Nakajima 281LY-B User Manual

INSTRUCTION

BOOK&PARTS

BOOK

MODEL

1

*~t**I~~~~J

EII1J*tJJ~~i'f

~

~

/

281LY-B

(Large rotary hook)

Single Needle, Lock Stich,

Compound Feed Sewing Machine

With

Automatic Thread Trimmer

t*~)

<$>NAKAJIMA

SEISAKUSHO CO.,LTD. J

§

~

y /;J$iWJO)

~'ii~···········

2

CAUTIONS

CONTENTS

BEFORE

OPERATING

THE

MACHINE

page

.......

2

1Y!ffl_LO)

1.

ft

2.

;J$i1W

2-1

.:c-

2-2

2-3

~lliiiO)Jfl{t~t········

rwll: ·

2-4

3

.1Y!ffl

~~y/0)1Y!v)7J

~~4-14

5.,%W

_t

3-1

IE

3-2

tP

3-3

~Jv

4-1

~tO)J&1t~t1J···......................

4-2

r

4-3

J:.*'O)illi

4-4

~~"'13ft~

4-5

*'

4-6

J:.*~~:t.J

4-7

r

4-8

*'If~

4-9

w

4-1o

~tc

4-11

J2S ~ lljtj ~ ............................ 9

4-12 w

4-13

~

~tt~t~!tJJaO)wH~f)]:·tiO)~~·...

4-15

~*

4-16

4-17

*W

4-18

*'W

4-19

4-20

1mW1*~-r............................

4-21 ;(

4-22

~"'13ft~

)Jj{

129

~'j_£~.......................

**................................... 2

0)

~11m·············

~

~

;;-

O)w

-7-

t

J:.f~JJ:O)~~.............

0)

~'ii

1W····

..

i

O)*ftrm~~··

~

7J

J'\'-O)Jf~1·J't

*0)~

~

1J......................... 6

L1J......................... 6

~

.::;............................. 7

O)il~..

*~~:t.J

X.J±:t.J

0)~~......

~

) { ;f, . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

O)~Ji('j..

n 70)001*...................... 8

X.JE

c

..till~

X.JE c J:.m

~ 7 7~

1m

!l!i

;e

.7..

0)

tJ

-71

tJ

O)¥!fi1J1Ji~·

;e

7-.0)x~

7-.J±O)j,mj~

~

~:.B~t;:,JJ.~t

•

:k'.t

~...............................

... · .. · ..

··

..

· 3

2

CAUTIONS

1.

SPECIFICATION

2.

PREPARATION

THE

X.1t

~

t · · · · · · · ....... ·

O);J"f~··.

.. ..

..

~.......................

···

..

·········

..

...................... 4

............... 5

.......................

O)~~n c ~

.................... 7

................

...

....

..

)EO)f1!!li1JjWj ~ .... 9

~

JEO)~li..t

;f,

")

~

O){)i:m;:..........

:fJJ

WH~

·mt

..

• ............ · 1 o

~;;-~f

...................

..

.... · ...... · ....

............................

.........................

glj~"'~J!t-~ilil<

..

· · 3

. .

.. . ..

. ... . 3

·····

..

····· 3

4

4

·····

.........

L~"'....

..

..

.. . .. ..

r

4

5

5

7

8

8

ill!w1Ji11:

9

10

10

11

11

11

12

12

....

12

13

2-1

SETTING

2-2

CONNECTING

2-3

SYNCHRONIZER

2-4

UPPER

3.

CAUTION

3-1

LUBRICATION

3-2

ADJUSTING

3-3

INSTALLING

4.

HOW

4-1

SETTING

4-2

WINDING

4-3

THREADING

4-4

ADJUSTING

4-5

THREAD

4-6

THE

4-7

ADJUSTING

4-8

THREAD

4-9

ADJUSTING

4-10

TIMING

4-11

ADJUSTING

4-12

ADJUSTING

AND

4-13

ALTERNATE

PRESSER

4-14

ADJUSTING

OF

4-15

POSITION

4-16

HOME

4-17

ADJUSTING

4-18

HOW

4-19

HOW

4-20

AUXILIARY

4-21

PRESSURE

4-22

STITCH

5.

PHENOMENA,

ITS

CORRECTIVE

THE

WHEN

MACHINE

AND

TO

SET

NEEDLE

OF

FEEDING

THE

NEEDLE

POSITION

TO

TO

LENGTH

................................................................

UP

THE

THE

INSTALLATION

LOWER

IN

USE

................................................................... 4

OF

THE

THE

THE

THE

NEEDLE

THE

BOBBIN

THE

THE

STITCH

TENSION

THREAD

THE

BOBBIN

TAKE

UP

THE

PRESSER

NEEDLE

THE

HEIGHT

THE

HEIGHT

FOOT

STROKE

FOOT

AND

THE

LONGITUDIAL

OF

THE

OF

THE

THREAD

MANUALLY

REPLACE

THREAD

OF

THE

REASON

THREAD

TRIMMING

OPERATING

THE

MACHINE

..........

.............................................................

BEFORE

MACHINE

MACHINE

NEEDLE

OPERATING

................................................ 3

WITH

MOTOR

.......................... 3

.......................................... 3

STOPPING

POSITIONS

............... 4

..........................................................

OILING

TO

THE

HOOK

PART

.................. 4

BELT

COVER

..

· .... · .... · ...... · .... ·

MACHINE

....................................................... 5

THREAD

UPPER

THREAD

LENGTH

............................................................. 7

TENSION

THREAD

SPRING

BAR

REVERSE

AND

................................................. 8

OF

AND

ROTATING

OF

FEED

OF

· ................ · .... · .... · ................ ·

FEEDING

THE

THE

FIXED

PRESSER

AMOUNT

FRAME

FEED

ROTARY

TRIMMING

OPERATE

KNIVES

TENSION

KNIFE

SPEED

..............................................

..................................

.......................................... 6

....................................... 6

AND

REVERSE

.......................................... 7

TENSION

PRESSED

FOOT

.............................................

CONTROLLER

FOOT

HOOK

DOG

............................... 9

FOOT

OF

.................................. · 9

POSITION

SOLENOID

KNIFE

CAM

THE

THREAD

..........................................

.........................................

..

· .... ·.......... 5

FEED

......... 7

......................... 8

....................... 8

.......................... 8

.. · .. · ..

·.... 9

.......................

.............................

...........................

TRIMMER

........................

........

10

10

10

11

II

11

12

12

12

AND

MEASURE

AT

..........................................

13

2

2

3

4

5

6 . ffi

JJJt

:g:~

&=6

..

..

..

.. . .. . ..

..

.. ..

.. . .. .. . ..

6-1

~ ~ ;;-tfB~

6-2

)'~-

·:;

.............................

1

)

.7.. ~ ..........................

.. .

..

14

14

18

6.

COMPONENT

6-1

MACHINE

6-2

LIST

-1-

OF

PARTS

PARTS

...............................................................

PARTS

· ................................................................

...................................................

14

14

18

.::.O)t..:O'I±,

NJ

t)

;?r

C 1

.::.

0)

~

~

I±,

fiiJ

J:

tJ

niH:·.Il·f.::.

t.:

~"'iT

"'\"'7-=E-

~

~;_,~.t:;!~t\t'J:'f"'t..:t.:~

.::."

~-\t'

i L

f..:o

;.-

O);Jin~

~+7t~i1\

<b

IE

L"

'{9,!\t

'1Jt~r£*

O)f!J!JfJ~#JIJ=.I:PF

J:

1.t:>fM{\t'lf1

L

-c

.:::ti'im"

c

'~

tJ

~

.t:>~rch-

':

~

tJ

LN.>Ifi

To

\t..:

iT

..

*1k <

i

t.=

<

t..:~':

O)'t\

.::."itffl

.::-~m

L.-c

<

Thank

you

for your purchasing our sewing machines. Please carefully

read this instruction book before operating the machine to prolong ther

machine life and

to

keep the machine always

in

good

condition .

~

~

/lltiliU(})C:··;t~

1)

~

~

/

':¥J:¥dl

L

~

\t' 1

-;I±,

;f@.:i;H:

~

~

\t

\1:

<

t.= ~ \t

\0

2)

fJ.J~-c

~

~

;.-

~ill!iliiT

ji-~T,f

-c.:c-7

J:

3)

-1&

T""l:.f:>{!J!\t'

4)

~

~f!Ht~"'J:

5)

.:c- 7

O)~IJ

flm

1

Htt?W.

-f,:l±-¥~

2)

~

~

3)

~ ~ ;.-~fims~fftJ-t

~'lt?W.A1·;~-f-~t;})-:>l

4)

~ ~ ;,-~!fiii=J:ll±,

'J

T C

5)~Jv

~1.1?

..

I±Tch!P-~

-O)IHJ~ii~fljiMtL-c

tJ

h.

-c

J~n;fatn·ffiJ

M

0)

1

7J

J.IIUJI±

(f.:_'~

~ / ~ill!ttrit"

1

-O)~Yt~U:1<n~

;?rJE

L

\t

'il\ii'lli~

J:.

(})

'-.

;tl\

A 1 ·:,.f-

~

;.-

~A.

A.tl~\t'""l:

illiifi.i!:f:l

..

\t'o

-Ni!J:,:ffl,

f(t~~""l:T

i'

~

0)"1:

7J;<-,

91-

L

t..:~RTl.~""l:

Qtl!fr,

J!~;?rJ?,

t~ri£

~

\t

\

)ilil!£

liT

<

t.:~"'o

L"

'!ill

'i--r-t

~ric

h.!f!

1{1j]ht;1.

o)

L,

2,

\t'o

Q c

~I±,

l±f

~!fi1~nO)~~tl1~~':-=p

':

L-c

<

t.:~"'o

~

tL

"(\t'Qitti±&O'!iLt§

L

-c

< t.:

~

\t

'o

n Q t

~, & a·~

<

t.=~

xu·

A-n

J{-

t

~

~ v ~Jv

(

t_:~\tlo

l±fh.Jt(,

U!i~~ili:--:Jitt..:

i:>

~

~ ( f.:_·~

fftff-

F~nr~~:~~t

~

~ / ~ill!

~

;.-

"'o

r~

':m

~

A.~t~

i'

~9~-t c ~

V~Jv

i',

tJ,

~a-ffi'i"'t..:

\t

'o

""C\t'~t~rg.,

!Iii

L ~ "'

CAUTIONS

;.-

~JI'i L ~

~-f-1:@1

1

U±f~lf!ffi~

OOOs.p.m.

L

-c

·:,.f-~

A.tt.

J,j.

..

:=:;tH

1) Never operate the machine without lubrication.

2)

3)

4)

5) Confirm the ratings of your power source

CAUTIONS

i!Eq!i'fl

l±j·J·O)

",--r

1±,

*~*'

~J

-r:·

<

t.:

~

<

t.=

·ll·f

.:c-

L i

.::

"'o

1) Don't put your hand under the needle

2)

3)

4)

5)

BEFORE

After setting

direction; lower the needle

handweel's revolution by momentarily switching the power

(correct rotational direction

viewed

Run

the newly installed machine at a speed of 2.000

for the first 4 week.

Don't hold the machine by its synchronizer behind the handweel when

you

move

on

the motor (power voltage, phase etc.).

switch and the machine is running.

Don't put your hand into the thread take-up cover while the machine is

running.

Don't forget

head backwards

Never bring your fingers or hair close

handweel,

may

lead to serious personal injuries.

If

your machine

guard. never operate your machine with any of them removed.

up

your machine, make sure that it runs

from

the handweel's end).

the machine head for installation.

IN

OPERATION

to

cut off the power supply before

or

replace the V-belt.

V -belt. bobbin winder wheel or motor during operation. It

is

provided with a belt cover, finger guard and eye

OPERATION

in

the correct

by

turning the handweel and witch the

of

the hand wheel: counterclockwise when

s.p.m.

or lower

by

the machine plate stuck

when

you turn

to.

or place anything

"on"

you

tilt the machine

the power

on

"on"

the

1.

1±

til

f,.l

13fwl&

Automatic backtacking device

m

Application

f~

Thread

ftv

Sewing speed

ftv'

Stitch length

~NM-A

Needle

;fiJI

Presser

Sewing hook

*'~

Lubrication

-c-

Motor specifications

fJf(

MODEL

LftP¥dn

~

,r~

m

to

be

'~]jt

u~~~if:j)

(MAX)

~

!{:

~

~o-7

bar

stroke

X J: I)

Jil:

feet lift

n

Needle

~

iJIJ

~-

{l:t'A

SPECIFICATIONS

used

With backtacking by push button

Medium-heavy

;flflX.J:,f9

9mm by hand lever

Hand oiling (Hook

mm

~lillif!Z~i!l2

Large

-¥~

LiJ:idl

2P-400W

281LY-B

7

·;~-7-1<·;~7f.t

If!

1!/-!JW

•

l!/-!JW

and heavy weight materials

#

40-

# 8

2400

s.p.m

0-8

mm

38

mm

IUU:,f15mm

15mm by knee lifter

DPX17

#23

f/1~

rotary

hook

(1ii$13fiJJt~idJ)

part

lubricated automatically)

(Electro-motor)

o.:c-7

o?.~*~tt.~i?{~

O:i2it),

0

0 Lower the speed

0 Please

-7-IJ

Jv

r I± M

~

\t'o

:iilt

~r,f--c1~ffl

~\t'o

*i,

*' ~ /

'±·£·-fJ.IJffl

1~ffl

L

""C

Use

M type of motor pulley

and V-belt.

thread was cut

ated.

do

component parts especially

such as the

bobbin case and bobbin.

-JJ..o·~

~

~1~ffl

L

--c'

t.::.t..:tJlfr

;f{~/7-;1.,

< t.:

~

" 'o

in

by

use our selected

feed

dog,

L

-c

<

0) ~ 0)

case the

over

hook,

..

t.=

~

he-

·~

-2-

2.

)lfiiij(J)~ii

2-1

~

~

/O)flj;t

I)~

:,

/

(ilfB~~Q

't-r

< t.!

~

~

L,

~~fj~$~f5:r~-ttiTo

2)

u-

~~J:~f~ilt,iOOO)f)J:flU:Jf~

"lo

~ ~ 1t't7~r~"

O)~JfljyiJr*

ittt

t.!~tifZffl~tJ!ji)f~~A..

"lo

.mif•J"

~tnhr.JfiJ~~"

~

l t

u-

~·mdttJr:ffi:

~ < ~

~,

f'f.~fj~$7Jrf5:r

"'C'tJ&N·

l t

;JtreliJJJ

~3e

ft~t-r

< t.!

~

<

f'F~~

Li-to

2.

PREPARATION

OPERATING

2-1

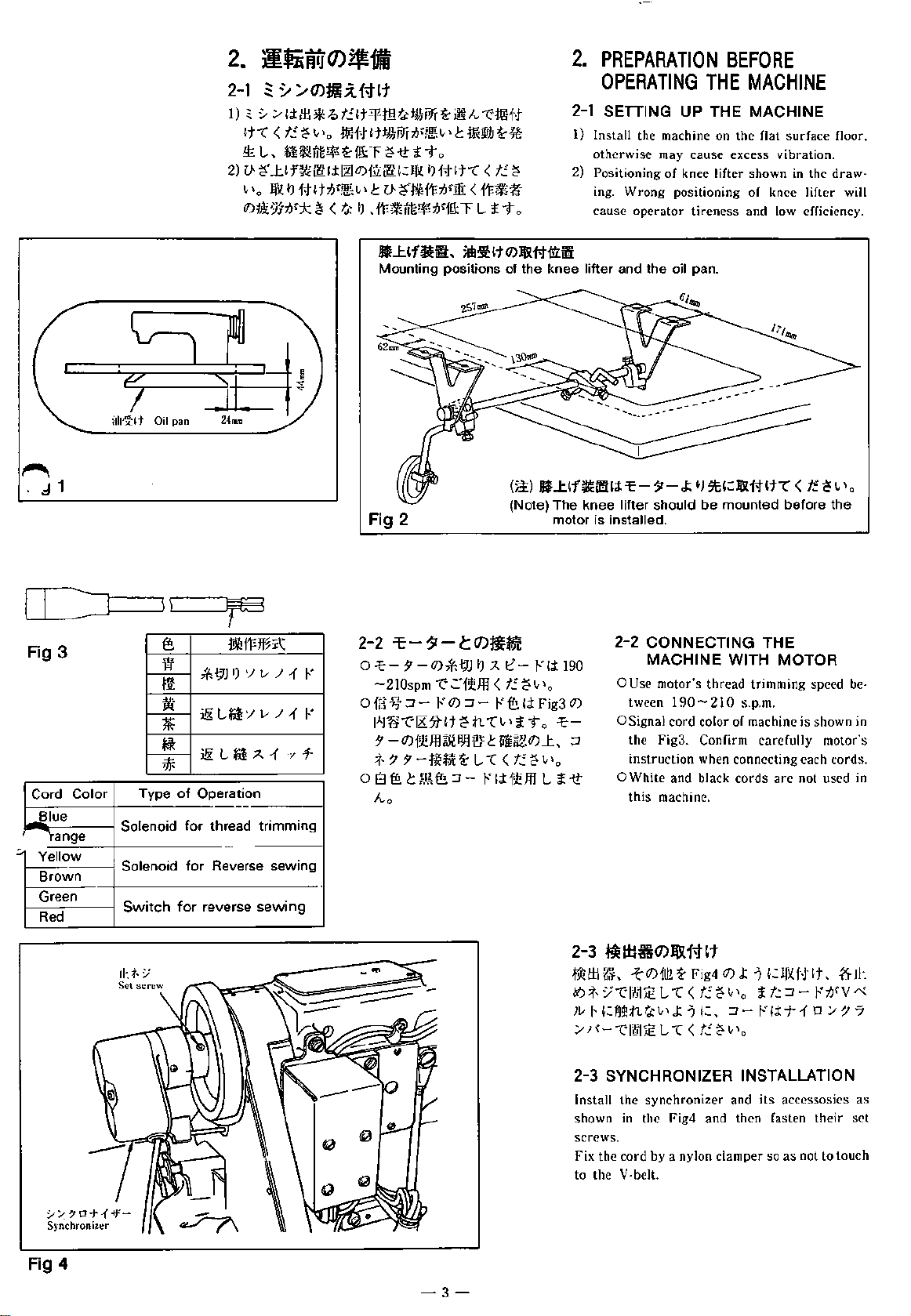

SETTING UP THE MACHINE

1) Install the machine on

otherwise

2)

Positioning of knee lifter shown in the

ing.

cause

Wrong

operator

may

positioning of knee lifter will

BEFORE

THE

the

cause

excess vibration.

tireness

and low efficiency.

MACHINE

flat

surface

floor.

draw-

Fig 3

Cord Color

~lue

~ange

'

::.,

Yellow

Brown

Green

Red

(5

Ff

1=1

14.

~

~

7}f.

Type

Solenoid

Solenoid

Switch

t!lf'F~~

*{JJ

I)'/

i!&L*ii'JvJ1V

i!! L

*-it!

of

Operation

for

thread trimming

for

Reverse sewing

for

reverse

v J 1 V

A 1

·'j

sewing

1-

BJ:.tf~&..

Mounting positions of the knee lifter and the oil pan.

Fig 2

2-2 -1:-11-t

0 .:c-

7'

-210spm

o

f~%

:1

J*J~"t:'IKJJ-~t

7'

-

0)

;f, 7

7'

o 8

1§.

t

A..o

a§

tt

O)JR1tW:iii

()i:)

JJlJ:.~f~fi!U;t

(Note) The knee lifter should be mounted before the

O)flfjC

-

0)

*

~J

~ A ~-

-e.:.~f!l!.ffl

-

r"

0)

:1

-

~

tt

"t"ltl

f~ffl

~RJIJH!f

t

-f~~~

~~

:1-

L "(

F

F

(j:

(

t.!~

1.-lo

r"

f!!

'±

Fig3

i-to

«{H.{!.

0)

J:.,

(f.!~

\tl

(if~ffl

L

-1:-11-

motor is installed.

2-2 CONNECTING THE

190

0)

.:c-

:1

0

i-tt

MACHINE WITH MOTOR

0 Use motor's

tween

OSignal cord color of machine is shown in

the Fig3.

instruction when connecting each cords.

0 White and black

this

machine.

J::

•J

StH:liUttt"C <

thread

trimming speed

190-210

s.p.m.

Confirm carefully motor's

cords

are

not used in

tf.

~

t

'o

be-

Fig 4

-3-

2-3

~WftO)J&ittt

;t.)Hl:\

~,

.:t-

O)ftf!

~

Fig4

0)

.J:

-J

~:

Jfl(

f·Ht, ~

fiJ

;f...

V'"'C'~I~

Jv

r

~=A~!tt~~tl.J:

/

r~-

L

"t"

( t!.

~

'-'

-J

~:,

::1-

"'C'I!'!I~

L "t' < t.!

~

ltlo

\o

it:.

J.."(±-T1

:I-

t:tJrv «

a::,;-

7 7

2-3 SYNCHRONIZER INSTALLATION

Install the

shown in the Fig4 and then fasten

screws.

Fix

to the V -belt.

synchronizer

the

cord by a nylon clamper so

and its accessosies

their

as

not to touch

1l:

as

set

Fig 5

2-4

J:.

w

.d::flLfi(})

w

11:

m:

flt

{/)

w~

-ft

-I&ft1fJI!t

"\

t ;-o

(~m.:c-

liJH!H:fJE-::>

1:111

liT

$~t,~IJ.g:

~lt'o

*

ff

ft[~J

ft![rJJ

~

3.

"'C

.ll:

f)i:

m

#.Jfi(J)$\.t,~IJ.e:t~r7-

l::

-itT

.11:

f)i:

1m:(})

~-tt-r~:q=r"

~

-tti{ll~:p}~~

"'o

f:i!JIIJ:.O))i:~

••

~I±

Mi

1:11

~

F"..

~~;t

~.:

e:

~:

~-

Q)J&:t&"\m

<

t!.~

"'o)

~~ifij(J)

~fll:tm:~:

Wid~

I±..

',

L

*}]e)

:;tdlJ

;}(~:*'WJ

~

q.y-::>

(/)

.t

'l

"'(

-e

tJ

<

t)

t)

<

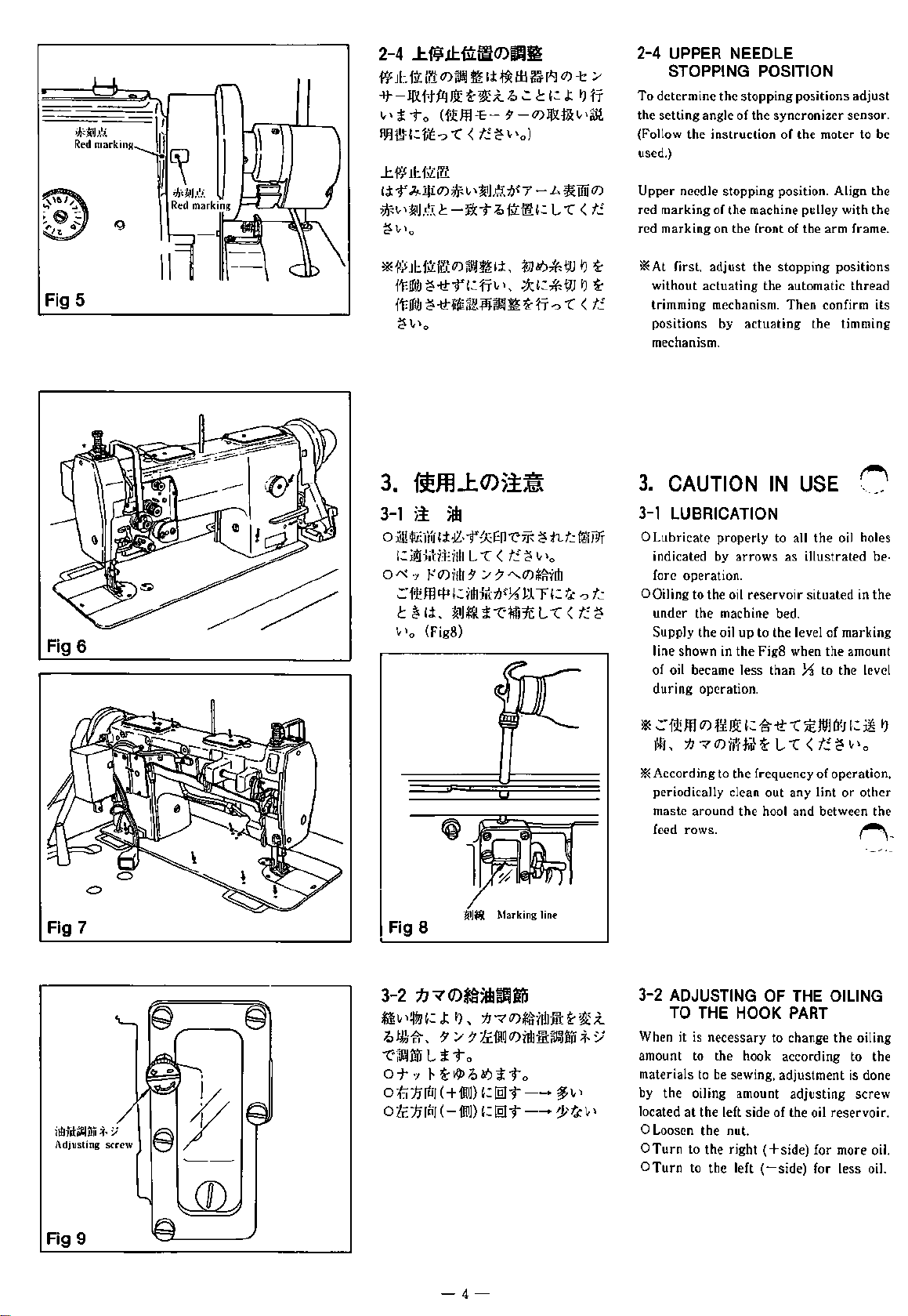

2-4 UPPER NEEDLE

:;.;

To determine the stopping positions

fr

the setting angle of the syncronizer sensor.

(Follow the instruction of the moter to be

used.)

Upper needle stopping position. Align the

red marking of the machine pulley with the

t!.

red marking on the front of the arm frame.

*At

~

~

t!.

3.

STOPPING POSITION

adjust

first, adjust the stopping positions

without actuating the automatic thread

trimming mechanism. Then confirm its

positions by actuating the timming

mechanism.

CAUTION

IN

USE

Fig

Fig

6

7

3-1

)i

5m

o ill!iliilili

o

I±

._e,

-r

~

~n

~:~ID:i±rdi

A::

·:1

.::1!l!ffl

l::

~

\.tlo

L

-r

<

r·

(J)rffi ~ :;.;

~=P

I±..

(Fig8)

7

~:rm.mt~r~

~IJij!l

i

"efl!i1E

~~

!tiJfl

I Fig 8

Marking

-r:iF

~

n

t::.

w

rfr

t!.

~

"'o

A..(J)~rm

1-1 T ':

Jd:

"?

t::.

L

"'C

<

t!.

~

line

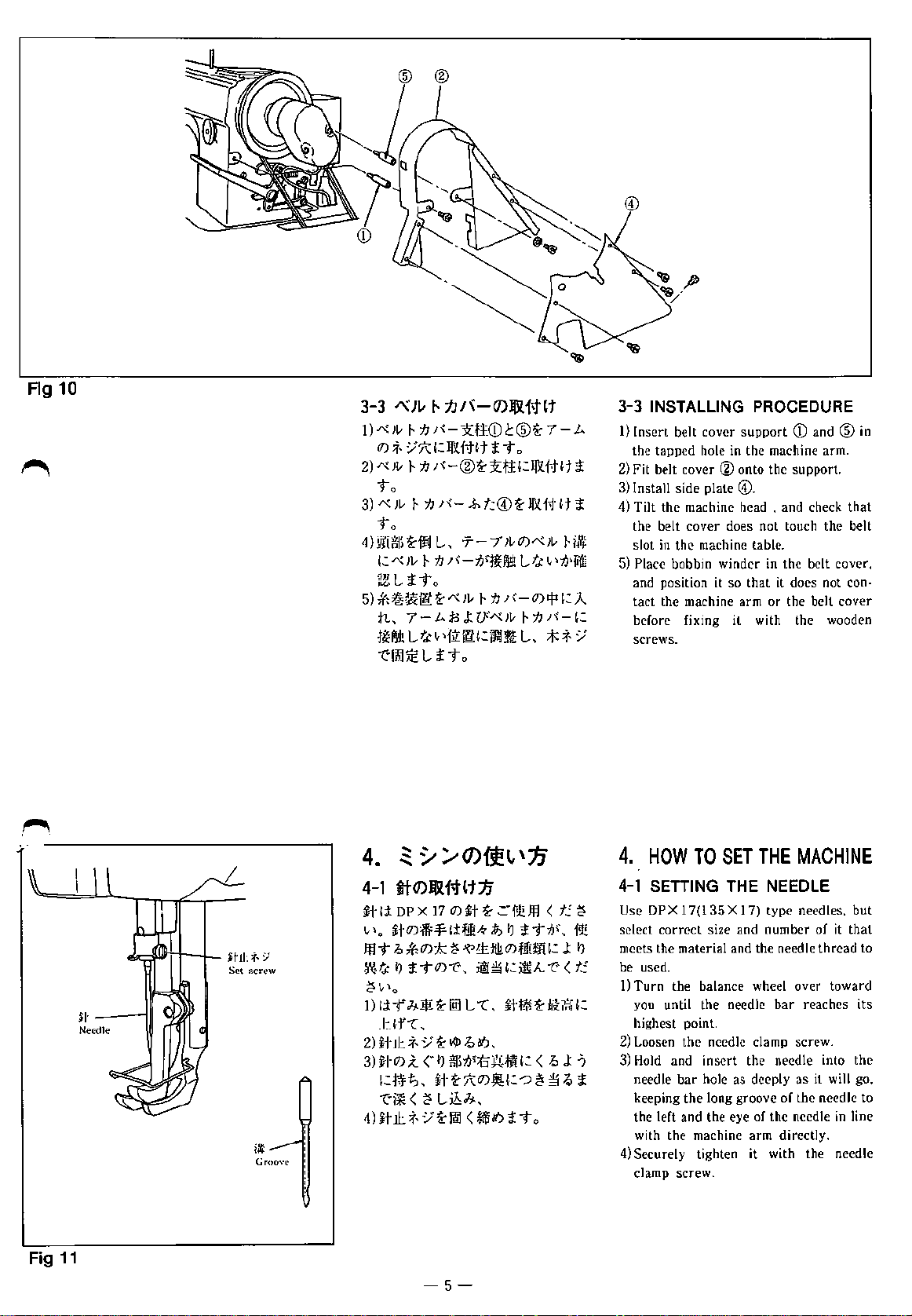

3-1

LUBRICATION

0 Lubricate properly to all the oil holes

indicated by

fore operation .

OOiling to the oil

under the machine bed.

Supply the oil up to the level of marking

line shown in the Fig8 when the amount

of oil became less than

during operation.

*

.::

1!!!

ffl

t~L

7J

*According

periodically clean out any lint

maste around the hool and between the

feed rows.

arrows

as

reservoir

illustrated be·

situated in the

X to the level

(/)

li

J3t

':

it

-tt

"'(

5E

Wl

(I~

7

(J)jJ!Hi

~

L

--c

<

t!.

~

to the frequency of operation,

or

~:

*

"\o

other

t)

tJ

-:;r

3-2

~"

~-~-

"t:itl~ii?i

0-T·:~

O;(jjj(ti}

Oti:}J(ti} (-ff{IJ)

(J)ft8'5fbltJP

,~

~:

.t

tJ

..

:11

7

{/)*ffrm:m:

~/7~-{/)~•~m~~

L i To

r~L-<PocV>iTo

(+ff{IJ)

':ffiiT--

':ffil""t--

Fig 9

-4-

~

~

;t

~"'

~'~"'

3-2 ADJUSTING OF THE OILING

TO

THE HOOK

When it is necessary to change the oiling

amount to the hook according to the

materials to be sewing, adjustment is done

by the oiling amount adjusting

located

at

the left side of the oil reservoir.

0 Loosen the nut.

OTurn

OTurn

to the right

to the left

PART

(+side)

(-side)

screw

for more oil.

for less oil.

Fig

10

3-3

~JII

f-..

7.11~-0):Qi'(ttt

1)~Jv

J..

7.7

;'(-:fttCDc®~7-~

0) ~ ..

~~t~:Jf~ft~t

2)

~Jv

J..

7.7

;'(-@~J(Jt:,:JfRft~ti

iTo

To

3)

~Jv

J..

7J

;'(-kf.:@~Jf~f·J~t

To

4

HJH~i~

~if~

L

..

7 -

7·

Jv

0)

~

Jv

t:~Jv

r

7.7

;-(-tJ~:JlA!h

~LiTo

5)*~~~~~~;v

n,

7-~.BJ:u·~,v

f~A!h

L~~tlft£1i':~rt

"t:~]£

liTo

L~~tltJ\~'lli

J..

7J

;'(-O)I=jlt:A.

J..

7J;'(-':

L

..

*~'

r

3-3 INSTALLING PROCEDURE

1)

Insert belt cover support

i

i.flt

~

the tapped hole

2)

Fit belt cover

3)

Install side

4)

Tilt the machine head . and check that

the belt cover does not touch the belt

slot

in

the machine table.

5)

Place bobbin winder

and position it so that it does not

tact the machine arm or the belt cover

before fixing it with the wooden

screws.

in

the machine arm.

®onto

plate@.

CD

and ®

the support.

in

the belt cover.

in

con-

4.

~

~

Fig

11

illf

Groove

/0)-{E~

4-1

tf"O):Qi'(ttt1J

jt

li

DP X 17

It l

j·j·O):m:-¥,if.f!4 ~ 'J

0

m-t

~/f-O)::k~~~!fl!.O)ftm':

~~

'J

~\tl

0

1)

lif.;l;.!fi~lill

..t~f""('

2)

~b!:;f,

3)

~tO)

':t#f?,

"t:i* <

4)

~t

.tl:;f,

0)

jt

i TO)"t:

..

L

~ ~ ~ ~ ~

X.("

'J

ffi5il~~~·'=

~i-~1\:0)!~H:--:J

~

L~.;£;.

v·

~

l]i]

<~~i-to

'1i

~

.::."f9!ffl

i

Til~·

~~~:~A-

""C

..

ll-f~~hii¥:i':

..

<

~ ~ ~

..

-5-

(

t!.

-r:·

~

..

J:

<

J:

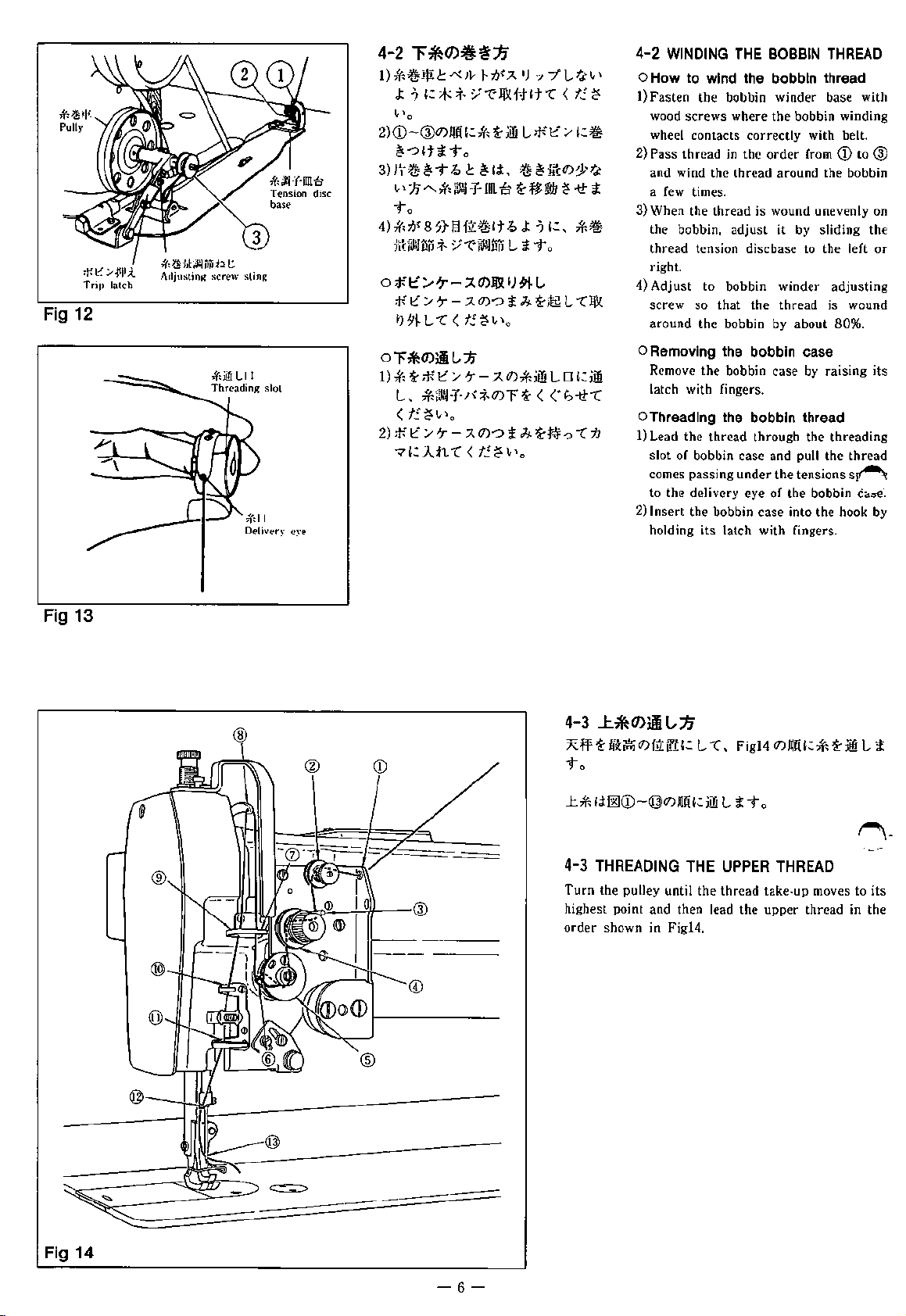

4.

HOW

TO

SET

THE

4-1

SETTING THE NEEDLE

Use

DP

X 1 7(

135

~

select correct size and number of it that

f1!

meets the material and the needle thread

'J

be

t!.

-?

i

used.

1)

Turn the balance wheel over toward

you

until the needle bar reaches its

highest point.

2)

Loosen the needle clamp screw.

3)

Hold

and insert the needle into the

needle bar hole as deeply as it will

keeping the long groove of the needle

the left and the eye of the needle

with the machine arm directly.

4) Securely tighten it with the needle

clamp screw.

X 1 7) type needles. but

MACHINE

to

go,

to

in

line

Fig

;f.' 1!.;;

Trip

12

.fiJI

latch

k~J.Ht~nnt:1

.it

Adjusting

t.

screw

sting

4-2

l'*(J)https://manualmachine.com/j

1)

*'~!fU::

J:

\tlo

2)Q)-@O)JIIJH:*-

~--::>,tiTo

3)

11~

"l1J

-7

':

* ~ ..

~

T Q c

A..*

""''v

t-

V"

""C'

~

WsFf

nn

t~rA

•J

"J

7

I&

ft

't

"'(

a-:im

L;F~ / ':~

'i~ ~ ~

a

a-

ntJJ

11!:0)1;-tj:

L/j:\tl

( t!.

r:

-tt i

To

4)

*-ilf 8 7t

mil"~

0

;j{~

if.e'/7-A(J)--=>iJi..a-~L"'C~

tJ

13

f)'L~'t

ill~,

V"""C'~1lll

/'r-

,A(/)J&

9i-L "'C

(

t!.

r:

"\o

Q

J:

-7

LiTo

•J ~ [.,

':'

*~

4-2

WINDING

OHow to wind the bobbin thread

r:

1)

Fasten

screws

wood

wheel contacts correctly with belt.

2)

Pass

thread

and wind the

a few times.

3) When the thread is wound unevenly on

the bobbin,

thread

4)

screw

around

tension discbase to the left

right.

Adjust

so

THE

BOBBIN

the bobbin winder base with

where the bobbin winding

in

the

order

thread

around the bobbin

adjust

it by sliding the

to bobbin

that

the bobbin by about

the

winder

thread

THREAD

from

adjusting

is wound

80%.

CD

to @

or

Fig 13

®

O"'f*(J)liL,"Ji

1)

*-

a-

;}{

e'

/ 7 - A

L ,

*'

jUA)

-1-;

<t!.r:\t\0

2)

if. e'

/7-

7

':

.A.tt

"'(

" ~ ..

A

0)--::>

<

t!.

(J)

r:

0)

""f

i

"\0

*

:im

L 0

':

:iffi

a-

<

("

I?

-tt

"'C

Ji..

a-t#'?"'(

71

4-3 J:.*O)JiiJ/J

;R

ff

a-

To

o Removing the bobbin case

Remove the bobbin case by

latch with fingers.

OThreading the bobbin thread

1)

Lead the

slot of bobbin case and pull the

comes passing

to the delivery eye of the bobbin

2)

Insert

holding its latch with fingers.

Nlt

f.:j

(J)

f)'{

thread

through the

under

the tensions

the bobbin case into the hook by

flU: L "'C

~

Fig

14

(J)

raising

threading

JqfH: *-a-

thread

s~

ca.:se·.

:im

L i

its

Fig 14

-6-

4-3

THREADING THE

Turn

the pulley until the

highest point and then lead the

order

shown in Fig14.

UPPER

thread

THREAD

take-up moves to its

upper

thread

in the

Loading...

Loading...