NAiS FP, FPS, FPG-C32T, FPG-C32T2, FPG-C24R2 User Manual

PROGRAMMABLE CONTROLLER

User’s Manual

[Applicable PLC]

FPΣControl units

FPG-C32T

•

FPG-C32T2

•

FPG-C24R2

•

FP

Σ

This manual was created using Adobe Acrobat.

Adobe, the Adobe logo, and Acrobat are trademarks

of Adobe Systems Incorporated.

http://www.naisplc.com

Table of Contents

FPΣ

i

Table of Contents

Before You Start viii....................................................

Programming Tool Restrictions xi........................................

Compatibility with the FP0 xii............................................

Chapter 1 Functions and Restrictions of the Unit

1.1 Features and Functions of the Unit 1 - 3...............................

1.2 Unit Types 1 - 6....................................................

1.2.1 FPΣ Control Unit 1 - 6.......................................

1.2.2 FPΣ Expansion Unit 1 - 6.....................................

1.2.3 Units for FP0 and FPΣ 1 - 6..................................

1.2.4 Communication Cassette 1 - 6................................

1.3 Restrictions on Unit Combinations 1 - 7................................

1.3.1 Restrictions on the Number of Expansion Units

(for FP0 expansion unit) 1

-

7.................................

1.3.2 Restrictions on the Number of Units for Expansion

(for FPΣ expansion unit) 1-8.................................

1.4 Programming Tools 1 - 9.............................................

1.4.1 Tools Needed for Programming 1 - 9..........................

1.4.2 Software Environment and Suitable Cable 1 - 9.................

Chapter 2 Specifications and Functions of Control Unit

2.1 Parts and Functions 2 - 3............................................

2.1.1 Parts and Functions 2 - 3....................................

2.1.2 Tool Port Specification 2 - 6..................................

2.1.3 Communication Cassette 2 - 6................................

2.2 Input and Output Specifications 2 - 7..................................

2.2.1 Input Specifications 2 - 7.....................................

2.2.2 Output Specifications 2 - 9...................................

2.3 Terminal Layout Diagram 2 - 12........................................

2.3.1 Control Unit (for C32T and C32T2) 2 - 12.......................

2.3.2 Control Unit (for C24R2) 2 - 12.................................

Chapter 3 Expansion

3.1 Type of Expansion Unit 3 - 3.........................................

Table of Contents FPΣ

ii

3.2 Expansion Method of Units for FP0 and FPΣ 3 - 4.......................

3.3 Expansion Method of FPΣ Expansion Unit 3 - 5.........................

3.4 Specifications of FPΣ Expansion Unit 3 - 6.............................

3.4.1 FPΣ Expansion I/O Unit 3 - 6.................................

Chapter 4 I/O Allocation

4.1 I/O Allocation 4 - 3..................................................

4.1.1 I/O Number of FPΣ Control Unit 4 - 3..........................

4.1.2 I/O Number of FPΣ Expansion Unit (for left side expansion) 4 - 4..

4.1.3 I/O Number of FP0 Expansion Unit (for right side expansion) 4 - 5.

4.1.4 I/O Number of FP0 Analog I/O Unit (for right side expansion) 4 - 5.

4.1.5 I/O Number of FP0 A/D Conversion Unit

(for right side expansion) 4 - 5................................

4.1.6 I/O Number of FP0 I/O Link Unit (for right side expansion) 4 - 6...

Chapter 5 Installation and Wiring

5.1 Installation 5 - 3....................................................

5.1.1 Installation Environment and Space 5 - 3.......................

5.1.2 Installation and Removal 5 - 6................................

5.2 Wiring of Power Supply 5 - 9.........................................

5.2.1 Wiring of Power Supply 5 - 9.................................

5.2.2 Grounding 5 - 11.............................................

5.3 Wiring of Input and Output 5 - 12......................................

5.3.1 Input Wiring 5 - 12...........................................

5.3.2 Output Wiring 5 - 15..........................................

5.3.3 Precautions Regarding Input and Output Wirings 5 - 16...........

5.4 Wiring of MIL Connector Type 5 - 17...................................

5.5 Wiring of Terminal Block Type 5 - 20....................................

5.6 Safety Measures 5 - 22...............................................

5.6.1 Safety Measures 5 - 22.......................................

5.6.2 Momentary Power Failures 5 - 23..............................

5.6.3 Protection of Power Supply and Output Sections 5 - 23...........

5.7 Backup Battery 5 - 24................................................

5.7.1 Installation of Backup Battery 5 - 24............................

5.7.2 System Register Setting 5 - 25.................................

5.7.3 Lifetime of Backup Battery 5 - 26...............................

Table of Contents

FPΣ

iii

Chapter 6 High-speed Counter and Pulse Output Functions

6.1 Overview of Each Functions 6 - 3.....................................

6.1.1 Three Functions that Use Built-in High-speed Counter 6 - 3......

6.1.2 Performance of Built-in High-speed Counter 6 - 4...............

6.2 Function Specifications and Restricted Items 6 - 5......................

6.2.1 Table of Specifications 6 - 5..................................

6.2.2 Function being Used and Restrictions 6 - 7.....................

6.2.3 Booting Time 6 - 9..........................................

6.3 High-speed Counter Function 6 - 10...................................

6.3.1 Overview of High-speed Counter Function 6 - 10.................

6.3.2 Types of Input Modes 6 - 10...................................

6.3.3 Min. Input Pulse Width 6 - 12..................................

6.3.4 I/O Allocation 6 - 12..........................................

6.3.5 Instructions Used with High-speed Counter Function 6 - 13........

6.3.6 Sample Program 6 - 16.......................................

6.4 Pulse Output Function 6 - 20..........................................

6.4.1 Overview of Pulse Output Function 6 - 20.......................

6.4.2 T ypes of Pulse Output Method 6 - 21...........................

6.4.3 I/O Allocation 6 - 22..........................................

6.4.4 Control Mode 6 - 23..........................................

6.4.5 Instructions Used with Pulse Output Function 6 - 24..............

6.4.6 Sample Program for Positioning Control 6 - 43...................

6.5 PWM Output Function 6 - 56..........................................

6.5.1 Overview of PWM Output Function 6 - 56.......................

6.5.2 Instruction Used with PWM Output Function 6 - 56...............

Chapter 7 Communication Cassette

7.1 Communication Functions of FPΣ 7 - 3................................

7.1.1 Functions of Communication Cassette 7 - 3....................

7.2 Communication Cassette 7 - 6........................................

7.2.1 T ype of Communication Cassette 7 - 6.........................

7.2.2 Names and Principle Applications of the Ports 7 - 7..............

7.2.3 Communication Specifications of Communication Cassette 7 - 8..

7.3 Attachment of Communication Cassette 7 - 10...........................

7.3.1 Attachment Procedure 7 - 10..................................

Table of Contents

FPΣ

iv

7.4 Wiring of Communication Cassette 7 - 11...............................

7.4.1 Wiring the Connector with the Communication Cassette 7 - 11.....

7.4.2 Tool for Tightening Communication Connector Terminal Block 7 - 12

7.4.3 Wiring Method 7 - 12.........................................

7.4.4 Cautions Regarding Wiring 7 - 12..............................

Chapter 8 Communication Function 1 Computer Link

8.1 Computer Link 8 - 3.................................................

8.1.1 Overview of Function 8 - 3...................................

8.1.2 Explanation of Operation when Using a Computer Link 8 - 4......

8.1.3 Format of Command and Response 8 - 5......................

8.1.4 Types of Commands that Can Be Used 8 - 8...................

8.1.5 Setting the Communication Parameters when

Using a Computer Link 8 - 10..........................................

8.1.6 Restriction 8 - 10.............................................

8.2 Connection Example with External Device 8 - 11.........................

8.2.1 Connection Example with External Device

(1:1 communication with computer) 8 - 11......................

8.2.2 Connection Example with External Device

(1:1 communication with programmable display “GT10/GT30”) 8 - 14

8.3 Computer Link (1:N communication) 8 - 18..............................

8.3.1 Overview of 1:N Communication 8 - 18.........................

8.3.2 Communication Cassette Used for 1:N Communication 8 - 18......

8.3.3 Settings of System Register and Unit No. 8 - 19..................

8.3.4 Connection with External Device 8 - 22.........................

Chapter 9 Communication Function 2 General-purpose

Serial Communication

9.1 General-purpose Serial Communication 9 - 3..........................

9.1.1 Overview of Function 9 - 3...................................

9.1.2 Program of General-purpose Serial Communication 9 - 5........

9.1.3 Communication Parameter Settings when Using

General-purpose Serial Communications 9

-

6..................

9.2 Overview of Communication with External Devices 9 - 8.................

9.2.1 Data Transmission to External Device 9 - 8.....................

9.2.2 Receiving Data from External Device 9 - 12......................

Table of Contents

FPΣ

v

9.3 Connection Example with External Devices 9 - 16........................

9.3.1 Connection Example with External Device

(1:1 communication with Micro-Imagechecker) 9 - 16.............

9.3.2 Connection Example with External Device

(1:1 communication with FP series PLC) 9 - 22..................

9.4 Data Transmitted and Received with the FPΣ 9 - 29......................

9.5 1:N Communication 9 - 31............................................

9.5.1 Overview of 1:N Communication 9 - 31.........................

9.5.2 Communication Cassette Used with 1 : N Communication 9 - 31...

9.5.3 Setting of System Register 9 - 32..............................

9.6 Flag Operations When Using Serial Communication 9 - 33................

9.6.1 When “STX not exist” is Set for Start Code and “CR” is

Set for End Code 9 - 33.......................................

9.6.2 When “STX” is Set for Start Code and “ETX” is Set for

End Code 9 - 35.............................................

9.7 Changing the Communication Mode of COM. Port 9 - 37..................

Chapter 10 Communication Function 3 PLC Link Function

10.1 PLC Link 10 - 3......................................................

10.1.1 Overview of Function 10 - 3...................................

10.2 Communication Parameter Settings 10 - 5..............................

10.2.1 Setting of Communication Mode 10 - 5..........................

10.2.2 Setting of Unit No. 10 - 6......................................

10.2.3 Allocation of Link Relay and Link Register 10 - 10.................

10.2.4 Setting the Largest Station Number for a PLC Link 10 - 16..........

10.3 Monitoring When a PLC Link is Being Used 10 - 17........................

10.3.1 Monitoring Using Relays 10 - 17.................................

10.4 Connection Example of PLC Link 10 - 18.................................

10.4.1 Using a PLC Link with Three FPΣ Units 10 - 18....................

10.4.2 Sample Programs 10 - 21......................................

10.5 PLC Link Response Time 10 - 22.......................................

10.5.1 PLC Link Response Time 10 - 22................................

10.5.2 Shortening the Transmission Cycle Time When There are

Stations That Have not been Added to the Link 10

-

25.............

10.5.3 Error Detection Time for Transmission Assurance Relays 10 - 26....

Table of Contents

FPΣ

vi

Chapter 11 Other Functions

11.1 Analog Potentiometer 11 - 3...........................................

11.1.1 Overview of Analog Potentiometer 11 - 3........................

11.1.2 Example Showing How the Analog Potentiometers are Used 11 - 3.

11.2 Clock/Calendar Function 11 - 4........................................

11.2.1 Area for Clock/Calendar Function 11 - 4.........................

11.2.2 Setting of Clock/Calendar Function 11 - 4.......................

11.2.3 Precautions Concerning Backup of Clock/Calendar Data 11 - 5....

11.2.4 Example Showing the Clock/Calendar being Used 11 - 6..........

Chapter 12 Self-Diagnostic and Troubleshooting

12.1 Self-Diagnostic Function 12 - 3........................................

12.1.1 LED Display for Status Condition 12 - 3.........................

12.1.2 Operation on Error 12 - 4......................................

12.2 Troubleshooting 12 - 5................................................

12.2.1 If the ERROR/ALARM LED Flashes 12 - 5.......................

12.2.2 If the ERROR/ALARM LED Lights 12 - 7........................

12.2.3 If None of the LEDs Light 12 - 7................................

12.2.4 If Outputting does not Occur as Desired 12 - 8...................

12.2.5 If a Protect Error Message Appears 12 - 10.......................

12.2.6 If the Program Mode does not Change to RUN 12 - 10.............

12.2.7 If a Transmission Error has Occurred 12 - 11.....................

Chapter 13 Specifications

13.1 Table of Specifications 13 - 3..........................................

13.1.1 General Specifications 13 - 3..................................

13.1.2 Performance Specifications 13 - 5..............................

13.2 I/O No. Allocation 13 - 10..............................................

13.3 Relays, Memory Areas and Constants 13 - 12............................

13.4 Table of System Registers 13 - 14.......................................

13.4.1 System Registers 13 - 14......................................

13.4.2 Table of System Registers 13 - 16...............................

13.5 Table of Special Internal Relays 13 - 21..................................

13.6 Table of Special Data Registers 13 - 28..................................

Table of Contents

FPΣ

vii

13.7 Table of Error Cords 13 - 42............................................

13.7.1 Table of Syntax Check Error 13 - 42.............................

13.7.2 Table of Self-Diagnostic Error 13 - 43............................

13.8 Table of Instructions 13 - 44............................................

13.9 MEWTOCOL-COM Communication Commands 13 - 66...................

13.10 Hexadecimal/Binary/BCD 13 - 67.......................................

13.11 ASCII Codes 13 - 68..................................................

13.12Dimensions 13 - 69...................................................

13.12.1 Control Unit 13 - 69............................................

13.12.2 Expansion Unit 13 - 70.........................................

Index

I-1..............................................................

Record of changes

R-1..............................................

Before You Start FPΣ

viii

Before You Start

Installation environment

Do not use the FPΣ unit where it will be exposed to the following:

Direct sunlight and ambient temperatures outside the

range of 0_Cto55_C/32_F to 131_F.

Ambient humidity outside the range of 30% to 85% RH

and sudden temperature changes causing condensation.

Inflammable or corresive gas.

Excessive vibration or shock.

Excessive airborne dust, metal particles or salts.

Water or oil in any from including spray or mist.

Benzine, paint thinner, alcohol or other organic solvents

or strong alkaline solutions such as ammonia or caustic

soda.

Influence from power transmission lines, high voltage

equipment, power cables, power equipment, radio

transmitters, or any other equipment that would generate

high switching surges.

Static electricity

Before touching the unit, always touch a grounded piece

of metal in order to discharge static electricity.

In dry locations, excessive static electricity can cause

problems.

Cleaning

Do not use thinner based cleaners because they deform

the unit case and fade the colors.

Power supplies

An insulated power supply with an internal protective

circuit should be used. The power supply for the control

unit operation is a non-insulated circuit, so if an

incorrect voltage is directly applied, the internal circuit

may be damaged or destroyed.

If using a power supply without a protective circuit,

power should be supplied through a protective element

such as a fuse.

Before You Start

FPΣ

ix

Power supply sequence

Have the power supply sequence such that the power

supply of the control unit turns off before the power

supply for input and output.

If the power supply for input and output is turned off

before the power supply of the control unit, the control

unit will detect the input fluctuations and may begin an

unscheduled operation.

Before turning on the power

Whenturningonthepowerfor the first time, be sure to taketheprecautionsgivenbelow.

When performing installation, check to make sure that

there are no scraps of wiring, particularly conductive

fragments, adhering to the unit.

Verify that the power supply wiring, I/O wiring, and power

supply voltage are all correct.

Sufficiently tighten the installation screws and terminal

screws.

Set the mode selector to PROG. mode.

Before entering a program

Be sure to perform a program clear operation before entering a program.

Operation procedure when using FPWIN GR Ver.2

Procedure:

1. Select “On

line Edit Mode” on the FPWIN GR

“On l

ine” menu.

2. Select “Cl

ear Program” on the “Edit” menu.

3. When the confirmation dialog box is displayed, click

on “Y

es” to clear the program.

Before You Start

FPΣ

x

Request concerning program storage

To prevent the accidental loss of programs, the user should consider the following

measures.

Drafting of documents

To avoid accidentally losing programs, destroying files, or

overwriting the contents of a file, documents should be

printed out and then saved.

Specifying the password carefully

The password setting is designed to avoid programs being

accidentally overwritten. If the password is forgotten,

however, it will be impossible to overwrite the program even if

you want to. Also, if a password is forcibly bypassed, the

program is deleted. When specifying the password, note it in

the specifications manual or in another safe location in case

it is forgotten at some point.

Programming Tool Restrictions

FPΣ

xi

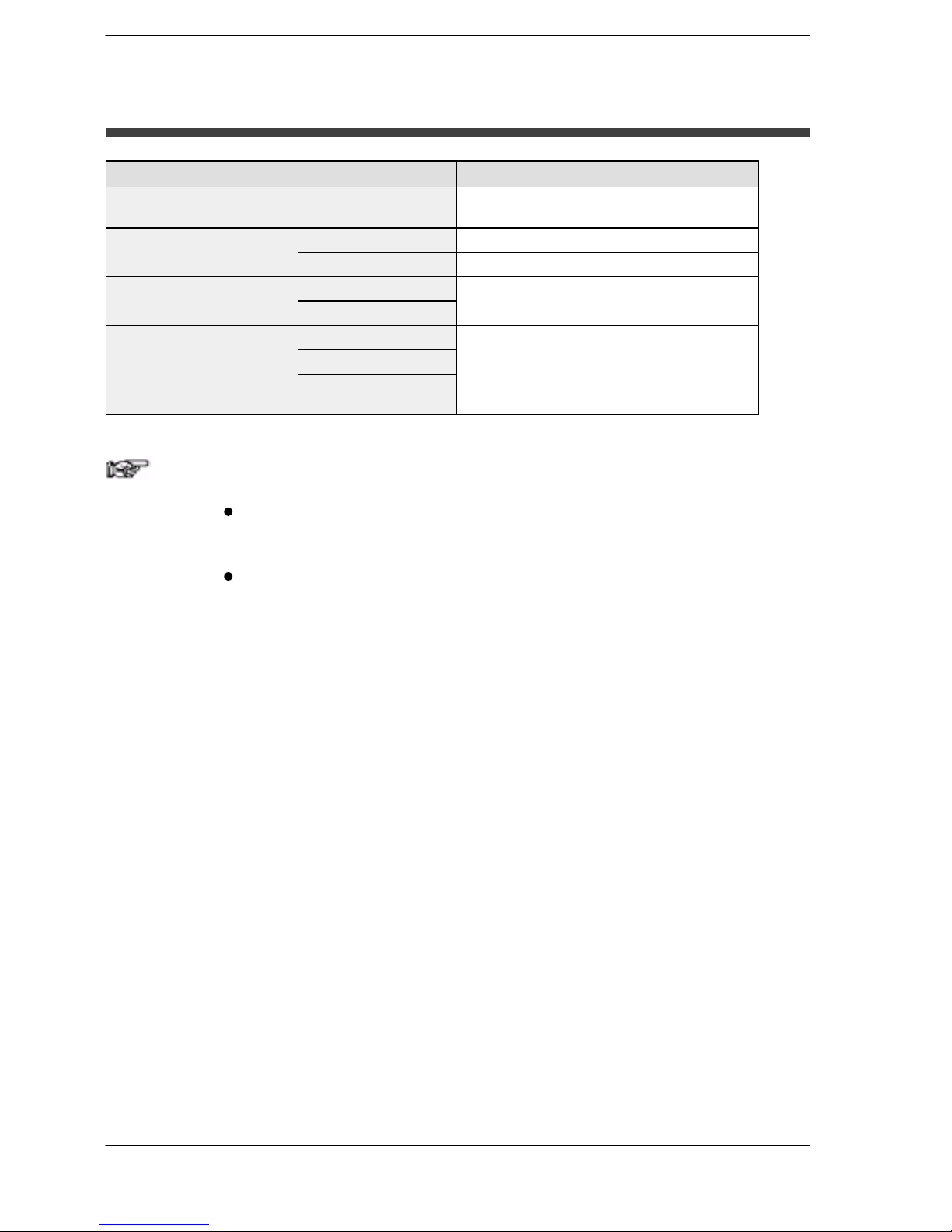

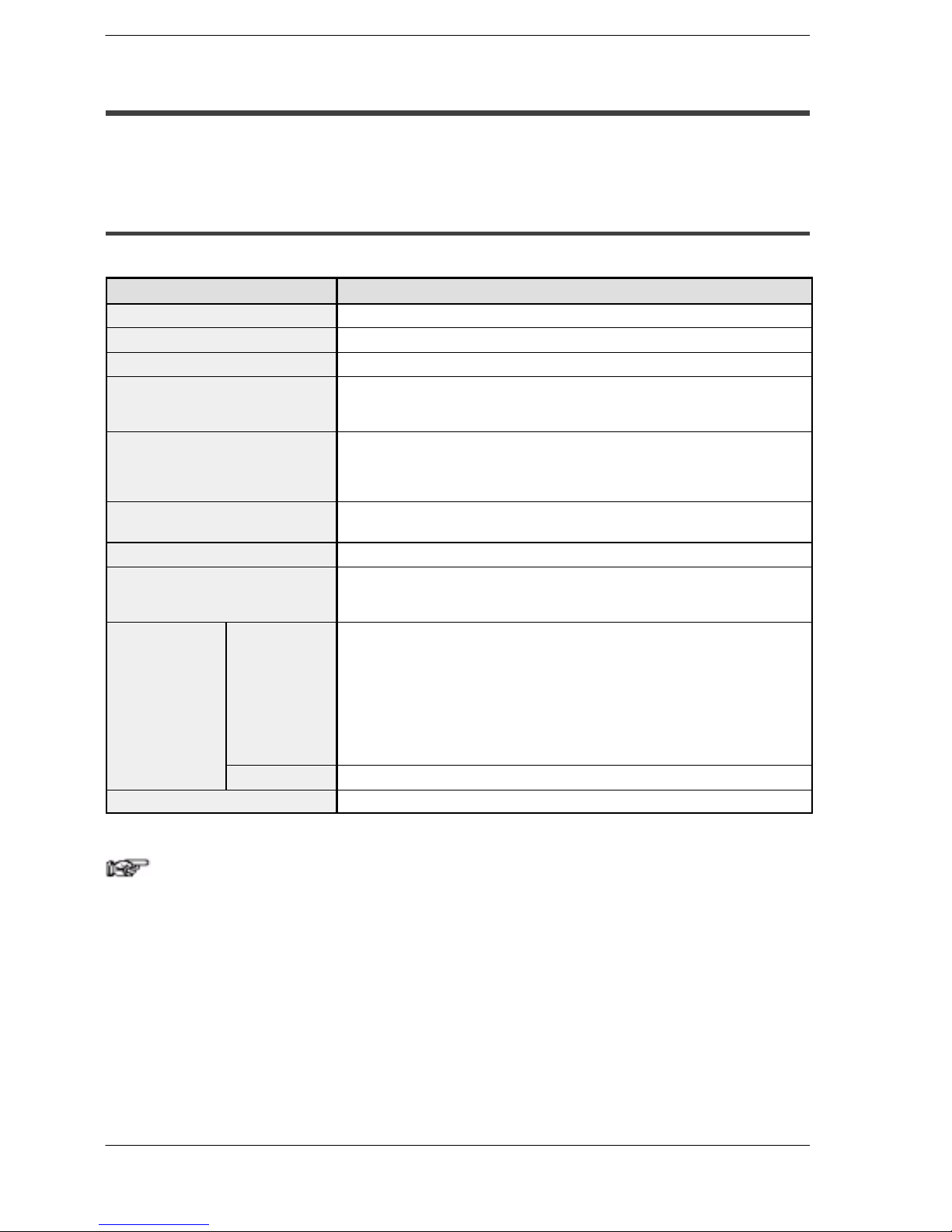

Programming Tool Restrictions

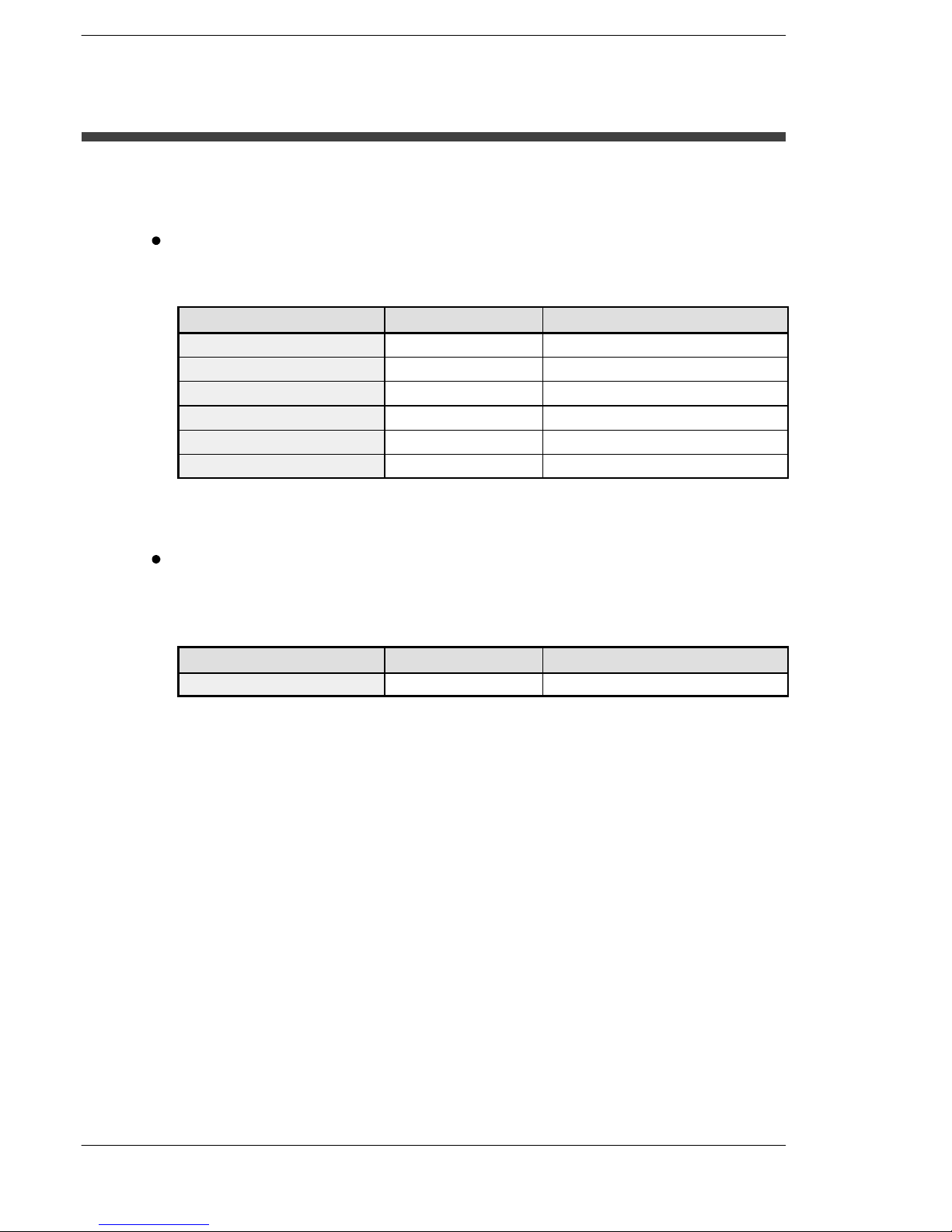

Type of programming tool Instruction used/function restrictions

Windows software

Conforms to IEC61131-3

FPWIN Pro Ver.4

All instructions and functions can be used.

FPWIN GR Ver.2

All instructions and functions can be used.

W

ind

ows software

FPWIN GR Ver.1

Not used

NPST-GR Ver.4

MS-DOSsof

tware

NPST-GR Ver.3

N

ot use

d

AFP1114V2

Handy programming unit

AFP1114

y

pg g

(FP programmer)

AFP1112A

AFP1112

Not

used

Notes

Precautions concerning programming tools

Programming tools used with the FPΣ require FPWIN Pro Ver. 4 or

later or Ver . 2 or a subsequent version of the FPWIN GR. Please be

aware that other tools cannot be used.

Either “FPWIN Pro Ver.4.1 or later” or “FPWIN GR Ver. 2.1 or later”

are necessary for use the C32T2 and C24R2 types control unit.

Compatibility with the FP0

FPΣ

xii

Compatibility with the FP0

Program compatibility

The following points require attention if using FP0 programs on the FPΣ.

Pulse output function

With the FPΣ, please be aware that the following changes

have been made to instructions concerning pulse output.

Instruction For the FP0 For the FPΣ

Trapezoidal control

F168 (SPD1) F171 (SPDH)

Jog feed

F169 (PLS) F172 (PLSH)

Data table control

None F174 (SP0H)

Linear interpolation control

None F175 (SPSH)

Circular interpolation control

None F176 (SPCH)

PWM output

F170 (PWM) F173 (PWMH)

* Linear and circular interpolation control can be used only with the

FPΣ Control Unit C32T2.

Serial data communication function

With the FPΣ, please be aware that the following changes

have been made to instructions concerning serial data

communication.

Instruction For the FP0 For the FPΣ

Serial data communication

F144 (TRNS) F159 (MTRN)

* The F159 (MTRN) instruction is used only with an FPΣ in which

the conventional F144 (TRNS) instruction has been set up to

correspond to multiple communication ports. Please be aware

that the conventional F144 (TRNS) instruction cannot be used

with the FPΣ.

Chapter 1

Functions and Restrictions of the Unit

1.1 Features and Functions of the Unit 1 - 3................

1.2 Unit Types 1 - 6......................................

1.3 Restrictions on Unit Combinations 1 - 7.................

1.4 Programming Tools 1 - 9..............................

FPΣFunctions and Restrictions of the Unit

1-2

FPΣ 1.1 Features and Functions of the Unit

1-3

1.1 Features and Functions of the Unit

Powerful control capabilities

All of the functions of a mid-scale PLC are packed into the compact body size of the

32-point type FP0. A program capacity of 12 k steps is provided as a standard feature,

so you never have to worry about how much memory is left as you’re programming. In

addition, 32 k words are reserved for data registers, so large volumes of data can be

compiled and multiple operations can be processed without running out of memory.

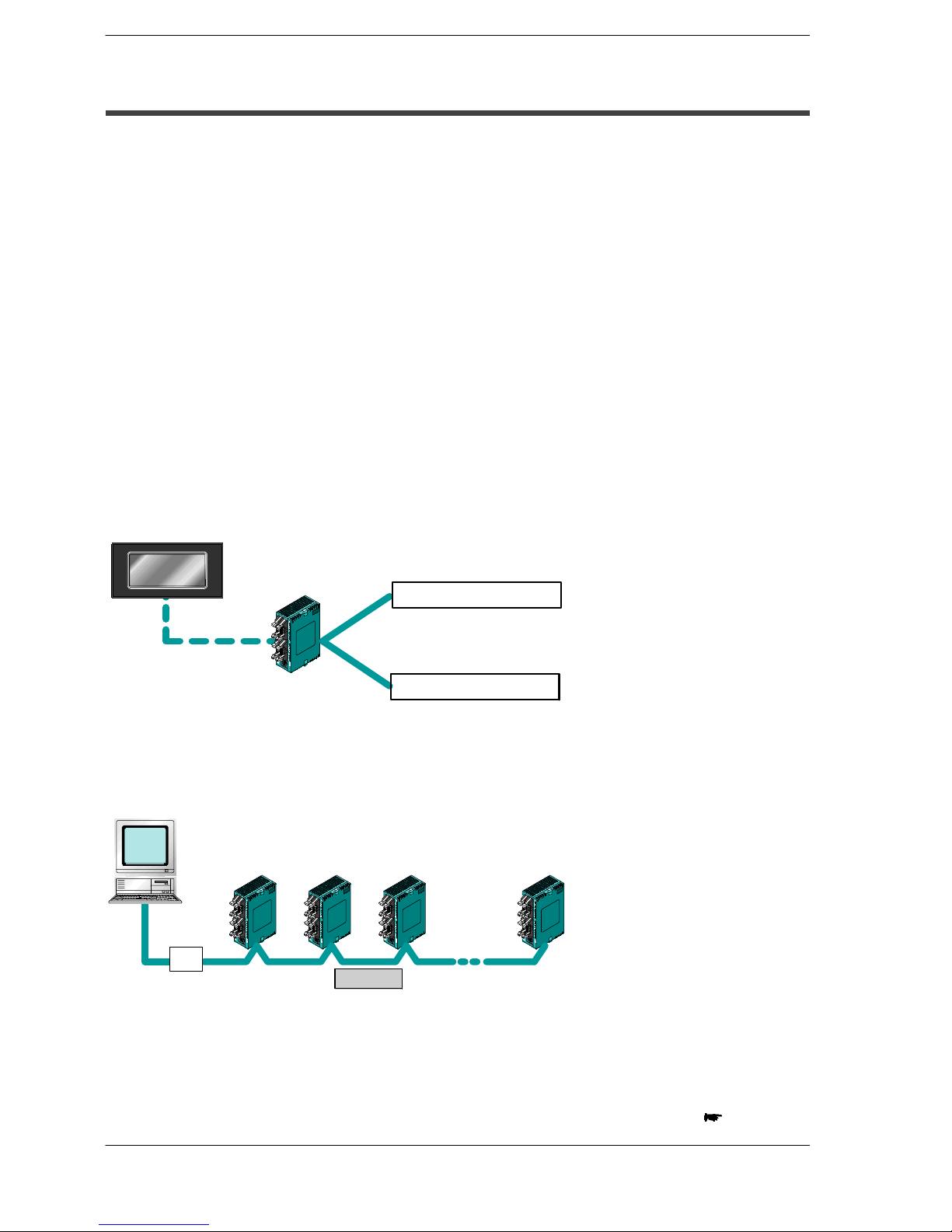

A full range of communication functions

Using the Tool port (RS232C) provided as a standard feature on the main unit,

communication can be carried out with a display panel or computer. Additionally,

communication cassettes with RS232C and RS485 interfaces are available as an

option. Installing a 2-channel RS232C type communication cassette in the FPΣ makes

it possible to connect two devices with RS232C port. A full lineup of communication

functions means you can also work with 1:N communication and PLC link function (up

to 16 units).

Controlling two devices with RS232C port with one FP

Σ

Display panel

The Toolport can beused

toconnecta displaypanel

or other device.

Device with RS232C port

When using the 2-channel RS232C type communication cassette

Two devices with RS232C port can be connected.

Device with RS232C port

FPΣ

Figure 1: Features-communication (RS232C)

1:N communication possible with up to 99 stations (units)

Communication is possible with up to 99 units.

Commercial adapter

Computer

When using the 1-channel RS485 type communication cassette

FPΣ

No.1

FPΣ

No.2

FPΣ

No.3

FPΣ

No.99

RS485

Figure 2: Features-communication (C-NET)

next page

FPΣ

Functions and Restrictions of the Unit

1-4

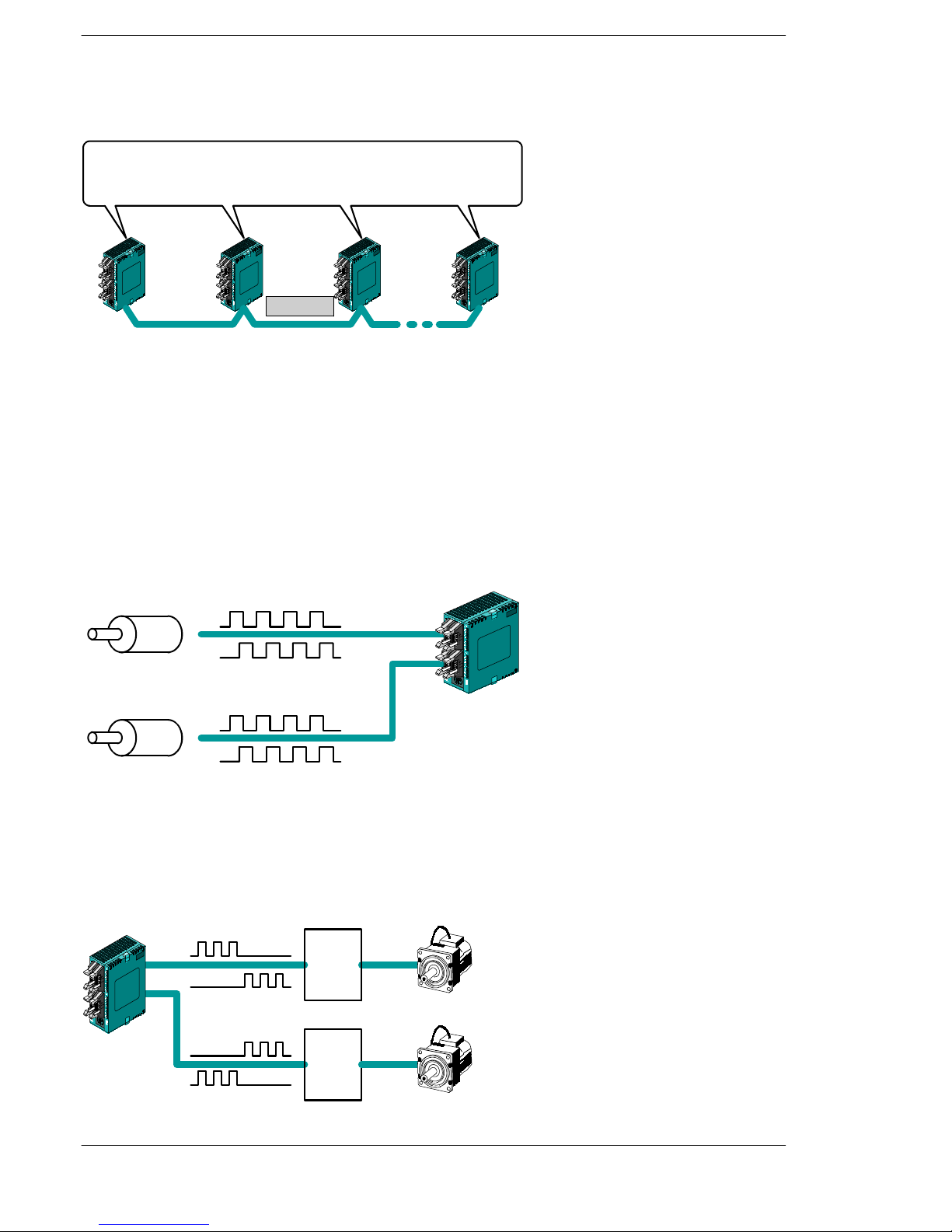

Data can be shared among up to 16 FPΣ units using

the PLC link function.

Data can be shared among the various PLCs using the PLC link function.

When using the 1-channel RS485 type communication cassette

FPΣ

No.1

FPΣ

No.2

FPΣ

No.3

FPΣ

No.16

RS485

Figure 3: Features-communication (PLC link)

Positioning control supported through high-speed counter and pulse output

A high-speed counter and pulse output functions are provided as standard features.

The pulse output function supports frequencies of up to 100 kHz, enabling positioning

control using a stepping motor or servo motor.

Measurement using high-speed counter supported

Encoder

Single phase: Max. 50 kHz, Two-phase: Max. 20 kHz

Encoder

FPΣ

Increment input mode, decrement input mode, 2-phase input mode, individual input mode, and

direction discrimination mode are supported.

Pulse input

Pulse input

Figure 4: Features-High-speed counter

FPΣ

Positioning control based on pulse output supported

Pulse output

1-channel: Max. 100 kHz, 2-channel: Max. 60 kHz

Mortor

driver

CW/CCW and Pulse/sign outputs are supported.

Pulse output

Mortor

driver

Mortor

Mortor

Figure 5: Features-Pulse output

FPΣ

1.1 Features and Functions of the Unit

1-5

Analog control supported

An analog potentiometer (volume dial) is provided as a standard feature. This can be

used in applications such as analog timers, without using the programming tools. An

analog unit is also available as the intelligent unit.

FPΣ

Functions and Restrictions of the Unit

1-6

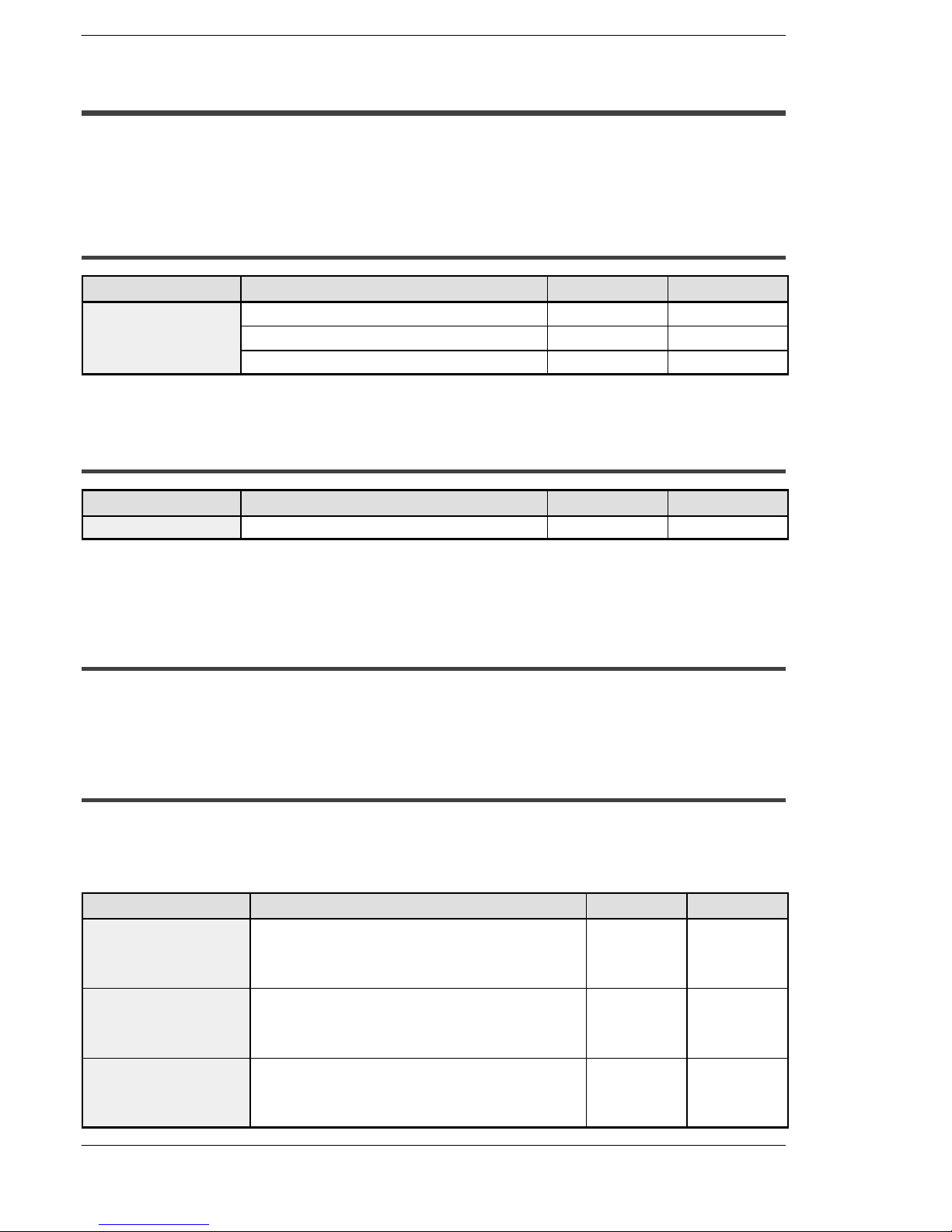

1.2 Unit Types

This section explains the type of unit used with the FPΣ and about the optional

communication cassette.

1.2.1 FPΣ Control Unit

Name Number of I/O points Part No. Product No.

Input: 16 points/Transistor output: 16 points FPG-C32T AFPG2543

FPΣ Control unit

Input: 16 points/Transistor output: 16 points FPG-C32T2 AFPG2643

Input: 16 points/Relay output: 8 points FPG-C24R2 AFPG2423

1.2.2 FPΣ Expansion Unit

Name Number of I/O points Part No. Product No.

FPΣ expansion I/O unit Input: 32 points/Transistor output: 32 points FPG-XY64D2T AFPG3467

* The FPΣ expansion I/O unit can be used for “FPG-C32T2 and FPG-C24R2” FPΣ

control units.

1.2.3 Units for FP0 and FPΣ

The FPΣ can be used the FP0 series expansion I/O unit, power supply unit, and

intelligent unit.

1.2.4 Communication Cassette

A detachable communication cassette (optional) should be used when using the

various functions such as the computer link, serial data communication, and PLC link

functions.

Name Description Part No. Product No.

FPΣ Communication

cassette 1-channel

RS232C type

This communication cassette is a 1-channel unit with

a five-wire RS232C port. It supports 1 : 1 computer

links and general-purpose serial communication. RS/

CS control is possible.

FPG-COM1 AFPG801

FPΣ Communication

cassette 2-channel

RS232C type

This communication cassette is a 2-channel unit with

a three-wire RS232C port. It supports 1 : 1 computer

links and general-purpose serial communication.

Communication with two external devices is possible.

FPG-COM2 AFPG802

FPΣ Communication

cassette 1-channel

RS485 type

This communication cassette is a 1-channel unit with

a two-wire RS485 port. It supports 1 : N computer

links(C-NET),general-purposeserialcommunication,

and a PLC link.

FPG-COM3 AFPG803

FPΣ

1.3 Restrictions on Unit Combinations

1-7

1.3 Restrictions on Unit Combinations

This section contains restrictions on unit combinations.

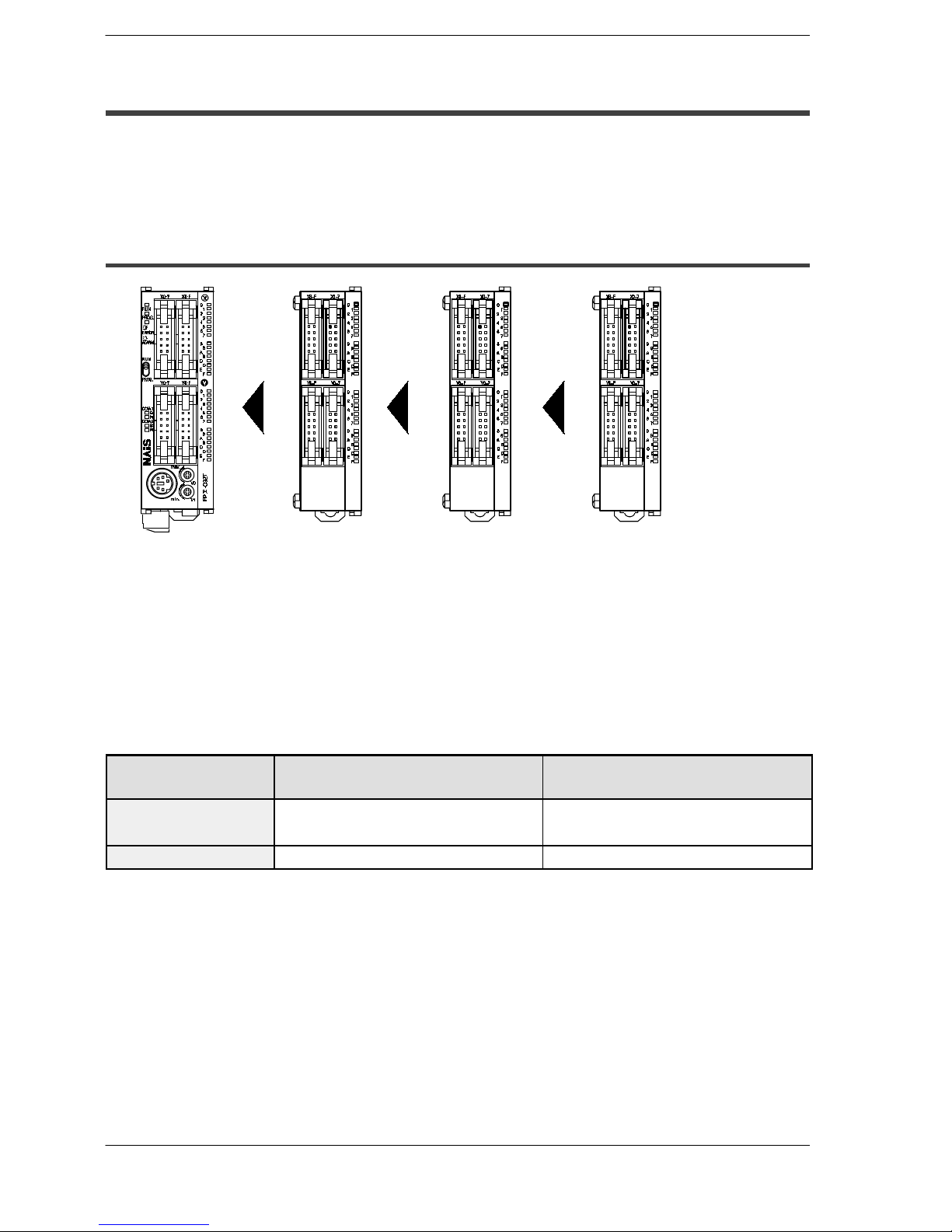

1.3.1 Restrictions on the Number of Expansion Units

(for FP0 expansion unit)

Control unit Unit 1 for expansion

(Maximum possible

expansion is with a

total of three units)

Unit 2 for expansion Unit 3 for expansion

Figure 6: Restriction on unit combinations

Up to three expansion units can be added at the right of the FPΣ, these expansion units being

either expansion units or intelligent units from the earlier FP0 series, or a combination of the

two.

There are no restrictions on the type and the order in which expansion units are installed.

A combination of relay output types and transistor output types is also possible.

Controllable I/O Points

Type of control unit

Number of I/O points when using

control unit

Number of I/O points when using

FP0 expansion unit

FPG-C32T

FPG-C32T2

32 points Max. 128 points

FPG-C24R2 24 points Max. 120 points

FPΣ

Functions and Restrictions of the Unit

1-8

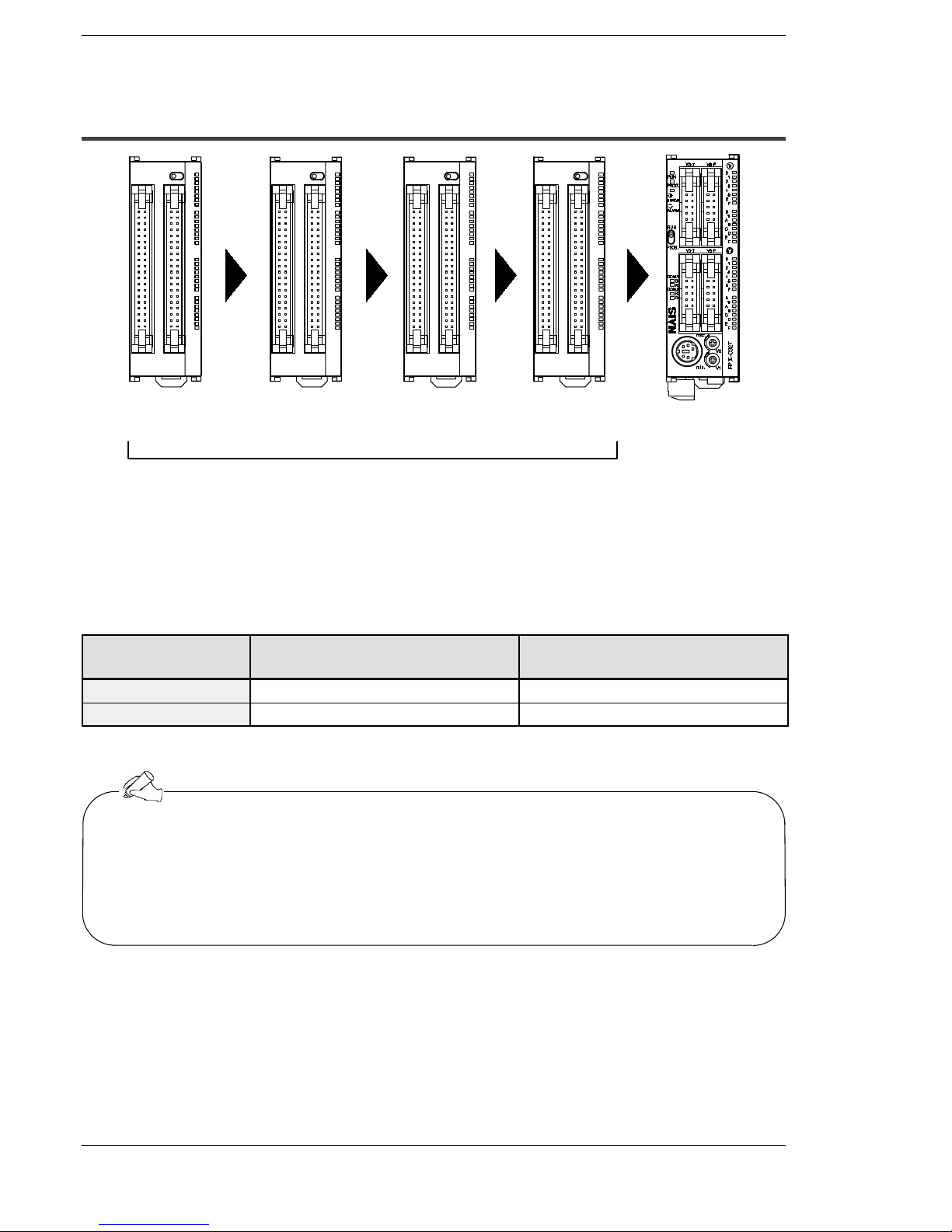

1.3.2 Restrictions on the Number of Units for Expansion (for FPΣ

expansion unit)

Control unitExpansion unit 1Expansion unit 2Expansion unit 3Expansion unit 4

Max. possible expansion is with a total of four units.

Up to four dedicated FPΣ expansion units can be added at the left of the FPΣ.

The 64 points type expansion unit consist of 32 input points and 32 transistor output

points.

Controllable I/O Points

Type of control unit

Number of I/O points when using

control unit

Number of I/O points when using

FPΣ expansion unit

FPG-C32T2 32 points Max. 288 points

FPG-C24R2 24 points Max. 280 points

The FPΣ expansion unit cannot be used for FPG-C32T.

Tip

If using FP0 expansion units and FPΣ expansion units in combination, the number

of input and output points can be expanded to a maximum of 384 points for the

FPG-C32T2 and 376 points for the FPG-C24R2.

FPΣ

1.4 Programming Tools

1-9

1.4 Programming Tools

This section explains about the programming tools for FPΣ.

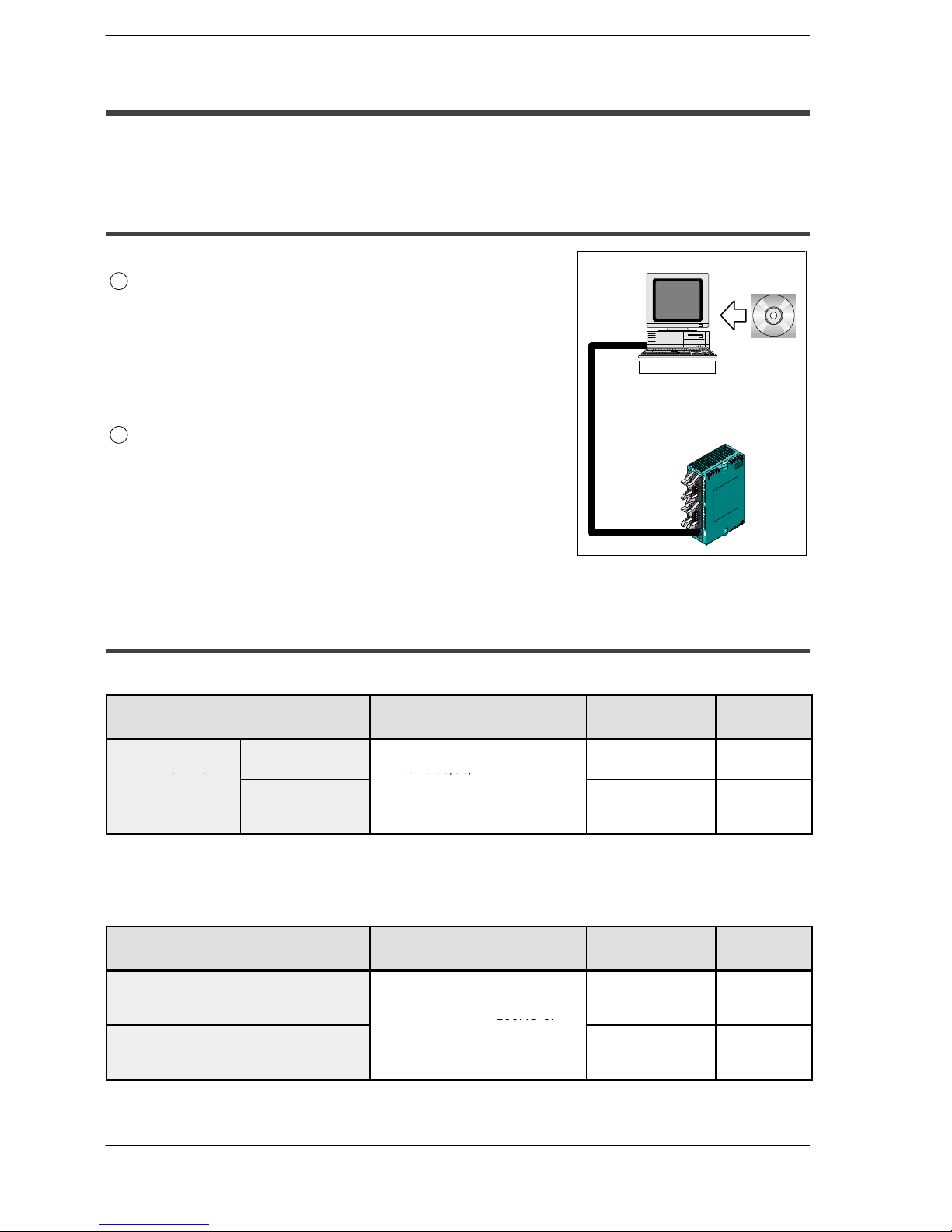

1.4.1 Tools Needed for Programming

FPΣ

Computer

PC connection cable

1

Programming tool software

The tool software can also be used with the FP series.

The “FPWIN Pro Ver. 4” or “FPWIN GR Ver. 2” Windows

software is used with the FPΣ.

The earlier FPWIN GR Ver. 1x, NPST-GR, and FP Programmer cannot be used.

2

PC connection cable

This cable needed for connection between the FPΣ and

the computer.

Programming

tool software

FPΣ

Figure 7: Programming tools

1.4.2 Software Environment and Suitable Cable

Standard ladder diagram tool software “FPWIN-GR Ver.2”

Type of software

OS (Operating

system)

Hard disk

capacity

Part No.

Product

No.

FPWIN-GR Ver. 2

English-language

software

Windows 95/98/

FPWINGRF-EN2 AFPS10520

FPWIN

GRVer.2

English-language

menu

Upgrade (to

upgrade from

Ver.1.1)

Windows

95/98/

Me/2000/NT

(Ver. 4.0 or later)

30MB or more

FPWINGRR-EN2 AFPS10520R

Conforms to IEC61131-3 programming tool software “FPWIN-Pro Ver.4”

Type of software

OS (Operating

system)

Hard disk

capacity

Part No.

Product

No.

FPWIN Pro Ver. 4 Full type

(for all type FP series PLC)

Englishlanguage

menu

Windows 95/98/

100MB or

FPWINPROF-EN4 AFPS50540

FPWIN Pro Ver. 4 Small type

(for FP0, FPΣ, FP1, and

FP-M)

Englishlanguage

menu

Me/

2000

/NT

(Ver. 4.0 or later)

100MB

or

more

FPWINPROS-EN4 AFPS51540

FPΣ

Functions and Restrictions of the Unit

1-10

Type of computer and suitable cable

Type of computer Cable Cable specification

IBM PC/AT or

Part No.: AFC8503 D-Sub 9-pin female-Mini DIN 5-pin male

IBM

PC/A

T

or

its compatible machine

Part No.: AFC8513 D-Sub 25-pin male-Mini DIN 5-pin male

Chapter 2

Specifications and Functions of Control

Unit

2.1 Parts and Functions 2 - 3.............................

2.2 Input and Output Specifications 2 - 7...................

2.3 Terminal Layout Diagram 2 - 12........................

FPΣSpecifications and Functions of Control Unit

2-2

FPΣ 2.1 Parts and Functions

2-3

2.1 Parts and Functions

This section explains about the parts and functions of FPΣ control unit.

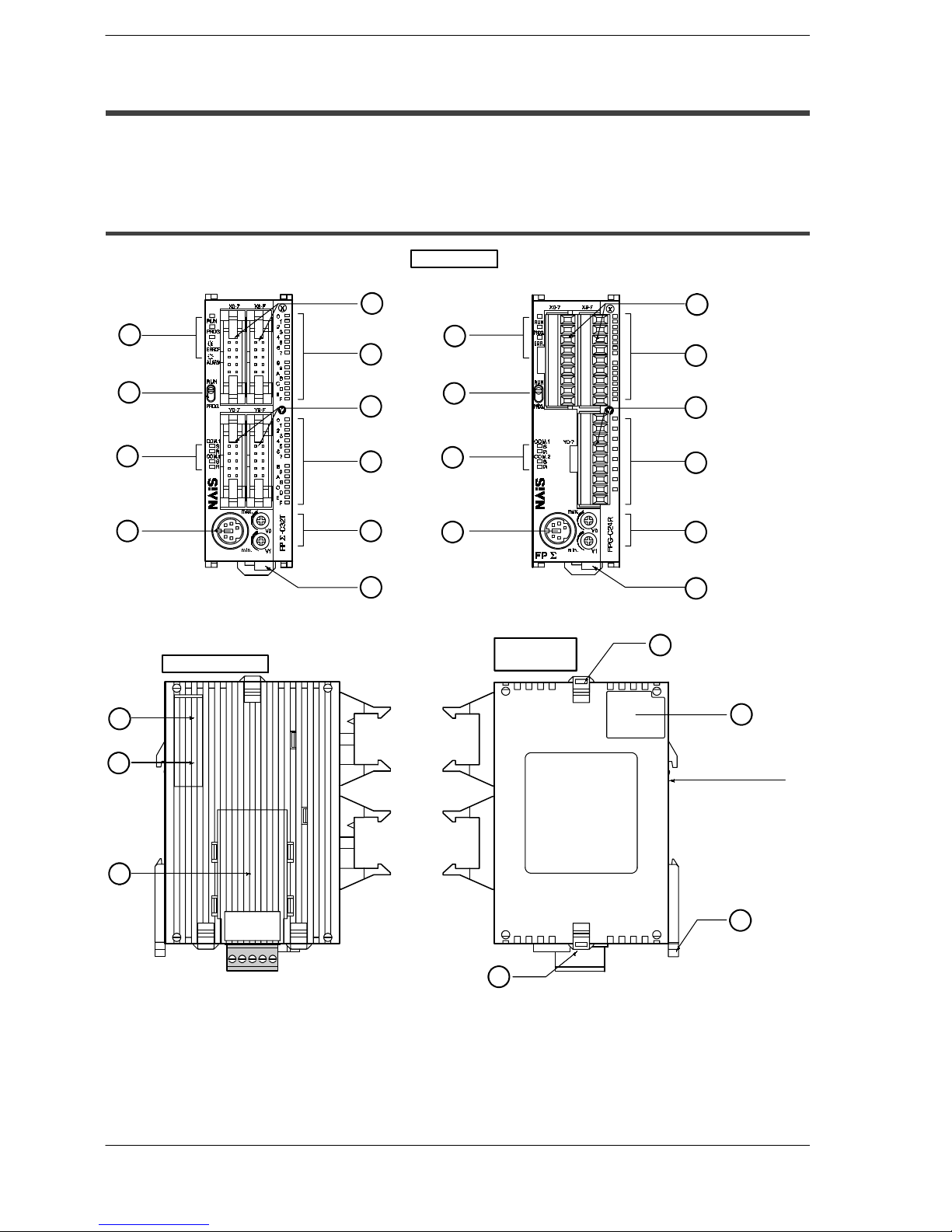

2.1.1 Parts and Functions

EXPANSION

CONNECTOR

FPG-C32T

FPG-C32T2

FPG-C24R2

Front view

Left side view

Right side

view

DIN standard rail

attachment

For all type control unit

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

11

13

12

14

14

15

16

Figure 8: FPΣ Parts and Functions

FPΣ

Specifications and Functions of Control Unit

2-4

1

Status indicator LEDs

These LEDs display the current mode of operation or the occurrence of an error.

LED LED and operation status

RUN (green) Lights when in the RUN mode and indicates that the program is being executed.

It flashes during forced input/output.

(The RUN and PROG LEDs flash alternately.)

PROG. (green) Lights when in the PROG. mode and indicates that operation has stopped.

It flashes during forced input/output.

(The RUN and PROG LEDs flash alternately.)

ERROR/ALARM (red) Flashes when an error is detected during the self-diagnostic function.

Lights if a hardware error occurs, or if operation slows because of the program, and

the watchdog timer is activated.

2

RUN/PROG. mode switch

This switch is used to change the operation mode of the PLC.

Switch position Operation mode

RUN (upward) This sets the RUN mode. The program is executed and operation begins.

PROG. (downward) This sets the PROG. mode.The operation stops. In this mode, programming canbe

done using tools.

When performing remote switching from the programming tool, the position of the mode

switch and the actual mode of operation may differ. Verify the mode with the status indicator

LED. Otherwise, restart the FPΣ and change the mode of operation with the RUN/PROG.

mode switch.

3

Communication status LEDs

These display the communication status of the COM.1 and COM.2 ports.

LED LED and communication status

COM.1 S Transmitted data

Flashes while data is being transmitted

monitor

Goes out when no data is being transmitted

R Received data

Flashes while data is being received

monitor

Goes out when no data is being received

COM.2 S Transmitted data mo-

Flashes while data is being transmitted

nitor

Goes out when no data is being transmitted

R Received data

Flashes while data is being received

monitor

Goes out when no data is being received

4

Tool port (RS232C)

This port is used to connect a programming tool.

5

Input connector (10 pins × 2)

6

Input indicator LEDs

FPΣ

2.1 Parts and Functions

2-5

7

Output connector (10 pins × 2)

8

Output indicator LEDs

9

Analog potentiometer (analog dial)

Turning this dial changes the values of special data registers DT90040 and DT90041 within

the range of K0 to K1000. It can be used for analog timers and other applications.

10

Power supply connector (24 V DC)

Supply 24 V DC. It is connected using the power supply cable (AFP0581) that comes with the

unit.

11

Left-side connector for FPΣexpansion

This is used to connect dedicated FPΣ expansion units on the left side of the control unit with

the internal circuits.

*The FPG-C32T2 and FPG-C24R2 control units are equipped with this connector, but the

FPG-C32T is not.

12

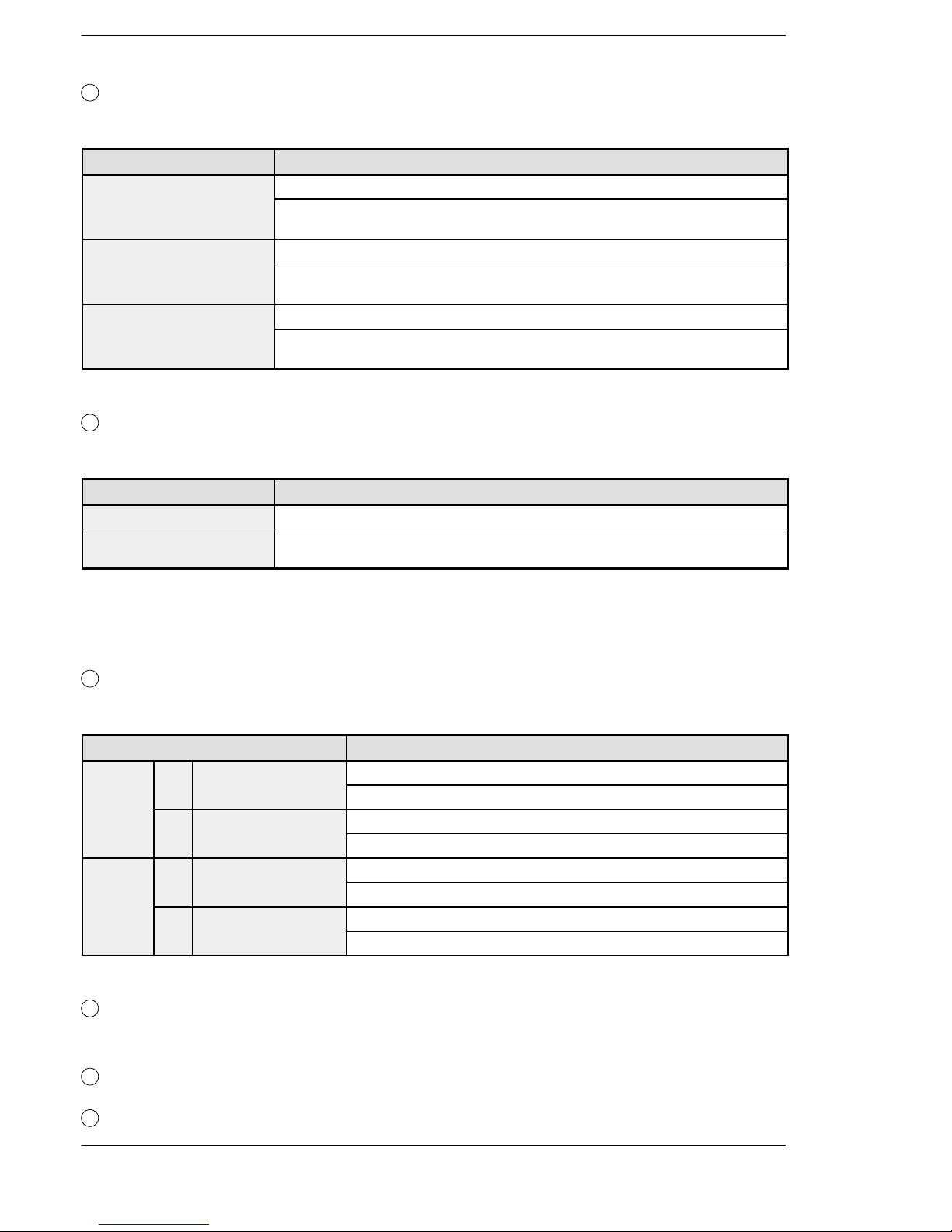

Unit No. (Station No.) setting switch

This unit No. (station No.) is specified when using the communication functions provided on

the optional communication cassettes.

The unit No. (station No.) setting switch is located under the cover on the back of the

unit. Specify the unit (station) number using the selector switch and the dial.

Figure 9: FPΣ Parts and Functions (Unit No. setting switch)

13

Communication cassette (option)

This is the optional cassette type adapter used when communication is carried out.

Any one of the following the cassette types may be installed.

- 1-channel RS232C type

- 2-channel RS232C type

- 1-channel RS485 type

14

Expansion hook

This hook is used to secure expansion units. The hook is also used for installation on flat type

mounting plate (AFP0804).

15

Right-side connector for FP0 expansion

Connects an expansion unit to the internal circuit of the control unit.

16

DIN rail attachment lever

The FPΣ unit enables attachment at a touch to a DIN rail. The lever is also used for

installation on slim 30 type mounting plate (AFP0811).

FPΣ

Specifications and Functions of Control Unit

2-6

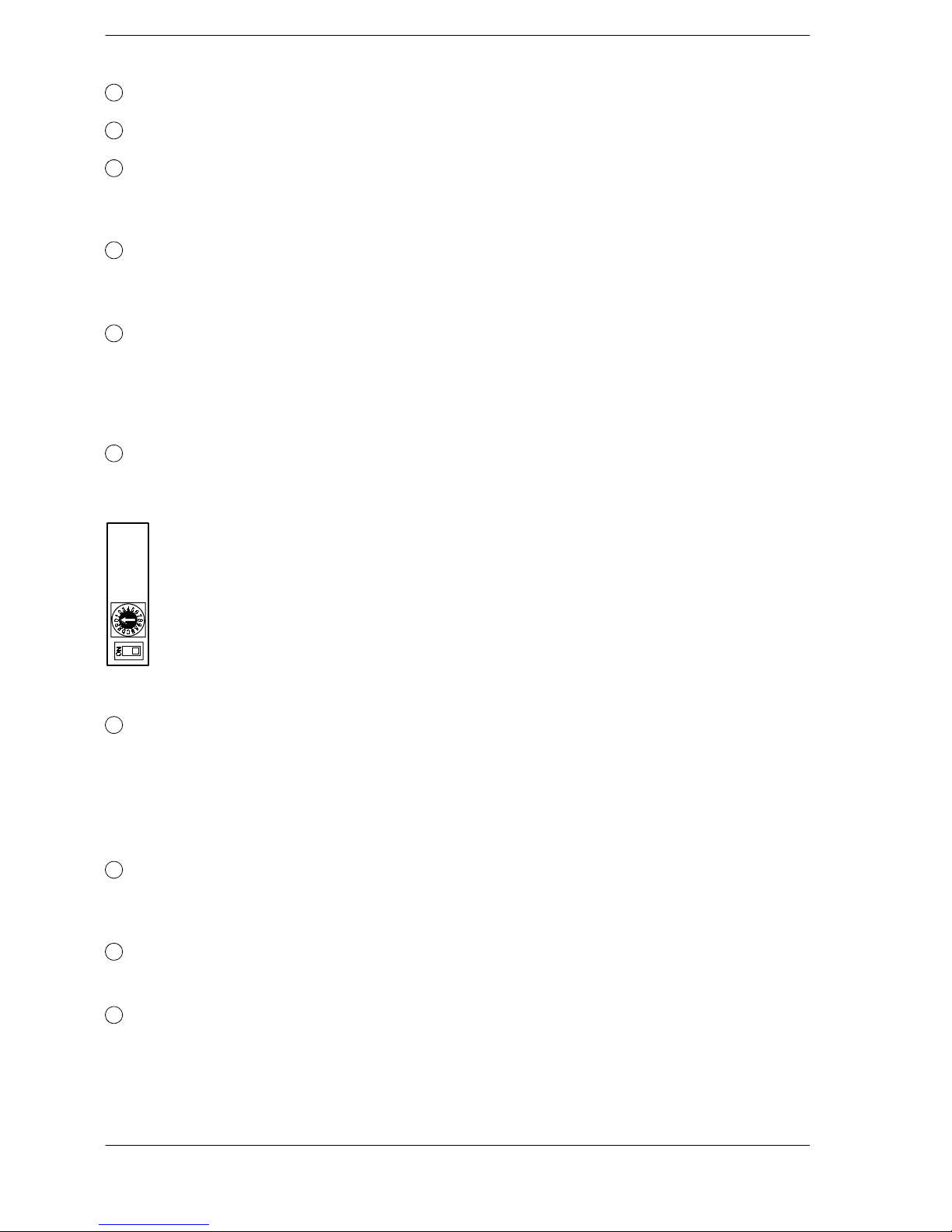

2.1.2 Tool Port Specification

A commercial mini-DIN 5-pin connector is used for the Tool port on the control unit.

Pin no. Signal name Abbreviation Signal direction

1

Signal Ground SG —

2

Transmitted Data SD Unit → External device

3

Received Data RD Unit ← External device

4

(Not used) — —

5

+5V +5V Unit → External device

Figure 10: FPΣ Parts and Functions (Tool port)

The following are the default settings set when the unit is shipped from the factory .The

system registers should be used to change these.

- Baud rate 9600 bps......

- Character bit 8 bit...

- Parity check Odd parity....

- Stop bit length 1 bit..

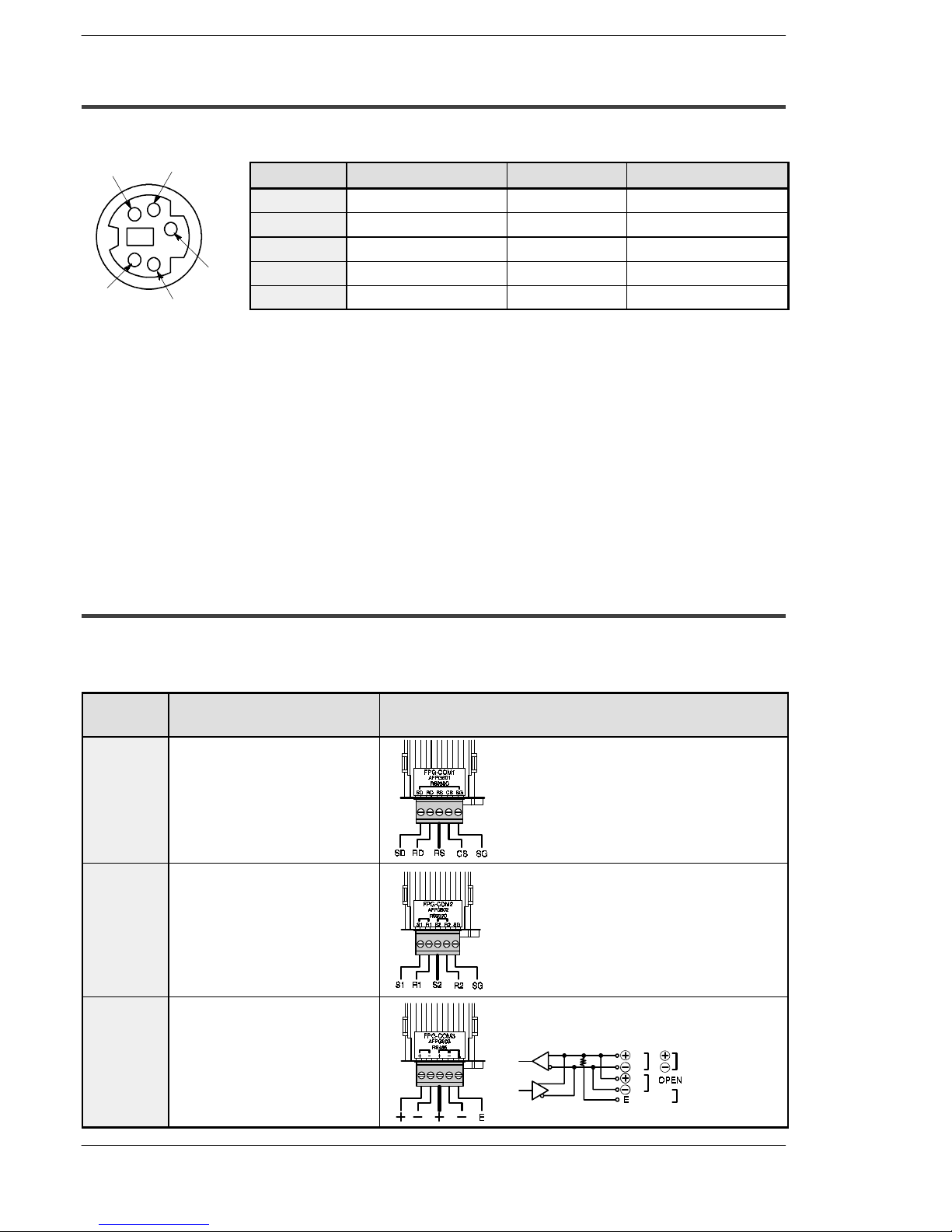

2.1.3 Communication Cassette

The detachable communication cassette (optional) can be selected from among the

three types shown below.

Type Applicable communication

function

Terminal layout diagram

1-channel

RS232C

type

Computer link

General-purpose serial

communication

SD: Transmitted Data (Output)

RD: Received Data (Input)

RS: Request to Send (Output)

CS: Clear to Send (Input)

SG: Signal Ground

2-channel

RS232C

type

Computer link

General-purpose serial

communication

S1: Transmitted Data (Output) (COM.1)

R1: Received Data (Input) (COM.1)

S2: Transmitted Data (Output) (COM.2)

R2: Received Data (Input) (COM.2)

SG: Signal Ground (COM.1 and 2)

1-channel

RS485 type

Computer link

General-purpose serial

communication

PLC link

General

station

Terminal

station

Short

1

3

5

4

2

FPΣ

2.2 Input and Output Specifications

2-7

2.2 Input and Output Specifications

This section contains input and output specifications of FPΣ control unit.

2.2.1 Input Specifications

Input specifications (for all type)

Item Description

Insulation method

Optical coupler

Rated input voltage

24 V DC

Operating voltage range

21.6 to 26.4 V DC

Rated input current

For X0, X1, X3, X4:approx. 8 mA

For X2, X5 to X7: approx. 4.3 mA

For X8 to XF: approx. 3.5 mA

Input points per common

For C32T, C32T2: 16 points/common

For C24R2: 8 points/common

(Either the positive or negative of the input powersupply can be connected to

common terminal.)

Min. on voltage/Min. on current

For X0, X1, X3, X4:19.2 V DC/6 mA

For X2, X5 to XF: 19.2V DC/3 mA

Max. off voltage/Max. off current

2.4 V DC/1.3 mA

Input impedance

For X0, X1, X3, X4:3 kΩ

For X2, X5 to X7: 5.6 kΩ

For X8 to XF: 6.8 kΩ

Response time off → on

For input X0, X1, X3, X4:

1 ms or less: normal input

5 µs or less: high-speed counter, pulse catch, interrupt input settings

For input X2, X5 to X7:

1 ms or less: normal input

100 µs or less: high-speed counter, pulse catch, interrupt input settings

For input X8 to XF:

1 ms or less: normal input only

on → off

Same as above

Operating mode indicator

LED display

Note

X0 through X7 are inputs for the high-speed counter and have a

fast response time. If used as normal inputs, we recommend

inserting a timer in the ladder program as chattering and noise

may be interpreted as an input signal.

Also, the above specifications apply when the rated input voltage

is 24 VDC and the temperature is 25°C/70°F.

Loading...

Loading...