RD

∗

∗

Transfer type is coming soon.

26.5GHz, 18GHz

COAXIAL SWITCH

FEATURES

1. High frequency characteristics

(Impedance 50Ω)

Frequency

(GHz)

V.S.W.R.

(max.)

Insertion

loss

(dB. max.)

Isolation

(dB. min.)

*: 18 to 26.5GHz characteristics can be applied

26.5GHz type only

2. SPDT and transfer type available

3. High sensitivity

Nominal operating power:

840 mW (SPDT, Failsafe type)

1540 mW (Transfer, Failsafe type)

4. Long life: 5 × 10

–1 –4 –8 –12.4 –18 –26.5*

1.1 1.15 1.25 1.35 1.5 1.7

0.2 0.3 0.4 0.5 0.8

85 80 70 65 60 55

6

(SPDT)

RD COAXIAL

SWITCHES

TYPICAL APPLICATIONS

Wireless and mobile communication

infrastructure

• Cellular phone base stations

• Amplifier switching

Measurement instruments

• All types of inspection equipment

ATTENTION

Transfer type is coming soon.

SPECIFICATIONS

Contact

Arrangement SPDT Transfer

Contact material Gold plating

Initial contact resistance Max. 100m

Rating Contact input power*

Contact rating Max. 30V 100mA Max. 5V 100mA

Indicator rating

High frequency

characteristics

(Impedance 50Ω)

Expected life

(min. operation)

Initial contact resistance

(Measured by 5V 100mA)

V.S.W.R. (max.) 1.1 1.15 1.25 1.35 1.5 1.7

Insertion loss (dB, max.) 0.2 0.3 0.4 0.5 0.8

Isolation (dB, min.) 85 80 70 65 60 55

Mechanical (at 180 cpm) 5 × 10

Electrical (at 20 cpm)

1

(V.S.W.R 1.15 or less, no contact switching, ambient temperature 40°C [SPDT], 25°C [Transfer])

to 1 GHz 1 to 4 4 to 8 8 to12.4 12.4 to 18 18 to 26.5

5 × 106 (5W, to 3GHz, impedance 50Ω,

V.S.W.R.; max. 1.2)

120W 3GHz

Max. 1

Characteristics

Initial insulation resistance*

Initial breakdown

3

voltage*

Operate time*4 (at 20°C) Max. 15ms Max. 20ms

Shock resistance

Vibration resistance

Conditions for operation, transport and storage*

(Not freezing and condensing at low temperature)

Unit weight (Approx.) 50g 1.76oz 110g 3.88oz

Remarks

*1Please verify the usability of input power under actual conditions because heat

generated from connectors can influence connection.

2

Measurement at same location as “Initial breakdown voltage” section.

*

*3Detection current: 10mA

4

Nominal operating voltage applied to the coil, excluding contact bounce time.

*

2

Between open contacts 500 Vrms for 1 min.

Between contact and coil 500 Vrms for 1 min.

Between contact and earth terminal 500 Vrms for 1 min.

Between coil and earth terminal 500 Vrms for 1 min.

Functional*

Destructive*

Functional*

Destructive 10 to 55 Hz at double amplitude of 5mm

8

Ambient temp –55°C to +85°C –67°F to +185°F

Humidity 5 to 85% R.H.

5

6

7

*5Half-wave pulse of sine wave: 11ms, detection time: 10µs.

*6Half-wave pulse of sine wave: 11ms

*

*8Refer to 4. Conditions for operation, transport and storage mentioned in NOTES.

SPDT Transfer

10 to 55 Hz at double amplitude of 3mm

7

Detection time: 10µs

Ω

Ω

6

106 (5W, to 3GHz, impedance 50Ω,

V.S.W.R.; max. 1.2)

Min. 1,000 M

500 m/s

1,000 m/s

Ω

2

2

1

RD

ORDERING INFORMATION

RDAEx.

Product

name

RD

Note: Sealed types are also available. (SPDT type only)

Frequency

1: to 18GHz (SPDT)

2: to 18GHz (Transfer)

5: to 26.5GHz (SPDT)

6: to 26.5GHz (Transfer)

Operating function

00: Failsafe

20: Latching

51: Latching with TTL driver

(with self cut-off function)

TYPES

1. SPDT

1) Solder terminal

Operating function

Failsafe

Latching

Latching with TTL driver

(with self cut-off function)

Note: Standard packing; Carton: 1 pc. Case: 20 pcs.

Nominal operating

voltage, V DC

4.5 ARD1004H ARD1004HQ ARD5004H ARD5004HQ

12 ARD10012 ARD10012Q ARD50012 ARD50012Q

24 ARD10024 ARD10024Q ARD50024 ARD50024Q

4.5 ARD1204H ARD1204HQ ARD5204H ARD5204HQ

12 ARD12012 ARD12012Q ARD52012 ARD52012Q

24 ARD12024 ARD12024Q ARD52024 ARD52024Q

5 ARD15105 ARD15105Q ARD55105 ARD55105Q

12 ARD15112 ARD15112Q ARD55112 ARD55112Q

24 ARD15124 ARD15124Q ARD55124 ARD55124Q

4H:

18GHz type 26.5GHz type

No HF datasheet

attached

Nominal operating

voltage, V DC

4.5V (Failsafe,

Latching type only)

05:

5V (Latching with

TTL driver type only)

12:

12V

24:

24V

HF datasheet

attached

Operation terminal

Nil:

Solder terminal

C:

Connector cable

(SPDT type only)

No HF datasheet

attached

HF data attached

Nil:

No HF test data

attached

Q:

HF test data attached

HF datasheet

attached

2) Connector cable

Operating function

Failsafe

Latching

Latching with TTL driver

(with self cut-off function)

Note: Standard packing; Carton: 1 pc. Case: 10 pcs.

Nominal operating

voltage, V DC

4.5 ARD1004HC ARD1004HCQ ARD5004HC ARD5004HCQ

12 ARD10012C ARD10012CQ ARD50012C ARD50012CQ

24 ARD10024C ARD10024CQ ARD50024C ARD50024CQ

4.5 ARD1204HC ARD1204HCQ ARD5204HC ARD5204HCQ

12 ARD12012C ARD12012CQ ARD52012C ARD52012CQ

24 ARD12024C ARD12024CQ ARD52024C ARD52024CQ

5 ARD15105C ARD15105CQ ARD55105C ARD55105CQ

12 ARD15112C ARD15112CQ ARD55112C ARD55112CQ

24 ARD15124C ARD15124CQ ARD55124C ARD55124CQ

2. T ransfer

1) Solder terminal

Operating function

Failsafe

Latching

Latching with TTL driver

(with self cut-off function)

Note: Standard packing; Carton: 1 pc. Case: 10 pcs.

Nominal operating

voltage, V DC

4.5 ARD2004H ARD2004HQ ARD6004H ARD6004HQ

12 ARD20012 ARD20012Q ARD60012 ARD60012Q

24 ARD20024 ARD20024Q ARD60024 ARD60024Q

4.5 ARD2204H ARD2204HQ ARD6204H ARD6204HQ

12 ARD22012 ARD22012Q ARD62012 ARD62012Q

24 ARD22024 ARD22024Q ARD62024 ARD62024Q

5 ARD25105 ARD25105Q ARD65105 ARD65105Q

12 ARD25112 ARD25112Q ARD65112 ARD65112Q

24 ARD25124 ARD25124Q ARD65124 ARD65124Q

18GHz type 26.5GHz type

No HF datasheet

attached

18GHz type 26.5GHz type

No HF datasheet

attached

HF datasheet

attached

HF datasheet

attached

No HF datasheet

attached

No HF datasheet

attached

HF datasheet

attached

HF datasheet

attached

2

COIL DATA (at 20°C 68°F)

1. SPDT

1) Failsafe type

Nominal operating voltage,

V DC

4.5 24.2 840

12 172 840

24 594 970

2) Latching type

Nominal operating voltage,

V DC

4.5 28.9 700

12 192 750

24 640 900

3) Latching with TTL driver type (with self cut-off function)

Nominal operating voltage,

V DC

5

12

24

2. T ransfer

1) Failsafe type

Nominal operating voltage,

V DC

4.5 13.2 1540

12 93.6 1540

24 345 1670

2) Latching type

Nominal operating voltage,

V DC

4.5 16.8 1200

12 115 1250

24 411 1400

3) Latching with TTL driver type (with self cut-off function)

Nominal operating voltage,

V DC

5

12

24

Coil resistance, Ω (±:10%) Nominal power consumption, mW

Coil resistance, Ω (±:10%) Nominal power consumption, mW

TTL logic level (see TTL logic level range)

ON OFF

2.4 to 5.5V 0 to 0.5V

Coil resistance, Ω (±:10%) Nominal power consumption, mW

Coil resistance, Ω (±:10%) Nominal power consumption, mW

TTL logic level (see TTL logic level range)

ON OFF

2.4 to 5.5V 0 to 0.5V

RD

Switching frequency

Max. 180 cpm

(ON time : OFF time = 1 : 1)

Switching frequency

Max. 180 cpm

(ON time : OFF time = 1 : 1)

• Operating voltage range

1) Failsafe type 2) Latching type 3) Latching with TTL driver type

(with self cut-off function)

12

4.5V24

6

5.25

4.5

3.75

3

2.25

1.5

0.75

0

12

V

V

32

16

28

14

24

12

20

10

16

8

12

6

8

4

4

2

0

0

–55–40 0–20 20

Nominal voltage

Allowable range

for use

Recommended

operation voltage range

Recommended

release voltage range

Ambient temperature °C

4.5V24

V

V

32

16

6

28

14

5.25

24

12

4.5

20

10

3.75

16

8

3

12

6

2.25

8

4

1.5

4

2

0.75

0

0

8540 60

0

–55–40 0–20 20 8540 60

Nominal voltage

Allowable range

for use

Recommended

set/reset voltage range

Ambient temperature °C

5V24

6.67

5.83

5

4.17

3.33

2.5

1.67

0.83

0

12

V

V

32

16

28

14

24

12

20

10

16

8

12

6

8

4

4

2

0

0

–55–40 0–20 20 8540 60

Allowable range

for use

Recommended set/reset

voltage range

Ambient temperature °C

Nominal voltage

3

RD

4) TTL Logic level range

5.5

5

4

3

2.4

2

1

0.5

0

–55–40 0–20 20 8540 60

Ambient temperature °C

ON

OFF

DIMENSIONS

1. SPDT

1) Solder terminal

4.3

.169

39.0

1.535

4.5

.177

7.3

.287

3-SMA connector

2.1

.083

3.5

.138

3.5

.138

2.0

.079

11.2

.441

COMNC NO

GND

Serial No.

+

11.2

.441

22.4

.882

30.0

1.181

34.0

1.339

Indicator

Coil

3.5

.138

Solder terminal

2-3.1 dia.

2-.122 dia.

2-2.4 dia.

2-.094 dia.

7.0

.276

0.3

.012

7.2

.283

13.2

.520

Tolerance: ±0.3 ±.012

mm inch

Failsafe Latching Latching with TTL driver

(with self cut-off function)

Coil 1

Coil 2

COM12

GND 21

Serial No.

21 COM

Indicator

Coil

21 COM

Indicator terminal

Coil terminal

Logic 2

GND

Logic 1

V

211COM

Indicator

Coil

GND 2V

Serial No.

NC

GND

COMNC NO

GND

Serial No.

NOCOM

GND

Indicator

Coil

+

4

RD

2) Connector cable

5.95

.234

12.55

.494

1.2

.047

mm inch

Indicator Coil

Pin No.

123456789

Fail safe – NC COM NO – – GND + –

Latching – 1 COM 2 – – GND 1 2

Latching with

TTL driver

1

2345

Pin No.

6789

25.0

.984

30.8

1.213

– 1 COM 2 – V GND

D-sub connector

pin contact type

3.05 dia.

.120 dia.

Logic 1Logic

2

±10

110.0

±.394

4.331

39.0

1.535

4.5

.177

7.3

.287

3-SMA connector

2.1

.083

COMNC NO

GND

Serial No.

+

11.2

.441

22.4

.882

30.0

1.181

34.0

1.339

PVC wires

Indicator

Coil

2-3.1 dia.

2-.122 dia.

2-2.4 dia.

2-.094 dia.

13.2

.520

7.2

.283

Tolerance: ±0.3 ±.012

5

RD

V

GND

Logic 1

Logic 2

1

COM

2

Coil terminal Indicator terminal

2. T ransfer

3-3.80 dia.

3-.150 dia.

20.3

.799

9.65

.380

4-SMA connector

32.0

1.260

45.70

1.799

15.24

.600

32.0

1.260

16.2

.638

0.30

.012

mm inch

5.08

Max. 5.0

.197

10.15

.400

9.65

39.0

.380

1.535

7.2

.283

J2J1

16.2

.638

1 to 1.5

.039 to .059

J4J3

5.08

.200

2.00

.079

.200

5.08

.200

Solder terminal

55.5

2.185

Fail safe

Latching

Latching with TTL driver

Failsafe Latching Latching with TTL driver

(with self cut-off function)

Coil terminal Indicator terminal

GND

NC

COM

NO

Coil terminal Indicator terminal

GND

1

2

1

COM

2

Tolerance: ±0.3 ±.012

J1

J3

J2

J4

NC: J1-J2, J3-J4

NO: J1-J3, J2-J4

POS1: J1-J2, J3-J4

POS2: J1-J3, J2-J4

POS1: J1-J2, J3-J4

POS2: J1-J3, J2-J4

6

1GHz 4GHz

12.4GHz8GHz 18GHz 26.5GHz

Frequency

80

70

100

90

0

20

10

60

40

50

30

Isolation, dB

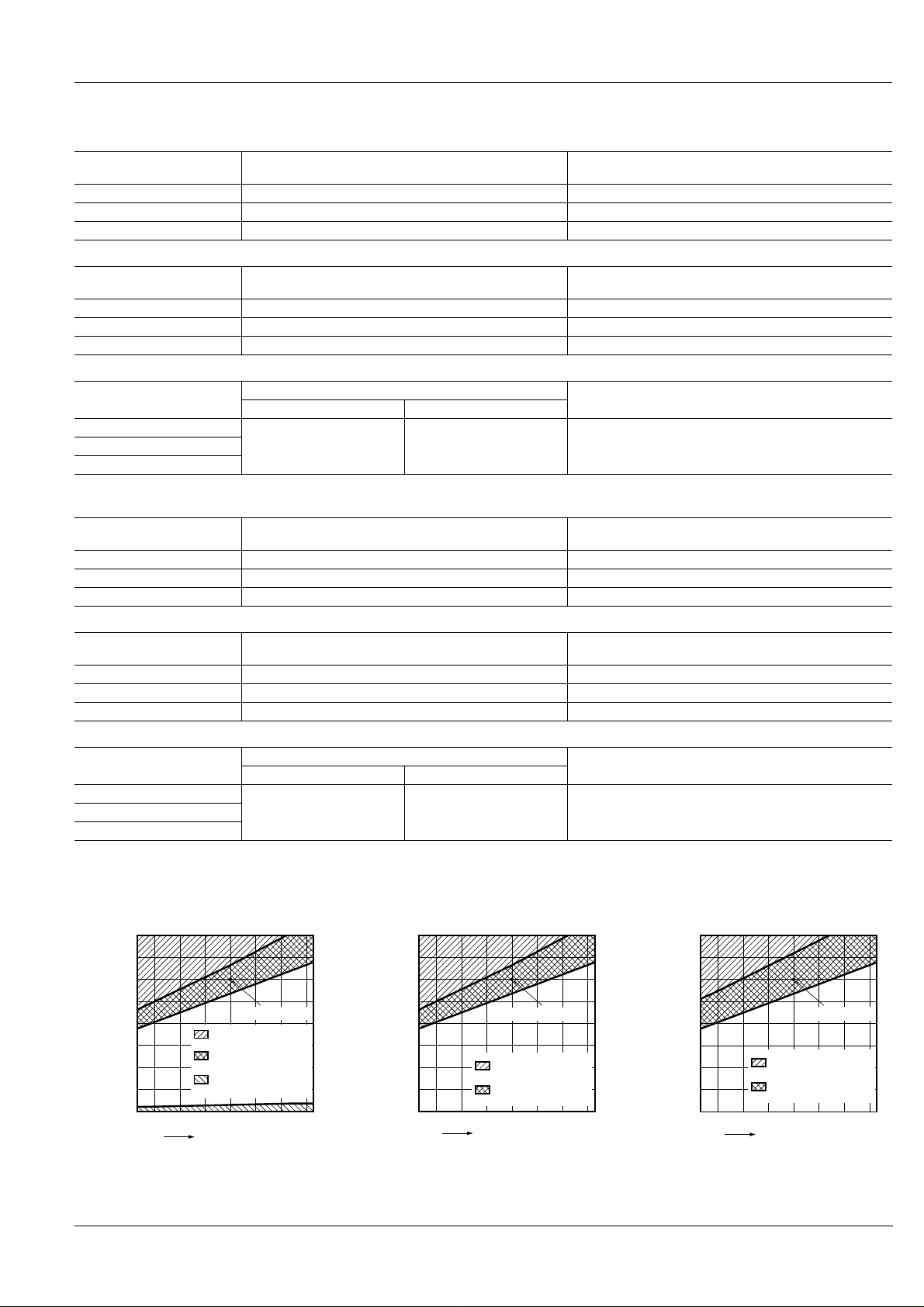

REFERENCE DATA

80

90

100

0

10

20

60

70

30

40

50

1GHz 4GHz

12.4GHz8GHz 18GHz 26.5GHz

Isolation, dB

Frequency

1-(1). High frequency characteristics (SPDT)

Sample: ARD10012

Measuring method: Measured with HP network analyzer (HP8510).

• V.S.W.R. • Insertion loss • Isolation

1.9

1.8

1.7

1.6

1.5

V.S.W.R.

1.4

1.3

1.2

1.1

1.0

1GHz 4GHz

12.4GHz8GHz 18GHz 26.5GHz

Frequency

1-(2). High frequency characteristics (Transfer)

Sample: ARD60012

Measuring method: Measured with HP network analyzer (HP8510).

• V.S.W.R. • Insertion loss • Isolation

1.9

1.8

1.7

1.6

1.5

V.S.W.R.

1.4

1.3

1.2

1.1

1.0

1GHz 4GHz

12.4GHz8GHz 18GHz 26.5GHz

Frequency

0

0.1

0.2

0.3

0.4

0.5

Insertion loss, dB

0.6

0.7

0.8

0.9

1.0

1GHz 4GHz

0

0.1

0.2

0.3

0.4

0.5

Insertion loss, dB

0.6

0.7

0.8

0.9

1.0

1GHz 4GHz

12.4GHz8GHz 18GHz 26.5GHz

Frequency

12.4GHz8GHz 18GHz 26.5GHz

Frequency

RD

7

RD

,

,

NOTES

1. Coil operating power

Pure DC current should be applied to the

coil. The wav e form should be rectangular.

If it includes ripple, the ripple factor should

be less than 5%.

However, check it with the actual circuit

since the characteristics may be slightly

different. The nominal operating voltage

should be applied to the coil for more than

50 ms to set/reset the latching type relay.

Please use the latching type for circuits

that are continually powered for long

periods of time.

2. Coil connection

When connecting coils, refer to the wiring

diagram to prevent mis-operation or

malfunction.

3. Connection of coil indicator and

washing conditions

1) The connection of coil indicator

terminal shall be done by soldering.

Soldering conditions

Max. 260°C 500°F (solder temp) within

10sec (soldering time)

Max. 350°C 662°F (solder temp) within

3sec (soldering time)

2) This product is not sealed type,

therefore washing is not allowed.

4. Usage, transport and storage

conditions

1) Ambient temperature, humidity, and

atmospheric pressure during usage,

transport, and storage of the relay:

(1) T emper ature:

–55 to +85°C –67 to +185°F

(2) Humidity: 5 to 85% RH

(Avoid freezing and condensation.)

The humidity range varies with the

temperature. Use within the range

indicated in the graph below.

(3) Atmospheric pressure: 86 to 106 kPa

Temperature and humidity range for

usage, transport, and storage:

Humidity, %RH

85

Tolerance range

(Avoid freezing when

,

used at temperatures

lower than 0°C 32°F)

–55

–67

(Avoid

condensation when

used at temperatures

higher than 0°C 32°F)

5

0

+32

Temperature, °C °F

,

+85

+185

2) Condensation

Condensation forms when there is a

sudden change in temperature under high

temperature and high humidity conditions.

Condensation will cause deterioration of

the relay insulation.

3) Freezing

Condensation or other moisture may

freeze on the relay when the temperature

is lower than 0°C 32°F. This causes

problems such as sticking of movable

parts or operational time lags.

4) Low temperature, low humidity

environments.

The plastic becomes brittle if the relay is

exposed to a low temperature, low

humidity environment for long periods of

time.

5) Low-temperature and low-humidity

atmosphere.

When exposed to low temperature and

low humidity for a long time, the relay’s

plastic casing may become breakable.

5. Other handling precautions.

1) The relay’s on/off service life is based

on standard test conditions (temperature:

15 to 35°C 59 to 95°F, humidity: 25 to

75%) specified in JIS C5442-1996. Life

will depend on many factors of your

system: coil drive circuit, type of load,

switching intervals, switching phase,

ambient conditions, to name a few.

2) Use the relay within specifications such

as coil rating, contact rating and on/off

service life. If used beyond limits, the rela y

may overheat, generate smoke or catch

fire.

3) Be careful not to drop the relay. If

accidentally dropped, carefully check its

appearance and characteristics before

use.

4) Be careful to wire the relay correctly.

Otherwise, malfunction, overheat, fire or

other trouble may occur.

5) The latching type rela y is shipped in the

reset position. But jolts during transport or

impacts during installation can move it to

the set position. It is , therefore, advisable

to build a circuit in

which the relay can be initialized (set and

reset) just after turning on the power.

6) If a relay stays on in a circuit for many

months or years at a time without being

activated, circuit design should be

reviewed so that the relay can remain

non-excited. A coil that receives current

all the time heats, which degrades

insulation earlier than expected. A

latching type relay is recommended for

such circuits.

7) For SMA connectors, we recommend a

torque of 0.90±0.1 N·m for installation,

which falls within the prescribed torque of

MIL-C-39012. Please be aware that

conditions might be different depending

on the connector materials and how it

interacts with surrounding materials.

8) Please do not use silicon based

substances such as silicon rubber, silicon

oil, silicon coatings and silicon fillings, in

the vicinity of the relay. Doing so may

cause volatile silicon gas to form which

may lead to contact failure due to the

adherence of silicon on the contacts when

they open and close in this atmosphere.

Please contact ..........

200303

8

These materials are printed on ECF pulp.

These materials are printed with earth-friendly vegetable-based (soybean oil) ink.

Matsushita Electric W orks, Ltd.

Automation Controls Company

K

Head Office: 1048, Kadoma, Kadoma-shi, Osaka 571-8686, Japan

K

Telephone: Japan (81) Osaka (06) 6908-1050

K

Facsimile: Japan (81) Osaka (06) 6908-5781

http://www.nais-e.com/

COPYRIGHT © 2003 All Rights Reserved

Specifications are subject to change without notice. Printed in Japan.

Loading...

Loading...