NAiS GT01 Technical Manual

Programmable Display GT01 Technical Manual

ARCT1F381E ’03.4

http://www.naisplc.com/

Programmable Display

GT01

Technical Manual

■ Applicable Product

• GT01

This manual was created using Adobe Acrobat.

Adobe, the Adobe logo, and Acrobat are trademarks

of Adobe Systems Incorporated.

SAFETY PRECAUTIONS

[ALWAYS OBSERVE THESE PRECAUTIONS]

Before installing, operating, servicing or inspecting this product, please make sure

you have read this manual and the explanations of how procedures are carried out,

and make sure the product is used correctly.

This manual uses two safety standard levels: “WARNING” and “CAUTION”.

WARNING

Erroneous handling of an item marked with this label can cause fatal or critical

injury to the user.

•

If this product is used in applications where accidents involving bodily

injury and/or significant damage may be conceivable, measures should

be taken to ensure adequate safety, such as the use of duplicate safety

mechanisms.

•

The functions of the GT main unit should not be used to design systems

which may pose a threat to human life or which may cause severe injury

or damage. Designs should include safety mechanisms for use in the

event that switch functions do not function correctly.

•

Do not use this product in an environment where combustible gases are

present. This can cause explosion.

•

Do not dispose of it by incineration. This can cause it to explode.

CAUTION

Erroneous handling of an item marked with this label can cause injury to the

user, or physical damage to property.

•

This product should not be used outside of the stated specifications

ranges for ratings, service life, configuration factors and other

elements. This can cause abnormal generation of heat and smoke.

•

The operational force of the touch panel should be kept to 0.98 N or

lower. Operating the touch panel at a higher force could cause damage.

•

Never touch terminals while the power supply is on. This can cause

electric shock.

•

Never disassemble or alter this product. This can cause electric shock

and smoke generation.

i

How This Manual Is Configured

GT series Main Unit

Before Using the GT series

This section describes items that should be confirmed and precautions that should

be observed before the GT series are used.

Chapter 1. Specifications

This chapter contains the names and specifications of the various parts of the GT

series, as well as a table of functions, wiring diagrams, and dimensions.

Chapter 2. Installation and Wiring

Thischapter explainshow theGT series should be installedand howwiring should be

connected.

Chapter 3. Setup

Thischapter describes the setup procedures necessary when using the GT series for

the first time.

Chapter 4. Connecting and Communicating with the PLC

This chapter explains how to connect the GT series to the PLC and the FP series by

Matsushita, and how to set up communications between the units.

Chapter 5. GT series Configuration Settings

This chapter describes the configuration settings for the GT series, and how they

should be entered.

Chapter 6. Using the Various Functions

Functions such as switching GT series screens, backlighting, and buzzer control are

explained here.

Chapter 7. Servicing and Maintenance

This chapter describes servicing and maintenance procedures for the GT series, as

well as how optional items are handled.

Chapter 8. Troubleshooting

This explains what to do if there appears to be something wrong with the GT series,

or an error occurs.

Chapter 9. Documentation

Thissection includesBIN/HEX/BCD codecorrespondence tables, ASCII code tables,

cable specifications, and other information.

GT seriesTable of Contents

ii

Table of Contents

GT Series Main Unit

Before Using the GT

GT Series Usage Procedures ix..............................................

Confirming the Package Contents xi..........................................

GT Series System Configuration xiv..........................................

Products for the GT Series xv................................................

An Overview of GT01 Functions xvi...........................................

Chapter 1 Specifications

1.1 GT01 Specifications 3..................................................

1.1.1 General Specifications 3........................................

1.1.2 Display 3......................................................

1.1.3 Functions 4....................................................

1.1.4 Touch Key 4...................................................

1.1.5 Memory (1) 4..................................................

1.1.6 Interface 5....................................................

1.2 GT01 Names and Functions of Parts 6...................................

1.2.1 GT01 (front) 6.................................................

1.2.2 GT01 (rear) 6..................................................

1.2.3 Names and Functions of Parts 7.................................

1.3 Internal Wiring Connections for Ports 8...................................

1.3.1 COM. Port 8...................................................

1.3.2 TOOL Port 8...................................................

1.4 Dimensions 9.........................................................

1.4.1 GT01 Dimensions 9............................................

1.4.2 GT01 Panel Cutout Dimensions 10...............................

Chapter 2 Installation and Wiring

2.1 Installation 13.........................................................

2.1.1 Installation Environment 13......................................

2.1.2 GT01 Installation Method 15.....................................

2.2 Wiring the Power Supply 16.............................................

2.2.1 Wiring the Power Supply 16.....................................

Table of Contents

GT series

iii

2.3 Wiring the COM. Port 17................................................

2.3.1 Wiring the COM. Port 17........................................

2.3.2 Wiring Method 17..............................................

2.3.3 Precautions Concerning Wiring 18................................

GT seriesTable of Contents

iv

Chapter 3 Setup

3.1 Setup Procedure for the GT01 21........................................

3.1.1 Setup Procedure 21............................................

3.2 Setting the Basic Communication Area Between the GT01 and PLC 24.......

3.2.1 What is the Basic Communication Area? 24.......................

3.2.2 GT01 Basic Communication Area Map 26.........................

Chapter 4 Connecting and Communicating with the PLC

4.1 Connecting the FPΣ 29.................................................

4.1.1 Connecting to the TOOL Port 29.................................

4.2 Connecting the FP0 30.................................................

4.2.1 Connecting to the TOOL Port 30.................................

4.3 Connecting the FP2/FP2SH 31..........................................

4.3.1 Connecting to the TOOL Port 31.................................

4.4 Connecting the FP-M 32................................................

4.4.1 Connecting to the TOOL Port 32.................................

4.5 Automatic Communication Settings Function 33............................

4.6 Through Function 35...................................................

Chapter 5 GT01 Configuration Settings

5.1 GT01 Configuration Settings 39..........................................

5.1.1 Two Types of GT01 Configuration Settings 39......................

5.2 Entering Configuration Settings from GTWIN Screen Creation Tool 40........

5.2.1 Opening the GT Configuration Settings 40.........................

5.2.2 GT Configuration Settings: “Basic Setup” 41.......................

5.2.3 GT Configuration Settings: “Communication Parameters” 43.........

5.2.4 GT Configuration Settings: “Auto-Paging” 46......................

5.2.5 GT Configuration Settings: “Startup Screen Settings” 48.............

5.2.6 GT Configuration Settings: “Setup” 50............................

5.3 Entering Configuration Settings from the GT01 Main Unit 52.................

5.3.1 What is the System Menu? 52...................................

5.3.2 Bringing Up the System Menu 52.................................

5.3.3 Setting Mode: “Communication Parameters”

(COM. Port / TOOL Port) 53.....................................

5.3.4 Setting Mode: “Liquid Crystal Display Contrast Adjustment” (Contrast)5

5

Table of Contents

GT series

v

5.3.5 Setting Mode: “Memory Initialization” (Clear Memory) 56............

5.3.6 Test Mode: “Self-Diagnosis” 57..................................

5.3.7 Inhibiting the System Menu Display 58............................

GT seriesTable of Contents

vi

Chapter 6 How the Various Functions Are Used

6.1 Switching Screens 61..................................................

6.1.1 Switching the Screen from the PLC 61............................

6.1.2 Switching the Screen with the GT Main Unit 62.....................

6.2 Basic Communication Area to PLC and Bit Device Functions (GT01) 67.......

6.2.1 Bit Device Functions 67.........................................

Chapter 7 Servicing and Maintenance

7.1 Replacing the Front Panel Protective Sheet 71.............................

7.1.1 About the Front Panel Protective Sheet 71........................

7.1.2 Replacing the Front Panel Protective Sheet 71.....................

7.2 Replacing the Waterproof Packing 72.....................................

7.2.1 About the Waterproof Packing 72.................................

7.2.2 Replacing the Waterproof Packing 72.............................

Chapter 8 Troubleshooting

8.1 What to Do If Something Unusual Occurs (GT01) 75.......................

8.2 Error Codes and How to Handle Them 78.................................

8.2.1 About Error Codes 78...........................................

8.2.2 GT Series Error Codes 78.......................................

8.2.3 PLC Error Codes 79............................................

8.3 Table of Screen Messages 80...........................................

8.3.1 Table of GT01 Screen Messages 80..............................

Appendix Information

A.1 BIN/HEX/BCD Code Correspondence Table 83............................

A.2 ASCII Code Table 84...................................................

A.3 Cable Specifications 85.................................................

A.3.1 PLC Communication Cable: Mini-DIN 5-pin Loose-Wire

(AIGT8142) 85.................................................

GT series

vii

Before Using the GT

This section describes items that should be confirmed and precautions that should be

observedbefore the GTseriesis used. Makesureyou read thissectionbefore using the

GT series.

GT series

viii

GT Series Usage Procedures

GT series

ix

GT Series Usage Procedures

If you are using the GT series for the first time, please follow the procedure outlined

below.

Procedure For Using the GT series

1. Confirm the items included with the product. page xi

Please confirm that all of the items have been included with the product you have

purchased. Products are carefully checked before being shipped, but if you do find

anything missing, please contact your dealer.

2. Install and wire the main unit.

page 13

Install the main unit, and connect the power supply, PLC connection cable and other

wiring. When installing and wiring the product, carefully read the explanation on pages

13 to 15 concerning the installation environment,and make sure the productis installed

correctly, in an appropriate environment. For information on connecting the product to

the FP series PLC, and on entering communications settings, please see page 29 and

subsequent pages.

3. Set up the main unit.

page 21

When the product is shipped from the factory,it is set up with specifications that enable

connection to the FP series PLC. If you plan to use the product without changing these

settings,nosetupisrequired,butifyouplantochangethesettings,youwillneedtofollow

thesetupprocedureoutlinedonpage21andsubsequent pages.Particularlywithregard

to the basic communication area to the PLC and other devices, please confirm the

settings carefully and change only those that are necessary.

J Main cases in which setup is necessary

·

When the device being connected is a general-purpose serial device (such as

a computer or microcomputer board)

·

When the basic communication area for the device is different from that

set when the product is shipped

4. Check communication with the external device (PLC, etc.).

page 30

Check the connections and communication with the external device. Connections and

communication with devices in the FP series PLC vary depending on the device, so

check the information on page 30 and subsequent pages.

5. Enter the operating environment settings.

page 39

In addition to the setup described at step 4, various detailed settings can be entered for

the GT01 operating environment. Enter any necessary operating environment settings,

referring to page 39 and subsequent pages.

GT seriesGT Series Usage Procedures

x

6. Install the screen creation tool.

Install the Terminal GTWIN screen creation tool in the personal computer.

7. Create the screen contents.

Create the screen contents using the Terminal GTWIN screen creation tool, and send

the screen to the GT main unit. For information on creating screens and on operating

GTWIN, please refer to the Help function that comes with GTWIN.

8. Test the operation.

Connect the GT main unit containing the screen data to an external device (PLC or

general-purpose serial device), and check the operation contents.

Confirming the Package Contents

GT series

xi

Confirming the Package Contents

Checkto make sure the necessary itemshave been included with the product youhave

purchased.

Items Included with the GT01 (AIGT0030B1, AIGT0030H1)

Main unit

Set of attachment fittings

Attachment fittings x 4 Attachment screws x 4

Installation instructions

Please read these instructions carefully

before using the product.

Waterproof packing

One piece of waterproof packing has

been attached to unit.

Thefollowing maintenancepartisavailable: AIGT081 (10 piece set)

CAUTION

•

There is a film over the front panel protective sheet. Remove this film

when using the unit. For instructions on removing the film, see page

71.

•

Front panel protective sheets for replacement are available as a

separate purchase (AIGT083). Please see page xv.

•

Waterproof packings for replacement are available as a separate

purchase (AIGT081). Please see page xv.

GT seriesConfirming the Package Contents

xii

Items Included with the Terminal GTWIN English-language version

(AIGT8001V2)

Terminal GTWIN CD-ROM

Software usage license agreement and user card

Readthe “Software usagelicense agreement” carefully, and fill in the user card. Please

return the user card to Matsushita.

GT10/GT30 Technical Manual GT01 Technical Manual

This is the manual you are currently reading. It contains instructions on installing and

booting GTWIN. Please read it carefully before using your product.

CAUTION

About the software usage license agreement and user card

•

Before using GTWIN, read the “Software usage license agreement”

carefully.

•

The license agreement comes as a set with the user card. Fill in the

user card, and return it to Matsushita. The user card is necessary in

order to obtain support services such as future version upgrades and

technical support. Don’t forget to return the card in order to be

eligible for such services.

•

The serial number needed in order to install GTWIN is found on the

user card. Please make a copy of it before returning the card, and

keep it in a safe place.

Confirming the Package Contents

GT series

xiii

Items Included With the PLC Connection Cable (AIGT8142 / AIP81842)

Cable

Oneofthe following twocableshasbeenincludedwiththe product youhavepurchased.

AIGT8142

(2 m/6.56 ft)

AIP81842

(2 m/6.56 ft)

Wiring diagram

The package includes a diagram that shows the internal wiring of the cables pictured

above.

REFERENCE

For information on connecting and wiring the cables shown above and

the PLC, please refer to Chapter 4, “Connecting and Communicating

with the PLC”.

Items Included with the Front Panel Protective Sheet (AIGT080)

Front panel protective sheet

Optional protective sheets are available to protect and keep the GT series touch panel

clean.Pleaseuseifyouwishtoprotectthefrontpanelfrom dirt and prevent degradation.

Installation instructions

Please read these instructions carefully before installing the product.

REFERENCE

For information on replacing the front panel protective sheet, please

refer to page 71.

GT seriesGT Series System Configuration

xiv

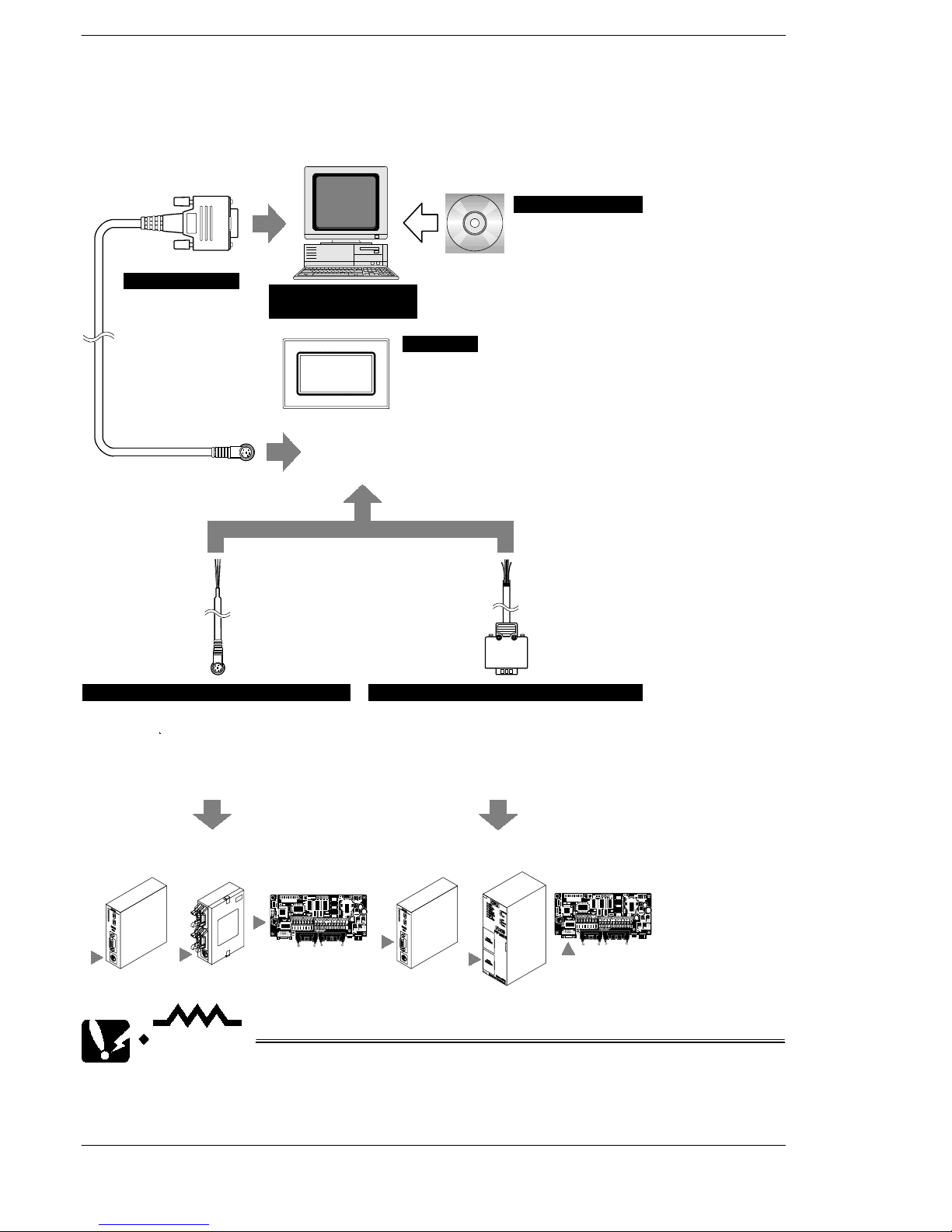

GT Series System Configuration

The following devices are necessary in order to use the GT series.

Connecting cable

Screen transfer cable

D-sub 9-pin -

mini-DIN 5-pin

(3 m/9.84 ft)

Product No.: AFC8503

Commercially available

personal computer

Screen creation tool

Terminal GTWIN

English-language version

Windows 95/98/2000/NT supported

GTWIN CD-ROM

Technical Manual included as accessory

Product No.: AIGT8001V2

GT01

STN monochrome liquid crystal display

Product No.: AIGT0030B1, AIGT0030H1

Main unit

Communication cable

PLC connecting cable (1)

For connection to TOOL port of FP0 / FP2 /

FP2SH / FP-M

Mini-DIN 5-pin loose-wire cable

(2 m/6.56 ft)

Product No.: AIGT8192

Connecting to the TOOL port of the FP0 /

FP2 / FP2SH / FP-M

Communication cable

PLC connecting cable (2)

For connection to COM. port of FP1 / FP2 / FP2SH / FP-M /

FP10SH, TOOL port of FP10SH, and computer communication unit

of FP2 / FP3

D-sub 9-pin loose-wire cable (2 m/6.56 ft)

Product No.: AIP81842

Connecting to the COM. port of FP1 / FP2 / FP2SH / FP-M /

FP10SH and computer communication unit of FP2/FP3

CAUTION

Connecting to the COM. port of the PLC

Because connecting the unit to the COM. port of the FPΣ/FP0 requires a

loose-wire connection, this cable is not available.

Products for the GT Series

GT series

xv

Products for the GT Series

Products types

Item Name Contents

Product

No.

Programmable display unit

RS232C, Black (Charcoal gray) AIGT0030B1

GT01mai

nunit

main unit

RS232C, ashgray AIGT0030H1

Terminal

GTWIN

English- langua

ge version

- “Terminal GTWIN” English-language screen creation tool

(CD-ROM)

- Set of GT01 Technical manuals (English)

AIGT8001V2

Screen transfer

cable

Cable for transferring data between GTWIN and GT (3 m/9.84 ft) AFC8503

PLC

connecting

cable (1)

For connection to TOOL port of FP0 / FPΣ / FP2 / FP2SH / FP-M

Mini-DIN 5-pin loose-wire cable (2 m/6.56 ft)

AIGT8142

PLC

connecting

cable (2)

For connection to COM. port of FP10SH, and other PLC COM. port

D-sub 9-pin loose-wire cable (2 m/6.56 ft)

AIP81842

Front panel

protective

sheet

Front panel protective sheet for GT01 (for replacement).

Teninset.

* 1 sheet included with GT01 when shipped.

AIGT080

CAUTION

•

Connecting to the COM. port of the FP0

Because connecting the unit to the COM. port of the FPΣ/FP0 requires

a loose-wire connection, this cable is not available.

•

About the manual packed with the Terminal GTWIN English-language

version

The manual you are currently reading is included as an accessory

with the Terminal GTWIN English-language version. This manual

contains information only on procedures such as installing GTWIN.

For detailed information on operating GTWIN, please refer to the Help

function in the software.

GT seriesAn Overview of GT01 Functions

xvi

An Overview of GT01 Functions

3 colors can be displayed, to reflect the status

Various messages and graphics can be displayed on the liquid crystal display screen,

whichmeasures 128x 64dots, aswell aslamps, internalPLC data,graphs, clocks, and

otherinformation.Inaddition,backlightingisavailableinthreecolors,green,orange,and

red, so that information can be color-coded. This makes it easy to grasp information at

a glance.

Analog touch panel provided

GT01 comes with a compact touch panel. Switches and a keyboard can be laid out, so

operationis possibleby simplytouching the screen. Since this is ananalog touchpanel,

the freedom with which you can change the size of and layout switches is greater than

that possible with digital switches.

Screens can be created easily, using special tools

Screen contents can be easily created using the dedicated Terminal GTWIN tool (runs

on Windows 95/98/2000/NT/XP). Screens are put together simply by selecting parts

from a library and positioning them in place.

An Overview of GT01 Functions

GT series

xvii

Ultra-thin body is only 24 mm/0.94 inch deep

The in-panel depth is a mere 24 mm/0.94 inch (including the fittings), configuring an

ultra-thin body and taking up a bare minimum of space.

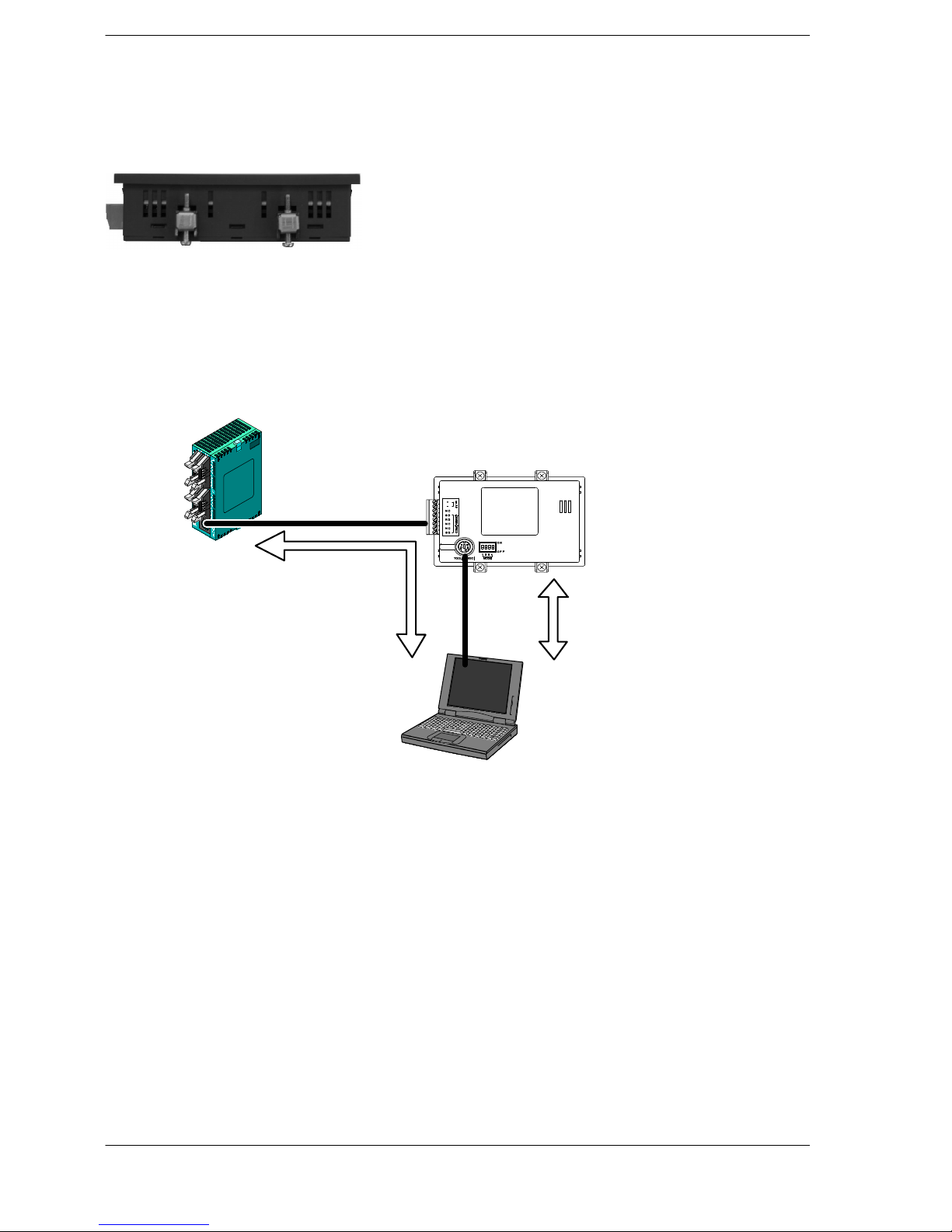

Through function is convenient for debugging

Ifconnectionsaremadeasshowninthe diagram,aconvenient“through” functionmakes

itpossible to transferdata from theGT01 and carryoutPLCdebugging atthesame time

that communication is going on between the GT01 and the FP series PLC. This

significantly boosts efficiency in the workplace.

PLC

GT01

Cable connected to

the TOOL port of the

PLC.

Screen

transfer

cable

AFC8503

PLC debugging

Screen data

being sent

and received

Screen creation tool GTWIN

FP series programming tool

FPWIN GR

Personal computer

The FPWIN GR can be booted on

the computer being used to edit GT

series screens, and PLC programs

edited and monitored through the

GT series.

Maintenance is easier than ever before

LEDsare usedfor thebacklight. Thiseliminates the need for troublesome replacement.

Also, screen data is saved to F-ROM and batteries are not used. (There is no clock

function.) You may safely use the GT01 for a very long time.

GT seriesAn Overview of GT01 Functions

xviii

Chapter 1

Specifications

GT seriesSpecifications

2

SpecificationsGTseries

3

1.1 GT01 Specifications

1.1 GT01 Specifications

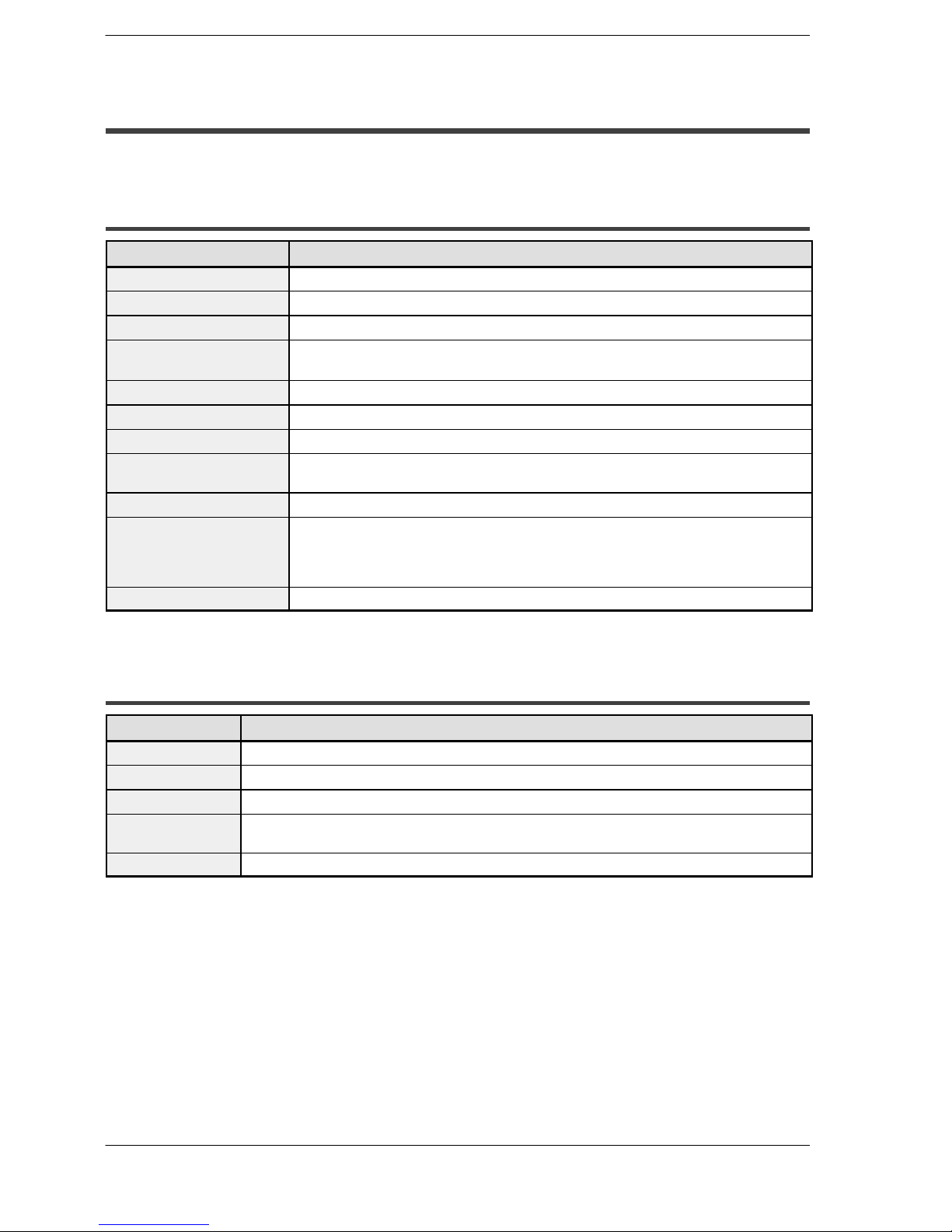

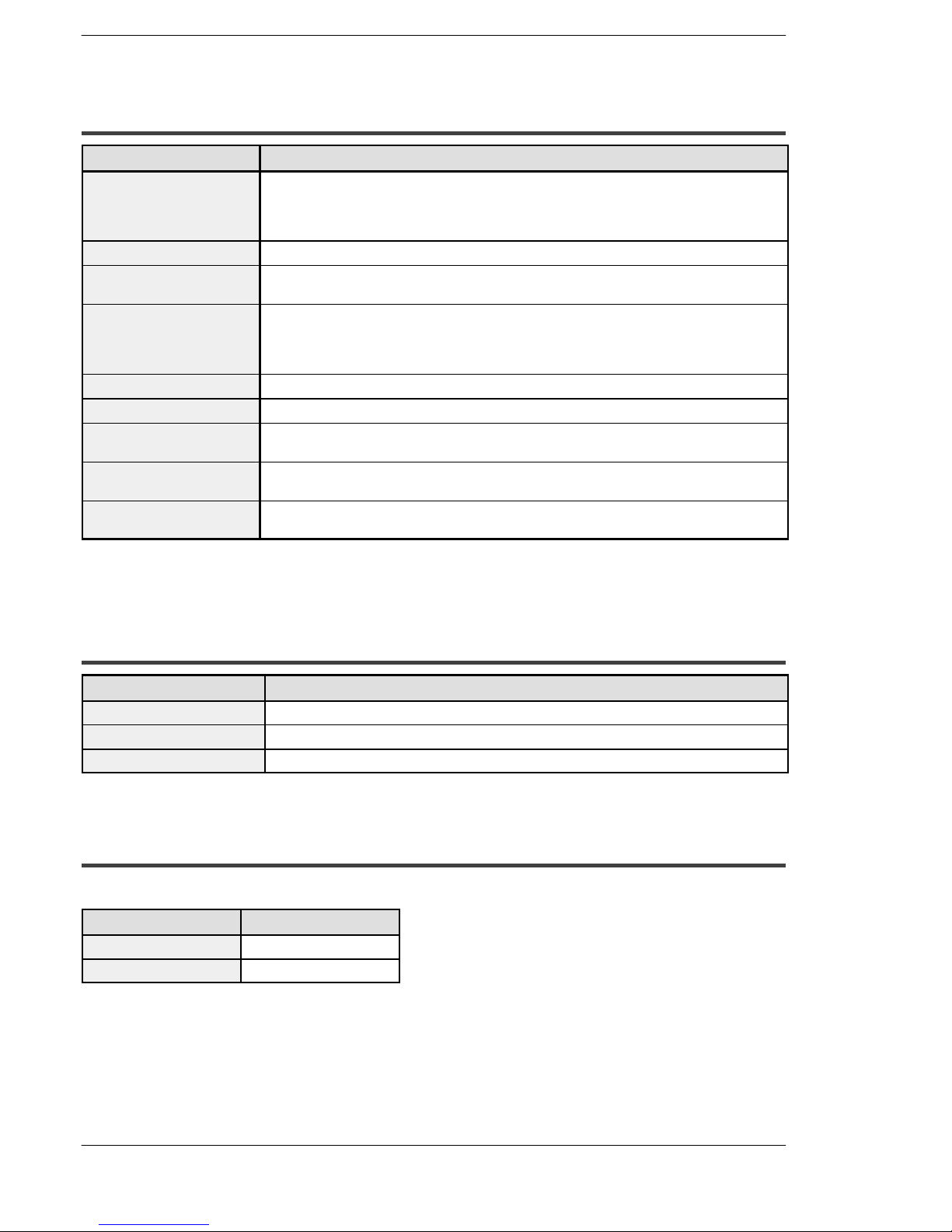

1.1.1 General Specifications

Item GT01 specifications

Rated voltage 5VDC

Operating voltage range 4.5 to 5.5 V DC

Power consumption 1 W max.

Ambient temperature

0°Cto50°C/32°F to 122°F

(5 V DC max. if installed horizontally)

Ambient humidity 20% RH to 85% RH (non condensing)

Storage temperature

-20°Cto60°C/-4°F to 140°F

Storage humidity 10% RH to 85% RH (non condensing)

Vibration resistance

10Hz to 55 Hz (1-minute cycle)

Amplitude: 0.75 mm, 10 min on 3 axes

Shock resistance 98 m/s2min., 4 times on 3 axes

Protective construction

IP65 (in initial status)

Dustproof and drip-proof from front panel only (packing used on panel contact surface)

* When reattaching, replace waterproof packing.

Mass Approx. 160 g/5.644 oz

1.1.2 Display

I

tem

GT01

spec

ifi

cations

Display STN monochrome LCD

Resolution 128 (W) x 64 (H) dots

Display color 2 colors (black/white)

Displayable area

78.5 (W) x 37.1 (H) mm

3.09 (W) inch x 1.46 (H) inch

Backlight 3-color LED backlight (green, red, orange)

GT seriesSpecifications

4

1.1 GT01 Specifications

1.1.3 Functions

Item GT01 specifications

Displayable fonts

Fixed fonts: 1/4 width (8 x 8), half width (16 x 8), full width (16 x 16)

Half width and full width characters can be displayed at same width, doubled width, or

quadrupled width

True Type fonts

Character types Alphanumeric characters

Graphics

Straight lines, continuous straight lines, squares, circles, ovals, arcs, elliptic arcs, fan

shapes, elliptic fan shapes, beveled squares, bitmaps

Number of screens

Screen numbers that can be set: Base screens No. 00 to FF (HEX)

Number of screens that can be registered varies depending on registered contents.

No. of parts that can be registered for one screen: 256 (Note: this includes the number of message part replacements.)

Part functions Messages, lamps, switches, data, bar graphs, clocks, keyboard

Contrast

adjustment Contrast can be adjusted using touch panel operation

Automatic

communication settings

Settings for communication between dedicated software and PLC set automatically by

connecting cable

Debugging functions

Through function (PLC can be debugged from personal computer by connecting computer to TOOL port and PLC to COM. port)

Screen creation

Dedicated software Terminal GTWIN used.

Applicable OS: Windows 95/98/2000/NT/XP

* Clock functions are not available.

1.1.4 Touch Key

Item GT01 specifications

Touch key Analog touch key

Touch key operation 0.5 N max.

Touch key life Min. 10

6

1.1.5 Memory (1)

Screen data and GTWIN Configuration Settings data

I

tem

GT01

spec

ifi

cations

Memory type F-ROM

Memory capacity 384 kbytes

SpecificationsGTseries

5

1.1 GT01 Specifications

1.1.6 Interface

Item GT01 specifications

Communications ratings Conforms to RS232C

Baud rate: 9600, 19200, 38400, 57600, 115200 bits/s

COM.

Port

Conditi

onsfor

communications with

external devices

Data bits: 7 or 8 bits

Parity: None, Odd, Even

Stop bits: 1 bit

Protocol FP series supported/general-purpose RS232C supported

Connector Connector terminal base (8-pin)

Communications ratings Conforms to RS232C

TOOL

port

Conditions for

communications with

external devices

Baud rate: 9600, 19200, 115200 bits/s

Data bits: 8 bits

Parity: None, Odd, Even

Stop bits: 1 bit

Protocol Dedicated protocol

Connector

Mini-DIN (5-pin)

GT seriesSpecifications

6

1.2 GT01 Names and Functions of Parts

1.2 GT01 Names and Functions of Parts

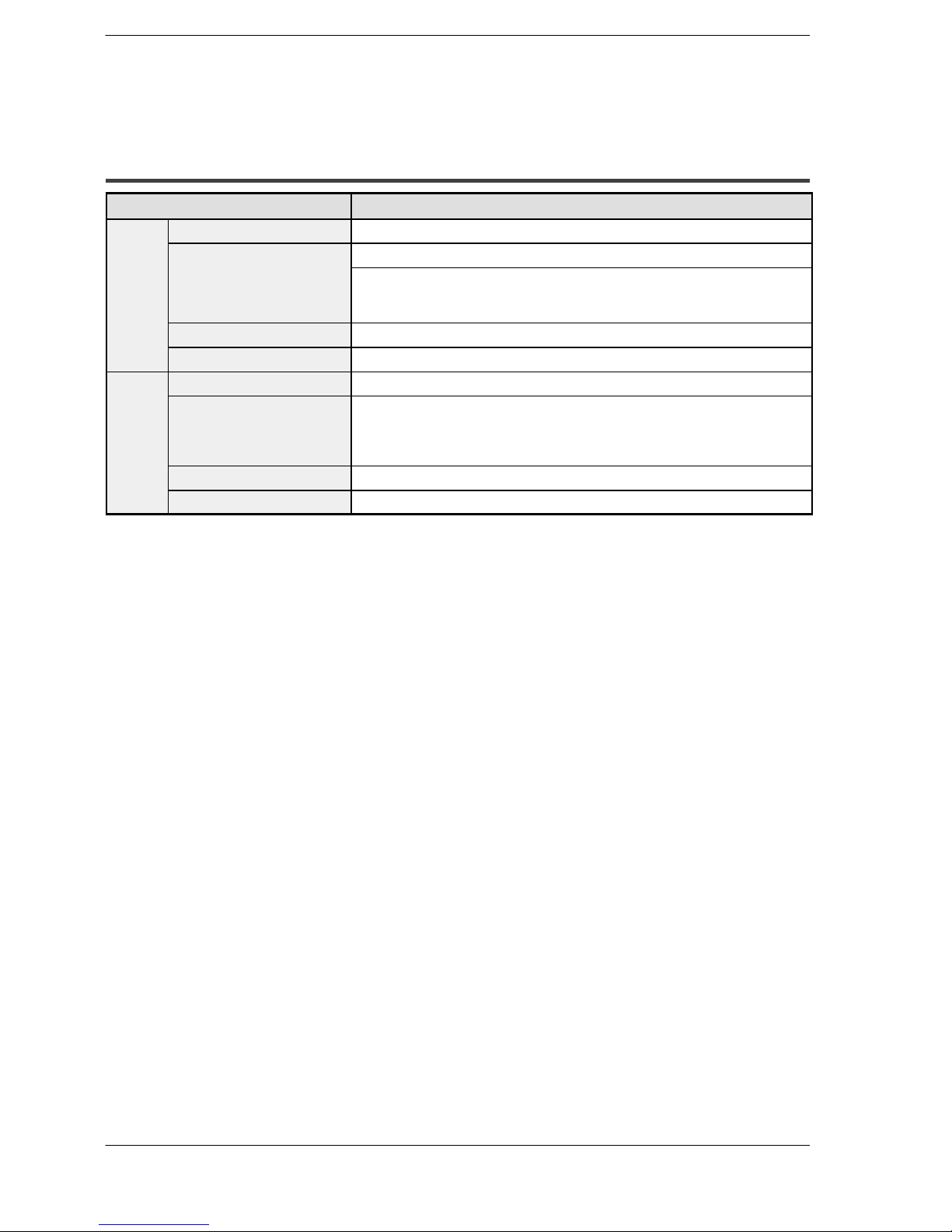

1.2.1 GT01 (front)

F

Liquid crystal display panel

(touch panel)

1

1.2.2 GT01 (rear)

F

COM. port and power supply terminal

2

F

Waterproof packing

5

F

TOOL port

3

F

4

Operation mode setting switches

SpecificationsGTseries

7

1.2 GT01 Names and Functions of Parts

1.2.3 Names and Functions of Parts

(1) Liquid crystal display panel / touch panel

Various screens are displayed here. A touch panel is provided on the liquid crystal

display panel, and switches can be operated and data entered simply by touching the

panel.

Optionalprotectivesheetsarealsoavailableto protectthetouchpanel and keepitclean.

(A sheet is affixed to the touch panel to protect it from scratches when shipping. Please

remove it before using the GT01.)

(2) COM. port (PLC/external device connection port) and power supply terminal

This is an RS232C port for connectingto a PLC, hostPC, or microcomputer board, and

a 5 V DC operation power supply terminal. (The GT01 is shipped with one

communications connector.)

(3) TOOL port (GTWIN connection port)

This port is used to connect a personal computer in which the screen creation tool

GTWIN has been installed, using a dedicated cable (AFC8503).

(4) Operation mode setting switches

With the GT01, screen data and configuration settings data are stored in an internal

F-ROM, so no battery backup is needed.

The operation mode setting switch has a switch that prohibits access to the System

Menu.

Switch no. Function OFF ON

1

Usage inhibited Should always be in the OFF position

when unit is used

2 Inhibits system menu shift Shift possible Shift inhibited

3 Usage inhibited Should always be in the OFF position

4

when unit is used

(5) Waterproof packing

This assures that the front panel is waterproof. One piece is provided as an accessory

when the unit is shipped.

Operation mode setting

switches

(settings when shipped)

GT seriesSpecifications

8

1.3 Internal Wiring Connections for Ports

1.3 Internal Wiring Connections for Ports

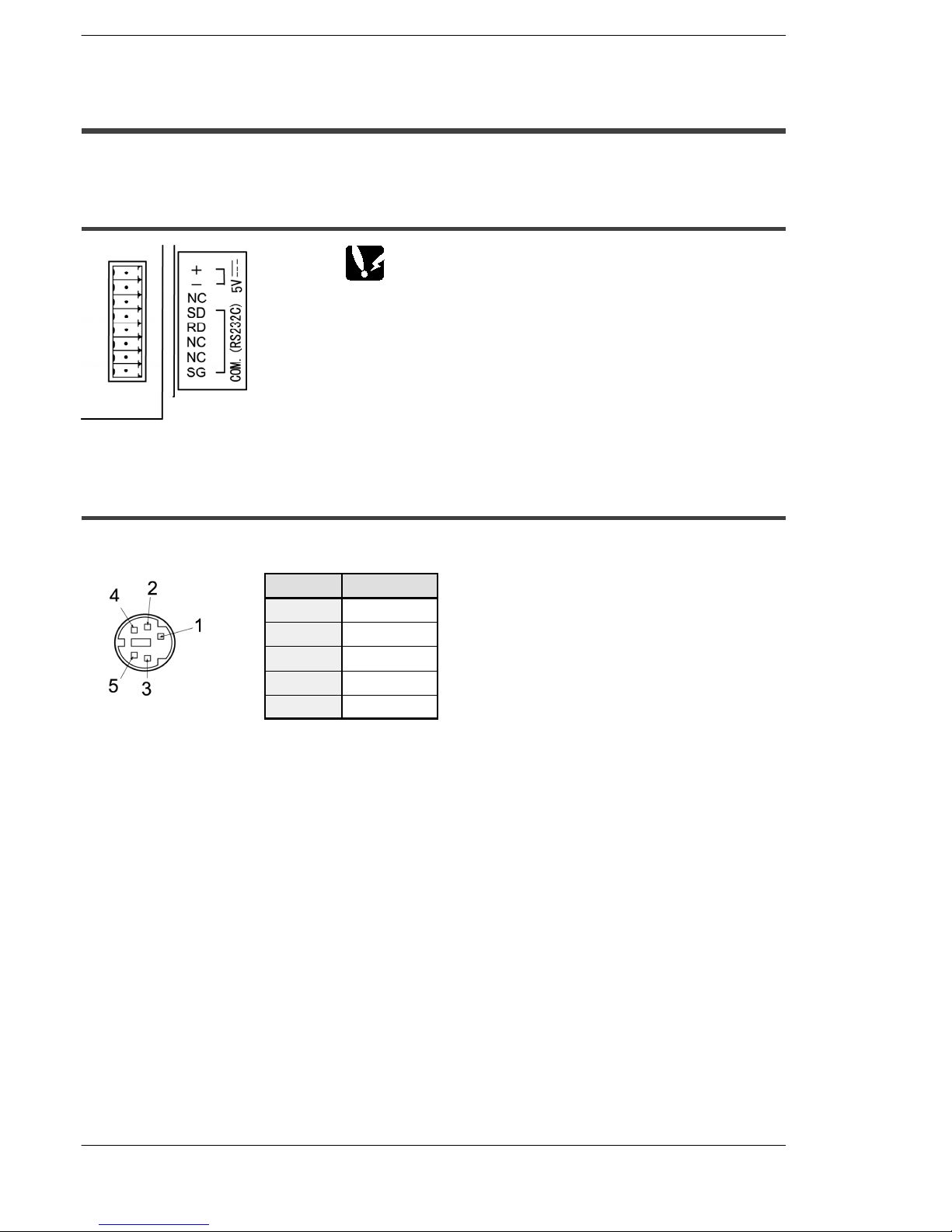

1.3.1 COM. Port

Wiring and cables should be laid out in such a way

that cables are not affected by external noise. Also,

shielded wiring should be used for cables.

1.3.2 TOOL Port

Pin No. Contents

1 SG

2 SD

3 RD

4 N.C.

5 N.C.

SpecificationsGTseries

9

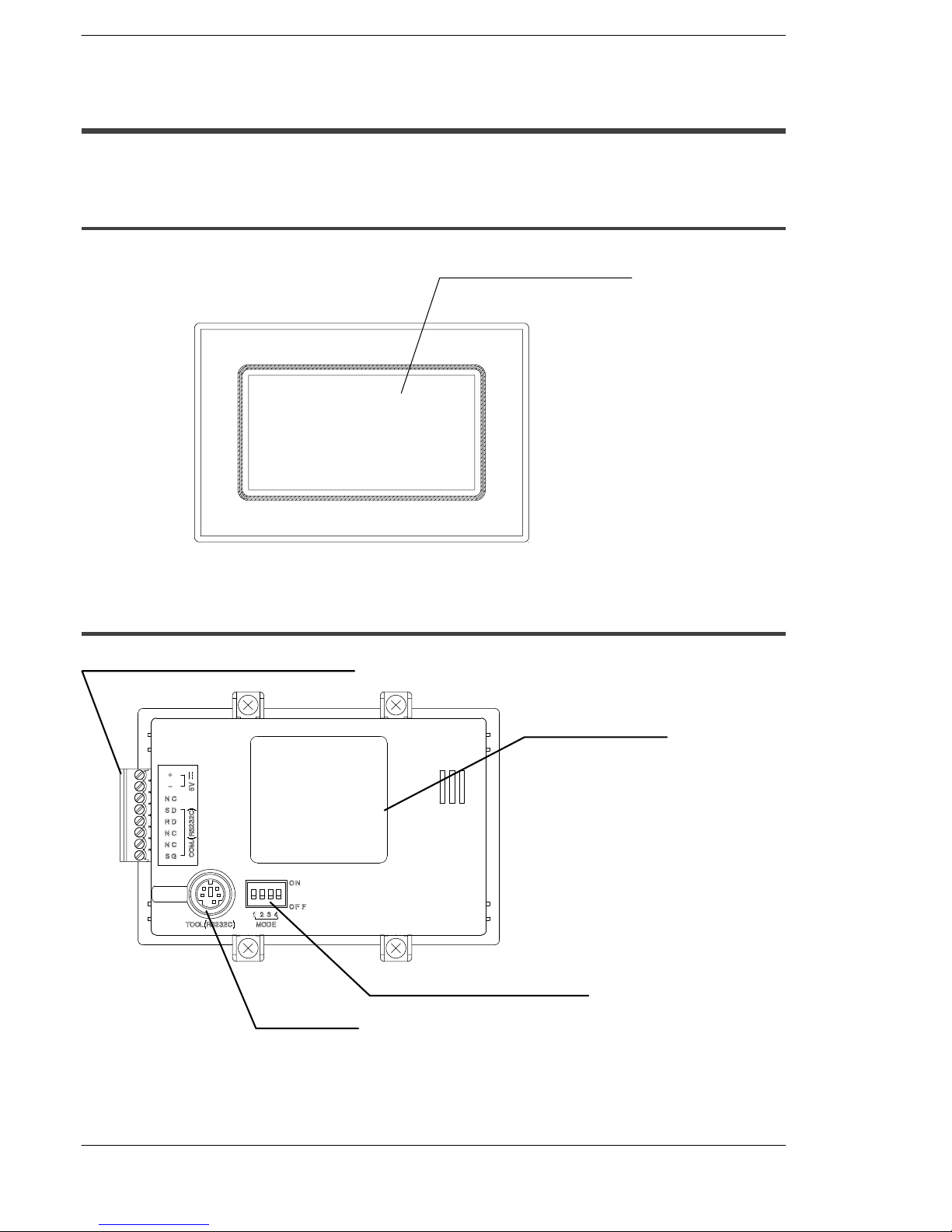

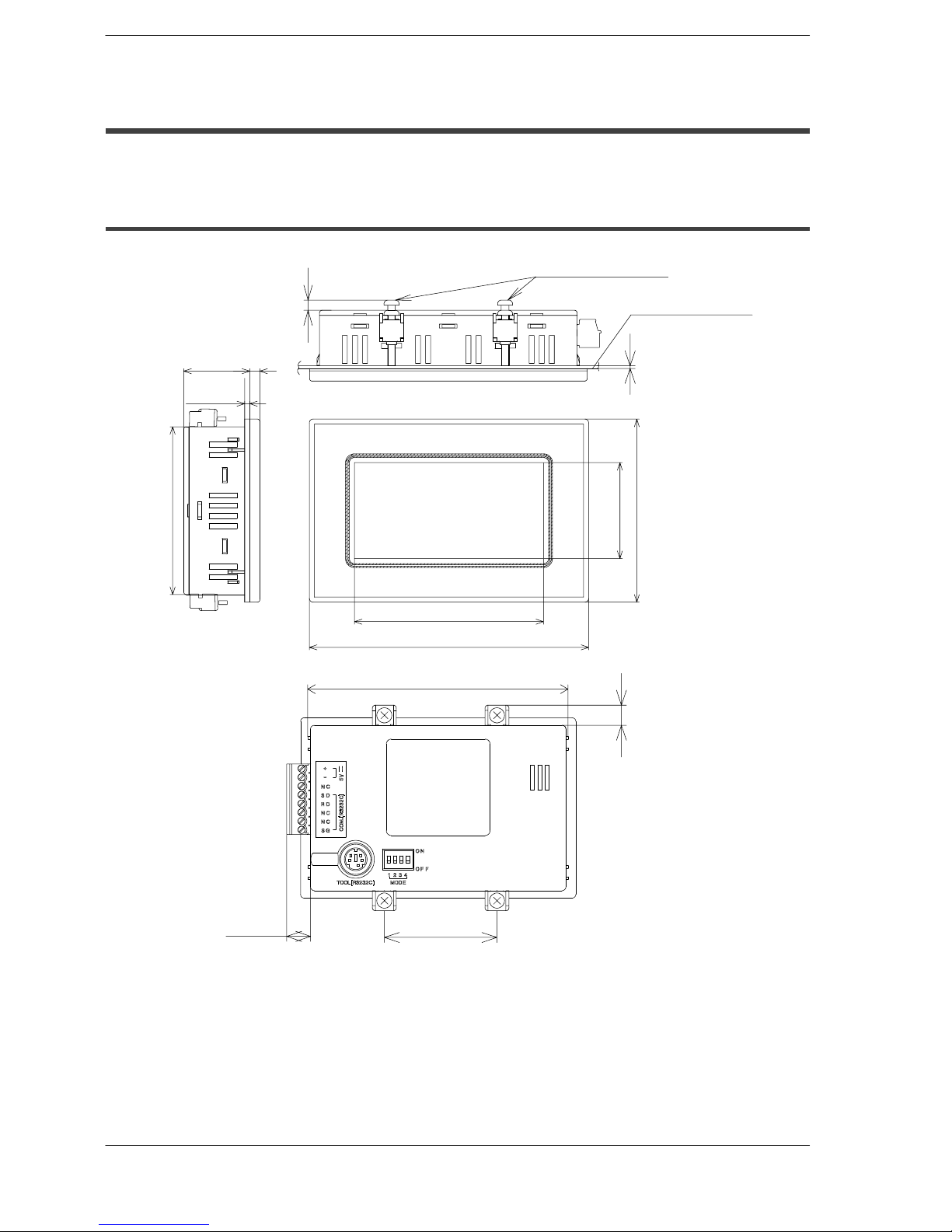

1.4 Dimensions

1.4 Dimensions

1.4.1 GT01 Dimensions

45 / 1.77

110 / 4.33

72 / 2.83

4/

0.16

4 / 0.16

1 / 0.04

37.7 / 1.48

(Display unit)

74.5 / 2.93 (Display unit)

2 / 0.08

(Packing)

66 / 2.60

24 / 0.94

104 / 4.09

9.5 / 0.37

Panel thickness

5 mm 0.20 inch

Mounting panel

8 / 0.31

GT seriesSpecifications

10

1.4 Dimensions

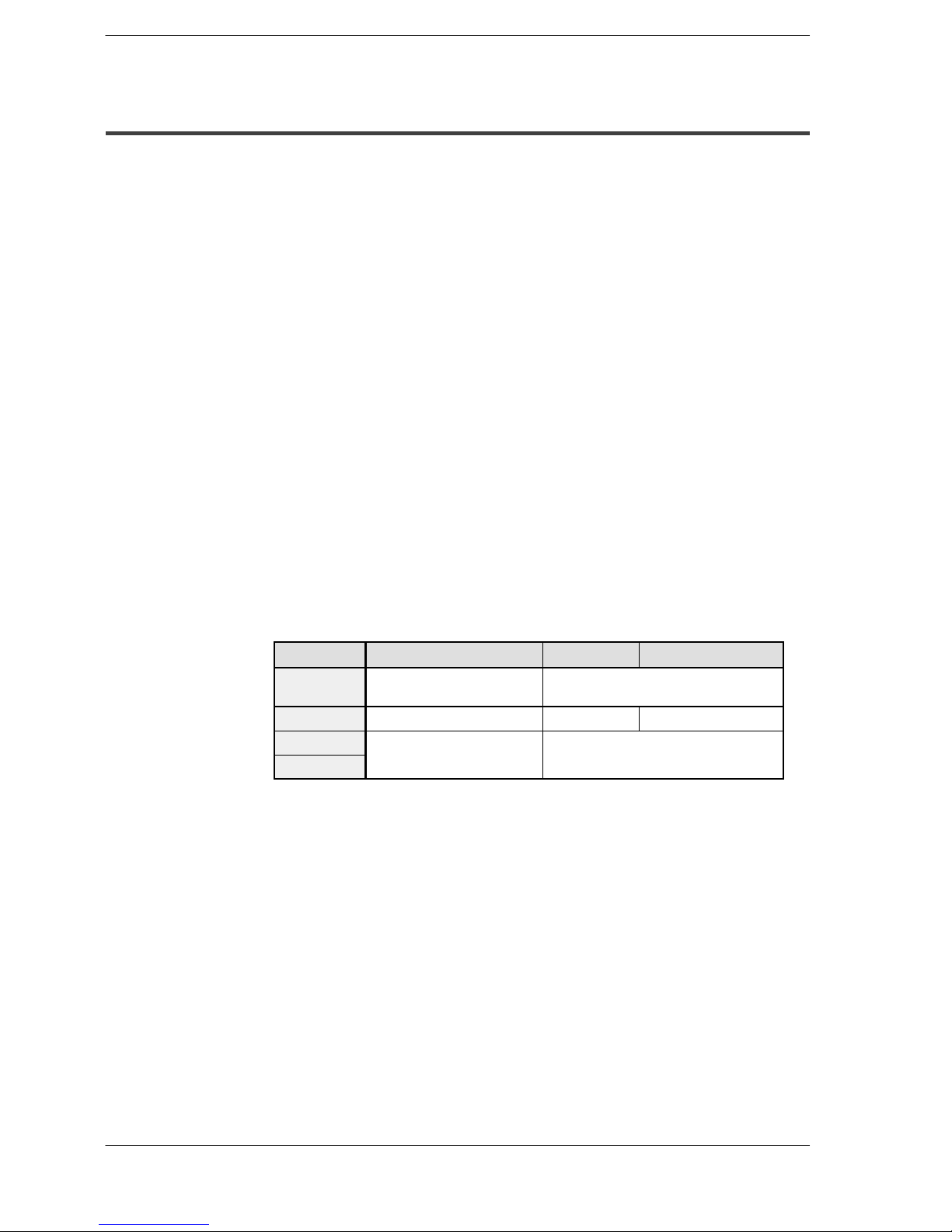

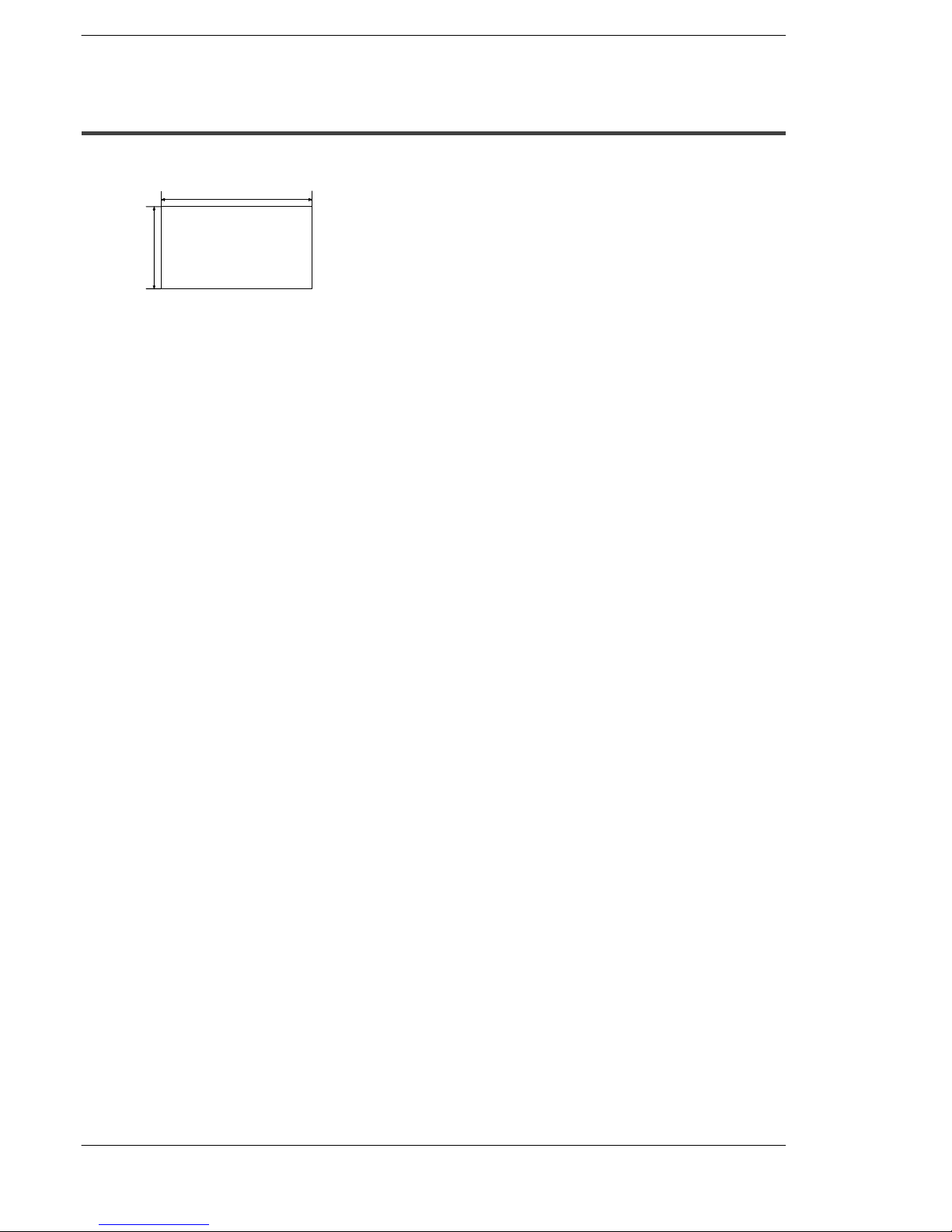

1.4.2 GT01 Panel Cutout Dimensions

The panel cutout dimensions of the GT01 are as shown below.

Applicable panel thickness:

1.0mm to 5.0mm

0.04inch to 0.20inch

105.00/ 4.13

+0.04

/ 2.64

+0.04

67.0

+

1

+1

0

*During installation when there will be other parts installed to the panel and wiring

performed, we recommend that you provide a 30 to 50 mm clearance around the GT01

as a precaution against potential cable damage and to improve work efficiency when

performing the installation.

Caution 1: Be absolutely sure not to seal the slits on the GT01.

Loading...

Loading...