Update 1

AQUA JET

ROSTA SPRING SHAFT ASSEMBLY

REPLACEMENT INSTRUCTIONS

SAFETY WARNINGS

Ensure that the machine is switched OFF and disconnected from the mains supply

before commencing any work.

To maintain safety and minimise the risk of injury to personnel or damage to the

machine follow the Instructions for Replacement precisely

Some of the parts to be removed are heavy. Ensure that at least two people are available

to remove these items.

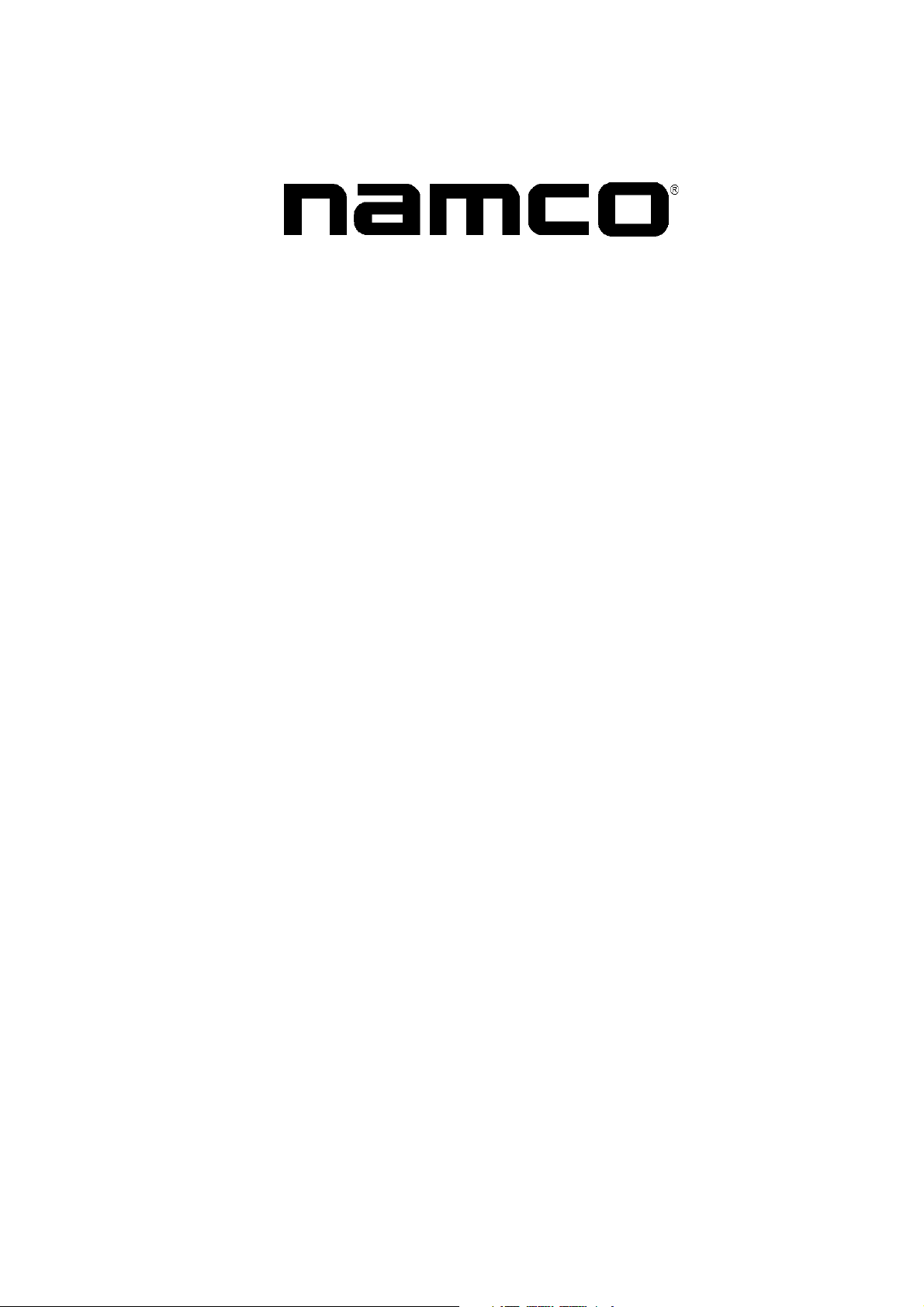

The air line connectors design is such that the more the tube is pulled, the tighter the

connection becomes, so it is imperative that the blue locking ring is pushed towards the

connector when removing the air tubes.

The compressor used in this machine has a reservoir tank and a loud hissing noise will

be heard as the air is released when the first air tube is disconnected.

Take care not to squash or bend any of the air tubes during disassembly or reassembly.

If there are any doubts or queries please telephone Technical Service on 0181-324-6120

for advice before continuing.

TOOLS and PARTS REQUIRED

Ratchet Handle

Ratchet Handle Extension Bar

Hex Sockets ............... 10mm

13mm

17mm

„

9

/

AF

16

Spanner ..................... 13mm

Pozi Driver ................. No.2

Hex Wrench ............... 8mm

Security Wrench for M5 Security Button Head Screws

Rosta Spring Shaft Assembly ....... Part No 46000088A (Supplied)

10ml Loctite 242............................ Part No 95000004 (Supplied)

Castrol LM Grease ........................ Part No - - - - - - - (Supplied)

1. Remove 4off Hex Head Screws (M8x60). Raise the level

adjusters on the Ride Assembly and separate the ride assembly

from the monitor cabinet only sufficiently enough to disconnect

the connectors and air line.

Note: Ensure that the blue locking ring is pushed towards the

connector when removing the air tube. There may be a loud

“hissing” noise as the air in the compressor tank is released,

2. Move the ride assembly away from the monitor cabinet to give

sufficient room to work and lower the level adjusters to keep the

ride assembly stationary whilst working.

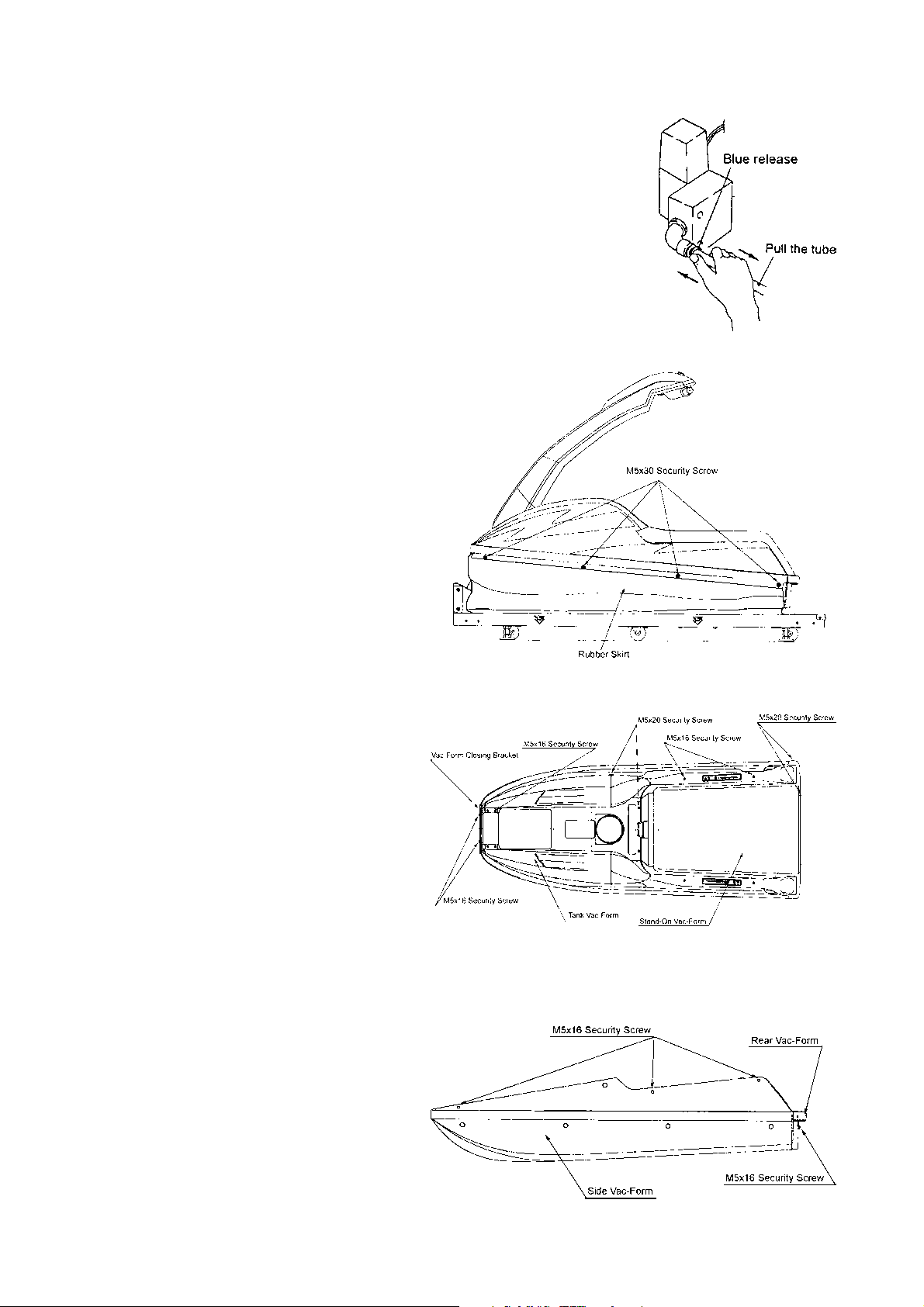

3. Remove 8off Security Screws

(M5x30), 4ea side, and remove

the rubber skirts, complete with

fixing brackets and lay on the

Main Base Assy.

Note: Take care not to bend or

distort the long fixing brackets.

4. Remove 8off Security screws

(M5x16), 4ea side, and remove

the Vac-Form Closing Bracket.

5. Remove 4off Security Screw

(M5x16) and 4off Security Screw

(M5x20) and remove the Tank

Vac-Form.

Note: Lift the Vac-Form and turn it

through 90° to remove it from the

Control Arm assembly.

6. Remove 4off Security Screw

(M5x16) and 4off Security Screw

(M5x20) and remove the StandOn Vac-Form.

7. Remove 6off Security Screw

(M5x16), 3 screws each side, and

remove the Side Vac-Forms.

8. Remove 2off Security Screw

(M5x16) and remove the Rear

Vac-Form.

Loading...

Loading...