NAiS GT, GT01, GT11, GT30 Technical Manual

Programmable Display

GT Series

Technical Manual

Applicable Product

• GT01

• GT11

• GT30

http://www.naisplc.com/

This manual was created using Adobe Acrobat.

Adobe, the Adobe logo, and Acrobat are trademarks

of Adobe Systems Incorporated.

GT Series Technical Manual

ARCT1F398E ’04.11

Table of contents

Before You Start----------------------------------------------------------------------------------------------------------------ⅰⅰⅰⅰ

Usage Procedures-------------------------------------------------------------------------------------------------------------ⅲⅲⅲⅲ

Confirming the Package Contens----------------------------------------------------------------------------------------ⅳⅳⅳⅳ

GT series System Configuration (GT01 and GT11)-----------------------------------------------------------------ⅸⅸⅸⅸ

GT series System Configuration (GT30)-------------------------------------------------------------------------------ⅹⅹⅹⅹ

Products Types and Manuals-------------------------------------------------------------------------------------------ⅹⅰ

An overview of GT Series Functions---------------------------------------------------------------------------------ⅹⅲ

ⅹⅰ

ⅹⅰⅹⅰ

ⅹⅲ

ⅹⅲⅹⅲ

1 Specifications 1-1

1.1 GT01 Specifications 1-2

1.1.1 General Specifications 1-2

1.1.2 Display 1-2

1.1.3 Functions 1-3

1.1.4 Touch Key 1-3

1.1.5 Memory 1-3

1.1.6 Serial Interface 1-4

1.2 GT11 Specifications 1-5

1.2.1 General Specifications 1-5

1.2.2 Display 1-5

1.2.3 Functions 1-6

1.2.4 Touch Key 1-6

1.2.5 Memory 1-6

1.2.6 Serial Interface 1-7

1.3 GT30 Specifications 1-8

1.3.1 General Specifications 1-8

1.3.2 Display 1-8

1.3.3 Functions 1-9

1.3.4 Touch Key 1-9

1.3.5 Memory 1-9

1.3.6 Serial Interface 1-10

1.4 Names and Functions of Parts 1-11

1.4.1 GT01 and GT11 1-11

1.4.2 GT30 1-14

1.5 Internal Wiring Connections for Ports 1-16

1.5.1 COM. Port (GT01) 1-16

1.5.2 COM. Port (GT11) 1-18

1.5.3 COM. Port (GT30) 1-19

1.5.4 TOOL Port 1-19

1.6 Dimensions 1-20

1.6.1 GT01 1-20

1.6.2 GT11 1-21

1.6.3 GT30 1-22

2 Installation and Wiring 2-1

2.1 Installation 2-2

2.1.1 Installation Environment 2-2

2.1.2 GT01 and GT11 Installation Method 2-3

2.1.3 GT30 Installation Method 2-4

2.2 Wiring the Power Supply 2-5

2.2.1 Wiring the Power supply 2-5

2.2.2 Grounding 2-6

2.3 Wiring the COM. Port 2-7

3 Setup 3-1

3.1 Setup Procedure for the GT 3-2

3.2 Setting the Basic Communication Area Between the GT and PLC 3-4

3.2.1 What is the Basic Communication Area? 3-4

3.2.2 Settings in GTWIN 3-5

3.2.3 GT01 Basic Communication Area Map 3-6

3.2.4 GT11 Basic Communication Area Map 3-7

3.2.5 GT30 Basic Communication Area Map 3-8

4 Connecting and Communicating with the PLC 4-1

4.1 Connecting GT01/GT11 with PLC 4-2

4.1.1 Connecting to the TOOL port of FPΣ / FP0 / FP-e (1) (Direct Connection to GT01) 4-2

4.1.2 Connecting to the TOOL port of FPΣ / FP0 / FP-e (2) 4-3

4.1.3 Connecting to the TOOL port of FP2 / FP2SH (1) (Direct Connection to GT01) 4-4

4.1.4 Connecting to the TOOL port of FP2 / FP2SH (2) 4-5

4.1.5 Connecting to the TOOL port of FP10SH (1) (Direct Connection to GT01) 4-6

4.1.6 Connecting to the TOOL port of FP10SH (2) 4-7

4.1.7 Connecting to the TOOL port of FP-M (1) (Direct Connection to GT01) 4-8

4.1.8 Connecting to the TOOL port of FP-M (2) 4-9

4.1.9 Connecting to the COM. port of FPΣ / FP0 / FP-e 4-10

4.1.10 Connecting to the COM port of FP1 / FP2SH / FP-M 4-12

4.1.11 Connecting to the COM port of FP10SH 4-13

4.1.12 Connecting to the FP2 / FP2SH Computer Communication Unit 4-14

4.1.13 Connecting to the FP10SH / FP3 Computer Communication Unit 4-15

4.1.14 Cautions Regarding Direct Connection of GT01 (5V DC type) to the FP Series TOOL

Port 4-16

4.1.15 How to Make Communication Settings Using the FPWIN GR and FPWIN Pro 4-17

4.1.16 Automatic Communication Settings Function 4-19

4.1.17 Through Function 4-20

4.1.18 Connecting a PLC by Mitsubishi Electric Corporation 4-21

4.1.19 Connecitng the PROVISER Tcmini Series by Toshiba Machine Co., Ltd. 4-27

4.1.20 Connecitng the S7-200 Series by Siemens K. K. 4-28

4.1.21 Connecitng a PLC by Modicon 4-29

4.1.22 Connecting PLCs by Omron Corporation 4-30

4.1.23 Connecting a PLC by Yokogawa Electric Corporation 4-37

4.1.24 Connecting a Sereial Device 4-39

4.2 Connecting GT30 with PLC 4-40

4.2.1 Connecting to the FPΣ 4-40

4.2.2 Connecting to the FP0 4-42

4.2.3 Connecting to the FP1 4-44

4.2.4 Connecting to the FP2/FP2SH 4-45

4.2.5 Connecting to the FP2/FP2SH Computer Communication Unit 4-47

4.2.6 Connecting to the FP10SH 4-48

4.2.7 Connecting to the FP10SH/FP3 Computer Communication Unit 4-50

4.2.8 Connecting to the FP-M 4-51

4.2.9 Atutomatic Communication Settings Function 4-53

4.2.10 Through Function 4-54

4.2.11 Connecitng a PLC by Mitsubishi Electric Corporation 4-55

4.2.12 Connecting PLCs by Omron Corporation 4-56

4.2.13 Connecting a PLC by Yokogawa Electric Corporation 4-62

5 GT Configuration Settings 5-1

5.1 GT Configuration Settings 5-2

5.2 Entering Configuration Settings from GTWIN Screen Creation Tool 5-3

5.2.1 GT Configuration Settings: “Basic Setup” 5-3

5.2.2 GT Configuration Settings: “Communication Parameters” 5-6

5.2.3 GT Configuration Settings: “Auto-Paging” 5-8

5.2.4 GT Configuration Settings: “Startup Screen Settings” 5-9

5.2.5 GT Configuration Settings: “Setup” (For GT01) 5-10

5.2.6 GT Configuration Settings: “Setup” (For GT11) 5-12

5.2.7 GT Configuration Settings: “Setup” (For GT30) 5-15

5.2.8 GT Configuration Settings: “Hold Device Value” 5-18

5.3 Entering Configuration Settings from the GT01 and GT11 Main Unit 5-20

5.3.1 Bringing Up the System Menu 5-20

5.3.2 Setting Mode: “Communication Parameters” (COM. Port / TOOL Port) 5-21

5.3.3 Setting Mode: “Liquid Crystal Display Contrast Adjustment” (Contrast) 5-23

5.3.4 Setting Mode: “Memory Initialization” (Clear Memory) 5-24

5.3.5 Setting Mode: “Touch Switch Adjustment” (T. SW) 5-25

5.3.6 Setting Mode: “Self-Diagnosis” (Test Mode) 5-26

5.3.7 Inhibiting the System Menu Display 5-27

5.4 Entering Configuration Settings from the GT30 Main Unit 5-28

5.4.1 Bringing Up the System Menu 5-28

5.4.2 Setting Mode: “Liquid Crystal Display Contrast Adjustment” (Contrast) 5-29

5.4.3 Setting Mode: “Clock Settings” (Clock) 5-30

5.4.4 Setting Mode: “Communication Parameters” (TOOL Port / COM. Port) 5-31

5.4.5 Setting Mode: “Memory Initialization” (Clear Memory) 5-33

5.4.6 Setting Mode: “Self-Diagnosis” (Test Menu) 5-34

5.4.7 Inhibiting the System Menu Display 5-35

6 How the Various Functions Are Used 6-1

6.1 Switching Screens 6-2

6.1.1 Switching the Screen from the PLC 6-2

6.1.2 Switching the Screen with the GT Main Unit 6-3

6.2 Basic Communication Area to PLC and Bit Device Functions (GT01) 6-6

6.3 Basic Communication Area to PLC and Bit Device Functions (GT11) 6-7

6.4 Basic Communication Area to PLC and Bit Device Functions (GT30) 6-9

7 Servicing and Maintenance 7-1

7.1 What the Battery Does (GT11) 7-2

7.2 What the Battery Does (GT30) 7-3

7.3 About the Front Panel Protective Sheet 7-4

7.4 About the Waterproof Packing 7-5

7.5 Replacing the Backlight (Sold Separately) (Applies Only to GT30) 7-6

8 Troubleshooting 8-1

8.1 What to DO If Something Unusual Occurs (GT01 & GT11) 8-2

8.2 What to DO If Something Unusual Occurs (GT30) 8-5

8.3 Error Codes and How to Handle Them 8-8

8.3.1 About Error Codes 8-8

8.3.2 GT Weries Error Codes 8-8

8.3.3 When Connected to a FP Series PLC 8-9

8.3.4 When Connected to a PLC (FX Series) Made by Mitsubishi Electric Corporation 8-10

8.3.5 When Connected to a PLC Made by Omron Corporation 8-10

8.4 Table of Screen Messages 8-11

9 Documentation 9-1

9.1 BIN/HEX/BCD Code Correspondence Table 9-2

9.2 ASCII Code Table 9-3

9.3 Cable Specifications 9-4

9.3.1 FP series TOOL Port Connection Cable: Mini-DIN 5-pin Loose Wire (AIGT8142) 9-4

9.3.2 Mitsubishi Electric FX series TOOL Port Communication Cable (AIGT8152) 9-4

9.3.3 PLC Communication Cable: Mini-DIN 5-pin Loose Wire (AIGT816*) 9-4

9.3.4 PLC Communication Cable: Mini-DIN 8-pin Loose Wire (AIGT8175) 9-5

9.3.5 PLC Communication Cable: D-SUB 9-pin Loose Wire (AIP81842) 9-5

9.3.6 PLC Communication Cable: Mini-DIN 5-pin Loose Wire (AIGT8192) 9-5

9.4 Summary of Features and Compatible Versions 9-6

10 Terminal GTWIN 10-1

10.1 Precautions Before Using GTWIN 10-2

10.1.1 Special Precautions 10-3

10.2 Installing GTWIN 10-4

10.3 Booting GTWIN 10-8

10.4 Exiting GTWIN 10-9

10.5 Procedures for Using GTWIN 10-10

Before You Start

Usage conditions

When installing the product, make sure it is used within the range of the general specifications. Do not

use in the following environments:

• Areas whwere the unit may come in contact with water (the unit is warranted by IP65 for the installed

panel, but this applies to initial values and operation cannot be guaranteed in areas where the unit is

constantly subjected to water or to extreme temperature or humidity.)

• Areas where the ambient temperature exceeds the range 0 to 50 °C.

• Areas where the ambient humidity exceeds 20 to 85% RH (at 25 °C non-condensing).

• If the control panel and other parts are installed in an environment where the air tends to be poorly

ventilated, forced cooling should be used to keep the ambient temperature of the from going over 50 °C.

This prevents the temperature of the GT main unit from rising.

• Locations where condensation may form because of sudden fluctuations in temperature.

• Locations where flammable or corrosive gases are present.

• Locations where there are high concentrations of dust or iron filings.

• Locations where substances such as organic solvents (thinner, benzene, etc.) or strong alkali

substances (ammonia, caustic soda, etc.) might adhere to the product.

• Locations where the product is subject to extreme vibration and/or impact.

• Avoid installing the product near high-voltage lines, high-voltage devices, power lines, power devices,

amateur radio sets and other transmitters, and devices that generate strong current surges.

• Avoid locations where the display unit is subject to direct sunlight.

Safety precautions

The switch functions of the programmable display unit should not be used to design systems which may

pose a threat to human life or which may cause severe injury or damage. Designs should include safety

mechanisms for use in the event that switch functions do not function correctly.

Power supply wiring

• For the power supply, use twisted wire (strand wire).

• There is sufficient noise resistance to offset power line noise, but we recommend reducing noise by

measures such as installing an insulated transformer.

• Separate wiring systems should be used for the power supply unit and the operating unit.

Static Electricity/Noise

• Keep the GT main unit, PLC connecting cable, and other wiring as far away as possible from

machines which are likely to produce noise (welding equipment, power lines, inverters, motors, etc.)

• For use in environments where the frequent occurrence of static electricity, radiation, or induced noise

can be expected, the use of shielded cable on all wiring and grounding of shield (1-point ground) is

recommended. When wiring the equipment, shielded wires should be electrically insulated to signal

lines and signal grounds.

• If excessive static electricity is applied to the panel surface, the LCD display unit may be damaged.

i

Other precautions

• Do not connect any devices other than our Programmer II to the TOOL port.

• Always operate the touch panel with fingers as the touch panel may be damaged due to the excessive

load or shock (caused when being operated with any tools). Also, if the touch panel is pressed like

kneading, the electrode may be worn out exceptionally, and cause the malfunction. Operate with a

single touch of the panel.

• Do not disassemble, reassemble or remodel the GT main unit as we cannot assure the performance if

you have done such things.

Battery

Do not leave the battery in the unit when it is not used. There is a possibility of leak if it is left being

discharged.

ii

Usage Procedures

If you are using the GT series for the first time, please follow the procedure outlined below.

1. Confirm the items included with the product. Next page

Please confirm that all of the items have been included with the product you have purchased. Products

are carefully checked before being shipped, but if you do find anything missing, please contact your

dealer.

2. Install and wire the main unit. Chapter 2

Install the main unit, and connect the power supply, PLC connection cable and other wiring.

For information on connecting the product to the FP series PLC, and on entering communications

settings,

Reference: <Chapter 4 Connecting and Communicating with the PLC>

3. Set up the main unit. Chapter 3

When the product is shipped from the factory, it is set up with specifications that enable connection to

the FP series PLC. If you plan to use the product without changing these settings, no setup is required,

but if you plan to change the settings, you will need to follow the setup procedure. Particularly with

regard to the basic communication area to the PLC and other devices, please confirm the settings

carefully and change only those that are necessary.

Main cases in which setup is necessary

• When the device being connected is a general-purpose serial device (such as a computer or

microcomputer board).

• When the basic communication area for the device is different from that set when the product is

shipped.

4. Check communication with the external device (PLC, etc.). Chapter 4

Check the connections and communication with the external device. Connections and communication

with devices in the FP series PLC vary depending on the device.

5. Enter the operating environment settings Chapter 5

In addition to the setup described at step 4, various detailed settings can be entered from the GT main

unit operating environment.

6. Install the screen creation tool.

Install the Terminal GTWIN screen creation tool in the personal computer.

7. Create the screen contents.

Create the screen contents using the Terminal GTWIN screen creation tool, and send the screen to the

GT main unit. For information on creating screens and on operating GTWIN, please refer to the HELP

function that comes with GTWIN.

8. Test the operation.

Connect the GT main unit containing the screen data to an external device (PLC or general-purpose

serial device), and check the operation contents.

iii

Confirming the Package Contents

Check to make sure the necessary items have been included with the product you have purchased.

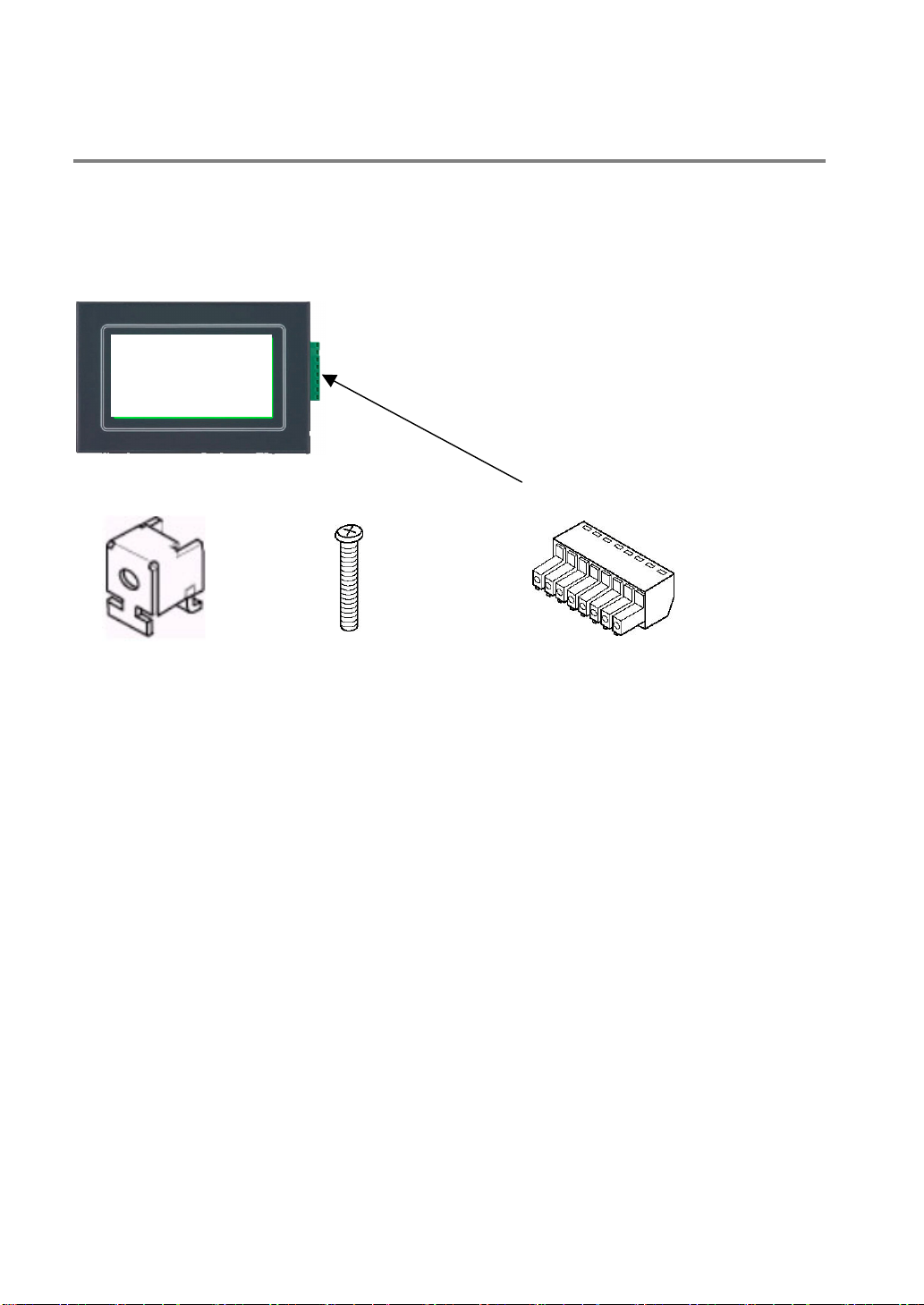

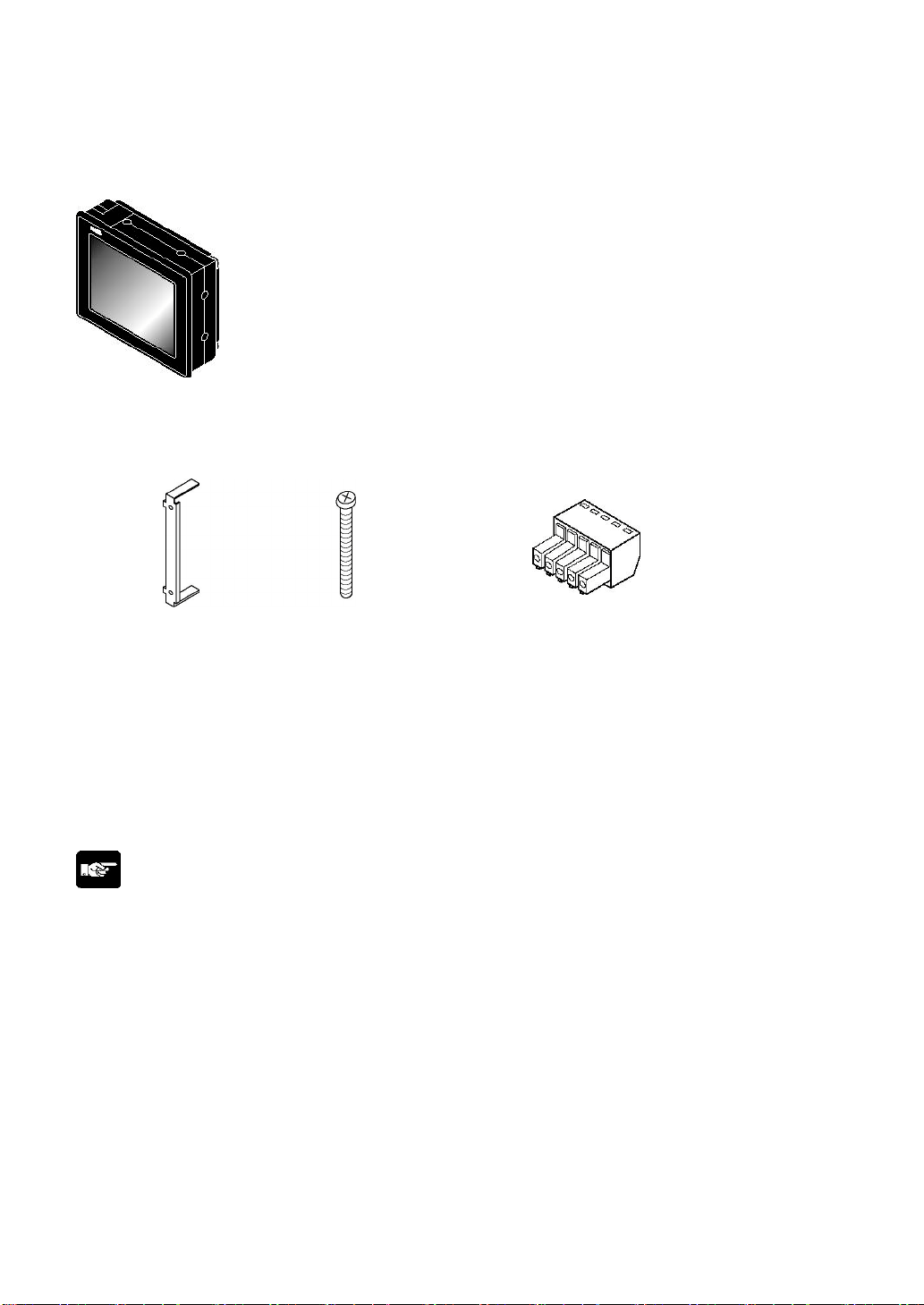

Items included with the GT01

Main unit (Photo is AIGT0030B1)

Set of attachment fittings Connector for communications (x1)

Attachment fittings x 4 Attachment screws x 4

Repair parts are available.

AIGT083 (contains 5 sets.)

* 4 pcs of attachment fittings and 4 pcs of

attachment screws are contained in one set.

Repair parts are available.

AIGT084 (contains 5 pcs.)

Installation instructions

Please read these instructions carefully before

using the product.

◯1 There is a film over the front panel protective sheet. Remove this film when using the unit

2

◯

Front panel protective sheets for replacement are available as a separate purchase AIGT080 (10

sheet set).

Waterproof packing

One piece of waterproof packing has been

attached to unit.

The following maintenance part is available:

AIGT081 (10 piece set)

iv

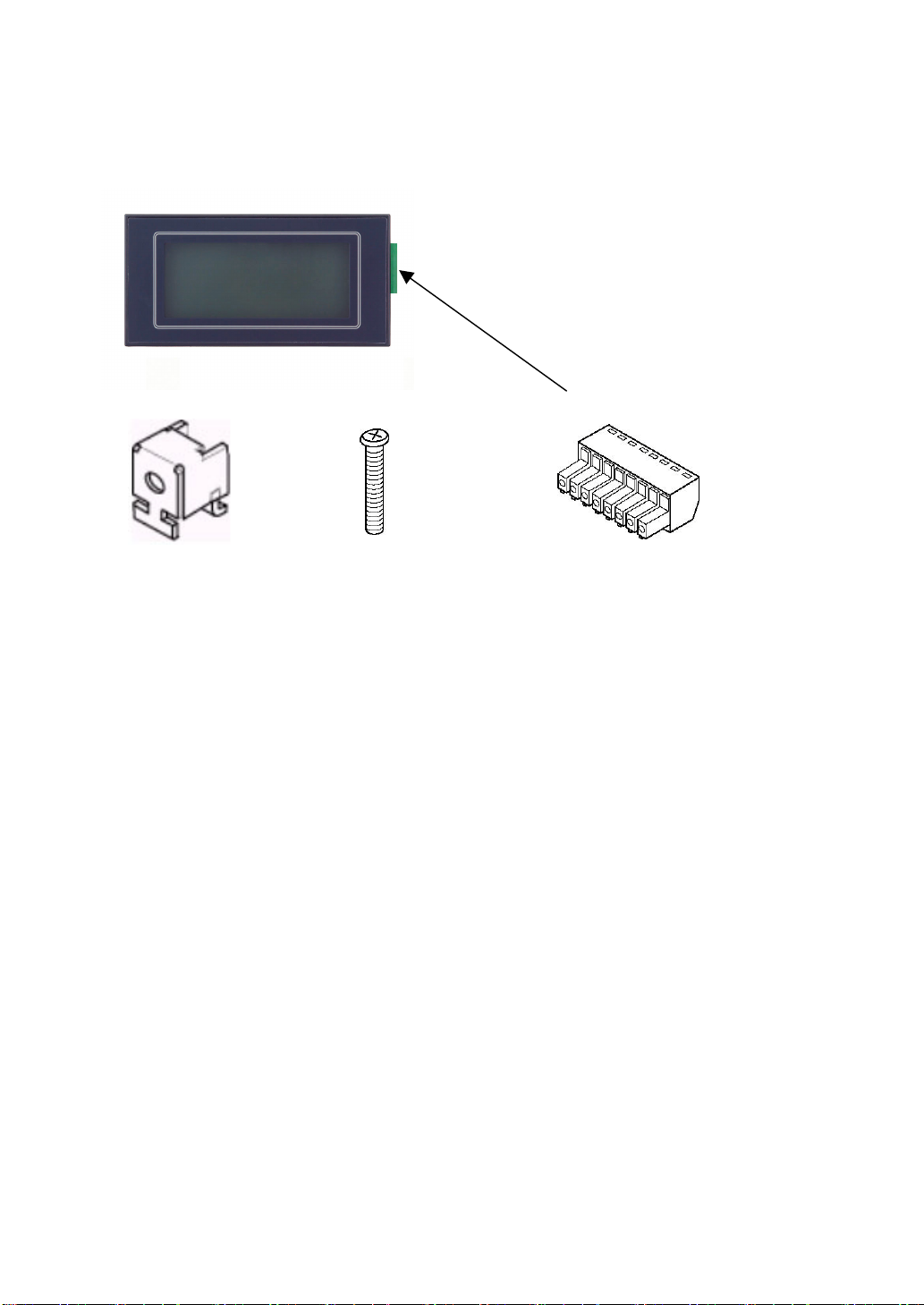

Items included with the GT11

Main unit (Photo is AIGT2030B)

Set of attachment fittings Connector for communications (x1)

Attachment fittings x 4 Attachment screws x 4

Repair parts are available.

AIGT084 (contains 5 pcs.)

Repair parts are available.

AIGT083 (contains 5 sets.)

* 4 pcs of attachment fittings and 4 pcs of

attachment screws are contained in one set.

Installation instructions

Please read these instructions carefully before

using the product.

Waterproof packing

One piece of waterproof packing has been

attached to unit.

The following maintenance part is available:

AIGT181 (10 piece set)

◯1 There is a film over the front panel protective sheet. Remove this film when using the unit

2

◯

Front panel protective sheets for replacement are available as a separate purchase AIGT280 (10

sheet set).

v

Items included with the GT30 (AIGT3100B and AIGT3300B)

Main unit

STN monochrome liquid crystal display type: AIGT3100B

STN color liquid crystal display type: AIGT3300B

Set of attachment fittings Connector for communications (x1)

Fittings x 2 Screws x 4

Front panel protective sheet

There is a front panel protective sheet, available as

an optional product, attached to the front panel of

the unit.

Installation instructions

Please read these instructions carefully before

using the product.

Note:

• There is a film over the front panel protective sheet. Remove this film when using the unit.

• Front panel protective sheets for replacement are available as a separate purchase (AIGT380).

• Waterproof packings for replacement are available as a separate purchase (AIGT381).

• A replacement backlight is available as a separate purchase (AIGT382).

• The commercially available CR2032 should be used for battery replacement.

Waterproof packing

One piece of waterproof packing has been

attached to unit.

vi

Items included with the Terminal GTWIN English-language version (AIGT8001V2)

Terminal GTWIN CD-ROM

Software usage license agreement and user card

Read the “Software usage license agreement” carefully, and fill in the user card. Please return the user

card to Matsushita.

GT series Technical Manual

ARCT1F398E

This is the manual you are currently reading. It contains instructions on installing and booting GTWIN.

Please read it carefully before using your product.

About the manual for the screen creation software tool

The GT Series Technical Manual provides an installation guide. However, for detailed operation

procedures please use the help function. The Terminal GTWIN Operational Guide Book (ARCT1F357E),

which covers basic operation, is also available. Please contact us if you would like a copy.

Note:

About the software usage license agreement and user card

• Before using GTWIN, readthe “Software usage license agreement” carefully.

• The license agreement comes as a set with the user card. Fill in the user card, and return it to

Matsushita. The user card is necessary in order to obtain support services such as future version

upgrades and technical support. Don’t forget to return the card in order to be eligible for such services.

• The serial number needed in order to install GTWIN is found on the user card. Please make a copy of

it before returning the card, and keep it in a safe place.

vii

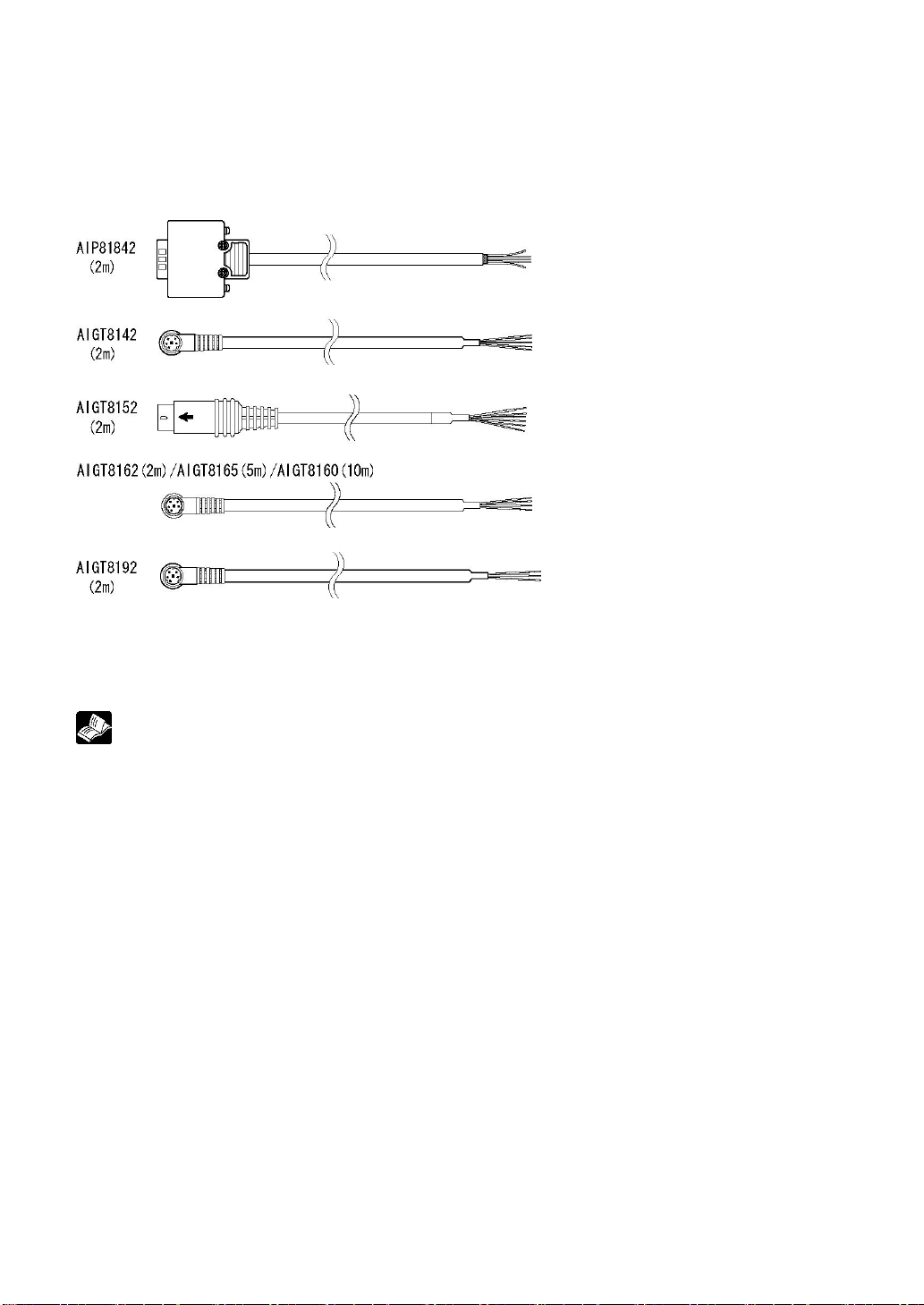

Items included with the PLC conncation cable (AIP81842/AIGT8142/AIGT8152/AIGT8162)

Cable

One of the following cables has been included with the product you have purchased.

Wiring diagram

The package includes a diagram that shows the internal wiring of the cables pictured above. AIGT816* is

only a RS232C cable and is for use when the GT01 is using separate power supply or for GT11.

Reference:

For information on connecting and wiring the cables shown above and the PLC, refer to <Chapter 4

Connecting and Communicating with the PLC”.

viii

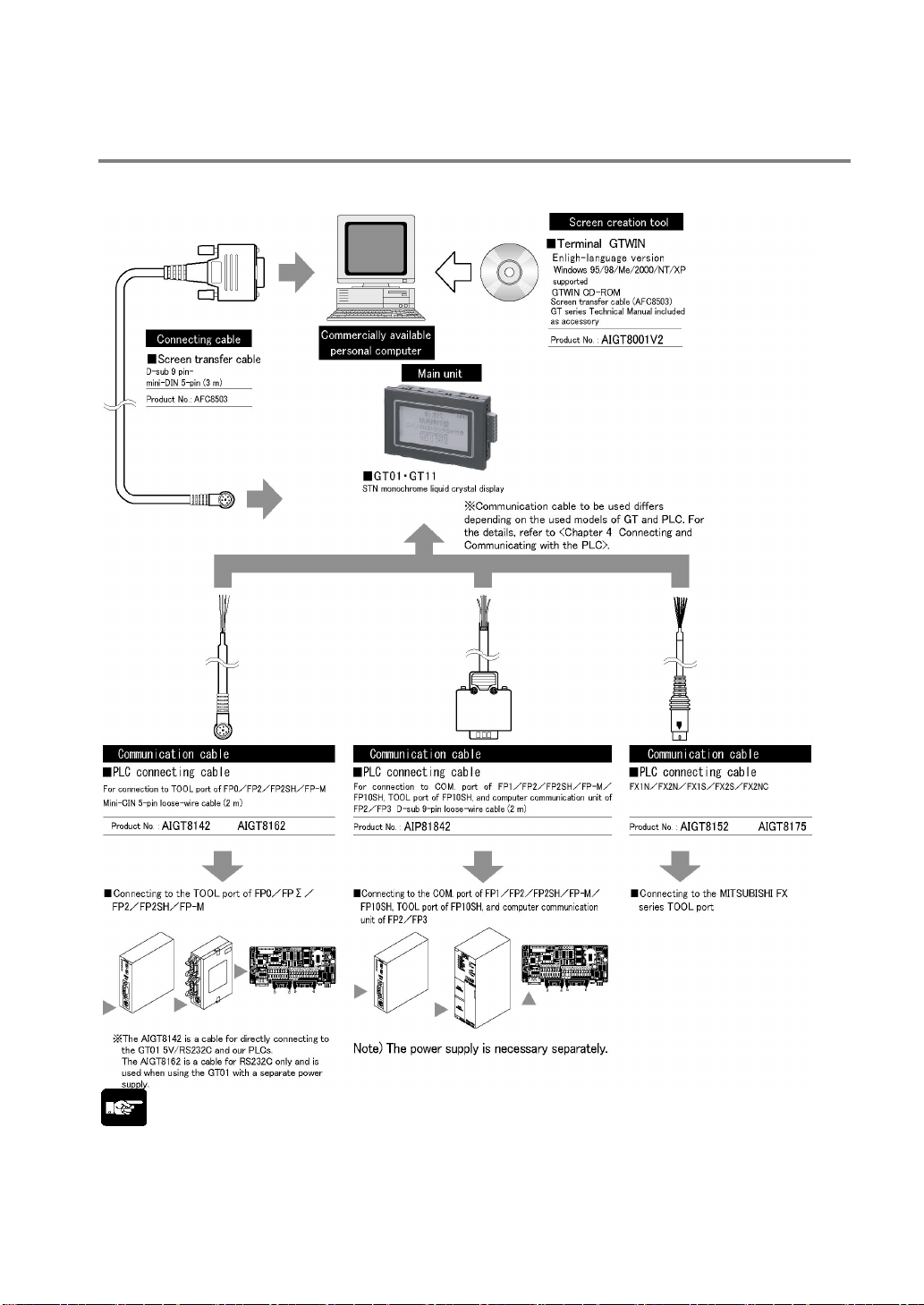

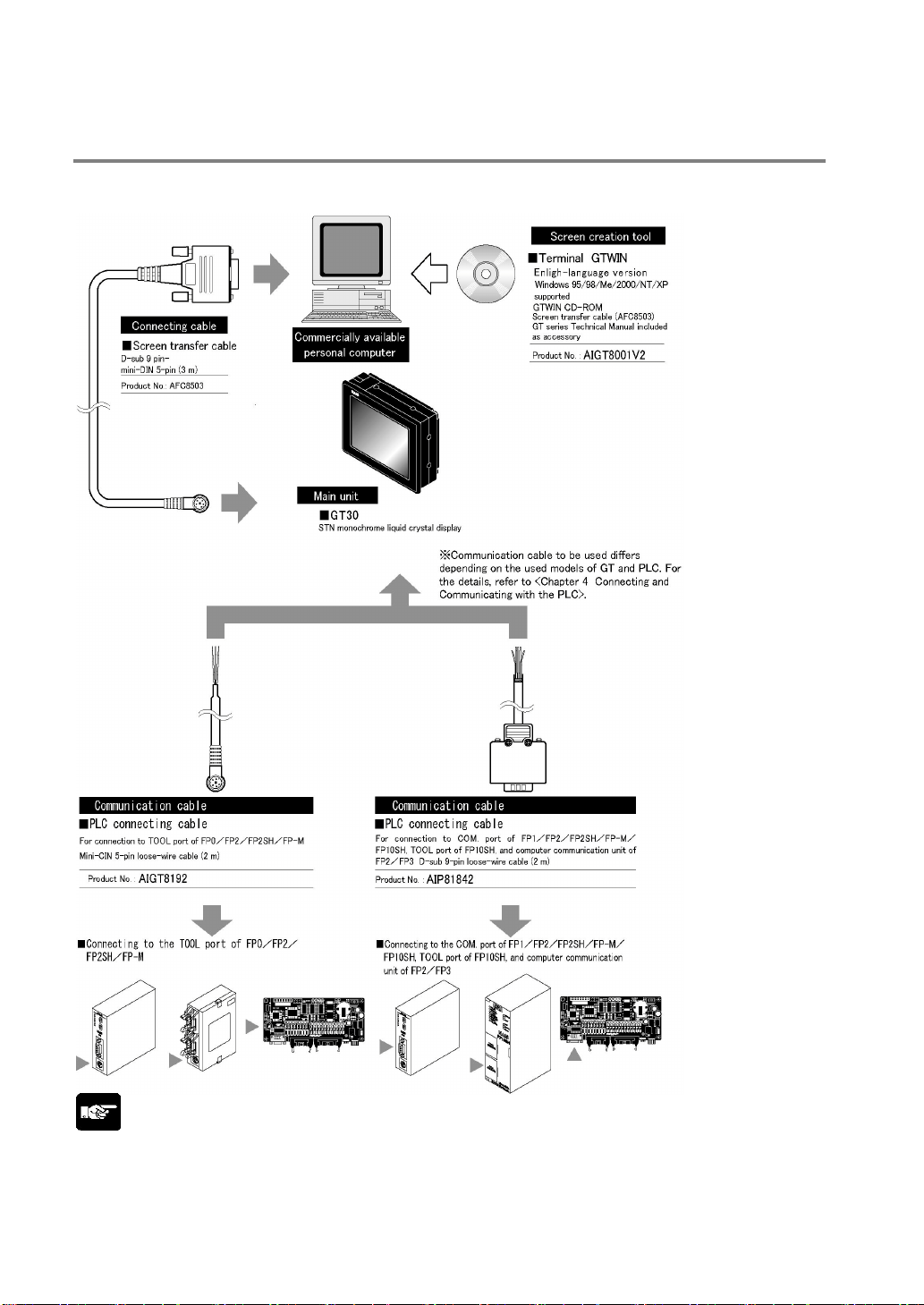

GT Series System Configuration (GT01 and GT11)

The following devices are necessary in order to use the GT series.

Note:

Connecting to the COM. port of the PLC

Because connecting the unit to the COM. port of the FPΣ/FP0 requires a loose-wire connection, this

cable is not available.

ix

GT Series System Configuration (GT30)

The following devices are necessary in order to use the GT series.

Note:

Connecting to the COM. port of the PLC

Because connecting the unit to the COM. port of the FPΣ/FP0 requires a loose-wire connection, this

cable is not available.

x

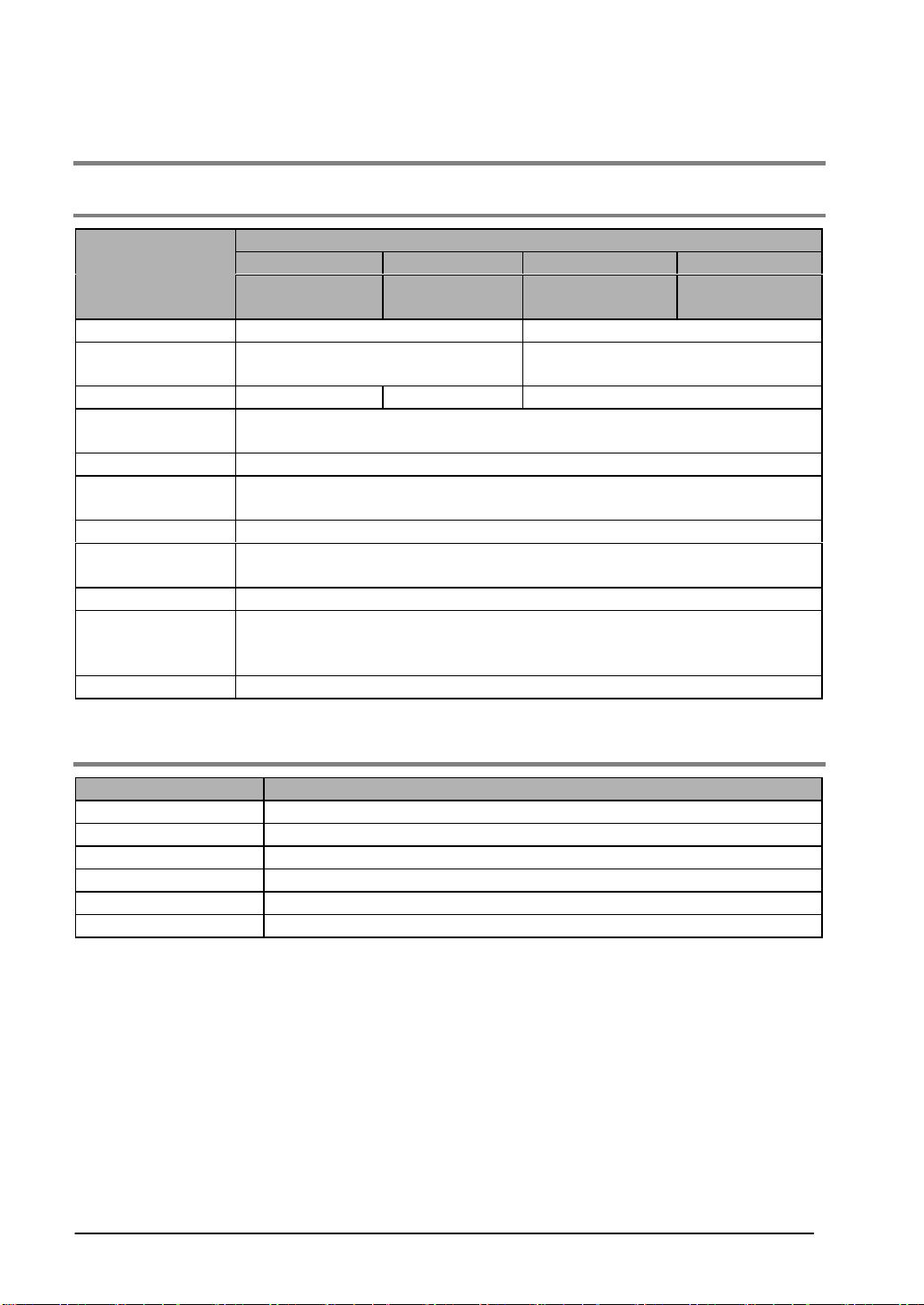

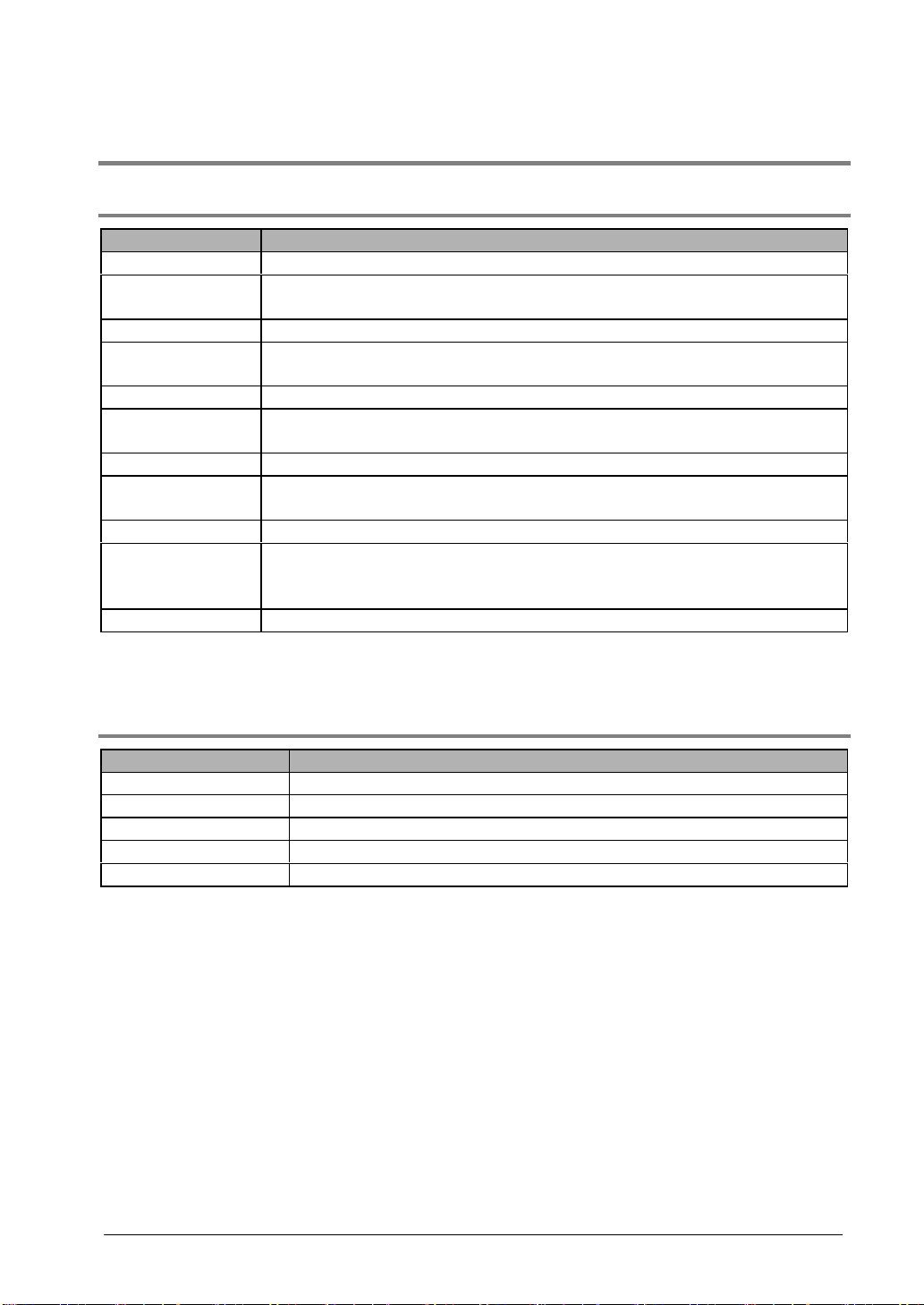

Products Types and Manuals

Products types for the GT series

Item name Contents Product No.

Black AIGT0030B1

Ashgray AIGT0030H1

Black AIGT0032B1

Ashgray AIGT0032H1

Black AIGT0030B

Ashgray AIGT0030H

Black AIGT0032B

Ashgray AIGT0032H

Black AIGT2030B

Ashgray AIGT2030H

Black AIGT2032B

Ashgray AIGT2032H

Black AIGT3100B

Ashgray AIGT3100H

Black AIGT3300B

Ashgray AIGT3300H

AIGT8001V2

AIGT8142

AIGT8152

AIGT8162

AIGT8165

AIGT8160

AIGT8175

AIGT8192

AIP81842

GT01 main unit

GT11 main unit

GT30 main unit

Terminal GTWIN

Ver. 2 Englishlanguage version

Terminal GTWIN

upgrade version

PLC direct

cables

PLC connecting

cables

Screen transfer

cable

RS232C type

5V DC

STN monochrome

liquid crystal display

24V DC

STN monochrome

liquid crystal display

STN monochrome

liquid crystal display

STN color liquid

crystal displa

- “Terminal GTWIN” English-language screen creation tool (CDROM)

- Set of GT series Hardware Manuals

Upgrade “Terminal GTWIN” screen creation tool Ver. 1 to Ver. 2 AIGT8001V2R

For direct connection to GT01 (5V DC/RS232C) and TOOL port

of PLCs (FP-3/FP0/FPΣ/FP2/FP2SH/FP-M). Mini-DIN 5-pin

(2 m)

For direction connection to GT01 (5V DC/RS422) and

MITSUBISHI FX series. Mini-DIN 8-pin (2 m)

For connection to GT01 (24V DC), GT11 and PLCs. Mini-DIN 5pin loose-wire cable (2 m)

For connection to GT01 (24V DC), GT11 and PLCs. Mini-DIN 5pin loose-wire cable (5 m)

For connection to GT01 (24V DC), GT11 and PLCs. Mini-DIN 5pin loose-wire cable (10 m)

For connection to GT01 (24V DC), GT11 and Mitsubishi FX

series. Mini-DIN 8-pin loose-wire cable (5 m)

For connection to GT10, GT30 and TOOL port of PLCs (FP3/FP0/FPΣ/FP2/FP2SH/FP-M). Mini-DIN 8-pin loose-wire cable

(2 m)

For connection to COM. port of FP1/FP2/FP2SH/FPM/FP10SH, TOOL port of FP10SH, and computer

communication unit of FP2/FP3. D-SUB 9-pin loose-wire cable

(2 m)

Screen data transfer caable for GTWIN and GT series AFC8503

y

24V DC

24V DC

RS422/RS485

type

RS232C type

RS422/RS485

type

RS232C type

RS422/RS485

type

RS232C type

RS232C type

xi

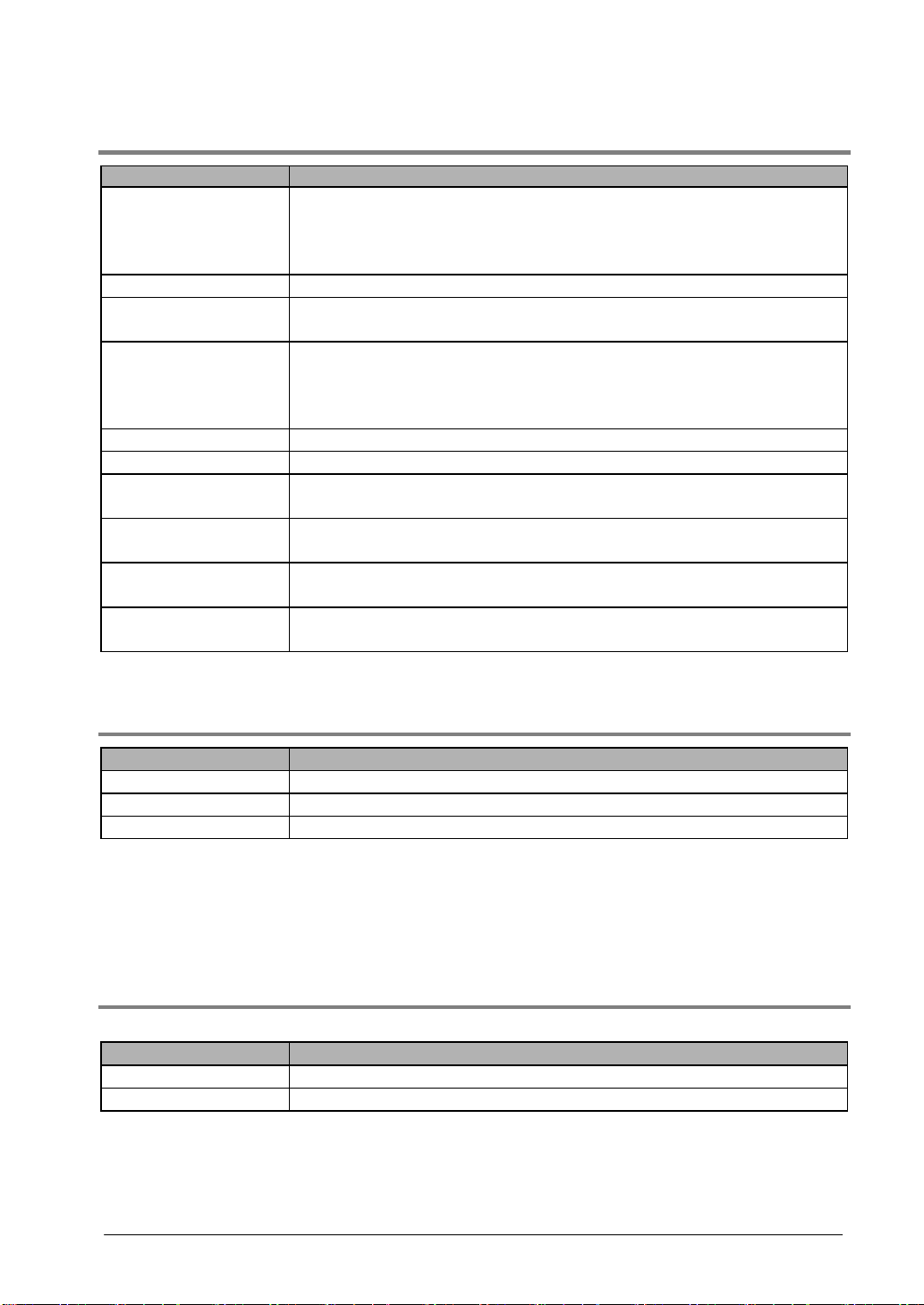

Item name Contents Product No.

Screen transfer

cable

Front panel

protective sheet

Waterproof

packing

Replacement

backlight

Attachment

fittings

Connector

Screen data transfer caable for GTWIN and GT series. Mini-DIN

5-pin straight type

Front panel protective sheet for GT01. 10 in set. (sold

separately)

Front panel protective sheet for GT11. 10 in set. (sold

separately)

Front panel protective sheet for GT10 (for replacement). 10 in

set. * 1 sheet included with the main unit when shipped.

Front panel protective sheet for GT30 (for replacement). 10 in

set. * 1 sheet included with the main unit when shipped.

Waterproof packing for GT01 ( for replacement). 10 in set.

* 1 sheet included with the main unit when shipped.

Waterproof packing for GT10/GT11 ( for replacement). 10 in

set. * 1 sheet included with the main unit when shipped.

Waterproof packing for GT30 ( for replacement). 10 in set.

* 1 sheet included with the main unit when shipped.

This is the replacement backlight for the GT30

color/monochrome liquid crystal display.

AFC8503S

AIGT080

AIGT280

AIGT180

AIGT380

AIGT081

AIGT181

AIGT381

AIGT382

Attachment fittings for GT01/GT11. 5 set (4 pcs./set) AIGT083

Attachment fittings for GT10. 5 set (4 pcs./set) AIGT183

Attachment fittings for GT30. 5 set (2 pcs./set) AIGT383

COM port connector for GT01/GT11. 5 set AIGT084

COM port connector for GT10/GT30. 5 set AIGT184

Note:

• Connecting to the COM. port of the FP0

Because connecting the unit to the COM. port of the FPΣ/FP0 requires a loose-wire connection, this

cable is not available.

• The AIGT8142 is a cable for directly connecting to the 5 V type GT01 and the FP series TOOL port.

(Power can be supplied from the FP series.)

• The AIGT8162, AIGT8165 and AIGT8160 is the cables for connecting the GT01 (24V DC, RS232C),

GT11 and the TOOL port of our PLCs.

• The AIGT8192 is a cable for connecting the GT30 and the TOOL port of our PLCs.

Types of manuals

Manual name Contents

Terminal GTWIN

Operational Guide

Note1)

Book

Explains basic screen creation

methods.

Manual

number

ARCT1F357E No

Manual included

in GTWIN

Explains about protocols and

GT Multi-purpose

Serial Communications

Manual

handling when controlling the GT

Series using communicating from

an external device such as PC

ARCT1F356E No

board.

GT series Technical

Manual

Note2)

Explains about the hardware

specifications and handling

procedures.

ARCT1F398E Yes

Note1) Only covers basic operation. Please use the help function for detailed operation procedures.

Note2) Contains a GTWIN installation guide.

xii

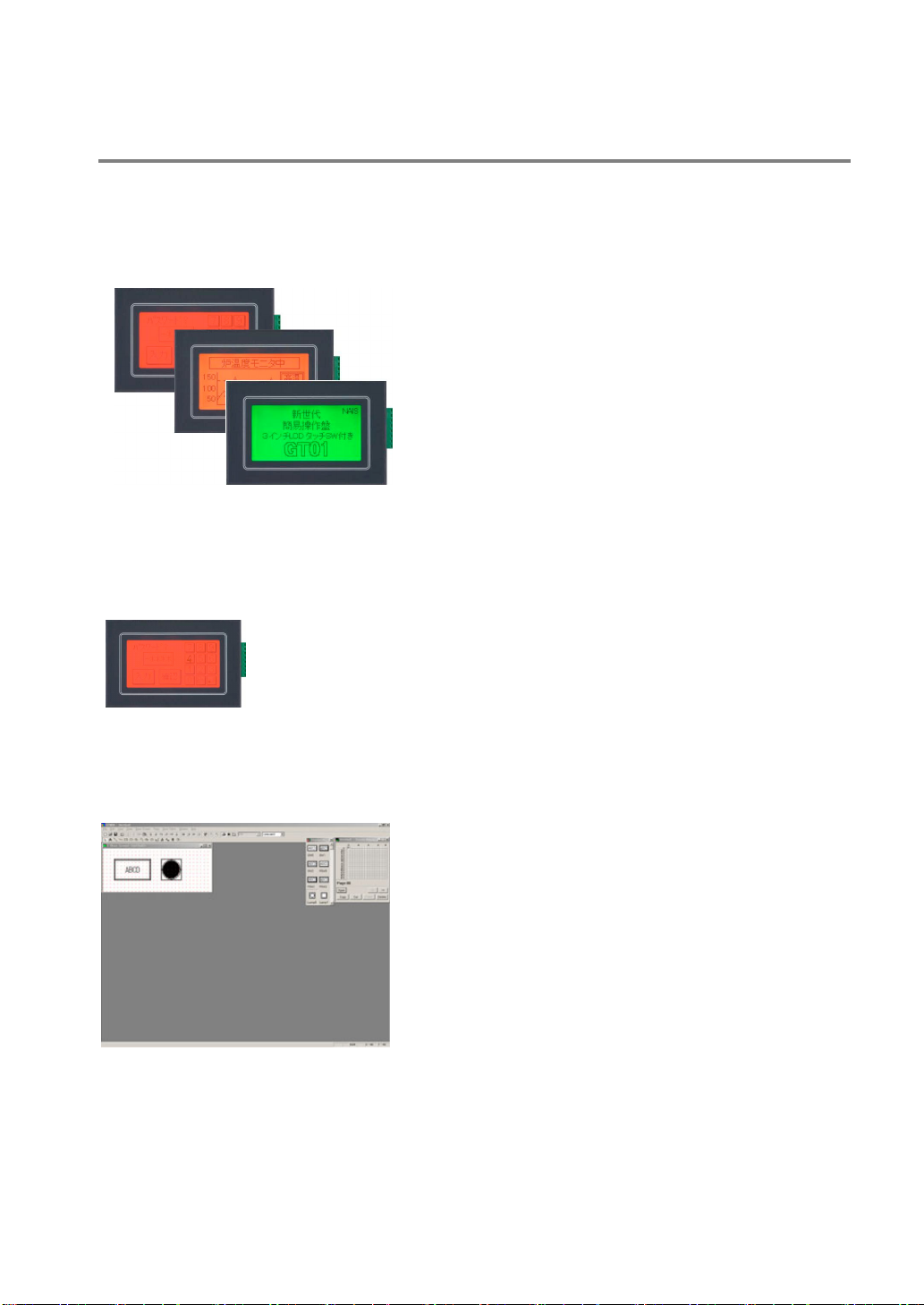

An Overview of GT Series Functions

3 colors can be displayed, to reflect the status (GT01 and GT11)

Various messages and graphics can be displayed on the liquid crystal display screen, as well as lamps,

internal PLC data and graphs. In addition, backlighting is available in three colors, green, orange, and

red, so that information can be color-coded. This makes it easy to grasp information at a glance.

Red

Orange

Green

High-resolution touch panel provided (GT01 and GT11)

A compact touch panel is provided with on-screen switches and a keyboard, letting you operate the unit

simply by touching the screen. As this is an analog touch panel, numerous switches can be used and

allows maximum flexibility in the switch layout and size.

Screens can be created easily, using special tools (GT01, GT11 and GT30)

Screen contents can be easily created using the dedicated Terminal GTWIN tool (runs on Windows

95/98/2000/NT/XP). Screens are put together simply by selecting parts from a library and positioning

them in place.

Screen data of the other models can be used with the model conversion function.

Screen data can be converted from the small-sized screen to the large-sized one. For the details, refer to

Terminal GTWIN Operational Guide Book.

xiii

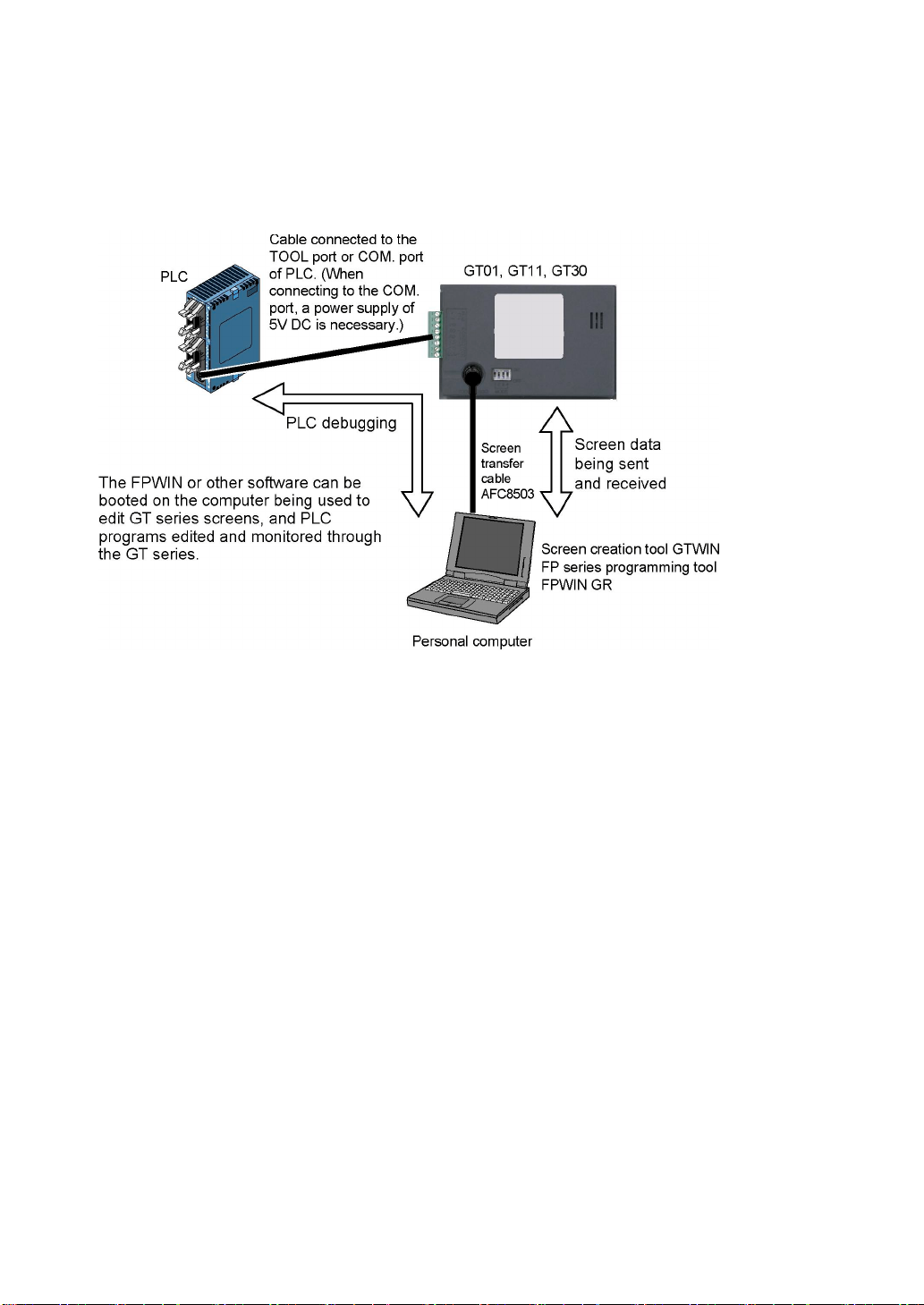

Through function is convenient for debugging (GT01, GT11 and GT30)

If connections are made as shown in the diagram, a convenient “through” function makes it possible to

transfer data from the GT and carry out PLC debugging at the same time that communication is going on

between the GT and the FP series PLC. This significantly boosts efficiency in the workplace.

xiv

Chapter 1

Specifications

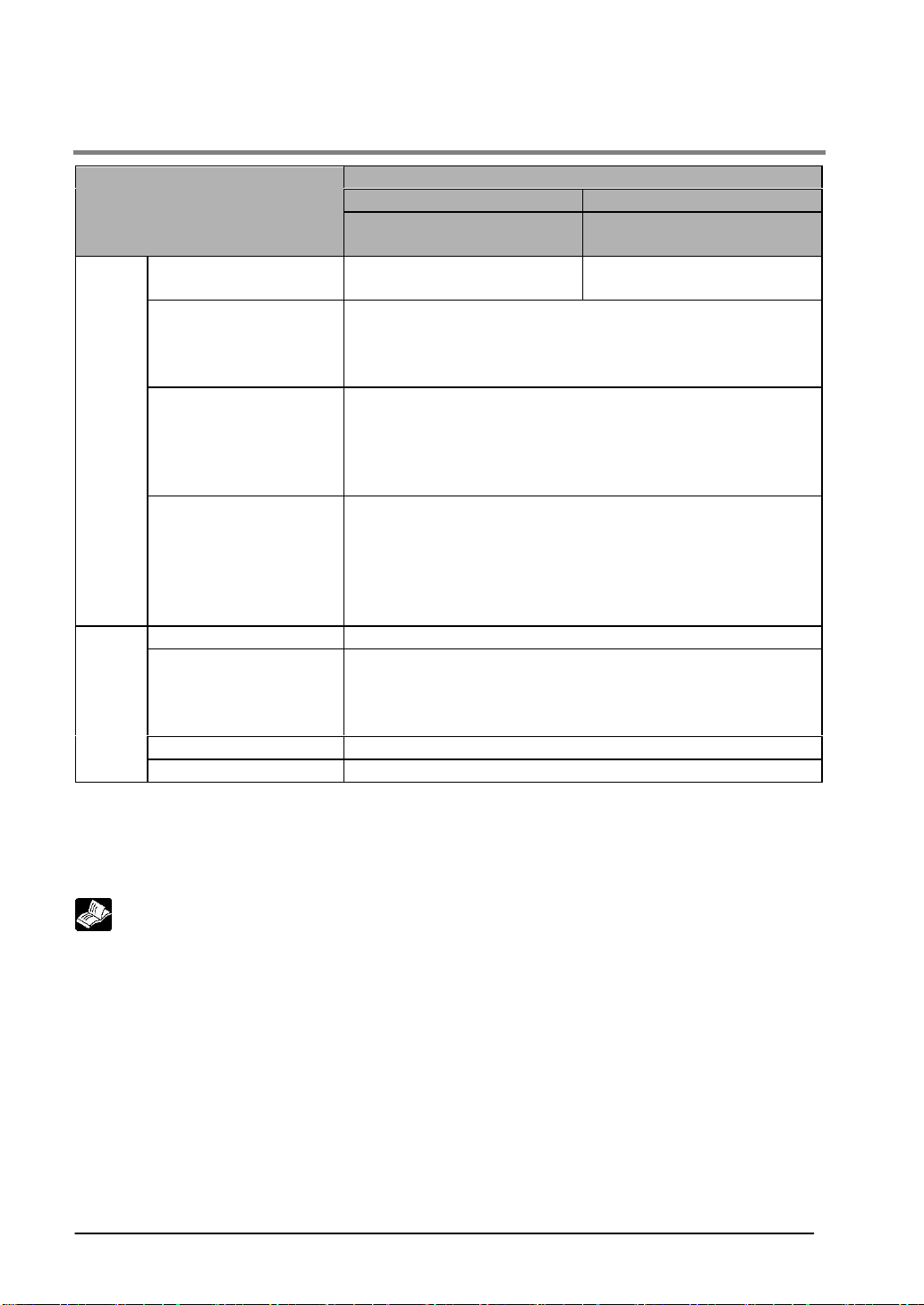

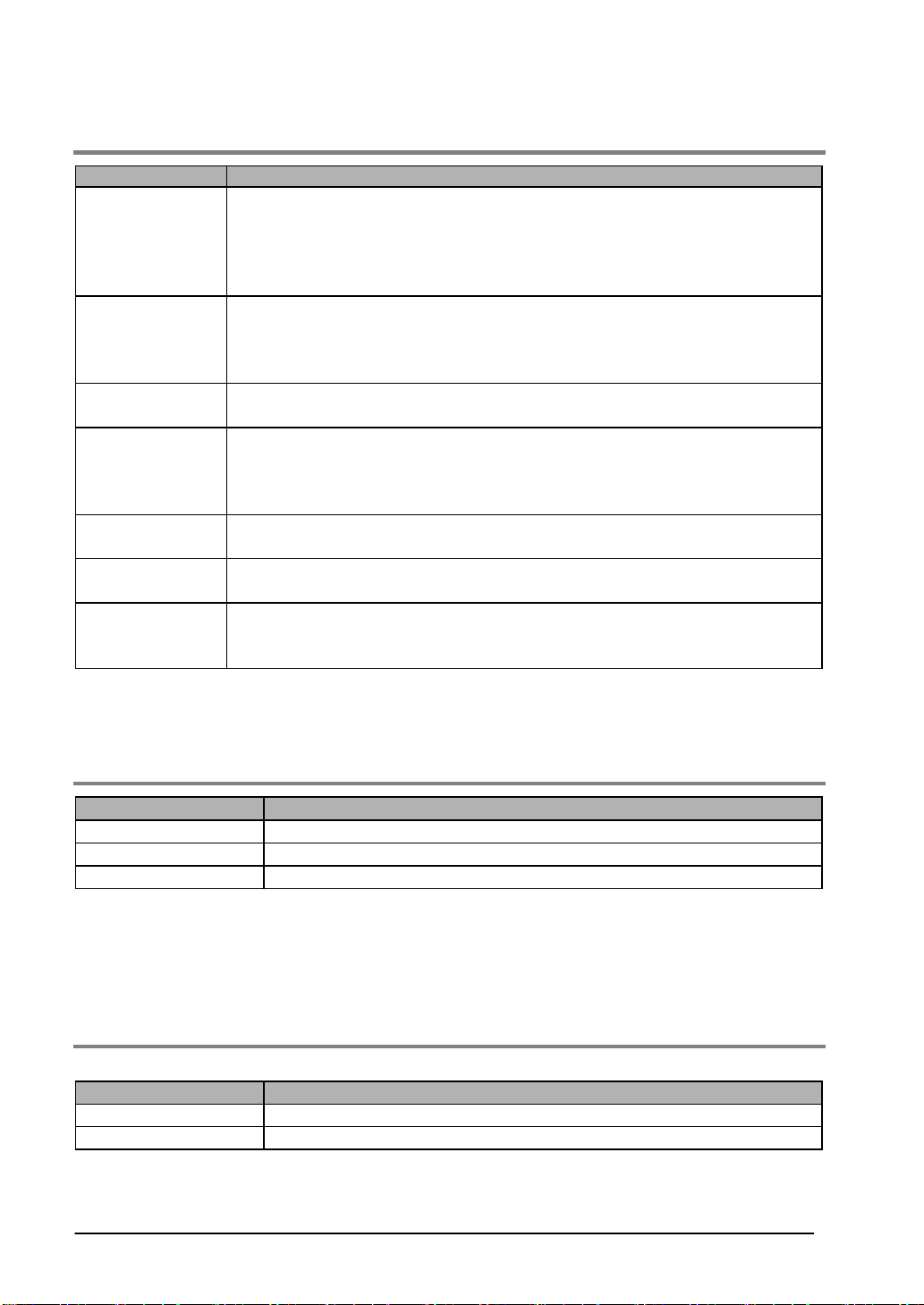

1.1 GT01 Specifications

1.1.1 General Specifications

GT01 specifications

Item

Rated voltage 5 V DC 24 V DC

Operating voltage

range

Power consumption 1W or less 1.1 W or less 2 W or less

Ambient

temperature

Ambient humidity 20 to 85% RH (at 25 °C, non-condensing)

Storage

temperature

Storage humidity 10 to 85% RH (at 25 °C, non-condensing)

Vibration resistance

Shock resistance 98 m/s2 or more, 4 times on 3 axes

Protective

construction

Weight Approx. 160 g

5V, RS232C type 5V, RS422 type 24V, RS232C type 24V, RS422 type

AIGT0030B1/

AIGT0030H1

4.5 to 5.5 V DC 21.6 to 26.4 V DC

0 to +50 °C

-20 to +60 °C

10 to 55 Hz (1-minute cycle)

Amplitude: 0.75 mm, 10 min on 3 axes

IP65 (in initial status)

Dustproof and drip-proof from front panel only (packing used on panel contact

surface) * When reattaching, replace waterproof packing.

AIGT0032B1/

AIGT0032H1

AIGT0030B/

AIGT0030H

AIGT0032B/

AIGT0032H

1.1.2 Display

Item GT01 specifications

Display STN monochrome LCD

Resolution 128 (W) x 64 (H) dots

Display color 2 colors (balck/white)

Displayable area 70.38 (W) x 35.18 (H) mm

LCD life Average 50,000 hours (at 25 °C room temperature)

Backlight 3-color LED backlight (green, red, orange) * No need to replace.

1-2

1.1.3 Functions

Item GT01 specifications

Fixed fonts: 1/4 width (8 x 8), half width (16 x 8), full width (16 x 16)

Displayable fonts

Character types Alphanumeric characters

Graphics

Number of screens

Part functions Messages, lamps, switches, data, bar graphs, keyboard, line chart

Contrast adjustment Contrast can be adjusted using touch panel operation.

Automatic

communication settings

Debugging functions

Screen creation

Password function

Note) Clock functions are not available.

Half width and full width characters can be displayed at same width,

doubled width, or quadrupled width

True Type fonts and Windows fonts

Straight lines, continuous straight lines, squares, circles, ovals, arcs, elliptic

arcs, fan shapes, elliptic fan shapes, beveled squares, bitmaps

Approx. 160 screens

Screen numbers that can be set: Base screens No. 00 to FF

* Number of screens that can be registered varies depending on registered

contents.

Setting for communication between dedicated software and PLC set

automatically by connecting cable.

Through function (PLC can be debugged from personal computer by

connecting computer to TOOL port and PLC to COM. port.)

Dedicated software is used.

Applicable OS: Windows 95/98/Me/2000/NT/XP

Screen data transfer or capture cannot be executed without a password

(screen data protection function).

1.1.4 Touch Key

Item GT01 specifications

Touch key Analog touch key

Touch key operation 0.5 N or less

Touch key life Min. 10

Note1) The GT01 touch-switches operate using analog resistance membrane. Do not press two or more

points on the screen at the same time. Doing so might operate a switch located between those

points if one exists.

Note2) This touch-panel is designed to be operated by touching. Please realize that the positional

accuracy of the switches is based on the size of a finger.

6

1.1.5 Memory

Screen data and GTWIN Configuration Settings data

Item GT01 specifications

Memory type F-ROM

Memory chapacity 384 kbytes

1-3

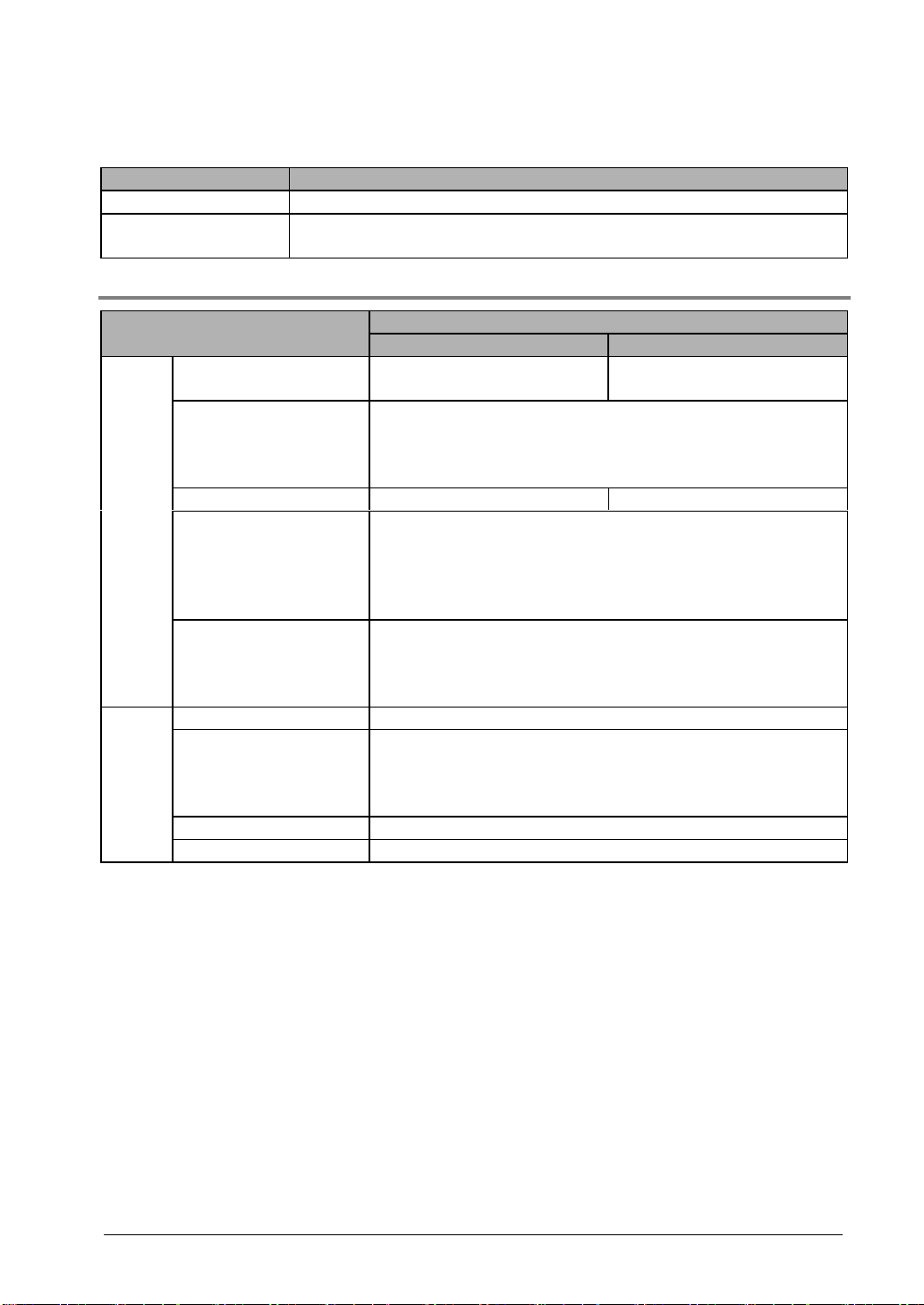

1.1.6 Serial Interface

GT01 specifications

Item

Communications ratings

Conditions for

communications with

external devices

COM.

port

TOOL

port

Note1) RS232C data transmission speed is 19,200 bit/s and the maximum cable length is 15 m.

Note2) Maximum cable length for RS422 data transmission is 30 m for the 5 V type and 500 m for the

Note3) When running a 5 V type directly with the PLC power supply, please comply with the PLC

Protocol

Connector

Communications ratings Conforms to RS232C (Non insulation type)

Conditions for

communications with

external devices

Protocol Dedicated protocol

Connector Mini-DIN (5-pin)

24 V type.

restrictions. For this reason, you may not be able to use at the distances given above.

Conforms to RS232C

(Non insulation type)

Baud rate: 9600, 19200, 38400, 57600, 115200 bps

Data bits: 7 or 8 bits

Parity: Non, Odd, Even

Stop bit: 1 bit

Supports MEW FP Series/General-purpose Serial/Mitsubishi FX

Series/Mitsubishi A (calculator link) Series/Omron SYSMAC-C

Series/Modbus (RTU)/Siemens S7-200 Series/Toshiba Machine

PROVISOR TCmini Series/Yokogawa FA-M3 Series/AllenBradly SLC500 Series/LG MASTER-K (Cnet) Series

Connector terminal base (8-pin)

* Regarding power supply voltage, please pay due consideration

to the cable length so that the applied voltage is within the

operation voltage range. Also, when supplying power from a

power supply separate from the PLC, please make sure the

power cable is no longer than 10 m.

Baud rate: 9600, 19200, 115200 bps

Data bits: 8 bits

Parity: Non, Odd, Even

Stop bit: 1 bit

RS232C type RS422 type

AIGT0030B1/AIGT0030H1

AIGT0030B/AIGT0030H

AIGT0032B1/AIGT0032H1

AIGT0032B/AIGT0032H

Conforms to RS422

(Non insulation type)

Reference:

For information on connecting and wiring the cables, refer to <Chapter 4 Connecting and

Communicating with the PLC> and <GTWIN HELP>..

1-4

1.2 GT11 Specifications

1.2.1 General Specifications

Item GT11 specifications

Rated voltage 24 V DC

Operating voltage

range

Power consumption 2.4 W or less (100 mA or less)

Ambient

temperature

Ambient humidity 20 to 85% RH (at 25 °C, non-condensing)

Storage

temperature

Storage humidity 10 to 85% RH (at 25 °C, non-condensing)

Vibration resistance

Shock resistance 98 m/s2 or more, 4 times on 3 axes

Protective

construction

Weight Approx. 230 g

Note) If using cables other than the cables manufactured by us, use shielded cables, and attach ferrite

cores for the noiseproof measures if necessary.

21.6 to 26.4 V DC

0 to +50 °C

-20 to +60 °C

10 to 55 Hz (1-minute cycle)

Amplitude: 0.75 mm, 10 min on 3 axes

IP65 (in initial status)

Dustproof and drip-proof from front panel only (packing used on panel contact

surface) * When reattaching, replace waterproof packing.

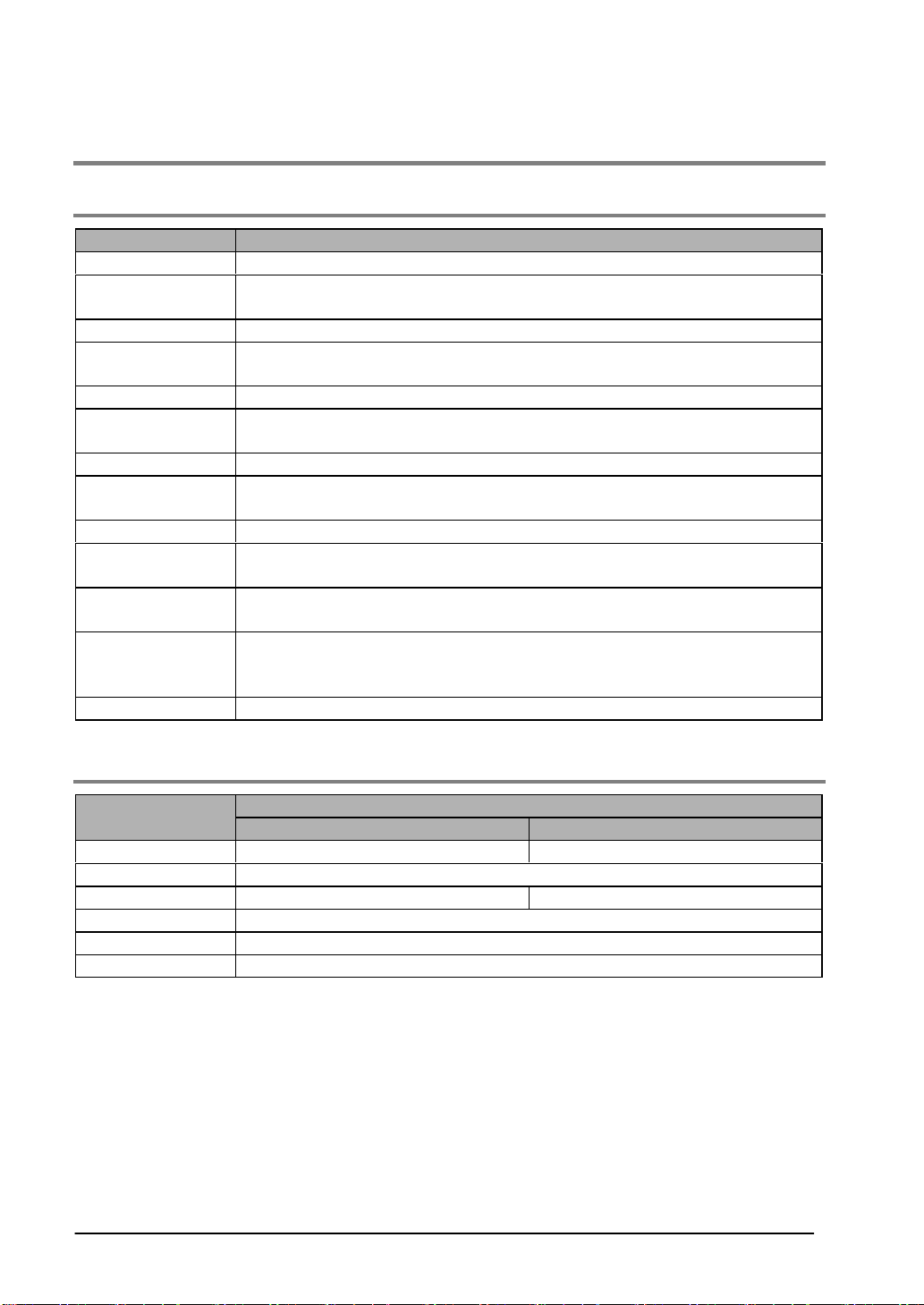

1.2.2 Display

Item GT11 specifications

Display STN monochrome LCD

Resolution 240 (W) x 96 (H) dots

Displayable area 96.0 (W) x 35.4 (H) mm

Backlight 3-color LED backlight (green, red, orange)

Contrast adjustment Contrast can be adjusted on the menu screen.

1-5

1.2.3 Functions

Item GT01 specifications

Fixed fonts: 1/4 width (8 x 8), half width (16 x 8), full width (16 x 16)

Half width and full width characters can be displayed at same width, doubled

Displayable fonts

Character types

Graphics

Number of

screens

Part functions

Other functions

Through function

Note1) The clock part can be indicated by referring to external clock data.

Note2) When using the built-in clock or bakcing up the alaram history , purchase and install a

commercial battery.

width, or quadrupled width

True Type fonts: 10, 12, 14, 16, 24, 26, 28, 32, 36, 48, 64 dots and Windows

True Type fonts

Alphanumeric characters

(English, Japanese, Korean, Germany, French, Spanish, Simplified Chinese and

Traditional Chinese characters can be displayed using the screen creation tool

GTWIN.)

Straight lines, continuous straight lines, squares, circles, ovals, arcs, elliptic arcs,

fan shapes, elliptic fan shapes, beveled squares, bitmaps

Approx. 250 screens (monochrome LCD type)

Screen numbers that can be set: Base screens No. 00 to 3FF

* Number of screens that can be registered varies depending on registered

contents.

Messages, lamps, switches, data, bar graphs, keyboard, line graphs

Note2)

Recipe functionm Flow display function, Write device function,

Note2)

Alarm history function

, Multi language exchange function

PLC can be communicated with personal computer by connecting computer to

TOOL port and PLC to COM. port. (This function is not available for PLCs

manufactured by other companies.)

Clock Note1)

1.2.4 Touch Key

Item GT11 specifications

Touch key Analog touch key (resistive film type)

Touch key operation 0.5 N or less

Touch key life Min. 10

6

Note1) The GT01 touch-switches operate using analog resistance membrane. Do not press two or more

points on the screen at the same time. Doing so might operate a switch located between those

points if one exists.

Note2) This touch-panel is designed to be operated by touching. Please realize that the positional

accuracy of the switches is based on the size of a finger.

1.2.5 Memory

Screen data and GTWIN Configuration Settings data

Item GT11 specifications

Memory type F-ROM

Memory chapacity 1.375 Mbytes

1-6

Clock data, PLC device storage data (24 words max.) and alarm history

Item GT11 specifications

Memory SRAM

Memory backup

Lithium battery (replaceable type)

CR2032 (commercially available)

1.2.6 Serial Interface

COM.

port

TOOL

port

Item

Communications ratings

Conditions for

communications with

external devices

Transmission distance Max. 15 m (RS232C) Max. 500 m (RS422)

Protocol

Connector

Communications ratings Conforms to RS232C (Non insulation type)

Conditions for

communications with

external devices

Protocol Dedicated protocol for GT

Connector Mini-DIN (5-pin)

AIGT2030B/AIGT2030H AIGT2032B/AIGT2032H

Conforms to RS232C

(Non insulation type)

Baud rate: 9600, 19200, 38400, 57600, 115200 bps

Data bits: 7 or 8 bits

Parity: Non, Odd, Even

Stop bit: 1 bit

Supports MEW FP Series/General-purpose Serial/Mitsubishi FX

Series/Mitsubishi A (calculator link) Series/Omron SYSMAC-C

Series/Modbus (RTU)/Siemens S7-200 Series/Toshiba Machine

PROVISOR TCmini Series/Yokogawa FA-M3 Series/AllenBradly SLC500 Series/LG MASTER-K (Cnet) Series

Connector terminal base (8-pin)

* Regarding power supply voltage, please pay due consideration

to the cable length so that the applied voltage is within the

operation voltage range.

Baud rate: 9600, 19200, 115200 bps

Data bits: 8 bits

Parity: Non, Odd, Even

Stop bit: 1 bit

GT11 specifications

Conforms to RS422

(Non insulation type)

1-7

1.3 GT30 Specifications

1.3.1 General Specifications

Item GT30 specifications

Rated voltage 24 V DC

Operating voltage

range

Power consumption 10 W or less

Ambient

temperature

Ambient humidity 20 to 85% RH (at 25 °C, non-condensing)

Storage

temperature

Storage humidity 10 to 85% RH (at 25 °C, non-condensing)

Vibration resistance

Shock resistance 98 m/s2 or more, 4 times on 3 axes

Noise immunity

Static noise

resistance

Protective

construction

Weight Approx. 440 g

21.6 to 26.4 V DC

0 to +50 °C (25 V DC max. if installed horizonally)

-20 to +60 °C

10 to 55 Hz (1-minute cycle)

Amplitude: 0.75 mm, 10 min on 3 axes

1,000 V[p-p] min., pulse width 50 ns, 1µs between power supply terminals

(based on noise simulator)

5,000 V min. (panel display)

IP65 (in initial status)

Dustproof and drip-proof from front panel only (packing used on panel contact

surface) * When reattaching, replace waterproof packing.

1.3.2 Display

Item

Display STN monochrome LCD STN color LCD

Resolution 320 (W) x 240 (H) dots

Display color 2 colors (balck/white) 16 colors

Displayable area 118.18 (W) x 89.38 (H) mm

LCD life Average 50,000 hours (at 25 °C room temperature)

Backlight CFL *Average backlight service life: 50,000 hours (25 °C)

1-8

AIGT3100B AIGT3300B

GT30 specifications

Loading...

Loading...