(pending)

53.3±0.3

2.098±.012

2 Form A 2 Form B

53.3±0.3

2.098±.012

4 Form A 4 Form B

25.0

.984

16.5±0.5

.650±.020

POLARISED, MONOSTABLE

SAFETY RELAY

FEATURES

• High contact reliability

High contact reliability is achieved through

the use of a double contact.

• Forced operation contacts

(2 Form A 2 Form B)

N.O. and N.C. side contacts are

connected through a card so that one

33±0.5

1.299±.020

16.5±0.5

.650±.020

mm inch

interacts with the other in movement. In

case of a contact welding, the other keeps

a min. 0.5mm .020inch contact gap.

• Independent operation contacts

(4 Form A 4 Form B)

There are 4 points of forced operation

contacts.

Each pair of contacts is free from the main

armature and is independent from each

other. So if a N.O. pair of contacts are

welded, the other 3 N.O. contacts are not

effected (operate properly) That enables

to plan a circuit to detect welding or go

back to the beginning condition.

SF-RELAYS

Double contact

• Separated chamber structure (2 Form

A 2 Form B, 4 Form A 4 Form B)

N.O. and N.C. side contacts are put in

each own space surrounded with a card

and a body-separater. That prevents short

circuit between contacts, which is caused

by their springs welding or damaged.

• High breakdown voltage 2,500 Vrms

between contacts and coil

• High sensitivity

Realizes thin shape and high sensitivity

(500 mW nominal operating power) by

utilizing high-efficiency polarized

magnetic circuit with 4-gap balanced

armature.

• Complies with safety standards

Standard products are UL, CSA, TÜV and

SEV certified. Comform to European

standards. TÜV certified (945/EL, 178/

88). Complies with SUVA European

standard.

SPECIFICATIONS

Contact

Contact arrangement

Initial contact resistance, max.

(By voltage drop 6 V DC 1 A)

Contact material Gold-flashed silver alloy

Nominal switching

Rating

(resistive)

Expected

life (min.

operations)

capacity

Max. switching power 1,500 VA, 180 W

Max. switching voltage 440 V AC, 30 V DC

Max. carrying current 6 A

Mechanical (at 180 cpm) 10

Electrical (at 20 cpm) 10

2 Form A

2 Form B

6 A 250 V AC, 6 A 30 V DC

Coil

Nominal operating power 500 mW

Remarks

* Specifications will vary with foreign standards certification ratings.

1

Measurement at same location as “Initial breakdown voltage” section

*

*2Detection current: 10mA

3

Excluding contact bounce time

*

*4Half-wave pulse of sine wave: 11ms; detection time: 10µs

*5Half-wave pulse of sine wave: 6ms

*6Detection time: 10µs

7

Refer to 6. Usage, transport and storage mentioned in NOTES

*

30 m

4 Form A

4 Form B

Ω

7

5

Characteristics

Contact arrangement

Max. operating speed 180 cpm (at nominal voltage)

Initial insulation resistance*

Initial

breakdown

voltage*

Operate time*

Release time (without diode)*

(at nominal voltage)

Temperature rise (at nominal voltage)

(at 20°C)

Shock resistance

Vibration resistance

Conditions for operation,

transport and storage*

freezing and condensing at

low temperature)

Unit weight

Between open contacts 1,300 Vrms

Between contact sets 2,500 Vrms

2

Between contact and coil 2,500 Vrms

3

(at nominal voltage) Approx. 17 ms Approx. 18 ms

1

3

Functional*

Destructive*

Functional*

Destructive

Ambient

7

(Not

temp.

Humidity 5 to 85% R.H.

2 Form A

2 Form B

Min. 1,000 MΩ at 500 V DC

Approx. 7 ms Approx. 6 ms

with nominal coil voltage and

4

5

6

38 g 1.34 oz

Max. 45°C

at 6 A carry current

Min. 294 m/s2 {30 G}

Min. 980 m/s2 {100 G}

10 to 55 Hz at double

amplitude of 2 mm

10 to 55 Hz at double

amplitude of 2 mm

–40°C to +70°C

–40°F to +158°F

Approx.

4 Form A

4 Form B

Approx.

47 g 1.66 oz

4

ORDERING INFORMATION

Ex. SF 2 D DC 5 V

Contact arrangement Coil voltage

DC 5, 12, 24, 48, 60 V2: 2 Form A 2 Form B

4: 4 Form A 4 Form B

UL/CSA, TÜV, SEV approved type is standard

TYPES AND COIL DATA (at 20°C 68°F)

Contact

arrangement

2 Form A

2 Form B

4 Form A

4 Form B

Part No.

Nominal

voltage, V DC

SF2D-DC5V 5 3.75 0.5 50 100 500 6

SF2D-DC12V 12 9 1.2 288 41.7 500 14.4

SF2D-DC24V 24 18 2.4 1.152 20.8 500 28.8

SF2D-DC48V 48 36 4.8 4.608 10.4 500 57.6

SF2D-DC60V 60 45 6.0 7.200 8.3 500 72

SF4D-DC5V 5 3.75 0.75 50 100 500 6

SF4D-DC12V 12 9 1.8 288 41.7 500 14.4

SF4D-DC24V 24 18 3.6 1.152 20.8 500 28.8

SF4D-DC48V 48 36 7.2 4.608 10.4 500 57.6

SF4D-DC60V 60 45 9.0 7.200 8.3 500 72

Pick-up

voltage, VDC

(max.)

voltage, V DC

DIMENSIONS

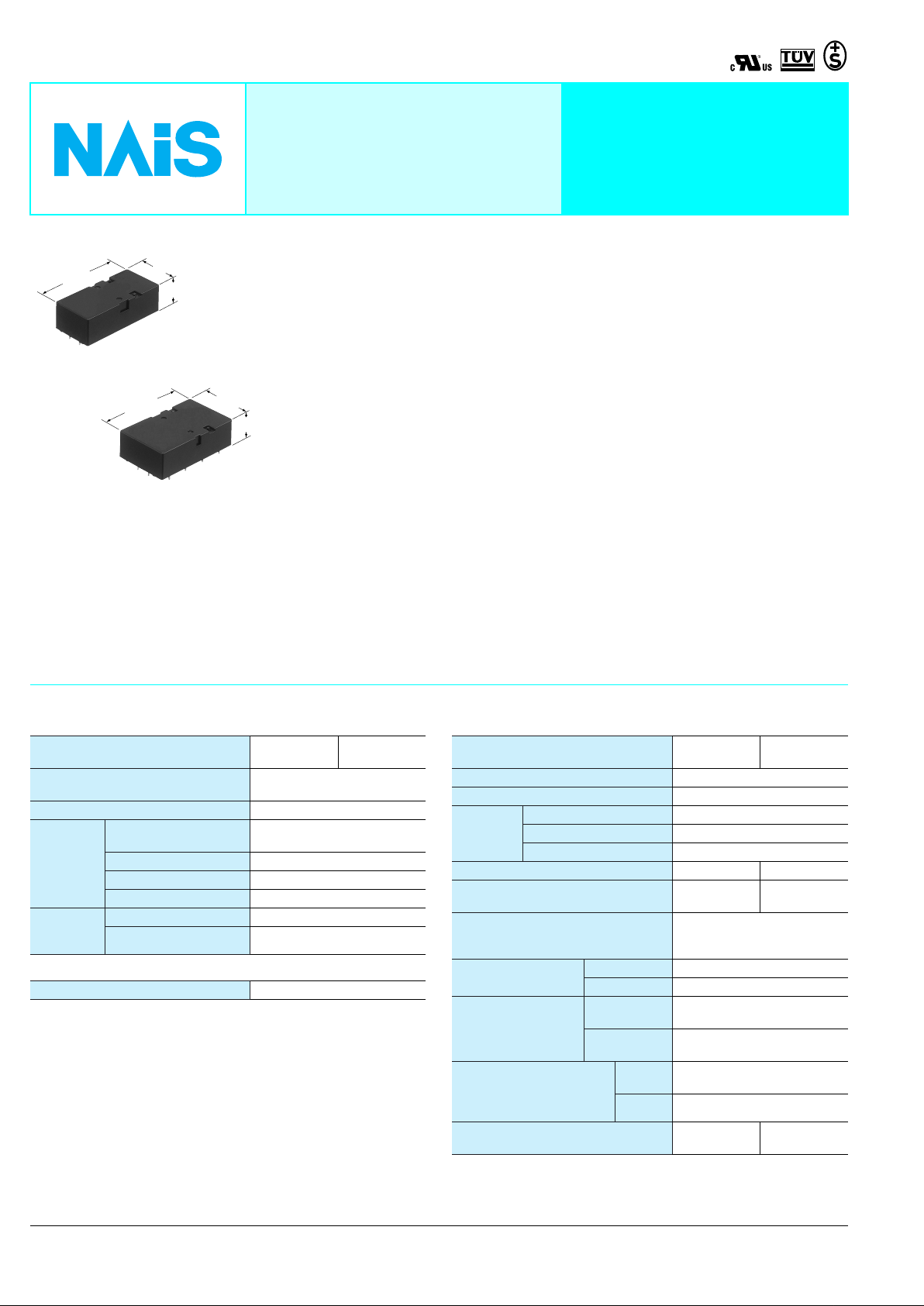

1. 2 Form A 2 Form B

12.7

12.7

12.7

25.0

.984

7.62

.300

5.08

.200

.500

53.3±0.3

2.098±.012

6587

1

2

109

.500

.500

TYPICAL APPLICATIONS

• Industrial equipment such as presses and machine tools

Drop-out

(min.)

.630±.020

3.0±0.5

.118±.020

1211

Coil resistance

16±0.5

0.5

.020

12.7

.500

Ω

(±10%)

Nominal

operating

current,

mA (±10%)

Nominal

operating

power, mW

Schematic (Bottom view)

5

1

2

9 101112

PC board pattern (Bottom view)

2.54

10-.055 DIA. HOLES

2.54

.100

.100

Max. allow able

voltage, V DC

mm inch

678

10-1.4 DIA. HOLES

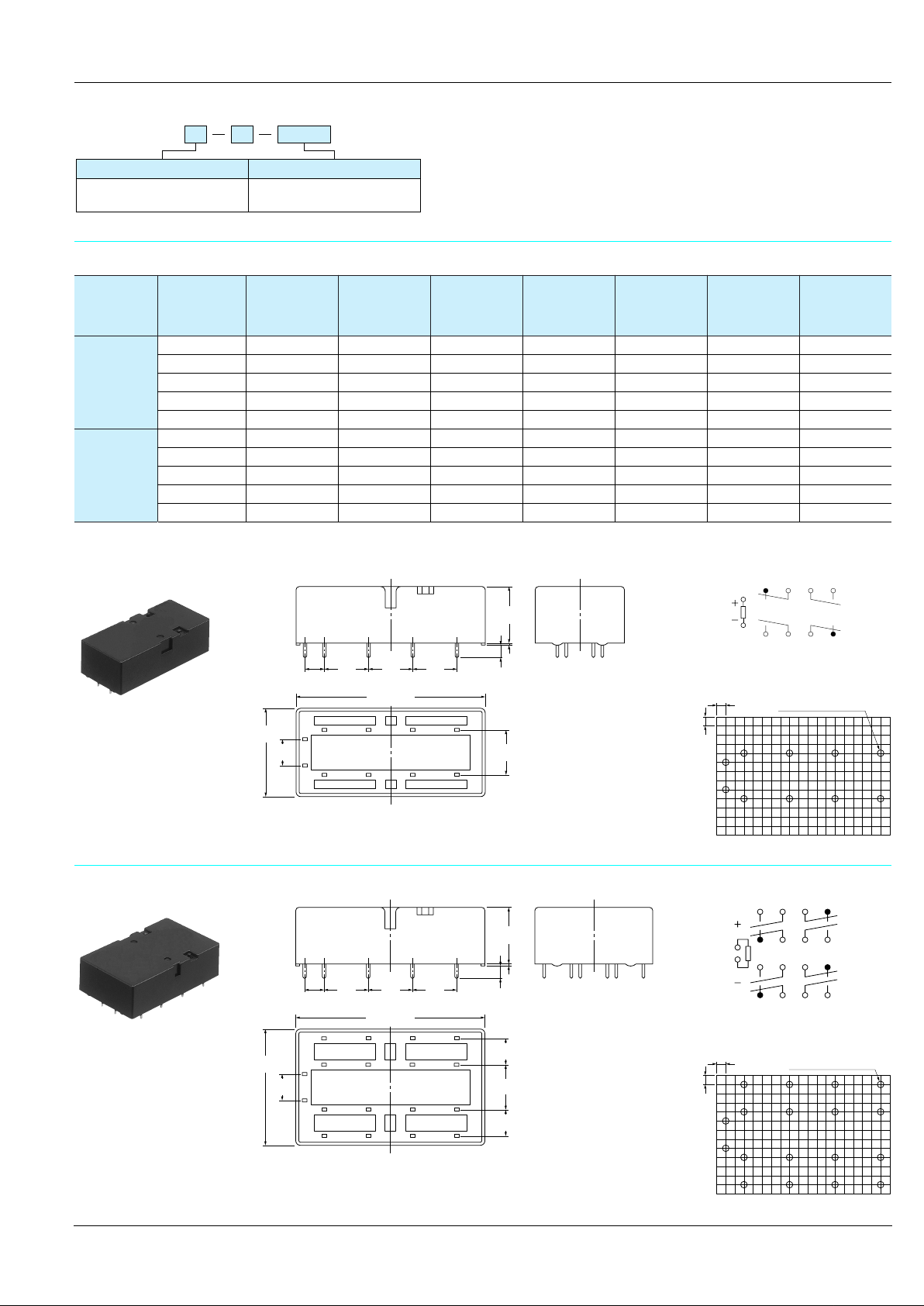

2. 4 Form A 4 Form B

33±0.5

1.299±.020

7.62

.300

5.08

.200

General tolerance: ±0.3 ±.012

Tolerance: ±0.1 ±.004

Schematic (Bottom view)

13

14615716

16±0.5

.630±.020

0.3

.012

3.0±0.5

12.7

12.7

12.7

.500

.500

53.3±0.3

2.098±.012

1413 1615

65

1

2

109

1817 2019

.500

.118±.020

87

1211

7.62

.300

12.7

.500

7.62

.300

2.54

.100

1

5

9171018111912

2

8

20

PC board pattern (Bottom view)

2.54

.100

18-1.4 DIA. HOLES

18-.055 DIA. HOLES

General tolerance: ±0.3 ±.012

Tolerance: ±0.1 ±.004

5

REFERENCE DATA

-40 -20 0

20

40 60 80

-50

100

50

-100

Drop-out voltage

Pick-up voltage

Ambient

temperature, °C

Rate of

change, %

1. Operate/release time (without diode)

Tested sample: SF2D-DC24V

Quantity: n = 20

50

2. Temperature rise

Tested sample: SF4D-DC24V

Quantity: n = 6

Coil applied voltage: 100%V, 120%V

Contact carry current: 6A

30

3. Ambient temperature characteristics

Tested sample: SF4D-DC12V

Quantity: n = 6

40

30

20

Operate/release time, ms

10

0

Operate time

Release time

8070 10090 120 130110

Coil applied voltage, %V

Max.

x

Min.

Max.

x

Min.

25

20

15

Temperature rise, °C

10

5

0

Inside the coil

Contact

120100 110

Coil applied voltage, %V

6

THE OPERATION OF SF RELAYS (when contacts are welded)

SF relays work to maintain a normal operating state even when the contact welding occur by overloading or short-circuit

currents. It is easy to make weld detection circuits and safety circuits in the design to ensure safety even if contacts weld.

Internal Contacts Weld

If the internal contacts (No. 2, 3, 6, and 7) weld of 4a4b type, the armature becomes non-operational and the contact gaps of each of

the four form “a” contacts are maintained at greater than 0.5 mm .020 inch. Reliab le isolation is thus ensured. The 2a2b type oper ates

in the same way.

No.8

No.7

No.1

No.2

No.8

No.7

No.1

No.2

If the No. 2 contact welds.

Each of the four form “a” contacts (No. 1, 3, 5,

and 7) maintains a gap of greater than 0.5 mm

No.6

No.5

Non-energized

No.3

No.4

No.6

No.5

Energized (when no. 2 contact is welded)

No.3

No.4

.020 inch.

External Contacts Weld

If the external contacts (No. 1, 4, 5, and 8) weld of 4a4b type, gaps of greater than 0.5 mm .020 inch are maintained between adjacent

contacts and the other contacts return by an non-energized.

No.8

No.7

No.6

No.5

Energized

No.1

No.2

No.3

No.4

No.8

No.7

No.6

No.5

Non-energized (when no. 1 contact is welded)

No.1

If the No. 1 contact welds.

The adjacent No. 2 contact maintains a gap of

No.2

greater than 0.5 mm .020 inch. The other

contacts, because the coil is not energized,

return to their normal return state; each of

No.3

form “a” contacts (No. 3, 5, and 7) maintains a

contact gap of greater than 0.5 mm .020 inch;

No.4

each of the form “b” contacts (No. 4, 6, and 8)

return to a closed state.

If external connections are made in series.

Even if one of the contacts welds, the other contacts

operate independently and the contact gaps are

maintained at greater than 0.5 mm .020 inch.

Energized

Non-energized

Weld

Contact gap

min 0.5 mm .020 inch

Contact Operation Table

The table below shows the state of the other contacts. In case of form “a” contact weld the coil applied voltage is 0 V.

In case of form “b” contact weld the coil applied voltage is nominal.

No.8

No.7

No.6

No.5

Contact No. No.1 No.2 No.3 No.4

Terminal No.

20–19 12–11 8–716–15

No.1

No.2

No.3

No.4

No.5 No.6 No.7 No.8

13–14 5–69–10 17–18

Contact No.

Contact No. 1 2 3 4 5 6 7 8

1 >0.5 >0.5

2 >0.5 >0.5 >0.5 >0.5

3 >0.5 >0.5 >0.5 >0.5

Welded

contact

No.

4

≠

5 >0.5

6 >0.5 >0.5 >0.5 >0.5

7 >0.5 >0.5 >0.5 >0.5

8

≠

Note: Contact gaps are shown at the initial state.

If the contact transfer is caused by load switching, it is necessary to check the actual loading.

State of other contacts

>0.5 >0.5

≠

>0.5

>0.5

≠

≠

≠

>0.5

>0.5

≠

≠

≠

>0.5

>0.5

≠

>0.5 >0.5

>0.5 >0.5

≠

>0.5

≠

>0.5: contact gap

is kept at min. 0.5

mm .020 inch

≠

: contact closed

Empty cells: either

closed or open

7

NOTES

;;

;;

;;

;;

;;

;;

;;

;;

;;

;;

;

Tolerance range

(Avoid

condensation when

used at temperatures

higher than 0°C 32°F)

(Avoid freezing when

used at temperatures

lower than 0°C 32°F)

85

5

–40

–40

0

+32

+70

+158

Temperature, °C °F

Humidity, %R.H.

1. Coil operating power

Pure DC current should be applied to the

coil. The wav e form should be rectangular.

If it includes ripple, the ripple factor should

be less than 5%. However, check it with

the actual circuit since the characteristics

may be slightly different.

2. Coil connection

When connecting coils, refer to the wiring

diagram to prevent mis-operation or

malfunction.

3. Cleaning

For automatic cleaning, the boiling

method is recommended. A void ultrasonic

cleaning which subjects the relays to high

frequency vibrations, which may cause

the contacts to stick.

It is recommended that a fluorinated

hydrocarbon or other alcoholic solvents

be used.

4. Soldering

We recommend the following soldering

conditions

1) Automatic soldering

1) Preheating: 100°C 212°F, max. 60 s

2) Soldering: 250°C 482°F, max. 5 s

5. Others

1) If the relay has been dropped, the

appearance and characteristics should

always be checked before use.

2) The cycle lifetime is defined under the

standard test condition specified in the

JIS* C 5442-1986 standard (temperature

15 to 35°C 59 to 95°F, humidity 25 to

85%). Chec k this with the real device as it

is affected by coil driving circuit, load type,

activation frequency, activation

phase,ambient conditions and other

factors.

Also, be especially careful of loads such

as those listed below.

(1) When used for AC load-operating and

the operating phase is synchronous.

Rocking and fusing can easily occur due

to contact shifting.

(2) High-frequency load-operating

When high-frequency opening and

closing of the relay is performed with a

load that causes arcs at the contacts,

nitrogen and oxygen in the air is fused by

the arc energy and HNO

is formed. This

3

can corrode metal materials.

Three countermeasures for these are

listed here.

1. Incorporate an arc-extinguishing

circuit.

2. Lower the operating frequency

3. Lower the ambient humidity

3) For secure operations, the voltage

applied to the coil should be nominal

voltage. In addition, please note that pickup and drop-out voltage will vary

according to the ambient temperature and

operation conditions.

4) Heat, smoke, and ev en a fire may occur

if the relay is used in conditions outside of

the allowable ranges for the coil ratings,

contact ratings, operating cycle lifetime,

and other specifications. Therefore, do

not use the relay if these ratings are

exceeded. Also, make sure that the relay

is wired correctly.

5) Incorrect wiring may cause unexpected

events or the generation of heat or flames.

6) Check the ambient conditions when

storing or transporting the relays and

devices containing the relays . F reezing or

condensation may occur in the relay,

causing functional damage. Avoid

subjecting the relays to heavy loads, or

strong vibration and shocks.

6. Usage, transport and storage

conditions

1) Ambient temperature, humidity, and

atmospheric pressure during usage,

transport, and storage of the relay:

(1) T emper ature:

–40 to +70°C –40 to +158°F

(2) Humidity: 5 to 85% RH

(Avoid freezing and condensation.)

The humidity range varies with the

temperature. Use within the range

indicated in the graph below.

;

;;

;;;;

;;

;

;

;;;;;;

;;;;;

;;;;;;;

;;;;;;;

;;;;;;;;

;;;;;;;;

(3) Atmospheric pressure: 86 to 106 kPa

Temperature and humidity range for

usage, transport, and storage:

2) Condensation

Condensation forms when there is a

sudden change in temperature under high

temperature and high humidity conditions.

Condensation will cause deterioration of

the relay insulation.

3) Freezing

Condensation or other moisture may

freeze on the relay when the

temperatures is lower than 0°C 32°F. This

causes problems such as sticking of

movable parts or operational time lags.

4) Low temperature, low humidity

environments

The plastic becomes brittle if the relay is

exposed to a low temperature, low

humidity environment for long periods of

time.

2/19/2003 All Rights Reserved, © Copyright Matsushita Electric Works, Ltd.

Go To Online Catalog

Loading...

Loading...