Service Manual

DVD-15

5 Disc MusicBank DVD Changer

CONTENTS |

|

|

1. |

GENERAL .............................................................................................................................. |

2 |

2. |

REMOVAL PROCEDURES .................................................................................................... |

4 |

3. |

ELECTRICAL ADJUSTMENT ............................................................................................... |

9 |

|

3-1 Measurement instruments and jigs .................................................................................. |

9 |

|

3-2 Parts location for adjustment ............................................................................................ |

9 |

|

3-3 Adjustment Procedure .................................................................................................... |

10 |

|

3-4 RAM Clear ...................................................................................................................... |

11 |

4. |

MECHANICAL ASS’Y AND PARTS LIST ........................................................................... |

12 |

|

4-1 Synthesis Ass’y .............................................................................................................. |

12 |

|

4-2 Mechanism Ass’y DVD-15 (A01) ................................................................................... |

14 |

|

4-3 Motor Chassis EX Ass’y (B01) ....................................................................................... |

16 |

|

4-4 Loading EX Ass’y ADJ-3 (B02) ..................................................................................... |

17 |

|

4-5 DVD Traverse Ass’y ADJ-3 (B03) ................................................................................... |

19 |

|

4-6 Pakage Ass’y and Accessory Ass’y ............................................................................... |

20 |

5. |

ELECTRICAL PARTS LIST ................................................................................................. |

21 |

6. |

RECOMMENDED SPARE PARTS LIST .............................................................................. |

26 |

7. |

IC BLOCK DIAGRAMS ........................................................................................................ |

27 |

8. |

SPECIFICATIONS ................................................................................................................ |

49 |

For Schematic Diagrams, and Mounting Diagrams, see the separate volume.

R

1

1. GENERAL

1.1 Product Code

V685

1.2 Destinations

BS, CAN, CH, DA, EP, HK, JPN, OTR, TW, USA, KR, AUS

Abbreviations |

|

CAN - Canada |

CH - China |

DA - South America |

EP - Europe |

HK - Hong Kong |

JPN - Japan |

OTR - Other |

TW - Taiwan |

U.K. - United Kingdom |

USA - U.S.A. |

KR - Korea |

AUS - Australia |

1.3 Cautions / Warnings

(1) Product Safety Notice

Parts marked with the symbol  in the schematic diagram have critical characteristics.

in the schematic diagram have critical characteristics.

Use ONLY replacement parts recommended by the manufacturer. It is recommended that the unit be operated from a suitable DC supply or batteries during initial check-out procedures.

(2) Leakage Current Check / Resistance Check

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis resistance check. If the leakage current exceeds 0.5 milliamp, or if the resistance from chassis to either side of the power cord is less than 240 k ohms, the unit is defective.

WARNING–DO NOT return the unit to the customer until the problem is located and corrected.

(3) Protection of Eyes from Laser Beam

To protect eyes from invisible laser beam during servic-

ing, DO NOT LOOK AT THE LASER BEAM on the

Changer.

(4) Laser Caution

CAUTION

Adjusting the knobs, switches, and controls etc. or taking actions not specified herein may result in a harmful emission of laser beams. This Changer must be adjusted and repaired only by qualified service personnel.

OBSERVERA!

Sådana inställningar av rattarna, omkopplarna eller övriga kontrollknappar som inte är beskriva i bruksanvisningen kan resultera i farlig laserutstrålning. Justering eller reparation av denna kompaktskivspelare skall endast utföras av kvalificerad servicepersonal.

OBS!

Indstilling af knapper, cmskiftere og øvrige kontrolknapper, som ikke følger den i brugsanvisningen beskrevne måde, kan resultere i farlig laserudstråling. Justering eller reparation af denno CD-afspiller må kun udføres af kvalificeret servicepersonale.

OBS!

Justering av ratt, brytere og kontroller andre enn de som er beskrevet her, kan resultere i farlig laserbestråling. Justering eller reparasjon av denne kompaktdiskspilleren ma bare utføres av kvalifiserte fagfolk.

HUOMAUTUS

Jos nuppeja, kyikimiä ja säätimiä ym, säädetään tai laitetta käytetään toisella tavalla kuin on selostettu, tuloksena saattaa olla vaarallista lasersäteiden vuotoa. CD-soittimen säätö ja korjaus on jätettävä aina asiantuntevan huoltoteknikon tehtäväksi

CLASS 1 LASER PRODUCT

KLASSE 1 LASER PRODUKT

LUOKAN 1 LASER LAITE

KLASS 1 LASER APPARAT

THIS DVD PLAYER IS CLASSIFIED AS A CLASS 1 LASER PRODUCT. THE CLASS 1 LASER PRODUCT LABEL IS LOCATED ON THE REAR EXTERIOR.

CAUTION ; INVISIBLE LASER RADIATION WHEN OPEN

AND INTERLOCKS DEFEATED. AVOID EXPOSURE TO BEAM.

ADVARSEL ;USYNLIG LASERSTRALING VED ABNING,

NAR SIKKERHEDSAFBRYDERE ER UDE AF FUNKTION

UNDGA UDS TTELSE FOR STRALING.

VARO ; AVATTAESSA JA SUOJALUKITUS OHITETTAESSA

OLET ALTTIINA NAKYMATTOMALLE LASERSATEILYLLE.

ALA KATSO SATEESEEN !

VARNING ; OSYNLIG LASERSTRALNING NAR DENNA

DEL AR OPPNAD OCH SPARREN AR URKOPPLAD.

BETRAKTA EJ STRALEN !

2

GENERAL

1.4 Caution for handling Laser Pickup of DVD Player

[Electric Influence because of impressed electricity]

Laser pickup of a DVD player is weaker and more sensitive than that of CD player, it is possible to damage the pickup under specific electrical environments, such as impressed or leaked electricity, including static electricity. Electricity that is impressed during modification for zone coding, or through updating the micro processor and so forth, may influence the laser pickup.

Prevention of Impressed Electricity

• In general

It is very difficult to specify why and how static electricity is impressed. It is important to thoroughly ground the working bench and fasten the antistatic electricity wrist band, as well as carry out the daily management of isolating the resistor of the soldering iron and the leaked current in the working room.

Unfortunately, it is impossible for us, even as the supplier, to assure that all these conditions are met at any distributor or subsidiary that does not have an identical situation to that of the manufacturing site. Consequently, we do not recommend any modification for zone coding, that can be a negative factor against quality assurance, and we consider pickup failure of any unit modified for zone coding to be out of warranty.

Condition of Soldering lron

•How to prevent or discharge the impressed electricity

Please refer to the following items.

1) Grounding

When you repair a laser pickup, first ground the human body, as well as the measuring instruments and other tools (with particular caution to the soldering iron). What's more, your workbench and floor should desirably be grounded using a conductive sheet or copper plate. Be careful so as not to let your clothes touch the laser pickup, as static electricity on the clothes may be released even if your body is grounded.

2) Discharge of electricity

Be sure to discharge electricity from objects brought into contact with the laser pickup (i.e., soldering iron, tweezers, probes, volt-ohm-meter probes, etc.) before starting work by contacting them with the DVD player's chassis. Also, never touch the laser pickup while power is applied.

3) Soldering iron

The soldering iron for use in repair work should be: (1) a ceramic soldering iron, (2) a soldering iron with its metal part grounded, or (3) a soldering iron whose insulation resistance after power application is 10 M-ohm or more at 500 VDC. Soldering should be completed promptly, at a soldering iron temperature of 320° C ideally. (39W). A soldering iron heated above this temperature can break down the laser diode.

Type |

Output Wattage |

Tip Temperature |

Isolated Resistance |

Leaked Current |

|

For IC or LSl |

13-18W |

300± 40° C |

≥ 100MΩ |

≤ |

1.0µ A |

|

|

|

|

|

|

For Elec. Part |

23-30W |

360± 40° C |

≥ 50MΩ |

≤ |

2.0µ A |

Note: A precise digital tester is needed to measure the leaked current.

3

2. REMOVAL PROCEDURES

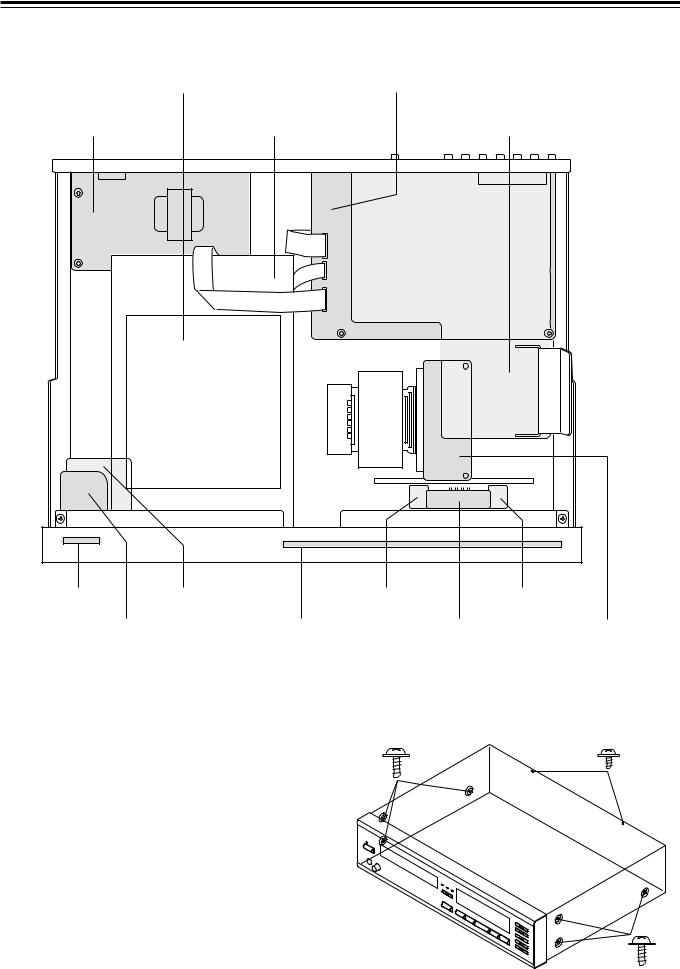

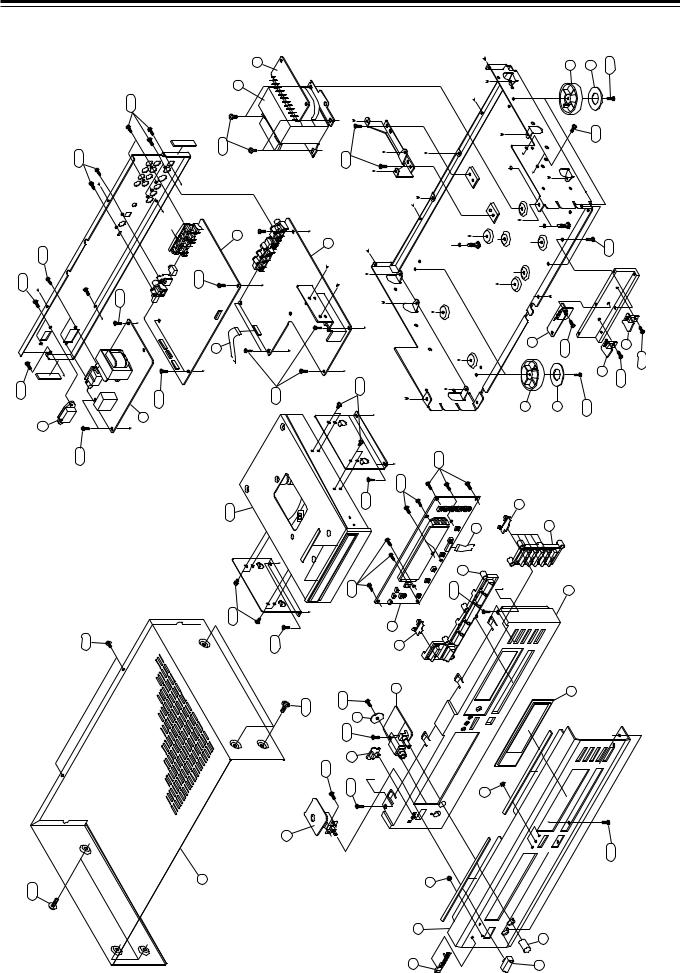

• Location of Major Parts

DVD Main P.C.B. Ass'y

(Bottom side of Mechanism BLK) |

Digital P.C.B. Ass'y |

|

P-Supply P.C.B. Ass'y |

Mechanism BLK Ass'y |

Output P.C.B. Ass'y |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

REG 5V P.C.B. Ass'y |

|

|

|

|

|

|

|

|

|

|

||

LED P.C.B. Ass'y H.P P.C.B. Ass'y |

|

REG 3V P.C.B. Ass'y |

|

|

|

|||||

Power-SW P.C.B. Ass'y |

Front P.C.B. Ass'y |

Diode P.C.B. Ass'y |

M-Trance P.C.B. Ass'y |

|||||||

(The Mechanism P.C.B. Ass’y is constructed on the DVD Mechanism Block.)

Fig. 2-1 Top View

2.1 Top Cover (Refer to Fig. 2-2)

1)Remove the 8 screws and detach the Top Cover from the main body.

Fig. 2-2

4

REMOVAL PROCEDURES

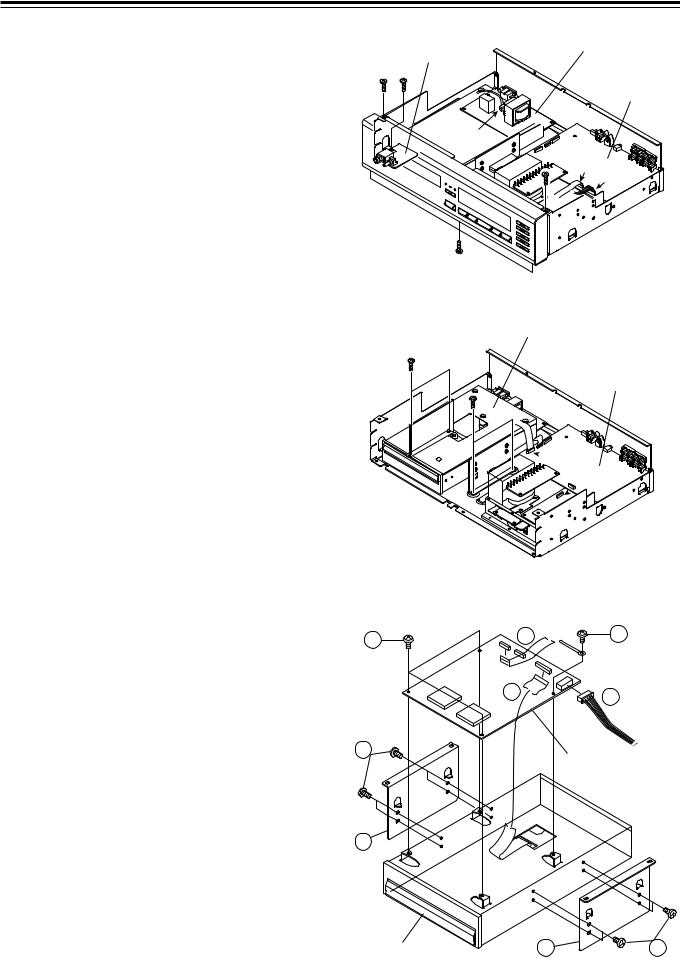

2.2 Front Panel (Refer to Fig. 2-3)

1)Remove the 5 screws on the front panel.

2)Remove the screws holding the H.P P.C.B. Ass’y. The screws can be reached by going through the hole in the left side Power-SW P.C.B. Ass’y.

3)Disconnect the P702 on the P-Supply P.C.B. Ass’y and disconnect the P530 and P200 on the Digital P.C.B. Ass’y.

4)Remove the front panel in front of you by pulling it outward, keeping it level as you pull.

P-Supply P.C.B. Ass'y

H.P P.C.B. Ass'y

Digital

P.C.B. Ass'y

P702

P530

P200

Fig.2-3

2.3 Mechanism Block (Refer to Fig. 2-4)

1)Disconnect the flexible cable from the P550 and P570 on the Digital P.C.B. Ass’y.

2)Disconnect the P540 on the Output P.C.B. Ass’y.

3)Remove the 4 screws and detach the machanism from the

main body.

2.4 DVD Main P.C.B. Ass’y (Refer to Fig. 2-5) |

1 |

1)Remove the 4 screws “1” on the DVD Main P.C.B. Ass’y.

2)Disconnect the three connectors “a” , “b” and “c” on the DVD Main P.C.B. Ass’y.

2

2.5 Mechanism Ass’y (Refer to Fig. 2-5)

1) Remove the DVD Main P.C.B. Ass’y.

2) Remove the 8 screws "2" in the diagram, and then remove the left and right plates "3".

3

Mechanism Block

Digital P.C.B. Ass'y

P570

P570

P550

P550

P540

P540

Fig.2-4 |

|

a |

1 |

c |

b |

|

DVD Main P.C.B. Ass'

Mechanism Ass'y 3 2

Fig.2-5

5

REMOVAL PROCEDURES

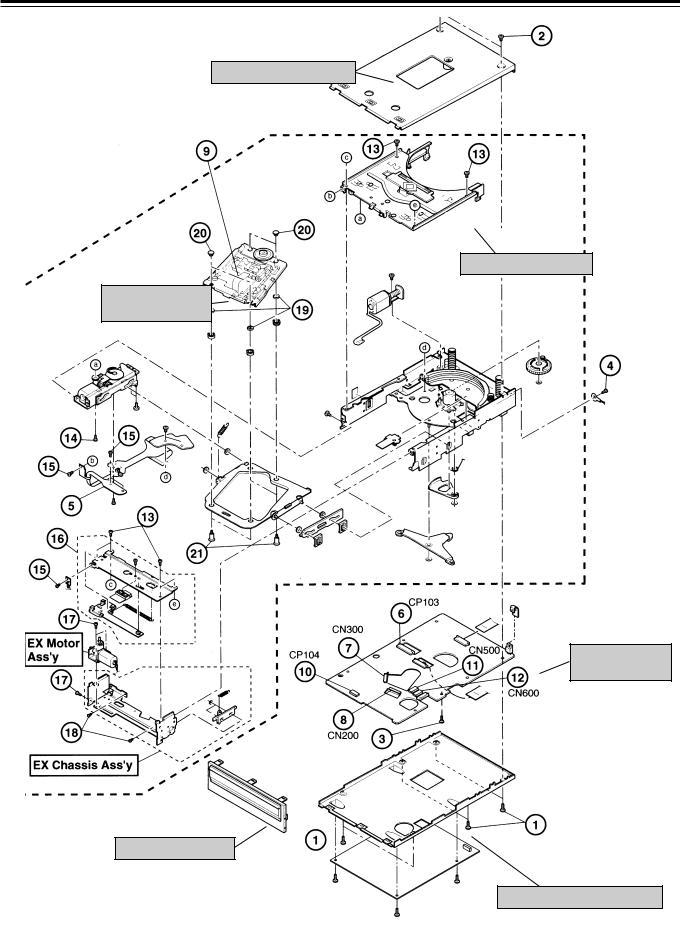

2.6. Bottom Cover EX Ass'y, Top Cover EX Ass'y |

6) Pull the edges of the connector CN200 "8" on the Mecha- |

|

|

and F Panel EX Ass'y(Refer to Fig. 2-7) |

nism P.C.B. Ass'y to unlock the connector edges and care- |

1) Remove the 6 screws "1" (M2.6x5 + Pan (#0 Type 3)) and |

fully pull out the Pickup Flexible P.C.B. "9". |

|

|

detach the Bottom Cover EX Ass'y. |

7) Carefully disconnect the 3 connectors CPI04 "10" (EX Mo- |

2) Remove the 2 screws "2" (M2.6x3 + Pan), and detach the |

tor Ass'y), CN50011" " (Sled Motor Ass'y), and CN60012" " |

|

|

Top Cover EX Ass'y and F Panel EX Ass'y. |

(Inner Switch) |

|

|

8) Remove the Mechanism P.C.B. Ass'y from the Mechanism |

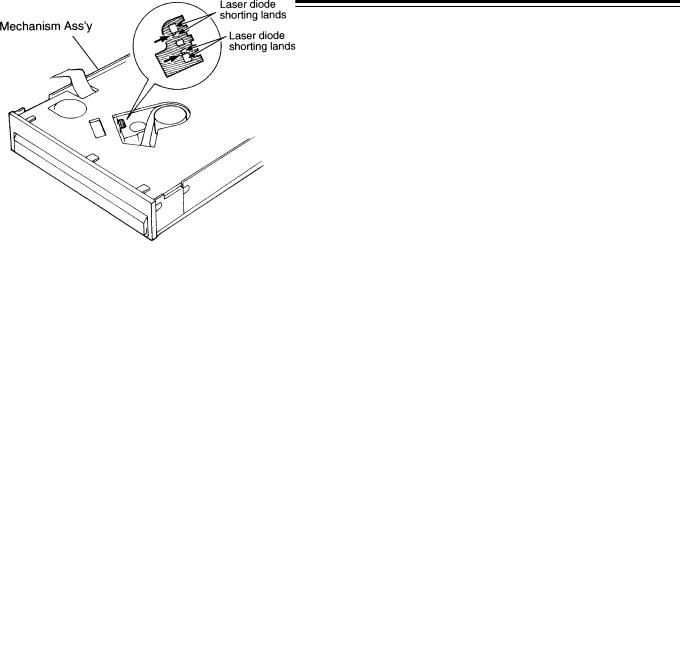

2.7. Mechanism P.C.B. Ass'y(Refer to Fig. 2-7) |

Ass'y. |

|

1) Remove the Bottom Cover EX Ass'y, Top Cover EX Ass'y |

|

|

|

and F Panel EX Ass'y. See item 2.6. |

2.8. Loading EX Ass'y(Refer to Fig. 2-7) |

2) |

Shorting the laser diode shorting land of the DVD Traverse |

1) Remove the Mechanism P.C.B Ass'y. See item 2.7. |

|

Ass'y: |

2) Remove the 6 screws "13" (ST2.6x3 + Pan (#0 Type 3)), 1 |

|

Short the laser diode shorting lands (2 places shown by the |

screw "14" (M1.7x2.5 + Pan (#0 Type 3) (Black)), and 4 |

|

arrows) with a soldering iron before removing the Mecha- |

screws "15" (M2x2 + Pan (#0 Type 3) (Black)). |

|

nism P.C.B. Ass'y. |

• Note when reassembling: |

|

Note: Use a soldering iron whose metal part is grounded or |

When reassembling the Mecha Flexible P.C B. Ass'y 5"", |

|

a ceramic soldering iron. |

move it to the front side. |

|

CAUTION: Do not disconnect the Flexible Cable from the |

Be sure that the shutter is positioned in the center of the |

|

connector P200 on the Mechanism P.C.B. Ass'y unless the |

shutter sensor on the Mecha Flexible P.C.B. Ass'y, when the |

|

laser shorting lands (2 places) are shorted. |

shutter of the Loading EX Ass'y is closed by hand, |

|

|

3) Remove the EX Loading Chassis block "16" backward while |

|

|

lifting its to the right side a little. |

|

|

4) Remove the Loading EX Ass'y while lifting it. |

|

|

• Note: Do not damage the Catch Arm Ass'y and the Loading |

|

|

Link Ass'y of the Loading EX Ass'y. |

|

|

2.9. DVD Traverse Ass'y(Refer to Fig. 2-7) |

|

|

1) Remove the Loading EX Ass'y. See item 2.8. |

|

|

2) Remove the 3 screws "17" (ST2 6x3 + Pan (#0 Type 3)) and |

|

|

remove the EX Motor Ass'y. |

|

|

3) Remove the 3 screws "18" (ST2.6x3 + Pan (#0 Type 3)) and |

|

|

remove the EX Chassis Ass'y. |

|

|

4) Remove the 4 pcs. of Damper Screw SL"19", 4 pcs of and |

|

|

SUS Collar B "20", and 4 pcs of SUS Collar T "21", and |

|

|

detach the DVD Traverse Ass'y. |

[Shorting the Laser Diode Shorting Lands of the DVD Traverse |

Notes: |

|

Ass'y] |

1. Pay attention so as not to damage the Door Sensor P.C B. |

|

|

|

of the Mecha Flexible P.C.B. "5". |

• |

Note when reassembling: |

2. Assemble the Door Sensor P.C.B. so as not it is inclined. |

|

Unsolder the laser diode shorting lands after reassembling |

3. Be sure that the projection of the Front Door Ass'y can be |

|

the Mechanism P.C.B. Ass'y. |

correctly inserted into the Door Sensor. |

3) Remove 1 screw "3" (M2.6x3.5 + Pan (#0 Type 3)) and 1 |

|

|

|

screw "4" (M2.6x8 + Pan). |

|

4) Disconnect the Mecha Flexible P.C B. Ass'y 5"" by pulling |

|

|

|

the edges of the connector CP103 "6" on the Mechanism |

|

|

P.C.B. Ass'y to unlock the connector edges. |

|

5) |

Pull the edges of the connector CN300 "7" on the Mecha- |

|

|

nism P.C.B. Ass'y to unlock the connector edges and care- |

|

|

fully pull out the Traverse Flexible P.C.B. Ass'y. |

|

6

REMOVAL PROCEDURES

2.6. Top Cover EX Ass'y

2.8. Loading EX Ass'y

2.9.DVD Traverse Ass'y

2.7. Mechanism

P.C.B. Ass'y

2.6. Panel EX Ass'y

2.6. Bottom Cover EX Ass'y

Fig.2-7

7

REMOVAL PROCEDURES

2.10 Pickup (Refer to Fig.2-8)

Caution: Do not remove or loosen screws that are not in-

cluded in this procedure.

Note: After reassembling the Pickup, you need to perform “Tilt Adjustment” of the Pickup.

Preparation:

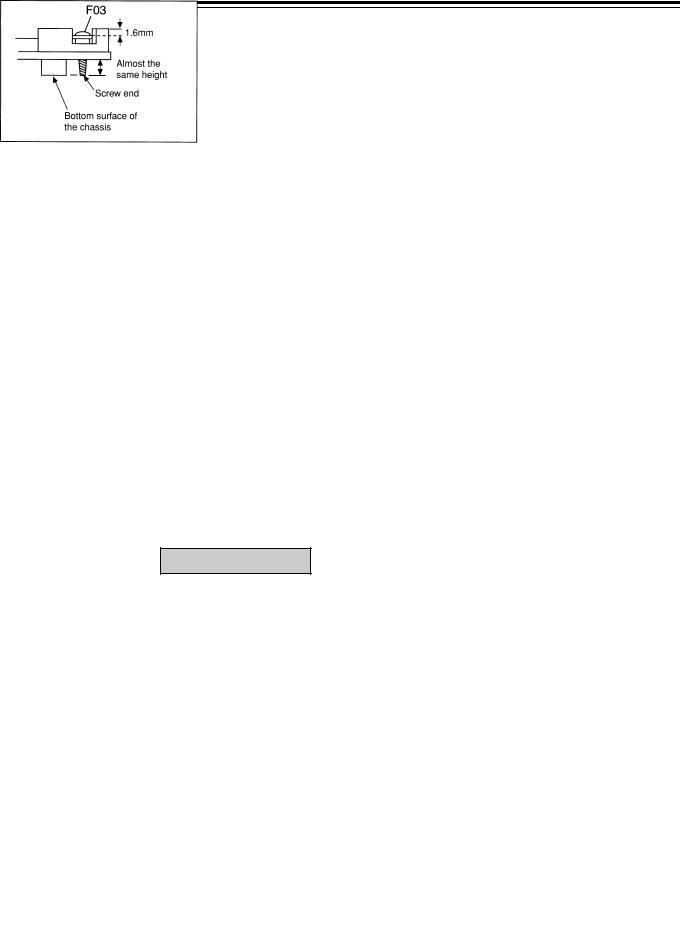

Since you need to reposition the screw F03 to the original position, check the current position before removing the screw F03.

•Give a mark on the head of screw F03 to allow easy repositioning.

•Check the end position of the screw F03. It will be almost the same as the bottom surface of the chassis.

1)Remove the DVD Traverse Ass’y. Refer to item 2.9.

2)Remove a screw F01 (M1.7x3.5+Pan CMT) and detach F02 (Hook L.S)

3)Give a mark to the screw F03 for repositioning.

4)Remove a screw F03 (Screw S) and detach F04/F05 (Pickup block).

F06 (SP Push Shaft) can be removed.

5)Pull out F04 (Shaft L) from F05 (Pickup).

Notes on reassembling:

•Assemble the screw F03 so that it is roughly positioned to the original position.

•Perform “Tilt Adjustment”. Refer to Stap 3 “Tilt Adjustment” in 3.3 “Adjustment procedure”

Do not remove or loosen

Fig.2-8

8

3. ELECTRICAL ADJUSTMENT

3.1 Measurement instruments and Jigs

1)DC Voltmeter

2)AC Voltmeter

3)Tracking Offset Meter LE-9055A or LTM-9055 (Leader Electronics Corp.)

4)A-BEX Vertical Deviation Test Disc TDV-562 (DA09206A)

5)SONY Test Disc Type 3

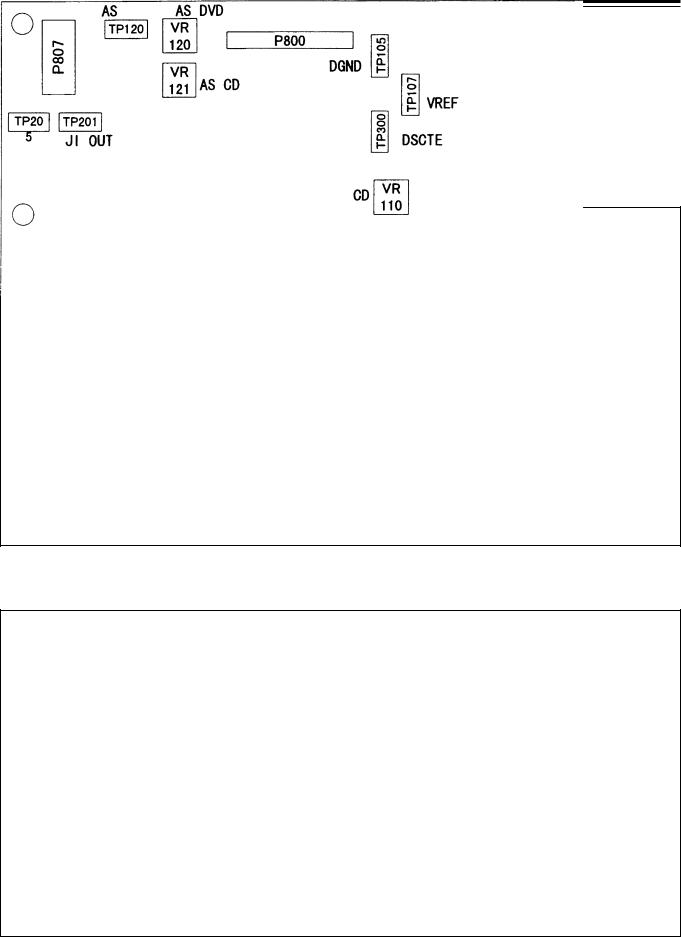

3.2Parts Location for Adjustment

Fig.3-1 Parts Location for Electorical Adjustment (DVD Main P.C.B. Ass’y)

Fig.3-2 Tilt Adjustment Screws (Mechanism Ass’y)

9

ELECTRICAL ADJUSTMENT

3.3 Adjustment procedure (Follow the next steps in order)

STEP |

|

ITEM |

SIGNAL |

|

OUTPUT |

ADJUSTMENT |

|

|

REMARKS |

|

||||||||||||||||

|

SOURCE |

|

CONNECTION |

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

1 |

DVD Adjust |

|

|

|

|

|

|

|

|

1. |

Connect each measuring instrument as follows: |

|||||||||||||||

|

|

Mode |

|

|

|

|

|

|

|

|

|

• Connect a DC voltmeter between TP120 (AS) (+ terminal) |

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

and TP107 (VREF) (- terminal) on the DVD Main P.C.B. Ass’y. |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

• Connect an AC voltmeter between TP201 (JI OUT) (+ termi- |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

nal) and TP105 (DGND) (-terminal) on the DVD Main P.C.B. |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ass’y. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Disc |

3 button |

|

• Connect a tracking offset meter between TP300 (DSCTE) (+ |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

terminal) and TP107 (VREF) (-terminal) on the DVD Main |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

P.C.B. Ass’y. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

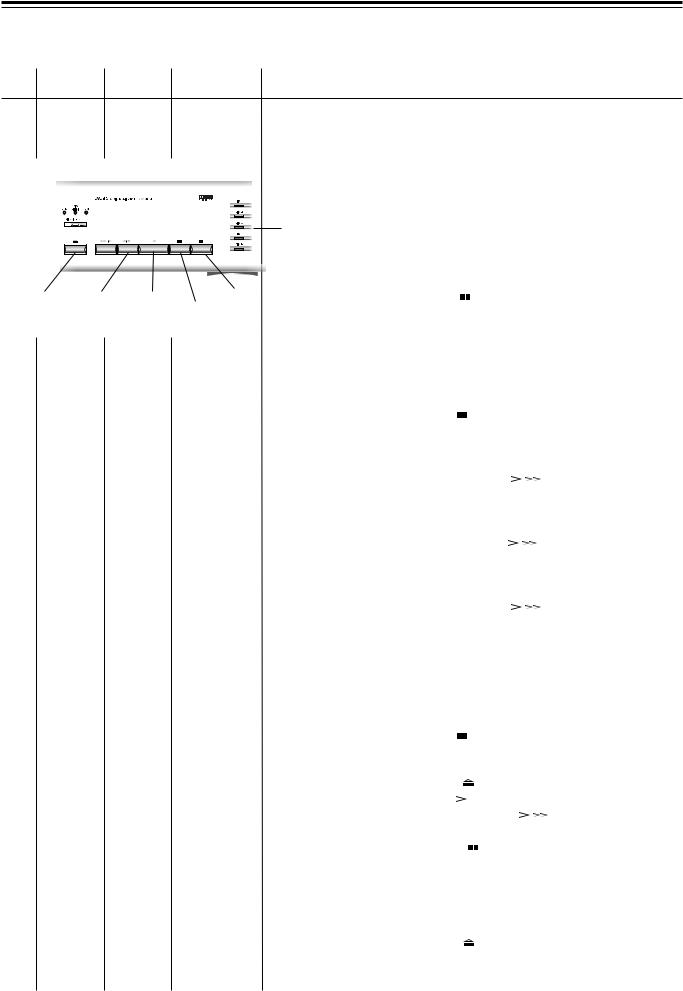

2. While pressing and holding the STOP button, press the POWER |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

button, then enter standby mode. (the indicator will light orange). |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

Eject button Forward Skip Play button |

|

Stop button |

|

|

3. Press the PAUSE ( |

) button and DISC 3 button for more than 2 |

|||||||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||

|

|

|

|

|

|

|

button |

Pause button |

|

|

|

seconds to engage the test mode. |

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Confirm that the following message appears on the display. |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

DVD ADJUST → |

DISC 1 T - 01 |

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

2 |

|

AS |

|

|

DC Voltmeter |

VR120 |

|

Note: Perform the adjustment in the order of “CD LD ON” and |

||||||||||||||||||

|

|

Adjustment |

|

|

between |

(for DVD,LD) |

|

“DVD LD ON” as mentioned below: |

|

|||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

TP120(AS)(+) |

|

|

1. |

Press the STOP ( |

) button once. |

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The message will change as follows: |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

and |

VR121 |

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

→ AS ADJUST → |

DVD LD ON |

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

TP107(VREF)(-) |

(for CD,LD) |

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

2. Adjust VR120 to obtain 0V ± 10 mV DC on the DC voltmeter. |

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

on DVD Main |

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

3. |

Press the FORWARD SKIP ( |

|

|

|

|

) button once. |

|||||||

|

|

|

|

|

|

|

|

|

|

|

P.C.B. Ass’y |

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The following message will appear on the display, |

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

→ CD LD ON |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4. |

Adjust VR121 to obtain 0V ± 10 mV DC on the DC voltmeter. |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5. |

Press the FORWARD SKIP ( |

|

|

|

|

) button again to select “DVD |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LD ON”, and confirm that the DC voltage is at the level that it was |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

adjusted to in step 2. If there is any deviance to the DC voltage, |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

re-adjust. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6. |

Press the FORWARD SKIP ( |

|

|

|

|

) button twice. |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The following message will appear on the display. |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CD LD ON → LD OFF |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The pickup will then move to the innermost position and stops |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

there. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7. Proceed to the next step. |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

3 |

|

Tilt |

DVD Vertical |

|

AC Voltmeter |

Tilt Screws |

1. |

Press the STOP ( |

) button once. |

|

||||||||||||||||

|

|

Adjustment |

Deviation |

|

between |

A and B |

|

Be sure that the following message appears on the display. |

||||||||||||||||||

|

|

|

|

→ MECHA ADJUST |

|

|||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

TP201(JI OUT) |

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

2. |

Press the EJECT ( |

) button and insert the DVD Test Disc. |

|||||||||||

|

|

|

|

|

|

|

|

|

Test Disc |

|

(+) and |

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

3. |

Press the PLAY ( |

) button to play back the disc. |

||||||||||||

|

|

|

|

|

|

|

|

|

TDV-562 |

TP105(DGND)(-) |

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

4. |

Press the FORWARD SKIP ( |

|

|

) button to play back the |

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

on DVD Main |

|

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

(DA09206) |

|

|

|

|

Chapter 16 (outermost track). |

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

P.C.B. Ass’y |

|

|

5. |

Press the PAUSE ( |

) button to pause the disc. (The disc will |

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

keep turning.) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

6. Turn Screw A to obtain the minimum reading on the AC voltmeter. |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7. Turn Screw B to obtain the minimum reading on the AC voltmeter. |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8. Repeat steps 6 and 7 several times until the minimum readings |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

are obtained. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9. |

Press the EJECT ( |

) button to eject the disc. |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10.Proceed to the next step. |

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10

ELECTRICAL ADJUSTMENT

STEP |

ITEM |

SIGNAL |

OUTPUT |

ADJUSTMENT |

REMARKS |

|

SOURCE |

CONNECTION |

|||||

|

|

|

|

4 CD Tracking CD Test Disc |

Tracking Offset |

VR110 |

1. |

Set the tracking offset meter as follows: |

|||

Adjustment |

SONY |

Meter |

|

|

• |

Sensitivity switch: |

HIGH (right side) |

|

Type 3 |

between |

|

|

• |

Level switch: |

MEASURE (left side) |

|

|

TP300(DSCTE) (+) |

|

|

• |

Center switch: |

MEASURE (center position) |

|

|

|

2. |

Insert the CD Test Disc. |

|||

|

|

and |

|

||||

|

|

|

3. |

Press the STOP ( |

) button once. |

||

|

|

TP107(VRFE)(-) |

|

||||

|

|

|

|

Be sure that the following message appears on the display. |

|||

|

|

on Main P.C.B. |

|

|

|||

|

|

|

|

|

→ CD ADJUST |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4. |

Adjust VR110 so that the center meter indicates 0 V as shown on |

||

|

|

|

|

|

the left. Also, be sure that the left side meter indicates around 1 V. |

||

|

|

|

|

5. |

Press the EJECT ( |

) button to eject the disc. |

|

|

|

|

|

6. |

Proceed to the next step to terminate the adjustment. |

||

When adjustment is finished, detach the voltmeter and press the Power button to turn the power off. The TEST MODE will be released once the power is off.

Apply paint lock the Screw A and B.

3.4 RAM Clear (System Controller & Mechanism Controller Clear)

Note: Before shipping perform the RAM Clear to perform the followings:

•To clear the usable setting values to the initial setting values.

•To perform initialization operation of the changer mechanism.

STEP |

ITEM |

SIGNAL |

OUTPUT |

ADJUSTMENT |

|

REMARKS |

|

SOURCE |

CONNECTION |

|

|||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

1 |

RAM Clear |

|

|

|

1. While pressing and holding |

the STOP button, press the POWER |

|

|

|

|

|

|

button, then enter standby mode. |

||

|

|

|

|

|

2. Remove all discs. |

|

|

|

|

|

|

|

3. Press and hold the PAUSE ( |

) and DISC 4 buttons for more than |

|

|

|

|

|

|

7 seconds. |

|

|

|

|

|

|

|

4. The following messages will appear on the display. |

||

|

|

|

|

|

RAM CLEAR 2 |

|

|

|

|

|

|

|

↓ |

(After 5 seconds) |

|

|

|

|

|

|

REGION X (X: 0 to 8) |

|

|

|

|

|

|

|

5. Then, the following operation will be done. |

||

|

|

|

|

|

• User setting values are reset to the initial setting values. |

||

|

|

|

|

|

• Changer mechanism is initialized. |

||

|

|

|

|

|

6. “Power OFF” will be displayed and the system is automatically shut |

||

|

|

|

|

|

off. |

|

|

|

|

|

|

|

POWER OFF (Standby mode) |

||

|

|

|

|

|

If the disc remains in the changer mechanism, power is not shut off |

||

|

|

|

|

|

and the display returns to the normal one. |

||

|

|

|

|

|

|

|

|

11

4. MECHANICAL ASS’Y AND PARTS LIST

4.1 Synthesis Ass’y

<![if ! IE]><![endif]>L04

<![if ! IE]><![endif]>L04

| <![if ! IE]> <![endif]>L04 |

|

| <![if ! IE]> <![endif]>L05 |

|

|

<![if ! IE]> <![endif]>L02 |

|

<![if ! IE]> <![endif]>A |

|

<![if ! IE]> <![endif]>D |

| <![if ! IE]> <![endif]>L04 |

<![if ! IE]> <![endif]>D |

|

|

| <![if ! IE]> <![endif]>23 |

<![if ! IE]> <![endif]>19 |

| <![if ! IE]> <![endif]>A |

|

|

<![if ! IE]> <![endif]>L02 |

<![endif]>L02

|

|

|

|

|

|

<![if ! IE]> <![endif]>D’ |

|

|

|

<![if ! IE]> <![endif]>25 |

|

|

|

|

|

|

<![if ! IE]> <![endif]>26 |

| <![if ! IE]> <![endif]>24 |

|

|

|

|

|

<![if ! IE]> <![endif]>C’ |

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>D’ |

|

|

|

|

<![if ! IE]> <![endif]>B’ |

|

|

|

|

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>B’ |

|

|

| <![if ! IE]> <![endif]>L10 |

|

<![if ! IE]> <![endif]>L11 |

<![if ! IE]> <![endif]>C’ |

|

<![if ! IE]> <![endif]>C’ |

|

<![if ! IE]> <![endif]>J |

|

|

|

|

<![if ! IE]> <![endif]>B’ |

|

|

|

|

<![if ! IE]> <![endif]>C’ |

| <![if ! IE]> <![endif]>D |

|

|

|

|

<![if ! IE]> <![endif]>A’ |

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>D’ |

|

|

|

| <![if ! IE]> <![endif]>D |

|

|

|

|

|

|

<![if ! IE]> <![endif]>H’ |

|

| <![if ! IE]> <![endif]>20 |

|

<![if ! IE]> <![endif]>C |

|

|

|

<![if ! IE]> <![endif]>E’ |

|

|

|

|

<![if ! IE]> <![endif]>21 |

<![if ! IE]> <![endif]>D’ |

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>J’ |

|

|

|

|

|

|

| <![if ! IE]> <![endif]>L09 |

<![if ! IE]> <![endif]>B |

<![if ! IE]> <![endif]>J’ |

<![if ! IE]> <![endif]>A’ |

|

|

<![if ! IE]> <![endif]>E’ |

|

<![if ! IE]> <![endif]>F’ |

|

|

|

<![if ! IE]> <![endif]>A’ |

|

<![if ! IE]> <![endif]>E’ |

|

|

|

|

|

|

<![if ! IE]> <![endif]>C |

|

|

|

|

|

| <![if ! IE]> <![endif]>22 |

|

<![if ! IE]> <![endif]>C |

|

|

<![if ! IE]> <![endif]>E’ |

|

<![if ! IE]> <![endif]>28 |

<![if ! IE]> <![endif]>L12 |

| <![if ! IE]> <![endif]>B |

|

<![if ! IE]> <![endif]>C |

|

|

|

|

|

|

| <![if ! IE]> <![endif]>L09 |

|

<![if ! IE]> <![endif]>L09 |

<![if ! IE]> <![endif]>L08 |

<![if ! IE]> <![endif]>H’ |

<![if ! IE]> <![endif]>G’ |

|

<![if ! IE]> <![endif]>26 |

<![if ! IE]> <![endif]>27 |

|

|

|

<![if ! IE]> <![endif]>E |

|

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>E |

<![if ! IE]> <![endif]>L06 |

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>L06 |

|

|

|

|

| <![if ! IE]> <![endif]>A01 |

|

|

<![if ! IE]> <![endif]>L07 |

|

|

|

<![if ! IE]> <![endif]>16 |

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>17 |

|

<![if ! IE]> <![endif]>15 |

|

|

<![if ! IE]> <![endif]>E |

|

|

|

|

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>13 |

|

|

|

|

<![if ! IE]> <![endif]>L06 |

|

|

<![if ! IE]> <![endif]>L04 |

<![if ! IE]> <![endif]>H |

|

<![if ! IE]> <![endif]>8 |

| <![if ! IE]> <![endif]>L08 |

|

<![if ! IE]> <![endif]>E |

|

<![if ! IE]> <![endif]>18 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

<![if ! IE]> <![endif]>L07 |

|

<![if ! IE]> <![endif]>14 |

|

|

|

|

| <![if ! IE]> <![endif]>27 |

<![if ! IE]> <![endif]>L04 |

<![endif]>L04

<![if ! IE]><![endif]>L13

<![if ! IE]><![endif]>30

<![if ! IE]><![endif]>L12

| <![if ! IE]> <![endif]>29 |

<![if ! IE]> <![endif]>L12 |

<![endif]>L04

| <![if ! IE]> <![endif]>L01 |

<![if ! IE]> <![endif]>L06 |

|

<![if ! IE]> <![endif]>12 |

|

<![if ! IE]> <![endif]>L03 |

|

<![if ! IE]> <![endif]>10 |

|

<![if ! IE]> <![endif]>L04 |

|

<![if ! IE]> <![endif]>L04 |

<![endif]>9

| <![if ! IE]> <![endif]>11 |

<![if ! IE]> <![endif]>7 |

<![endif]> G

G

<![endif]> H

H

<![endif]>6

<![if ! IE]><![endif]>F

<![if ! IE]><![endif]>L03

| <![if ! IE]> <![endif]>1 |

<![if ! IE]> <![endif]>6 |

| <![if ! IE]> <![endif]>L01 |

|

|

<![if ! IE]> <![endif]>2 |

|

<![if ! IE]> <![endif]>5 |

| <![if ! IE]> <![endif]>3 |

<![if ! IE]> <![endif]>4 |

Fig.4-1

12

MECHANICAL ASS’Y AND PARTS LIST

4.1 Synthesis Ass’y

Ref. No. |

Part No. |

Description |

Q'ty |

|

Ref. No. |

Part No. |

Description |

Q'ty |

1 |

0H08831A |

Top Cover BK |

1 |

|

|

BK10564A |

DIGITAL P.C.B. Ass’y Other NTSC |

1 |

|

|

(USA/CAN/UK/EP/AUS/DA) |

|

|

|

|

(KR/DA/TW) |

|

|

0H08832A |

Top Cover CG |

1 |

|

|

BK10566A |

DIGITAL P.C.B. Ass’y Other PAL |

1 |

|

|

(CH/JPN/OTR/HK/KR/TW) |

|

|

|

|

(CH/HK/AUS/OTR) |

|

2 |

0H08583C |

Dress Panel BK |

1 |

21 |

BK10255A |

OUTPUT P.C.B. Ass’y |

1 |

|

|

|

(USA/CAN/UK/EP/AUS/DA) |

|

|

|

|

(Except JPN/EP/UK) |

|

|

0H08584C |

Dress Panel CG |

1 |

|

|

BK10377A |

OUTPUT P.C.B. Ass’y |

1 |

|

|

(CH/JPN/OTR/HK/KR/TW) |

|

|

|

|

(JPN) |

|

3 |

2H00138A |

Logo Plate BK |

1 |

|

|

BK10378A |

OUTPUT P.C.B. Ass’y |

1 |

|

|

(USA/CAN/UK/EP/AUS/DA) |

|

|

|

|

(EP/UK) |

|

|

2H00139A |

Logo Plate CG |

1 |

22 |

0B85640A |

FFC 17P |

1 |

|

|

|

(CH/JPN/OTR/HK/KR/TW) |

|

23 |

0B70300A |

Slide SW L12-22A2 (SW701) |

1 |

|

4 |

0H08600A |

Power Knob BK |

1 |

|

|

|

(OTR/DA/TW only) |

|

|

|

(USA/CAN/UK/EP/AUS/DA) |

|

24 |

0B50459A |

Power Transformer 100-120V |

1 |

|

|

0H09025A |

Power Knob CG |

1 |

|

|

|

(JPN/USA/CAN) |

|

|

|

(CH/JPN/OTR/HK/KR/TW) |

|

|

|

0B50460A |

Power Transformer 115-230V |

1 |

5 |

0H07985A |

Headphone Volume knob BK |

1 |

|

|

|

(Except JPN/USA/CAN) |

|

|

|

(USA/CAN/UK/EP/AUS/DA) |

|

25 |

BK10376A |

M-Trans P.C.B. Ass’y |

1 |

|

|

0H09026A |

Headphone Volume knob CG |

1 |

26 |

0H08470A |

55 Foot A |

4 |

|

|

|

(CH/JPN/OTR/HK/KR/TW) |

|

27 |

0J08423A |

Foot Sheet (20) |

4 |

|

6 |

0H08500A |

Indicator |

4 |

28 |

BK10565A |

DIODE P.C.B. Ass’y |

1 |

|

7 |

0H08596C |

Display Lens |

1 |

29 |

BK10557A |

REG.3V P.C.B. Ass’y |

1 |

|

8 |

0H08585E |

Front Panel BK |

1 |

30 |

BK10556A |

REG.5V P.C.B. Ass’y |

1 |

|

|

|

(USA/CAN/UK/EP/AUS/DA) |

|

|

A01 |

----------- |

MECHANISM Ass’y DVD-15 |

1 |

|

0H08586D |

Dress Panel CG |

1 |

|

L01 |

0E03032A |

BT4x8+Washer Faced (Black) |

|

|

|

(CH/JPN/OTR/HK/KR/TW) |

|

|

|

|

(USA/CAN/UK/EP/AUS/DA) |

|

9 |

BK10268A |

POW SW P.C.B. Ass’y |

1 |

|

|

0E04146A |

BT4x8+Pan Flange |

|

10 |

BK10257A |

LED P.C.B. Ass’y |

1 |

|

|

|

(CH/JPN/OTR/HK/KR/TW) |

|

11 |

BK10254A |

HP P.C.B. Ass’y Except EP |

1 |

|

L02 |

0E03632A |

BT3x8+Binding with washer (Black) |

|

|

BK10574A |

HP P.C.B. Ass’y |

1 |

|

|

|

(USA/CAN/UK/EP/AUS/DA) |

|

|

|

(EP/UK) |

|

|

|

0E04147A |

BT3x8+Binding with washer |

|

12 |

0J08637A |

Line Cord washar |

1 |

|

|

|

(CH/JPN/OTR/HK/KR/TW) |

|

13 |

0H08592B |

Control Button BK |

1 |

|

L03 |

0E03897A |

BT3x10+Binding Projected (Black) |

|

|

|

(USA/CAN/UK/EP/AUS/DA) |

|

|

|

|

(USA/CAN/UK/EP/AUS/DA) |

|

|

0H08593B |

Control Button CG |

1 |

|

|

0E04372A |

BT3x10+Binding Projected |

|

|

|

(CH/JPN/OTR/HK/KR/TW) |

|

|

|

|

(CH/JPN/OTR/HK/KR/TW) |

|

14 |

0H08605B |

Control Lens |

1 |

|

L04 |

0E00921A |

BT3x8+Binding (Black) |

|

15 |

0H08590B |

Disc Select Button BK |

1 |

|

L05 |

0E03137A |

M3x10+Binding (OTR/DA/TW) |

|

|

|

(USA/CAN/UK/EP/AUS/DA) |

|

|

L06 |

0E00865A |

BT3x10+Binding |

|

|

0H08591B |

Disc Select Button CG |

1 |

|

L07 |

0E03854A |

BT3x6+Binding with washer |

|

|

|

(CH/JPN/OTR/HK/KR/TW) |

|

|

L08 |

0E00992A |

M3x4+Binding |

|

16 |

0H08604B |

Disc Select Lens |

5 |

|

L09 |

0E00877A |

ST3x5+Binding |

|

17 |

0B85637A |

FFC 13P |

1 |

|

L10 |

0E03438A |

ST4x6+Binding |

|

18 |

BK10253A |

FRONT P.C.B. Ass’y |

1 |

|

L11 |

0E00857A |

BT3x6+Binding |

|

19 |

BK10269A |

P-SUPPLY P.C.B. Ass’y |

1 |

|

L12 |

0E00986A |

M3x10+Binding |

|

|

|

(USA/CAN) |

|

|

L13 |

0E00896A |

M3x6+Binding |

|

|

BK10379A |

P-SUPPLY P.C.B. Ass’y |

1 |

|

L14 |

0E00964A |

M3x5+Binding |

|

|

|

(JPN) |

|

|

|

|

|

|

|

BK10380A |

P-SUPPLY P.C.B. Ass’y |

1 |

|

|

|

|

|

|

|

(DA/OTR) |

|

|

|

|

|

|

|

BK10381A |

P-SUPPLY P.C.B. Ass’y |

1 |

|

|

|

|

|

|

|

(EP/UK) |

|

|

|

|

|

|

|

BK10382A |

P-SUPPLY P.C.B. Ass’y |

1 |

|

|

|

|

|

|

|

(CH/HK/KR/SA) |

|

|

|

|

|

|

|

BK10383A |

P-SUPPLY PCB Ass’y |

1 |

|

|

|

|

|

|

|

(TW) |

|

|

|

|

|

|

20 |

BK10258A |

DIGITAL P.C.B. Ass’y |

1 |

|

|

|

|

|

|

|

(USA/CAN) |

|

|

|

|

|

|

|

BK10562A |

DIGITAL P.C.B. Ass’y |

1 |

|

|

|

|

|

|

|

(JPN) |

|

|

|

|

|

|

|

BK10563A |

DIGITAL P.C.B. Ass’y |

1 |

|

|

|

|

|

|

|

(EP/UK) |

|

|

|

|

|

|

13

MECHANICAL ASS’Y AND PARTS LIST

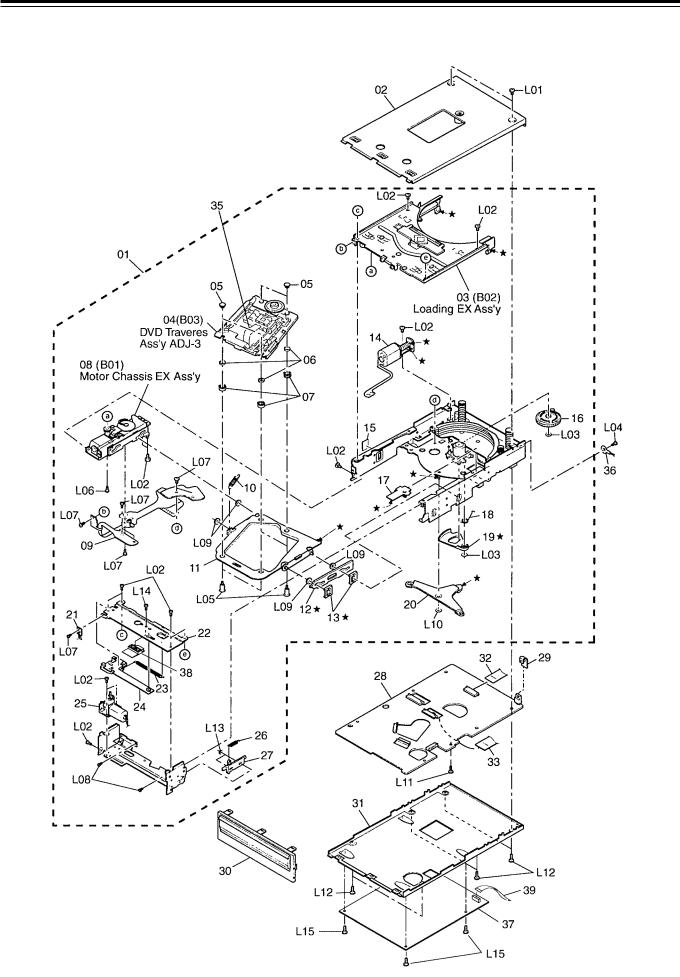

4.2 Mechanism Ass’y DVD-15 (A01)

Fig.4-2

14

MECHANICAL ASS’Y AND PARTS LIST

4.2 Mechanism Ass’y DVD-15 (A01)

Ref. No. |

Part No. |

Description |

Q'ty |

A01 |

--------- |

Mechanism Ass’y Black |

|

|

--------- |

Mechanism Ass’y Gold |

|

01 |

CG09508A |

Machanism Deck Ass’y ADJ-3 |

1 |

02 |

CA09393A |

Top Cover EX Ass’y |

1 |

03 |

CA09505A |

Loading EX Ass’y |

1 |

04 |

CA09479A |

DVD Traverse Ass’y ADJ-3 |

1 |

05 |

0C10325B |

SUS Collar T |

4 |

06 |

0C10326A |

SUS Collar B |

4 |

07 |

0C10279A |

Damper S SL |

4 |

08 |

CA09415A |

Motor Chassis EX Ass’y |

1 |

09 |

BA09736A |

Mecha Flexible P.C.B. Ass’y |

1 |

10 |

0C10286A |

Anti Rattle Spring SL |

1 |

11 |

CA09392B |

SUS Base ADT S Ass’y |

1 |

12 |

0C10185B |

Mechanism UD Sub Cam SL |

1 |

13 |

0C10186A |

UD S Cam Guide SL |

2 |

14 |

CA09351A |

Stocker Motor SL Ass’y |

1 |

15 |

0J08004A |

Dust Seal Emergency SL |

1 |

16 |

0C10175A |

Stocker Position Gear SL |

1 |

17 |

0C10211B |

Plate Spring SL |

1 |

18 |

0C10184A |

Disc Lock Spring SL |

1 |

19 |

0C10183A |

Disc Lock Arm SL |

1 |

20 |

0C10187A |

UD Link Arm SL |

1 |

22 |

0C10306C |

EX Loading Chassis |

1 |

23 |

0C10351A |

EX Loading Return Spring |

1 |

24 |

CA09407A |

Mov G Plat Ass’y |

1 |

25 |

CA09408A |

EX Motor Ass’y |

1 |

26 |

0C10250A |

Shutter Spring SL |

1 |

27 |

0C10305B |

Sub Cam Extension |

1 |

28 |

BA10323A |

Mechanism P.C.B. Ass’y (C3M1) |

1 |

29 |

0J08023A |

Heat sink Reg |

1 |

30 |

HA08369C |

ME F Panel Ass’y BK |

1 |

|

|

(UK/EP/USA/CAN/AUS/DA) |

|

|

HA08370C |

ME F Panel Ass’y CG |

1 |

|

|

(JPN/DU/CH/HK/KR/TW) |

|

31 |

CA09394A |

Bottom Cover EX Ass’y |

1 |

32 |

0B85926A |

FFC 14P |

1 |

33 |

0B85438A |

40P Flexible Wire |

1 |

35 |

0B85437A |

30P Flexible Wire (Pickup) |

1 |

36 |

0B85493A |

1P Wire GND D202 |

1 |

37 |

BK10567A |

DVD Main P.C.B. Ass’y (C3M1) |

1 |

38 |

0C10350A |

D Guide upside Ex |

1 |

39 |

0B85927A |

FFC 24P |

1 |

L01 |

0E00120A |

M2.6x3+Pan |

|

L02 |

0E03964A |

ST2.6x3+Pan (#0 Type 3) |

|

L03 |

0E03955A |

Cut Washer 2.2x4.2x0.2 |

|

L04 |

0E04036A |

M2.6x8+Pan |

|

L05 |

0C10287A |

Damper Screw SL |

|

L06 |

0E03845A |

M1.7x2.5+Pan (#0 Type 3) (Black) |

|

L07 |

0E03945A |

M2x2+Pan (#0 Type 3) (Black) |

|

L08 |

0E03953A |

M2x2+Pan (#0 Type 1) |

|

L09 |

0E03971A |

Pet Washer |

|

L10 |

0E03956A |

Cut Washer 3.2x5.2x0.2 |

|

L11 |

0E03947A |

M2.6x3.5+Pan (#0 Type 3) |

|

L12 |

0E04032A |

M2.6x5+Pan (#0 Type 3) |

|

L13 |

0E03954A |

Cut Washer 1.6x3.2x0.2 |

|

L14 |

0E00955A |

BT2x4+Binding |

|

L15 |

0E00964A |

M3x5+Binding |

|

We suggest that you use grease FL-955/G-4270 or equivalent type.

The company dealing FL-955/G-4270 is as follows:

• FL-955 : Kanto Chemicals Co., Ltd.

2-7 Kanda Sakuma-cho, Chiyoda-ku, Tokyo, Japan

Apply FL-955 (grease) to the following places (marked with ) when parts are replaced.

Ref. No. |

Location |

Remarks |

03 |

Loading EX Ass’y |

|

|

Edges which areinserted into the chassis plate |

|

11 |

SUS Bass ADT S Ass’y |

|

|

• Contact part with the Plate Spring SL (Ref. No. 17) |

|

12 |

Mecha UD Sub Cam SL |

Whole surface |

13 |

UD S Cam Guide SL (2 pcs.) |

Whole surface |

14Stocker Motor SL Ass’y

•Motor Shaft Worm Gear

•Motor Shaft End

17 |

Plate Spring SL |

|

|

Contact part (bottom end) with the SUS Base X Sub |

|

|

Ass’y (Ref, No. 11) |

|

19 |

Disc Lock Arm SL |

Whole surface |

20UD Link Arm SL

• Around the Top End

---Shaft for UD Link Arm SL (Ref. No. 20)

15

MECHANICAL ASS’Y AND PARTS LIST

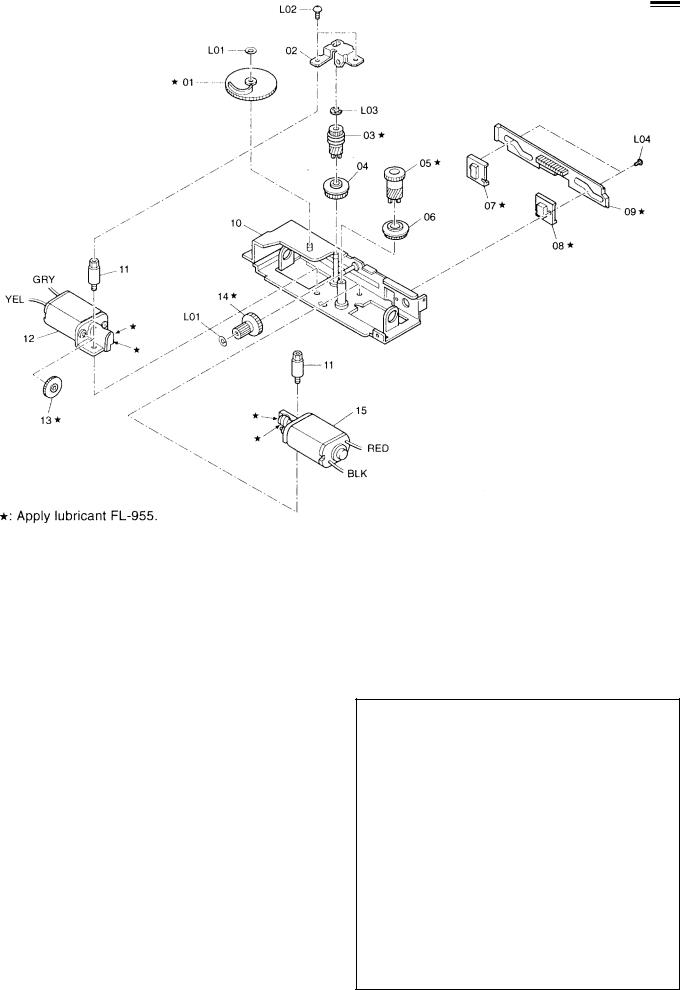

4.3 Motor Chassis EX Ass’y (B01)

Fig.4-3

4.3 Motor Chassis EX Ass’y (B01)

Ref. No. |

Part No. |

Description |

Q'ty |

B01 |

CA09415A |

Motor Chassis EX Ass’y |

|

01 |

0C10238A |

Loading Plate Cam SL |

1 |

02 |

0C10240A |

UD Worm Plate SL |

1 |

03 |

0C10233A |

UD Worm Gear SL |

1 |

04 |

0C10235A |

Mecha Sensor Ring SL |

1 |

05 |

0C10236A |

Loading Worm Gear SL |

1 |

06 |

0C10237A |

Loading Sensor Ring SL |

1 |

07 |

0C10208A |

UD Cam Guide SL |

1 |

08 |

0C10242A |

UD Cam Guide W SL |

1 |

09 |

0C10232A |

UD Cam SL |

1 |

10 |

CA09338A |

Motor Chassis SA S Ass’y |

1 |

11 |

0C10241A |

Bracket Screw SL |

2 |

12 |

CA09417A |

UD Motor EX Ass’y |

1 |

13 |

0C10239A |

Emergency Gear SL |

1 |

14 |

0C10234A |

Mecha UD Gear SL |

1 |

15 |

CA09416A |

Loading Motor EX Ass’y |

1 |

L01 |

0E03955A |

Cut Washer 2.2x4.2x0.2 |

|

L02 |

0E03947A |

M2.6x3.5+Pan (#0 Type 3) |

|

L03 |

0E00222A |

E-Ring 2.0 mm |

|

L04 |

0E03967A |

M1.4x2+Pan (#0 Type 1) (Black) |

|

Apply FL-955 (grease) to the following places (marked with ) when parts are replaced.

Ref. No. |

Location |

Remarks |

01 |

Loading Plate Cam SL |

Whole surface |

03 |

UD Worm Gear SL |

Whole surface |

05 |

Loading Worm Gear SL |

Whole surface |

07 |

UD Cam Guide SL |

Whole surface |

08 |

UD Cam Guide W SL |

Whole surface |

09 |

UD Cam SL |

Whole surface |

12UD Motor EX Ass’y

•Motor Shaft Worm Gear

•Motor Shaft End

13 |

Emergency Gear SL |

Whole surface |

14 |

Mecha UD Gear SL |

Whole surface |

15Loading Motor EX Ass’y Emergency Gear SL

•Motor Shaft Worm Gear

•Motor Shaft End

16

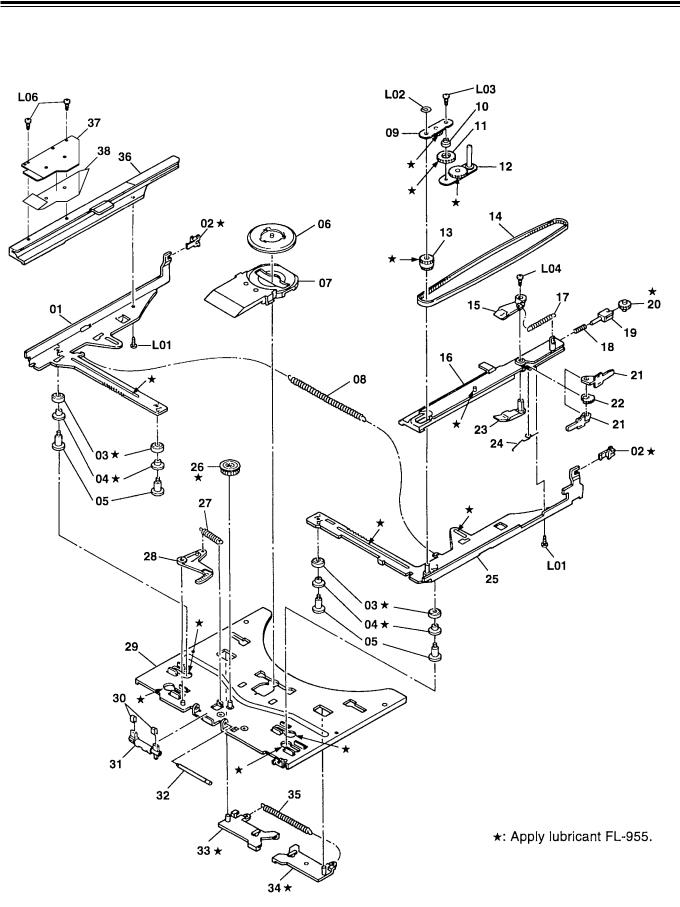

MECHANICAL ASS’Y AND PARTS LIST

4.4 Loading EX Ass’y ADJ-3 (B02)

Fig.4-4

17

MECHANICAL ASS’Y AND PARTS LIST

4.4 Loading EX Ass’y ADJ-3 (B02)

Ref. No. |

Part No. |

Description |

Q'ty |

B02 |

CA09505A |

Loadig EX Ass’y ADJ-3 |

1 |

01 |

0C10201A |

Loading Plate R SL |

1 |

02 |

0C10215A |

LP Slider SL |

2 |

03 |

0C10295A |

Loading Roller |

4 |

04 |

0C10296A |

Screw Collar |

4 |

05 |

0C10294A |

Loading Screw |

4 |

06 |

CA09403A |

Clamper ADT Ass’y |

1 |

07 |

0C10203A |

Disc Guide Upper SL |

1 |

08 |

0C10252A |

Loading Return Spring SL |

1 |

09 |

CA09356A |

Loading Link B SL S Ass’y |

1 |

10 |

0C10248A |

Loading Idler Gear L SL |

1 |

11 |

0C10247A |

Loading Gear Collar SL |

1 |

12 |

CA09355A |

Loading Link A SL S Ass’y |

1 |

13 |

0C10213A |

Timing Gear SL |

1 |

14 |

0C10190A |

Timing Belt SL |

1 |

15 |

CA09335A |

Disc Fin Arm LO SL S Ass’y |

1 |

16 |

0C10199A |

Disc Guide L SL |

1 |

17 |

0C10214A |

Catch Arm Spring SL |

1 |

18 |

0C10193A |

Pulley Spring SL |

1 |

19 |

0C10192A |

Pulley Fork SL |

1 |

20 |

0C10191A |

Idler Pulley SL |

1 |

21 |

0C10195B |

Lapping Arm SL |

2 |

22 |

0C10194A |

Disc Catch Gear SL |

1 |

23 |

CA09336A |

Disc Fin Arm SL S Ass’y |

1 |

24 |

0C10196C |

Lapping Arm Spring |

1 |

25 |

CA09337A |

Loading Plate L SL A Ass’y |

1 |

26 |

0C10251A |

Loading Center Gear SL |

1 |

27 |

0C10250A |

Shutter Spring SL |

1 |

28 |

0C10204A |

Shutter Lever SL |

1 |

29 |

CA09361A |

Loading Chassis SL S Ass’y |

1 |

30 |

0C10255A |

Shutter Arm Cushion SL |

2 |

31 |

0C10249A |

Shutter Arm SL |

1 |

32 |

0C10254A |

Shutter Arm Shaft SL |

1 |

33 |

0C10206A |

Clamp Holder R SL |

1 |

34 |

0C10205A |

Clamp Holder L SL |

1 |

35 |

0C10253A |

Clamper Return Spring SL |

1 |

36 |

CA09395B |

Disc Guide R EX S Ass’y |

1 |

37 |

0C10581A |

D Guide R side EX |

1 |

38 |

0C10582A |

D Guide Sheet EX |

1 |

L01 |

0E03961A |

BT2x4+Pan (#0 Type 1) (Black) |

|

L02 |

0E03955A |

Cut Washer 2.2x4.2x0.2 |

|

L03 |

0E03969A |

M1.4x3+Pan (#0 Type 3) |

|

L04 |

0E03963A |

BT1.7x3+Pan (#0 Type 1) (Black) |

|

L05 |

0E00793A |

BT2x6+Pan |

|

Apply FL-955 (grease) to the following places (marked with ) when parts are replaced.

Ref. No. |

Location |

Remarks |

01 |

Loading Plate R SL |

Groove |

02 |

LP Slider SL |

Whole surface (2 places) |

03 |

Loading Roller |

Whole surface (4 places) |

04 |

Screw Collar |

Whole surface (4 places) |

09 |

Loading Link B SL S Ass’y |

Gear surface |

10 |

Loading Idler Gear L SL |

Gear surface |

12 |

Loading Link A SL S Ass’y |

Gear surface |

13 |

Timing Gear SL |

Gear surface |

16 |

Disc Guide L SL |

Stud |

20 |

Idler Pulley SL |

Whole surface |

25 |

Loading Plate L SL A Ass’y |

Grooves (2 places) |

26 |

Loading Center Gear SL |

Whole surface |

29 |

Loading Chassis SL S Ass’y |

Holes (4 places) |

33 |

Clamp Holder R SL |

Whole surface |

34 |

Clamp Holder L SL |

Whole surface |

18

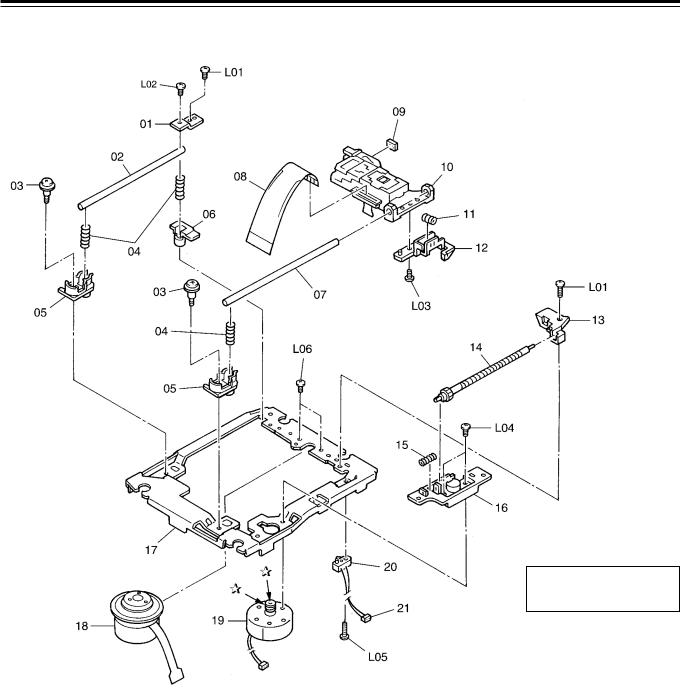

MECHANICAL ASS’Y AND PARTS LIST

4.5 DVD Traverse Ass’y ADJ-3 (B03)

: Apply lubricant PG-663

Apply PG-663

19: Gear and Gear Top

|

|

|

|

|

|

|

|

Lubricant: |

|

|

|

|

|

|

|

|

|

We suggest that you use PG-663 or |

|

|

|

|

|

|

|

|

|

equivalent type. |

|

|

|

|

|

|

|

|

|

Please contact: |

|

|

|

|

|

|

|

|

|

Dowcorning Co., Ltd. |

|

|

|

|

|

|

|

|

|

1-1-3 Marunouchi, Chiyoda-ku, |

|

|

|

|

|

Fig.4-5 |

|

Tokyo, Japan |

|

||

4.5 DVD Traverse Ass’y ADJ-3 (B03) |

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|||

Ref. No. |

Part No. |

Description |

Q'ty |

|

|

Ref. No. |

Part No. |

Description |

Q'ty |

B03 |

CA09479A |

DVD Traverse Ass’y ADJ-3 |

|

13 |

0C10537A |

Holder Shaft 1 |

1 |

||

01 |

0C10559A |

Holder Shaft 3 |

1 |

14 |

CA09487A |

Shaft Screw Ass’y |

1 |

||

02 |

0C10532A |

Shaft R |

1 |

15 |

0C10524A |

SP Push L.S |

1 |

||

03 |

0C10534A |

Screw S |

2 |

16 |

0C10539A |

Holder Motor |

1 |

||

04 |

0C10525A |

SP Push Shaft |

3 |

17 |

0C10530A |

Traverse-P Chassis |

1 |

||

05 |

0C10536A |

Holder SP |

2 |

18 |

0B90969A |

M. CDS8A50T30-A/TT |

1 |

||

06 |

0C10558A |

Holder SP 2 |

1 |

19 |

CA09488A |

Sled Motor Ass’y |

1 |

||

07 |

0C10531A |

Shaft L |

1 |

20 |

0B70304A |

Switch MPU10420MLB0 |

1 |

||

08 |

0B85437A |

30P Flexible wire (Pickup) |

1 |

21 |

0B85699A |

2P Wire Ass’y L100 |

1 |

||

|

(Note: Do not included in the DVD Traverse Ass’y (CA09479A). |

|

|

L01 |

0E04250A |

ST2x5+Pan CMT |

|

||

09 |

0C10583A |

Cushion PU 7x4x2.5 |

1 |

|

|

L02 |

0E04256A |

M2x4+Pan BNI |

|

10 |

0B90967A |

Pick-up VED0383-AK |

1 |

|

|

L03 |

0E04248A |

M1.7x3.5+Pan CMT |

|

11 |

0C10526A |

SP Push Hook |

1 |

|

|

L04 |

0E04248A |

M1.7x3.5+Pan CMT |

|

12 |

0C10535A |

Hook L.S |

1 |

|

|

L05 |

0E04249A |

ST2x8+Binding CMT |

|

|

|

|

|

|

|

L06 |

0E04247A |

M1.7x2.5+Pan BZN |

|

19

MECHANICAL ASS’Y AND PARTS LIST

4.6 Pakage Ass’y and Accessory Ass’y

2

1

4.6 Pakage Ass’y and Accessory Ass’y

Ref. No. |

Part No. |

Description |

Q'ty |

1 |

0F05622B |

Carton Box |

1 |

2 |

0F05623B |

Packing |

2 |

3 |

0F04458A |

Sheet |

1 |

--- |

0B85744A |

Code YAF11-0642 (UK/EP) |

1 |

--- |

0B85745A |

Code R-C275VP (JPN/OTR/AUS 1 |

|

|

|

/USA/CAN/CH/DA/HK/KR/TW) |

|

--- |

0B90451A |

Batery UM3X1 |

2 |

--- |

0D03092B |

Poly Bag |

1 |

--- |

0F04860A |

Poly Bag (UK/HK only) |

1 |

--- |

0D07238A |

AC Cord UL (USA/CAN) |

1 |

--- |

0D07239A |

AC Cord EP (EP) |

1 |

--- |

0D07240A |

AC Cord DA/DU (DA/OTR/TW) |

1 |

--- |

0D07241A |

AC Cord DM (JPN) |

1 |

--- |

0D07242A |

AC Cord BS/HK (UK/HK) |

1 |

Accessory Ass'y

2

3

Fig.4-6

Ref. No. |

Part No. |

Description |

Q'ty |

--- |

0D07243A |

AC Cord CH (CH) |

1 |

--- |

0D07244A |

AC Cord KR (KR) |

1 |

--- |

0D07245A |

AC Cord SA (AUS) |

1 |

--- |

0D07355A |

Owner’s Manual Japanise (JPN) |

1 |

--- |

0D07356A |

Owner’s Manual English |

1 |

|

|

(Except JPN) |

|

--- |

0D07357A |

Owner’s Manual Franch |

1 |

|

|

(USA/CAN/EP) |

|

--- |

0D07358A |

Owner’s Manual German (EP) |

1 |

--- |

0D07359A |

Owner’s Manual Spanish |

1 |

|

|

(USA/CAN/EP/DA) |

|

--- |

0D07360A |

Owner’s Manual Italian (EP) |

1 |

--- |

0H08216A |

CD Single Adaptor (JPN) |

1 |

--- |

HG08343A |

Remote Control Unit |

1 |

20

5. ELECTRICAL PARTS LIST

Notes:

1.Abbreviations

TR-Transistor, SID-Slicon Diode, ZD-Zener Diode,

RC-Cement Resistor, RF-Fail Safe Type Resistor,

RK-Carbon Resistor.

IC-Integrated Circuit, CML-Mylar Capacitor,

CC-Ceramic Capacitor, CE-Electrolytic Capacitor.

2.Parts marked with * show chip parts.

5.1 Mechanism P.C.B. Ass’y (C3M1)

Ref. No. |

Part No. |

|

Description |

Q'ty |

|

BA10323A |

|

Mech P.C.B. Ass’y C3M1 |

|

CN100 |

0B85425A |

|

40P F Connector* |

1 |

CN200 |

0B85424A |

|

30P F Connector* |

1 |

CN300 |

0B85420A |

|

11P F Connector* |

1 |

CN501 |

0B80941A |

|

14P F Connector * |

1 |

CP103 |

0B84785A |

|

22P F Connector* |

1 |

CP502 |

0B85421A |

|

13P F Connector* |

1 |

D011 |

0B12249A |

SID |

1SS133 |

1 |

D031,032 |

0B12249A |

SID |

1SS133 |

2 |

D404 |

0B10540A |

SID |

MA152WA* |

1 |

D406 |

0B10540A |

SID |

MA152WA* |

1 |

D516 |

0B10539A |

SID |

MA152WK* |

1 |

D518 |

0B12249A |

SID |

1SS133 |

1 |

ICP01 |

0B12918A |

IC |

ICP 0.5A* |

1 |

Q001 |

0B14013A |

TR |

DTC144EK* |

1 |

Q031,032 |

0B12901A |

TR |

2SB1132R * |

2 |

Q033,034 |

0B14227A |

TR |

2SA1576 S * |

2 |

Q035 |

0B14188A |

TR |

2SC4081 R * |

1 |

Q036 |

0B10882A |

TR |

DTC114TKA* |

1 |

Q037 |

0B14188A |

TR |

2SC4081 R * |

1 |

Q038 |

0B14002A |

TR |

DTA114EK* |

1 |

Q090 |

0B14167A |

TR |

2SC2412K * |

1 |

Q401 |

0B10792A |

TR |

2SB1182QR* |

1 |

Q402 |

0B14167A |

TR |

2SC2412K * |

1 |

Q403 |

0B10901A |

TR |

2SD2153TL* |

1 |

Q404 |

0B10930A |

TR |

2SD1758F * |

1 |

Q411,412 |

0B14167A |

TR |

2SC2412K * |

2 |

Q501 |

0B14167A |

TR |

2SC2412K * |

1 |

Q502 |

0B14013A |

TR |

DTC144EK* |

1 |

Q511,512 |

0B14018A |

TR |

DTC143TK* |

2 |

Q513,514 |

0B14018A |

TR |

DTC143TK* |

2 |

Q515 |

0B14018A |

TR |

DTC143TK* |

1 |

U001 |

0B12868A |

IC |

BA6859AFP* |

1 |

U002 |

0B12867A |

IC |

BA5938FM* |

1 |

U003 |

0B11001A |

IC |

NJM4558M |

1 |

U004 |

0B06404A |

IC |

NJM2904M |

1 |

U105,106 |

0B10719A |

IC |

TA8409F * |

2 |

U107,108 |

0B10719A |

IC |

TA8409F * |

2 |

U401 |

0B10566A |

IC |

PQ09RF1 |

1 |

U501 |

0B13256A |

IC |

HD6433396F* |

1 |

U502 |

0B11928A |

IC |

TC4049BF |

1 |

X501 |

0B90740A |

|

Resonator 6.00MHz |

1 |

Ref. No. |

Part No. |

|

Description |

Q'ty |

ZD033 |

0B12168A |

ZD |

RD10V JS B2 |

1 |

ZD401 |

0B12150A |

ZD |

RD5.6V JS B2 |

1 |

ZD402 |

0B12160A |

ZD |

RD7.5V JS B3 |

1 |

ZD403 |

0B12153A |

ZD |

RD6.2V JS B2 |

1 |

ZD404 |

0B12150A |

ZD |

RD5.6V JS B2 |

1 |

ZD502,503 |

0B12154A |

ZD |

RD6.2V JS B3 |

2 |

21

ELECTRICAL PARTS LIST

5.2 DVD Main P.C.B. Ass’y (C3M1)

Ref. No. |

Part No. |

|

Description |

Q'ty |

|

BK10567A |

|

DVD Main P.C.B. Ass’y C3M1 |

|

D101,102 |

0B13151A |

SID |

1SS355TE-17* |

2 |

D103 |

0B13151A |

SID |

1SS355TE-17* |

1 |

D120 |

0B13151A |

SID |

1SS355TE-17* |

1 |

D190 |

0B13151A |

SID |

1SS355TE-17* |

1 |

D191 |

0B13152A |

SID |

DA204U-T106* |

1 |

D193 |

0B13151A |

SID |

1SS355TE-17* |

1 |

D209 |

0B13151A |

SID |

1SS355TE-17* |

1 |

D300,301 |

0B13151A |

SID |

1SS355TE-17* |

2 |

D500,501 |

0B13151A |

SID |

1SS355TE-17* |

2 |

D850 |

0B13153A |

SID |

UMN11N-TN* |

1 |

D901 |

0B13153A |

SID |

UMN11N-TN* |

1 |

D902,903 |

0B13151A |

SID |

1SS355TE-17* |

2 |

IC100 |

0B13171A |

IC |

CYC11AP000* |

1 |

IC110,111 |

0B13179A |

IC |

NJM4558M* |

2 |

IC120 |

0B13169A |

IC |

BU4011BFV-E2* |

1 |

IC121,122 |

0B13170A |

IC |

BU4S81-TR* |

2 |

IC201 |

0B13172A |

IC |

CYC12MP000* |

1 |

IC202 |

0B13190A |

IC |

TC7SHU04FU* |

1 |

IC203 |

0B13179A |

IC |

NJM4558M* |

1 |

IC300 |

0B13177A |

IC |

MN67700VRZB* |

1 |

IC311 |

0B13190A |

IC |

TC7SHU04FU* |

1 |

IC410,411 |

0B13178A |

IC |

NJM2903V* |

2 |

IC412 |

0B13169A |

IC |

BU4011BFV-E2* |

1 |

IC490 |

0B13165A |

IC |

MN66261 |

1 |

IC500 |

0B13173A |

IC |

CYC13DD000* |

1 |

IC501 |

0B13175A |

IC |

HY628100ALG-55* |

1 |

IC502 |

0B13174A |

IC |

HY57V161610DTC* |

1 |

IC503 |

0B13183A |

IC |

TC74VHC00FT* |

1 |

IC507 |

0B13186A |

IC |

TC74VHC32FTEL* |

1 |

IC550 |

0B13185A |

IC |

TC74VHC157FTEL* |

1 |

IC600 |

BA10572A |

|

DVD AK-SYS6 KIT |

1 |

IC602 |

BA10573A |

|

OPT ROM NC100503 KIT |

1 |

IC603 |

0B13176A |

IC |

M24C16-MN6T* |

1 |

IC605 |

0B13183A |

IC |

TC74VHC00FT* |

1 |

IC606 |

0B13189A |

IC |

TC74VHCT245AFT* |

1 |

IC607 |

0B13187A |

IC |

TC74VHC574FTEL* |

1 |

IC610 |

0B13191A |

IC |

TC7W04FUTE12L* |

1 |

IC611 |

0B13183A |

IC |

TC74VHC00FT* |

1 |

IC612 |

0B13193A |

IC |

TC7WH74FUTE12L* |

1 |

IC613 |

0B13184A |

IC |

TC74VHC08FTEL* |

1 |

IC614 |

0B13188A |

IC |

TC74VHC86FT* |

1 |

IC700 |

0B13195A |

IC |

ZIVA-3-PEO* |

1 |

IC701,702 |

0B13174A |

IC |

HY57V161610DTC* |

2 |

IC703 |

0B13192A |

IC |

TC7WH157FU* |

1 |

IC704 |

0B13181A |

IC |

SI-3025ALS-TL* |

1 |

IC800 |

0B13182A |

IC |

SM8701BM-ET* |

1 |

IC801 |

0B13194A |

IC |

TC7WU04FUTE12L* |

1 |