Page 1

OWNERS MANUAL

ST50BT

NaceCare Solutions

1205 Britannia Road East, Mississauga, ON L4W 1C7

Phone: 1-800-387-3210 Fax: 1-800-709-2896

Page 2

SUMMARY

SUMMARY..............................................................................................................................................................................................................2

ON CONSIGNMENT OF MACHINE......................................................................................................................................................................3

INTRODUCTION......................................................................................................................................................................................................3

MACHINE DESCRIPTION AND EXPECTED UTILIZATION.................................................................................................................................3

TECHNICAL DESCRIPTION....................................................................................................................................................................................4

SYMBOLS................................................................................................................................................................................................................5

MACHINE PREPARATION.....................................................................................................................................................................................6

UNPACKING THE MACHINE.....................................................................................................................................................................................................................6

SLIDING THE MAHCINE DOWN THE PALLET........................................................................................................................................................................................6

REFUELLIING (GAS ENGINE MACHINE ONLY).....................................................................................................................................................................................6

INSTALLING THE BATTERY (BATTERY OPERATED MACHINE ONLY)...............................................................................................................................................7

CONNECTING BATTERY CHARGER..........................................................................................................................................................................................................7

BATTERY RECHARGING.............................................................................................................................................................................................................................7

GENERAL SAFETY REGULATIONS.......................................................................................................................................................................8

OPERATING THE MACHINE.................................................................................................................................................................................9

WORKING POSITION..................................................................................................................................................................................................................................9

CONTROL COMPONENTS AND THEIR POSITIONS..............................................................................................................................................................................9

START UP.......................................................................................................................................................................................................................................................9

WORK.................................................................................................................................................................................................................... 10

UPON COMPLETION OF WORK........................................................................................................................................................................ 12

MAINTENANCE OPERATIONS .......................................................................................................................................................................... 13

CLEANING THE FILTER..............................................................................................................................................................................................................................13

ADJUSTING THE SIDE BRUSH................................................................................................................................................................................................................14

ADJUSTING THE CENTRAL BRUSH........................................................................................................................................................................................................14

ENGINE MAINTENANCE..........................................................................................................................................................................................................................14

MAINTENANCE PROCEDURES REQUIRING THE INTERVENTION OF PROFESSIONALS...........................................................................................................14

TROUBLE SHOOTING GUIDE:............................................................................................................................................................................ 15

THE CENTRAL BRUSH DOES NOT CLEAN............................................................................................................................................................................................15

THE MACHINE CREATES AIRBORNE DUST WHEN WORKING.......................................................................................................................................................15

EXCESSIVE OR ABNORMAL NOIS FROM THE CENTRAL BRUSH...................................................................................................................................................15

SCRAPPING OF THE MACHINE........................................................................................................................................................................16

2

Page 3

On consignment of machine

When the machine is consigned to the customer, an

immediate check must be performed to find out whether the

machine has suffered damage during transportation. If

damage has occurred, get the shipping agent to verify

immediately the amount and nature of the damage suffered

and at the same time informs our claim department. It is only

by prompt action of this type that compensation for damage

may be successfully claimed.

Introduction

Any machine can work efficiently and successfully only when

used properly and maintained in fully efficient working order.

We therefore invite you to read this instruction manual

thoroughly and to resort it whenever difficulties arise while

working with the machine. Besides we inform you that our

Customer Service in co-operation with our agents are always

at your disposal for any question or for direct intervention.

Machine description and expected

utilization

SWEEPTEC 50 BT is a battery-powered electric sweeping

machine used to clean both interior and exterior surfaces

paved with concrete and asphalt or covered with tiles. It is

designed to work on dry surfaces but can also work on wet

surfaces if the suction system is kept closed.

Machines are provided with: a central brush to brush up and

collect dirt, a side brush for cleaning corners, a suction system

with a filter to prevent dust form being blown into the

atmosphere and a dirt collection bin.

Do not use the machines for other purposes but the above

mentioned.

3

Page 4

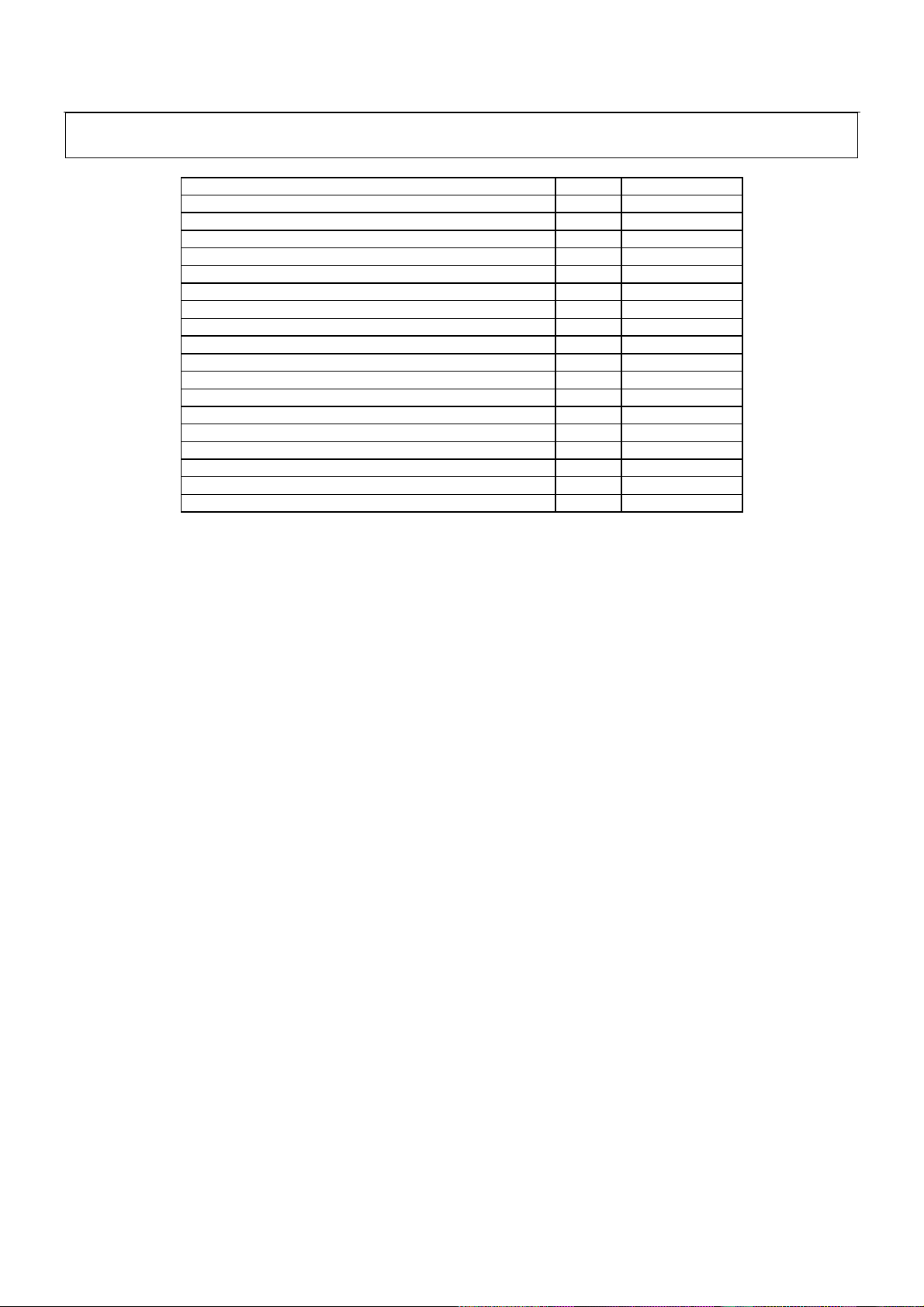

TECHNICAL DESCRIPTION

TECHNICAL DESCRIPTION U/M Sweeptec 50BT

Cleaning width mm 650

Working capacity m2/h 2600

Maximum hill climbing % 10

Size of central brush mm 500

Volume of dirt hopper l 40

Electric engine V 12

Electric engine W 600

Filter surface area m2 2.5

Traction mechanical

Forward speed km/h 4

Machine length mm 1430

Machine height mm 1000

Machine width mm 660

Battery V/Ah 12/140

Battery weight kg 28,5

Machine weight (empty and without battery) kg 75

Noise level (IEC 704/1) dB (A) 68

Vibration level m/sec.2 0,12

4

Page 5

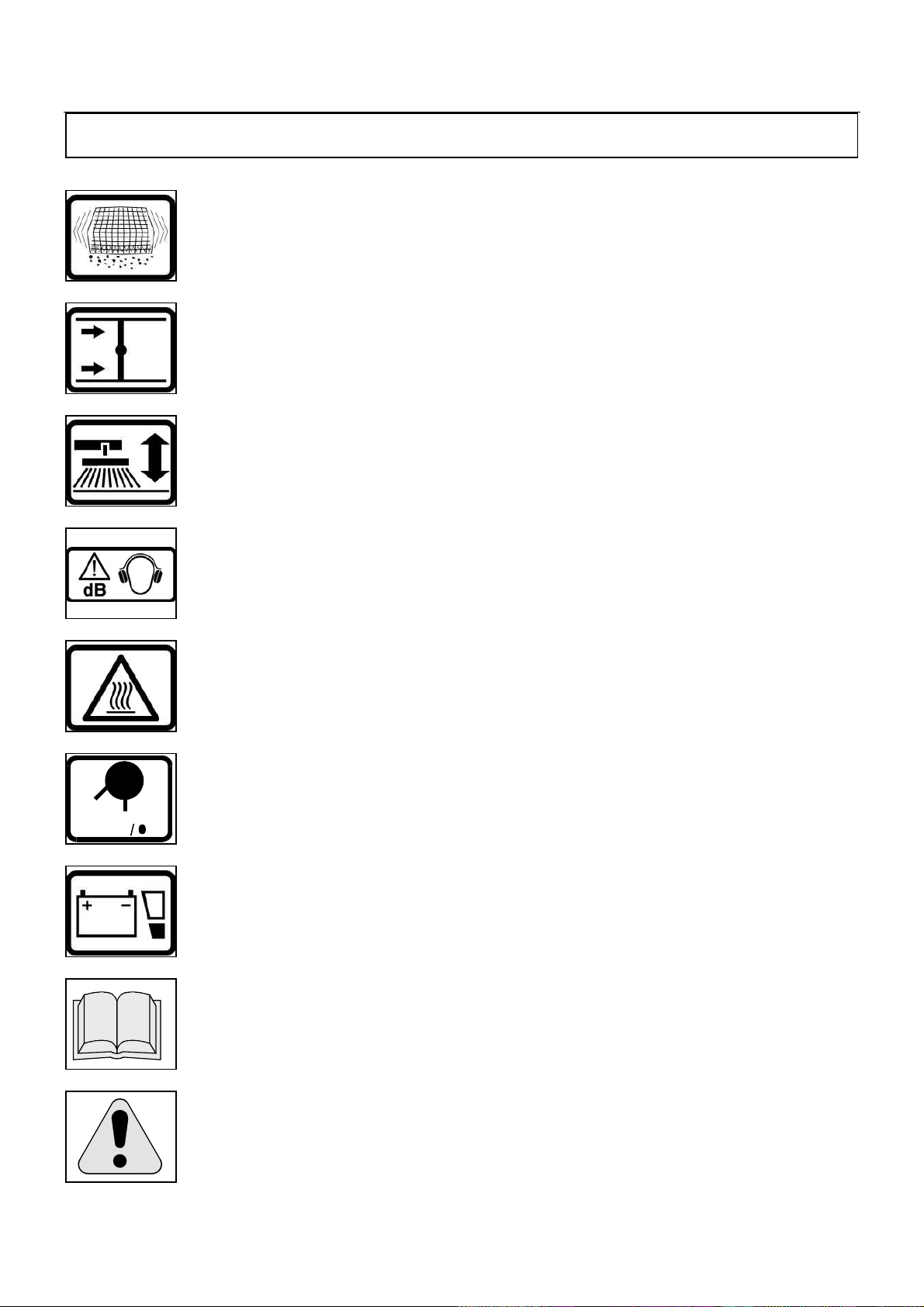

SYMBOLS

Filter shaker

Suction interruption

Side brush

Wearing the protection headset

Pay attention to hot parts

On/off (battery-operated machine only)

ON / 1

Indicates the battery charge level (battery-operated machine only)

Open book symbol

Indicates the user to carefully read this manual before using the machine.

Warning symbol

Carefully read paragraphs preceded by this symbol, for user and machine safety.

5

Page 6

MACHINE PREPARATION

UNPACKING THE MACHINE

Figure 2

The machine is delivered packed on pallet. To move it use a fork truck or a pulley block

with sling (see Figure 3).

To remove the package proceed as follows:

• Remove the fixing tapes.

• Remove the metal staples at package base.

• Take the cardboard box off.

Package size: cm 153x76x119

Weight of packed machine s50B : P = 95 Kg

Weight of packed machine s50S : P = 103.5 Kg

Figure 3

SLIDING THE MAHCINE DOWN THE PALLET

Figure 4

• Place a sliding board near the pallet.

• Pull the machine backwards and make it pass over the blocking ledges.

• Slide the machine down along the board.

REFUELLIING (GAS ENGINE MACHINE ONLY)

WARNING

Before refuelling you should carefully read the information contained in the engine’s

specific OPERATING AND MAINTENANCE INSTRUCTIONS, delivered together with the

machine.

6

Page 7

MACHINE PREPARATION

INSTALLING THE BATTERY (BATTERY OPERATED MACHINE ONLY)

Figure 5

We recommend, in order to have good operating autonomy, installing a

12Vx140Ah/20h battery. Make sure that the battery is charged before installing.

WARNING: carefully follow the battery constructor or distributor’s

instructions for the maintenance, the first charge and the daily recharging.

Professionals must carry out all the installing and maintenance procedures.

Installation instructions:

• Turn push-button (d) to off.

Figure 6

• Open the machine cover

• Put the battery in its compartment.

• Connect the positive and negative connections as shown in the figure.

• Close the cover.

CONNECTING BATTERY CHARGER

Figure 7

Under the bonnet you find the connector where the battery charger connectors shall

be connected. The coupling connector is delivered in the bag together with this

instruction manual and it should be mounted on the battery charger cables, paying

attention to polarity.

BATTERY RECHARGING

To avoid permanent damage to the batteries, do not ever allow them to run down

completely and recharge them within few minutes after the battery indicator, figure 4,

(e) starts flashing.

WARNING: Do not ever allow batteries to run completely down, even when

the machine is not used. During recharging check the electrolyte level and add distilled

water, if necessary.

WARNING: Danger of gas exhalation and corrosive substances emission.

Fire danger: do not approach with flames.

7

Page 8

GENERAL SAFETY REGULATIONS

Please keep strictly to the following regulations in order to avoid any damage to the user or to the machine.

Read thoroughly all labels on the machine, do not ever cover them and replace them immediately when damaged.

Read operating instructions WITH DUE CARE before starting up the machine or performing maintenance.

The best working conditions are at a temperature ranging from -10° and + 40°C and with humidity between 30% and 95%.

For storing the machine temperatures from -25° e +55° C are tolerated.

Turn the machine off and wear protective gloves before performing any repa ir or maintenance.

The use of the machine within closed premises must be in compliance with the regulations in force in the country where

the machine is used.

Before refuelling always switch off the engine. Let it cool down a few minutes before starting refuelling.

Do not touch discharge system, cylinder or other parts subject to overheating. You could get burnt.

Do not use the machine as a means of transport.

Do not ever use the machine for different purposes than those indicated and in particular do not use the side brush to

polish shoes or any other object.

Do not use the machine in explosive environment.

Never use the machine to sweep up burning materials (burning cigarette butts, etc.).

Never use the machine to collect toxic dusts or debris.

In case of fire use a dry powder extinguisher. Never use water.

Do not place anything containing liquids on the machine.

Always make sure that working surfaces, slabs and ramps can support machine weight.

While working, keep an appropriate safety distance from persons present on the working area, in particular from children.

Do no t put hands inside the machine while it is working.

Do not remove fairings and/or protections while the machine is working.

Do not operate the machine without the protections.

Do not come close to the machi ne wearin g clothes, which could get entangled. Do not EVER wear scarves, shawls, foulards

and wide clothes in general.

Wear the headset to protect hearing when you operate with petrol engine machines.

Do not suck in any ropes, iron wires or cables: they could get entangled to the central brush and cause friction.

Should you single out any anomalies of the machine, we invite you to adjust or to repair the machine only in presence of

qualified personnel. Otherwise, especially in case of anomalies to electric parts, ask for assistance to Customer Service.

In case you need spare parts, always ask for original spare parts to our agent or Customer Service.

Do not ever damage any safety device and check them up regularly.

Do not wash the machine with direct water jet or with corrosive liquids or substances.

Turn the machine off whenever dangerous malfunctions arise.

Do not hit any shelving or scaffolding to prevent objects from falling.

Do not exceed the declared hill climbing capacity otherwise the machine could become unstable and have braking

problems.

Machine is to be used by qualified personnel only.

Before using the machine, make sure that all doors ad covering are positioned as shown in this use and maintenance

manual.

For the discharge of collected materials, carefully keep to the law in force.

8

Page 9

OPERATING THE MACHINE

WORKING POSITION

Figure 8

The operator stands on the ground to operate the machine, moving behind it and

holding it by its handle.

CONTROL COMPONENTS AND THEIR POSITIONS

Figure 9

• Suction off (a): this moves a flap to close off the fan's suction duct.

• Filter-shaker (b): manual control to shake dust off the filter.

• Side brush lever (c): pull this lever out to lift the side brush. Push the lever up to

release it and lower the brush.

Figure 10

BATTERY OPERATED MACHINE ONLY

• On/off push button (d).

• Battery charge signal (e).

START UP

GAS ENGINE VERSION

Start the engine following the information given in the engine's specific OPERATING

AND MAINTENANCE INSTRUCTIONS.

BATTERY-OPERATED MACHINE

(see Figure 10)

• Turn the on/off push button (d) to “on”.

9

Page 10

WORK

Figure 11

• As the side brush is not provided with suction, use it on borders only.

Figure 12

• Push the machine to move forward.

Figure 13

TRACTION VERSION

• Pull the traction handle to move forward.

Figure 14

• In case of bulky waste, press down on the handle to raise the front of the

machine, to allow the central brush to sweep it up.

10

Page 11

WORK

Figure 15

For efficient suction clean the filter approximately every 10 minutes. Proceed as

follows:

– turn suction off (lever a);

– actuate manual filter-shaker several times (lever b);

– turn suction back and start working.

• Turn suction off (lever a) when you are about to start working on wet or damp

floor surfaces.

Figure 16

• Periodically check the dirt collection bin, pulling it out from the machine after

releasing its hooks. Empty it as necessary. It should be remembered that the weight of

collected dirt is proportional to the weight of swept materials.

Figure 17

BATTERY OPERATED MACHINE ONLY

• Check the battery lever indicator (e):

red = run-down battery

green = charged battery.

11

Page 12

UPON COMPLETION OF WORK

GAS ENGINE VERSION

• Stop the engine, carefully following the information given in the engine’s specific

OPERATING AND MAINTENANCE INSTRUCTIONS.

BATTERY OPERATED VERSION

• Stop the machine by turning the on/off push-button (d) (see figure 10) to “off”

BOTH VERSIONS

• Always park the machine on the level.

• Actuate the filter-shaker several times.

• Empty the waste bin.

12

Page 13

MAINTENANCE OPERATIONS

WARNING: Before any adjustment and/or maintenance procedure always

switch off the machine.

CLEANING THE FILTER

WARNING: always wear glove while doing this operation to avoid contact

with dangerous substances.

Carefully clean the filter once a week by proceeding as follows:

Figure 18

• Turn the machine off.

• Remove the debris hopper.

• Lift the filter-shake and clamp it in its lifted position using the special pin

furnished with the machine.

• Unscrew knobs (b) and release and lift bracket (a).

• Pull out the filter panel.

Figure 19

• Carefully clean the filter using a vacuum cleaner or by manually shaking it.

• Reassemble by repeating the previous procedures in reverse order.

13

Page 14

MAINTENANCE OPERATIONS

ADJUSTING THE SIDE BRUSH

Figure 20

To adjust the brush height, regulate the screw (a) placed inside the brush bearing

bracket (b).

The brush should be pressed on the floor for about 2 cm.

ADJUSTING THE CENTRAL BRUSH

Figure 21

The central brush should work pressed on the floor for about 7/8 mm. To adjust its

height, regulate the two register screws (a) and (b) on both sides of the machine.

Adjusting the central brush make sure to keep it aligned.

ENGINE MAINTENANCE

Keep scrupulously to the engine maintenance guidelines given in the

engine’s specific OPERATING AND MAINTENACE BOOKLET.

MAINTENANCE PROCEDURES REQUIRING THE INTERVENTION OF PROFESSIONALS

For the following maintenance procedures we invite you to ask for assistance to our

Customer Service, organised in co-operation with our agents, since these procedures

require a specific technical competence and appropriate equipment.

• Replacing the central brush.

• Replacing the side brush.

• Replacing the belts.

14

Page 15

TROUBLE SHOOTING GUIDE:

THE CENTRAL BRUSH DOES NOT CLEAN

• The brush is worn or improperly positioned: adjust its position or, if necessary, have

it replaced at your nearest service centre.

• The waste bin is full: empty it.

• The brush does not rotate because the belt is broken: have it replaced at your

nearest service centre.

THE MACHINE CREATES AIRBORNE DUST WHEN WORKING

• Flaps ensuring good suction are torn. Replace them.

• The filter is clogged: thoroughly clean the filter.

• The front flap is broken and the machine throws heavy dirt and waste forward:

replace the front flap.

EXCESSIVE OR ABNORMAL NOIS FROM THE CENTRAL BRUSH

• Material is wound around the brush: remove it.

15

Page 16

SCRAPPING OF THE MACHINE

The machine is composed of: iron materials, plastics, and rubber. The battery-operated

version of the machine is also equipped with a battery which may have to be replaced

several times during the working life of the machine. Turn to authorized waste

collection and disposal agencies for ecological waste disposal when replacing the

battery or demolishing the machine.

16

Loading...

Loading...