Page 1

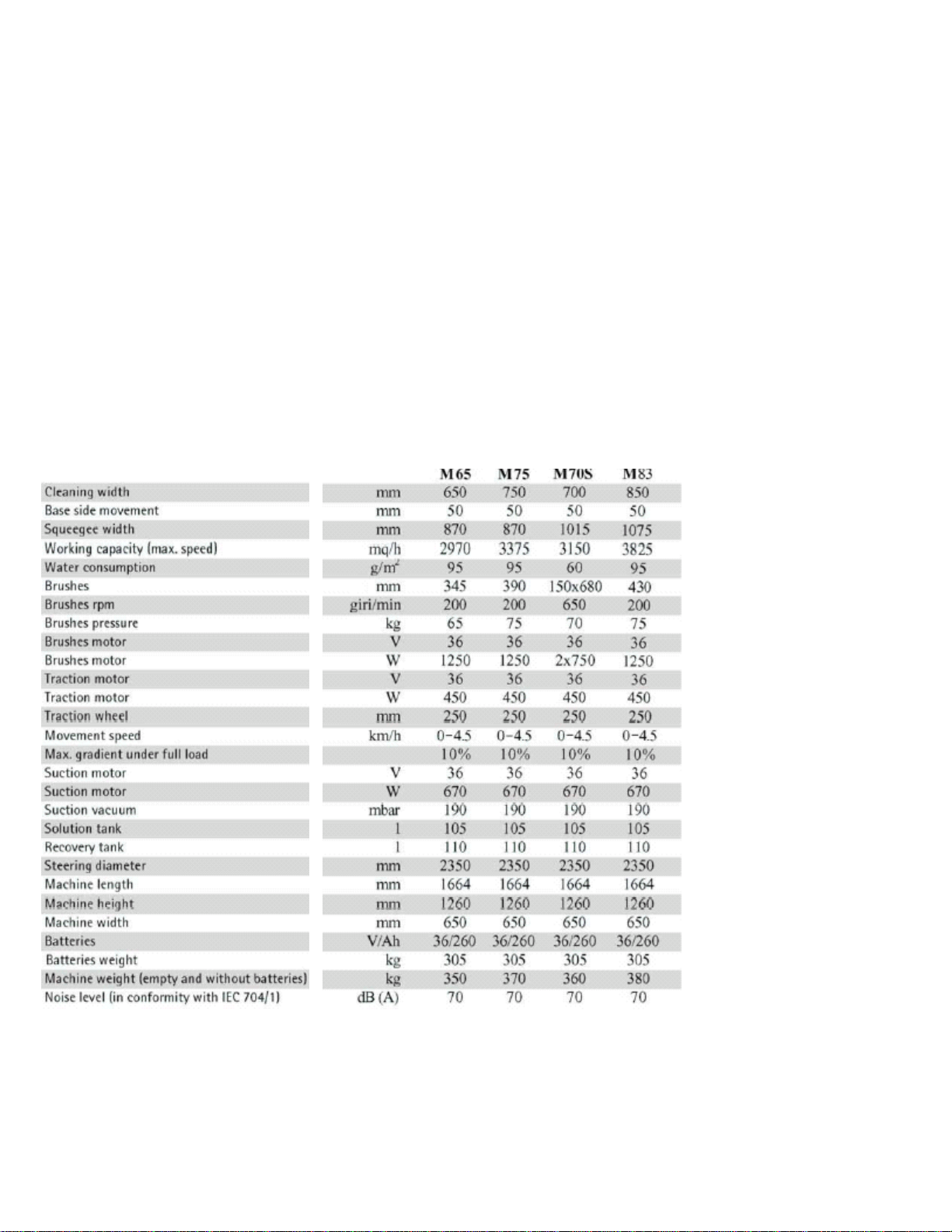

OWNERS MANUAL

ST900 SERIES

1205 Britannia Road East, Mississauga, ON L4W 1C7

Phone: 1-800-387-3210 Fax: 1-800-709-2896

Page 2

ON CONSIGNMENT OF THE MACHINE

When the machine is consigned to the customer, an immediate check must be performed tonsure all the material mentioned in

the shipping documents have been received and moreover to find out that the machine hasn’t suffered damage during

transportation. If damage has occurred, get the shipping agent to verify immediately the amount and nature of the damage

suffered and at the same time informs our claim department. It is only by prompt action of this type that compensation for

damage may be successfully claimed.

INTRODUCTION

This is a floor-cleaning machine, which, using the mechanic abrasive action of two rotary brushes and the chemical action of

a water-detergent solution, is able to clean any type of floor. During its advance movement, it picks up the removed dirt and

the detergent solution, which has not been absorbed by the floor. The machine must be used only for such purpose. We would

impress upon you that any machine will function efficiently and operate successfully, only if used correctly and maintained in

fully efficient working order. We therefore suggest you to read this instruction booklet carefully and re-read it whenever

difficulties arise in the course of machine use. Our Service Department is at your disposal for all such advice and servicing as

may prove necessary.

NOTE:M65=ST965

M70=ST980

M75=ST985

M83=ST995

- 1 -

Page 3

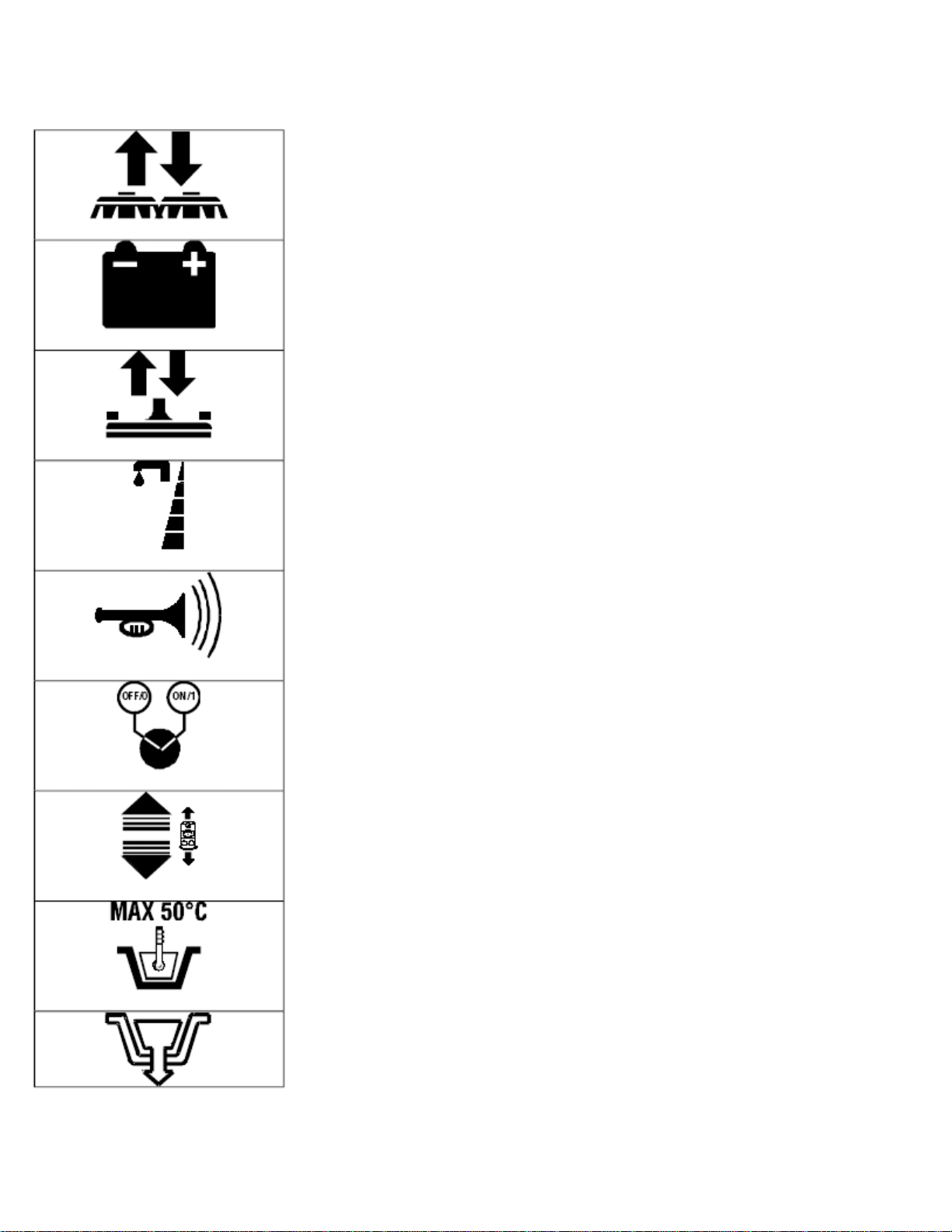

Symbol denoting up - down of the brushes base. It is used to indicate

the switch to raise or lower the brushes base.

Symbol denoting charge level of the batteries.

Symbol denoting up - down of the squeegee. It is used to indicate the

switch to raise or lower the squeegee.

Symbol denoting regulation cock.

Symbol denoting the horn button.

Symbol denoting the MAIN POWER on/off switch.

Symbol denoting the forward/reverse switch. According to its position

the machine moves forward or backward.

Symbol denoting maximum temperature of the cleaning solution to be

used.

Symbol denoting the drain hose of the recovery tank.

- 2 -

Page 4

HOW TO HANDLE THE PACKED MACHINE

Figure 1

The machine is packed in a specific packageprovided on a pallet so

that it can be moved with a forklift. The packages cannot be placed

top of each other.

Total weight:

- Magna 65- 420 kg

- Magna 75-83: 440 kg-

- Magna 70S: 420 kg

- The overall dimensions are:

- Magna 65/75/70S/83A

- 1600 mm B : 930 mm C : 1780 mm

HOW TO UNPACK THE MACHINE

Figure 2

1. Remove the outer package.

2. The machine is fixed on the pallet with wooden wedges, which

block the wheels.

3. Remove these wedges.

Figure 3

4. Using a chute, get the machine down from the pallet, pushing it

in reverse motion. Avoid violent blows to the baseunit

5. Keep the pallet for future transport necessities.

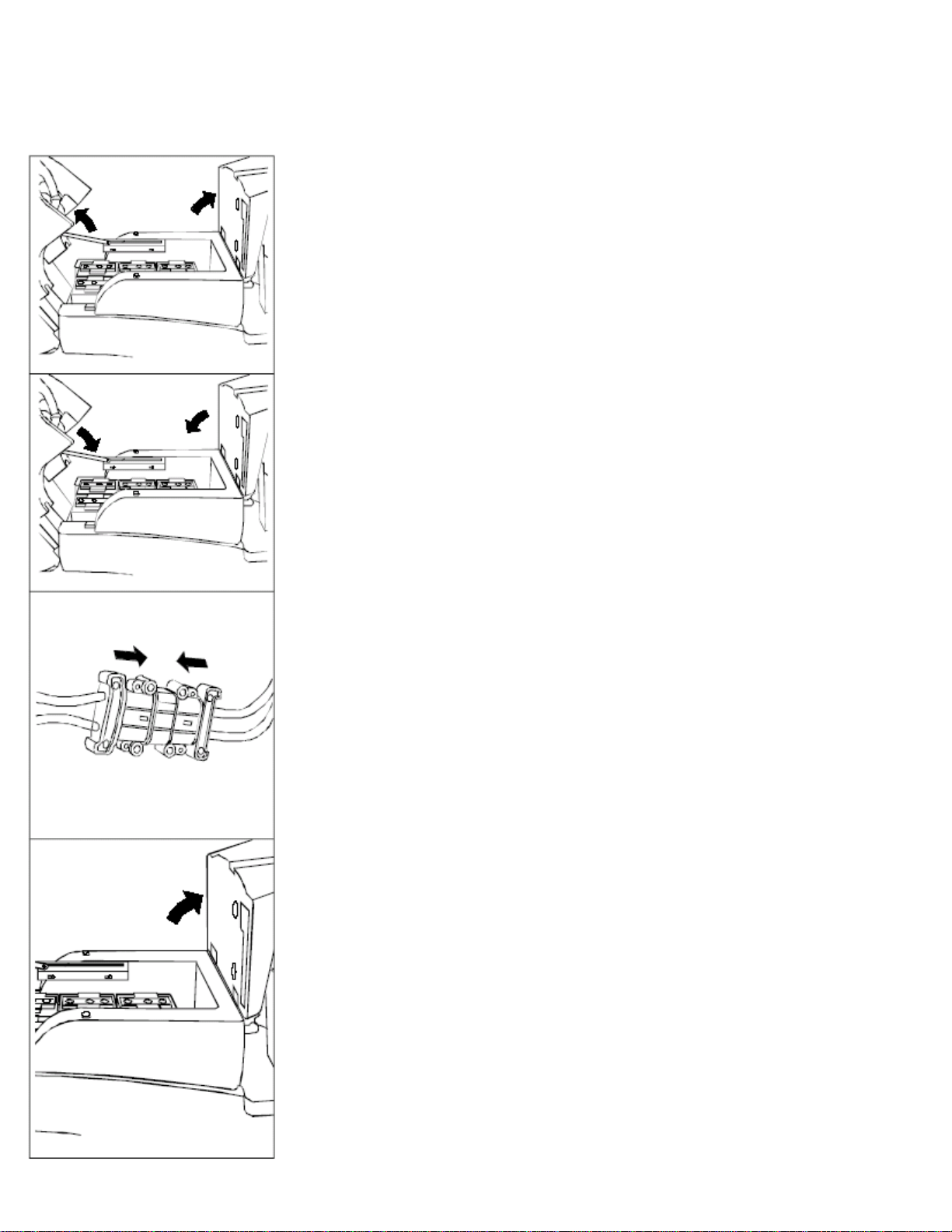

INSTALLATION OF THE BATTERIES INTO THE MACHINE

Figure 4

The batteries are fitted in the appropriate compartment under the seat

and under the recovery tank and must be handled by using

appropriate lifting equipment suitable both for the weight and for the

coupler system. They must moreover satisfy the requirements quoted

in the Specification CEI 21-5. For maintenance and daily recharge of

the batteries, it is necessary to follow strictly all the instructions given

by the manufacturer or from his dealer. Specialized staff must carry

out all the installation and maintenance operations.

- 3 -

Page 5

Figure 5

For battery installation:

1. Lift the base support of the seat.

2. Lean the seat on to the steering wheel

3. Rotate back the recovery tank towards the rear until it locks in

place.

4. Put the batteries into position and connect the battery cables.

Figure 6

5. Unfasten the support and put the recovery tank into its working

position

6. Lower the base support of the seat.

CONNECTION OF THE BATTERY CHARGER

Figure 7

1. Raise the seat base support.

2. Disconnect the machine connector from the battery connector.

3. Connect the battery charger directly to the battery connector.

The coupling connector of the battery charger is delivered in the

bag where this instruction booklet is found and must be

assembled on the battery charger cables following the suitable

instructions (see instruction booklet of the battery charger).

ATTENTION: this operation must be carried out by specialized staff.

A wrong or defective connection of the cables to the connector may

cause serious damages to people or things.

RECHARGE OF THE BATTERIES

Figure 8

Make sure that the battery charger fits the installed batteries either for

capacity or for type (lead/acid or GEL and equivalents).

ATTENTION: never charge a GEL battery with an unsuitable battery

charger. Carefully follow the instructions given by the manufacturer

of batteries and battery charger. To prevent permanent damage to the

batteries, avoid their complete discharge and effect recharging within

a few minutes after that the signal lamp of discharged batteries begins

to blink.

NOTE: Never leave the batteries completely discharged, even if the

machine is not being used. When recharging the batteries, keep the

base support of the seat lifted. After every 20 recharging operations,

- 4 -

Page 6

check the level of the electrolyte and, if necessary, top off with

distilled water.

LEVEL INDICATOR FOR THE CHARGE OF

THEBATTERIES

Figure 9

The batteries’ indicator is digital with 4 fixed positions and a blinking

one. The numbers which appear on the display show the approximate

charge level.4 = maximum charge, 3 = charge 3/4,2 = charge 2/4, 1

= charge 1/4,0 = (blinking) discharged batteries .

ATTENTION: A few seconds after the meter reads “0” it will start

blinking; the brush motor will then automatically switch off. Anyway,

the machine can finish to dry before recharging the batteries.

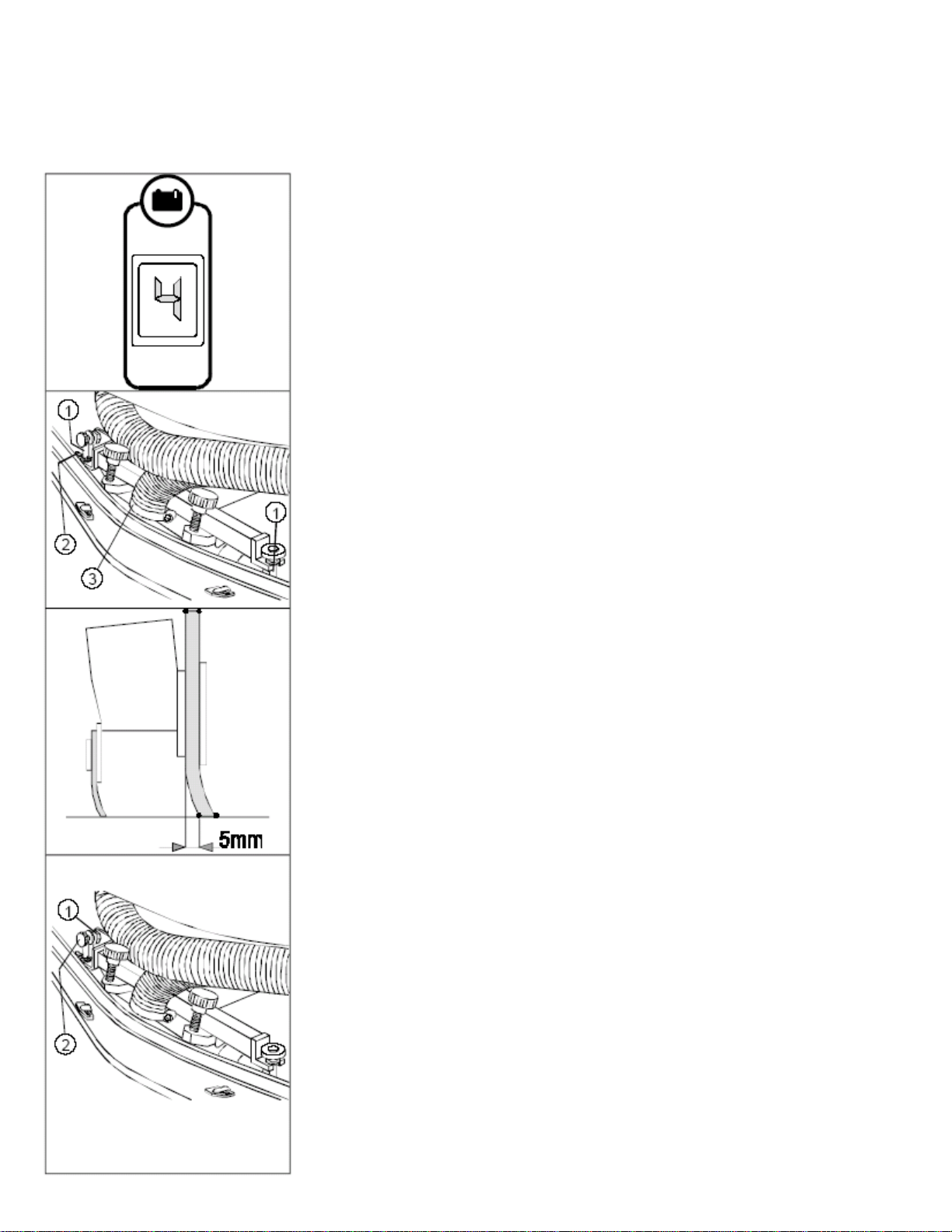

SQUEEGEE

Figure 10

The squeegee, which is packed separately from the machine, should

be installed onto the machine as shown in the figure. Insert the stud

bolts on the squeegee (1) into the proper slotted hole in the support

frame. Install the hair pin (2) into the stud bolthole. Fit the suction

hose (3) into its coupling and fix it with the appropriate clamp.

Figure 11

During operation, the rear rubber has to work slightly tilted

backwards and this equally in its whole length for about 5 mm. This

allows using the squeegee four times before it has to be replaced.

Figure 12

If it is necessary to increase the rubber bending in the central part, tilt

the squeegee body backwards, loosen the adjuster nut (1) and rotate

the knob (2) counter-clockwise. If the rubber bending is to be

noticeable at the sides of the squeegee, loosen the adjuster nut (1) and

rotate the knob (2) clockwise. After regulations have been done fix

the adjuster nut.

- 5 -

Page 7

ADJUSTMENT HEIGHT SQUEEGEE SUPPORT

Figure 13

The squeegee has to be regulated in height depending on the wearing

of the rubbers. To adjust this it is necessary to act on the knobs

(1):

- By rotating clockwise the squeegee raises;

- By rotating counter-clockwise the squeegee lowers. It is

important that the right and left little wheels are set at the same

height, only in this way the squeegee can work parallel to the

floor.

ASSEMBLY OF WASHING OR WASHING/SCRUBBINGUNIT

Figure 14

The machine is supplied as a base unit. Their are two different

washing units available, to be chosen according to the type of floor

and its conditions:

1. Washing unit with brushes. Suitable for all types of floor, and

used for routine maintenance scrubbing. Also can be used for

aggressive scrubbing, cleaning, and stripping by increasing

pressure.

2. Washing & sweeping unit with cylindrical brooms. Suitable for

rough, uneven, and grouted surfaces. Will scrub and sweep

debris in one pass and collect the solid debris into a hopper

without obstructing the squeegee rubbers.

WASHING UNIT ASSEMBLY (brushes)

Figure 15

1. Loosen the knobs (1) from the horizontal pins on the left side of

the units and rotate them outwards.

2. Position the base under the machine into the proper controls (2)

3. Rotate the knobs toward the inner part of the base and stop

them.

4. Connect the quick water coupling (3).

ADJUSTMENT HEIGHT SPLASH GUARDSRUBBERS OF

THE WASHING UNIT

Figure 16

During working operation the base splashguards rubbers must skim

over the floor.

1. To vary the height of the support, and therefore of the

splashguards rubbers, the horizontal knobs (1) must be screwed

or unscrewed.

2. After regulating correctly the rubber height, stop the knobs.

- 6 -

Page 8

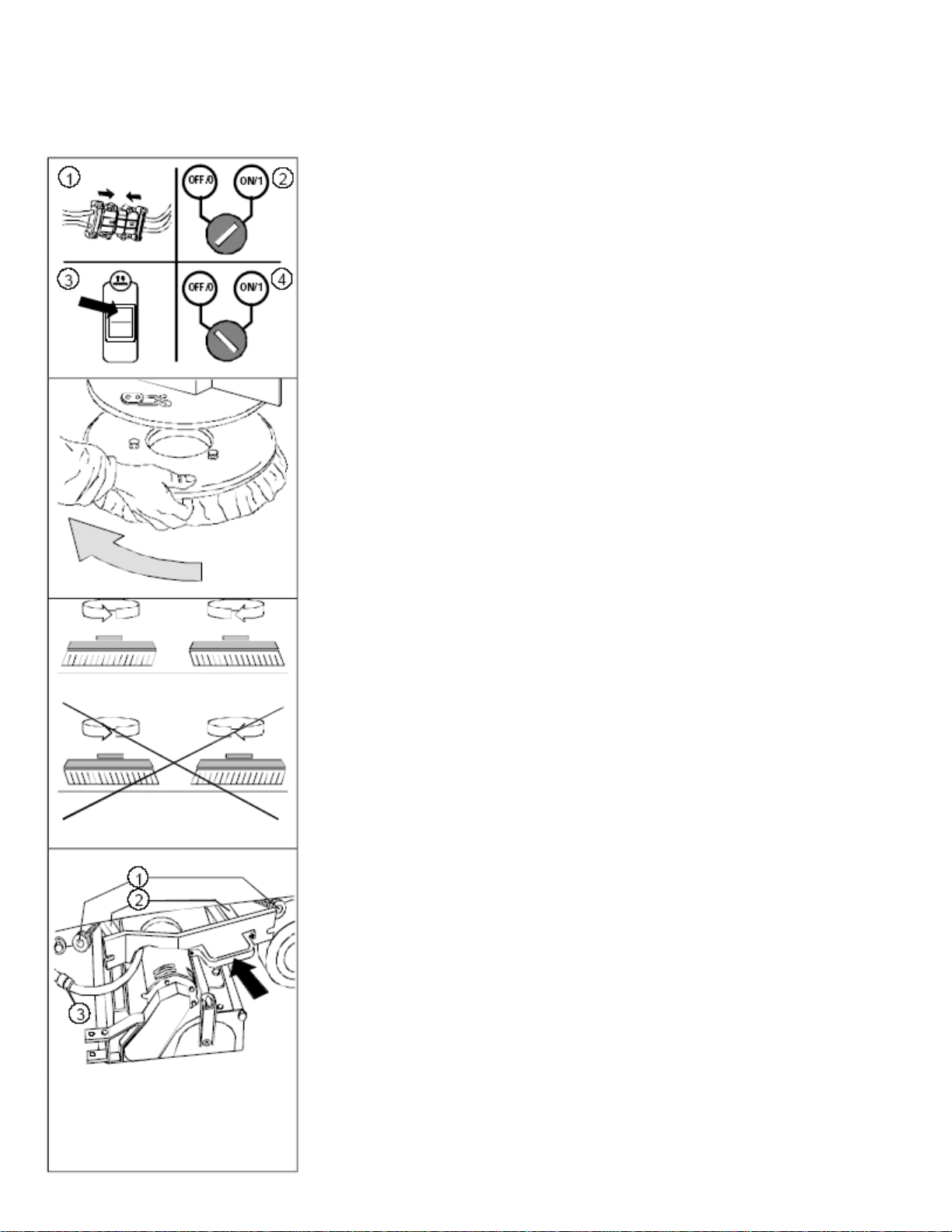

BRUSHES ASSEMBLY

Figure 17

1. Connect the battery connector.

2. Turn the key switch to the ON position.

3. With the switch raise the base.

4. Turn the key switch to the OFF position and remove key from

the instrument panel.

ATTENTION: To carry out the brush assembly operation with the

current connected could cause serious damage to machine and

persons.

Figure 18

5. With the brush base in UP position, insert the brushes into the

seat of the plate under the base until the three buttons fit into the

holes of the plate. Turn the brush so that the buttons are pushed

towards their retaining springs until the brush is clamped in

place. The figure shows the direction of rotation for the

coupling of the right brush. The left brush has to be rotated

inversely.

ATTENTION: use gloves to protect your hands when performing the

steps listed above.

Figure 19

6. It is recommended to invert daily the position of the right brush

with the left one and vice versa. If the brushes are not new and

they show deformed bristles, its better to reassemble them in the

same position (the right to the right side and the left to the left

side), to avoid that the different inclination of the bristles causes

an overload to the brushes motor and excessive vibrations.

WASHING/SCRUBBING UNIT ASSEMBLY (cylindrical brooms)

Figure 20

1. Loosen the knobs (1) from the horizontal pins on the left side of

the units and rotate outwards.

2. Position the base under the machine in the proper controls (2).

3. Rotate the knobs towards the inner part of the base and stop

them.

4. Connect the quick water coupling (3).

- 7 -

Page 9

CYLINDRICAL BROOMS ASSEMBLY

Figure 21

1. Connect the battery connector.

2. Turn the key into position ON.

3. Move the switch to raise the base.

4. Turn the key into position OFF and take it off from the

instrument board.

5. Take off the side splash guards (see ASSEMBLY AND

DISASSEMBLY ORREGULATION SIDE SPLASH GUARDS

OFTHE WASHING/SCRUBBING BASE).

ATTENTION: To carry out the brush assembly operation with the

current connected could cause serious damage to machine and

persons

Figure 22

6. With the base in UP position unfasten, by pushing downwards

and then outwards, the two movable supports (1).

7. Insert the broom into the tunnel till you block it in the holder

hub, keeping the “v” shaping as in the picture.

8. Insert the idle hub of the movable support into the brooms and

into the spring.

9. Push the support downwards, and then inwards to refasten in the

bayonet cap.

10. Regulate the brushes adjustment with the screw (2)

11. Repeat the operation also for the second support.

12. Reassemble the side splash guards (see ASSEMBLY AND

DISASSEMBLY OR REGULATIONSIDE SPLASH GUARDS

OF THEWASHING/SCRUBBING BASE).

ATTENTION: Use gloves to protect your hands when performing the

steps listed above. SIDE SPLASH GUARDS ASSEMBLY

ANDDISASSEMBLY OF WASHING/SCRUBBINGBASE

Figure 23

This operation is to be made with the base down.

1. Take off the pin (1).

2. Remove the pin (2).

3. Position the bar in the proper support.

4. Reassemble all parts following the above operations in reverse.

HOPPER

Figure 24

Check that the hopper is latched and locked.

- 8 -

Page 10

SOLUTION WATER

Figure 25

Fill the solution tank with clean water at a temperature not more than

50° C and add liquid detergent in the proper concentration following

the instructions of the manufacturer. Excess foam in the recovery tank

could damage the suction motor, so use only the minimum amount of

detergent necessary.

ATTENTION! Always use low foam detergent. To avoid the

production of foam, before starting to clean, put a minimum quantity

of antifoam liquid into the recovery tank. Never use pure acid.

RECOVERY TANK

Figure 26

Check that the inspection cover has been tightened,

Figure 27

And that the exhaust plug of the tank

Figure 28

And the plug of the exhaust pipe is closed.

- 9 -

Page 11

The rules below have to be followed carefully in order to avoid injury to the operator

and damage to the machine.

? Read the labels carefully on the machine. Do not cover

them for any reason and replace them immediately if

damaged.

? Exclusively authorized staff that has been instructed for

its use must use the machine.

? During the operation of the machine, pay attention to

other people around you, especially children.

? Do not mix different kinds of detergents. Avoid harmful

odors.

? Do not place any liquid containers on to the machine.

? The storage temperature has to be between -25°C and

+ 55° C.

? The perfect operating temperature should be between

0°C and 40°C.

? The humidity should be between 30 and 95 %.

? Do not use the machine in explosive atmosphere.

? Do not use the machine as a means of transport.

? Do not use acid solutions, which could damage the

machine.

? In order to prevent floor damage, do not leave brushes

running when machine is standing still.

? Do not vacuum inflammable liquids.

? In case of fire, use a powder extinguisher.

? Do not use water. Do not strike shelving or scaffoldings,

where there is danger of falling objects.

? Adapt the utilization speed to the adhesion conditions.

? Do not exceed the declared hill climbing capacity;

otherwise the machine could become unstable.

? When the machine is in parking position, take off the key

and insert the parking brake.

? The machine has to carry out simultaneously the

operations of washing and drying. Different operations

have to be carried out in areas, which are not permitted

for the passage of non-employed staff. Signal the areas

of moist floors with suitable signs.

? If the machine does not work properly, check by

conducting simple maintenance procedures. Otherwise,

it is better to ask for FINAP technical service.

? Where parts are required, ask for ORIGINAL spare parts

to an agent and/or to an authorized NACECARE

SOLUTIONS dealer.

? For any maintenance operation take off the power

supply from the machine.

? Do not take off the pieces, which require the use of tools

to be removed.

? Do not wash the machine with direct water jets or with

high water pressure nor with corrosive material.

? After every 200 working hours have a machine checked

by a NACECARE SOLUTIONS service department.

? The machine should not be abandoned, because of the

presence of toxic-harmful materials (batteries, oil etc.).

- 10 -

Page 12

This disposal must be subject to the rules which provide

for its scrapping in appropriate centers.

Figure 29

1. Carry out the operations for the preparation of the machine.

2. Sit on the driver’s seat.

3. Check that the parking brake is released (1).

4. Turn the key of the general switch (2) clockwise of a quarter

turn. Immediately the battery display (3) and the hour meter

(4) switch on.

Figure 30

5. Position the switch of the squeegee up/down (1) into

position down, the suction motor works.

6. Push the switch of the brushes base up/down (2) into

position down, till you reach the stroke end. The brushes

will start rotating only by operating the accelerator pedal.

Figure 31

7. Collocate forward the drive selector (1).

Figure 32

8. Open the cock by lowering the lever. The water is dispensed

only when the machine is moving forward.

- 11 -

Page 13

Figure 33

9. Press the accelerator pedal. The machine

begins to move, the squeegee begins to lower itself and

the brushes start to rotate. During the first metres of

operating, check that the quantity of the detergent

solution is sufficient and that the squeegee dries

perfectly. The machine will now start working

efficiently until the detergent solution runs out.

Figure 34

Whenever the machine develops operating problems

during operation, immediately apply the emergency

brake by, 1.) Depressing brake pedal and moving footpedal backwards to lock, at the same time 2.) Turn the

key counter-clockwise to the OFF position. To re-start

after resolving the problem, turn the key clockwise and

release the emergency parking brake by depressing and

pushing the pedal forward.

Figure 35

The machine will not start if the operator is not properly

seated.

RECOVERY TANK – FULL

The machine is equipped with a float that works when

the recovery tank is full. When the float is activated due

to a full tank the vacuum motor shuts OFF. When this

occurs, immediately drain and empty the recovery tank.

- 12 -

Page 14

TRACTION

Figure 36

These machines are equipped with electronically commanded

traction, with three speeds forwards and one backwards. To move

the machine, it is necessary to turn the key and then move forwards

(forward movement) or backwards (rear movement) the switch (1).

Press the drive pedal and the machine will start to move.

Depressing the pedal, similar to an automobile, regulates the

machine speed.

Figure 37

NOTE: During reverse motion, the squeegee raises automatically

and the water supply stops automatically.

BRAKES

Figure 38

The machine is equipped with an electronic braking system. To

brake, in normal conditions, it is sufficient to take the foot off the

movement pedal.

Figure 39

In case of bad operation of this brake, or in case of necessity

(interruption, danger), act upon the mechanical pedal brake

pushing downwards and pulling towards oneself till the lever is

fastened.

- 13 -

Page 15

HORN

Figure 40

The machine is equipped with a horn activated by

the button on the instrument control panel. In reverse

the horn works automatically.

BLINKING LIGHT

Figure 41

The machine is equipped with a blinking light that

turns on automatically when you turn the key switch

to the ON position.

- 14 -

Page 16

Figure 42

Having finished the job and before any type of maintenance is

done:

1. Close the cock (1).

2. Push the brushes base switch (2) into the UP position, till

reaching the maximum UP position.

Figure 43

3. Position the switch of squeegee up/down (1) into central

position, so that the suction motor keeps on working to empty

the suction hose for about 20 seconds, then position it into

the UP/OFF position.

4. Bring the machine to the place provided for the water

outlet/drainage.

5. Turn the key of the general switch (2) 1/4 round counterclockwise.

Figure 44

6. Take off the exhaust pipe from its hook, unscrew the exhaust

plug and empty the recovery tank. To simplify draining

operation, it is recommended to hold the hose bent with one

hand and with the other unscrew the knob and take off the

plug. Slowly straighten the hose and the liquid will start

draining at the desired speed. This operation has to be carried

out using gloves to protect from contact with dangerous

solutions.

ATTENTION: This operation must be made by using gloves to

protect from the contact with dangerous solutions.

7. The squeegee has to be lifted when the machine is not

operating. In this way damage to the squeegee rubbers is

avoided.

8. Take off the brushes and clean them with a water jet (for the

brushes disassembly please read further on under

“DISASSEMBLY OF THE BRUSHES”).

Figure 45

Remove the hopper unit (if washing/sweeping unit is being used)

to empty debris, and then clean out carefully.

ATTENTION: This operation must be made using gloves to

protect from the contact with dangerous solutions.

- 15 -

Page 17

CLEANING OF THE RECOVERY TANK

Figure 46

1. Empty the tank through the flexible hose, unscrewing of

some turns the knob and then taking off the plug

ATTENTION: this operation must be made by using gloves to

protect from the contact with dangerous solutions.

Figure 47

2. Open the side plug by unscrewing the knob and rotating the

closing blade

3. Rinse the tank and clean the exhaust plug

4. Check the perfect position of the side plug gasket

5. Retighten the side plug and the plug onto the exhaust pipe.

CLEANING OF THE SQUEEGEE

Clean the squeegee with a water jet. Check the rubber wear and if

necessary, turn them upside-down or change them. The careful

cleaning of the complete suction group assures higher life of the

suction motor.

REPLACEMENT OF THE SQUEEGEE RUBBER

Figure 48

If the squeegee rubber is worn and does not dry well, it is possible

to change the drying edge proceeding as follows:

1. Push and rotate the fixing plates

2. Slip off the rubber blade and the rubber itself

3. Turn the rubber upside-down and if necessary, replace it

4. Adjust the squeegee height as indicated in “ADJUSTMENT

HEIGHT SQUEEGEESUPPORT” under

“MACHINEPREPARATION”

5. Reassemble everything repeating inversely above operations.

- 16 -

Page 18

FILTER AND RECOVERY TANK CLEANING

Figure 50

1. Turn over forwards the seat.

2. Take the plug (1) off the recovery tank.

3. Remove the filter with the antifoam protection.

4. Rotate counter clockwise the filter inside the protection till it

is free and take it off the protection.

5. With a jet of water clean the walls and the filter bottom.

Carry out the washing operations carefully on all the parts.

6. Reassemble everything again following inversely above

operations.

BRUSHES DISASSEMBLY

Figure 51

1. Connect the battery connector if it is not connected.

2. Turn the key in position ON.

3. With the switch of brushes base up/down raise the base (if it

is not already up).

4. Turn the key into position OFF and take it off the board.

ATTENTION: to carry out the brush assembly operation with the

connected current on it may cause damage to the hands.

Figure 52

5. Rotate the brush so that it comes out the seat of the brushes

holder plate as indicated in the picture. In the picture the

rotation direction for the right brush release is indicated, for

the left one rotate in reverse direction.

ATTENTION: this operation must be made by using gloves to

protect from the contact with dangerous materials and solutions.

ATTENTION: in case of brushes block follow the procedure till

point 4, remove the cover unscrewing the knobs; rotate the brush

till the Hole of the brushes holder plate is under the hole of the

base, insert a screwdriver in the hole and block the plate. Rotate

hard the brush till the release.

6. Reassemble everything again following inversely above

operations.

- 17 -

Page 19

BROOMS DISASSEMBLY

Figure 53

1. Connect the battery connector.

2. Turn the key into position ON.

3. With the switch of brushes base up/down, raise the base (if it is

not already up).

4. Turn the key into position OFF and take it off the board.

ATTENTION: to carry out the brush assembly operation with the

connected current on it may cause damage to the hands.

Figure 54

5. Remove the side splash guards

6. With the base in position up release, pushing downwards and

then outwards, the two movable supports (1).

7. Remove the brush.

8. Repeat the operation also for the second support.

ATTENTION: this operation must be made by using gloves to protect

from the possible contact with dangerous materials and solutions.

ATTENTION: The cylindrical brush unit, when not in use, should not

be stored directly on the brushes. This could cause deformity to the

bristles and upon re-assembly to the machine, produce strong and

dangerous vibrations.

HOPPER CLEANING

Figure 55

1. Release and rotate the left side splashguard.

2. Remove the hopper (1).

3. Empty it and clean it with a jet of water

4. Reassemble the hopper.

5. Refasten the left side splashguard.

- 18 -

Page 20

SQUEEGEE REAR RUBBER REPLACEMENT

Figure 56

If the squeegee rear rubber is worn and does not dry well, it is

possible to change the drying edge proceeding as follows:

1. Push and rotate the fixing plates.

2. Slip off the rubber blade and the rubber itself.

3. Turn the rubber upside-down and if necessary, replace it.

4. Reassemble everything repeating inversely above operations.

Adjust the squeegee height according to the rubber (see

“ADJUSTMENT HEIGHT SQUEEGEESUPPORT”).

SQUEEGEE FRONT RUBBER REPLACEMENT

Figure 57

If the squeegee front rubber is worn there is no good suction and

therefore the machine does not dry well. In this case to change it

proceed as follows:

1. Take the squeegee off the machine (1).

2. Loosen the screws that block the front rubber.

3. Slip off the rubber blade.

4. Slip off the rubber and replace it.

5. Reassemble everything repeating inversely above operations.

ADJUSTMENT SPLASH GUARD WASHINGBASE (brushes)

Figure 58

Periodically proceed with the height adjustment of the side covers of

the base. This operation has to be carried out with the base down.

1. Loosen the fixing knobs of the covers (1)

2. Position the covers again

3. Screw the knobs again.

It is important to remember that the rubber must skim over the floor

and be parallel to it.

REPLACEMENT OF SPLASH GUARDSRUBBERS WASHING

BASE

Figure 59

Check periodically the wear state of the base splashguards. In case of

necessity, to replace them, proceed as follows:

1. Disassemble the covers unscrewing the knobs (1).

2. Unscrew the blades that block the splashguards rubbers.

3. Take the splashguards off and replace them.

4. Reassemble everything again following inversely above

operations.

- 19 -

Page 21

ADJUSTMENT SPLASH GUARDSWASHING/SCRUBBING

BASE (brooms)

Figure 60

Periodically proceed with the height adjustment of the side

splashguards of the base. This operation has to be carried out with the

base down.

1. Loosen the fixing lock nut of the support bars (1).

2. Regulate the splashguards with the screw (2).

3. Block the lock nut (1). Keep in mind that the rubber must skim

the floor and be parallel to it.

CLEANING OF THE SUCTION HOSE

Figure 61

Whenever suction seems to be unsatisfactory, check that the suction

hose is not obstructed. Eventually, clean it with a water jet introduced

from the side where it is being connected to the tank. Proceed as

follows:

1. Loosen the clamp, which tightens the hose.

Figure 622.

2. Clean with a water jet introduced from the side where it is

connected to the tank.

3. Reassemble everything proceeding inversely with above

operations.

ATTENTION: this operation must be made by using gloves to protect

from the possible contact with dangerous materials and solutions.

- 20 -

Page 22

INSUFFICIENT WATER ONTO THE BRUSHES

Figure 63

1. Make sure that the cock is open.

2. 2. Make sure that there is water in the solution tank.

Figure 64

3. Clean the solution filter.

4. Check that no thermal protection (circuit breaker) is activated.

(See THERMAL PROTECTORS).

THE MACHINE DOES NOT CLEANSATISFACTORILY

1. Check the brushes and replace them if necessary (the brushes

have to be replaced when the bristles reach approximately 15

mm height). To replace the brushes see “BRUSHES

DISASSEMBLY” or “BRUSHES ASSEMBLY”

2. Use a different kind of brushes to the ones fitted as standard.

For cleaning operations on floors where the dirt proves to be

particularly resistant, we recommend using special brushes,

which may be supplied optionally according to, needs (see

under “CHOICE AND USE OFBRUSHES”).

3.

THE SQUEEGEE DOES NOT DRY PERFECTLY

1. Check that the squeegee is clean.

2. Adjust the height of the squeegee support (see “MACHINE

PREPARATION”).

3. Clean the whole suction group (see” WEEKLY

MAINTENANCE” and “WEEKLYMAINTENANCE”)

4. Replace the rubbers, if worn (see” WEEKLY

MAINTENANCE”)

5. Check that no thermal protection (cicuit breaker) is activated.

(See THERMAL PROTECTION).

- 21 -

Page 23

THE SUCTION MOTOR DOES NOT FUNCTION

Figure 65

Check that the squeegee is in its working position and/or that the

squeegee up/down switch is in the working position.

THE MACHINE DOES NOT START

Figure 66

1. The operator must be properly seated

2. Check that the parking brake is not engaged.

3. Check that the general switch key is on

4. Check that the batteries are properly connected.

5. Check that the batteries are fully charged by the battery

indicator.

6. Check that no thermal protection is activated. (See THERMAL

PROTECTORS).

THE BRUSHES MOTOR DOES NOT WORK

Figure 67

ATTENTION: To avoid damage to the floor, the motor starts only

when the machine goes forward.

1. Check that the base is down.

2. Check that the batteries are fully charged.

3. Verify the electrical connection of the washing unit is

operational.

IT IS NOT POSSIBLE TO RAISE OR LOWER THEBASE

Check that no thermal protection is occurred. (See THERMAL

PROTECTORS).

- 22 -

Page 24

THE HORN DOES NOT WORK

Check that no thermal protection is occurred. (See THERMAL

PROTECTORS).

EXCESSIVE FOAM PRODUCTION

Check that a low foam detergent has been used. If required, add a

small quantity of antifoam liquid into the recovery tank. Remember

that, when the floor is not very dirty, more foam is generated. In this

case dilute more the detergent.

THERMAL PROTECTORS (Circuit Breakers)

Figure 68

There is a thermal protections system for the following functions:

1. Base up/down actuator.

2. Solenoid valve and water pump.

4. General protection.

5. Squeegee up/down actuator

6. Traction In case of block of the specific function put back in

operation the functioning pushing the proper button, near the

symbol of the function itself. The control panel is mounted in

the panel under the steering wheel.

- 23 -

Page 25

It is used on all types of floors, which are hot water resistant (not more than 60°C).

The Polypropylene brush is non-hygroscopic and therefore keeps its characteristics

even if working on wet floors.

It is used on all types of floors with excellent wear and hot water resistance (more

than 60°C). The nylon is hygroscopic and so working wet, in time, it looses its

characteristics.

The brush bristles are charged with very aggressive abrasives. It is used to clean

very dirty floors. To avoid floor damages, work strictly only with the necessary

pressure.

Bristles are made of steel wire or flat blades or are mixed steel and synthetic fibres.

The steel wire brush is used to remove scale from badly uneven floors or floors with

wide joints between tiles. Brushes with flat steel bristles (stiffer) are used to clean

the toughest scale.

The thicker the bristles are, the more rigid they will be. These ones are therefore

used on smooth floors or with small joints. On uneven floors with deep joints it is

recommended that, softer bristles, which enter more easily in depth, be used. Please

bear in mind that, when the bristles are worn out and get too short, they will get

rigid and cannot penetrate anymore. As well as for thick bristles, the brush will

begin to jump.

The pad holder is recommended to clean glossy areas. There are two types of pad

holders: 1.The traditional pad holder is equipped with anchor points which allow

the abrasive pad to be held and dragged during the work process. 2.The pad holder

is of the

Type, apart from the anchor points, is equipped with a central blocking release

system made in plastic. This allows a perfect match with the abrasive pad and to

hold it without the risk of falling down. This type of pad holder is recommended

especially for machines with more brushes, where the centering of the pads is

difficult.

POLYPROPYLENE BRUSH (PPL)

NYLON BRUSH

TYNEX BRUSH

STEEL BRUSHES

THICKNESS OF THE BRISTLES

PAD HOLDER

CENTER LOCK

- 24 -

Loading...

Loading...