Page 1

®

Reference

Information

Cylindicator Sensor

Design Guide

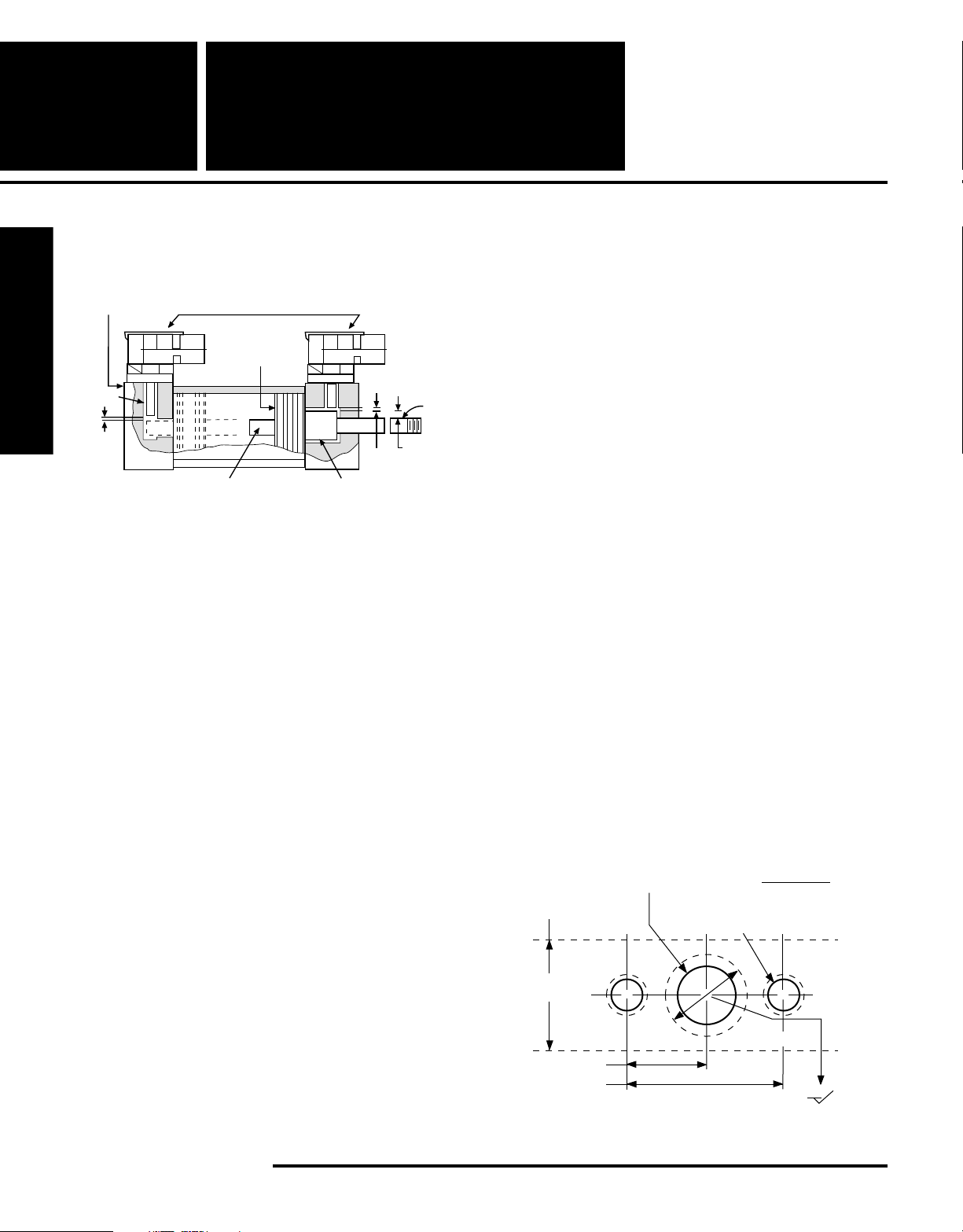

Cylindicator Sensor Installation

CYLINDICATOR MAY

ALSO BE MOUNTED

ON THIS SURFACE.

SPACER MAY BE

REQUIRED

PROBE

Proximity Sensors

AIR

GAP

CYLINDICATOR SENSORS

Proper operation of your Namco Cylindicator depends in large

part on these factors:

Establishment of a proper air gap between

the probe face and the target.

The air gap is the actual distance between the tip of the probe

and the part of the piston which is the “target.” The target can

be the collar or cushion sleeve, cushion spear, or the end of

the rod inside the cylinder. This target must be close enough

to actuate the Cylindicator Sensor but not so close as to

actually contact the probe.

Experience has shown an air gap of 0.025 inches to be

optimum in most applications. The air gap should always be

greater than 0.015 inches and less than 0.045 inches, including

worst case tolerances. Gaps in excess of 0.045 inches are not

recommended and could result in inconsistent operation.

Assuring a minimum “step distance” between

the cushion collar and the piston rod.

Standard Namco Cylindicator Sensors have a nominal sensing

range of 0.080 inches beyond the stated probe length. The

minimum step distance (cushion to rod) must be greater than

0.095 inches to guarantee that the sensor will “drop out” when

the target is no longer present. This minimum step distance

accounts for mechanical tolerances, temperature effects, and

hysteresis effects.

Sensing a known metallic target.

In all applications referred to in this publication, the target is

assumed to be of a ferrous metal. Consult Namco if a different

metal such as aluminum, brass, or stainless steel must be

used as the sensing range is reduced.

ADD SPACER IF REQUIRED.

TO USE SAME PROBE LENGTH

AT ROD END AS AT CAP END

PISTON

CUSHION

SPEAR

Figure 1

CUSHION COLLAR

OR SLEEVE

AIR

GAP

ROD

STEP

DISTANCE

Mounting to a proper cylinder endcap.

The clearance hole for the sensing probe must be 0.560"

diameter minimum/0.580" diameter maximum. The end block

must be designed so that the probe tip is flush to 0.04"

extended beyond surrounding metal within 0.5" of the probe

side walls.

Other Tips:

• Never operate the cylinder at pressures which exceed the

Cylindicator sensor’s ratings.

• Do not exceed ambient temperature range.

• The Cylindicator Sensor must be positioned so that the

target area (cushion spear, cushion collar, etc.) will completely cover the probe sensing face when the sensor is

operated.

• Do not mount the Cylindicator Sensor on the bottom of the

cylinder. Debris could accumulate around the probe which

might cause damage or inconsistent operation.

• All Cylindicator Sensors are completely epoxy potted and as

such contain no serviceable parts inside. Do not remove

the cover or tamper with the cable or connector.

• Cylindicator Sensors must have the O-Ring probe seal that

is supplied with each unit installed around the probe before

mounting.

• Do not attempt to modify the probe by cutting, grinding,

filing, etc.

Mounting Dimensions and Template

CYLINDEREND

CAP MINIMUM

THICKNESS

1.00"

(25.4)

0.70"(17.0)

1.40"(35.0)

PROBECLEARANCE

DRILL & TAP 2HOLES

1/4-20NCx.500"DEEP

+++

C

L

(full scale)

0.56"(14.1)

0.58"(14.7)

OFCYLINDER

0.90"(23.0)

63

DIA.

DIA.

MIN.DIA.

100

Namco • 2013 West Meeting Street • Lancaster, SC 29720 • 1-803-286-8491 • FAX: 1-800-678-6263

Page 2

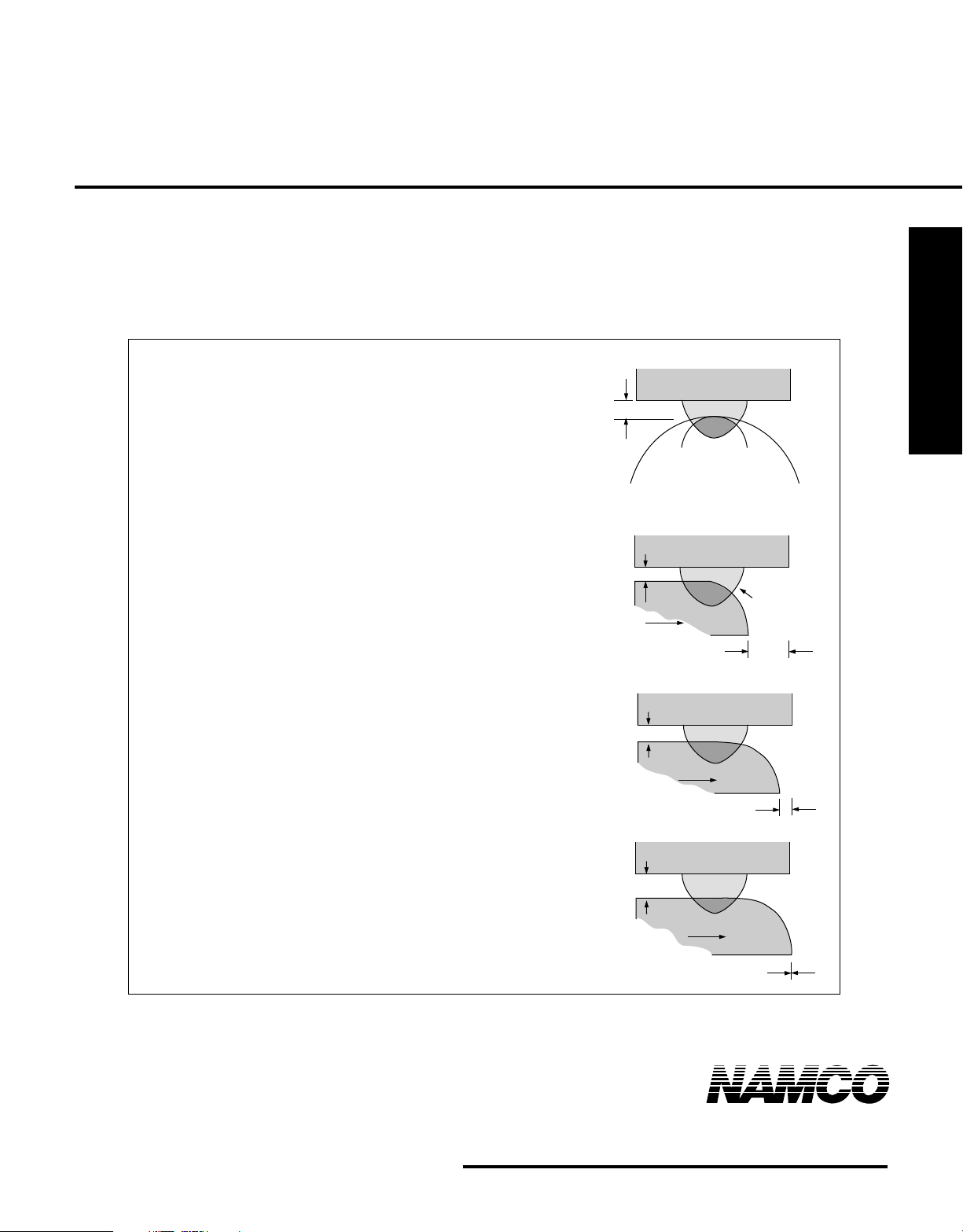

“Stroke To Go” vs. “Air Gap”

“Stroke To Go”

The amount of stroke remaining in the cylinder after

the Cylindicator Sensor activates.

NOTE: If a cylinder is mechanically restrained from

going full stroke — no target will be present for the

switch to detect (no switch output).

Target End View

Smaller diameter targets have less metal in the sensing field at a

constant air gap. Loss of stroke-to-go is more pronounced on

smaller bore cylinders as air gap increases.

Switch Actuated

Recommended nominal air gap distance provides the stated

maximum stroke to go.

Switch Actuated

Variations from the recommended nominal air gap distance results

in loss of stroke to go.

AIR GAP

LARGE

TARGET

AIR GAP = 0.025"

AIR GAP = 0.045"

PROBE

SMALL

TARGET

PROBE

TARGET

STROKE TO GO

PROBE

TARGET

LESS STROKE TO GO

RADIO

FREQUENCY

CONE

Proximity Sensors

Switch Probably Not Actuated

Increased variations from the recommended nominal air gap

distance results in little or no stroke to go and possible erratic

operation.

*Loss of stated maximum stroke to go can prevent the proximity sensor

from activating in plant equipment and tools with positive stops.

PROBE

AIR GAP > 0.045"

TARGET

LITTLE OR NO STROKE TO GO

2013 West Meeting Street • Lancaster, SC 29720

1-803-286-8491 • FAX: 1-800-678-6263

www.namcocontrols.com

For technical assistance, call 1-800-NAMTECH

101

Loading...

Loading...