Nakajima 181L-2, 181L-20 User Manual

INSTRUCTION

BOOK&PARTS

BOOK

MODEL

181L-2

181L-20

1

*~t*@J:."""Fl2S

'J

Single Needle,

&

Lower

Feed

Lockstitch,

Sewing

Machine

Upper

~

NAKAJIMA

SEISAKUSHO

CO., LTD.

J(

;ff!Jt

1

.1±

2

.5J;ijii"Wjo:>~ffm

2-1

2-2

~

.................................... 1

1*

....................................

~~;,~I;

:i:l

i...fttt ........................ 2

13£

....................................... 2

CONTENTS

OUT

1 .

1

SPECIFICATION

2.

LINE

.....................................................................

PREPARATION

2-1

SETTING

2-2

SEWING

BEFORE

UP

THE

SPEED··

.. · ......

I

......................................................

OPERATING

MACHINE................................................ 2

··

....

····

..

··

.. · ... · .. · .. · .. · .. · ......

THE

MACHINE

····

........ ·

!

... ·..

2

3-1

3-2

4.

~

4-1

4-2 r

4-3

4-4 *

4-5

4-6

4-7

4-8

4-9

4-10

4-11

-l-70...

.

/~

5

6 •

fl'i..GX:

3 0 CAUTION

3-1

tt

~m·······································

tJ~~~*~im~~

~

/O)~~)j]

fi"~*

I)

*<7)$YiiJ······················

.J::*<7)1J~tt1J······························

~

*lf>C.

~

.1~

iiJI.:r.J±jJ

J2i

t)

lir~

~13J;1ill

*'JJE.tiiJii...J£.<7)~iJl

itt

l]?~mfi*"'""""'""""'"""

iEJ!!!*I~'

....

~

3 / /

.:gB

titJ

········

...........................

f>J-tt1J

........................... 3

...........

-1-

................................. 5

;f,

................................. 5

(/')~~

........................... 6

c;................................. 6

t~

L~~,

..................... 6

.................. 1

13

1:

''/

7-

........................ 8

0

\)

'\-

\/

........................

·······

··

···

······ · ······

3

3

4

4

8

9 5 o

....

· ·

10

4 0

6 0

LUBRICATION

3-2

ADJUSTING

HOW

4-1

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-9

4-10

4-11

TO

INSERTING

WINDING

THREADING

THREAD

THREAD

ADJUSTING

ADJUSTING

ADJUSTING

ADJUSTMENT

TIMING

FORWARD

OPTIONAL

COMPONENT

IN

USE

....................................................................... 3

OF

THE

OILING

TO

THE

HOOK

SET THE

THE

NEEDLE

THE

BOBBIN

THE

TENSION

TAKE

UP

THE

THE

THE

OF

BETWEEN

AND

REVERSE

PARTS

MACHINE

....................................................

THREAD

UPPER

THREAD

............................................................... 5

SPRING

PRESSURE

HEIGHT

STITCH

THE

OUTSIDE

NEEDLE

..

......

.... ....

OF

PRESSURE

OF

FEED

LENGTH

FOOT

AND

ROTALY

STITCH

LENGTH

....

..

...................................... 4

....

DOG

AND

................................................

PARTS

..........................................

PART

................. 3

....

...

.... .... ....

.....

... ...

...

.... ....

..

....

...... ......

....

FOOT

.....

......

.....

................................ 6

REVERSE

AND

FEED

...... 6

INSIDE

FOOT

....

HOOK

.................. 8

.......................... 8

~

..

· 7

to

4-

5

6

9

1

8

,/{-

.{t

~

'/

litJ

IJ

I)

A r

..............................

A r

..........................

·

..

·

12

13

7 .

LIST

8 .

ACCESSORIES

OF

PARTs

LIST

.......................................................

................................................

~

13

OUTLINE

~ 1 ~

181

L

~I~JJJ ~ ~

1

*'t:t.t.,mJ:

1)

-g.!!fi{JI:~1t~t~ttt.:J:i~StJtflf'Mii,

,;

~

~.m*m,

.tl:

l,

2)

*l§

li

.t

tJ

,

- r

'd:

-

r-

A.tt,

-If§

ft.<

3)

~~~

¥Pi,

=*.ftllitJ*lP,

f±~I:M/it--c-2:

1

r*

J

~

~tt1:

~j,E l f::.~

7"'

1-\'

Jvfjf'F--c-,

¥P

x.

IJ(15mm

c'(l):flR%1~.

;1.. ~ :.--

'd:

tJ

i l f.:o

l::litim Jj:.t;l

*tJ,

7'7-r~:.--r#~•l-r~t>.~~~¥~-~

1f1

/ (j:,

1:1ill~ii:,

~

=--

-c·-t

0

t*Jlpf·n,

l

P*lP§--c-*lt~~(l)jffiJMilfiftf~iWj~i

0 ~ 9mmi

*

-r:

J:

tJ

* -t (1)

w

x.

J:

tJ

1il:

~-lP

lJ:

c'(l)f'F~

P~1!f

~fJHJt-t

e:.--7·,

1"1

:.---r·1

*-to

IJ

/ 1

~ff1Jj:\(l)}J%}JJJ

3~PJtic%~11lJIDIJL.T,

m~,,

t:>

~;

h,

1n*

tJ

iJ

:;p~

~~Jj

This is a single needle, lock

hook and upper and lower feed industrial sewing machine designed

for sewing of medium and heavy duty materials.

1)

To

-r-·~im-r~2;,

-r·,

~·

·'}

~·£·-i!

c -t

1:1&~-r·,

~

t:..

~'

:.--7-~4,

X,

IL~J::fl:

-r

(1) m p

-r

:.--

r ,

:.-

~

1f

1

~·

:.--

7"

~

::1

J¥%Jf:l~(l)!lllffi

..,.

7 7 7

.Af1-lf11!&

J:>l?~~*lP

1.1'.

rJ

2)

3 ) In

stitch,

Rationally designed upper feed1mechanism

in

linkage with the feed dog

stitching without puckering

sewing materials, which

sewned

Adjustable widely the length of

the graduation dial and this is especially suitable

ing on

finish. Big adjustment of the

0 cording works

piled

"sub-class"

binders and

much.

tents,

15

leathers,

order

products

mm

.

seats,

by

the

repuired

etc

to meet various sewing purposes,

model machines,

so

on

.•

will

canvas,

knee

assist

results

lifter

on

link type take-up,

performs

to

obtain smooth and clean

or

wrinkle on various kinds

in

increasing quality

stitch

between

etc.,

required on long

presser

indispensable the piping

the

materials

presser

your sewing requirements

feet

suGh

feet,

rotary

perfectly

0 - 9

mm

for

the

stitch

lift between

as

sponge,

our

prepared

feed dogs,

very

of

of

by

sew-

or

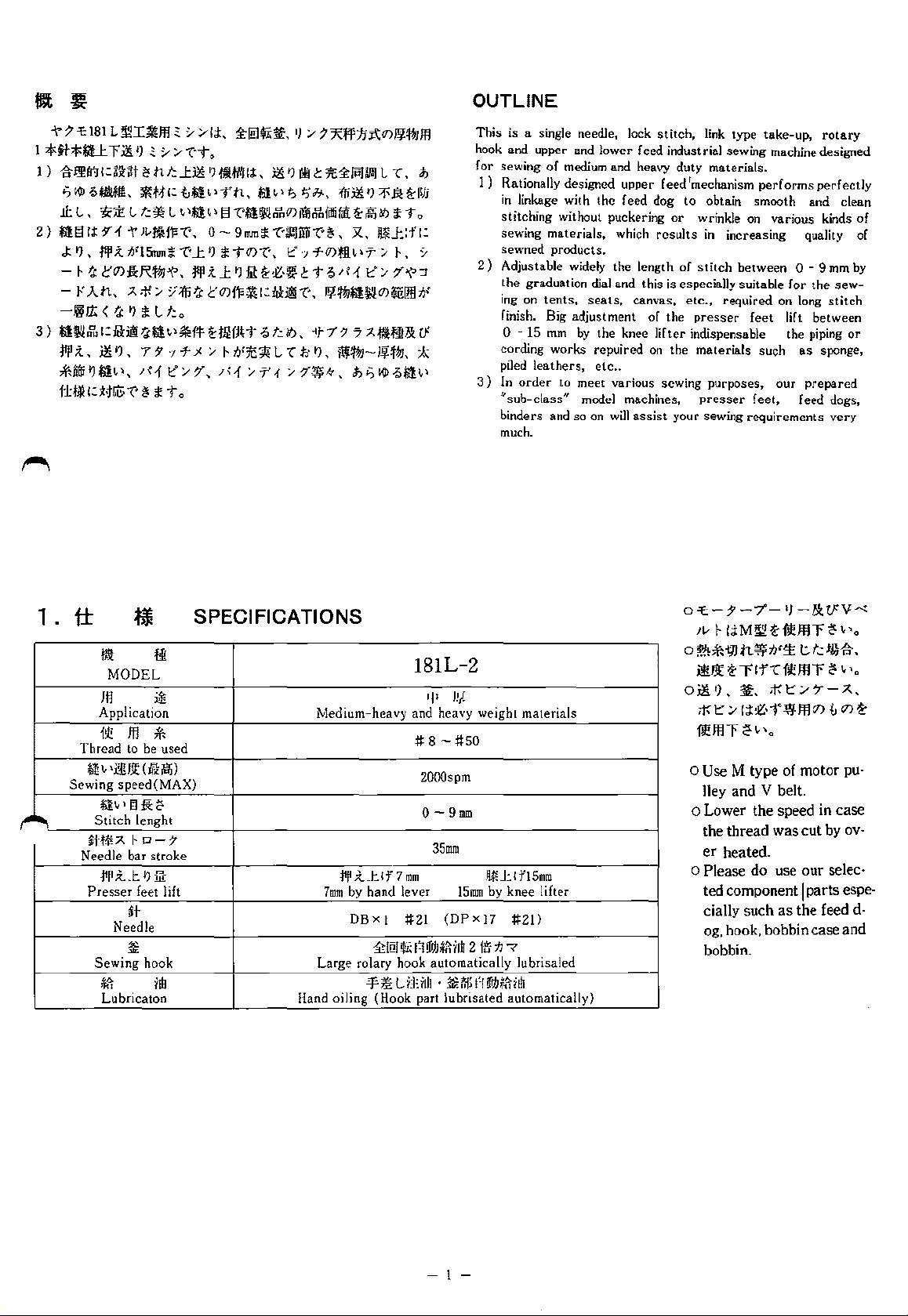

1 .

1±

Thread to be used

~"'~Jt(J&;gj)

Sewing speed (MAX)

,....~

~N~.A

Needle bar stroke

Presser feet lift

m

ffl

Application

1!1!

~lt,§:N;~

Stitch lenght

~PX...t

MODEL

ffl

r

o-7

IJ

ft

~

*'

:ill:

n

Needle

5&

Sewing hook

*it

Lubricaton

idl

SPECIFICATIONS

Medium-heavy and heavy weight materials

¥JIX.J:If7

7mm

by

DB

Large rolary hook automatically lubrisaled

Hand oiling (Hook part lubrisated automatically)

18IL-2

IJI

l!t

# 8

-#50

2000spm

0-9mm

35mm

mm

hand lever

xi

:tf:21

~@]~§!f~J*-ititl1211!7J

-=F~

L

1J:11h

•

Jm..ttf15mm

15mm

by

knee lifter

(DP X

17

:tf:21)

7

5/if,i~

I~

lliil*it7dl

o.:C-?-7"-IJ

Jv

1--

{j:M~~N!nrf~"'o

o?.~*"Wtt~1J'~

J!B£

~

"'ftf"t"

0

j!

I) ,

1it,

*~ / {;j:~·"f.\¥Jfi(7)

N!mr~

o Use M type of motor

-&t.FY-"-

-Rt!Jfir

ift" ~ :/

~,,0

tt..:.tlh{},

~

~,

'o

7-

A.,

t

(/)

pu-

~

lley and V belt.

o Lower the speed

the thread was cut by

er

heated.

in

case

ov-

o Please do use our selec-

ted component I parts espe-

cially such

og,

hook, bobbin case and

bobbin.

as

the feed

d-

-1-

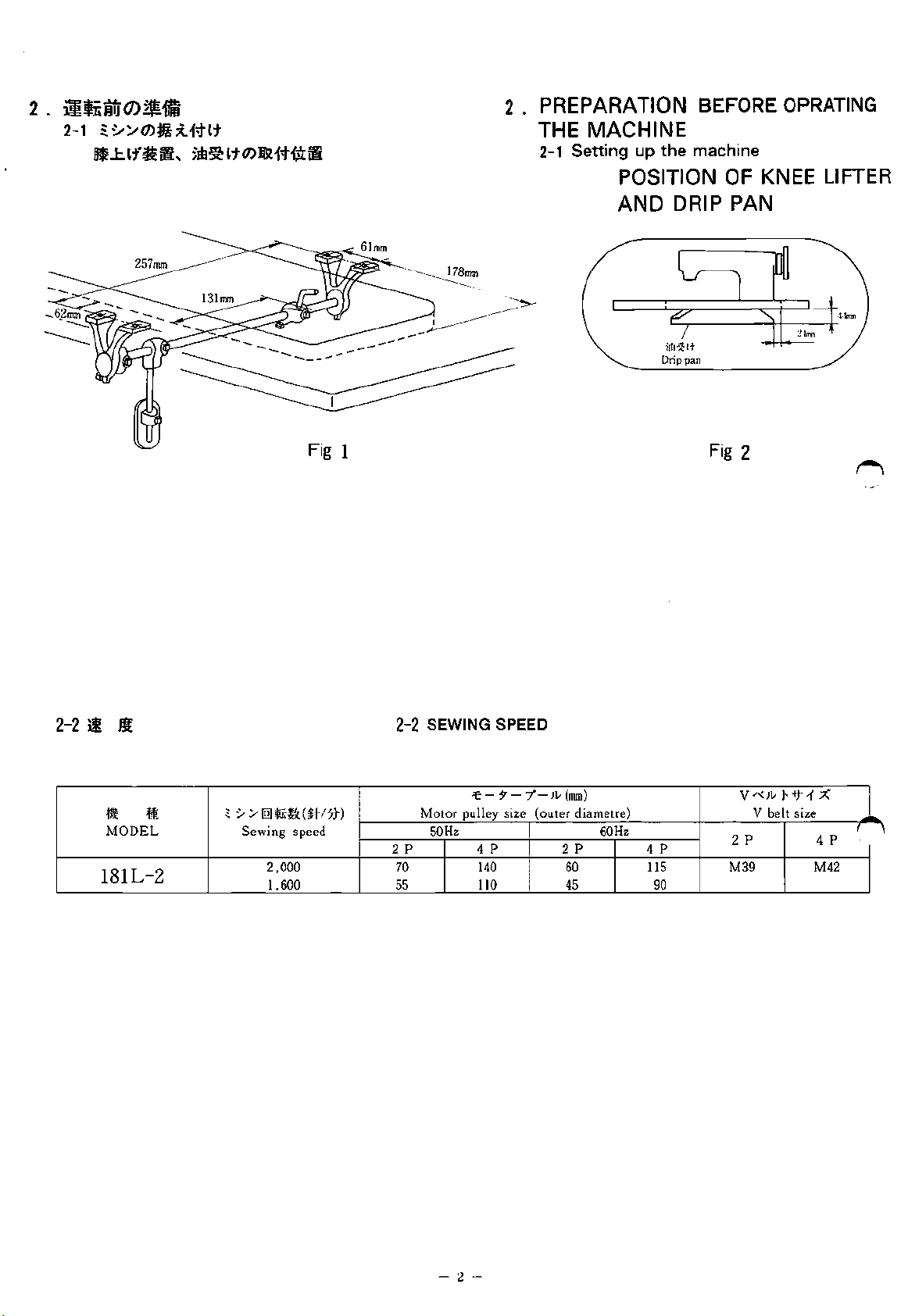

2 .

li

.i

8U

(/)

i1tiim

2-1

~ ~ ~

0)

ti

;{

DlJ:.tf~im\

i-4"

t t

5m~

ttO)J8li'4-itifii

Fig

1

2 . PREPARATION

THE

2-1 Setting up the machine

MACHINE

POSITION

AND

DRIP PAN

BEFORE

OF

KNEE LIFTER

Fig

2

OPRATING

2-2

11

11

f,.l

MODEL

181L-2

fi

~

~

/ tmiliitt(Jf/5)-)

Sewing

2,000

1,600

speed

2-2

SEWING SPEED

.:c-

~-

7"-

Motor

pulley size (outer diametre) V belt size

50Hz 60Hz

2P

70

55

4 p 2 p 4 p

140

110

Jv

(mm)

60

45

115

90

v

-"{

Jv

1--

-IT

1 X

2 p 4 p

M39 M42

l

-,

-2-

3 • '!lm

3-1

o

im

c:)Mil:tl:ilh

o"""

=~m!=f:t

t

(

J:.Q)

j~~Jh

4i~

M

(i

~·

."

r

(l)idJ?

c:?mil:tJ"~J:lr

~

,i,

~~J~i

Fig5)

-r

9c

L

"'Cr~

Fig 5

3-2

11

?O)**~mWAJiil

ff.&~,~mc:.t

.Qt~{?

-c·~im

o

-r

o

t:11Jiol ( +{KIJ)

0

tJ:jJioJ

."

..

L 1

r

•J

..

?

/?

li:flllj(7)ifh11t~ltii*:;

-to

~

vJ>

o

&~:>

':ffi]T-

(

-1J!IJ)

':

j:£~

~P

-c·~

~

tt

t.:

fi

JiJT

~'o

:;..-1 "(l)*g.iru

c:

~

"?

t.:

-c·*'1i1t:

L

'lr~~'o

:IJ'7'(7)*f5'irn:lil:~~.t

1

-to

$-

~'

fillT-1;'7J.·

~'

3 . CAUTION

3-1

LUBRICATION

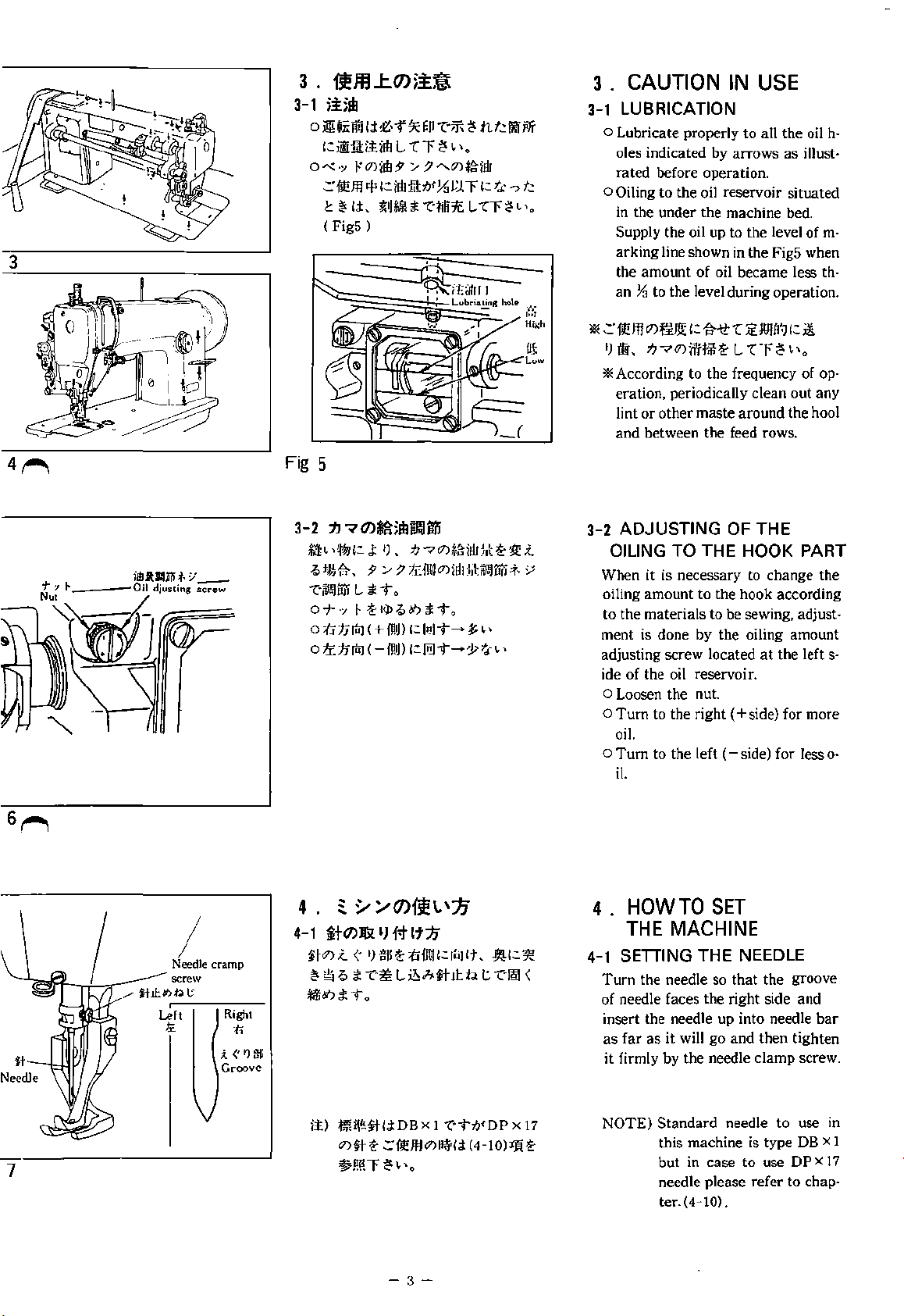

o Lubricate properly to all the

oles indicated by arrows

rated before operation.

o Oiling to the oil reservoir situated

in

the under the machine bed.

Supply the oil up to the level of

arking line shown in the Fig5 when

the amount of oil became less

an ~ to the level during operation.

*

=~m(7)mttc:1?-tt-r:J£MA"Jc:*

'J

tU..

:IJ

'?(l)iJff-ffi'~

*According to the frequency of

eration, periodically clean out any

lint or other maste around the hool

and between the feed rows.

3-2

ADJUSTING OF THE

OILING TO THE HOOK PART

When it is necessary to change the

oiling amount to the hook according

to the materials to be sewing,

ment

is

done by the oiling amount

adjusting screw located

ide of the oil reservoir.

o Loosen the nut.

o Turn to the right (+side) for more

oil.

o Turn to the left

il.

IN

USE

L

'lr

at

(-side)

oil

as

illust-

~

~

'o

adjust-

the left

for less

h-

m-

th-

op-

s-

o-

6~

7

I

I

Needle cramp

Right

ti

.t

<·

Groove

4 .

~

~

~Q)'(i\,

4-1

atO)~

Jt(7)

~

~ o 1-c-~

.t

<·

'J

IJ

~B

it

~

**&>':>iTo

t')

$

i.:E)

~~it,iDBX1'l"T1J"DPX17

(l)iJ-~

.::.'~ffl(l)~(j:

~P.~r~~'o

'1i

tt1.7

tiffiiH:IoJ

LJbhibl:b

't

...

t

-c·~

(4-10):rJ{

,:~

<

~

4.

HOWTO

THE

4-1

SETTING THE NEEDLE

Turn the needle so that the groove

of needle faces the right side and

insert the needle

as

far as it will go and then tighten

it firmly by the needle clamp screw .

NOTE) Standard needle to use

this machine is type

but in case to use

needle please refer to chap-

ter.

SET

MACHINE

up

into needle

(4-10).

DB

DP x

bar

in

x 1

17

-3-

Loading...

Loading...