Page 1

Reference

PLATE

TARGET

OSCILLATOR DETECTOR OUTPUT

Proximity

Information

Sensors

Principles of Operation

Inductive

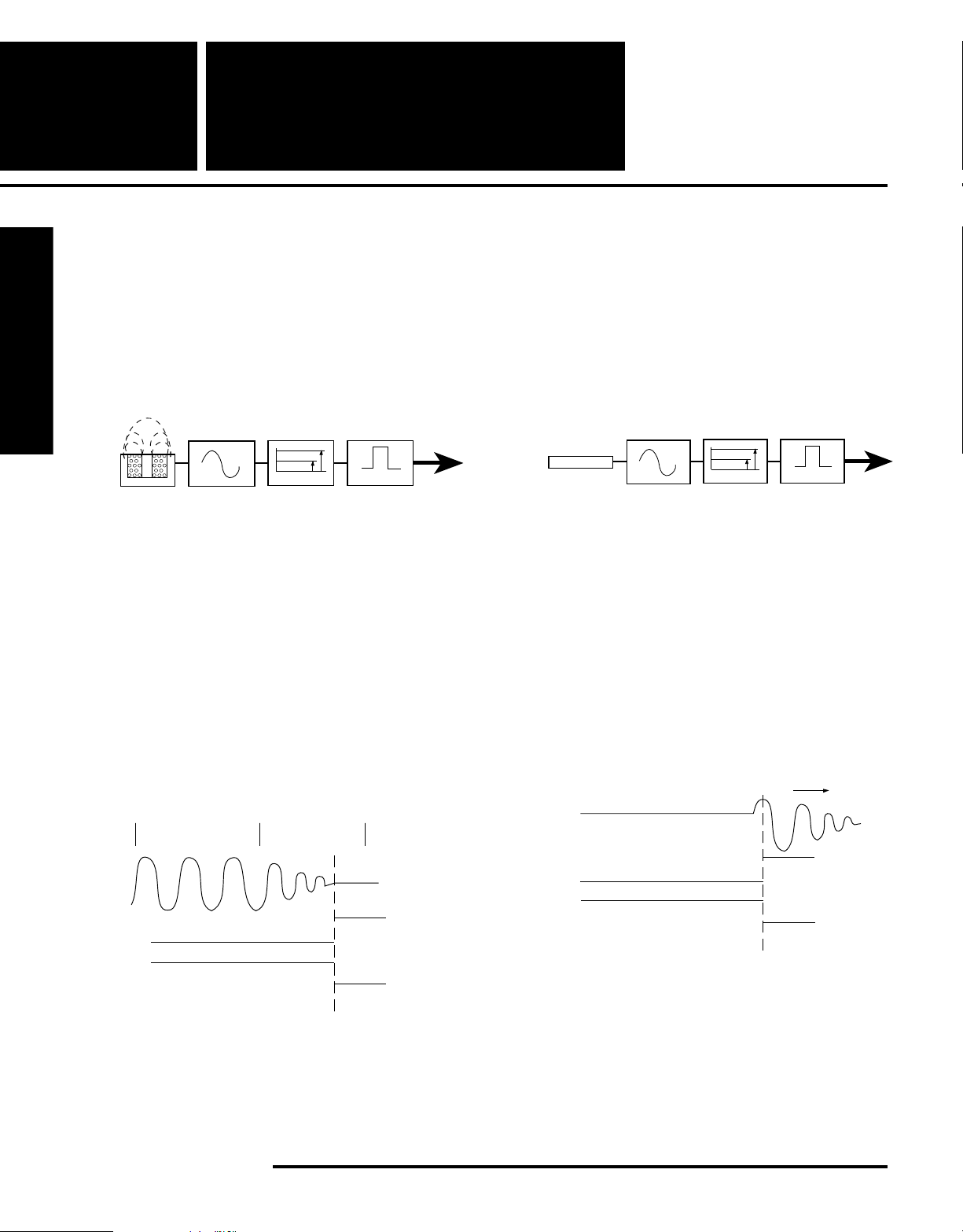

Proximity sensors are generally constructed with four main

elements: (1) a coil and ferrite core assembly; (2) an oscillator; (3) a convertor/trigger circuit (detector) and; (4) an

output device.

Proximity Sensors

TARGET

COIL OSCILLATOR DETECTOR OUTPUT

Figure 1

Capacitive

Essentially similar except that the coil is replaced by a

sensing plate, and the oscillator is not running until the

object to be detected is within range.

Figure 3

The oscillator creates a radio frequency field that is shaped

and defined by the coil and core. As a target is placed in this

field, eddy currents are set up in the surface of the target.

The oscillator, being a limited power device, will lower its

amplitude as the eddy currents are produced. The convertor/

trigger circuit rectifies the AC sine wave signal to DC,

compares the level against a preset reference, and actuates

the sensor output if a target is present. Switching is clean,

with none of the bounce of mechanical switches.

No Target Present

Normally Open

Sensor Output

Normally Closed

Sensor Output

in Sensing Field

Output non-conducting

"OFF"

Output conducting

"ON"

Target Entering

Sensing Field

Figure 2

Output conducting

"ON"

Output non-conducting

"OFF"

Capacitive sensors depend on the coupling between the

sensing plate and earth ground. If a target is placed within

range, the capacitance level will vary depending on target

density, conductivity, and relative humidity. If the adjustment

potentiometer is correctly set, the oscillator will be turned on

when a target is within range.

Target Entering

Sensing Field

Output conducting

"ON"

Output non-conducting

"OFF"

Normally Open

Sensor Output

Normally Closed

Sensor Output

No Target Present

in Sensing Field

Output non-conducting

"OFF"

Output conducting

"ON"

Figure 4

Important Note: Never use a metal body capacitive sensor in

wet environments. Moisture between the sensing plate and

the metal body will cause the sensor to “lock on.” For wet

environments, always use a plastic bodied sensor.

90

Namco • 2013 West Meeting Street • Lancaster, SC 29720 • 1-803-286-8491 • FAX: 1-800-678-6263

Page 2

Inductive Sensor Selection

1. Target Identification

This is the most critical step in proper application of inductive and capacitive sensors. Most application problems stem

from improper selection of a sensor for a particular target.

This usually comes from a desire to “standardize” a design.

Generally the following rules apply to all inductive sensors:

The sensor face should equal or be smaller than the

target surface area. All manufacturers calibrate the range

of a particular sensor with a “standard target.” This

standard target is always larger than the diameter of the

sensor face. Although it is possible to sense targets

smaller than the sensor face diameter, rated range

cannot be achieved using a target that is smaller than

the sensor face. The following changes in the sensing

range will occur if the dimensions of the target are larger

or smaller than the standard target specified.

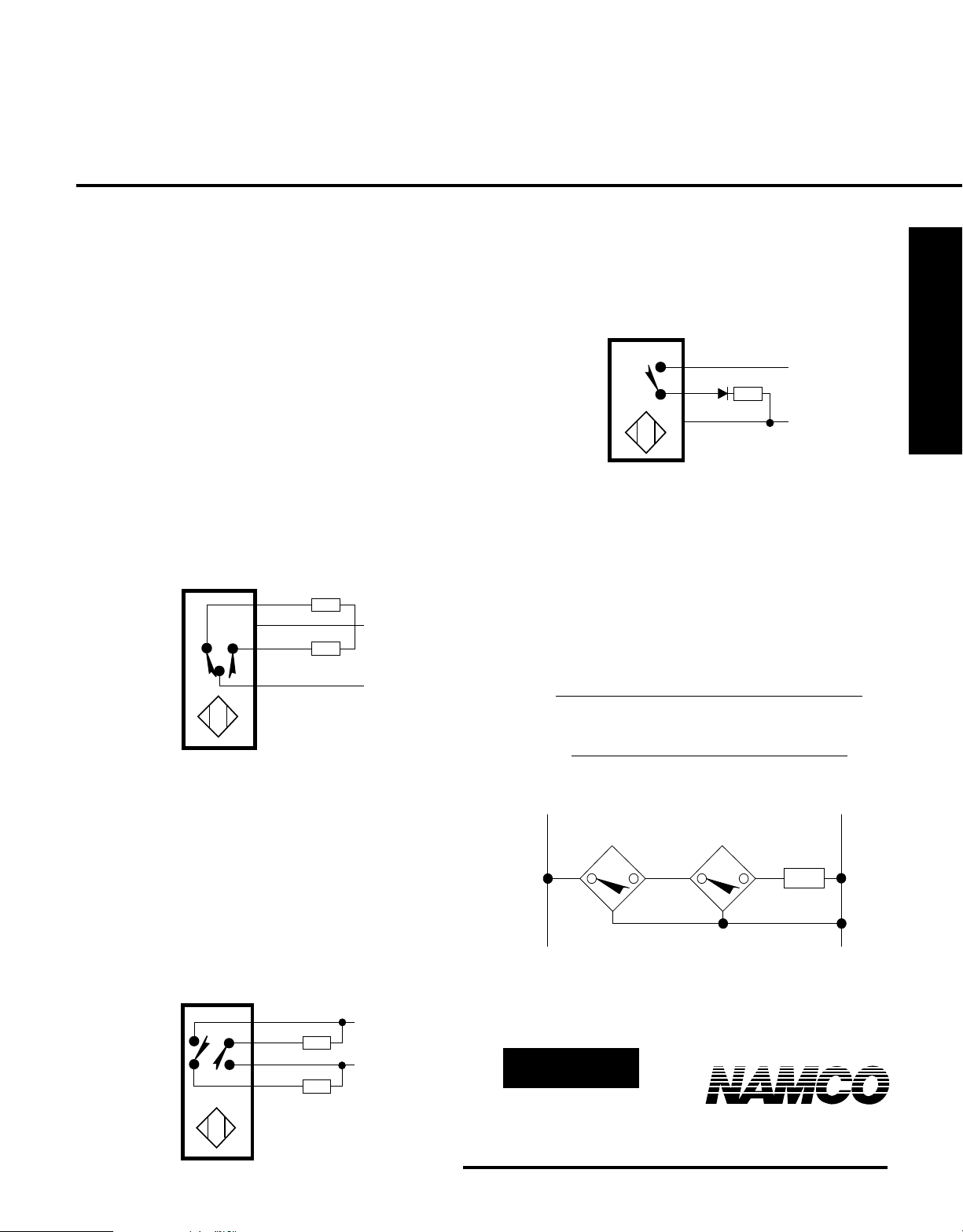

Target 150 125 (Standard 75 50 25 12.5

size in % Target)

Deviation

from Sn in %

+10 +7 0 -7 -14 -27 -45

100

Figure 5

2. Air Gap Determination

When examining your application, remember that most

shielded inductive sensors (Fig. 6) will have a maximum

range that is approximately one third of the diameter of the

sensing face.

SHIELDED SENSOR

TARGET

METAL

SHIELD

METAL

SHIELD

It is often necessary to allow a rather large air gap between

the target and the sensor. When this is required, an

unshielded sensor (Fig. 7) will be required. The unshielded

sensor will generally have the plastic “nose” of the sensor

projecting out of the metal barrel, or (plastic bodied types) it

will not have a shielding ring around the core. These

unshielded sensors will typically sense at ranges 3 to 50

percent greater than shielded types. A penalty is paid,

however, as it is necessary to provide a metal-free area

around the sensor that is much larger than the shielded types.

NONSHIELDED SENSOR

FERRITE CORE

Figure 7

(See 3. Mounting Clearances)

Positioning of the sensor should allow the target to penetrate

approximately 30% into the field to allow for manufacturing

tolerances, resistance to vibration, and inaccuracies that are

common to all initial start-ups.

When determining the air gap (sensing distance) required, it

should be noted that an inductive sensor will produce its

rated range only against a standard target of mild steel. Other

materials will reduce the sensing range (SN) as follows:

Mild Steel SN x 1.0

Aluminum Foil SN x 1.0

Stainless Steel SN x 0.85

Brass SN x 0.5

Copper SN x 0.46

Aluminum SN x 0.4

Proximity Sensors

FERRITE CORE

Figure 6

Continued on

next page.

➟

2013 West Meeting Street • Lancaster, SC 29720

1-803-286-8491 • FAX: 1-800-678-6263

www.namcocontrols.com

For technical assistance, call 1-800-NAMTECH

91

Page 3

Reference

Proximity

Information

Sensors

Example: If a sensor with a 5mm sensing range is used to

sense a standard target made of copper, the sensing

range of the sensor is reduced as indicated below:

5mm (0.46) = 2.3mm (maximum)

When mounting a sensor it is always preferred to position the

target so that it “slides by” the sensor face. This type of

mounting will ensure that the sensor face is not damaged by

contact with the target. If your application dictates a “head on”

approach, it is essential that the target does not use the sensor

Proximity Sensors

face as a physical stop. Failure to provide clearance in either

the slide-by or head-on modes will result in damage to the

sensor and possible failure of the device.

Hysteresis (Fig. 8) must be allowed for as the target must

move far enough away from the sensing field so that the

sensor cannot detect it. If a target is placed within the hysteresis band, vibration of the target can cause the switch to turn

on and off rapidly (“chatter”). All sensor manufacturers build in

a certain amount of hysteresis to minimize chatter.

SHIELDED SENSORS

(FLUSH MOUNTABLE)

3x RANGE MIN.

DIA. (D)

UNSHIELDED SENSORS

REQUIRE METAL-FREE AREA

MINIMUM SPACING REQUIRED

D (DIAMETER OF SENSOR)

D

standard

moving direction

release point

operate point

sensing range

proximity sensor

Figure 8

target

hysteresis

3. Mounting Clearances

Mounting of sensors should follow industry accepted

practices as shown. Failure to properly position the sensor is

the single largest cause of field problems.

MINIMUM SPACING REQUIRED

2 X D (DIAMETER OF SENSOR)

DD

SENSORS MUST BE MOUNTED SUCH THAT SURROUNDING METAL

OPPOSING SENSORS

MAINTAIN 6 X RANGE

MIN. SPACING

3x RANGE MIN.

IS NOT IN THE SENSING AREA.

Figure 9

D

D

6 x RANGE

MIN.

DD

2DD

92

Namco • 2013 West Meeting Street • Lancaster, SC 29720 • 1-803-286-8491 • FAX: 1-800-678-6263

Page 4

4. Housing Selection

After you have determined the target and air gap, it is then

possible to select the style of housing for the application.

Sensors are typically grouped according to range against a

standard target. The most often used types are the metal barrel

styles. These are great for general purpose uses but should not

be used in areas where liquids are present. For wet environments, the all-plastic types are preferred. To determine your

best specific type, consult the Enclosure Types below.

Industrial Control Equipment - UL 508

Table 6.1 – Enclosure Designations

Various accessories are available for sealing, conduit, and

mounting. Also, many sensors are available with quick

disconnects. This is more expensive initially but can be

justified if the sensor is placed on moving equipment where

the cable is flexed often. The weak link then becomes the

entry point of the cable to the housing. When failure occurs,

it is necessary to replace the complete assembly because the

cable failed. It’s also easier to position the sensor mechanically, then complete the electrical wiring.

Proximity Sensors

Designation Intended Use and Description

1

2

3

3R

3S

4

Indoor use primarily to provide protection against

contact with the enclosed equipment and against a

limited amount of falling dirt.

Indoor use to provide a degree of protection

against limited amounts of falling water and dirt.

Outdoor use to provide a degree of protection

against windblown dust and windblown rain;

undamaged by the formation of ice on the

enclosure.

Outdoor use to provide a degree of protection

against falling rain; undamaged by the formation

of ice on the enclosure.

Outdoor use to provide a degree of protection

against windblown dust, windblown rain, and

sleet; external mechanisms remain operable while

ice laden.

Either indoor or outdoor use to provide a degree

of protection against falling rain, splashing water,

and hose-directed water; undamaged by the

formation of ice on the enclosure.

Designation Intended Use and Description

4X

6

6P

11

12, 12K

13

Either indoor or outdoor use to provide a degree

of protection against falling rain, splashing

water, and hose-directed water; undamaged by

the formation of ice on the enclosure; resists

corrosion.

Indoor or outdoor use to provide against the

entry of water during temporary, limited

submersion; undamaged by the formation of ice

on the enclosure.

Indoor and outdoor use to provide a degree of

protection against the entry of water during

prolonged submersion at limited depths.

Indoor use to provide by oil immersion a degree

of protection of the enclosed equipment against

the corrosion effects of corrosive liquids and

gases.

Indoor use to provide a degree of protection

against dust, dirt, fiber flyings, dripping water,

and external condensation of noncorrosive

liquids.

Indoor use to provide a degree of protection

against lint, dust seepage, external condensation, and spraying of water, oil, and noncorrosive liquids.

Table 6.1 revised December 5, 1986

©

Copyright 1977, Underwriters Laboratories Inc.

Continued on

next page.

➟

2013 West Meeting Street • Lancaster, SC 29720

1-803-286-8491 • FAX: 1-800-678-6263

www.namcocontrols.com

For technical assistance, call 1-800-NAMTECH

93

Page 5

Reference

Proximity Sensor

Information

Information

Electrical Considerations

Namco offers sensors that are suitable for direct connection

to most common types of control systems. The most

common types are listed below:

1. Relay Systems

2. Programmable Controllers

3.Custom Microprocessors

4. Output Devices (Solenoids)

Proximity Sensors

When specifying a particular output type, at no time should

the appropriate specifications of the particular sensor be

exceeded or sensor failure may result.

A switch in a protective interlocking circuit should be used

with at least one other device that will provide a redundant

protective function, and the circuit should be so arranged

that either device will interrupt the intended operation of the

controlled equipment. (Proposed NEMA ICS 2-225.95 std.)

RANGE vs. CURRENT

(TYPICAL)

4.0

Response Curve

3.8

3.6

3.4

3.2

3.0

2.8

I(mA)

2.6

2.4

2.2

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

10 20 30 40 50 60 70 80 90 100

% of Range

Namur Sensors

Namur refers to the standards committee of measurement

and control of the chemical industry of Europe. Namco

sensors comply with DIN 19234, and therefore are compatible with the Namur requirements.

This type of sensor contains only the “front end” of the

typical proximity sensor coupled to an output transistor that

will vary the current (not voltage) in proportion to the target

distance (Fig. 10). This type of sensor is normally connected

to an external amplifier which will provide the switch closure

to an external control system. It is possible to interface these

sensors to either custom external solid state relays or PLC

(Programmable Logic Control) systems with the appropriate

input card. When used with an approved intrinsically-safe

control amplifier, Namur sensors can be used in hazardous

areas. Please consult factory for application details.

When the target is not present, the sensor passes a small

amount of current (> 2.2mA). The current decreases in a

non-linear fashion as the target enters the sensing field. This

action is similar to a variable resistor. (See Figure 10.)

Figure 10

Suggested On/Off Output Circuits

for NAMUR Sensors

+7 to +9VDC

+8VDC

White

Black

White

Black

1KΩ

360Ω

4.7KΩ 2.2KΩ

100Ω

910Ω

100Ω

.1µf

+

Op-Amp

_

Load

470KΩ

Output

94

Namco • 2013 West Meeting Street • Lancaster, SC 29720 • 1-803-286-8491 • FAX: 1-800-678-6263

Page 6

DC Sensors

LOAD

BLUE

BROWN

+

_

BLACK

Available as either current sinking (NPN) or current sourcing

(PNP), this type of sensor will provide the fastest output

switching available.

The voltage range is typically 10-30 VDC with minimal drop

across the output transistor for easy connection to programmable controllers. Most DC sensors include reverse polarity

and short circuit protection as standard features.

Normally open output sensors are used in most applications.

Normally closed output sensors can be made to order.

Complimentary (one output “on,” one output “off”) output

sensors (Fig. 11) can be used as a normally open and

normally closed sensor at the same time. This convenient

sensor can be used to replace a normally open sensor or a

normally closed sensor. Simply hook up the desired output

and either tape or cut off the load lead that is not being used.

NPN (SINKING) N.O. & N.C.

WHITE NC

BROWN

BLACK NO

BLUE

Figure 11

LOAD

+

LOAD

_

When connecting DC sensors to inductive loads, it is suggested that a diode be placed in the circuit to cancel any

kickback that may damage the output of the sensor. (See

Figure 13.)

Proximity Sensors

Figure 13

Series Connection:

AND circuits can be made by series connection of

normally open output sensors.

NAND circuits can be made by series connection of

normally closed output sensors.

The maximum number of sensors that may be wired in series

is equal to the lowest number of the following two equations:

# Sensors =

Supply Voltage - Min. Operating Voltage of Load

Voltage Drop Across Each Sensor

# Sensors =

Max. Sensor Output Current - Load Current

No Load Current of Sensor

Dual output (NPN & PNP) sensors (Fig. 12) can have either

output connected to a load, or each output connected to its own

load, but not both to the same load. If the two outputs are each

connected to separate loads as shown in Figure 12, the sum

of the two load currents must not exceed the maximum load

current of sensor (typically 200mA). This particular sensor

output configuration is designed to minimize replacement

inventories. It does not have complementary switching

capabilities, i.e., both of the outputs switch either “on” or

“off” at the same time.

NPN (SINKING) & PNP (SOURCING)

BROWN

BLACK NPN

BLUE

WHITE PNP

Figure 12

+

LOAD

_

LOAD

+ –

+ +

_ _

PNP Output shown - for NPN Output reverse V

LOAD

supply

and

sensor polarities.

Continued on

next page.

➟

2013 West Meeting Street • Lancaster, SC 29720

1-803-286-8491 • FAX: 1-800-678-6263

www.namcocontrols.com

For technical assistance, call 1-800-NAMTECH

95

Page 7

Reference

Proximity

Information

In a long series string, it is possible to exceed the current

handling capacity of the last or first sensor due to the sensor

current requirements plus the load. This problem can be

circumvented by alternating types; i.e., PNP, NPN, PNP, etc.

Wiring the sensors in this manner will allow an infinite

number to be wired in series.

Parallel Connection:

Proximity Sensors

OR circuits can be made by parallel connection of

normally open output sensors.

NOR circuits can be made by parallel connection of

normally closed output sensors.

The maximum number of sensors that may be wired in

parallel is equal to the current capacity of the voltage supply

used.

+ —

Sensors

Series Connection:

Note:

Connection of more than two AC sensors in series, is

NOT recommended

AND circuits can be made by series connection of

normally open output sensors.

NAND circuits can be made by series connection of

normally closed output sensors.

The maximum number of sensors that may be wired in

series:

# Sensors =

Supply Voltage - Min. Operating Voltage of Load

Voltage Drop Across Each Sensor

LOAD

+

+

NPN Output shown - For PNP Output reverse V

sensor polarities.

—

—

and

supply

AC Sensors

AC sensors can also be connected to the same types of

control systems as the DC types but are typically load

powered. This configuration is a result of user demands for

the high reliability of solid state sensors coupled to the

requirement for minimal wiring.

In operation, the AC sensor will draw a small amount of

current through the load with no target present. This current

typically is less than 1.7mA allowing direct connection to

programmable controller input cards with no shunt resistor

required. This current must be allowed for when designing

parallel logic circuits as the leakage currents may become

large enough to actuate the load. This can be overcome by

application of a properly sized shunt resistor.

L1

LOAD

When a target is placed in the field and the sensor actuates,

the amount of voltage available to the load will be reduced by

approximately 8-10 volts. This value is critical in series

circuits. Calculations for each series circuit must be made to

ensure that enough voltage is available to actuate the load.

The same problem exists when attempting to use a two-wire

AC sensor at low AC voltages. For instance, if a 20-250 VAC

sensor is used at 24VAC, the voltage available to the load will

be between 14-18 VAC.

Parallel Connection:

OR circuits can be made by parallel connection of

normally open output sensors.

NOR circuits can be made by parallel connection of

normally closed output sensors.

The maximum number of sensors that may be wired in

parallel is

# Sensors =

Holding Current of Load

Leakage Current of Each Sensor

L2

96

Namco • 2013 West Meeting Street • Lancaster, SC 29720 • 1-803-286-8491 • FAX: 1-800-678-6263

Page 8

L1

LOAD

L2

All AC sensors have switching speeds that are much lower

than their DC counterparts. Typical switching speeds are 20

to 30 Hz.

Short circuit protection is a feature of many types of Namco

sensors. This internal circuit will protect the sensor if the

load inrush current exceeds 3 amperes. In the event of a

large inrush current, the sensor will trip into “short circuit”

mode. On standard ET/ER series sensors the LED does not

illuminate. On WFI sensors both LEDs will flash, and the

output current will be limited to approximately 2.5 mA. To

restore the sensor it is necessary to remove power for

approximately one second. The sensor will not function in

SCP mode.

The short circuit protection feature is designed to protect the

sensor and not the external circuit. The short circuit protection feature does not eliminate the need for branch circuit

fusing.

Capacitive Sensors

Capacitive sensors are unique in that they will sense most

materials including non-metallics. The actual sensing is

performed by a circuit containing an oscillator, detector

stage, and an output stage similar to the inductive type

sensor. The differences are (1) the oscillator is not running

when a target is not present, and (2) the sensing portion of

the sensor is a special plate in the sensing surface of the

sensor. This plate also has an opposing connection-to-earth

ground through the detection circuit. When an object is

placed near the sensing plate, the dielectric constant of the

material will allow coupling from the sensing plate through

the air-to-earth ground thus starting the oscillator. To

provide adjustment for the various types of materials and

their different dielectric constants, an adjustment potentiometer is typically provided.

This change in dielectric constant is a requirement for

accurate sensing. If a material has a very low dielectric

constant, the sensor must be in very close proximity to the

material being sensed. Conversely, a material with a high

dielectric constant can be sensed at a greater distance.

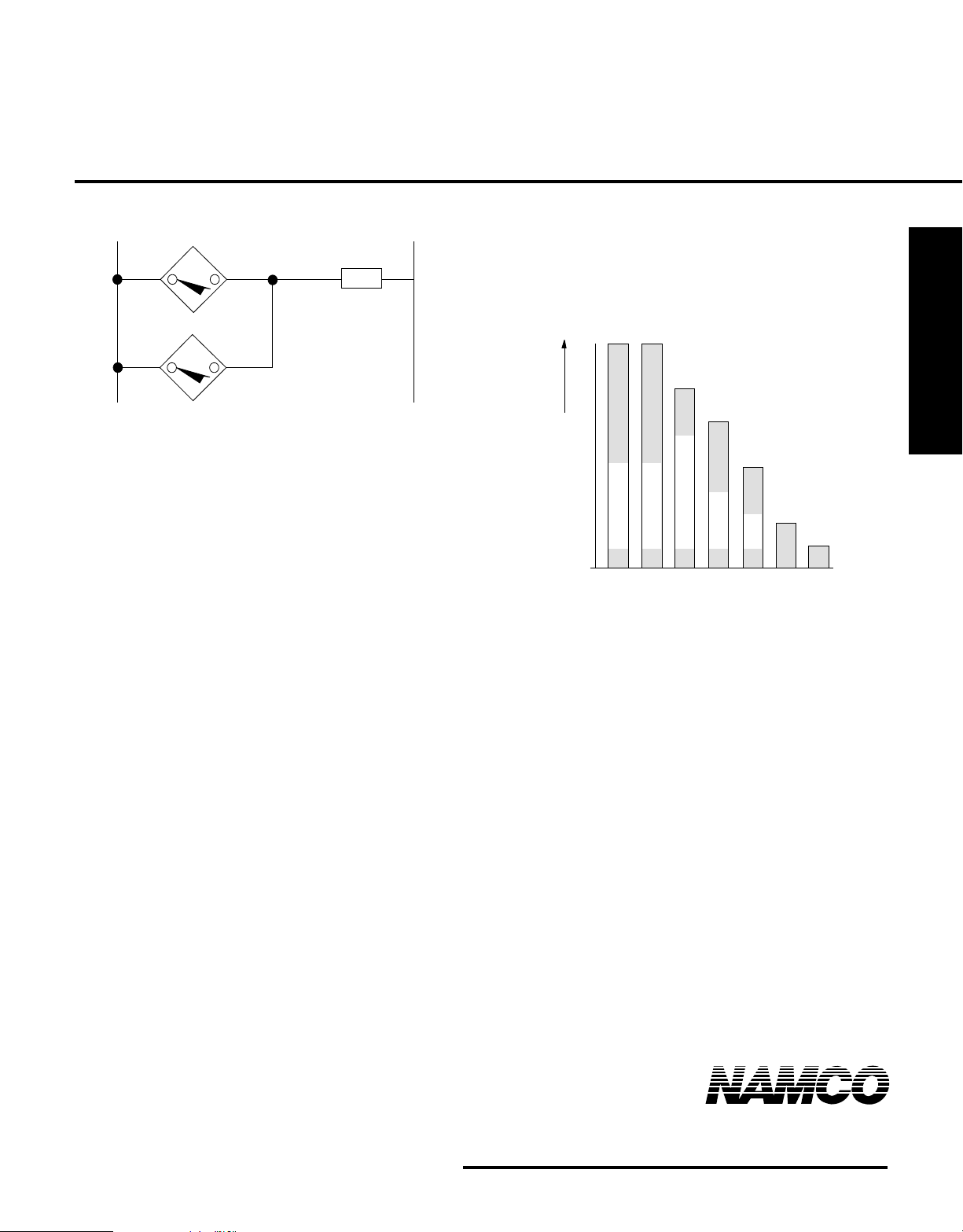

The diagram below shows the reduction created by different

materials.

100

-

-

%

80

-

-

-

60

-

-

40

Sensing Range

20

-

-

-

0

grounded water

grounded metal

dry wood

water with no ground

glass

PVC

card board

Materials with a high dielectric constant can be sensed

through the walls of a container with a lower dielectric

constant. Example: sensing water level in a boiler sight glass

tube.

Application Cautions

1. The adjustment potentiometer is a non-linear device. Do

not attempt to adjust the sensor beyond 2/3 of the maximum

range obtained on a given material.

2. Never use a sensor with a metal housing in a damp

environment. If the face of the metal housing sensor is

splashed, the sensor will turn “On” and will not turn “Off”

until the water is removed.

3. Because the capacitive sensor depends on coupling

through the air, maximum range will be greater on hot,

humid days. It may be possible to sense a particular material

only on days when the humidity is high.

4. To determine if the material you wish to sense can be

sensed reliably, Namco recommends actual testing. If this is

not practical, consult our Applications Engineering Department.

2013 West Meeting Street • Lancaster, SC 29720

1-803-286-8491 • FAX: 1-800-678-6263

www.namcocontrols.com

Proximity Sensors

For technical assistance, call 1-800-NAMTECH

97

Loading...

Loading...