NAMCO Bandai Games 90500019 User Manual

IT IS THE RESPONSIBILITY OF THE OPERATOR TO MAINTAIN CUSTOMER SAFETY

AT ALL TIMES

Part No. 90500019

ACE DRIVER

DELUXE

Operators Manual

, AND IT IS IMPERATIVE THAT THE DETAILS SET OUT IN THIS

MANUAL ARE FOLLOWED PRECISELY

.

SAFETY W ARNING

In Order to Use This Machine Safely

In order to use this machine safely, be sure to read this Operators Manual and the

Installation and Commissioning manual carefully before installation and use of the

machine.

Whenever the owner of this machine entrusts disassembly, installation,

adjustment, routine maintenance or trouble shooting to another person, the owner

should ensure that they read the appropriate precautions and relevant sections of this

manual before starting work.

In order that no accidents occur when the machine is in operation, strictly

follow the notes on safety described below. Also, carefully read section 3,

"Precautions".

Warnings for Operation

NOTE:

NOTE:

NOTE:

NOTE:

Warnings for Disassembly, Installation, Routine Maintenance and Troubleshooting

DANGER:

DANGER:

DANGER:

DANGER:

NOTE:

Only operate this machine after checking that it has been installed correctly

and in accordance with the Installation and Commissioning manual.

Parts of this machine move during game play, so there are places where

the distance between the stationary section and moveable section changes.

There are warning stickers to keep hands and feet clear of moving parts,

however if the operator feels that a customer playing the game is in any

danger, he should warn the customer accordingly.

The warning stickers must always be kept in good condition and replaced if

worn so that the customer can read them clearly.

If there is an error or problem with this machine, operation must be

stopped immediately. (If the Drive Castor is worn out, it should be handled

according to section 6-9, "Handling Drive Castor Wear".)

Namco Ltd. bears absolutely no responsibility for accidents or injuries

resulting from unauthorized changes to the machine.

Ensure that the machine has been turned OFF before making adjustments

or carrying out maintenance. Also ensure only qualified personnel carry out

maintenance or turn the power ON to this machine.

The power supply and inside the monitor will remain hot and have areas of

high voltage even though the machine has been turned OFF, and there is a

possibility of burns or electric shock. Be careful not to touch these areas.

In order to avoid injuries due to mis-operation, be sure that the voltage of

the power supply is within the prescribed limits. Also to prevent possible

electric shocks due to failure, this machine MUST be fitted with a securely

connected earthed plug.

Do not turn the main power switch ON until the machine has been installed

correctly.

© 1994 Ltd - all rights reserved.

No part of this publication may be reproduced by any mechanical, photographic or electronic

process, or in the form of phonographic recording, nor may it be stored in a retrieval system,

transmitted or otherwise copied for public or private use, without permission from namco

Ltd.

While the information contained in this manual is given in good faith and was accurate at the

time of publication, BRENT LEISURE LIMITED reserve the right to make changes and

alterations without notice.

This machine has been manufactured in accordance with European Community directives

(1st. January 1995), and as such bears the

this machine must be in accordance with European Community directives (1st. January

1995).

If you make any unauthorised changes to this product, you may contravene European

Community directives (1st. January 1995)

Published by:

BRENT LEISURE Ltd.

Unit 1 Brent Crescent,

London. NW10 0QT

marking. Any changes or modifications to

Phone:- 0181-965-0550

Fax:- 0181-961-0574

Content s

1. HOW TO PLAY ...............................................................................................................1

2. SPECIFICATIONS .......................................................................................................... 2

3. PRECAUTIONS ..............................................................................................................4

3-1. Notes on Operation ............................................................................................. 4

3-2 Notes on Installation ...........................................................................................5

3-3. Notes on Moving and Shipping..........................................................................6

3-4 Notes on Handling...............................................................................................7

4. MAJOR COMPONENTS ................................................................................................8

5 ADJUSTMENTS .............................................................................................................9

5-1 Turning on the Power .........................................................................................9

5-2 Adjustment Switches ..........................................................................................9

5-3 Test Mode ........................................................................................................... 10

5-3-1 Coin Options ......................................................................................... 11

5-3-2 Game Options......................................................................................12

5-3-3 I/O Test..................................................................................................14

5-3-4 Switch Test ............................................................................................ 15

5-3-5 Motor Test..............................................................................................16

5-3-6 Motion Stop Test ................................................................................... 1 6

5-3-7 Lamp Test..............................................................................................17

5-3-8 LED Test................................................................................................17

5-3-9 Sound Test ............................................................................................ 1 8

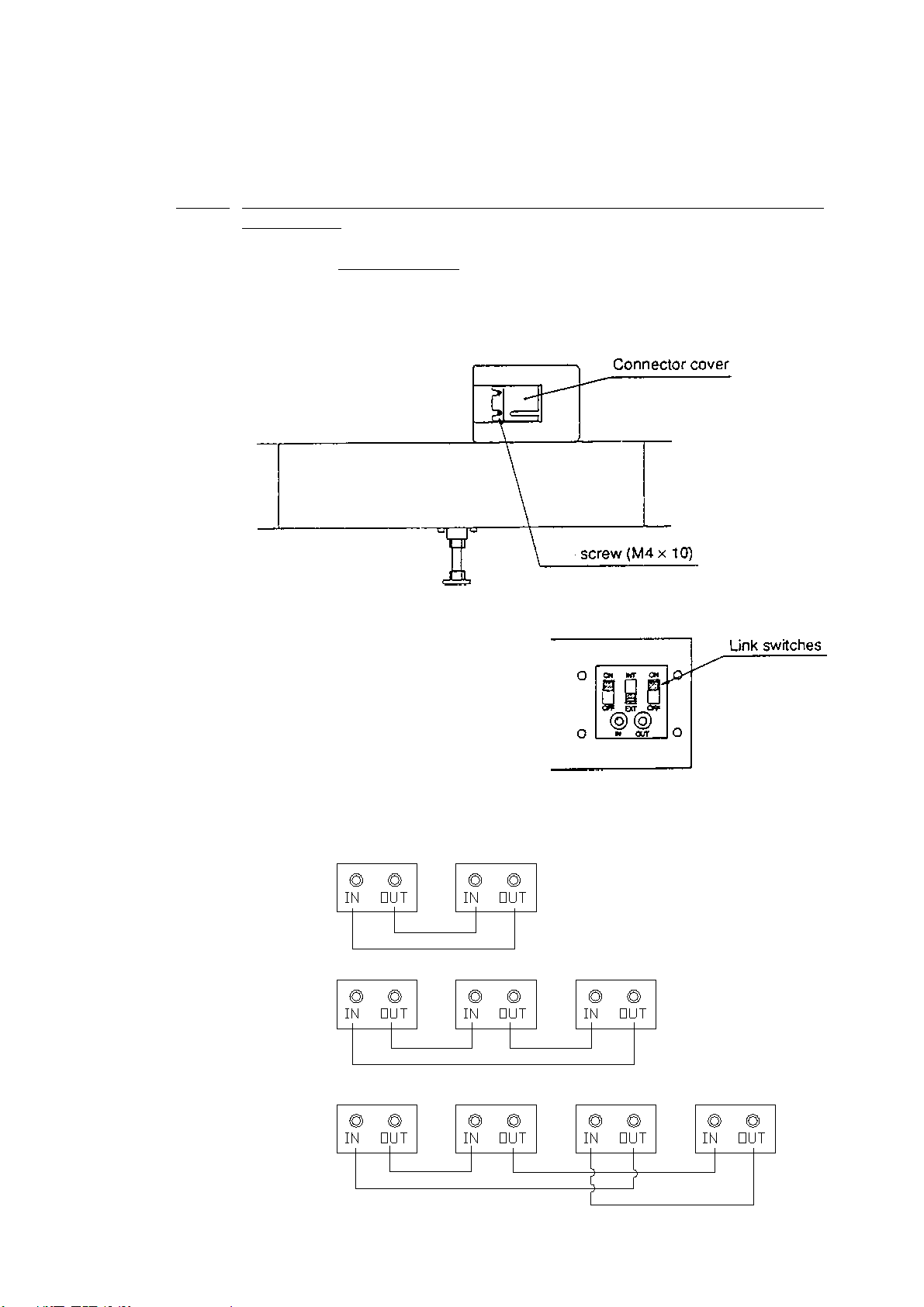

5-4 Linking Two or More Machines. ....................................................................... 19

5-4-1 Setting the Link Switches .....................................................................20

5-5 Adjustments When Replacing Parts (Initialization)........................................21

6. MAINTENANCE ............................................................................................................22

6-1 Cleaning the Under Base.................................................................................. 22

6-2. Sign Assembly ................................................................................................... 23

6-2-1. Replacing the Fluorescent Tube and Reflector Lamp .........................23

6-2-2. Replacing the LED Drive PCB..............................................................23

6-3. Main tower Assy .................................................................................................24

6-3-1. Replacing Fluorescent Lamp and Reflector Lamp...............................24

6-3-2. Removing the Game PCB ....................................................................24

6-3-3. Removing the Shield Case ................................................................... 2 5

6-3-4. Removing the I/O Board .......................................................................2 5

6-3-5 Replacing the Switch Mode Power Supply and Fuses. .......................2 6

6-3-6 Replacing the Amplifier. ........................................................................ 2 6

6-4. Removing the Monitor.......................................................................................27

6-5. Steering and Shift Lever...................................................................................29

6-5-1. Replacing the Steering Wheel ..............................................................29

6-5-2. Shift Assembly Maintenance ................................................................29

6-5-3. Replacing the Steering Drive PCB .......................................................3 0

6-5-4. Replacing the Time Belt ........................................................................31

6-5-5. Replacing the Motor and Motor Brush..................................................32

6-5-6 Replacing the Pulley .............................................................................33

6-5-7. Replacing the Fuse...............................................................................3 4

6-5-8. Replacing the Control Pot.....................................................................34

6-6. Replacing the Seat ............................................................................................35

6-6-1. Removing the Seat ...............................................................................3 5

6-6-2. Installing the Seat .................................................................................3 7

6-7. Under Base Assembly.......................................................................................38

6-7-1. Removing the Rear Covers (L), (R)......................................................38

6-7-2. Names of Under Base Parts.................................................................3 9

6-7-3. Replacing the Drive Castor................................................................... 3 9

6-7-4. Replacing the Drum Drive PCB and Motion Stop PCB........................4 2

6-7-5. Replacing the V Belts ...........................................................................43

6-7-6. Replacing the Motor and Motor Brushes..............................................44

6-7-7. Replacing the Motor Fuse .....................................................................44

6-8. AB Pedal Assembly ...........................................................................................45

6-8-1. Removing the AB Pedal Assembly .......................................................45

6-8-2. Replacing the Control Pots...................................................................4 5

6-9. Handling Drive Castor Wear.............................................................................46

6-9-1. Checking drive Castor Wear .................................................................46

6-9-2. Action When the Drive Castor is Worn Out .........................................46

7. TROUBLESHOOTING .................................................................................................47

8. PARTS ..........................................................................................................................48

9. SCHEMATICS ............................................................................................................... 90

1. HOW TO PLAY

• This machine is a multi-player racing game that allows several people to play at

the same time, up to a maximum number of eight.

• When two or three players are competing against each other, the computer car

is included and competition is between four cars.

When four or more players compete against each other, competition is amongst

those players only.

When only one player is playing, he/she competes against the computer cars.

[Game Summary]

• The object of the game is to complete the set number of laps as fast as possible

within the set time.

• The game is over after completing the set number of laps. The finishing position,

lap time, and total time are displayed at the end of the game.

• If the set time runs out (becomes "0") before the laps are completed, the game

is over.

[Starting the Game]

• Insert a coin/s. Move the shift lever up or down to select the method of shifting,

AT (auto) or MT (manual) and then depress the accelerator.

• Next, move the shift lever up or down to select the level of difficulty (beginner,

expert, expert (pro)) and then depress the accelerator. Expert (pro) is selected

by selecting expert and depressing the accelerator while at the same time

pressing the view change button. In a linked game expert (pro) class is set only

if all participating players select it.

• After making selections, wait for the empty seat entry.

• A linked game starts when all of the connected seats have been entered, or

when another player enters from another seat within twenty seconds after the

coin/s have been inserted.

If there is no entry by another person within the twenty seconds, the game starts

as a single player.

• A single player game can be started without waiting for other players by inserting

a coin/s while pressing the view change button.

Page 1

2. SPECIFICATIONS

POWER SUPPLY :- 220/240volts AC

POWER CONSUMPTION:- 720W

MONITOR :- Hantarex 28" Polo Colour Monitor with auto degauss.

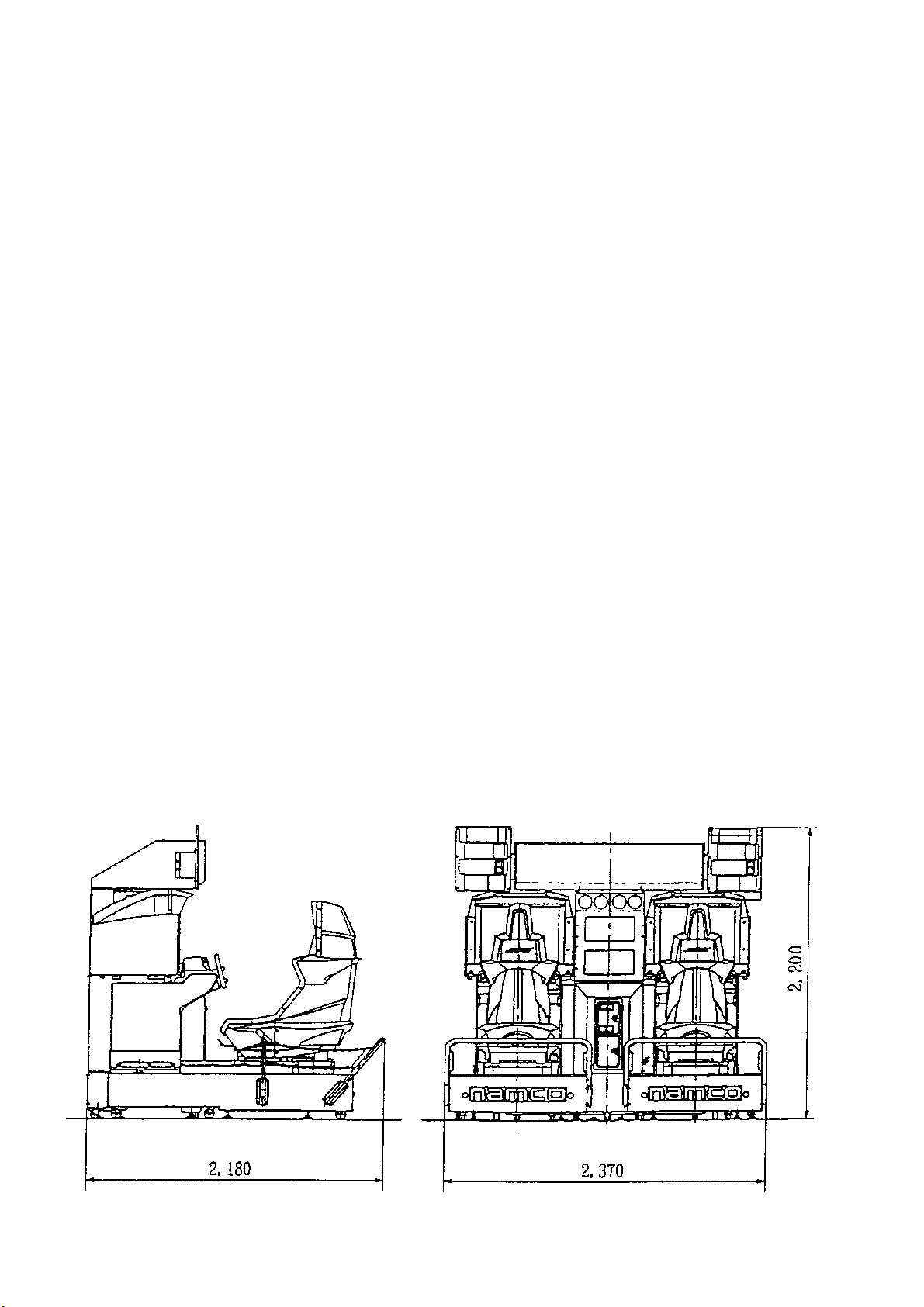

DIMENSIONS :-

- Assembled: 2,370mm(w) x 2,180mm(d) x 2,200mm(h)

- Separated: Seat Assy 1,070mm(w) x 2,030mm(d) x 1,640mm(h)

Tower Assy 2,100mm(w) x 850mm(d) x 1,760mm(h)

Header Assy 1,380mm(w) x 842mm(d) x 325mm(h)

Sign Boards 440mm(w) x 170mm(d) x 490mm(h)

WEIGHT:-

- Assembled: 1,112kg

- Separated: Seat Assy 360kg (x2)

Tower Assy 348kg

Header Assy 32kg

Sign Boards 6kg (x2)

Page 2

ACCESSORIES :-

Keys: (Cash Door)..................................................... 2

IEC Mains Lead .................................................................. 1

Operators Manual ............................................................... 1

Installation & Commissioning Manual ................................ 1

Monitor Manual...................................................................1

Car Number Decal Set - Large .......................................... 2

Car Number Decal Set - Small...........................................1

M10 Security Wrench.........................................................1

M8 Security Wrench...........................................................1

M6 Security Wrench...........................................................1

M5 Security Wrench...........................................................1

Link Cable 6 metre .............................................................1

(Coin Door)......................................................2

(Back Door).....................................................2e a

Steering Control Pot (Cont. Rotation) ................................1

Header Sign Board - LHS ..................................................1

Header Sign Board - RHS.................................................. 1

Seat Base Extension Brkt - LHS/RHS ...............................4

Floor Safety Mat - LHS....................................................... 1

Floor Safety Mat - RHS ......................................................1

Floor Safety Mat - Centre...................................................1

Rear Guard Fence .............................................................. 1

Rear Guard Fence Securing Brkt ....................................... 4

Safety Skirt ........................................................................ 2

Safety Skirt Stay ................................................................. 2

M10x25 Hex Head Screw ............................................... 12

M10 Flat Washer - H/Duty............................................... 12

M10 Spring Washer Type B ............................................ 12

M8x20 Security Button Head Screw ...............................40

M8 Flat Washer - H/Duty................................................. 40

M8 Spring Washer Type B .............................................. 40

M6x20 Security Button Head Screw ................................. 4

M5x16 Security Button Head Screw ................................. 6

M5x12 Security Button Head Screw ................................. 4

No6x½" Pozi Flange Head Screw..................................... 4

Page 3

3. PRECAUTIONS

Be sure to read this section carefully

3-1. Notes on Operation

NOTE:

NOTE:

NOTE:

NOTE:

NOTE:

NOTE:

Parts of this machine move to the left and right during the game. In order to maintain

the customer's safety, the operator should strictly follow the appropriate precautions.

Only operate this machine after checking that it has been installed correctly

and in accordance with the Installation and Commissioning manual.

The supplied guard fence is to ensure customers do not get too close to the

machine or get injured. Make sure that the fence is fitted to the machine

correctly and the rubber safety mats are in place.

Parts of this machine move during game play, so there are places where

the distance between the stationary section and moveable section changes.

There are warning stickers to keep hands and feet clear of moving parts,

however if the operator feels that a customer playing the game is in any

danger, he should warn the customer accordingly.

Ensure customers do not get hurt by leaning or climbing on the seat base or

fence. Be especially careful in the case of young children.

The warning stickers must always be kept in good condition and replaced if

worn so that the customer can read them clearly.

If there is an error or problem with this machine, operation must be

stopped immediately .

NOTE:

Ensure no items are placed on the seat base next to the seat

assemblies to prevent damage to the machine.

Page 4

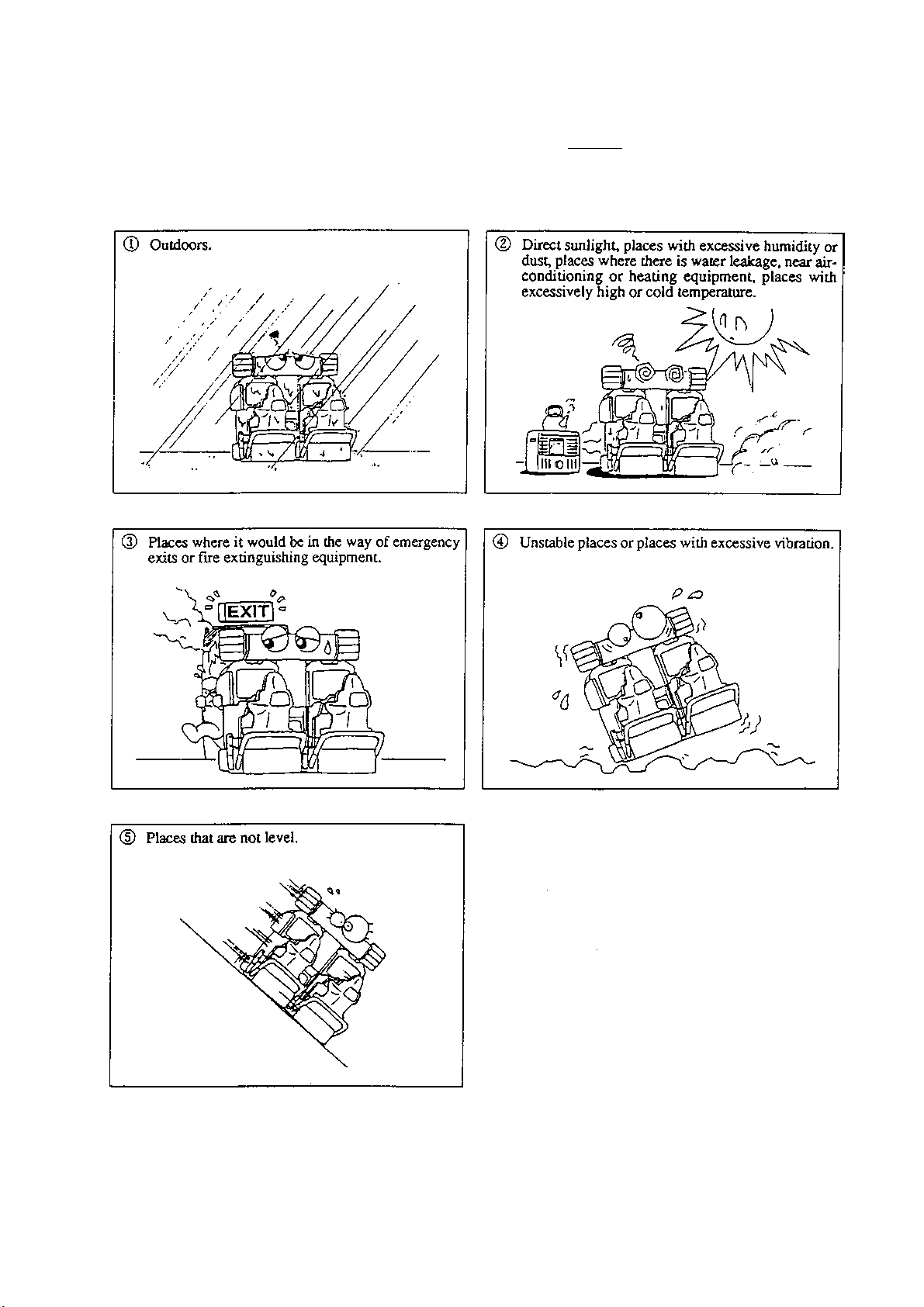

3-2 Notes on Installation

1. This machine is designed for indoor use only.

following places:

Do not install the machine in the

Page 5

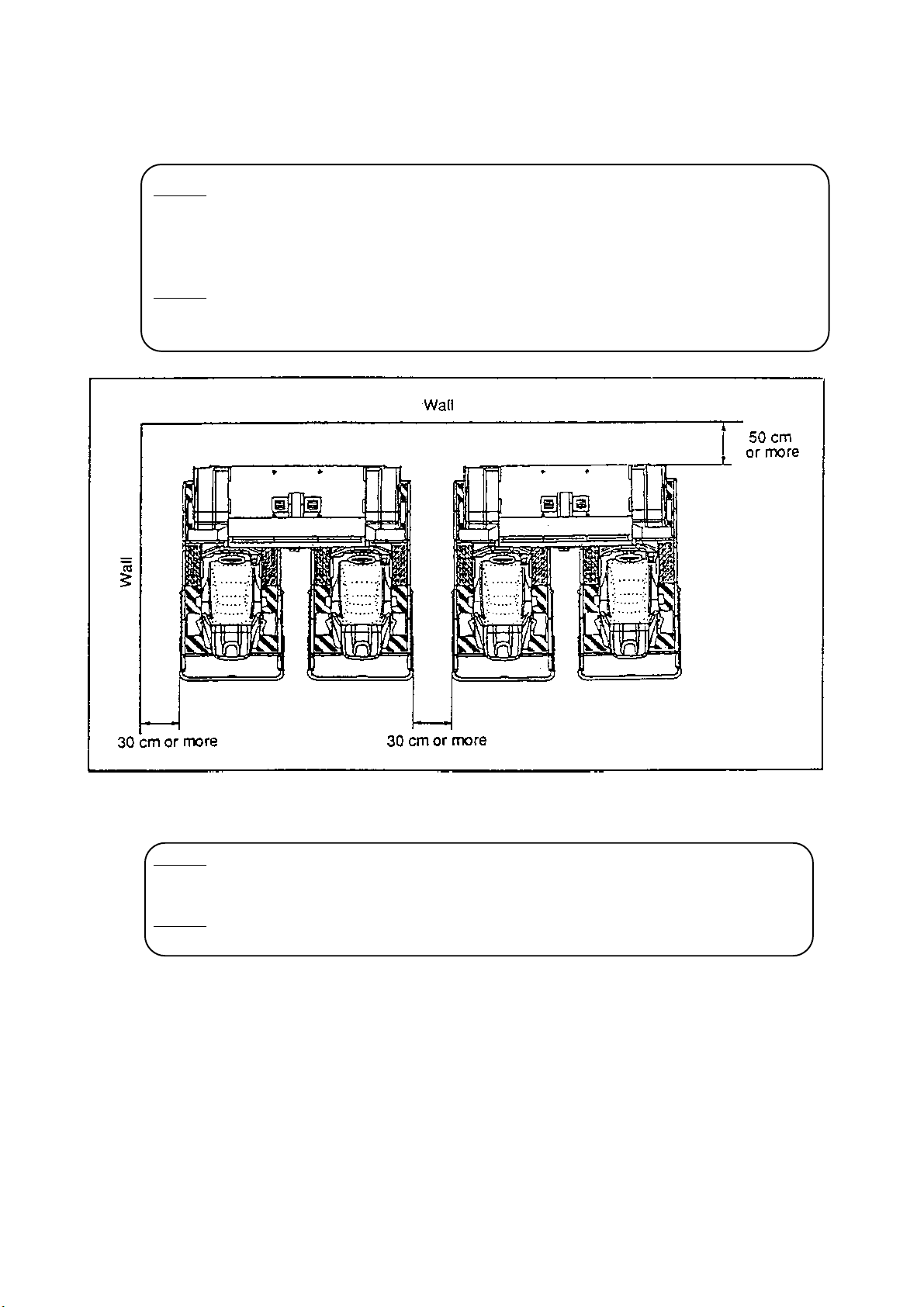

2. If this machine is installed next to walls or other machines, ensure there is

plenty of space between them

NOTE:

NOTE:

So that customers are not crushed or injured while the machine is

moving, ensure that it is separated from walls or other machines by at

least 30cm.

In order that the PCB rack or power supply can be removed for service,

make sure that the rear of the machine is separated from a wall or

other machine by a distance of at least 50cm or more.

3-3. Notes on Moving and Shipping

NOTE:

NOTE:

• Take care not to damage the machine when moving or shipping.

• Take care not to rope moulded (plastic) parts when shipping.

• Ensure that the levellers are raised fully when moving the machine, even for

• The seat assy, tower assy and side boards must be separated when shipping.

• If a forklift is used to move the machine, use it only to move the seat assembly

If the seat assembly is not secured to the seat base, there is a danger of the

seat assembly moving left or right during shipping. Ensure that the shipping

brackets (two for each seat assembly) are fitted securely.

The tower assembly has a high centre of gravity and is unstable when

standing alone. Do not use a forklift when moving or shipping.

short distances.

and only insert the forks in the places indicated on the side of the assembly.

Page 6

3-4 Notes on Handling

DANGER

DANGER

DANGER

be

DANGER

DANGER

NOTES:

The Mains voltage to this machine should be within the range of

220 to 240v AC and the transformer input matched accordingly.

Be sure that the power is turned OFF when replacing parts and

connecting/disconnecting connectors.

to prevent possible electric shocks due to failure, this machine MUST

fitted with a securely connected earthed plug.

The monitor and power supply contain areas of very high voltage. Be

extremely careful when inspecting or making adjustments.

When unplugging the game from an electrical outlet, always grasp the

plug, not the mains lead.

• Always return PC Boards to your dealer for repair. Never test the PCB for

continuity with a multimeter or similar device. The PCB contains sensitive

devices which could be damaged or even destroyed by the internal voltage of

such test equipment.

• Adjustments are required after replacing the game PCB, ROM, Steering Assy,

AB Pedal Assy and control pots.

Adjustments should be performed as described in section 5-4, "Adjustments

when Replacing Parts" (page 19).

• After initial installation or if the number of machines linked together changes, it

may be necessary to use the test mode to change the settings and link switch

settings. (Refer to section5-4, "Linking Two or More Machines" (page 19).

Page 7

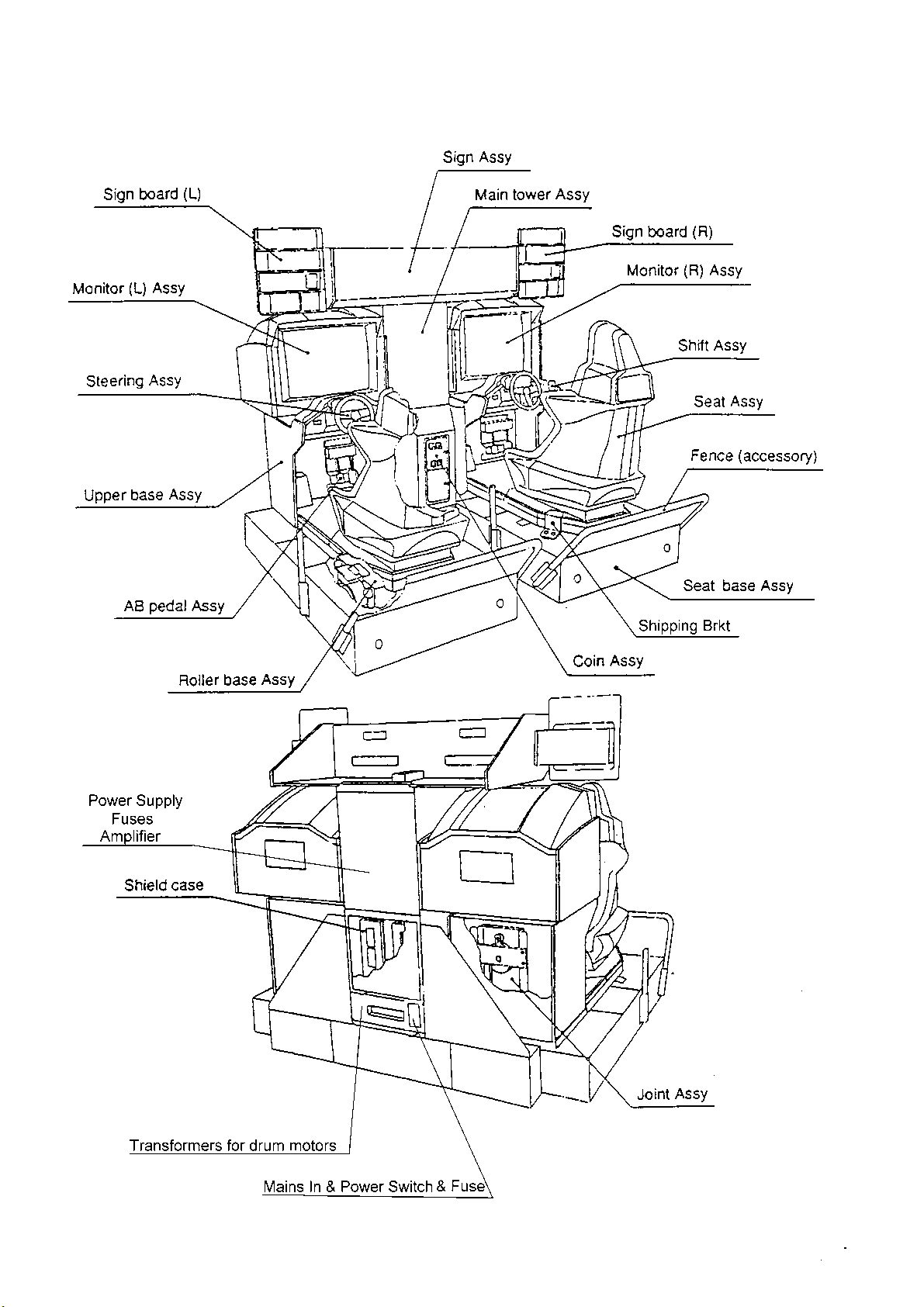

4. MAJOR COMPONENTS

Page 8

5 ADJUSTMENTS

5-1 Turning on the Power

After the machine has been installed, turn ON the power.

The Power switch is located on the rear of the upper tower

section. (See section 4 "Major Components" (page 8).)

5-2 Adjustment Switches

The adjustment switches are located inside the coin door.

1. Service Switch

Press this switch to obtain game credits without incrementing the play

meters.

2. Test Switch

Slide this switch "ON" to enter test mode.

Test mode allows game testing and the changing of game settings. (Refer to

section 5-3 "Test Mode" (page 10).)

Service Bracket

Page 9

5-3 Test Mode

1. Open the coin door and slide the test switch "ON". The "Menu Screen" will be

displayed on the monitor.

2. Select the test required by moving the shift lever up or down. The colour of

the selected test will change.

3. Enter the selected test by stepping on the accelerator. Select "EXIT" to

return to the "Menu Screen" (step on the accelerator when using the monitor

test screen).

4. After testing is completed, ensure that the test switch is returned to the

"OFF" position to return to game mode.

The Test Switch must always be in the "OFF" position for normal game mode.

MENU

COIN OPTIONS ------ (1) Sets the price of play. (See 5-3-1)

GAME OPTIONS ------ (2) Sets the game options.(See 5-3-2)

I/O TEST ------ (3) Used for testing the switches and motor.

MONITOR TEST ------ (4) Used for adjusting the monitor.

SOUND TEST ------ (5) Used for adjusting the speaker volume.

ADS DATA ------ (6) Displays the accumulated game data.

OTHERS ------ (7) Used for testing the PC boards and for

GAS: ENTER SHIFT: CHOOSE

(See 5-3-3)

(See 5-3-9)

initializing all of the settings.

Page 10

5-3-1 Coin Options

a. Select item (1)

"COIN OPTIONS"

on the menu screen,

to set the game cost

and related settings.

b. Use the shift lever to

select the required

item then step on

the accelerator.

c. Use the shift lever to

change the settings

then step on the

accelerator to store

the new values.

d. Select "EXIT" to

return to the menu

screen.

COIN OPTIONS [DEFAULT IN GREEN]

GAME COST

1 COIN 1 CREDIT ........... (a)

COIN1 MECH VALUE

1 COIN COUNT AS 1 COIN ........... (b)

COIN MECH 2 VALUE

1 COIN COUNT AS 1 COIN ........... (c)

BONUS FOR QUANTITY BUY IN

NONE ........... (d)

FREE PLAY

OFF ........... (e)

EXIT

GAS: ENTER SHIFT: CHOOSE

Note:- The price of play on this machine is set within the Cashflow Coin Mech. Ensure that

the Coin Options on the screen are set as shown in the following table.

METISTNETNOCYROTCAF

TES

tsoCemaG)a( 9-1elbattes------tiderc1rofderiuqersnioC1

eulaVhceM1nioC)b( 9-1elbattes--

eulaVhceM2nioC)c( 9-1elbattes------niocrepretemnoseslupforebmuN1

oB)d(nisniocdeificepstaeslupniocartxEENON

nioCsun

yalPeerF)e( oN/seY------rotareleccagnisserpybdetratsemaGON

----niocrepretemnoseslupforebmuN1

Page 11

5-3-2 Game Options

a. Select item (2) "GAME

OPTIONS" on the

menu screen to set the

game options.

GAME OPTIONS [DEFAULT IN GREEN]

PCB ID NUMBER ................. (a)

b. Use the shift lever to

select the required item

then step on the

accelerator.

c. Use the shift lever to

change the settings

then step on the

accelerator to store the

new values.

d. Select "EXIT" to return

to the menu screen.

Note: Race Class (c) must

be set first before

changing items (d),

(e), or (f).

(See page 13 for descriptions)

TEAM COLOUR BLUE3 .................(b)

RACE CLASS BEG EXP P RO ................. (c)

DIFFICULTY B B B ................. (d)

LAPS [LINK] 3 3 4 ................. (e)

LAPS [SOLO] 3 3 4 ................. (f)

SPEED DISPLAY KM/H ................. (g)

SOUND IN ATTRACT ON ................. (h)

EXIT

GAS: ENTER SHIFT: CHOOSE

NOTES

• The rank (level of difficulty) and number of laps must be set the same

on all positions that are linked.

• The PCB number of the seat furthest left (when facing the front of the

machine) should be set to 1, and the other seats set to 2, 3, 4 and so

on in order from left to right. The PCB number of the farthest right

position should equal the number of positions linked.

• Settings other than those described will cause the machine to operate

incorrectly.

Page 12

METINOITPIRCSEDTESYROTCAF

rebmuNBCP)a( emasehtevahsnoitisopdeknilehtfoenontahtostesebdluohsrebmunBCPehT

re

bmun

ruoloCmaeT)b(DER62ro52

EULB4ro3

WOLLEY81ro71

NEERG21ro11

seerhtnahteromnehW*

.sruolocmaetemasehtrofdesu

ecaR)c(

ssalC

GEB

PXE

ORP

()trohs(Dot)gnol(A

stinUodeepS)g(

dnuoStcarttA)h(

HPM/H/MK

FFO/NO

)emit(levelytluciffidemaG)d()trohs(Dot)gno

)emagdeknil(spalforebmuN)e(6ot3

)yalpolos(spalforebmuN)f(6ot3

)emit(levelytluciffidemaG)d()trohs(

)emagdeknil(spalforebmuN)e(6ot3

)yalpolos(spalforebmuN)f(6ot3

)emit(levelytluciffidemaG)d

)emagdeknil(spalforebmuN)e(6ot3

)yalpolos(spalforebmuN)f(6ot3

l(A

Dot)gnol(A

ebdluohssrebmunecartnereffid,deknilera)staes6(ste

B

3

3

B

3

3

B

4

4

PM

H

NO

Page 13

5-3-3 I/O Test

1. Select item (3) "I/O TEST" on the menu screen.

2. Use the shift lever to select the required item then step on the accelerator.

I/O TEST

DIP 2 12345678 ........... (a) Option Switch (CPU-PCB Sw2)

3 12345678 ........... (b) Option Switch (CPU-PCB Sw1)

LINK ON 2 COUNT 0 ........... (c) Link Check

SWITCH ........... (d) Switch Test

MOTOR ........... (e) Motor Test

LAMP ........... (f) Lamp Test

LED ........... (g) LED Test

EXIT

GAS: ENTER SHIFT: CHOOSE

(a) Displays the state of the option switch, SW2, on the game PC board (CPU-

PCB).

(b) Displays the state of the option switch, SW3, on the game PC board (CPU-

PVB). For both items (a) and (b), the switch is ON when the numbers are shown

in red.

(c) Displays the number of positions linked. If there is a link error, "ERROR" is

displayed. The numbers to the right of "COUNT", display the number of link

errors detected during the I/O test.

(d) Tests the switches. (See 5-3-4.)

(e) Tests the motors. (See 5-3-5.)

(f) Tests the lamps. (See 5-3-7.)

(g) Tests the LEDs. (See 5-3-8.)

Page 14

5-3-4 Switch Test

The following screen is displayed when "SWITCH" is selected on the I/O

screen.

I/O TEST

DIP 2 12345678

3 12345678

LINK ON 2 COUNT 0

SWITCH

(a) Accelerator ................ GAS: *0000 COIN 1: OFF ..............(e) Coin 1 switch

(b) Brake ................ BRAKE *0000 COIN 2: OF F ..............(f) Coin 2 switch

(c) Steering ................ STEER *0000 SERVICE: OFF ..............(g) Service switch

(d) Shift ................ SHIFT CENTRE VIEW: OFF ..............(h) View change switch

TO EXIT, STEP ON GAS AND SHIFT UP

(a) When the accelerator is stepped on, the number increases in the + direction.

(b) When the brake is stepped on, the number increases in the + direction.

(c) When the steering wheel is turned to the right, the number increases in the +

direction, and when it is turned to the left, it increases in the - direction.

When items (a), (b), and (c) are in their middle position, "0000" is displayed. (It is

normal for the last digit to change.) Just before the steering wheel is as far as it

will go, or just before stepping on the accelerator or brake as far as they will go,

"OK" will be displayed to the right of the number if everything is correct.

(d) Displays the position of the shift lever (CENTRE, UP, DOWN) and the state of

the switches.

When the shift lever is pressed forward, switch 1 goes "ON" and "DOWN" is

displayed, and when it is pulled back, switch 2 goes "ON" and "UP" is displayed.

(e) When coin 1 switch is operated, "ON" is displayed.

(f) Unused.

(g) Goes "ON" when the service switch inside the coin door is pressed.

(h) Goes "ON" when the view change button is pressed

To return to the menu screen, move the shift lever up and step on the accelerator.

Page 15

5-3-5 Motor Test

The following screen is displayed when "MOTOR" is selected on the I/O screen.

I/O TEST

DIP 2 12345678

3 12345678

LINK ON 2 COUNT O

SWITCH

MOTOR

BASE MOTOR OFF ............... (a) Seat motor test

STEERING OFF TORQUE 00 ............... (b) Steering motor test

EXIT

GAS: TURN SHIFT: CHOOSE

(a) Tests the seat roller motor.

When "BASE MOTOR" is selected and the accelerator is pressed the test is

"ON" and the motor starts to operate. Pressing the accelerator again turns the

test "OFF" and the motor stops.

(b) Tests the steering feedback motor.

When "STEERING" is selected and the accelerator is pressed the test is "ON"

and the motor will start and turn the steering wheel left and right.

When performing this test, ensure that test (a) "BASE MOTOR" is also "ON".

Pressing the accelerator turns the test "OFF" and the motor will stop.

Select "EXIT" to return to the I/O test screen.

Note: Performing the steering motor test can be dangerous, sit on the

seat properly, and take hands off the steering wheel.

5-3-6 Motion Stop Test

The Stop Motion Switches will illuminate as soon as the test switch is

turned ON.

To test the motion stop switches enter motor test (Refer to section 5-3-5,

"Motor Test" above.) and select Base Motor ON.

Each time a stop motion switch is pressed, the motor will stop and restart

when the switch is released.

NOTE: If this switch is pressed during game mode, the seat motion will stop

and stay off for the remaining duration of the game

Page 16

5-3-7 Lamp Test

The following screen is displayed when "LAMP" is selected on the I/O screen.

I/O TEST

DIP 2 12345678

3 12345678

LINK ON 2 COUNT 0

LAMP

TOP LAMP ........................ (a)

SIGNAL LAMP RED ........................ (b)

SIGNAL LAMP GREEN ........................ (c)

EXIT

GAS: LIGHT SHIFT: CHOOSE

(a) Tests the top lamp.

(b) Tests the red signal lamp.

(c) Tests the green signal lamp.

Select "EXIT" to return to the I/O test screen.

5-3-8 LED Test

The following screen appears when "LED" is selected on the I/O test screen.

I/O TEST

DIP 2 12345678

3 12345678

LINK ON 2 COUNT 0

LED ................. (a)

ÛÛÛÛ

ÛÛ

ÛÛ

ÛÛÛÛ

ÛÛ

ÛÛ

ÛÛÛÛ Û

EXIT

GAS: LIGHT SHIFT: CHOOSE

(a) Tests the finish position LED.

Select "EXIT" to return to the I/O test screen.

Page 17

5-3-9 Sound Test

To adjust the sound volume, select "SOUND TEST" in the menu screen. The

following screen will be displayed.

SOUND TEST [DEFAULT IN GREEN]

VOLUME [MAX 63]

LEFT RIGHT

(a) Left speaker volume ................. 40 40 ........(b) Right speaker volume

SONG 40

EXIT

GAS: ENTER SHIFT: CHOOSE

Select (a) or (b) by using the shift lever, the characters will blink in red, when the

accelerator is pressed the numbers will start to blink. Moving the shift lever up will

increase the number, moving the shift lever down will decrease the number.

The volume can be adjusted in 64 steps, with 00 the lowest and 63 the loudest. The

factory setting is "40"

Select "EXIT" to return to the menu screen

Page 18

5-4 Linking Two or More Machines.

Up to four machines (8 seats) can be linked together.

The machines should be linked as described below.

NOTE: Each machine can draw up to 8 amps. Make sure that the power supply

is adequate.

1) Ensure that the power is "OFF".

2) Loosen the two screws (M4x10) on the back of the tower assy, and remove the

connector cover.

3) Set the link switches to "ON" , "EXT",

and "ON". (See Diag.)

4) Use the supplied link cable and connect

the machines between "IN" and "OUT"

sockets (See Diag.)

[Examples of Linked Machines]

a) 2 Machines

(4 Seats)

b) 3 Machines

(6 Seats)

c) 4 Machines

(8 Seats)

Page 19

5) Turn the power to each machine "ON", and set the PCB ID using the test mode.

(Refer to section 5-3-2, "Setting the Game Options" (page 11))

Note: Settings other than those described will cause the machine to operate

incorrectly.

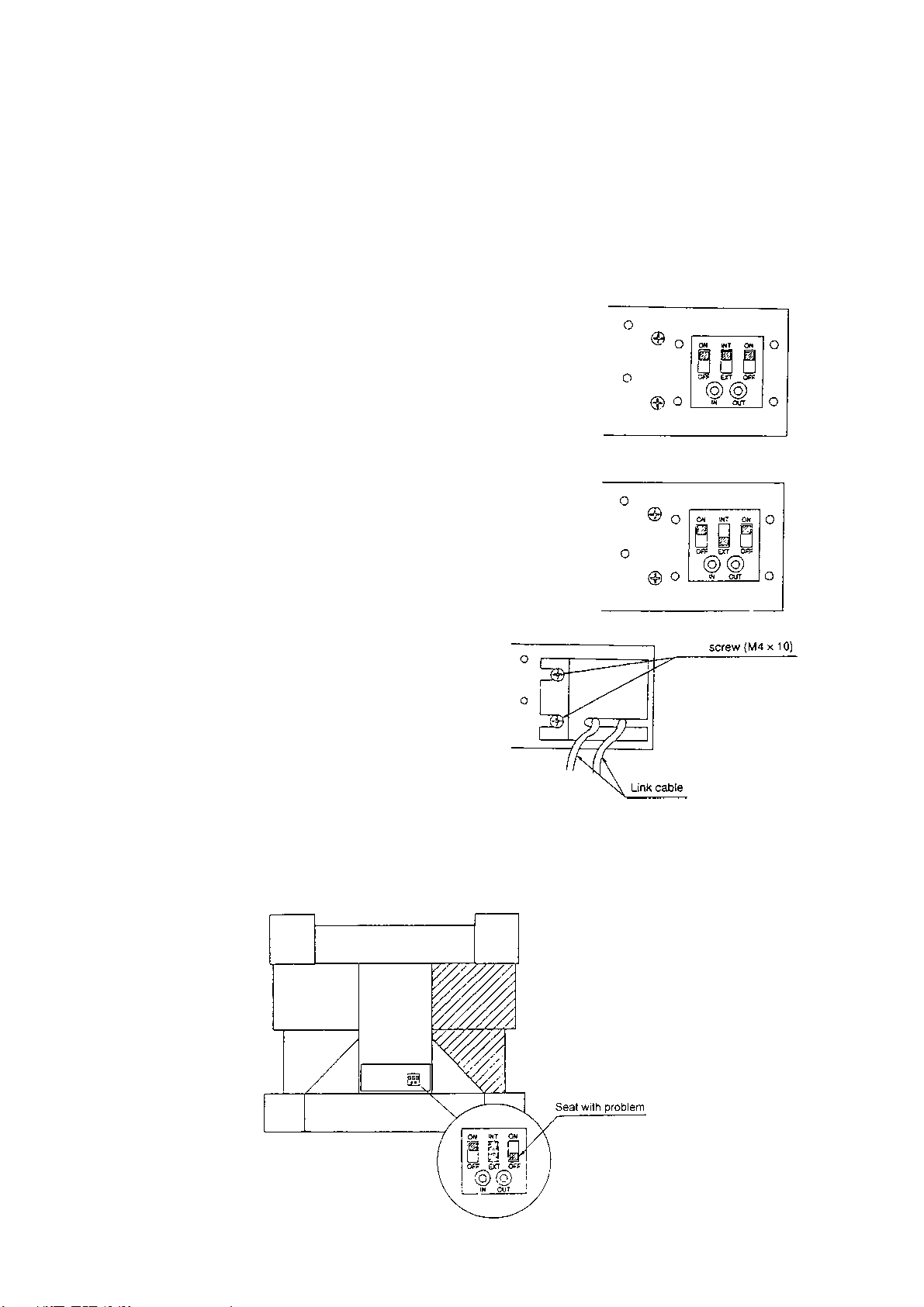

5-4-1 Setting the Link Switches

The link switches are used to set the connection between seats and machines.

1). Setting only one machine (2 seats)

Set the link switches to "ON", "INT", and "ON".

Note: Do not use a link cable.

2) Setting two or more machines.

Set the link switches to "ON", "EXT", and "ON".

3) Install the connector cover using

the two screws (M4x10).

The link procedure is now complete.

4) Setting for faulty PCB.

If the game PCB of only one side is faulty, set the link on that side to "OFF"

[Example of setting for faulty left side]

Page 20

5-5 Adjustments When Replacing Parts (Initialization)

The following adjustments should always be performed after replacing the game PC

board, ROM, Steering Assy, Pedal Assy, or Control Pots.

The game will not operate correctly if these adjustments are not made.

a) Ensure that accelerator and brake pedals are fully returned.

b) Place the steering wheel to it's centre position and remove hands from the

wheel

The steering wheel does not return to centre by itself.)

(

c) Slide the test switch "ON" while pressing the service switch. The following

ADJUST MODE

BASE BIAS VALUE

STEER: **** **** 0000

GAS: **** **** 0000

BRAKE: **** **** 0000

ADJUST WHILE PRESSING

SERVICE SWITCH.

TO EXIT, TURN OFF TEST SWITCH.

screen will be displayed on the monitor.

d) Press the service switch to reset all values to 0000

e) Fully depress and release the accelerator, then the brake, then turn the steering

wheel fully left and right.

f) Slide the test switch "OFF" to return to normal game mode.

If the above initialization does not perform correctly, repeat two or three times.

*

Page 21

6. MAINTENANCE

DANGER: In order to prevent injury or electric shock to service personnel,

ensure that the MAIN POWER IS OFF before attempting any

maintenance.

DANGER: Before performing any work not described in this manual, be sure to

contact your distributor first to receive instructions or answers to

questions.

NOTE: This machine has a moving mechanism, and uses a drive castor in

the base assy (see section 6-7, "Under Base Assy"). When the

castor wears out, the seat assembly can be moved left to right easily

by hand.

movable seat assy using the shipping brackets until the castor has

been replaced with a new one. (Refer to section 6-9, "Handling Drive

Castor Wear".)

Turn OFF the motor power switch in the base assy and secure the

NOTE: As the drive castor wears, worn material is deposited in the base

assy and should be removed approximately once a month. (Refer to

section 6-1, "Cleaning the Under Base.)

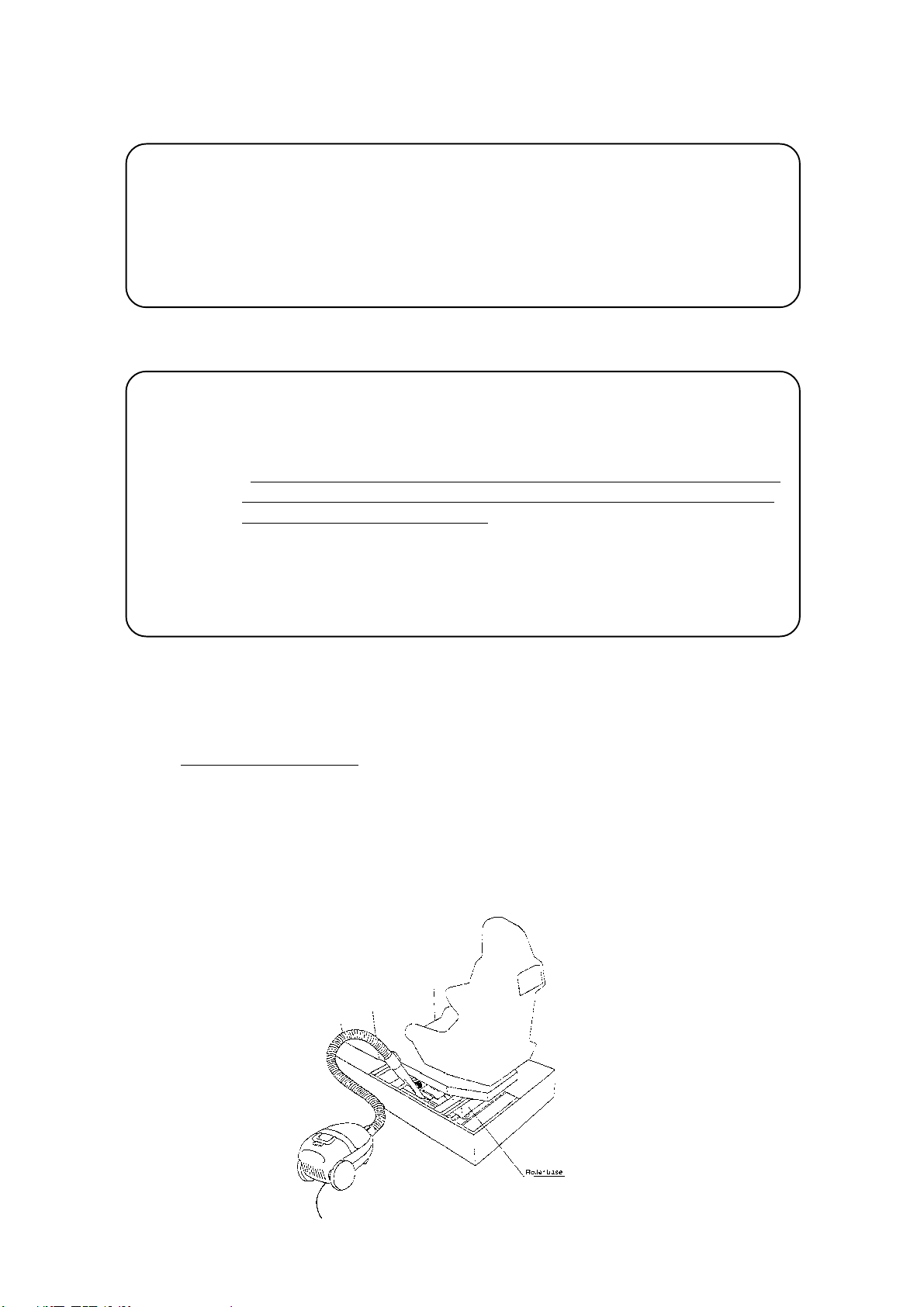

6-1 Cleaning the Under Base

The worn material from the drive castor should be removed once a month.

1) Switch the power OFF

2) Remove the rear covers (L), (R).

(Refer to section 6-7-1, "Removing the Rear Covers (L), (R)")

3) Move the seat assy by hand, and use a vacuum cleaner to remove the worn

material that has collected under the roller. (Refer to section 6-7, "Under

Base Assy".)

Page 22

6-2. Sign Assembly

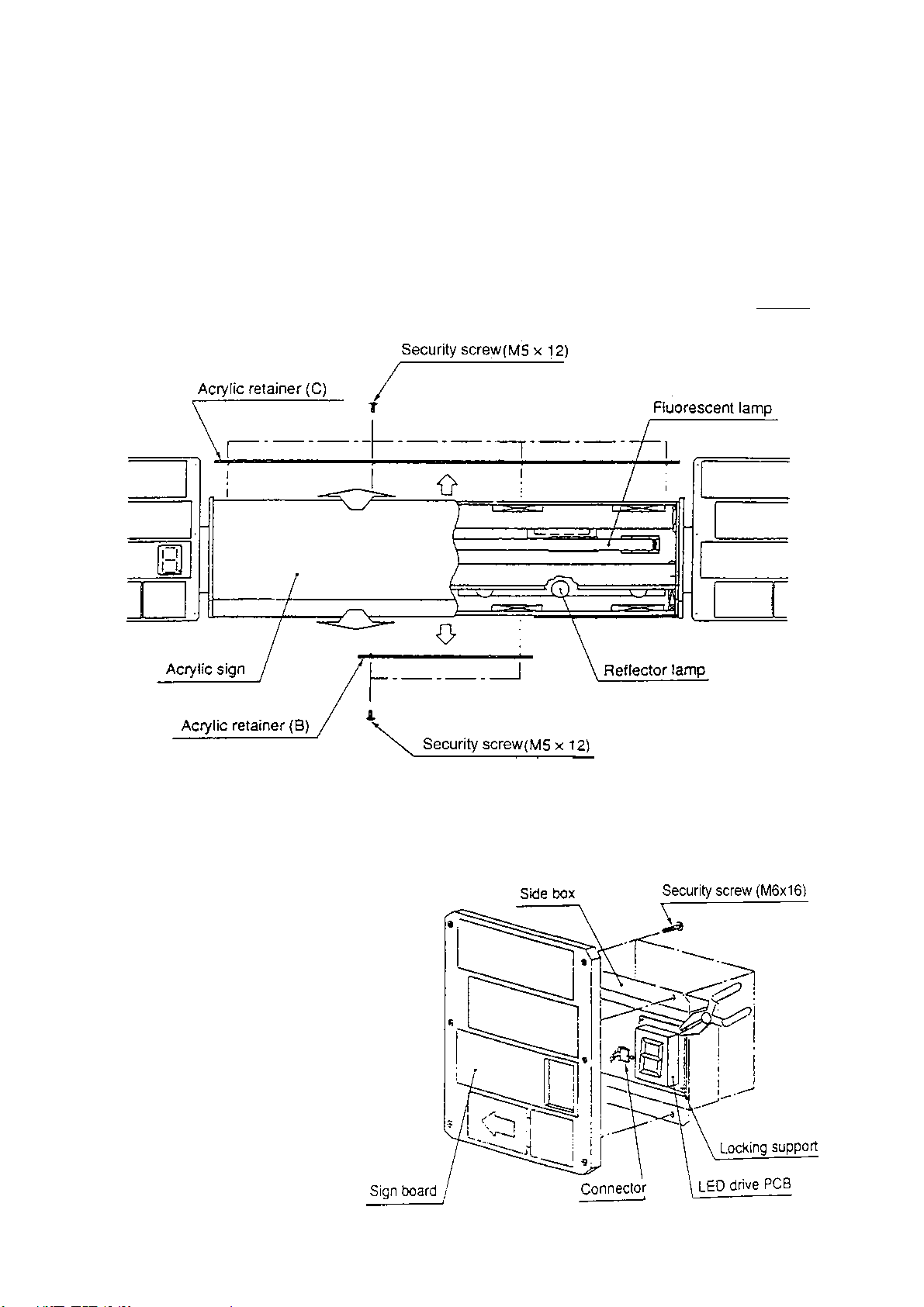

6-2-1. Replacing the Fluorescent Tube and Reflector Lamp

1) Remove the two security screws (M5x12) and remove the acrylic retainer (B).

2) Remove the four Security screws (M5x12) and remove the acrylic retainer

(C).

3) Pull the acrylic sign forward to remove it.

4) Replace the fluorescent lamp 4ft..

5) Unscrew the reflector lamp (240v 25w E14 only) to the left to remove. Refit

by screwing the lamp to the right. (

Warning: Make sure the lamp is not hot

before touching it.)

6-2-2. Replacing the LED

Drive PCB

6) Remove the four

security screws

(M6x16), and remove

the sign board.

7) Disconnect the

connector.

8) Carefully close the

support locking ramp

with pliers, and gently

remove the board

from each support in

turn. Replace the

board by pushing

gently pushing the

board on to each

support.

Page 23

6-3. Main tower Assy.

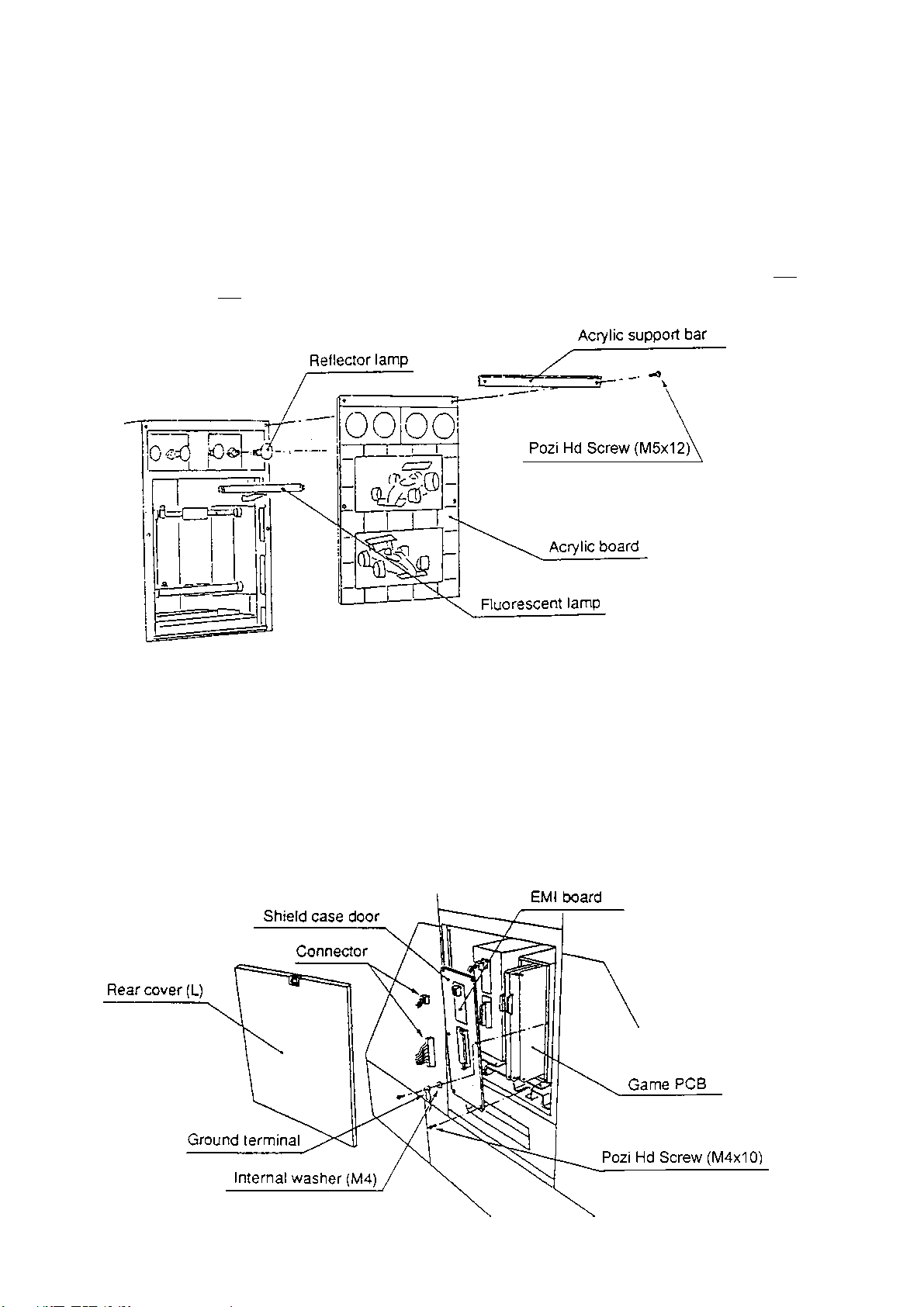

6-3-1. Replacing Fluorescent Lamp and Reflector Lamp

1) Remove the four security screws (M5x12) and the acrylic support bar, then

remove the acrylic board.

2) Replace the fluorescent lamp (12").

3) Unscrew the reflector lamp ( 240v 25w E14 only) to the left to remove.

Refit by screwing the lamp to the right. (

hot before touching it.)

Warning: Make sure the lamp is not

6-3-2. Removing the Game PCB

1) Remove the rear cover (L).

2) Disconnect the two connectors on the EMI board. Remove the six pozi

head screws (M4x10) to remove the shield case door and earth terminal,

being very careful of the connector that connects the EMI board and Game

PCB, then remove the Game PCB.

Note: Be careful not to lose the internal washer (M4).

Page 24

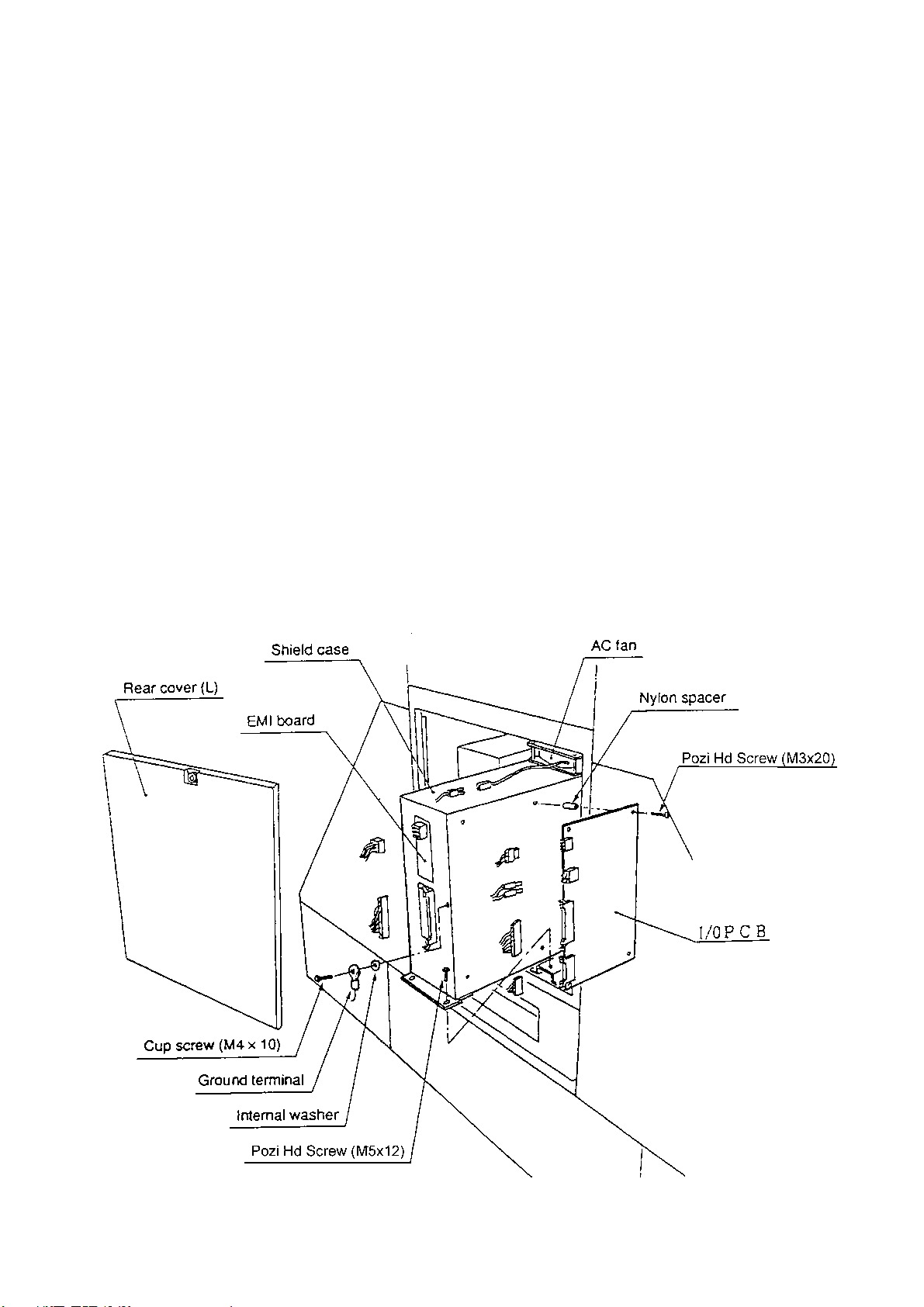

6-3-3. Removing the Shield Case

1) Remove the rear cover (L).

2) Remove the Pozi head screw (M4x10), and remove the earth terminal.

(

Note: Be careful not to lose the internal washer (M4).

3) Disconnect the two connectors on the EMI board, the AC fan connector,

and the four connectors on the I/O PCB.

4) Remove the two Pozi head screws (M5x12), then remove the shield case.

6-3-4. Removing the I/O Board

1) Pull out the shield case until the I/O board can be seen.

(Refer to section 6-3-3, above, "Removing the Shield Case".)

2) Remove the four Pozi head screws (M3x20).

(

Note: Be careful not to lose the four nylon spacers.

3) Remove the I/O PCB.

Page 25

Loading...

Loading...