16A, COMPACT AND

HIGH INSULATION

POWER LATCHING RELAY

VDE

pendingpending

DJ-RELAYS

FEATURES

1. Latching operation

Latching via a polarized magnetic circuit

structure allows remote operation and

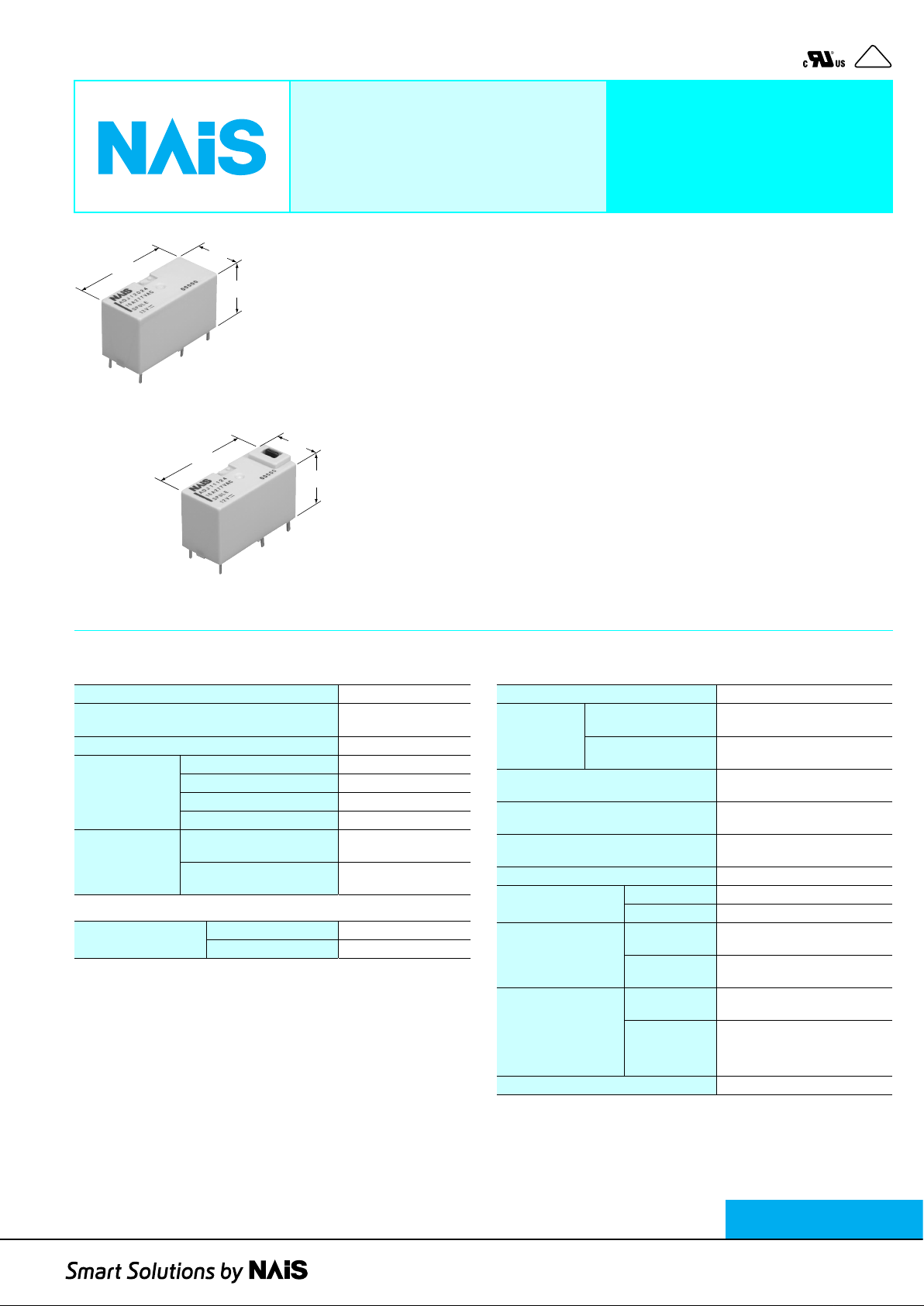

29.0

1.142

13.0

.512

16.0

.630

lower energy consumption

2. Compact with high capacity

16A contact rating in a compact 29 x 13 x

16.5 mm (L x W x H) size.

3. Low power consumption

Without test button

1 coil latching: 150mW

2 coil latching: 250mW

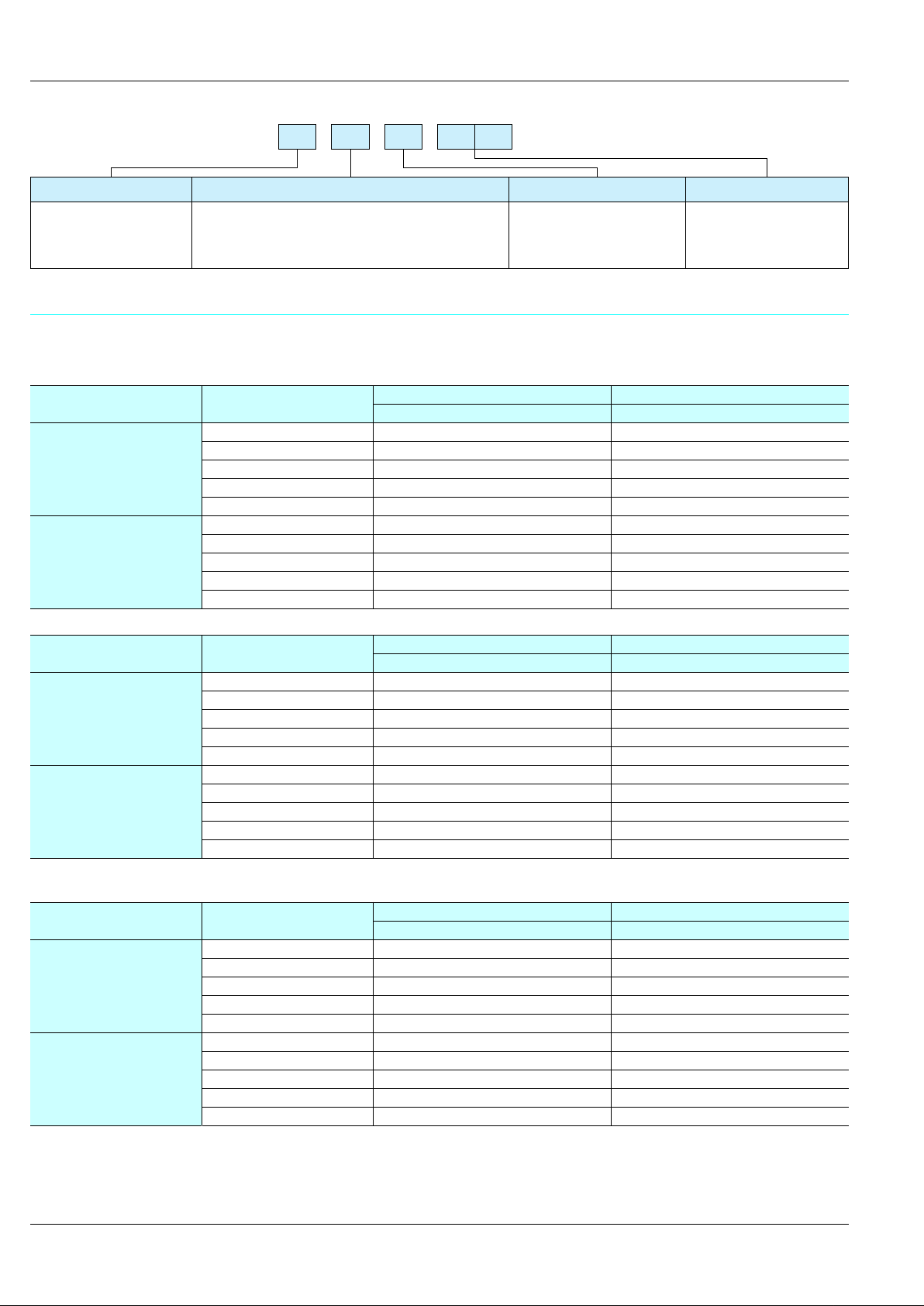

29.0

1.142

13.0

.512

16.0

.630

4. High insulation

Both clearance and creepage distance

between coil and contact are at 8 mm min.

5. With operation verification function

A test button (manual lever) type to

facilitate circuit checks is also available.

With test button

SPECIFICATIONS

Contact

Arrangement 1 Form A, 1 Form C

Initial contact resistance, max.

(By voltage drop 6 V DC 1 A)

Contact material Silver alloy

Nominal switching capacity 16 A 250V AC

Rating

(resistive load)

Expected life

(min. operations)

Max. switching power 4,000 V A

Max. switching voltage 250V AC

Max. switching current 16 A

Mechanical

(at 180 cpm)

Electrical (Resistive load)*

(at 20 cpm)

1

Coil

Nominal operating

power

Remarks

* Specifications will vary with foreign standards certification ratings.

*1With breathing holes open

2

Measurement at same location as “Initial breakdown voltage” section.

*

*3Detection current: 10mA

4

Wave is standard shock voltage of ±1.2 × 50µs according to JEC-212-1981

*

*5Excluding contact bounce time.

6

By resistive method, max. switching current

*

*7Half-wave pulse of sine wave: 11 ms; detection time: 10 µs

*8Half-wave pulse of sine wave: 6 ms

9

Detection time: 10 µs

*

*10Refer to 5. Usage, transport and storage conditions mentioned in NOTES

1 coil latching 150mW

2 coil latching 250mW

100 m

Ω

6

5×10

105 (at 16A 250V AC)

TYPICAL APPLICATIONS

• Network for household appliances

(Motor control, Light control)

• Time switches

Characteristics

Initial insulation resistance*

Initial

breakdown

voltage*

Surge voltage between contact and

4

coil*

Set time*

(at nominal voltage)

Reset time*

(at nominal voltage)

Temperature rise (at 70°C)*

Shock

resistance

Vibration

resistance

Conditions for

operation, transport

and storage*

(Not freezing and

condensing at low

temperature)

Unit weight Approx. 14 g .49 oz

Between open

contacts

Between contacts and

3

coil

5

5

10

2

6

Functional*

Destructive*

Functional*

Destructive

Ambient

temperature

Humidity 5 to 85% R.H.

Min. 1,000 MΩ (at 500 V DC)

1,000 Vrms for 1 min.

4,000 Vrms for 1 min.

Min. 10,000 V (initial)

Approx. 10ms

Approx. 10ms

Max. 55°C

7

8

9

Min. 200 m/s2 {20 G}

Min. 1,000 m/s2 {100 G}

10 to 55Hz

at double amplitude of 2.0mm

10 to 55Hz

at double amplitude of 3.0mm

–40°C to +70°C

–40°F to +158°F

http://www.naisrelay.com/

DJ RELAY

ASCT1B258E ’03.1

New

1

DJ

ORDERING INFORMATION

Ex. ADJ

Contact arrangement

1: 1 Form C

2: 1 Form A

Note: Standard packing: Carton: 100 pcs, Case: 500 pcs

Operating function and protective construction Auxiliary function Coil voltage (DC)

1: 1 coil latching, Flux-resistant type

2: 1 coil latching, Sealed type

3: 2 coil latching, Flux-resistant type

4: 2 coil latching, Sealed type

TYPES

1. Without test button

1) Flux-resistant type

Contact arrangement Coil voltage, V DC

5 ADJ21005 ADJ23005

6 ADJ21006 ADJ23006

1 Form A

1 Form C

2) Sealed type

Contact arrangement Coil voltage, V DC

1 Form A

1 Form C

2. With test button

Flux-resistant type

Contact arrangement Coil voltage, V DC

1 Form A

1 Form C

12 ADJ21012 ADJ23012

24 ADJ21024 ADJ23024

48 ADJ21048 ADJ23048

5 ADJ11005 ADJ13005

6 ADJ11006 ADJ13006

12 ADJ11012 ADJ13012

24 ADJ11024 ADJ13024

48 ADJ11048 ADJ13048

5 ADJ22005 ADJ24005

6 ADJ22006 ADJ24006

12 ADJ22012 ADJ24012

24 ADJ22024 ADJ24024

48 ADJ22048 ADJ24048

5 ADJ12005 ADJ14005

6 ADJ12006 ADJ14006

12 ADJ12012 ADJ14012

24 ADJ12024 ADJ14024

48 ADJ12048 ADJ14048

5 ADJ21105 ADJ23105

6 ADJ21106 ADJ23106

12 ADJ21112 ADJ23112

24 ADJ21124 ADJ23124

48 ADJ21148 ADJ23148

5 ADJ11105 ADJ13105

6 ADJ11106 ADJ13106

12 ADJ11112 ADJ13112

24 ADJ11124 ADJ13124

48 ADJ11148 ADJ13148

0: Without test button

1: With test button

1 coil latching type 2 coil latching type

Part No. Part No.

1 coil latching type 2 coil latching type

Part No. Part No.

1 coil latching type 2 coil latching type

Part No. Part No.

05: 5 V

06: 6 V

12: 12 V

24: 24 V

48: 48 V

2

COIL DATA (at 20°C 68°F)

10.16

.400

3.50

.138

13.0

.512

42−1

+8

−9

−8

+142

42−1

+8

−9

−8

+142

• 1 coil latching type

Nominal voltage,

V DC

5 3.5 3.5 167

6 4.2 4.2 240 7.8

12 8.4 8.4 960 15.6

24 16.8 16.8 3,840 31.2

48 33.6 33.6 15,360 62.4

Set voltage,

max. V DC

(initial)

• 2 coil latching type

Nominal voltage,

V DC

5 3.5 3.5 100

6 4.2 4.2 144 7.8

12 8.4 8.4 576 15.6

24 16.8 16.8 2,304 31.2

48 33.6 33.6 9,216 62.4

Set voltage,

max. V DC

(initial)

DIMENSIONS

1. 1 Form A, without test button

16.0

.630

Reset voltage,

max. V DC

(initial)

Reset voltage,

max. V DC

(initial)

Coil resistance,

Ω (±

10%)

Coil resistance,

Ω (±

10%)

1 coil latching type 2 coil latching type

3.50

.138

Nominal operating

power,

mW

150

Nominal operating

power,

mW

250

PC board pattern (Bottom view)

1.50 dia.

.059 dia.

5.08

.200

5.08

.200

5.08

.200

15.24

.600

2 coil latching type only

DJ

Max. allowable

voltage,

V DC

6.5

Max. allowable

voltage,

V DC

6.5

mm inch

5.08

.200

Tolerance: ±0.1 ±.004

1.80

.071

2. 1 Form A, with test button

16.0

.630

1.80

.071

15.24

.600

15.24

.600

29.0

1.142

.248

29.0

1.142

6.3

10.16

.400

10.16

.400

10.16

.400

13.0

.512

General tolerance: ±0.3 ±.012

1 coil latching type 2 coil latching type

9.0

.354

18.2

.717

3.50

.138

10.16

.400

13.0

.512

3.50

.138

9.0

.354

10.16

.400

13.0

.512

Schematic (Bottom view)

1 coil latching type

(Reset condition)

2 coil latching type

(Reset condition)

PC board pattern (Bottom view)

1.50 dia.

.059 dia.

5.08

.200

5.08

.200

5.08

.200

15.24

.600

2 coil latching type only

Tolerance: ±0.1 ±.004

Schematic (Bottom view)

1 coil latching type

2 coil latching type

5.08

.200

General tolerance: ±0.3 ±.012

(Reset condition)

(Reset condition)

3

DJ

10.16

.400

3.50

.138

13.0

.512

2 coil latching type only

15.24

.600

1.50 dia.

.059 dia.

5.08

.200

5.08

.200

5.08

.200

5.08

.200

2 coil latching type only

15.24

.600

1.50 dia.

.059 dia.

5.08

.200

5.08

.200

5.08

.200

5.08

.200

3. 1 Form C, without test button

16.0

.630

1.80

.071

4. 1 Form C, with test button

15.24

.600

5.08

.200

29.0

1.142

.248

6.3

1 coil latching type 2 coil latching type

3.50

.138

10.16

5.08

.200

.400

13.0

.512

General tolerance: ±0.3 ±.012

1 coil latching type 2 coil latching type

9.0

.354

9.0

.354

PC board pattern (Bottom view)

Tolerance: ±0.1 ±.004

Schematic (Bottom view)

1 coil latching type

−1

+8

6

(Reset condition)

2 coil latching type

+1

42

−9

−8

(Reset condition)

PC board pattern (Bottom view)

mm inch

42

6

16.0

.630

1.80

.071

15.24

.600

5.08

.200

29.0

1.142

5.08

.200

18.2

.717

3.50

.138

10.16

.400

13.0

.512

General tolerance: ±0.3 ±.012

3.50

.138

10.16

.400

13.0

.512

Schematic (Bottom view)

1 coil latching type

−1

+8

42

6

(Reset condition)

Tolerance: ±0.1 ±.004

2 coil latching type

+1

−9

−8

42

6

(Reset condition)

4

REFERENCE DATA

1. Max. switching capacity 2. Temperature rise

100

AC resistive load

16

10

Contact current, A

100 100 1,000

Contact voltage, V

Sample: ADJ12024, 6 pcs.

Coil applied voltage: 0 %V, Contact current: 16 A, 20 A

Measured portion: Contact, Ambient temperature:

25°C 77°F, 85°C 185°F

40

35

30

25

20

15

Temperature rise, °C

10

5

0

010 25

51520

Contact current, A

+25°C

+85°C

3. Set and Reset time

Sample: ADJ12024, 10 pcs

30

25

20

15

10

Set and Reset time, ms

5

0

70 90 130

80 100 110 120

Coil applied voltage, %V

Max.

x

Min.

DJ

4. Ambient temperature characteristics

Sample: ADJ12024, 6pcs

Ambient temperature: –40 to +85°C –40 to 185°F

30

Set

Reset

20

10

Change rate

-40-60 -20 02040 60 80 100

to nominal V, %V

Ambient

temperature, °C

-10

-20

-30

NOTES

1. Coil operating power

Pure DC current should be applied to the

coil. The wav e form should be rectangular.

If it includes ripple, the ripple factor should

be less than 5%. However, check it with

the actual circuit since the characteristics

may be slightly different.

2. Coil connection

When connecting coils, refer to the wiring

diagram to prevent mis-operation or

malfunction.

3. Soldering

We recommend the following soldering

conditions

Soldering: 200°C 392° F, max. 5 s

4. Others

1) If the relay has been dropped, the

appearance and characteristics should

always be checked before use.

2) The cycle lifetime is defined under the

standard test condition specified in the

JIS* C 5442-1996 standard (temperature

15 to 35°C 59 to 95°F, humidity 25 to

5. Influence of adjacent mounting

Sample: ADJ12024, 6pcs

Ambient temperature: Room temperature

5

Set voltage

0

-5

5

0

Change rate to nominal V, %V

Reset voltage

-5

Distance between relays , mm

OFF

OFF

OFF

121086402

85%). Chec k this with the real device as it

is affected by coil driving circuit, load type,

activation frequency, activation

phase,ambient conditions and other

factors.

Also, be especially careful of loads such

as those listed below.

• When used for AC load-operating and

the operating phase is synchronous.

Rocking and fusing can easily occur due

to contact shifting.

• High-frequency load-operating

When high-frequency opening and

closing of the relay is performed with a

load that causes arcs at the contacts,

nitrogen and oxygen in the air is fused by

the arc energy and HNO

3

is formed. This

can corrode metal materials.

Three countermeasures for these are

listed here.

• Incorporate an arc-extinguishing circuit.

• Lower the operating frequency

• Lower the ambient humidity

3) For secure operations, the voltage

applied to the coil should be nominal

voltage. In addition, please note that pickup and drop-out voltage will vary

according to the ambient temperature and

operation conditions.

4) Heat, smoke, and ev en a fire may occur

if the relay is used in conditions outside of

the allowable ranges for the coil ratings,

contact ratings, operating cycle lifetime,

and other specifications. Therefore, do

not use the relay if these ratings are

exceeded. Also, make sure that the relay

is wired correctly.

5) Incorrect wiring may cause unexpected

events or the generation of heat or flames .

6) Check the ambient conditions when

storing or transporting the relays and

devices containing the relays . F reezing or

condensation may occur in the relay,

causing functional damage. Avoid

subjecting the relays to heavy loads, or

strong vibration and shocks.

5

DJ

,,,,

,,,,,,

,,,,,,,,

,,,,,,,,,,

,,,,,,,,,,

,,,,,,,,,

,,,,,,,,

,,,,,,

,,,,

,,

5. Usage, transport and storage

conditions

1) Ambient temperature, humidity, and

atmospheric pressure during usage,

transport, and storage of the relay:

• Temperature:

–40 to +70°C –40 to +158°F

• Humidity: 5 to 85% RH

(Avoid freezing and condensation.)

The humidity range varies with the

temperature. Use within the range

indicated in the graph below.

Humidity, %RH

85

Tolerance range

(Avoid freezing

when used at

temperatures lower

than 0°C 32°F

–40

–40

(Avoid

condensation

when used at

temperatures higher

than 0°C 32°F

5

0

+32

Temperature, °C °F

70

+158

• Atmospheric pressure: 86 to 106 kPa

Temperature and humidity range for

usage, transport, and storage

2) Condensation

Condensation forms when there is a

sudden change in temperature under high

temperature and high humidity conditions.

Condensation will cause deterioration of

the relay insulation.

3) Freezing

Condensation or other moisture may

freeze on the relay when the

temperatures is lower than 0°C 32° F . This

causes problems such as sticking of

movable parts or operational time lags.

4) Low temperature, low humidity

environments

The plastic becomes brittle if the relay is

exposed to a low temperature, low

humidity environment for long periods of

time.

6. Test button (manual lever) operation

The relay contacts switch over as follows:

Set condition Reset condition

1/31/2003 All Rights Reserved, © Copyright Matsushita Electric Works, Ltd.

Go To Online Catalog

Loading...

Loading...