Page 1

ST800 SERIES

OWNERS MANUAL

NACECARE SOLUTIONS

1205 Britannia Rd E.

Mississauga, ON

L4W 1C7

TOLL FREE: 1 800 387 3210

TOLL FREE FAX: 1 800 709 2896

Page 2

ST875 ST880 ST885

Page 3

Indicates the Solution Valve Adjustment

Indicates the Solution Valve is on when illuminated

Battery charge level indicator

Indicates the brush motor switch

Indicates the traction motor

Indicates the parking break is activated when illuminated

Indicates squeegee lift/lower lever

Brush base lift/lower symbol

Hand brake symbol

Page 4

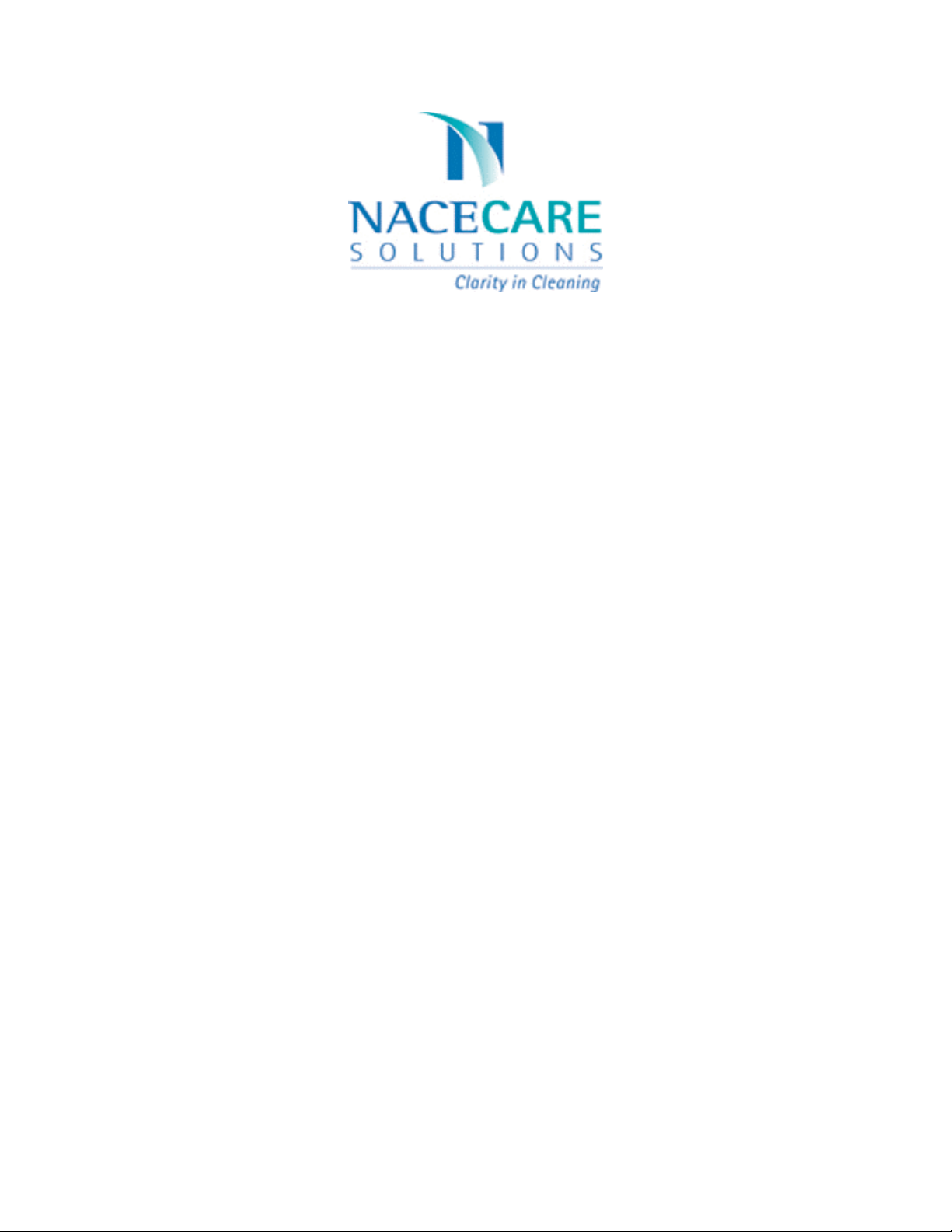

MOVING THE PACKAGED MACHINE

The machine is contained in specific packing with a platform so that a

forklift can move it. No more than two packing crates can be stacked on

each other. The total weight is 232 kg. For ST875 machines and 257 kg for

ST885.

Packing dimensions are:

ST875 ST880 ST885

A: 1.27M 1.27M 1.27M

B: 76CM 1.02M 1.02M

C: 1.68M 1.75M 1.75M

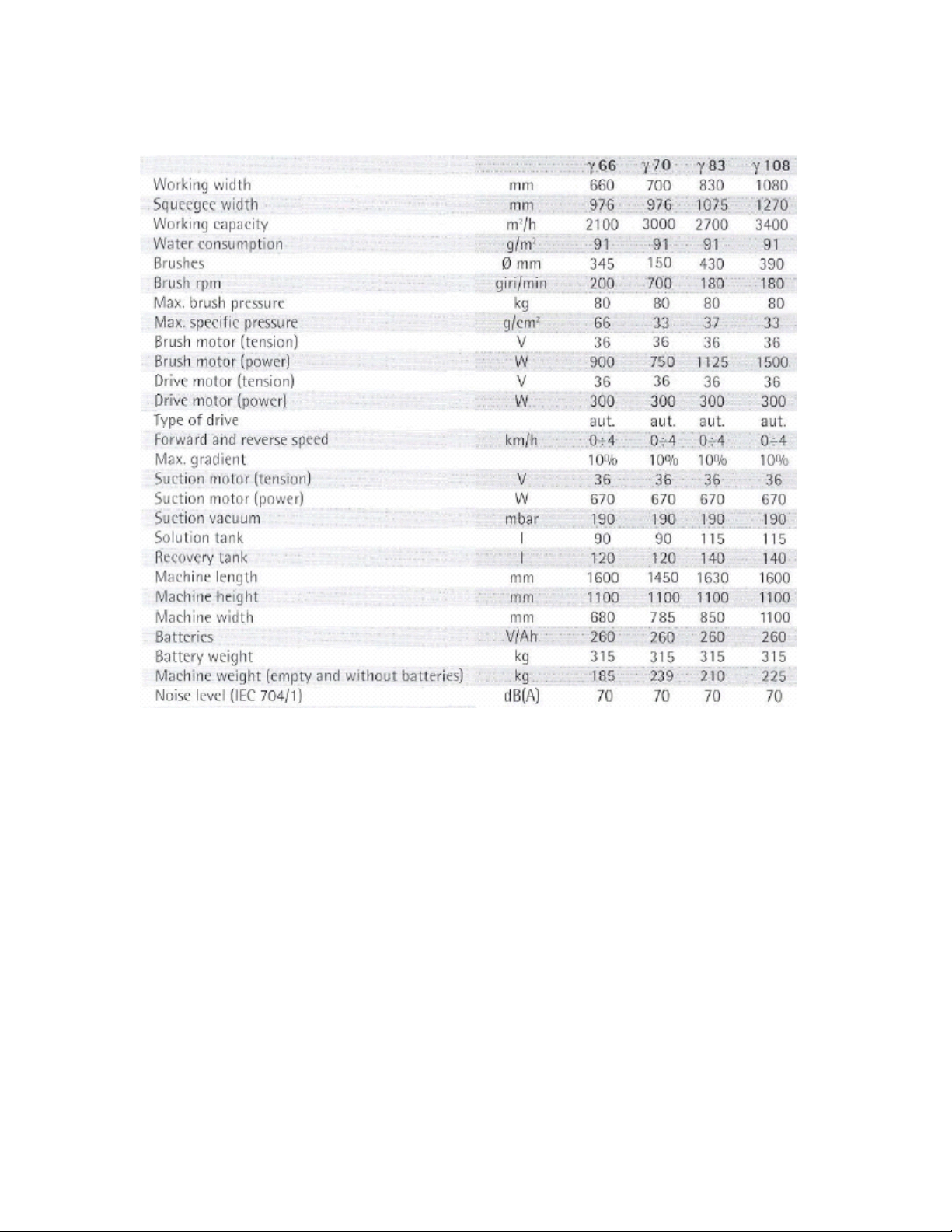

HOW TO UNPACK THE MACHINE

1. Remove outer packing

2. Cut the strap holding the machine to the skid.

3. Place a ramp in front of the skid, lift the brush base up and push

the machine backwards off of the skid.

4. Be sure to keep the skid and other packing materials if you plan to

transport the machine again.

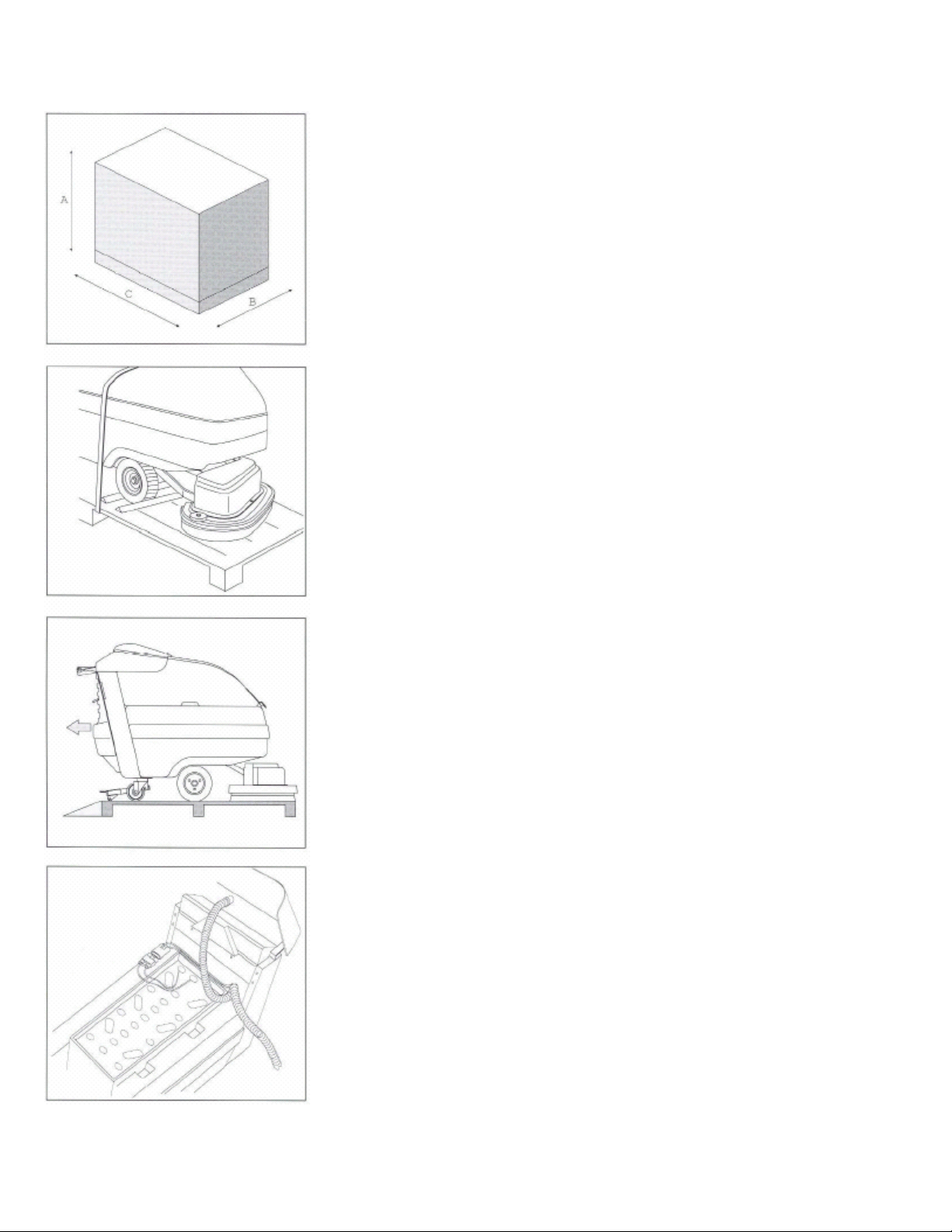

BATTERY INSTALLATION

The battery compartment is located below the recovery tank on the unit.

Use caution when lowering the batteries in to the compartment, as you do

not want to short out the battery posts.

Note: When using Wet Lead Acid batteries, be sure to follow all

manufacturers procedures for battery handling and daily maintenance.

Page 5

CONNECTING THE TRACTION MOTOR CABLE

When you receive the machine, the traction motor is disconnected to protect

other electrical parts of the machine. Connecting this wire must be done by

authorized service personnel.

CONNECTING THE BATTERY CONNECTOR

The battery connector (1) should be connected to the machine connector (2)

CONNECTING THE BATTERY CHARGER

The battery connector (1) must fit in to the corresponding connector on the

battery charger. The battery charging connector is packaged inside the

manual bag when the machine is received. The battery charging connector

must be installed on to the battery charger as per instructions.

BATTERY CHARGING

To avoid permanent damage to the batteries, they should never be

completely discharged. When the battery meter starts to flash “0”, return the

machine to the charging station and connect the battery charger.

NOTE: Never leave the batteries in a discharged state, even if the machine

is not being used, make sure that the batteries have a charge in them.

NOTE: For Wet Lead Acid batteries, only distilled water can be used to

top them up.

BATTERY LEVEL INDICATOR

The battery level indicator shows the charge remaining in the battery pack

as follows.

4: Fully charged

3: ¾ of charge remaining

2: ½ of charge remaining

1: ¼ of charge remaining

0: Batteries need to be recharged.

Note: When the flashing 0 appears on the battery indicator, the brushes will

automatically shut down. The machine then has enough of a charge left to

return it to the recharging area.

Page 6

SQUEEGEE

The squeegee comes un-attached in the box for packi ng reasons. The

squeegee must be installed on the machine as shown.

The rear rubber, during operation, must be slightly and uniformly bent back

about 5 mm. along its entire length. It may be necessary, to increase

curvature of the rubber in its central section, to slope the squeegee body

backwards. This is done by rotating adjustment unit (2, fig. 31 counterclockwise. To increase curvature on the outside sections of the ru bber just

rotate adjustment unit (2, fig. 3) clockwise.

ADJUSTING THE HEIGHT OF THE SOUEEGEE SUPPORT The

squeegee must be adjusted in height depending on rubber wear.

Do this using knob (1):

- Turning them clockwise raises the squeegee:

- Turning them counter-clockwise lowers the squeegee. The right and

left wheels must be adjusted at the same height, otherwise the squeegee

cannot work parallel to the floor.

INSTALLING THE BRUSHES

- Use lever (1) to lift the base (lever downwards)

- Turn key (2) to OFF and remove it from the control panel

(installing the brushes with power on m a y cause injury)

Page 7

MACHINE PREPARATION

• With the base raised thread the brushes into the seat on the plate below

the base, turning them until the three lugs enter the holes on the plate.

Turn them abruptly to push the lugs towards the retaining spring so that

the brush locks in place. The photo shows the direction of rotation for

installing the right brush. Rotate the opposite direction to install the left

brush.

We recommend inverting right and left brushes every day. If the brushes are

not new and have distorted bristles then it is best to install them always in

the same position (the right brush on the right side and the left brush on the

left side) to prevent bristles with a different slope from overloading the

brush motor and causing excess vibrations.

RECOVERY TANK

Open hood (I) and block it in its high position with support (2)

Check:

- That cover (3) is properly inserted in its seat with the two anchors (4)

closed

- That plug (51 is properly anchored (it must not pull out when it is lifted,

otherwise turn it clockwise);

- That vacuum hose (6) is inserted in its seat.

SOLUTION TANK

Fill the solution tank with clean water at a temperature not in excess of 50C

Add liquid detergent in the amounts and using the procedures recommended

by the detergent manufacturer. Use only a minimal percentage of detergent

to prevent formation of an excess quantity of foam since too much foam

may damage the vacuum motor. NOTE: Always use low-foam detergent

Introduce a small amount of anti-foam detergent in the recovery tank before

starting to work to be sure to prevent foam from bang generated never use

pure acids.

Page 8

Follow these instructions carefully

to avoid harm to the operator and damage to the machine

• Read

the labels on the machine with attention. Never cover them for any reason and always

~immediately replace them if they are damaged

• Neve

r mix different types of detergents this could generate no xi o us gases. Never set containers

of liquid on the machine

• Al

• M

• Opt

• Relativ

• Neve

• Neve

• Neve

• Av

• Neve

• Use a

• Do no

• Adjust

• Nev

• Whe

• The m

ways remove the recovery tank when perform i ng bat t ery rec har gi n g or m a i nte nance.

achine storage temperature must be between -25°C and +5°C

imum operating temperature is between O°C and 40°C

e humidity must be between 30 and 95%.

r use the machine in an explosive environment.

r use the machine to transport goods.

r use acid solutions, which could damage the machine.

oid running the brushes with the machine stopped, this could damage the floor.

r vacuum flammable liquids

powder fire extinguisher in case of fire. Do not use water

t hit against shelving or scaffolding when there is a danger of falling objects.

operating speed according to traction conditions

er exceed the maximum slope limits this could cause instability

never you park the machine remove the key and apply the parking brake.

achine must perform washing and drying operations simultaneously. Any other operations

must be done in zones where the presence of unauthorized persons is prohibited. Signal wet

floors with suitable signs.

• Whe

never the machine has operating troubles check to make sure these are not due to

insufficient maintenance.

• Whe

n replacing machine parts always ask for ORIGINAL spare parts from your Authorized

Agent and/or Retailer.

• Immediately e

• Always c

• Neve

• Neve

• Have

r remove guards that require tools for rem oval.

r wash the machine with direct or pressurized jets of water or with corrosive substances.

you’re nearest service center check the machine every 200 operating hours.

ngage the emergency brake in case of danger

ut out the electric power supply to the machine whenever maintenance is performed.

Page 9

WORK

- Set the machine up for operation.

- Check that the parking brake is released (1).

- Connect the connector to the batteries (2).

- Turn the main switch key (3) a quarter turn clockwise. The main green

signal lamp (4)

- Press brush switch (1)

- Press vacuum switch (2)

- Use lever (3) to adjust water flow

- Push lever (1) forward to lower the base

- Lower the squeegee by pushing lever (2) forward

The machine will start to move when directional lever (1) is pushed

forward. Check, during the first few meters of wash, that brush pressure is

adequate bee "BRUSH PRESSURE below), that the amount of water is

sufficient and that the squeegee dries the floor perfectly.

The machine will now start to work at full efficiency until the solution

water is finished.

Page 10

Immediately apply emergency brake (11 on the right side of the machine

whenever problems arise during operation. This con trol stops forward

movement by the machine. To start to work again, after solving the

problem, just raise lever (1) and push direction al lever (2) forward.

OVERFLOW DEVICE

The machine has a float that trips whenever the recovery tank 1s full. This

causes the aspiration tube to close. In this case you should empty the

recovery tank

BRUSH PRESSURE

Use lever (1) to adjust brush pressure There are three preset positions The

greatest pressure is when the lever 1s in its highest position Pressure should

be selected depending on the type of floor and the amount of dirt Too much

pressure causes Increased brush wear and greater energy consumption.

Page 11

TRACTION

These machines are equipped with electronically controlled traction with

continuous speed variation. Maximum speed can be selected according to

three levels:

• For very dim floors, where it is necessary top proceed slowly, or for

paths with lots of obstacles where great steering precision is required.

• For loose or uneven floors where a high speed could cause drying

problems.

• For normal floor maintenance cleaning.

The operator selects the optimum speed based on what happens while he

works and on his own experience.

To move the machine turn key (1), check that the speed is engaged (2) and

then turn the directional lever (3) on the handlebar fo rward backward

movement) or backward (reverse movement).

BRAKES

The machine has two brakes. The working brake is cont r ol le d by lever (2)

on the left hand side of the machine. The parking brake is activated by lever

(2) on the right hand side.

Page 12

UPON COMPLETION OF WORK

After the operator is completed his/her work.

• Close the water valve (3)

• Raise the brush base (1)

• Raise the squeegee (2)

- Turn the brush switch off (1)

- Turn the vacuum motor switch off (2)

- Move the machine to the area where it is to be drained

- Turn the key switch off (3)

- Lift hood (1) and keep it lifted by rotating support (2) backwards. This

frees recovery tank drain tube (3).

- Remove the drain tube from its seat, unscrew the drain plug and empty

the recovery tank (Lift the right side of the tank a few centimeters to

accelerate final emptying phases). These operations must be performed

wearing rubber gloves to protect against contact with dangerous

solutions.

- Thesqueegee should be raised when the machine is not in use to

prevent permanent distortion of the rubber strips.

- Remove the brushes and clean them with a jet of water (see "BRUSH

REMOVAL" below).

Page 13

CLEANING THE RECOVERY TANK

• Open the hood and keep it lifted using its support

- Remove the drain tube from its seat. Empty the tank through the drain

tube by turning the knob a few turns and then pulling out the plug.

- Remove the tank cover, releasing it from retaining clips (l)

- Rinse the inside of the tank thoroughly with a jet of water. Siightly

liftthe tank, using its handle, to improve dirt removal. It is best to do

this after totally removing the tank from the machine.

- Put the tank backin the machine and put the piug back on the drain tube

CLEANING THE RECOVERY TANK FILTER

• Remove plug (1) from the recovery tank cover.

• Pull out the filter with its foam-protection unit.

• Turn the filter inside the foam-protection unit counter-clockwise to

release it and pull It out

• Use a jet of water to clean the walls and the bottom of the f~lter Clean

all parts thoroughly and carefully

• Replace everything by foliowing the above indicated procedure in

reverse order

Page 14

CLEANING THE SQUEEGEE

The squeegee must be in perfect working condition to achieve a good

drying process. It must be clean and its rubbers must be in good condition.

Proceed as follows to clean the squeegee:

• Remove it from the machine by pulling pin (1) out from column (2).

Clean the interior with a jet of water.

• Loosen knobs (3), remove block (4) and check that there is no dirt inside.

• Check the condition of the rubbers and reverse or replace them as

necessary.

• Replace everything on the machine.

REPLACING THE REAR SQUEEGEE RUBBER

The drying edge can be changed if the squeegee rubber is worn and does

not dry properly:

• Use a hammer to push and rotate lock plates (1) in the directions

indicated by the arrow.

• Pull out the rubber-pressing blade and the rubber.

• Turn the rubber over or replace it if necessary.

• Check the height of the squeegee, Adjust using knobs (2) as necessary.

• Replace everything by carrying out these procedures in reverse order.

REMOVING THE BRUSHES

- Push lever (1) down to raise the base

- Turn key (2) to OFF and remove it from the control panel (removing the

brushes with power on may cause Injury to the han ds ).

- Rotate the brush, with the base raised, until it exits from the brushbearing plate as illustrated. The picture shows the direction of rotation for

releasing the right brush. Rotate in the opposite direction for the left

brush.

Page 15

INSUFFICIENT WATER TO THE BRUSHES

• Check that the valve is open (signal lamp on).

• Check that there is water in the solution tank

MACHINE DOES NOT CLEAN WELL

- Check the condition of the brushes and replace if necessary (brushes must

be replaced when bristles are 15 mm. high).

- Check that brush pressure insufficient. Increase as necessary using lever

(1).

SQUEEGEE DOES NOT DRY PERFECTLY

• Check that the squeegee is clean.

• Check all adjustments (see "PREPARING THE MACHINE'].

• Clean the entire aspiration unit (see 'DAILY MAINTENANCE")

• Replace worn rubbers.

Page 16

VACUUM UNIT DOES NOT OPERATE

- Check that aspiration motor switch (1) is on.

- Check if the recovery tank is full.

TOO MUCH FOAM IS GENERATED

Check that low-foam detergent is used. Add, if necessary, a small quantity

of anti-foam liquid to the recovery lark.

Remember that more foam is generated when the floor to be cleaned is not

very dirty. In this case use a more diluted detergent solution.

CHOICE OF BRUSHES

POLYPROPYLENE BRUSHES

[PPL) These are used on all types of floors and offer good resistance to

wear and to hot water (not more than WCI. PPL is not hygroscopic and

preserves its characteristics even when wet NYLON BRUSHES

These are used on all types of floors and offer good resistance to wear and

to hot water (even more than WCI. Nylon is hygroscopic and consequently

tends, over a period of time, to lose its characteristics when working on wet

floors.

TYNEX BRUSHES

The bristles on these brushes are impregnated with highly aggressive

abrasives. These are used to clean very dirty floors we recommend using

only the bare pressure necessary to prevent damage to the floor.

STEEL BRUSHES

Bristles are made of steel wire or flat blades or are mixed steel and synthetic

fibers. The steel wire brush is used to remove scale from badly uneven

floors or floors with wide joints between tiles. Brushes with flat steel

bristles (stiffer) are used to clean the toughest scale.

BRUSH THICKNESS

Thicker bristles are stiffer and should be used on smooth floors or floors

with narrow joints between tiles. We recommend using softer bristles when

floors are uneven or have deep joints or raised edge s. So ft er bris t le s

penetrate easier into joints. Remember that when brush bristles are worn

and become too short they become stiffer and are no longer able to

penetrate in depth. This is also because, as when using bristles that are too

big, the brush tends to jump and skip.

DRIVE DISKS

Drive disks are recommended for cleaning polished surfaces. There are two

types of drive disk: Traditional drive disks with sets of anchor stubs that

retain and drive the abrasive disk during operation.

CENTER LOCK

Drive disks that, in addition to anchor stubs, also have a plastic snap-in

center lock system. This permits perfect centering of the abrasive disk and

ensures it is kept anchored without detaching. This type of drive disk is best

for machines with several brushes where it is difficult to center the abrasive

disks.

Loading...

Loading...