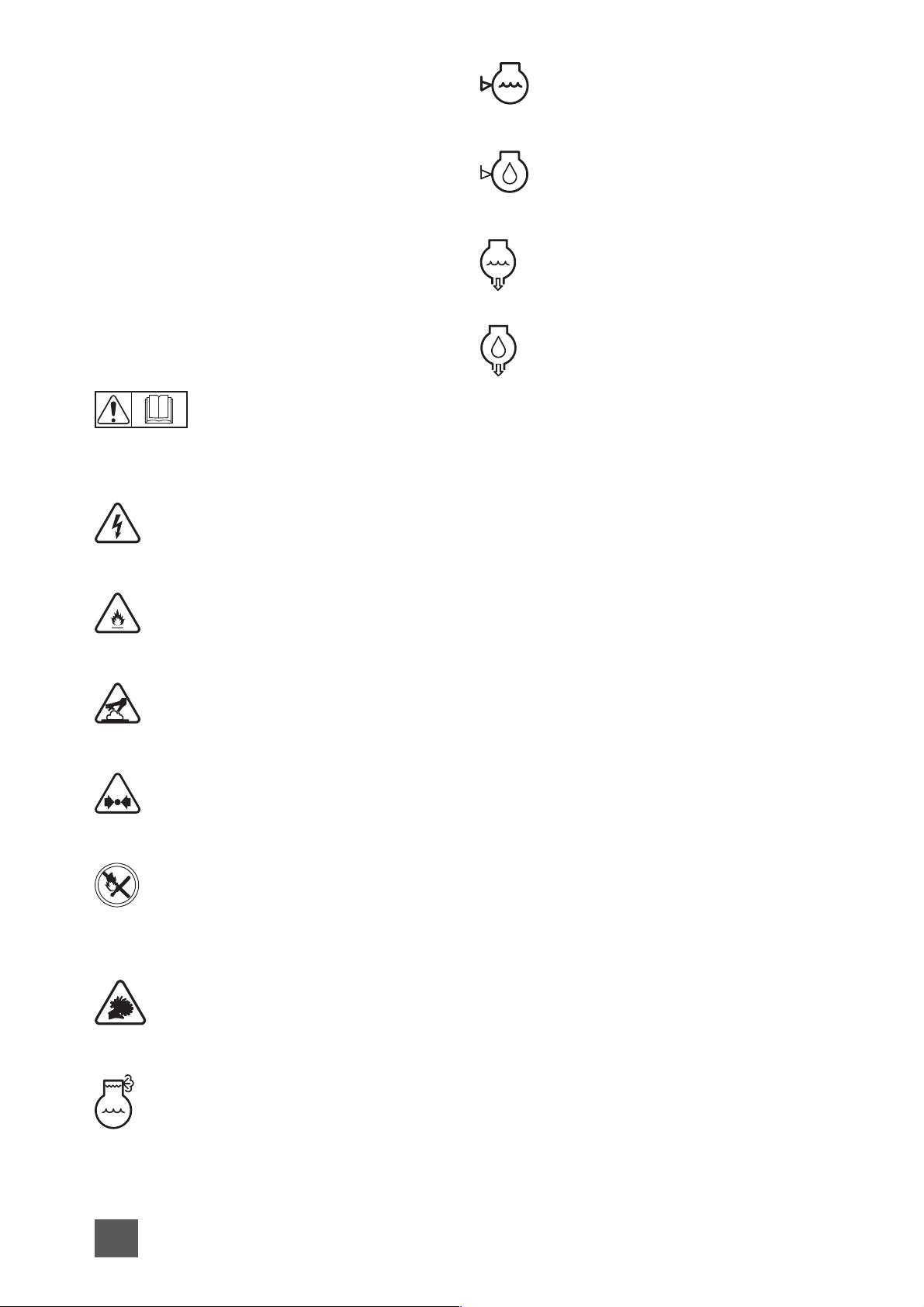

Safety icons

Several stickers are fixed directly

on the engine. They are intended

to help you to quickly identify the

location of certain components

and avoid possible hazards when

working on the engine.

Ensure these stickers are always

visible and change them if necessary.

Refers to important informations and instructions to follow

before handling the engine.

Indicates possible electrical

hazards.

This icon indicates a risk of

fire.

Indicates hot parts entailing

substantial risks of burns.

Indicates an area containing

pressurised fluids.

Stipulates that no flames or

sparks should be created in the

vicinity.

Indicates hazardous rotating

parts.

Indicates the de-aeration

orifice(s) (air bleed).

Indicates where to check the

coolant level.

Indicates where to check the

engine oil level.

Indicates the coolant drain

orifice.

Indicates the oil drain orifice.

4

Safety

precautions

Exhaust gas

Exhaust gases contain carbon

monoxide. This colourless and

odourless gas is extremely harmful and could lead to poisoning

which could result in loss of

consciousness or death. The first

symptoms of carbon monoxide

intoxication are as follows:

• Dizziness

• Nausea

• Headache

• Throbbing temples

• Vomiting

• Fatigue and falling asleep

• Tense muscles

If you or anyone else in the vicinity

of the engine experiences any of

these symptoms, leave the area

of operation of the engine and find

fresh air. If the symptoms persist,

consult a doctor and have the engine checked.

Ensure the exhaust circuit correctly

expels the gas produced by the

engine. Regularly check that the

exhaust circuit is free of leaks and

that the exhaust elbow is in good

condition.

Burns

Never touch the hot parts of the

engine! An operational engine gets

very hot: the exhaust system, turbocompressor (if equipped), starter,

oil sump, oil, coolant in the hoses

and pipes are hot and can burn.

Fluids ejected under pressure can

cause serious injury. Release all

the pressure in the circuits before

removing the caps. Never open the

oil circuit and coolant caps when

the engine is operational and/or

hot. Never start or run the engine

when the oil fill and coolant caps

are not screwed on as hot oil or

coolant could spray out.

If you come into contact with any

of these fluids, consult a doctor

immediately. If the engine gets too

hot, switch it off and disconnect it

and wait for it to cool down before

checking for failure.

Fire

Do not smoke near the engine and

keep it away from sources of ignition (flames or sparks) or any other

potential flammable vapour or liquid

sources. Do not run the engine

without the air filter.

Do not run the engine in an area

in which flammable or explosive

materials are stored or where gas

is present. Ensure there are no

flammable liquids in the engine

compartment.

5

Immediately clean up any liquids

spilled and keep the engine compartment clean and accessible so

as to minimise the risk of fire. Be

careful as fuel can burn. Damaged

pipes can lead to fire.

Explosion

Explosions caused by fuel vapour

can cause serious injury! Carefully

follow the safety rules when filling

the fuel.

Open and ventilate the storage

area of the engine after filling.

Check that there are no fuel vapours or leaks before starting the

fan (if fitted). Switch the fan on for 5

minutes before starting the engine.

All fuel vapours are flammable

and explosive. Be careful when

handling and storing fuel. Store

the fuel in a ventilated area away

from sources of ignition (sparks

or flames) and out of the reach of

children.

Stop the engine before filling with

fuel or lubricant. Do not smoke near

the engine and keep it away from

sources of ignition (flames) when

filling with fuel and/or lubricant.

Wear gloves when investigating

possible leaks.

Do not alter or damage the fuel circuit. Close the fuel circuit whenever

you work on it. Ensure you always

have an appropriate working fire

extinguisher to hand.

Hazardous Voltage/

Electrical Shock

Electrocution is possible whenever

electricity is present. Hazardous

voltage can cause severe injury

or death. Operate the engine only

when all guards and electrical enclosures are in place.

Open the main circuit breakers

of all power sources before servicing the equipment. Configure the

installation to electrically ground the

engine, transfer switch, and related

equipment and electrical circuits to

comply with applicable codes and

standards.

Never contact electrical leads or

appliances when standing in water

or on wet ground because these

conditions increase the risk of

electrocution. The voltage at these

terminals can cause death.

Short circuits can cause bodily

injury and/or equipment damage

Remove all jewellery before servicing the equipment.

Hazardous backfeed voltage can

cause severe injury or death.

Connect the engine to the building/marina electrical system only

through an approved device. Work

on the electrical circuit should only

be carried out by qualified technicians.

Operations on the shore power

equipment must only be carried out

by electricians authorized to work

with high voltage installations.

6

Special attention must be brought

on boat with metallic hull, especially

concerning the protection of the

persons against electrical shock

and the protection against galvanic

and electrolytic corrosion.

Battery acid

The acid in batteries can cause

serious injury and even death!

When servicing the batteries, wear

protective gloves and goggles. Batteries contain sulphuric acid which

is highly corrosive.

Acid can spurt from batteries when

they are handled. If the acid comes

into contact with the skin, rinse thoroughly in fresh water and consult

a doctor.

Risk of battery explosion

A battery explosion can cause

serious injury and even death! Ensure the battery storage compartment is corrected ventilated.

Do not smoke near the batteries

and keep them away from sources

of ignition (flames or sparks). They

produce hydrogen which could

ignite or explode on contact with an

electrical arc or a flame.

Switch off all electrical appliances

in the vicinity when you are working

on the batteries.

Ventilate correctly storage batteries

compartment. Avoid touching the

battery terminals with metal tools

so that no sparks are created which

could cause an explosion. Remove

the rings, bracelets and necklaces

before handing the batteries.

Rotating parts

Rotating parts can be extremely

dangerous and cause serious injury

and even death!

Do not work on the engine when

it is operational. If work on the

engine when running is absolutely

necessary, do not touch any hot or

rotating parts.

Baggy clothing, hair or objects

could be pulled in and/or caught

and cause serious injury or substantial property damage.

Do not wear bracelets, necklaces

or rings when working on a engine.

Check that the bolts and screws

are properly tightened and that

the protection mechanisms are in

place. Do not check the tension of

the alternator belt when the engine

is operational.

7

Accidental starting

Accidental starting can cause serious injury and even death!

Disconnect the battery before working on the engine. Ensure no one

is alongside the engine or working

on before starting it. A rotating

propeller can cause serious injury

or death. Ensure all the protection

mechanisms are in place before

starting the engine.

Chemical products

The different fluids used to run the

engine are a health hazard. Carefully read the instructions on the

packaging of these products and

always check that the ventilation in

the hold space is adequate.

Follow environmental regulations

concerning the disposal of oil, fuel,

coolant, filters and batteries. Do

not put your hands over pipes when

looking for possible leaks.

Water ingress

The engine should be protected

against from water ingress by any

means. Water ingress leads to

complete engine failure. This is not

cover under any warranty terms.

Water can enter the engine after

filling the exhaust system.

Correct installation of the engine on

your boat is of the greatest importance for safe navigation and pro-

tection of the environment. The first

protection against water ingress is

a correct installation of the engine.

A correct use of the engine is also

important to protect the engine

against water ingress. The operator/owner is responsible for the

correct operation of the engine and

for the implementation of all necessary means to protect the engine

against water intrusion.

After a vessel capsizing, or if the

engine has been filled with water,

do not start the engine, except in

extreme emergencies, and contact

an authorized Nanni dealer.

8

About the engine

Engine identification

Both the engine and the transmission has an identification plate that

contain several informations.

Keep these plates accessible and

in good condition. Record and keep

the engine and transmission serial

number and designation. These

numbers should always be quoted

when ordering service and replacement parts.

The engine identification plate is as

follow:

• TYP indicates the commercial

designation of the engine.

• NR indicates the engine serial

number.

• CODE lists various specifications

of the engine.

Break in

Operate the engine with care for

the first 50 hours of operation.

Do not race the engine while it is

cold. Do not operate it at full load

except for short periods. Never

run the engine at constant engine

speed for long periods during the

break in period.

Check the oil and coolant level

frequently during the running-in

period. The oil consumption can be

more important during the runningin period.

Engine installation

The installation must be carried out

by an authorized Nanni workshop

in accordance with the installation

instructions. Correct installation

of the engine is of the greatest

importance for safe navigation and

protection of the environment.

It also ensure maximum service life

under normal conditions of use.

Engine damage caused by failure

to follow installation instructions is

not covered by the warranty.

9

OVERVIEW

4

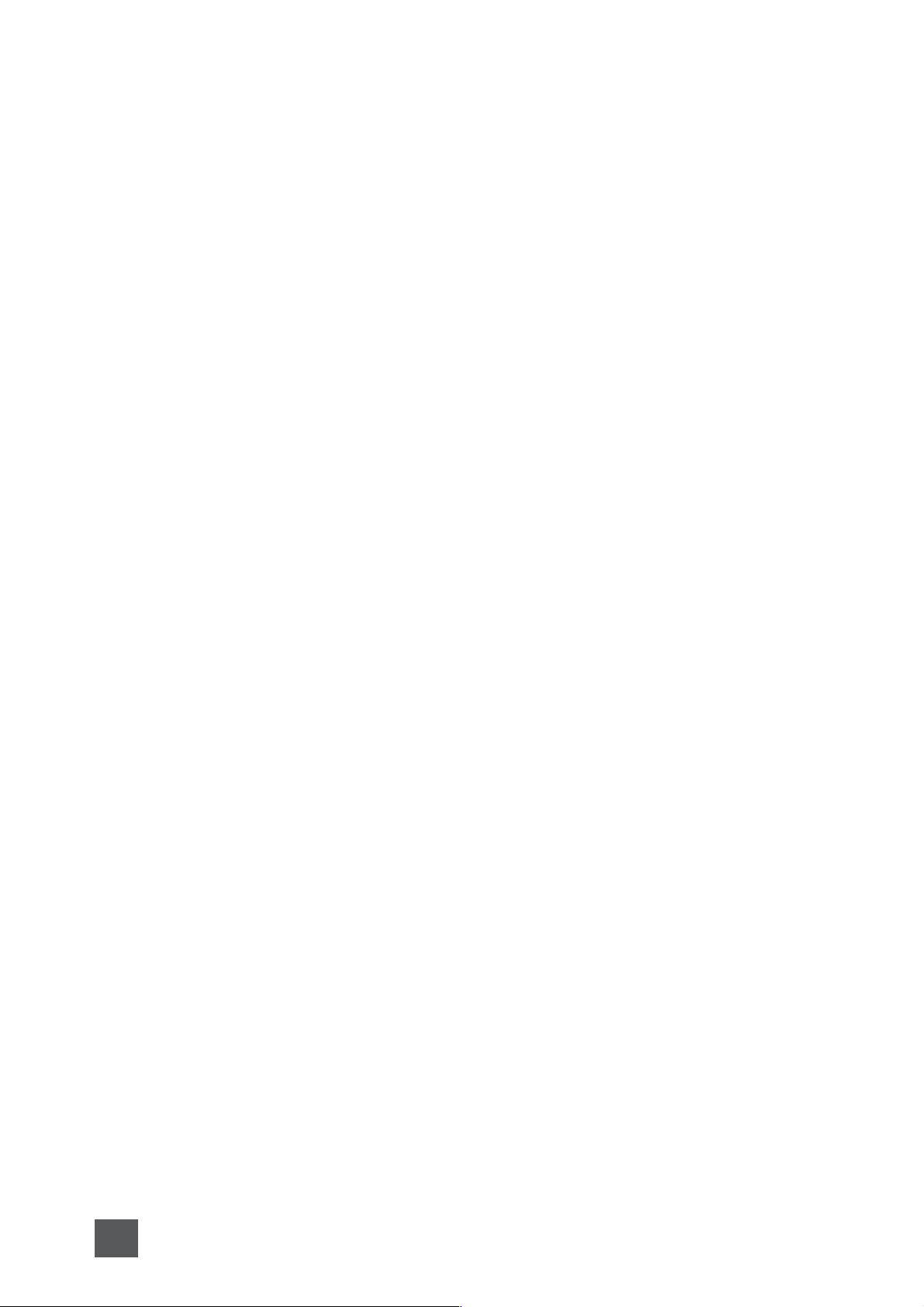

Remote Control

The remote control is an optional

extra not in the scope of supply

of the engine. The remote control

installed on the boat can be different than the ones shown in this

document.

On most boats, the control lever

controls both the engine rpm and

the gear shift (ahead / astern).

However, some boats can be

equipped with a separated shift

command.

It can also be fitted with a neutral

safety switch that prevents the

engine from starting until the lever

is in neutral position.

Consult the boat builder or your

Nanni dealer if you are not sure

about the operation of the remote

control.

Power Take Off

Some engines can be fit with a

Power Take Off system. This system allows to power accessories

like bilge pump, watermaker, etc.

NOTICE: Any mechanical power

taken from the engine from a PTO

reduces the power delivered to the

propeller. The use of a PTO should

always be studied and approved

by the R&D department of Nanni

Industries S.A.S France. Contact

your Nanni dealer for more informations.

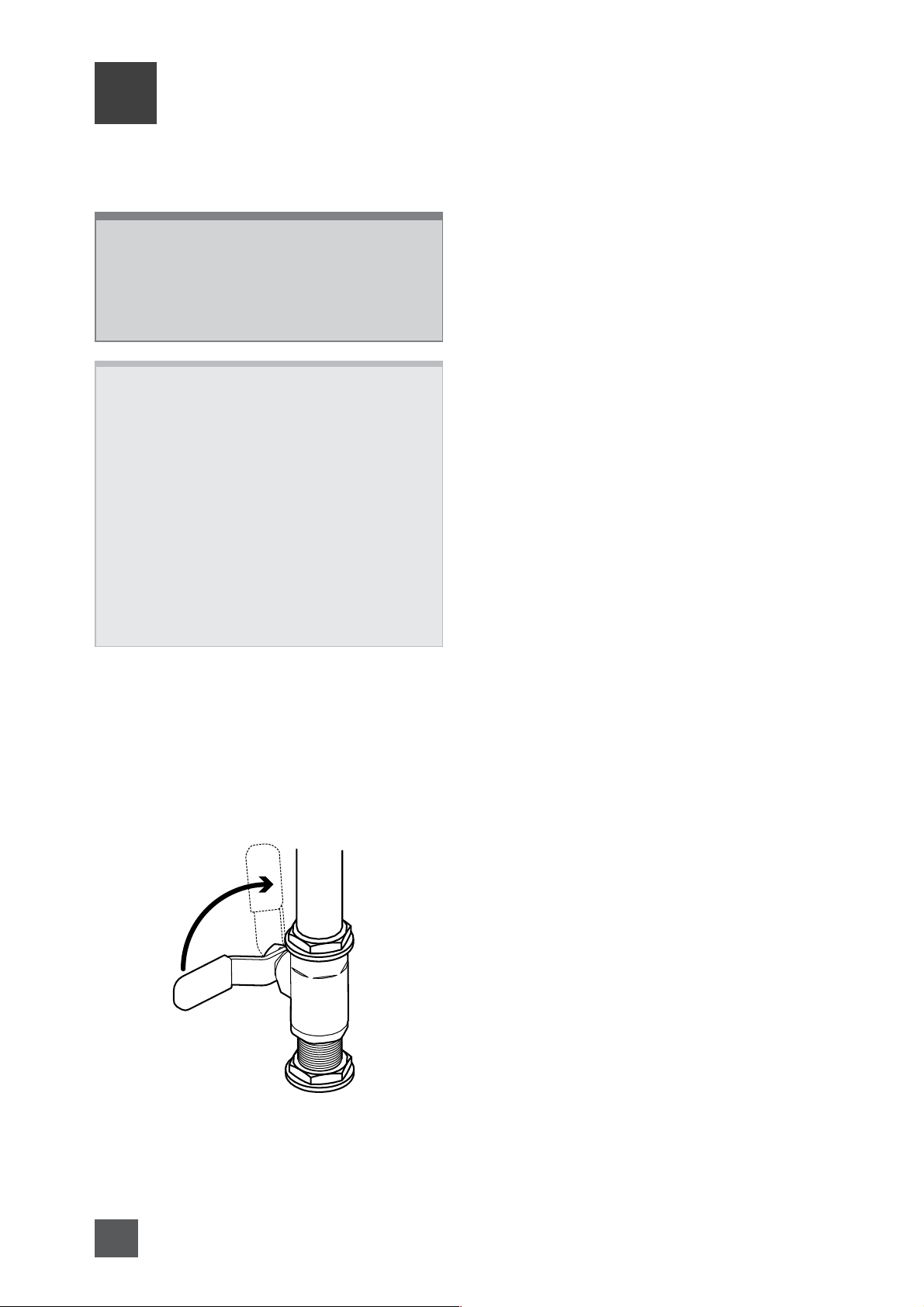

Trolling valve

The Trolling valve system allows

to reduce the rotation speed of the

propeller below its speed when the

engine is at idle. The boat speed is

reduced by 30% to 70%.

I CAUTION

The Trolling valve system must

never be used for manoeuvring.

It also must never be used at an

engine speed of more than 1200

rpm.

10

Operation in cold

weather conditions

Nanni engines are designed to operate effectively in cold weather.

However, for effective starting

and cold weather operation, extra

care are necessary. Contact your

Nanni dealer for additional information and local availability of cold

weather aids.

WINTER GRADE FUEL

Winter grade fuel allows to protect

the injection system when temperatures fall below 5°C (40°F). Winter

grade fuel is best suited for cold

weather operation thanks to its

lower cloud and lower pour points.

However, using winter grade fuel

may reduce power and fuel efficiency as winter grade fuel has a lower

BTU (heat content) rating. Check

the grade of fuel being used before

troubleshooting for low power complaints in cold weather operation.

In all cases, fuel quality and fuel

sulfur content must comply with all

existing emissions regulation for the

area in which the engine operates.

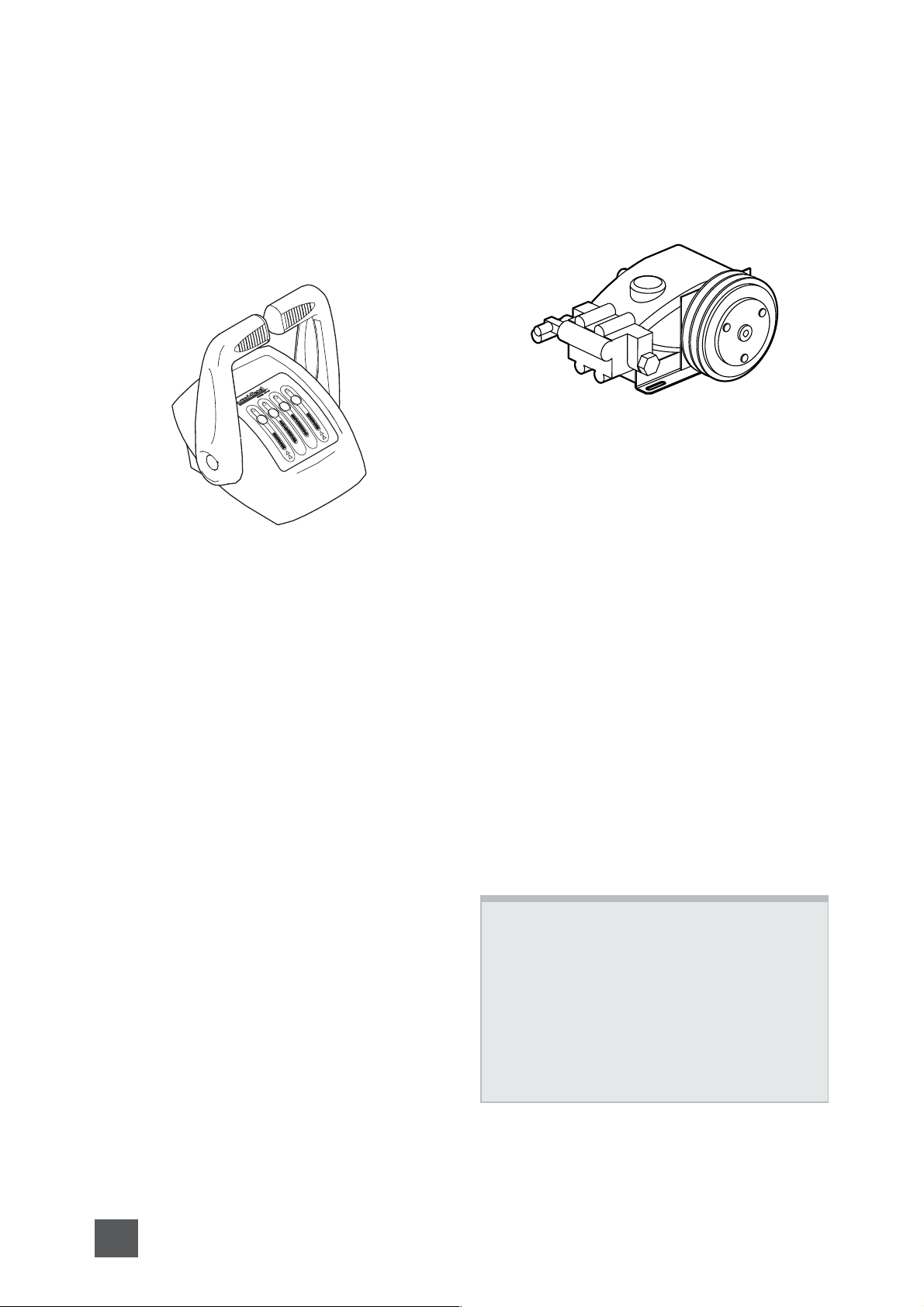

Oil viscosity

Use seasonal grade viscosity

engine oil based on the expected

air temperature range between oil

changes.

Follow the diagram below to adapt

the oil viscosity:

50 C

SAE 5W-30

SAE 10W-30

SAE 15W-40

SAE 15W-40

o

40 C

o

30 C

o

20 C

o

10 C

o

0 C

o

-10 C

o

-20 C

o

-30 C

o

-40 C

o

122 F

o

50 F

o

32 F

o

14 F

o

-4 F

o

-22 F

o

-40 F

o

104 F

o

68 F

o

86 F

o

As an option, some engines are

available with an air intake heater to aid cold weather starting.

Contact your Nanni dealer for more

informations.

11

Engine homologation

The engine type can be exhaust

emission certified. It means that

Nanni guarantees that all engines

of the same type that are manufactured are approved and certified by

the authorities in accordance with

different exhaust emissions standards.

However, for the engine to be in accordance with this standards, special requirements for maintenance

and service are to be followed:

• Only Nanni replacement parts

must be used.

• Maintenance intervals must be

observed.

• The engine must not be modified

in any way except with accessories and service kits approved by

Nanni Industries S.A.S. France.

• Service of the fuel system must

always be carried out by an authorized Nanni workshop.

• No modifications to the air intake

and exhaust system may be

undertaken.

• Seals may only be broken by

authorized personnel.

• The operation instructions stated

in the relevant manuals should

be follow by the user.

Nanni’s responsibility for the engine

specification being in accordance

with the certification will be invalidate if one or several of this conditions are not followed.

Environmental

responsibility

Nanni designs its engines to have

minimum environmental impact.

This objective, however, can only

be achieved with your full cooperation.

Our operating and maintenance

instructions are to help you to protect your engine and adopt environmentally responsible behaviour.

Ensure you only use the fuels and

oils recommended. Using another type of fuel or oil could cause

major malfunctions, an higher fuel

consumption, a reduced engine

service life, and a greater discharge

of exhaust gases.

When draining the oil and changing

the oil or fuel filter, dispose of the

waste in an appropriate container.

These fluids cause major damage

to flora and fauna if discharged into

nature. Use an absorption kit in the

event of accidental discharge of oil

or fuel into the water.

12

Warranty

This manual is supplemented by

a Warranty Information Booklet.

We recommend that you read this

publication thoroughly.

Pay special attention to the applicable duty cycle and to the limitations that result. Failure to comply

with the warranty conditions will

void the Warranty.

The validity of the Warranty is also

dependent on proper installation

and maintenance operation being

carried out by an authorized Nanni

representative.

NOTICE: Late or improper maintenance or use of spare parts other

than Nanni original spare parts will

invalidate Nanni’s responsibility for

the engine accordance with homologation and will void the Warranty.

Modifications to the engine’s settings, as well as any other technical modification (accessories,

spare parts, additional equipment,

etc) ARE FORBIDDEN WITH-

OUT WRITTEN AUTHORIZATION

FROM NANNI INDUSTRIES S.A.S.

Any modification will void the Warranty. Damage caused by failure

to follow operation instructions or

incorrect operation is also not covered by the warranty.

Commissioning

inspection

Commissioning inspection is a

condition of the validity of the Limited Warranty. Moreover, it allows

the registration of the product at the

factory and record important informations regarding the product.

By registering the product, you will

receive the best warranty coverage

possible and Nanni will be able to

contact you in the event of updates

or service notifications.

Operations to be performed during

commissioning inspection are specified in the Warranty Booklet. The

commissioning inspection must be

signed by the seller and the owner

of the engine.

It’s the owner responsibility to

control that the commissioning

inspection has been fully completed and signed by the person who

carried out the inspection.

The informations regarding the

RPM must be taken using an electronic tachometer. Never use the

tachometer of the instrument panel

for this purpose.

13

About the

propeller

The propeller is a critical component of the propulsion system. It

converts the engine power in thrust.

To be efficient, the propeller must

be perfectly adapted to the boat

and to its use.

In all cases, the propeller should

allow the engine to reach its rated

rpm with the maximum boat load.

A faulty operation of the engine is

often due to an inadequate and / or

damaged propeller.

Behaviour of the

boat

If this is your first boat or if you are

not familiar with the boat, we urge

you to practice controlling the boat

at slow speed as a first step.

Avoid violent manoeuvres or

unexpected speed changes while

sailing. People can fall over or

overboard.

Keep also in mind that the weight

distribution (passengers, equipments, etc.) inside the boat has

an impact on the behaviour of the

boat when cruising. Depending the

position of the load, the behaviour

of the boat may change, particularly

in the case of a planning hull.

The condition of the hull and the

propeller is also a critical factor. A

dirty and / or damaged hull will modify the behaviour of the boat and

therefore the engine performance.

It can also cause cavitation which

can seriously erode the surface of

the propeller, the drive, etc.

14

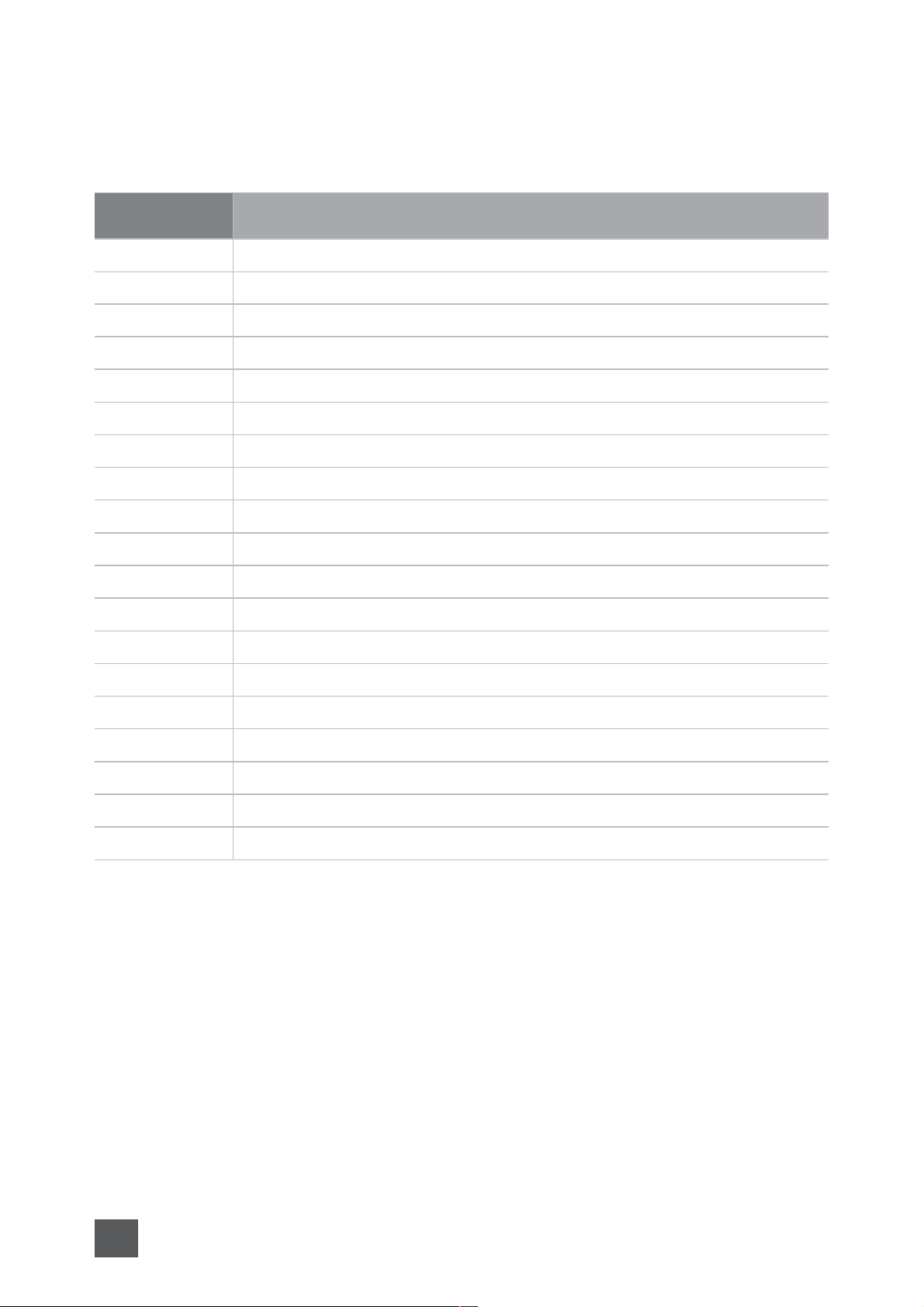

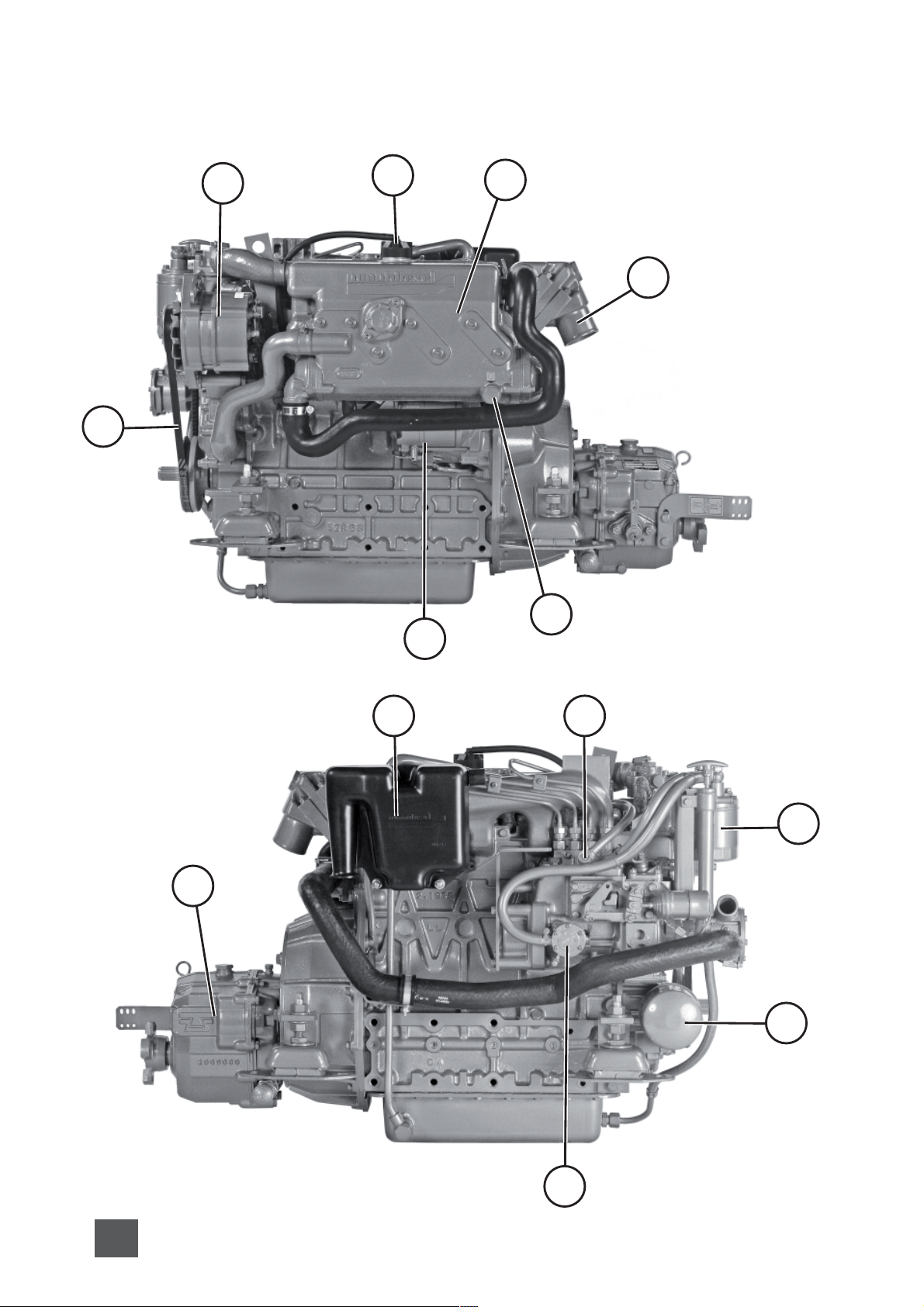

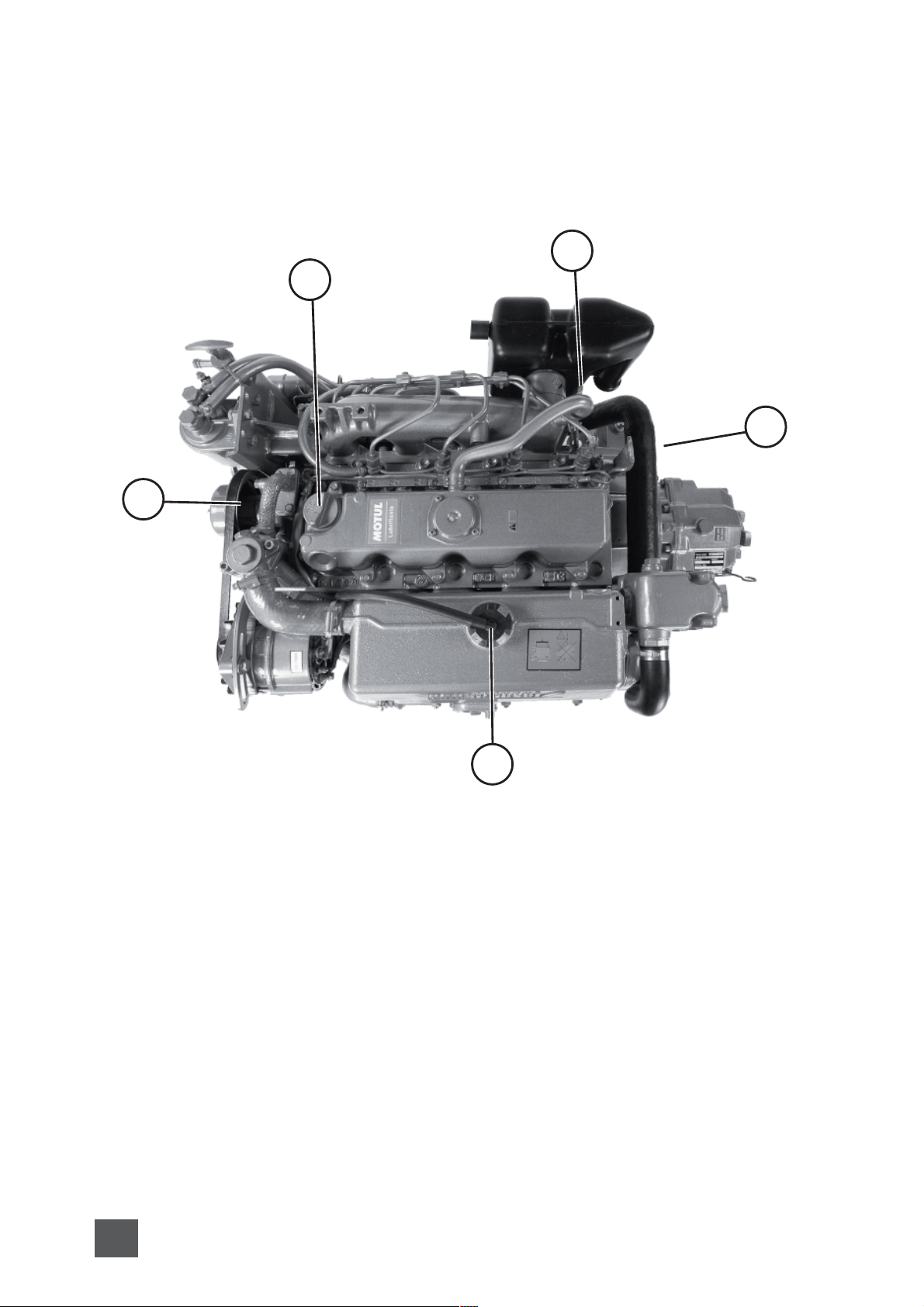

Engine main components

NOTICE: The engine may not be exactly as represented here. Some components may not be part of the engine ordered.

P/N COMPONENTS

1 Alternator

2 Alternator belt

3 Starter

4 Fuses box

5 Air filter

6 Fuel filter

7 Fuel feed pump

8 Fuel injection pump

9 Heat exchanger

10 Coolant filler plug

11 Coolant pump

12 Recovery tank

13 Coolant drain plug

14 Raw water pump

15 Oil filter

16 Oil filler port

17 Oil gauge

18 Water cooled exhaust elbow

19 Transmission

15

N4.40 / N4.43HD / N4.47MD / N4.50

16

18

19

1

9

3

13

2

8

15

10

5

7

6

17

N4.40 / N4.43HD / N4.47MD / N4.50

10

4

14

16

17

18

Note

I WARNING

Read the starting and stopping

instructions before operating the

engine.

The instrument panel provides you

with important informations about

the engine.

NOTICE: This chapter only describes instruments and panels that

come standard on Nanni engines.

Contact your dealer if the boat is fitted with instruments not described

in this chapter or if you are not sure

about their function. Depending

the boat, the warning lamps and

the instruments can be installed

separately without the panel shown

here.

On some boats, a panel without key

is used as an additional instrument

panel in Flying Bridge position. A

main panel fitted with a key switch

generally located in the wheelhouse is used to prevent unauthorized starting from the additional

panel. To start the engine using

the additional panel, the key of the

main panel should be switched to

IGNITION position.

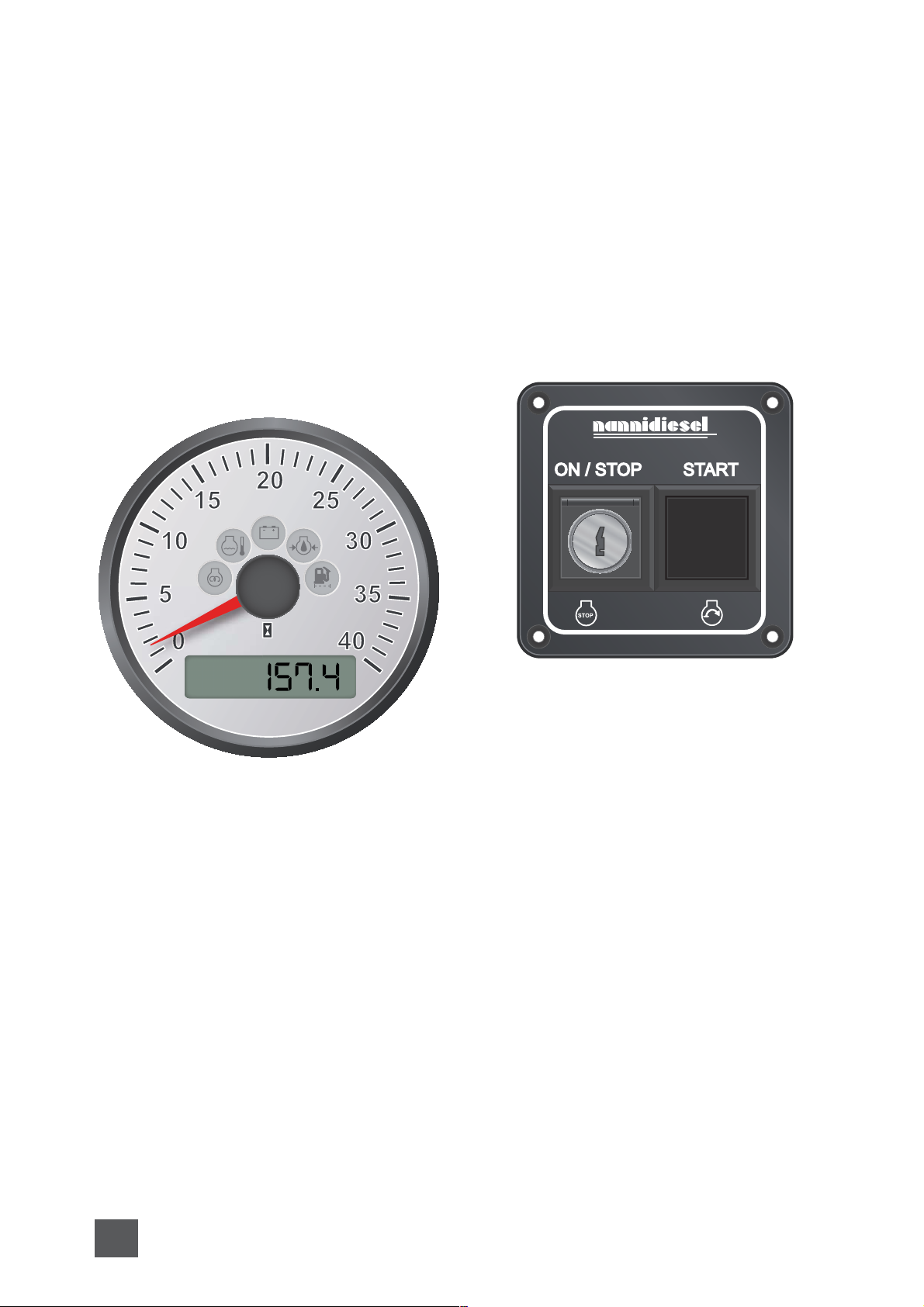

Standard panel

A4 PANEL

RPM x 100

C4 PANEL

RPM x 100

19

INSTRUMENTS PANEL

5

Instrumentation

Tachometer & Warning

lamps

The analog tachometer displays the

engine speed. Multiply the indicated

value by 100 to get the revolutions

per minute of the engine.

The function of the warning lamps

is explained in the following pages.

RPM x 100

Hourmeter & Voltmeter

The display at the bottom of the

dial shows the operating time of the

engine in hours

When the system voltage is

connected, the display indicates the

voltage at the battery terminals.

Starter switch

The starter switch allows to start

and stop the engine.

The ON/STOP switch allows to

connect the system voltage and to

stop the engine.

The START button allows to pre-

heat the engine and engage the

starter.

20

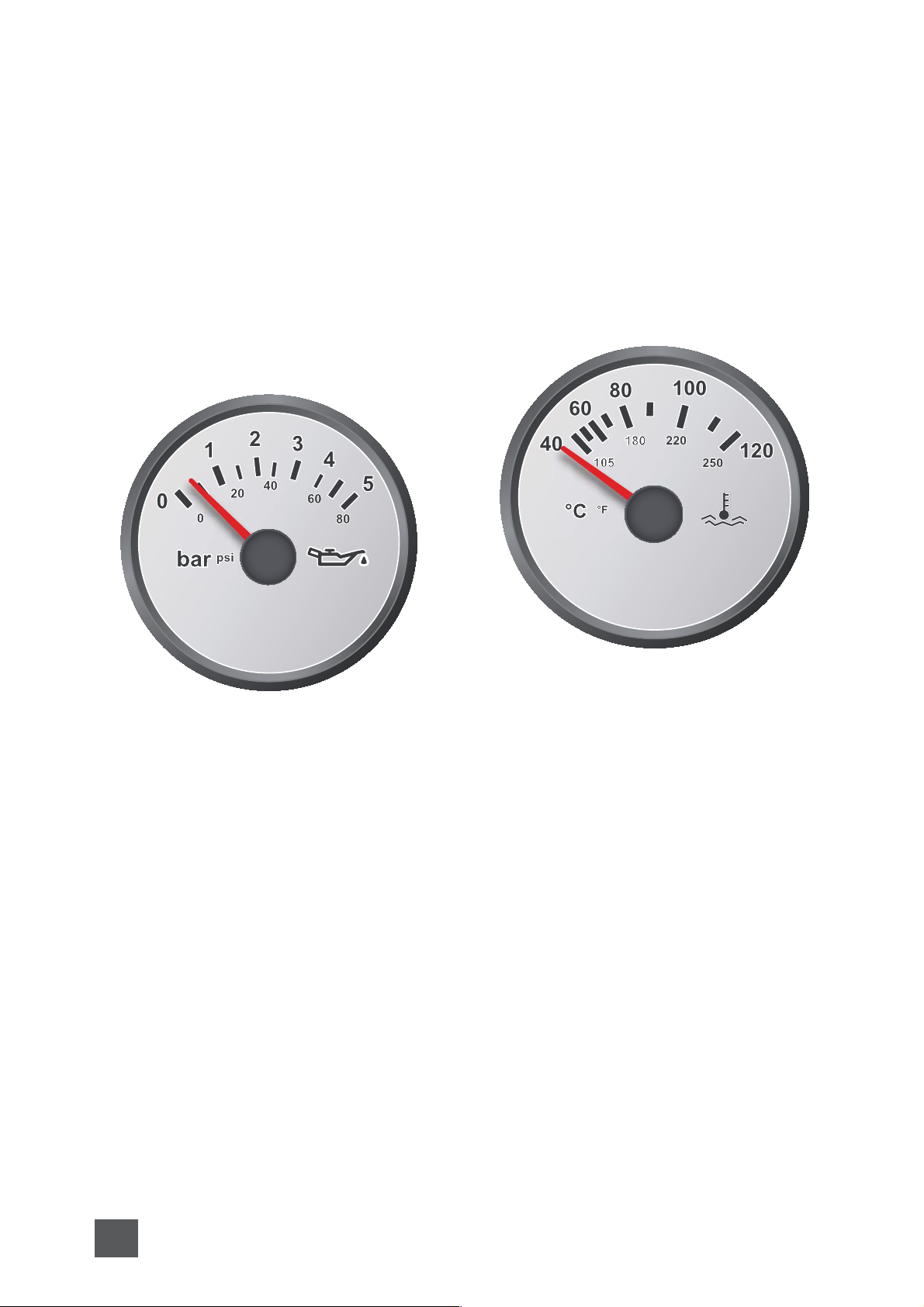

Engine oil pressure

indicator

NOTICE: This indicator does not

show the engine oil level. This

indicator shows the oil pressure in

bar and psi.

If the oil pressure in the lubrication

circuit is too low, the acoustic alarm

sounds and the corresponding warning lamp comes on.

Coolant temperature

indicator

Indicates the coolant temperature in

Celsius and in Fahrenheit degrees.

If the coolant temperature is too

high, the acoustic alarm sounds

and the corresponding warning

lamp comes on.

21

Warning lamps

COOLANT TEMPERATURE

This warning lamp comes on and

the alarm sounds when the coolant

temperature is too high.

I DANGER

Never open the coolant filler cap

or any plug of the cooling system

when the engine is warm. Steam

or hot fluid can spray out.

I CAUTION

If this alarm comes on while

the engine is running, stop the

engine, except in extreme emergencies, and check the coolant

level, the belt condition, the raw

water filter condition, and that

the sea cock is open.

Operating the engine while

the coolant temperature is too

high can lead to severe engine

damage. Do not operate the

engine if the problem persists

and contact a Nanni workshop

as soon as possible.

BATTERY CHARGE

This warning lamp comes on when

the system voltage is connected.

If this lamp lights up when the

engine is running, it indicates that

the alternator of the engine is not

charging.

The cause can be a fault in the

electrical system or because the

alternator belt is slack.

I CAUTION

If this alarm comes on while

operating the engine, stop the

engine, except in extreme emergencies, and check components

of the belt system. Also check

components of the electrical

system (fuses, battery, etc).

Do not operate the engine if

the problem persist and contact

a Nanni workshop as soon as

possible.

22

PREHEATING

This lamp comes on when the glow

plugs (if fitted) are activated.

ENGINE OIL PRESSURE

This warning lamp lights up and the

alarm sounds when the engine oil

pressure is too low.

I CAUTION

If this alarm comes on while

operating the engine, stop the

engine, except in extreme emergencies, and check the engine

oil level and the oil filter condition.

Operate the engine when the

oil pressure is too low can lead

to severe engine damage. Do

not operate the engine if the problem persist and contact a Nanni

workshop as soon as possible.

WATER IN FUEL FILTER

This lamp lights up and the alarm

sounds when there is too much

water in the fuel filter of the engine

(not applicable on some engines).

If this alarm comes on, stop the

engine and drain the water in the

fuel filter.

23

Note

24

Before starting

I WARNING

Put all the protective covers back

before starting the engine.

I CAUTION

Open the sea cock (if equipped)

before starting the engine. The

raw water pump impeller will be

damaged if it runs dry even for

few seconds, and may lead to

engine overheating.

Perform all of the following operations before starting the engine:

1. Open sea cock (if fitted). Prime

the raw water system if necessary.

2. Start the compartment fan (if

fitted) for at least five minutes.

Otherwise, open the hold.

3. Check that there is sufficient

fuel.

4. Move the control lever to the

neutral position.

5. Open fuel cock, prime the system if necessary.

6. Check the engine and transmission oil level and fill with the

recommended oil if necessary.

7. Check the coolant level, top up

if necessary.

8. Check the control cables,

grease the connections if necessary.

9. Check there are no fuel, oil,

coolant or water leaks.

10. Check the alternator belt.

11. Switch ON the main switches.

25

OPERATION

6

Starting the

engine

I DANGER

The propeller can cause serious injury when rotating. Check

that nobody is in the water near

the propeller before starting.

Never use a start spray or any

other equivalent product These

products are highly flammable.

I CAUTION

Always preheat the engine.

Never race the engine while it is

cold.

Do not crank the engine continuously for more than 10 seconds at a time. Let it cool down

for 2 minutes between cranking

attempts. Failure to follow these

guidelines may result in starter

motor burnout.

If the engine don’t start after

3 attempts, remove the key and

drain the water in the waterlock.

Failure to do so may lead to water ingress in the cylinders.

NOTICE: When starting the engine

for the first time, let it run at idle

for several minutes and check for

leaks or malfunction.

Starting using booster

batteries

I CAUTION

Make sure to use batteries with

the same rated voltage as the

engine’s system voltage.

1. Connect the jumper cable to the

positive pole (+) of the flat battery,

then to the positive pole (+) of the

booster battery.

2. Connect the jumper cable to the

negative pole (-) of the booster

battery. Then connect the other

end of the cable to a bolt on the

clutch of the engine block.

I DANGER

On an engine with a two pole

electrical system, connect the

other end of the jumper cable

to the negative pole (-) of the

booster battery.

3. Start the engine following the

starting procedure.

4. Let the engine run at idle for

few minutes to charge the battery.

5. Stop the engine and remove

the cables in the exact reverse

order from installation.

26

Panel with key

1. Move the control lever to the

neutral position.

2. Insert the key in the ON/STOP

starter switch.

3. Turn the key a quarter-turn to

the right. All the warning lamps

come on and the acoustic alarm

sounds. After a few seconds, only

the ENGINE OIL PRESSURE

and BATTERY CHARGE LAMPS

remain lit.

4. Press the START button

halfway to start preheating. Hold

the button for 5 to 15 seconds,

depending on ambient temperature to preheat the engine.

5. Press fully to start the engine.

Once the engine has started, release the button, all lamps go out.

6. If the engine is fit with water

cooled exhaust elbow, check

that water flows from the exhaust

outlet at the hull. If the water does

not flow, stop the engine and

check the raw water system.

Panel without key

1. Switch the key of the main panel to ignition (if equipped).

2. Move the control lever to the

neutral position.

3. Press the ON/STOP button. All

the warning lamps come on and

the acoustic alarm sounds. After

a few seconds, only the ENGINE

OIL PRESSURE and BATTERY

CHARGE LAMPS remain lit.

4. Press the START button

halfway to start preheating. Hold

the button for 5 to 15 seconds,

depending on ambient temperature to preheat the engine.

5. Press fully to start the engine.

Once the engine has started, release the button, all lamps go out.

6. If the engine is fit with water

cooled exhaust elbow, check that

raw water flows from the exhaust

outlet at the hull. If the water does

not flow, stop the engine and

check the raw water system.

27

Loading...

Loading...